Patents

Literature

94 results about "Suberic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Suberic acid, also octanedioic acid, is a dicarboxylic acid, with formula C₈H₁₄O₄. It is a colorless crystalline solid used in drug syntheses and plastics manufacture. Its name is derived from the Latin word suber which means cork.

Supported catalysts for the fixation of carbon dioxide into aliphatic polycarbonates and a process for preparing the same

InactiveUS6844287B2Improve efficiencyWeight increaseOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsGlutaric acidCarboxylic acid

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Composition and method for diversion agents for acid stimulation of subterranean formations

InactiveUS6994166B2Effectively and temporarily divertLess permeableFluid removalFlushingCarboxylic acidSolid particle

It has been discovered that solid, particulate dicarboxylic acids are useful as diverting agents in methods for acidizing subterranean formations to improve the uniformity of the acid treatments (acid displacement) by diverting acid to intervals of relatively less permeability. Particularly suitable solid, particulate dicarboxylic acids include, but are not necessarily limited to, those insoluble in both aqueous and hydrocarbon liquids, but which are soluble in mutual solvents or alcohol blends. These acids may have melting points of from about 180 to about 300° F. (about 82 to about 149° C.), formula molecular weights of from 146 to 400, and mesh sizes of from about 20 mesh to about 400 mesh (about 841 to about 38 microns). Particular dicarboxylic acids that fit this description include, but are not necessarily limited to, dodecanedioic acid, undecanedioic acid, decanedioic acid, azelaic acid, suberic acid, and mixtures thereof.

Owner:SUPERIOR ENERGY SERVICES LLC

Supported catalysts for the fixation of carbon dioxide into aliphatic polycarbonates and a process for preparing the same

InactiveUS20030134740A1High catalytic efficiencyHigh molecular weightOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsGlutaric acidCarboxylic acid

The present invention provides a process for preparing supported zinc dicarboxylate catalysts with high activity for the copolymerization of carbon dioxide and epoxides by supporting zinc dicarboxylate on silica support. The zinc dicarboxylate may be synthesized from zinc oxide and dicarboxylic acid such as succinic acid, glutaric acid, adipic acid, pimelic acid and suberic acid. The silica support can be selected from the group consisting of aerosil, silica gel for chromatography or reagent grade silicon dioxide. The supporting process is performed in a planetary ball grinder under vacuum.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

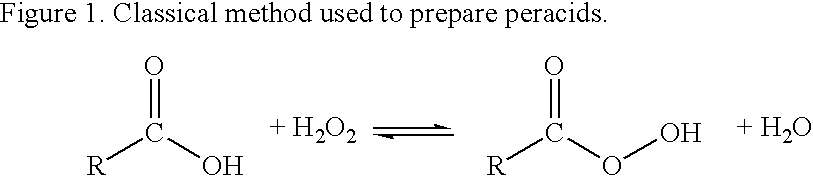

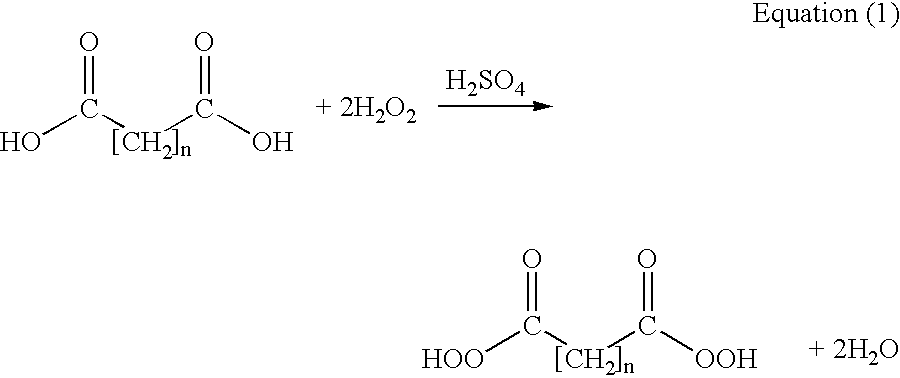

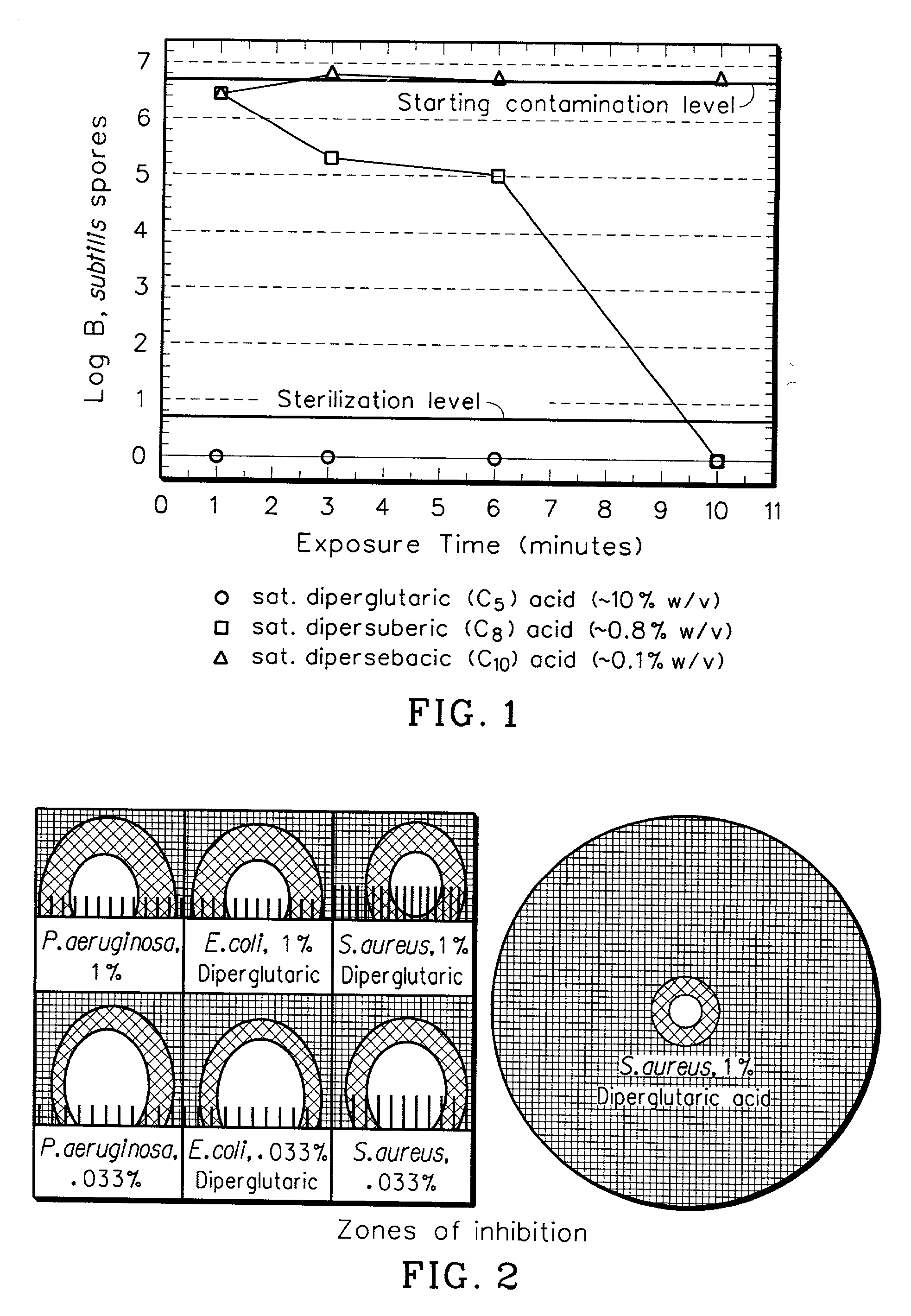

Methods of sterilizing with dipercarboxylic acids

Dry dipercarboxylic acid material and methods of using dry dipercarboxylic acid particulates to form novel sterilizing solutions or liquid chemical germicides. The dipercarboxylic acids or organic diperoxygen compounds can be synthesized and isolated as solid powders with an extended shelf life. The powders are also soluble in water for quickly preparing liquid disinfectant solutions, whenever and wherever desired, from a potable water source. The dry dipercarboxylic acid materials are selected from diperglutaric acid, diperadipic acid, diperpimelic acid, dipersuberic acid, and diperazelaic acid. Upon dissolution into water, these compounds have demonstrated the ability to inactivate high numbers of spores, including sterilization of medical equipment in 10 minutes at room temperature.

