Polyacetal resin composition and its production method

A technology of polyacetal resin and composition, which is applied in the field of polyacetal resin composition and its manufacture, can solve the problems of lack of activity, insufficient adhesion, lack of activity of polyacetal resin, etc., and achieve excellent creep properties, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

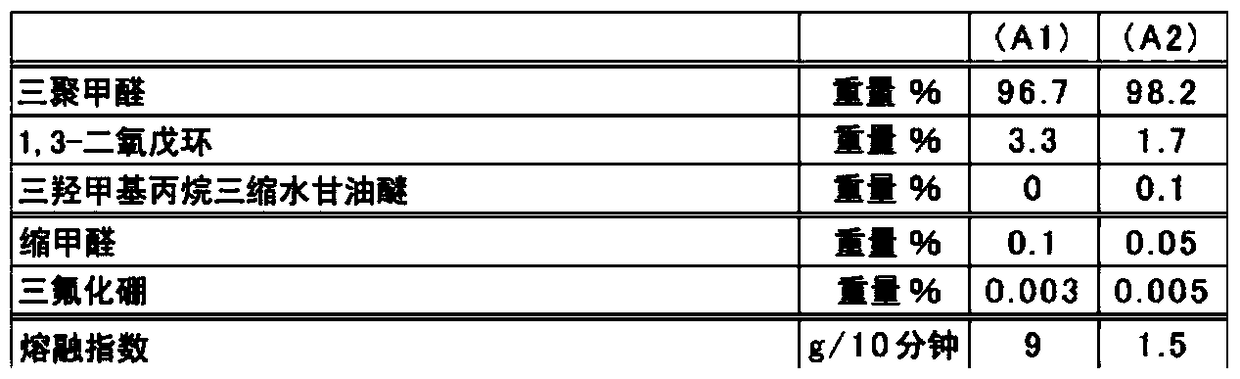

preparation example Construction

[0042] The preparation method of (A1) component is not specifically limited, It can prepare using a well-known method.

[0043] [(A2) Polyacetal resin having a branched or cross-linked structure]

[0044] Although not essential, (A) polyacetal resin may contain (A2) polyacetal resin which has a branched or crosslinked structure. The component (A2) is obtained by further adding a compound capable of copolymerizing with formaldehyde, paraformaldehyde, etc., and forming a branched chain unit or a crosslinking unit through the copolymerization to the raw materials used in the production of the component (A1), and copolymerizing, thereby get.

[0045] For example, by further adding a substituent monofunctional glycidyl compound (such as phenyl glycidyl ether, butyl glycidyl ether, etc.) polyacetal resin. Moreover, the polyacetal resin which has a crosslinked structure can be obtained by adding and copolymerizing a polyfunctional glycidyl ether compound to (A11) component and (A1...

