Patents

Literature

133results about How to "Low gel content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biodegradable polyester resin composition, preparation method therefor, and foamed article and molded article produced therefrom

A biodegradable polyester resin composition which comprises a thermoplastic polymer comprising 100 parts by mass of an aliphatic polyester (A) and 0.01 to 5 parts by mass of a (meth)acrylic ester (B1) and / or a glycidyl ether (B2, and has a gelation index (1) of not lower than 0.1% and a gelation index (2) of not higher than 0.5%.

Owner:UNITIKA LTD

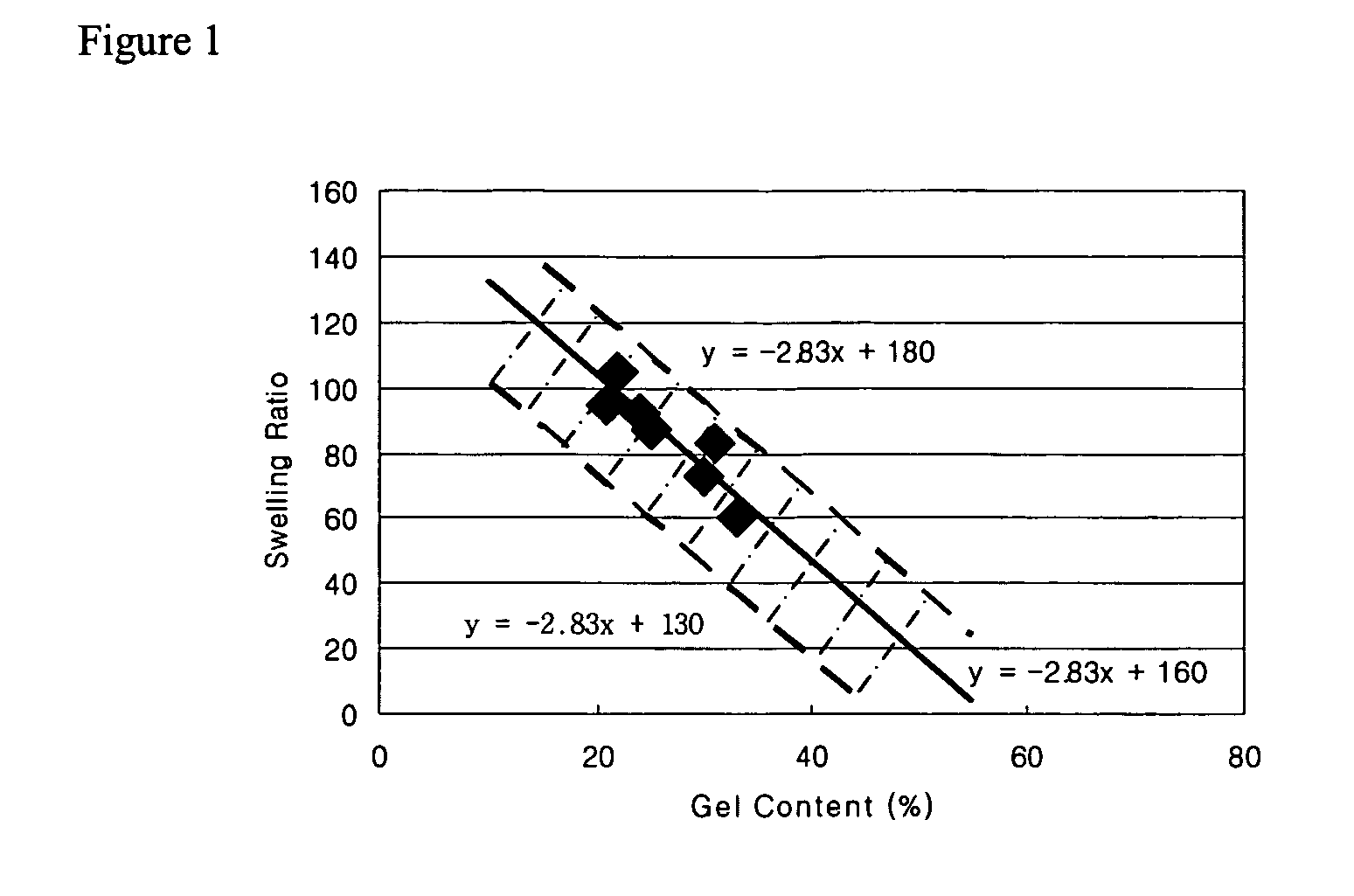

Acrylic pressure-sensitive adhesive composition for polarizing film

ActiveUS20070055006A1Improve light leakagePreventing operability decreaseEster polymer adhesivesEmulsion paintsPolymer scienceSwelling ratio

