Patents

Literature

47 results about "Jacobsite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Jacobsite is a manganese iron oxide mineral. It is in the spinel group and forms a solid solution series with magnetite. The chemical formula is MnFe₂O₄ or with oxidation states and substitutions: (Mn²⁺,Fe²⁺,Mg)(Fe³⁺,Mn³⁺)₂O₄.

Cordierite nucleated glass prepared by using flyash and its preparation method

The present invention relates to an iolite pyroceram prepared by using flyash as main raw material and its preparation method. Its composition includes (wt%) 45-77% of flyash, 5-15% of alumina powder of bauxite, 10-25% of basic magnesium carbonate or magnesite or brucite or magnesium oxide powder, 3-10% of methyl cellulose and 3-30% of water.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Two comprehensive utilization methods of boron mud, giobertite and talc deposit for preparing magnesia and silicon dioxide

The invention provides two environment-friendly metallurgy methods for comprehensively utilizing boron sludge, magnesite and talc ore to prepare magnesium oxide and silicon dioxide. The methods comprise the following: (1) steps of milling, carrying out magnetic separation for iron removal, carrying out acid treatment, carrying out alkali treatment, preparing magnesium oxide and carrying out carbonation decomposition for preparing silicon dioxide; and (2) steps of milling, carrying out magnetic separation for iron removal, carrying out alkali treatment, carrying out water soaking treatment, filtering, separating, preparing magnesium oxide and carrying out carbonation decomposition for preparing silicon dioxide. The invention has the advantages that the methods allow all reaction media to be reclaimed, are simple in process flow and equipment, discharge no solid, liquid or gaseous waste, cause no secondary pollution, can use lower cost to realize the high added value comprehensive utilization of magnesium and silicon in the boron sludge, the magnesite and the talc ore.

Owner:NORTHEASTERN UNIV

Synthesis of modified maghemite and jacobsite nanoparticles

ActiveUS7622423B1Good removal effectEfficient removalMaterial nanotechnologyOther chemical processesMaghemiteMagnetite Nanoparticles

