Patents

Literature

64results about How to "Enhance chemical affinity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

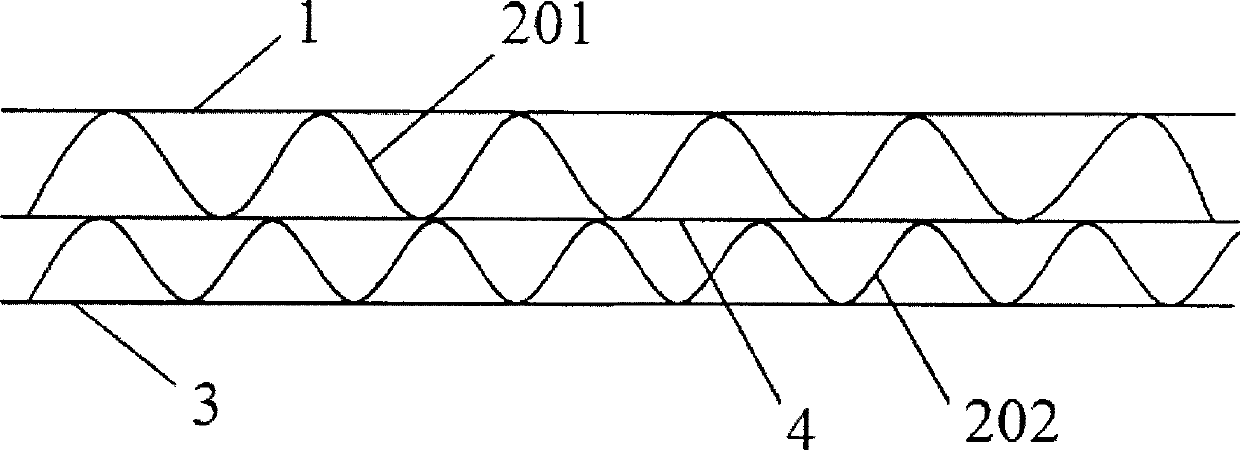

Elastomeric laminate and elastomeric film

InactiveUS20110177735A1Improve heat resistanceImprove thermal stabilitySynthetic resin layered productsPaper/cardboard layered productsElastomerEngineering

An elastomeric laminate and an elastomeric film are provided. The elastomeric film can be a monolayer elastomeric film or a multilayer elastomeric film, wherein the monolayer elastomeric film includes an olefin-based elastomeric polymer and an effective polymer, and the multilayer elastomeric film when used as an alternative includes a first elastomeric member layer, and a second elastomeric member layer. The first elastomeric member layer includes at least one olefin-based elastomeric polymer, and at least one first draw down polymer. The second elastomeric member layer includes at least one elastomeric polymer and at least one second draw down polymer. The monolayer elastomeric film or the multilayer elastomeric film, and the elastic carrier are laminated together to form the elastomeric laminate.

Owner:CHENG KENNETH +1

Reinforcing filler used for rubber latex product, preparation method thereof and application thereof

ActiveCN101696282APrevent each other from approachingClose to each other to preventPigment treatment with macromolecular organic compoundsPigment physical treatmentParaffin waxCellulose

The invention relates to reinforcing filler used for a rubber latex product, a preparation method thereof and application thereof. The reinforcing filler consists of the following components in part by weight: 50 to 80 parts of base material, 0.01 to 0.4 part of dispersant, 0.001 to 0.5 part of surface treating agent, 0.01 to 1 part of emulsion and 20 to 50 parts of water, wherein the base material is any one of heavy calcium carbonate powder, kaolin powder and argil powder; the dispersant is any one of casein, methylene dinaphthalene sodium sulfonate, sodium polyacrylate, potassium hydroxide and ammonia water; the surface treating agent is any one of bentonite, cellulose, swelling soil and attapulgite; and the emulsion is any one of mineral oil, vaseline, liquid paraffin and polyoxychloroethylene wax. The reinforcing filler has economic formulation and good reinforcing effect. The preparation method is a conventional stirring and grinding method. The process is simple, and little equipment is used. The application comprises the following steps: adding the reinforcing filler into rubber latex, blending the mixture evenly, forming a layer of film on a die by adopting a soaking and casting method, and then drying the film for 15 to 30 minutes at a temperature of between 110 and 130 DEG C to obtain the reinforced filled rubber latex product. The reinforcing filler is favorable for improving the tensile strength of the rubber latex product and reducing the usage amount of the latex.

Owner:BENGBU RUIJIE TECH

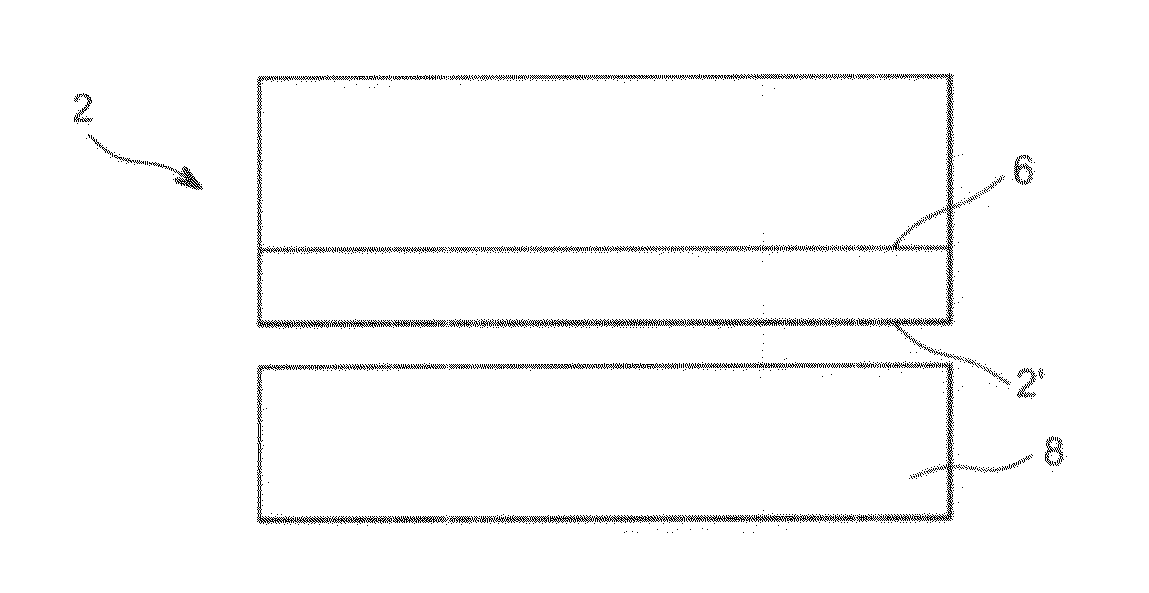

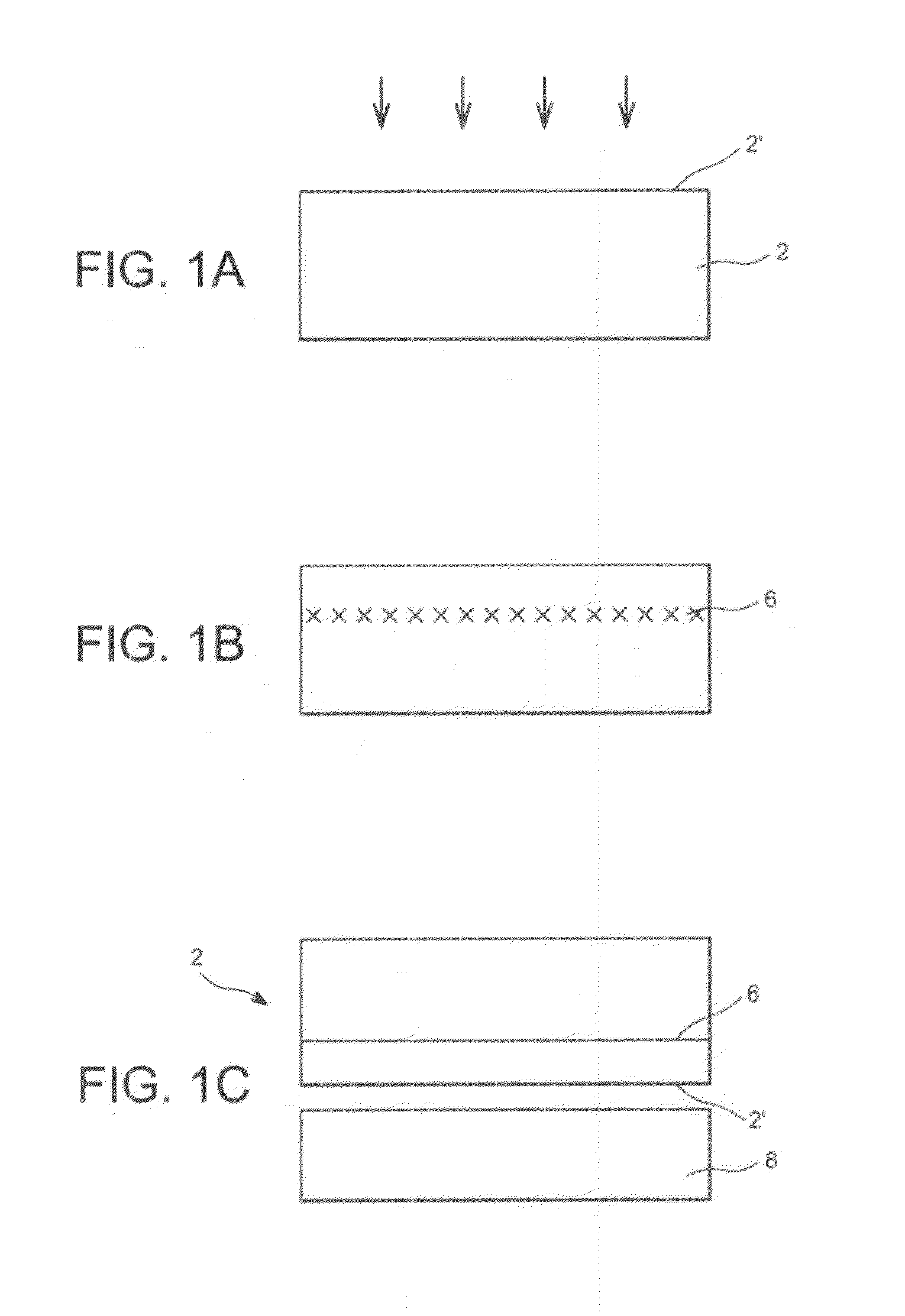

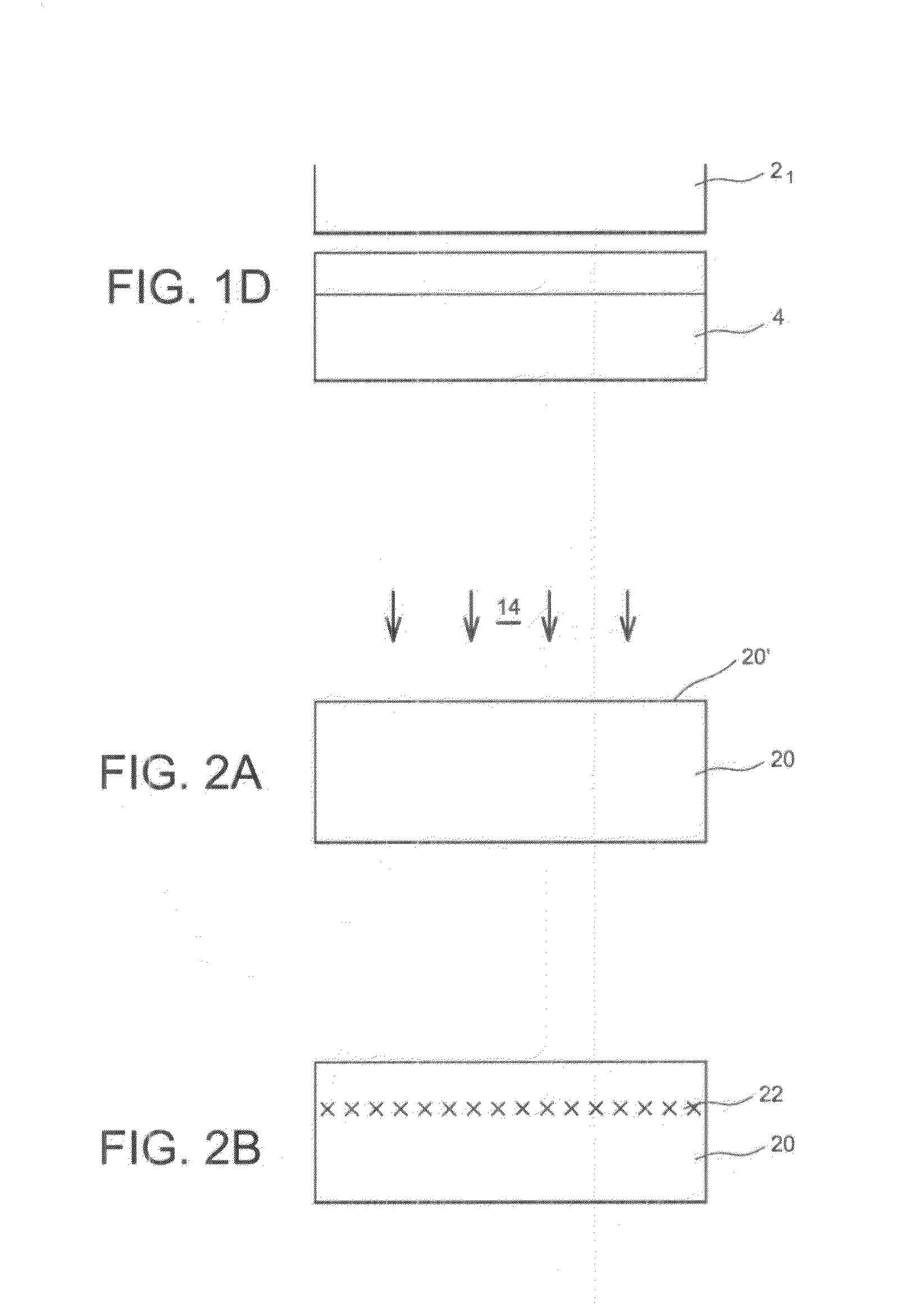

Process for forming a crack in a material

ActiveUS20140113434A1Efficient trappingEnhance chemical affinitySemiconductor/solid-state device manufacturingLithiumHydrogen

A process for forming a layer (26) of semiconductor material from a substrate (20), or donor substrate, made of the same semiconductor material is described, comprising:formation in said donor substrate of a high lithium concentration zone (22), with a concentration between 5×1018 atoms / cm3 and 5×1020 atoms / cm3,then a hydrogen implantation (24) in the donor substrate, in, or in the vicinity of, the high lithium concentration zone,application of a stiffener (19) with the donor substrate,application of a thermal budget to result in the detachment of the layer (34) defined by the implantation.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

