Patents

Literature

40results about How to "Excellent creep properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat resistant austenitic stainless steel

InactiveUS6485679B1High creep rupture strengthGood steam oxidation resistanceRigid pipesHeat exchange apparatusAustenitic stainless steelTungsten

A heat resistant austenitic stainless steel with high strength at elevated temperatures, good steam oxidation resistance, good fire side corrosion resistance, and a sufficient structural stability, suitable for use in boilers operating at high temperatures has a composition (by weight) of. 0.04 to 0.10% carbon (C), not more than 0.4% silicon (Si), not more than 0.6% manganese (MN), 20 to 27% chromium (Cr), 22.5 to 32% nickel (Ni), not more than 0.5% molybdenum (Mo), 0,20 to 0.60% niobium (Nb), 0.4 to 4.0% tungsten (W), 0.10 to 0.30% nitrogen (N), 0.002 to 0.008% boron (B), less than 0.05% aluminium (Al), at least one of the elements Mg and Ca in amounts less than 0.010% Mg and less than 0.010% Ca, and the balance being iron and inevitable impuities.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

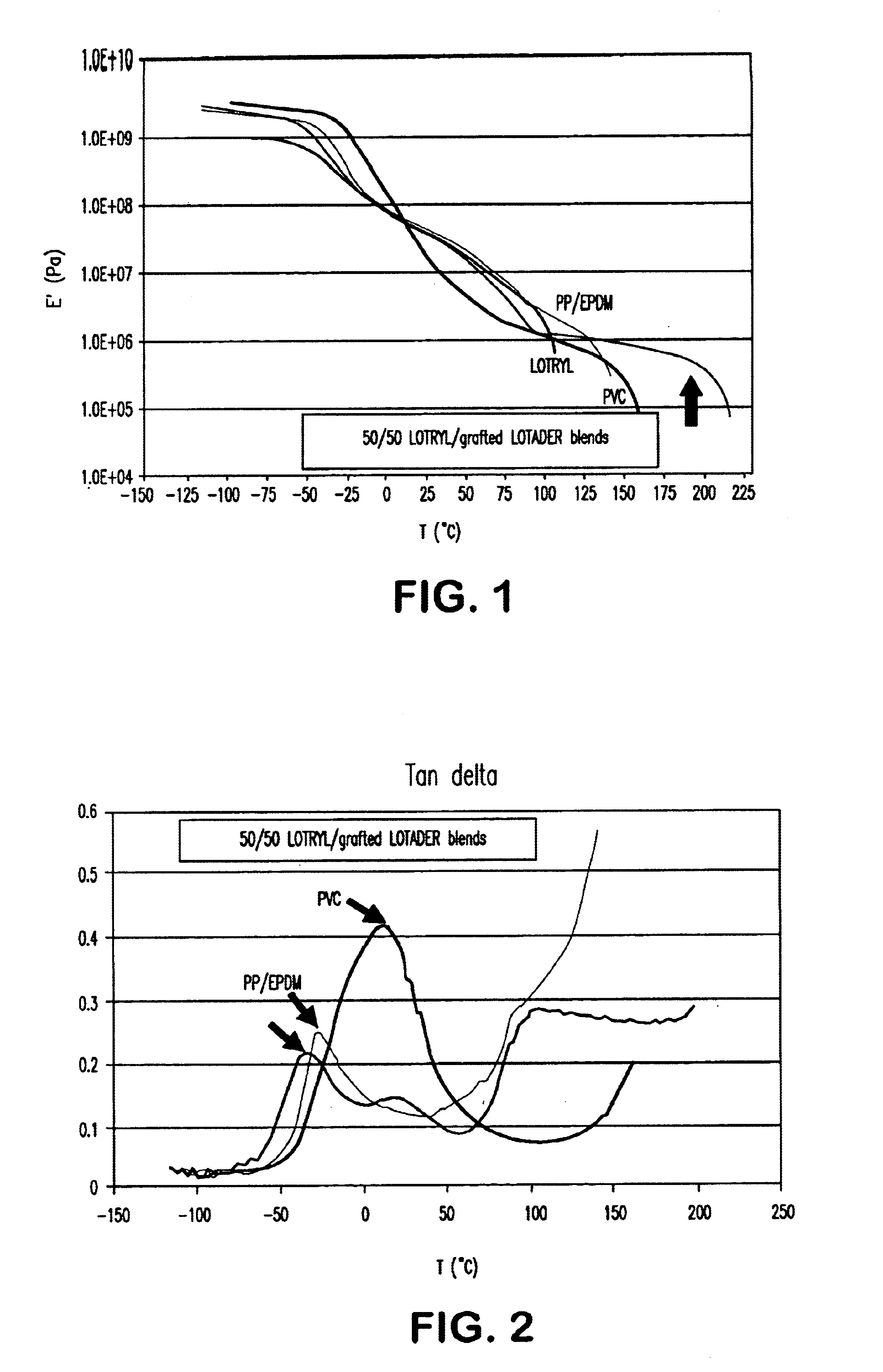

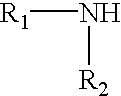

Mixture of grafted polyamide-block and flexible polyolefin copolymers

InactiveUS6875520B2Soft touchResidual stressSynthetic resin layered productsInsulated cablesPolyolefinGeomembrane

The invention concerns a mixture comprising by weight, the total being 100%, 1 to 100% if a polyamide block copolymer consisting of a basic polyolefin chain and on an average at least a polyamide graft wherein: the grafts are fixed to the basic chain by the radicals of an unsaturated monomer (X) having a function capable of reacting with a polyamide with amine terminal, the radicals of the unsaturated monomer (X) are fixed to the basic chain by grafting or copolymerization from its double bond; 99 to 0% of a flexible polyolefin with elastic modulus in flexure less than 50 MPa at 23° C. and having a crystalline melting point ranging between 60° C. and 100° C. Said mixtures are useful for making films, tanks, geomembrane protective fabrics produced by extrusion, products obtained by calendering, thermocladding / forming, protective films for electric cables and skins using slush molding technique.