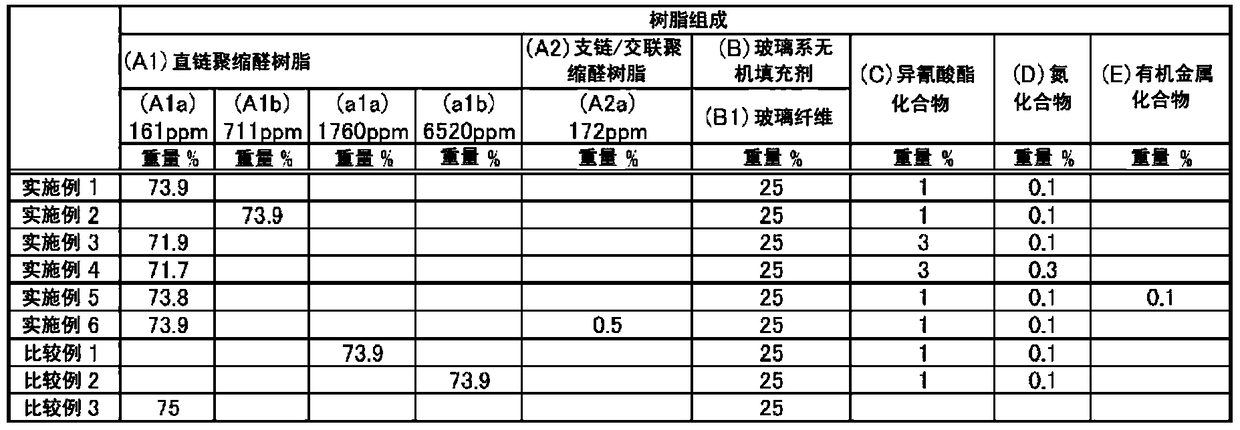

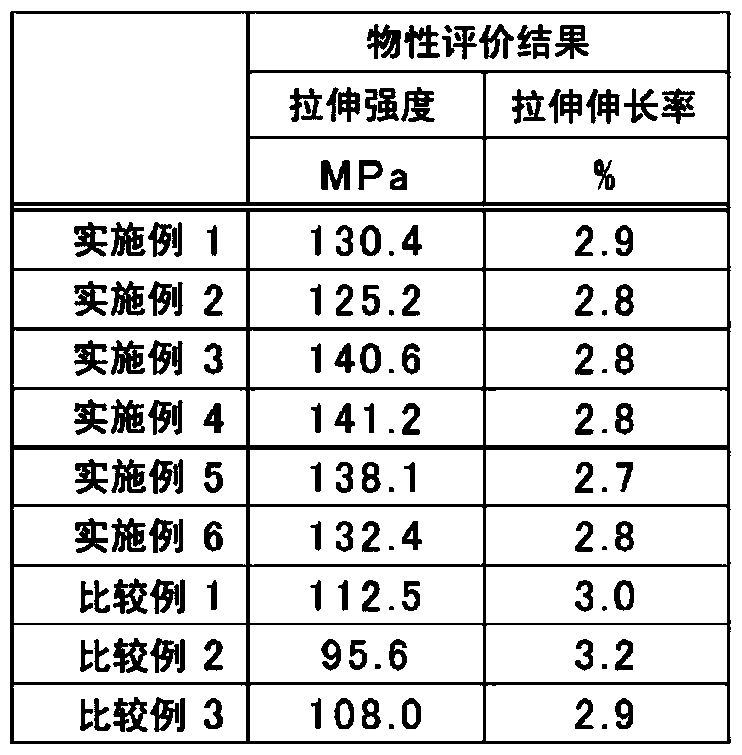

Embodiment 1~6、 comparative example 1~3

[0095] When using glass fiber etc. as (B) glass-based inorganic filler

[0096] First, in order to provide a polyacetal resin composition having high strength, excellent hot water resistance, and excellent creep characteristics, a case where a polyacetal resin composition is obtained using glass fiber or the like as (B) glass-based inorganic filler will be described.

[0097] [table 3]

[0098]

[0099] In Table 3, each component is as follows.

[0100] (A1) Polyacetal resin having a substantially linear molecular structure

[0101] (A1a), (A1b), (a1a) and (a1b) obtained in above

[0102] (A2) Polyacetal resin having a branched or crosslinked structure

[0103] (A2a) obtained in the above

[0104] (B) Glass-based inorganic filler

[0105] (B1) Glass fiber CS03MA409B (manufactured by Owens Corning Corporation)

[0106] (C) Trifunctional isocyanate compound

[0107] Isophorone diisocyanate trimer Vestanat T1890 / 100 (manufactured by Degussa Japan Co., Ltd.)

[0108] ...

Embodiment 7、8、 comparative example 4

[0122] When using glass beads etc. as (B) glass-based inorganic filler

[0123] Next, in order to provide the polyacetal resin composition which contributes to reduction of anisotropy, the case where the polyacetal resin composition is obtained using glass beads etc. as (B) glass-type inorganic filler is demonstrated.

[0124] [table 5]

[0125]

[0126] In Table 5, glass beads EGB731B (manufactured by Potters-Ballotini Co., Ltd.) were used as the (B) glass-based inorganic filler. Other components are the same as in Example 1 above.

[0127] To the polyacetal resin described in Table 5, the (B2) component, (C) component, (D) component and (E) component described in Table 3 were added according to the ratio shown in Table 5, and the cylinder temperature was adjusted to Melt-kneading was carried out in an extruder at 200° C. to prepare granular polyacetal resin compositions of Examples 7 and 8 and Comparative Example 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com