Patents

Literature

83 results about "Maghemite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

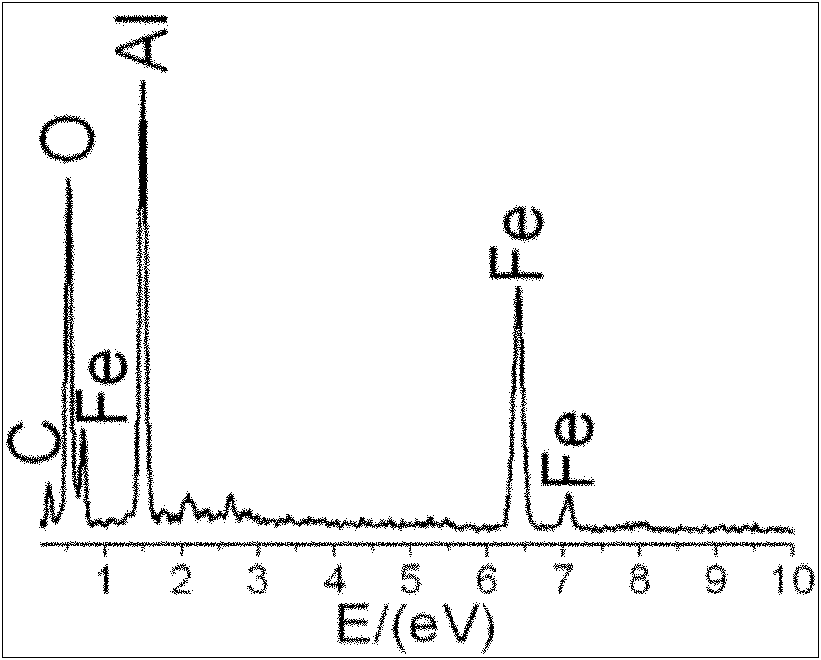

Maghemite (Fe₂O₃, γ-Fe₂O₃) is a member of the family of iron oxides. It has the same spinel ferrite structure as magnetite and is also ferrimagnetic. Maghemite can be considered as an Fe(II)-deficient magnetite with formula (Feᴵᴵᴵ₈)A[Fe₄₀/₃ᴵᴵᴵ□₈/₃]BO₃2 where □ represents a vacancy, A indicates tetrahedral and B octahedral positioning.

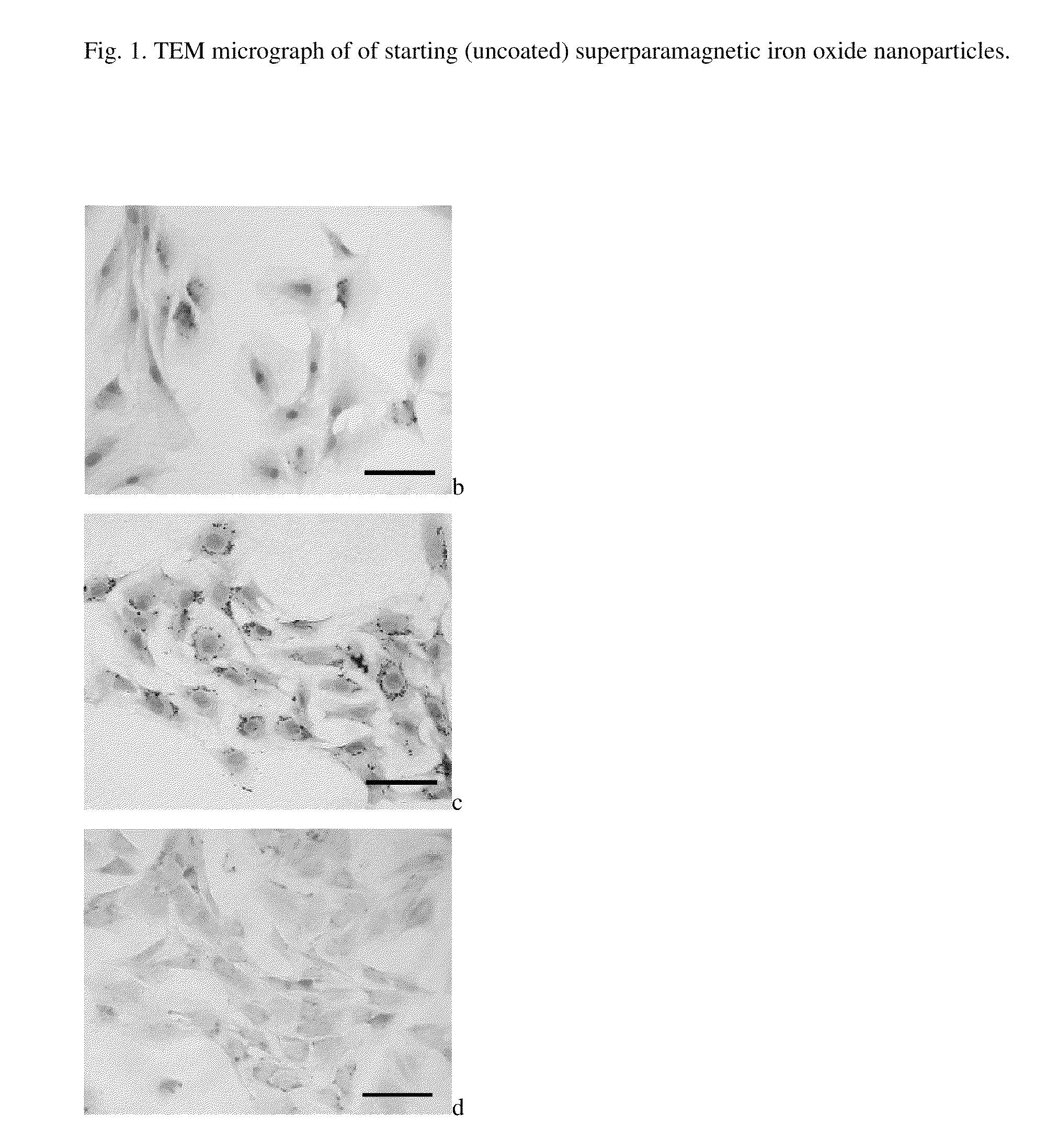

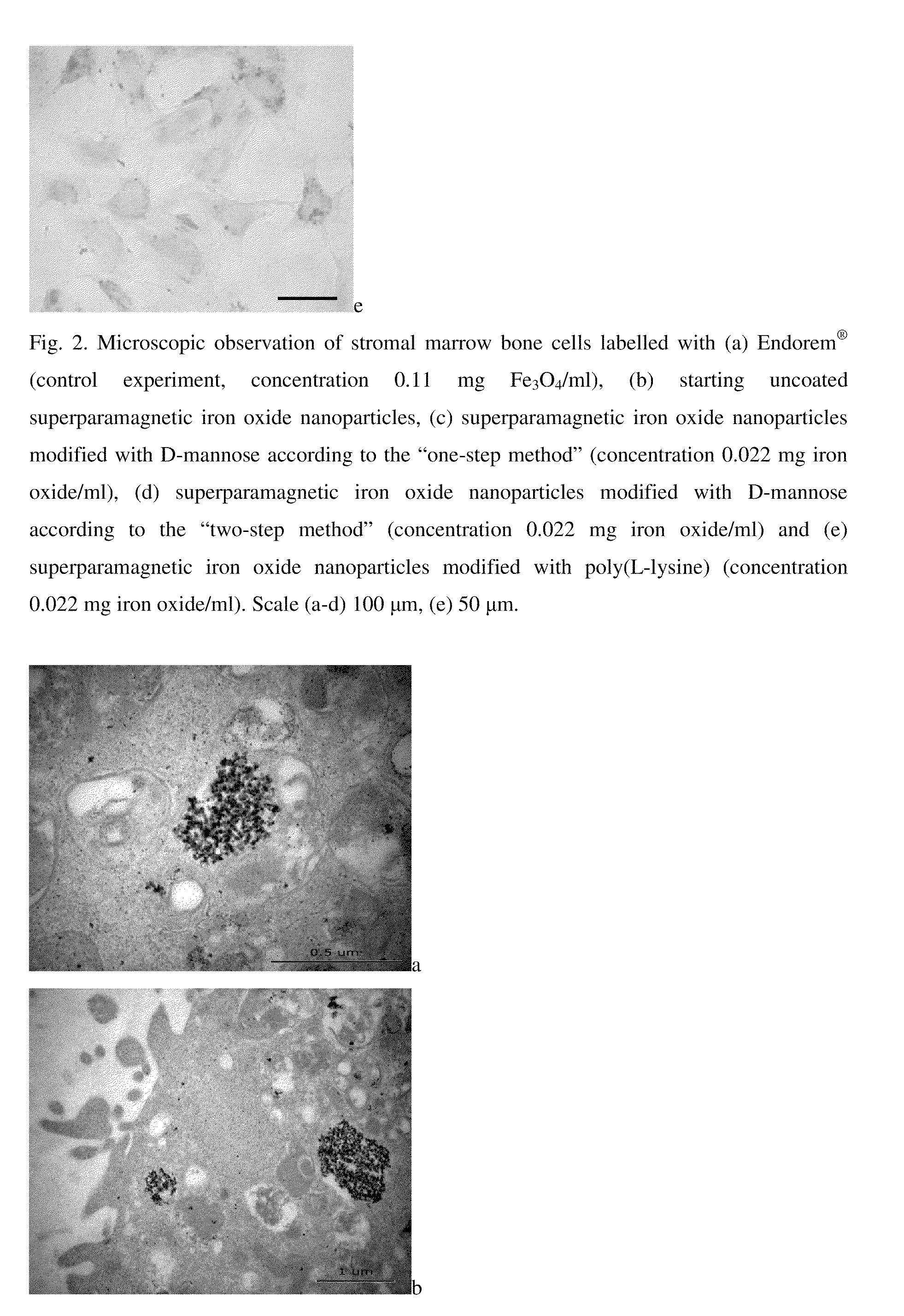

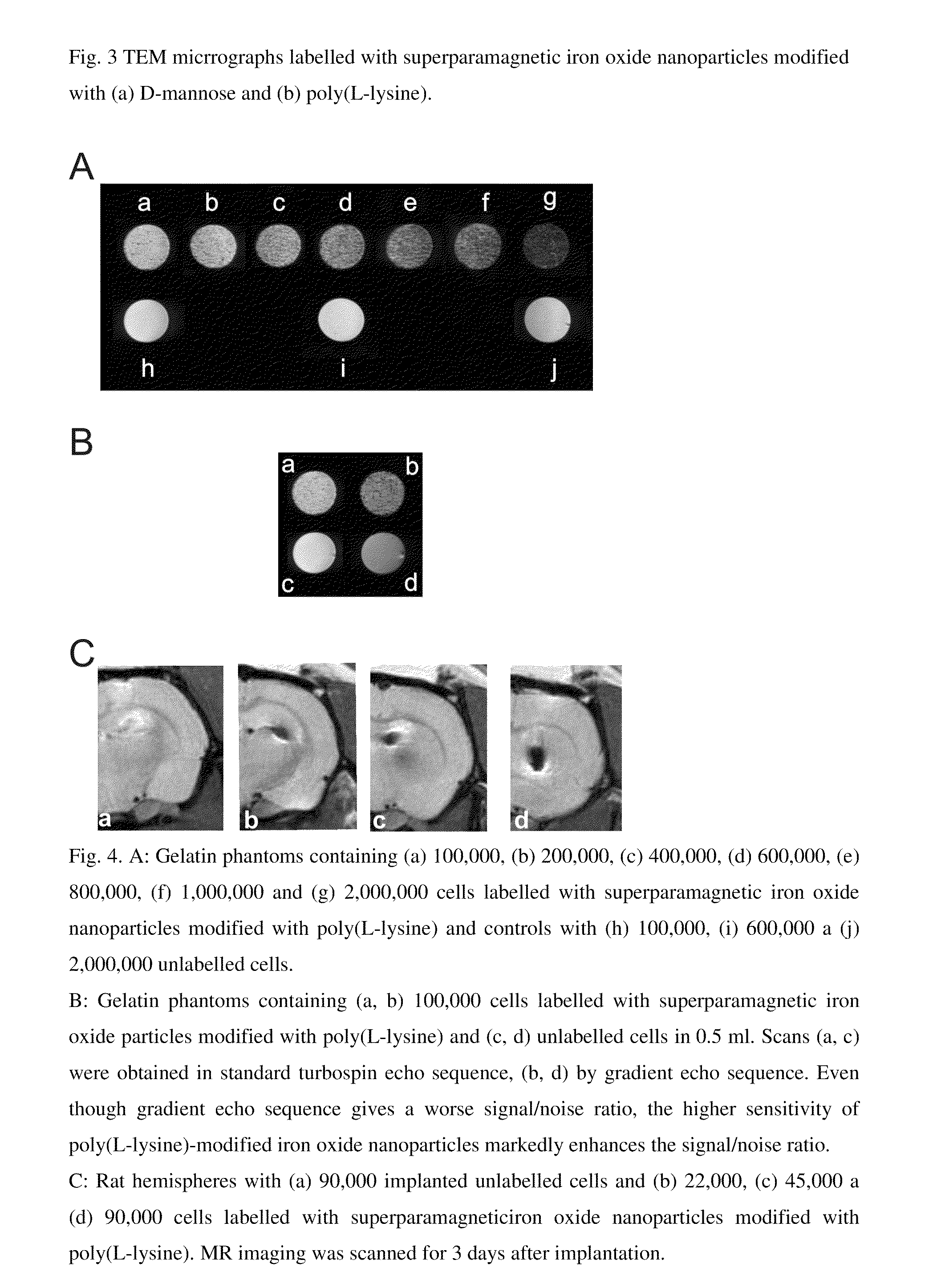

Superparamagnetic Nanoparticles Based on Iron Oxides with Modified Surface, Method of Their Preparation and Application

InactiveUS20090309597A1Less loadImprove abilitiesPigmenting treatmentMaterial nanotechnologyArginineDextran

