Patents

Literature

102 results about "Pimelic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pimelic acid is the organic compound with the formula HO₂C(CH₂)₅CO₂H. Derivatives of pimelic acid are involved in the biosynthesis of the amino acid called lysine. Pimelic acid is one CH₂ unit longer than a related dicarboxylic acid, adipic acid, a precursor to many polyesters and polyamides. It is the final member of the mnemonic used to aid recollection of the order of the first six dicarboxylic acids using their common (not IUPAC) nomenclature: Dicarboxylic acid...

Organisms for the production of cyclohexanone

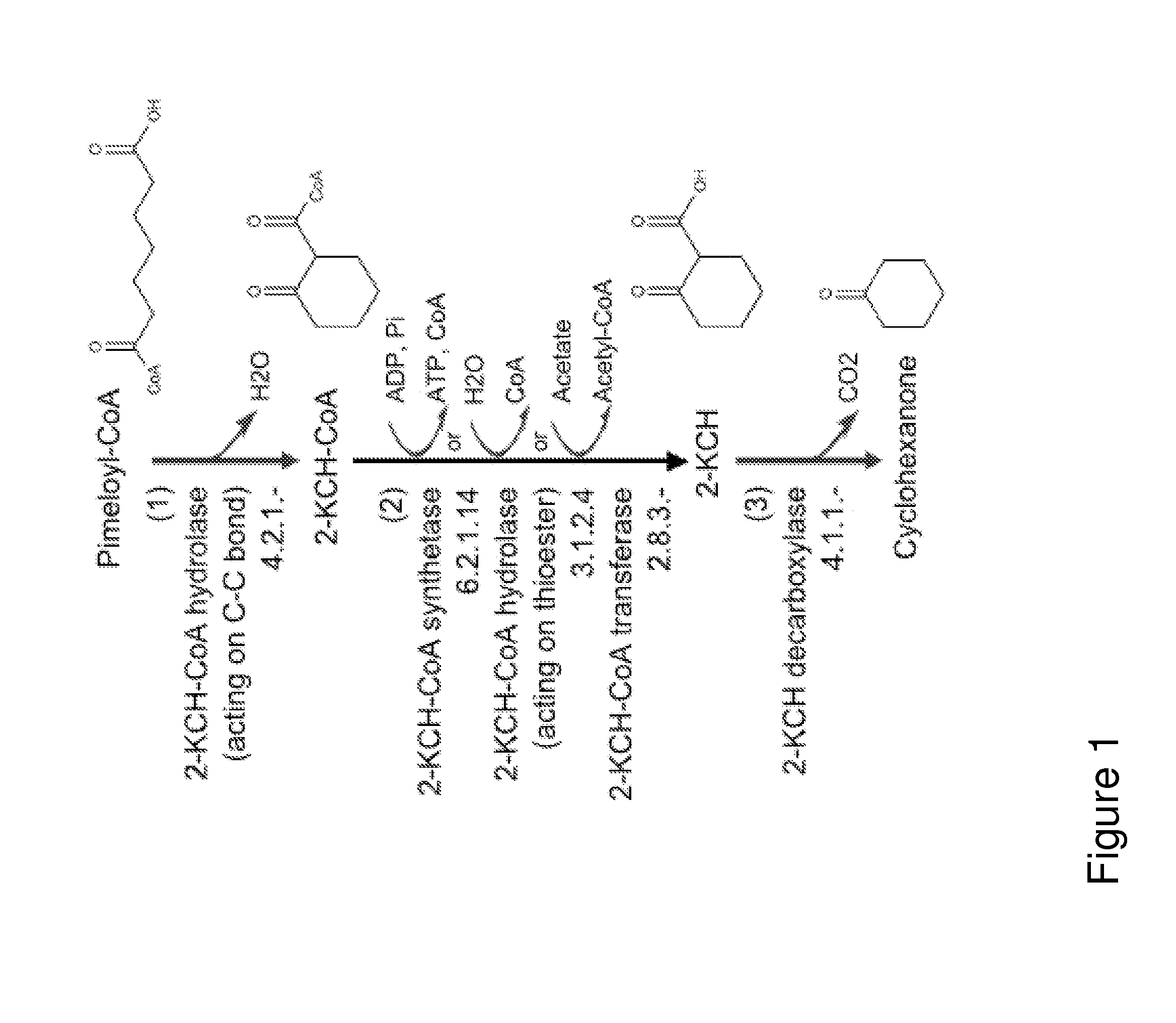

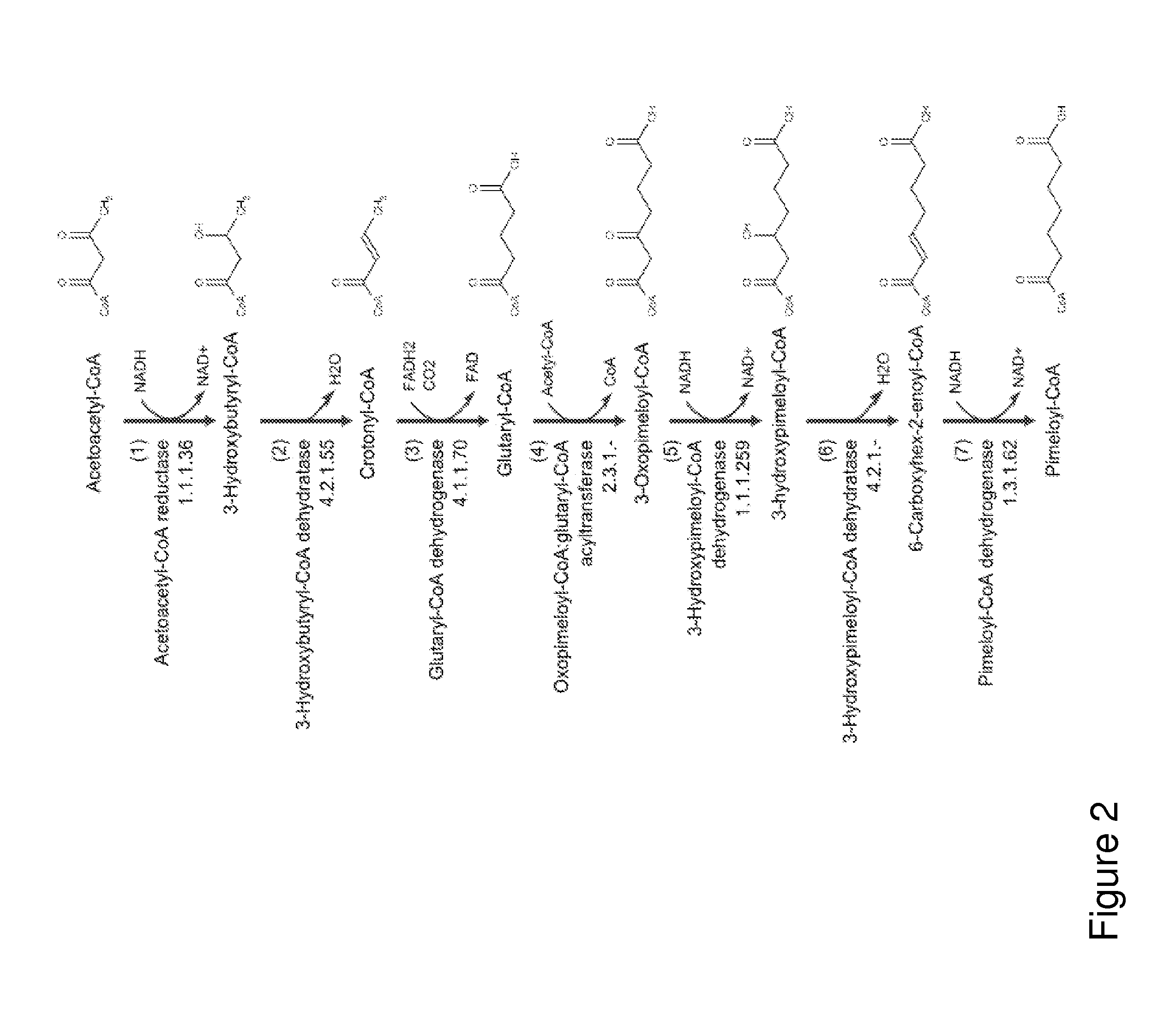

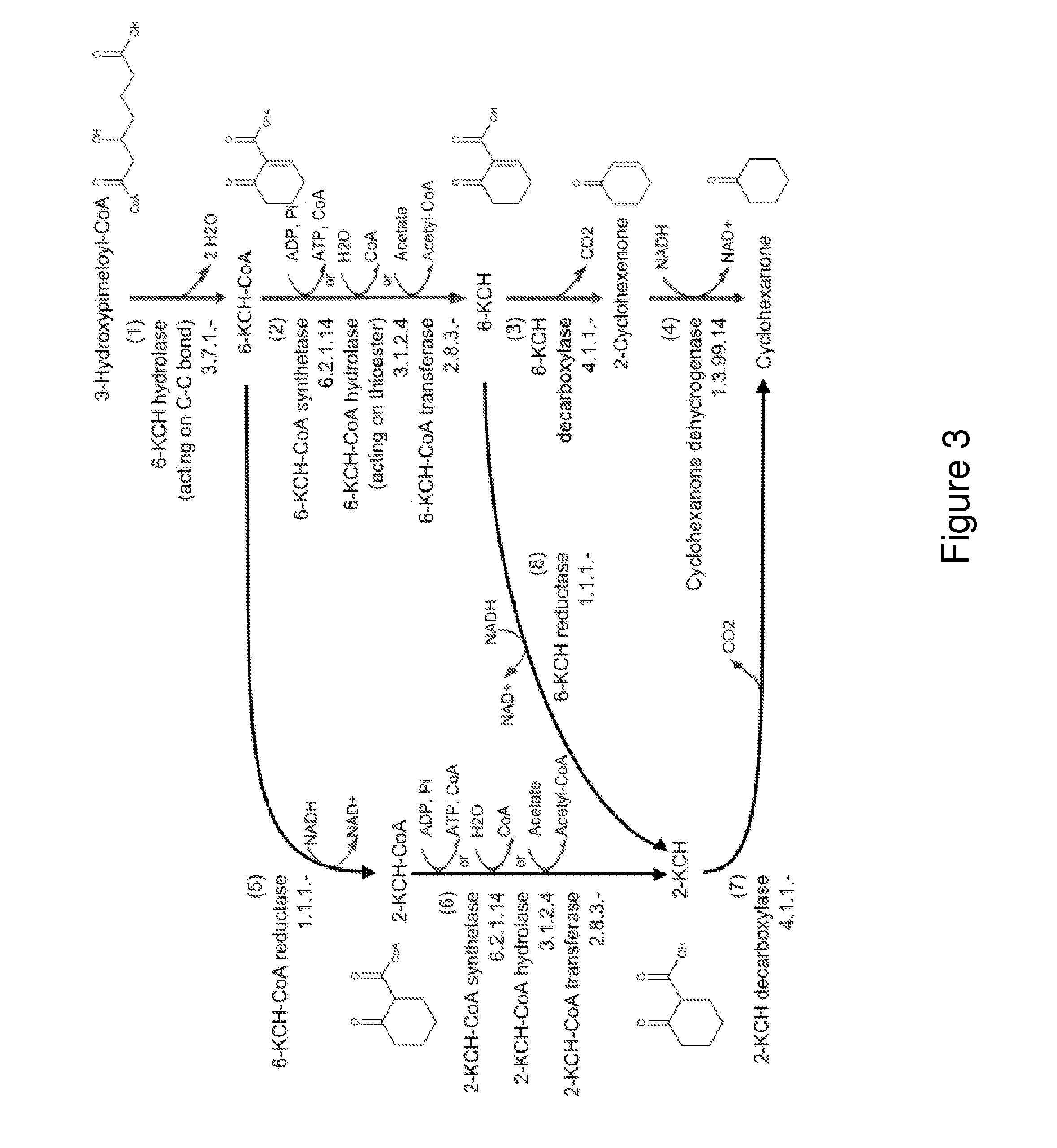

A non-naturally occurring microbial organism has cyclohexanone pathways that include at least one exogenous nucleic acid encoding a cyclohexanone pathway enzyme. A pathway includes a 2-ketocyclohexane-1-carboxyl-CoA hydrolase (acting on C—C bond), a 2-ketocyclohexane-1-carboxylate decarboxylase and an enzyme selected from a 2-ketocyclohexane-1-carboxyl-CoA hydrolase (acting on thioester), a 2-ketocyclohexane-1-carboxyl-CoA transferase, and a 2-ketocyclohexane-1-carboxyl-CoA synthetase. A pathway includes an enzyme selected from a 6-ketocyclohex-1-ene-1-carboxyl-CoA hydrolase (acting on C—C bond), a 6-ketocyclohex-1-ene-1-carboxyl-CoA synthetase, a 6-ketocyclohex-1-ene-1-carboxyl-CoA hydrolase (acting on thioester), a 6-ketocyclohex-1-ene-1-carboxyl-CoA transferase, a 6-ketocyclohex-1-ene-1-carboxyl-CoA reductase, a 6-ketocyclohex-1-ene-1-carboxylate decarboxylase, a 6-ketocyclohex-1-ene-1-carboxylate reductase, a 2-ketocyclohexane-1-carboxyl-CoA synthetase, a 2-ketocyclohexane-1-carboxyl-CoA transferase, a 2-ketocyclohexane-1-carboxyl-CoA hydrolase (acting on thioester), a 2-ketocyclohexane-1-carboxylate decarboxylase, and a cyclohexanone dehydrogenase. A pathway includes an adipate semialdehyde dehydratase, a cyclohexane-1,2-diol dehydrogenase, and a cyclohexane-1,2-diol dehydratase. A pathway includes a 3-oxopimelate decarboxylase, a 4-acetylbutyrate dehydratase, a 3-hydroxycyclohexanone dehydrogenase, a 2-cyclohexenone hydratase, a cyclohexanone dehydrogenase and an enzyme selected from a 3-oxopimeloyl-CoA synthetase, a 3-oxopimeloyl-CoA hydrolase (acting on thioester), and a 3-oxopimeloyl-coA transferase. Each these pathways can include a PEP carboxykinase. A method for producing cyclohexanone includes culturing these non-naturally occurring microbial organisms.

Owner:GENOMATICA INC

Supported catalysts for the fixation of carbon dioxide into aliphatic polycarbonates and a process for preparing the same

InactiveUS6844287B2Improve efficiencyWeight increaseOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsGlutaric acidCarboxylic acid

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Supported catalysts for the fixation of carbon dioxide into aliphatic polycarbonates and a process for preparing the same

InactiveUS20030134740A1High catalytic efficiencyHigh molecular weightOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsGlutaric acidCarboxylic acid

The present invention provides a process for preparing supported zinc dicarboxylate catalysts with high activity for the copolymerization of carbon dioxide and epoxides by supporting zinc dicarboxylate on silica support. The zinc dicarboxylate may be synthesized from zinc oxide and dicarboxylic acid such as succinic acid, glutaric acid, adipic acid, pimelic acid and suberic acid. The silica support can be selected from the group consisting of aerosil, silica gel for chromatography or reagent grade silicon dioxide. The supporting process is performed in a planetary ball grinder under vacuum.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