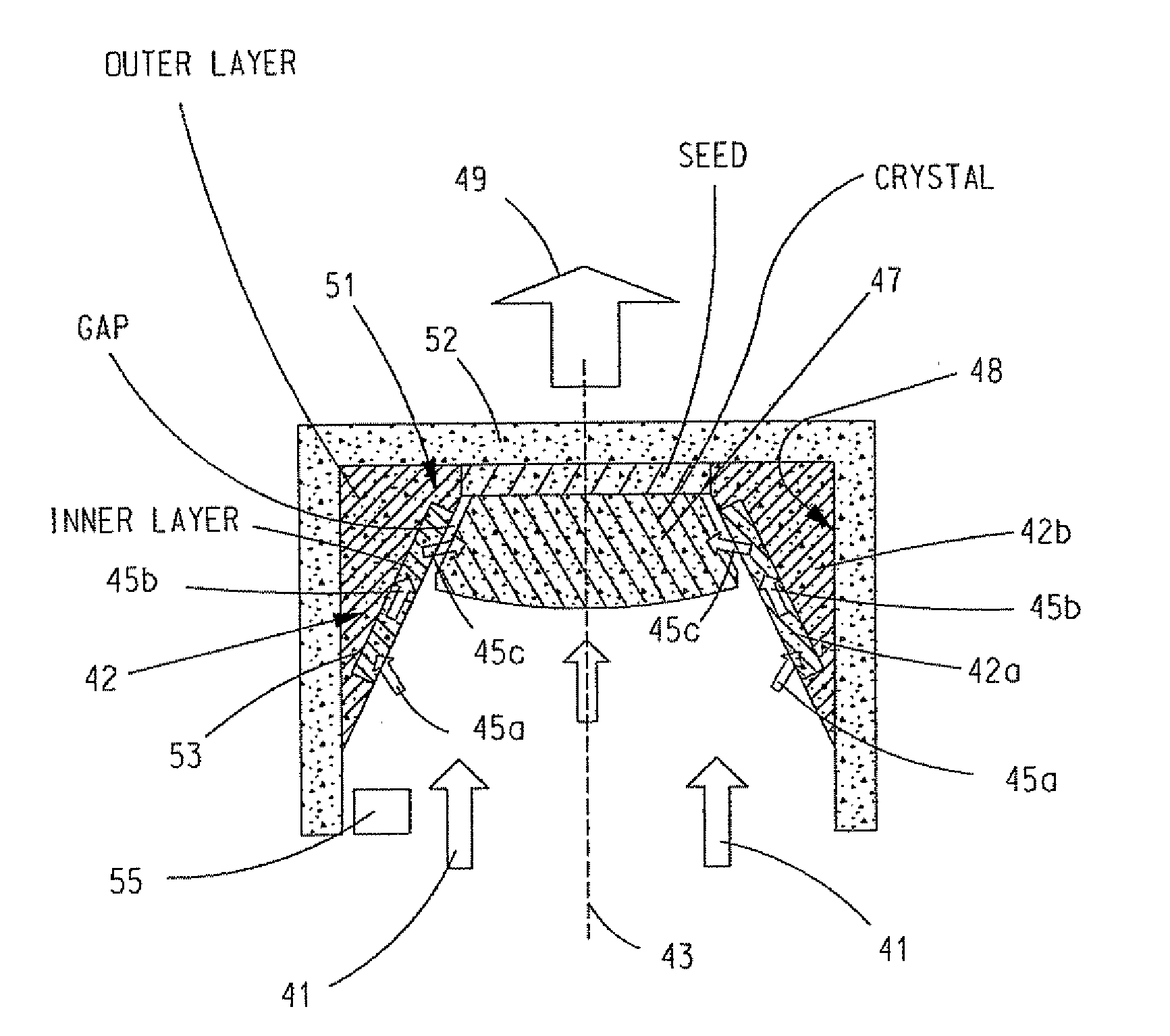

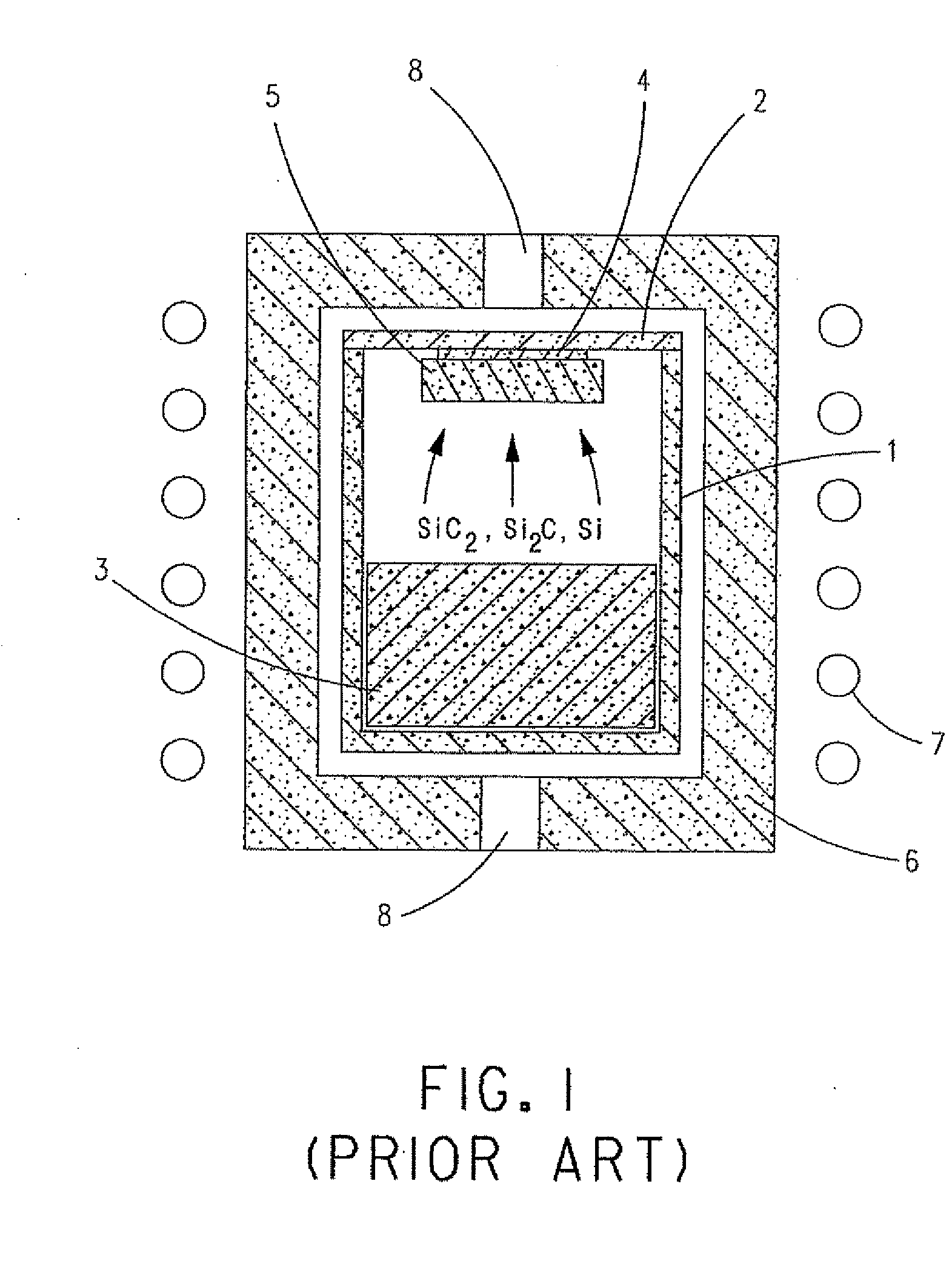

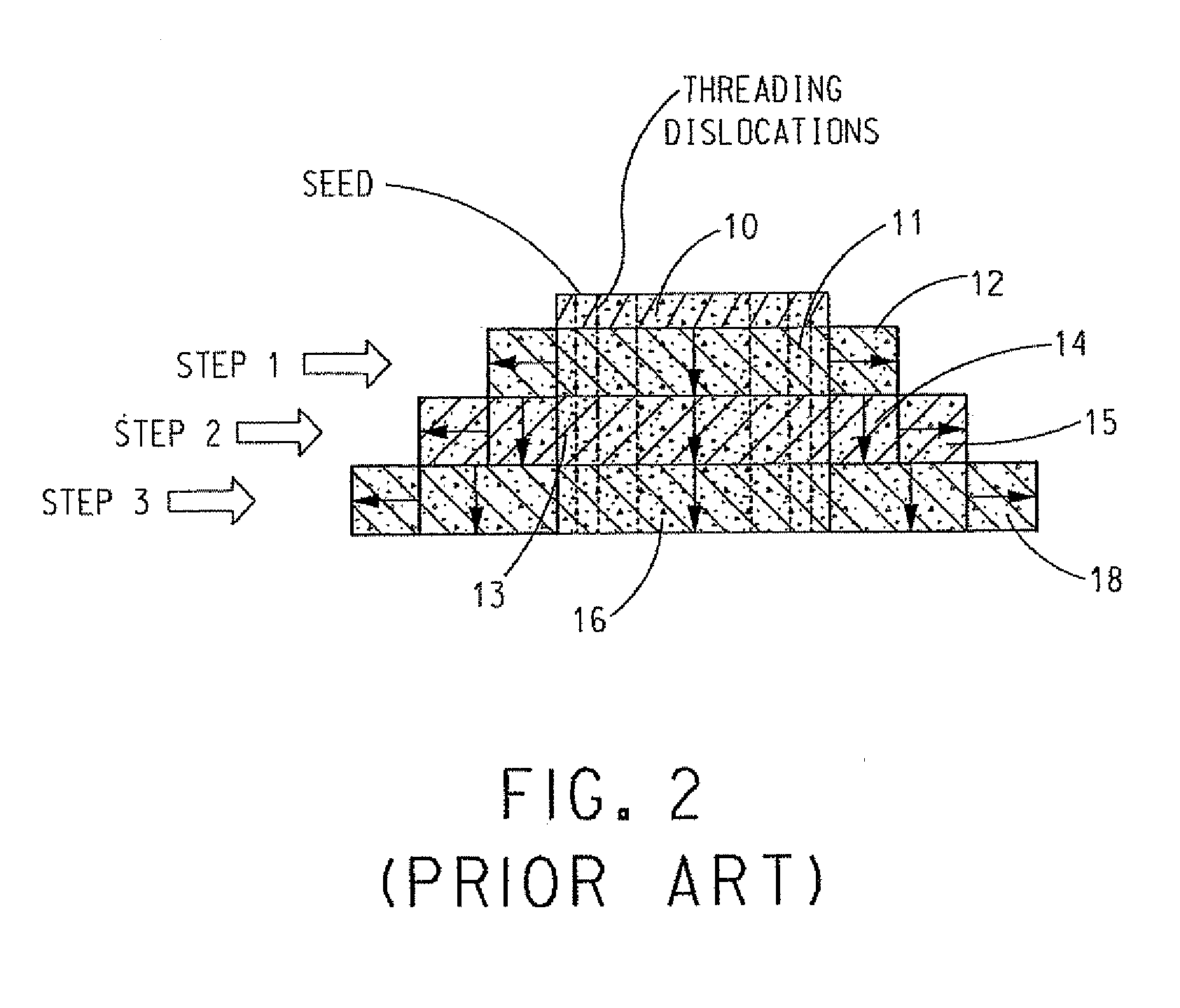

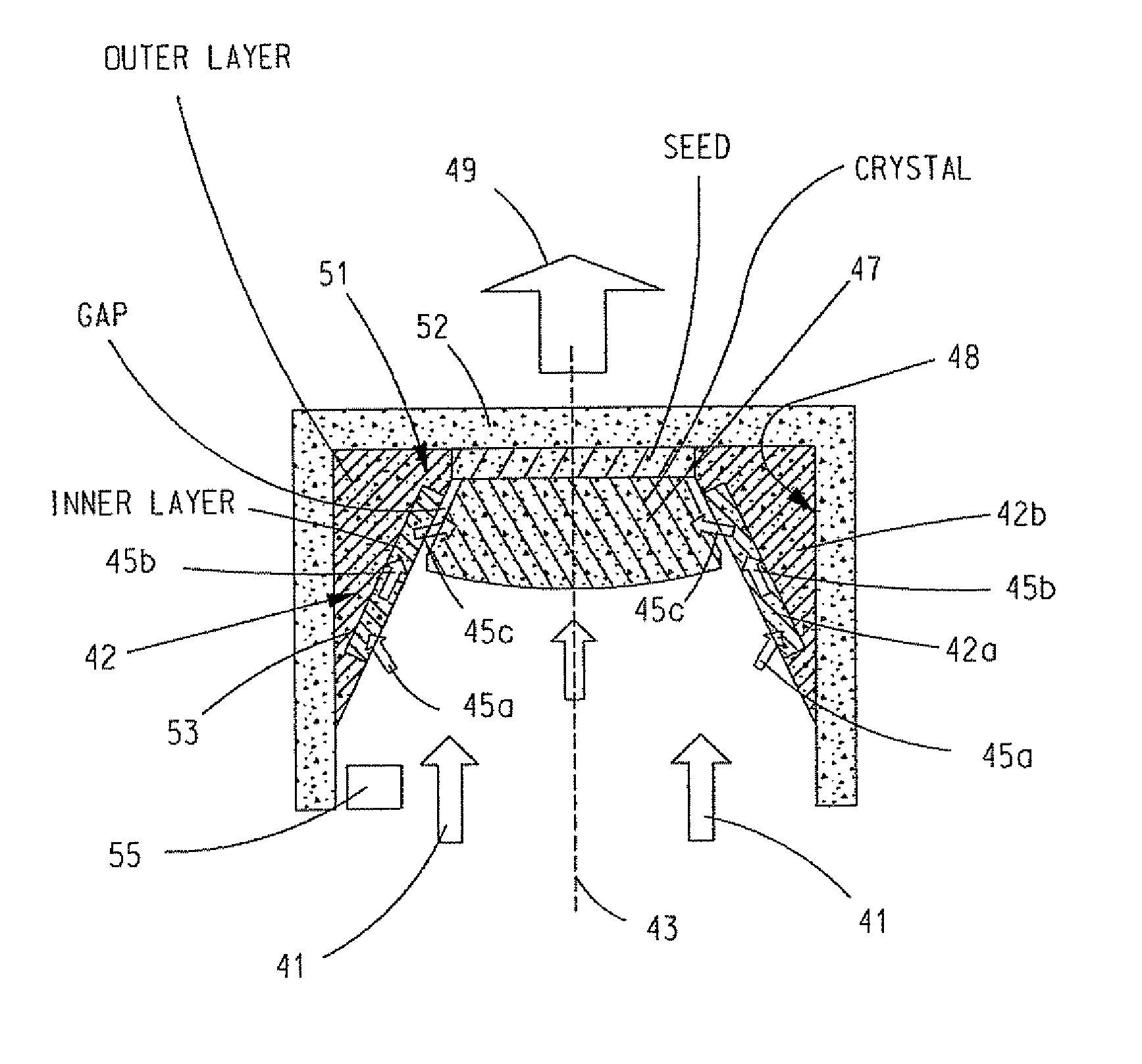

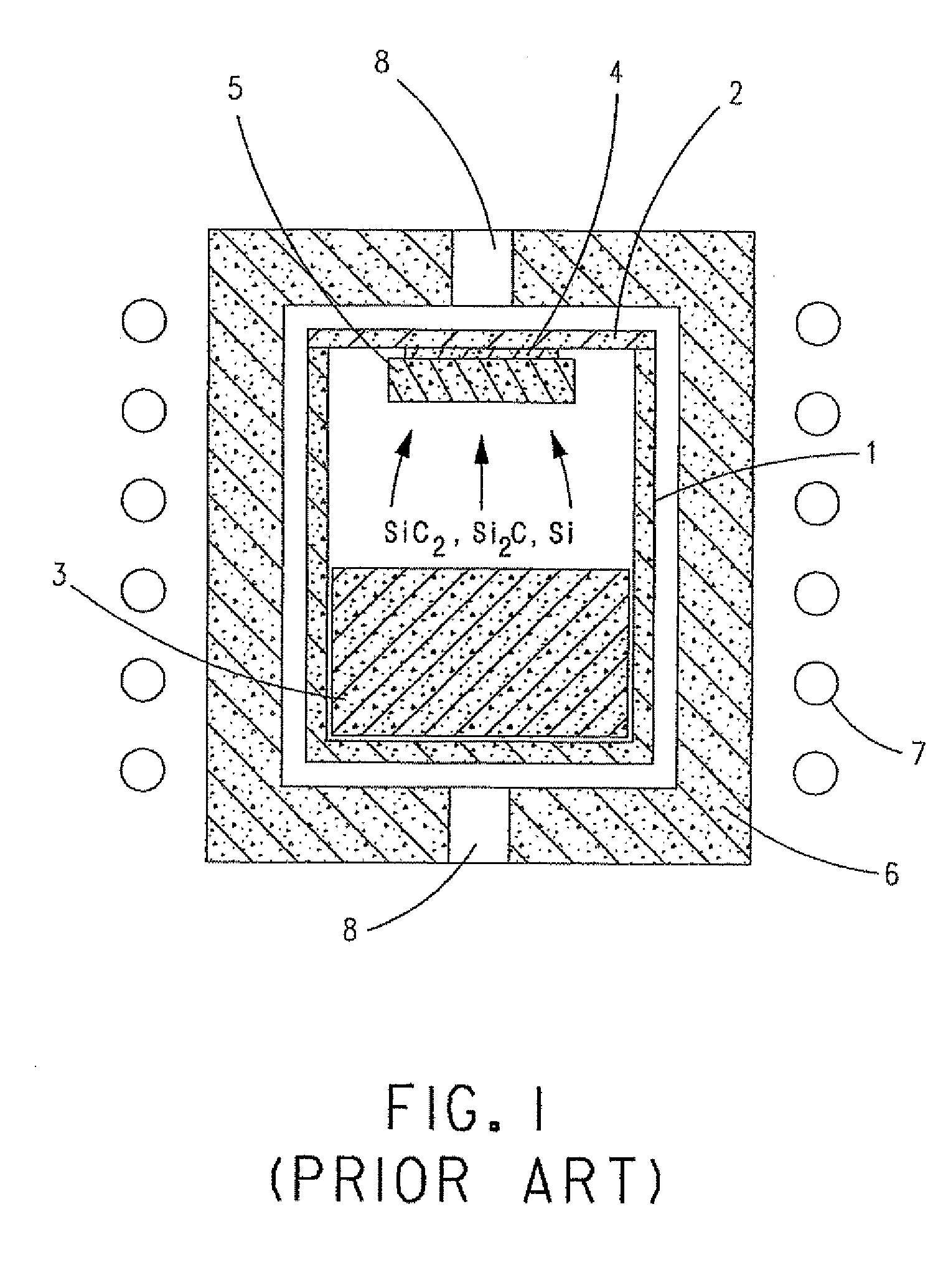

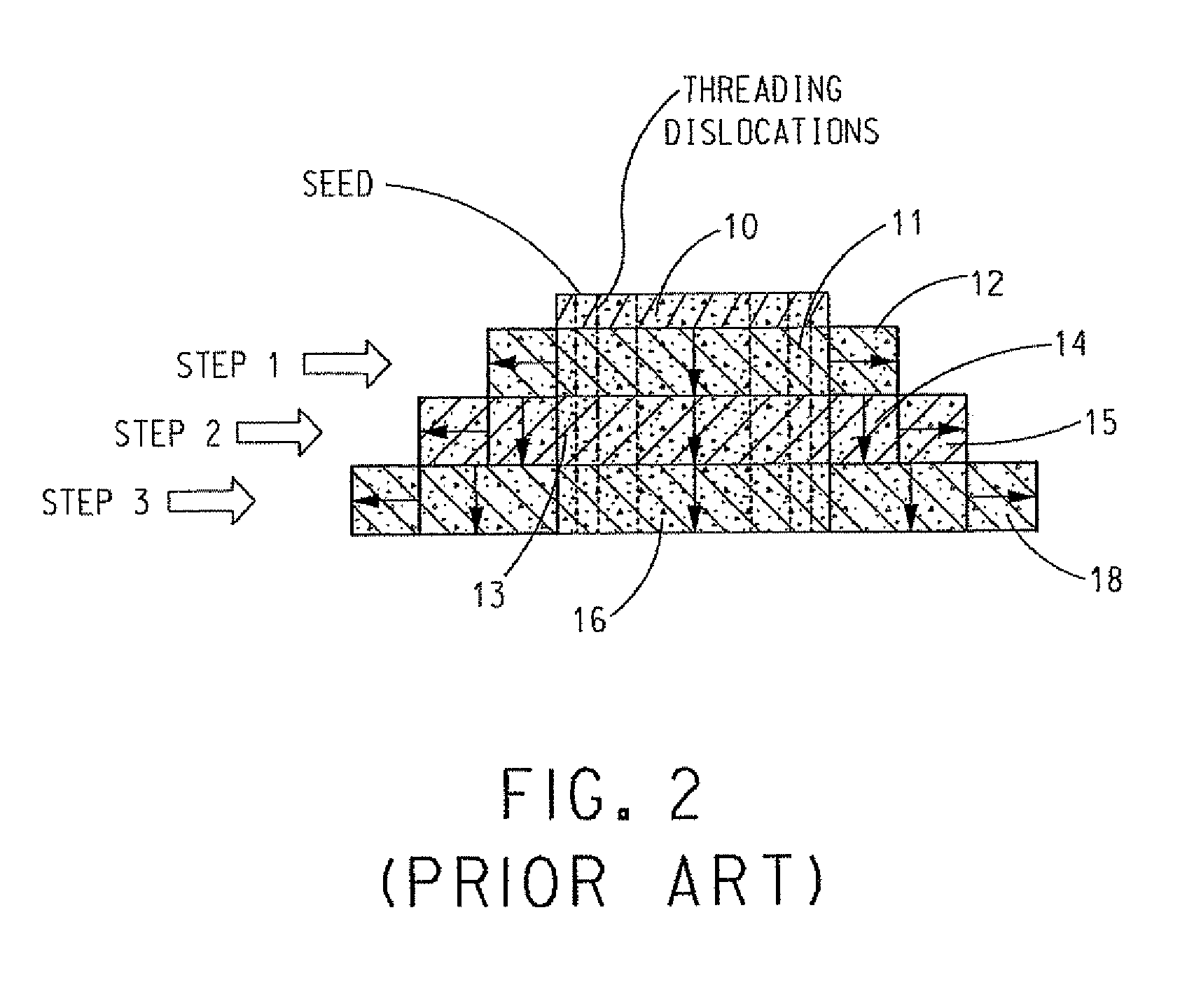

GUIDED DIAMETER SiC SUBLIMATION GROWTH WITH MULTI-LAYER GROWTH GUIDE

ActiveUS20100061914A1Improve thermal conductivityLow thermal conductivityAfter-treatment apparatusPolycrystalline material growthSource materialCrucible

In the growth of a SiC boule, a growth guide is provided inside of a growth crucible that is charged with SiC source material at a bottom of the crucible and a SiC seed crystal at a top of the crucible. The growth guide has an inner layer that defines at least part of an opening in the growth guide and an outer layer that supports the inner layer in the crucible. The opening faces the source material with the seed crystal positioned at an end of the opening opposite the source material. The inner layer is formed from a first material having a higher thermal conductivity than the second, different material forming the outer layer. The source material is sublimation grown on the seed crystal in the growth crucible via the opening in the growth guide to thereby form the SiC boule on the seed crystal.