Owner:LYNNTECH INT

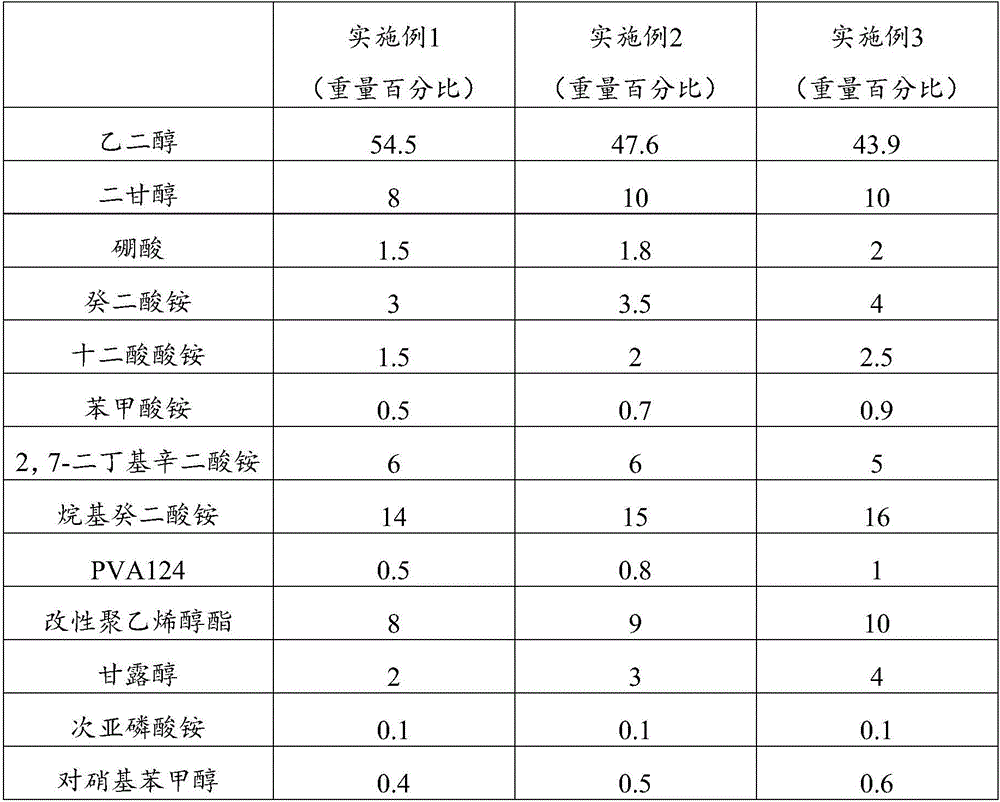

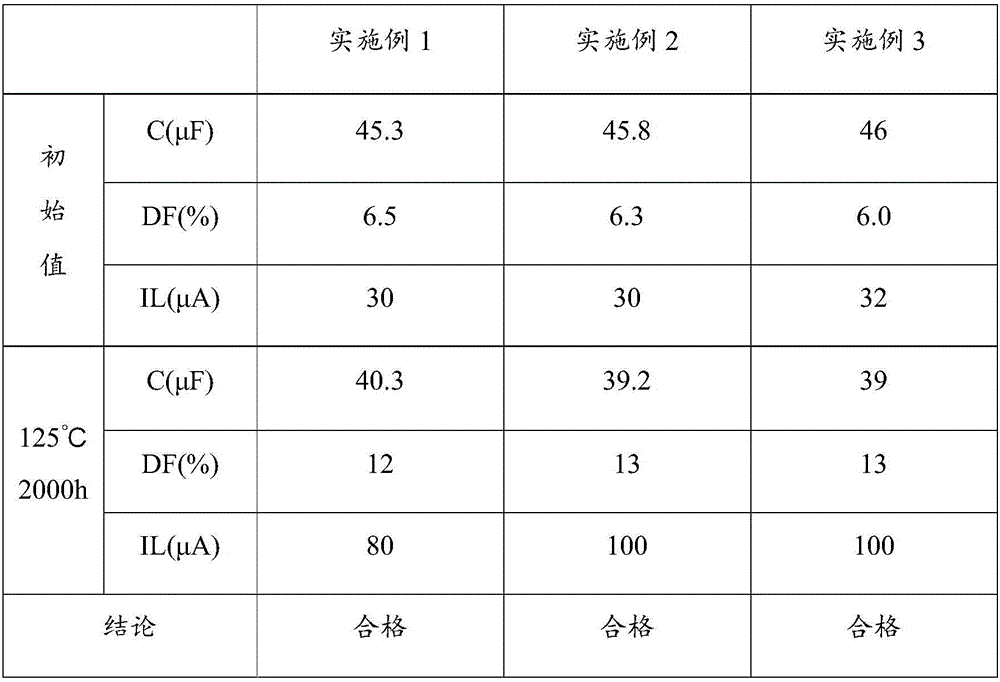

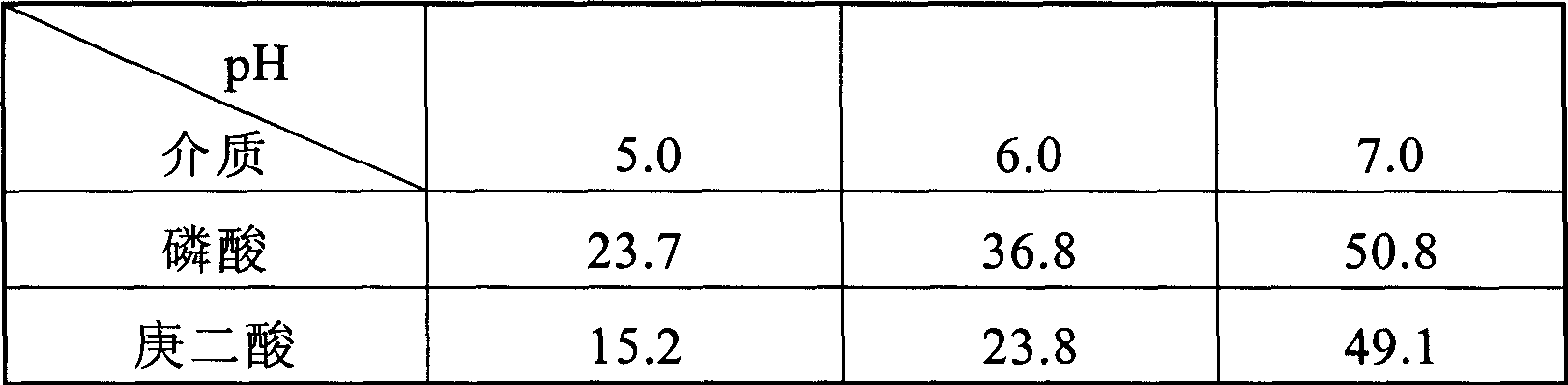

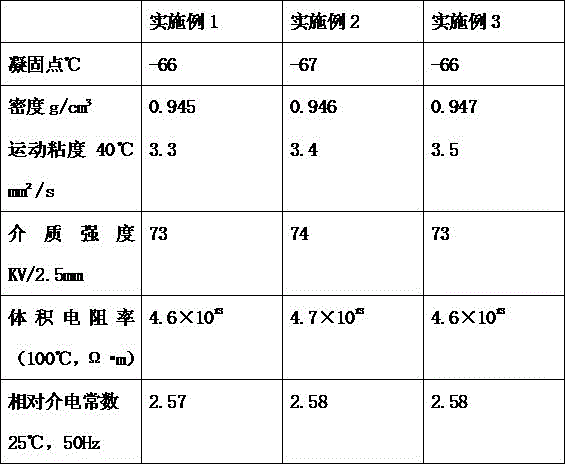

Electrolyte, electrolyte preparation method and aluminum electrolytic capacitor

ActiveCN106098379AImprove temperature resistanceImprove stabilityLiquid electrolytic capacitorsSolventTemperature resistance

The invention discloses an electrolyte, an electrolyte preparation method and an aluminum electrolytic capacitor. The electrolyte comprises, by weight percentage, 50-65w% of solvent, 23-33w% of solute, and 8-19w% of additive. The solute includes boric acid, ammonium benzoate, at least one material selected from ammonium dodecanedioate and 2,7-dibutyl octanedioic acid ammonium, and at least one material selected from ammonium sebate and alkyl ammonium sebate. Through the technical scheme, the temperature resistance performance and stability of the aluminum electrolytic capacitor are improved.

Owner:惠州市智胜新电子技术有限公司

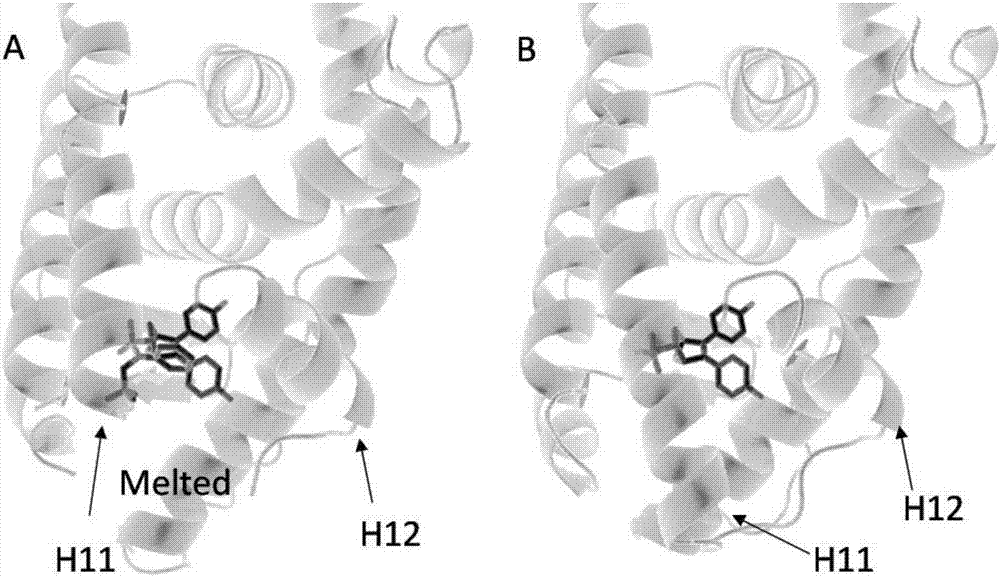

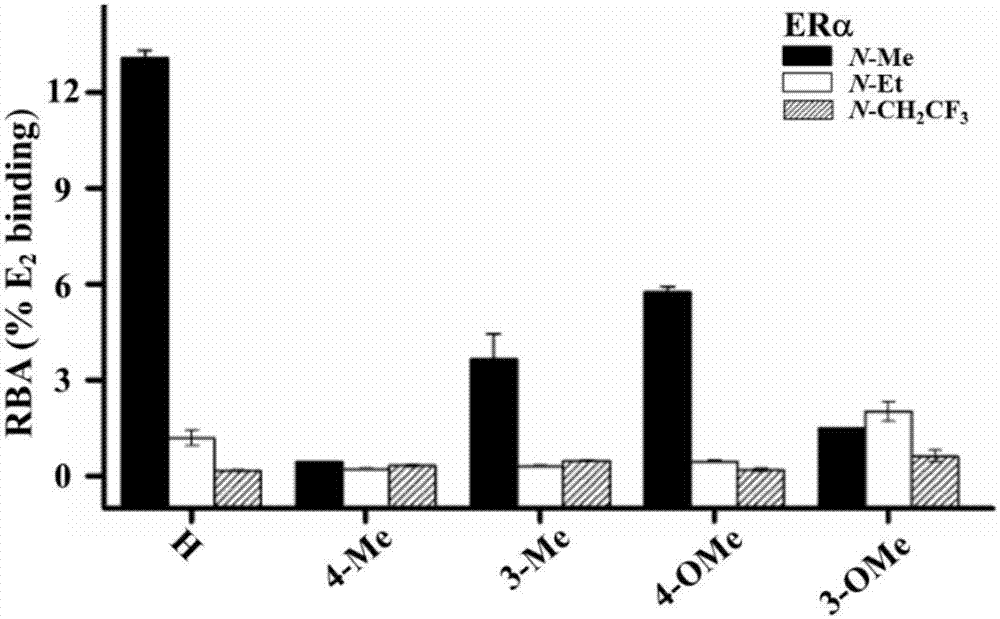

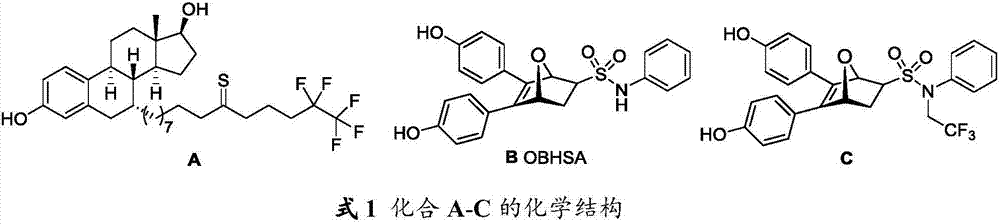

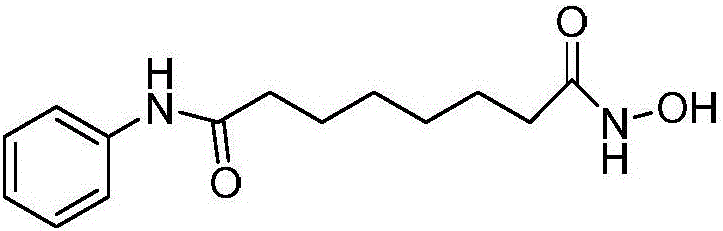

Oxygen bridge bis-heptylene sulfonamide compound containing suberic acid monoanilide group as well as synthesizing method, application and anti-breast cancer drug composition of oxygen bridge bis-heptylene sulfonamide compound

The invention belongs to technical field of medicines and specifically relates to an oxygen bridge bis-heptylene sulfonamide compound containing a suberic acid monoanilide group as well as a synthesizing method, application and an anti-breast cancer drug composition of the oxygen bridge bis-heptylene sulfonamide compound. The oxygen bridge bis-heptylene sulfonamide compound containing the suberic acid monoanilide group is prepared by one-step reaction of the following raw materials: 3-(4-hydroxyphenyl)-4-suberic acid monoanilino-furan and an ethenyl sulfonamide derivative at the temperature of 90 DEG C for 3 without a solvent or a catalyst. The oxygen bridge bis-heptylene sulfonamide compound is different from the existing anti-breast cancer drug tamoxifen in action modes and is an anti-breast cancer compound acting on an estrogen receptor and histone histone deacetylase dual target sites.