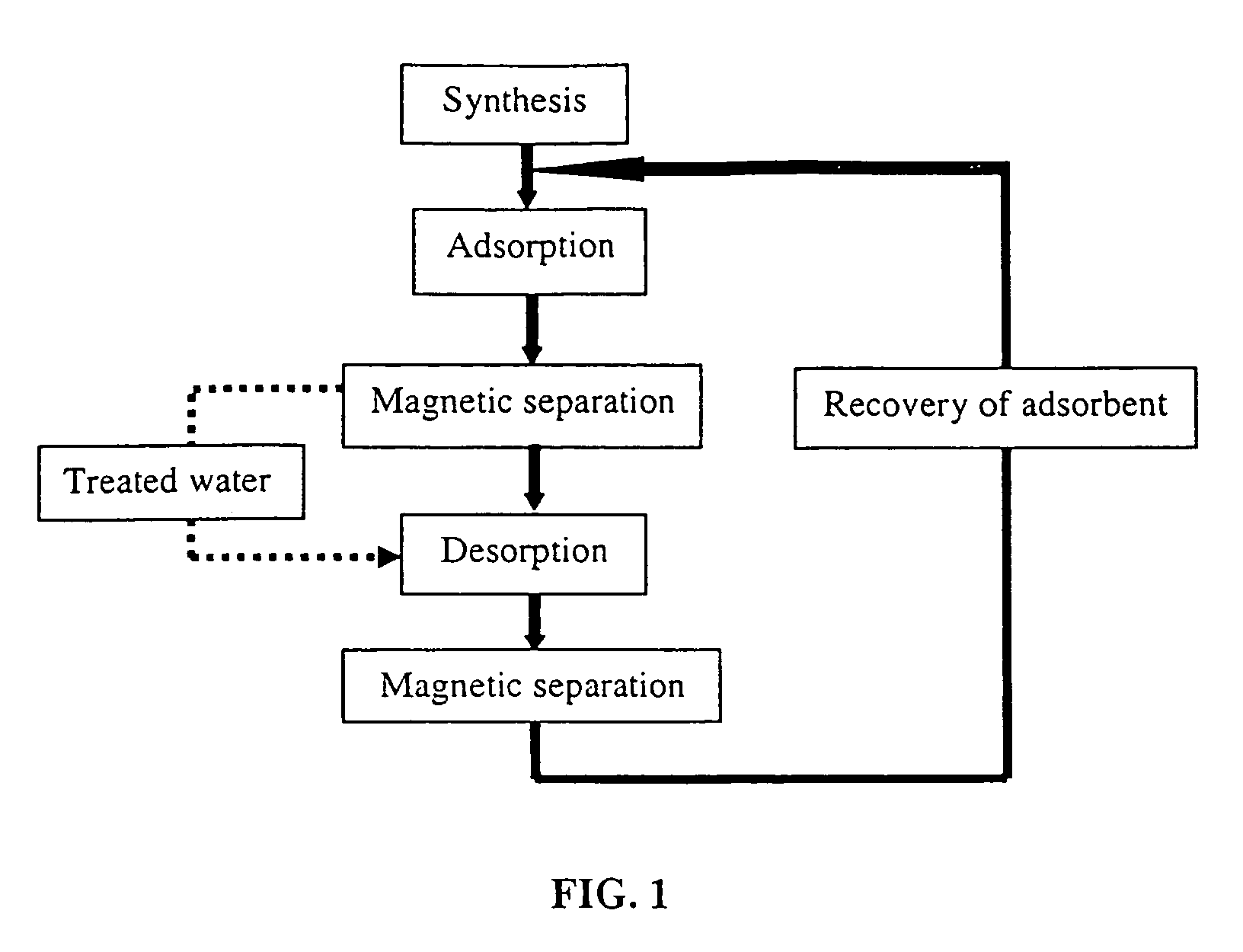

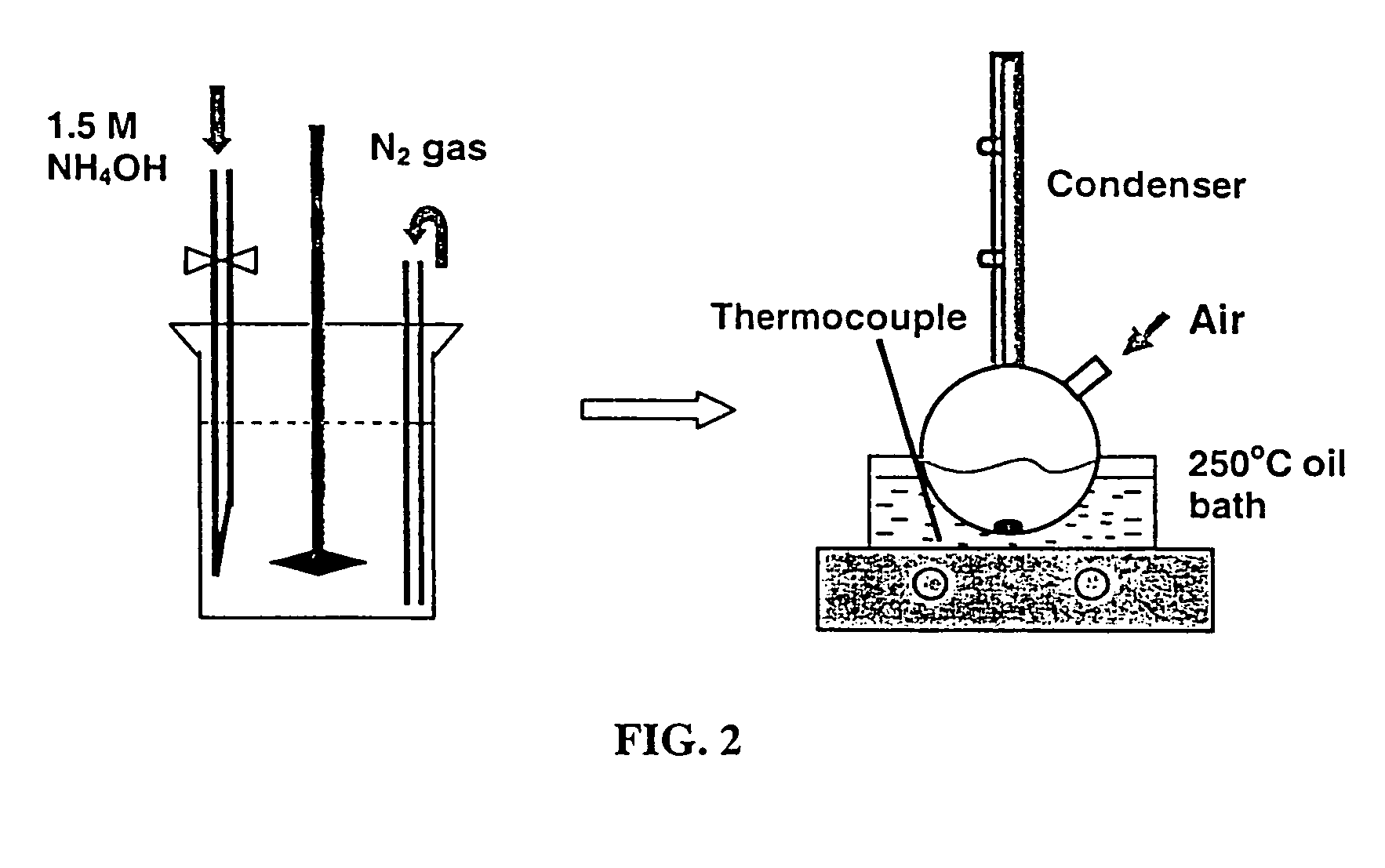

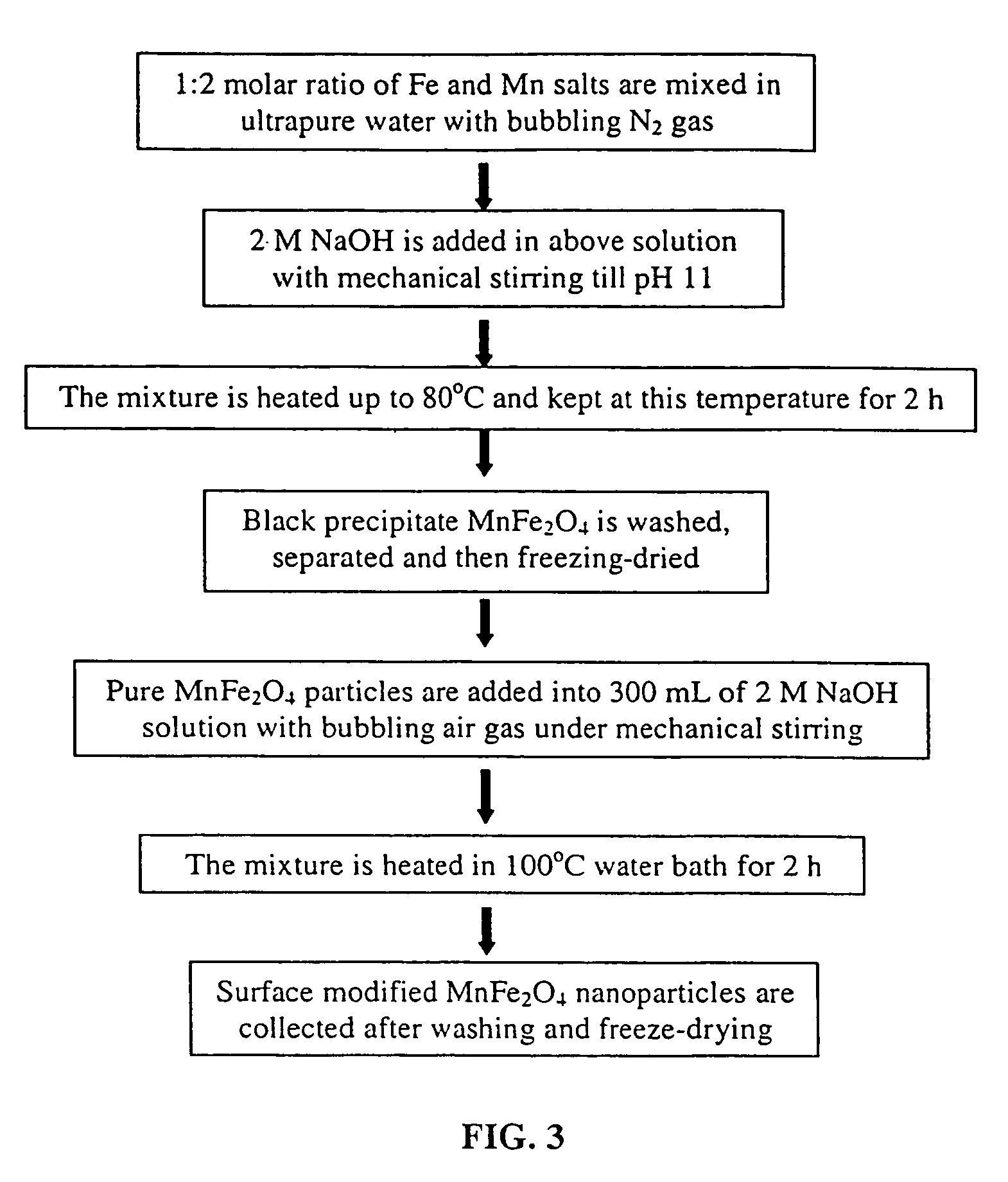

The present invention provides a method for making modified jacobsite, Al-doped maghemite or modified maghemite nanoparticles that can be used to adsorb heavy metals, such as Cr(VI), found in wastewater. The magnetic nanoparticles can be separated using a magnetic field after adsorbing heavy metals from wastewater, and processed for reused.

Owner:THE HONG KONG UNIV OF SCI & TECH

Method for preparing magnesium with silica-alumina alloy as electronating agent

A method for preparing magnesium with silica-alumina alloy as reducing agent includes: using dolomite and magnesite as raw materials, silica-alumina alloy as reducing agent, reducing calcined dolomite, and producing magnesium. Its technological process is: raw material->calcined dolomite and caustic magnesite->furnish->briquetting->grinding powder->vacuum reducing->magnesium, casting and magnesium ingot. Its furnish is: calcined dolomite (24%Mg), caustic magnesite (50%Mg). Its silica-alumina alloy component and preparation are: calcined dolomite: caustic magnesite: silica-alumina= 3.8-4.0: 0.8-1.2:1-1.4. It achieves low cost and high profit.

Owner:郭清富

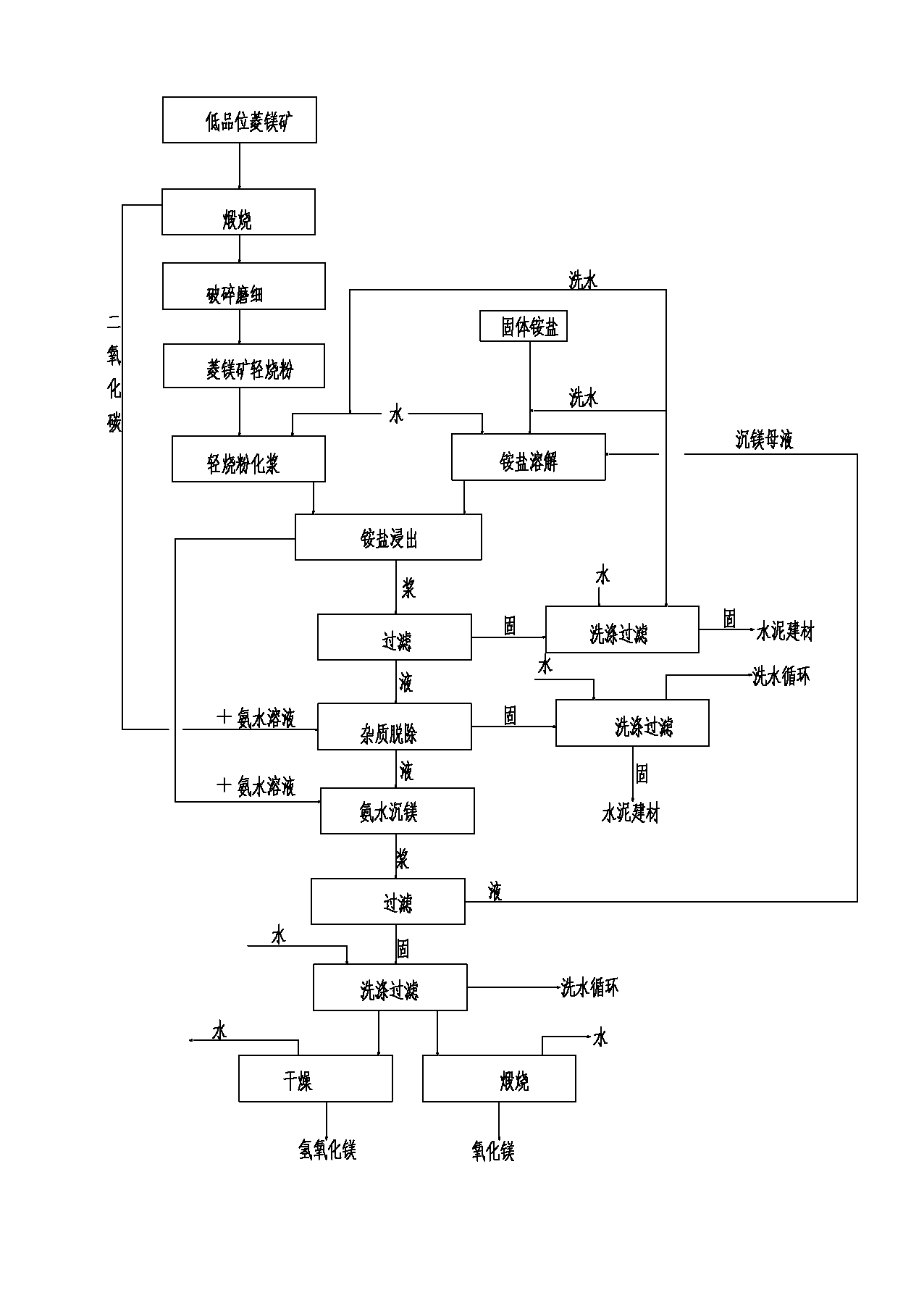

Method of producing high-purity magnesium hydroxide and magnesium oxide by low-grade magnesite

InactiveCN103011630AReduce pollutionTake advantage ofMagnesium hydroxideLime productionStrong acidsMagnesite