Owner:II VI DELAWARE INC

No-baking and no-steaming environment protection solid fly ash-cinder brick

InactiveCN1931772AImprove early strengthGood compatibilitySolid waste managementCooking & bakingFly ash brick

The present invention relates to green building material, and features that the no-braking and no-steaming green brick is produced with cementing industrial waste, small amount of cement, aggregate and admixture. Cementing industrial waste, such as fly ash, calcium carbide slime, etc, cement, aggregate and admixture in certain weight proportion are produced into the no-braking and no-steaming green brick through mixing, forming, curing, stocking, naturally curing and inspection. The brick meets the requirement of fly ash brick, and has the features of saving clay resource, no need of steam curing, simple production and low cost.

Owner:HENAN POLYTECHNIC UNIV

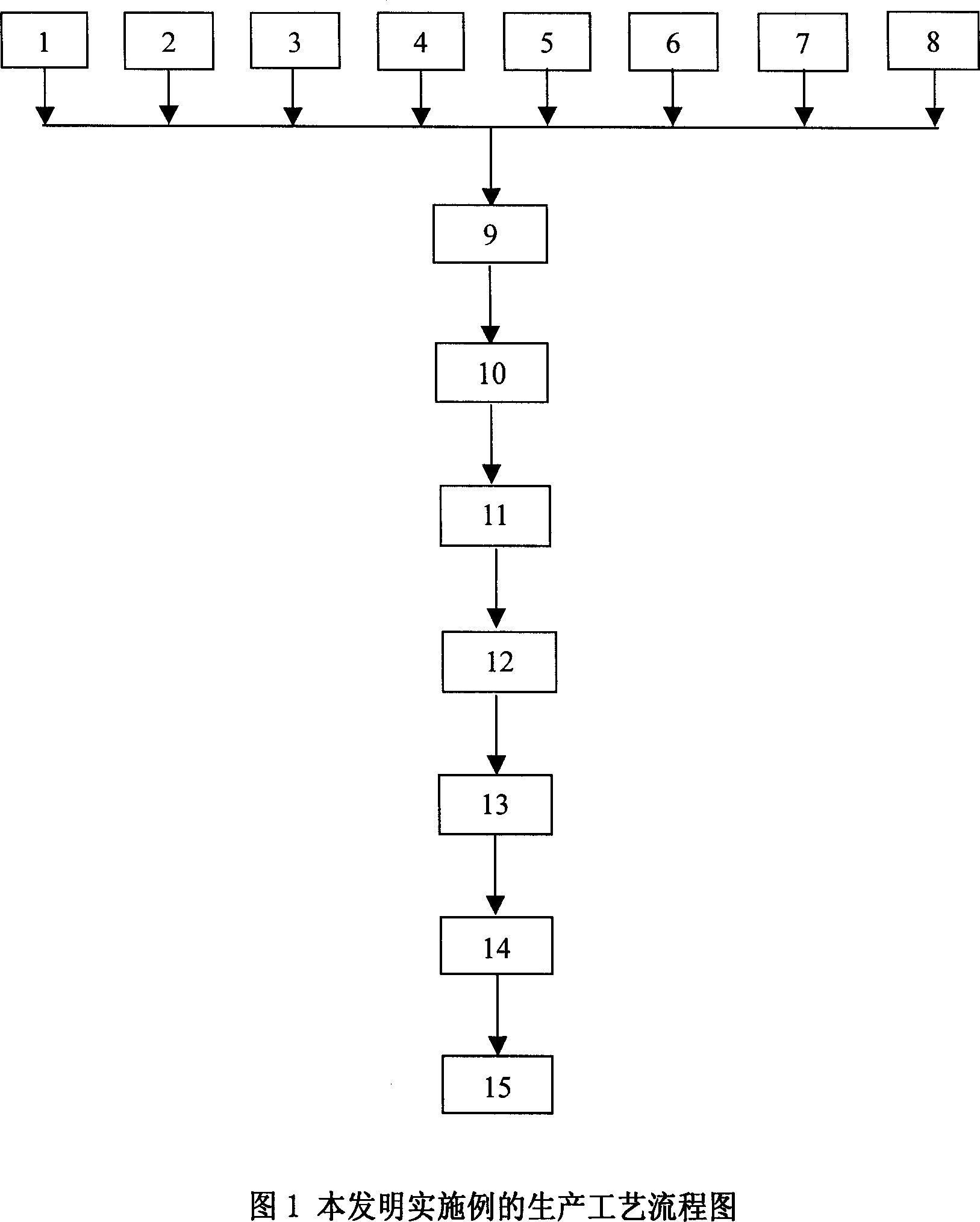

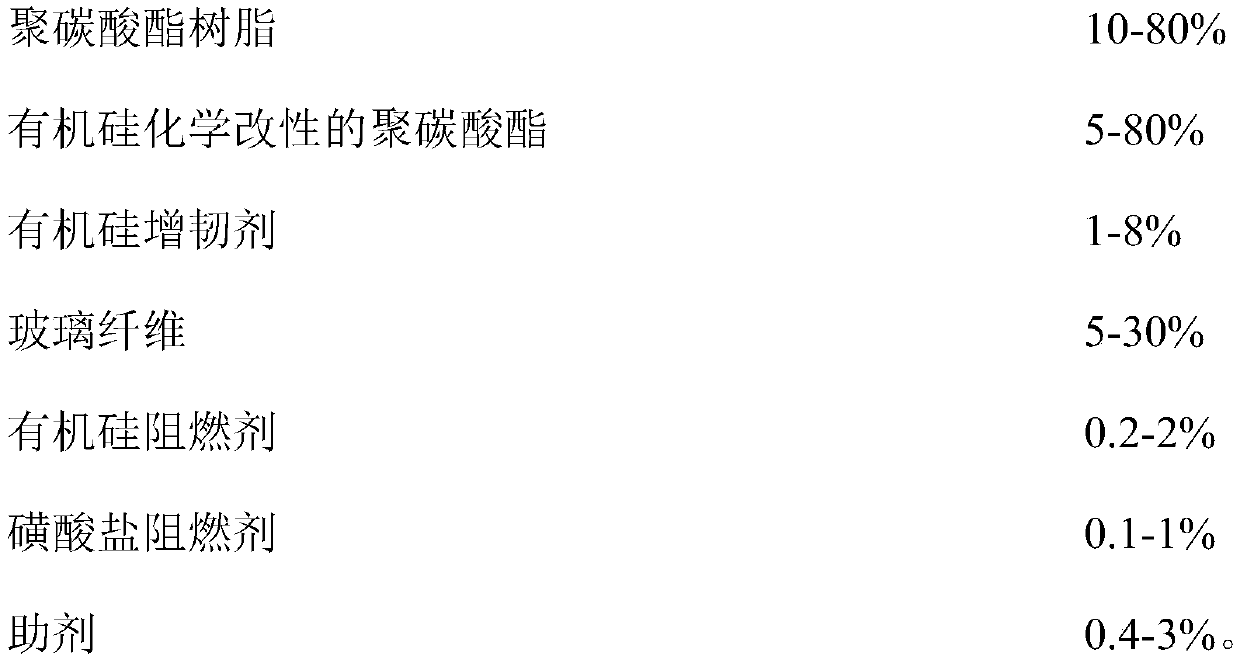

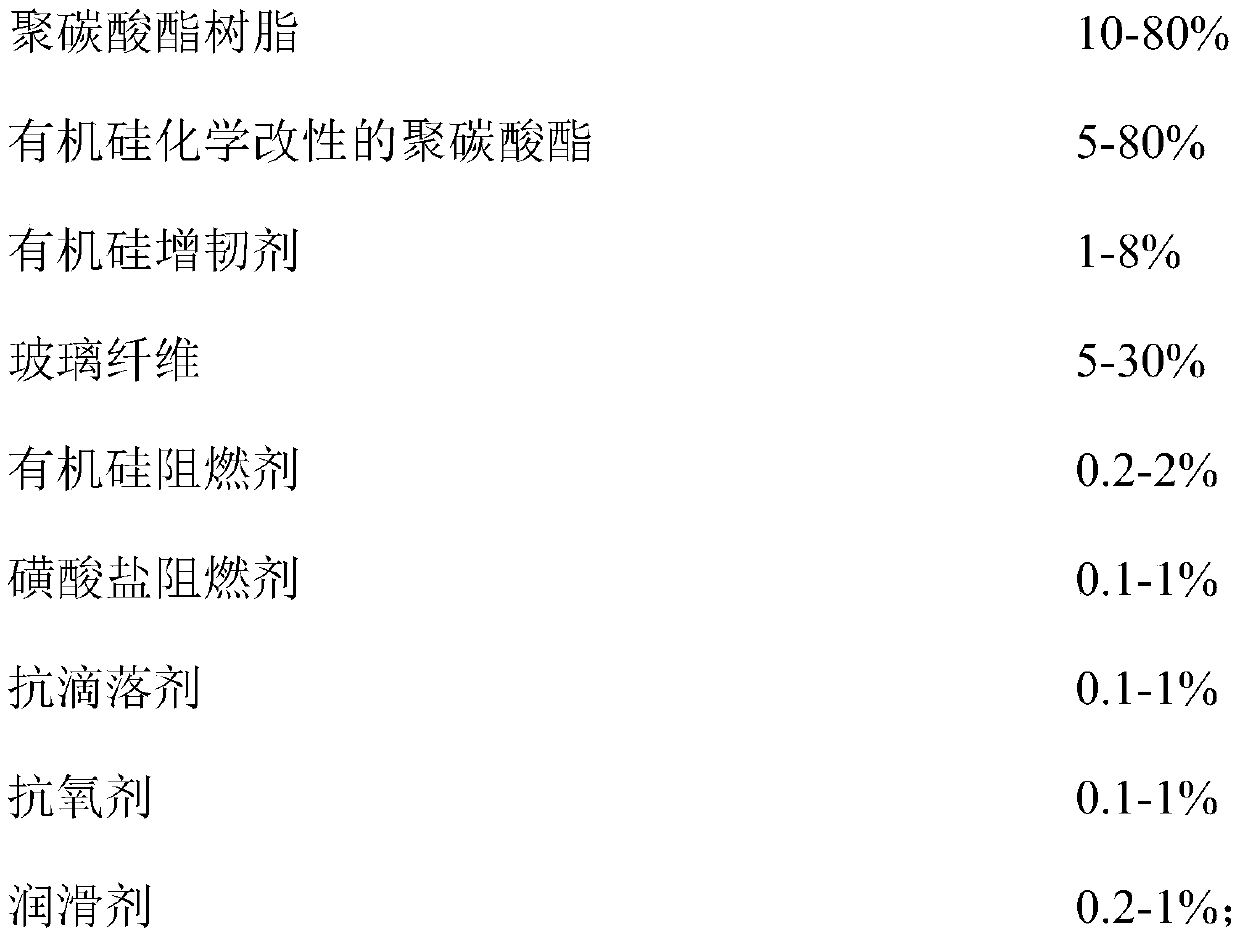

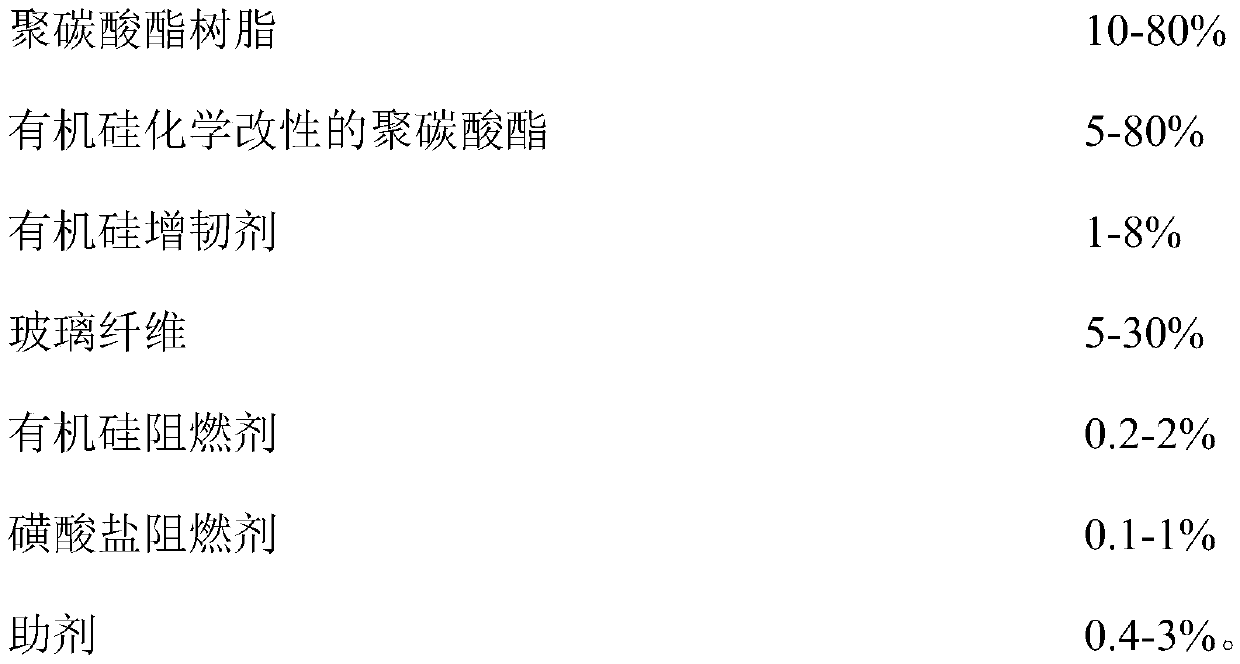

Glass-fiber-reinforced flame-retardant polycarbonate composite material, and preparation method and applications thereof

The invention relates to a glass-fiber-reinforced flame-retardant polycarbonate composite material, and a preparation method and applications thereof. The glass-fiber-reinforced flame-retardant polycarbonate composite material comprises, by mass, polycarbonate resin of 10 to 80%, silicone chemically modified polycarbonate of 5 to 80%, silicone toughening agent of 1 to 8%, glass fiber of 5 to 30%,silicone flame retardant of 0.2 to 2%, sulfonate flame retardant of 0.1 to 1%, and an auxiliary agent of 0.4 to 3%. The glass-fiber-reinforced flame-retardant polycarbonate composite material possesses excellent low temperature impact resistance, flame resistance, rigidity, heat resistance, and hydrolysis resistance, contains no halogen, and is friendly to the environment.

Owner:SHENZHEN HALCYON NEW MATERIALS

Aluminum alloy sodium-free refining agent and application thereof

The invention provides an aluminum alloy sodium-free refining agent and belongs to the technical field of casting of aluminum alloys. The sodium-free refining agent comprises the following raw materials in parts by weight: 30-35 parts of K2CO3, 10-12 parts of potassium fluoroaluminate, 5-10 parts of CaF2, 12-18 parts of LiCl, 3-5 parts of calcium oxide, 30-35 parts of BalF3, 5-10 parts of K2SiF6, 10-15 parts of C6Cl6, 5-10 parts of TiO2 and 3-8 parts of CaCl. The aluminum alloy sodium-free refining agent is free of impurity sodium; meanwhile, rare-earth metals are added into the sodium-free refining agent; the rare-earth metals have high chemical affinity with impurity elements such as H2 and S and the like; the rare-earth metals and various impurity elements form compounds; the influence of harmful impurities can be eliminated; the rare-earth metals have the functions of modifying and refining the aluminum alloy structure; the dendrite spacing of the aluminum alloy is effectively reduced; the as-cast grains are refined; the mechanical performance of the alloy is improved; meanwhile, the smelting temperature of the aluminum alloy is maintained at 710-730 DEG C in the process of using the aluminum alloy sodium-free refining agent, so that the effect of removing impurity elements such as H2 and S and the like is more significant.