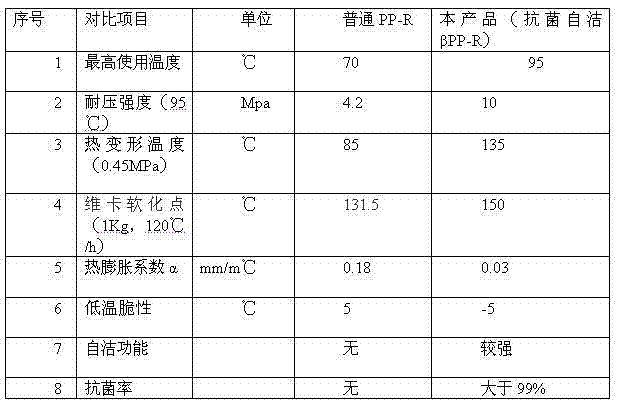

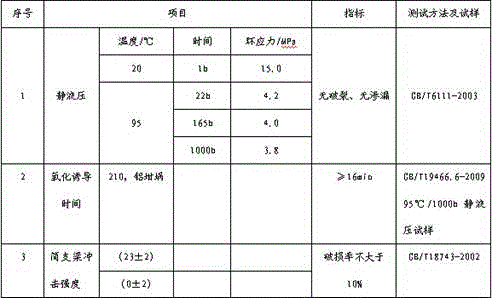

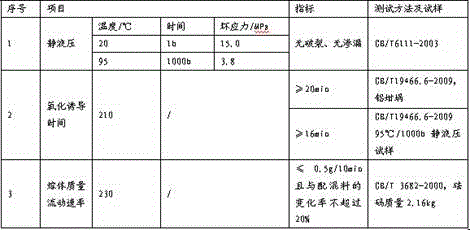

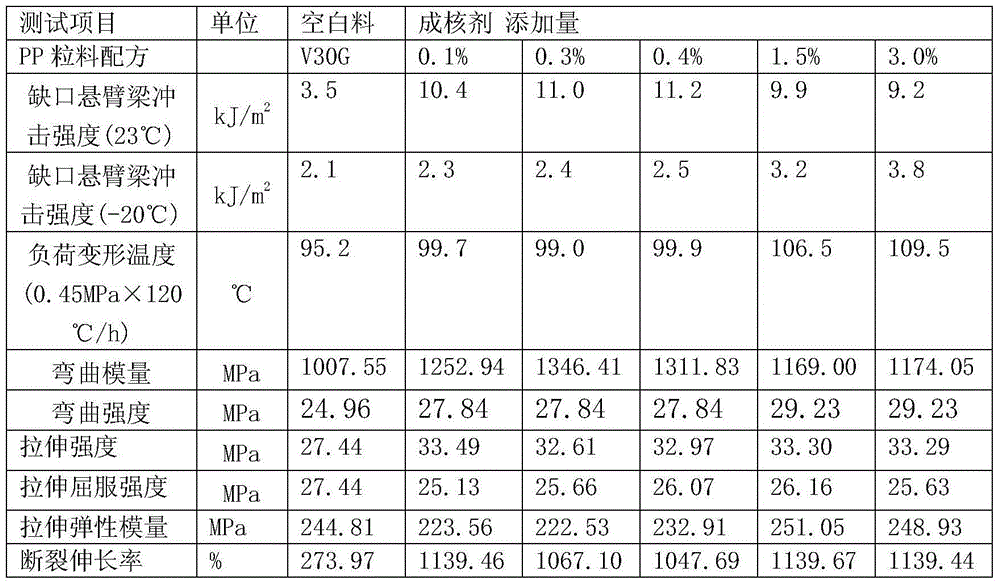

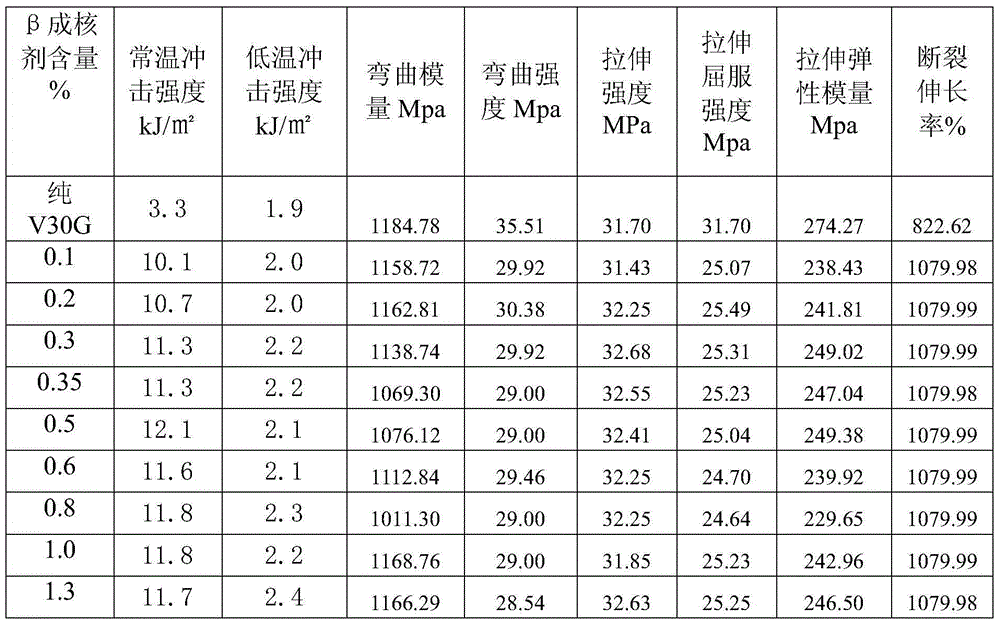

Self-cleaning antibacterial beta-crystal form PP-R cold-hot water pipe material and preparation method thereof

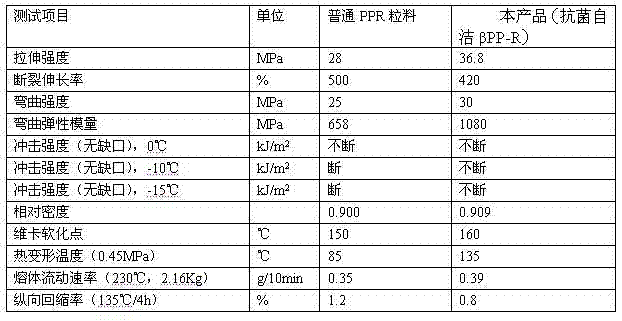

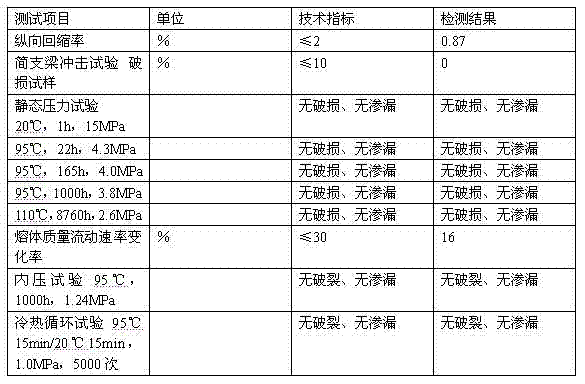

InactiveCN102226028AGood room temperatureImprove low temperature impact strengthRigid pipesThermal deformationInjection molding machine

The invention relates to a self-cleaning antibacterial beta-crystal form PP-R cold-hot water pipe material. The preparation method comprises the following steps of mixing calcium stearate and lanthana, adding pimelic acid into the mixture to cause a reaction, then adding nano-calcium carbonate into the reaction products obtained from the previous step and stirring uniformly to obtain a composite beta-crystal form nucleating agent, mixing orderly PP-R4220 resin, white oil 10, the composite beta-crystal form nucleating agent and anti-oxidants to produce a mixture, feeding the mixture into a parallel double screw extruder to produce beta PP-R resin particles, adding a silver ion salt and a zinc ion salt into nano-titanium dioxide, then mixing the nano-titanium dioxide, the beta PP-R resin particles and poly propylene wax to form a mixture, feeding the mixture into a parallel double screw extruder to produce a composite antibacterial mother material, and mixing uniformly the beta PP-R resin particles, the composite antibacterial mother material, poly propylene wax, methyl phenyl silicone oil and ultra -fine talc powder to form a mixture, feeding the mixture into an extruder or an injection machine to produce a self-cleaning antibacterial beta-crystal form PP-R cold-hot water pipe material. The material has the advantages of high usage temperature of 95 DEG C, high compressive strength, high thermal deformation temperature, high Vicat softening point, good self-clean performance and antibacterial effects.

