Patents

Literature

57 results about "EDDHA" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

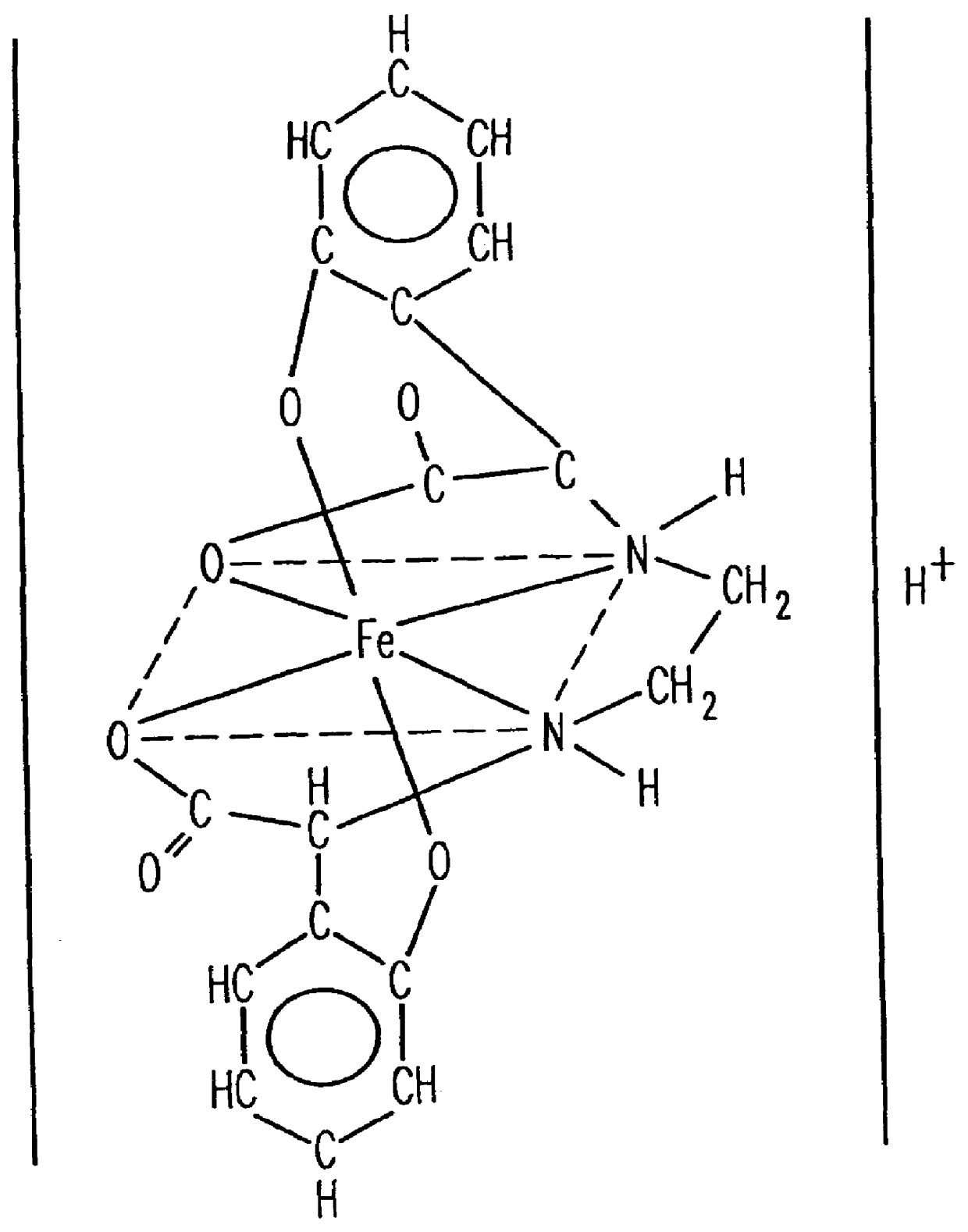

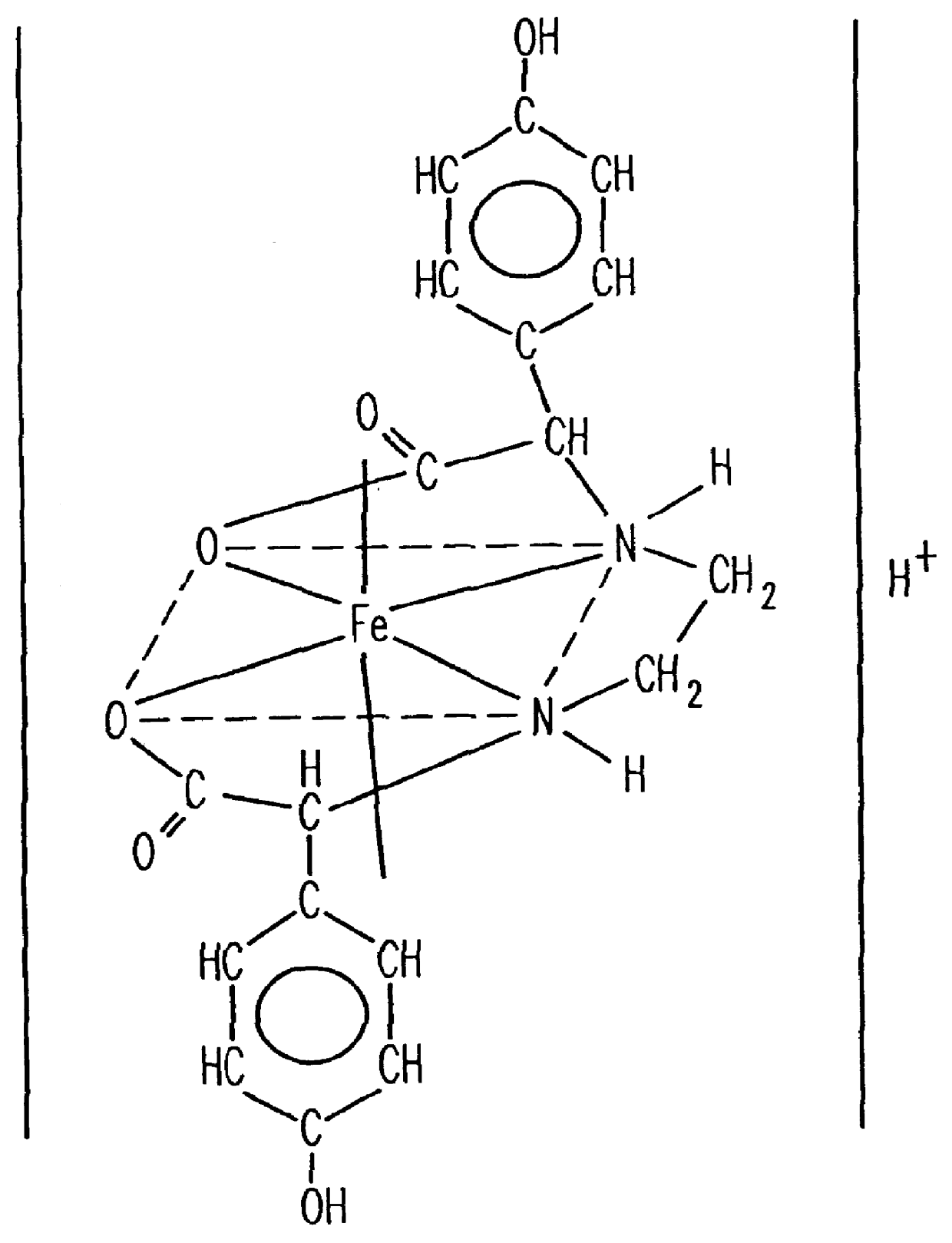

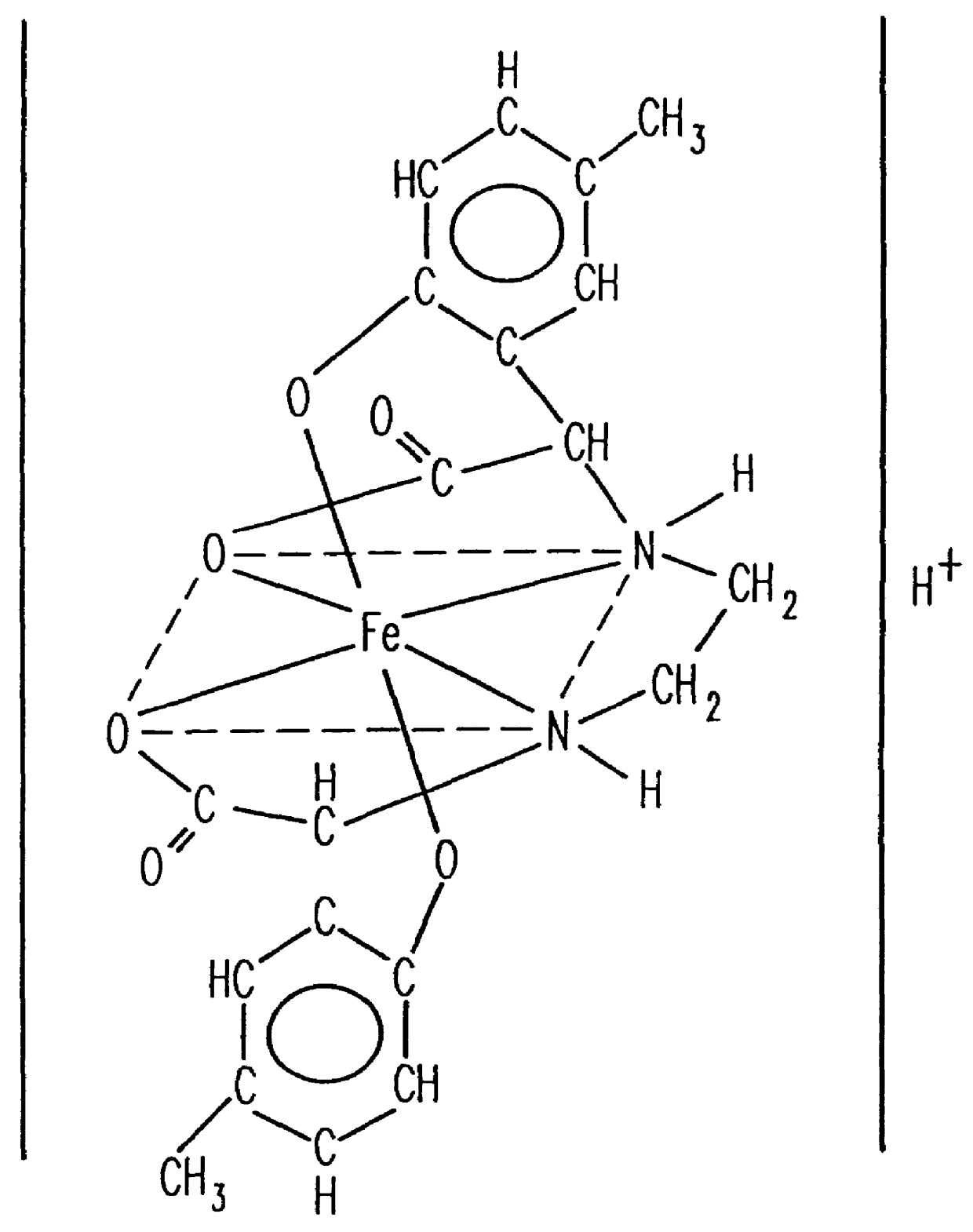

EDDHA or ethylenediamine-N,N′-bis(2-hydroxyphenylacetic acid) is a chelating agent. Like EDTA, it binds metal ions as a hexadentate ligand, using two amines, two phenolate centers, and two carboxylates as the six binding sites. The complexes are typically anionic. The ligand itself is a white, water soluble powder. Both the free ligand and its tetraanionic chelating agent are abbreviated EDDHA. In contrast to EDDHA, most related aminopolycarboxylic acid chelating agents feature tertiary amines and few have phenolate groups.

Fungicidal and bactericidal compositions for plants containing compounds in the form of heavy metal chelates

InactiveUS6139879AImproved antifungalImproved antibacterial compositionBiocideHeavy metal active ingredientsEthylenediamineFungicide

The present invention relates to heavy metal chelate compositions, which are used as fungicides and bactericides, and methods of using the compositions. In particular, the present invention relates to a chelate, that is an EDDHA (copper-ethylenediamine-di-o-hydroxyphenylacetic acid), combined with a heavy metal, including iron, tin, zinc, manganese, copper, and combinations thereof.