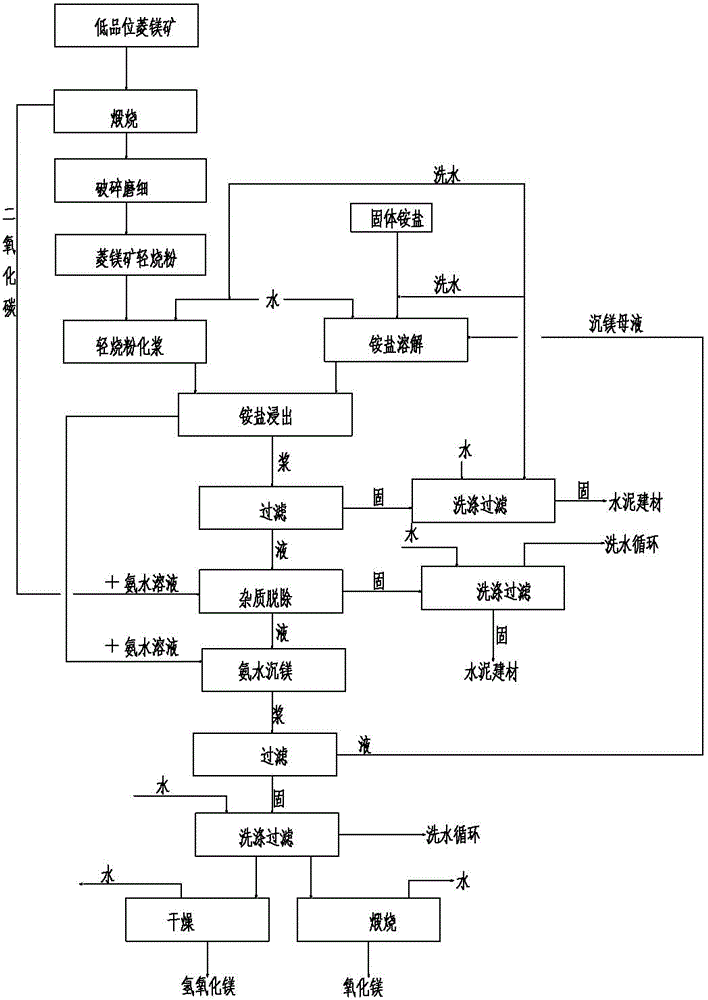

The invention relates to the field of mineral resource processing technology, in particular to a method of producing high-purity magnesium hydroxide and magnesium oxide by low-grade magnesite. The method comprises the following steps: calcining low-grade magnesite in a calcining furnace at calcining temperature to obtain light-calcining magnesite ore and carbon dioxide, recovering the carbon dioxide, and crushing the calcined light-calcining magnesite ore. By utilizing a method of realizing leaching, purification and separation coupling of the low-grade magnesite and producing high-pruity magnesium hydroxide and magnesium oxide through recycling of ammonia-ammonium slat, the advantages of preparing high-purity products by adopting the traditional bittern-ammonia process can be fully achieved, the method is of green and cycling clean production technique method, no wastes are emitted in the whole process, resources can be comprehensively utilized, the utilization rate of the magnesite resource can be improved, strong acid is not consumed in the technique process, other constitutions are fully utilized, the pollution to the environment can be reduced, and the method provides a new approach for reasonably developing and utilizing the low-grade magnesite resources.