Owner:HUBEI YANGTIAN PLASTIC PROD CO LTD

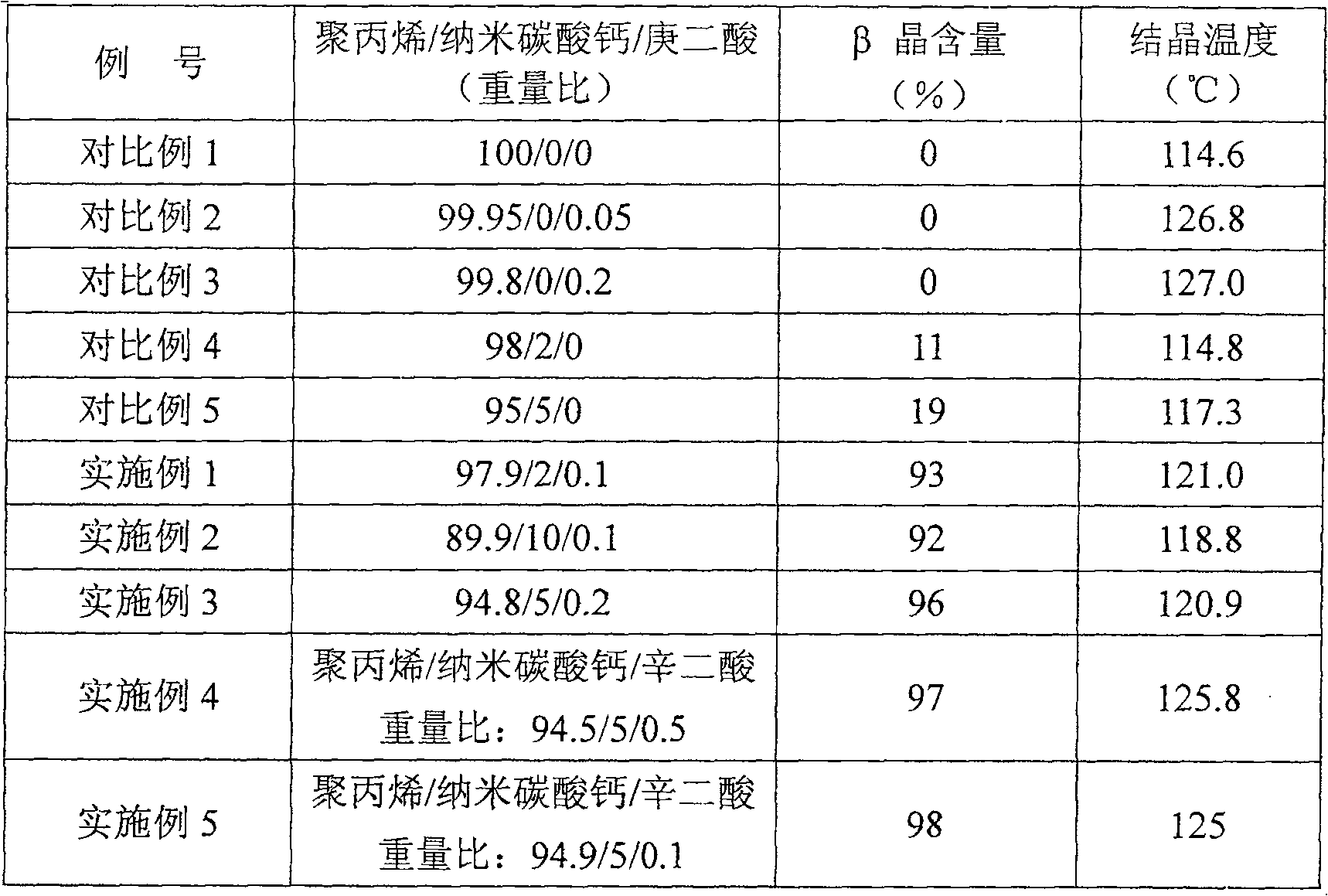

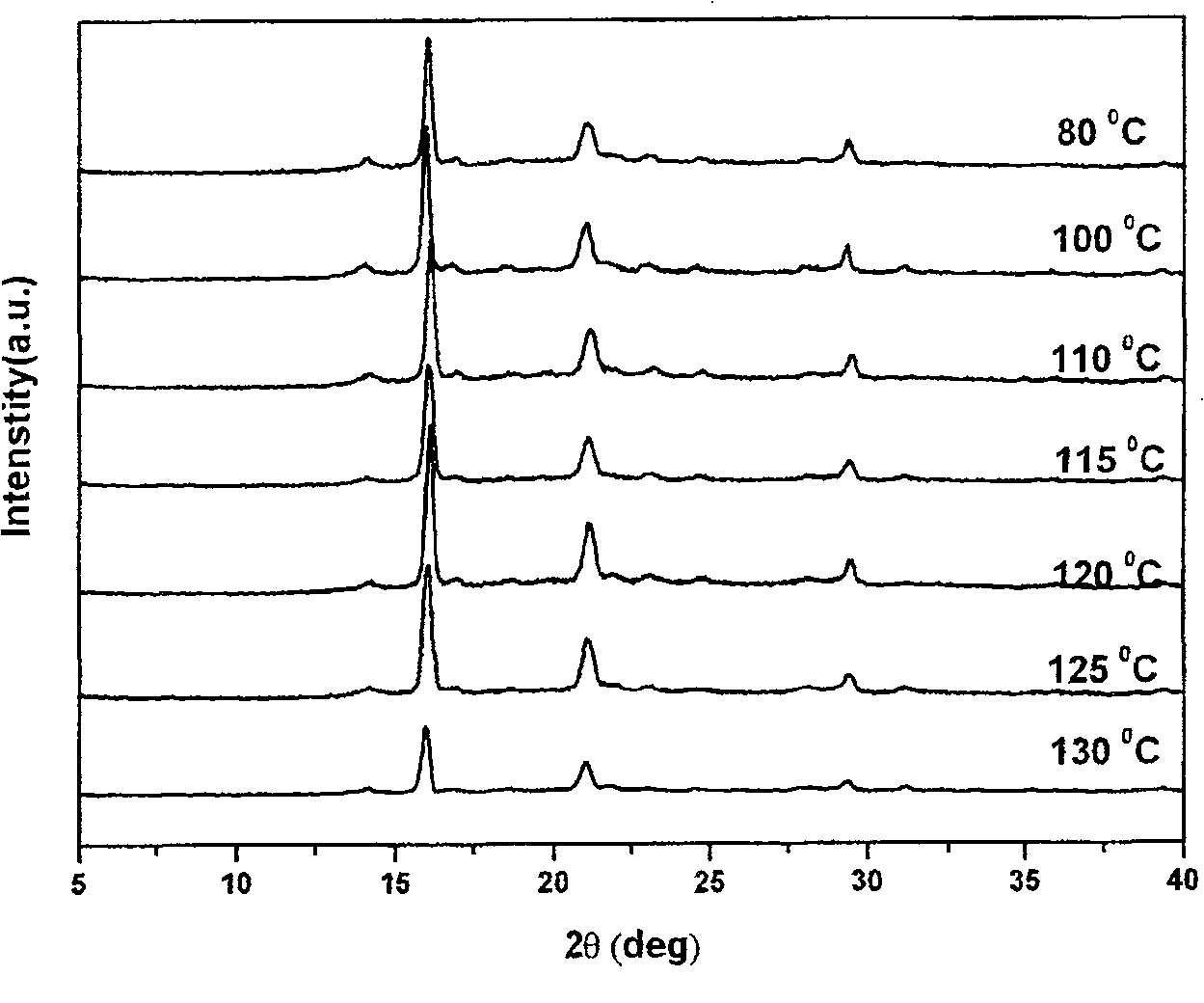

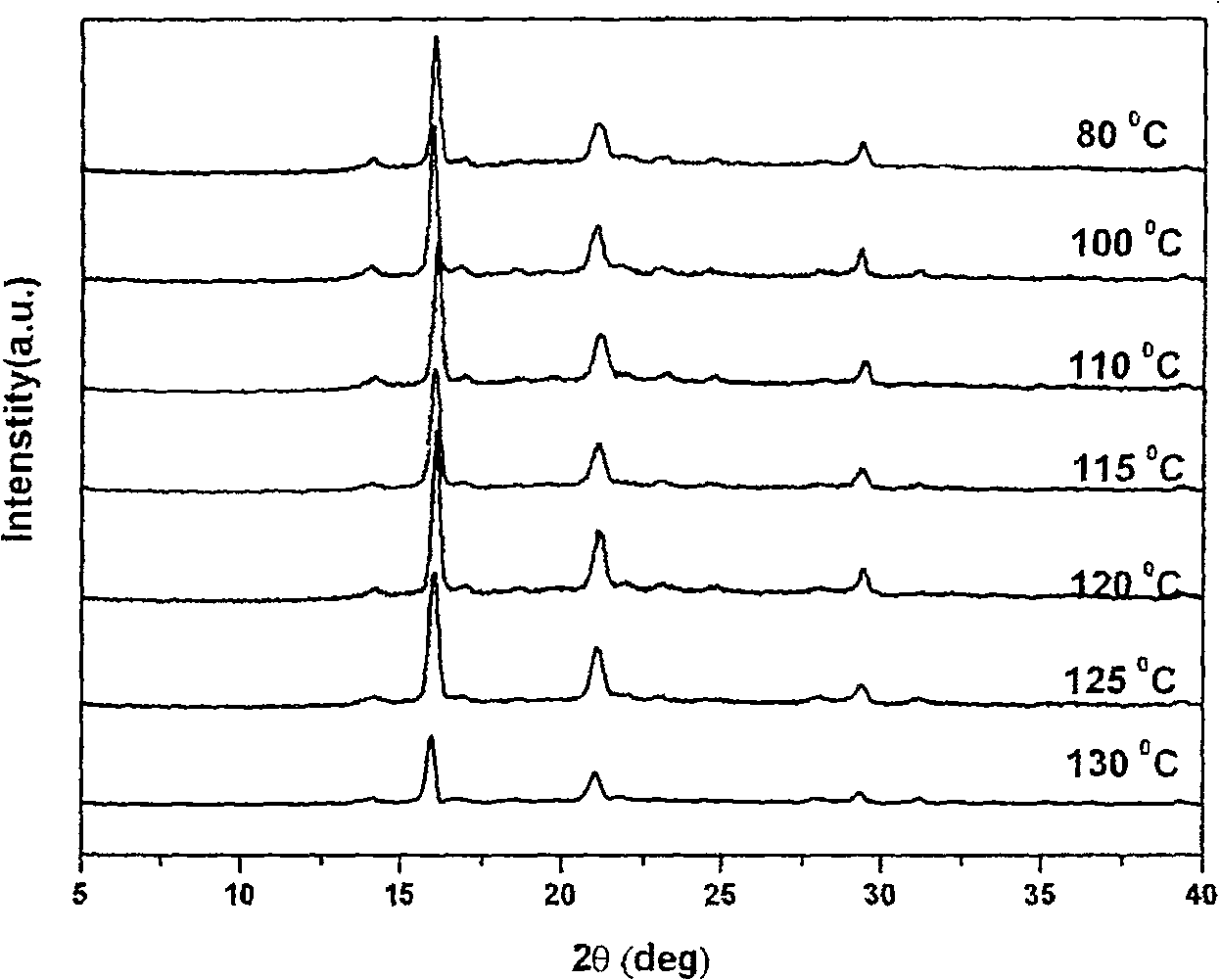

Supported beta crystal core formation agent and preparation method thereof

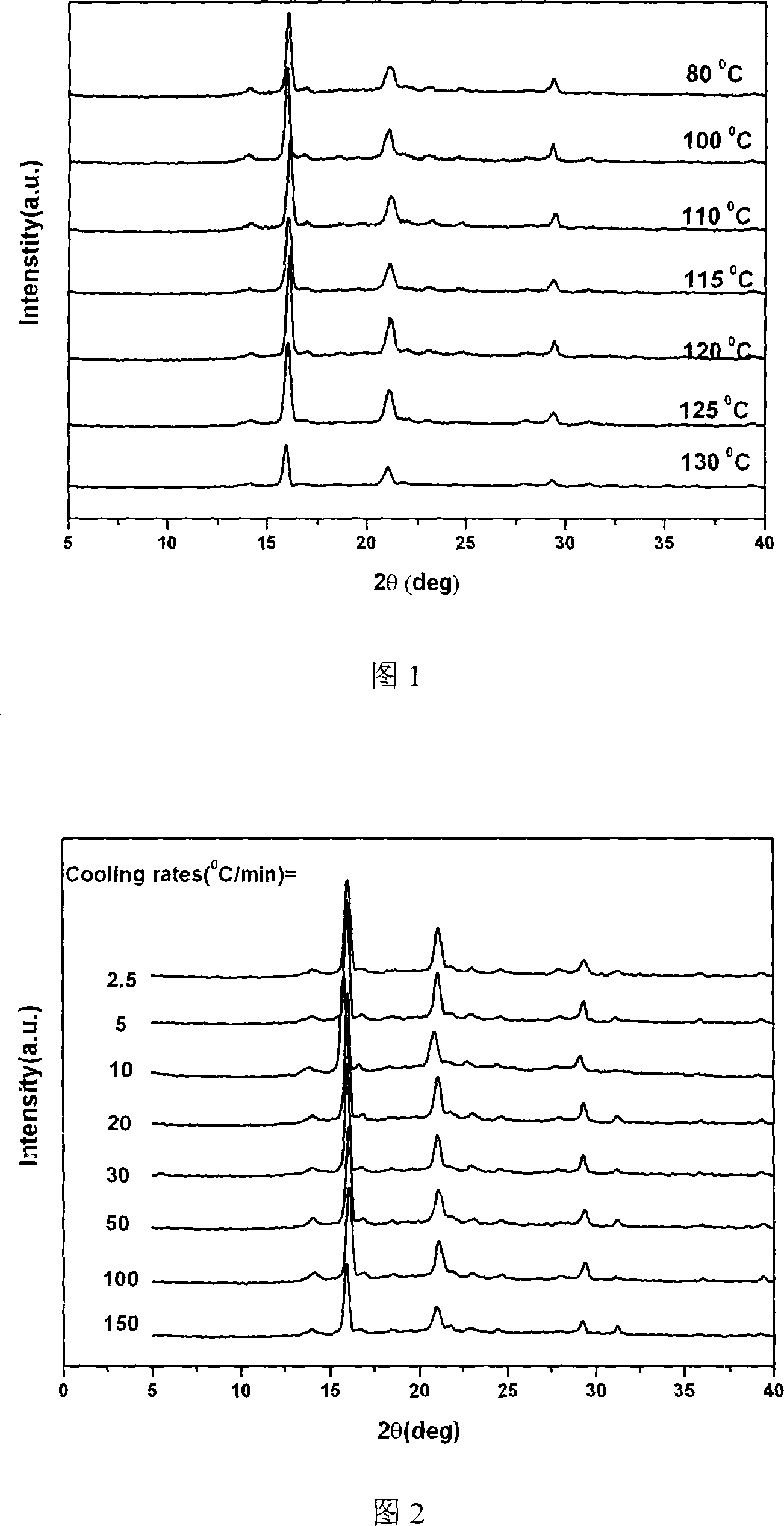

ActiveCN101157771AIncreased effective nucleation sitesHigh nucleation efficiencyChemical reactionCarboxylic acid

The present invention discloses a load-type Beta-nucleating agent and a preparation method thereof, the load-type Beta-nucleating agent of the present invention consists of nano calcium carbonate and aliphatic dicarboxylic acid, and the weight ratio of which is 5 to 1000: 1. The present invention adopts the nano calcium carbonate with a big surface area as a carrier, adopts a simple method to highly disperse the dicarboxylic acid on the nano-calcium carbonate surface, makes use of a chemical reaction of the nano-calcium carbonate and the dicarboxylic acid to form the high efficient beta-nucleating agent which is the same with the mixture of pimelic acid and calcium stearate aiming at the problems of the existing beta-nucleating agents. The present invention realizes the purposes of reducing the consumption of the dicarboxylic acid, reducing the cost and improving the nucleating efficiency as the dicarboxylic acid on the nano-calcium carbonate is highly dispersed and the effective nucleating points are only formed on the surface of the nano-calcium carbonate.

Owner:SUN YAT SEN UNIV

Process for the hydrogenation of a lactone or of a carboxylic acid or an ester having a gamma-carbonyl group

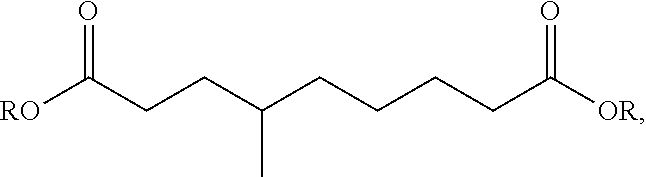

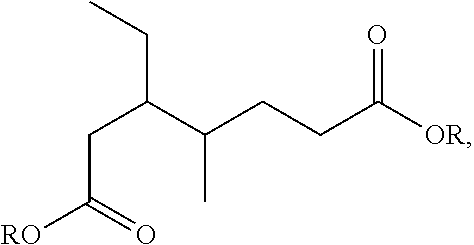

InactiveUS8003818B2Well formedOrganic compound preparationCarboxylic compound preparationPtru catalystEthyl group

The invention provides a process for the hydrogenation of a reactant selected from the group consisting of: at the ring-closing carbon atom and has a proton at a(a) a 5- or 6-membered lactone that is substituted carbon atom adjacent to the ring-closing carbon atom;(b) an ester of a carboxylic acid having a gamma-carbonyl group and a proton at a carbon atom adjacent to the carbon atom of the carbonyl group; and(c) a carboxylic acid having a gamma-carbonyl group and a proton at a carbon atom adjacent to the carbon atom of the carbonyl group,wherein the reactant is contacted with a strongly acidic heterogeneous catalyst comprising a hydrogenating metal, in the presence of hydrogen, at a temperature in the range of from 100 to 350° C. and a pressure in the range of from 1 to 150 bar (absolute).The invention further provides a fuel composition, preferably a diesel composition, comprising di-alkyl 4-methylnonanedioate or di-alkyl 3-ethyl-4-methylheptanedioate.

Owner:SHELL OIL CO

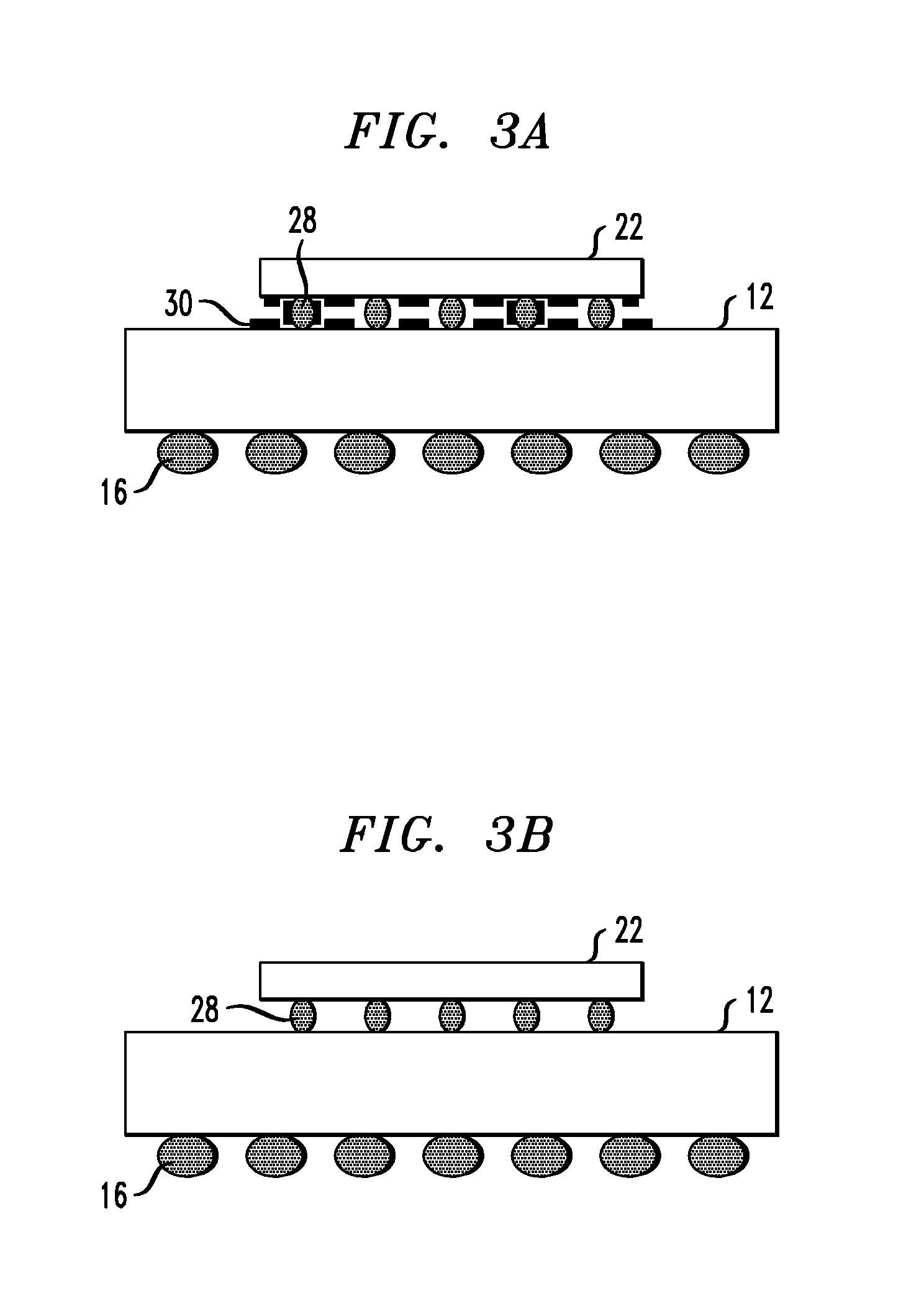

Flux Composition and Techniques for Use Thereof

The present invention is directed to flux compositions and uses thereof. One composition comprises an activator, a medium-viscosity solvent being a polymer, and a high-viscosity solvent being a copolymer containing first monomers and second monomers. Another composition comprises an activator, and a high-viscosity solvent comprising a copolymer containing first monomers and second monomers. Another composition comprises an activator of 6-12 percent by weight of glutaric acid, pimelic acid, tartaric acid, or mixtures thereof, and a medium-viscosity solvent of 88-94 percent by weight comprising a polymer with hydroxyl end groups. Another composition comprises an activator in a liquid state comprising poly(ethylene glycol)-diacid, and a medium-viscosity solvent comprising a polymer with hydroxyl end groups. A soldering method for joining objects is also provided, comprising the steps of applying a flux composition to at least a portion of one or more of the objects, and joining the objects.

Owner:IBM CORP

Supported beta crystal core formation agent and preparation method thereof

ActiveCN101157771BIncreased effective nucleation sitesHigh nucleation efficiencyChemical reactionCarboxylic acid

The present invention discloses a load-type Beta-nucleating agent and a preparation method thereof, the load-type Beta-nucleating agent of the present invention consists of nano calcium carbonate and aliphatic dicarboxylic acid, and the weight ratio of which is 5 to 1000: 1. The present invention adopts the nano calcium carbonate with a big surface area as a carrier, adopts a simple method to highly disperse the dicarboxylic acid on the nano-calcium carbonate surface, makes use of a chemical reaction of the nano-calcium carbonate and the dicarboxylic acid to form the high efficient beta-nucleating agent which is the same with the mixture of pimelic acid and calcium stearate aiming at the problems of the existing beta-nucleating agents. The present invention realizes the purposes of reducing the consumption of the dicarboxylic acid, reducing the cost and improving the nucleating efficiency as the dicarboxylic acid on the nano-calcium carbonate is highly dispersed and the effective nucleating points are only formed on the surface of the nano-calcium carbonate.

Owner:SUN YAT SEN UNIV

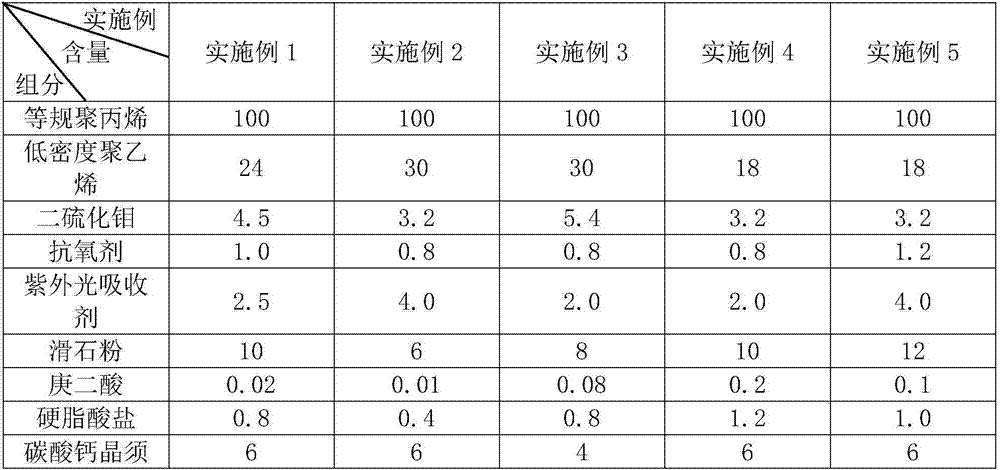

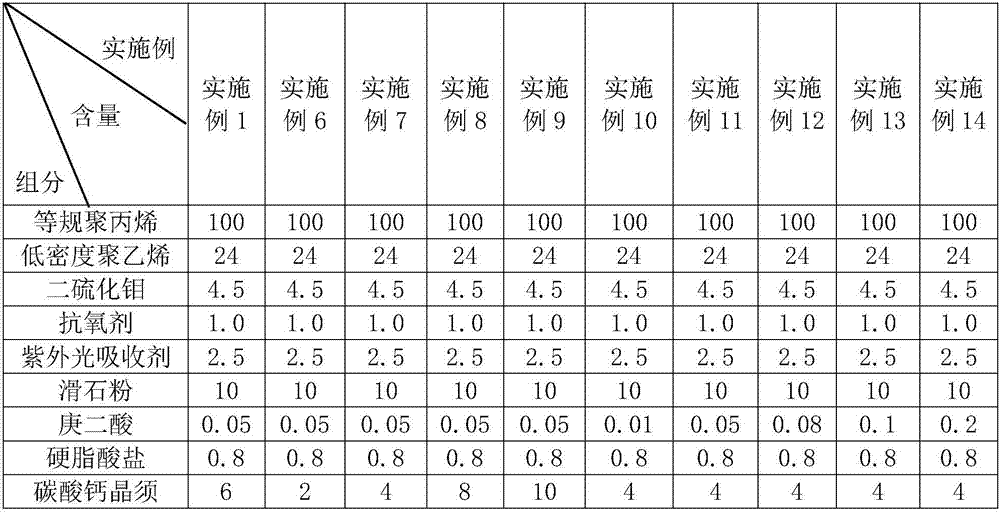

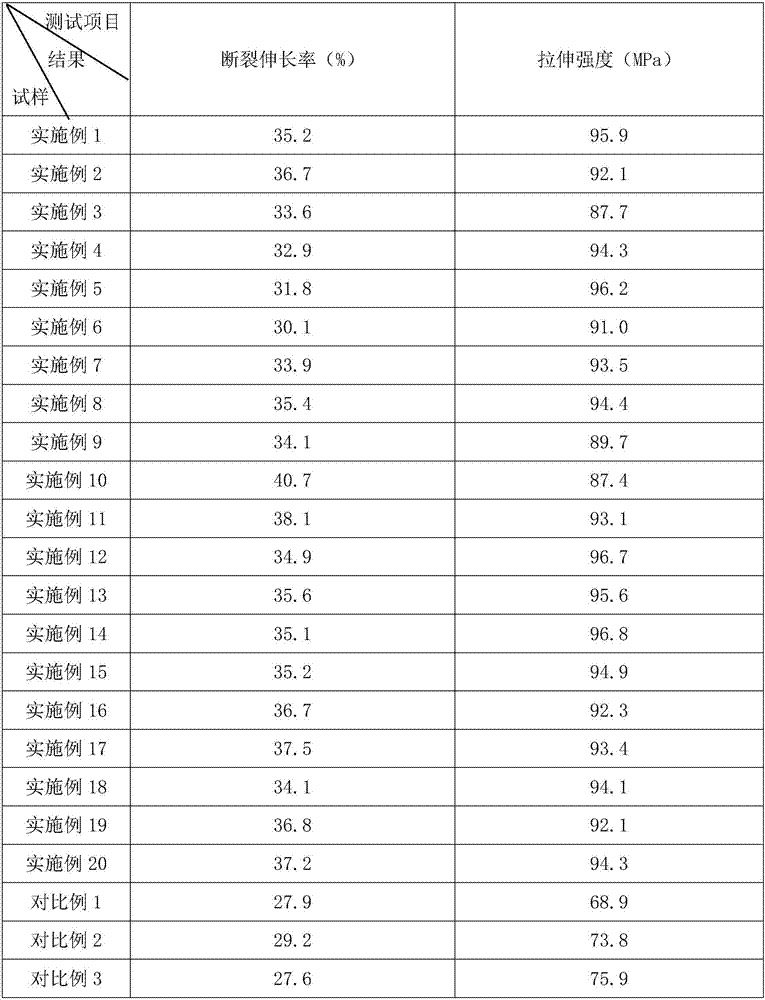

Material for reinforced plastic woven bag

The invention discloses a material for a reinforced plastic woven bag. The material is characterized by being prepared from the following raw materials in parts by weight: 100 parts of isotactic polypropylene, 18 to 30 parts of low density polyethylene, 3.2 to 5.4 parts of molybdenum disulfide, 0.8 to 1.2 parts of an antioxidant, 2 to 4 parts of an ultraviolet absorbent, 6 to 12 parts of talcum powder, 0.01 to 0.2 part of pimelic acid, 0.4 to 1.2 parts of stearate and 2 to 10 parts of calcium carbonate whiskers, wherein stearate comprises calcium stearate. The material has the advantages of high tensile strength and high toughness.