Owner:武汉宏兹生物技术有限公司

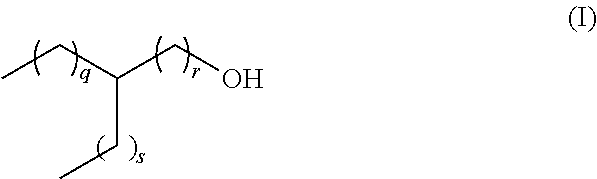

Composition for low temperature

Lubricant composition comprising a dicarboxylic acid ester component which is formed from a dicarboxylic acid selected from the list consisting of adipic acid, phthalic acid, pimilic acid, suberic acid, azelaic acid and sebacic acid, and mixtures thereof and a branched aliphatic alcohol R—OH which is defined according to the following formula (I)whereas q, r and s are defined as follows,q+r=4 to 9,s=0 to 5,q=1 to 8, andr=1 to 6,andan ethylene-propylene copolymer.

Owner:BASF AG

Composition for measuring glucose having improved substrate specificity

InactiveCN1912132AHigh precisionMicrobiological testing/measurementN-Butyric acid2-ketoglutaric acid

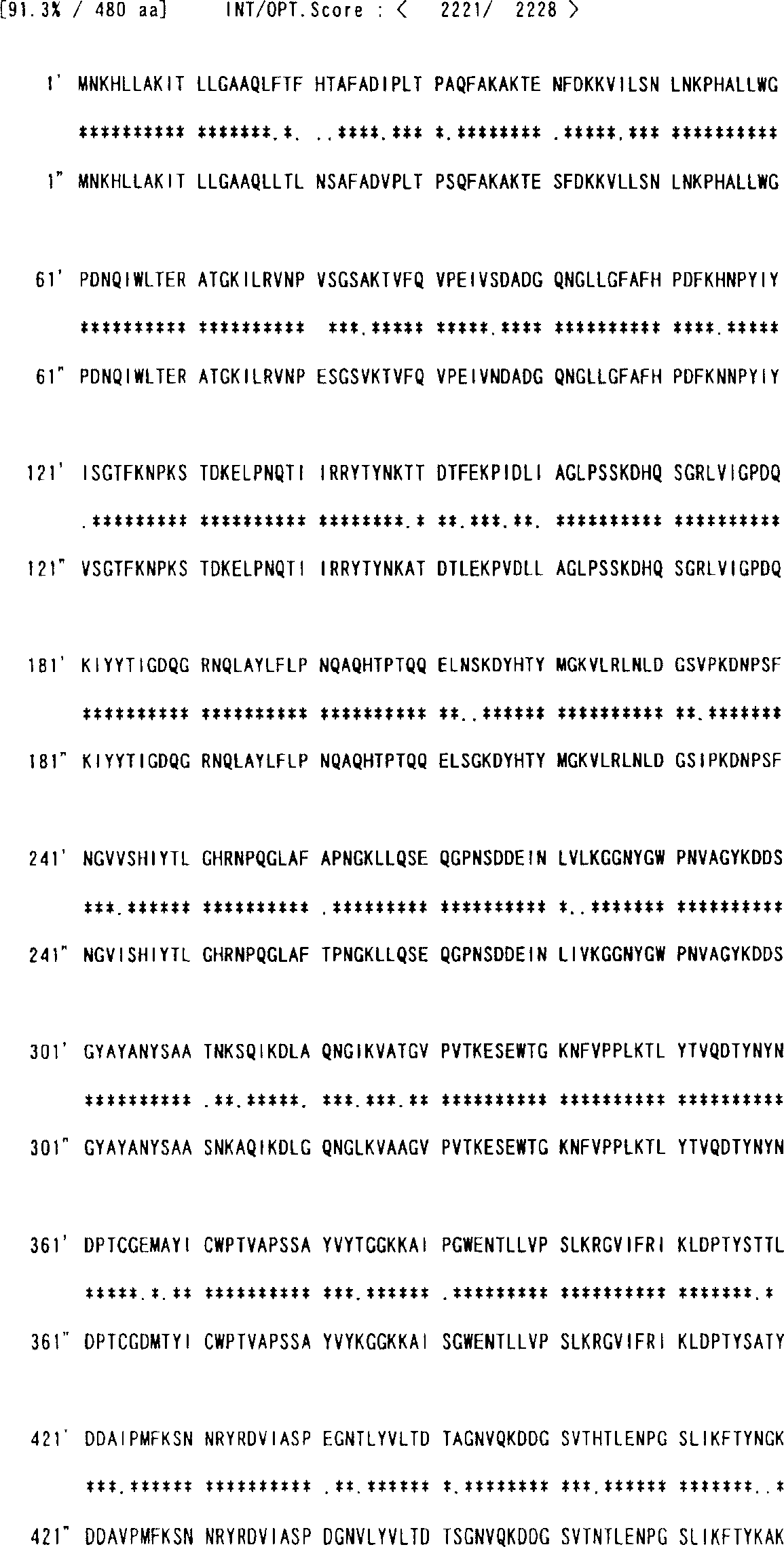

The present invention relates to a method for lowering activity with respect to maltose in glucose measurement comprising a step of reacting modified pyrroloquinoline quinone dependent glucose dehydrogenase subjected to amino acid sequence modification, wherein pyrroloquinoline quinone dependent glucose dehydrogenase is reacted in the presence of at least one type of substance selected from the group comprising succinic acid, malonic acid, glutaric acid, malic acid, phthalic acid, 2-ketoglutaric acid, 3,3-dimethylglutaric acid, pimeric acid, suberic acid, adipic acid, maleic acid, potassium chloride, ammonium chloride, diammonium hydrogen citrate, L-lysine, taurine, calcium glycerate, amino-n-butyric acid, sodium glycolate, sodium alpha-ketoglutarate, fumaric acid, glycine, glutamic acid, serine and citric acid.

Owner:TOYO TOYOBO CO LTD

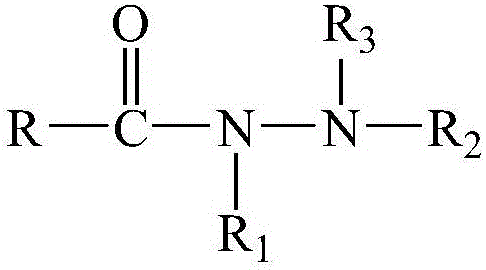

Chlorine fastness improver, and preparation method and application thereof

ActiveCN105839405AEasy to prepareImprove color fastness to chlorineFibre typesDyeing processBenzoic hydrazideAcrylate ester

The invention discloses a chlorine fastness improver, and a preparation method and an application thereof. The chlorine fastness improver comprises, by mass, 1-5% of polyacrylate, 5-48% of a hydrazide derivative, 0.5-6% of a dispersant, and the balance of water. The hydrazide derivative concretely is one or more of octanedioic dihydrazide, azelaic dihydrazide, sebacic dihydrazide, dodecanedioic dihydrazide, isonicotinoylhydrazine, 1,2-diisonicotinic acid hydrazide, 1,2-dimethyl-1,2-dibenzoylhydrazine and isophthalic dihydrazide. The preparation method of the chlorine fastness improver is simple, and the chlorine fastness improver makes chinlon and spandex swimming suit dyed fabrics have the advantages of effectively improved chlorine fastness, small color change, good handle, good chlorine fastness and good water wash resistance.