Owner:贵州航天风华精密设备有限公司

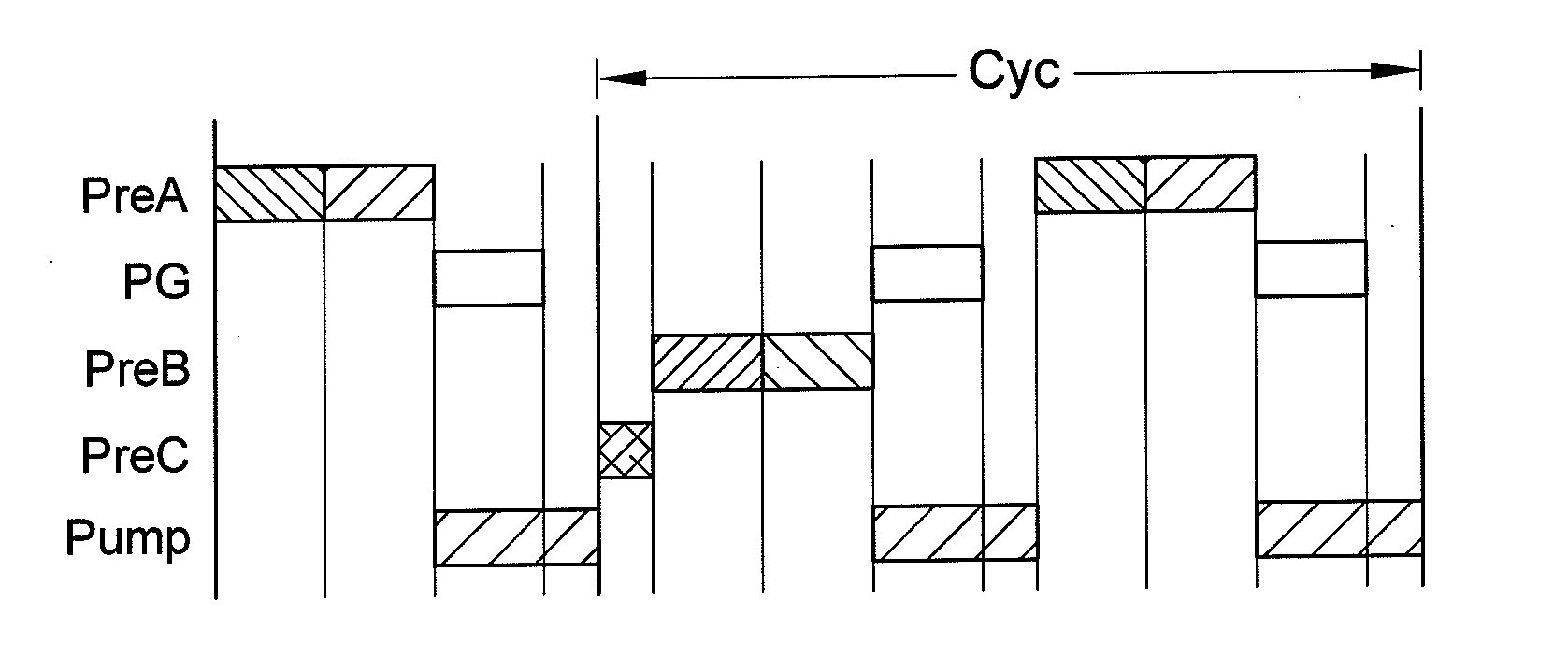

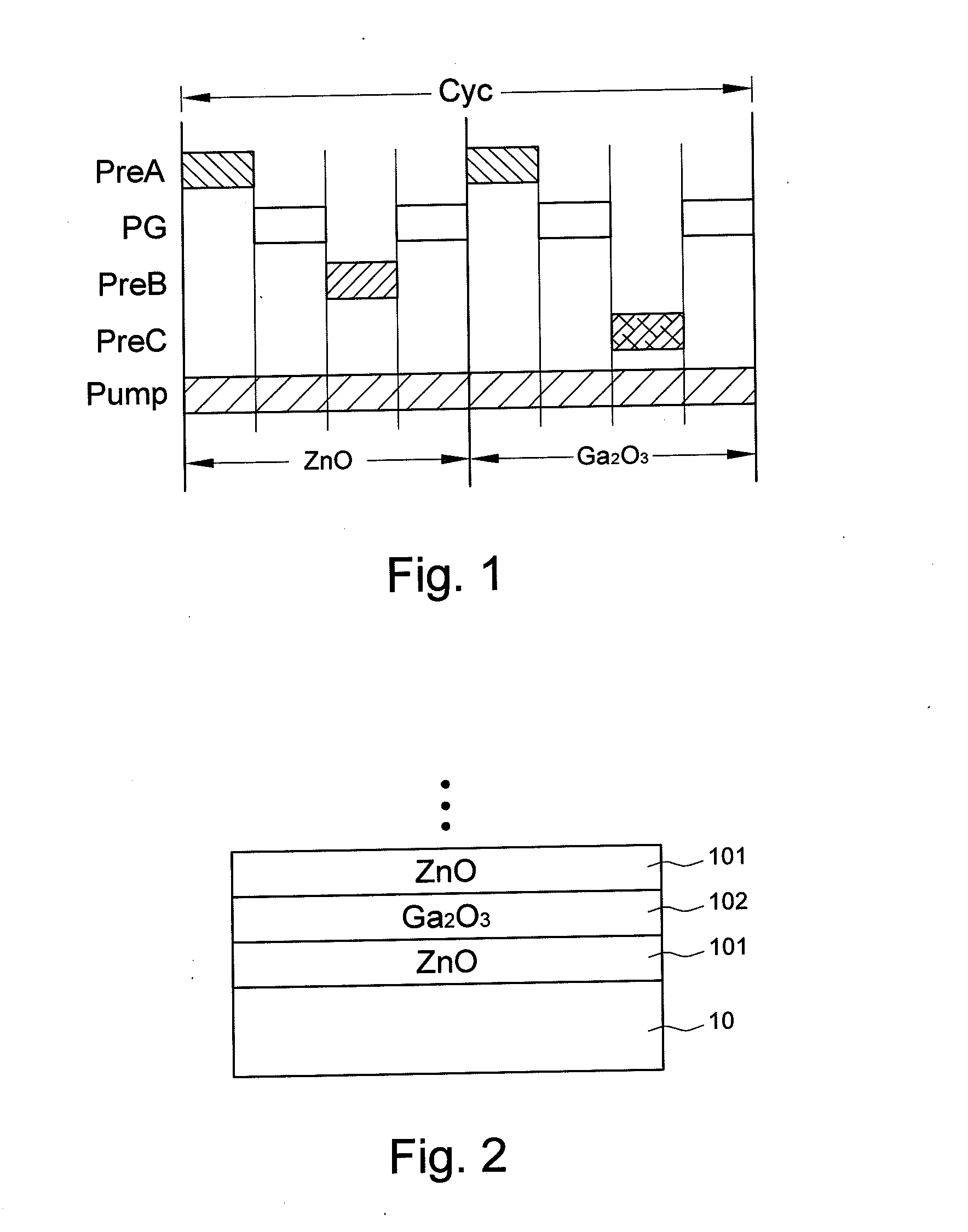

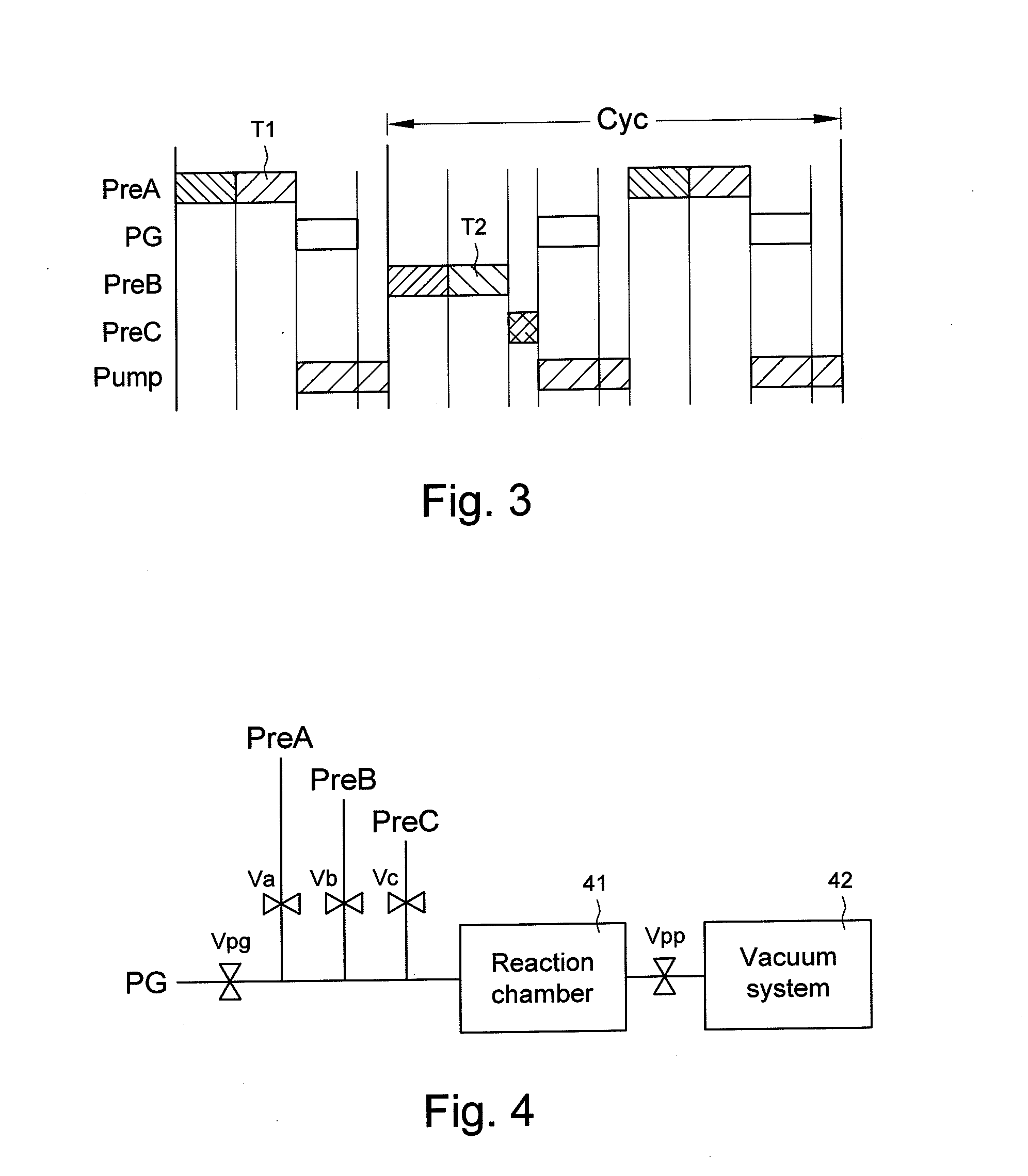

Doping method of atomic layer deposition

ActiveUS20130209685A1Prevent annealingEnhance chemical affinityVacuum evaporation coatingSputtering coatingAtomic layer depositionReaction chamber

A doping method of atomic layer deposition includes providing a substrate in a reaction chamber; and performing at least one atomic layer deposition cycle to form a film on a surface of the substrate. The atomic layer deposition cycle includes passing first precursors into the reaction chamber to let first atoms included in the first precursors combine with reaction sites of the substrate; and passing second precursors into the reaction chamber to let second atoms included in the second precursors combine with the reaction sites uncombined with the first atoms or substitute at least part of the first atoms to combine with the reaction sites of the substrate. The above-mentioned doping method of atomic layer deposition is capable of preparing large area and uniformity of doping film without annealing process or with low temperature annealing process.

Owner:NAT SYNCHROTRON RADIATION RES CENT

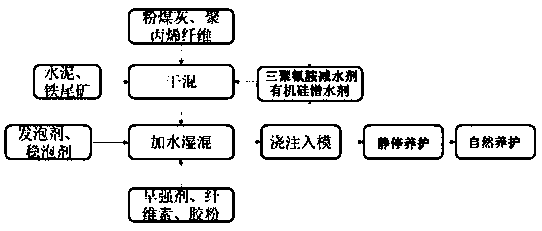

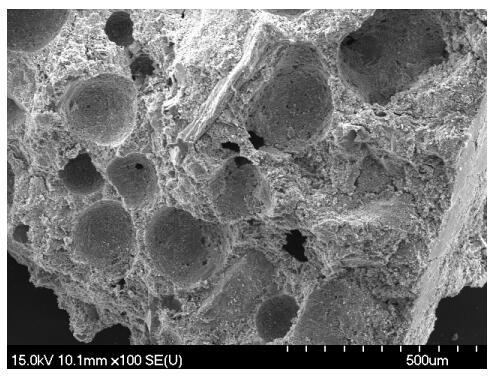

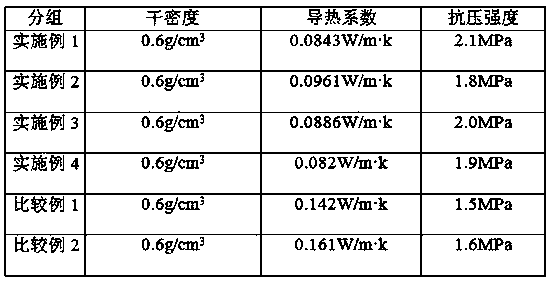

Foam aerated concrete building block prepared from iron tailings at normal temperature and under normal pressure and preparation method of foam aerated concrete building block

The invention discloses a foam aerated concrete block prepared from iron tailings at normal temperature and under normal pressure and a preparation method of the foam aerated concrete building block.The foamed aerated concrete block comprises the following components in percentage by weight: 20-50% of the iron tailings, 30-60% of cement, 2-4% of an early strength agent, 3-10% of fly ash, 1-3% ofcellulose, 1-3% of glue powder, 2-4% of polypropylene fibers, 1-2% of a foaming agent, 1-2% of a melamine water reducer, 1-2% of an organic silicon hydrophobic agent and 0.5-1.5% of a foam stabilizer.The foam concrete building block prepared by the invention has lower density, higher porosity, higher sound insulation property and stronger heat insulation property after being tested; the foam concrete building block prepared by the invention has excellent performance, and in a process of preparing the foam aerated concrete building block, process steps are simple, the reaction treatment time is extremely fast, the curing method is simple, and the production efficiency of enterprises can be greatly improved.

Owner:ZHEJIANG UNIV OF TECH

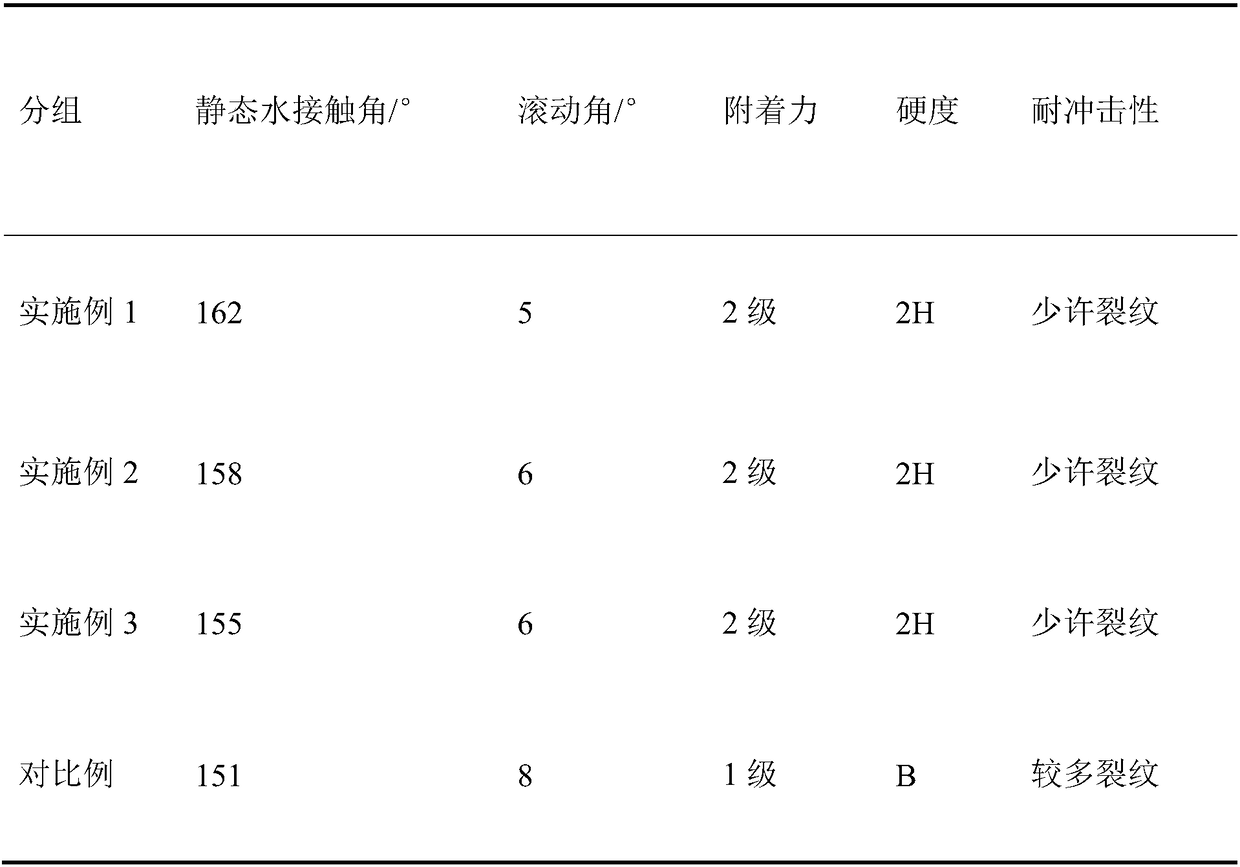

Superhydrophobic anticorrosive coating for marine concrete and preparation method thereof

ActiveCN108546483AImprove adhesionImprove frost resistanceAnti-corrosive paintsMaterials science2-methyl-1-propanol

The invention discloses a superhydrophobic anticorrosive coating for marine concrete, the superhydrophobic anticorrosive coating is prepared from the following raw materials by weight: 60-80 parts ofmodified silicon-acrylic emulsion, 1-2 parts of orthosilicate, 4-6 parts of methyltriethoxysilane, 30-40 parts of ethanol, 0.5-1 part of 2-amino-2-methyl-1-propanol and 5-10 parts of ammonia water. The invention also discloses a preparation method of the superhydrophobic anticorrosive paint for the marine concrete. The superhydrophobic anticorrosive paint for the marine concrete has the excellentperformances of long-lasting weather resistance and long-lasting corrosion resistance, and has broad market development prospects. The methyltriethoxysilane and the ethyl orthosilicate are hydrolyzedand polycondensed in the modified silicone-acrylic emulsion to form an inorganic network, and the organic-inorganic hybrid superhydrophobic anticorrosive coating can be obtained.