Owner:浙江海威包装有限公司

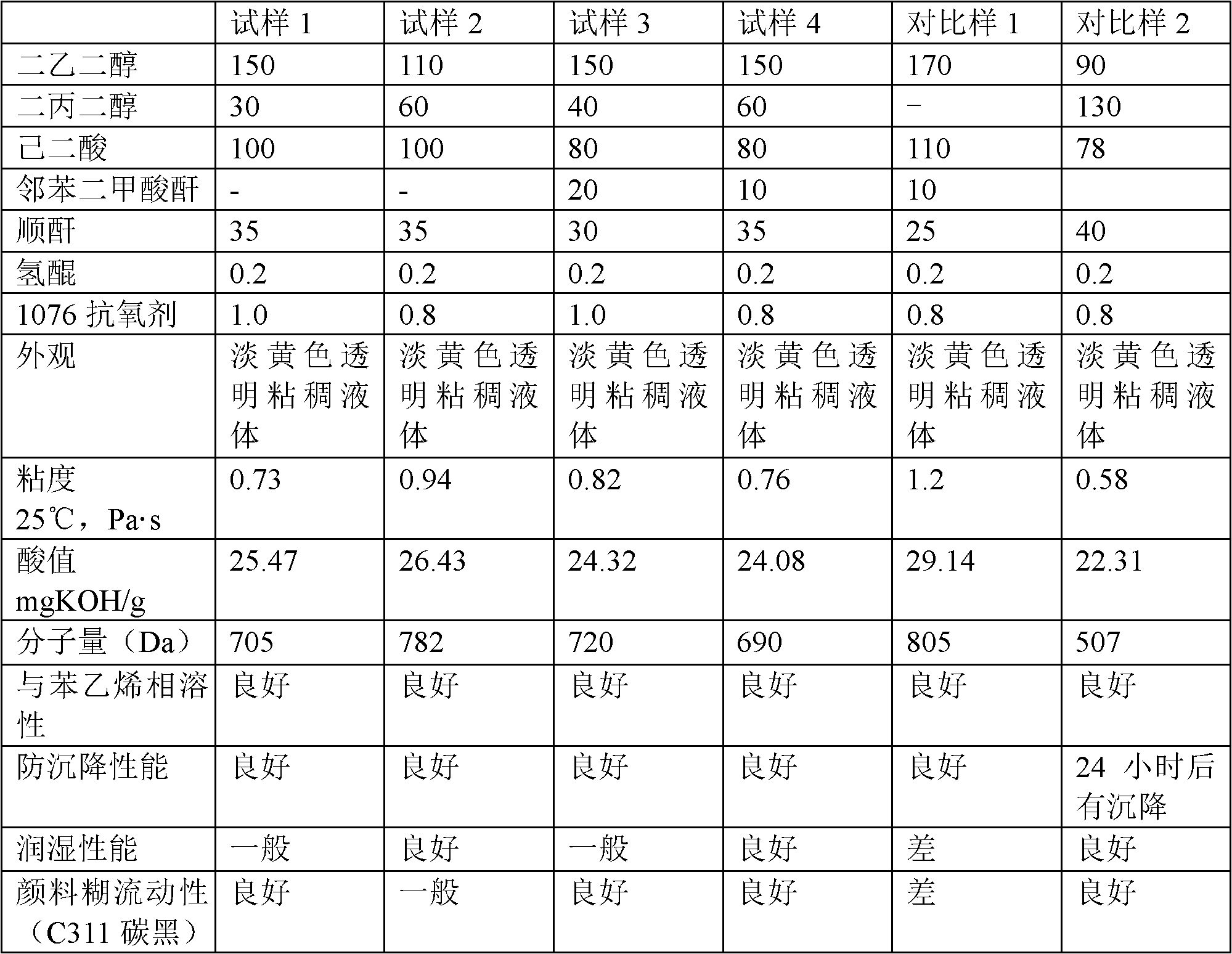

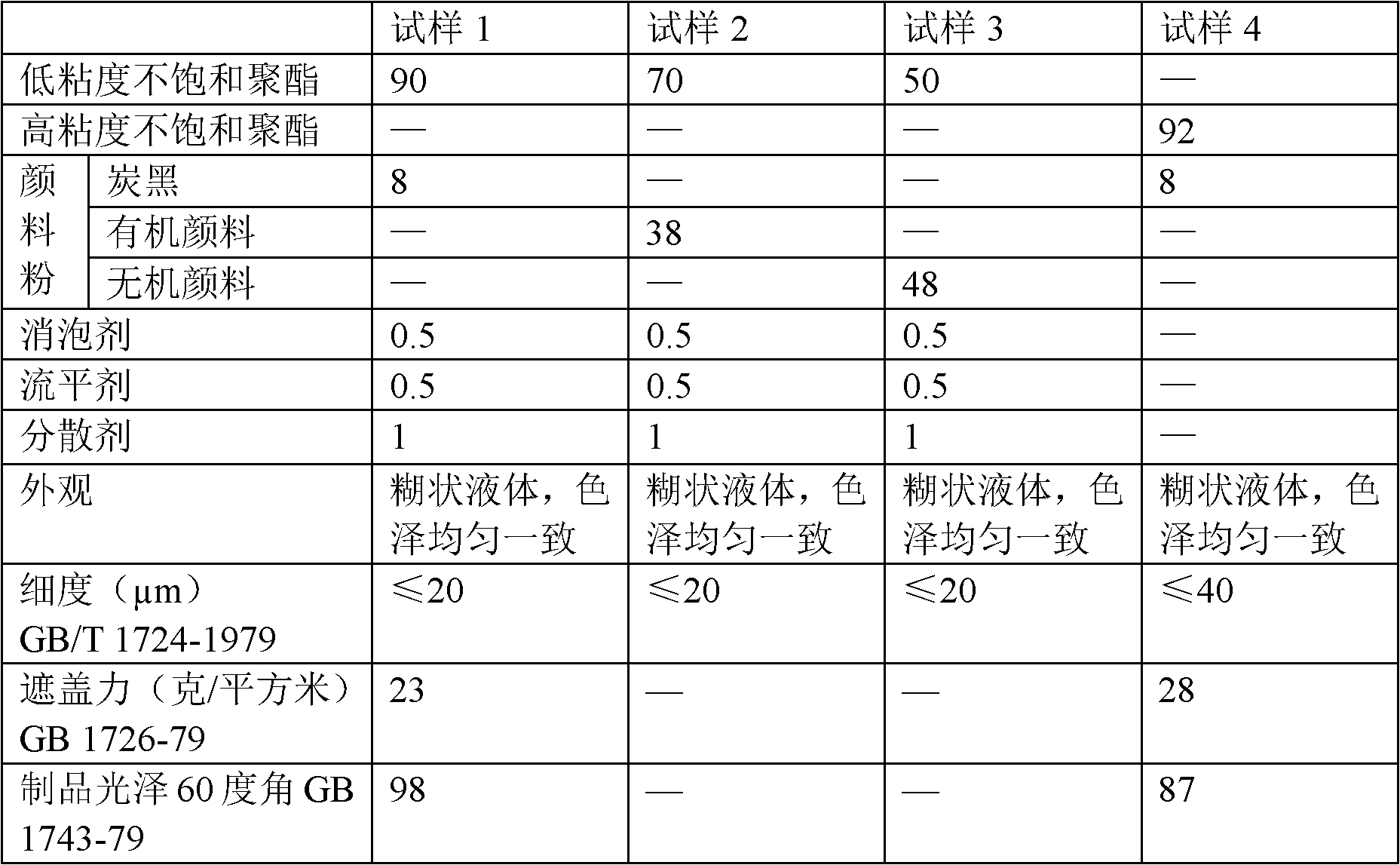

Unsaturated polyester with low viscosity and application thereof

InactiveCN103172844AReduce processing timeQuality improvementOrganic dyesPigment pastesGlutaric acidButanedioic acid

The invention relates to unsaturated polyester with low viscosity. The polyester is mainly polymerized by 17-21 parts by weight of dihydric alcohol, 8-10 parts by weight of saturated binary acid and 3-3.5 parts by w eight of unsaturated binary acid, wherein the saturated binary acid is selected from one or more of oxalic acid, malonic acid, butanedioic acid, glutaric acid, adipic acid, pimelic acid, octanedioic acid, azelaic acid and sebacic acid, and the unsaturated binary acid is selected from one or more of butenedioic acid, phthalic acid, isophthalic acid and terephthalic acid. According to GB / T7193.1-2008 standard, the viscosity of unsaturated polyester is 0.60-1.00Pa.s, and the polyester can be used as a carrier for processing or manufacturing pigment paste by a sanding process, so that the processing time of the pigment paste is remarkably shortened, the production efficiency is improved, and the production cost is lowered.

Owner:CHANGZHOU HUARUN COMPOSITE MATERIALS +1

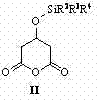

Preparation method of (3R,5R)-3,5-dihydroxy-6-methyl cyan-caproate

InactiveCN102827030AHigh yieldHigh stereoselectivityCarboxylic acid nitrile preparationOrganic compound preparationCyanide compoundPtru catalyst

The invention relates to a preparation method of (3R, 5R)-3,5-dihydroxy-6-methyl cyan-caproate (I) and belongs to the technical field of pharmaceutical chemistry. The preparation method concretely comprises the following steps of: firstly, carrying out asymmetric catalysis alcoholysis on 3-siloxy cyclopentane anhydride (II) to prepare (R)-3-siloxy-5-alkoxy-5-oxo-pentanoate (III); secondly, condensing the (R)-3-siloxy-5-alkoxy-5-oxo-pentanoate (III) and methyl cyanoacetate to prepare (R)-2-cyano-3-oxo-5-siloxy diethyl pimelate (IV); thirdly, carrying out decarboxylation on the (R)-2-cyano-3-oxo-5-siloxy diethyl pimelate (IV) to prepare (R)-3-hydroxy-5-oxo-6-benzyl cyanohexanoate (V) by using desilicication protective groups; and fourthly, carrying out asymmetric reduction on the (R)-3-hydroxy-5-oxo-6-benzyl cyanohexanoate to prepare a product of (3R,5R)-3,5-dihydroxy-6-methyl cyan-caproate (I). The preparation method is mild in reaction conditions, simple and convenient to operate, high in stereoselectivity, environment-friendly, and suitable for industrial production; and products have high yield, the used chiral catalyst is small in dosage and can be recovered with fix quantify, raw materials which are easily obtained are low in cost, and particularly hypertoxic cyanides are avoided.

Owner:FUDAN UNIV

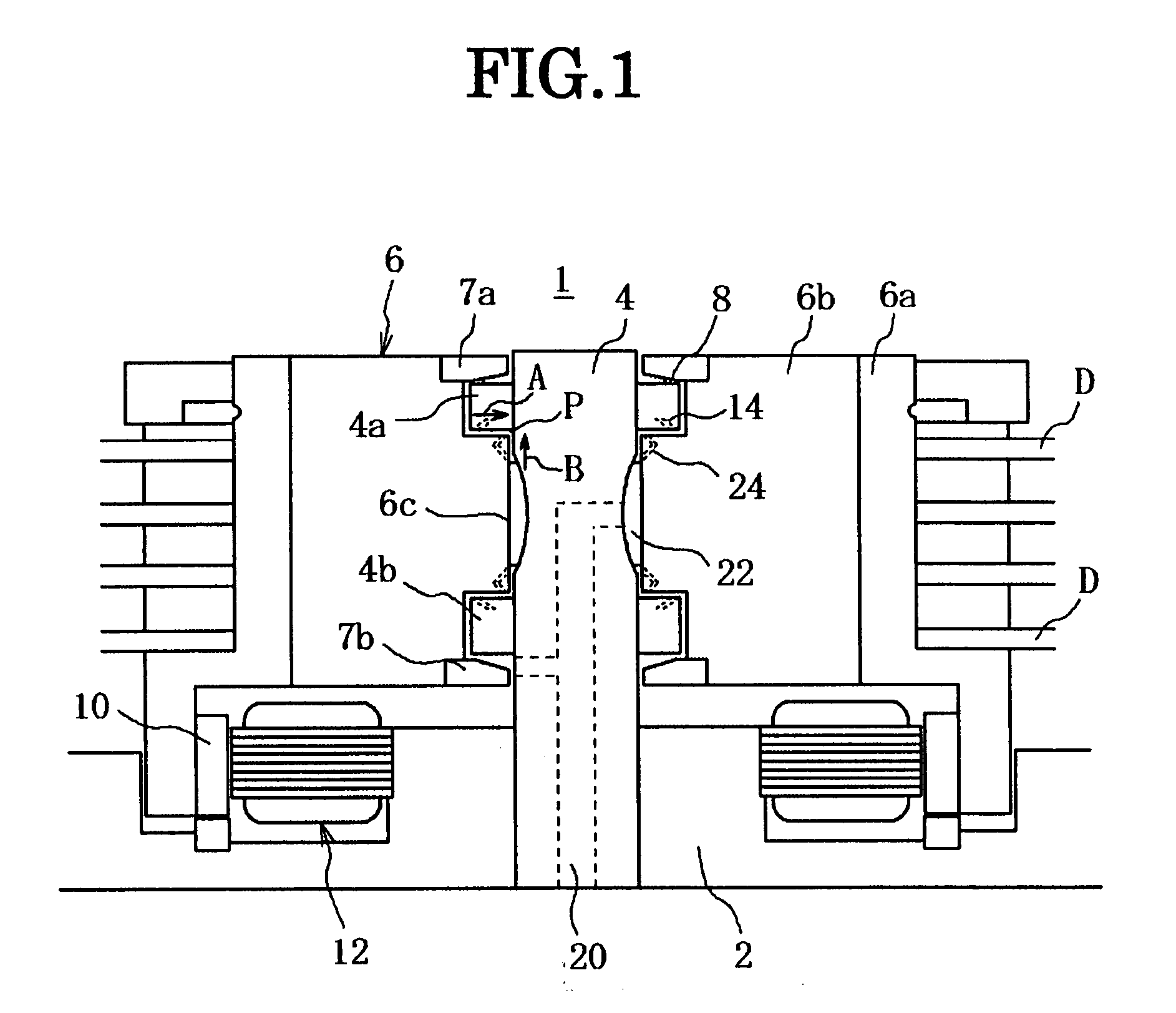

Lubricating oil for fluid bearing, and fluid bearing and method for lubricating fluid bearing by using the lubricating oil

InactiveUS20090318317A1Low viscosityReduce evaporationOrganic chemistryShaftsGlutaric acidEvaporation

Disclosed is a lubricating oil for a fluid bearing, which has a low viscosity, a reduced amount of evaporation, and superior low-temperature flowability. The lubricating oil includes, as a base oil, a high-purity diester synthesized from a carboxylic acid material containing 90 mass % or more of azelaic acid and an alcohol material containing 90 mass % or more of 2-ethyl-1-hexanol. The carboxylic acid material contains glutaric acid, adipic acid, pimelic acid, suberic acid, sebacic acid and 1,9-nanomethylenedicarboxylic acid in a total amount of 5 mass % or less.

Owner:JAPAN ENERGY CORP +1

Beta-crystal PPR pipe and preparation method thereof

The invention provides a preparation method for a beta-crystal PPR pipe, and belongs to the technical field of chemical building materials. The heat resistance and the impact property of the PPR pipe are improved, and the processability of the PPR pipe is improved. The beta-crystal PPR pipe comprises the following components in parts by weight: 100 parts of PPR resin, 0.001-2 parts of a calcium stearate / pimelic acid Beta-crystal nucleating agent, 0.001-3 parts of aromatic amide, 0.1-15 parts of nano-inorganic powder, 0.01-1 part of a rheological agent, 0.01-1 part of an inorganic antibacterial agent, 0.01-0.3 part of an antioxidant, and 1-10 parts of color masterbatch. When the beta-crystal PPR pipe is prepared, the PPR resin, the beta-crystal nucleating agent, nano calcium carbonate, the rheological agent, the antioxidant and the color masterbatch are uniformly mixed to obtain a mixture, and the mixture is melt-extruded by a single screw extruder, shaped, cooled, pulled, cut and packed to obtain the beta-crystal PPR pipe.