Owner:东莞市中纺化工有限公司 +1

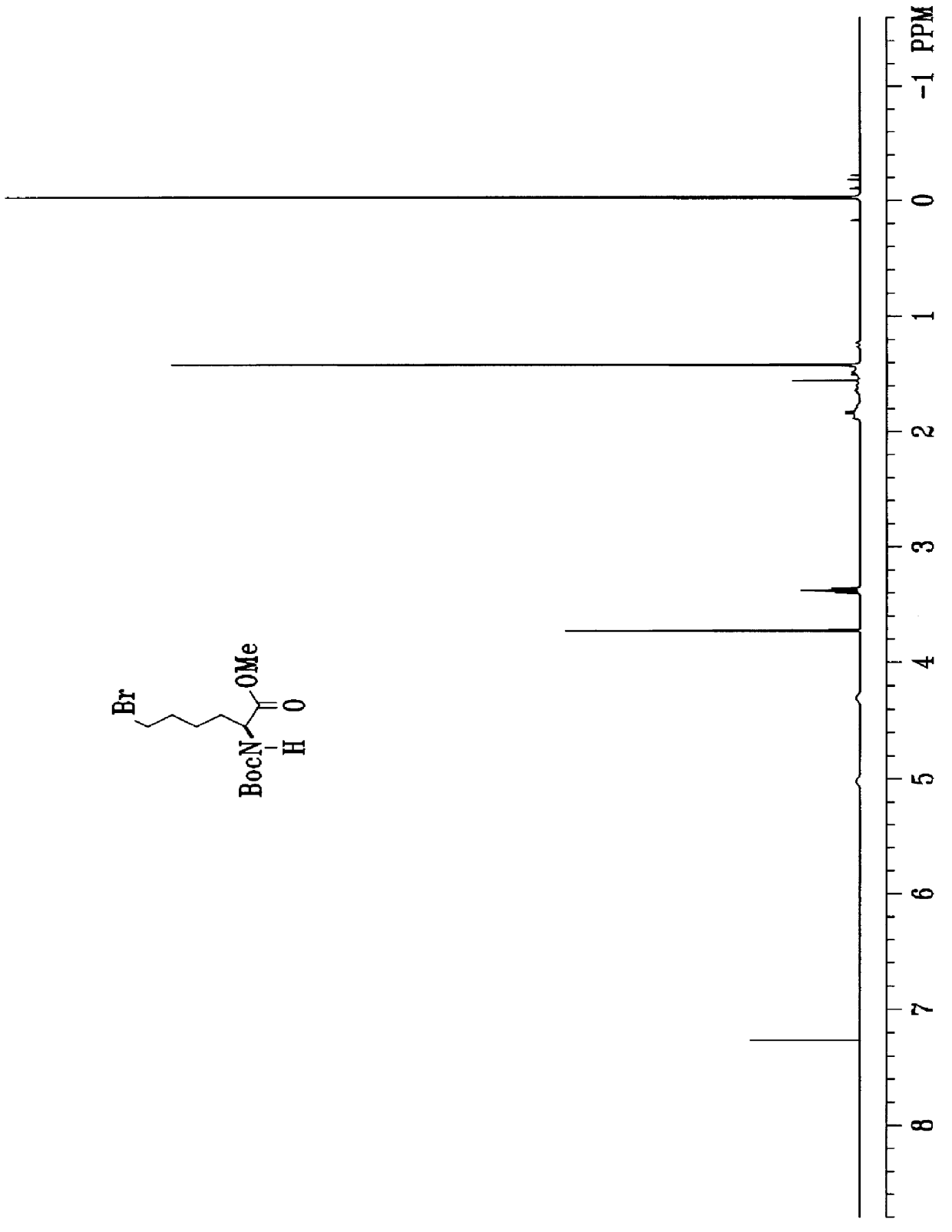

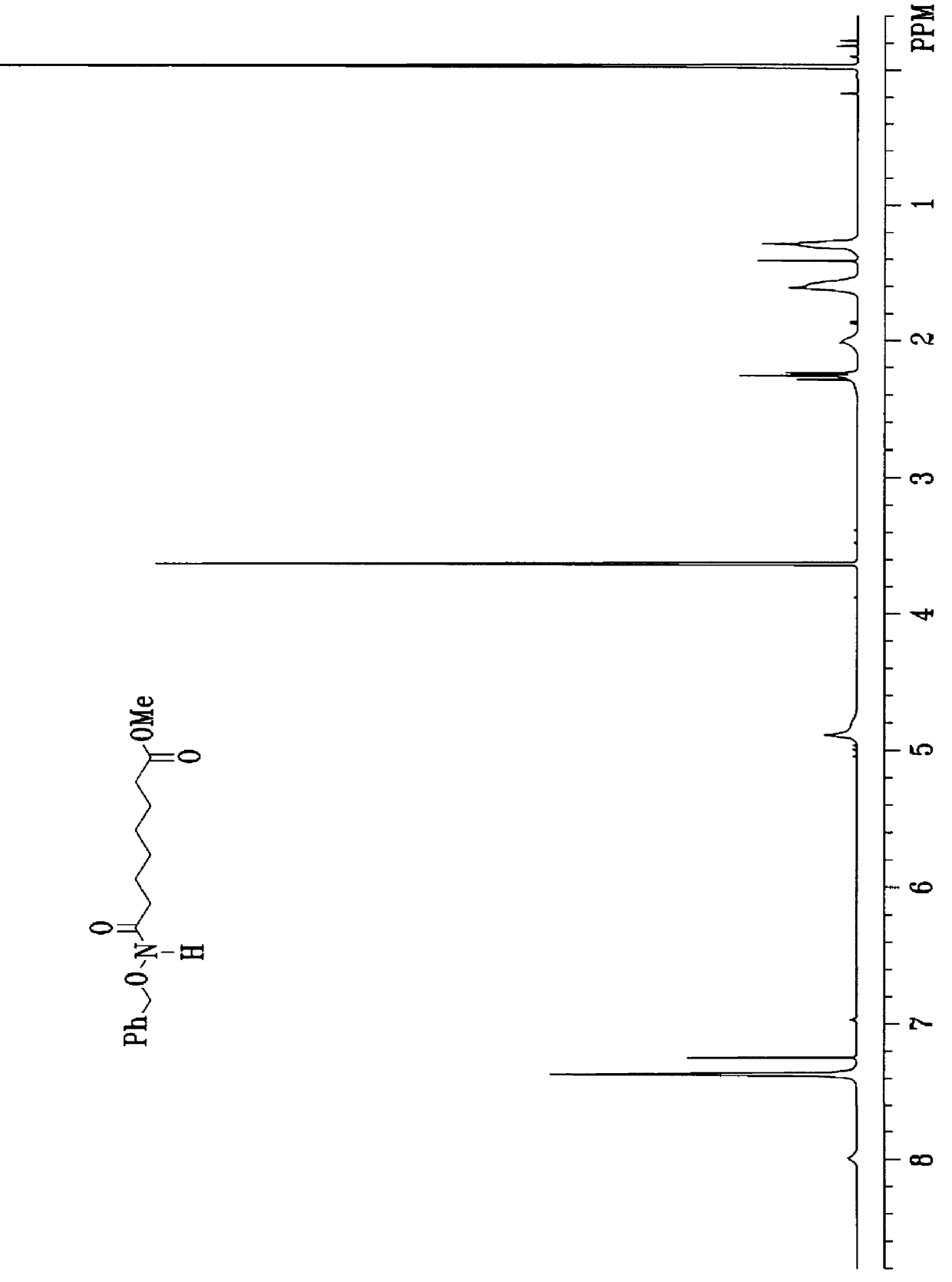

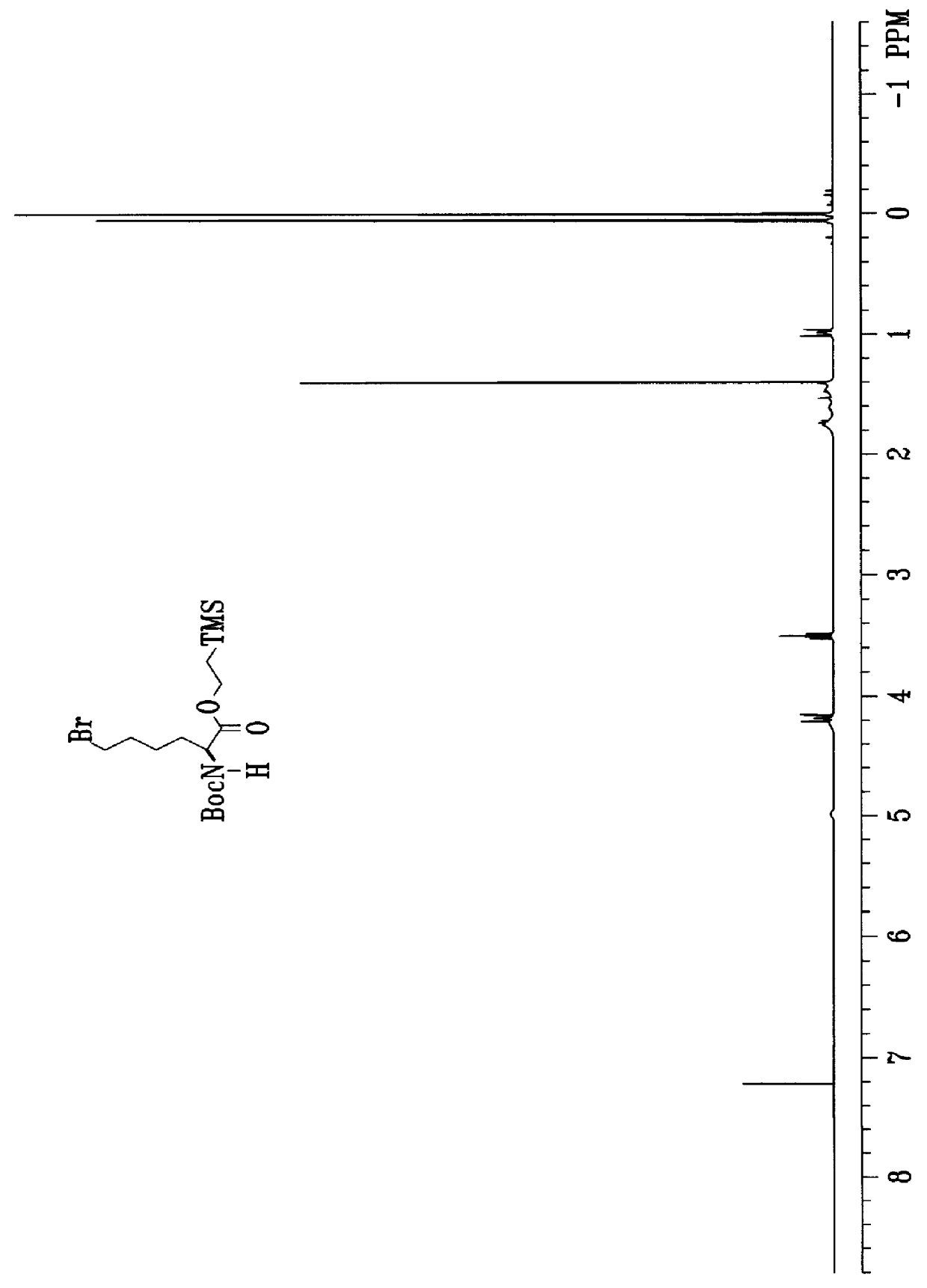

Process for the synthesis of exochelins

InactiveUS6063919AProtects against oxidative damageReduce harmOrganic chemistry methodsDepsipeptidesExochelinsHydrogen

A process for the synthesis of an Exochelin comprising the steps of generating L-N-[(2-benzyloxy-(benzoyl)] serine or L-N-[2-benzyloxy (benzoyl)] threonine, creating L-N-t-Boc- epsilon -hydroxynorleucine and reacting same to produce L-N-Boc- epsilon -bromonorleucine trimethylsilylethyl ester, providing a dicarboxylic acid and forming an O-benzyl methyl hydroxamate from the dicarboxylic acid, coupling the O-benzyl methyl hydroxamate with the L-N-Boc- epsilon -bromonorleucine trimethylsilylethyl ester to give an L-N2-Boc-N6-methyl,N6-(benzyloxy) lysine 2-trimethylsilylethyl ester which incorporates the dicarboxylic acid as modified above, removing the N-tert-butoxycarbonyl protecting group from the L-N2-Boc-N6-methyl, N6-(benzyloxy) lysine 2-trimethylsilylethyl ester to yield a substituted lysine, and coupling the same with the L-N-[2-benzyloxy (benzoyl) serine or -threonine to yield a 2-trimethyl silylethyl ester of dibenzyl Exochelic acid, transforming the 2-trimethyl silylethyl ester of dibenzyl Exochelic acid to dibenzyl Exochelic acid, preparing benzyl epi-cobactin, forming an ester bond between the dibenzyl Exochelic acid and benzyl epi-cobactin to form an intermediate, and, hydrogenolytically removing three benzyl groups from said intermediate, resulting in the synthesized Exochelin. More particularly, a synthesis for Exochelin 786SM (R) is disclosed wherein the dicarboxylic acid is suberic acid and the serine form is utilized.

Owner:KEYSTONE BIOMEDICAL

Lubricating oil for fluid bearing, and fluid bearing and method for lubricating fluid bearing by using the lubricating oil

InactiveUS20090318317A1Low viscosityReduce evaporationOrganic chemistryShaftsGlutaric acidEvaporation

Disclosed is a lubricating oil for a fluid bearing, which has a low viscosity, a reduced amount of evaporation, and superior low-temperature flowability. The lubricating oil includes, as a base oil, a high-purity diester synthesized from a carboxylic acid material containing 90 mass % or more of azelaic acid and an alcohol material containing 90 mass % or more of 2-ethyl-1-hexanol. The carboxylic acid material contains glutaric acid, adipic acid, pimelic acid, suberic acid, sebacic acid and 1,9-nanomethylenedicarboxylic acid in a total amount of 5 mass % or less.

