Method for producing high-purity magnesium hydroxide and magnesium oxide from low-grade magnesite

A magnesium hydroxide and magnesite technology, which is applied in the production of magnesium hydroxide and lime, can solve the problems of strong acid consumption, pollution, and underutilization of other components, and achieve the goal of reducing pollution and improving resource utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

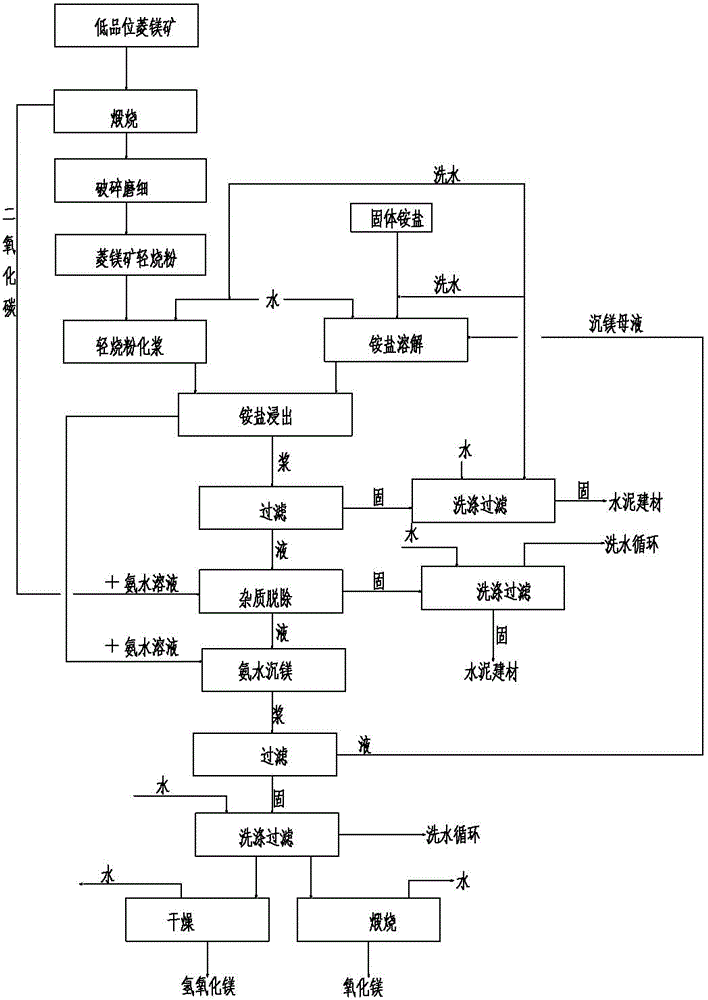

Image

Examples

Embodiment 1

[0025] Embodiment 1, the method for preparing high-purity magnesium hydroxide and magnesium oxide from this low-grade magnesite is carried out as follows:

[0026] Take 1000g magnesite and calcinate it in a calciner at 950°C for 3 hours (the loss on ignition rate is 47.5%), recover the carbon dioxide decomposed by calcination; crush the calcined magnesite ore and grind it into 200 mesh to 300 mesh Purpose Lightly burned powder: add 980ml of water to the lightly burned powder and stir evenly to prepare a lightly burned powder slurry with a concentration of 35%. Take 1150g of ammonium chloride, add 2500ml of water and stir to dissolve, and then prepare 25% ammonium chloride solution; light calcined powder slurry and ammonium chloride solution are reacted in an enamel kettle with stirring and heating, the reaction temperature is 105°C, and the reaction time is 3h. The ammonia gas, Magnesium chloride and calcium chloride, the ammonia gas is recovered and condensed into ammonia wat...

Embodiment 2

[0027] Embodiment 2, the method for preparing high-purity magnesium hydroxide and magnesium oxide from this low-grade magnesite is carried out according to the following steps:

[0028] Take 1000g magnesite and calcinate it in a calcination furnace at 1000°C for 3 hours (the loss on ignition rate is 49.8%), recover the carbon dioxide decomposed by calcination, crush the calcined magnesite ore, and grind it into -200 mesh light For the burnt powder, add 1000ml of water to the lightly burnt powder and stir to prepare a lightly burnt powder slurry with a concentration of 35%; take 1200g of ammonium chloride; add 3800ml of water, stir to dissolve, and prepare a 20% Ammonium chloride solution; lightly burned powder slurry reacts with ammonium chloride solution in a stirred and heated enamel kettle, the reaction temperature is 110°C, and the reaction time is 3 hours. During the reaction, ammonia gas, magnesium chloride and chloride gas are generated. Calcium and ammonia gas are reco...

Embodiment 3

[0029] Embodiment 3, the method for preparing high-purity magnesium hydroxide and magnesium oxide from this low-grade magnesite is carried out according to the following steps:

[0030] Take 1000g magnesite and calcinate it in a calcination furnace at 900°C to 1100°C for 3 hours (the loss on ignition rate is 49.8%), recover the carbon dioxide decomposed by calcination, crush the lightly burned ore of calcined magnesite, and grind it into - 200 mesh to +300 mesh lightly burned powder; add 1000ml of water to the lightly burned powder and stir to prepare lightly burned powder slurry with a concentration of 30% to 40%; take 1200g of ammonium chloride, add water 3800ml, stirred and dissolved, and prepared into 20% to 30% ammonium chloride solution; lightly burned powder slurry and ammonium chloride solution were carried out in an enamel kettle with stirring and heating, and the reaction temperature was 100°C to 120°C. The time is 2h to 4h, the ammonia gas, magnesium chloride and calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com