Foam aerated concrete building block prepared from iron tailings at normal temperature and under normal pressure and preparation method of foam aerated concrete building block

A technology of aerated concrete and iron tailings, applied in the field of inorganic materials, can solve the problems of restricting large-scale production, low safety factor, and high price, and achieve the effects of fast reaction and processing time, low equipment requirements, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

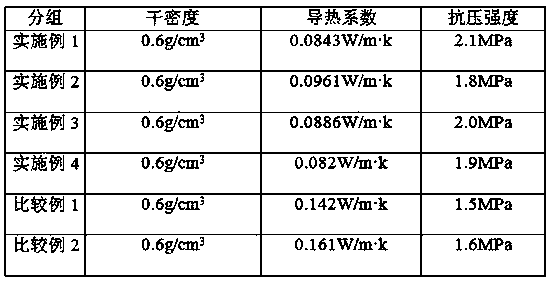

[0027] Example 1 Preparation of foam aerated concrete block

[0028] The foamed aerated concrete block consists of the following components in terms of weight percentage: iron tailings 35%, cement 41%, early strength agent 2%, fly ash 10%, hydroxymethyl cellulose 2%, Rubber powder 3%, polypropylene fiber 2%, foaming agent 1%, melamine water reducing agent 2%, silicone water repellent agent 1%, silicone resin polyether emulsion foam stabilizer 1%.

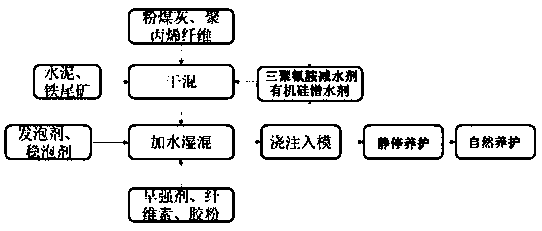

[0029] In parts by weight, the preparation method of the foamed aerated concrete block comprises the following steps:

[0030] 1) Grind the iron tailings with a ball mill to obtain iron tailings powder;

[0031] 2) Take 35 parts of iron tailings powder obtained in step 1), 41 parts of cement, 10 parts of fly ash, 2 parts of polypropylene fiber, 2 parts of melamine water reducing agent, and 1 part of organic silicon water repellent, dry mix and stir to obtain Dry mixed raw materials;

[0032] 3) Add 2 parts of hydroxymethyl cellulose, 3 part...

Embodiment 2

[0035] Example 2 Preparation of foam aerated concrete block

[0036] The foamed aerated concrete block is composed of the following components in terms of weight percentage: iron tailings 50%, cement 30%, early strength agent 3%, fly ash 3%, hydroxymethyl cellulose 1%, Rubber powder 2%, polypropylene fiber 4%, foaming agent 2%, melamine water reducing agent 2%, silicone water repellent agent 2%, silicone resin polyether emulsion foam stabilizer 1%.

[0037] In parts by weight, the preparation method of the foamed aerated concrete block comprises the following steps:

[0038] 1) Grind the iron tailings with a ball mill to obtain iron tailings powder;

[0039] 2) Take 50 parts of iron tailings powder obtained in step 1), 30 parts of cement, 2 parts of melamine water reducing agent, 2 parts of organosilicon water repellent, 3 parts of fly ash, 4 parts of polypropylene fiber, dry mix and stir uniformly to obtain Dry mixed raw materials;

[0040] 3) Add 1 part of hydroxymethyl cellulose, 2...

Embodiment 3

[0042] Example 3 Preparation of foam aerated concrete block

[0043] The foamed aerated concrete block is composed of the following components in terms of weight percentage: iron tailings 43%, cement 39%, early strength agent 2%, fly ash 5%, hydroxymethyl cellulose 3%, Rubber powder 1%, polypropylene fiber 2%, foaming agent 1%, melamine water reducing agent 2%, silicone water repellent agent 1%, silicone resin polyether emulsion foam stabilizer 1%.

[0044] In parts by weight, the preparation method of the foamed aerated concrete block comprises the following steps:

[0045] 1) Grind the iron tailings with a ball mill to obtain iron tailings powder;

[0046] 2) Take 43 parts of iron tailings powder obtained in step 1), 39 parts of cement, 5 parts of fly ash, 2 parts of polypropylene fiber, 2 parts of melamine water reducing agent, and 1 part of organosilicon water repellent. Dry mixed raw materials;

[0047] 3) Add 3 parts of hydroxymethyl cellulose, 1 part of rubber powder, 2 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com