Owner:FOLIAR NUTRIENTS

Organic titanium-potassium fertilizer and preparation method thereof

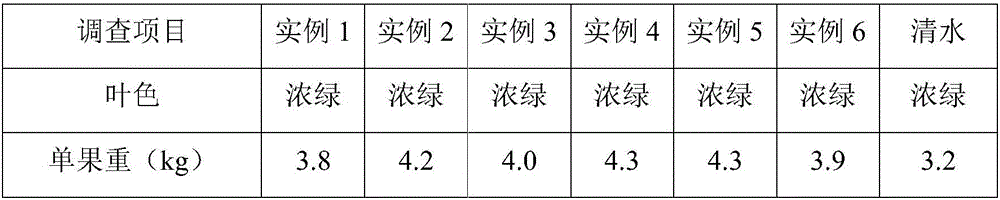

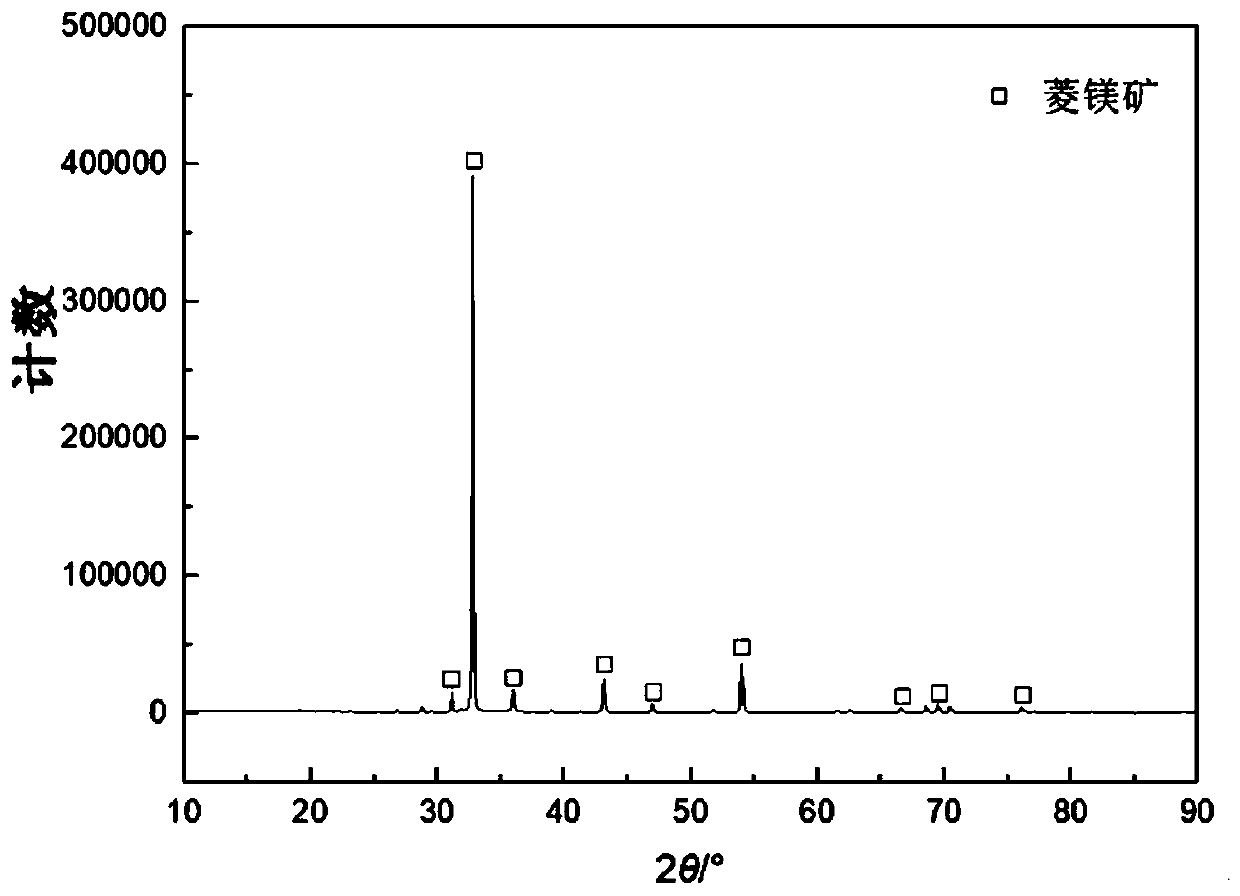

The invention discloses organic titanium-potassium fertilizer and a preparation method thereof. The fertilizer is characterized in that the fertilizer takes water as solvent; and the compositions of the fertilizer in every liter of water are: 5 to 100g of organic chelated titanium, 75 to 200g of glucose, 600 to 800g of potassium citrate, 0 to 130g of borax or boric acid, 0 to 90g of humic acid or potassium humate, 0 to 60g of EDDHA chelating agent and 7 to 12g of auxiliary agent. The organic titanium-potassium fertilizer not only makes effective use of the prior fertilizer resources to change the status quo of constant high potassium fertilizer price in China, relieve contradictions between supply and demand and save resource, but also overcomes the differences between southern China and northern China in climate, soil, and the like, thereby playing a remarkable role in solving soil hardening, salinization and acidification. The fertilizer can also improve adverse circumstance resistance of crops, and is suitable for soil of various climates and various crops; moreover, the fertilizer better ensures yield increase of various crops and solves the problems of farmers such as low economic benefits, income increase, labor intensity reduction and the like; meanwhile, the fertilizer is propitious to advocate rational application of the fertilizer and improve the quality of farm products.

Owner:榆林好婆姨农业科技有限公司

Dyeing process for jacquard fluff top fabric

InactiveCN105297483AHigh color fastnessImprove dyeing uniformityDyeing processDiphenyl etherSulfonate

The invention discloses a dyeing process for a jacquard fluff top fabric. The dyeing process comprises the steps as follows: 1) adding the following components in parts by weight in a dye vat: 19 parts of water, 0.9 part of EDDHA-FeNa, 1.4 parts of alkyl phthalimide compounds, 2.1 parts of diphenyl ether tetracarboxylic dianhydride, 1.3 parts of benzyl naphthalene sulfonate, 5 parts of natural plant pigment, 0.9 part of hexyldecanol and 1.6 parts of dodecyl trimethyl ammonium chloride, and stirring the mixture to be uniform; 2) soaking wool tops in the dye vat for 70 minutes; 3) drying the soaked wool tops at 80 DEG C; 4) immersing the dried wool tops in clear water to be washed for 15 minutes; 5) taking the washed wool tops out of the water and naturally airing the wool tops. The dyeing process for the jacquard fluff top fabric is high in dyed wool top color fastness, good in dyeing uniformity, and free of dyeing defect.

Owner:常熟市新华源有色毛条厂

Short-process low-temperature dyeing aid and preparation method thereof

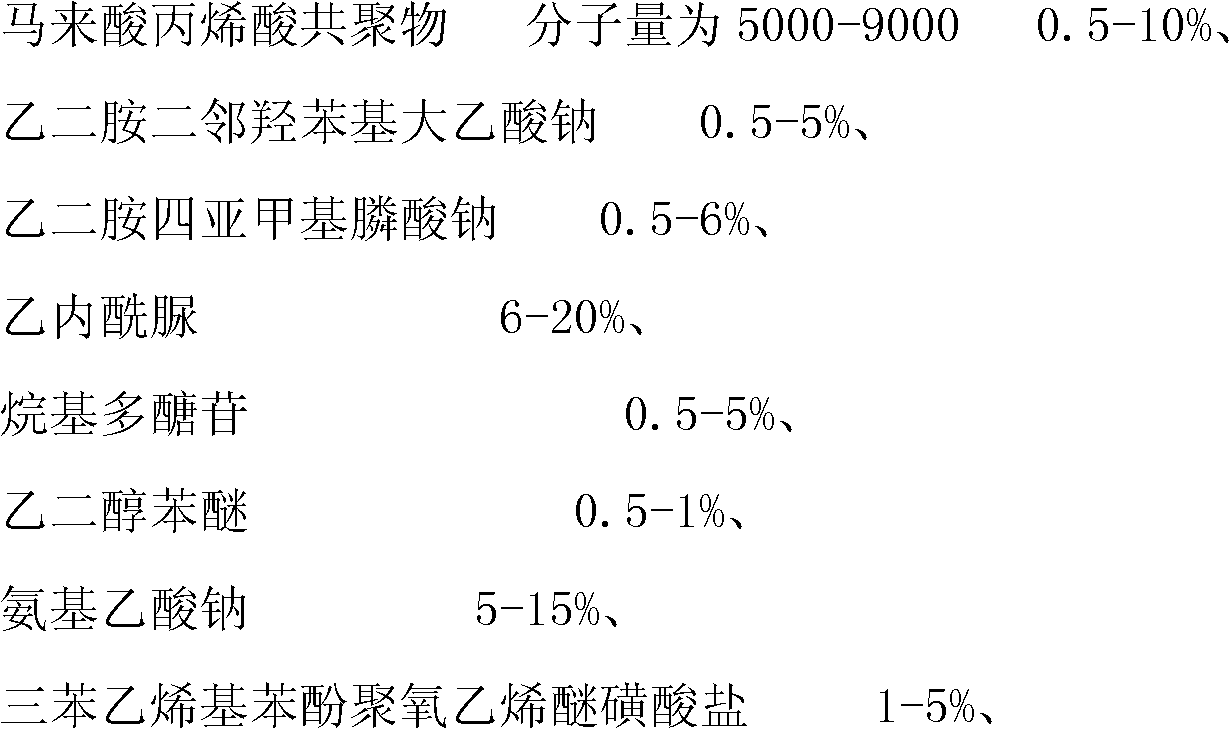

ActiveCN102619101AEliminate reduction cleaning processLower dyeing temperatureDyeing processYarnPolyester