Owner:LIAOCHENG UNIV

Washing-free soldering flux

InactiveCN105127616ALow solid contentPrevent oxidationWelding/cutting media/materialsSoldering mediaGlutaric acidButanedioic acid

The invention discloses a washing-free soldering flux which comprises the following components in parts by weight: 20 parts of rosin, 20 parts of resin, 2-3 parts of butanedioic acid, 2-3 parts of glutaric acid, 2-3 parts of sebacic acid, 2-3 parts of pimelic acid, 0.5 part of an anti-corrosive agent, 0.5 part of a co-solvent, 0.5 part of a film forming agent, and 50 parts of an organic solvent. Through the adoption of the scheme, the washing-free soldering flux has the advantages that the solid content is low, oxides are effectively removed, oxidation is prevented, the surface tension of a welding material is reduced, washing is avoided, the service life is long, the performance is stable, the sources are wide, and the use is safe; and the washing-free soldering flux has a wide market prospect in popularization of the washing-free soldering flux.

Owner:SUZHOU LOTTE CHEM TECH

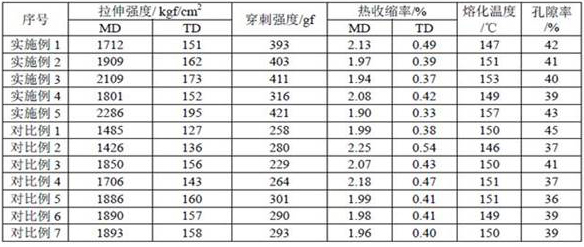

High-strength three-layer co-extrusion lithium ion battery diaphragm and preparation method thereof

ActiveCN114497896AHigh crystallinityImprove puncture strengthSecondary cellsCell component detailsPhysical chemistryStearic acid

The invention relates to the technical field of lithium ion battery diaphragms, and discloses a high-strength three-layer co-extrusion lithium ion battery diaphragm and a preparation method thereof.The diaphragm comprises a layer B and layers A arranged on the two sides of the layer B; the component of the layer A comprises co-polypropylene, and the melt index of the co-polypropylene at 230 DEG C is greater than or equal to 30 g / 10 min; the layer B is prepared from the following components in parts by weight: 90 to 99 parts of homo-polypropylene and 1 to 10 parts of lubricating nucleating particles, and the melt index of the homo-polypropylene at 230 DEG C is 1 to 5g / 10min; the lubricating nucleation particles are prepared from polytetrafluoroethylene micro powder, pimelic acid and calcium stearate through step-by-step ball milling. According to the invention, the diaphragm with an A / B / A structure is prepared from two different types of polypropylene with relatively large melt index difference in a three-layer co-extrusion manner, and the lubricating nucleation particles are added into the middle layer, so that the mechanical property of the diaphragm is effectively improved while the processing property of the diaphragm is ensured.

Owner:NINGBO CHANGYANG TECH

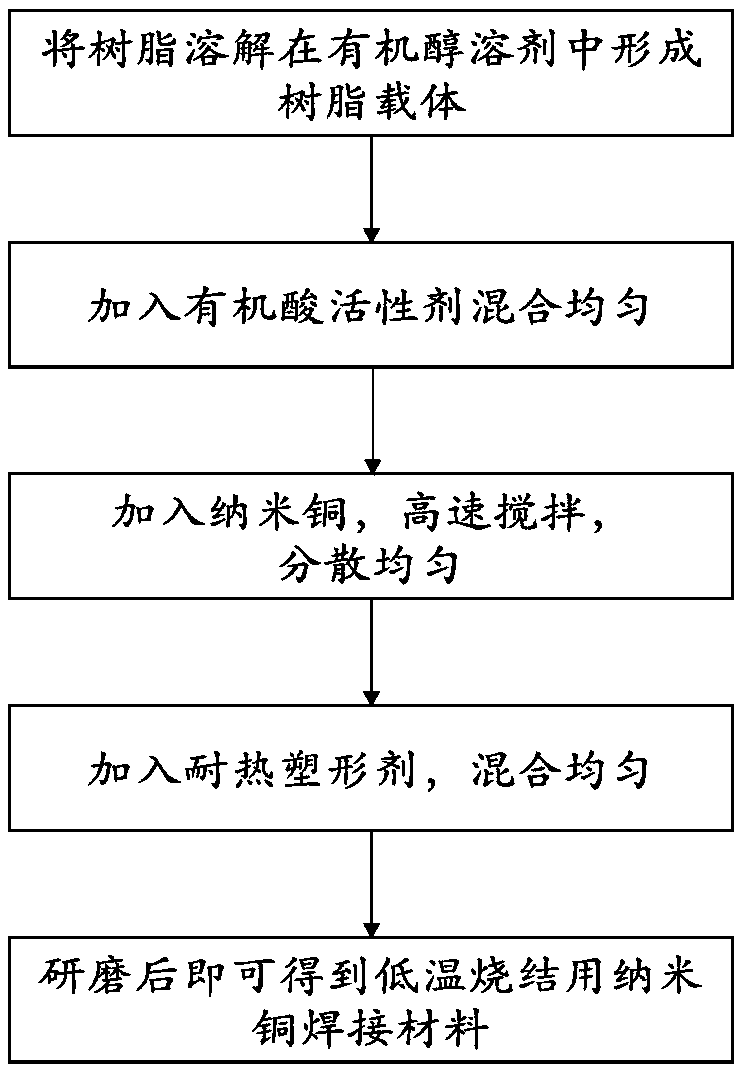

Preparing method of low-temperature nano copper welding material

InactiveCN107553007AImprove conductivityPrevent or reduce oxidationWelding/cutting media/materialsSoldering mediaGlutaric acidSalicylic acid

The invention provides a preparing method of a low-temperature nano copper welding material. The method comprises the steps that resin and organic alcohol are mixed, and a resin carrier is obtained; the resin carrier, the organic alcohol and nano copper are mixed, stirring is carried out until the nano copper is evenly dispersed, then, a mixture is evenly mixed a heat-resisting shaping agent, grinding is carried out, and the low-temperature nano copper welding material is obtained; the organic acid is selected from one or multiple of adipic acid, oxalic acid, malonic acid, succinic acid, sebacic acid, pimelic acid, malic acid, succinic acid, glutaric acid, dimethyl glutaric acid, o-hydroxybenzoic acid, phthalic acid, salicylic acid and itaconic acid. The manner that the resin, the organicalcohol and the organic acid are adopted to serve as a flux to be mixed with the nano copper, and the welding material is prepared is adopted, the organic acid is used, oxidization of the nano copperin the use process can be effectively prevented or reduced, and conductivity of welding materials can be improved; the welding materials can clean the welding copper face, and product reliability is improved; in the sintering process, the organic acid is gradually dissipated, and the effect that the welding material residue do not need to be cleaned is achieved.

Owner:GUANGDONG UNIV OF TECH

Method for preparing high-purity graphene

The invention provides a method for preparing high-purity graphene. The method comprises the following steps: (1) respectively grinding and screening graphite and pimelic acid to obtain graphite powder having an average grain diameter of 210-480mu m and pimelic acid powder having an average grain diameter of 60-200mu m; (2) weighing the graphite powder and the pimelic acid powder in a weight ratio of 1:1-1:4 to prepare a carboxylated graphene turbid solution; (3) putting the carboxylated graphene turbid solution in an ultrasonic device to obtain a carboxylated graphene suspension; (4) adding a meta-aluminate solution into the carboxylated graphene suspension, and stirring to obtain a mixed solution of meta-aluminate and carboxylated graphene; filtering the mixed solution, carrying out microwave heating and activating treatment on the filtered substances, cooling, pickling, washing, filtering and drying to obtain graphene. The method is low in material cost, simple in manufacture process and convenient for large-scale production, and the prepared graphene has a relatively high specific surface area.

Owner:郴州博太超细石墨股份有限公司

Cat face pheromone and application thereof

PendingCN112516128AAlleviate or relieve stressful behaviorLow costNervous disorderEster active ingredientsMethyl linoleateDIMETHYL SEBACATE

The invention discloses cat face pheromone and application thereof. The cat face pheromone comprises a cat face pheromone analogue and a solvent, and the cat face pheromone analogue comprises methyl laurate, methyl myristate, methyl palmitate, methyl oleate, methyl linoleate and dimethyl sebacate. The cat face pheromone can be used for preparing a preparation for reducing and relieving anxiety andconflicts after a cat is blended into a new environment, is suitable for a scene that the surrounding environment of the cat is changed, and can ease or relieve stress behaviors of the cat in the newenvironment, such as abnormal emotion and even pathological diseases; and meanwhile, since dimethyl heptanedioate and dimethyl azelate which are relatively high in price are not adopted for the cat face pheromone analogue and the cat face pheromone, the cost of the used raw materials is relatively low, the product is suitable for mass production, the purity of the raw materials is improved, the product quality is improved, and the effect is exerted.

Owner:上海弗艾柏生物科技有限公司

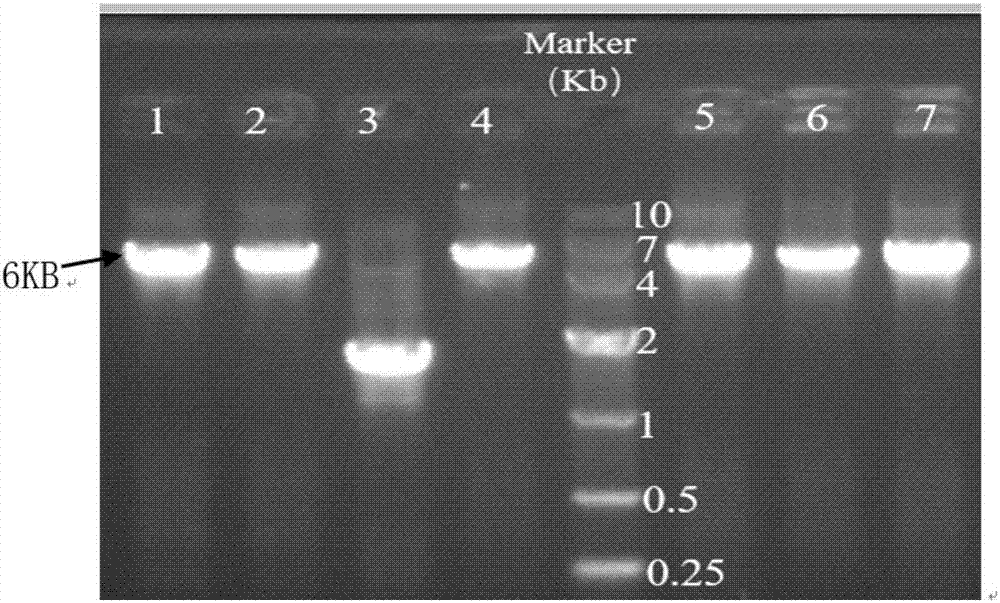

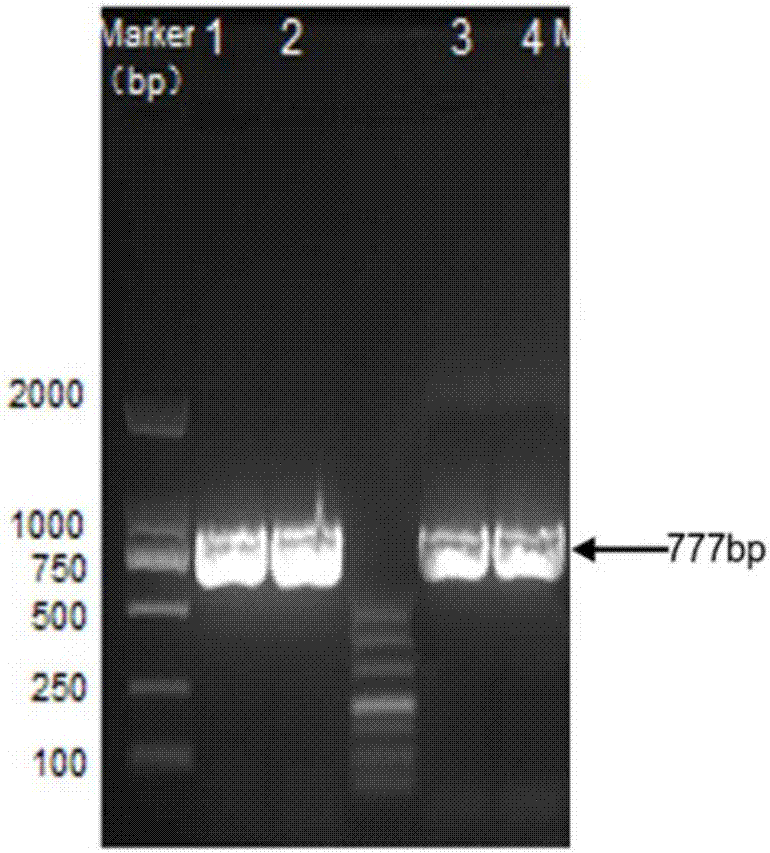

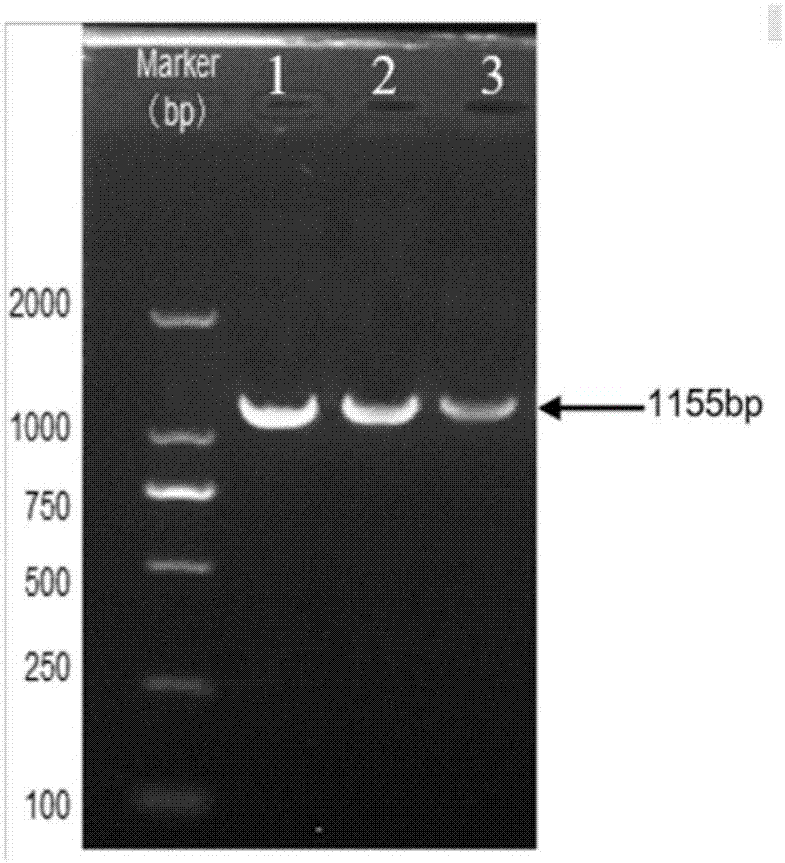

Plasmid and cell for promoting biotin synthesis and method for promoting synthesis of biotin

ActiveCN107099497AHigh synthesis efficiencyEfficient synthesisBacteriaTransferasesBiotechnologyS-Adenosyl-l-methionine

The invention discloses a method for promoting synthesis of biotin, and bioW gene sequence in B.subtilis168 and S-Adenosyl-L-methionine (SAM) synthase (Sam2) gene sequence in S.cerevisiae ZJU001 are used for promoting synthesis of the biotin by two pieces of biotin operon genes bioBFHCD and bioA. Gene engineering bacteria obtained by the method has efficient biotin synthesis ability, the yield of the biotin produced in a medium with pimelic acid as a substrate by fed-batch fermentation can reach 417mg / L, is 200 times of that of the biotin produced by original Escherichia coli, and the productive rate reaches 10.4mg / (L.h).