Owner:ATOFINA

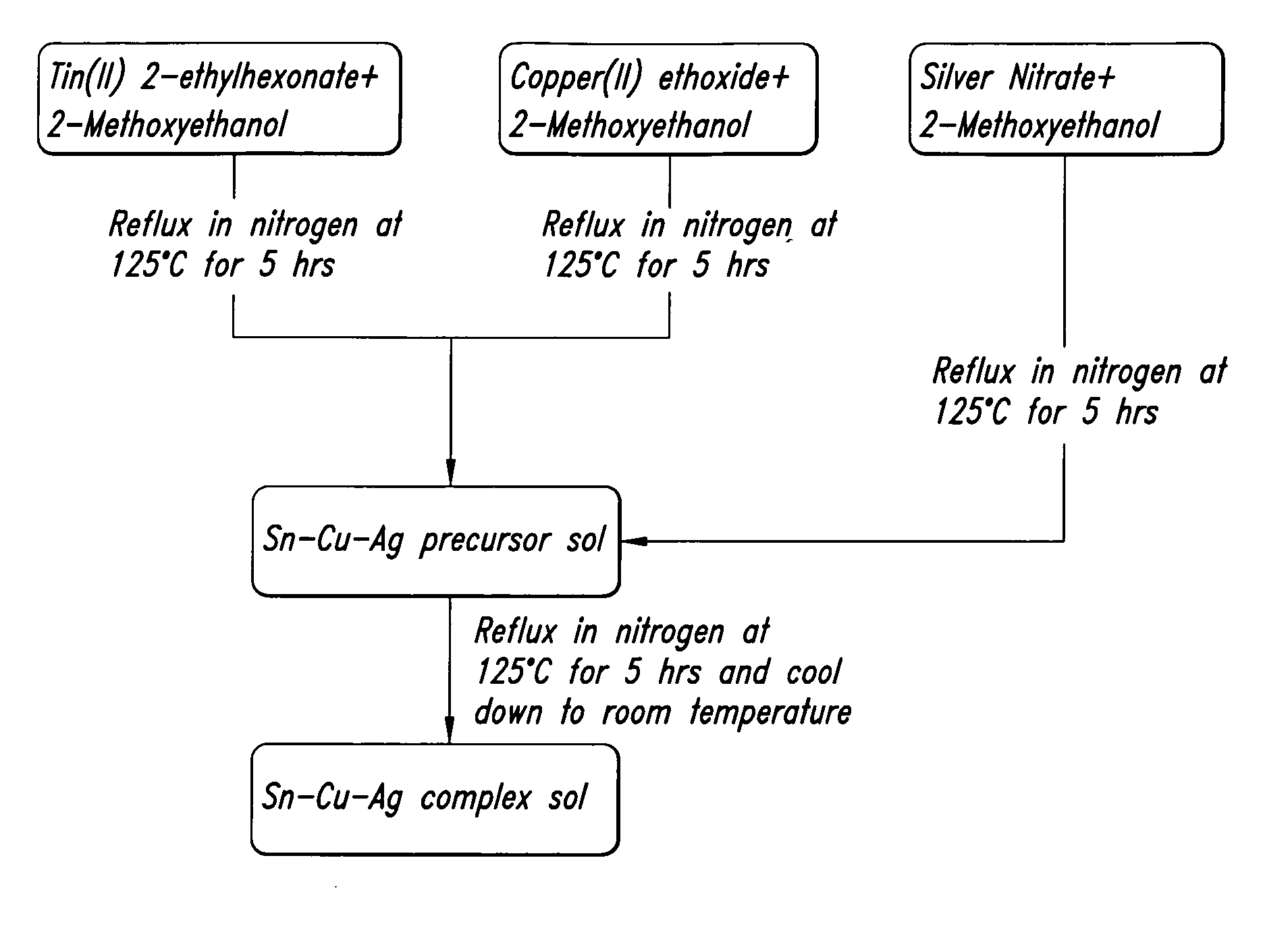

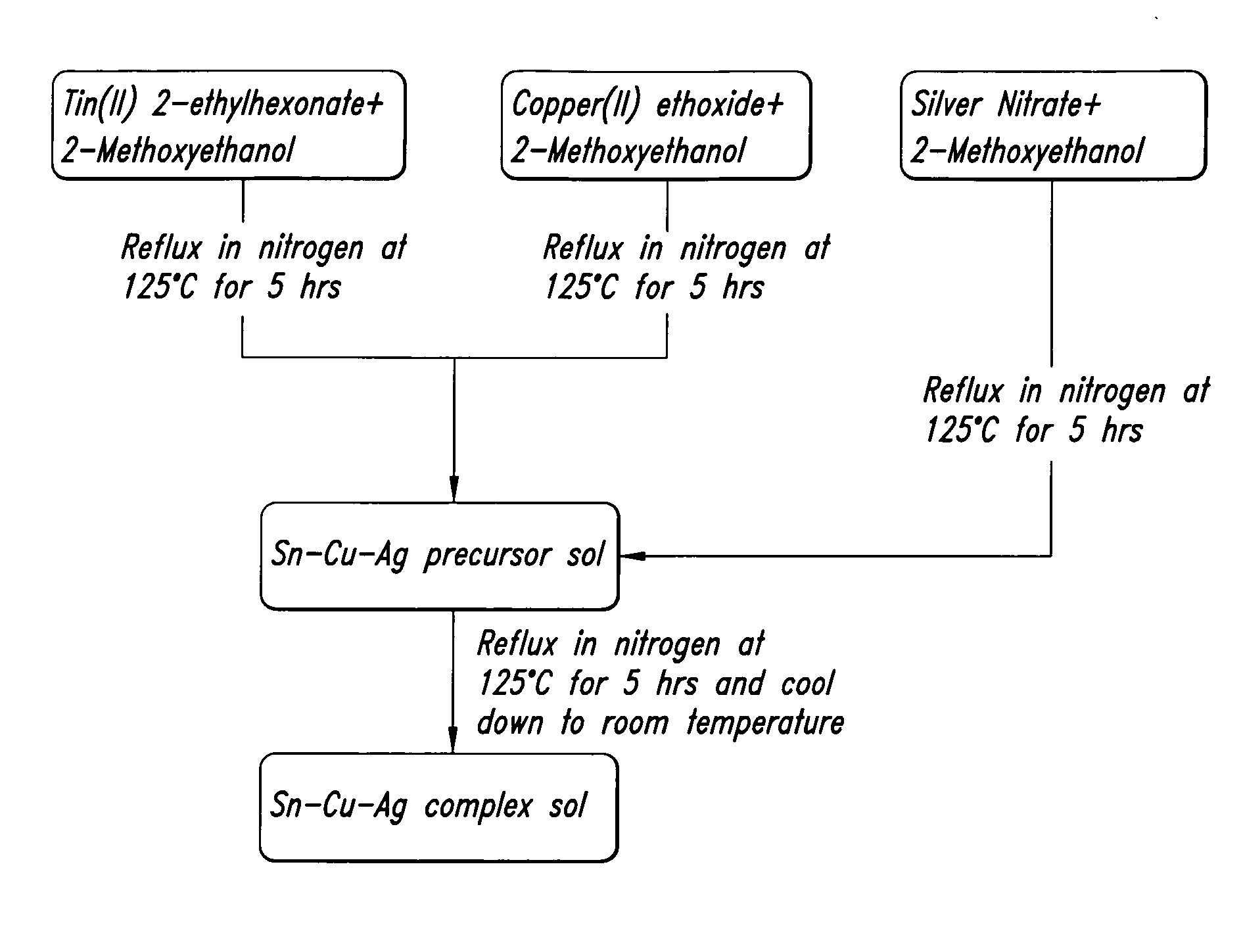

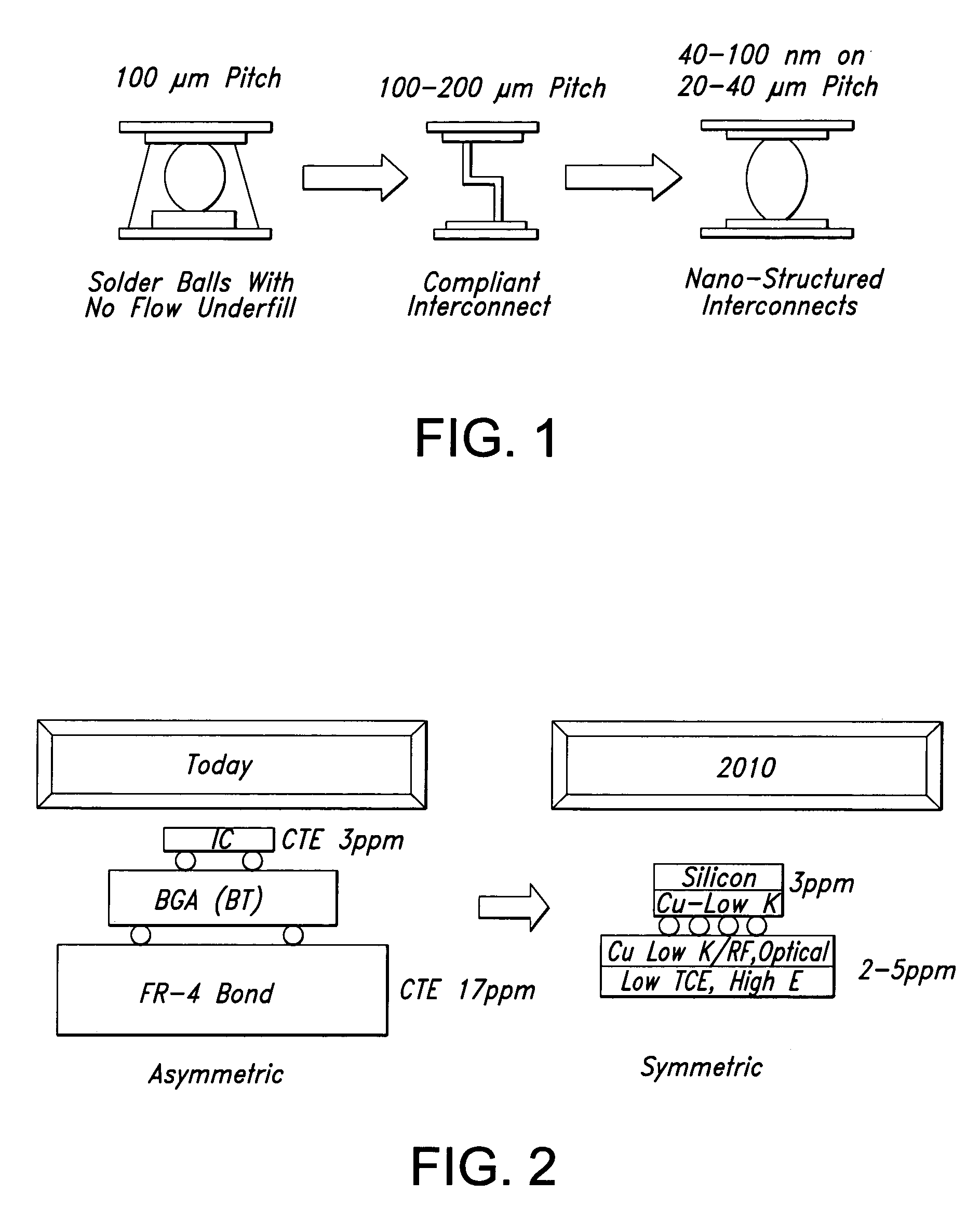

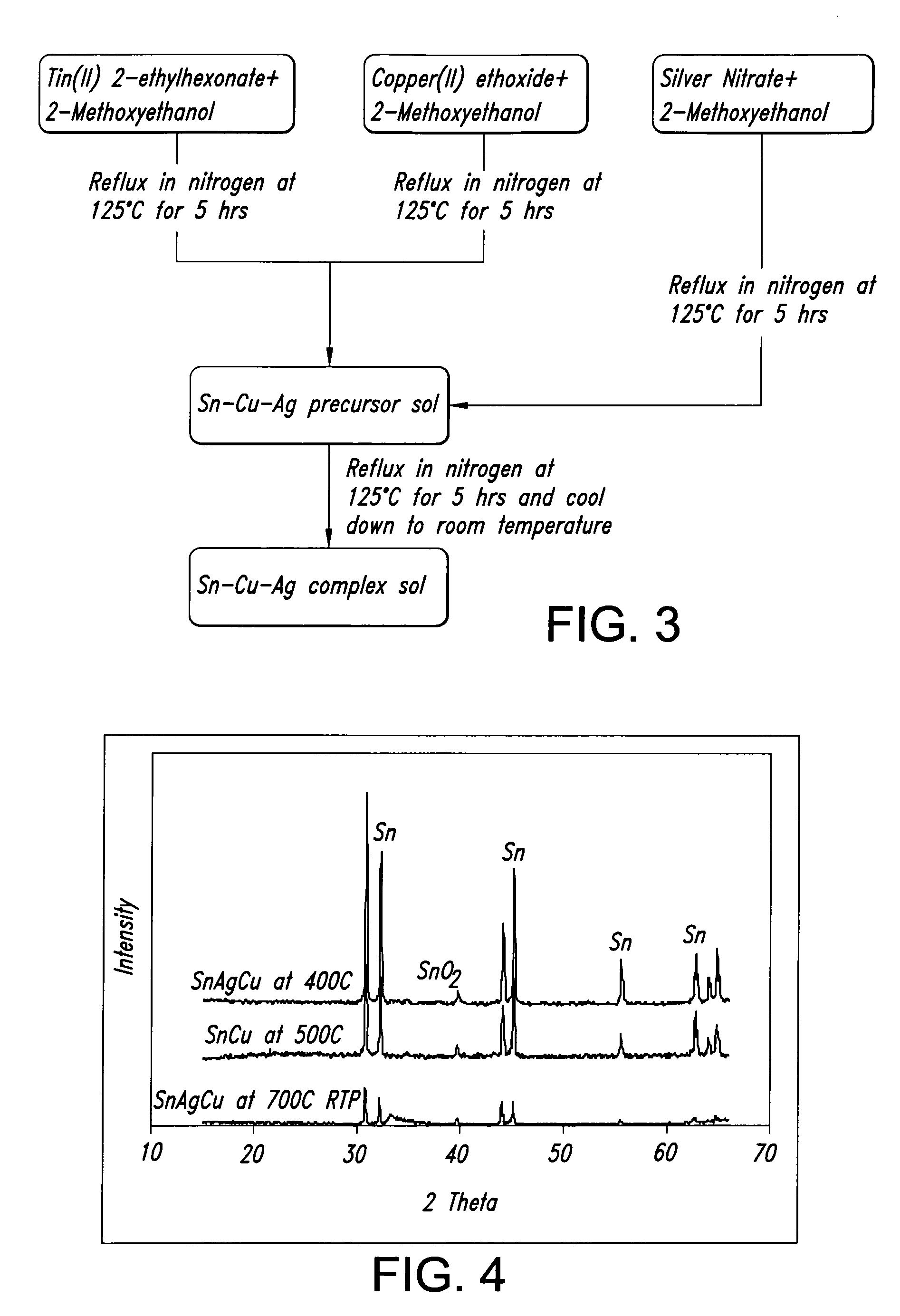

Lead-free bonding systems

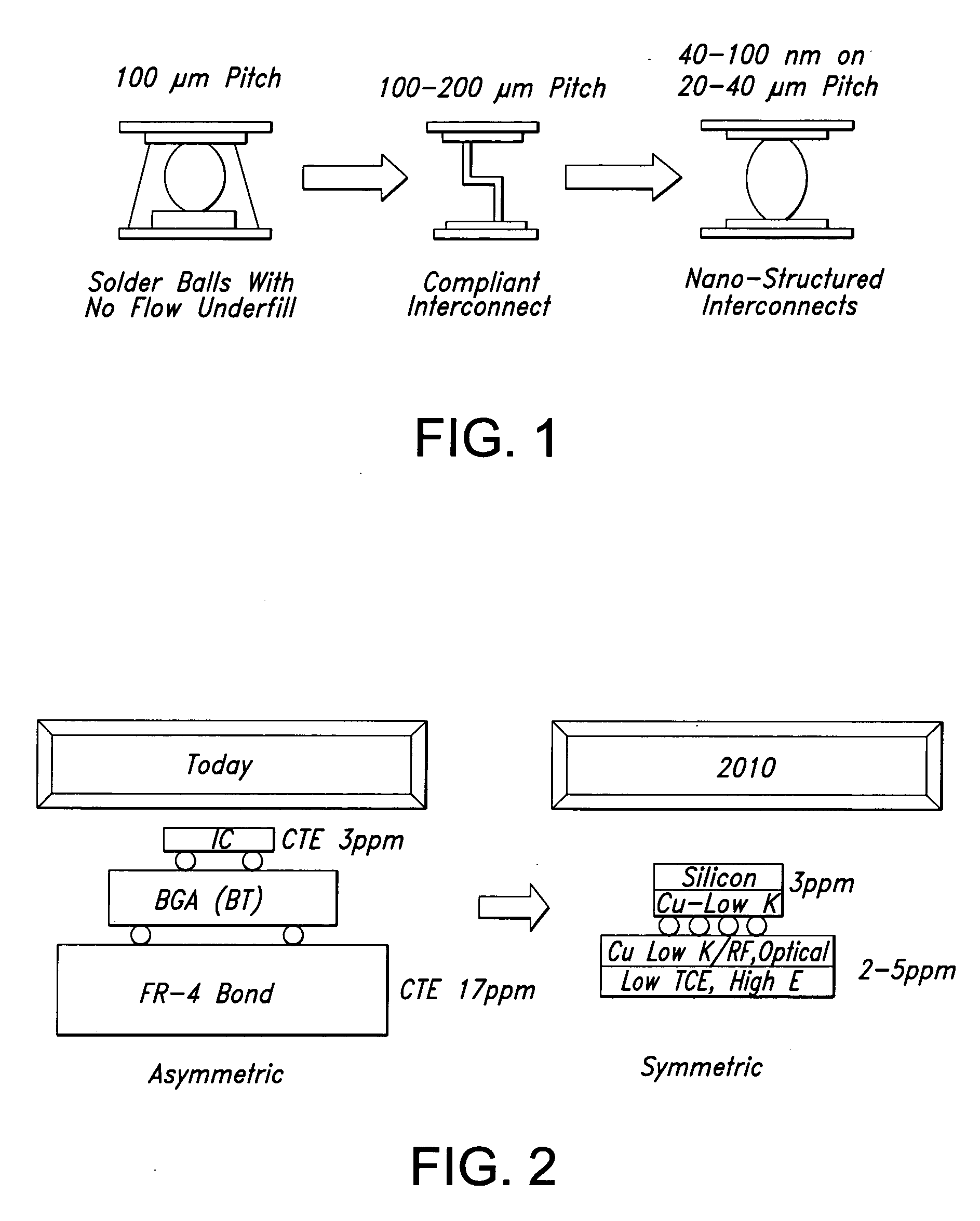

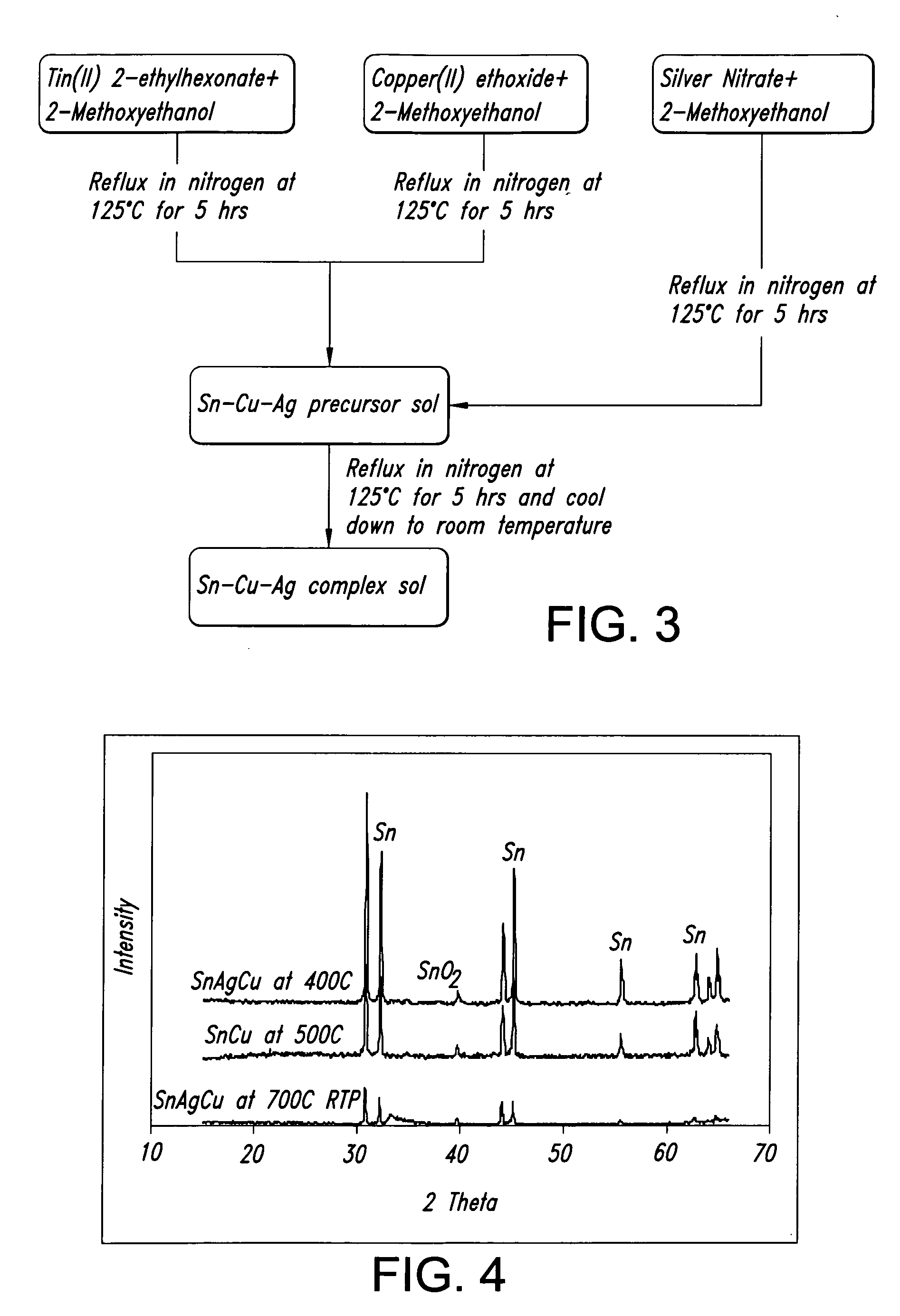

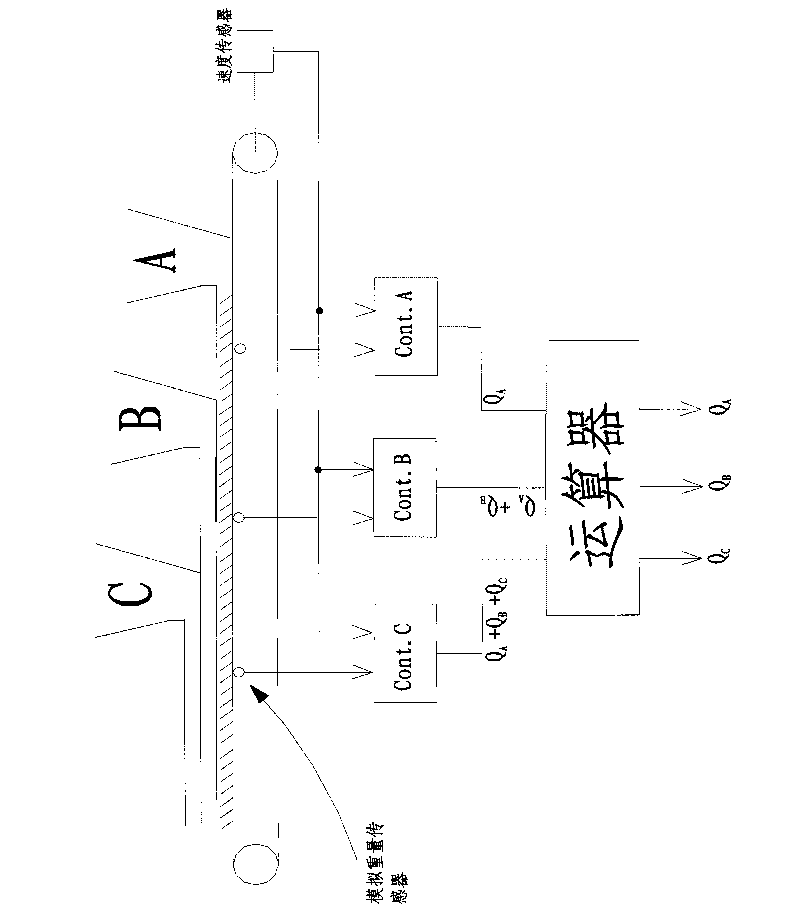

InactiveUS20050274227A1Improve mechanical propertiesHigh bandwidthMolten spray coatingVacuum evaporation coatingBonding processHermetic packaging

Nano-structured interconnect formation and a reworkable bonding process using solder films. Large area fabrication of nano-structured interconnects is demonstrated at a very fine pitch. This technology can be used for pushing the limits of current flip chip bonding in terms of pitch, number of I / Os, superior combination of electrical and mechanical properties as well as reworkability. Sol-gel and electroless processes were developed to demonstrate film bonding interfaces between metallic pads and nano interconnects. Solution-derived nano-solder technology is an attractive low-cost method for several applications such as MEMS hermetic packaging, compliant interconnect bonding and bump-less nano-interconnects.

Owner:GEORGIA TECH RES CORP

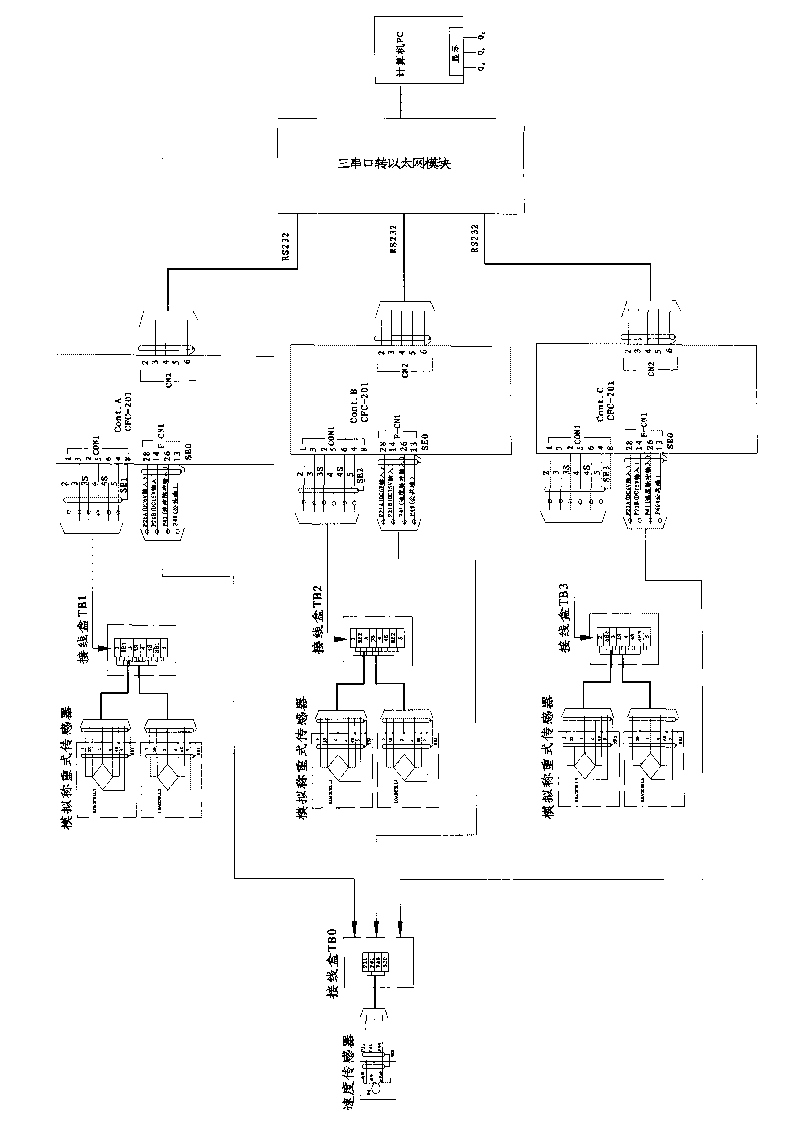

Belt conveyor based multi-material belt weighing system

ActiveCN101692006AImprove continuityAutomatic height adjustmentWeighing apparatus for continuous material flowMulti materialDrive motor

The invention discloses a belt conveyor based multi-material belt weighing system, which comprises a belt conveyor and a plurality of feed inlets above the belt conveyor. The belt conveyor comprises a plurality of weighing devices for metering materials, a speed measuring sensor, a main drive motor and an integrating control instrument, wherein each weighing device comprises a metering roller and two weighing sensors; and the weighing sensors transmit weight signals to the integrating control instrument. Different or same materials are filled through the plurality of feed inlets; the plurality of weighing devices are arranged in front of the running direction of a belt respectively; and the integrating control instrument meters the instantaneous flow respectively so as to realize the continuous and accumulated multi-material weighing or the quantitative-control continuous and accumulated multi-material weighing on one belt conveyor.

Owner:SHANGHAI YAMATO SCALE

Medium-strength corrosion-resistant weldable crack-arrest titanium alloy and preparation method thereof

The invention discloses a medium-strength corrosion-resistant weldable crack-arrest titanium alloy. The titanium alloy is composed of, by mass percentage, 3.0-7.0% of an alpha stabilizing element Al, 1.5-4.5% of beta stabilizing elements of Mo, V, Nb and Ni, 0.5-3.0% of neutral elements of Zr and Sn, 0.01-0.3% of a Si element and the balance Ti and inevitable impurities, wherein, by mass percentage, 0-1% of Mo, 0-3% of V, 0-1% of Nb, 0.5% of Ni, 0-2% of Zr and 0-3% of Sn are included. The titanium alloy has the good strength, plasticity and toughness matching, the yield strength Rp0.2 is larger than or equal to 640 MPa, the tensile strength Rm is larger than or equal to 740 MPa, the elongation A is larger than or equal to 15%, the fracture toughness KIC is larger than or equal to 140 MPa.m<1 / 2>, and the impact toughness KV2 is larger than or equal to 80J; the alloy has the good crack arrest performance, and the dynamic tearing energy DTE is larger than or equal to 800 J; and meanwhile the good welding performance and resistance to seawater corrosion are achieved, the welding coefficient is larger than or equal to 0.95, the KISCC is larger than or equal to 95 MPa.m<1 / 2>, and the medium-strength corrosion-resistant weldable crack-arrest titanium alloy has the good technical application and market prospects in the fields of ship and marine engineering.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

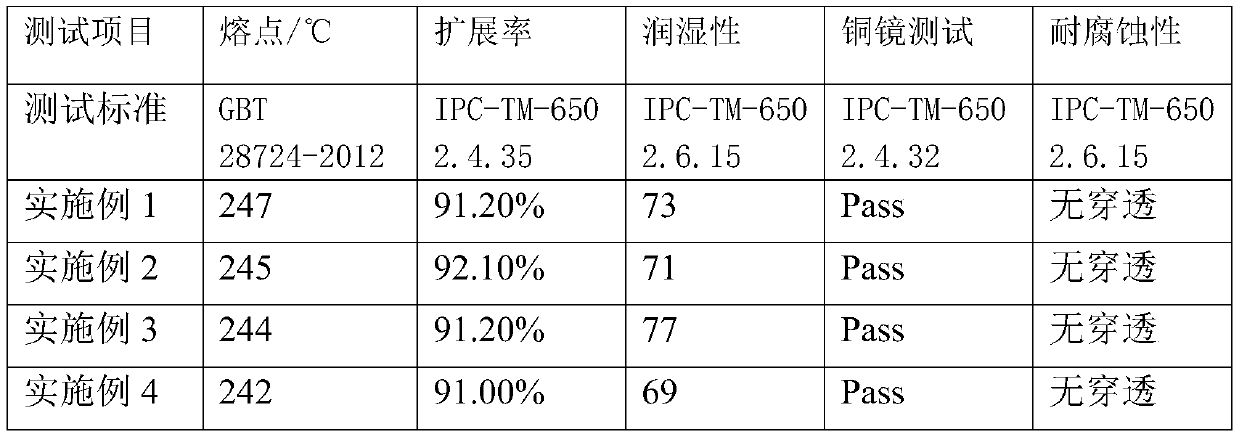

Lead-free tin-based solder for solar photovoltaic module and preparation method thereof

InactiveCN103801853AImprove wettabilityReduce performance degradationWelding/cutting media/materialsSoldering mediaIndiumSurface oxidation

The invention provides lead-free tin-based solder for a solar photovoltaic module. The lead-free tin-based solder comprises, by mass, stibium 0.05 percent-0.15 percent, silver 0.01 percent-0.05 percent, copper 0.1 percent-0.4 percent, indium 0.01 percent-0.05 percent, bismuth 0.2 percent-0.5 percent, gallium 0.06 percent-0.10 percent, phosphorus 0.02 percent-0.09 percent and the balance tin and inevitable impurities. The invention further provides a manufacturing method of the lead-free tin-based solder. The manufacturing method comprises the step that stibium, silver, copper, indium, bismuth, gallium, tin and phosphorus are placed into a smelting furnace according to the mass percentage and are smelted in an inert atmosphere or a vacuum condition, and the lead-free tin-based solder for the solar photovoltaic module is obtained. According to the lead-free tin-based solder for the solar photovoltaic module, melting temperature is low, surface gloss is good, surface oxidation resistance is high, wetting performance is good, and welding quality is superior. Besides, the lead-free tin-based solder is economical, environmentally friendly and free of threat to human health, thereby being applicable to large-scale industrial production.

Owner:THE NORTHWEST MACHINE

Magnesium based alloy

InactiveUS20100310409A1Excellent creep propertiesImprove die casting effectRare-earth elementManganese

A magnesium based alloy consisting of, by weight: 2-5% rare earth elements, wherein the alloy contains lanthanum and cerium as rare earth elements and the lanthanum content is greater than the cerium content; 0.2-0.8% zinc; 0-0.15% aluminium; 0-0.5% yttrium or gadolinium; 0-0.2% zirconium, 0-0.3% manganese; 0-0.1% calcium; 0-25 ppm beryllium; and the remainder being magnesium except for incidental impurities.

Owner:CAST CRC

Wood Fiber Plastic Composites

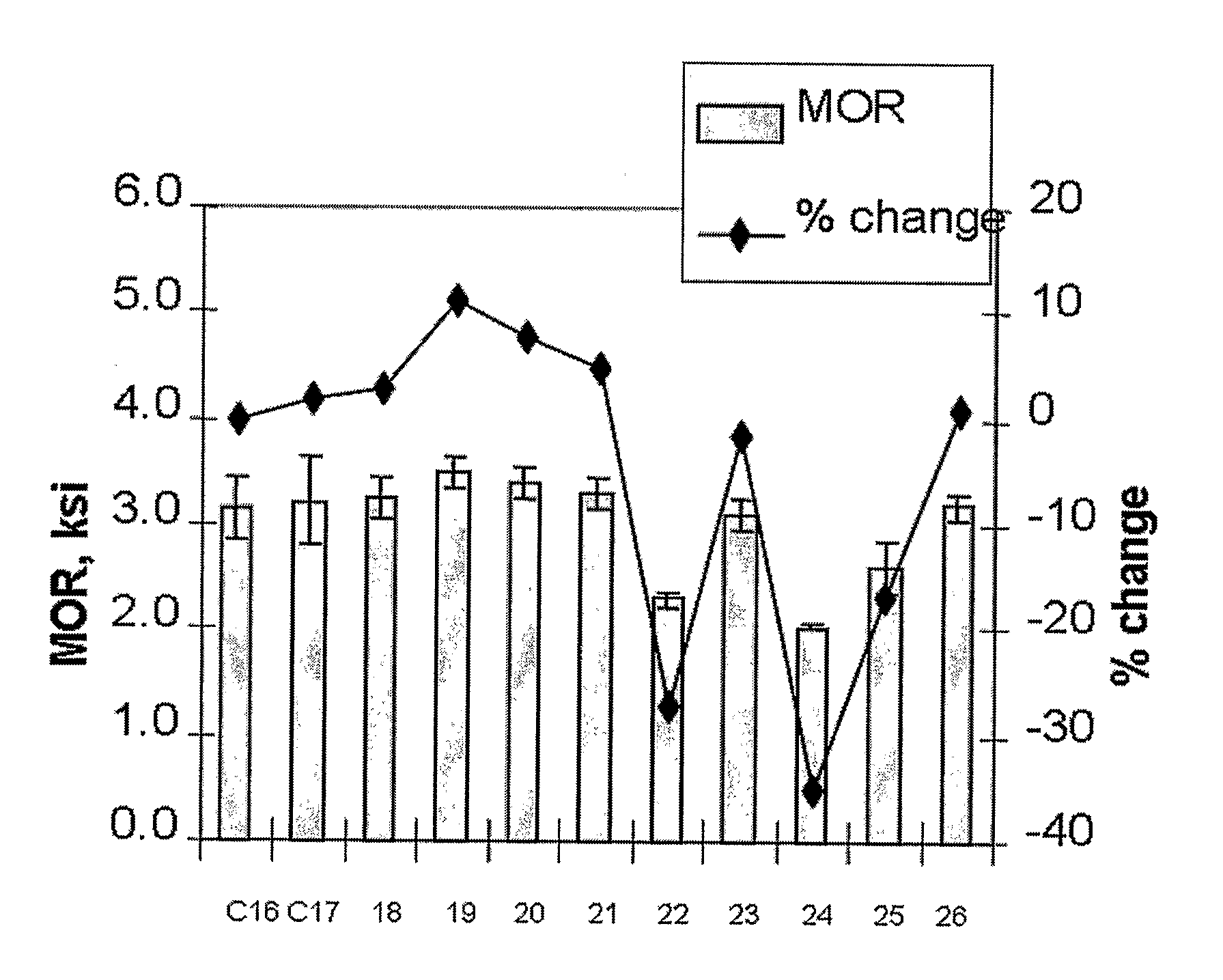

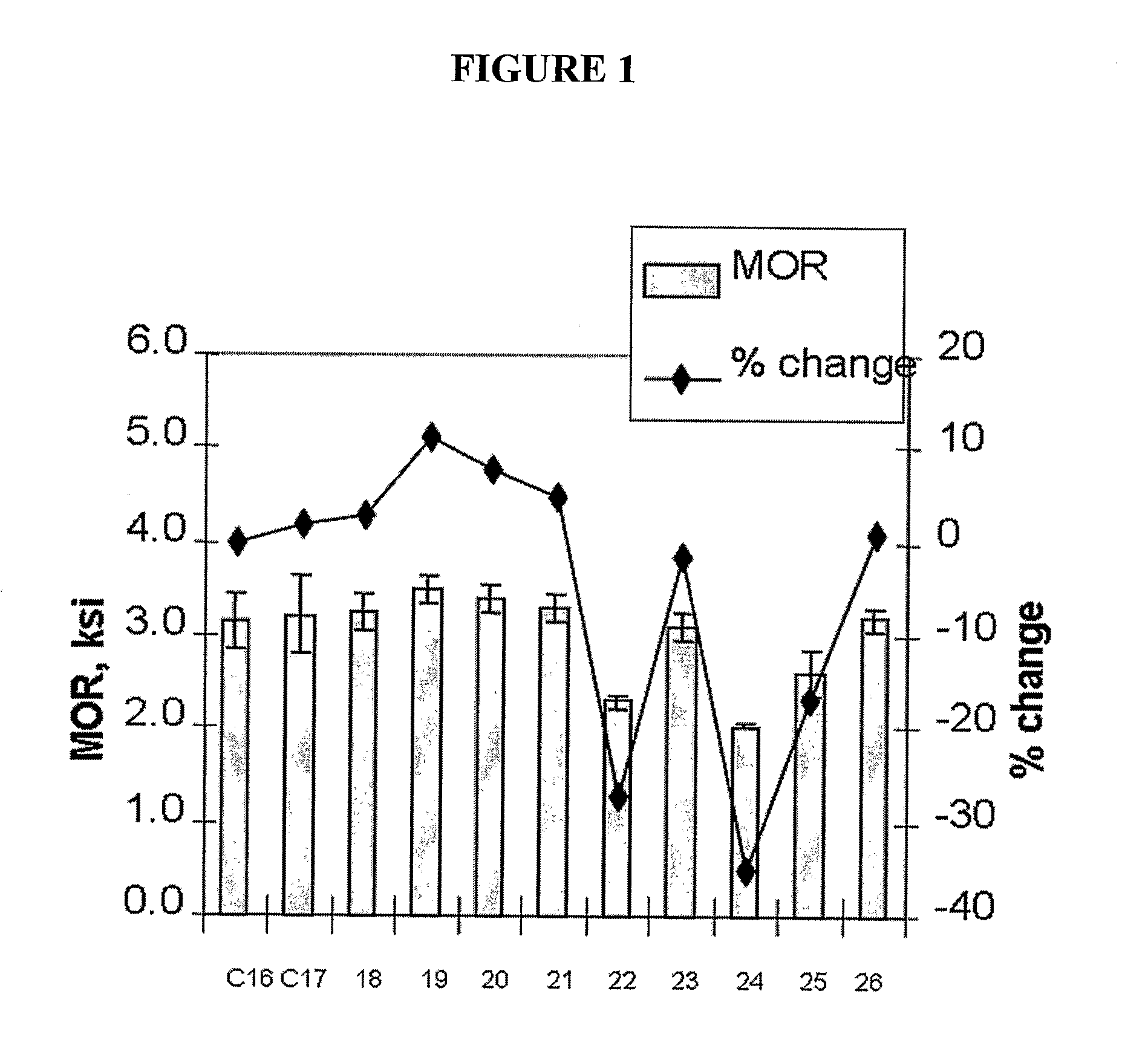

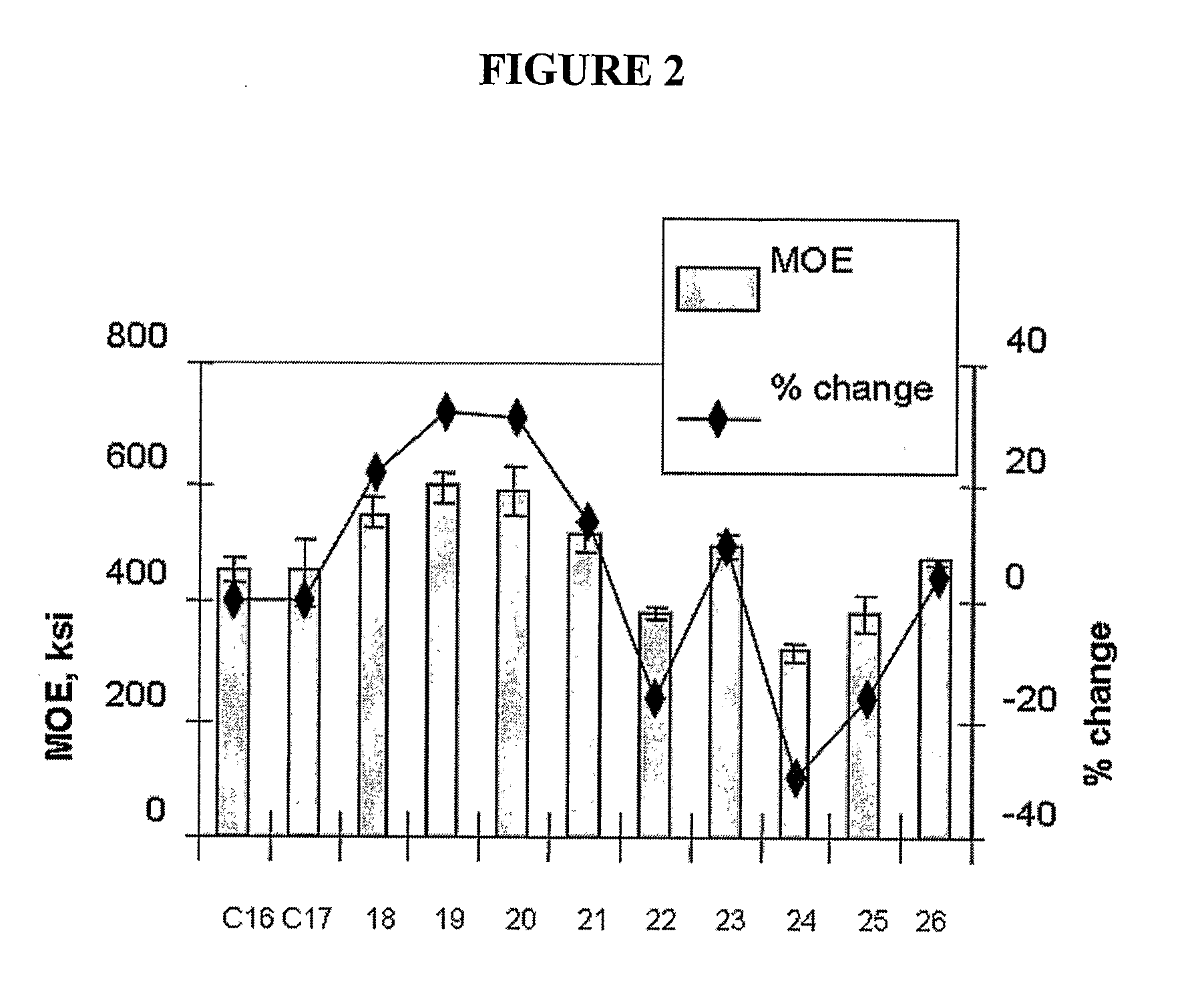

InactiveUS20080011194A1Excellent creep propertiesConstantWood working apparatusInorganic adhesivesFiberThermoplastic

Described herein are composite compositions and methods for making such compositions. The composition includes or is the reaction product of a cellulosic material, an organic component, and a thermoplastic. Some useful organic components include a silane-containing polymer. Some of the compositions have improved physical properties such as tensile properties, improved strength, and reduced water absorption.