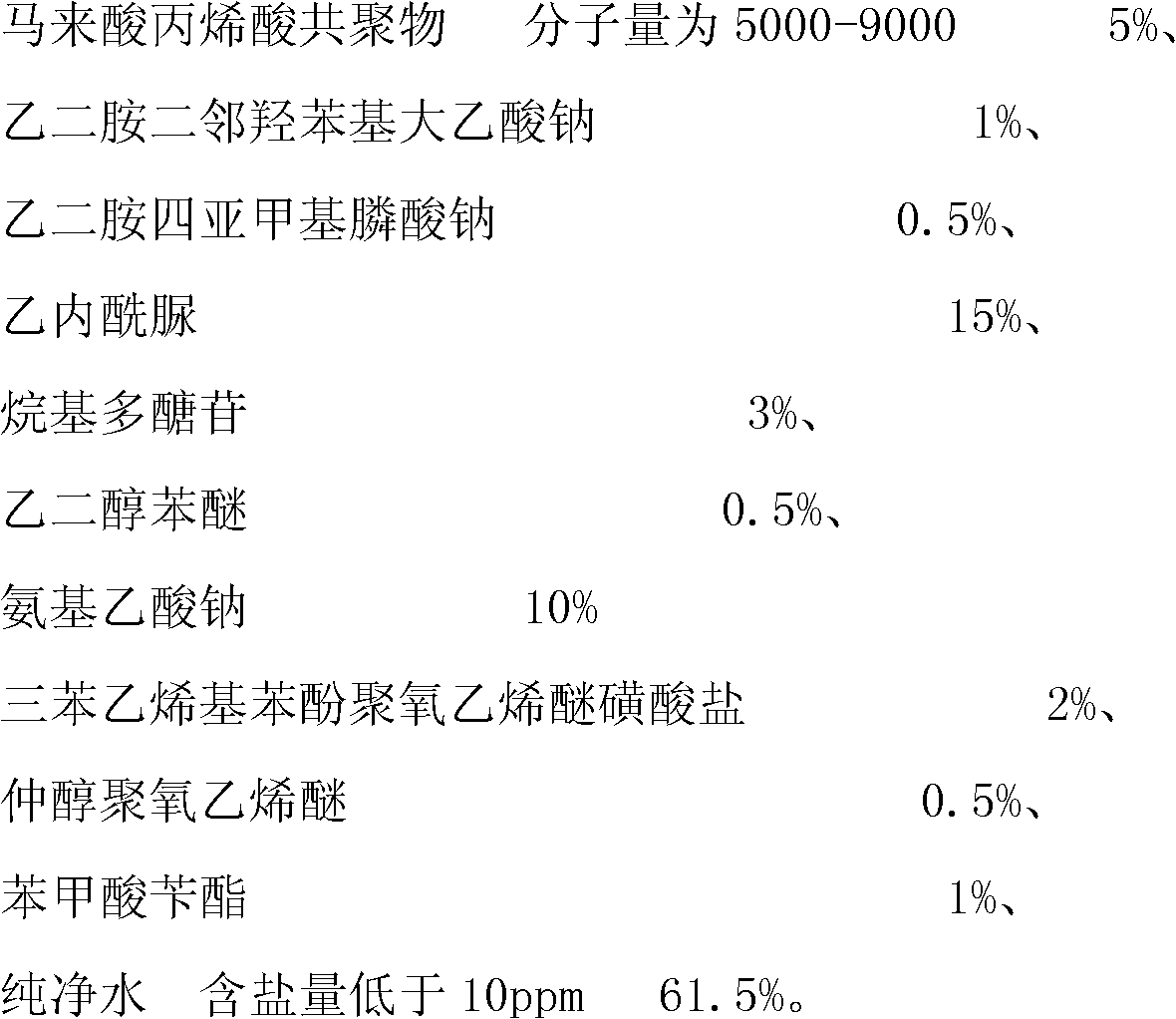

The invention relates to the field of dyeing, in particular to a short-process low-temperature dyeing aid and a preparation method thereof. The short-process low-temperature dyeing aid is characterized by mainly comprising the following components in percentage by weight: maleic acid acrylic copolymer, sodium ethylene diamine di-orthohydroxyphenyl aceticacid (EDDHA), ethylene diamine tetra sodium, hydantoin, alkyl polysaccharide, ethylene glycol phenylate, sodium glycinate, tristyrylphenol ethoxylates sulfonate, secondary alcohol polyoxyethylene ether, benzyl benzoate and the like. Compared with the prior art, the aid and the method have the advantages that the conventional pretreatment and dyeing processing mode of polyester and blended (yarns) fabrics is thoroughly changed, namely pretreatment processes of the yarns and the fabrics which comprise a yarn and knitwear oil removing process, a woven fabric desizing process, a slight decrement process, a polyester / cotton fabric bleaching treatment process and other processes are combined with a dyeing process to form a one bath treatment process; and the dyeing temperature of one bath dyeing is reduced, reduction clearing processes of most of dyed fabrics are eliminated, water is saved by more than 60 percent, and electricity is saved by more than 30 percent.

Owner:杭州彩润科技有限公司

Fertilizer composition for improving stress resistance of land planted pear trees

ActiveCN103936500AStrong noveltyPracticalFertilizer mixturesArbuscular mycorrhizal fungiPhenylacetic acid

A fertilizer composition for improving stress resistance of land planted pear trees comprises arbuscular mycorrhizal fungi, betaine, salicylic acid, ethylenediamine-N,N'-bis(2-hydroxyphenylacetic acid) ferric-sodium complex (EDDHA-Fe), a chelate zinc fertilizer titanium zinc ethylenediaminetetraacetate, a promoter and fertilizers containing other elements. Contained arbuscular mycorrhizal fungi is capable of substantially improving stress resistance on drought, waterlogging disaster, salt and alkali, high temperature, heavy metal toxicity, toxic organics and the like of pear trees, and promoting absorption of soil mineral nutritional elements by soil. Betaine and salicylic acid are capable of inducing to improve crop resistance on adverse situations such as drought, freeze injury and the like.

Owner:SHANDONG INST OF POMOLOGY

Composition for preventing and treating fruit-cracking disease, sunscald and navel orange yellowing disease of crop fruits as well as preparation method thereof

The invention discloses a combination for prevention and cure of the disease of dehiscent fruit, sunscorch and yellow-navel disease. The combination is prepared with raw materials with the following weight percentage: 0.5-0.7 percent of EDDHA-Fe, 0.7-1.3 percent of EDTA zinc-titanium, 3.0-4.2 percent of EDTA manganese-titanium, 1.0-1.5 percent of EDTA calcium- titanium, 2.5-3.5 percent of high polymerized sulfonated naphthalene formaldehyde, 0.3-0.7 percent of EDTA titanium and 88-92 percent of deionized water. The invention has the advantages of that: 1) after the product is sprayed on the crops, the flexibility and expansion strength of the fruit skin can be improved, and the phenomenon of dehiscent fruit due to the poor flexibility of the fruit skin is avoided; besides, the effective constituents of the invention carry large quantity of moisture to penetrate from the foliages toward the fruits rapidly supplement the fruit moisture, and as a result, sunscorch is avoided; 2) the product is capable to enhance the adverse-resisting property of the plant, increase the anti-disease capability so that to achieve the effects of prevention and cure of dehiscent fruit, sunscorch and yellow-navel; 3) the invention is capable to improve the activity of microelements and enhance the microelement absorbing capacity of the plant.

Owner:徐风云

Nicotine-reducing potassium-increasing agent for cured tobacco and application method thereof

InactiveCN102807444ALower nicotine levelsUniform absorptionFertilizer mixturesEthylenediamineNicotiana tabacum

The invention discloses a nicotine-reducing potassium-increasing agent for cured tobacco and an application method thereof. The nicotine-reducing potassium-increasing agent for cured tobacco is composed of the components by weight: 0.2-3% of arginine, 0.3-7% of methionine, 2-7% of sodium silicomolybdate, 2-10% of P2O5, 2-9% of K2O, 0.01-1% of EDDHA (ethylenediamine di-2-hydroxyphenyl acetic acid)-Fe, 0.01-3% of EDTA (ethylenediamine tetraacetic acid)-Zn, 0.01-2% of EDTA-Mn, 0-2% of rapin lactone, 0-15% of sulfosalicylic acid, 0.1-10% of salicylic acid and the balance of water. A nicotine-reducing potassium-increasing composition for cured tobacco contains at least one of rapin lactone or 5-sulfosalicylic acid. According to the nicotine-reducing potassium-increasing agent for cured tobacco, nutritive elements, microelements for helping plants to absorb the nutritive elements and plant growth regulators for regulating plant growth are reasonably mixed, so that the element absorption and distribution of the tobacco are more balanced, the nicotine content of the cured tobacco is reduced, the potassium content of the cured tobacco is increased, the contents and ratio of nicotine and potassium in the cured tobacco conform to the requirements of high-quality cured tobacco, and the yield and quality of tobacco leaf are improved.

Owner:SOUTH CHINA AGRI UNIV +1

Liquid phase load type gas desulfurizing agent

ActiveCN102824823AEmission reductionImprove desulfurization effectDispersed particle separationSodium bicarbonateO-Hydroxyphenylacetate

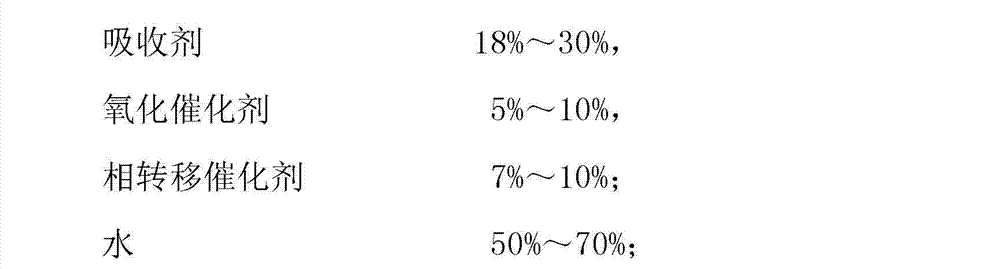

The invention relates to a liquid phase load type gas desulfurizing agent. The liquid phase load type gas desulfurizing agent comprises two components A and B, wherein the component A consists of absorbent (sodium carbonate and / or potassium carbonate and / or sodium bicarbonate and the like), oxidation catalyst (EDTA (ethylene diamine tetraacetic acid iron) and / or EDDHA (ethylenediamine di(O-hydroxyphenylacetate))-Fe and / or sulfonated cobalt phthalocyanine and the like), phase-transfer catalyst (methylamine or octylamine and the like) and water, and the component B adopts activated coke and / or activated carbon and / or semi coke and / or aluminium oxide and the like. Before packaging and transporting or constructing and loading, the component A is sprayed or sprinkled onto the component B to completely soak the component B or directly mixed with the component B, so the liquid phase load type gas desulfurizing agent is obtained. Compared with the prior art, the liquid phase load type gas desulfurizing agent has the advantages of less investment, high sulfur content, simplicity in operation, low operation cost, low energy consumption, good gaseous hydrogen sulfide removal effect, wide application scope and the like, and is used for effectively solving the problem of gaseous hydrogen sulfide removal during the gas purification process when synthesis gas, coke-oven gas, reservoir gas, shale gas and the like are produced or exploited.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Fruit and vegetable nutrient solution

InactiveCN108033842AFull of nutritionPromote growthMagnesium fertilisersAlkali orthophosphate fertiliserContinuous croppingPhosphate

The invention discloses a fruit and vegetable nutrient solution. The fruit and vegetable nutrient solution comprises a solution A and a solution B, wherein the solution A mainly consists of the following components: calcium nitrate, potassium nitrate, ethylenediamine-N,N'-bis(2-hydroxyphenylacetic acid) ferric-sodium complex (EDDHA-Fe), ethylene diamine tetraacetic acid disodium ferric salt (EDTA-Fe); and the solution B mainly consists of the following components: magnesium sulfate heptahydrate, potassium sulfate, potassium dihydrogen phosphate, manganese sulfate tetrahydrate, boric acid, zincsulfate heptahydrate, copper sulphate pentahydrate, and ammonium molybdate. The fruit and vegetable nutrient solution is rich in nutrients, does not contain harmful substances, promotes crop growth,is suitable for hydroponic and substrate culture, and is suitable for large-scale popularization; and the culture solution and matrix of the nutrient solution are easy to renew, and pathogenic bacteria are also easy to remove, so that disease and pest control and soil disinfection are almost not needed, and continuous cropping obstacle can be avoided.

Owner:贵州华以农业科技有限公司

Erythrocyte preservation fluid and preservation apparatus

InactiveCN109566602AReduce agglutinationLong storage timeDead animal preservationRed blood cellD-Glucose

The invention relates to an erythrocyte preservation fluid. The erythrocyte preservation fluid comprises the following components: 0.2-0.6mg / ml adenine, 20-50mg / ml glucose, 5-15mg / ml sodium citrate, 0.02-0.06mg / ml sodium dihydrogen phosphate, 1.0-3.0mg / ml anticoagulation agents, and 5-20mg / ml film protective agents, wherein the anticoagulation agents are selected from one or more of EDTA-3K and EDDHA salts. By the aid of the erythrocyte preservation fluid, the coagulability of erythrocytes in the preservation process can be reduced, erythrocyte preservation time can be prolonged, and erythrocyte hemolysis can be reduced.

Owner:NINGBO AJCORE BIOSCIENCES INC

Synergist and preparation method thereof

InactiveCN106748137AImprove compound effectImprove absorption and utilizationBiocidePlant growth regulatorsRhamnolipidBetaine

The invention discloses a synergist and a preparation method thereof. The synergist is prepared from the following raw materials in parts by weight: 0.5 to 5 parts of natural tea saponin, 0.1 to 1.0 part of rhamnolipid, 0.5 to 2 parts of glycine betaine, 4.9 to 8 parts of sulfomethylation humic acid, 2 to 4 parts of EDDHA chelating agent, 5 to 10 parts of complex carbohydrate, 1 to 5 parts of carapace and 0.5 to 1 part of a protective agent. The using amount of fertilizers and pesticides can be reduced by 30% to 50%, the absorption of fertilizers and pesticides is promoted, the problem of flocculent precipitate in fertilizer mixing process, fertilizer and pesticide mixing process and pesticide mixing process is solved, hard water is resisted, the crop growth is promoted, and the yield is improved.