Owner:ZHEJIANG UNIV

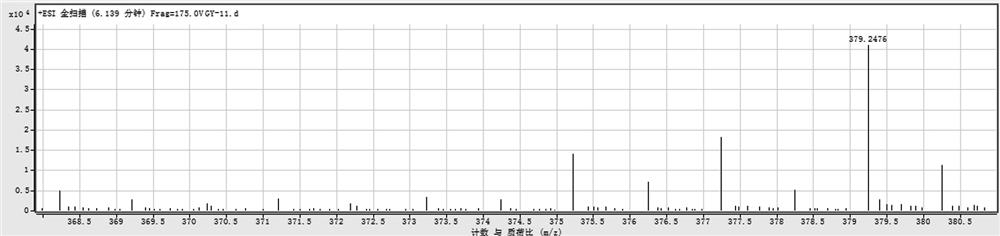

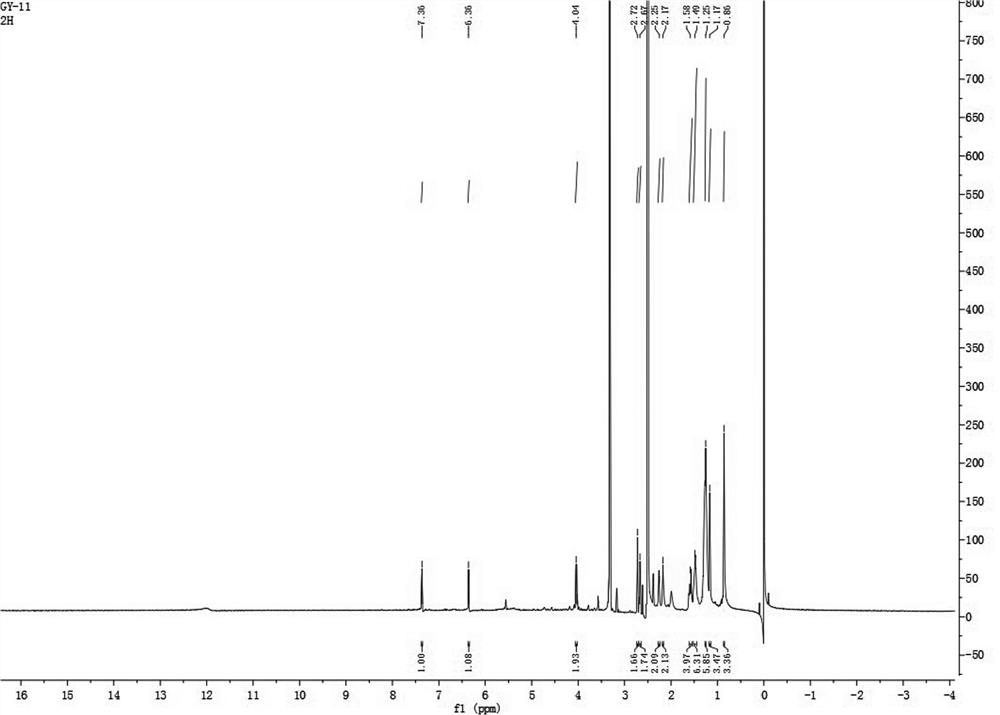

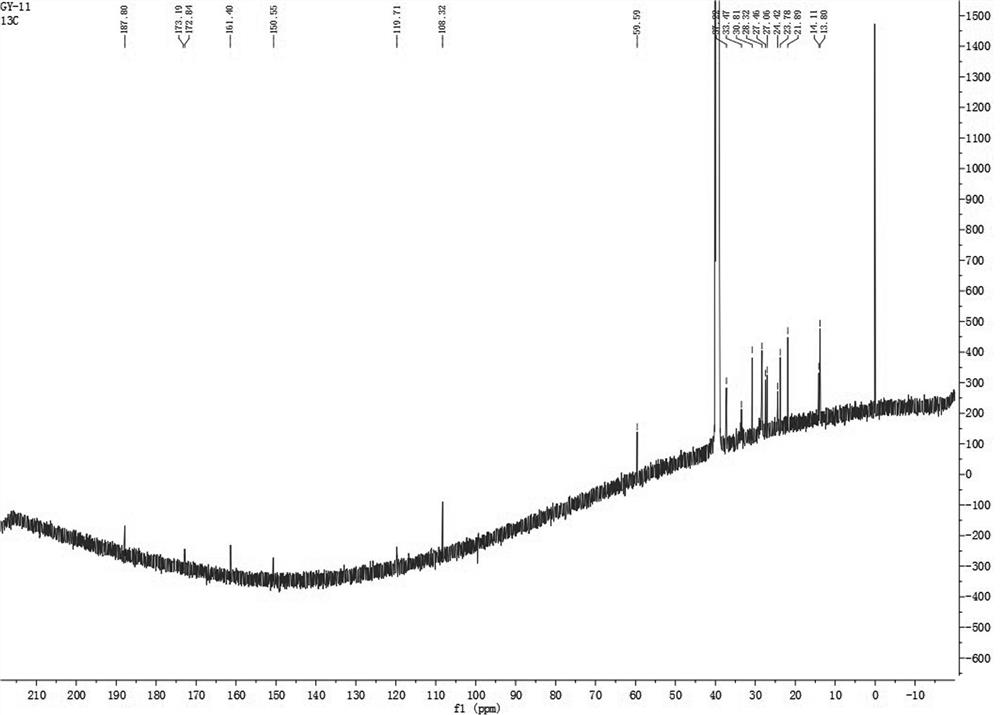

Ester compound with anti-tumor and anti-cholinesterase activity in purslane and extraction and separation method and application thereof

ActiveCN112300000AHigh purityHigh activityMulti-step food processesCarboxylic acid esters separation/purificationMedicinal herbsEthyl group

The invention relates to the field of traditional Chinese medicine extraction and separation, in particular to a new compound extracted, separated and identified from a purslane medicinal material andan extraction and separation method and application thereof. The invention provides 1-ethyl-7-(4-octyl-5-oxo cyclopentyl-1, 3-diene-1-yl) pimelate extracted from purslane and an extraction and separation method and application thereof. The ester compound is prepared by sequentially adopting alcohol decoction extraction, silica gel column chromatography, polyamide column chromatography, ODS medium-pressure column and Sephadex LH-20 purification and liquid phase separation. The extraction and separation method is simple, convenient, rapid and environment-friendly, the compound separated by themethod is relatively high in purity, and pharmacological experiments prove that the obtained compound has anti-tumor and anti-cholinesterase effects so that the new ester compound extracted from purslane and the salt and derivative thereof can be used as natural products to develop new traditional Chinese medicine, and wide medical application prospects are realized.

Owner:LIAONING UNIV OF TRADITIONAL CHINESE MEDICINE

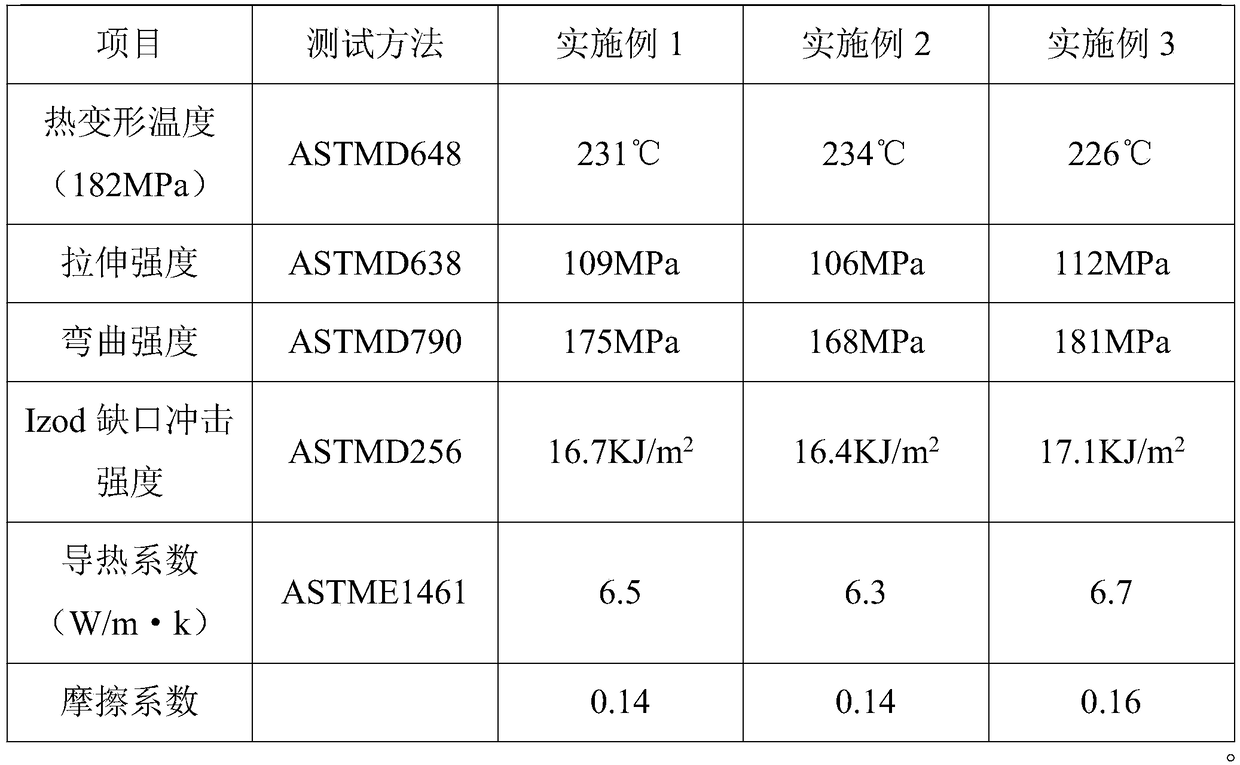

High-heat conduction wear-resistant high-temperature resistant composite material and preparation method thereof

InactiveCN108822531ALow thermal conductivityImprove high temperature resistanceHeat-exchange elementsPolyesterAluminate

The invention provides a high-heat conduction wear-resistant high-temperature resistant composite material and a preparation method thereof. The high-heat conduction wear-resistant high-temperature resistant composite material comprises the following raw materials in parts by weight: 60-80 parts of nylon, 10-20 parts of organosilicon-modified polyester acrylate, 1-3 parts of modified calcium sulfate whisker, 5-10 parts of magnesium oxide, 20-30 parts of modified graphene, 4-8 parts of a flexibilizer, 0.6-1.8 parts of a compatilizer, 0.2-0.6 parts of a lubricant, and 0.2-0.6 parts of an anti-oxidant. The modified graphene is mainly prepared by graphene, pimelic acid and sodium meta aluminate, and the modified calcium sulfate whisker is mainly prepared by the calcium sulfate whisker, zinc sulfate and an aluminate coupling agent. The preparation method is characterized in that the above raw materials are mixed by batches and are subjected to twin-screw extruded granulation. The nylon composite material has good heat conduction effect, high temperature resistance and antifriction performance, and other excellent mechanical properties.

Owner:WUHU YUANKUI NEW MATERIAL TECH CO LTD

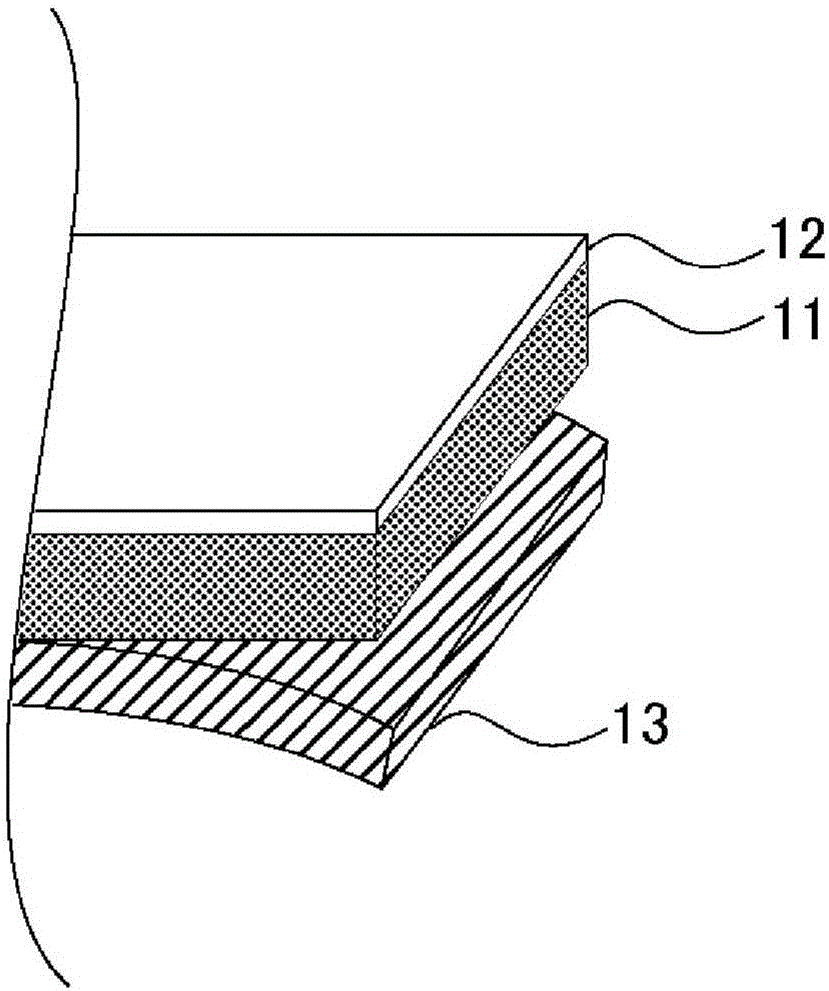

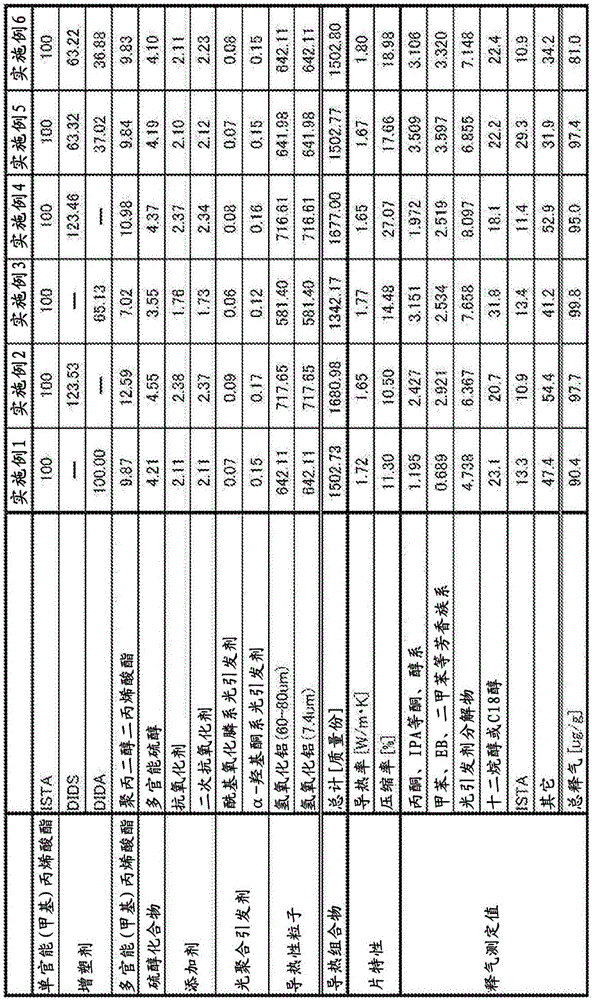

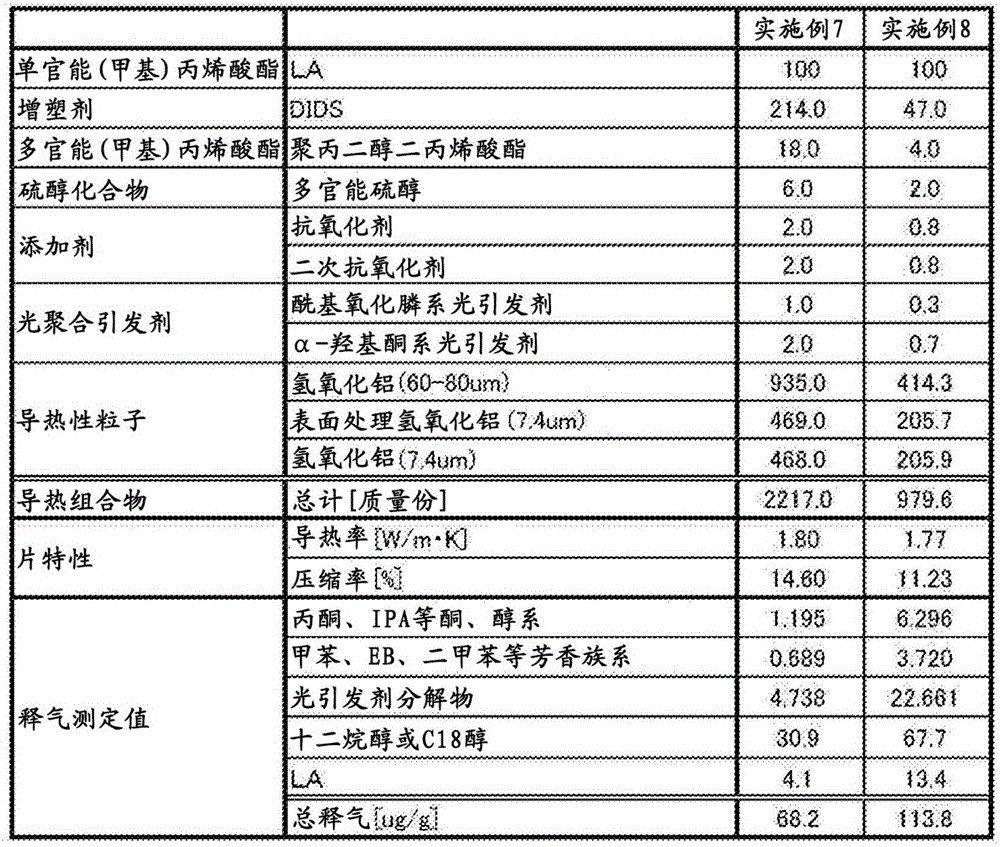

Acrylic thermally conductive composition, and thermally conductive sheet

ActiveCN106459237AGood flexibilitySemiconductor/solid-state device detailsSolid-state devicesThiolPlasticizer

Provided are: an acrylic thermally conductive composition capable of forming a sheet having excellent flexibility and capable of low outgassing; and a thermally conductive sheet. An acrylic thermally conductive composition containing a monofunctional (meth)acrylate, a multifunctional (meth)acrylate, a photopolymerization initiator, thermally conductive particles, a plasticizer, and a thiol compound, wherein the plasticizer comprises one or more types selected from adipate, a pimelic acid ester, a suberic acid ester, azelate, and a sebacic acid ester. Furthermore, the thiol compound is multifunctional thiol, and the thermally conductive sheet has a thermally conductive resin layer (11) obtained by photocuring the acrylic thermally conductive composition.