Owner:UNIV OF JINAN

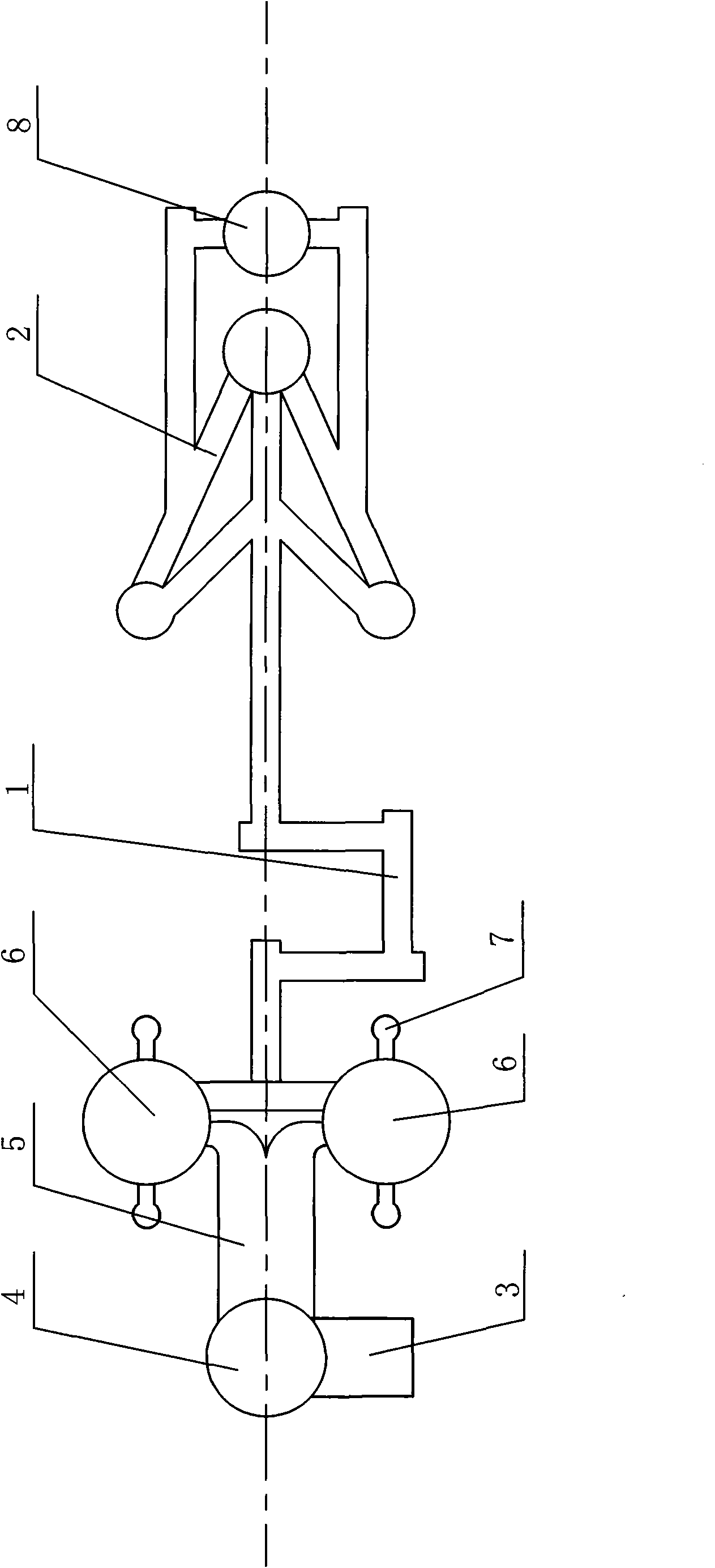

Pumped vacuum system and die casting method of magnesium alloy vacuum high-pressure die casting mould

The invention provides a pumped vacuum system and a die casting method of a magnesium alloy vacuum high-pressure die casting mould. Castings are better produced under vacuum state in order to have higher quality and meet the requirement of high cutting-edge technology occasions, therefore the mould has to undergo vacuum high-pressure die casting in order to solve the problem of flammability of magnesium alloys and overcome the pore defect and improve the quality of the castings and the productivity of the finished product. The pumped vacuum system comprises a gating system, wherein the gating system is connected with a labyrinth system (2) by an exhaust duct (1) and comprises a pressure chamber (3); the pressure chamber is connected with a sprue (4) of the labyrinth system; the sprue is connected with a runner (5); the runner is connected with inner casting gates (6) which are connected with the exhaust duct; the inner casting gates comprise overflow systems (7); and the labyrinth system is connected with vacuum valves (8). The invention is used for magnesium alloy die casting.

Owner:HARBIN UNIV OF SCI & TECH

Fluid-tight slide fastener

InactiveUS8166619B2Enhance chemical affinityHigh affinitySnap fastenersWire articlesPolyesterThermoplastic elastomer

A fluid-tight slide fastener including coated tapes equipped with teeth, opposite stops and a slider operable between the opposite stops to engage or disengage the teeth. The coated tapes include a core textile layer and a fluid-barrier coating made of a thermoplastic elastomer material (TPE), the teeth being made of a thermoplastic material. The textile material of the core layer of the coated tapes is chosen among polyester, polyamide and their blends or copolymers. The thermoplastic elastomer material of the coating is chosen between thermoplastic elastomer polyurethane (TPE-U) and thermoplastic elastomer polyester (TPE-E). The thermoplastic material of the teeth is chosen among PBT, ABS, polyamide and their blends or copolymers.

Owner:RIRI GROUP

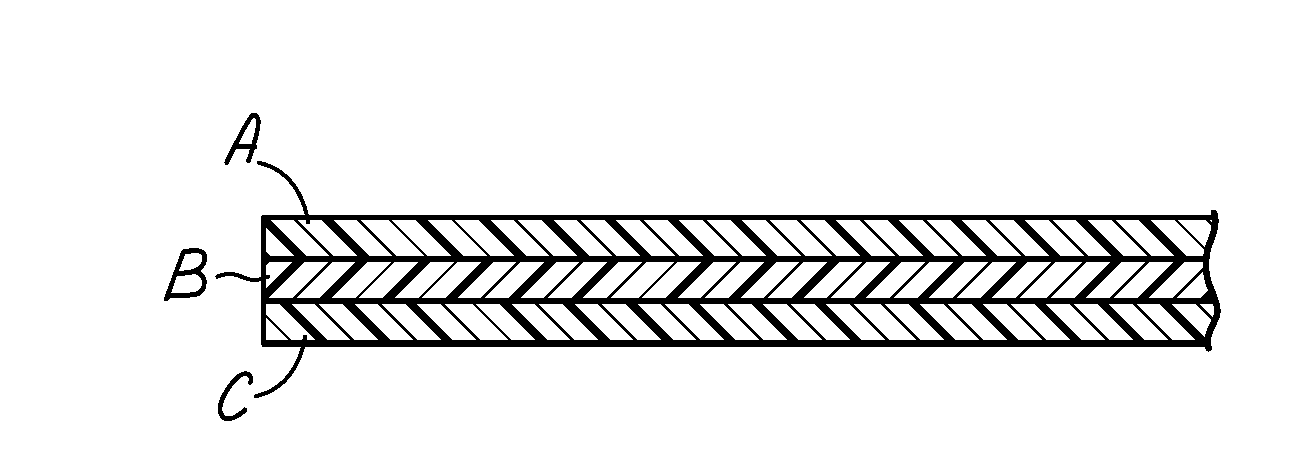

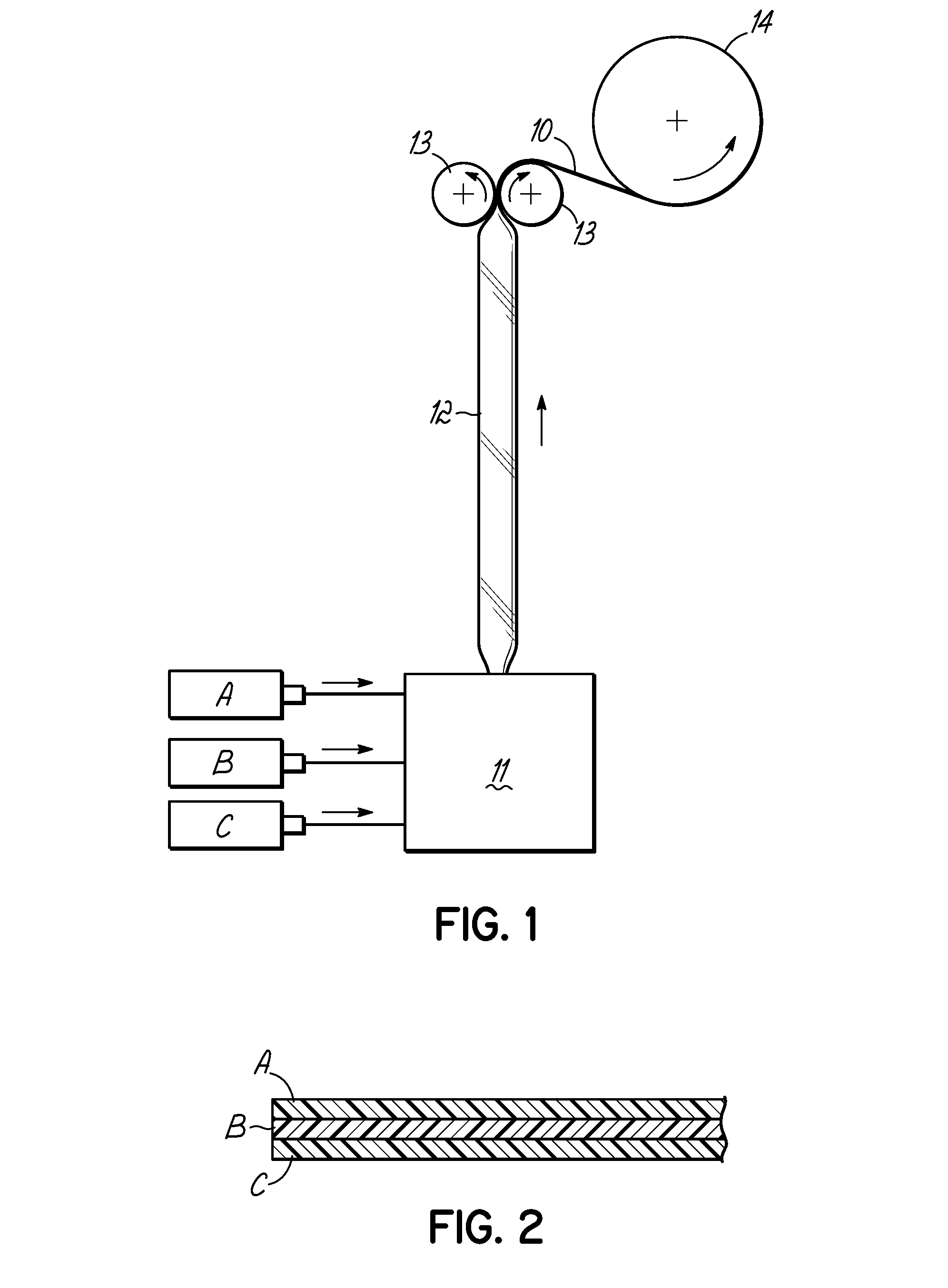

Elastomeric compositions for blown-film extrusion

InactiveUS20160168345A1Balanced propertyLow costSynthetic resin layered productsLaminationElastomerPolymer science

Improving processability of homogeneous extrusion blown elastomeric films by compatibilizing impact polystyrene in an effective amount with olefin elastomers and styrenic block copolymers.

Owner:CLOPAY PLASTIC

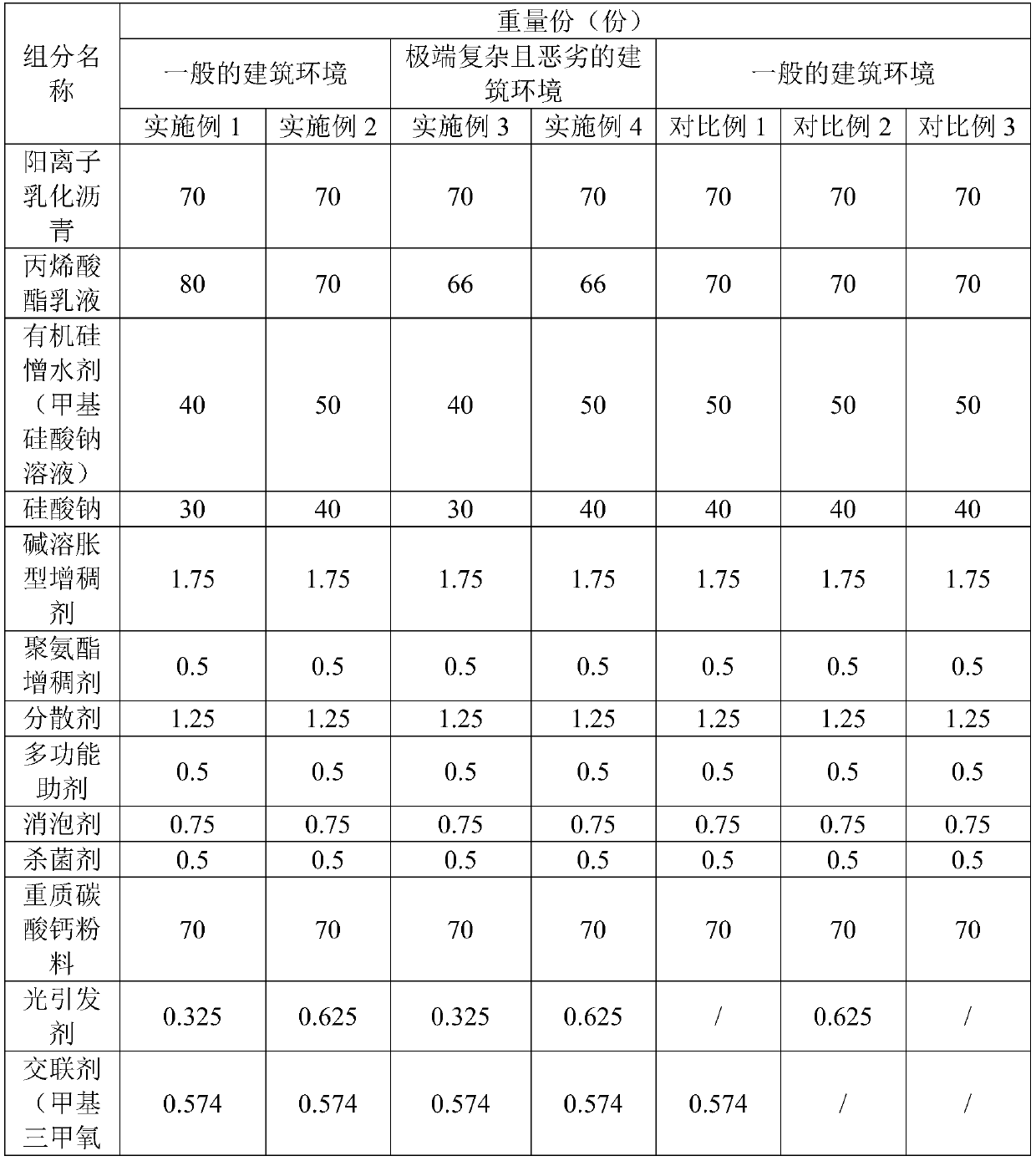

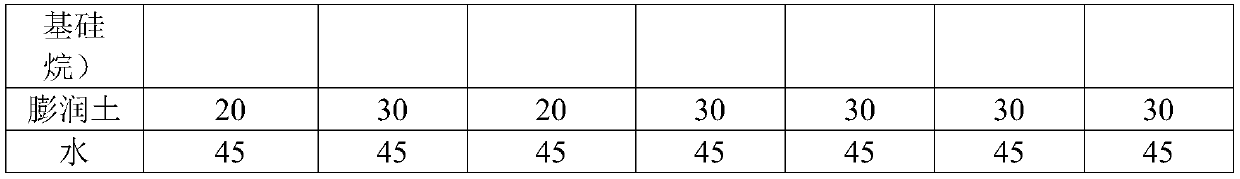

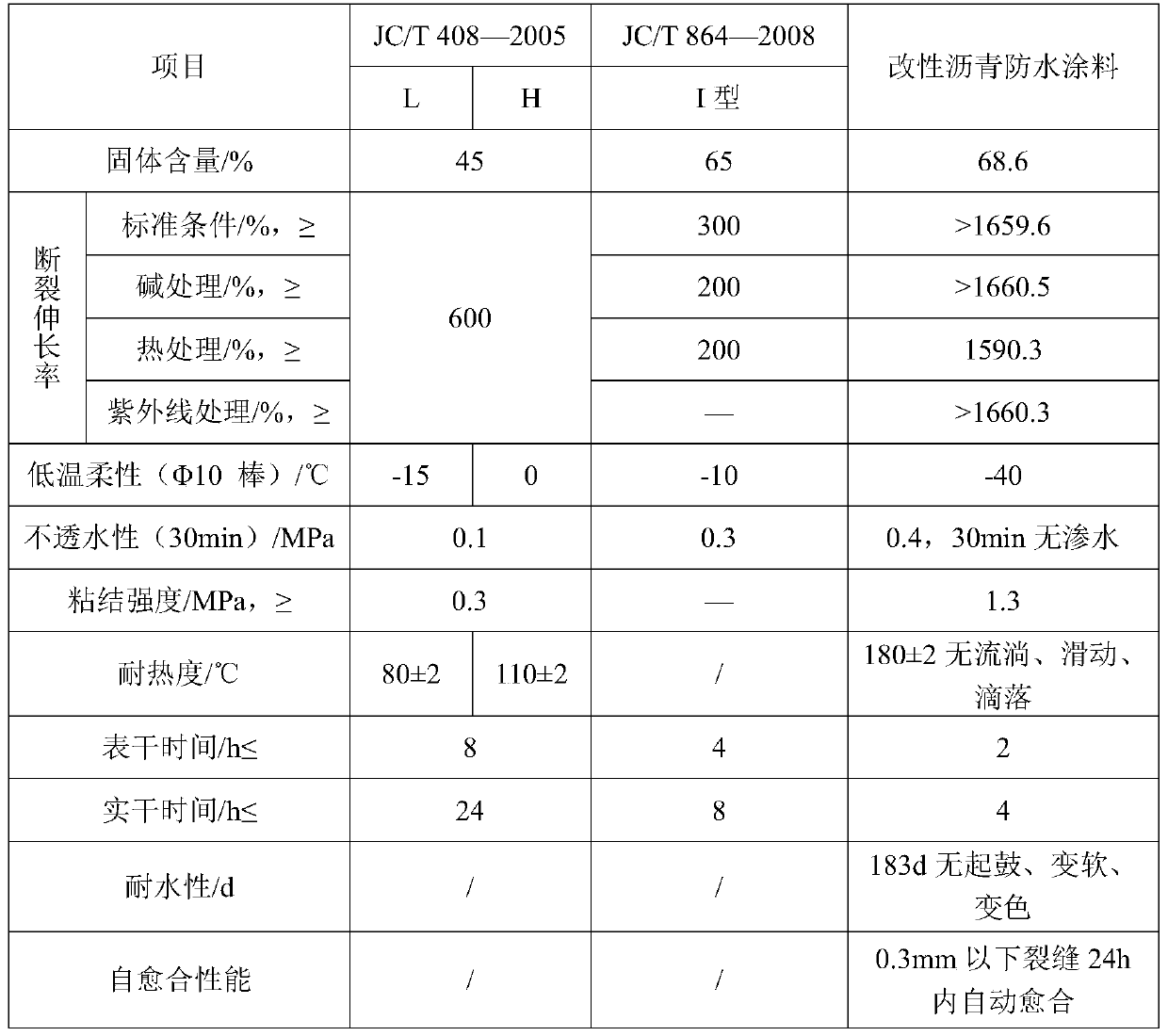

Water-based permeable self-healing high polymer modified asphalt waterproof coating with hydrophobic surface as well as preparation method and application thereof

InactiveCN111100555AImprove waterproof performanceGood compatibilityFireproof paintsBuilding insulationsPolymer scienceBituminous waterproofing

The invention discloses a water-based permeable self-healing high polymer modified asphalt waterproof coating with a hydrophobic surface as well as a preparation method and application thereof. The coating is prepared from emulsified asphalt, acrylate emulsion, an alkali swelling thickener, a polyurethane thickener, a dispersing agent, a multifunctional additive, a defoaming agent, a sterilizing agent, ground calcium carbonate powder, bentonite, an organic silicon water repellent, sodium silicate, a photoinitiator, a cross-linking agent and water. The coating disclosed by the invention mainlyhas rapid curing performance, self-healing performance, ultrahigh bonding strength and elongation rate and excellent water resistance and high and low temperature resistance, is suitable for various environments, can achieve a good waterproof effect on a building structure in any environment, is particularly suitable for waterproof engineering of various extremely complex environments, projects ofsome complex scenes and some special regions and projects, fills the blank of the material in severe cold regions, and is wide in application range.