Owner:SHANDONG ZHISHUN IMPORT & EXPORT CO LTD

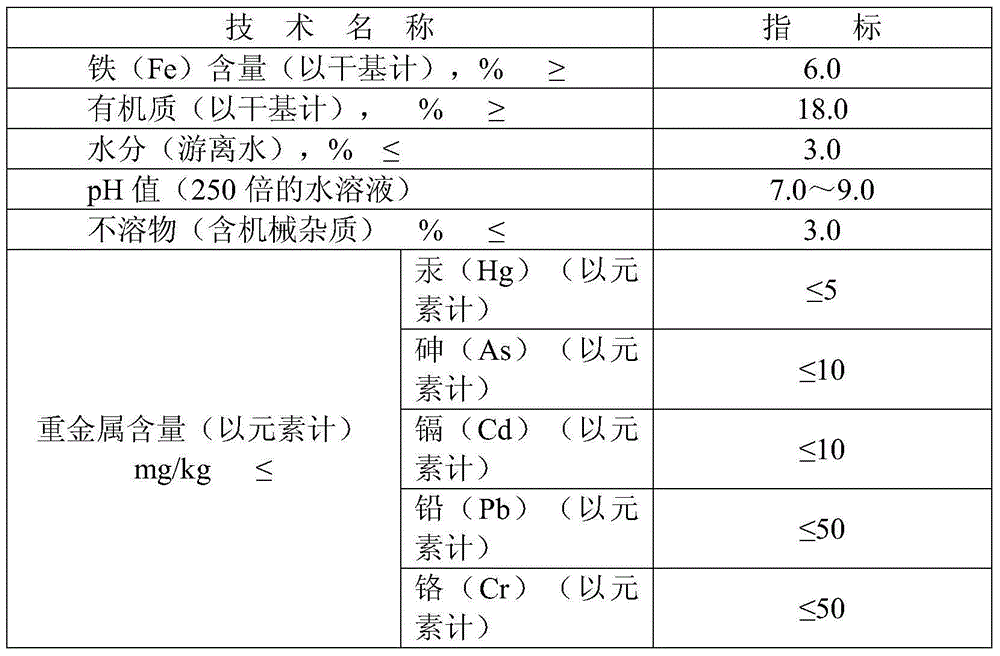

High-yield cultivation method of black rice

InactiveCN104285743AHas the function of strengthening the body and intelligenceEffective growth and developmentFertilising methodsLiquid fertilisersPhosphatePoultry manure

The invention discloses a high-yield cultivation method of black rice. The high-yield cultivation method includes before transplanting black rice seedlings, applying iron-rich base fertilizers into paddy fields and uniformly burying the same in soils during land preparation; spraying iron-rich leaf fertilizers at the initial stage of heading and flowering and the initial stage of filling of the rice, respectively. The iron-rich base fertilizer is composed of iron compound EDDHA powder, phosphate, poultry manure and green manure which are mixed and retted. The iron-rich leaf fertilizer is made by dissolving the iron compound EDDHA powder in the traditional Chinese medicine lixivium. By the use of the cultivation method, multiple chances are provided for the rice to take in the iron element from nutrition during growing, accordingly, the iron content of the rice is improved, and health care function is achieved. The black rice can be made in various rice foods, such as steamed rice, rice noodles, cakes, cookies and the like, without toxicity and side effects and is effective in improving human immunity.

Owner:广西博白县琼达农业科技有限公司

Organic fertilizer for promoting rapid growth of pinus massoniana and preparation method thereof

InactiveCN105859446APromote growthPrevent premature agingAlkali orthophosphate fertiliserExcrement fertilisersChelated zincInsect pest

The invention discloses an organic fertilizer for promoting rapid growth of pinus massoniana and a preparation method thereof. The problem that an existing fertilizer required by the pinus massoniana is mainly a nitrogen, phosphorus and potassium compound fertilizer, soil hardening is easily caused, the respiratory action of roots is reduced, plant diseases and insect pests and premature senility of the pinus massoniana are caused and accordingly the pinus massoniana grows slowly in the prior art is main solved. The preparation method of the organic fertilizer for promoting rapid growth of the pinus massoniana comprises the steps that firstly, cow dung, humus soil, basalt, nanometer cobalt, rape seed cakes and organic silicon are added to a fermentation tank, and then a fermentation material is obtained through fermentation and is dried; the dried fermentation material, sodium polyphosphate, limestone powder, borax, silicate fungicide, EDDHA chelated iron, amino acid chelated magnesium, amino acid chelated zinc, amino acid chelated copper, amino acid chelated boron and amino acid chelated manganese are evenly mixed and then the organic fertilizer is prepared. By the adoption of the scheme, the purpose of promoting the growth of the pinus massoniana is achieved.

Owner:重庆潭霖生态农业开发有限公司

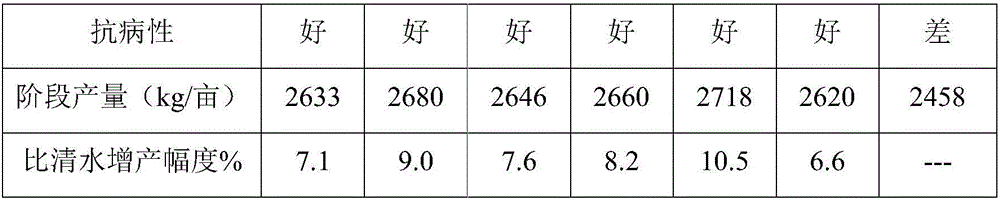

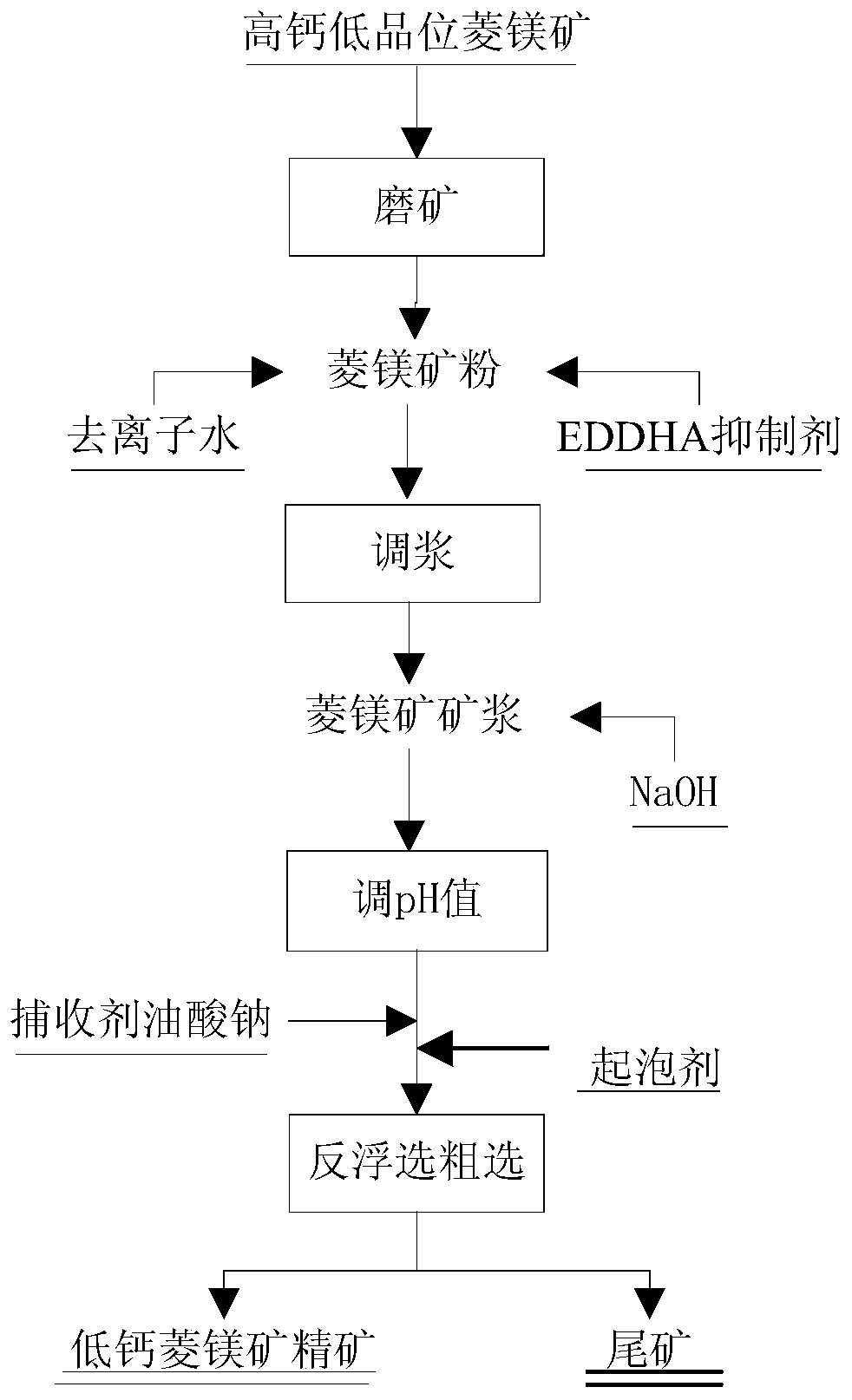

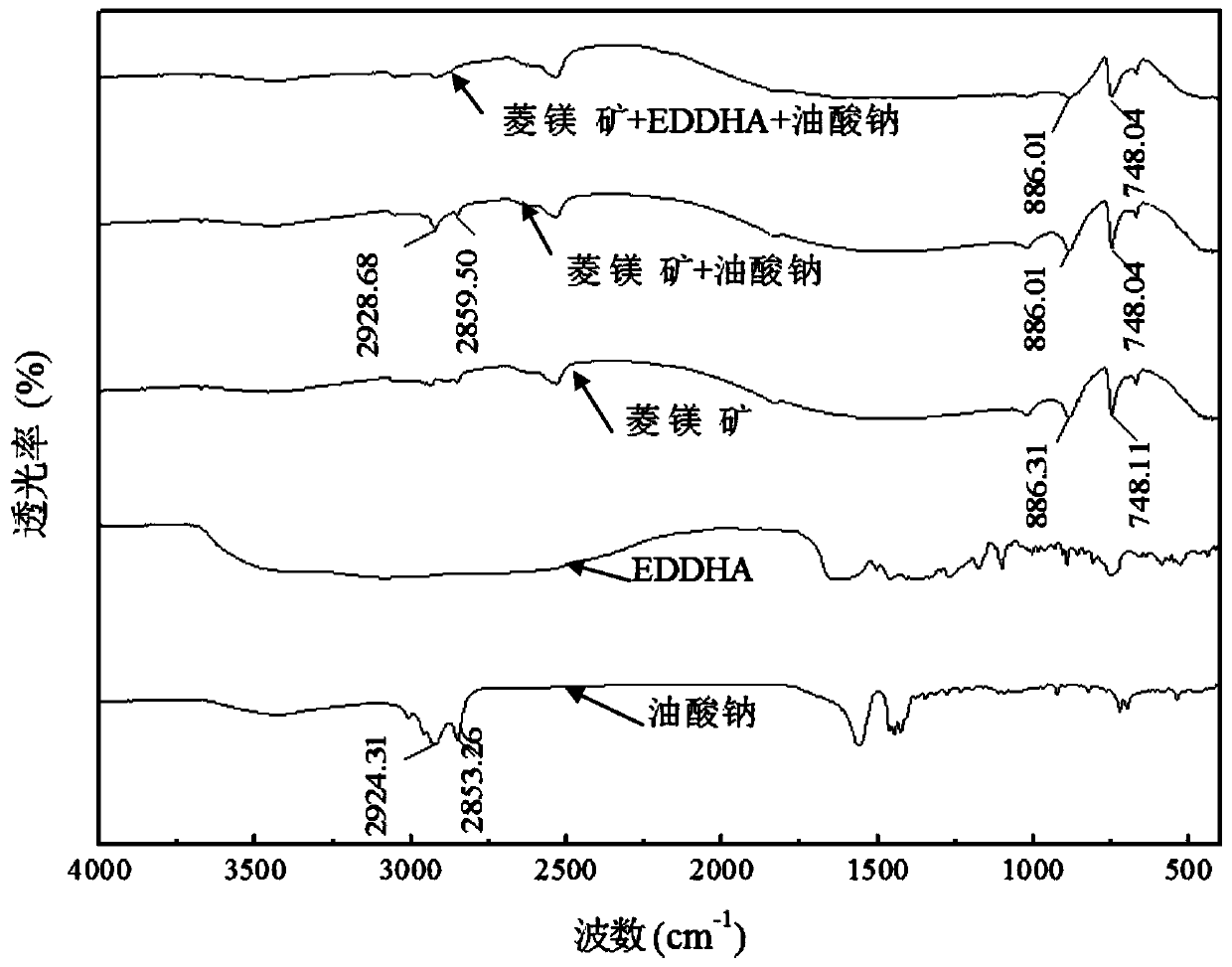

Method for reverse flotation decalcification of magnesite by adopting EDDHA inhibiting agents