Owner:JAPAN ENERGY CORP +1

Preparation method of double-layer Mxene film based on different interlayer spacing

ActiveCN113457448AEasy to operateReduce energy consumptionSemi-permeable membranesFilm baseFiltration

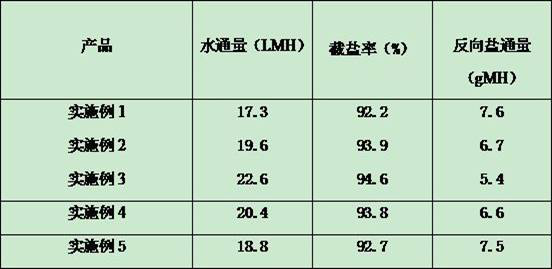

The invention discloses a preparation method of a double-layer Mxene membrane based on different interlayer spacing, which comprises the following steps: taking titanium aluminum carbide (Ti3AlC2), hydrochloric acid (HCl) and lithium fluoride (LiF) as raw materials and PVDF (Polyvinylidene Fluoride) as a base membrane, sequentially adding HCl, LiF and Ti3AlC2 in a mass ratio of (10-20): (1-1.8): 1 into a reactor, heating and stirring at 30-40 DEG C for 24-48 hours, and repeatedly washing, centrifuging and ultrasonically stripping to obtain an Mxene solution; taking a mixed solution of the MXene solution, magnesium chloride (MgCl) and maleic acid (MA) in an isovolumetric concentration ratio of 1: (0.5-1): (0.5-1), carrying out vacuum suction filtration on a base membrane, and carrying out vacuum drying at 70-80 DEG C for 5-6 hours to obtain an MXene membrane; and then taking a mixed solution of an MXene solution, sodium chloride (NaCl) and suberic acid (SA) with the isovolumetric concentration ratio of 1: (0.5-1): (0.5-1), carrying out vacuum suction filtration on the MXene membrane, and carrying out vacuum drying for 5-6 hours at the temperature of 70-80 DEG C to obtain the double-layer MXene membrane. The preparation method disclosed by the invention is simple, and the obtained double-layer membrane has relatively high water flux and salt rejection rate and relatively low reverse salt flux, can filter substances with different molecular sizes, and is mainly applied to the field of hard water softening.

Owner:CHONGQING TECH & BUSINESS UNIV

High-strength high-temperature-resistant polyvinyl chloride plastic

InactiveCN104262835AIncrease added valueOvercome the disadvantages of a single materialAntioxidantPolyvinyl chloride

The invention relates to a high-strength high-temperature-resistant polyvinyl chloride plastic which comprises 120 parts of polyvinyl chloride, 7 parts of vinyl acetate, 4 parts of calcium stearate, 1 part of ethylene propylene diene monomer rubber, 5 parts of octane diacid, 7 parts of polyethenoxy ether, 45 parts of ABS (acrylonitrile-butadiene-styrene) plastic, 1 part of heat-resistant agent and 2 parts of antioxidant. The plastic can fully display the advantages of the components in the material, can resist high temperature, overcomes the defects in the single material in the prior art, and has the advantages of low cost, higher added value and excellent comprehensive properties.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

Degradable plastic bag and production method thereof

InactiveCN110016179AImprove antibacterial propertiesGood biocompatibilityFiberLinear low-density polyethylene

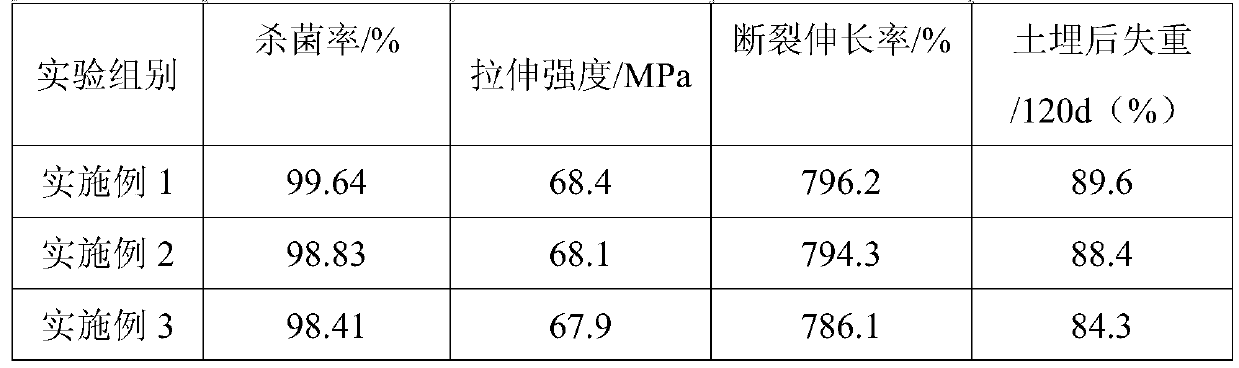

The invention discloses a degradable plastic bag. The degradable plastic bag comprises the following raw materials of an ethylene-acrylic acid copolymer, lignosulfonate, epichlorohydrin, a modified antibacterial agent, linear low-density polyethylene, polyvinyl alcohol, polylactic acid, pentaerythritol, suberic acid, diphenylmethane diisocyanate, dioctyl phthalate, a silane coupling agent KH-570,bamboo fibers, potato starch, montmorillonoid, konjac glucomannan, calcium carbonate, liquid paraffin, ethylene acrylic ester, glycerin and fatty acyl diethanol amine. A production method of the degradable plastic bag is further provided. The produced degradable plastic bag has excellent antibacterial performance and mechanical strength.

Owner:长沙而道新能源科技有限公司

Special aluminum electrolytic capacitor for vehicle-mounted electronics

ActiveCN111029152AExtended service lifeWide operating temperature rangeCapacitor housing/encapsulationCapacitanceElectrolytic agent

The invention discloses a special aluminum electrolytic capacitor for vehicle-mounted electronics. An electrolyte comprises the following components in percentage by weight: 20%-35% of solute, 15%-20%of additive and the balance of solvent, wherein the solute is ammonium azelate, ammonium adipate, ammonium suberate and carboxylate containing a cyclobutane group, the additive is a waterproof mixture, and the solvent is ethylene glycol, ammonium sebacate and branched carboxylate. A core package is soaked with electrolyte with specific composition and proportion; the anode foil is a formed voltage-withstanding aluminum foil adopting 1.6 times of capacitor rated voltage, and the anode foil adopts a corrosion energizing aluminum foil with energizing voltage of 530V; the contact resistance between the positive electrode guide pin and the anode foil is 0.8 momega or less; and the contact resistance between the negative electrode guide pin and electrode cathode foil is 1 momega or less. Through improvement of process materials and conditions and overall cooperation, the aluminum electrolytic capacitor has thermal stability within the temperature range of -40 DEG C to 125 DEG C and is longin service life at 105 DEG C.

Owner:ZHAOQING BERYL ELECTRONICS TECH

Semi-aromatic polyamide and polyamide molding composition composed of same

The invention discloses semi-aromatic polyamide which comprises the following repetitive units based on the molar content of all repetitive units of a chain segment: (a) 53 mol / % to 71 mol / % of a 10Tunit derived from 1,10-decamethylene diamine and terephthalic acid; and (b) 29 mol / % to 47 mol / % of a 10X unit derived from at least one of 1,10-decanediamine and isophthalic acid, 1,4-cyclohexanedicarboxylic acid, adipic acid, octanedioic acid, 1,10-decanedioic acid, 1,12-dodecanedioic acid, and pentadecanedioic acid; in the semi-aromatic polyamide, the molar content of bio-based carbon is 39 mol%-100 mol%; in the semi-aromatic polyamide, the amino content is 30-100 mol / ton, and the carboxyl content is 30-200 mol / ton. The semi-aromatic polyamide with excellent colorability is obtained by controlling the content of bio-based carbon, the content of amino and the content of carboxyl and matching the content of all the repetitive units with monomers.