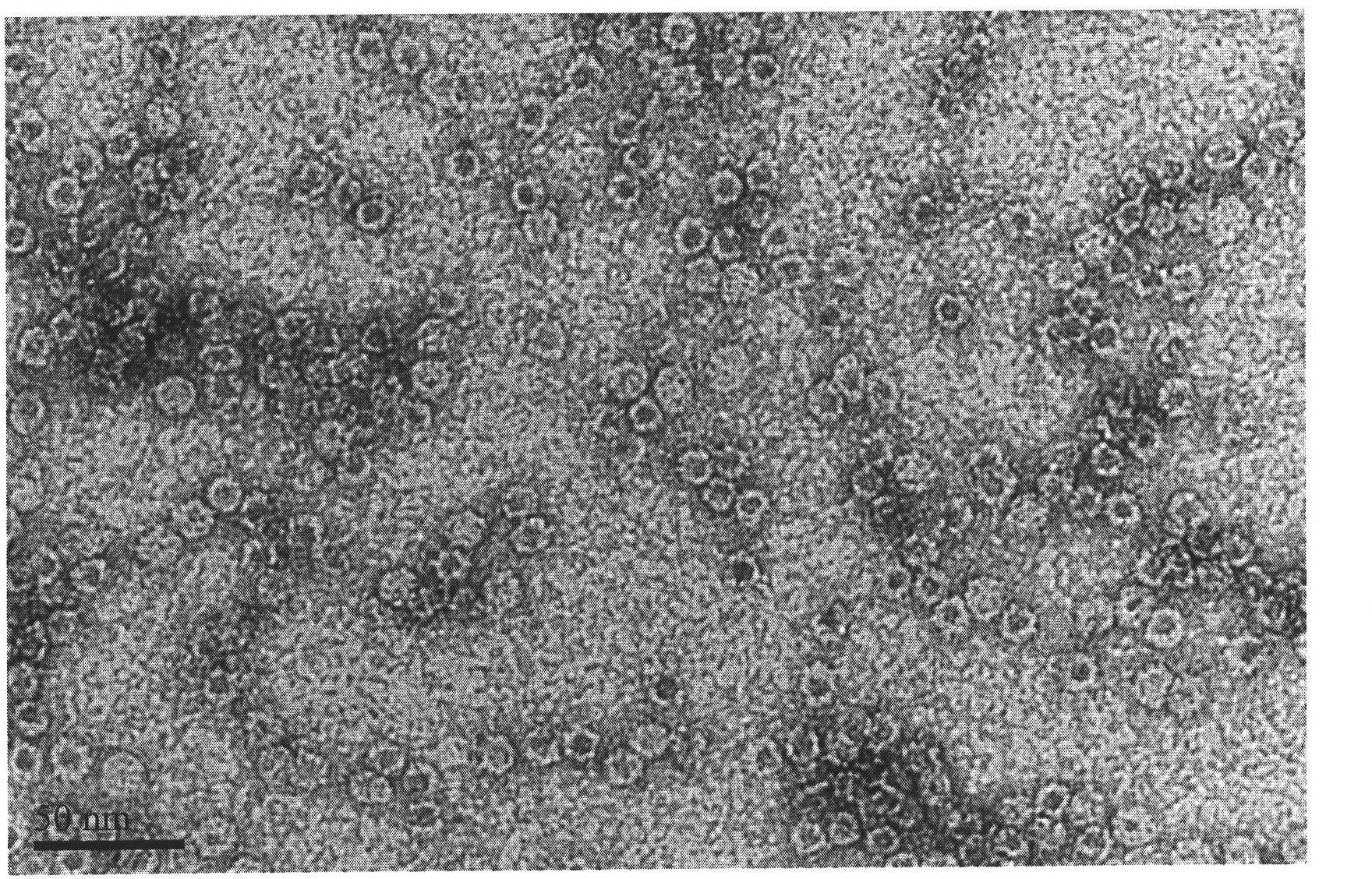

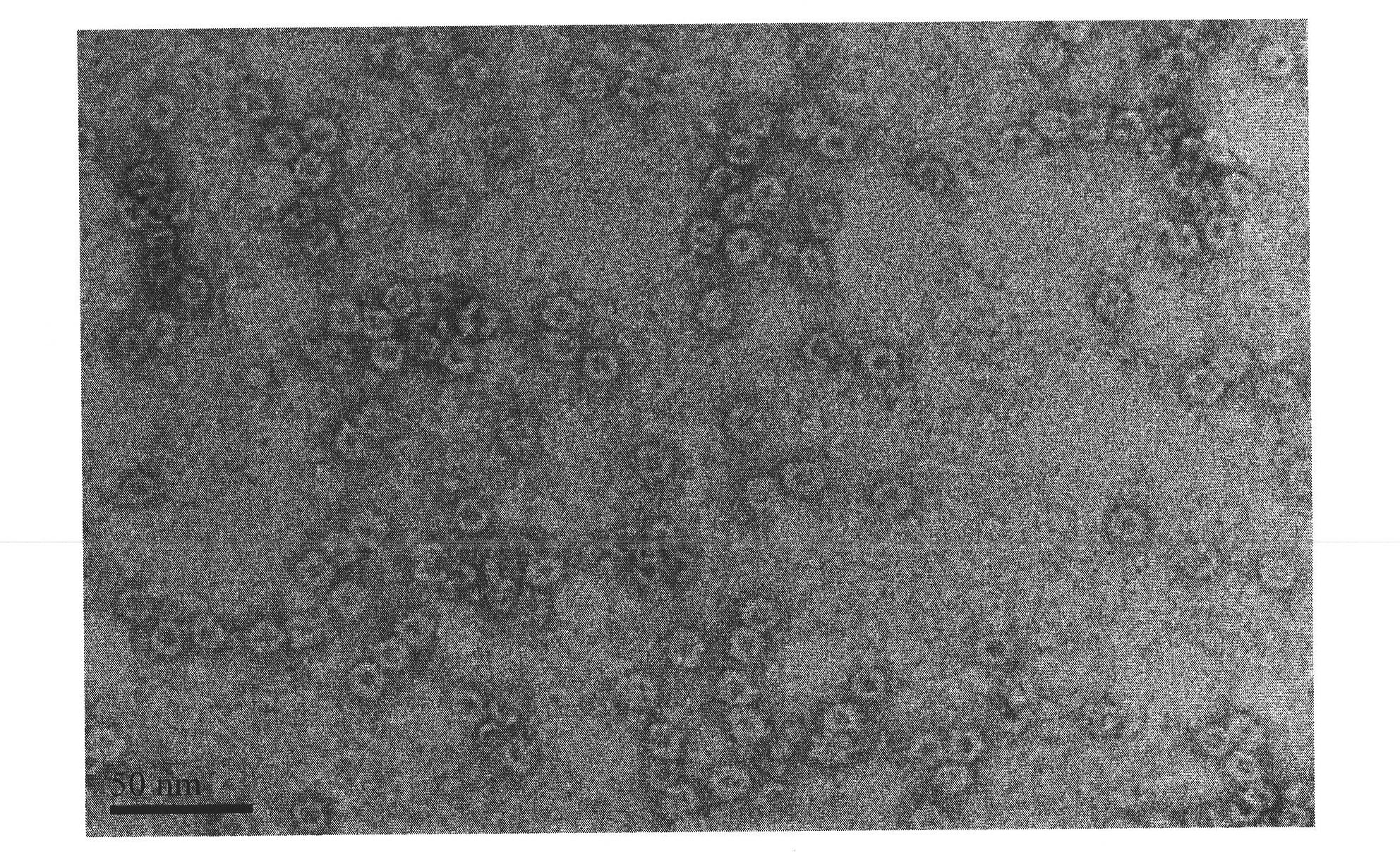

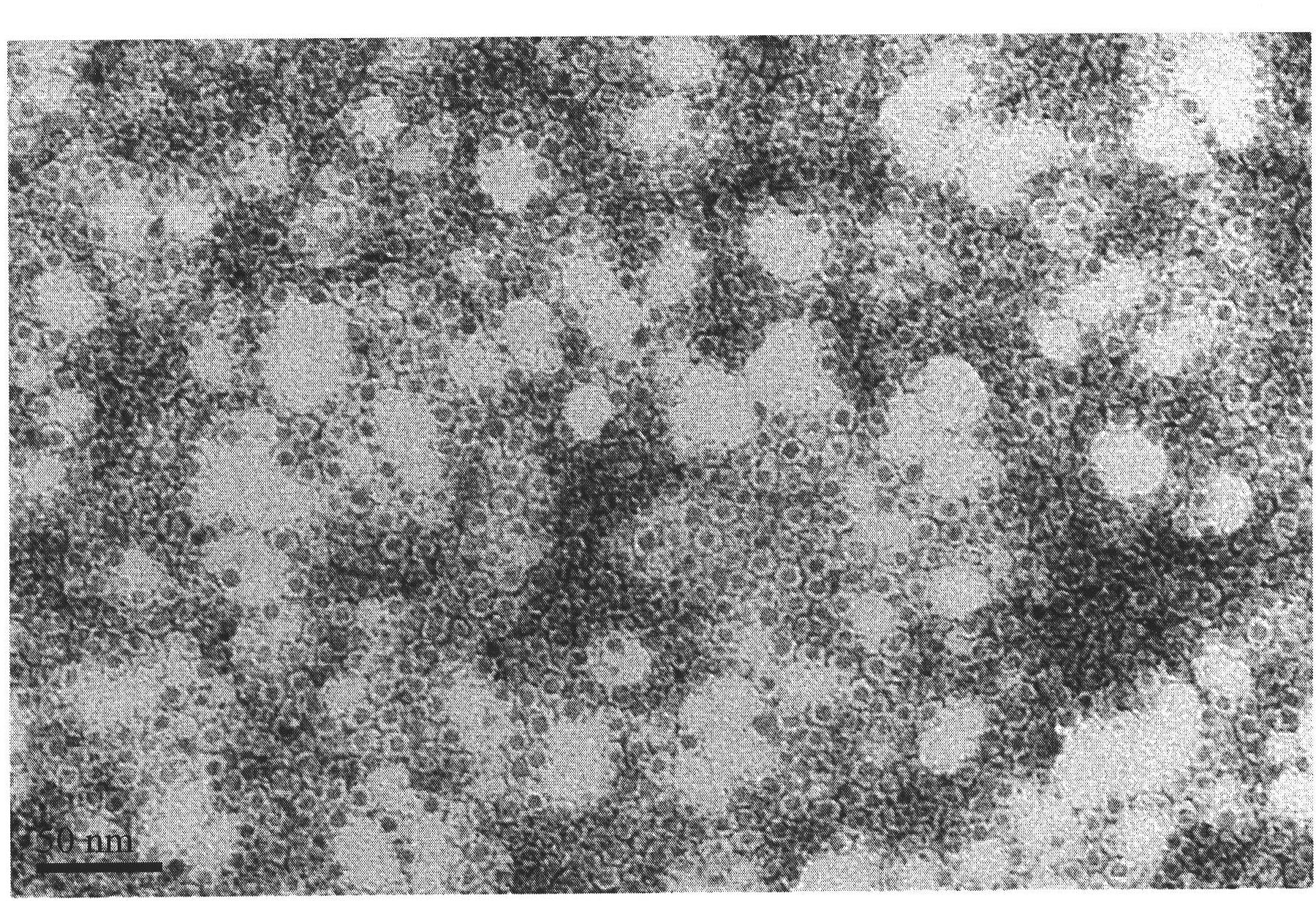

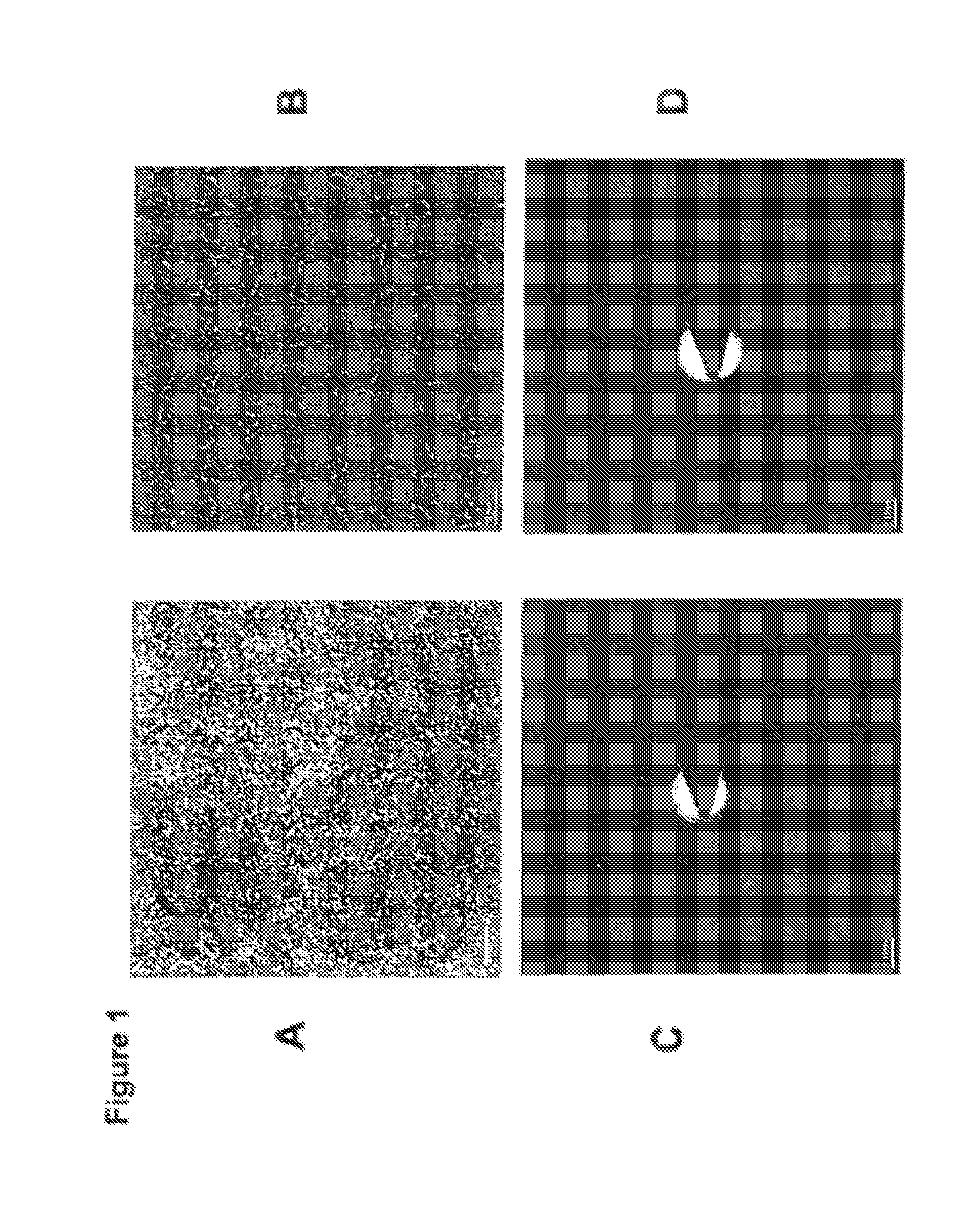

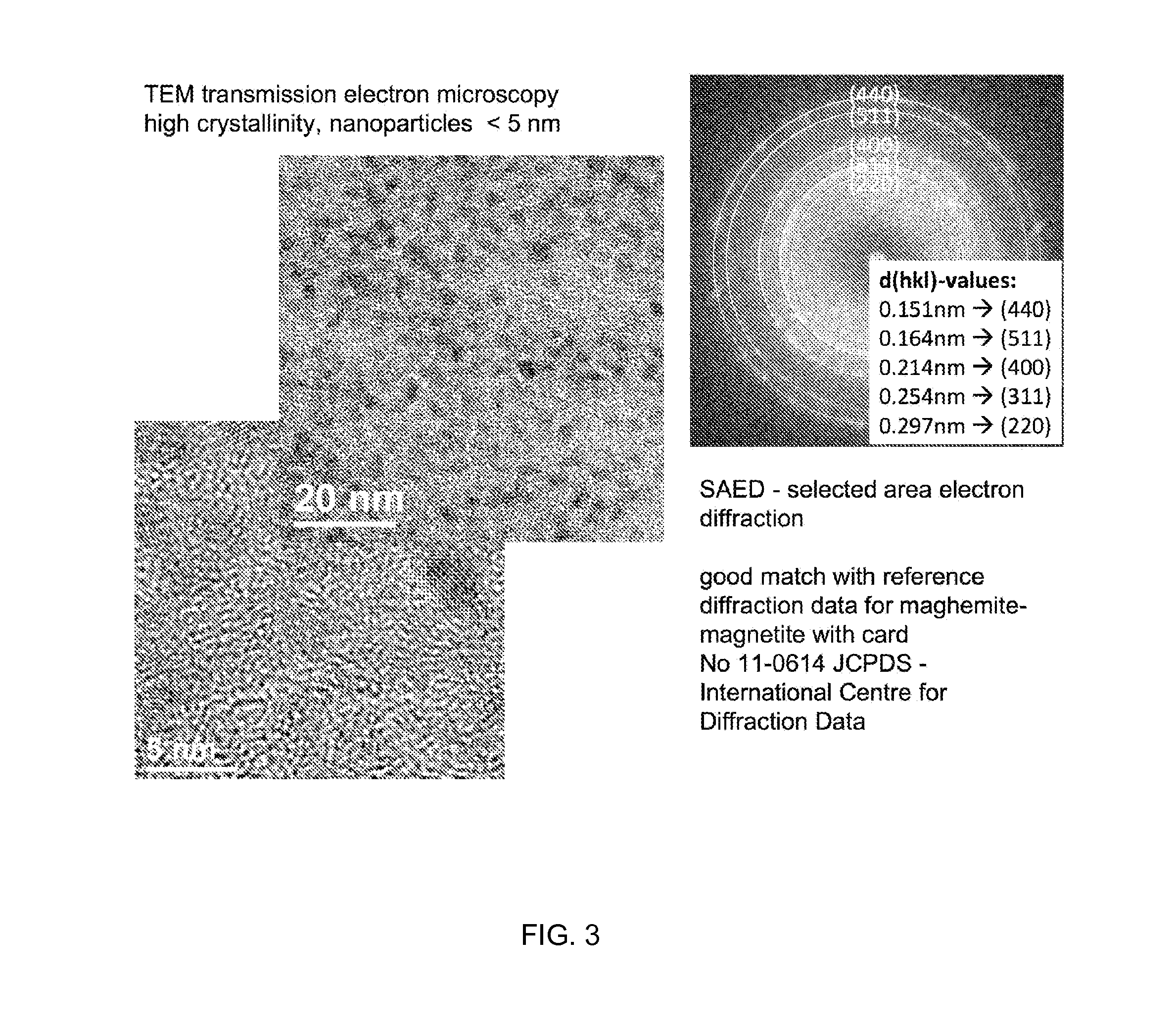

The subject of the invention is superparamagnetic nanoparticle probes based on iron oxides, to advantage magnetite or maghemite, with modified surface, coated with mono-, di- or polysaccharides from the group including D-arabinose, D-glucose, D-galactose, D-mannose, lactose, maltose, dextrans and dextrins, or with amino acids or poly(amino acid)s from the group including alanine, glycine, glutamine, asparagine, histidine, arginine, L-lysine, aspartic and glutamic acid or with synthetic polymers based on (meth)acrylic acid and their derivatives selected from the group containing poly(N,N-dimethylacrylamide), poly(N,N-dimethylmethacrylamide), poly(N,N-diethylacrylamide), poly(N,N-diethylmethacrylamide), poly(N-isopropylacrylamide), poly(N-isopropylmethacrylamide), which form a colloid consisting of particles with narrow distribution with polydispersity index smaller than 1.3, the average size of which amounts to 0.5-30 nm, to advantage 1-10 nm, the iron content is 70-99.9 wt. %, to advantage 90 wt. %, the modification agent content 0.1-30 wt. %, to advantage 10 wt. %.The particles of size smaller than 2 nm with polydispersity index smaller than 1.1 can be obtained by a modified method of preparation.Superparamagnetic nanoparticle probes according to the invention are prepared by pre-precipitation of colloidal Fe(OH)3 by the treatment of aqueous 0.1-0.2M solution of Fe(III) salt, to advantage FeCl3, with less than an equimolar amount of NH4OH, at 21° C., under sonication, to which a solution of a Fe(II) salt, to advantage FeCl2, is added in the mole ratio Fe(III) / Fe(II)=2 under sonication and the mixture is poured into five- to tenfold, to advantage eightfold, molar excess of 0.5M NH4OH. The mixture is left aging for 0-30 min, to advantage 15 min, and then the precipitate is repeatedly, to advantage 7-10 times, magnetically separated and washed with deionized water. Then 1-3 fold amount, to advantage 1.5 fold amount, relative to the amount of magnetite, of 0.1 M aqueous solution of sodium citrate is added and then, dropwise, 1-3 fold amount, to advantage 1.5 fold amount, relative to the amount of magnetite, of 0.7 M aqueous solution of sodium hypochlorite. The precipitate is repeatedly, to advantage 7-10 times, washed with deionized water under the formation of colloidal maghemite to which, after dilution, is added dropwise, to advantage under 5-min sonication, an aqueous solution of a modification agent, in the weight ratio modification agent / iron oxide=0.1-10, to advantage 0.2 for amino acids and poly(amino acid)s and 5 for saccharides.The particles smaller than 2 nm with polydispersity index smaller than 1.1 are prepared by mixing at 21° C. 1 volume part of 10-60 wt. %, to advantage 50 wt. %, of an aqueous solution of a saccharide, disaccharide or polysaccharide, such as D-arabinose, D-glucose, D-galactose, D-mannose, lactose, maltose, dextran and dextrins, and 1 volume part of aqueous solution of a Fe(II) and Fe(III) salt, to advantage FeCl2 and FeCl3, where the molar ratio Fe(III) / Fe(II)=2. A 5-15%, to advantage 7.5%, solution of NH4OH is added until pH 12 is attained and the mixture is heated at 60° C. for 15 min. The mixture is then sonicated at 350 W for 5 min and then washed for 24 h by dialysis in water using a membrane with molecular weight cut-off 14,000 until pH 7 is reached. The volume of solution is reduced by evaporation so that the final dry matter content is 50-100 mg / ml, to advantage 80 mg per 1 ml.Superparamagnetic nanoparticle probes according to the invention can be used for labelling cells used in magnetic resonance imaging for monitoring their movement, localization, survival and differentiation especially in detection of pathologies with cell dysfunction and of tissue regeneration and also for labelling and monitoring cells administered for cell therapy purposes, in particular embryonal stem cells, fetal stem cells, stem cells of an adult human including bone marrow stem cells, olfactory glial cells, fat tissue cells, in the recipient organism by magnetic resonance.The preparation of labelled cells proceeds by adding to the complete culture medium 5-20 μl, to advantage 10 μl, of a colloid containing 0.05-45 mg iron oxide per ml, to advantage 1-5 mg iron oxide per ml of the medium, and culturing the cells for a period of 1-7 days, to advantage for 1-3 days, at 37° C. and 5% of CO2.

Owner:INST OF MACROMOLECULAR CHEM ASCR V V I +1

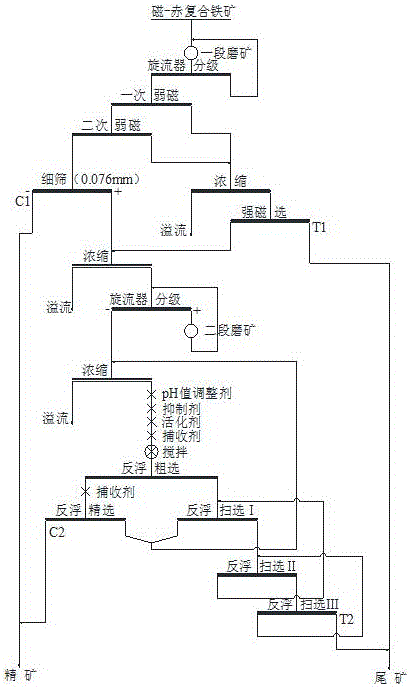

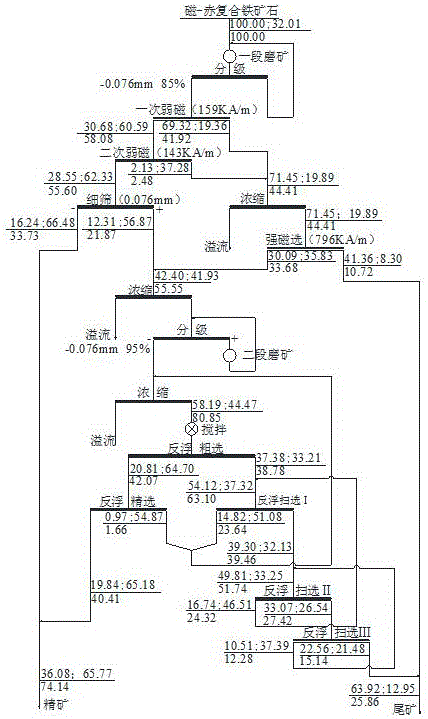

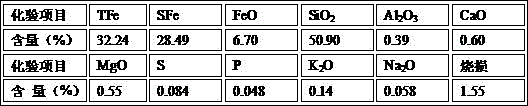

Compound maghemite ore dressing method

ActiveCN106076606AAdvantages of beneficiation methodIndicators are stableWet separationMaghemiteHigh intensity

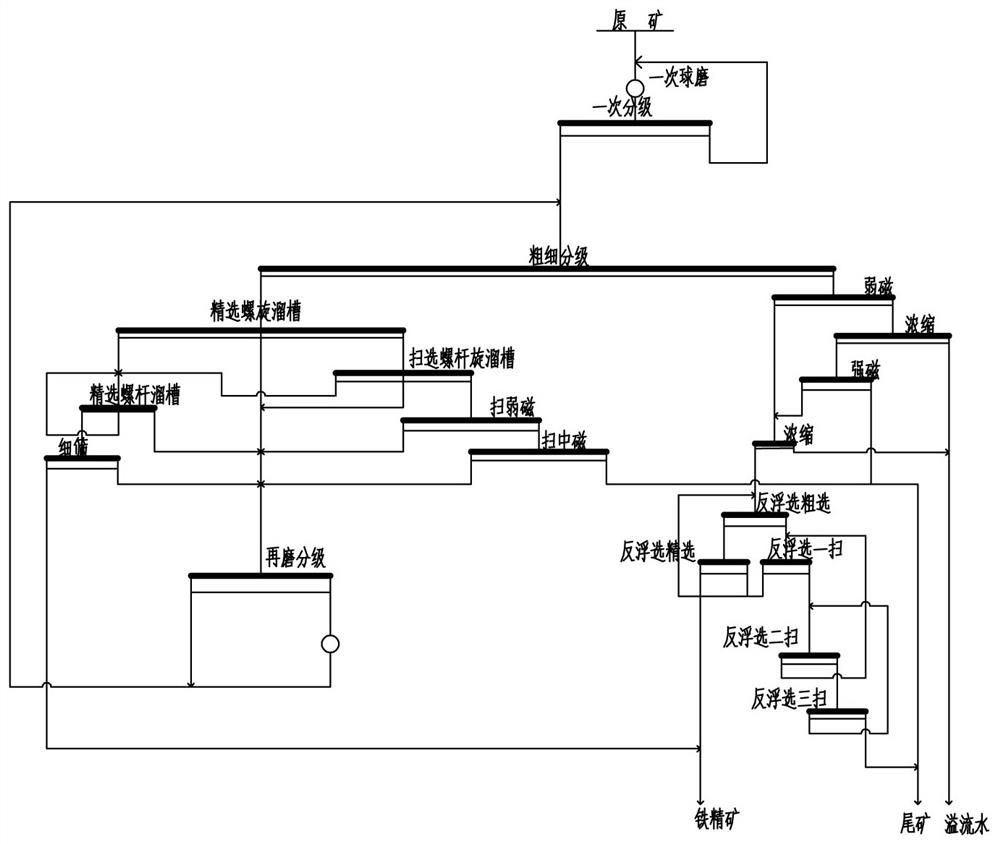

The invention discloses a compound maghemite ore dressing method. The compound maghemite ore dressing method comprises the following steps: feeding compound maghemite ore into an ore grinding-grading-low-intensity magnetic separation operation segment to obtain low intensity magnetic separation concentrate and low-intensity magnetic separation tailings; feeding the low-intensity magnetic separation concentrate into a fine sieving operation segment to obtain finely-sieved concentrate C1; feeding the low-intensity magnetic separation tailings into a high-intensity magnetic separation operation segment, and throwing out high-intensity magnetic separation tailings T1 to obtain high-intensity magnetic separation concentrate; combining coarse fraction low-intensity magnetic separation concentrate with the high-intensity magnetic separation concentrate, and feeding the mixture into a pre-grading-two-stage ore grinding-reverse flotation operation segment to obtain reverse flotation concentrate C2, and throwing out reverse flotation concentrate T2. In the method, staged ore grinding and high-intensity tailing throwing are adopted, so that discarding as soon as possible is realized; the low-intensity magnetic separation concentrate is obtained by fine sieving, so that collection as soon as possible is realized; oversize finely-sieved and high-intensity coarse concentrate is ground, so that the amount of ore ground at a second segment is lowered greatly, and energy-saving and consumption lowering are facilitated; an oversize finely-sieved product is reground and floated, so that the flotation grade is raised, and the adaptability of negative ion reverse floatation to ore characteristic fluctuation is improved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