InactiveCN110124851ASelective inhibitionShorten the flotation decalcification processFlotationDolomiteImpurity

The invention discloses a method for reverse flotation decalcification of magnesite by adopting EDDHA inhibiting agents, and belongs to the field of magnesite beneficiation and purification processes.In the method, low-grade high-calcium magnesite is crushed for ball milling; then, water and the EDDHA inhibiting agents are fed for pulping; the solid-liquid ratio of the EDDHA inhibiting agents tothe magnesite pulp is (60-90) mg: 1 L; and the mass concentration of the magnesite pulp is 10-30%. The pH value of the magnesite pulp is 10-12; sodium oleate is fed for reverse flotation and roughingdecalcification to obtain low-calcium magnesite concentrates; the recovery rate is 70-85%; and the recovery rate of MgO in the low-calcium magnesite concentrates is 65-85%. According to the floatability difference between the magnesite and impurity ores-dolomite in the magnesite under the effect of the EDDHA inhibiting agents, calcium ores in the magnesite are removed through the reverse flotationmethod, so that the quality of the magnesite is improved, and new agents are provided for beneficiation decalcification of the low-grade high-calcium magnesite.

Owner:NORTHEASTERN UNIV

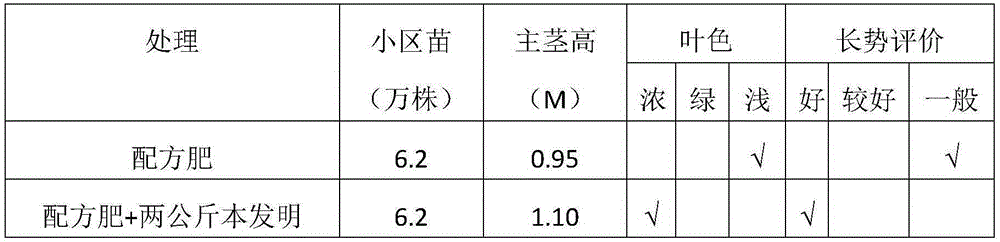

Formula fertilizer for promoting growth of rice

InactiveCN105875300AEffective growth and developmentHigh in seleniumRice cultivationFertilizer mixturesInorganic compoundPoultry manure

The invention discloses a formula fertilizer for promoting the growth of rice. Before the seedlings are transplanted, the selenium-rich base fertilizer is applied in the paddy field. The selenium-rich base fertilizer is made by mixing raw powder containing 6% EDDHA-Fe chelated iron, selenium inorganic compound sodium selenite, phosphate fertilizer, poultry manure and green manure. The selenium-enriched foliar fertilizer was sprayed once at the initial stage of heading and flowering of rice and the initial stage of grain filling respectively. The selenium-enriched foliage fertilizer is made by dissolving the selenium-containing inorganic compound sodium selenite in the leachate of traditional Chinese medicine. The invention enables the rice to have multiple opportunities to ingest selenium element from nutrition during the growth and development process, is beneficial to increase the selenium content of the rice, and has the function of health care. This kind of rice can be made into various rice foods, such as rice, rice noodles, cakes, biscuits, etc. It is non-toxic and has no side effects, and can enhance the immunity of the human body.

Owner:包宗辉

Dyeing auxiliary for blended yarn of wool and dacron

The invention relates to the field of dyeing auxiliaries, in particular to a dyeing auxiliary for blended yarn of wool and dacron. The dyeing auxiliary comprises tea polyphenol, borax, polyoxyethylene ether, branched heterogeneous alcohol ether, monoacetin, ethylene glycol butyl ether, sodium ferric EDDHA, tristyrylphenol polyoxyethylene ether ammonium sulfate and water. The dyeing auxiliary comprises, by mass, 2-5 parts of tea polyphenol, 5-10 parts of borax, 10-15 parts of polyoxyethylene ether, 3-5 parts of branched heterogeneous alcohol ether, 5-8 parts of monoacetin, 2-5 parts of ethylene glycol butyl ether, 1-2 parts of sodium ferric EDDHA, 3-6 parts of tristyrylphenol polyoxyethylene ether ammonium sulfate and 50-80 parts of water. The dyeing auxiliary for blended yarn of wool and dacron and dye are simultaneously added in the dyeing process, the color fastness of the blended yarn of the wool and the dacron can be effectively improved, dyeing is more even, stability is higher, and brightness can be kept longer.

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

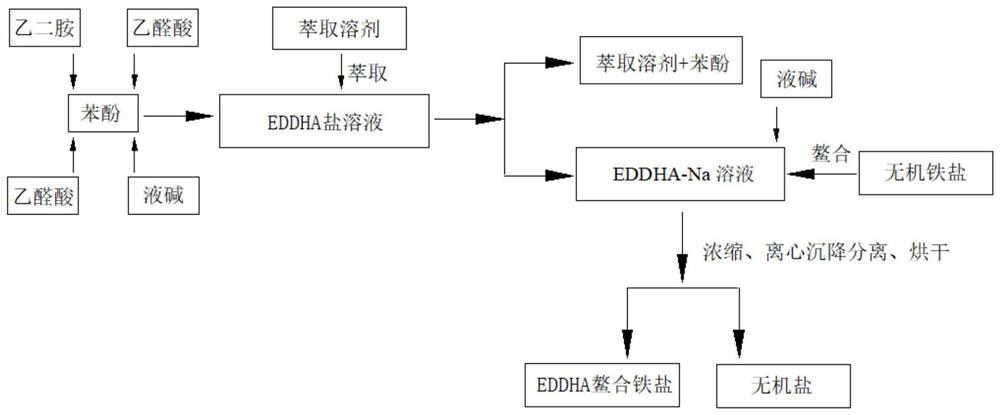

Preparation method of EDDHA chelated ferric salt

ActiveCN112778148AOrganic compound preparationAmino-carboxyl compound preparationChemical synthesisGlyoxylic acid

The invention relates to the technical field of chemical synthesis, and particularly discloses a preparation method of EDDHA chelated ferric salt. The preparation method of the EDDHA chelated ferric salt comprises the following process steps of: a, heating phenol to 40-70 DEG C, adding ethylenediamine and glyoxylic acid, and uniformly mixing to obtain an initial mixed material; b, adding glyoxylic acid and an alkaline aqueous solution into the initial mixed material to obtain a reaction raw material mixture; c, heating the reaction raw material mixture to 60-90 DEG C for reaction, and extracting a reaction product by using an extracting solvent to obtain an EDDHA salt solution; d, carrying out chelation reaction on the EDDHA salt solution and inorganic ferric salt to obtain an EDDHA chelated ferric salt solution; and e, carrying out concentration, centrifugal separation and drying treatment on the EDDHA chelated ferric salt solution to obtain the EDDHA chelated ferric salt. According to the preparation method of the EDDHA chelated ferric salt, provided by the invention, the EDDHA chelated ferric salt with high purity and high quality can be obtained.

Owner:HEBEI CHENGXIN

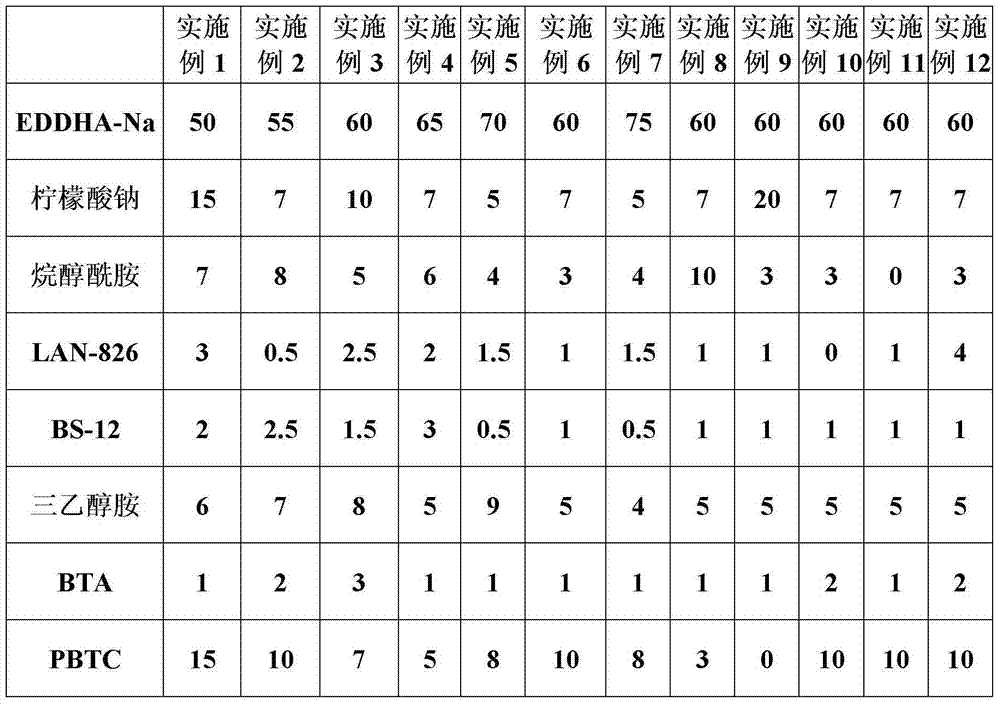

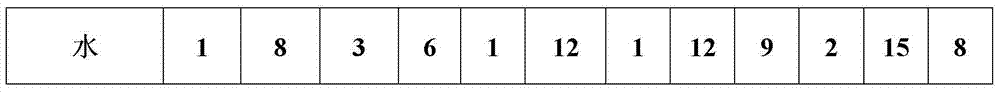

Cleaning agent for engine circulating cooling system, and preparation method and cleaning method thereof

InactiveCN103756804AWill not corrodeImprove anti-corrosion abilityAnionic-cationic-non-ionic surface-active compoundsMachines/enginesEngineeringCleaning methods

The invention provides a cleaning agent for an engine circulating cooling system, and a preparation method and a cleaning method thereof. The cleaning agent for the engine circulating cooling system contains 50-70% of EDDHA-Na, 5-15% of sodium citrate, 3-8% of alkanolamide, 0.5-3% of LAN-826, 0.5-3% of BS-12, 5-10% of triethanolamine, 1-3% of BTA, 5-15% of PBTC and 0-20% of water by weight. The cleaning agent is low-cost, effective, easy to manage, safe to use, simple and convenient to operate, and wide in application range; the cleaning agent has remarkable effects in the aspects, such as maintaining safety of the cooling system, recovering original performance of equipment, prolonging service life of the engine and saving energy. The cleaning agent can be used for cleaning engine circulating cooling water path, and has good corrosion inhibition and corrosion prevention function.