Owner:新疆蓝天镁业股份有限公司

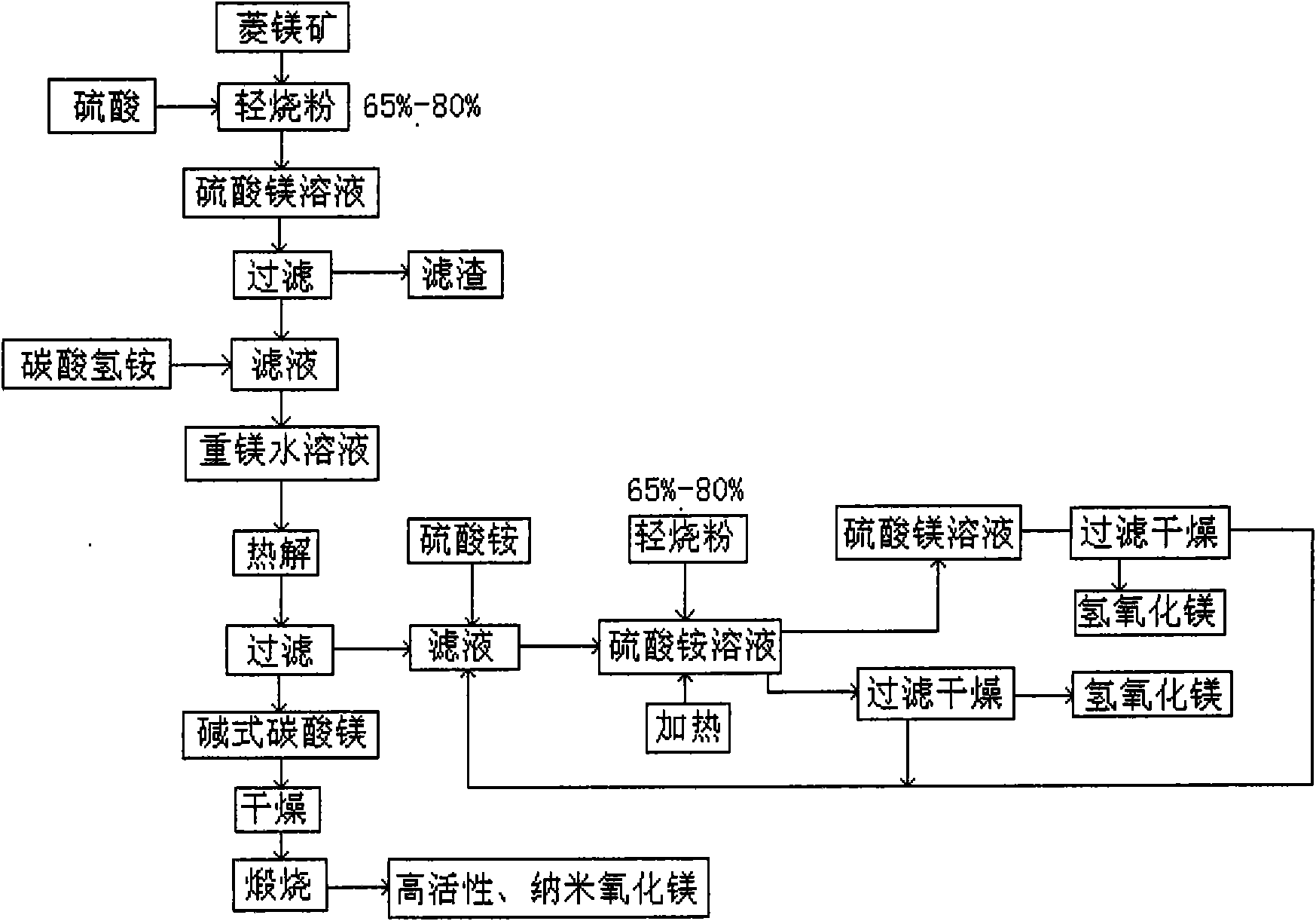

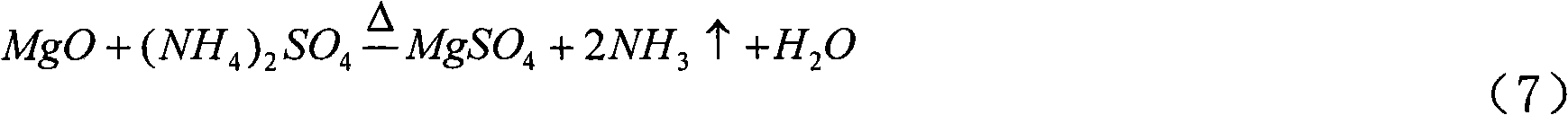

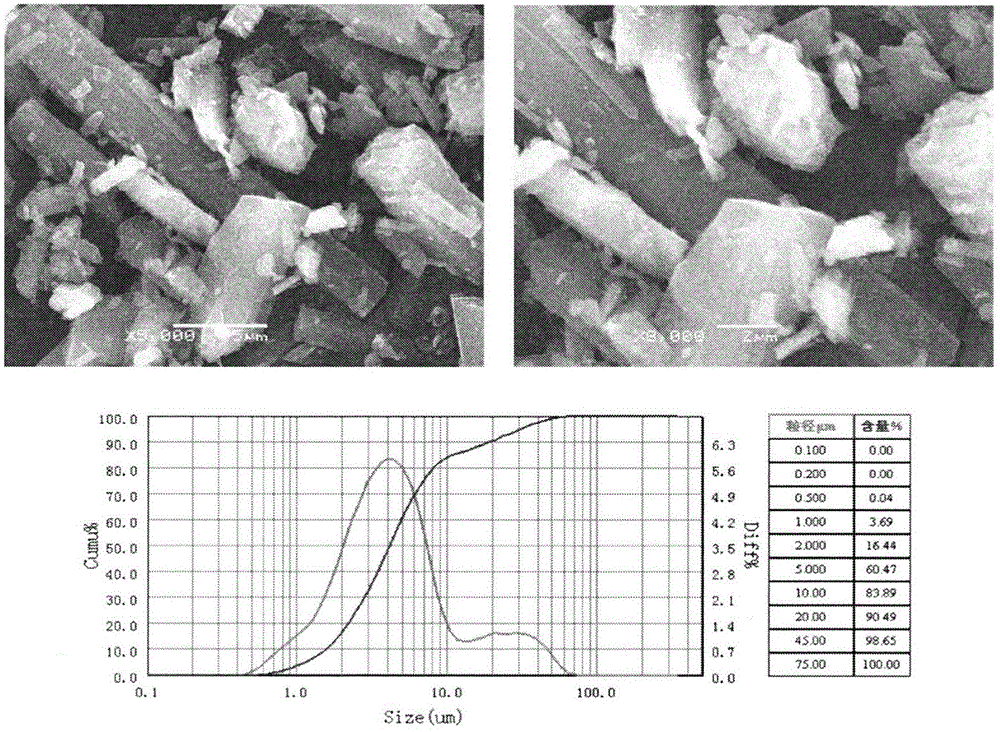

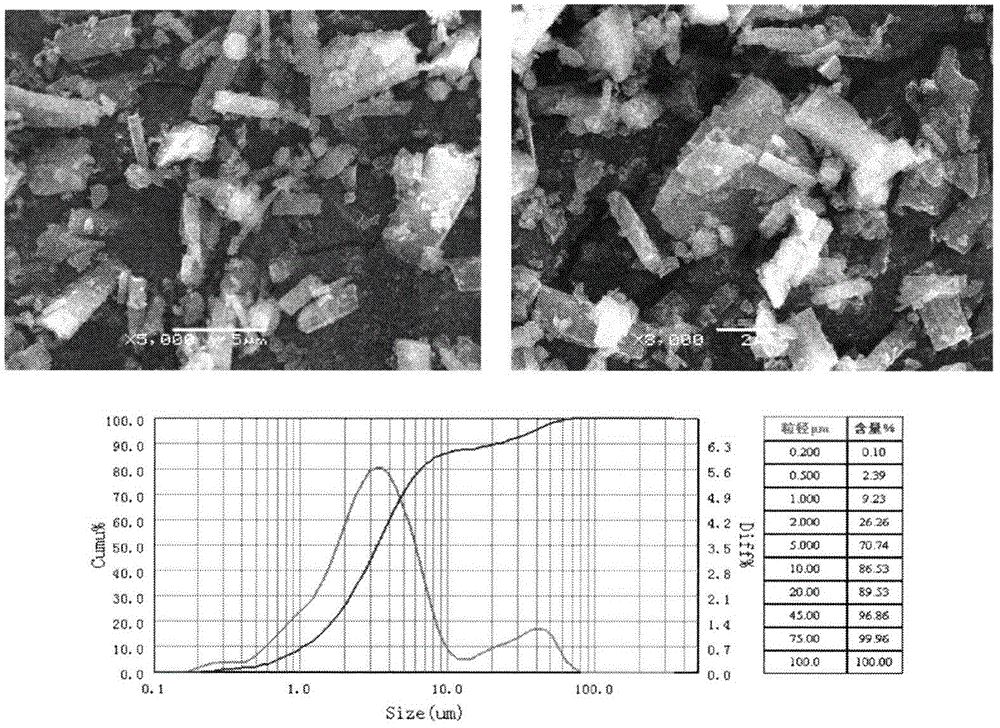

Method for producing high-activity nano magnesia by utilizing low-grade magnesite

InactiveCN101941723AHigh activityQuality improvementMagnesiaMagnesium hydroxideChemical reactionMagnesium salt

The invention relates to a method for producing high-activity nano magnesia by utilizing low-grade magnesite, in particular to a method for producing nano magnesite. The method utilizes a chemical reaction principle and comprises the following steps of: firstly, roasting low-grade magnesite or powdered ore to obtain magnesia, reacting the magnesia and sulphuric acid and filtering to obtain a magnesium sulfate solution; purifying the solution by adopting a neutralizer and an oxidant to obtain a purified magnesium sulfate solution; adding ammonium bicarbonate and a surfactant to the purified magnesium sulfate solution and roasting to obtain high-activity nano magnesia; heating and decomposing the ammonium sulfate contained filtrate obtained in the last step and light burning powder to obtain magnesium hydroxide at a flame retardant level; and filtering the magnesium hydroxide in a reactor to obtain magnesium hydroxide at an environmental protection level and recycling the filtrate without emission. Fibrous magnesium hydroxide, basic magnesium carbonate and high-activity nano magnesia are widely applied to flame retardance, smoke suppression, filling and reinforcement of rubber products, can be used as an adiabatic and high-temperature-resistant insulation material or can be used for manufacturing high-grade glass products, magnesium salts, paints, and the like.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Process for removing calcium from magnesite

The invention relates to a process for removing calcium from magnesite. The process is characterized by finally reducing the content of calcium oxide below 1.5% through magnesite calcination, slaking, calcium removal, filtration, washing, drying and other treatment procedures. The process has the following beneficial effects: the magnesium hydroxide product which is obtained after removing calcium and has content of calcium oxide being lower than 1.5% can be directly applied to the fields such as flame retardants, oil additives, water treatment neutralizers and the like; other high value-added magnesium-containing materials such as industrial magnesium oxide, electrician magnesium oxide, fused magnesium oxide, light magnesium carbonate and the like can be further processed and produced; and compared with the existing processes for removing calcium from magnesite, the process has the advantages of short flow, low cost, flexible product scheme, thorough calcium removal and the like.

Owner:LIAONING XINFAZHAN REFRACTORY MATERIAL GRP

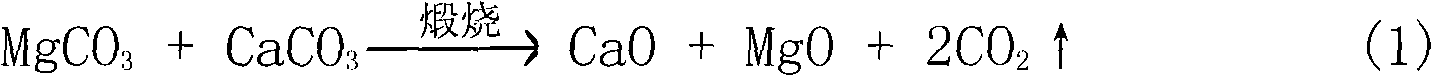

Method of producing magnesium hydroxide and light magnesium oxide using magnesite as raw material

InactiveCN1868952AImprove resource utilizationNo pollutionMagnesium hydroxideLime productionResource utilizationSlurry

A process for preparing magnesium hydroxide and light magnesium oxide from magnesite includes such steps as calcining the magnesite in carbonizing kiln to obtain magnesium oxide, preparing magnesium oxide slurry, carbonizing to become magnesium carbonate, acidolyzing to become soluble magnesium hydroxide, adding oxidant to the mixed acid solution for oxidizing the ferrous elements to become iron hydroxide, filtering for removing it, adding soluble magnesium hydroxide and ammonium salt solution, thermodecomposing to generate magnesium hydroxide, press filtering, and light burning or baking.

Owner:任建武

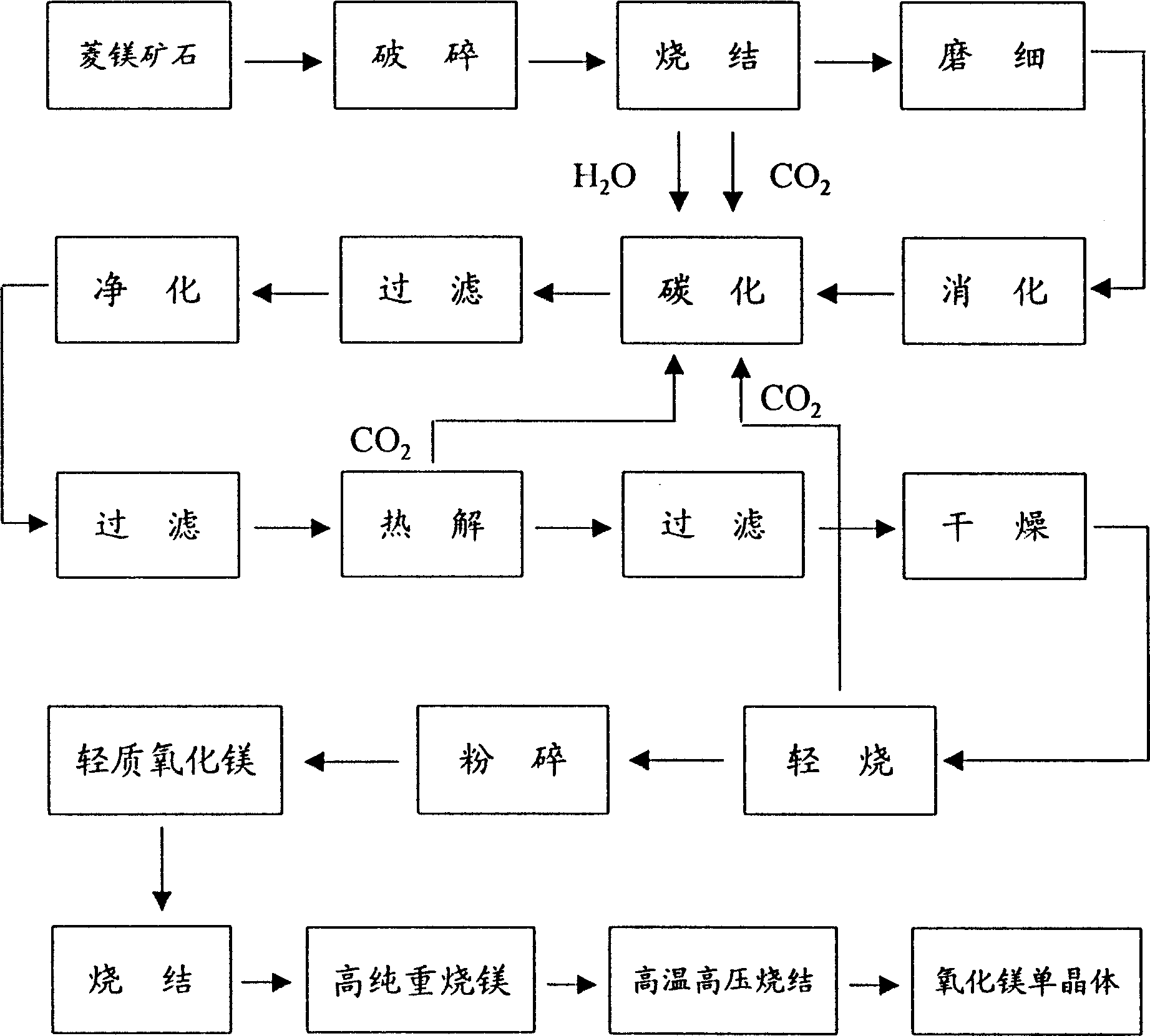

Process for producing high purity magnesium oxide monocrystal using waste magnesite ore

The production process of high purity magnesia monocrystal with magenesite ore of 35-44 % purity includes baking in reverberatory furnace to obtain light burnt magnesia, cooling and ball milling, digesting via adding water andp umping to carbonating pressure tank, adding water and CO2 gas while maintaining the temperature, stirring to slight acid, filtering before and after adding purifying agent in a storage tank, decomposing with hot vapor and separating deposit; filtering, depositing and stoving to obtain light magnesia; pressing to form balls and incineration to obtain heavy magnesia monocrystal material; crushing and sintering at high temperature and high pressure to obtain magnesia monocrystal.