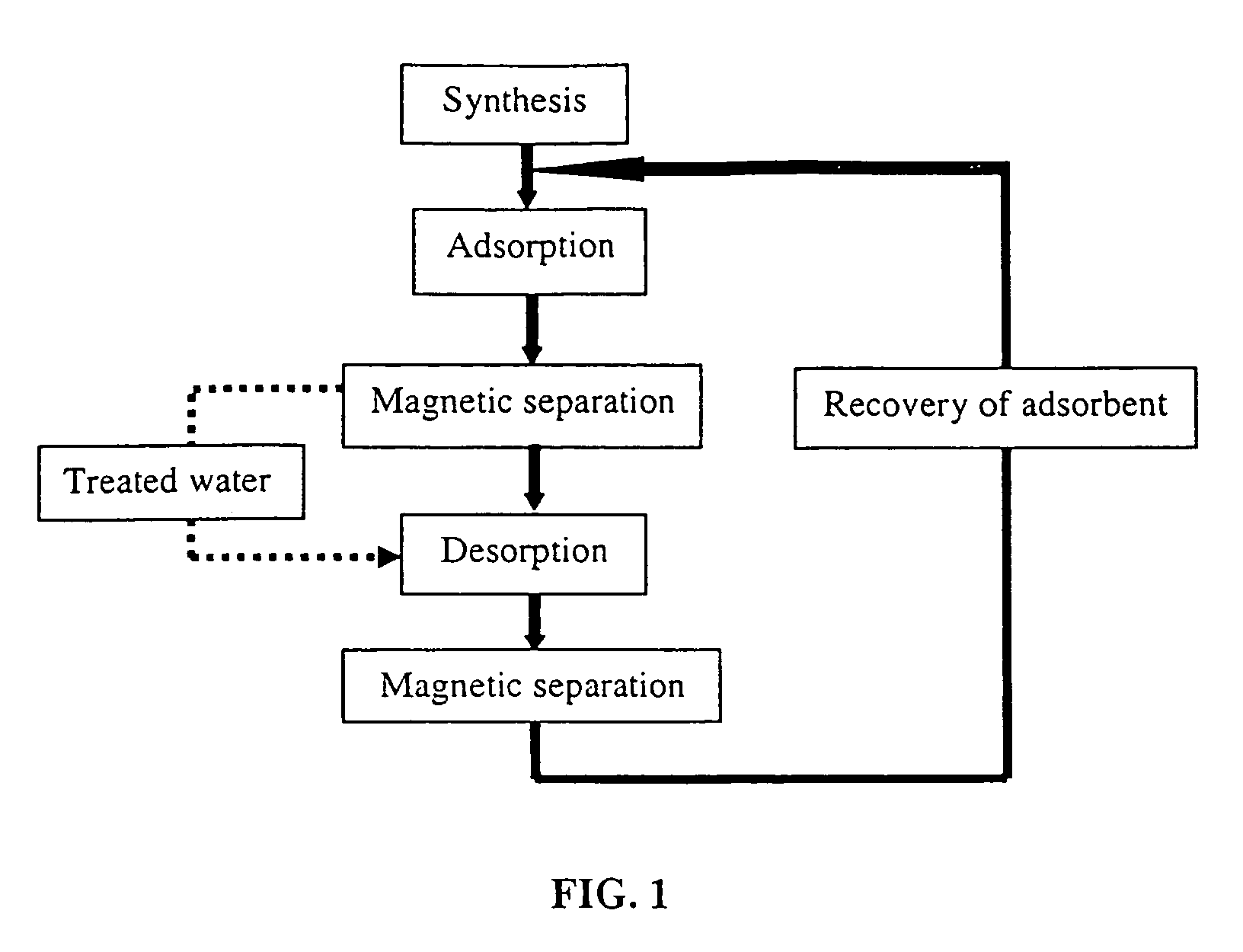

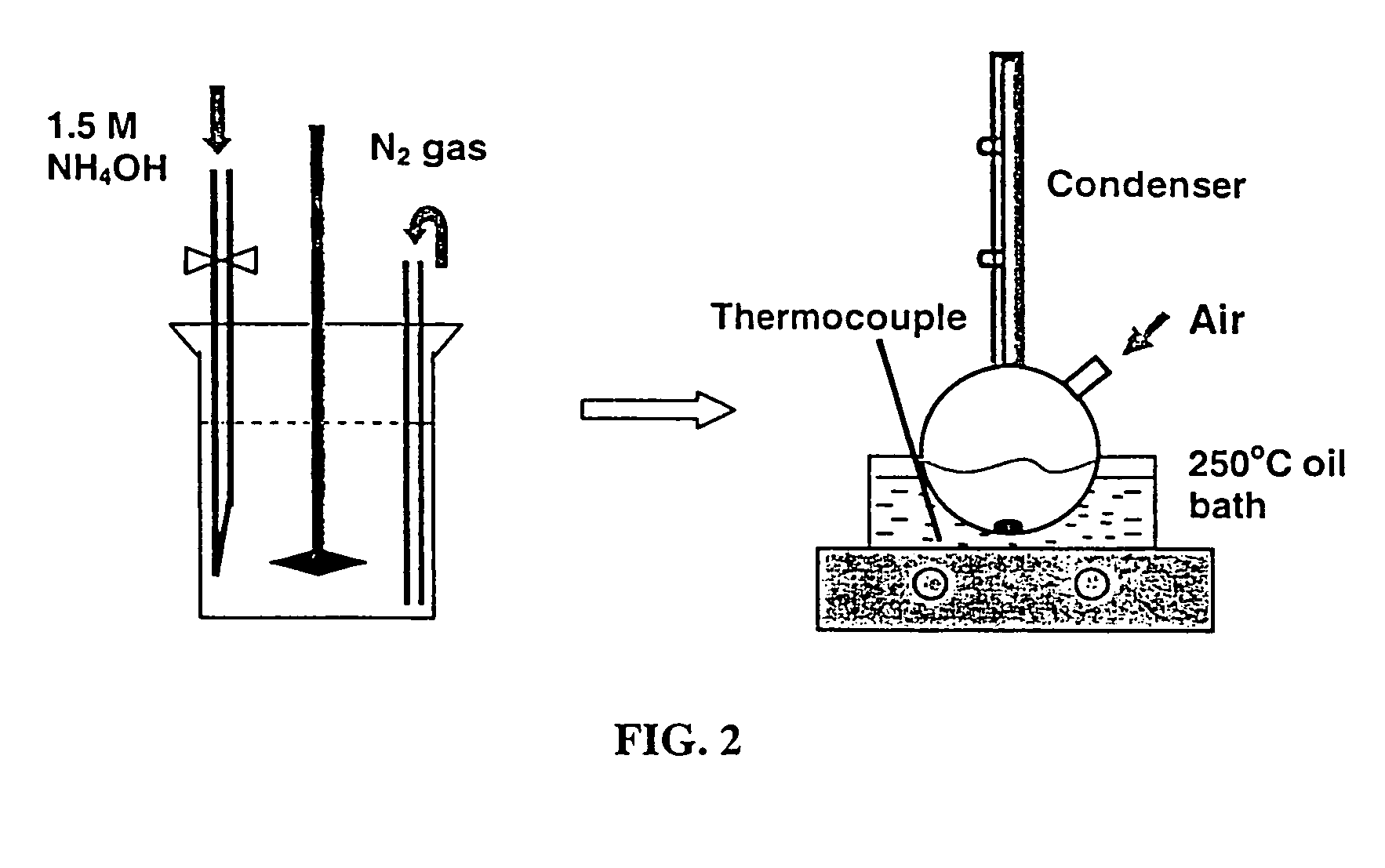

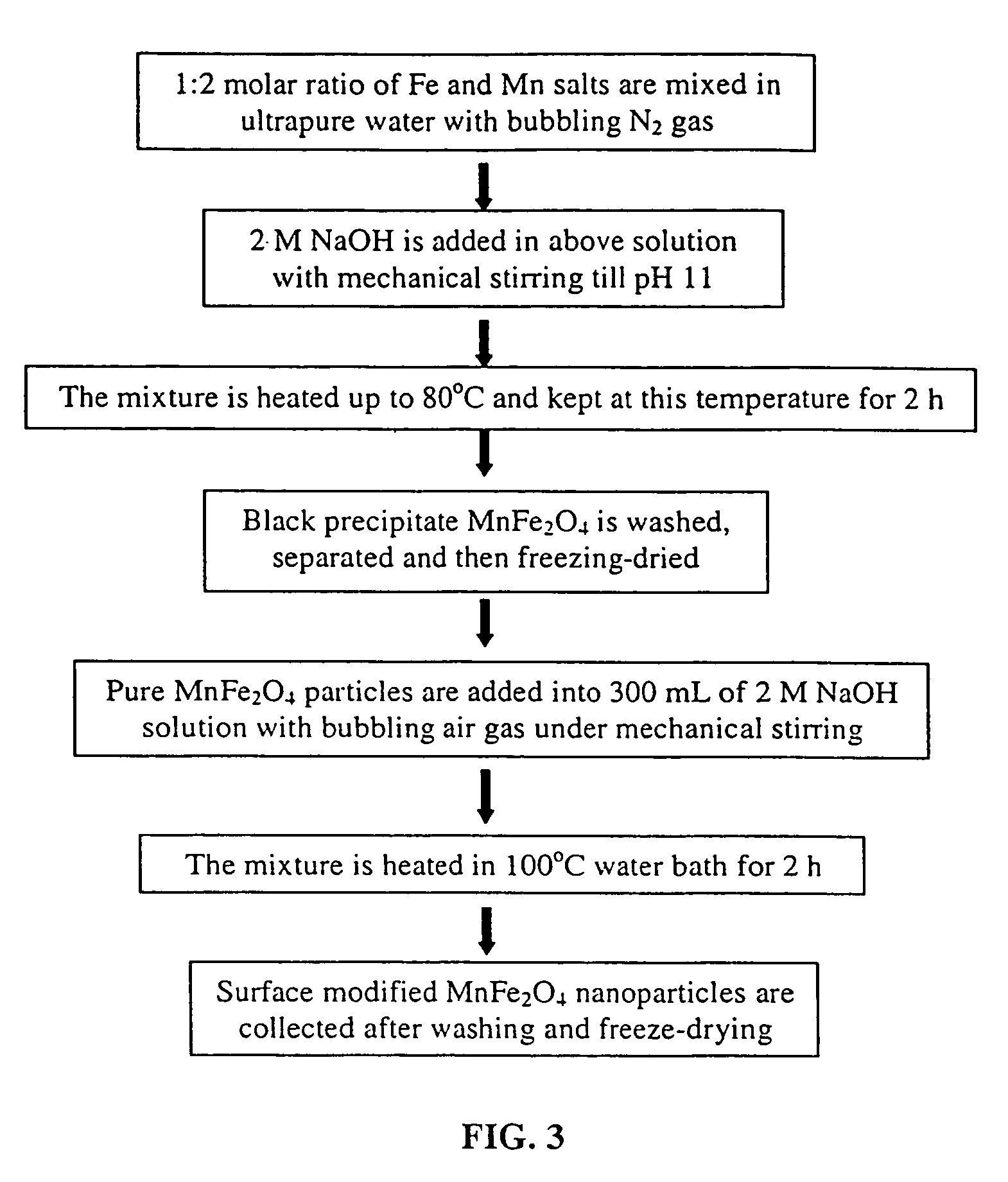

Synthesis of modified maghemite and jacobsite nanoparticles

ActiveUS7622423B1Good removal effectEfficient removalMaterial nanotechnologyOther chemical processesMaghemiteMagnetite Nanoparticles

The present invention provides a method for making modified jacobsite, Al-doped maghemite or modified maghemite nanoparticles that can be used to adsorb heavy metals, such as Cr(VI), found in wastewater. The magnetic nanoparticles can be separated using a magnetic field after adsorbing heavy metals from wastewater, and processed for reused.

Owner:THE HONG KONG UNIV OF SCI & TECH

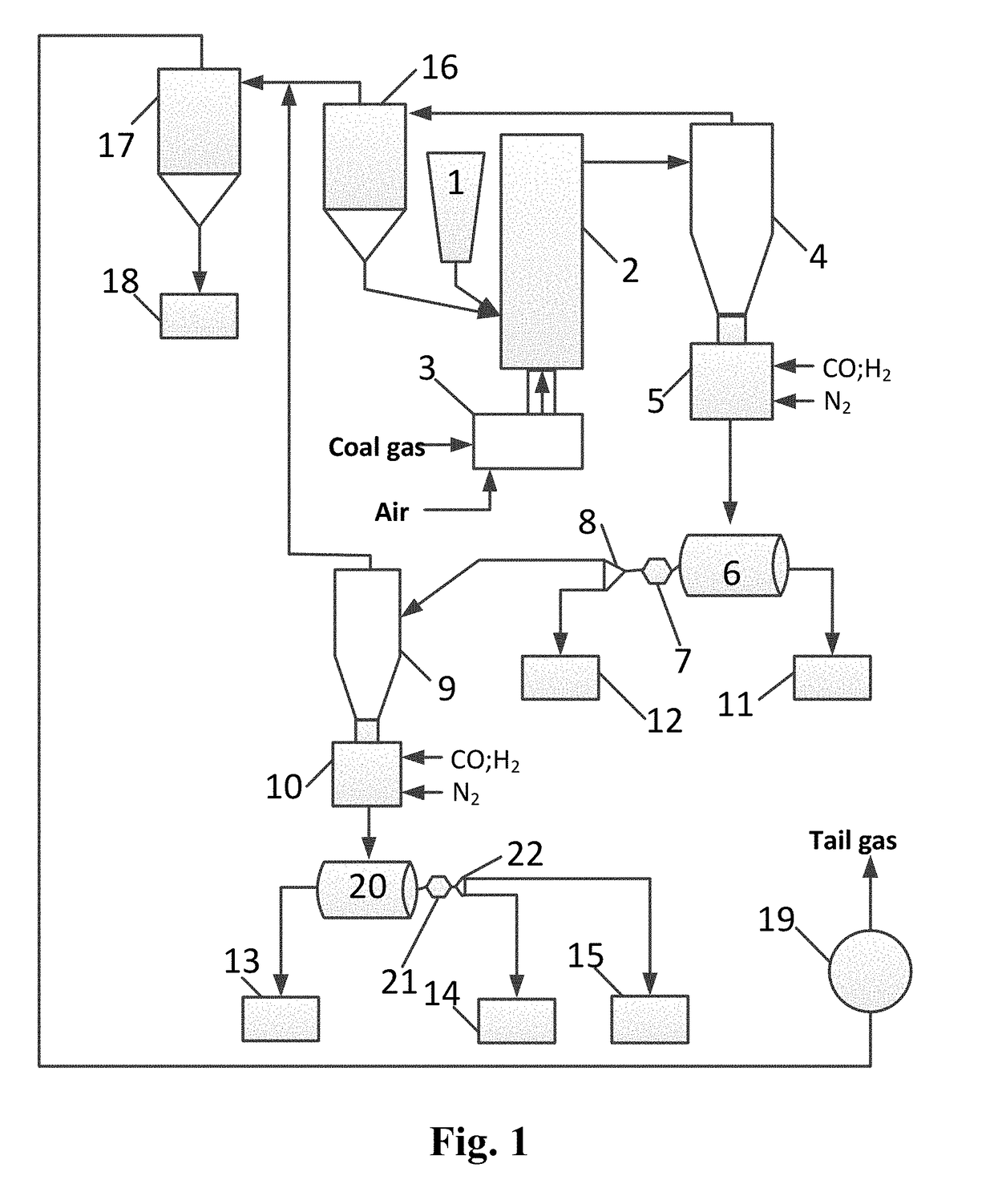

Multi-stage suspension magnetizing roasting-magnetic separation system device and method for refractory iron ore

ActiveUS20180361395A1Reduce energy consumptionHigh indexFluidised-bed furnacesMagnetic separationIronstoneMagnetic separator

The invention discloses a multi-stage suspension magnetizing roasting-magnetic separation system and method for refractory iron ore, which belongs to the field of mineral processing technology. This system comprises multistage suspension preheater, multistage suspension oxidizer, multistage suspension redactor, on-line grade analyzer, ore-like splitter, magnetic separator, dust remover, roots blower and other components and connection modes. The refractory iron ore treated by the present method can be produced to homogeneous magnetite or maghemite accurately, and through magnetic separation, on-line grade analyzer detection and ore-like splitter, the concentrate powder which reach the set grade can be obtained, and the unqualified ore powder enters the next stage of oxidation-reduction-magnetic separation-split treatment. Through the present system and method, products with different roasting quality can be obtained, and can avoid the phenomenon of over burning or under burning occurring in the past process and equipment.

Owner:NORTHEASTERN UNIV

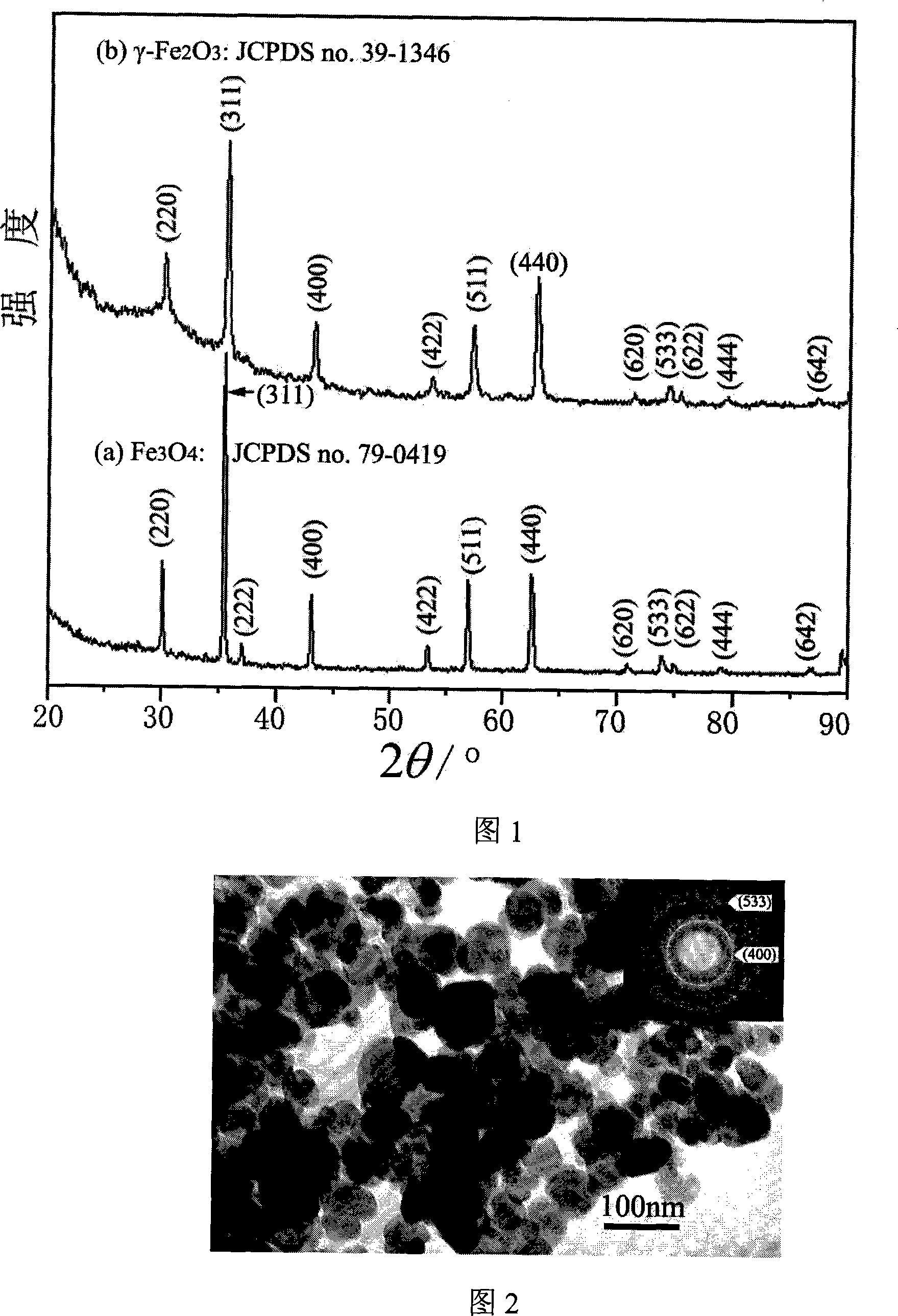

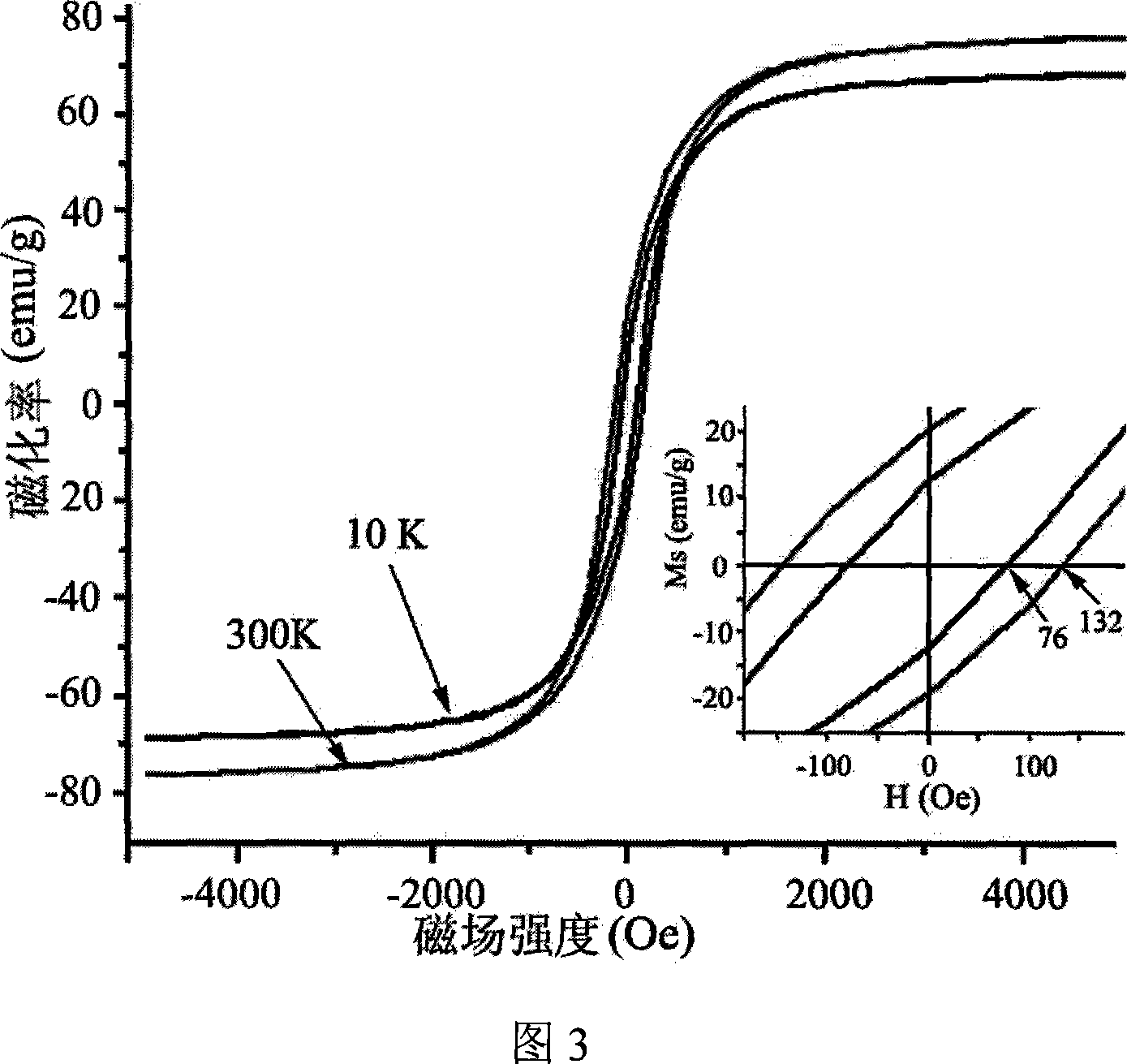

Preparation method for gamma-Fe2O3 magnetic nano particles

InactiveCN101125684APromote crystallizationGood dispersionInorganic material magnetismFerric oxidesFerrous saltsMagnetization

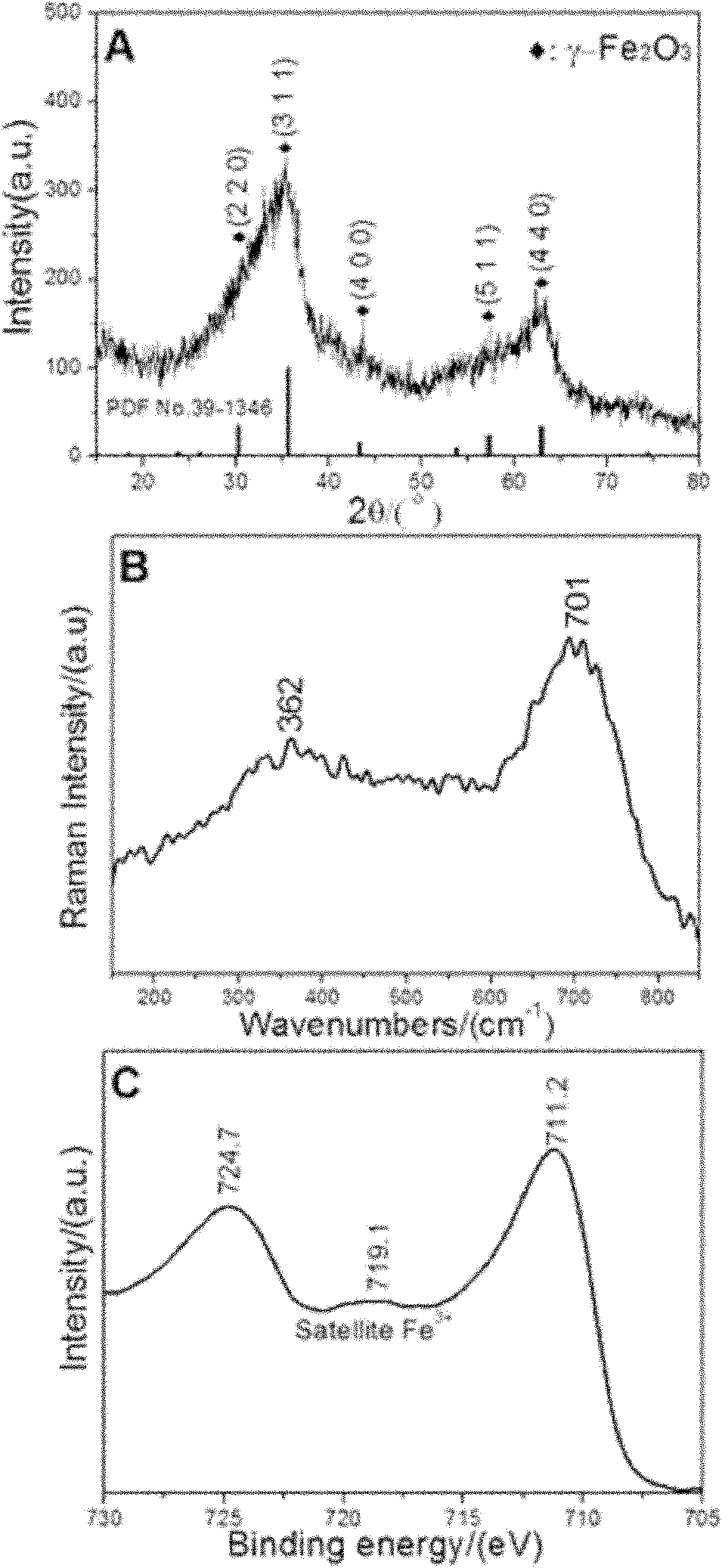

The invention discloses a preparation method of Gamma-Fe2O3 magnetic nanometer particles. The invention adopts a two-step hydro-thermal method and synthesizes maghemite (Gamma-Fe2O3) nanometer particles. Step 1: with ferrous salt, sodium hydroxide and hydrazine hydrate as raw materials, black Fe3O4 nanometer particles are synthesized by a hydro-thermal method. Step 2: with oxyful as oxidant, the black Fe3O4 nanometer particles obtained at Step 1 is thermal oxidized into mahogany Gamma-Fe2O3 nanometer particles. The Gamma-Fe2O3 nanometer particles obtained by the invention with particle size being 50-100 nanometers has excellent crystallization and dispersion and is magnetic with saturated magnetization rate being 68emu / g.