Owner:DEXERIALS CORP

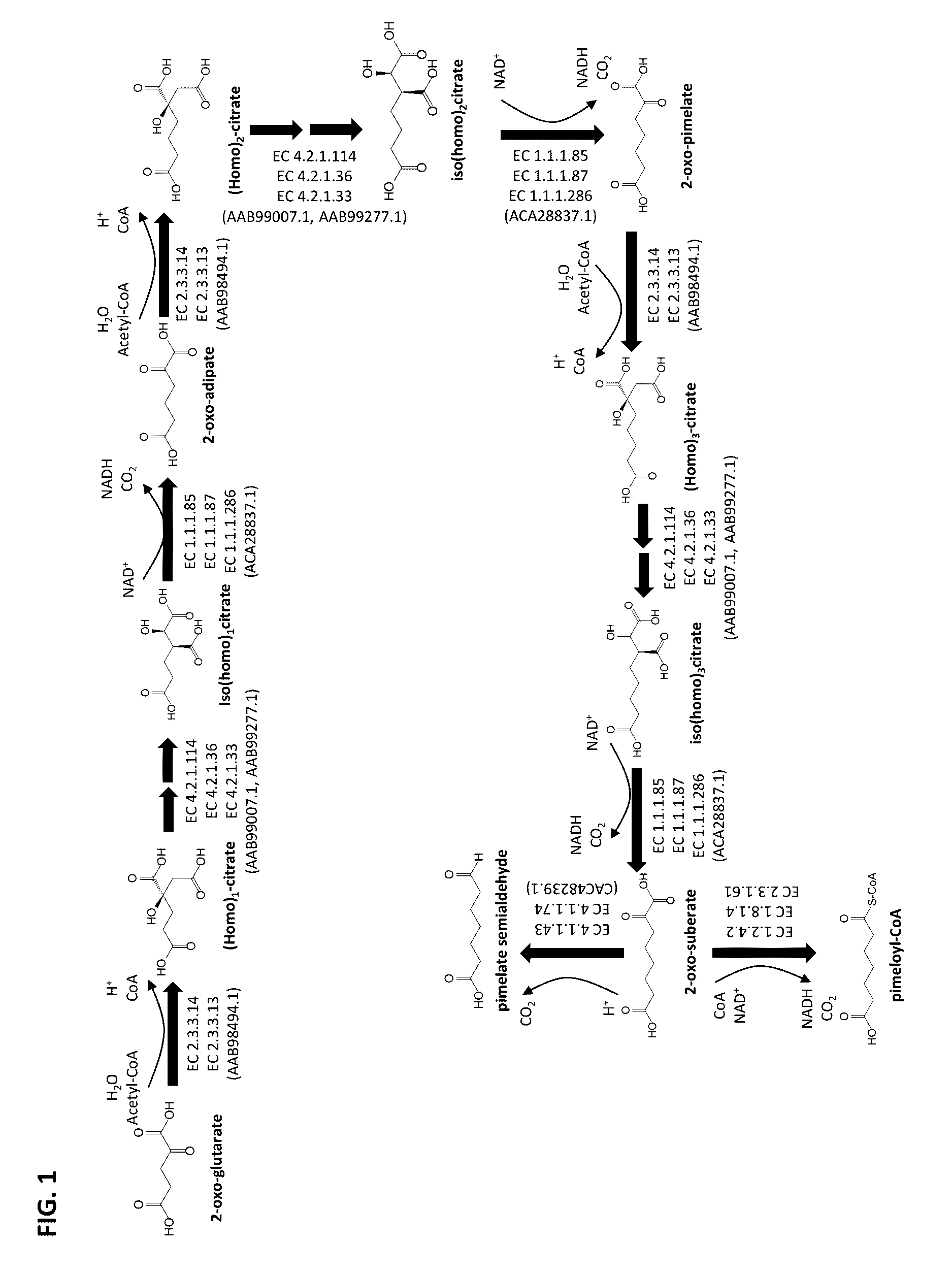

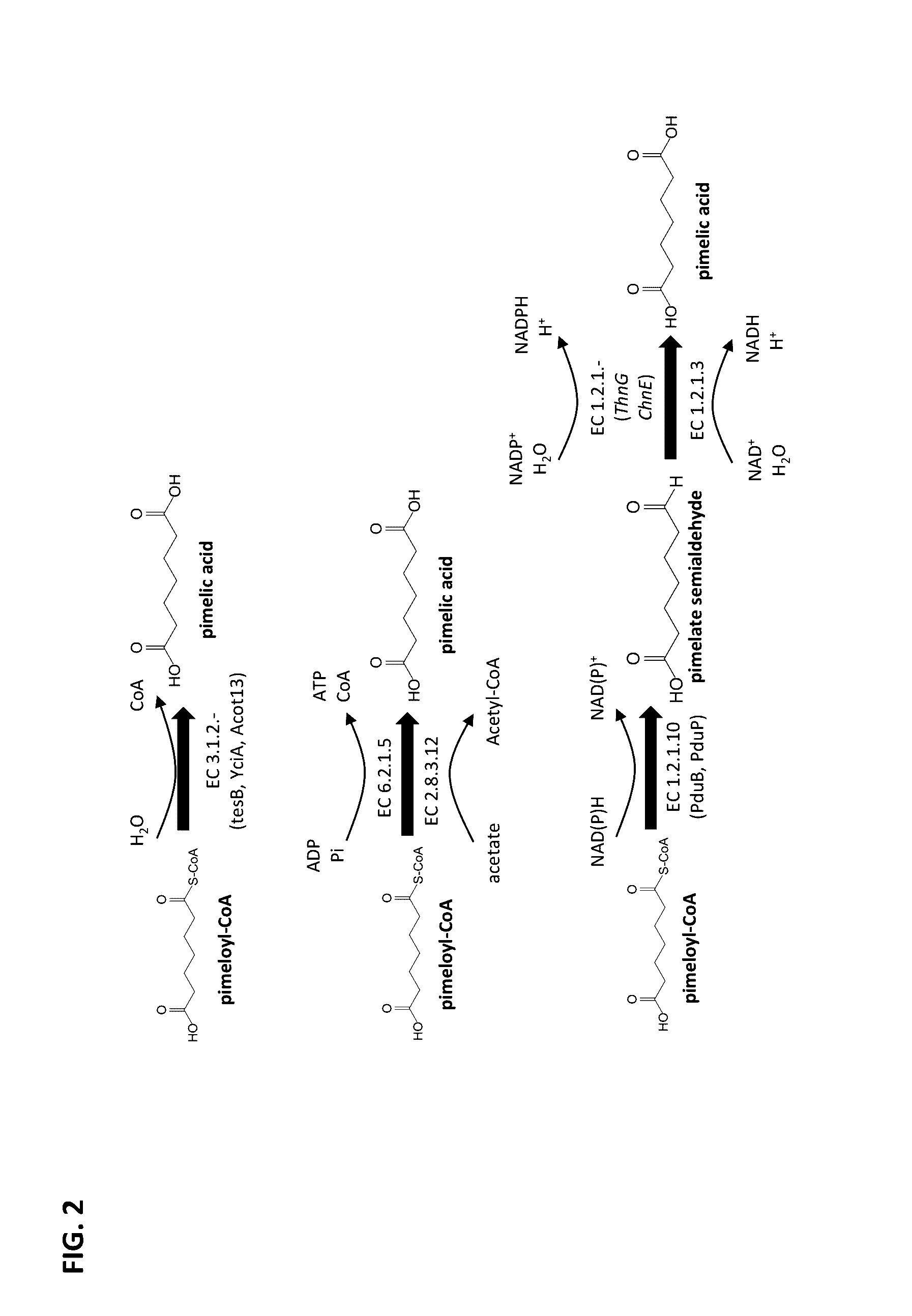

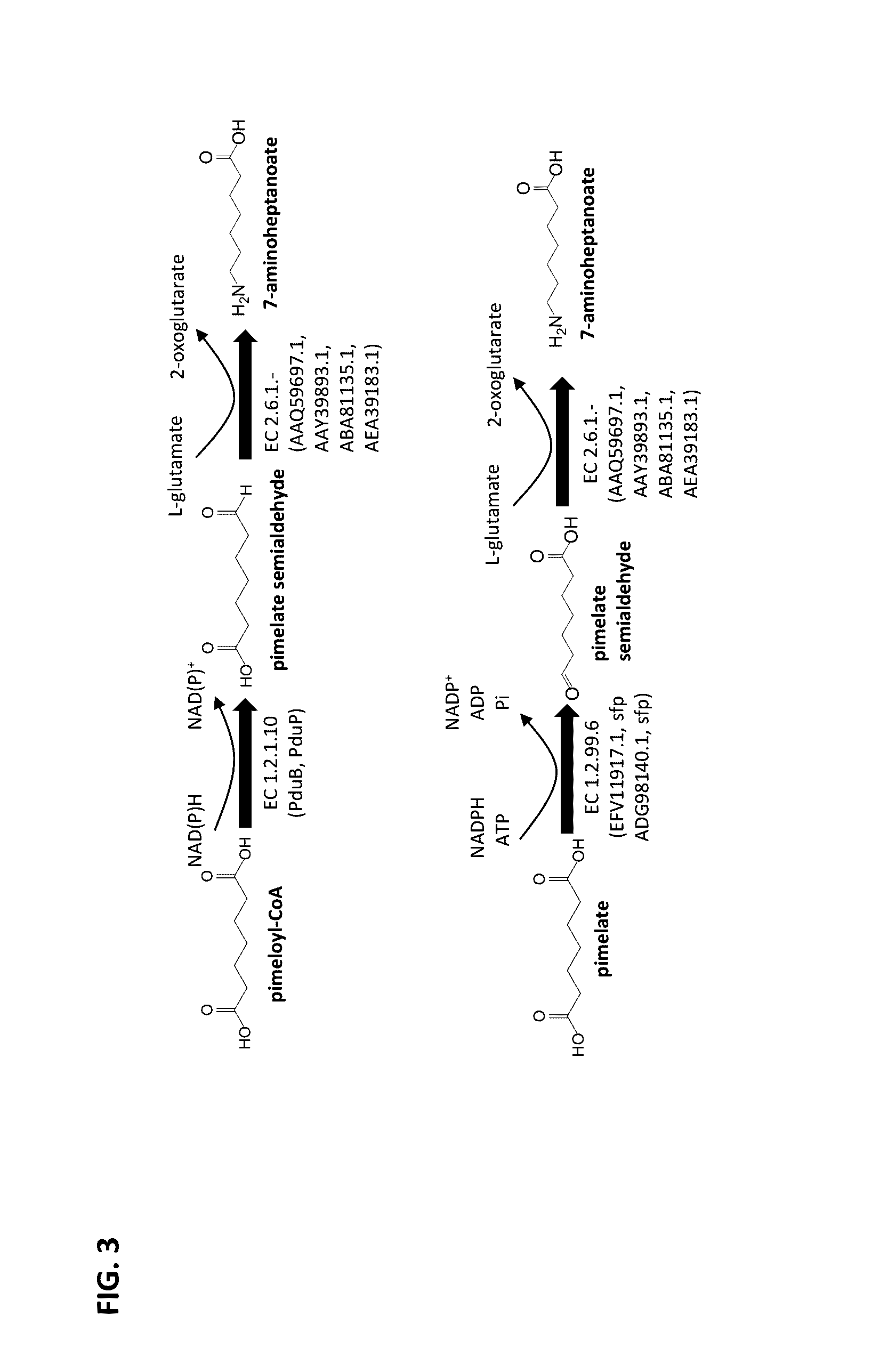

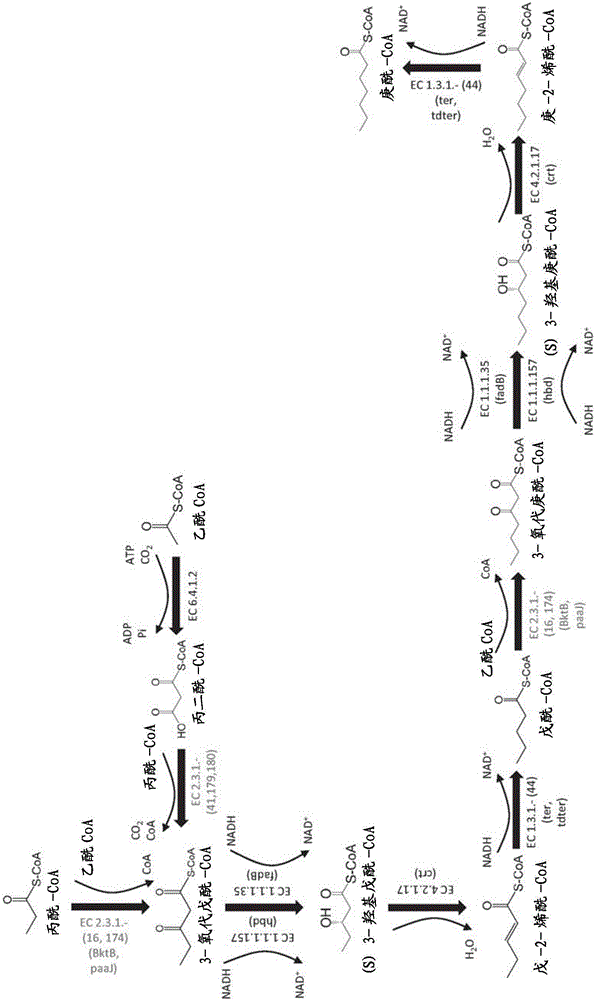

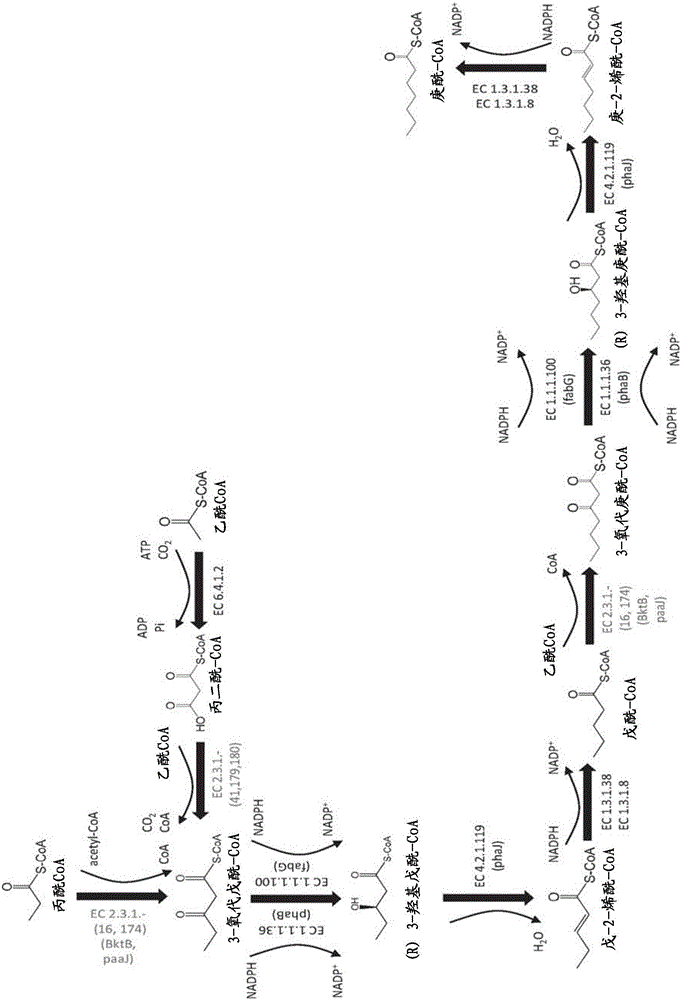

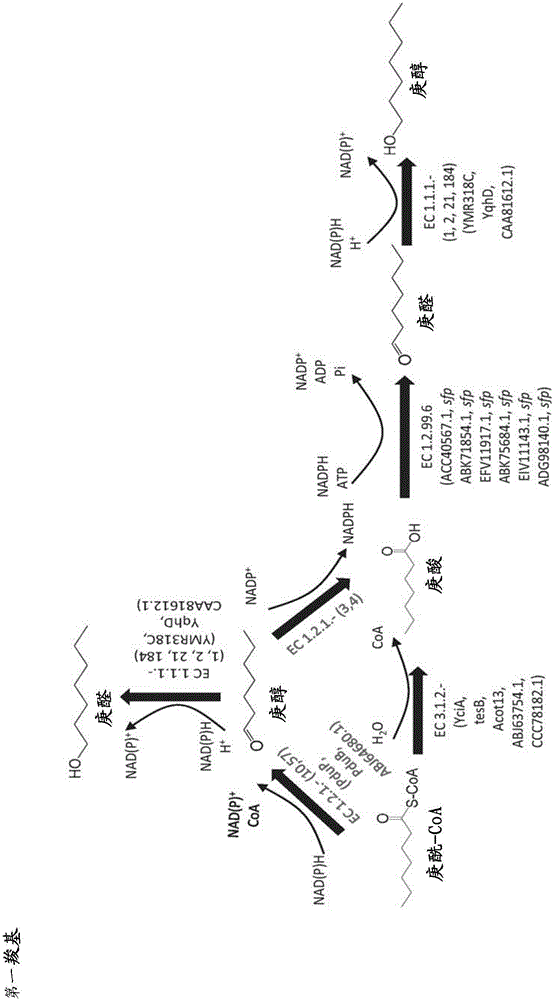

Methods of producing 7-carbon chemicals via c1 carbon chain elongation associated with coenzyme B synthesis

ActiveUS9580731B2High activityTolerance to high concentrations of a C7 building block can be improvedHydrolasesOxidoreductasesCarbon chainCoenzyme B

This document describes biochemical pathways for producing pimelic acid, 7-aminoheptanoic acid, 7-hydroxyheptanoic acid, heptamethylenediamine or 1,7-heptanediol by forming one or two terminal functional groups, each comprised of carboxyl, amine or hydroxyl group, in a C7 aliphatic backbone substrate. These pathways, metabolic engineering and cultivation strategies described herein rely on the C1 elongation enzymes or homolog associated with coenzyme B biosynthesis.

