High-intensity water-resistance corrugated board and preparation method thereof

A corrugated board and water resistance technology, applied in the field of corrugated board, can solve the problems of insufficient effectiveness of network cross-linked structure, poor water resistance of corn binder, low water resistance of surface film formation, etc. The effect of mechanical bonding force and strong water resistance strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

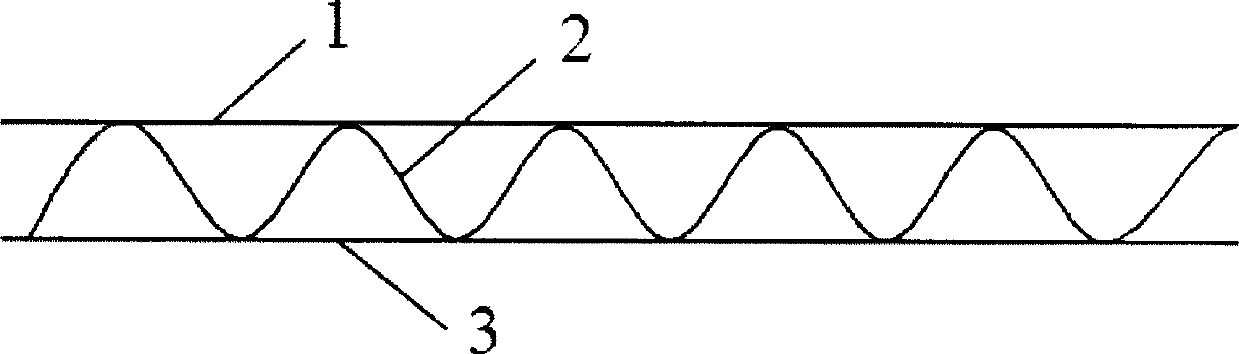

[0045] see figure 1 As shown, a high-strength water-resistant corrugated cardboard includes a face paper 1 and a back paper 3, a corrugated paper layer 2 is arranged between the face paper 1 and the back paper 3, and the peak surface of the corrugated paper layer 2 A high-strength water-resistant adhesive is coated between the face paper 1 and the back paper 3 .

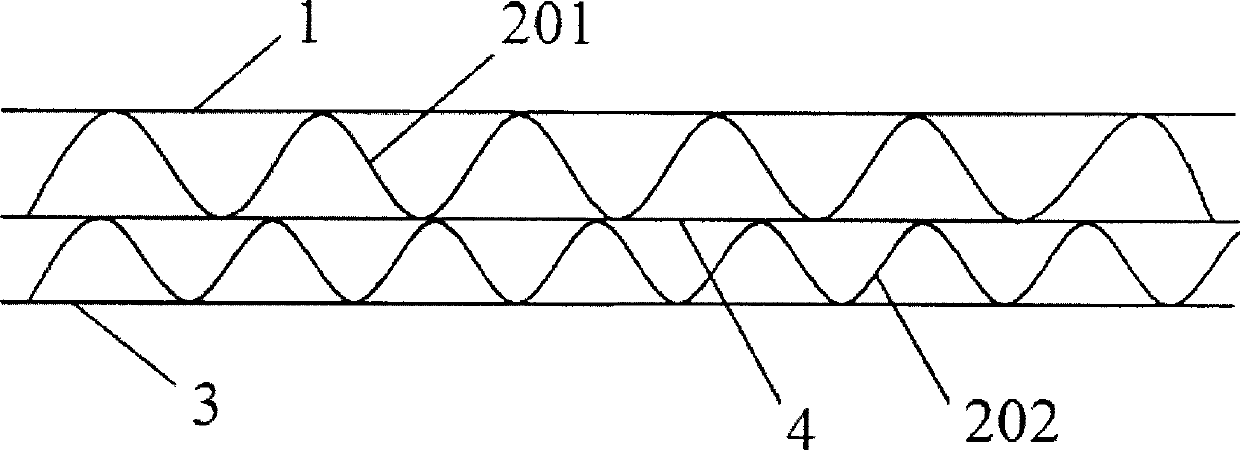

[0046] Further, see figure 2 As shown, the corrugated paper layer 2 is sequentially composed of the first corrugated paper 201, the middle paper 4 and the second corrugated paper 202, and the outer peak surfaces of the first and second corrugated papers 201, 202 constitute the corrugated paper layer 2, the inner peak surfaces of the first and second corrugated papers 201, 202 and the middle paper 4 are bonded by the high-strength water-resistant adhesive.

[0047] Further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com