Owner:SUZHOU GUARDEX NEW MATERIAL TECH CO LTD

Thermoplastic Resin Composition

Provided is a plant-derived resin composite material which has a sufficiently fast crystallization rate and excellent moldability and heat resistance by using a thermoplastic resin composition containing a plant-derived thermoplastic resin and an organic crystal nucleating agent which is composed of one or more low molecular weight compounds comprising at least two polar groups in the molecule, a spacing between any two of the polar groups being 34±4 angstroms.

Owner:NEC CORP

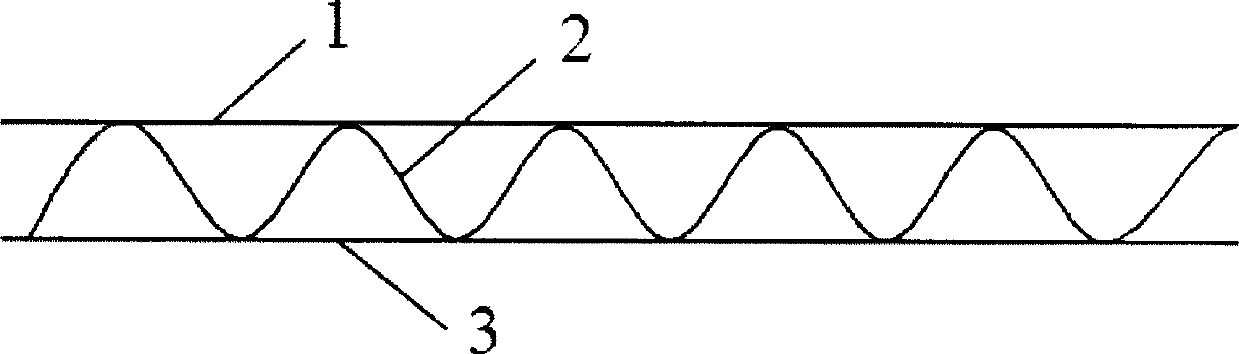

High-intensity water-resistance corrugated board and preparation method thereof

ActiveCN103103891AHigh water resistance strengthStrong water resistanceNon-fibrous pulp additionMechanical working/deformationCardboardAdhesive

The invention discloses a high-intensity water-resistance corrugated board and a preparation method of the high-intensity water-resistance corrugated board according to the national standard GB / T22873-2008. The high-intensity water-resistance corrugated board comprises surface paper and inner paper, wherein a corrugated paper layer is arranged between the surface paper and the inner paper; a high-intensity water-resistance adhesive is coated between the peak surface of the corrugated paper layer and the surface paper as well as the inner paper; a special water-resistance additive is added into the conventional corrugated board adhesive; and various technological parameters of a board automatic line are optimized by an ultrafine particle pulping technology, so that the water resistance of the corrugated board is greatly improved and is much higher than the advanced level of products of the same type in foreign countries.

Owner:DACHENG PACKAGING PROD SUZHOU

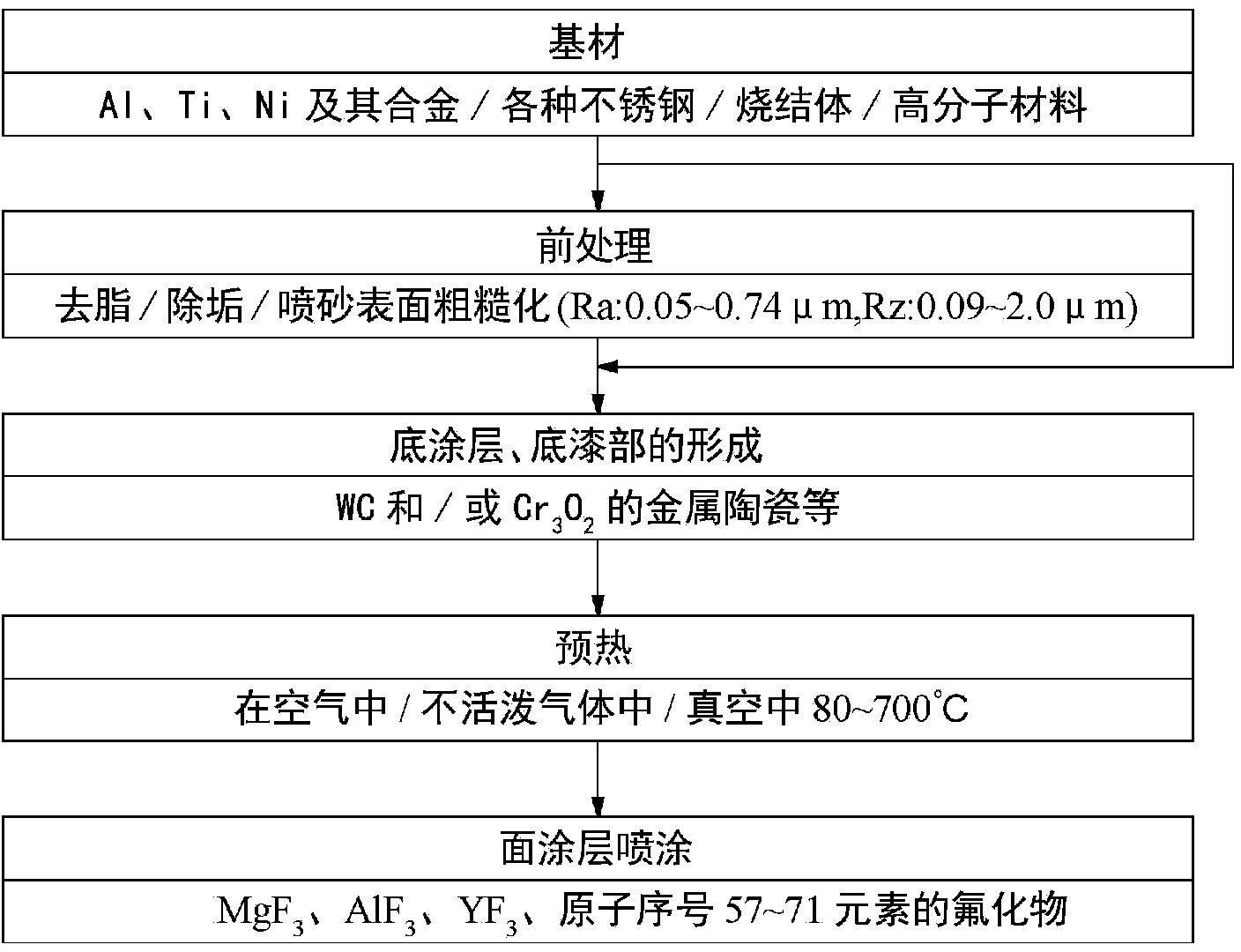

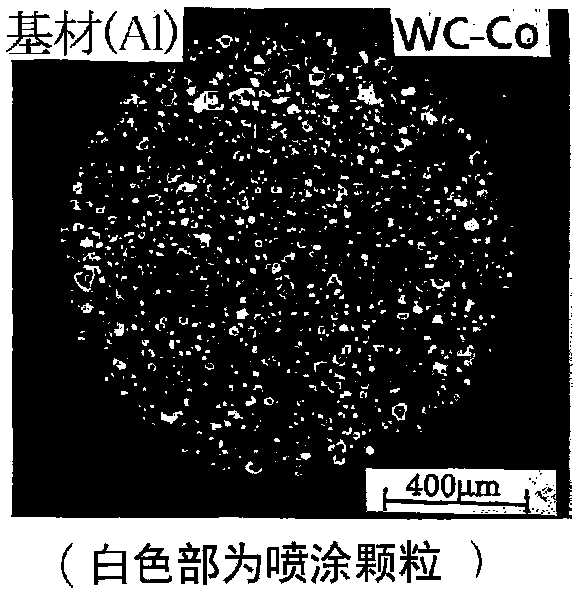

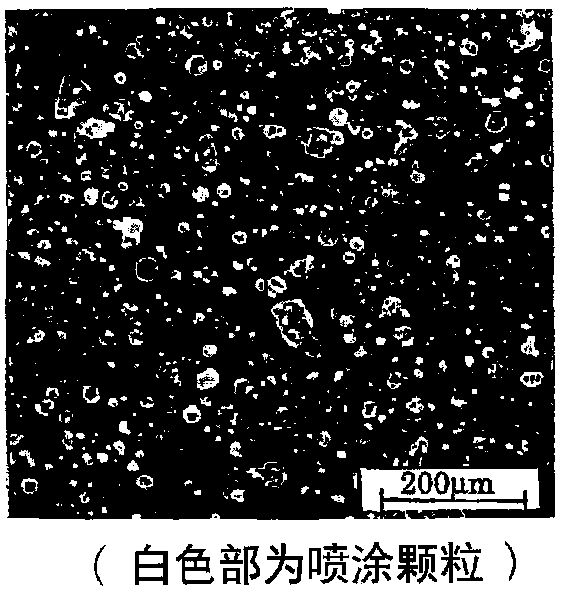

Method for forming fluoride spray coating, and member coated with fluoride spray coating

ActiveCN104204267AExcellent adhesionStrong compressive residual stressMolten spray coatingThin material handlingSpray coatingCarbide

Owner:TOCALO & HANTAI CO LTD

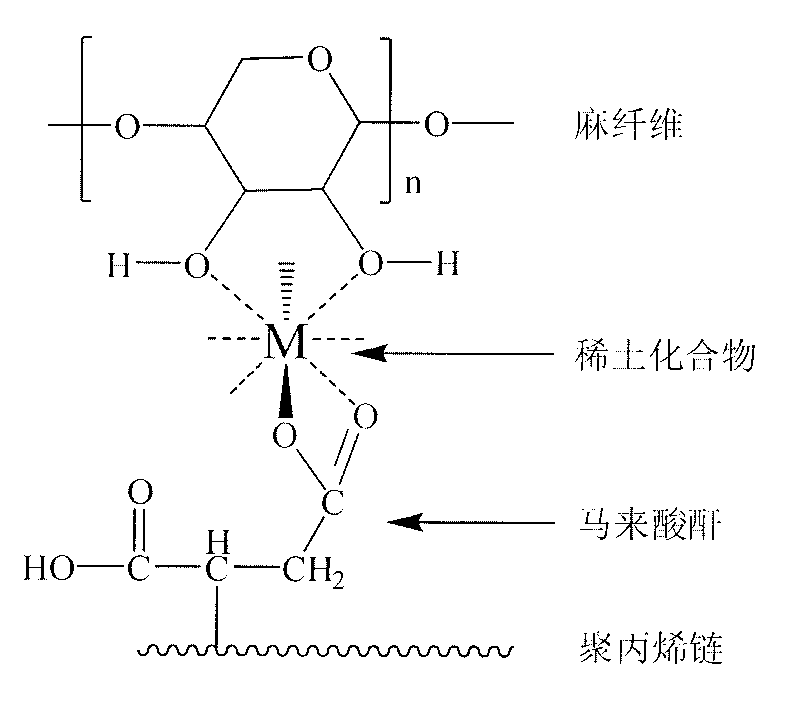

Compound modified biomass fibrilia and preparation method thereof

The invention relates to a compound modified biomass fibrilia and a preparation method thereof and develops a rare earth compound modified fibrilia, which is characterized in that maleic anhydride grafted polypropylene is grafted and coated on the outer surface of natural fibrilia modified by rare earth. The preparation method comprises the following steps of: impregnating the natural fibrilia in a certain rare earth solution at normal temperature or low temperature for 1-2 hours, filtering and drying; and then coating the maleic anhydride grafted polypropylene on the fibrilia treated by the rare earth by adopting an extruding method to obtain the compound modified biomass fibrilia. The compound modified method can effectively eliminate the problems of surface structural defects and impurities, change the surface polarity and the hydrophily, greatly improve the interface bonding force of the fibrilia and a polymer matrix material, can be expected to be made into a fibrilia / polymer composite material with strong interface bonding capability and excellent mechanical property and ensures that the modified natural fibrilia and a composite material thereof can be more widely applied to the field of buildings, vehicle trimmers, office furniture and the like. The modified method has the advantages of simple operation, scale, no pollution and environment friendlessness.

Owner:HUNAN UNIV +1

Aluminum alloy sodium-free refining agent containing rare earth

The invention discloses an aluminum alloy sodium-free refining agent containing rare earth. The aluminum alloy sodium-free refining agent comprises, by weight, 50-60 parts of KCl, 30-35 parts of K2CO3, 10-15 parts of LiCl, 30-35 parts of AlF3, 10-12 parts of potassium fluoroaluminate, 5-10 parts of CaF2, 5-10 parts of carbon powder, 15-25 parts of light calcium carbonate, 2-8 parts of CaO, 2-5 parts of fluorite and 5-10 parts of rare earth. By means of the refining agent, no impurity sodium is introduced into the aluminum alloy refining process, rare earth metal is added, and therefore the mechanical performance of alloy can be effectively improved.

Owner:广西平果铝合金精密铸件有限公司

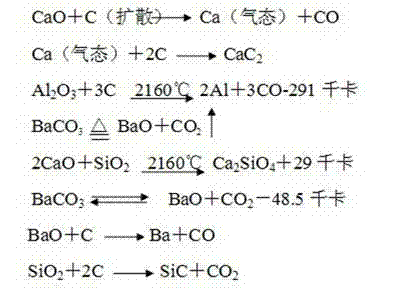

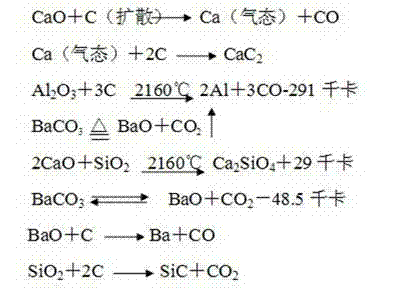

New silicon-aluminum-barium-calcium multicomponent deoxidation alloy for steelmaking and preparation technology thereof

The invention discloses a new silicon-aluminum-barium-calcium multicomponent deoxidation alloy for steelmaking and a preparation technology thereof. The alloy and preparation technology are mainly characterized in that the new silicon-aluminum-barium-calcium multicomponent deoxidation alloy for steelmaking is prepared by smelting quartz sand, barium carbonate, lime, wrought aluminum ore and silicon carbide in an electric-arc furnace; and the preparation technology comprises the following steps: mixing the quartz sand, wrought aluminum ore, barium carbonate, lime and silicon carbide raw materials at a weight ratio, adding the mixture into the electric-arc furnace lined with a carbon electrode lining, heating and melting for 120-150 minutes, refining, and discharging to obtain the silicon-aluminum-barium-calcium multicomponent deoxidation alloy. Compared with the traditional preparation technology, the preparation technology has the following advantages: electric energy is saved and 8000-9000kWh of power can be saved per ton. Wastes are reused. The carbon electrode, which replaces carbon, is used as the lining, so that every time the lining is repaired, the cost is reduced by 88.2% and the service life is prolonged by 3-5 days.

Owner:XICHUAN COUNTY SENLI IRON STEEL FURNACE CHARGE

Separation-resistant gas-barrier laminate

InactiveUS20110123744A1Prevent peelingPrevent interfacial peelingSynthetic resin layered productsRecord information storagePolyester resinSurface roughening

In a gas-barrier laminate having a layer structure of aromatic polyester resin / polyglycolic acid resin / aromatic polyester resin, a small amount of an aromatic polyester resin polymerized with a germanium compound (catalyst) is blended to the polyglycolic acid resin forming the core layer, thereby surface-roughening the polyglycolic acid resin layer. As a result, the peeling resistance between the polyglycolic acid resin / aromatic polyester resin layers is practically improved while maintaining a good gas-barrier property.

Owner:KUREHA KAGAKU KOGYO KK

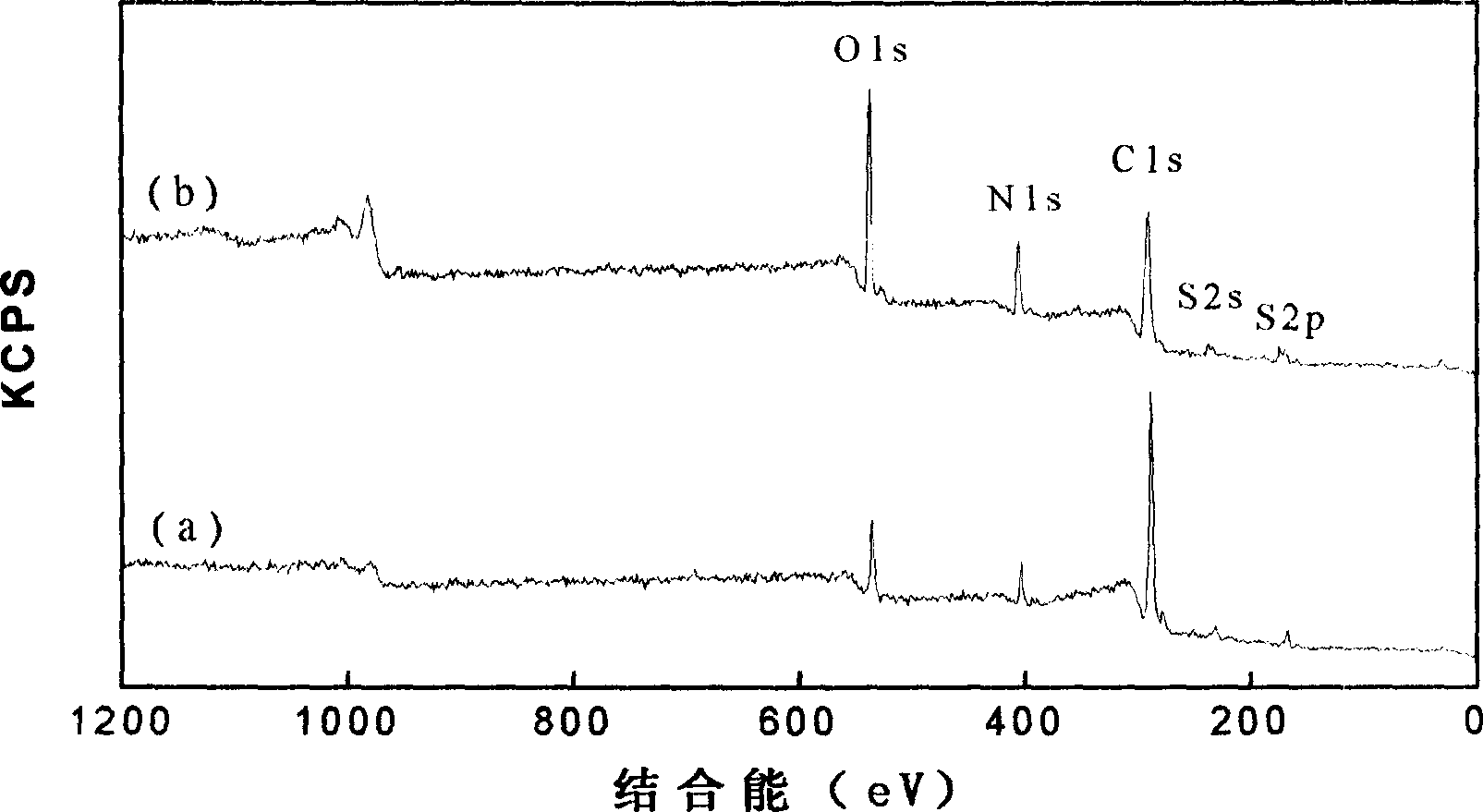

Low temperature dyeing method of wool fiber or fabric with surface nano structure

InactiveCN1548645ALarge specific surface areaImprove physical adsorptionDyeing processNano structuringHigh color

The present invention belongs to the field of dyeing and finishing processing of fabric, and is especially low temperature dyeing method of wool fiber or fabric with surface nano structure obtained via forming nano level embossed structure and active radical. After wool fiber or fabric is set inside low temperature plasma processing cavity, the pressure inside the cavity is first pumped to not higher than 10 Pa and then regulated with introduced non-polymerizing gas to 10-200 Pa and the wool fiber or fabric is discharged for low temperature plasma processing at power of 10-200 w for 1-30 min. The wool fiber or fabric through the low temperature plasma processing is low temperature dyed at temperature lower than 85 deg.c. The said process results in high color fastness, and can reduce residual dye in the effluent and waste water processing burdening.