Owner:ZHEJIANG SCI-TECH UNIV

Beneficiation process of maghemite

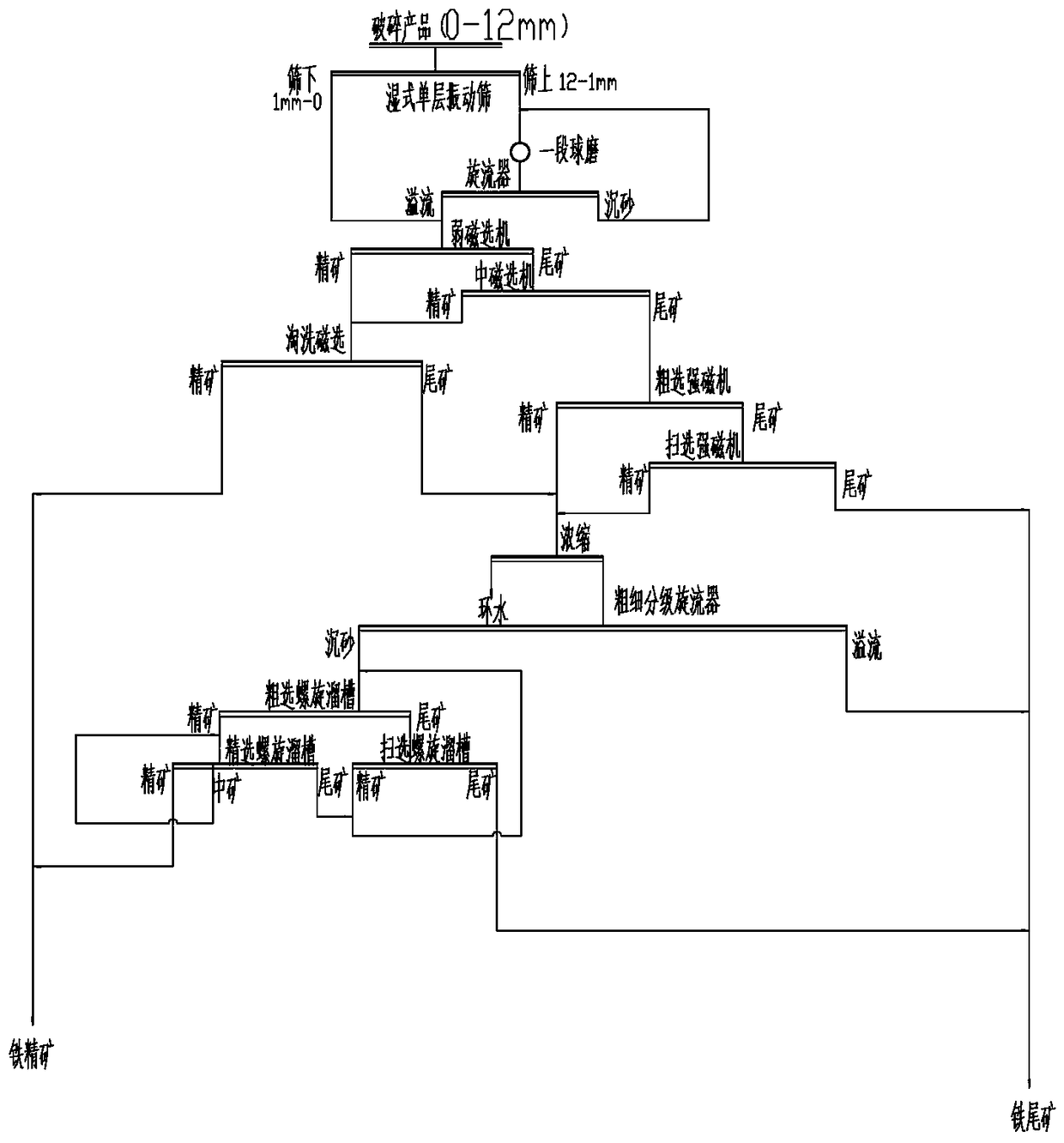

InactiveCN108580029AAvoid pollutionGuaranteed gradeMagnetic separationGrain treatmentsCycloneClosed loop

The invention relates to a beneficiation process of maghemite. Raw ores are the maghemite. The iron grade is 41%-43%. The content of ferruginous clay is over 30%. The beneficiation process of the maghemite is characterized in that crushed products with the grain size being 12-0 mm are processed according to the following technological flow comprising that (1) pre-grading and closed-loop ore grinding are conducted during ore grinding, (2) weak intensity magnetic separation-medium intensity magnetic separation-high intensity magnetic separation-elutriation magnetic separation are conducted during magnetic separation, and (3) spiral chute roughing separation, concentration and scavenging are conducted during gravity separation; and the comprehensive concentrates composed of magnetic separation concentrates and gravity separation concentrates are obtained, wherein the grade of the comprehensive concentrates is 62% or over, and the recovery rate is 62.00-63.00%. The beneficiation process ofthe maghemite has the advantages that the crushed products are graded in advance, only one-stage closed loop ore grinding is adopted, and therefore investment and energy consumption are reduced; (2)magnetic separation concentrates are directly obtained from the products of the one-stage ore grinding through an elutriation magnetic separator; and (3) tailing discarding is conducted on coarse andfine classification overflow of cyclone to remove the ferruginous clay before gravity separation, so that the influence of the ferruginous clay on the quality of the gravity separation concentrates islowered.

Owner:中冶北方(大连)工程技术有限公司

Carrier core material for an electrophotographic developer, carrier, and electrophotographic developer using the carrier

ActiveUS20090246677A1Little change in resistivityHigh image densityDevelopersBreaking strengthMaghemite

A carrier core material for an electrophotographic developer containing Li ferrite, maghemite, and Fe3O4, wherein a part thereof is substituted with Mn, a Li content is 1 to 2.5% by weight, a Mn content is 2 to 7.5% by weight, and a silicon content is 25 to 10,000 ppm, a compression breaking strength is 130 MPa or more, an SF-1 is 125 to 145, respective cumulative strengths of respective spinel crystal structure faces in X-ray diffraction satisfy a certain equation, a vacuum resistivity R500 across a 2 mm gap when a measurement voltage of 500 V is applied is 1×106 to 5×109Ω, and a vacuum resistivity R1000 across a 6.5 mm gap when a measurement voltage of 1,000 V is applied is 5×107 to 1×1010Ω.

Owner:MITSUI MINING & SMELTING CO LTD +1

Magnetic recording medium and process for producing the same

A magnetic recording medium of the present invention comprises: a plastic substrate; and a cobalt-containing maghemite thin film formed on said substrate, containing cobalt at a molar ratio of cobalt to iron of not more than 0.06:1, and having either a spacing of a plane (311) of not more than 2.510 Å, a spacing of a plane (222) of not more than 2.415 Å or a spacing of a plane (220) of not more than 2.950 Å; and has a coercive force of not less than 2,000 Oe. Such magnetic recording medium suitably applicable to existent magnetic recording systems using a ring-type magnetic head and capable of using a plastic substrate for providing a magnetic recording medium for high-density recording.

Owner:TODA IND

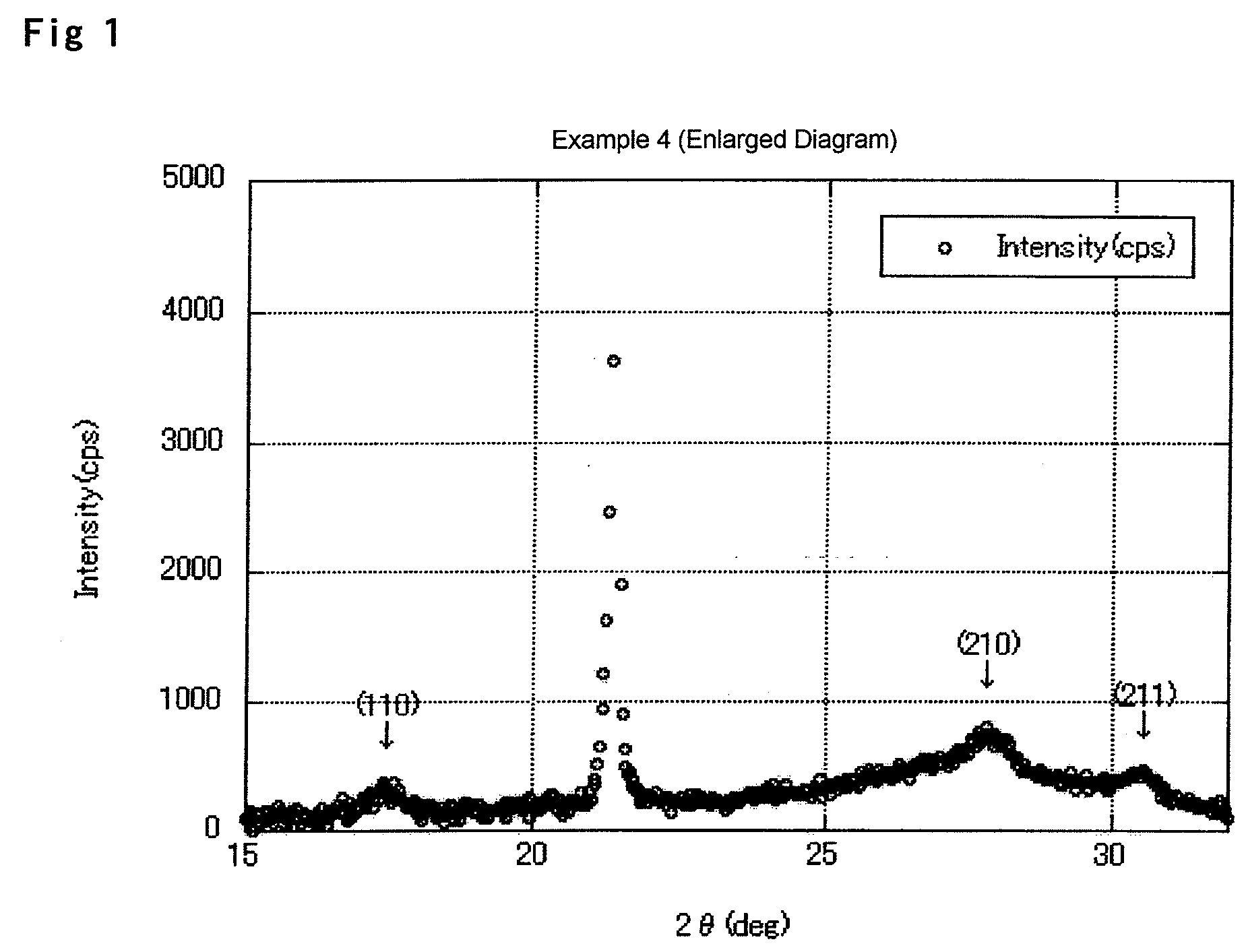

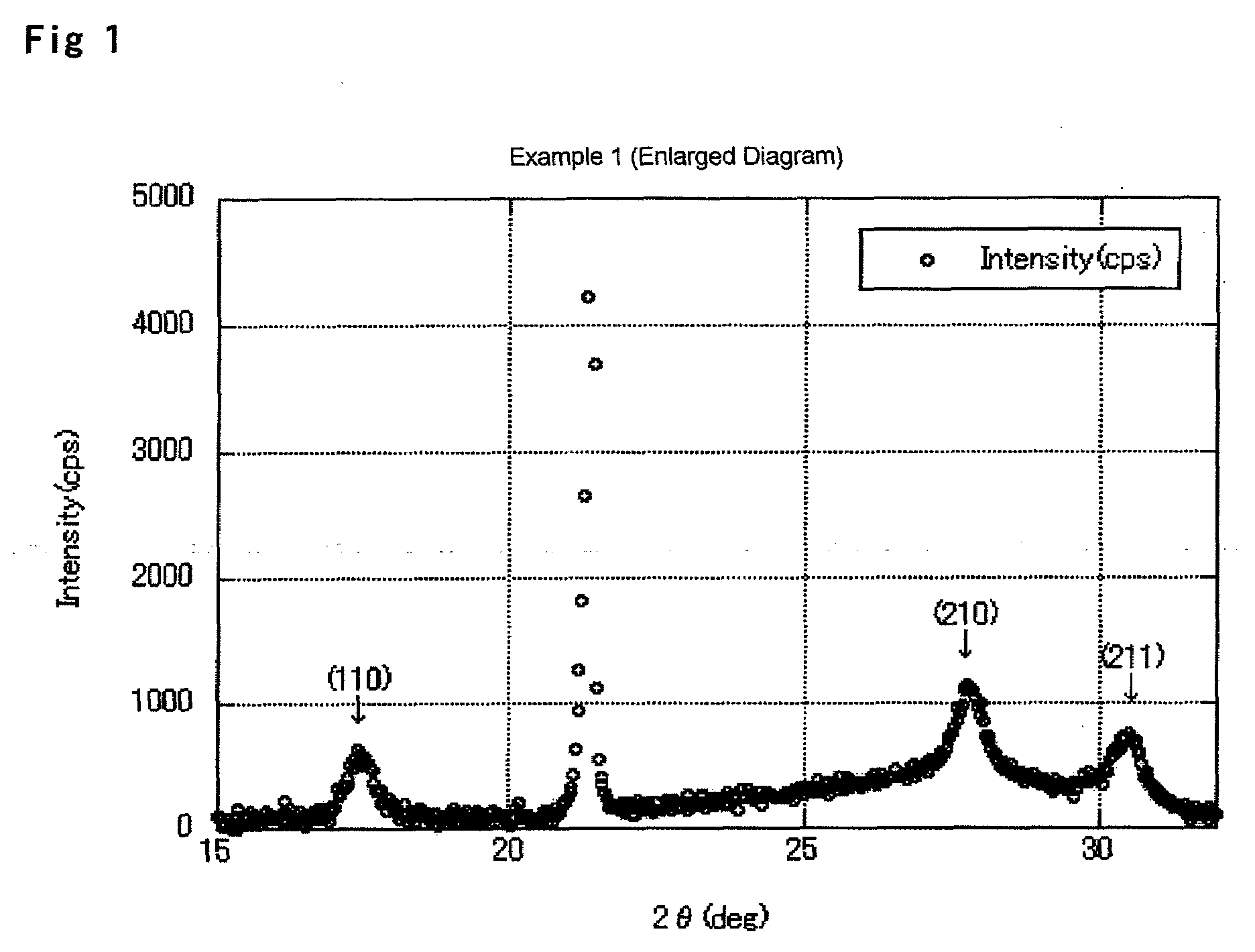

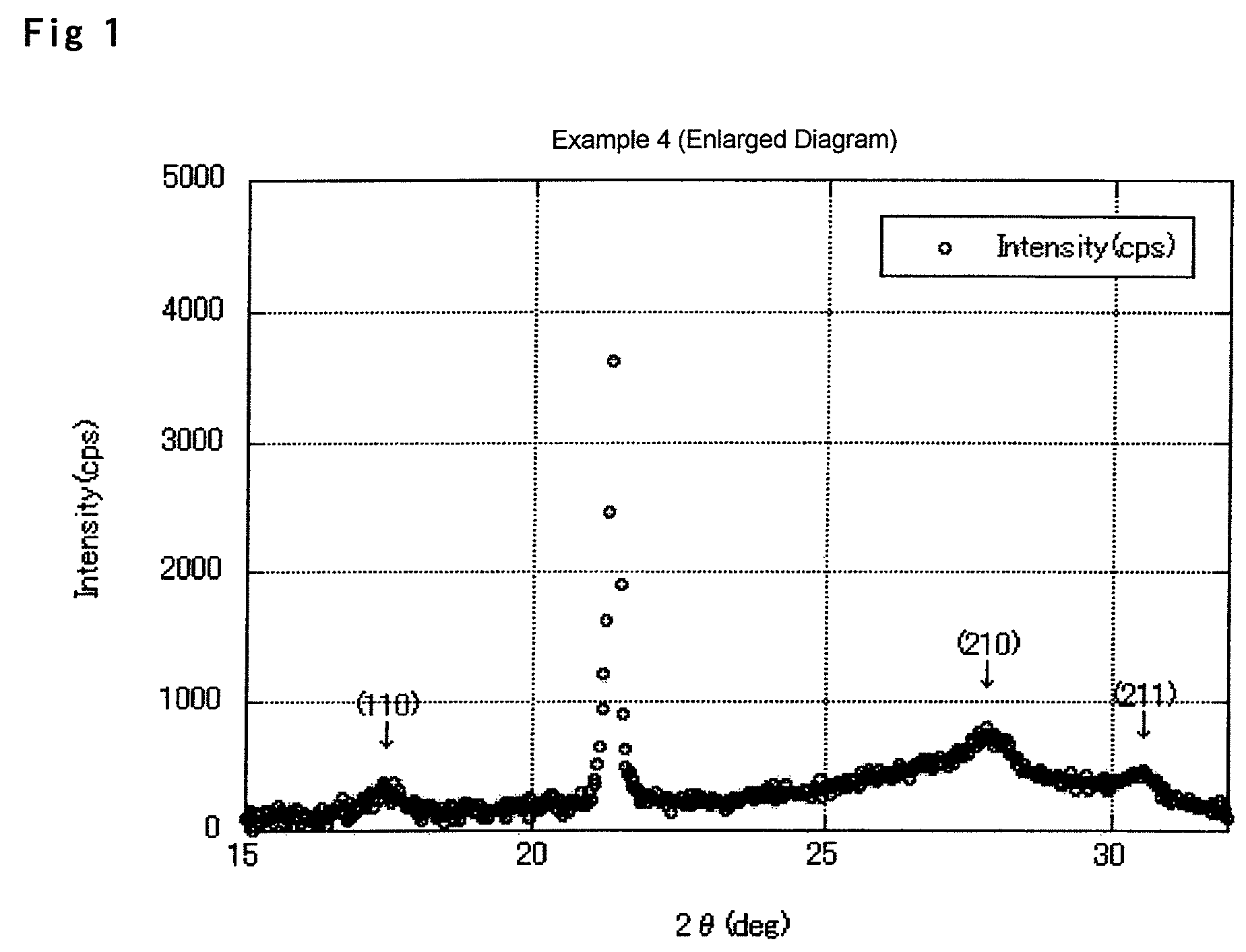

Carrier core material for electrophotographic developer, carrier, and electrophotographic developer using the carrier

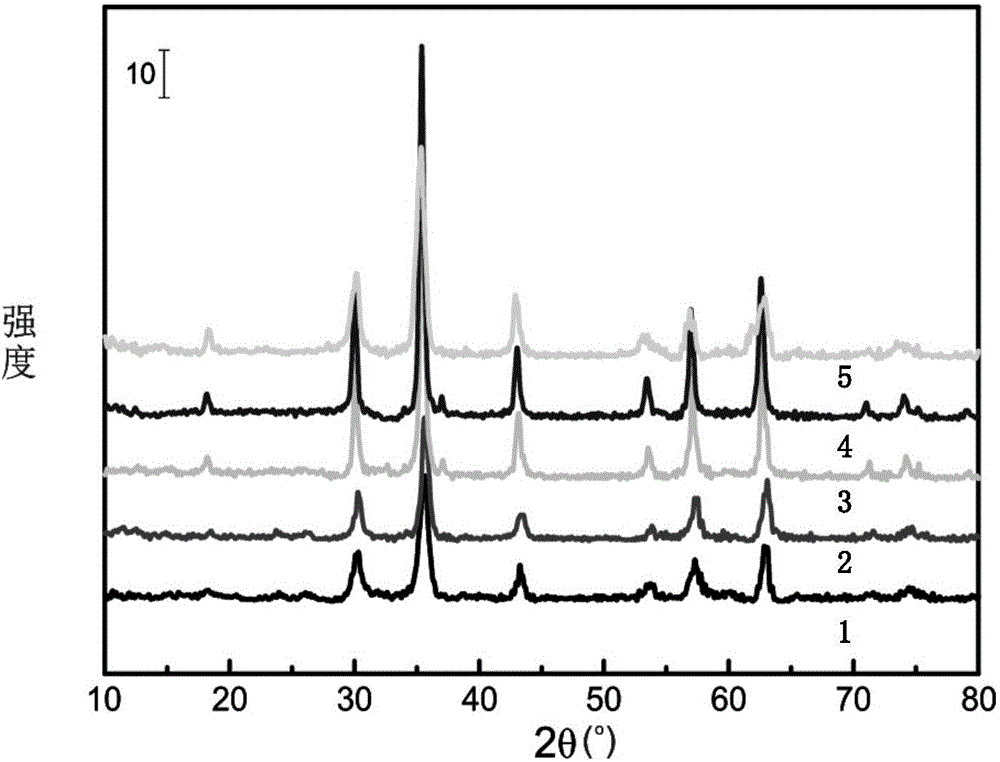

A carrier core material for an electrophotographic developer including Li ferrite, maghemite, and Fe3O4, wherein a part thereof is substituted with Mn, Li content is 1 to 2.5% by weight, Mn content is 2 to 7.5% by weight, and silicon content is 25 to 10,000 ppm, the following equation (1) is satisfied when respective integrated strengths of spinel crystal structure (110), (210), (211), and (311) faces in X-ray diffraction are respectively I110, I210, I211, and I311, a resistivity R50 of 50 V across a 6.5 mm gap is 5×107 to 7×108Ω, and a resistivity R1000 of V across a 6.5 mm gap is 1×107 to 8×108Ω.2<100×(I110+I210+I211) / I311<14 (1)

Owner:MITSUI MINING & SMELTING CO LTD +1

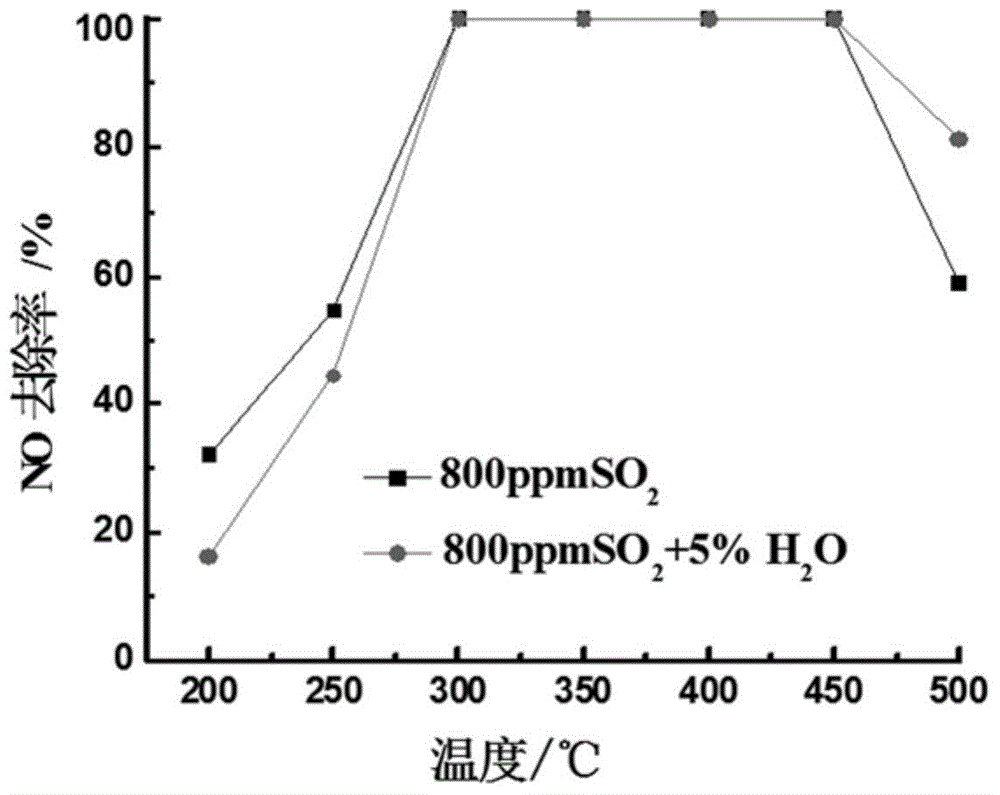

Magnetically separable and recyclable iron oxide SCR denitration catalyst and application method thereof

InactiveCN104971722AAchieve separationAchieve recyclingDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereHierarchical porous

The invention discloses a magnetically separable and recyclable iron oxide SCR denitration catalyst and an application method thereof. The catalyst is prepared through the following steps: with a limonite ore as a raw material, crushing and screening to form particles, calcining the particles in an atmosphere of hydrogen or carbon monoxide, so as to reduce goethite in the particles to be magnetite to obtain the catalyst, or further calcining in an air atmosphere, so that the magnetite is oxidized to be maghemite to obtain the catalyst, wherein the goethite content of the limonite ore is not less than 60%, the limonite ore has a nano-micro hierarchical porous structure, and the specific surface area of the limonite ore is not less than 10m<2> / g. When in use, the catalyst and ammonia are simultaneously fed into a flue gas flow at the temperature of 300-450 DEG C, and the catalyst and dust are together adsorbed onto the electrode plate of an electric dust collector or the surface of a filter bag and then are collected into a dust hopper through a dust cleaning method; the SCR denitration catalyst in the material discharged from the dust hopper is separated and recycled through a magnetic separation method; if inactivated, the SCR denitration catalyst can be washed and regenerated with water or weak aqua ammonia.

