Method for reverse flotation decalcification of magnesite by adopting EDDHA inhibiting agents

A magnesite and inhibitor technology, applied in the field of magnesite beneficiation and purification technology, achieves the effects of high content, shortened flotation decalcification process, and strong selective inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

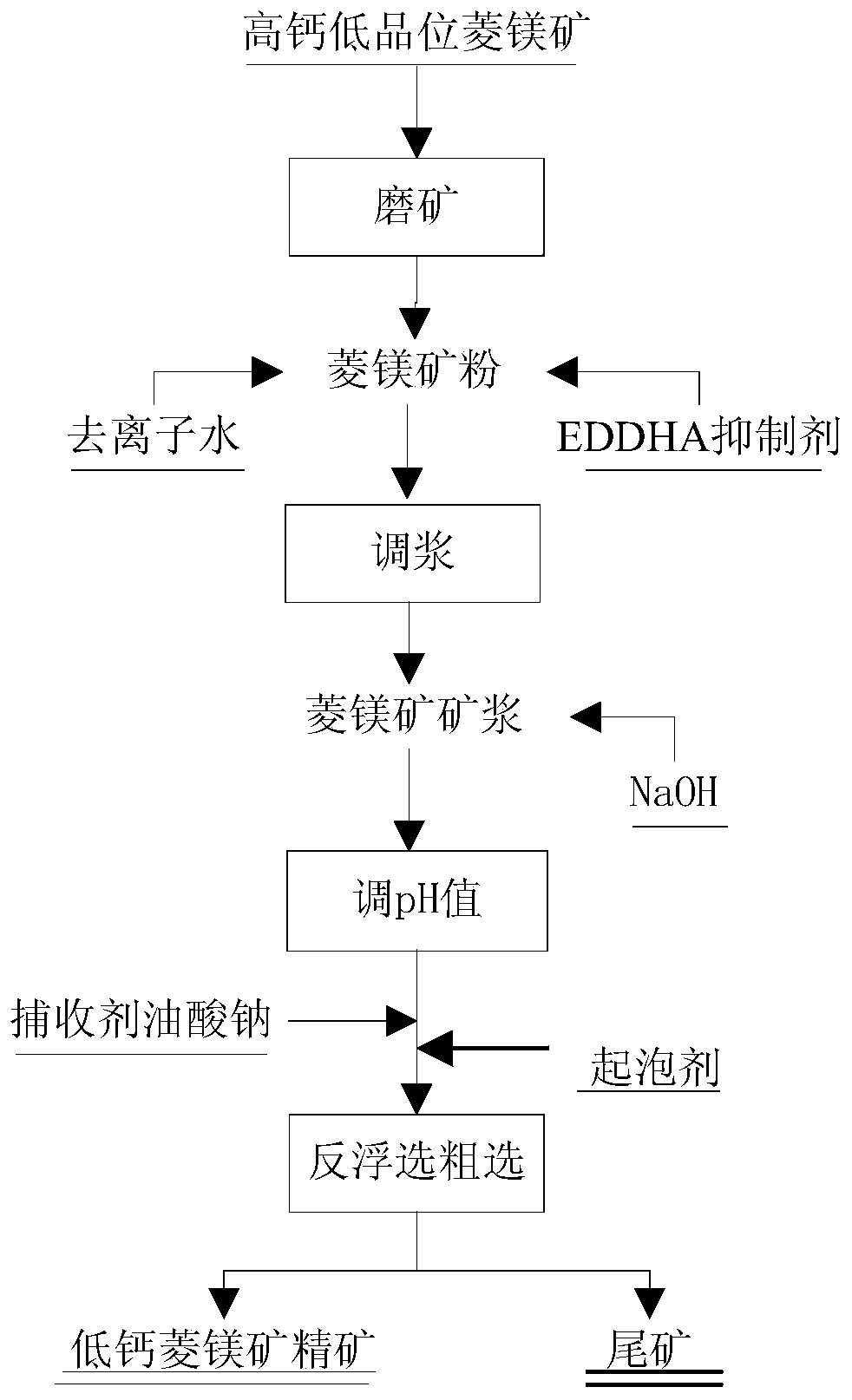

[0040] A kind of method that adopts EDDHA inhibitor to carry out the method for decalcification of magnesite reverse flotation, its flow chart is shown in figure 1 , including the following steps:

[0041] Step 1: Grinding

[0042] The raw material of high-calcium and low-grade magnesite is crushed and ball-milled to obtain magnesite powder; wherein, in the magnesite powder, the mass of magnesite powder with a particle size of less than 74 μm accounts for 65% of the total mass of magnesite powder;

[0043] Step 2: Blending

[0044] Put the magnesite powder with a particle size of less than 74 μm and accounting for 65% of the total magnesite powder mass in a hanging tank flotation machine, add deionized water and EDDHA inhibitor, wherein, according to the solid-to-liquid ratio, the EDDHA inhibitor : magnesite pulp=60mg: 1L, and mix evenly, adjust slurry to obtain magnesite pulp; wherein, the mass concentration of magnesite in the magnesite pulp is 10%;

[0045] Step 3: Rever...

Embodiment 2

[0055] A kind of method that adopts EDDHA inhibitor to carry out the method for decalcification of magnesite reverse flotation, its flow chart is shown in figure 1 , including the following steps:

[0056] Step 1: Grinding

[0057] The raw material of high-calcium and low-grade magnesite is crushed and ball-milled to obtain magnesite powder; among them, magnesite powder with a particle size of less than 74 μm accounts for 75% of the total magnesite powder;

[0058] Step 2: Blending

[0059] Put the magnesite powder with a particle size of less than 74 μm and accounting for 75% of the total magnesite powder in the hanging tank type flotation machine, add deionized water and EDDHA inhibitor, wherein, according to the solid-to-liquid ratio, the EDDHA inhibitor : magnesite pulp=70mg: 1L, and mix evenly, adjust slurry, obtain magnesite pulp; wherein, the mass concentration of magnesite in the magnesite pulp is 15%;

[0060] Step 3: Reverse Flotation Decalcification

[0061] At ...

Embodiment 3

[0065] A kind of method that adopts EDDHA inhibitor to carry out the method for decalcification of magnesite reverse flotation, its flow chart is shown in figure 1 , including the following steps:

[0066] Step 1: Grinding

[0067] The raw material of high-calcium and low-grade magnesite is crushed and ball-milled to obtain magnesite powder; among them, magnesite powder with a particle size of less than 74 μm accounts for 85% of the total magnesite powder;

[0068] Step 2: Blending

[0069] Put the magnesite powder with a particle size of less than 74 μm and accounting for 85% of the total magnesite powder in the hanging tank type flotation machine, add deionized water and EDDHA inhibitor, wherein, according to the solid-to-liquid ratio, the EDDHA inhibitor : magnesite pulp=80mg: 1L, and mix evenly, adjust slurry, obtain magnesite pulp; wherein, the mass concentration of magnesite in the magnesite pulp is 20%;

[0070] Step 3: Reverse Flotation Decalcification

[0071] At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com