Owner:KINGFA SCI & TECH CO LTD +1

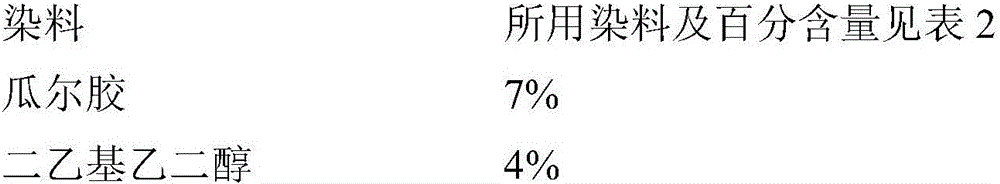

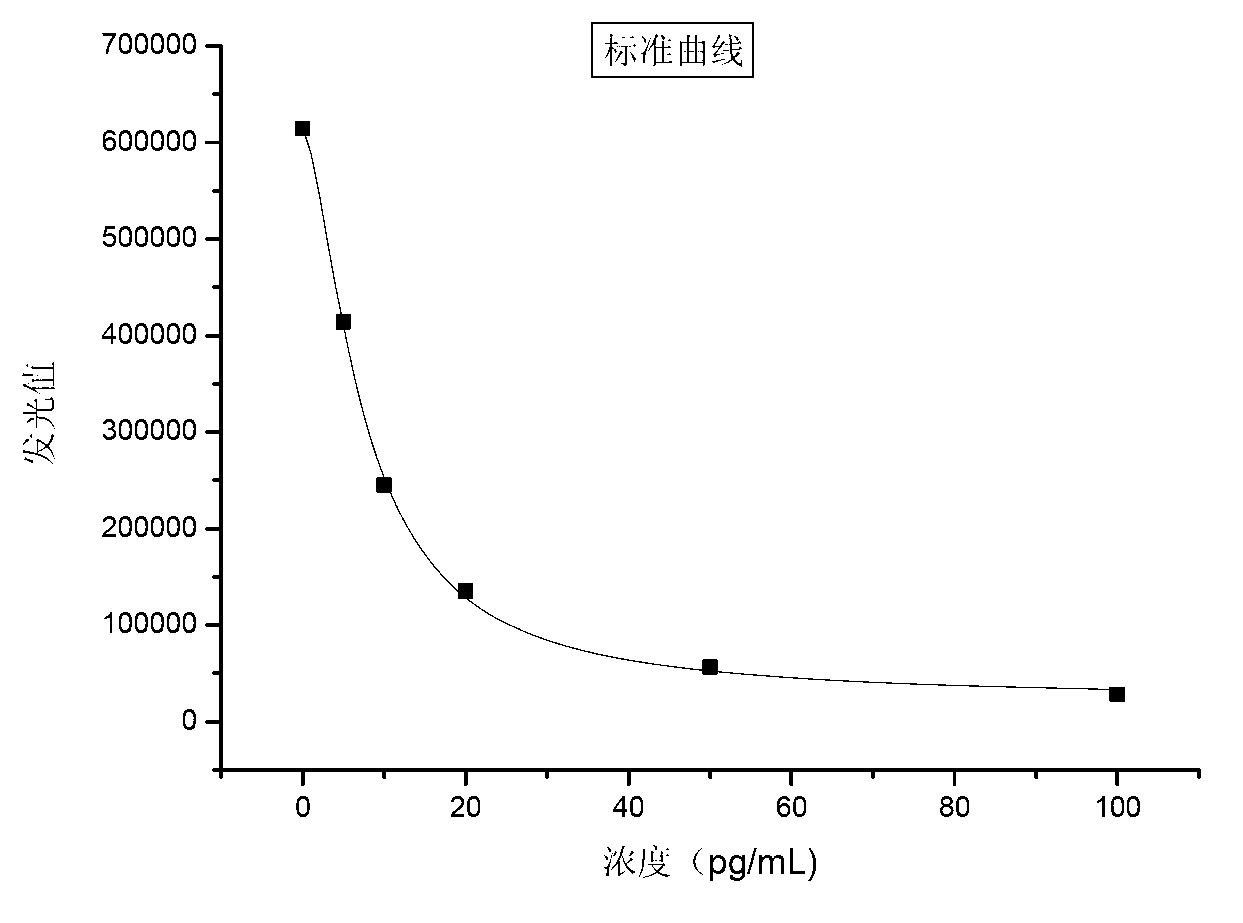

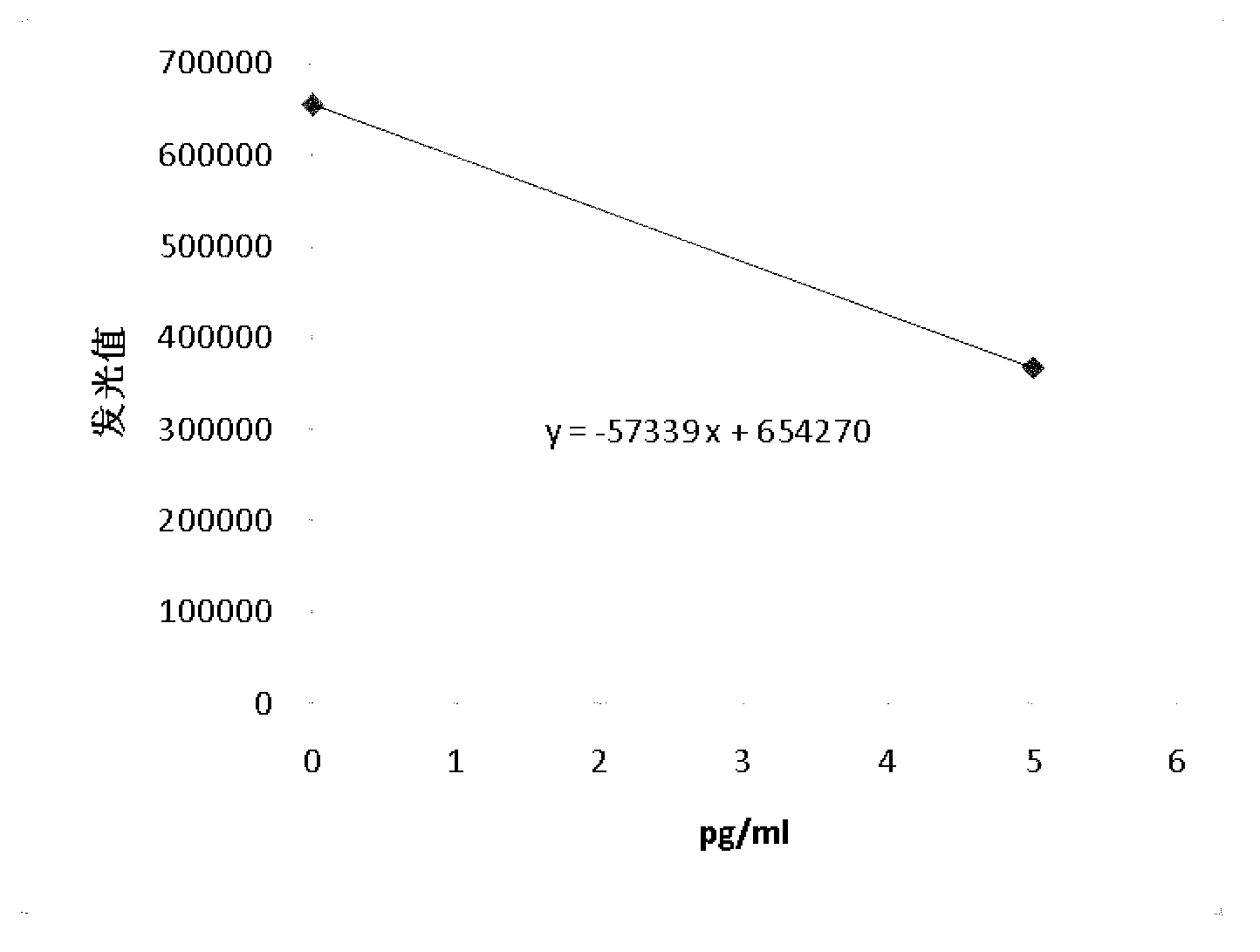

Free thyroxine nanometer magnetic particle chemiluminescence assay kit and preparation method thereof and detection method thereof

ActiveCN103063852AHigh precisionAnalysis of small differences between batchesChemiluminescene/bioluminescenceBiological testingAntigenMicroparticle

The invention relates to a free thyroxine nanometer magnetic particle chemiluminescence assay kit and a preparation method thereof and a detection method thereof. The free thyroxine nanometer magnetic particle chemiluminescence assay kit comprises solutions containing fluorescein-labeled free thyroid antibodies, suspension liquid of magnetic particles covered with fluorescein-resistance antibodies and solutions containing alkaline-phosphatase-labeled free thyroxine antigens, wherein the alkaline-phosphatase-labeled free thyroxine antigens are formed by the connection of alkaline phosphatase and the free thyroxine antigens through crosslinking agent suberic acid succinimide ester. The free thyroxine nanometer magnetic particle chemiluminescence assay kit and the preparation method thereof and the detection method thereof have the advantage of enabling the free thyroxine to be quantificationally detected on the condition of lower cost, higher accuracy and higher precision.

Owner:SUZHOU HAOOUBO BIOPHARML

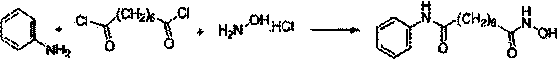

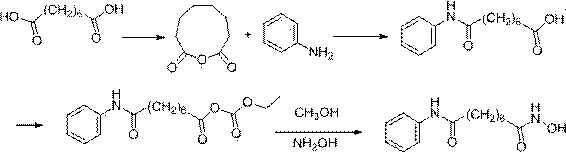

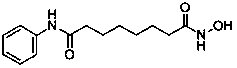

Method for synthesizing anti-cancer drug vorinostat

The invention relates to a method for synthesizing anti-cancer drug vorinostat and belongs to the field of drug synthesis technology. The method comprises the steps of: reacting octanedioic acid with aniline in the presence of perfluorinated sulfonic acid resin to obtain suberanilic acid; reacting the suberanilic acid with hydroxylamine in the presence of a condensation agent 1,3-dicyclohexyl carbodiimide; separating the product vorinostat. The intermediate product suberanilic acid prepared by the method is high in purity, good in yield, low in impurity content and is safe and environment-friendly, and therefore the prepared crude product vorinostat has high purity and good yield.

Owner:NANTONG FINC PHARMA CHEM

Preparation method of corn-flavored essence

The invention discloses a preparation method of a corn-flavored essence. The preparation method comprises the following steps: heating taken vitamin B1, L-arginine, L-aspartic acid, L-proline, L-lysine monohydrochloride, reducing sugar, water, propylene glycol and an oil soluble solvent to 95-110 DEG C under the stirring condition, carrying out condensation and reflux reaction for 3-8 hours, and cooling to a room temperature; and centrifuging and taking superstratum, so as to obtain an oil-soluble corn-flavored essence. With amino acid and reducing sugar as main raw materials, and oil such as suberic acid glyceride as solvents, the corn-flavored essence is prepared through maillard reaction; and the corn-flavored essence is high in aroma strength, excellent in high temperature resistance and applicable to the field of baking.

Owner:YUNNAN SHENBOYUAN BIOLOGICAL TECH

Method for preparing anticancer drug--Vorinostat

InactiveCN106187818AHigh yieldMild conditionsOrganic compound preparationCarboxylic acid amides preparationHydroxylamine HydrochlorideAniline

The invention discloses a method for preparing an anticancer drug--Vorinostat. The method comprises the following steps: 1) subjecting a hydrophilic substrate and octanedioic acid to contacting and carrying out self-assembling so as to obtain an octanedioic acid-substrate self-assembled film; 2) in the presence of 1,3-dicyclohexylcarbodiimide, subjecting the octanedioic acid-substrate self-assembled film to contacting with aniline in THF, after a reaction is completed, adding a 4M HCl solution and carrying out a reaction under stirring, and carrying out extraction with dichloromethane so as to obtain octanedioic acid monoanilide; and 3) subjecting octanedioic acid monoanilide and hydroxylamine hydrochloride to a reaction so as to obtain Vorinostat. The preparation method for Vorinostat provided by the invention provides a novel synthetic route for Vorinostat. By adopting the method for preparing Vorinostat provided by the invention, mild conditions and good selectivity are achieved; the time of the reaction, specifically the time of the aniline amidation reaction, is greatly reduced; meanwhile, the yield of Vorinostat is greatly improved.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