Owner:HEFEI UNIV OF TECH

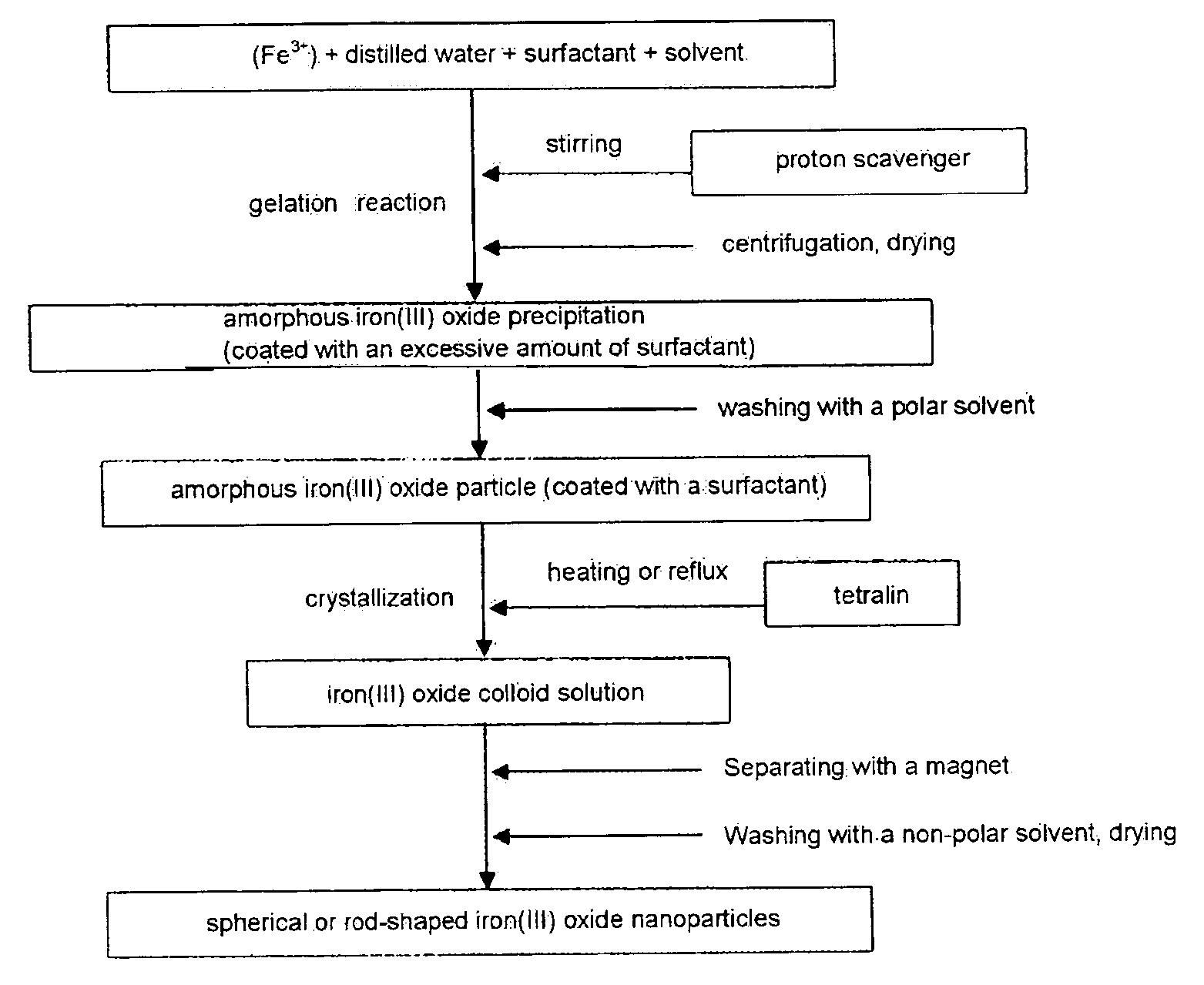

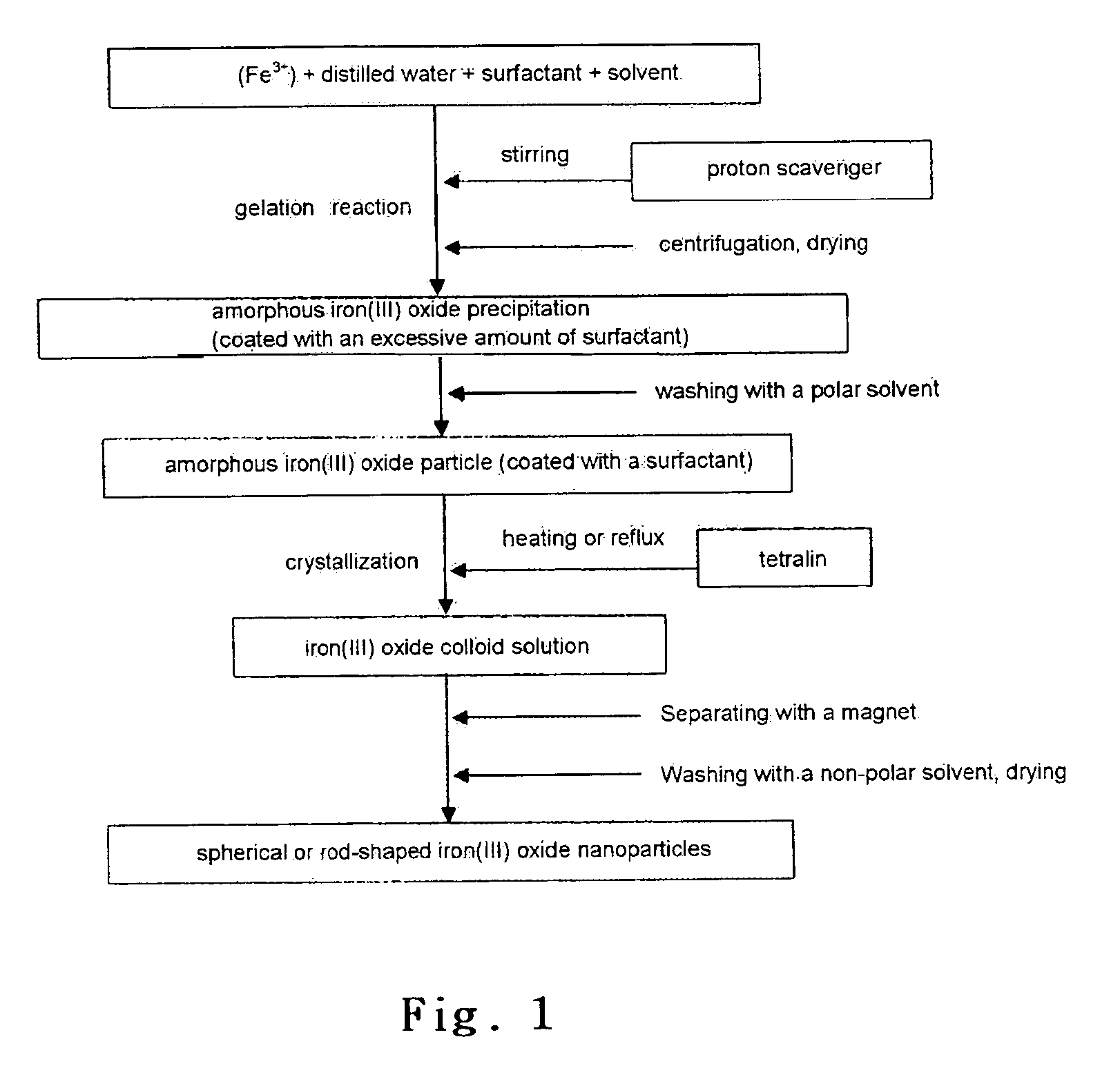

Shape anisotropic metal oxide nanoparticles and synthetic method thereof

InactiveUS7122168B2Excellent characteristicsGood shape anisotropyNanostructure manufactureTantalum compoundsScavengerMetal oxide nanoparticles

In a metal oxide nanoparticle and a synthetic method thereof, and in particular to maghemite (γ-Fe2O3) nanoparticles usable as a superhigh density magnetic recording substance by having good shape anisotropy and magnetic characteristics, hematite (α-Fe2O3) nanoparticles usable as a precursor to the maghemite or a catalyst, maghemite and hematite-mixed nanoparticles and a synthetic method thereof, the method for synthesizing metal oxide nanoparticles includes forming a reverse micelle solution by adding distilled water, a surfactant and a solvent to metallic salt not less than trivalent, precipitating and separating gel type amorphous metal oxide particles by adding proton scavenger to the reverse micelle solution; adjusting a molar ratio of metal oxide to the surfactant by washing the gel type amorphous metal oxide particles with a polar solvent; and crystallizing metal oxide nanoparticles through heating or reflux after dispersing the gel type amorphous metal oxide particles in a non-polar solvent having a high boiling point.

Owner:KOREA INST OF SCI & TECH

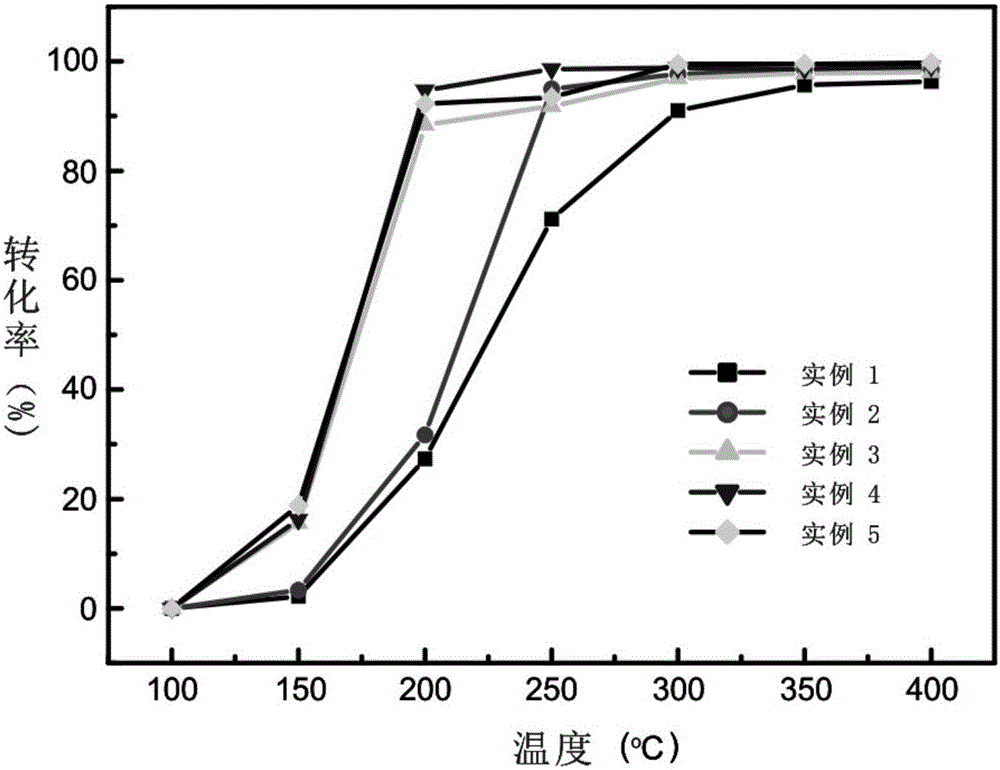

Manganese-doped maghemite catalyst used for thermal catalytic oxidation of formaldehyde, and preparation method thereof

ActiveCN105013502AHigh catalytic activityLow ignition temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationFreeze-drying

The invention discloses a manganese-doped maghemite catalyst used for thermal catalytic oxidation of formaldehyde, and a preparation method thereof. According to the preparation method, a ferric salt and a manganese salt are taken as the main raw materials; a manganese-doped maghemite precursor is synthesized via sodium hydroxide coprecipitation; and the manganese-doped maghemite precursor is subjected to washing, freeze drying, screening, and roasting oxidation so as to obtain the manganese-doped maghemite catalyst used for thermal catalytic oxidation of formaldehyde. The manganese-doped maghemite catalyst is granular, possesses spinel structures, and weak magnetism. The manganese-doped maghemite catalyst can be used for effective thermal catalytic oxidation of high-concentration formaldehyde, and can be used for removing high-concentration formaldehyde (>1000mL / m3) at 300 DEG C; formaldehyde removing rate is 90% or higher; catalytic activity is high; initiation temperature is low; thermal stability is excellent; separation and recovery are convenient; no secondary pollution is caused; cost is low; and the manganese-doped maghemite catalyst is suitable for purifying treatment of high concentration formaldehyde in industrial exhaust gas.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Animal magnetic ferritin material and its preparation method

InactiveCN102464715ASuitable for purificationSimple purification methodTransferrinsSolubilityPh control

The invention relates to an animal magnetic ferritin material comprising a complete animal ferritin shell and a magnetic nanoparticle core, the diameter of which ranges from 1 nanometer to 8 nanometers. With dispersibility and dissolvability in water and polar solvents, the core comprises magnetite or maghemite. The preparation method of the animal magnetic ferritin material consists of: 1) subjecting an animal offal to pulp refining, filtering and centrifugation to remove other proteins, then conducting nickel column and molecular sieve chromatography to separate monosomic natural ferritin; 2) in an acidic condition, carrying out reduction and denucleation to the natural ferritin so as to obtain denulceated ferritin; 3) taking hydrogen peroxide as an oxidizing agent, and adding it to a denulceated ferritin solution for reaction to synthesize animal magnetic ferritin, with the mole ratio of Fe(II) / H2O2 greater than or equal to 2:1, the pH controlled at 7.1-11, and the temperature maintained at 25-70DEG C; 4) separating the obtained animal magnetic ferritin so as to obtain monodispersed and nonmagnetic interacting animal magnetic ferritin particles. The invention also provides a preparation method.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Ore grinding weak-magnetic strong-magnetic gravity separation reverse flotation process for magnetic hematite ore

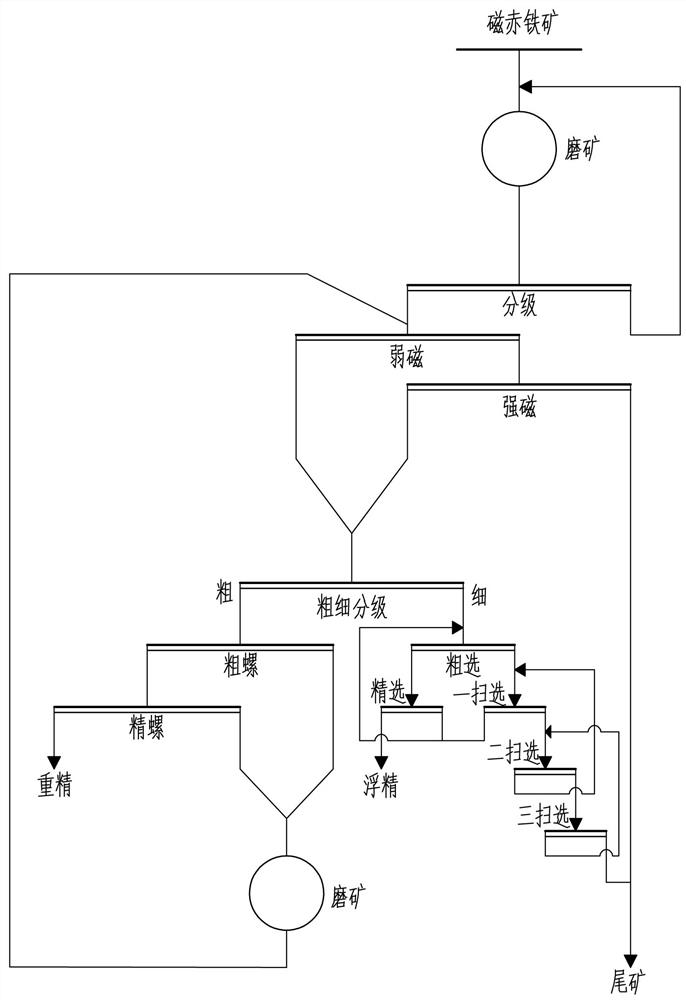

InactiveCN112588431AShorten the beneficiation processGood beneficiation indexFlotationMagnetic separationIronstoneMaghemite

The invention relates to an ore grinding weak-magnetic strong-magnetic gravity separation reverse flotation process for a magnetic hematite ore. The ore grinding weak-magnetic strong-magnetic gravityseparation reverse flotation process for the magnetic hematite ore is characterized by comprising the following steps that the magnetic hematite ore with the grade of 25%-45% and the magnetite distribution rate of more than or equal to 60% is subjected to grinding and weak and strong magnet separation tailing discarding, coarse-fine classification is carried out on weak and strong magnetic concentrate, coarse-fine spiral chute gravity separation is carried out on a coarse fraction to obtain gravity concentrate, and tailings in gravity separation are re-ground and then returned to the weak andstrong magnetic separation; reverse flotation of rough flotation-fine flotation-three scavenging is carried out on the fine fraction to obtain floating concentrate, and floating tailings are discarded; and the gravity concentrate and the floating concentrate are combined to form the final concentrate with the iron grade larger than or equal to 65% and the total recovery rate larger than or equal to 80%. The ore grinding weak-magnetic strong-magnetic gravity separation reverse flotation process for the magnetic hematite ore has the advantages that (1), the method is suitable for all iron ores with high magnetic iron content, and fine-grained embedded iron ores are included; (2), the existing process is remarkably shortened, the concentrate grade is high, and the recovery rate is high; and (3), the ore treatment amount of the magnetic gravity separation process is a main body part, equipment operation is stable, operation and control are simple, meanwhile, the flotation pressure is reduced, investment is low, energy is saved, and environment friendliness is achieved.

Owner:ANSTEEL GRP MINING CO LTD

Magnetic fertilizer and production method thereof

InactiveCN101440005AEasy to produceIncrease productionFertilizer mixturesGeneral chemistCompound (substance)

The invention relates to a magnetic fertilizer and a production method thereof. The magnetic fertilizer consists of chemical fertilizer, and is characterized by also comprising a magnetic substance, wherein mass ratio of the magnetic substance to the chemical fertilizer is between 0.1-5:100. The magnetic substance is selected from natural magnetic mineral, such as magnetite, maghemite and the like, and artificial permanent magnetic material, such as iron oxidization magnetic material, ferrimanganic permanent magnetic material or rear-earth permanent magnetic material. The production method for the magnetic fertilizer comprises the following steps: (1) firstly weighing a certain amount of common chemical fertilizer, and then mixing the common chemical fertilizer and the magnetic substance in a preset proportion; (2) stirring the mixture evenly; and (3) putting the evenly stirred mixture in magnetic field, and carrying out magnetization treatment on the mixture to obtain final products. The production method can improve the yield of grains remarkably, and reduce application amount of nitrogen at the same time, so as to reduce pollution of farm production to environment. The production method can conveniently produce the magnetic fertilizer.

Owner:NANJING NORMAL UNIVERSITY

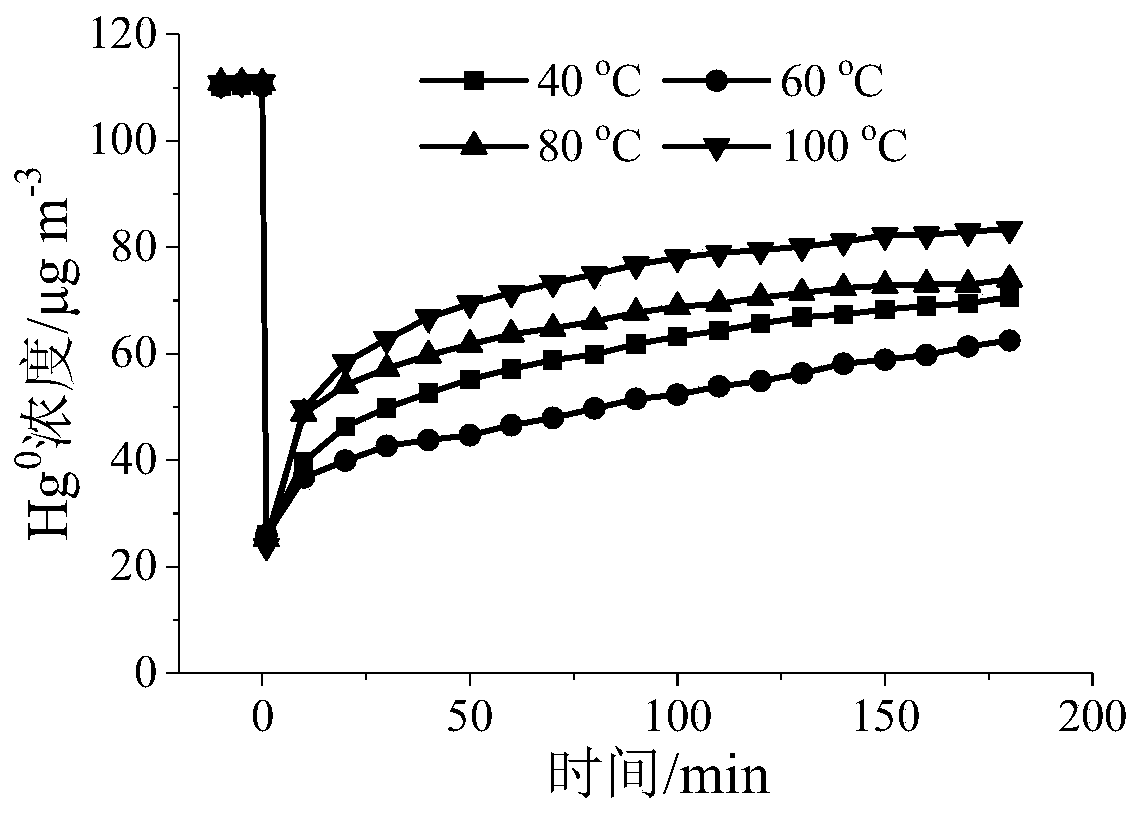

Magnetic renewable adsorbent for adsorbing gaseous zero-valent mercury and preparation method of magnetic renewable adsorbent

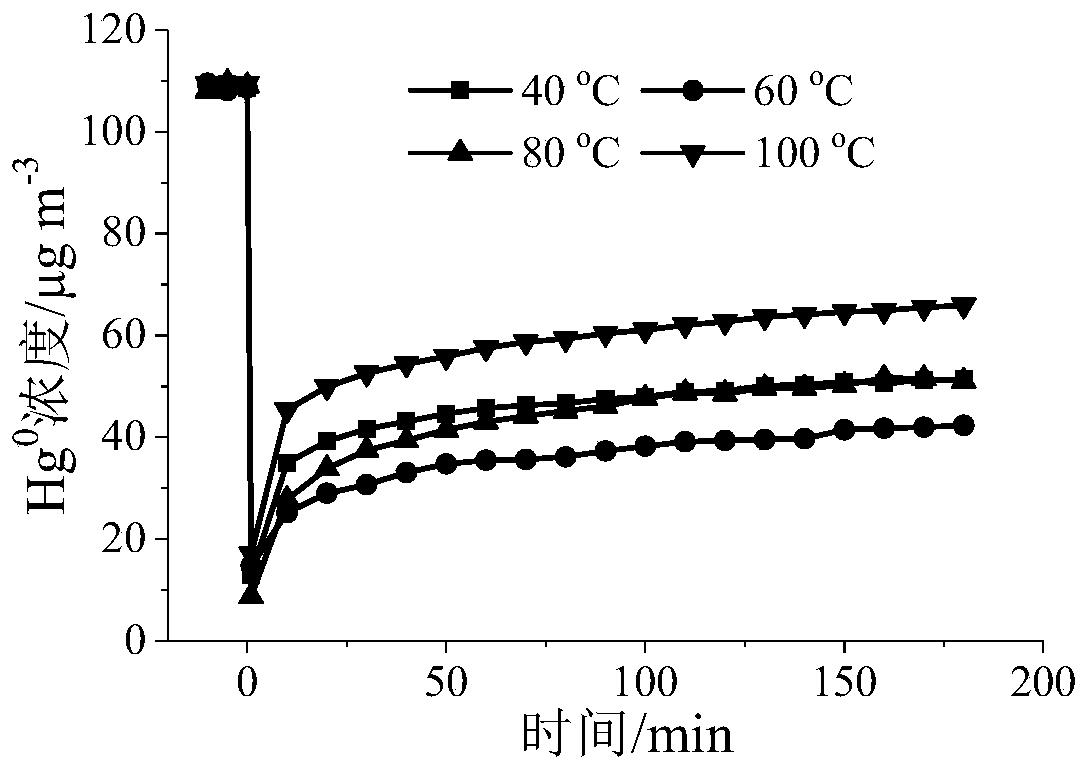

ActiveCN110801805AExcellent gaseous zero-valent mercury adsorption performanceStrong magneticGas treatmentOther chemical processesPhosphomolybdic acidSorbent

The invention discloses a magnetic renewable adsorbent for adsorbing gaseous zero-valent mercury and a preparation method of the magnetic renewable adsorbent, and belongs to the technical field of mercury adsorption. The adsorbent is formed by performing phosphomolybdic acid (HPMo) grafting on magnetite (Fe3O4) in a preparation process to form HPMo@Fe3O4, then performing high-temperature calcination to obtain MoO3@gamma-Fe2O3, and finally performing vulcanization modification. The phase change of maghemite is inhibited by a means of phosphomolybdic acid grafting, so as to improve the thermal stability of maghemite, and the magnetic property of maghemite is improved; meanwhile, the zero-valent mercury adsorption capacity of the phosphomolybdic acid grafted maghemite is improved by controlling the vulcanization effect of the surface of the phosphomolybdic acid grafted maghemite, the magnetic adsorbent which has excellent low-temperature zero-valent mercury adsorption capacity and can berecycled is prepared, and the magnetic adsorbent can be suitable for being combined with a wet-type electric precipitator to control mercury pollution of a coal-fired power plant in a centralized mode.