Owner:DOW GLOBAL TECH LLC

High-melting-point environment-friendly superfine solder wire applied to automatic welding and preparation method thereof

ActiveCN111590234AAvoid wastingImprove yieldWelding/cutting media/materialsSoldering mediaYttriumOxidation resistant

The invention discloses a high-melting-point environment-friendly superfine solder wire applied to automatic welding and a preparation method thereof. The high-melting-point environment-friendly superfine solder wire comprises 96.1%-98.0% of tin alloy and 2.0%-3.9% of soldering flux, wherein the tin alloy is prepared from tin, silver, copper, indium, cerium, vanadium and yttrium; the melting pointof added trace element vanadium is 1890 + / -10 DEG C, the added trace element vanadium belongs to high-melting-point rare metal, the heat resistance of the tin alloy can be enhanced, meanwhile, the abrasion resistance and bursting resistance of the solder wire are extremely good, the strength, hardness and heat resistance of the tin alloy can be obviously improved through adding yttrium, the melting point of the solder wire is increased, and meanwhile, the oxidation resistance and ductility of the tin alloy are enhanced; and the added cerium can change structure of a solder, thereby refining grains, reducing solder joint bridges, changing the surface wettability of the tin alloy, and enhancing the creep property and tensile property. The solder wire is high in melting point, excellent in tensile strength, free of lead and environmentally friendly, and when the solder wire is applied to the high-end application fields of intelligent mechanical arm welding and the like, high weldabilityand lead-free environmental protection development of products are achieved.

Owner:中山翰华锡业有限公司

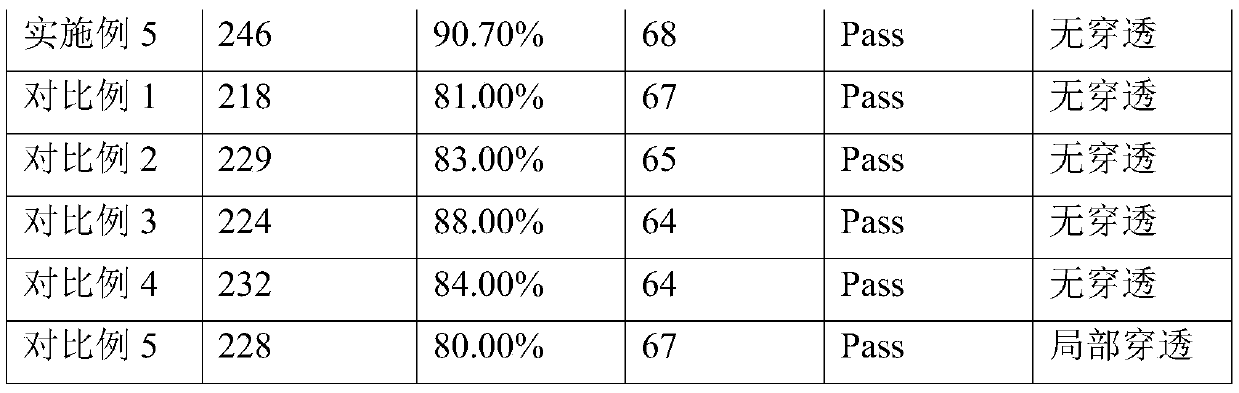

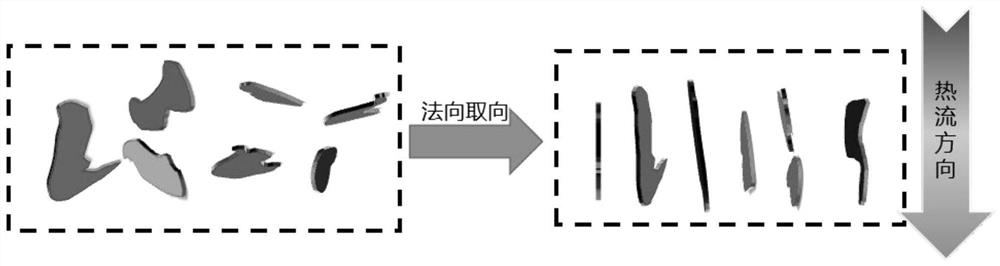

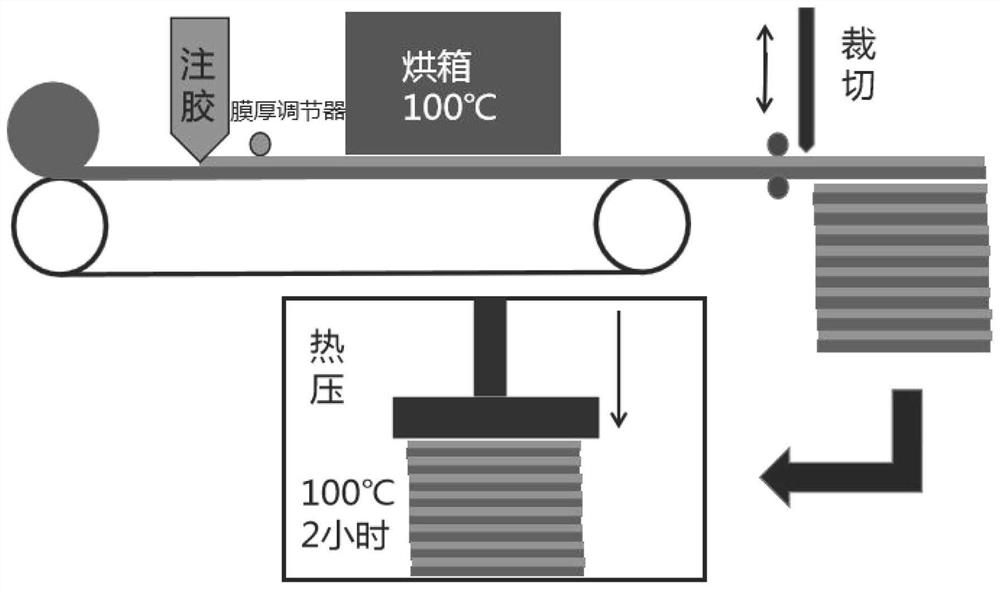

Preparation method of heat-conducting gasket with high normal heat conductivity and high elasticity

ActiveCN112679765AMechanical properties can be adjustedAdjust mechanical propertiesCooling/ventilation/heating modificationsPolymer sciencePolyolefin

The invention belongs to the technical field of preparation of heat conduction materials, and discloses a preparation method of a heat-conducting gasket with high normal heat conductivity and high elasticity. The preparation method comprises the following steps: (1) with a graphite film or a graphene film as a filler, carrying out plasma modification to obtain a first modified graphite film or graphene film; (2) hydroxylating the first modified graphite film or graphene film, and grafting a hydrolyzed coupling agent to obtain a second modified graphite film or graphene film; (3) coating the surface of the second modified graphite film or graphene film with polyolefin, carrying out pre-curing treatment, and conducting stacking by adopting a laminating process to obtain a graphite film or graphene film / polyolefin multi-layer composite structure formed body; and (4) after hot-pressing treatment, conducting cutting along a direction vertical to the upper surface and the lower surface of the multi-layer composite structure formed body to obtain the heat-conducting gasket. The obtained heat-conducting gasket is good in heat-conducting property, and when a filler content reaches 94.3%, the heat conductivity of the gasket reaches 726.1 W / (m.K).