Owner:吕佳成

Method for preparing caustic calcined magnesite from magnesite flotation tailings

The invention provides a method for preparing caustic calcined magnesite from magnesite flotation tailings. The method comprises the following steps: mixing materials, pelletizing, drying, roasting, washing, filtering and the like. According to the method, anhydrous magnesium chloride, magnesium chloride hexahydrate and corn starch are added into the magnesite flotation tailings to be compressed into compact balls; in a calcining process, activation energy hindering sintering is reduced; in addition, the anhydrous magnesium chloride and the magnesium chloride hexahydrate decompose out chlorideions in a roasting process, the chloride ions can promote magnesite decomposition in the roasting process, a magnesite flotation tailing roasting temperature is reduced, energy consumption is reduced, calcium carbonate in the tailings is simultaneously converted into calcium chloride, the calcium chloride is removed through washing, and an effect of removing calcium is achieved. According to themethod disclosed by the invention, the magnesite flotation tailings are utilized as a main raw material, and the magnesite flotation tailings have the advantages of wide sources and low cost; thus, the problem of environmental pollution caused by stockpiling the magnesite flotation tailings is solved, resourceful and reasonable utilization of the magnesite tailings is simultaneously achieved, theresource utilization rate is improved, and land occupation of the magnesite tailings is reduced.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

Purification method for low-grade magnesite via hydration

A purification method for low-grade magnesite via hydration, comprising: by using the low-grade magnesite as a raw material, calcining at 600-1000 DEG C to fully decompose the magnesite, and adding water to hydrate magnesium oxide obtained after the calcination; autogenous grinding and sieving magnesium hydroxide obtained by hydration, and by employing the characteristics of magnesium hydroxide obtained by hydration being the easily pulverized and easily separated from other mineral impurities, removing impurities with relatively high hardness such as calcium oxide, silica, alumina and iron oxide therein; and secondary calcining the magnesium hydroxide at 600-900DEG C to obtain the magnesium oxide with a purity higher than 97.5%. By adopting the method of the present invention, the low-grade magnesite can be effectively and fully used.

Owner:NORTHEASTERN UNIV

High-activity MgO/nanometer carbon composite powder and its preparation method

InactiveCN107651943AReduce manufacturing costGuaranteed decentralizationCeramicwareCarbon compositesRefractory

The invention belongs to the technical field of fireproof materials, and particularly relates to a high-activity MgO / nanometer carbon composite powder and its preparation method. The high-activity MgO / nanometer carbon composite powder is prepared from, by mass percent, 80-60% of magnesium carbonate of which grain diameter is more than 0.1 mm and not more than 0.5 mm, 15-5% of magnesium carbonate fine powder of which grain diameter is more than 0.074 mm and not more than 0.1 mm, 20-5% of reducing agent of which grain diameter is more than 44 mu m and not less more than 150 mu m, and 10-1% of catalyst; the total mass of the raw materials is 100%. The raw material is further added with hole expanding agent which is 0-1% of the total mass of the raw material. Different from the nano carbon prepared by traditional cracked phenolic resin, the composite powder of the high-activity MgO / nanometer carbon prepared by the invention applies the low-price and easy-acquired magnesite as carbon source, and has excellent performances of two raw materials; the composite powder has higher reaction activity and is more obvious in improving the comprehensive performance of the resisting materials.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Magnesite ore desilicication and decalcification method

The invention discloses a magnesite ore desilicication and decalcification method, which is used for dressing low-grade magnesite ore and improving the sorting effect. A magnesite ore one-time rough and two-time fine reverse flotation desilicication and acid leaching decalcification process is adopted; conventional amine chemicals are used as cation collectors, wherein the dosage for one-time reverse flotation is 75-100g / t, the dosage for the first time of fine reverse flotation is 50-70g / t and the dosage for the second time of fine reverse flotation is 25-30g / t, sodium hexametaphosphate and water glass are used as regulators, wherein the dosage of the hexametaphosphate is 150-200g / t and the dosage of the water glass is 1000-1500g / t; diluted hydrochloric acid is used for regulating pH to 5.0-5.5 and then flotation is conducted; after flotation, the concentration of ore pulp is regulated to 20-30 percent, concentrated hydrochloric acid is used for regulating pH, stirring is conducted at revolving speed of 600-700rpm and the ore pulp is leached by using acid for 40-60min. According to the feature of high content of silicon and calcium impurities in magnesite ore, after the content of silicon is reduced, the removal rate of high-calcium impurities can be remarkably improved.

Owner:UNIV OF SCI & TECH LIAONING

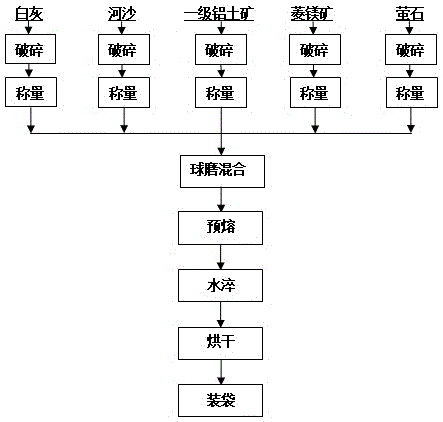

Preparation method for refining slag for smelting bearing steel

The invention relates to a preparation method for refining slag for smelting bearing steel. The slag system comprises components of, by mass, 38%-56% of CaO, 5%-12% of SiO2, 28%-48% of Al2O3, 2%-8% of MgO and 2%-6% of CaF2. The preparation method for the refining slag comprises the steps that, weighed fluorite, lime, bauxite, river sand and magnesite are treated and subjected to ball milling and mixed uniformly; then the mixture is put in a slag melting furnace to be heated, and slag materials are poured into a pelletization pond to be subjected to water quenching after being molten completely; and the slag materials are taken out to be dried, stored and packaged after being cooled. According to the preparation method for the refining slag for smelting the bearing steel, the refining slag prepared through the method is in an amorphous state and has the characteristics of being low in melting point, high in melting speed and the like; desulfuration can be performed efficiently and rapidly, inclusions in the steel are effectively adsorbed, and the problems of the high content, thick and big particles and the like of nonmetal inclusions in the traditional production process for the bearing steel are solved; the bearing steel has outstanding abrasion resistance and high fatigue strength, brittle fractures are reduced, the steel plasticity is improved, and the steel quality is guaranteed.

Owner:NORTHEASTERN UNIV

Preparation method for low-cost and high-whiteness calcined talcum

The invention relates to a preparation method for low-cost and high-whiteness calcined talcum, belonging to the technical field of ceramic raw materials. The preparation method is characterized by comprising the following preparation steps: preparing the following raw materials by weight: 15 to 60 parts of magnesite or magnesite flotation tailings, 15 to 60 parts of silica and 0 to 20 parts of talcum / talcum slag; mixing the raw materials, then carrying out calcination at 1000 DEG C to 1500 DEG C for 1 h to 8 h, and carrying out cooling to 25 DEG C to 40 DEG C so as to obtain calcined talcum powder / blocks. The method provided by the invention prepares a calcined talcum substitute used for ceramics by using the magnesite or the magnesite flotation tailings and the silica as main raw materials, utilizes cheap and low-grade magnesite or the magnesite flotation tailings and the silica and adopts a high-temperature solid-phase reaction process to directly prepare the calcined talcum substitute, and has low cost.

Owner:YINGKOU TENGLONG NEW MATERIALS +1

Method and apparatus for production of basic magnesium carbonate and magnesium oxide whisker from magnesite

InactiveCN106012024AIndustrial operation safetyRealize material carbon steelPolycrystalline material growthSingle crystal growth detailsHydromagnesiteCarbonization

The invention relates to a method and apparatus for production of basic magnesium carbonate and magnesium oxide whisker from magnesite. The invention utilizes non-acidolysis and non-alkalifying of magnesite to synthesize a precursor, then calcination is carried out to obtain magnesium oxide whisker, magnesite can be utilized to automatically synthesize basic magnesium carbonate and magnesium oxide whisker. The method consists of: taking magnesite as the raw material, carrying out calcination, powdering, carbonization and deslagging on the raw material to obtain a heavy magnesium solution, resolving the heavy magnesium solution to obtain a precursor, and drying the precursor to obtain magnesium carbonate whisker. The method does not involved acid or alkali, can enable automatic synthesis of the precursor and magnesium oxide whisker from magnesite, in the future the industrialized operation can be safer, and the equipment and pipeline can realize material carbon tempering. Also the carbon dioxide and water produced in the process can be recycled, thus realizing a green process.

Owner:李治涛

High-pressure dynamic reactive automatic compensation device

InactiveCN104449148AExtended service lifeWith heat insulationAnti-corrosive paintsElectrically-conductive paintsTetrafluoroborateAcrylic resin

The invention discloses a high-pressure dynamic reactive automatic compensation device comprising a shell, wherein a protective layer is coated on the shell and is prepared by virtue of the following steps: (1) adding 1.3 parts by weight of acrylic resin, 2.9 parts by weight of jacobsite powder, 1.8 parts by weight of tetraethylammonium tetrafluoroborate and 3.1 parts by weight of zinc dihydrogen phosphate into 9.1 parts by weight of deionized water, and fully stirring uniformly to obtain a bottom layer protective paint; (2) adding 4.1 parts by weight of fluoroolefin resin, 2.9 parts by weight of silicon dioxide, 1.6 parts by weight of dibutyl phthalate and 0.9 part by weight of poly aluminum phosphate into 10.6 parts by weight of deionized water, and fully stirring uniformly to obtain a surface layer protective paint; (3) spraying the bottom layer protective paint on the surface of the shell at first, curing and drying; and (4) spraying the surface layer protective paint, curing and drying. According to the high-pressure dynamic reactive automatic compensation device disclosed by the invention, the protective layer is coated on the shell, so that the service life of the high-pressure dynamic reactive automatic compensation device can be prolonged.