Owner:JIANGNAN UNIV

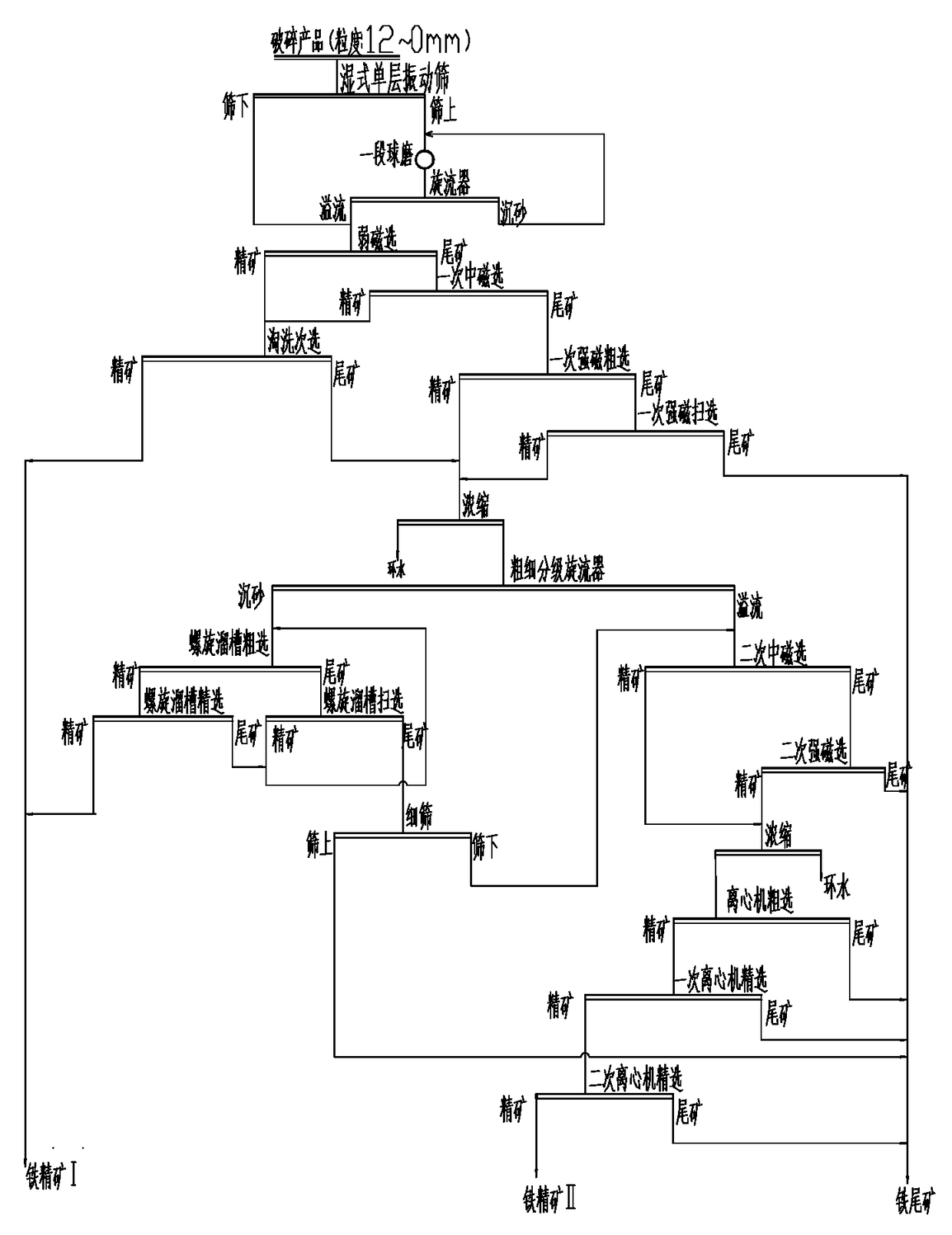

High-yield two-product mixed maghemite beneficiation process

The invention relates to a high-yield two-product mixed maghemite beneficiation process. The high-yield two-product mixed maghemite beneficiation process comprises three-section breakage including coarse breaking, medium breaking and fine breaking on mixed maghemite, and is characterized by further comprising the following steps: sieving operation, a one-section closed circuit grinding operation implemented by a one-section ball-milling-cyclone, primary beneficiation operation, coarse and fine classification operation, reselection operation, secondary magnetic separation operation and centrifuging operation; a primary magnetic separation operation sieve treats overflow products of one-section closed circuit grinding operation, sieving operation and undersizes, the coarse and fine classification operation treats bulk concentrate obtained by primary beneficiation, the reselection operation treats coarse grain products of the coarse and fine classification operation, the secondary beneficiation operation treats coarse particle products of the coarse and fine classification operation, and the centrifuging operation treats bulk concentrates of secondary weak magnetic separation. The high-yield two-product mixed maghemite beneficiation process has the advantages that iron ore concentrates I with grade being 62% for pelletizing raw materials and iron ore concentrates II with grade being 58% for sintered raw materials can be selected out.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

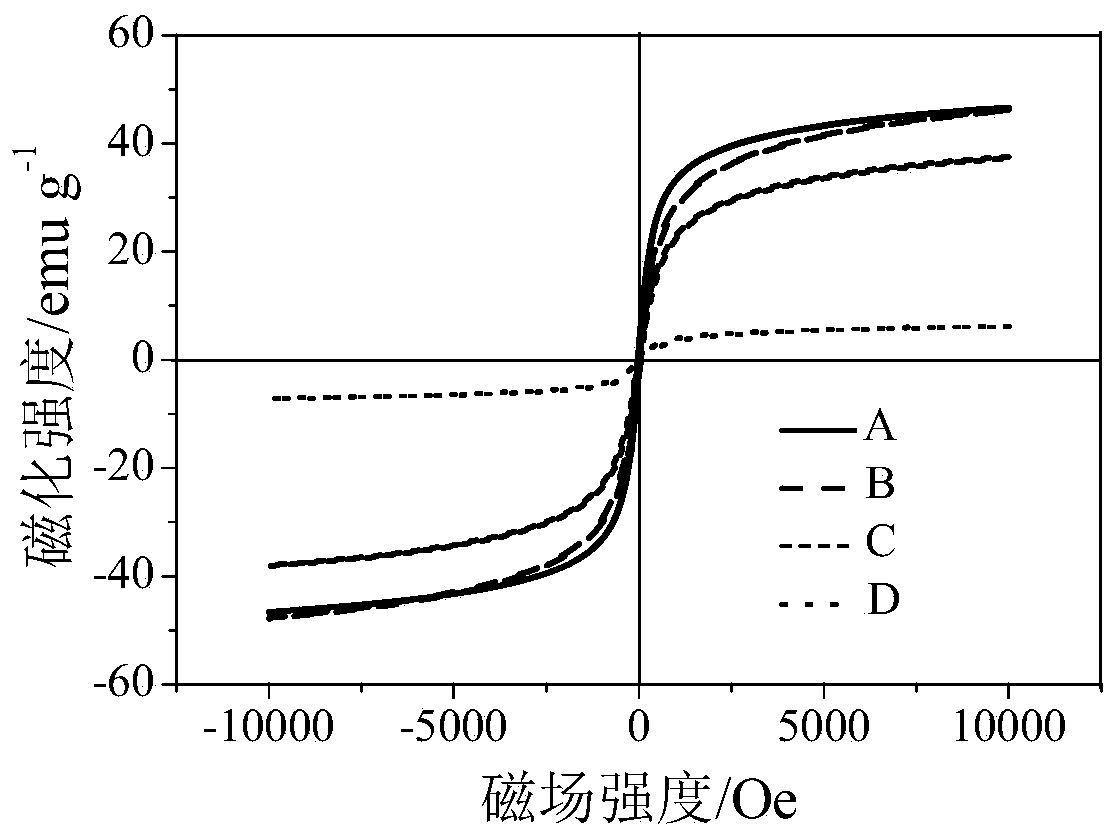

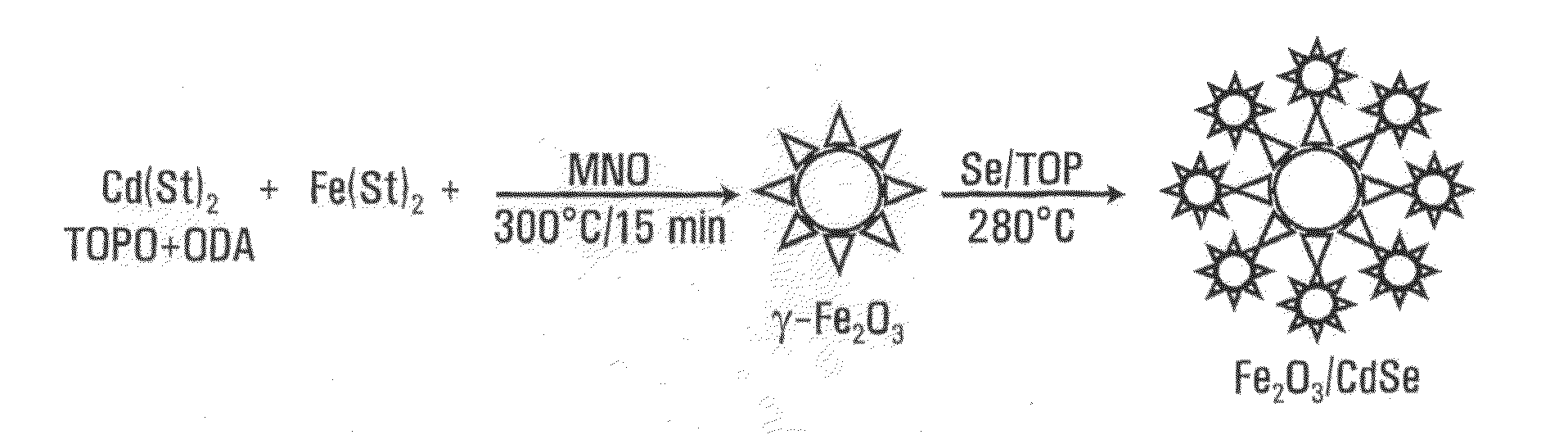

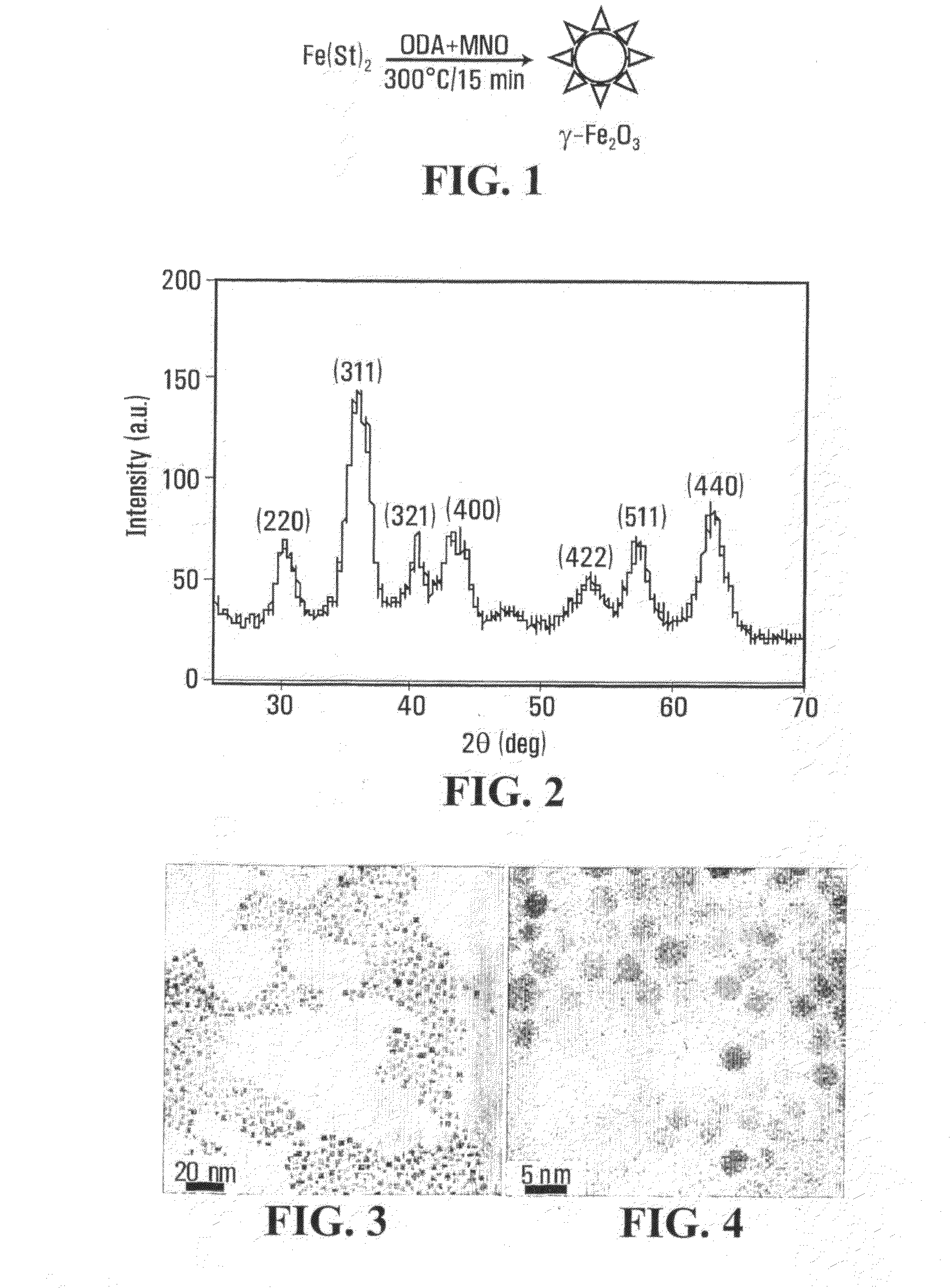

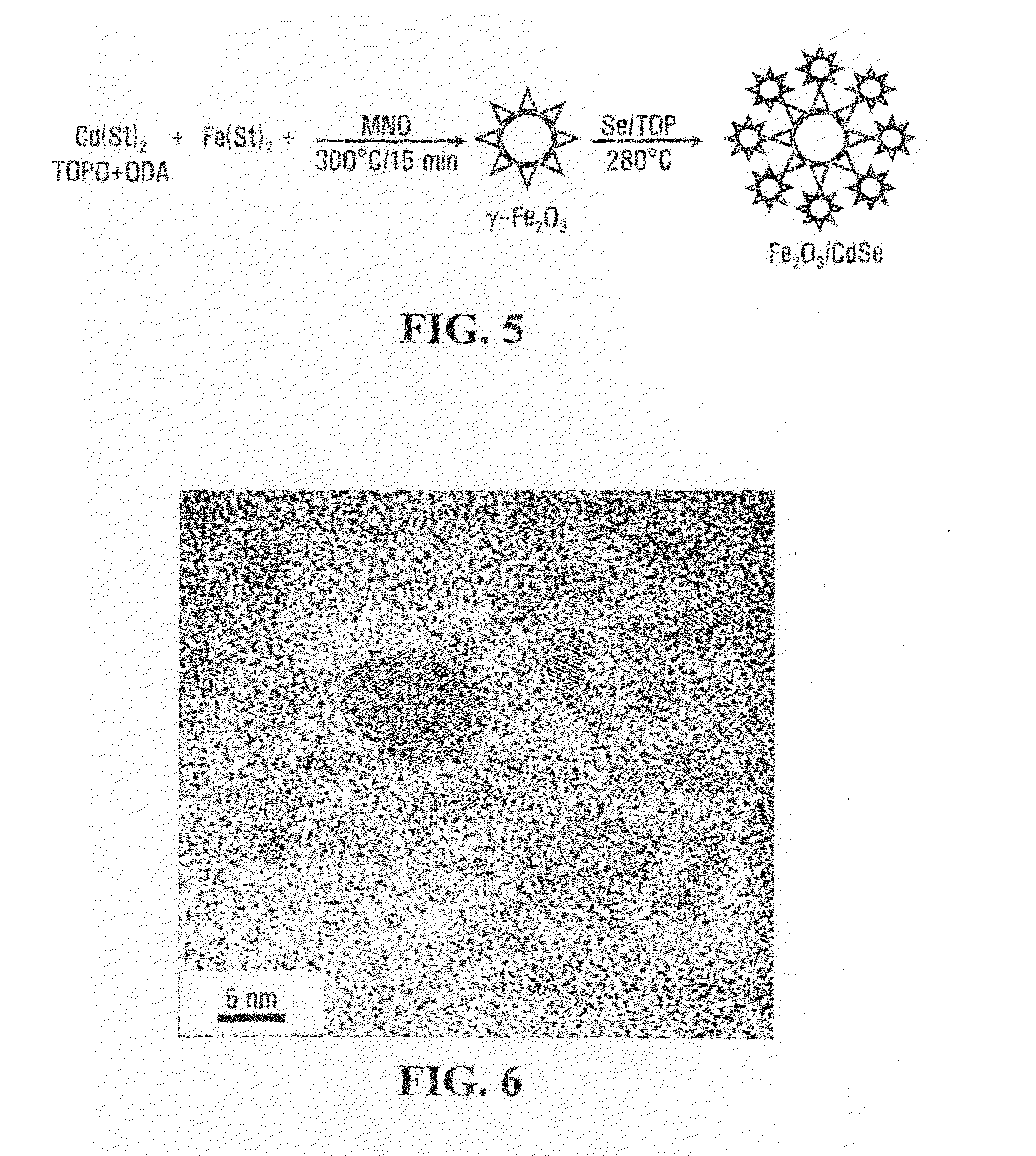

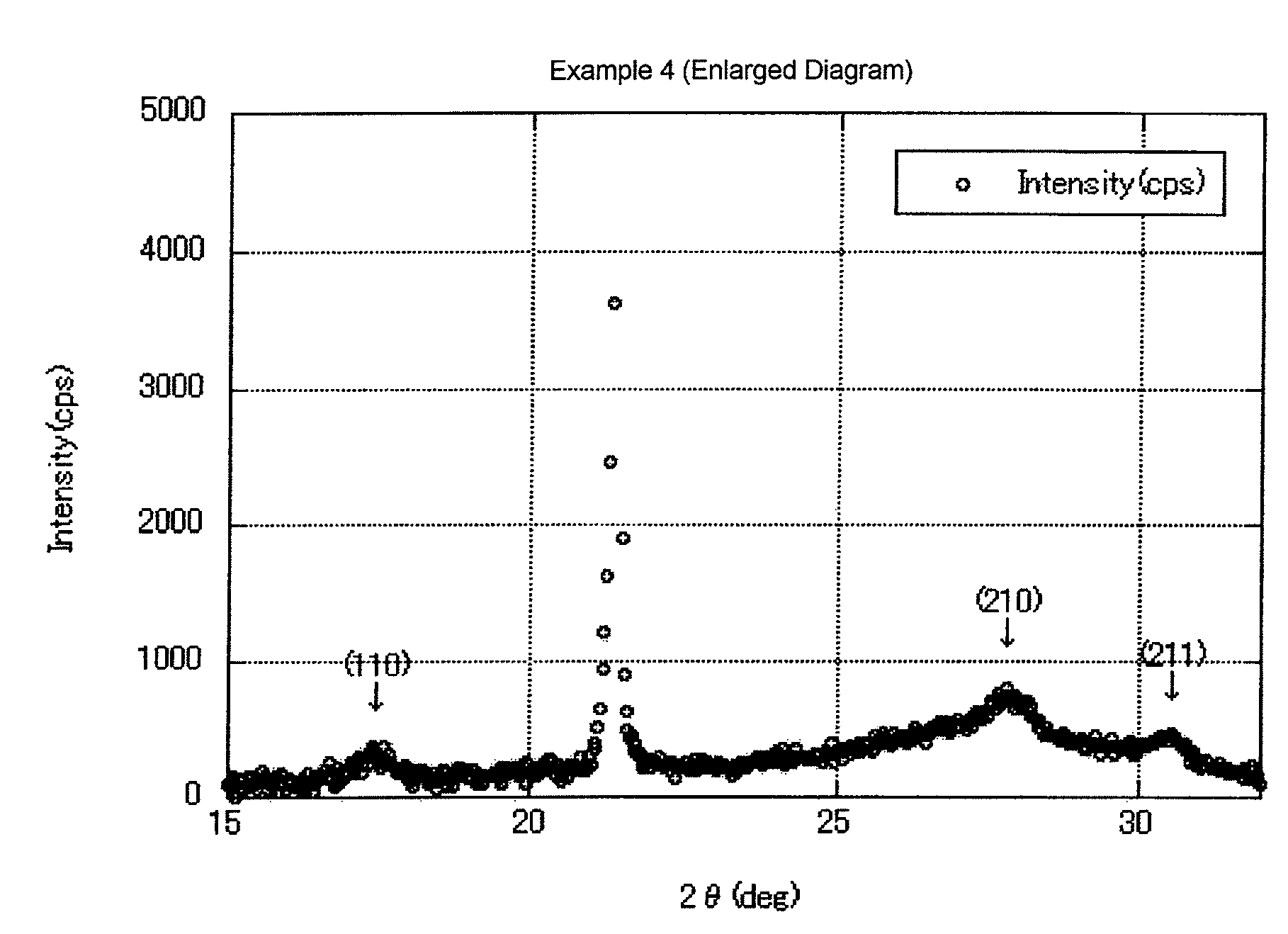

Magnetic nanoparticles, magnetic and fluorescent nanocomposite, and formation of maghemite by oxidizing iron stearate with methylmorpholine n-oxide

InactiveUS20100167057A1Material nanotechnologyFerroso-ferric oxidesFluorescenceMagnetite Nanoparticles

Maghemite (γ-Fe2O3) is formed by oxidizing iron stearate with methylmorpholine N-oxide (MNO). A mixture comprising iron stearate, MNO, a surfactant, and a solvent may be heated to maintain the mixture at a temperature of about 280 to about 320° C. for a sufficient period to form magnetic nanoparticles comprise maghemite. After heating, the mixture may be cooled to limit growth in size of the nanoparticles. The mixture may be heated for a period of about 15 minutes to about 30 minutes, such as about 15 minutes. The process may be adapted to also form quantum dots, and to form magnetic quantum dot (MQD) nanoparticles in an integrated process.

Owner:AGENCY FOR SCI TECH & RES

Carrier core material for an electrophotographic developer, carrier, and electrophotographic developer using the carrier

A carrier core material for an electrophotographic developer containing Li ferrite, maghemite, and Fe3O4, wherein a part thereof is substituted with Mn, a Li content is 1 to 2.5% by weight, a Mn content is 2 to 7.5% by weight, and a silicon content is 25 to 10,000 ppm, a compression breaking strength is 130 MPa or more, an SF-1 is 125 to 145, respective cumulative strengths of respective spinel crystal structure faces in X-ray diffraction satisfy a certain equation, a vacuum resistivity R500 across a 2 mm gap when a measurement voltage of 500 V is applied is 1×106 to 5×109 Ω, and a vacuum resistivity R1000 across a 6.5 mm gap when a measurement voltage of 1,000 V is applied is 5×107 to 1×1010 Ω.