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

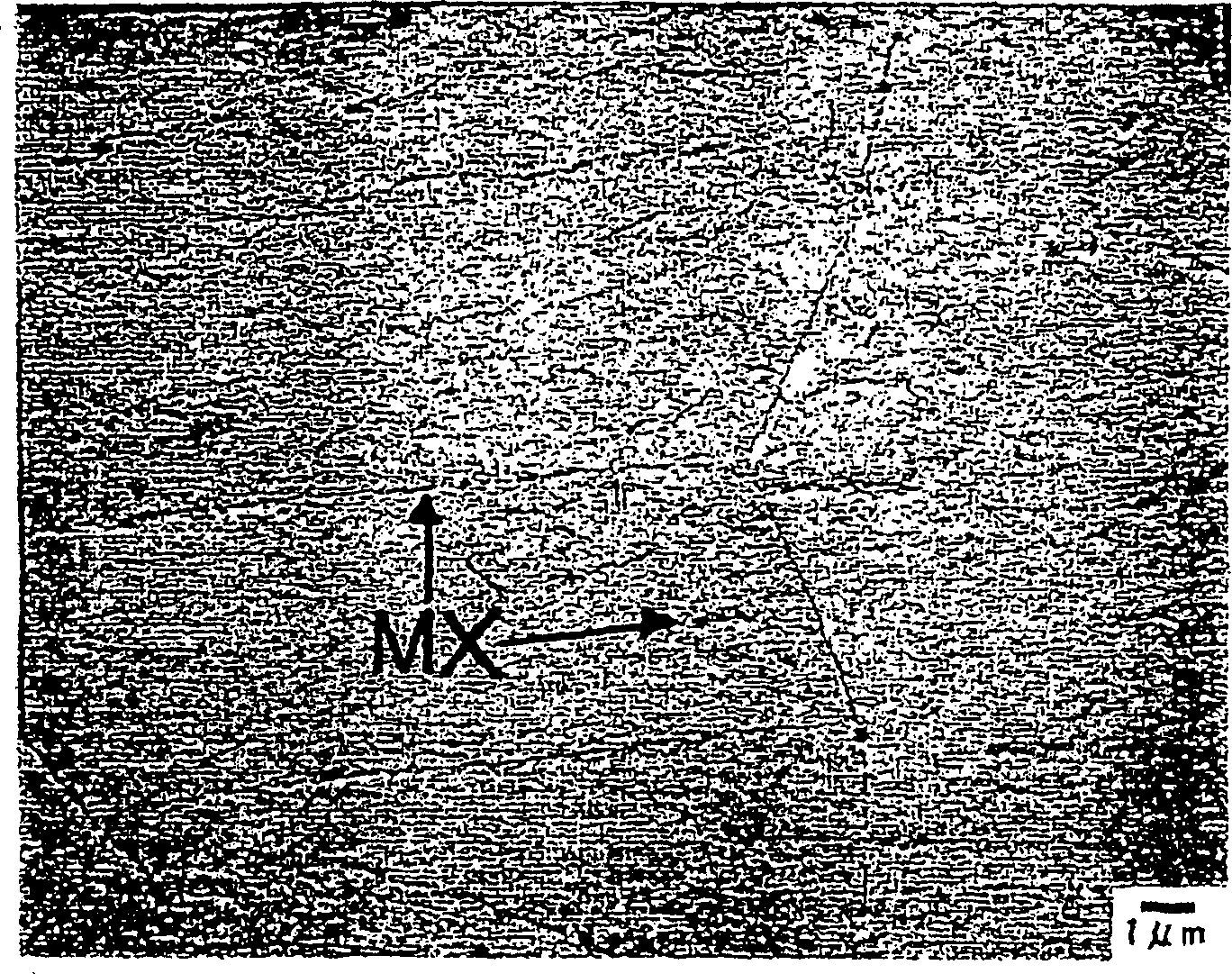

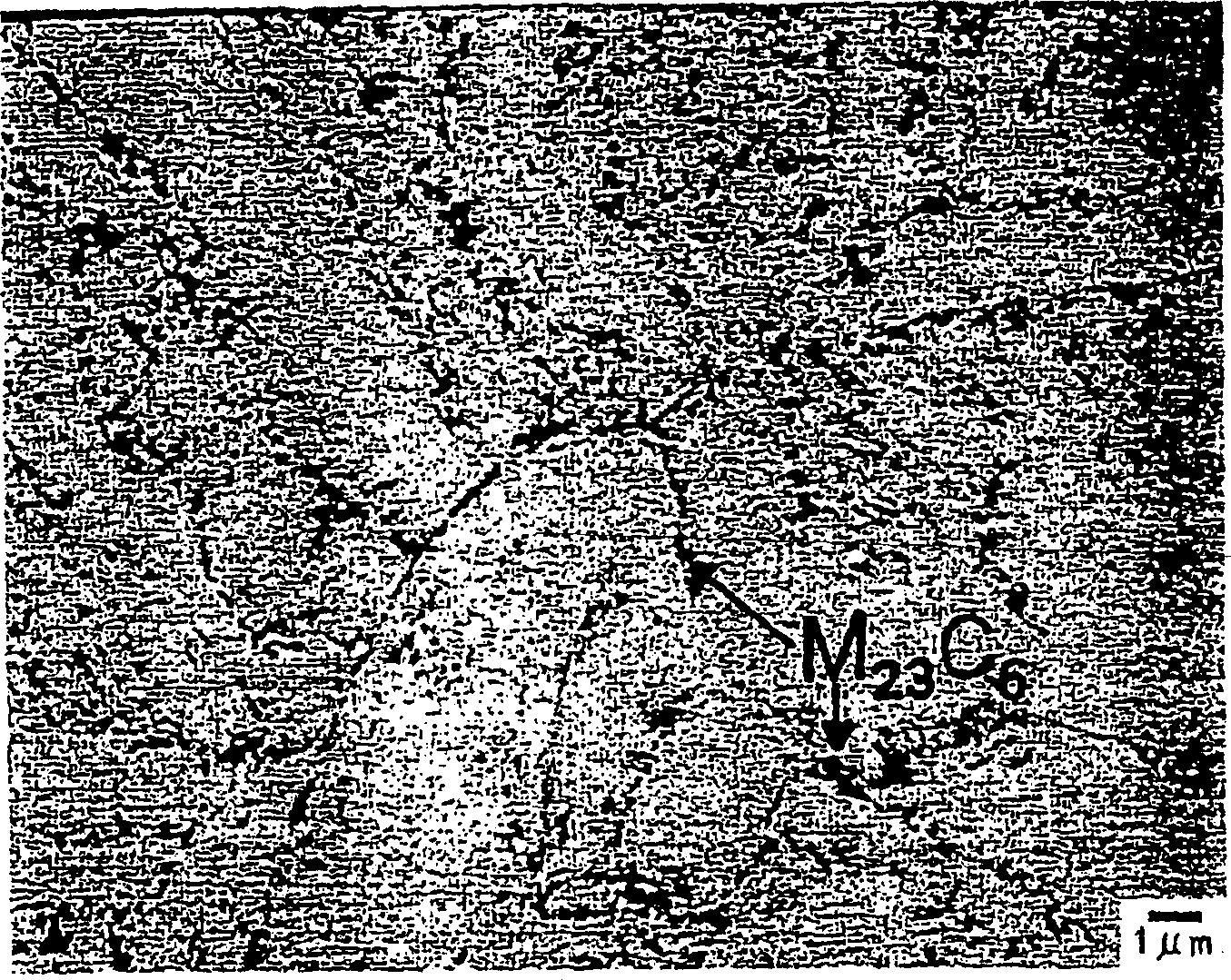

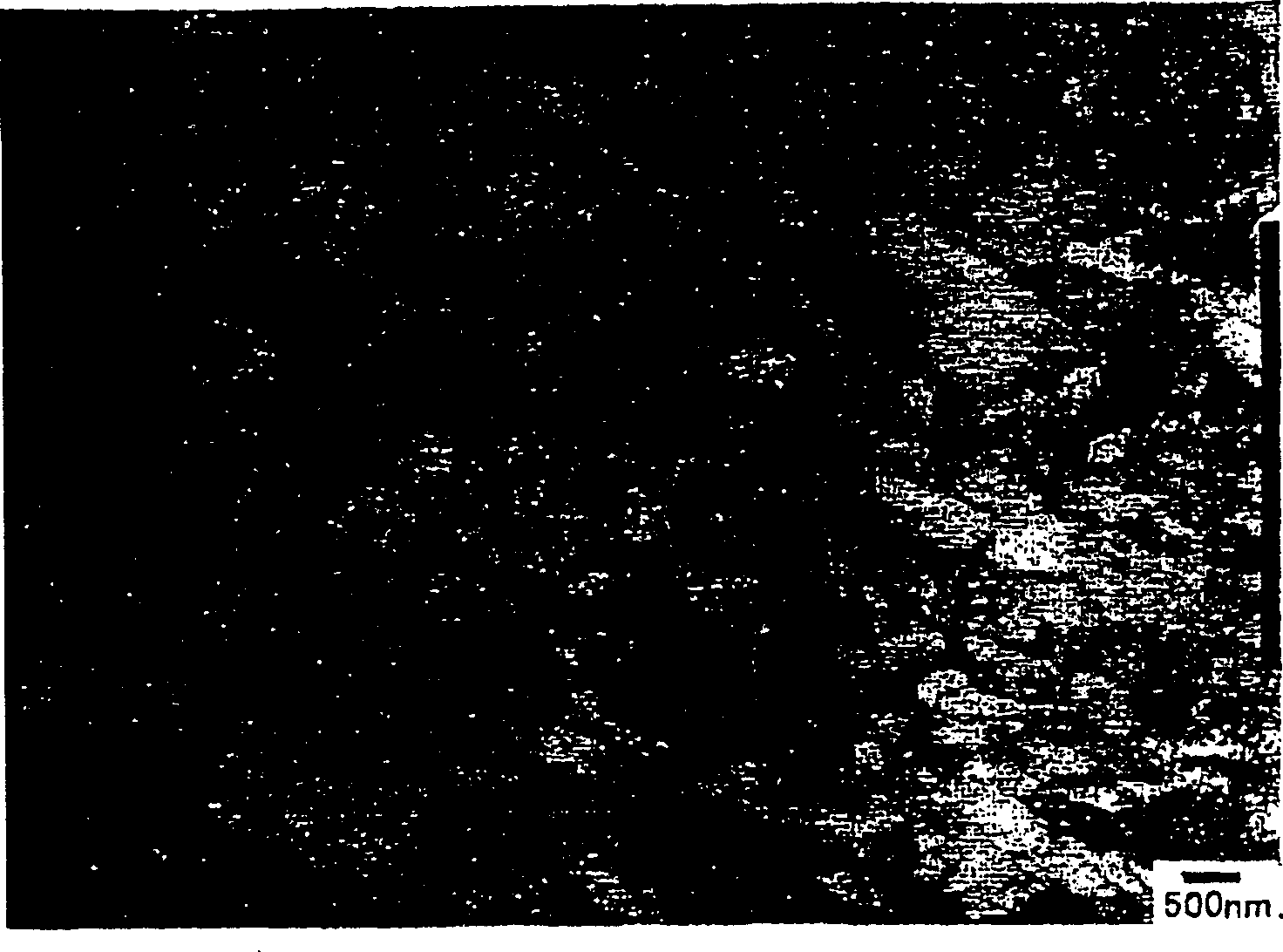

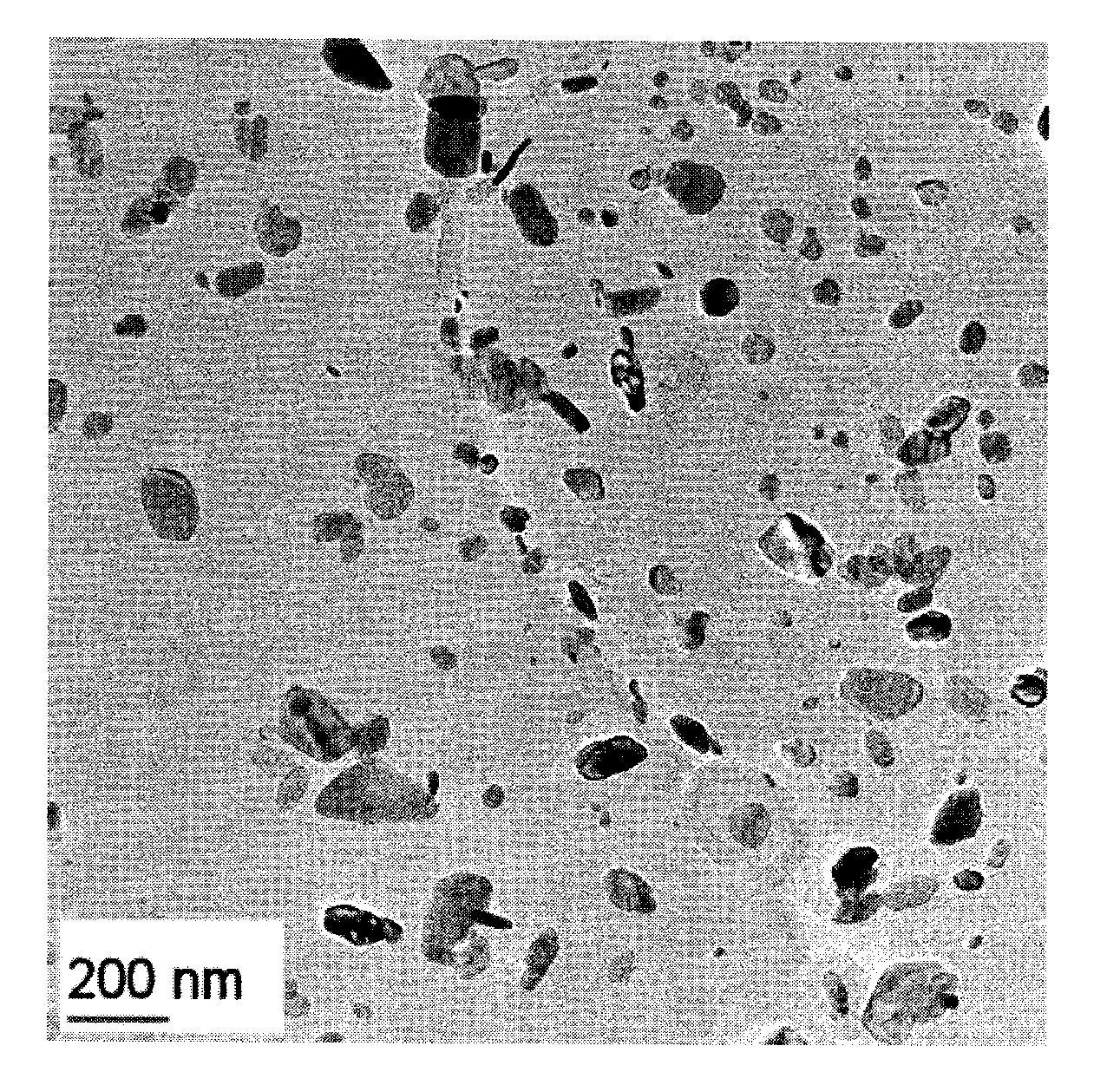

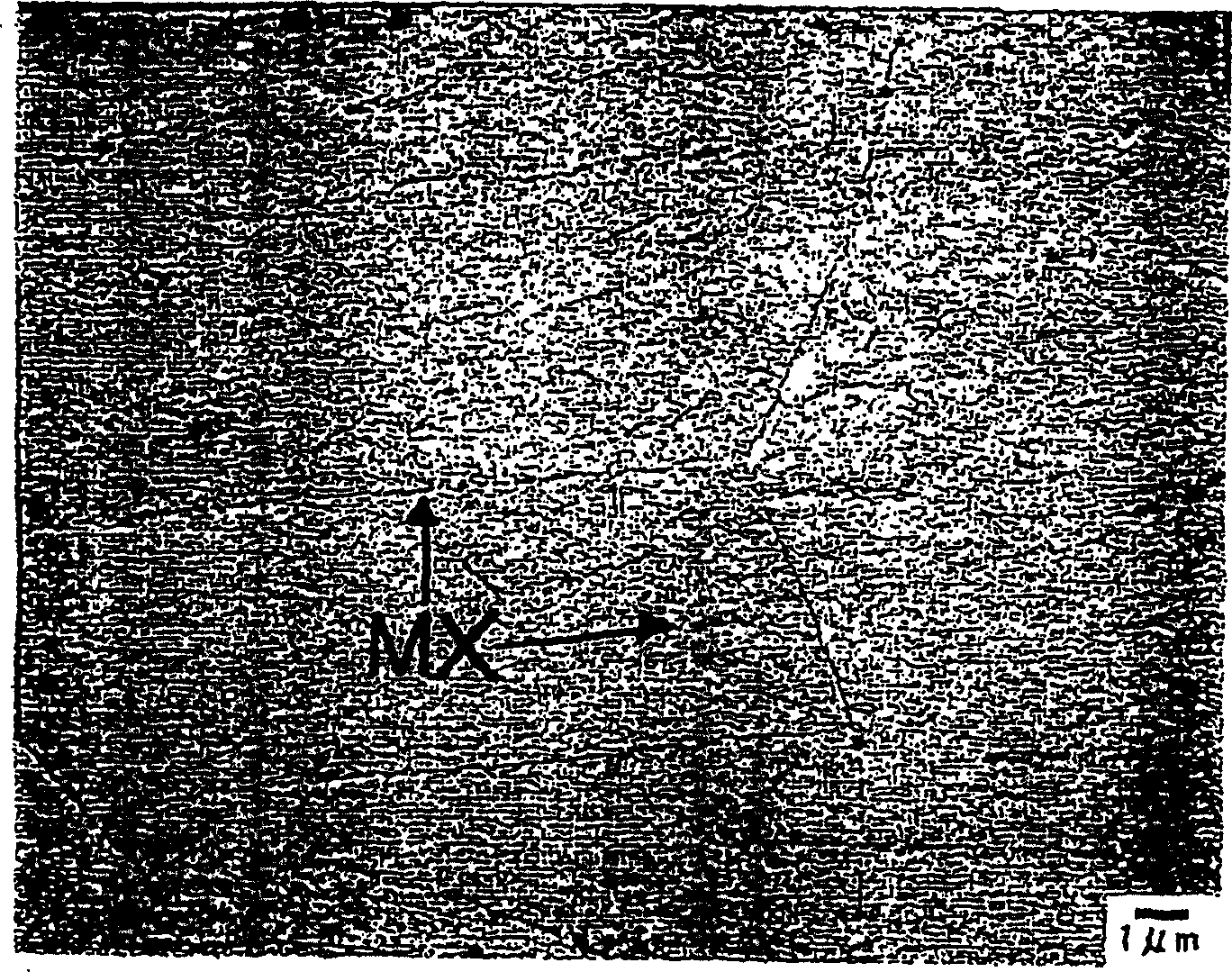

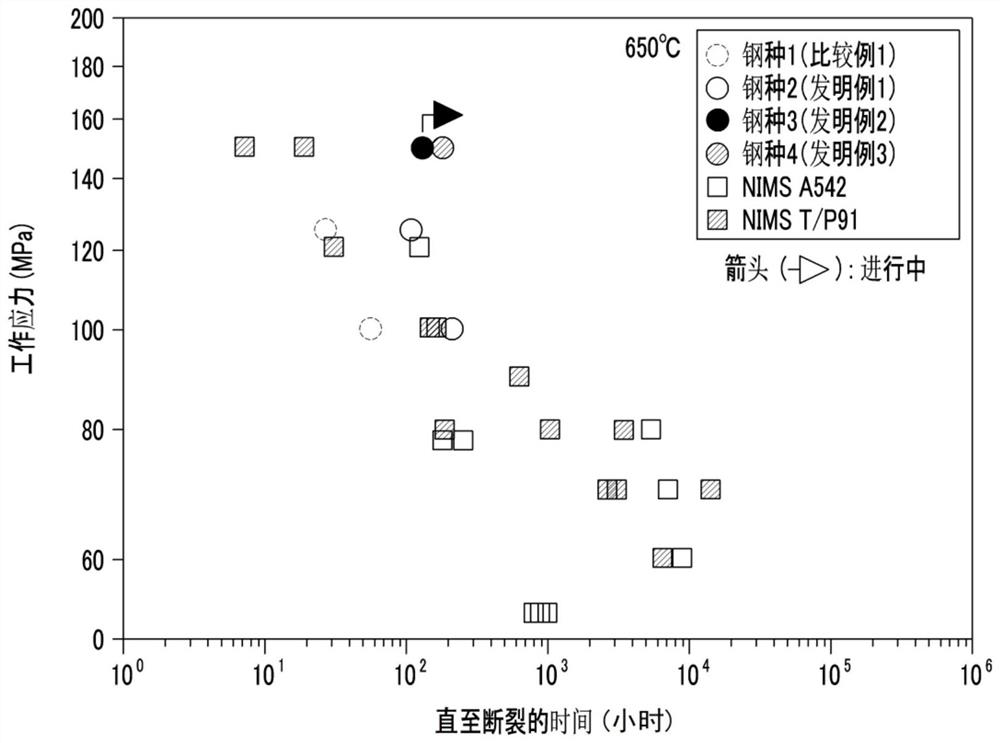

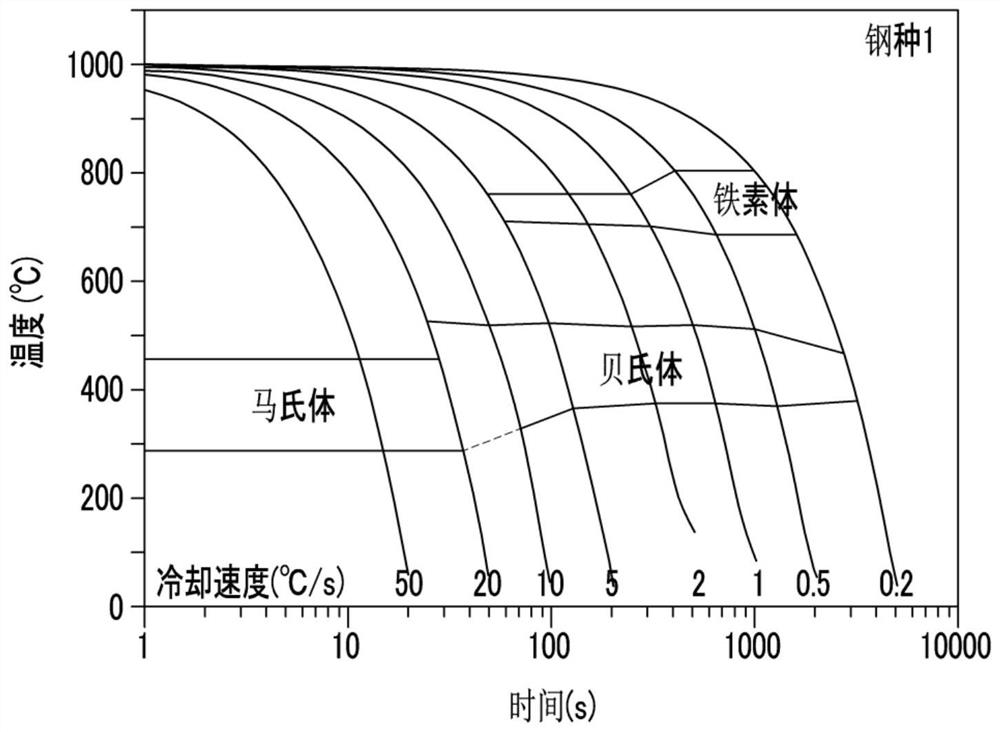

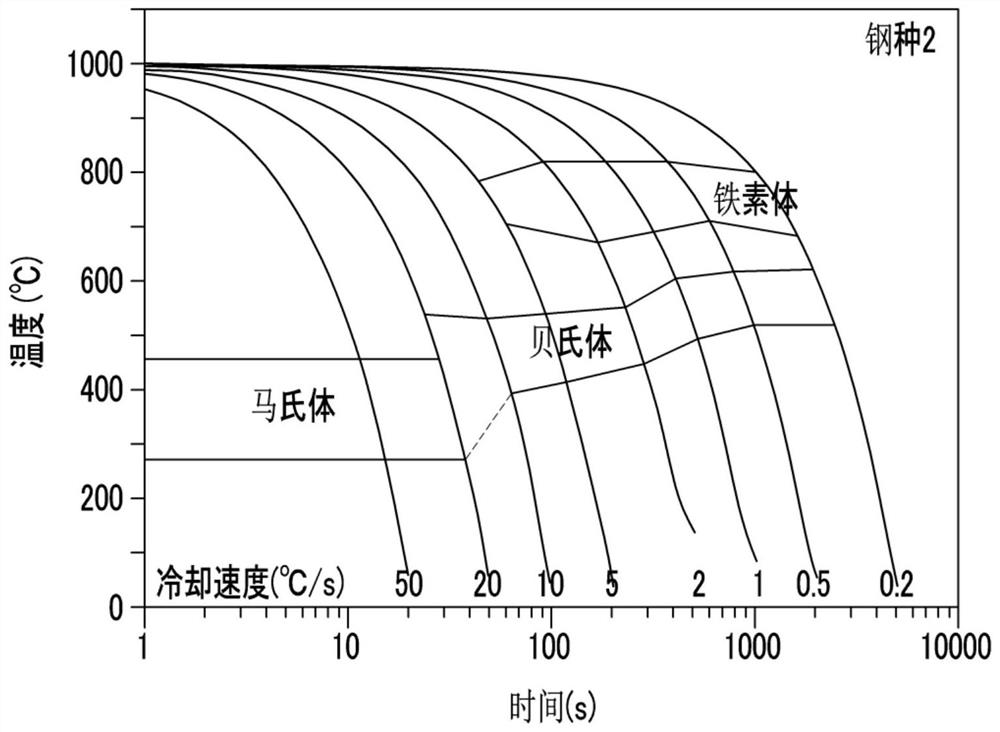

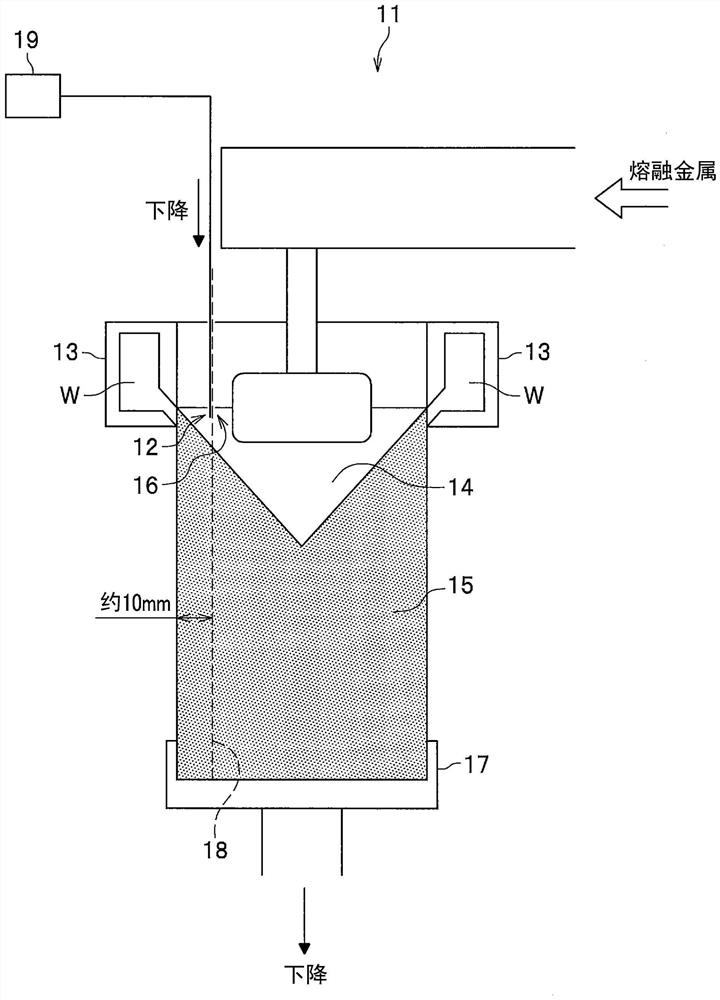

Ferritic heat-resistant steel and method for production thereof

A ferritic heat-resistant steel which comprises, in wt %, 1.0 to 13 % of chromium, 0.1 to 8.0 % of cobalt, 0.01 to 0.20 % of nitrogen, 3.0 % or less of nickel, 0.01 to 0.50 % of one or more elements selected from the group consisting of vanadium, niobium, tantalum, titanium, hafnium and zirconium, which form MX type precipitates, and 0.01 % or less of carbon, as constituting elements, the balance being substantially composed of iron and inevitable impurities, and has a metal structure wherein MX type precipitates are formed over the whole of grain boundaries and the surface within grains and M23C6 type precipitates are present on grain boundaries in an area percentage of 50 % or less. The ferritic heat-resistant steel exhibits excellent creep characteristics even at a high temperature exceeding 600 DEG C.

Owner:NAT INST FOR MATERIALS SCI +1

High-weldability environment-friendly superfine solder wire for intelligent manipulator welding and preparation method thereof

ActiveCN111590233AAvoid wastingHigh yieldWelding/cutting media/materialsSoldering mediaLutetiumCerium

The invention discloses a high-weldability environment-friendly superfine solder wire for intelligent manipulator welding and a preparation method thereof. The superfine solder wire comprises 96.9 wt%-98.1 wt% of solder alloy and 1.9 wt%-3.1 wt% of scaling powder, wherein the solder alloy comprises the components of tin, silver, copper, molybdenum, cerium, tellurium and lutetium, by adding the cerium, the structure of the solder can be changed, so that crystal grains are refined, solder joint bridges are reduced, the surface wettability of the solder alloy is changed, and the creep property and the tensile property are improved; the addition of tellurium can improve the corrosion resistance, the wear resistance and the strength of the material, the tensile strength of the solder can be improved, the generation of tin whiskers can be prevented; lutetium has good electrical conductivity and ductility and extremely high activity, and is excellent in effect of improving electric heating performance and oxidation resistance in soldering tin alloy powder, so that tensile strength and toughness of the solder are improved, the wettability of solder wires is good, the tensile strength is excellent, and lead-free and environment-friendly effects are achieved. The superfine solder wire has the advantages of being high in weldability and not prone to core breakage, and high weldability andlead-free environment-friendly development of products are achieved when the superfine solder wire is applied to the high-end application field of intelligent manipulator welding and the like.

Owner:中山翰华锡业有限公司

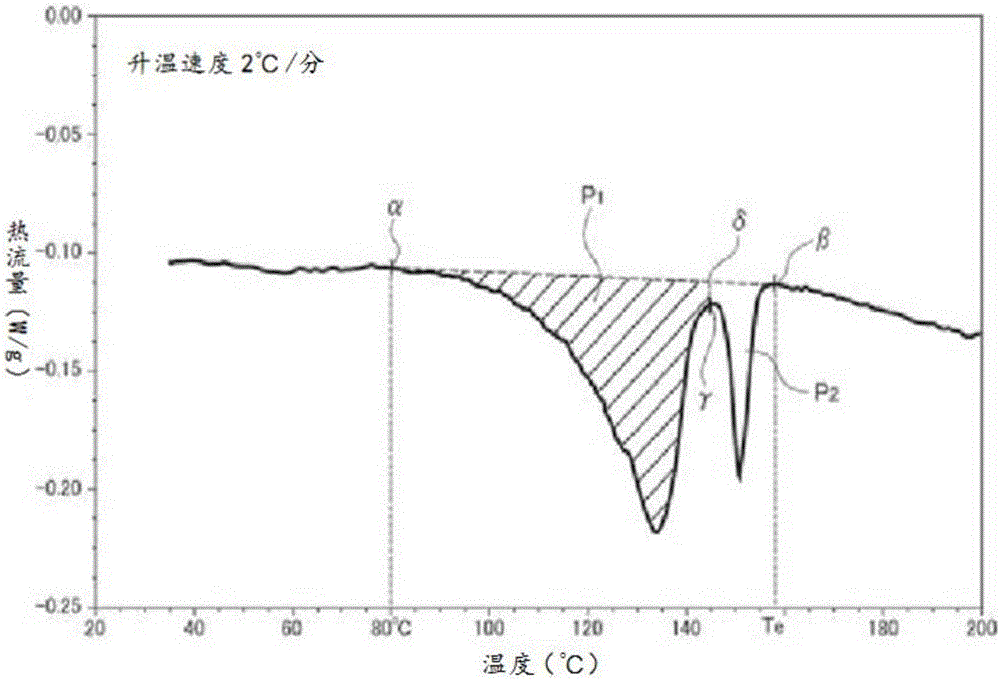

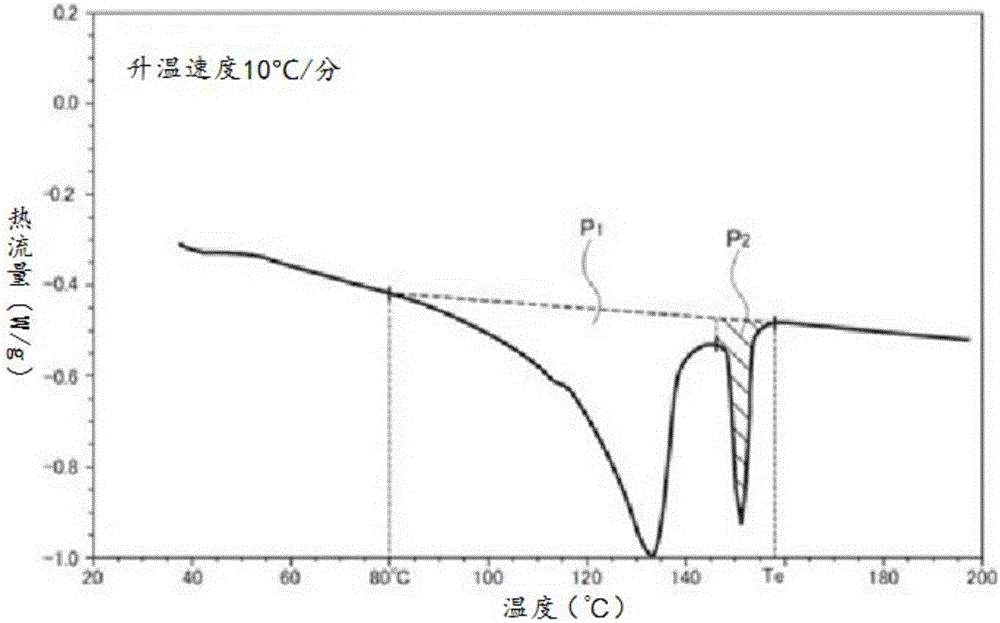

Propylene-based resin foam particle and foam particle molded body

The present invention is a propylene-based resin foam particle which includes a foamed ocre layer containing (a) a propylene-based resin composition that satisifies (i) and (ii) and a coating layer containing (b) an olefin-based resin that satisifies (iii) or (iv). (i) A mixture of (al) 75-98 wt.% of a propylene-based resin having a melting point of 100-140 DEG C and (a2) 25-2 wt.% of a propylene-based resin having a melting point of 140-165 DEG C. (ii) The difference between the melting point of the resin (a2) and that of the resin (a1) is 15 DEG C or more. (iii) A crystalline olefin-based resin which has a melting point (TmB) that is lower than the melting point (TmA) of the composition (a), and in which 0 DEG C<[TmA-TmB]<=80 DEG C. (iv) A non-crystalline olefin-based resin which has a softening point (TsB) that is lower than TmA, and in which 0 DEG C<[TmA-TsB]<=100 DEG C.