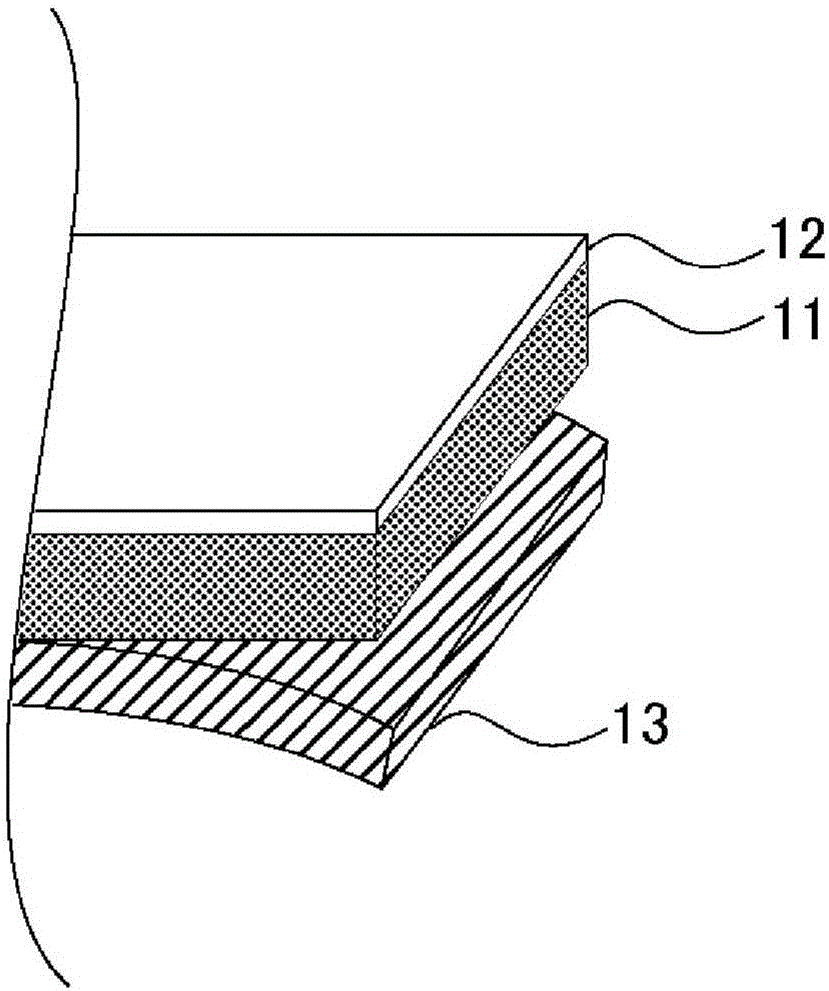

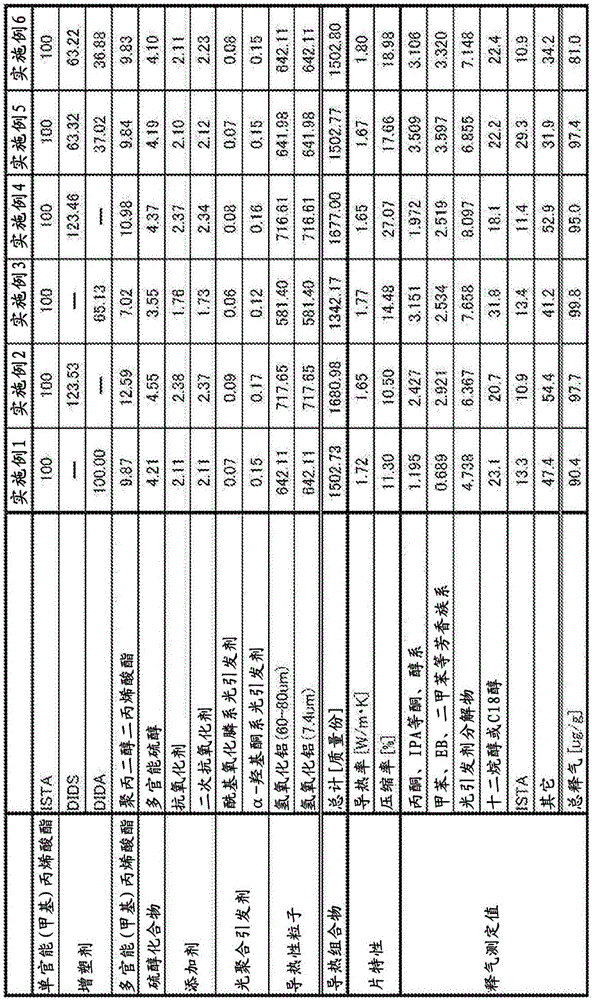

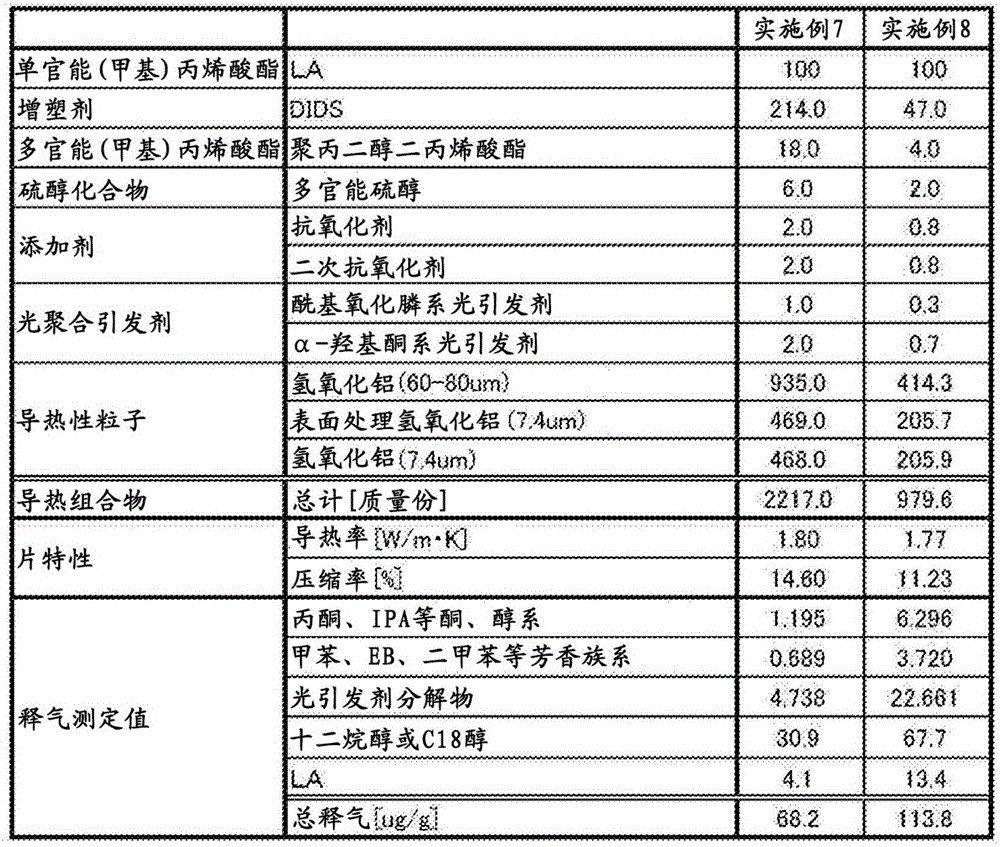

Acrylic thermally conductive composition, and thermally conductive sheet

ActiveCN106459237AGood flexibilitySemiconductor/solid-state device detailsSolid-state devicesThiolPlasticizer

Provided are: an acrylic thermally conductive composition capable of forming a sheet having excellent flexibility and capable of low outgassing; and a thermally conductive sheet. An acrylic thermally conductive composition containing a monofunctional (meth)acrylate, a multifunctional (meth)acrylate, a photopolymerization initiator, thermally conductive particles, a plasticizer, and a thiol compound, wherein the plasticizer comprises one or more types selected from adipate, a pimelic acid ester, a suberic acid ester, azelate, and a sebacic acid ester. Furthermore, the thiol compound is multifunctional thiol, and the thermally conductive sheet has a thermally conductive resin layer (11) obtained by photocuring the acrylic thermally conductive composition.

Owner:DEXERIALS CORP

Weather-proof polycarbonate plastic

InactiveCN103665813ASmall mechanical propertiesGood mechanical propertiesPolycarbonate plasticParaffin wax

The invention relates to weather-proof polycarbonate plastic which comprises the following components: 140 parts of polycarbonate, nanoscale titanium dioxide, 6 parts of polystyrene, 12 parts of chitosan, 2 parts of suberic acid, 20 parts of liquid paraffin, 4 parts of a plasticizer, 12 parts of zirconium phosphate, 2 parts of silver oxide, 7 parts of barium stearate, 1 part of polyoxyethylene ether, 2 parts of suberic acid, 5 parts of pentaerythritol, 5 parts of an antioxidant, 5 parts of a coupling agent and 9 parts of an uvioresistant agent. The plastic also comprises 12 parts of octadecanamide. After the plastic prepared by the invention is corroded by acid and alkali, the mechanical property is not reduced greatly; after a high-temperature high-humidity destructive test, the weather-proof polycarbonate plastic still has good mechanical properties.

Owner:QINGDAO KECHUANG PLASTIC MACHINERY

High temperature-resistant polyamide moulding compounds and uses thereof especially in the automotive sector

A polyamide moulding compound consisting of the following components (A)-(E):(A) 40-70 wt. % of at least one partially crystalline, partially aromatic polyamide, made up of:(a1) 60 to 75 wt. % of 6T units, formed from 1,6-hexanediamine and terephthalic acid;(a2) 20 to 35 wt. % of 6I units, formed from 1,6-hexanediamine and isophthalic acid;(a3) 3 to 15 wt. % of 612 units, formed from 1,6-hexanediamine and dodecanedioic acid; and(a4) 0 to 5 wt. % of one of the following units: 66 units, formed from 1,6-hexanediamine and adipic acid; 68 units, formed from 1,6-hexane-diamine and suberic acid; 69 units formed from 1,6-hexanediamine and azelaic acid; 610 units formed from 1,6-hexanediamine and sebacic acid; 6 units formed from ε-caprolactam; or a mixture of such units;wherein the sum of the components (a1) to (a4) makes up 100 wt. % of the polyamide (A);(B) 30-60 wt. % of fibrous reinforcing materials;(C) 0-30 wt. % of particulate fillers different from (B), (D) and (E);(D) 0-2.0 wt. % of heat stabilizers; and(E) 0-6 wt. % of auxiliary agents and / or additives, different from (A)-(D);wherein the sum of the components (A)-(E) makes up 100 wt. % is described, as well as corresponding moulded bodies and applications of such moulded bodies in particular as hollow bodies for contact with coolant liquid in the automotive sector.

Owner:EMS PATENT AG

Shock absorbing rubber

The invention discloses shock absorbing rubber. The shock absorbing rubber comprises the following ingredients: 100 parts by weight of butadiene styrene rubber, 20-30 parts by weight of natural rubber, 10-40 parts by weight of carbon black, 10-30 parts by weight of silicon dioxide, 2-20 parts by weight of suberic acid diethyl ester, 1-4 parts by weight of anti-aging agent, 1-5 parts by weight of vulcanizing agent, 1-5 parts by weight of accelerant and 3-8 parts by weight of cross-linking agent, wherein the weight ratio of the carbon black to the silicon dioxide is (1.5-2):1. Compared with existing shock absorbing rubber, the shock absorbing rubber has the advantage that the creep property is improved obviously.

Owner:LIUZHOU CITY TONGJIN AUTOMOBILE PARTS MFG CO LTD

High-tenacity automotive plastic

The invention discloses a high-tenacity automotive plastic. The high-tenacity automotive plastic is prepared from the following raw materials in parts by weight: 3-9 parts of chitosan, 5-8 parts of zirconium phosphate, 5-7 parts of polyoxyethylene ether, 2-6 parts of octanedioic acid, 4-9 parts of antimonous oxide, 1-5 parts of bamboo fibers, 6-10 parts of 3,3'-dodecyl thiodipropionate, 5-7 parts of tricresyl phosphate, 1-4 parts of dimethyl phthalate, 3-6 parts of alumina powder, 4-11 parts of PVC resin, 2-8 parts of calcium stearate, 1-3 parts of kaoline and 6-9 parts of pentaerythritol. The high-tenacity automotive plastic has the benefits of being higher in tenacity, good in mechanical property, higher in acid and alkali resistance and high in weather resistance.