Owner:MITSUI MINING & SMELTING CO LTD +1

Nanoparticulate phosphate adsorbent on the basis of maghemite or maghemite/magnetite, production and uses thereof

ActiveUS20140248363A1Minimizing contentGood storage stabilityHeavy metal active ingredientsOrganic active ingredientsPhysical chemistryMaghemite

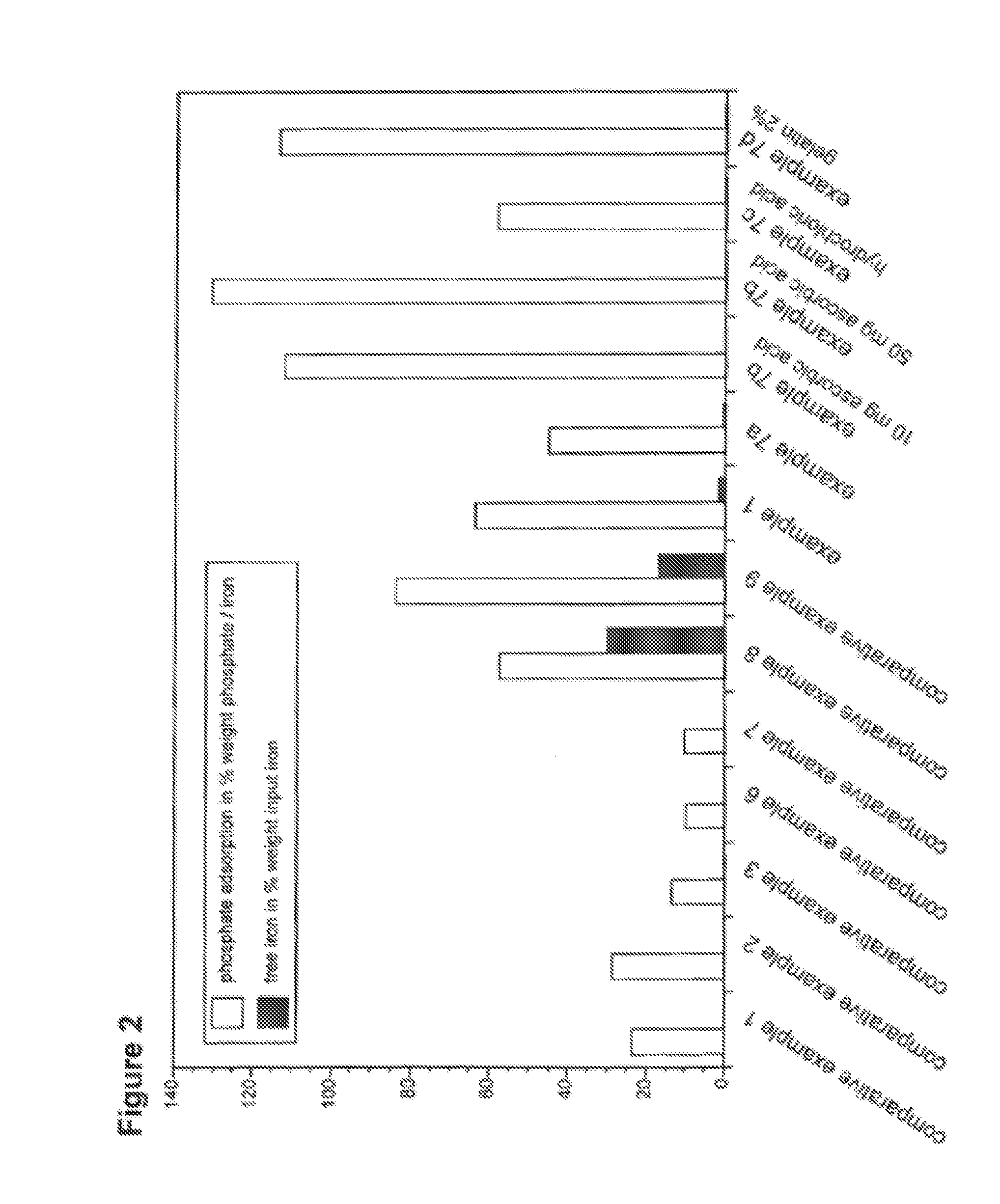

The present invention relates to a phosphate adsorbent on the basis of maghemite or maghemite / magnetite comprising (i) an iron oxide core comprising a crystal structure of inverse spinel iron oxide, (ii) a coating selected from monomeric carbohydrates, in particular monosaccharides or disaccharides, alditols, or mixtures thereof, and / or (iii) a pharmaceutical excipient selected from polymeric carbohydrates, wherein the phosphate adsorbent has the form of nanoparticles with a particle size of the iron oxide core (i) of less than 20 nm. The present invention further relates to a method for the production of a phosphate adsorbent on the basis of maghemite or maghemite / magnetite, to pharmaceutical compositions comprising the phosphate adsorbent, and to medical uses thereof, especially for the prevention and / or treatment of hyperphosphatemia.

Owner:TAUPITZ MATTHIAS +2

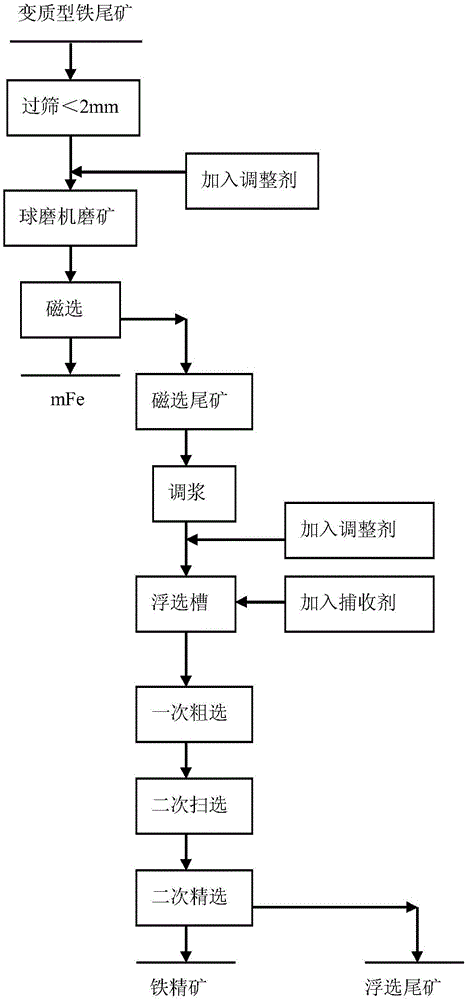

Iron separating method for metamorphic iron tailings

InactiveCN105126995AResolve recovery rateSolve the costMechanical material recoveryWet separationMaghemiteGoethite

The invention relates to an iron separating method for metamorphic iron tailings. According to magnetite, hematite, maghemite, goethite and limonite in the metamorphic iron tailings, the magnetic separation-flotation technology is adopted, and primary roughing, secondary scavenging and secondary concentration are carried out. By the adoption of the method, the problems that the iron separating recovery rate of the iron tailings is low and the recovery cost is high in all metamorphic iron tailing production countries for a long time are solved. Compared with the prior art, the method is free of pollution, capable of recovering soluble iron at a low cost, short in technological process, simple in technology, high in recovery rate, low in recovery cost and suitable for industrial production.

Owner:JILIN UNIV

High-heat-resistant nitride-based cermet mould and preparation method thereof

The invention discloses a high-heat-resistant nitride-based cermet mould and a preparation method thereof. The high-heat-resistant nitride-based cermet mould is prepared from, by weight, 70-80 parts of titanium nitride, 40-50 parts of aluminum nitride, 15-20 parts of nickel powder, 10-20 parts of realgar powder, 10-20 parts of dickite powder, 4-8 parts of maghemite, 6-8 parts of germanium dioxide, 3-6 parts of potassium oxide, 3-11 parts of stainless steel powder and 3-5 parts of oleic acid. The high-heat-resistant nitride-based cermet mould prepared according to the method has excellent heat stability, abrasion resistance, oxidation resistance and high temperature resistance. Compared with an existing cermet mould, the high-heat-resistant nitride-based cermet mould has advantages that the service life of the mould is remarkably prolonged, and the high-heat-resistant boride-based cermet mould can be better applied under severe conditions such as high temperature and high pressure and makes a prominent progress in reduction of processing cost, improvement of production efficiency and the like.

Owner:陆志强

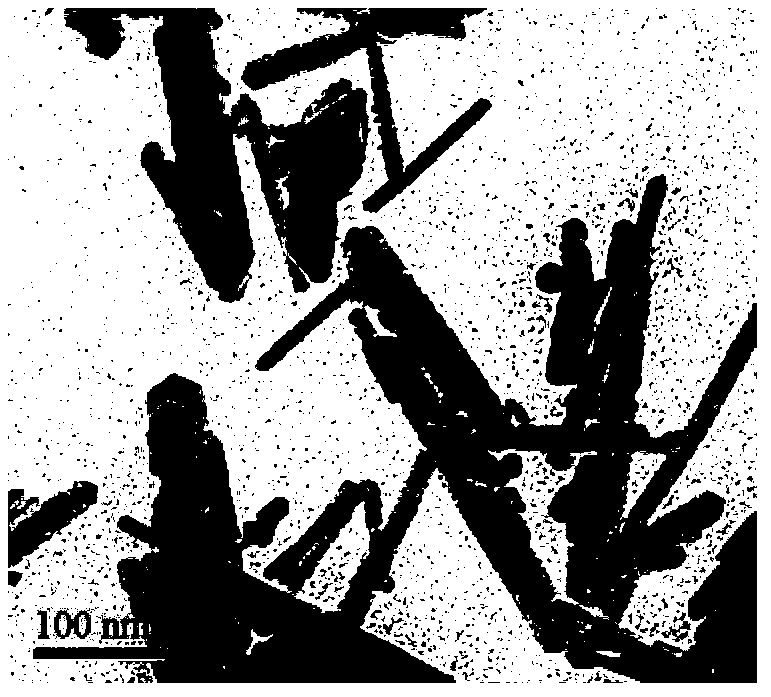

Preparation method of magnetic nanocrystals with adjustable morphology

InactiveCN103466716ALow costMild process conditionsMaterial nanotechnologyFerric oxidesMaghemiteNanocrystal

The invention discloses a preparation method of magnetic nanocrystals with adjustable morphology. The preparation method comprises following steps: step 1, preparation of ferrihydrite precursors, wherein hydrolysis reaction is promoted by adding CuO into a Fe(NO3)3 solution so as to obtain the ferrihydrite (Fe5O7OH.4H2O) precursors; and step 2, preparation of the magnetic nanocrystals, wherein a mixture of the ferrihydrite precursors, a FeCl2 solution and a NaOH solution is subjected to heating processing so as to obtain the maghemite (gamma-Fe2O3) nanocrystals. Technological conditions of the preparation method is mild, raw material cost is low, and it is possible to obtain ball-shaped, rod-shaped or sheet-shaped magnetic nanocrystals by controlling the synthesis conditions.

Owner:SOUTHWEST UNIVERSITY

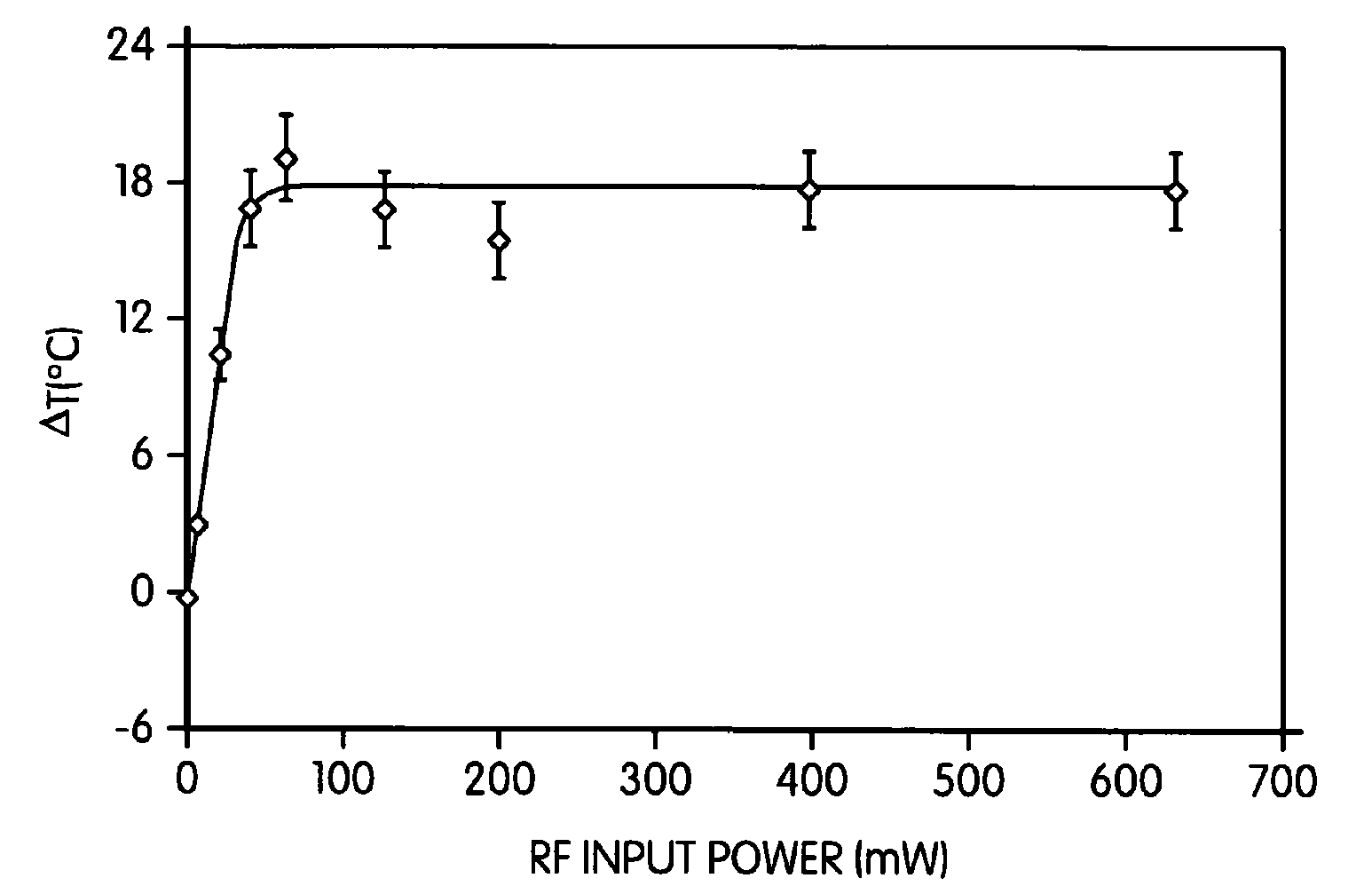

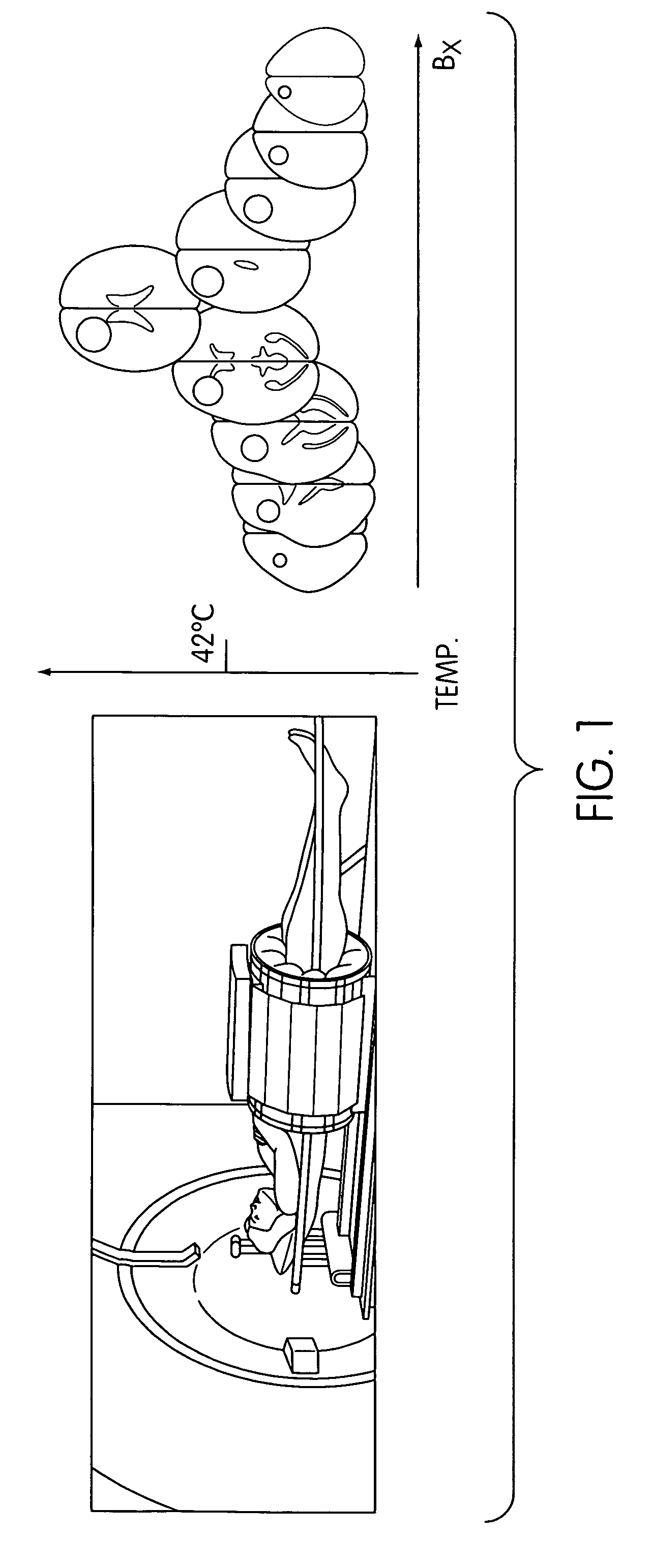

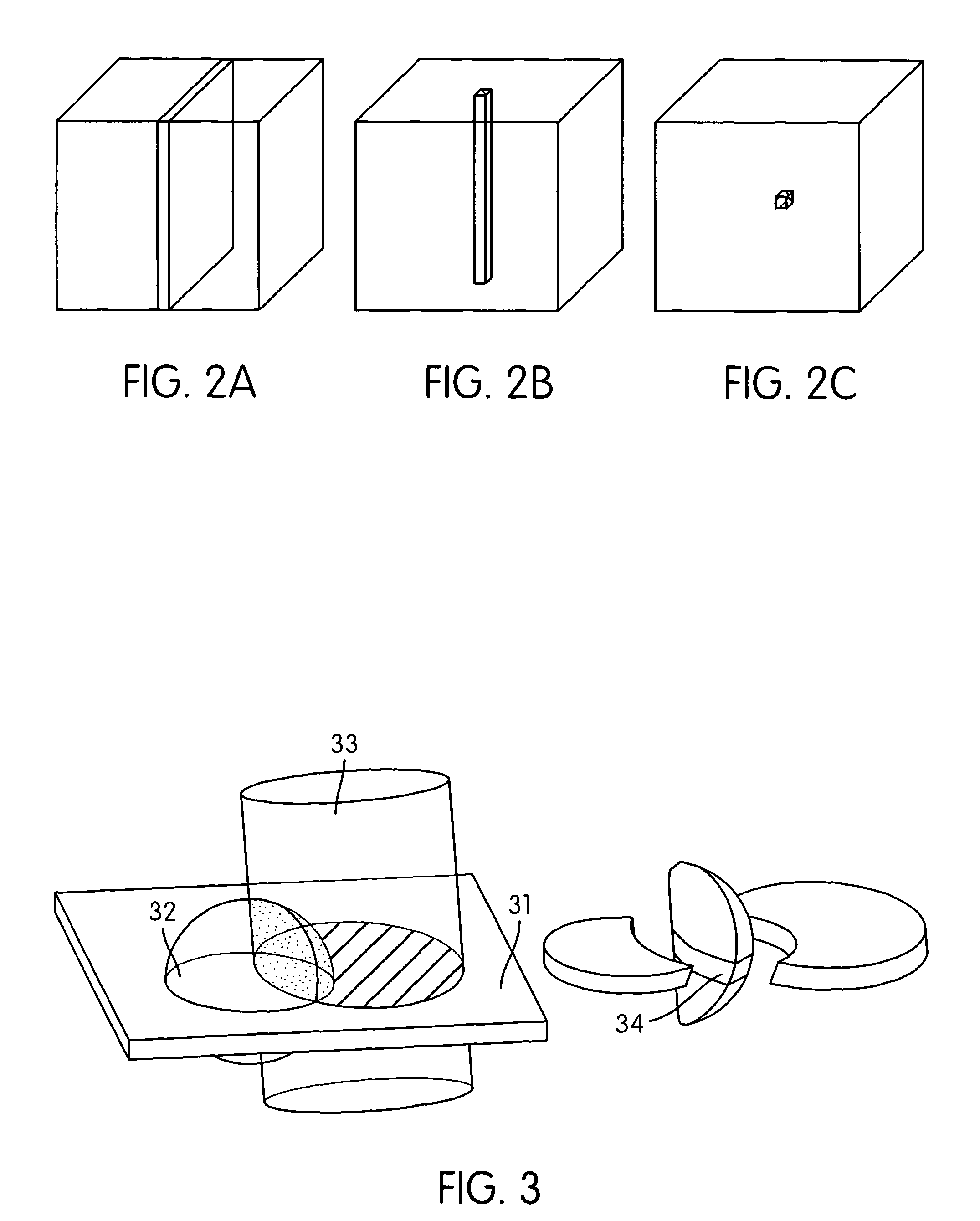

Remotely RF powered conformable thermal applicators

Owner:INTEMATIX

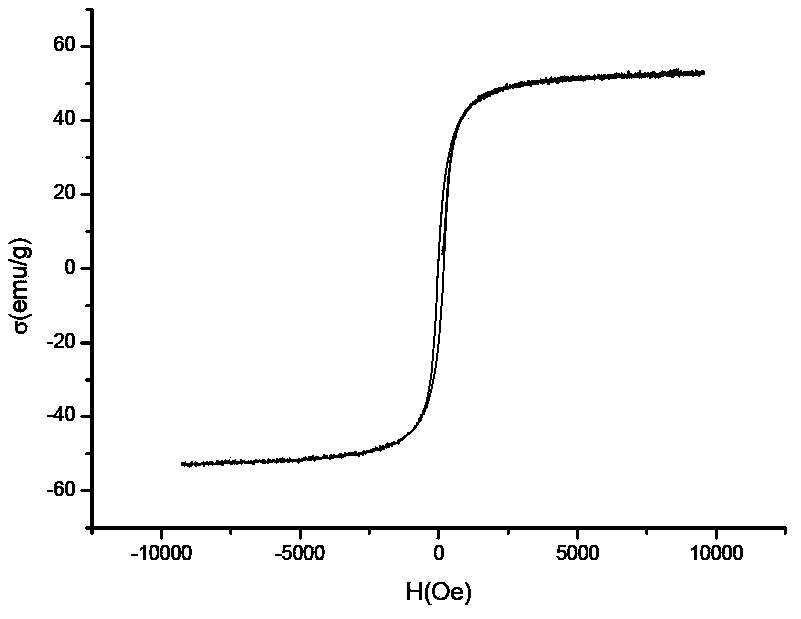

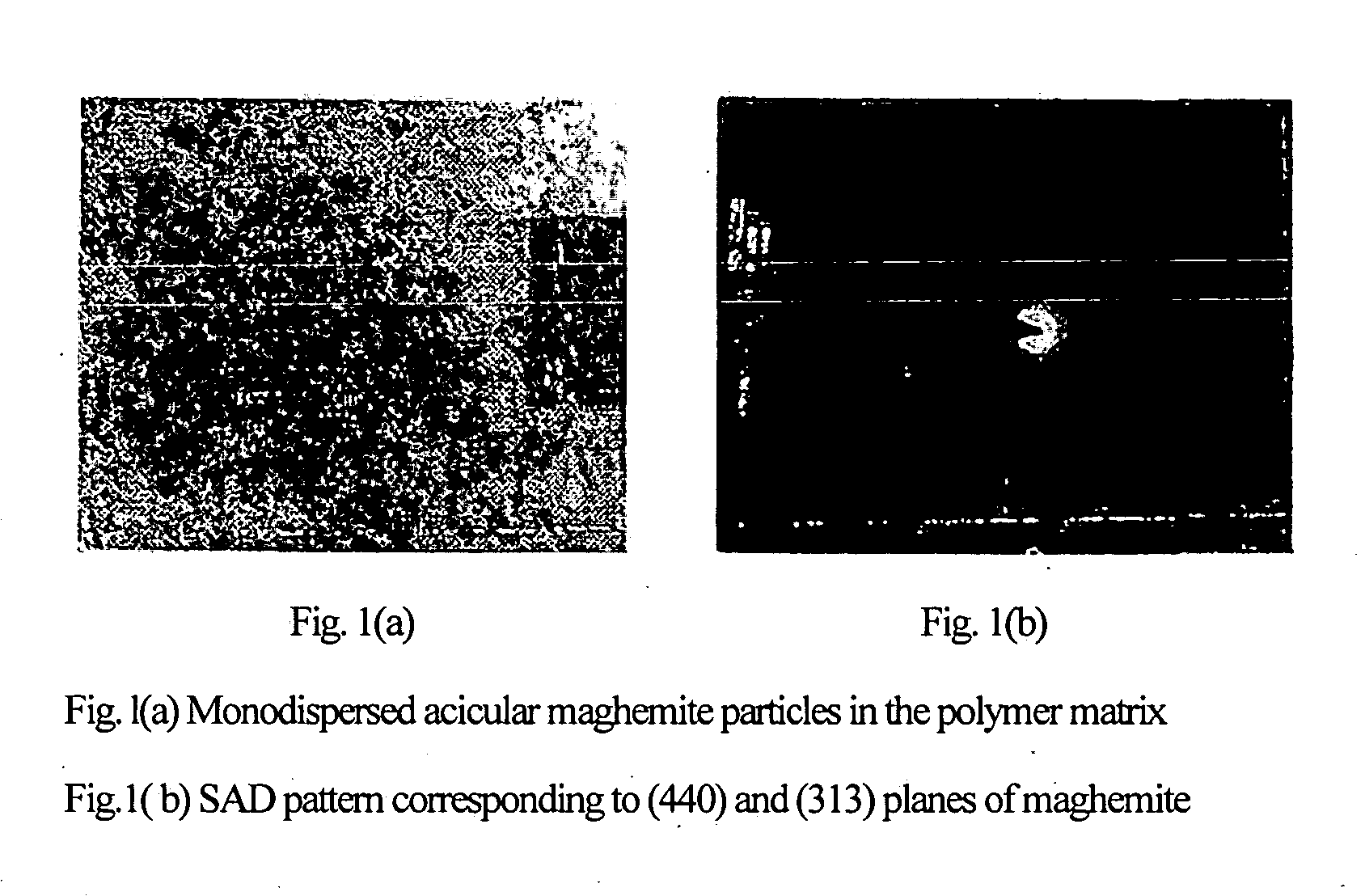

Single-step simple and economical process for the preparation of nanosized acicular magnetic iron oxide particles of maghemite phase

InactiveUS20040179997A1High magnetizationHigh coercivityMaterial nanotechnologyNanomagnetismMagnetic memoryRoom temperature

The present invention relates to a single-step simple and economical process for the preparation of nanosized acicular magnetic iron oxide particles of maghemite phase of size ranging between 300-350 nm in magnetic field at room temperature by biomimetic route, and a method of obtaining a magnetic memory storage device using the said particles.