Owner:JSP CORP

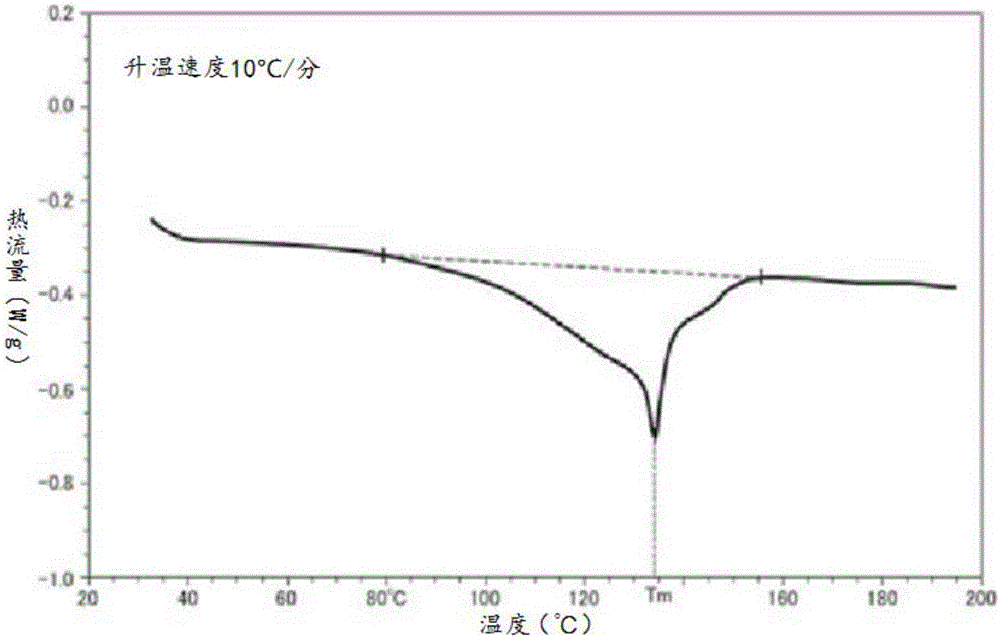

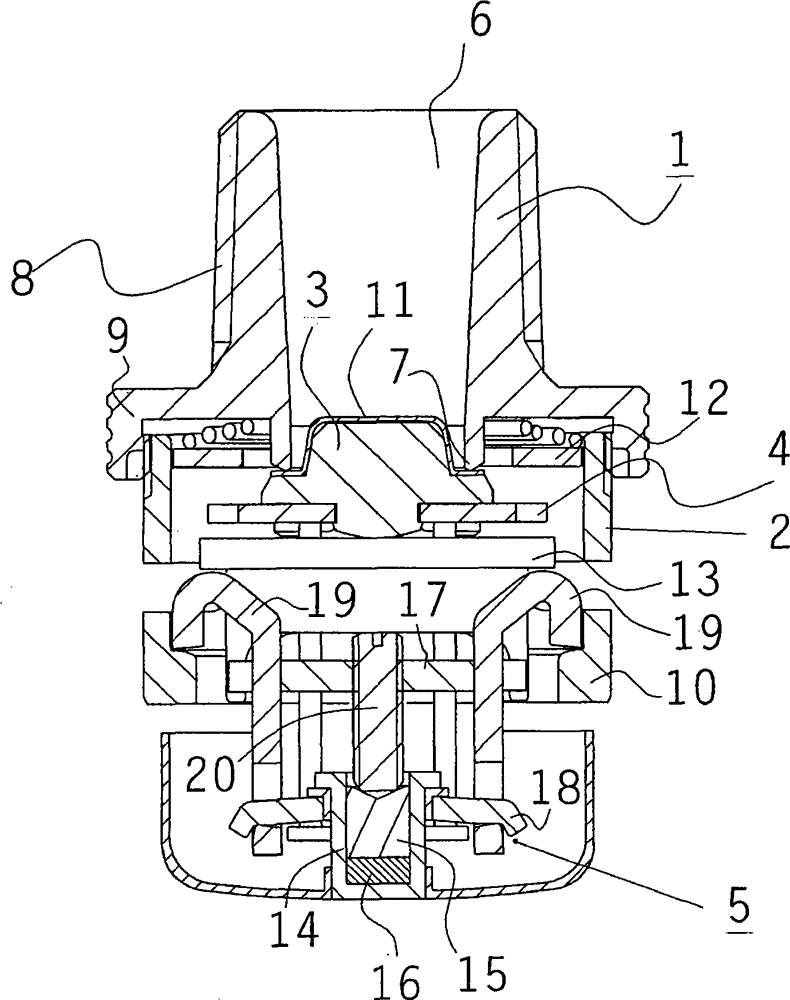

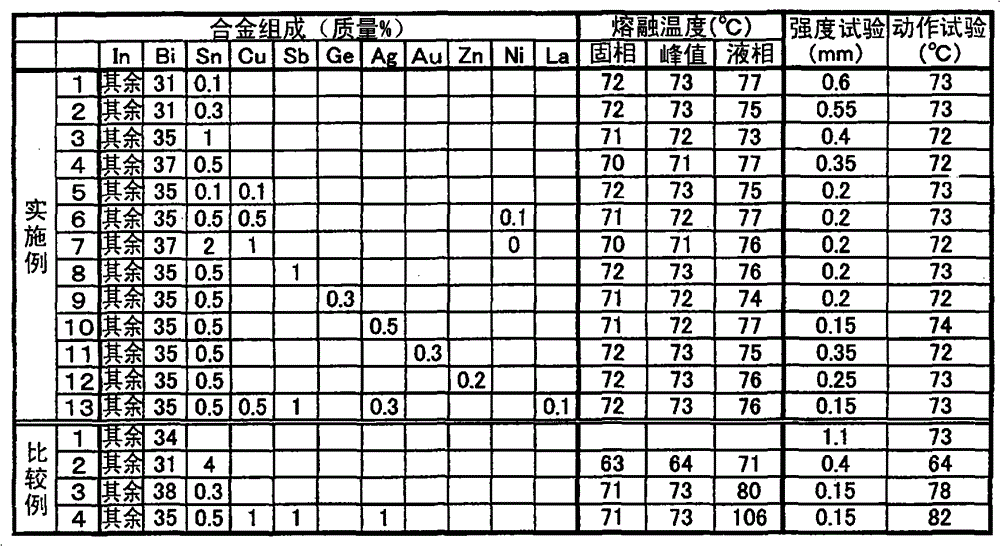

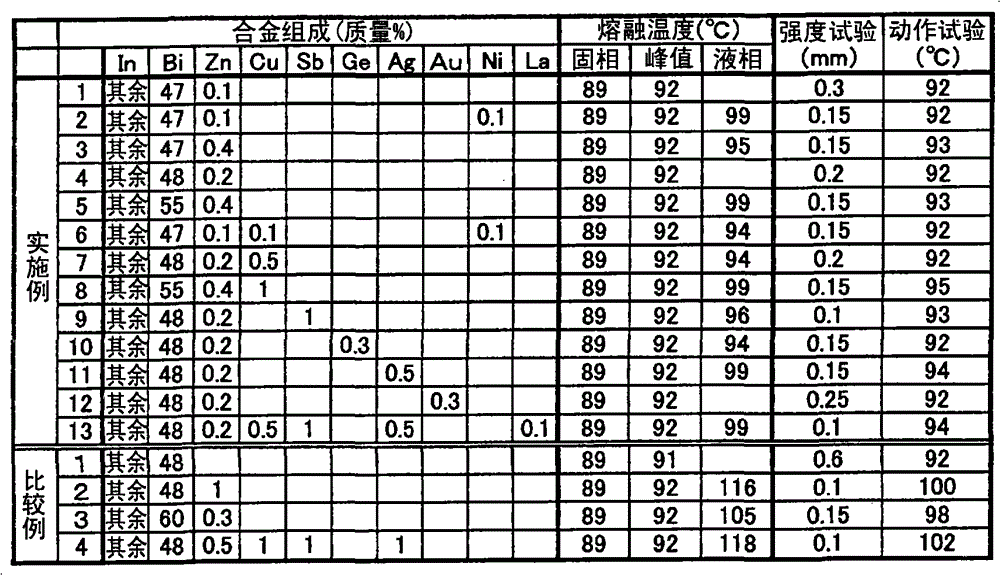

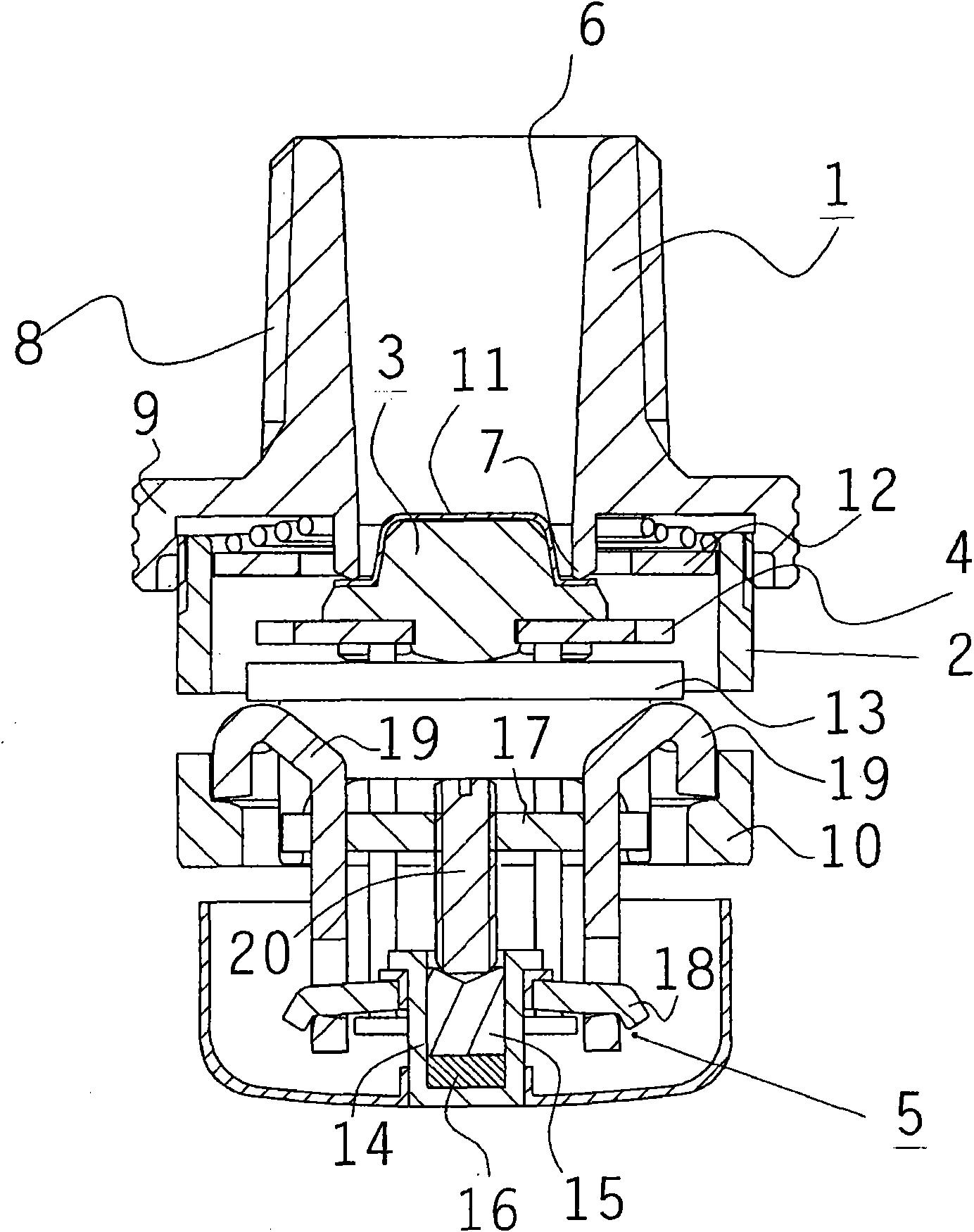

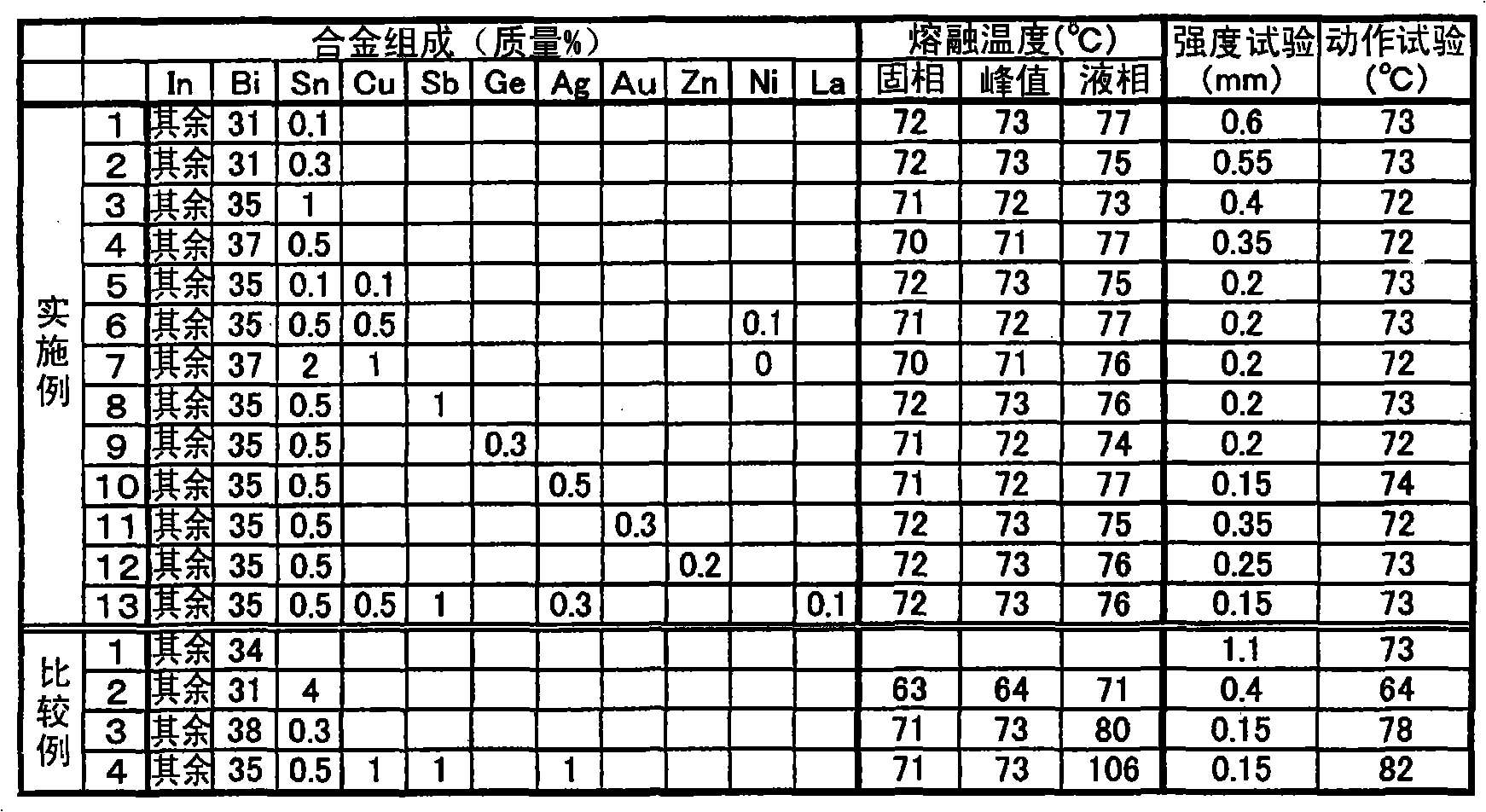

Thermally sensitive material and sprinkler head using the thermally sensitive material

ActiveCN101824573BExcellent creep propertiesMeet the durability testFire rescueDecompositionHeat sensitive

As the test temperature of a strength test for a sprinkler head is close to the melting temperature of a solder alloy of a thermal-induction decomposition part for the sprinkler head, thus a high-temperature area working on an automatic sprinkler is required to have creeping properties. However, compared with the past Pb or Cd sprinkler head, the sprinkler head not made of a Pb or Cd In-base alloy can not reach the creeping properties of the high-temperature area working on the automatic sprinkler, and sometimes the endurance test is unqualified. In the invention, alloy for a thermo-sensitive material fused at the temperature of 70-75 DEG C of the thermal-induction decomposition part for the sprinkler head comprises the following components by mass percent: 0.1-2.0% of Sn, 31-37% of Bi, the balance of In-base alloy; and alloy for a thermo-sensitive material fused at the temperature of 90-95 DEG C comprises the following components by mass percent: 0.05-0.4% of Zn, 43-55% of Bi and the balance of In-base alloy.

Owner:SENJU METAL IND CO LTD

Shock absorbing rubber

The invention discloses shock absorbing rubber. The shock absorbing rubber comprises the following ingredients: 100 parts by weight of butadiene styrene rubber, 20-30 parts by weight of natural rubber, 10-40 parts by weight of carbon black, 10-30 parts by weight of silicon dioxide, 2-20 parts by weight of suberic acid diethyl ester, 1-4 parts by weight of anti-aging agent, 1-5 parts by weight of vulcanizing agent, 1-5 parts by weight of accelerant and 3-8 parts by weight of cross-linking agent, wherein the weight ratio of the carbon black to the silicon dioxide is (1.5-2):1. Compared with existing shock absorbing rubber, the shock absorbing rubber has the advantage that the creep property is improved obviously.

Owner:LIUZHOU CITY TONGJIN AUTOMOBILE PARTS MFG CO LTD

Polyester resin composition, polyester fiber, polyester resin molded article, and process for production of nucleating agent for polyester resin

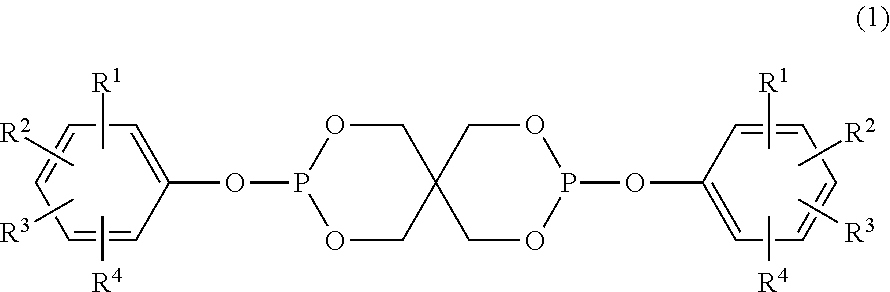

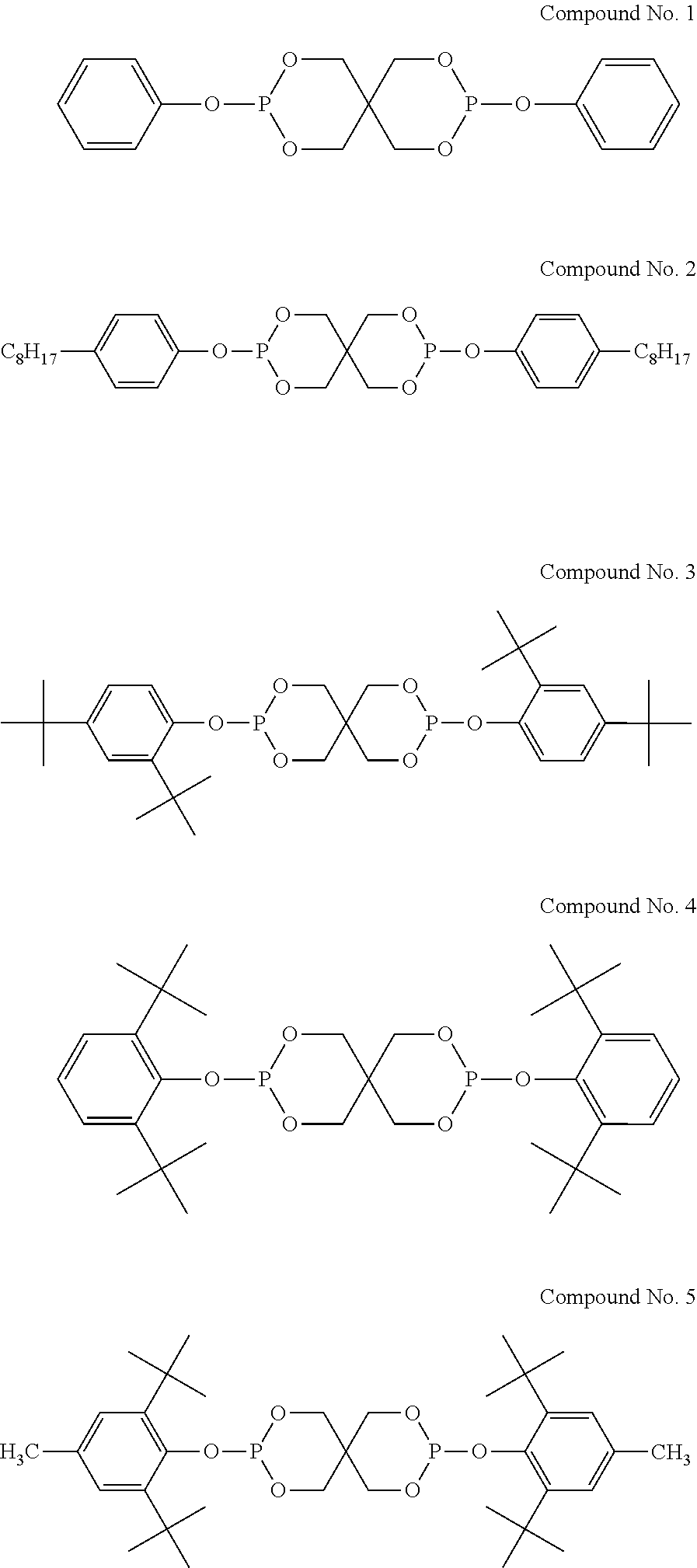

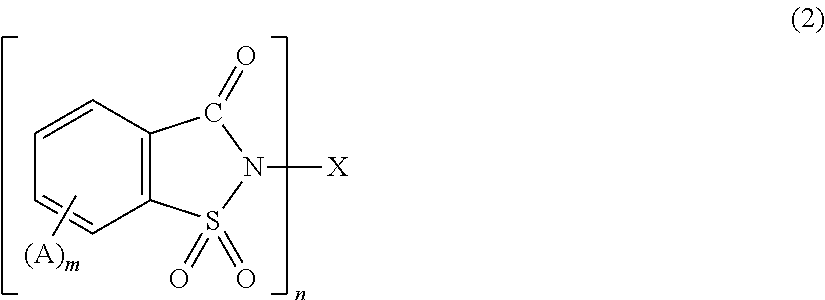

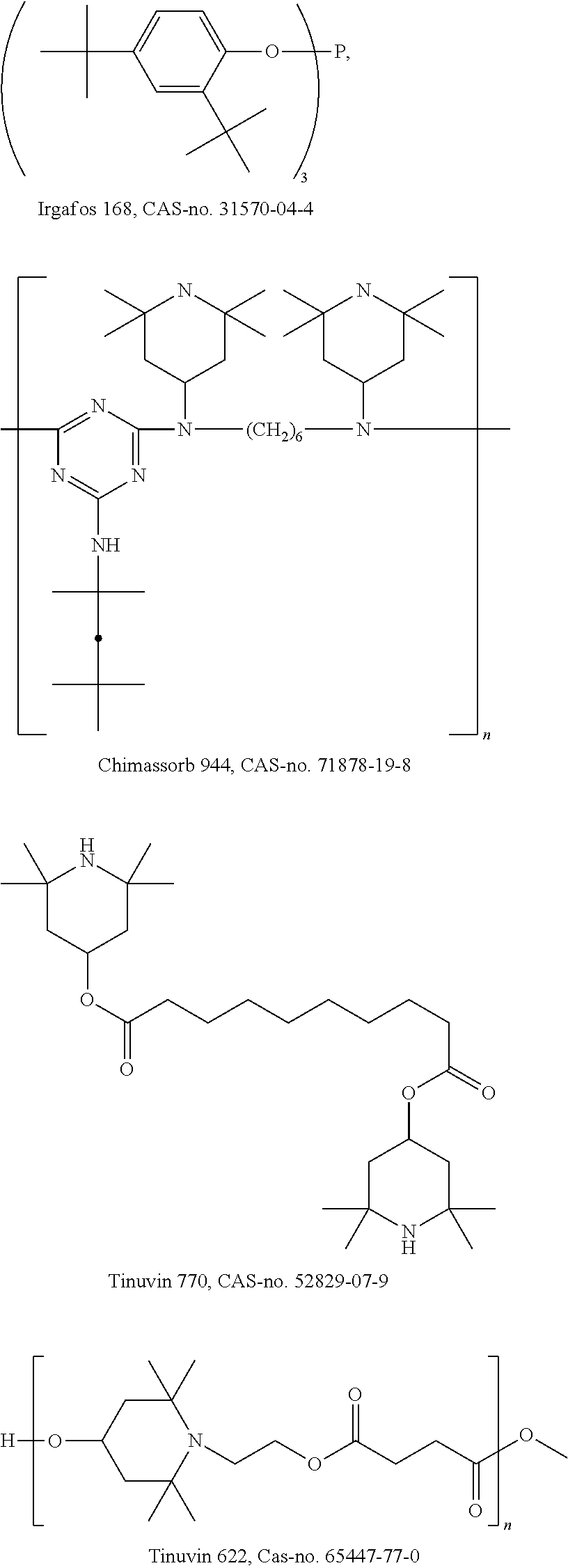

InactiveUS20140001672A1Excellent creep propertiesLow heat shrinkageThin material handlingFiberAntioxidant

Provided is a polyester resin composition comprising a sulfonamide compound as a nucleating agent, in which polyester resin composition coloring is inhibited.The polyester resin composition according to the present invention is a polyester resin composition comprising, with respect to 100 parts by mass of a polyester resin, 0.01 to 30 parts by mass of a phosphorus-based antioxidant (A) and 0.1 to 30 parts by mass of a sulfonamide compound metal salt (B),wherein the sulfonamide compound metal salt (B) has a water content of 0.1% to 20% based on the mass ratio with respect to the sulfonamide compound metal salt and not higher than 3% based on the mass ratio with respect to the polyester resin composition.

Owner:ADEKA CORP

Film with moderate crosslinking

InactiveUS20170283566A1Low gel contentProne to delaminationSynthetic resin layered productsGlass/slag layered productsChemistryCompound (substance)

A polymer composition with a polymer of ethylene with a comonomer with silane group(s) containing units and an additive that is an organic compound with at least one amine moiety that has a gel content less than 10 wt % after 7 days at ambient conditions and a gel content of at least 15 wt % gel content after 14 days at 100° C. The film can be used in a laminate.