Owner:青岛海蓝海洋复合功能材料科技有限公司

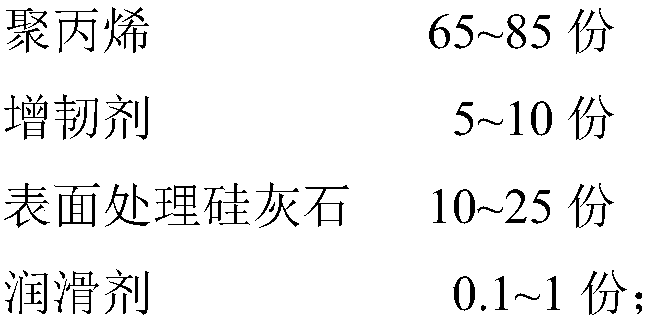

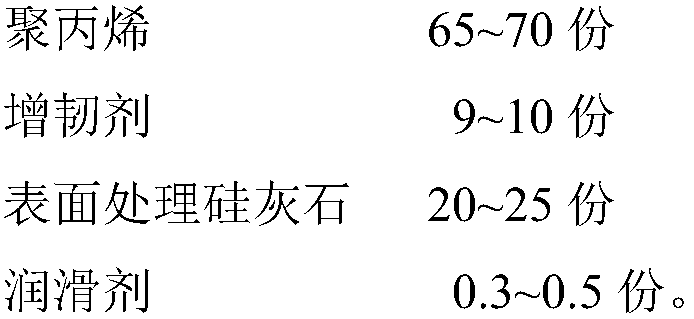

Wollastonite/polypropylene composite material and preparation method thereof

The invention discloses a wollastonite / polypropylene composite material and a preparation method thereof. The wollastonite / polypropylene composite material comprises, by weight, 65-85 parts of polypropylene, 5-10 parts of flexibilizers, 10-25 parts of surface treatment wollastonite and 0.1-1 part of lubricants, wherein the surface treatment wollastonite is prepared by the preparation method including the steps: adding wollastonite and surface treatment agents into a powder surface modification device according to the weight ratio of 100:(0.5-3) and performing surface coating treatment on the wollastonite. The surface treatment agents are selected from one or more of suberic acid, terephthalic acid and phthalic acid. The wollastonite / polypropylene composite material has excellent flowability and mechanical property.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

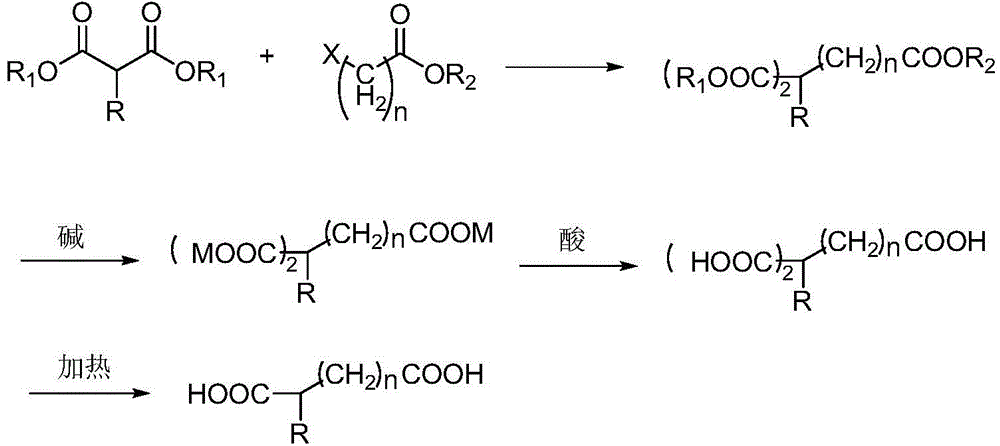

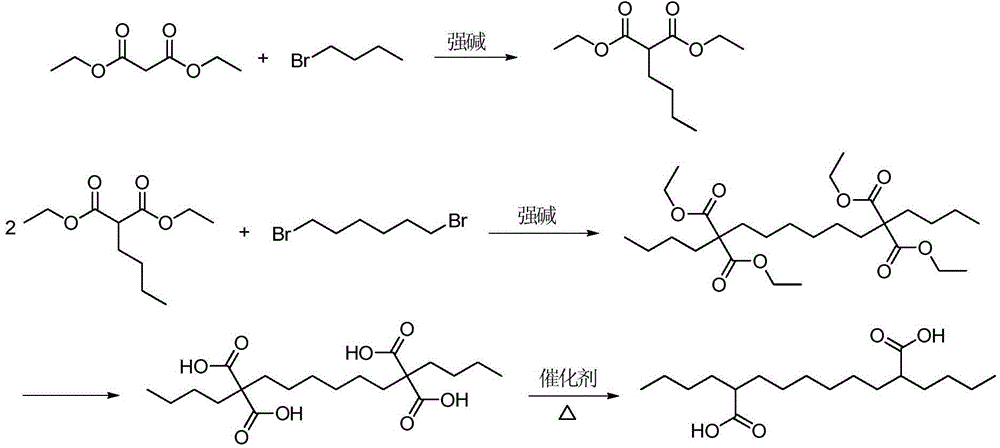

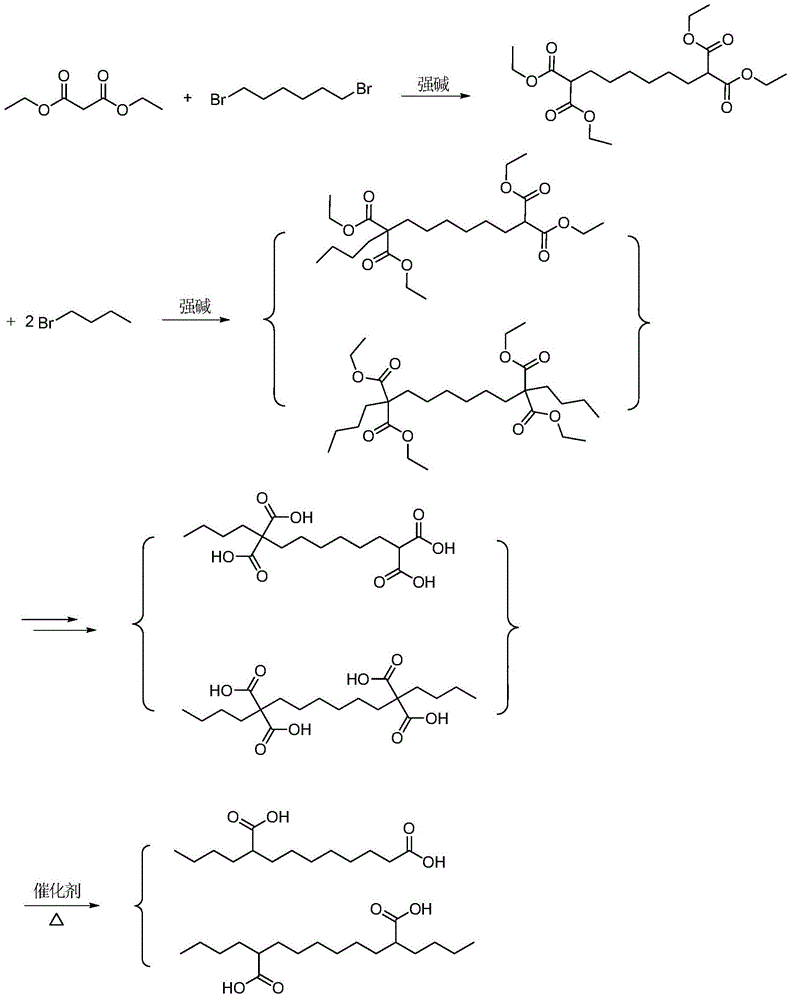

Co-production method for capacitance-grade 2-butylsebacic acid and 2, 9-butylsebacic acid

ActiveCN104447277AHigh purityImprove electrochemical performanceOrganic compound preparationCarboxylic acid esters preparationElectrolytic agentOctanoic Acids

The invention relates to a co-production method for capacitance-grade 2-butylsebacic acid and 2, 9-butylsebacic acid. The co-production method comprises the steps of carrying out nucleophilic substitution reaction on diethyl malonate and 1, 6-dibromohexane serving as raw materials in a strong alkali solution to obtain 2, 9-bis(ethoxycarbonyl)-diethyl sebacate, then, enabling 2, 9-bis(ethoxycarbonyl)-diethyl sebacate to react with n-butyl bromide in the strong alkali solution, and distilling to obtain 2-butyl-2, 9-diethoxycarbonyldiethyl sebacate and 2, 9-dibutyl-2, 9-diethoxycarbonyldiethyl sebacate; and respectively saponifying, acidifying and carrying out decarboxylic reaction to obtain 2-butylsebacic acid and 2, 9-butylsebacic acid. Due to the improvement on a technological process, a byproduct, namely 2-butyl-8-thyoxyloctanoic acid is prevented from being generated, and high-purity 2-butylsebacic acid has more excellent electrochemical properties than 2-butyloctanedioic acid sold on the market, so that the oxidation efficiency of electrolyte is increased, and the co-production method has favorable market prospects.

Owner:JIANGSU GUOTAI SUPER POWER NEW MATERIALS

Life-cycle anhydrous cooling liquid

InactiveCN104087263AHigh boiling pointRaise the equilibrium temperatureHeat-exchange elementsPolyethylene glycolEthyl group

The invention discloses life-cycle anhydrous cooling liquid, comprising the following raw materials in parts: 30-35 parts of triethanolamine, 15-20 parts of triisopropanolamine, 10-12 parts of triethylamine, 5-11 parts of dichloromethane, 6-8 parts of triethylamine hydrochloride, 2-4 parts of ethyl acetate, 16-18 parts of ethyl alcohol, 12-20 parts of acetic acid, 5-6 parts of acetone, 6-8 parts of banana oil, 5-8 parts of polyethylene glycol, 2-3 parts of polyfluoroalkyl ethyl, 2-4 parts of 3-substituted sulfenyl-5-(2-hydroxyphenyl)-4H-1,2,4-triazole compound, 2-5 parts of oxalic acid, 3-6 parts of trichloroacetic acid, 3-5 parts of tartaric acid, 3-4 parts of azelaic acid, 2-3 parts of octanedioic acid, 3-5 parts of potassium sorbate, 3-6 parts of sodium glutamate, 2-3 parts of sodium carbonate, 2-3 parts of sodium hydroxide, 5-6 parts of silicone oil and 6-7 parts of Janus green. The life-cycle anhydrous cooling liquid does not contain water, so that the boiling point and the corrosion resistance of the cooling liquid and the balance temperature of an engine can be greatly improved, the engine can run at full load and high load, and vehicles can safely run in severe environments such as highlands, deserts and the like.

Owner:张慧玲

Long life capacitor impregnating agent

InactiveCN106571228AIncrease energy densityFulfil requirementsFixed capacitor dielectricEngineeringRice Bran Extract

The invention discloses a long life capacitor impregnating agent comprising the following ingredients: castor oil, palm oil, vitamin E, accessory, diffusion agent MF, mustard oil, suberic acid and rice bran oil; the accessory comprises the following ingredients: potter clay, vermiculite, and diatomite. The long life capacitor impregnating agent is environmental protection and pollution free, good in usage effect, strong in high temperature resistance, good in heat dissipation, safe and reliable, and durable.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

Composition for low temperature

Lubricant composition comprising a dicarboxylic acid ester component which is formed from a dicarboxylic acid selected from the list consisting of adipic acid, phthalic acid, pimilic acid, suberic acid, azelaic acid and sebacic acid, and mixtures thereof and a branched aliphatic alcohol R—OH which is defined according to the following formula (I)whereas q, r and s are defined as follows,q+r=4 to 9,s=0 to 5,q=1 to 8, andr=1 to 6,andan ethylene-propylene copolymer.

Owner:BASF SE

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com