Owner:苏州菲斯特电力科技有限公司

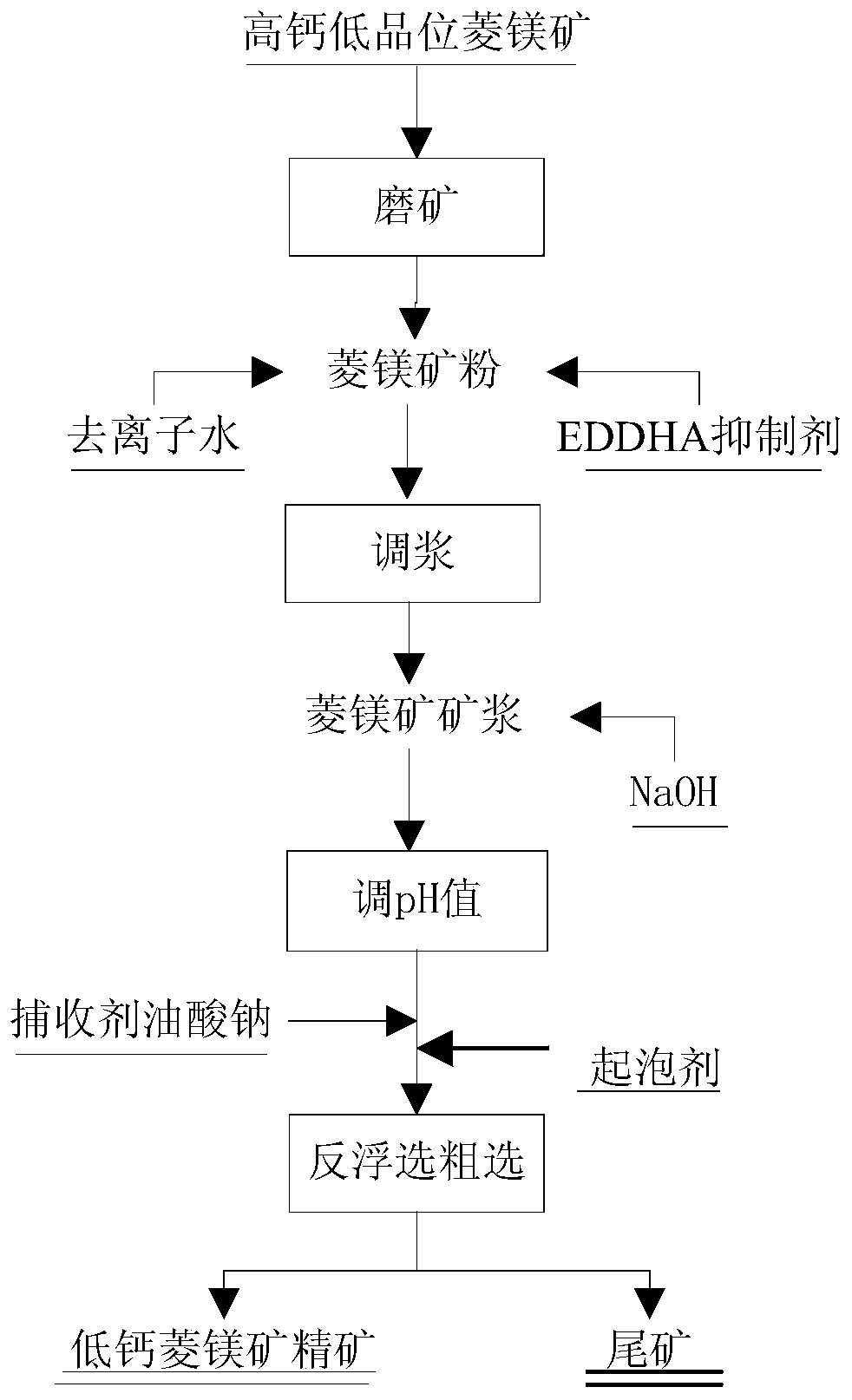

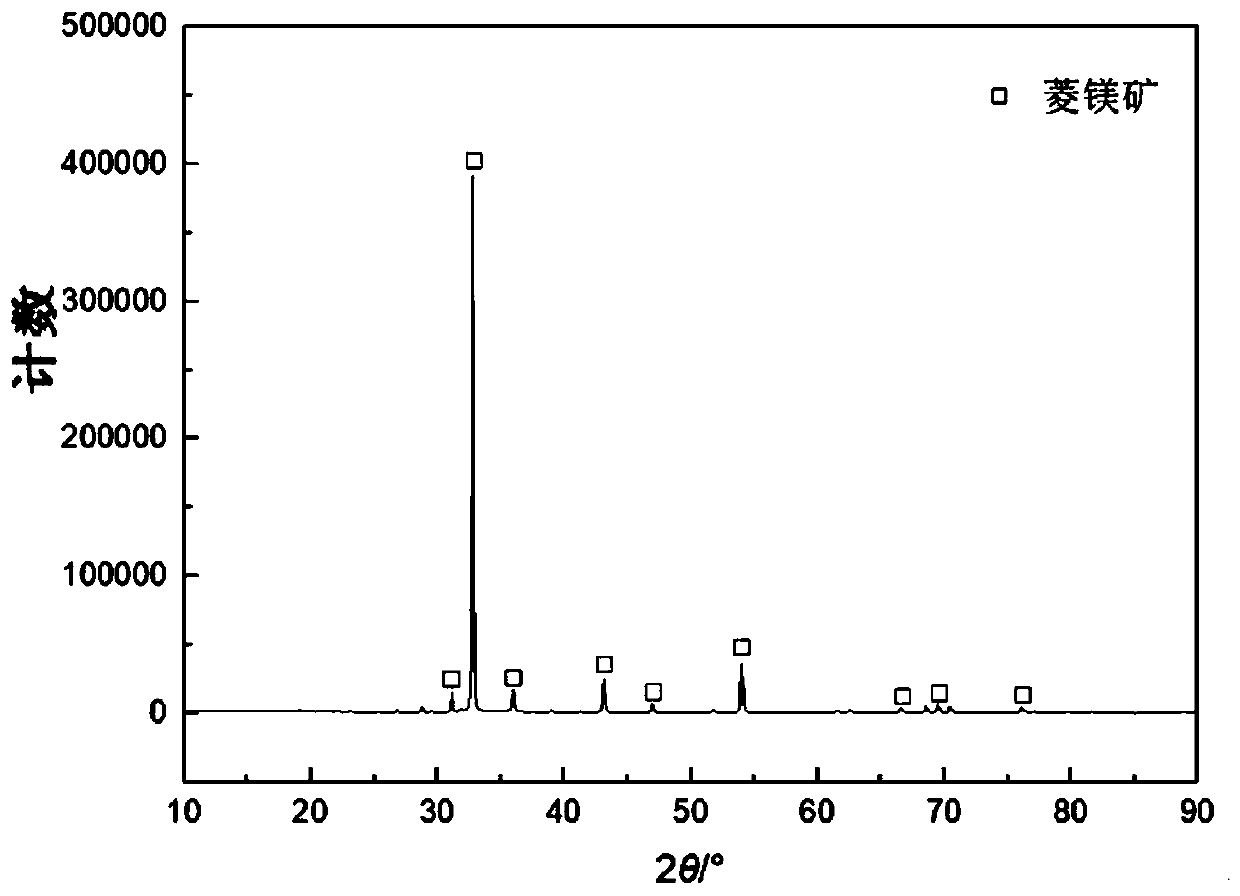

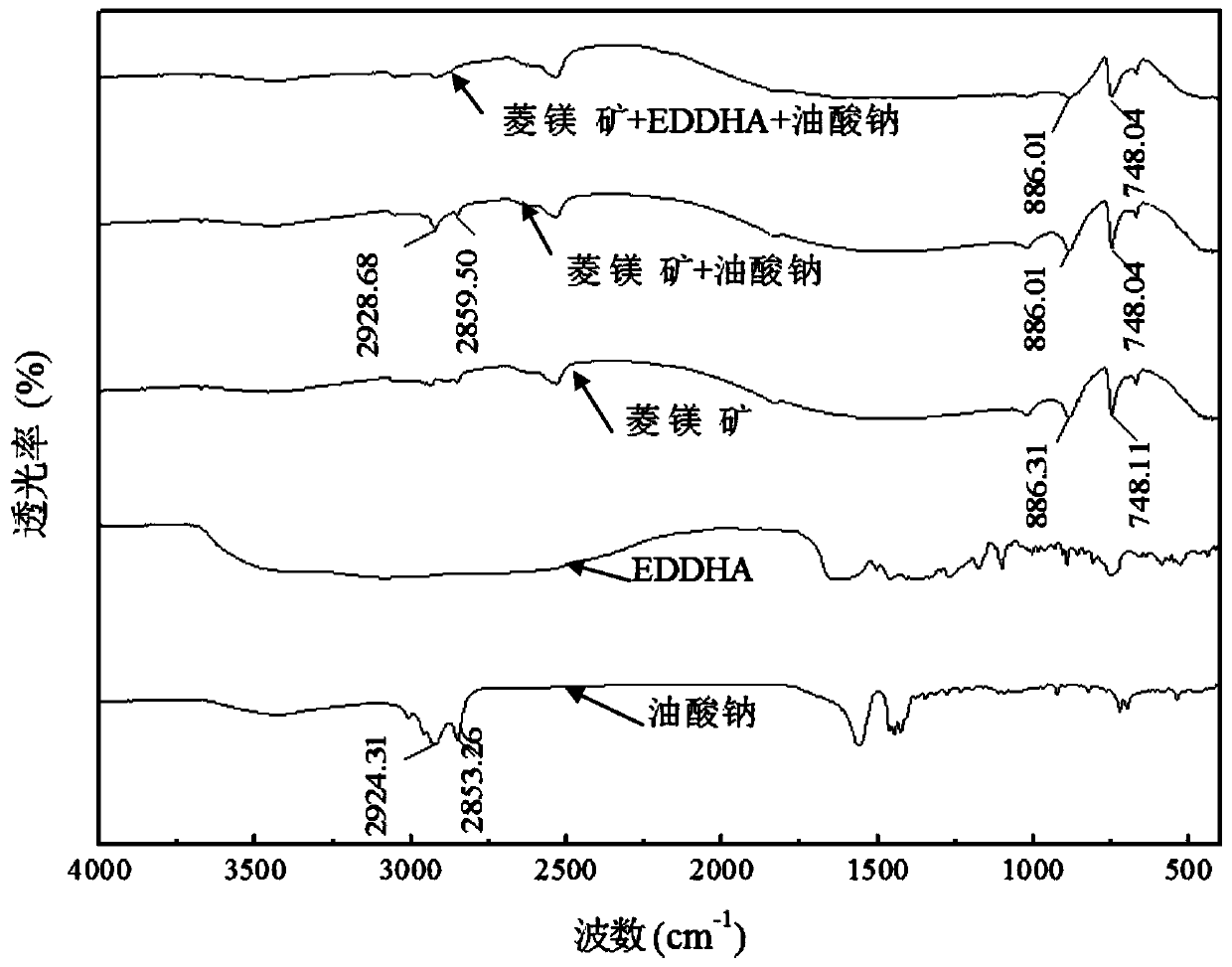

Method for reverse flotation decalcification of magnesite by adopting EDDHA inhibiting agents

InactiveCN110124851ASelective inhibitionShorten the flotation decalcification processFlotationDolomiteImpurity

The invention discloses a method for reverse flotation decalcification of magnesite by adopting EDDHA inhibiting agents, and belongs to the field of magnesite beneficiation and purification processes.In the method, low-grade high-calcium magnesite is crushed for ball milling; then, water and the EDDHA inhibiting agents are fed for pulping; the solid-liquid ratio of the EDDHA inhibiting agents tothe magnesite pulp is (60-90) mg: 1 L; and the mass concentration of the magnesite pulp is 10-30%. The pH value of the magnesite pulp is 10-12; sodium oleate is fed for reverse flotation and roughingdecalcification to obtain low-calcium magnesite concentrates; the recovery rate is 70-85%; and the recovery rate of MgO in the low-calcium magnesite concentrates is 65-85%. According to the floatability difference between the magnesite and impurity ores-dolomite in the magnesite under the effect of the EDDHA inhibiting agents, calcium ores in the magnesite are removed through the reverse flotationmethod, so that the quality of the magnesite is improved, and new agents are provided for beneficiation decalcification of the low-grade high-calcium magnesite.

Owner:NORTHEASTERN UNIV

Method for preparing high-activity magnesium oxide from magnesite

The invention provides a method for preparing high-activity magnesium oxide from magnesite. The method includes the following steps of breaking, grinding, twice calcinating, magnetic separating and the like. By means of the neutral-reduction two-section calcinating process, calcinating is conducted at a low temperature, it is ensured that the magnesite is decomposed into an MgO amorphous body under the low-temperature calcinating conditions, the magnesite is calcinated for decomposing one part under the neutral conditions, the MgCO3 can be incompletely decomposed to generate CO, the generatedCO is used for later-stage calcinating as reduction gas so that weak-magnetic iron minerals in the magnesite can be reduced into strong magnetic iron minerals, the undecomposed magnesite continues tobe decomposed in the reduction and calcinating process through magnetic separation removal, the magnesite is finally completely decomposed through calcinating under the two-section low-temperature conditions, the rapid generation of MgO crystals under the high-temperature conditions is avoided, the content of the MgO amorphous body in the obtained activated magnesium oxide is high, activity is high, and the citric acid detection CAA value is 13-15 seconds.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

Method for producing magnesium ammonium phosphate fertilizer by using light roasting powder to process phosphorus-containing and nitrogen-containing waste water

InactiveCN107459371ANo need to adjust pHSolve the use problemWater treatment parameter controlWater contaminantsMagnesium ammonium phosphateChemical measurement

The invention discloses a method for producing a magnesium ammonium phosphate fertilizer by using light roasting powder to process phosphorus-containing and nitrogen-containing waste water, and relates to a method for producing the magnesium ammonium phosphate fertilizer. The method comprises the following steps: using the light roasting powder obtained by calcining low-grade magnesite as a raw material, according to 10-15:1:0.6-1 of the optimal chemometry mole ratio of Mg:P:N in a mixed reaction system, adding the light roasting powder and phosphorus or nitrogen to the waste water containing the phosphorus and ammonia nitrogen, stirring in the normal temperature and pressure, stewing and precipitating, wherein the obtained precipitate is a controlled release fertilizer containing the magnesium ammonium phosphate. About the waste water which contains the phosphorus only and contains the nitrogen only, according to 10-20:1 of the optimal chemometry mole ratio of Mg:P, a certain amount of the light roasting powder is added to the waste water containing the phosphorus for recycling the phosphorus, the pH value of the reaction system is regulated, and the stirring reaction is executed in the normal temperature and pressure, the precipitate obtained by stewing and precipitating is the controlled release fertilizer containing the magnesium ammonium phosphate.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Method for roguing and purifying low-grade magnesite