Owner:BOREALIS AG

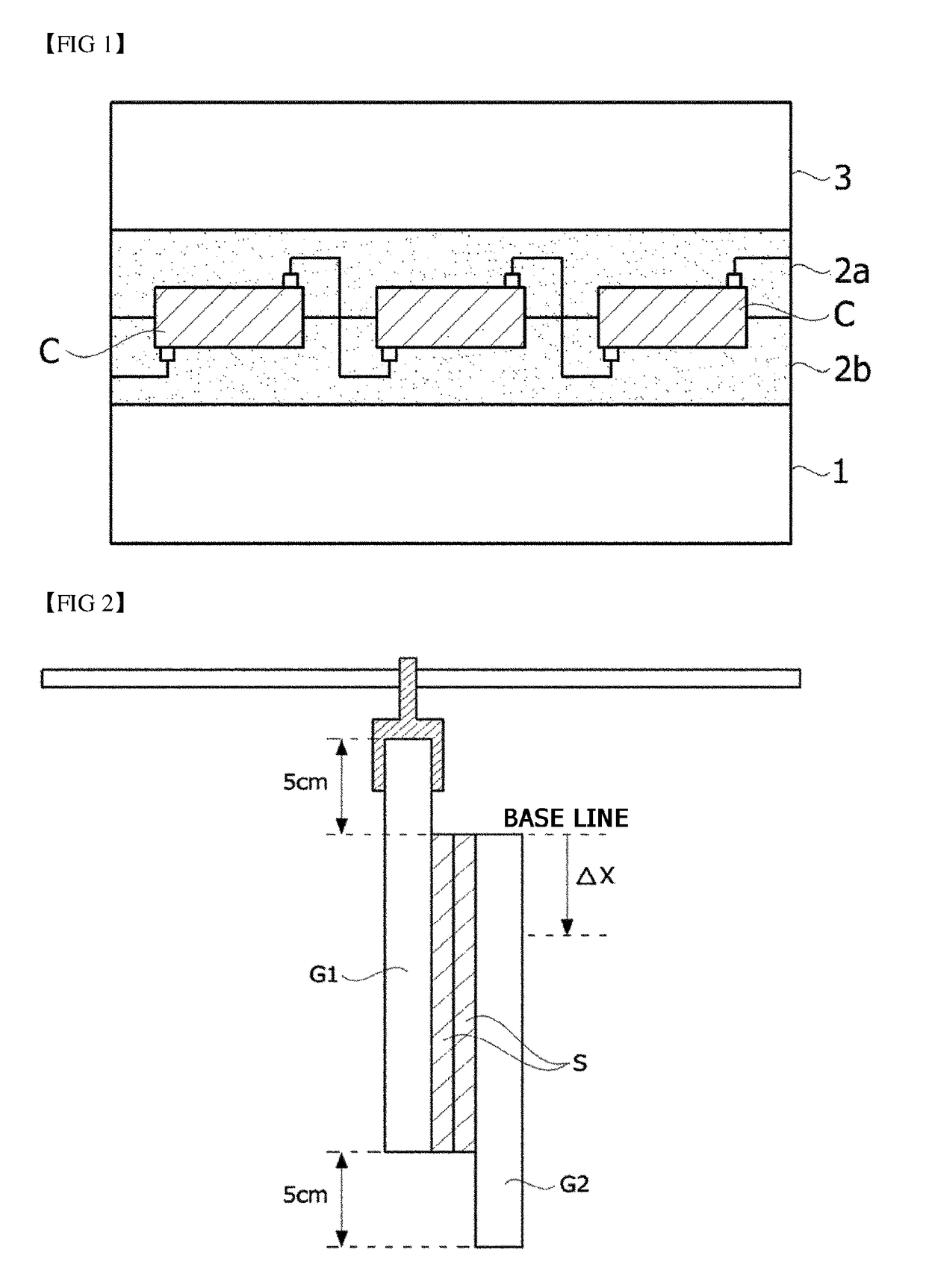

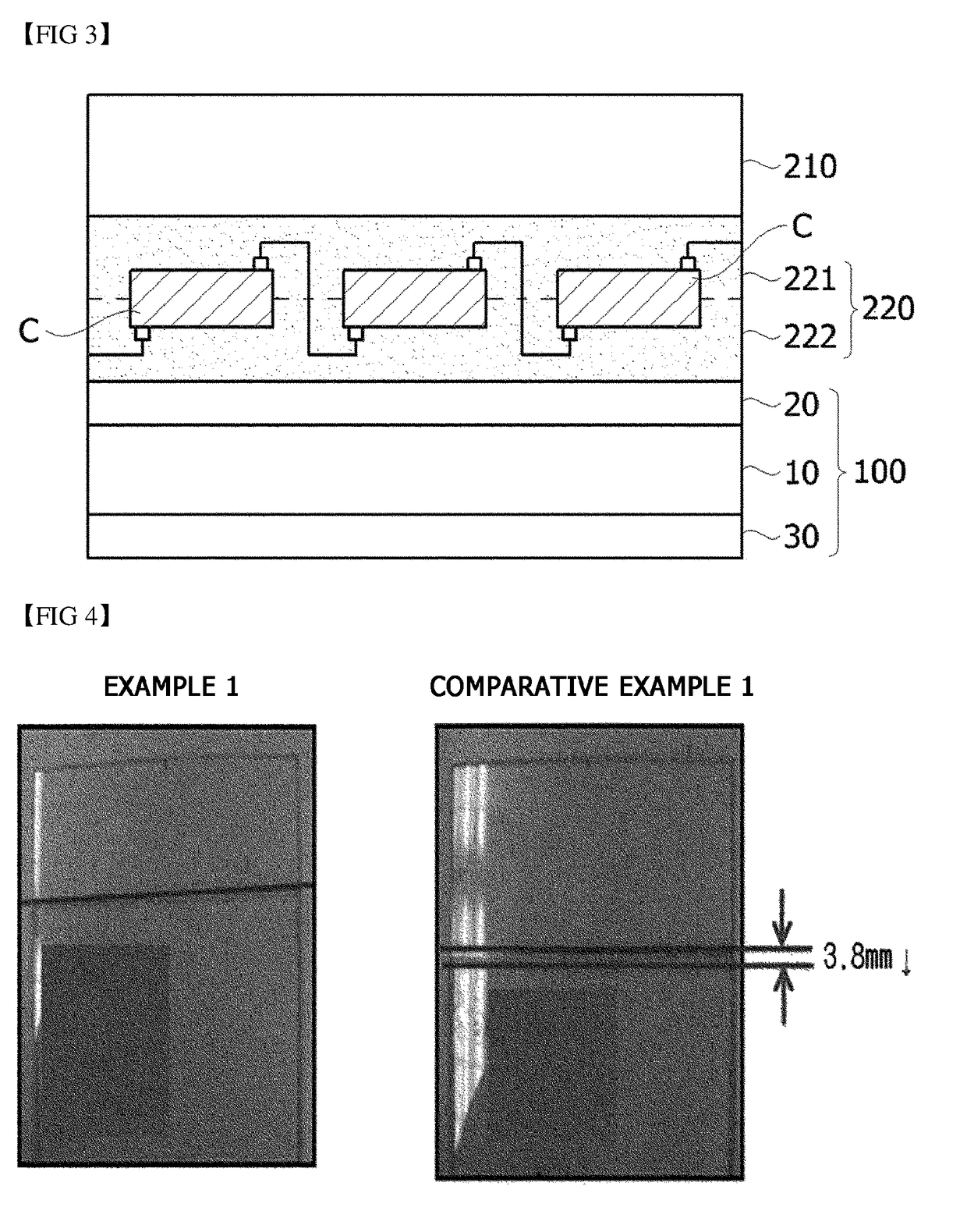

Encapsulant for PV module, method of manufacturing the same and PV module comprising the same

ActiveUS9806213B2Improve adhesion strengthExcellent creep propertiesFilm/foil adhesivesCoatingsHigh humidityHeat resistance

The present application relates to an encapsulant for a PV module, a method of manufacturing the same and a PV module. The encapsulant according to an embodiment of the present application has excellent heat resistance or the like and improved creep physical properties, and thus even when the encapsulant is used under conditions of a high temperature and / or high humidity for a long time, deformation is small and the encapsulant can exhibit excellent adhesive strength. Accordingly, when the encapsulant is applied to a PV module, durability or the like may be improved.

Owner:LG CHEM LTD

Lead-free bonding systems

InactiveUS7556189B2Improve mechanical propertiesHigh bandwidthMolten spray coatingVacuum evaporation coatingBonding processHermetic packaging

Nano-structured interconnect formation and a reworkable bonding process using solder films. Large area fabrication of nano-structured interconnects is demonstrated at a very fine pitch. This technology can be used for pushing the limits of current flip chip bonding in terms of pitch, number of I / Os, superior combination of electrical and mechanical properties as well as reworkability. Sol-gel and electroless processes were developed to demonstrate film bonding interfaces between metallic pads and nano interconnects. Solution-derived nano-solder technology is an attractive low-cost method for several applications such as MEMS hermetic packaging, compliant interconnect bonding and bump-less nano-interconnects.

Owner:GEORGIA TECH RES CORP

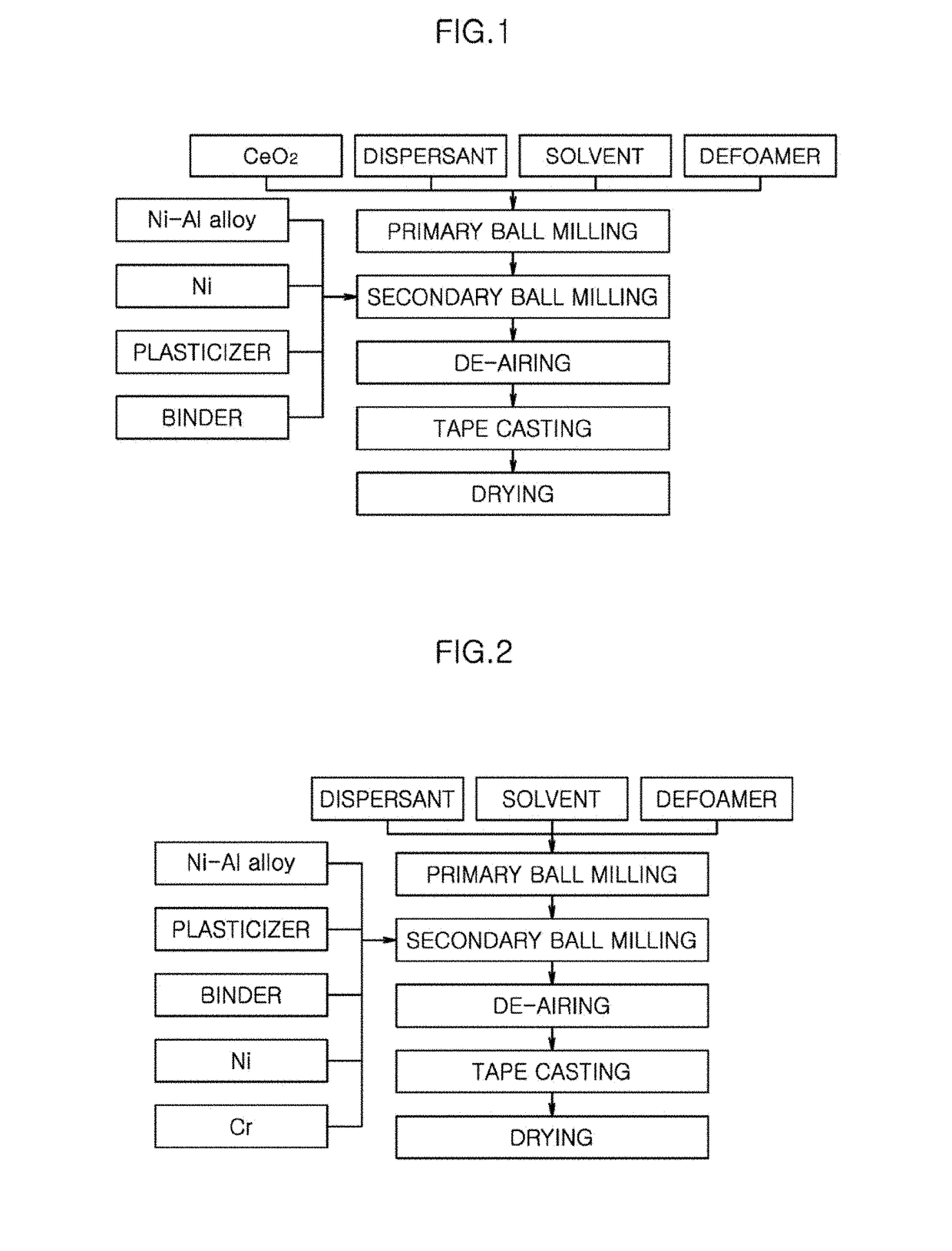

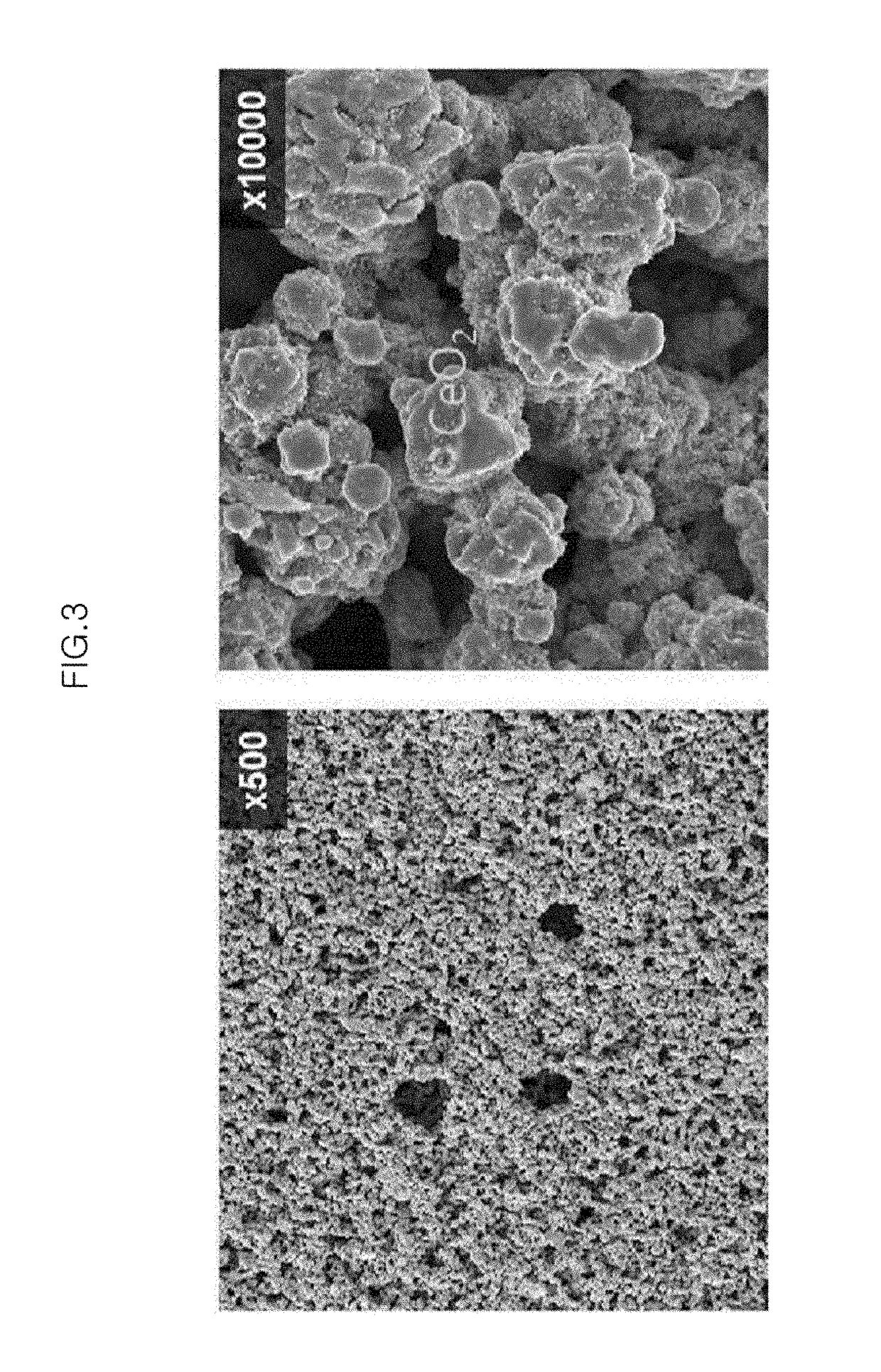

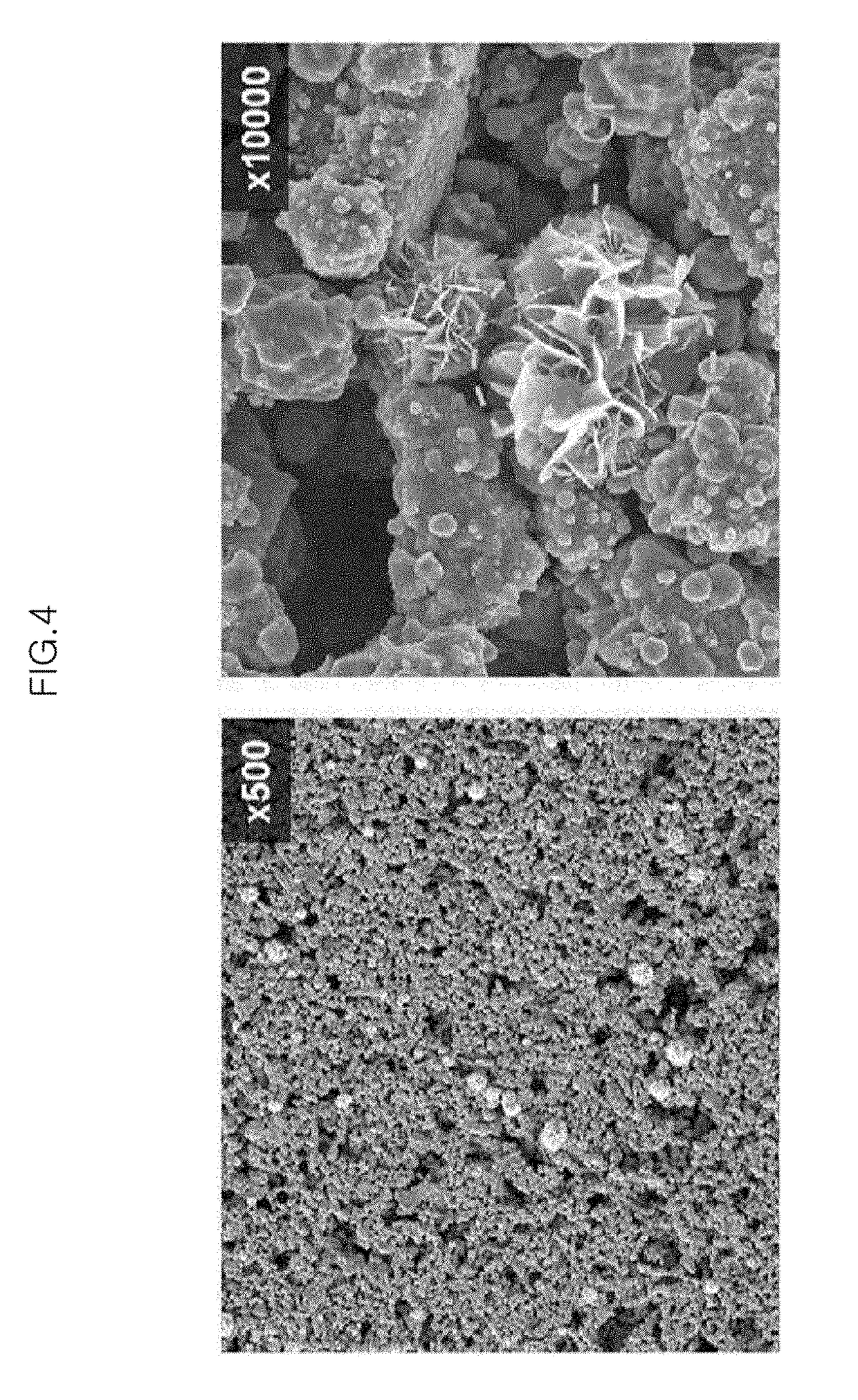

Anode for molten carbonate fuel cell having improved creep property, method for preparing the same, and molten carbonate fuel cell using the anode

ActiveUS20170187043A1Improve mechanical propertiesImprove propertiesCell electrodesFused electrolyte fuel cellsFuel cellsMolten carbonate fuel cell

Disclosed is an anode for a molten carbonate fuel cell (MCFC) having improved creep property by adding an additive for imparting creep resistance to nickel-aluminum alloy and nickel as materials for an anode. Improved sintering property, creep property and increased mechanical strength of a molten carbonate fuel cell may be obtained accordingly.

Owner:KOREA INST OF SCI & TECH

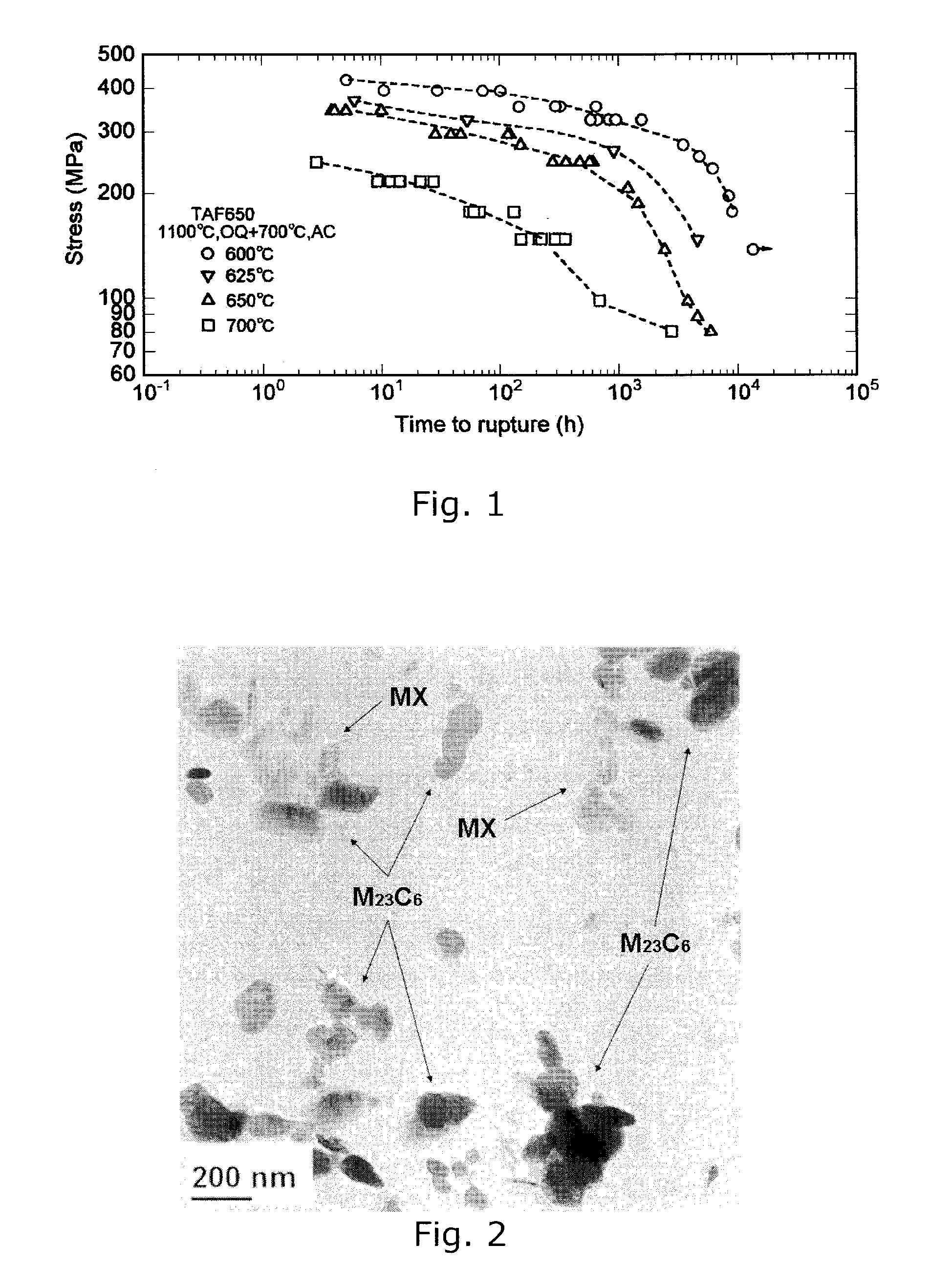

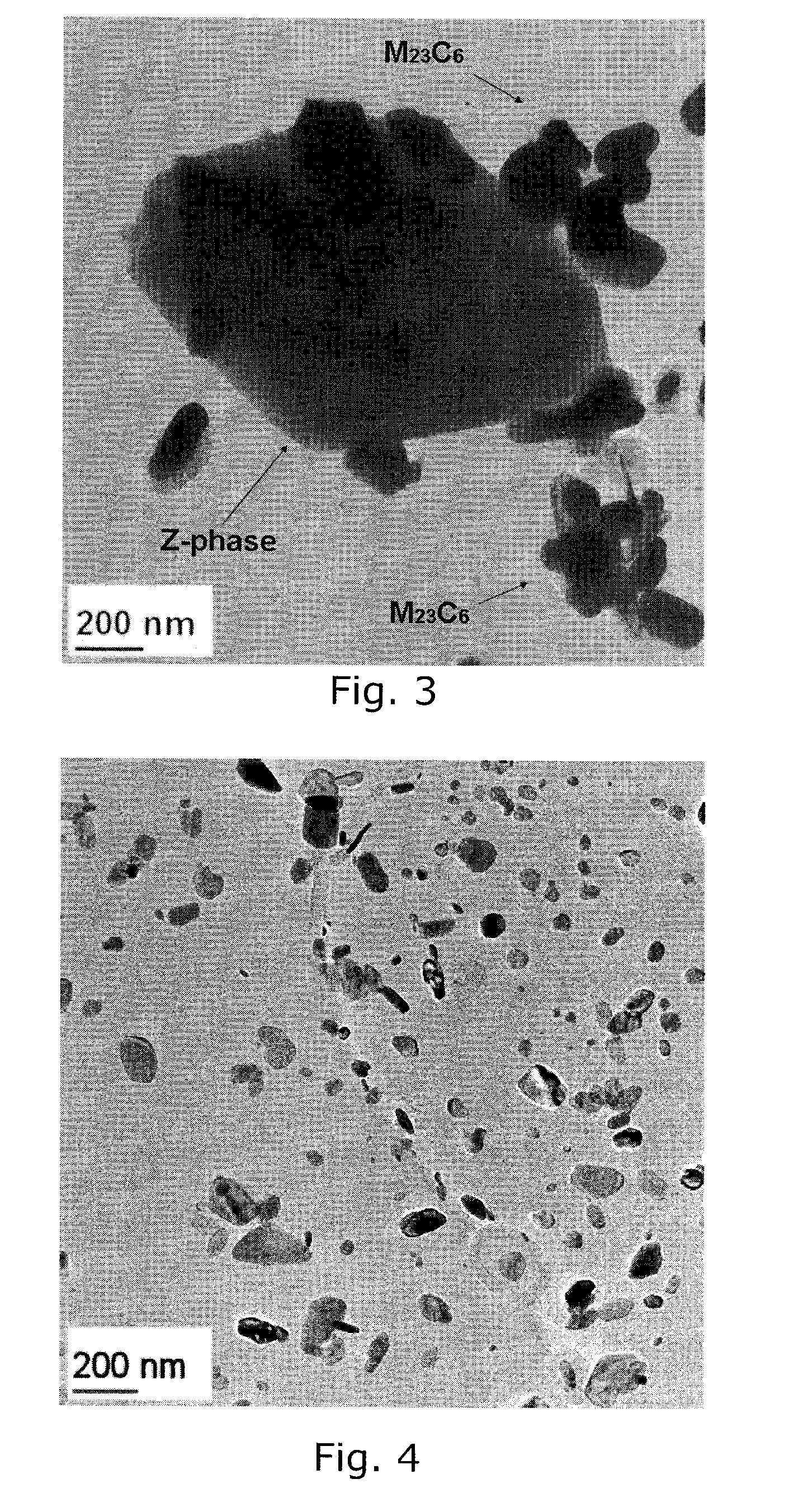

Martensitic Creep Resistant Steel Strengthened by Z-Phase

The present invention relates to steel alloys having a martensitic or martensitic-ferritic structure and comprising Z-phase (CrXN) particles, where X is one or more of the elements V, Nb, Ta, and where the Z-phase particles have an average size of less than 400 nm. The alloy comprises by wt % the following components: 9 to 15% Cr, 0.01-0.20% N, C in an amount less than 0.1%, one or more of: 0.01-0.5% V, 0.01-1% Nb, 0.01-2% Ta, and a balance being substantially iron and inevitable impurities. The invention further relates to a method of manufacturing such a steel alloy, a component comprising such a steel alloy, and to the use of such a steel alloy for high temperature components.

