Method for promoting magnetization reduction of oxidized iron ore with weak magnetism

A technology of iron oxide ore and weak magnetism, which is applied to the improvement of process efficiency, can solve the problems of iron oxide ore magnetization reduction rate reduction, difficult monomer dissociation of iron minerals, and difficulty in iron mineral separation, so as to avoid Effects of mutual sintering, process cleaning, and temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

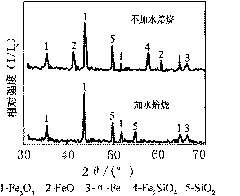

[0049] Example 1 In order to confirm that metal Fe is in H 2 Hematite can be magnetized and reduced indirectly under the promotion of O. A special magnetization-reduction roasting verification experiment was designed.

[0050] The experiment was carried out in a box-type resistance furnace. 20g of pure iron powder with a particle size of 0.6mm and 100g of pure hematite samples were placed separately in a sealed steel cylinder to keep the pure iron powder and pure hematite from direct contact. Add 10g of water or no water to the hematite, and then roast it in a reduction roasting furnace at 560 °C for 60 min. After reduction roasting, the samples were subjected to X-ray diffraction analysis, and compared with the X-ray diffraction analysis results of the samples before reduction roasting. . At the same time, the magnetic susceptibility reduction rate of hematite was analyzed with a magnetic separator.

[0051] figure 1 The results of X-ray diffraction analysis of pure hemati...

Embodiment 2

[0053] Example 2 The magnetization reduction roasting comparison experiment was carried out by using the slag obtained from pyrite for acid production as the weak magnetic iron oxide mineral material. The chemical composition of the pyrite slag is shown in Table 1, and the iron phase composition is shown in Table 2.

[0054] Table 1 Results of chemical multi-element analysis of slag (mass fraction) / %

[0055]

[0056] Table 2 Phase composition of iron in slag (mass fraction) / %

[0057]

[0058]

[0059] The experiment was also carried out in a box-type resistance furnace. Two equal pyrite slag samples (with a particle size of 3 mm) were taken each time, and one was added with 10% water, 5% waste iron wire and 5% slag mass. 15% of the calcined slag mass was added, and the other part was reduced and roasted for 60 min at different temperatures in Table 3, and then the magnetic separation performance of the calcined calcined was evaluated by a weak magnetic separator. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com