Owner:王盛

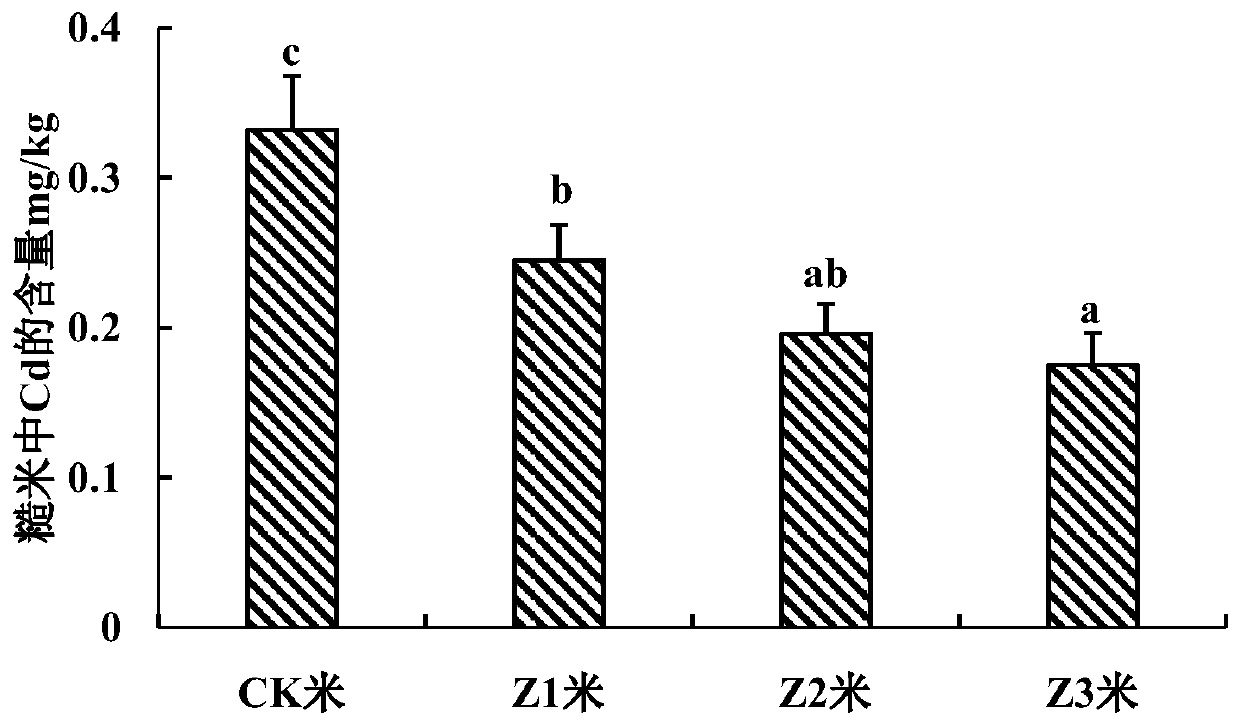

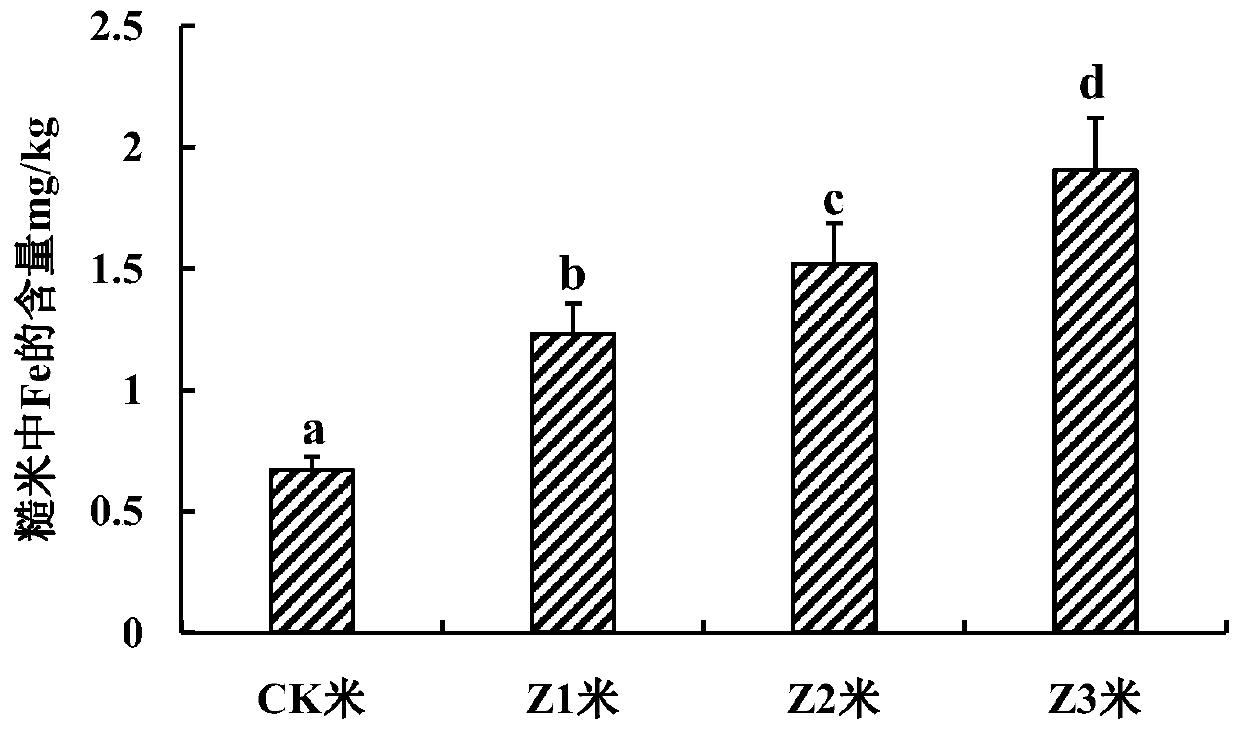

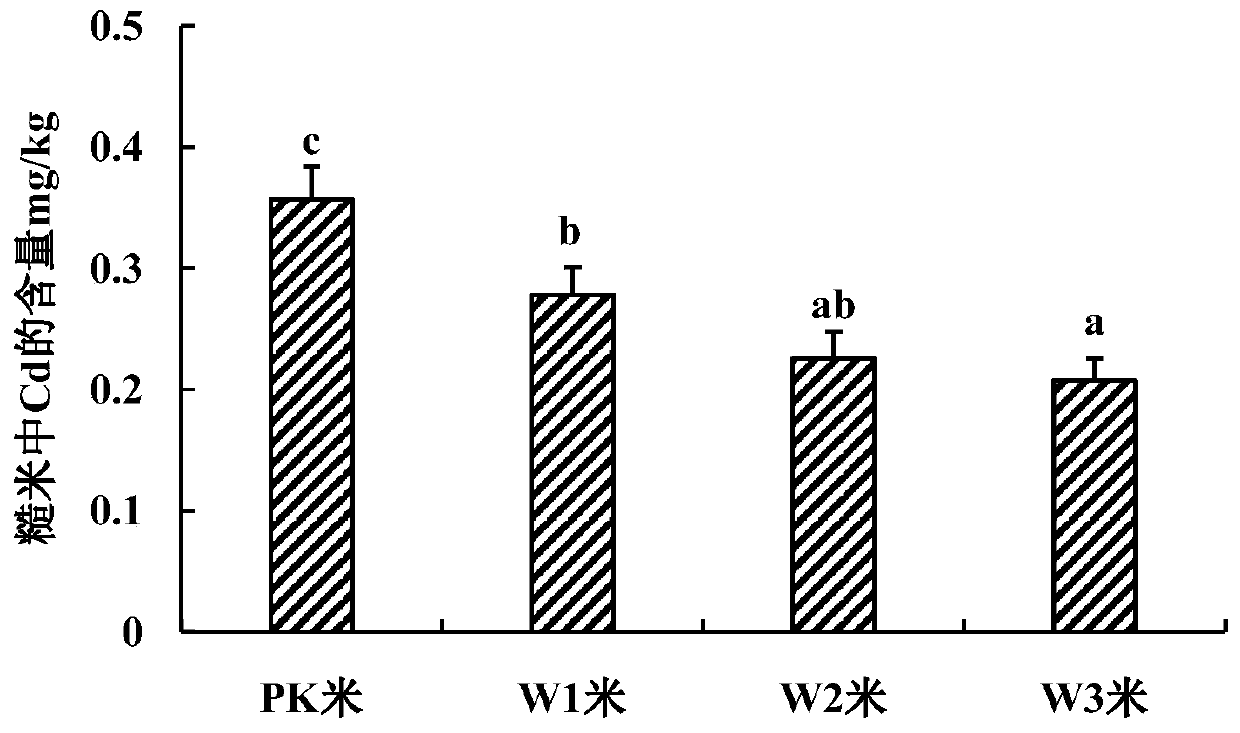

Rice leaf fertilizer capable of increasing yield and reducing cadmium and using method of rice leaf fertilizer

PendingCN110156519APromote photosynthesisImprove toleranceMagnesium fertilisersAlkali orthophosphate fertiliserPotassium nitrateAcetic acid

The invention relates to the fields of fertilizers and rice planting and specifically relates to a rice leaf fertilizer capable of increasing the yield and reducing cadmium. The rice leaf fertilizer comprises the following raw materials in parts by mass: 10-20 parts of EDDHA iron, 5-10 parts of urea, 1-5 parts of potassium nitrate, 1-5 parts of stabilizer, 0.5-2 parts of indoleacetic acid, 0.1-1 part of monopotassium phosphate, 0.1-0.5 part of sodium borate and 0.1-1 part of magnesium sulfate. The rice leaf fertilizer provided by the invention is obtained by multi-year repeated proportioning and experimenting and is capable of making up defects of an existing leaf fertilizer, increasing the content of an iron element in rice while effectively increasing the yield of rice and also remarkably reducing the content of a cadmium element as a heavy metal in the rice so as to have an obvious effect on increasing the yield and improving the quality of the existing rice.

Owner:HUNAN AGRICULTURAL UNIV

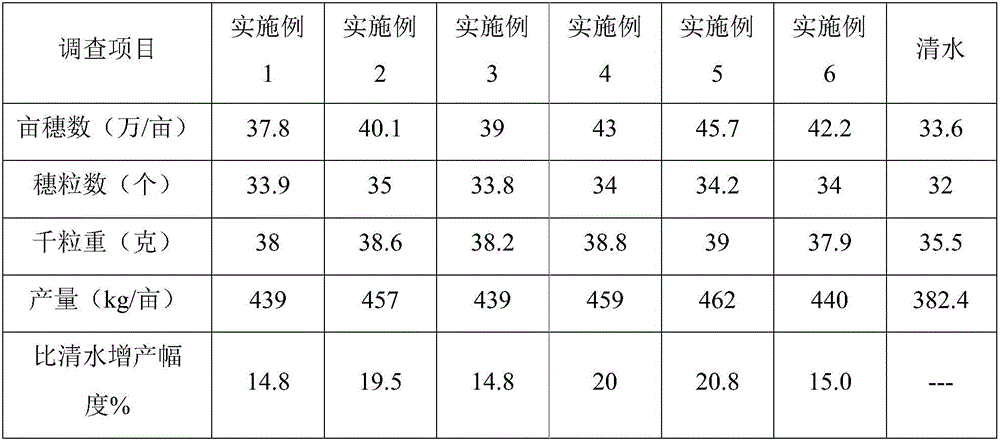

Formula fertilizer capable of promoting growth of paddy rice

InactiveCN105884556AEffective growth and developmentHigh in seleniumFertilizer mixturesInorganic compoundGreen manure

The invention discloses a formula fertilizer capable of promoting the growth of paddy rice. Before transplanting seedlings, a selenium enriched base fertilizer is applied to the paddy fields. The selenium enriched base fertilizer is prepared by mixing and composting EDDHA-Fe raw powder with a chelated iron content of 6%, a selenium inorganic compound (sodium selenite), phosphate fertilizer, manures of livestock and cattle, and green manure; and the base fertilizer is evenly sprayed and buried in soil during soil preparation. The selenium enriched foliar fertilizer is sprayed for once in the initial stage of head sprouting and flowering of paddy rice and the initial stage of grouting. The selenium enriched foliar fertilizer is prepared by dissolving a selenium containing inorganic compound (sodium selenite) into traditional Chinese medicine leachate. Through the technical scheme mentioned above, paddy rice can absorb the selenium element for many times during the growth period, the root of paddy rice becomes strong, the number of seedlings is increased, the rice spikes are plump, and the performance on resisting diseases and pests is enhanced.