Owner:DANMARKS TEKNISKE UNIV +1

Ferritic heat-resistant steel and method for production thereof

A ferritic heat-resistant steel which comprises, in wt %, 1.0 to 13 % of chromium, 0.1 to 8.0 % of cobalt, 0.01 to 0.20 % of nitrogen, 3.0 % or less of nickel, 0.01 to 0.50 % of one or more elements selected from the group consisting of vanadium, niobium, tantalum, titanium, hafnium and zirconium, which form MX type precipitates, and 0.01 % or less of carbon, as constituting elements, the balance being substantially composed of iron and inevitable impurities, and has a metal structure wherein MX type precipitates are formed over the whole of grain boundaries and the surface within grains and M23C6 type precipitates are present on grain boundaries in an area percentage of 50 % or less. The ferritic heat-resistant steel exhibits excellent creep characteristics even at a high temperature exceeding 600 DEG C.

Owner:NAT INST FOR MATERIALS SCI +1

Thermo-sensitive material and sprinkler head for using same

ActiveCN101824573AExcellent creep propertiesMeet the durability testFire rescueDecompositionHeat sensitive

As the test temperature of a strength test for a sprinkler head is close to the melting temperature of a solder alloy of a thermal-induction decomposition part for the sprinkler head, thus a high-temperature area working on an automatic sprinkler is required to have creeping properties. However, compared with the past Pb or Cd sprinkler head, the sprinkler head not made of a Pb or Cd In-base alloy can not reach the creeping properties of the high-temperature area working on the automatic sprinkler, and sometimes the endurance test is unqualified. In the invention, alloy for a thermo-sensitive material fused at the temperature of 70-75 DEG C of the thermal-induction decomposition part for the sprinkler head comprises the following components by mass percent: 0.1-2.0% of Sn, 31-37% of Bi, the balance of In-base alloy; and alloy for a thermo-sensitive material fused at the temperature of 90-95 DEG C comprises the following components by mass percent: 0.05-0.4% of Zn, 43-55% of Bi and the balance of In-base alloy.

Owner:SENJU METAL IND CO LTD

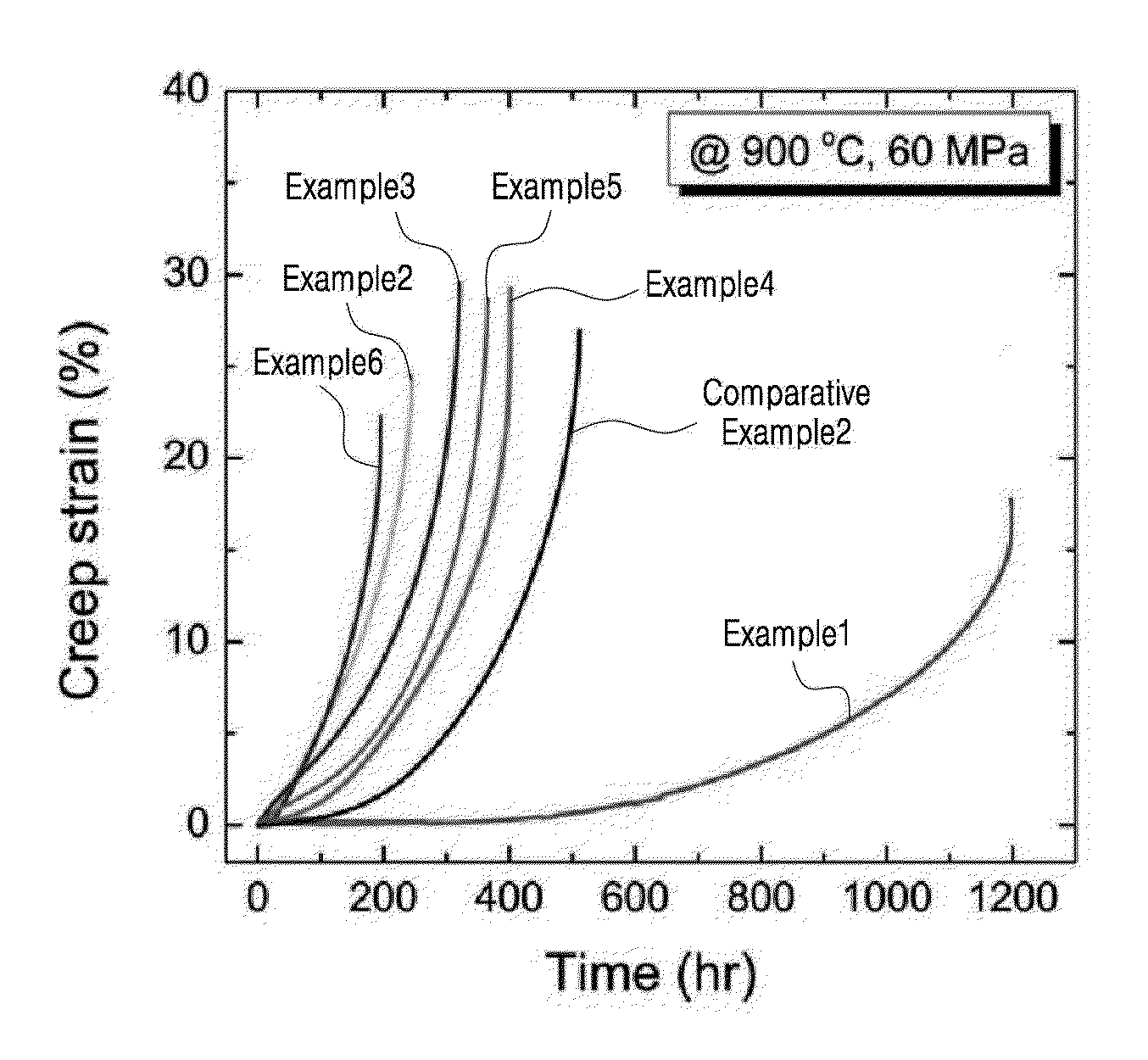

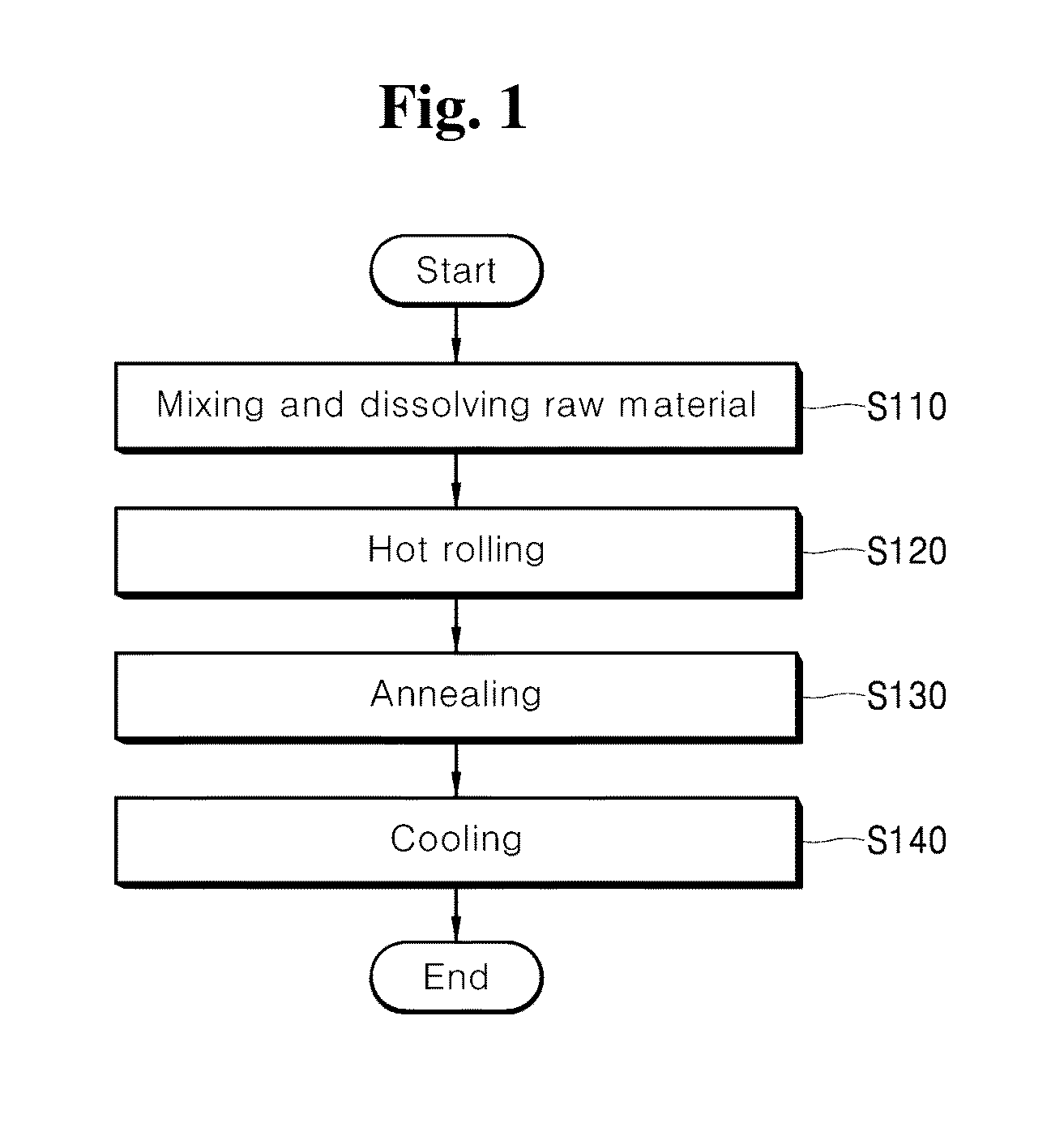

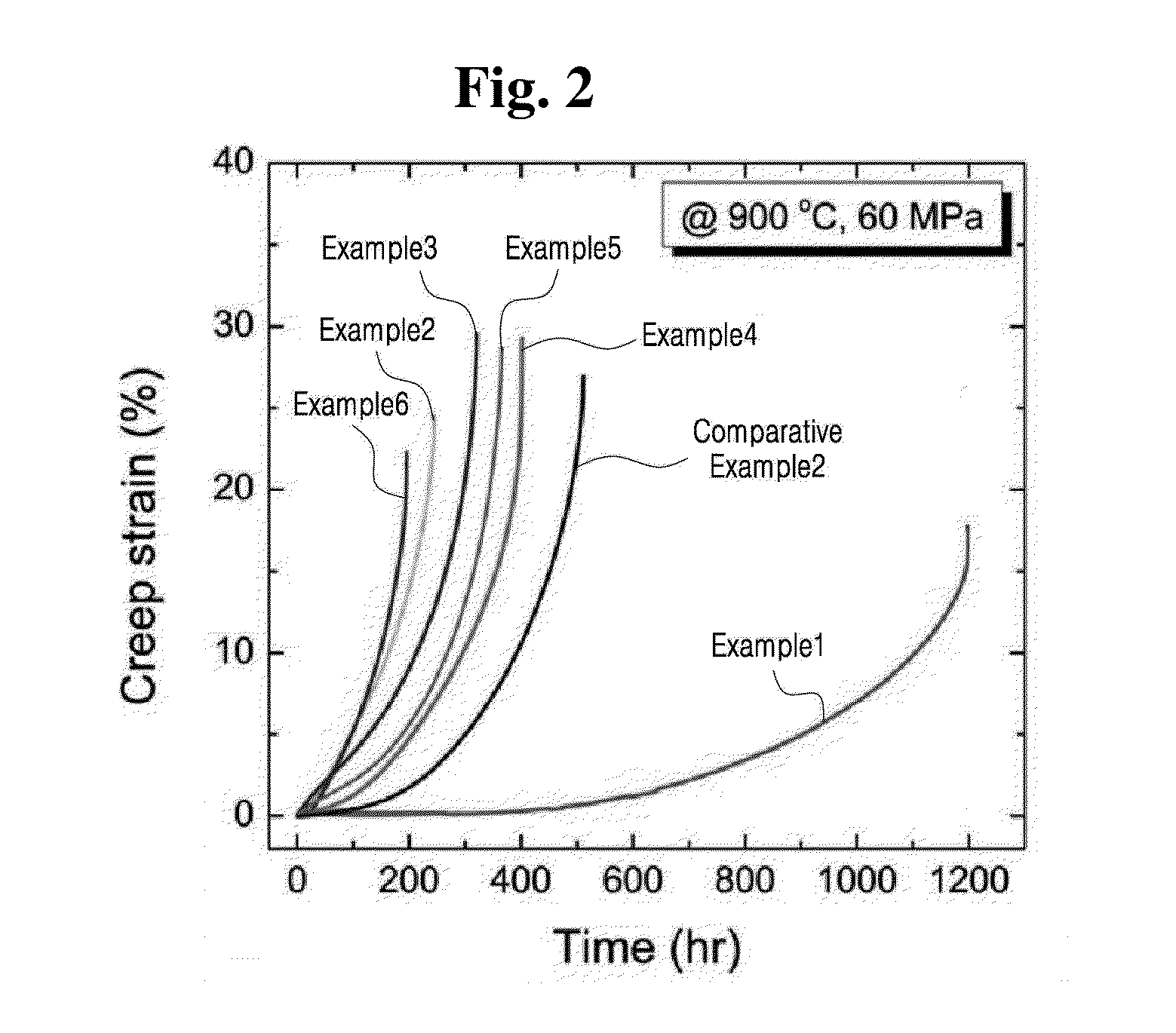

Ni-BASED SUPERALLOY WITH EXCELLENT OXIDIZATION RESISTANCE AND CREEP PROPERTY AND METHOD OF MANUFACTURING THE SAME

InactiveUS20160145729A1Excellent oxidization resistance and creep propertyExcellent creep propertiesRollsMetal rolling arrangementsManganeseLanthanum

The present disclosure relates to a Ni-based superalloy with excellent oxidation resistance and creep properties, which is suitable for parts of energy plants and chemical plants under a corrosive oxidative / reductive atmosphere, which stainless steel cannot withstand, through adjustment of alloy components and control of process conditions and a method of manufacturing the same. The Ni-based superalloy includes: chromium (Cr): 20˜26 wt %, tungsten (W): 13˜17 wt %, molybdenum (Mo): 1˜5 wt %, manganese (Mn): 0.1˜1.0 wt %, silicon (Si): 0.1˜0.6 wt %, aluminum (Al): 0.1˜1.0 wt %, lanthanum (La): 0.01˜0.06 wt %, carbon (C): 0.01˜0.20 wt %, and the balance of nickel (Ni) and unavoidable impurities.

Owner:KOREA INST OF MACHINERY & MATERIALS

A medium-strength corrosion-resistant weldable crack-stopping titanium alloy and its preparation method

The invention discloses a medium-strength corrosion-resistant weldable crack-arrest titanium alloy. The titanium alloy is composed of, by mass percentage, 3.0-7.0% of an alpha stabilizing element Al, 1.5-4.5% of beta stabilizing elements of Mo, V, Nb and Ni, 0.5-3.0% of neutral elements of Zr and Sn, 0.01-0.3% of a Si element and the balance Ti and inevitable impurities, wherein, by mass percentage, 0-1% of Mo, 0-3% of V, 0-1% of Nb, 0.5% of Ni, 0-2% of Zr and 0-3% of Sn are included. The titanium alloy has the good strength, plasticity and toughness matching, the yield strength Rp0.2 is larger than or equal to 640 MPa, the tensile strength Rm is larger than or equal to 740 MPa, the elongation A is larger than or equal to 15%, the fracture toughness KIC is larger than or equal to 140 MPa.m<1 / 2>, and the impact toughness KV2 is larger than or equal to 80J; the alloy has the good crack arrest performance, and the dynamic tearing energy DTE is larger than or equal to 800 J; and meanwhile the good welding performance and resistance to seawater corrosion are achieved, the welding coefficient is larger than or equal to 0.95, the KISCC is larger than or equal to 95 MPa.m<1 / 2>, and the medium-strength corrosion-resistant weldable crack-arrest titanium alloy has the good technical application and market prospects in the fields of ship and marine engineering.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

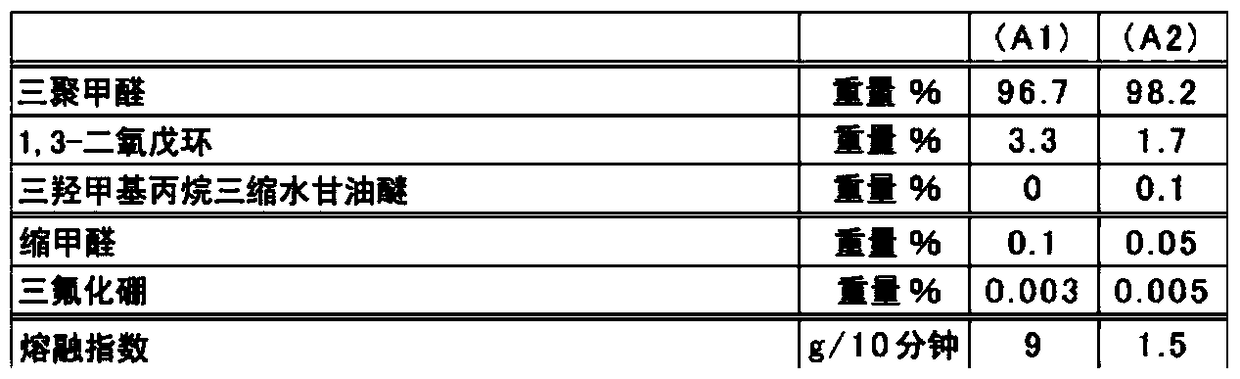

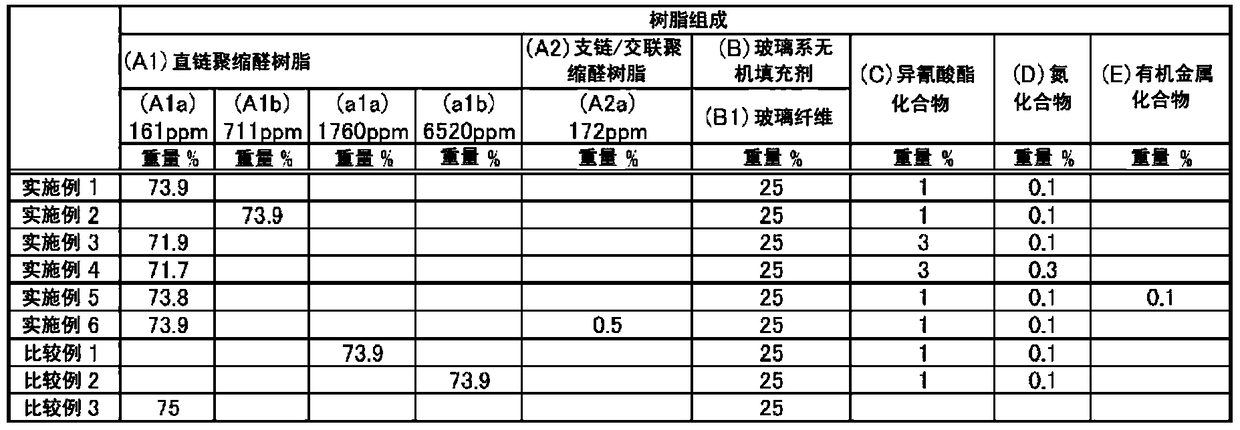

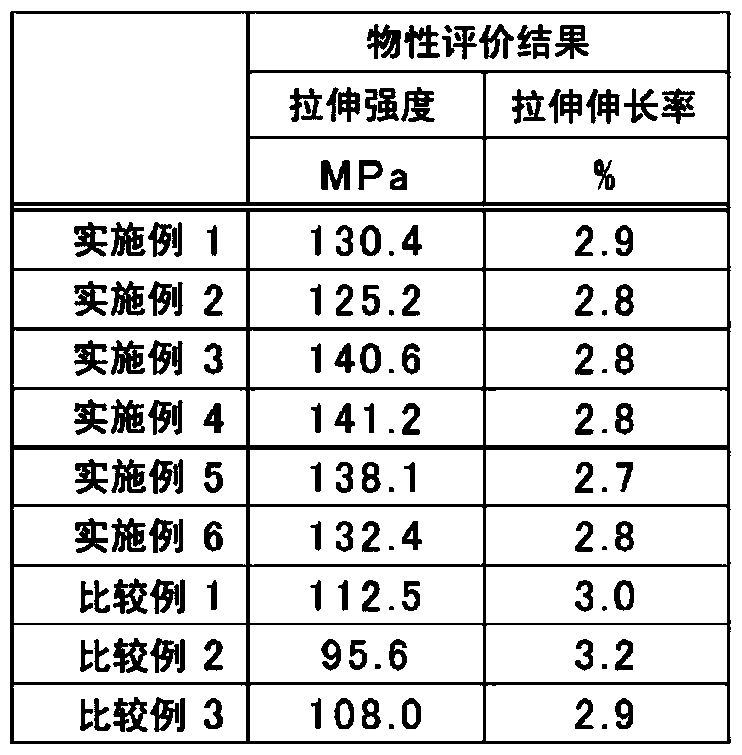

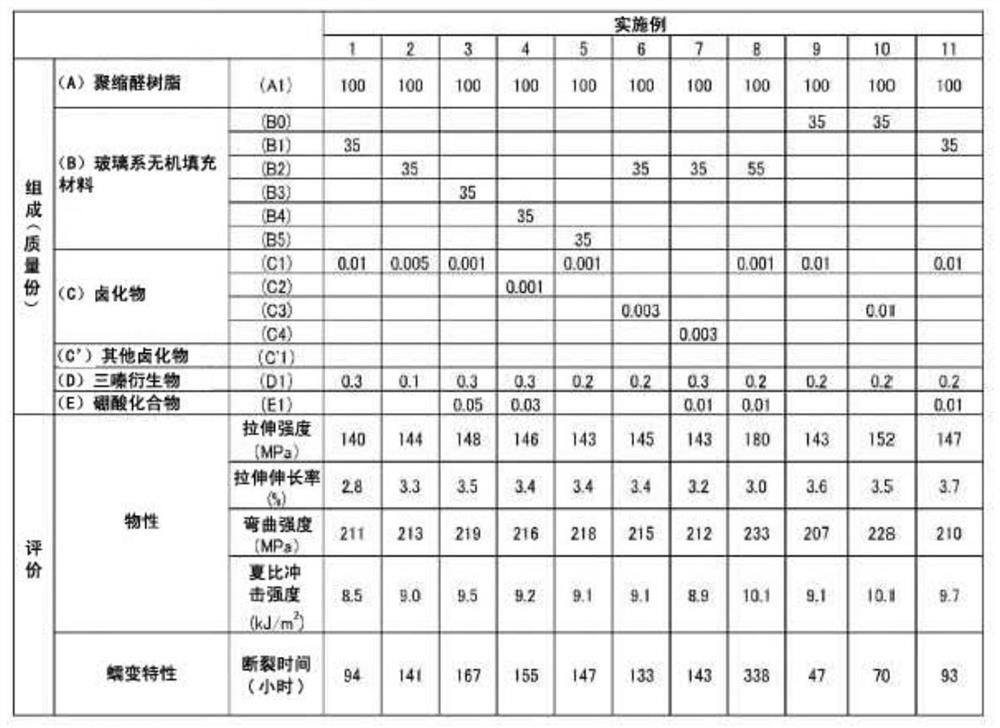

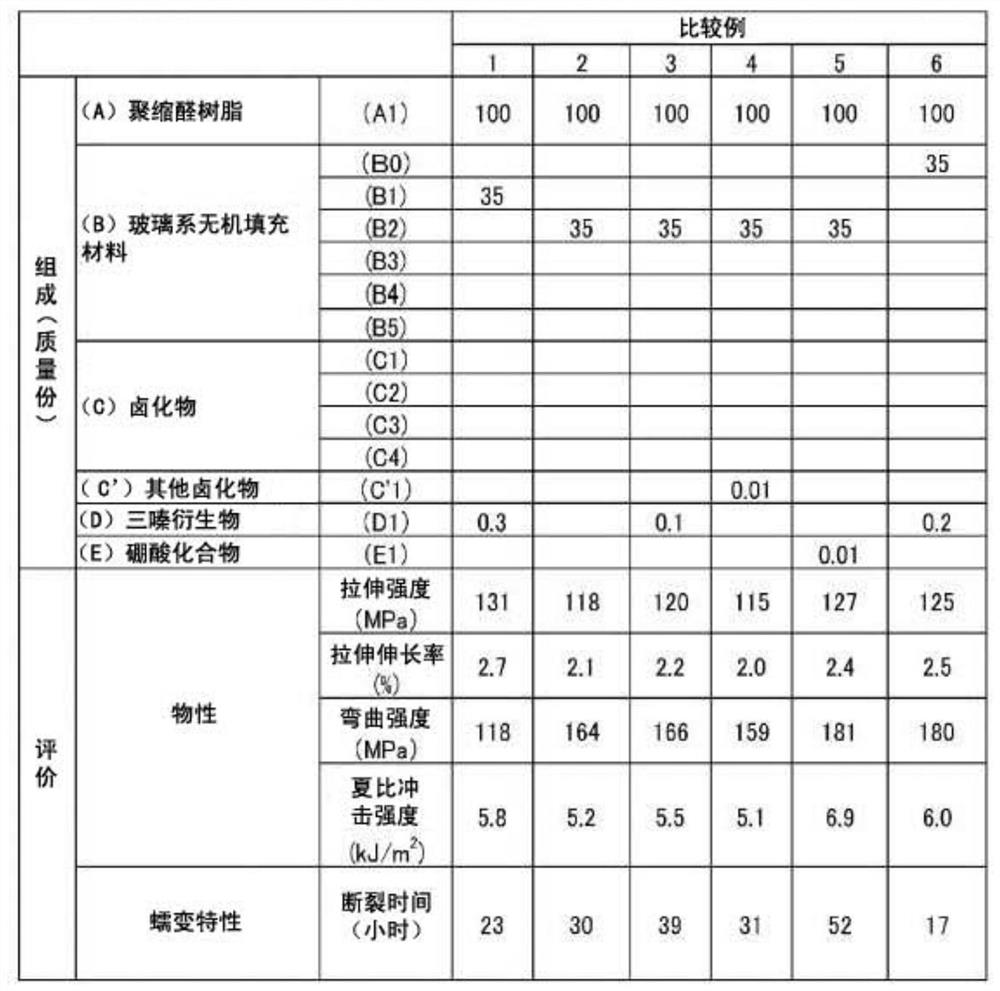

Polyacetal resin composition and its production method

To provide a polyacetal resin composition capable of satisfying demands for higher levels and various mechanical properties as the fields of use of polyacetal resins expand. The polyacetal resin composition of the present invention contains: (A) 30% to 95% by weight of polyacetal resin, (B) 5% to 50% by weight of glass-based inorganic filler subjected to silane coupling treatment, (C) 0.1% by weight to 10% by weight of a trifunctional isocyanate compound, and (D) 0.01% by weight to 0.5% by weight of a nitrogen compound having formaldehyde reactivity. When the component (B) is glass fibers or the like, the tensile strength is 120 MPa or more, and when the component (B) is glass beads or the like, the tensile strength is 60 MPa or more. This resin composition is obtained by mixing other components with (A) component which pre-dried until the moisture content became 1000 ppm or less.

