Long life capacitor impregnating agent

A technology of capacitors and impregnating agents, which is applied in the direction of capacitors, fixed capacitors, and fixed capacitor dielectrics. It can solve problems such as poor performance of impregnating agents, corrosion of capacitor plates, and impact on capacitor life, so as to improve dielectric strength and volume resistivity. , reduce corrosion, significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

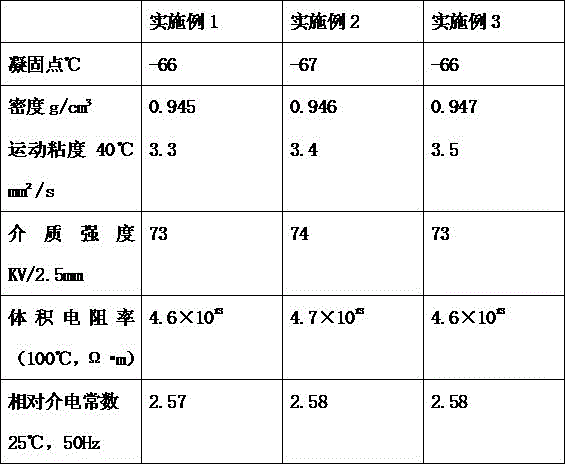

Embodiment 1

[0017] A long-life impregnating agent for capacitors, made of the following ingredients in parts by weight: castor oil 80, palm oil 28, vitamin E1, auxiliary material 4, diffusing agent MF0.8, mustard oil 4, suberic acid 8, rice bran oil 4 ; The auxiliary material is made of the following components in parts by weight: pottery clay 5, vermiculite 8, diatomite 3.

Embodiment 2

[0019] A high-life impregnating agent for capacitors, made of the following ingredients in parts by weight: castor oil 90, palm oil 35, vitamin E4, auxiliary materials 8, diffusing agent MF1.1, mustard oil 6, suberic acid 15, rice bran oil 6 ; The auxiliary material is made of the following components in parts by weight: clay 8, vermiculite 12, diatomite 5.

Embodiment 3

[0021] A high-life impregnating agent for capacitors, made of the following ingredients in parts by weight: castor oil 85, palm oil 30, vitamin E2, auxiliary materials 5, diffusing agent MF1, mustard oil 5, suberic acid 12, rice bran oil 5; The auxiliary materials are made of the following components in parts by weight: 6 pottery clays, 10 vermiculites, and 4 diatomites.

[0022] The preparation method of auxiliary material in the above-mentioned embodiment is:

[0023] ①Calcinate clay at 320°C for 18 minutes, add it to 5% sodium hypochlorite solution and soak for 18 minutes when cooled to 40°C, then filter, wash and dry;

[0024] ②Calcinate vermiculite at 270°C for 14min, add it to 8% sodium hypochlorite solution and soak for 14min when cooled to 45°C, then filter, wash and dry;

[0025] ③Calcinate diatomite at 220°C for 12min, add it to 12% ammonium acetate solution after cooling to 40°C, soak for 12min, then filter, then calcinate at 220°C for 10min, then cool to room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com