Owner:包春妹

Preparing process of EDDHA-Fe (ethydiaminedhephen acetic-Fe)

InactiveCN104817469ASimple production processReduce manufacturing costOrganic compound preparationAmino-carboxyl compound preparationBrown iron oxidePotassium permanganate

The invention discloses a preparing process of EDDHA-Fe (ethydiaminedhephen acetic-Fe). The preparing process includes the steps of 1, weighing the materials by weight, dissolving phenol in water as heavy as the same, adding potassium permanganate, ethylene diamine solution, glyoxylic acid solution and sodium hydroxide solution in order at the temperature of 55 DEG C to 60 DEG C, with the sodium hydroxide solution accounting for 5 / 11 of the total quantity of the sodium hydroxide solution, and performing mixing to obtain EDDHA-Na solution; 2, heating the EDDHA-Na to 90 DEG C to 95 DEG C, adding the sodium hydroxide solution and iron oxide powder, and holding the temperature for 2h to obtain EDDHA-Fe solution, with the added sodium hydroxide solution accounting for 6 / 11 of the total quantity of the sodium hydroxide solution. The preparing method has the advantages that the cost is low, no three wastes or pollution occurs during generation, and the prepared EDDHA-Fe has the effect of improving growth and fruiting yield of crops.

Owner:YANGLING YIMIAO AOHE TECH CO LTD

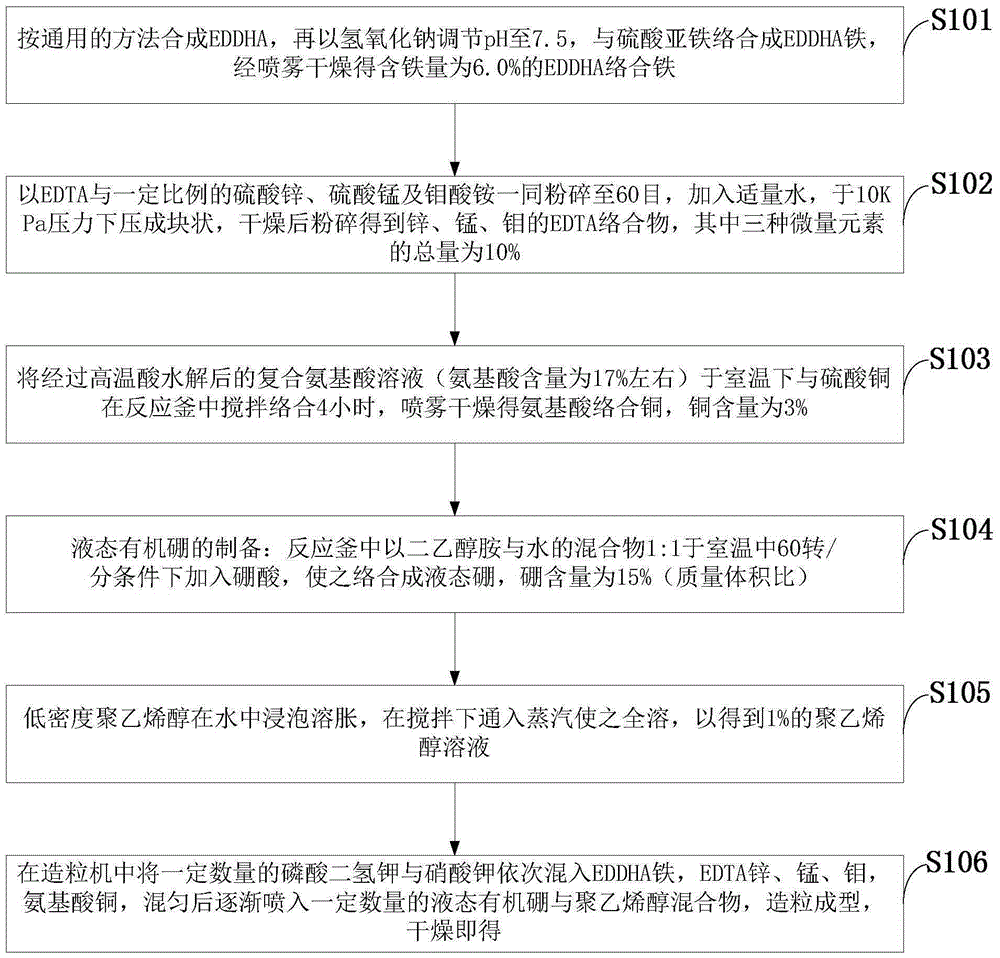

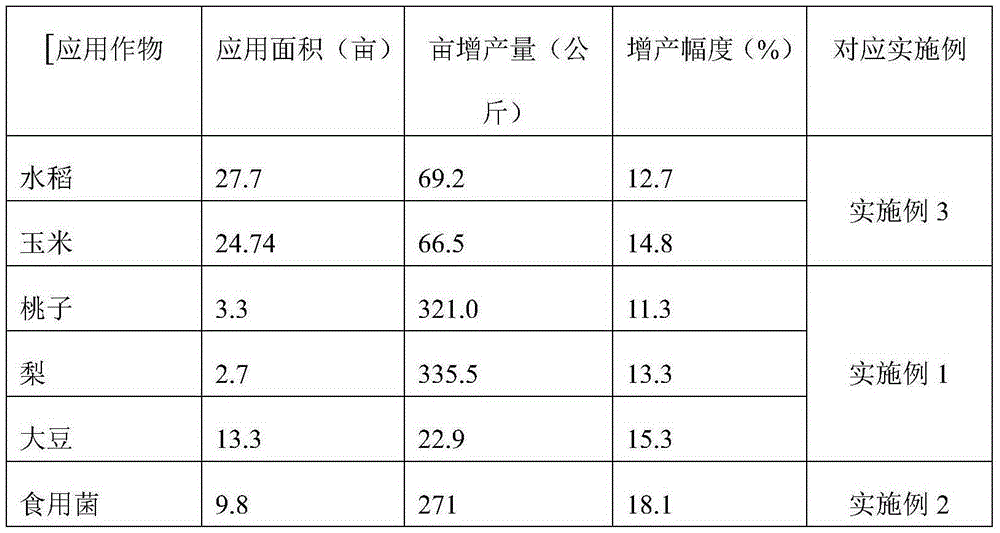

Complete complex fertilizer and production method thereof

InactiveCN105272567ASupplementary flexiblePromote absorptionFertilizer mixturesPolyvinyl alcoholPhosphate

The invention discloses a complete complex fertilizer and a production method thereof. The complete complex fertilizer comprises, in percent by mass, 30-60 parts of potassium dihydrogen phosphate, 30-60 parts of potassium nitrate, 1-5 parts of EDDHA iron,1-5 parts of EDTA zinc-manganese-molybdenum, 1-5 parts of copper amino acid,1-5 parts of liquid complex organic boron, and 1-5 parts of a polyvinyl alcohol solution with the concentration of 1%. The production method for the complete complex fertilizer comprises the following steps: mixing potassium dihydrogen phosphate and potassium nitrate successively with EDDH iron, EDTA zinc-manganese-molybdenum and copper amino acid in a granulator, uniformly mixing, then gradually spraying a mixture of liquid organic boron and polyvinyl alcohol, and performing granulation molding and drying, so as to obtain the complete complex fertilizer. The fertilizer contains macroelements and also contains medium and trace elements subjected to complexing, is high in nutrient utilization rate, diverse in usage manner, wide in usage scope and flexible for trace-element supplement, the ratio of trace elements can be flexibly adjusted according to the soil element lacking status and demands of different crops on trace elements, and the fertilizer is well applicable to soil testing and fertilizer recommendation.

Owner:SICHUAN TONGFENG TECH

Organic titanium calcium fertilizer and preparation method thereof

InactiveCN102584485AHigh in calciumSimple and fast operationFertilizer mixturesDistilled waterTitanium

The invention discloses an organic titanium calcium fertilizer which is prepared by taking the following materials in proportion: 800-1200ml distilled water, 5-100g organic titanium chelate, 40-200g glucose, 0-80g humic acid, 900-1600g calcium acetate and 300-1000g EDDHA chelant. A preparation method thereof comprises the following steps: 1) adding all components in proportion into distilled water, and stirring, thereby obtaining a uniform solution; 2) heating the solution at 40-65 DEG C for 1-2 hours; 3) reacting for 2-4 hours at 40-50 DEG C; and 4) after completely reacting, cooling for 1-1.5 hours, thereby obtaining the organic titanium calcium fertilizer. According to the physiological chrematistics and calcium-absorbing chrematistics of crops, the organic titanium chelate and the matters containing calcium ions are mixed, and then organic matters are added, and the chelation is further performed, so as to form a water-soluble active calcium, so that the organic titanium calcium fertilizer is suitable for fruit trees, vegetables and calcium-loving crops for efficiently absorbing calcium and overcomes the acalcicosis.

Owner:徐伟

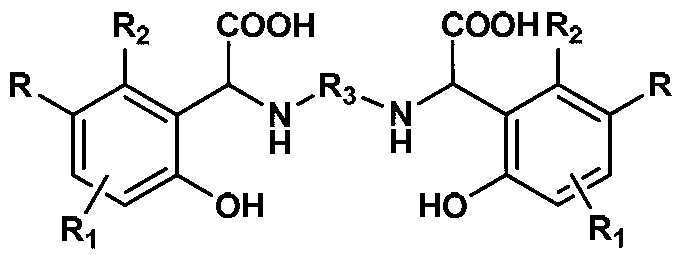

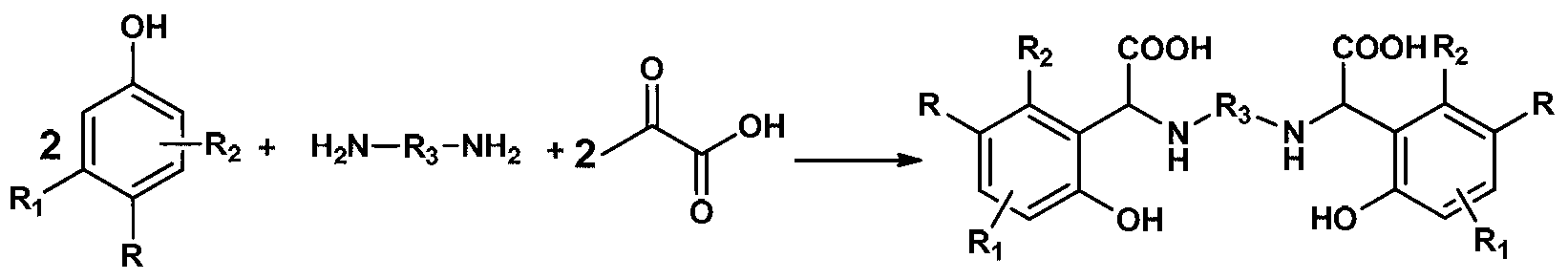

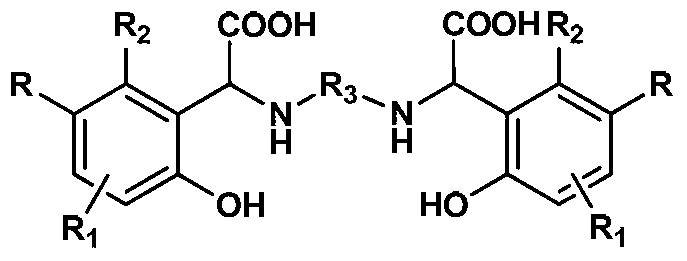

Chelating agent with high stability and high iron chelating ability and preparation method thereof

ActiveCN103304435AOvercoming the cumbersome synthesis stepsOvercome yieldOrganic compound preparationAmino-carboxyl compound preparationEthylenediamineMannich reaction

The invention relates to a chelating agent with high stability and high iron chelating ability and a preparation method thereof. The chelating agent is a target compound which is prepared from phenol derivatives, aliphatic diamine and glyoxalic acid aqueous solution serving as initial materials by mannich reaction in a one-step synthesis manner. By adopting the preparation method disclosed by the invention, the defects of fussy synthesis steps, low yield and poor selectivity of the traditional chelating agents such as EDDHA (ethylenediamine-N,N'-diacetic acid) are overcome; and the obtained chelate has higher stability and iron chelating ability relative to EDTA (ethylene diamine tetraacetic acid) and EDDHA.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Instant fruit swelling whole-process nutrition formula fertilizer for fruit trees

The invention discloses an instant fruit swelling whole-process nutrition formula fertilizer for fruit trees. The instant fruit swelling whole-process nutrition formula fertilizer comprises nitrogen, phosphorus pentoxide, potassium oxide, medium elements and trace elements. The medium elements include calcium, magnesium and sulfur, and the trace elements include boron, zinc, manganese and iron. The instant fruit swelling whole-process nutrition formula fertilizer has the advantages that the types and the quantities of nutrition elements required by growth of the fruit trees are provided according to research results of nutrition diagnosis on the fruit trees, the quantities of the nutrition elements required by the fruit trees in different growth periods are provided according to annual growth and development laws of the fruit trees, the sustained-release time and the controlled-release time of the nutrition elements are provided according to fertilizer application intervals, and full-nutrition formula fertilizer schemes are ultimately reasonably determined; the high-quality amide and nitrate nitrogen, water-soluble phosphate fertilizers and high-quality potash fertilizers are applied, and accordingly nitrogen, phosphorus and potassium nutrition can be provided for the fruit trees; EDTA (ethylene diamine tetraacetic acid) and EDDHA are subjected to complexing with the medium elements and the trace elements such as the zinc, the manganese, the iron, copper, the magnesium and the calcium, high-quality boric acid and the like, accordingly, the full-nutrition formula fertilizer which can meet nutrient requirements can be produced by the aid of processes for manufacturing compound fertilizers, the water solubility of the formula fertilizer can reach 90% at least, the duration of the formula fertilizer is 3-6 months, and the total nutrient content of the formula fertilizer is higher than 45%.