Owner:POLYPLASTICS CO LTD

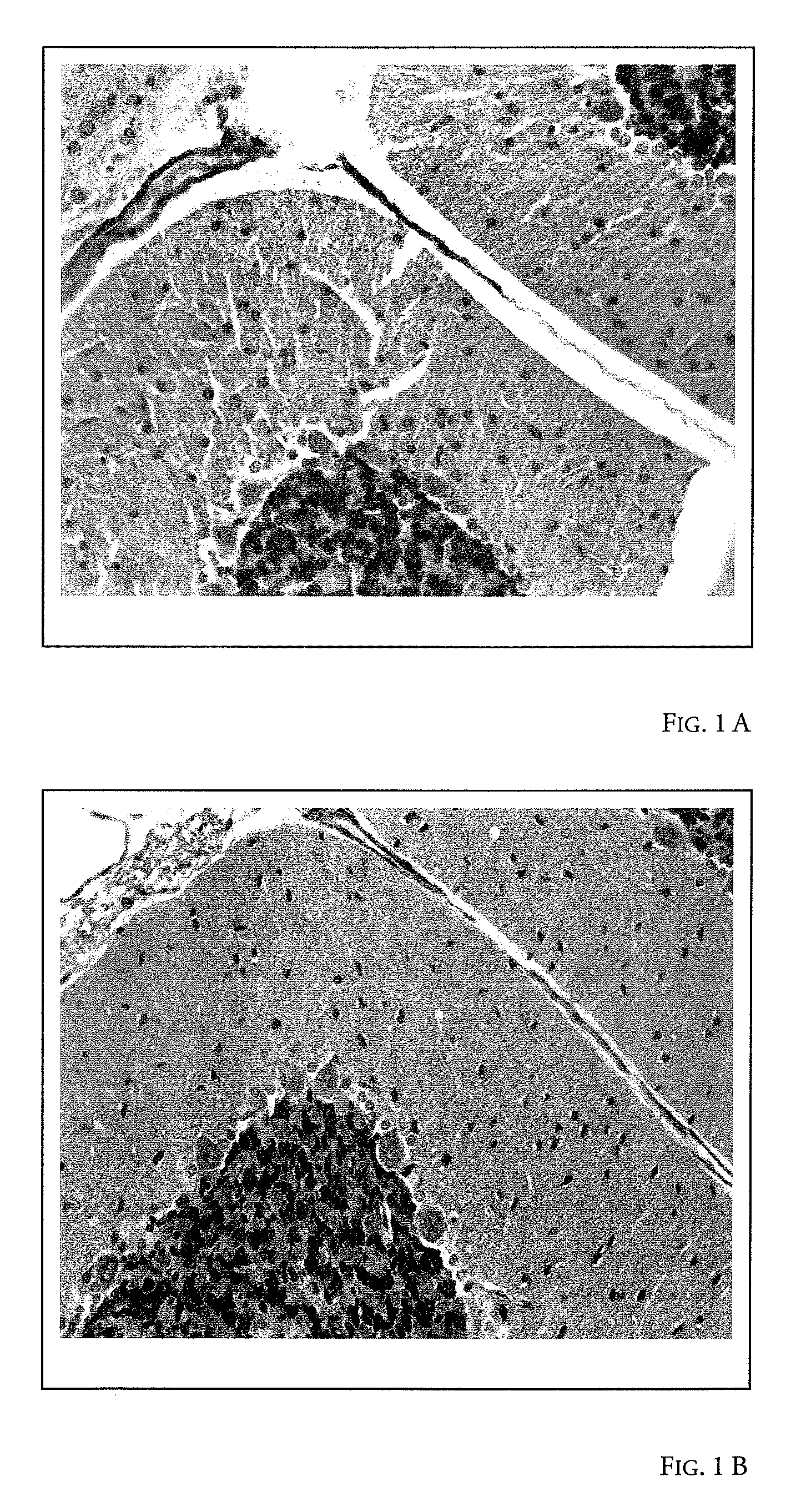

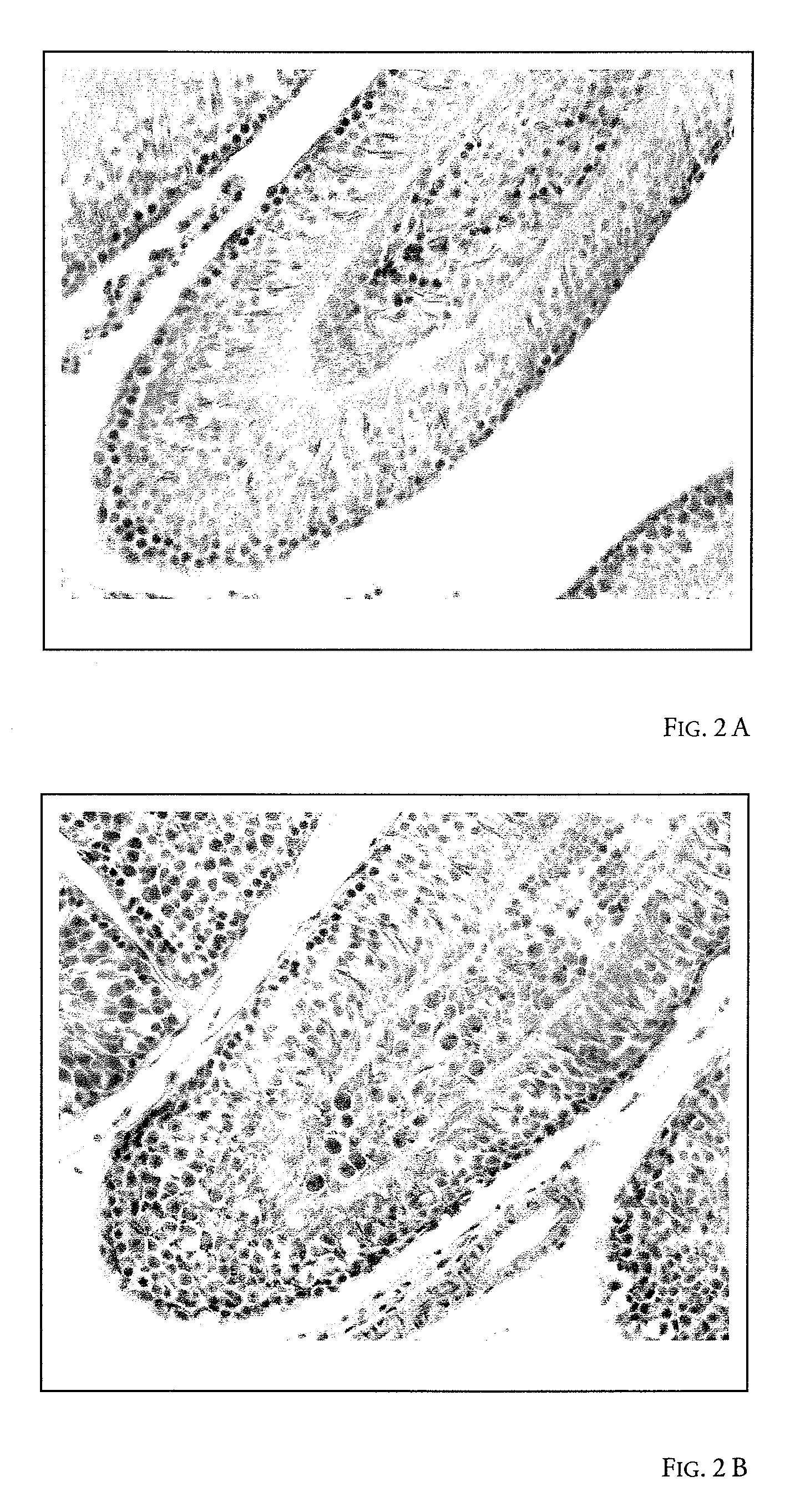

Formalin-free fixation agent for histological stains of tissue samples

InactiveUS9562836B2Easy to fixExcellent cuttabilityPreparing sample for investigationHistological stainingTissue sample

A fixation agent including at least one polyamine and at least one acidification agent. The quality and staining of tissue samples or tissue sections that have not been fixed with formalin is improved, with higher brilliance and color stability of the stain, allowing the tissue to be cut with a better quality without artifacts.

Owner:GERIGK ROBERTO

Method for producing polyacetal resin composition

The present invention relates to a method for producing a polyacetal resin composition. [Problem] To provide a method for producing a polyacetal resin composition having excellent mechanical properties such as tensile strength, tensile elongation, flexural strength, and impact resistance, particularly excellent creep properties. [Solution] A method for producing a polyacetal resin composition, wherein (B) a glass-based inorganic filler obtained by surface treatment with a silane coupling agent is added to 100 parts by mass of (A) polyacetal resin 1 mass part to 100 mass parts of the material, (C) 0.0001 mass part to 0.5 mass part of at least one halide selected from magnesium halide and ammonium halide, and (D) a triazine derivative having a nitrogen-containing functional group 0.002 mass parts or more and 10 mass parts or less are melt-kneaded and manufactured.

Owner:POLYPLASTICS CO LTD

Chromium-molybdenum steel plate having excellent creep strength and method for manufacturing same

ActiveCN113166901AExcellent creep propertiesExcellent high temperature creep lifeFurnace typesHeat treatment furnacesUltimate tensile strengthChromium

Provided are a chromium-molybdenum steel plate having excellent creep strength and a method for manufacturing same. The chromium-molybdenum steel plate of the present invention comprises, by weight%, 0.11-0.15% of C, 0.10% or less of Si (exclusive of 0%), 0.3-0.6% of Mn, 0.010% or less of S (exclusive of 0%), 0.015% or less of P (exclusive of 0%), 2.0-2.5% of Cr, 0.9-1.1% of Mo, 0.65-1.0% of V, 0.25% or less of Ni (exclusive of 0%), 0.20% or less of Cu (exclusive of 0%), 0.07% or less of Nb (exclusive of 0%), 0.03% or less of Ti (exclusive of 0%), 0.015% or less of N (exclusive of 0%), 0.025% or less of Al (exclusive of 0%), 0.002% or less of B (exclusive of 0%), and the remainder of Fe and unavoidable impurities.

Owner:浦项股份有限公司

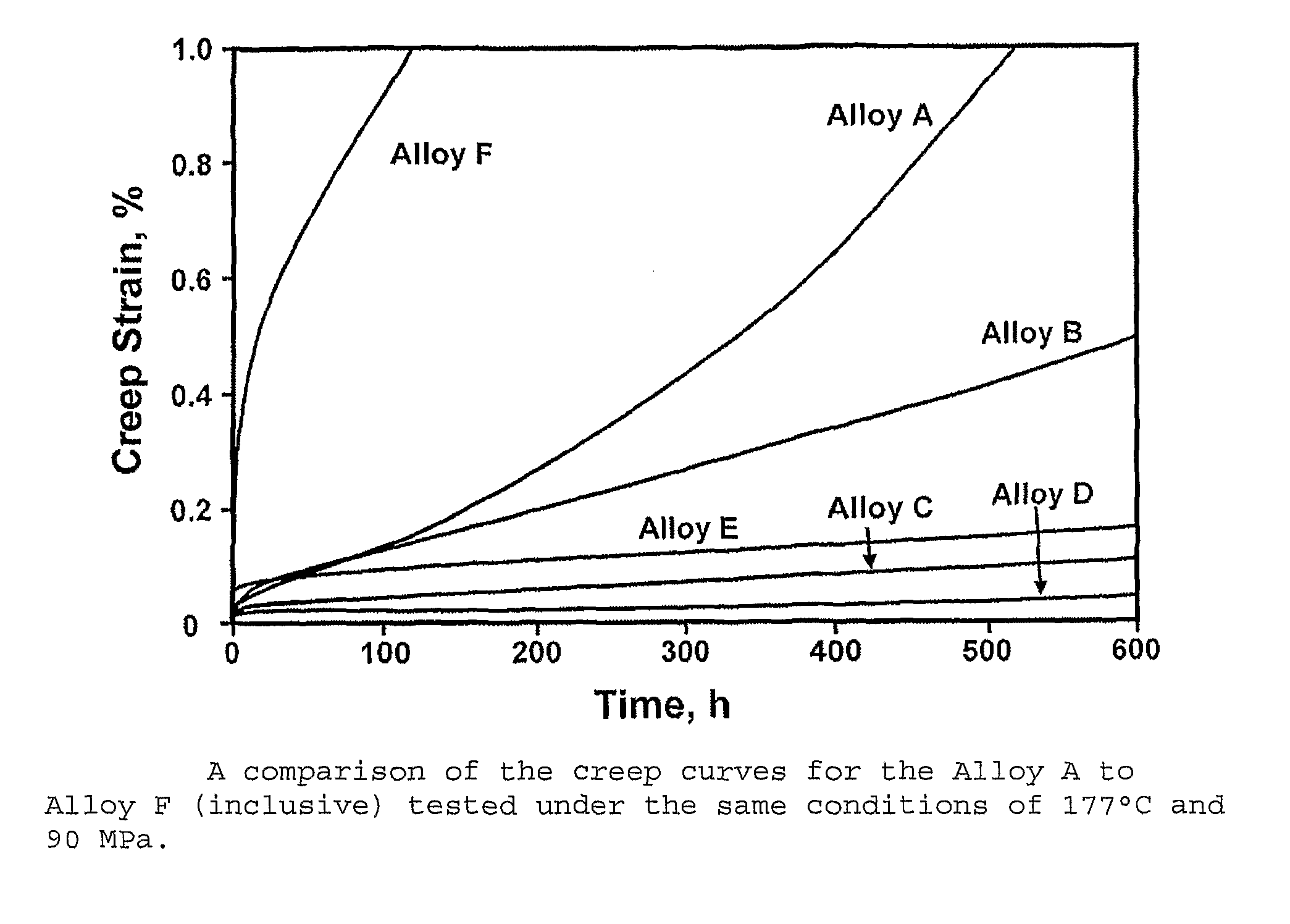

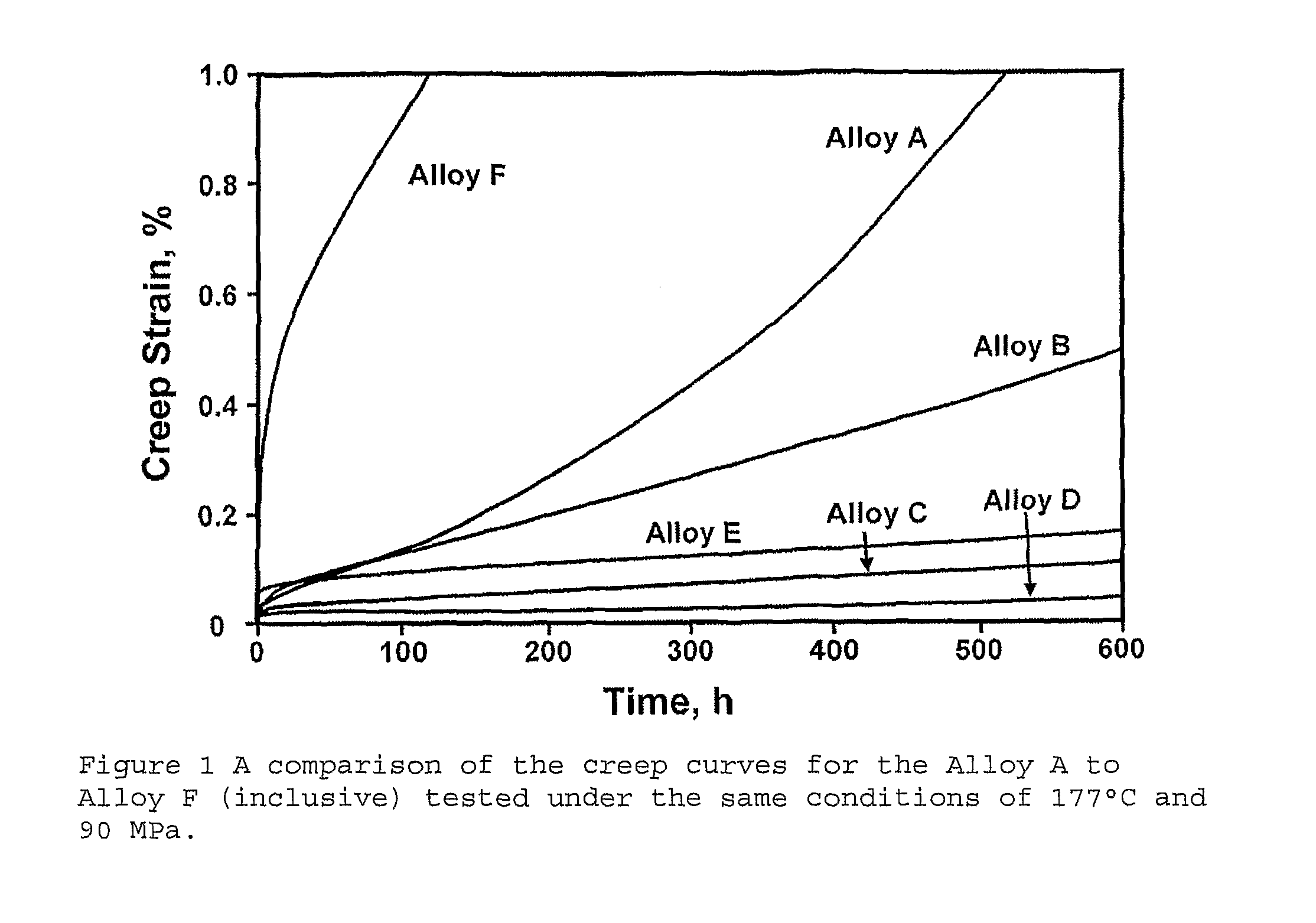

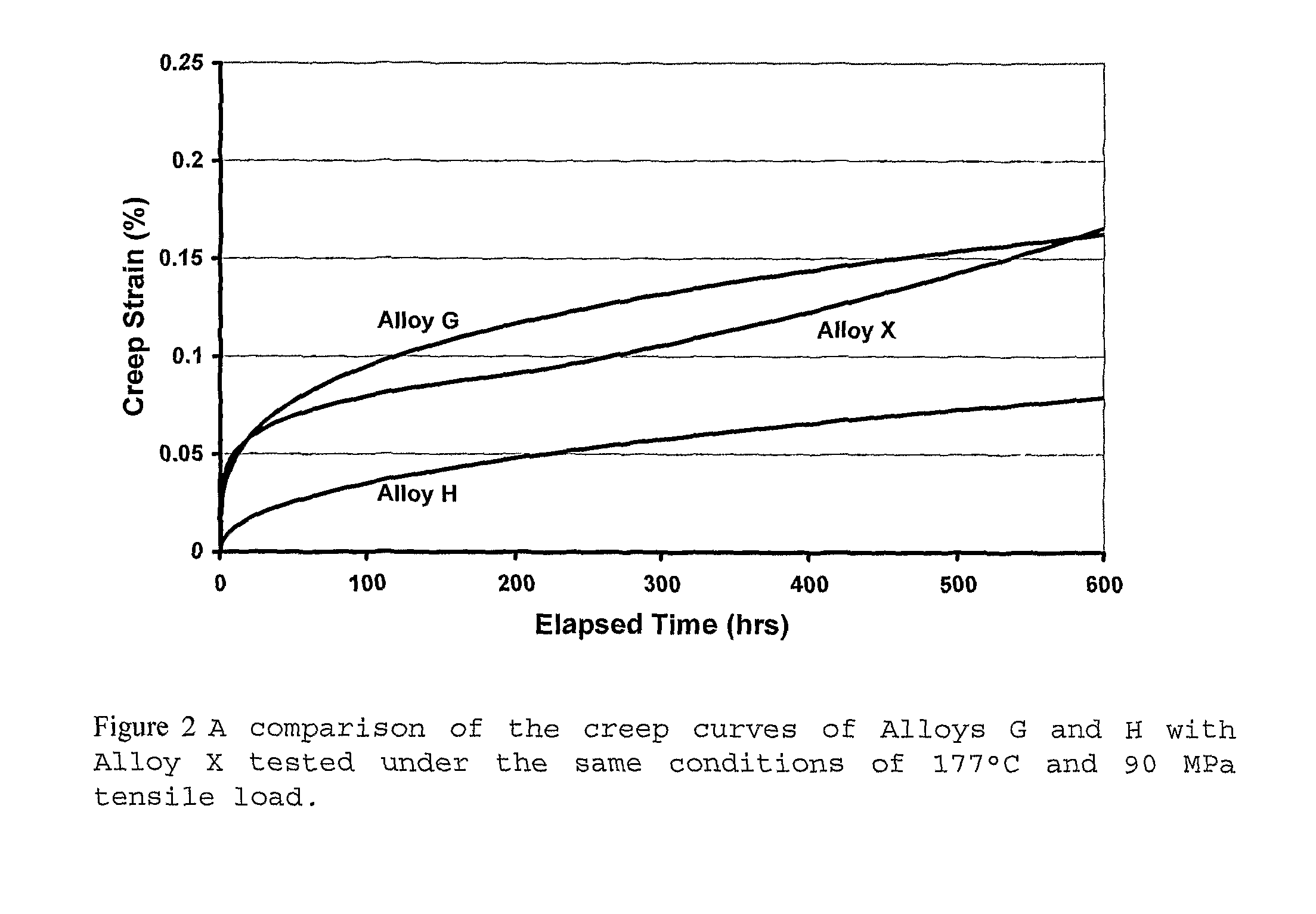

Forged aluminum alloy and manufacturing method for the same

PendingCN113322400AExcellent creep propertiesMetal-working apparatusFurnace typesAluminium alloyMetal

To provide a forged aluminum alloy excellent in creep characteristics and a manufacturing method for the forged aluminum alloy.A forged aluminum alloy contains Si: 0.10-0.25 mass %, Fe: 0.9-1.3 mass %, Cu: 1.9-2.7 mass %, Mg: 1.3-1.8 mass %, Zn: 0.10 mass % or less, Ni: 0.9-1.2 mass %, and Ti: 0.01-0.1 mass %, with the balance being Al and inevitable impurities, in which the total content of Fe and Ni is 2.2 mass % or less, the total content of Mn, Cr, and Zr is 0.20 mass % or less, the average equivalent circle diameter of an intermetallic compound is 4.5 [mu]m or less, and variation of distance between the intermetallic compounds in the ST direction is 2.3 or less.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com