InactiveCN106565115AEfficient purificationNo pollution in the processMaterial nanotechnologyMagnesiaTunnel kilnReverberatory furnace

The invention discloses a method for roguing and purifying a low-grade magnesite. The method comprises the steps of (1) adopting the low-grade magnesite as a raw material, and filtering the magnesite to filter out large impurities in the magnesite; (2) feeding the magnesite into a crusher and crushing the magnesite with the crushing parameters thereof as follows: grinding capacity: 6-10 m<3> / min, air pressure: 1 Mpa; (3) putting the crushed magnesite into a reverberatory furnace, a rotary kiln, a suspension furnace, a fluidized bed furnace or a tunnel kiln at 600 to 1000 DEG C to fully roast the crushed magnesite; (4) hydrating the lightly roasted magnesium oxide with water, and conducting the self-grinding; (5) finally, roasting magnesium hydroxide powders for a second time at 600 to 900 DEG C to obtain rogued and purified lightly roasted magnesium oxide powders. The above method improves the impurity-removing efficiency of magnesium oxide, and increases the purity of magnesium oxide.

Owner:营口镁质材料研究院有限公司

Preparation method of low-silicon high-calcium macrocrystalline fused magnesite

The invention discloses a preparation method of a low-silicon high-calcium macrocrystalline fused magnesite. The preparation method comprises the following steps: putting magnesite with the MgO content of over 45% into a light roasting furnace for continuous calcinations for 4 h, uniformly adding an Na2CO3 solution during calcinations, and smashing a product after calcinations to obtain a high-activity MgO powder; adding the high-purity graphite powder into the high-activity MgO powder, putting the mixture into a full-automatic electric smelting electric-arc furnace for smelting for 5 to 8 h,and carrying out classification crushing after the smelting is ended so as to obtain the low-silicon high-calcium macrocrystalline fused magnesite. According to the preparation method, a sodium carbonate solution is added, so that the melting point is effectively reduced, the calcination temperature is reduced, and the energy is saved; moreover, sodium silicate and carbon dioxide can be generatedthrough the reaction of sodium carbonate and impurity silicon dioxide, and the silicon dioxide impurity inside the magnesite can be effectively removed, so that the content of magnesium oxide is improved; the content of MgO inside the product reaches 99.90% or more than 99.90%, the calcium-silicate ratio reaches 2.30 or more, the fused magnesite has high high-temperature fire resistance and high-temperature scouring resistance, and the fused magnesite can be applied to the industries such as spaceflight, electrons, steel, metallurgy and the like as a high-quality advanced refractory material.

Owner:LIAONING XINFAZHAN REFRACTORY MATERIAL GRP

Separation method for calcite and magnesite

The invention provides a separation method for calcite and magnesite. The method comprises the following steps: in allusion to a pretreatment process of the separation, firstly regulating the pulp density of magnesite rough concentrate containing the calcite to be 30-50 wt%, adding a dispersing agent, and adding sulfuric acid solution after stirring for 2 minutes, regulating a pH value to be 1-3,and performing the solid-liquid separation after stirring for 20-60 s in a low speed; adding the separated solid to 2-5 wt% of polyvinyl alcohol solution, enabling the pulp density to be 10-30 wt%, adding the sulfuric acid solution after stirring for 2 minutes, and regulating the pH value to be 1-5, to obtain magnesite concentrate after the conventional flotation. The method is capable of reducingthe dosages of a collecting agent and a foaming agent, and getting the magnesite concentrate in high purity.