Owner:中科纳米技术工程中心有限公司

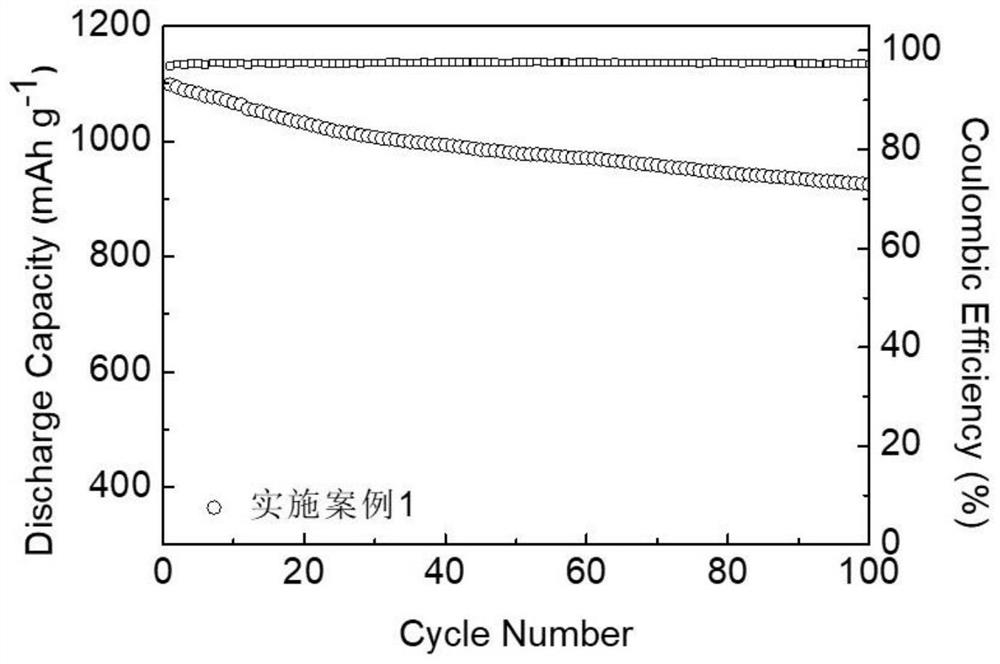

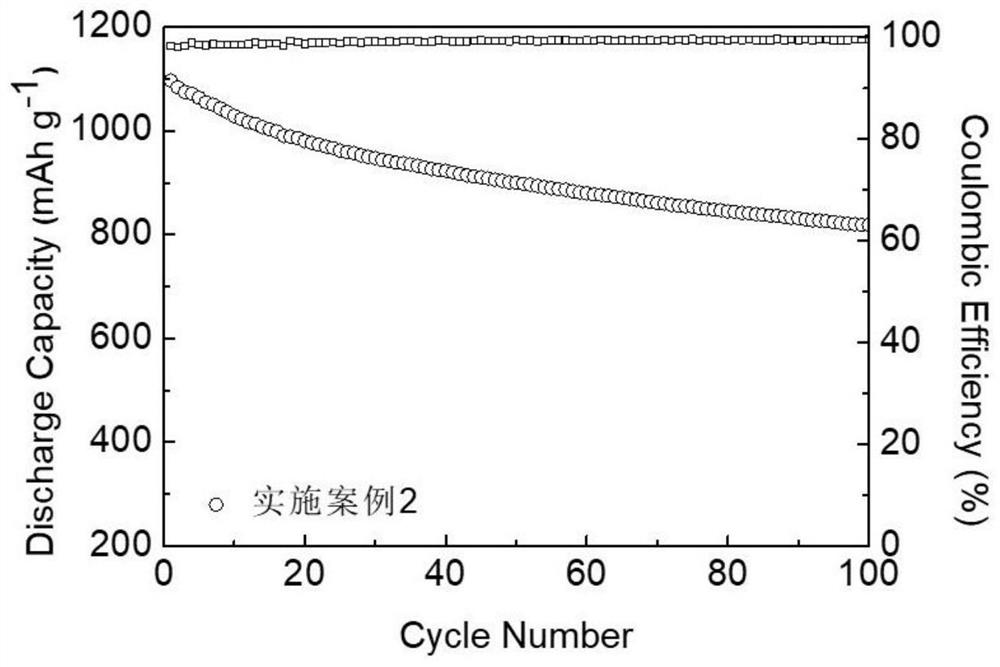

Preparation method of layered double hydroxide composite material for positive electrode of lithium-sulfur battery

ActiveCN113394381ALarge specific surface areaIncrease loadPositive electrodesLi-accumulatorsLithium–sulfur batteryCation exchange reaction

The invention belongs to the technical field of lithium-sulfur batteries, and particularly relates to a preparation method of a layered double hydroxide composite material for a positive electrode of a lithium-sulfur battery. The preparation method of the layered double hydroxide composite material for the positive electrode of the lithium-sulfur battery comprises the following steps: (1) synthesizing AC-FeCoNi; and (2) synthesizing Cu SAs / AC-FeCoNi. Copper atoms are introduced into AC-FeCoNi through an in-situ cation exchange reaction to prepare the Cu SAs / AC-FeCoNi composite material, and the preparation method is simple, effective and easy to operate; and the prepared composite material has high conductivity and high specific surface area, and has a stable three-dimensional structure.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Guided diameter SiC sublimation growth with multi-layer growth guide

ActiveUS8313720B2Improve thermal conductivityLow thermal conductivityAfter-treatment apparatusPolycrystalline material growthCrucibleSource material

In the growth of a SiC boule, a growth guide is provided inside of a growth crucible that is charged with SiC source material at a bottom of the crucible and a SiC seed crystal at a top of the crucible. The growth guide has an inner layer that defines at least part of an opening in the growth guide and an outer layer that supports the inner layer in the crucible. The opening faces the source material with the seed crystal positioned at an end of the opening opposite the source material. The inner layer is formed from a first material having a higher thermal conductivity than the second, different material forming the outer layer. The source material is sublimation grown on the seed crystal in the growth crucible via the opening in the growth guide to thereby form the SiC boule on the seed crystal.

Owner:II VI DELAWARE INC

Method for promoting magnetization reduction of oxidized iron ore with weak magnetism

InactiveCN101798624AImprove mass transfer efficiencyReduce the temperatureProcess efficiency improvementMagnetizationMagnetite

The invention relates to a method for promoting magnetization reduction of oxidized iron ore with weak magnetism. The method comprises the following steps of: (1) crushing an oxidized iron ore material with weak magnetism; (2) adding water in an amount which is 5 to 10 mass percent of the oxidized iron ore with weak magnetism; (3) according to the ferrous grade of the oxidized iron ore with weak magnetism, adding a scrap iron material serving as a reducing agent in an amount which is 3 to 20 mass percent of the oxidized iron ore with weak magnetism, and according to requirement, adding a carbon reducing agent in an amount which is 0 to 15 mass percent of the oxidized iron ore with weak magnetism; and (4) putting the materials in a reduction roaster for roasting to convert the oxidized iron ore with weak magnetism into magnetite with strong magnetism. The method has the advantages that: (1) the method can improve the mass transfer efficiency of the magnetization reduction reaction and reduce the temperature required by the reduction reaction; (2) the method can prevent the formation of iron aluminosilicate ore with weak magnetism and avoid mutual sintering between the iron ore and aluminosilicate impurity ore; and (3) the method can reduce the consumption of the reducing agent and has cleaner process.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Welding process of cubic boron nitride soldering materials

InactiveCN106031956AHigh reactivityEnhance chemical affinityOther manufacturing equipments/toolsWelding/cutting media/materialsWear resistantBoron nitride

The invention provides cubic boron nitride soldering materials and a process. The process includes taking silver and copper eutectic solder as the main body, adding a small amount of Ti as the active element, and uniformly mixing with CBN particles in a planetary ball mill, uniformly coating the mixed product on the surface of a steel substrate, and performing soldering and heating in a vacuum furnace to form a wear-resistant super-hard composite layer on the surface of the steel substrate. The soldering materials have good wetability to the substrate steel and can be uniformly distributed on the surface of the substrate steel to firmly solder the CBN to the steel surface.