Owner:COUNCIL OF SCI & IND RES

Magnetic recording medium

InactiveUS20070111038A1Excellent recording resolution performanceImprove coercive forceRecord information storageMagnetic recordingImage resolutionMaghemite

A magnetic recording medium comprises a polymer film substrate having an elongated shape or a polymer flexible substrate; an underlayer having a thickness of less than 10 nm, which is formed on the substrate; and a magnetic recording layer comprising a spinel iron oxide thin film containing maghemite as a main component, which is formed on the underlayer and has a coercive force of not less than 159 kA / m (2000 Oe). The present invention provides the magnetic recording medium comprising a spinel iron oxide thin film containing maghemite as a main component, which exhibits an excellent recording resolution performance while maintaining a high coercive force and a high coercive force squareness.

Owner:TODA IND

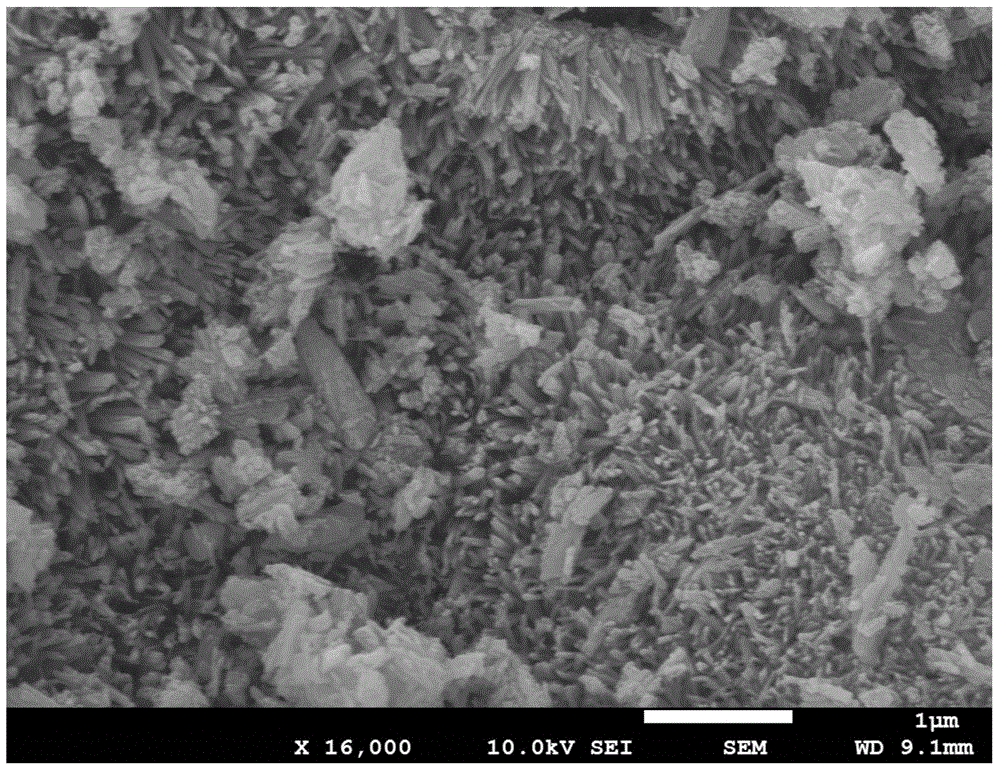

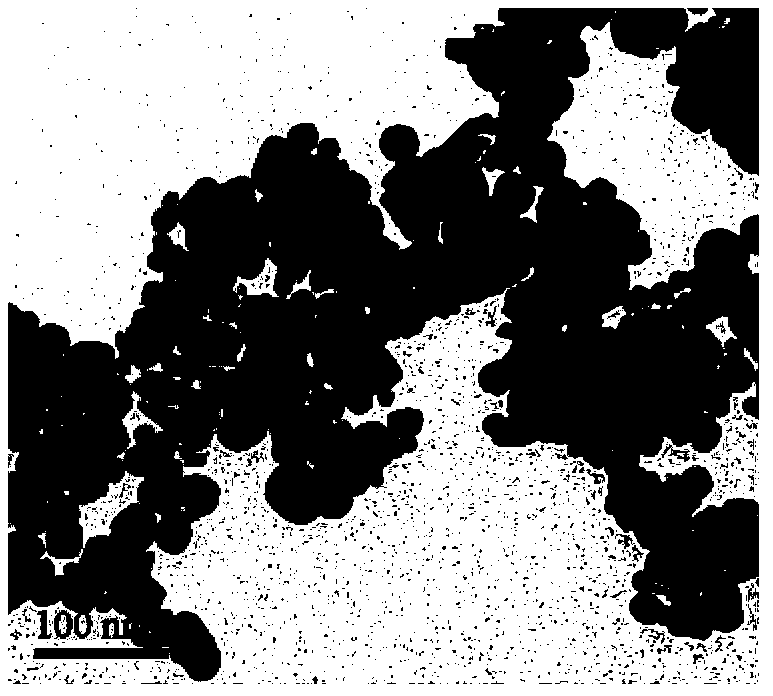

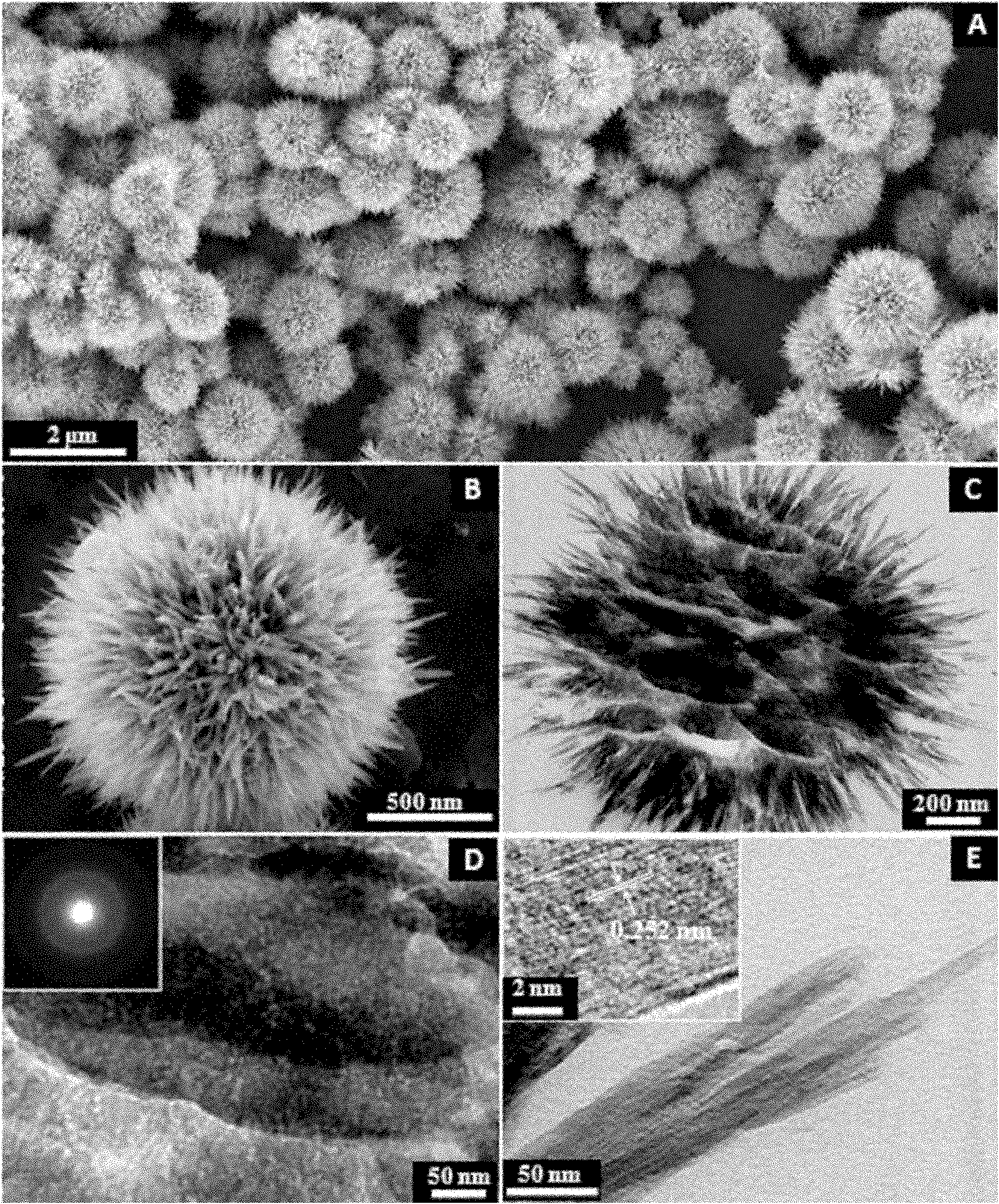

Chinese chestnut shaped ferric oxide shell structure magnetic absorbent particle and preparation method thereof

InactiveCN102151542AMild reaction conditionsLarge specific surface areaOther chemical processesWater contaminantsN dimethylformamideSorbent

The invention relates to a Chinese chestnut shaped ferric oxide shell structure magnetic absorbent particle as a water treatment agent for absorbing high-toxicity heavy metal ions and a preparation method thereof. The Chinese chestnut shaped ferric oxide shell structure magnetic absorbent particle is characterized in that the inside is of a porous structure formed by amorphous ferric oxide nano particles, and a shell is formed in a manner that a plurality of crystallized maghemite nano bars vertical grow on the amorphous ferric oxide nano particles. The preparation method comprises the steps of: mixing chloride, Fe(CO)5 and N,N-dimethylformamide according to the proportion of (0.01-1.6)mmol:0.50mL:(10-160)mL, and stirring to obtain a solution; and transferring the solution to an agitated reactor, heating at a temperature of 160-220 DEG C for 1-32h, and cooling to room temperature; collecting a brown settlement, cleaning and drying in vacuum to obtain the Chinese chestnut shaped ferric oxide shell structure magnetic absorbent particle. The invention has the advantages of simple synthesis method and mild reaction condition. The Chinese chestnut shaped ferric oxide shell structure magnetic absorbent particle has stronger absorbing capacity to heavy metal ions in water.

Owner:WUHAN UNIV OF TECH

Environmental-protection magnetic fertilizer and preparation process thereof

InactiveCN105347904AEasy to produceIncrease productionFertilizer mixturesGeneral chemistMagnetization

The present invention provides an environmental-protection magnetic fertilizer and a preparation process thereof, wherein the environmental-protection magnetic fertilizer is characterized by further containing a magnetic substance, wherein a mass ratio of the magnetic substance to the chemical fertilizer is 0.5-7:100, and the magnetic material is selected from a natural magnetic mineral such as magnetite, maghemite and the like, and an artificial permanent magnet magnetic material such as an iron oxide magnetic material, an iron-manganese permanent magnet material and a rare earth permanent magnet material. The magnetic fertilizer production method comprises: (1) weighing a certain amount of a common chemical fertilizer, and mixing with a magnetic substance according to a predetermined ratio; (2) uniformly stirring; and (3) placing the uniformly-stirred mixture into a magnetic field to carry out a magnetization treatment so as to obtain the final product. According to the present invention, the food yield can be significantly improved while the nitrogen consumption can be reduced so as to pollution of agricultural production on the environment; and the magnetic fertilizer can be conveniently produced through the method.

Owner:QINGDAO WEIYE FORGING & STAMPING MACHINERY CO LTD

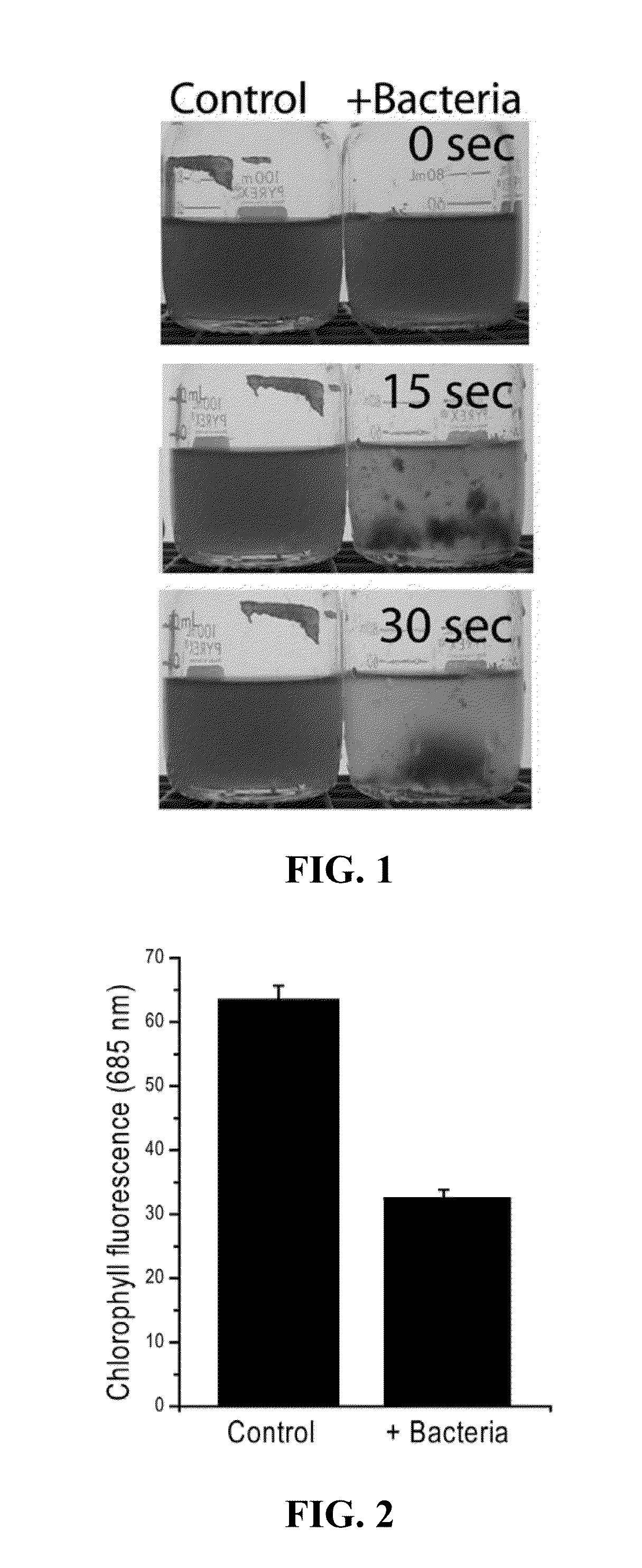

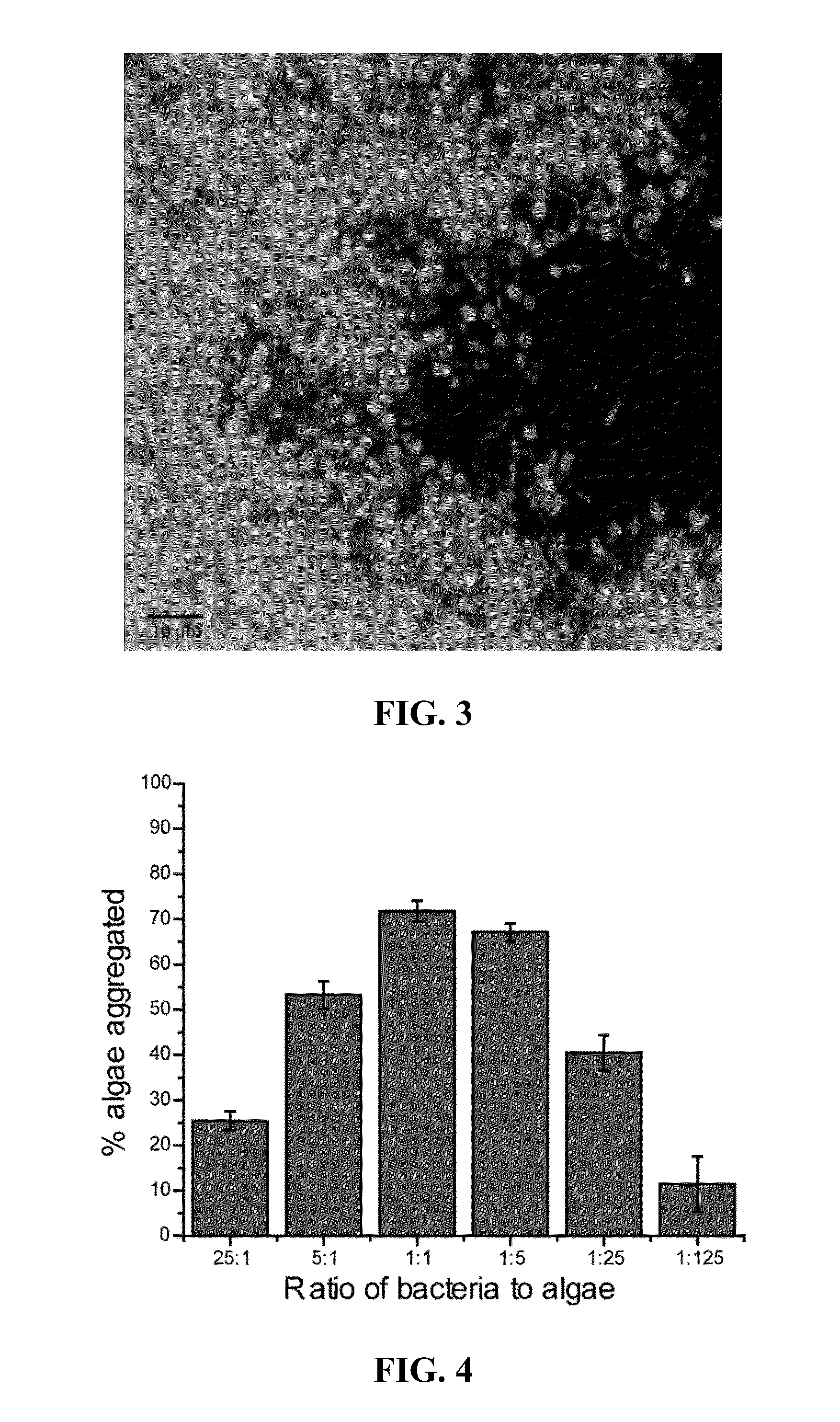

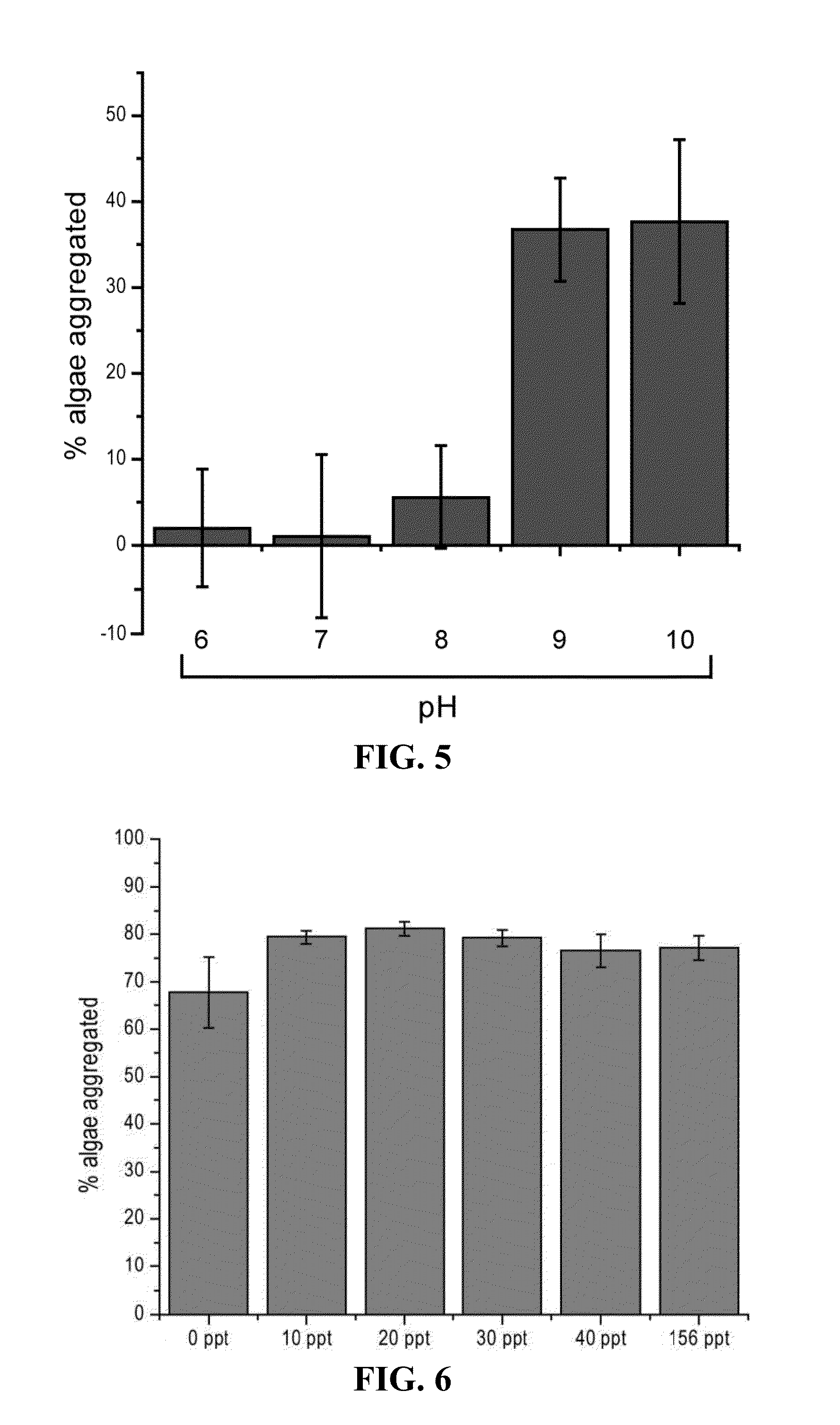

Compositions and Methods for Collecting Algae

ActiveUS20140248680A1Increasing algae aggregateIncreasing the algae aggregateBacteriaUnicellular algaeMaghemiteMicrobiology

Owner:UNIVERSITY OF MARYLAND CENTER FOR ENVIRONMENTAL SCIENCE

Iron oxide containing effect pigments, their manufacture and their use

ActiveUS20140099346A1Good lookingHeavy metal active ingredientsPigmenting treatmentParticulatesGas phase

An iron oxide containing effect pigment, and methods for producing and using the same are discussed. The iron oxide containing effect pigment may include an iron oxide coating in direct contact with a particulate substrate, which may have high levels of hematite, magnetite, or maghemite; and low amounts of toxic metals. A method for producing the pigment may include chemical vapor deposition of iron pentacarbonyl onto a particulate substrate. The iron oxide containing effect pigments may be incorporated into compositions, such as cosmetics.

Owner:SUN CHEM CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com