Owner:FUZHOU UNIV

Method for refining magnesium and reducing silicon from magnesite ores

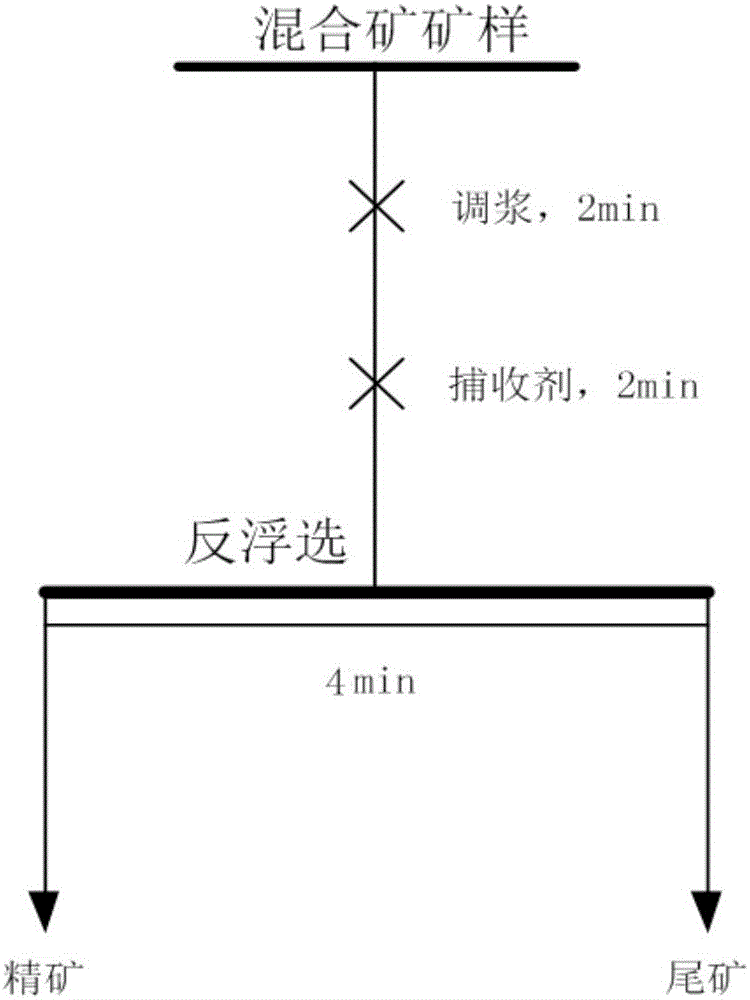

The invention relates to a method for refining magnesium and reducing silicon from magnesite ores, in particular to a method for refining magnesium and reducing silicon from the magnesite ores by reverse flotation, and belongs to the technical field of mineral flotation separation in mineral processing engineering. The method for refining magnesium and reducing silicon from the magnesite ores includes the steps: mixing magnesite ore samples to be processed with water to obtain ore pulp with the concentration of 28-32%; adding 30-60g / t of collecting agents into the uniformly stirred ore pulp; uniformly stirring the added collecting agents and then performing flotation, wherein the collecting agents are N, N-di (hydroxyethyl) lauryl amine or N, N-di (hydroxypropyl) lauryl amine. The method for refining magnesium and reducing silicon from the magnesite ores is simple in technological process and reagent system, convenient to operate and good in industrial feasibility.

Owner:NORTHEASTERN UNIV

Production method of light calcined magnesia

ActiveCN107010852AEfficient cost recyclingEfficient and low-cost recyclingLime productionJacobsiteHigh concentration

Owner:UNIV OF SCI & TECH LIAONING

Application of ammonium magnesium phosphate/nano magnesium hydroxide in treatment of wastewater containing heavy metals

ActiveCN110436598ARealize resource utilizationAchieve removalWater contaminantsWater/sewage treatmentMagnesium phosphateResource utilization

The invention provides an application of a magnesium ammonium phosphate / nano magnesium hydroxide mixture in treatment of wastewater containing heavy metals. In the application, the molar ratio of theammonium magnesium phosphate to the nano magnesium hydroxide to the heavy metals is 1:(2-10):(0.1-0.8), wherein the ammonium magnesium phosphate / nano magnesium hydroxide can be obtained through conversion from low-purity magnesium oxide which is a waste material. According to the method, the low-purity magnesium oxide waste can be converted into the nanoscale high-dispersion magnesium hydroxide, which can be used as a raw material for precipitating ammonia nitrogen in sewage through a magnesium ammonium phosphate method, resource utilization of low-purity magnesium oxide and low-grade magnesite is achieved, meanwhile, the heavy metals in heavy metal wastewater can be removed through the obtained magnesium ammonium phosphate and magnesium hydroxide mixture, and ammonia nitrogen and heavy metal ions in rare earth wastewater are removed at the same time.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

Method for producing high-purity magnesium hydroxide and magnesium oxide from low-grade magnesite

InactiveCN103011630BReduce pollutionTake advantage ofMagnesium hydroxideLime productionStrong acidsLower grade

Owner:新疆蓝天镁业股份有限公司

Clean fuel prepared from traditional Chinese medicine residues

The invention relates to a clean fuel prepared from traditional Chinese medicine residues, which comprises the following components in percentage by weight: 10-15 parts of coal gangue, 5-15 parts of jacobsite slag, 25-30 parts of industrial salt slurry, 1-5 parts of blast furnace slag, 30-40 parts of traditional Chinese medicine residue, 1-5 parts of combustion improver and 0.5-3 parts of synergist. The preparation process of the clean fuel comprises the following steps: baking the traditional Chinese medicine residues at high temperature to lower the water content to 1-4% below; and mixing and pulverizing the components, and finally, carrying out compression forming on the components by a forming machine. The clean fuel is simple in technique, provides a convenient environment-friendly treatment mode for traditional Chinese medicine residues discharged by the current enterprises, and converts the traditional Chinese medicine residues into energies, resources and harmless substances. After the traditional Chinese medicine residues and industrial solid waste are prepared into the clean fuel, the environmental pollution is reduced, and the economic value can be implemented.

Owner:TIANJIN SHENNONG ENVIRONMENTAL PROTECTION TECH CO LTD

Method for producing high-purity magnesium oxide through utilizing low-grade magnesium oxide and magnesite

InactiveCN103274611AHigh puritySolve the problem of polluting the environmentMagnesiaSocial benefitsMagnesium salt

The invention relates to a method for producing pure magnesium oxide, and concretely relates to a method for producing high-purity magnesium oxide through utilizing low-grade magnesium oxide and magnesite. The method comprises the following steps: adding a magnesium salt to low-grade magnesia having a magnesium oxide mass percentage content of 94.0-97.5% or magnesite having a magnesium oxide mass percentage content of 40.0-46.0%, uniformly mixing, and carrying out heating calcining to prepare high-purity magnesium oxide having a purity of above 98.0%. High-purity magnesium oxide is produced through the addition of the magnesium salt to the low-grade magnesium oxide and the heating treatment in the invention. The method solves a magnesium chloride-polluted environment problem generated in the sponge titanium production process, reduces the production cost, and brings considerable economic and social benefits.

Owner:重庆阁林环保科技有限公司

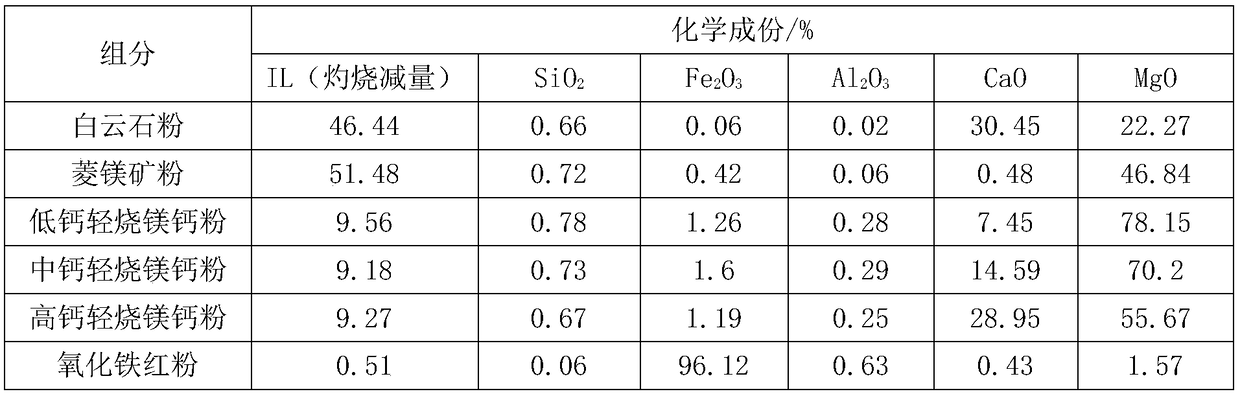

Magnesium-calcium-iron sand synthesized by taking dolomite and magnesite as raw materials and sintering and preparation method

The invention relates to magnesium-calcium-iron sand synthesized by taking dolomite and magnesite as raw materials and sintering and a preparation method. The magnesium-calcium-iron sand is prepared by taking dolomite powder and magnesite powder as the raw materials, iron oxide red powder as an additive and lightly-burnt magnesium-calcium powder as a binding agent through mixing, carrying out ballpressing / blank pressing, carrying out high-temperature sintering and crushing; the ratio of each component is as follows in parts by weight: 45 to 87 parts of the dolomite powder and the magnesite powder, 10 to 50 parts of the lightly-burnt magnesium-calcium powder and 3 to 5 parts of the iron oxide red powder; a finished product has physical and chemical indexes as follows: less than 1.5 percentof SiO2, 4 to 6 percent of Fe2O3, less than 0.4 percent of Al2O3, 8.0 to 32.0 percent of CaO and 60 to 83 percent of MgO. By adopting the magnesium-calcium-iron sand provided by the invention, the history that only a two-step calcination method can be used for producing the magnesium-calcium-iron sand in China for many years is finished; a technological flow is short and a production technology is simple; the probability of pollution and the production cost of a product are reduced; the quality of the product is relatively improved.

Owner:海城利尔麦格西塔材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com