Owner:洛阳新巨能高热技术有限公司

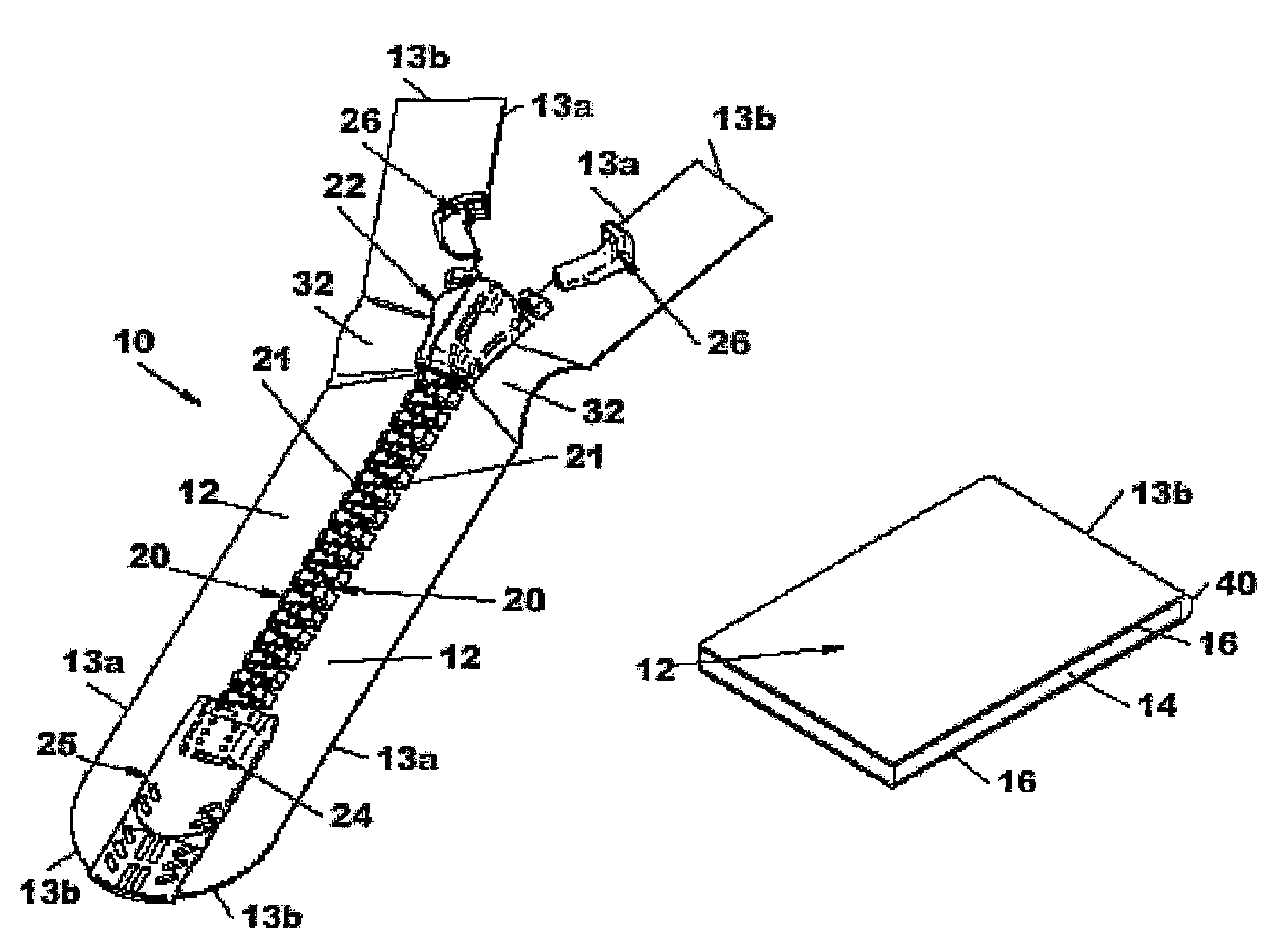

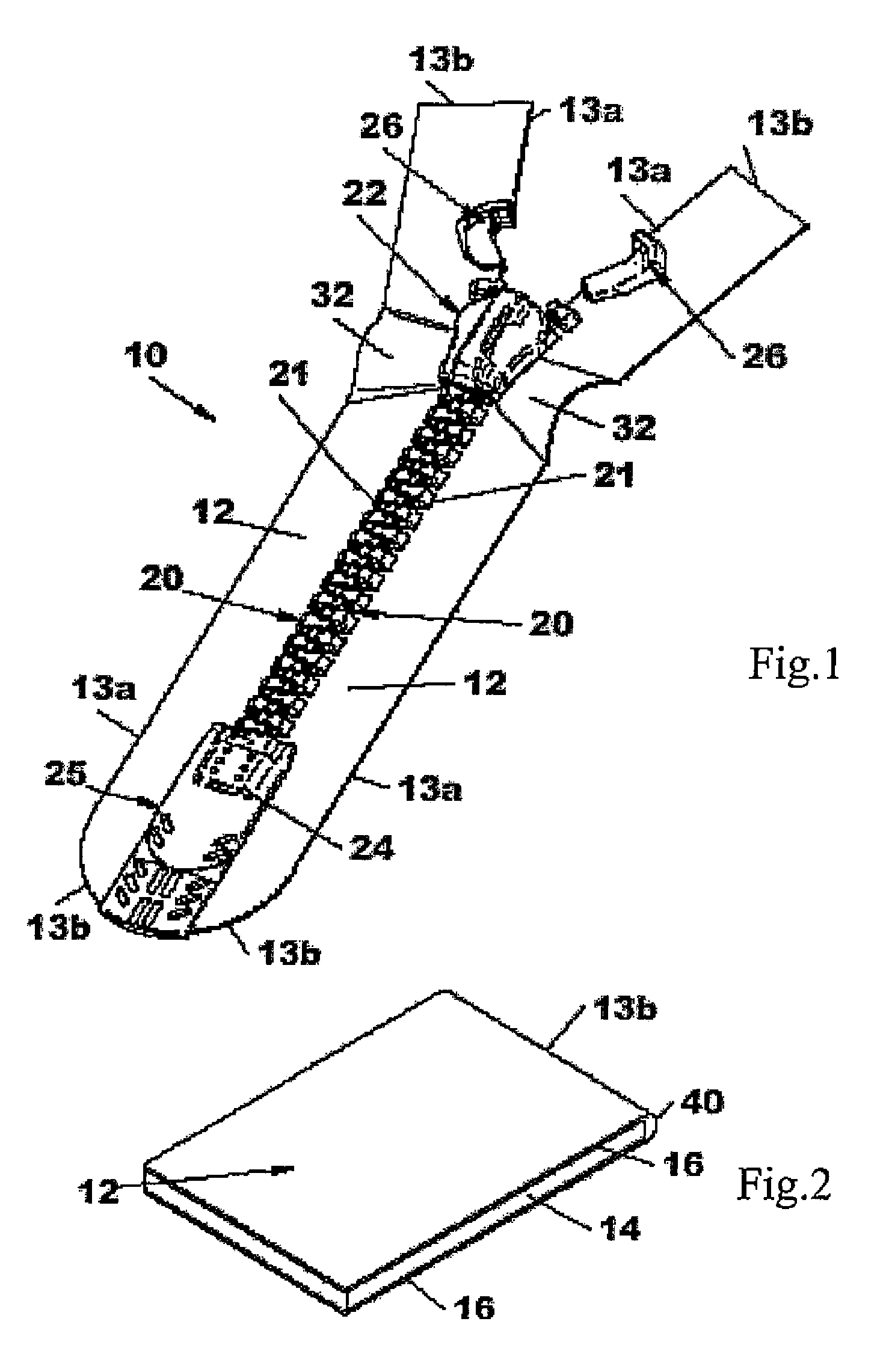

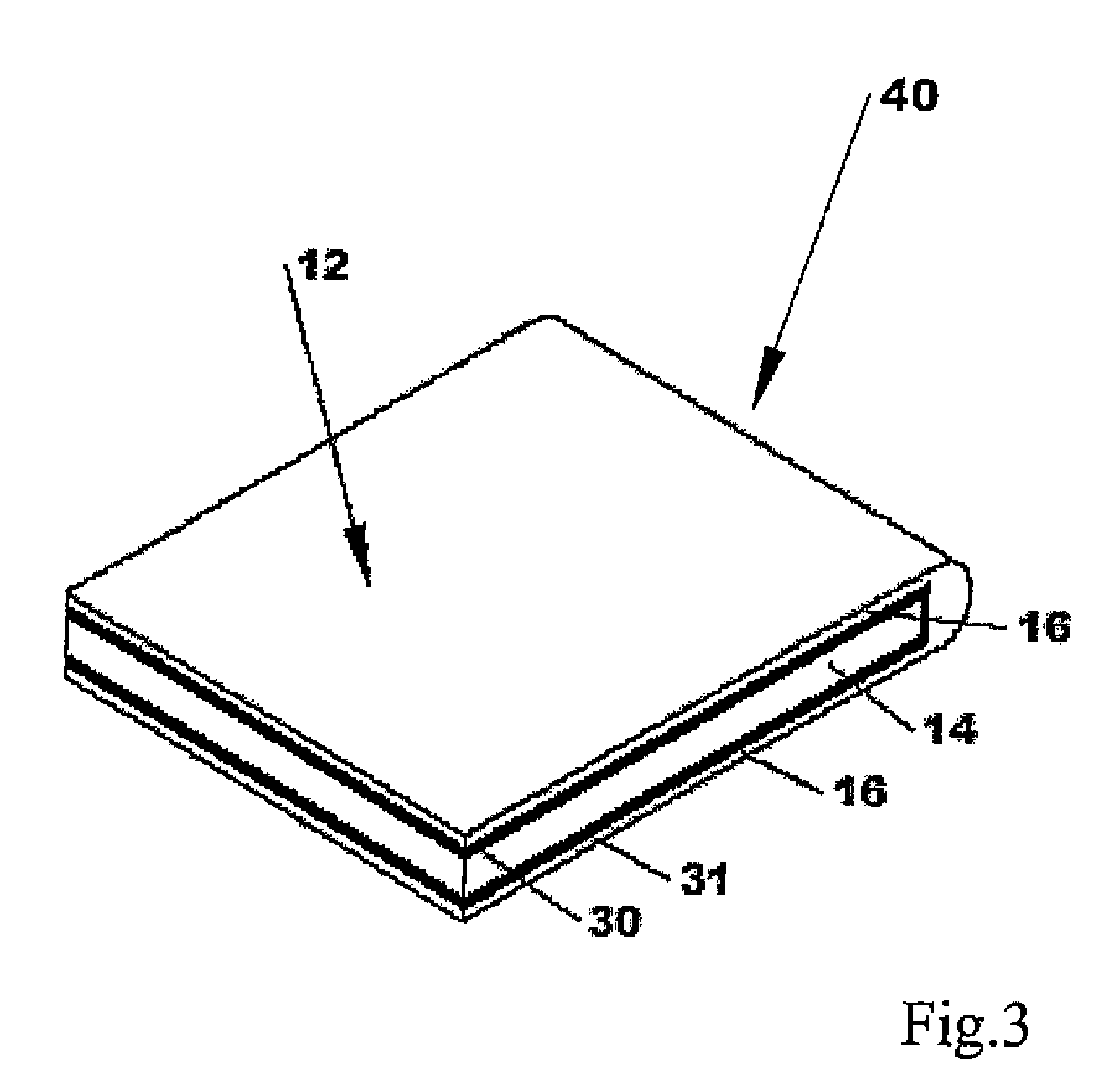

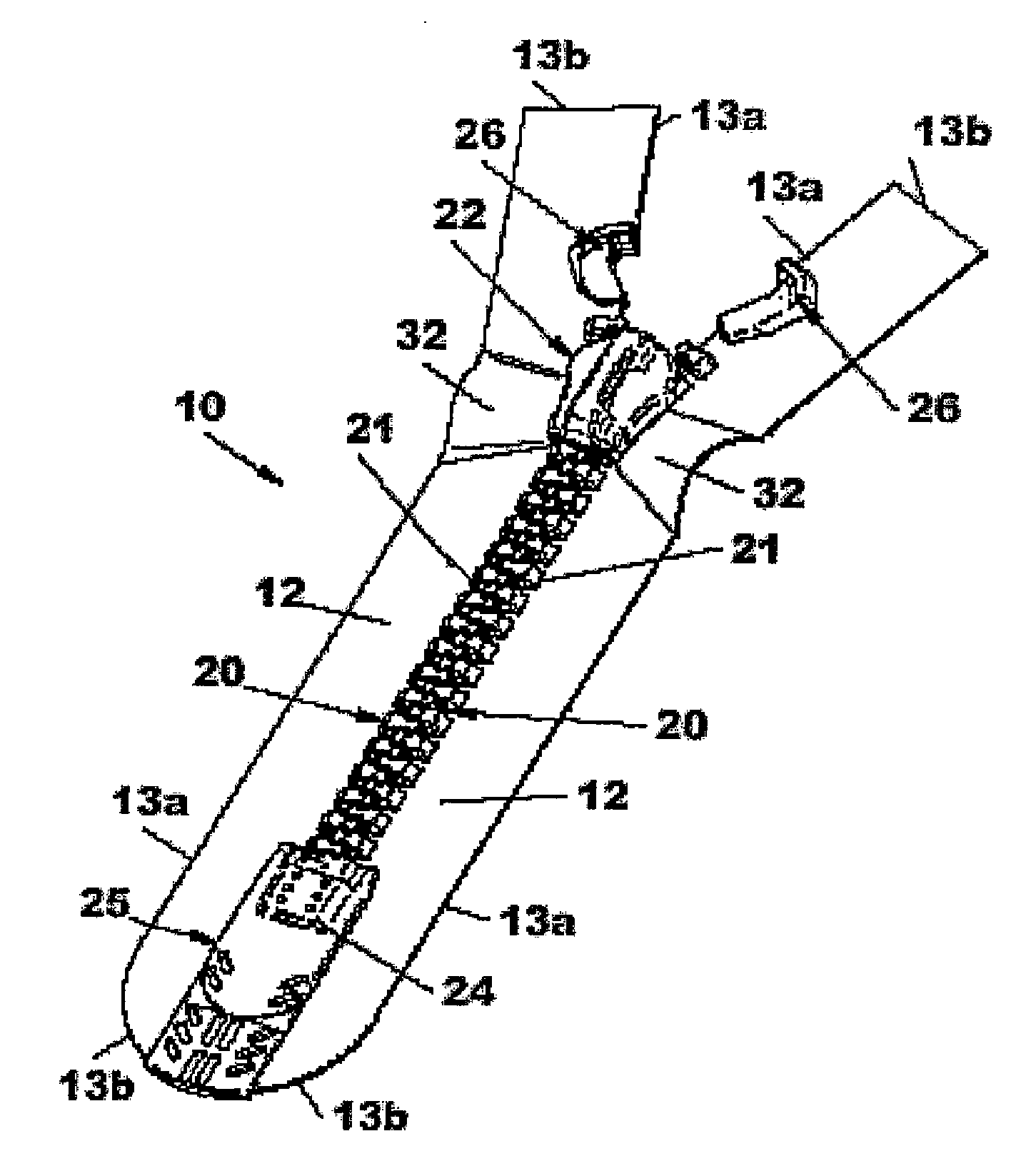

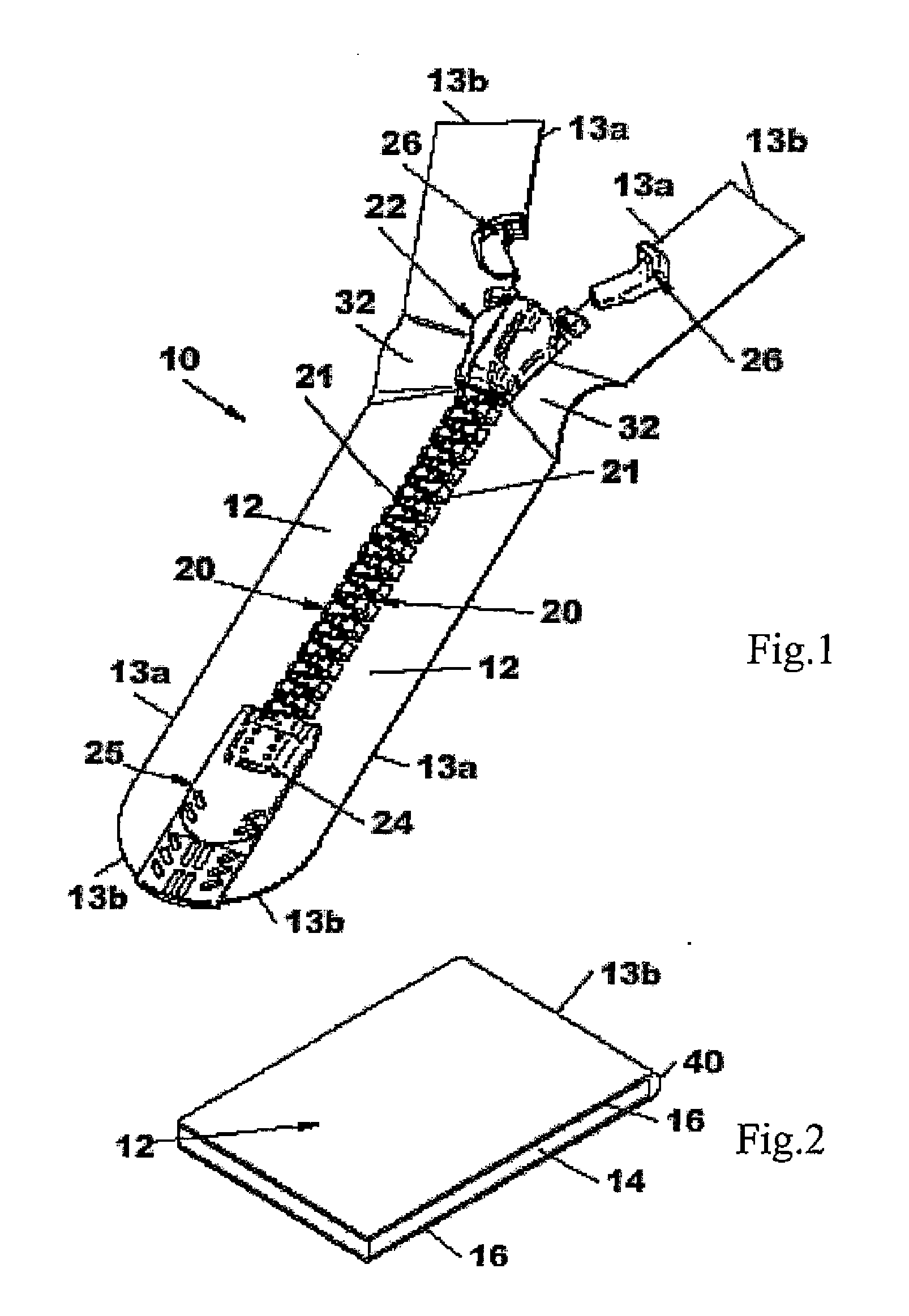

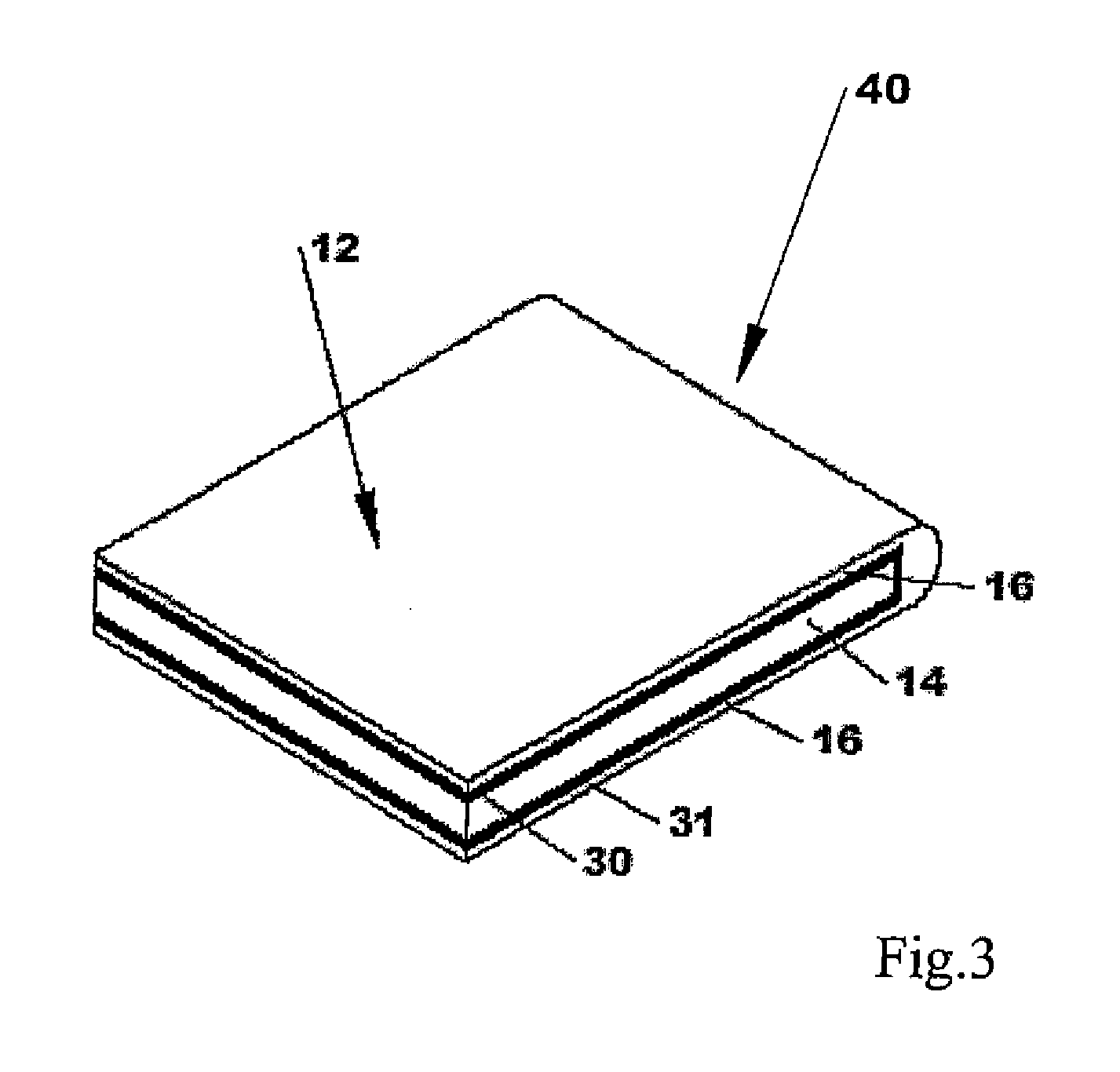

Fluid-Tight Slide Fastener

InactiveUS20080083098A1Improve the immunityStrong couplingSnap fastenersWire articlesThermoplastic elastomerPolyamide

Fluid-tight slide fastener (10) comprising a pair of tapes (12), each tape (12) having a layered structure comprising an inner reinforcing textile material layer (14) enveloped in a fluid barrier layer (16) made of a thermoplastic elastomer material (TPE), each tape (12) exhibiting a row (20) of aligned teeth (21) made of a thermoplastic material on at least a portion of one of the long sides (13a) thereof, the rows (20) of aligned teeth (21) of said pair of tapes (12) facing each other and being associated to opposite stops (24,26), and a slider (22) slidable between said opposite stops (24,26) for engaging in a fluid-tight way or disengaging said aligned teeth (21) respectively, characterized in that said textile material for the inner reinforcing layer (14) is chosen among polyester (PE), preferably PET, polyamide (PA) and their blends or copolymers; said thermoplastic elastomer material (TPE) for the fluid barrier layer (16) is chosen between thermoplastic elastomer polyurethane (TPE-U) and thermoplastic elastomer polyester (TPE-E), and said thermoplastic material for the teeth (21) is chosen among polybutylene terephthalate (PBT), acrylonitrile butadiene styrene (ABS), polyamide (PA) and their blends or copolymers.

Owner:RIRI GROUP

Rare-earth calcium-silicon-manganese deoxidizer and preparation method thereof

The invention discloses a rare-earth calcium-silicon-manganese deoxidizer and a preparation method thereof. The deoxidizing agent comprises the following components, by mass, 32-35% of Si, 16-18% of Ca, 10-12% of Mn, 8-10% of Re, less than or equal to 0.1% of P, less than or equal to 0.1% of S, less than or equal to 0.1 % of inevitable elements, and the balance Fe. According to the deoxidizer andthe method, the rare-earth calcium-silicon-manganese deoxidizer has the advantages of being extremely prone to react with oxygen at a high temperature and high in deoxidation efficiency; and meanwhile, crystal grains are modulated and fined, the defects of casting gas holes, needle holes and the like are avoided, and the mechanical property of the casting is improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Tin plating liquid with rear earth additive

The invention provides tin plating liquid with a rear earth additive. The rear earth additive, which is 0.2-0.3% of tin plating liquid in mass, is added in the tin plating liquid, and the rear earth additive comprises LaCl3, Y2O3 or CeO2. According to the technical effects provided by the invention, a proper amount of the rear earth additive is added, so that the higher current efficiency achieves a lower temperature, the micro-fractures is retained to form, and the corrosion resistance of the plated layer is improved. Meanwhile, the free increment amount of rear earth and lots of non-metal elements have larger negative values, so that the corresponding chemical affinities are strong. By adding rear earth ions in the plating liquid, the properties of the plating liquid in the traditional electroplating process can be effectively improved due to the activity of the rear earth elements.

Owner:吉安市荣泰电讯科技有限公司

Sagger for preparing artworks in ceramic firing process and preparation process of sagger

The invention relates to a sagger for preparing an artwork in a ceramic firing process and a preparation process of the sagger, wherein the sagger can improve the artistic value of the sagger and change the use purpose of the sagger. The inner surface of the sagger is provided with a glaze layer which is the same as ceramic artworks to be fired. Meanwhile, the sagger is prepared from the followingraw materials in parts by weight: 5 to 15 parts of purple kibushi kaolin, 17 to 25 parts of alkaline stone, 25 to 35 parts of clay, 30 to 40 parts of quartz, 0.1 to 1 part of dietary alkali, 5 to 20parts of white feldspar and 5 to 10 parts of aluminum oxide. Characters or patterns are also drawn or carved on the outer surface of the sagger; in the firing process of the ceramic artwork, firing ofthe sagger artwork is added, the compounding ingredients of the sagger are changed, the surface of the fired sagger is smoother, and the representation of artistic forms is facilitated; a glaze blankof the ceramic and a glaze blank of the sagger are coated with a same glaze, the surface glaze color of the fired ceramic is similar to the inner surface glaze color of the sagger, the anti-counterfeiting effect is achieved, the fired sagger can continue to contain the ceramic and can also exist in an independent artwork form, the value of the sagger is improved, the process cost is reduced, andthus the effect of saving resources is achieved.

Owner:侯俊功

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com