Owner:赵堃

Corrosion-resistant and rust-proof cleaning agent for metal equipment

A corrosion-resistant and rust-proof cleaning agent for metal equipment is prepared from raw materials in parts by weight as follows: 4-7 parts of halogenated hydantoin, 1.6-3.2 parts of molybdate, 4-8 parts of a surfactant, 5-7 parts of sodium lauryl sulfate, 2.5-5.5 parts of EDDHA-Na, 15-25 parts of sodium thiosulfate, 3-5 parts of sodium hydroxide, 2-4 parts of sucralose, 2.5-3.5 parts of an adsorbent, 2-7 parts of an organic silicon defoamer, 3-6 parts of polyethylene, 2-7 parts of calcium stearate, 3.5-4.5 parts of dodecane phenol polyoxyethylene and 2-4 parts of a flame retardant. The cleaning agent has the benefits as follows: the corrosion-resistant and rust-proof cleaning agent has excellent cleaning and corrosion-resistant performance and can delay corrosion to the equipment and prolong the service life effectively.

Owner:QINGDAO QIYUAN ZHENDONG ELECTRIC

Water-soluble solid organic complexed microelement fertilizer used for improving secondary salinization land, and production method thereof

InactiveCN106396872AGood water solubilityPromote growthBio-organic fraction processingMagnesium fertilisersSolubilityPotassium hydroxide

The invention discloses a water-soluble solid organic complexed microelement fertilizer used for improving secondary salinization land. The water-soluble solid organic complexed microelement fertilizer comprises, by mass, 1000-1500 parts of iron EDDHA, 1000-1300 parts of sodium alginate, 1000-1500 parts of zinc EDTA, 800-1200 parts of phosphorus ore powder, 1200-1800 parts of liquid complexed organic boron, 35-50 parts of potassium hydroxide, 10-20 parts of citric acid, 50-80 parts of magnesium sulfate, 60-90 parts of a compound enzyme preparation and 30-60 parts of ferment bacteria. The water-soluble solid organic complexed microelement fertilizer has the advantages of good water solubility, soil improvement, supplementation of trace elements, balancing of crop nutrients, fertilizer effect enhancement, growth promotion, good adversity resistance, and improvement of the yield and the quality of crops, can well cooperate with other compound fertilizers, and especially can be conveniently flexibly blended according to the practical needs of land and the growth of crops in order to realize great use convenience.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Composition useful in metal sulfide scale removal

ActiveUS20210102300A1Avoid it happening againSafe metal sulfide dissolutionPropanoic acidSulfide compound

The present invention discloses a method and a composition for removing metal sulfide scale present on the surface of a metal, said method comprising:providing a liquid composition comprising:a chelating agent and a counterion component selected from the group consisting of: sodium gluconate; gluconic acid; tetrasodium EDTA; EDTA; propylenediaminetetraacetic acid (PDTA); nitrilotriacetic acid (NTA); N-(2-hydroxyethyl) ethylenediaminetriacetic acid (HEDTA); diethylenetriaminepentaacetic acid (DTPA); hydroxyethyliminodiacetic acid (HEIDA); cyclohexylenediaminetetraacetic acid (CDTA); diphenylaminesulfonic acid (DPAS); ethylenediaminedi(o-hydroxyphenylacetic) acid (EDDHA); glucoheptonic acid; gluconic acid; oxalic acid; malonic acid; succinic acid; glutaric acid; adipic acid; pimelic acid; suberic acid; azelaic acid; sebacic acid; phthalic acid; terephthalic acid; aconitic acid; carballylic acid; trimesic acid; isocitric acid; citric acid; L-glutamic acid-N,N-diacetic acid (GLDA); salts thereof; and mixtures thereof; andan aldehyde; andwaterexposing a surface contaminated with said metal sulfide scale to the liquid composition;allowing sufficient time of exposure to remove said metal sulfide scale from the contaminated surface and sequestration of the sulfur ions from solution.

Owner:DORF KETAL CHEM FZE

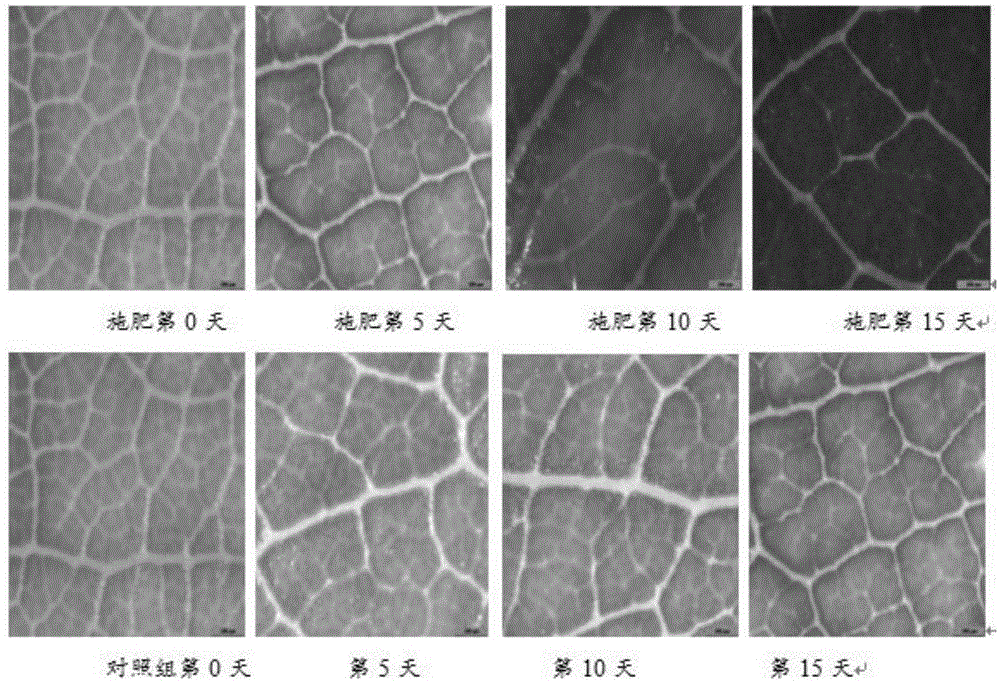

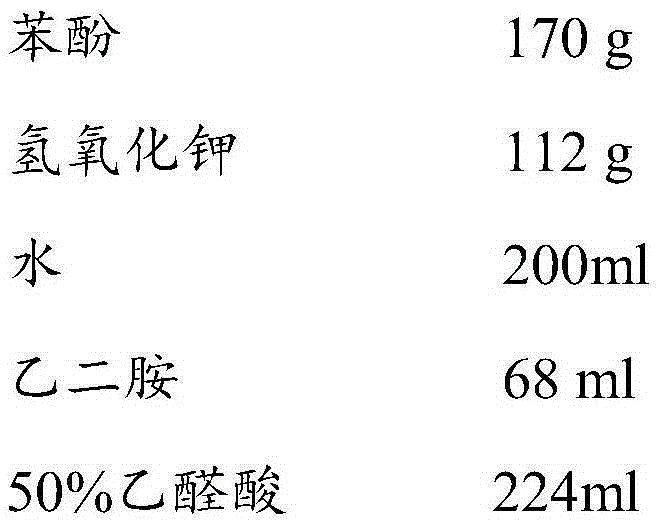

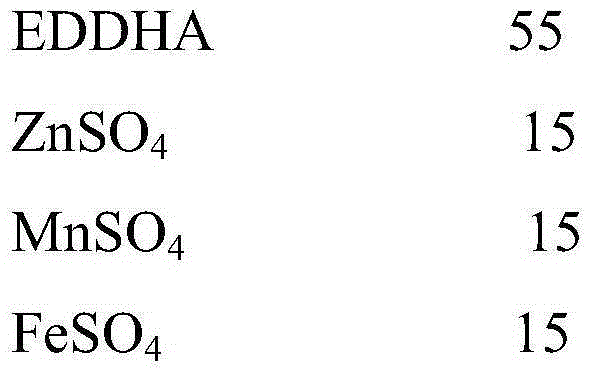

EDDHA chelated organic micro-fertilizer and preparation method thereof

InactiveCN105315088AImprove stabilityIncrease profitFertilizer mixturesSolubilityPotassium hydroxide

The invention provides an EDDHA chelated organic micro-fertilizer and a preparation method thereof. The method comprises the following steps: mixing and heating 150-200g of phenol, 200-500ml of water and 56-112g of potassium hydroxide to 65-75 DEG C; sequentially dropwise adding 50-80ml of ethidene diamine and 200-250ml of 50% glyoxylic acid in a stirring state, and lastingly heating and stirring for 1-2 hours after dropwise adding is ended, so as to obtain a synthetic EDDHA solution; adding microelements to water in a form of a soluble salt in a room-temperature condition, so as to obtain 0.3-0.5mol / L of microelement ionic solution; heating the obtained 400-700ml of EDDHA solution to 65-75 DEG C, adding 100ml of microelement ionic solution in the stirring state, further stirring for 1-2 hours after dropwise adding is ended, and supplementing 200ml of water until the volume reaches 1L, so as to obtain the EDDHA chelated organic micro-fertilizer in a liquid state or a solid state. The EDDHA chelated organic micro-fertilizer provided by the invention is a compound with high stability containing a plurality of microelements, has unique ultrahigh permeability and solubility in water, is not easy to run off, simple in preparation method and applicable to industrial production, and is easily absorbed by plants.

Owner:SICHUAN TONGFENG TECH

Method for directly preparing battery-grade lithium carbonate

ActiveCN110615453AComplexing ability unchangedDecreased or invalid complexation abilityLithium carbonates/bicarbonatesLithium carbonateImpurity

The invention provides a method for directly preparing battery-grade lithium carbonate, which comprises the following steps: 1) adding a sodium hydroxide solution into a lithium-containing solution tomake the pH value of the whole solution reach 12 or above, thus removing impurity metal ions in the solution, and filtering the solution to obtain a first refined lithium solution; 2) adding dilute acid into the first refined lithium solution, and adjusting the pH value to be less than or equal to 3 to obtain a second refined lithium solution; 3) adding a chelating agent into the second refined lithium solution, and then adding a sodium hydroxide solution to adjust the pH value of the solution to 6-8 to obtain a third refined lithium solution; and 4) adding a sodium carbonate solution into the third refined lithium solution, heating the third refined lithium solution to form a precipitate, and filtering the solution, and washing and drying the obtained precipitate to obtain the battery-grade lithium carbonate. According to the method, dilute acid is used for reversely adjusting the pH value, then EDDHA-Na is used for complexing metal impurity elements, then NaOH is used for reverselyadjusting the pH value, residual metal impurity elements are well removed, and the purity of lithium carbonate is improved.

Owner:GUANGZHOU TINCI MATERIALS TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com