Owner:INV NYLON CHEM AMERICAS LLC

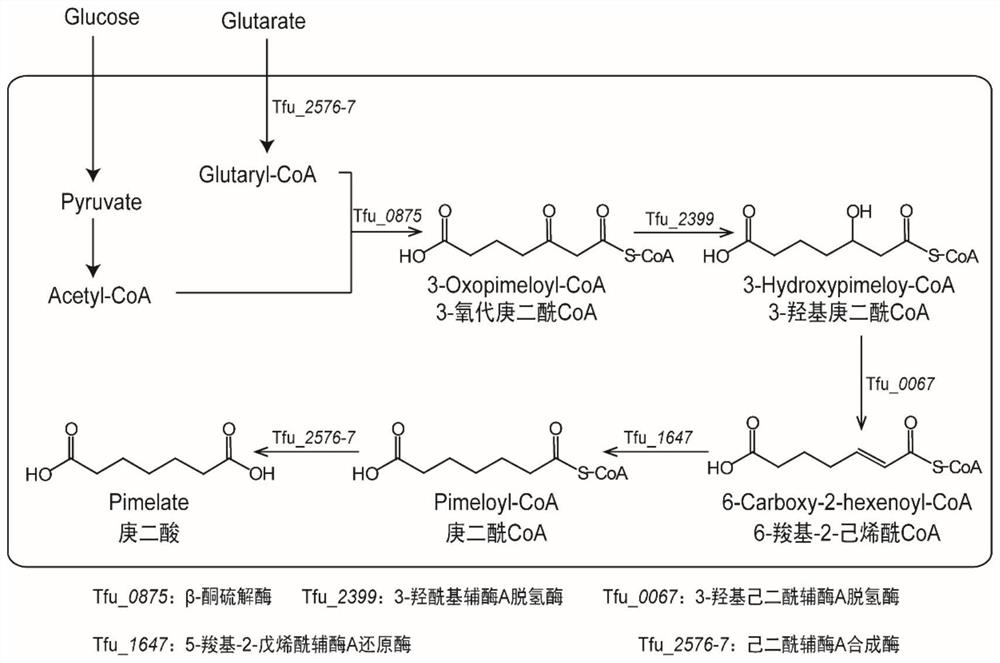

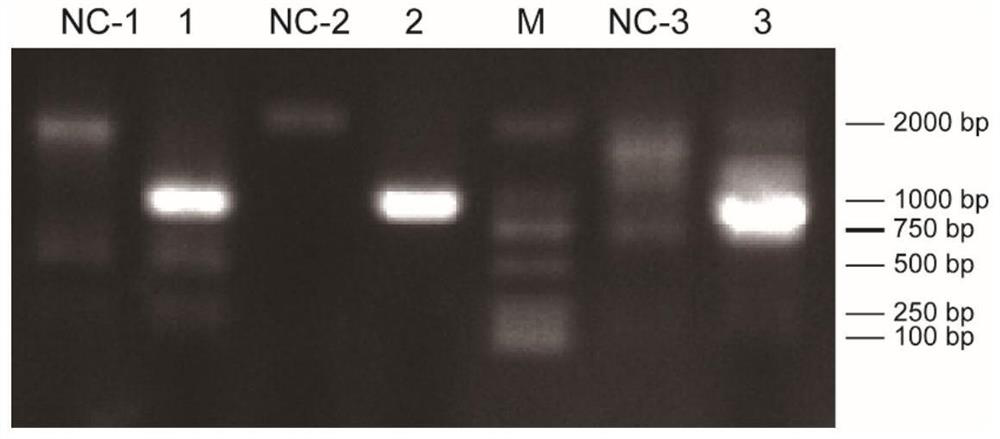

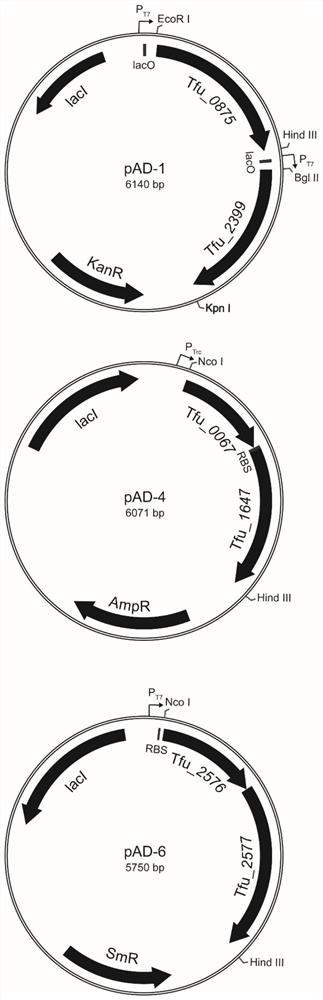

Full-biosynthesis method of pimelic acid

ActiveCN113817782ASimple processIncrease productionBacteriaMicroorganism based processesEscherichia coliCarboxyl radical

The invention discloses a full-biosynthesis method of pimelic acid, and belongs to the field of bioengineering. Escherichia coli BL21(DE3) with a lactate dehydrogenase gene (ldhA), an acetyl-CoA acetyltransferase gene (atoB) and a succinyl-CoA synthetase alpha subunit gene (sucD) knocked out is used as a host, genes of beta-ketothiolase, 3-hydroxyacyl-coenzyme A dehydrogenase, 3-hydroxyadipyl dehydrogenase, 5-carboxyl-2-pentenoyl coenzyme A reductase and adipyl coenzyme A synthetase from thermopsis fusca are overexpressed in modules, and the yield of pimelic acid can reach 252.60mg.L < -1 > through fermentation optimization of added inorganic salt in a culture medium. A new route is provided for synthesis of pimelic acid in the Escherichia coli host, and a new idea is provided for industrial fermentation production of pimelic acid.

Owner:JIANGNAN UNIV

Cement-based crystal master batch material and preparation method

The invention discloses a cement-based crystal master batch material and a preparation method. The material is prepared from, by weight, 0.5-0.7% of citric acid, 0.04-0.09% of sodium tartrate, 15-20%of tartaric acid, 0.3-0.6% of pimelic acid, 0.3-0.5% of copper formate tetrahydrate, 35-40% of dicalcium silicate compound powder materials, 0.02-0.05% of monox compound materials and the balance dicalcium silicate. The cement-based crystal master batch material is applied to cement, has better water-proof performance and is harmless to human bodies, and the preparation method is simple in processand low in production cost and is applicable to industrial production.

Owner:上海美澎材料科技有限公司

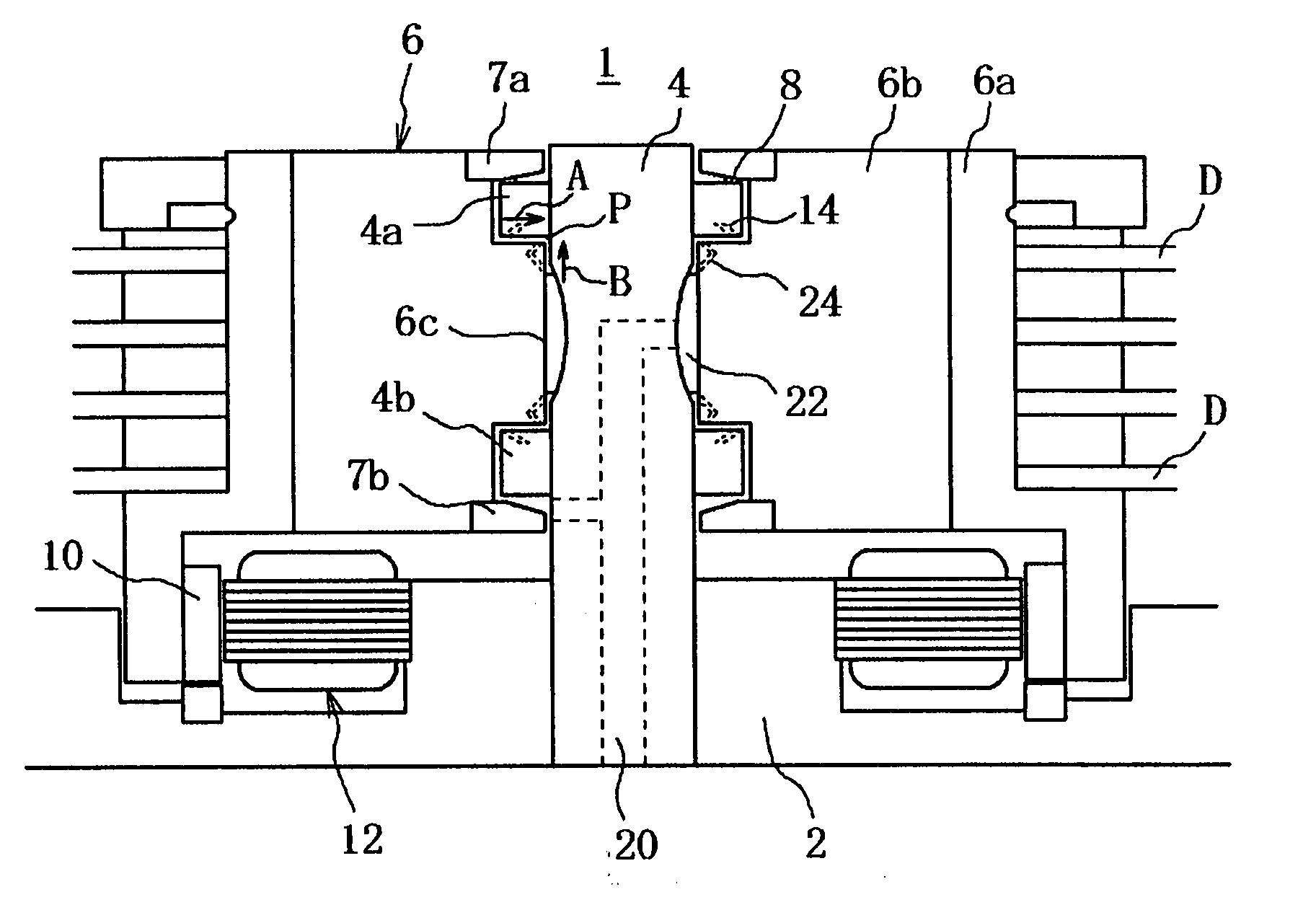

Beta-crystal PPR pipe fitting and production method thereof

The invention provides a production method of a beta-crystal PPR pipe fitting, and belongs to the technical field of chemical building materials. The method is used for improving the heat resistance, the impact performance and the processing performances of the PPR pipe fitting. The pipe fitting comprises, by weight, 100 parts of PPR resin, 0.001-2 parts of a calcium stearate / pimelic acid beta-crystal nucleating agent, 0.001-3 parts of aromatic amide, 0.1-10 parts of inorganic nano-powder, 0.01-1 part of a rheological agent, 0.01-3 parts of an inorganic antiseptic, 0.01-0.3 parts of an antioxidant and 1-10 parts of color master batches. The production method comprises the following steps: uniformly mixing the PPR resin, the beta-crystal nucleating agent, nanometer calcium carbonate, the rheological agent, the antioxidant and the color master batches, and carrying out injection molding through an injection machine in order to obtain the beta-crystal PPR pipe fitting.

Owner:LIAOCHENG UNIV

Methods, reagents and cells for biosynthesizing compounds

This document describes biochemical pathways for producing 7-hydroxyheptanoate methyl ester and heptanoic acid heptyl ester using one or more of a fatty acid O-methyltransferase, an alcohol O-acetyltransferase, and a monooxygenase, as well as recombinant hosts expressing one or more of such exogenous enzymes. 7-hydroxyheptanoate methyl esters and heptanoic acid heptyl esters can be enzymatically converted to pimelic acid, 7-aminoheptanoate, 7-hydroxyheptanoate, heptamethylenediamine, or 1,7-heptanediol.

Owner:INVISTA TEXTILES (U K) LTD

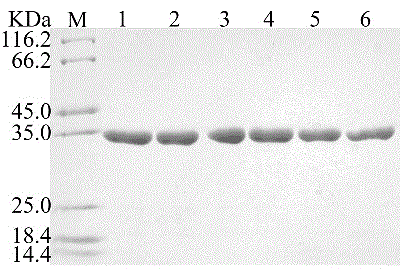

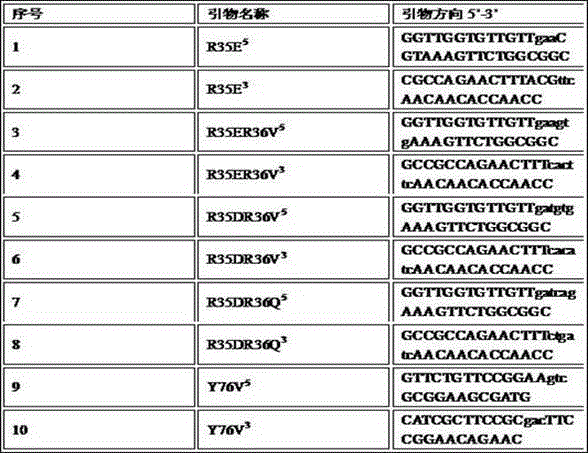

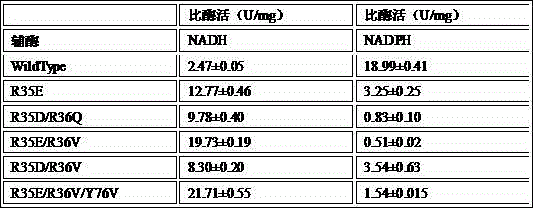

Symbiobacterium thermophilum meso-diaminopimelate dehydrogenase mutants

The invention discloses five symbiobacterium thermophilum meso-diaminopimelate dehydrogenase mutants after coenzyme specific turning. The source of used template enzyme is symbiobacterium thermophilum NADP(H) dependent meso-diaminopimelate dehydrogenase (StDapdh), after enzyme mutation, the amino acid residue with the homology comparison equivalent to the template enzyme site 35 is replaced by glutamic acid which is R35E, the amino acid residue with the homology comparison equivalent to the female parent enzyme site 35 and site 36 are respectively replaced by glutamic acid and valine which are R35E / R36V, the amino acid residue with the homology comparison equivalent to the female parent enzyme site 35 and site 36 are respectively replaced by aspartic acid and valine which are R35d / R36V, the amino acid residue with the homology comparison equivalent to the female parent enzyme site 35 and site 36 are respectively replaced by aspartic acid and glutamine which are R35d / R36Q, the amino acid residue with the homology comparison equivalent to the StDapdh site 35, site 36 and site 76 are respectively replaced by glutamic acid, valine and valine which are R35E / R36V / Y76V, according to the mutant enzyme, the coenzyme specificity is mutated from NADP(H) to NAD(H).

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Homo-polypropylene beta nucleating agent and preparation method thereof

The embodiments of the invention disclose a homo-polypropylene beta nucleating agent, comprising the following components in percentage by mass: 0.1-10% of an efficient beta nucleating agent, 1-5% of an acid absorbent, 1-5% of an excipient, 0-75% of rigid particles and 30-90% of a synergist, preferably, 0.8% of an efficient beta nucleating agent, 3% of an acid absorbent, 2.5% of an excipient, 43.7% of rigid particles and 50% of a synergist. The efficient beta nucleating agent is a pimelic acid metal salt; and the acid absorbent is a fatty acid metal salt. The pimelic acid metal salt comprises zinc pimelate and calcium pimelate. The fatty acid metal salt comprises a fatty acid zinc salt and a fatty acid calcium salt. The embodiments of the invention also disclose a preparation method of the homo-polypropylene beta nucleating agent. The homo-polypropylene beta nucleating agent has the characteristics of high nucleating efficiency and low cost, and greatly improves the toughness of homo-polypropylene when keeping the rigidity and break elongation of the homo-polypropylene.

Owner:方文川 +1

Non-volatile organic water-based soldering flux and preparation method thereof

PendingCN109530968AChemically stableNo irritating smellWelding/cutting media/materialsSoldering mediaWater basedAntioxidant

The invention provides a non-volatile organic water-based soldering flux and a preparation method thereof. The soldering flux is prepared from, by mass, 2.5-7% of an active agent, 2-5% of a surfactant, 0-0.6% of a film forming agent, 0.01-0.2% of an antioxidant, 0.01-0.2% of a corrosion inhibitor, and the balance being deionized solvent water, wherein the active agent is prepared by mixing at least two of itaconic acid, pimelic acid, DL-malic acid, dimethylol butyric acid and methyl succinic acid in a corresponding mass ratio of more than 0% at 30-60 DEG C; the film forming agent is triethanolamine; the antioxidant is hydroquinone; and the corrosion inhibitor is hydroxypropyl chitosan. The water-based soldering flux has no halogen, no rosin, less solid content and small residual after welding and reduces corrosion on a circuit board; the welded surfaces are clean and bright; the volatile gas is little; the irritating odor is inexistent; the health of the operators is not affected; andthe soldering flux is environmentally friendly.

Owner:CHONGQING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com