The present invention relates to an acrylic pressure sensitive adhesive composition comprising (meth)acrylic copolymers including alkyl(meth)acrylic acid ester monomer having 1˜12 carbon atoms of alkyl group, characterized in that the gel content is 10˜55%, the swelling ratio is 30˜110, the weight average molecular weight of sol eluted from the adhesive by ethyl acetate is at least 800,000, the molecular weight distribution is 2.0˜7.0; and a polarizer and a liquid crystal display comprising the above composition show excellent durability under a high temperature and humidity condition, and can improve the light leakage phenomenon and provide excellent operability at the time of manufacturing polarizer by effectively providing high modulus and stress release property.

Owner:SHANJIN OPTOELECTRONICS SUZHOU CO LTD

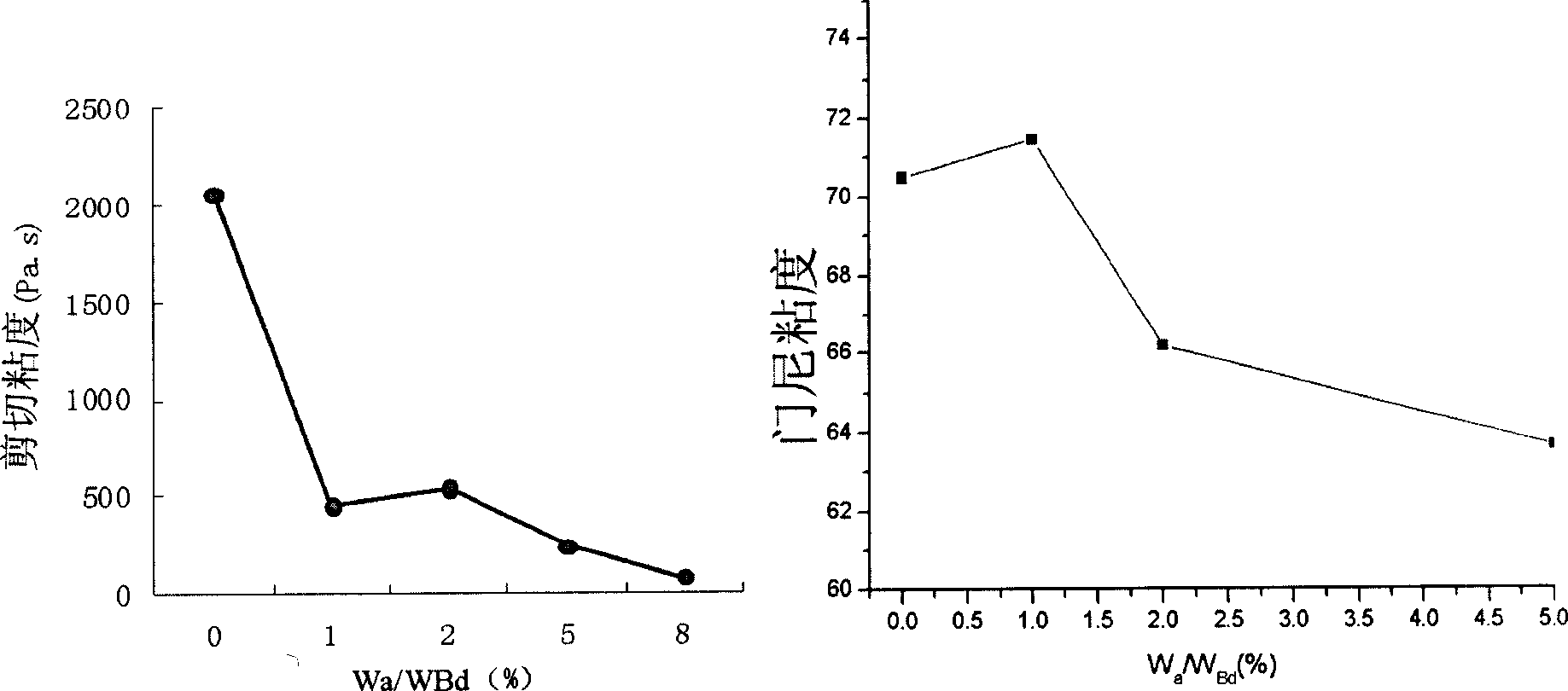

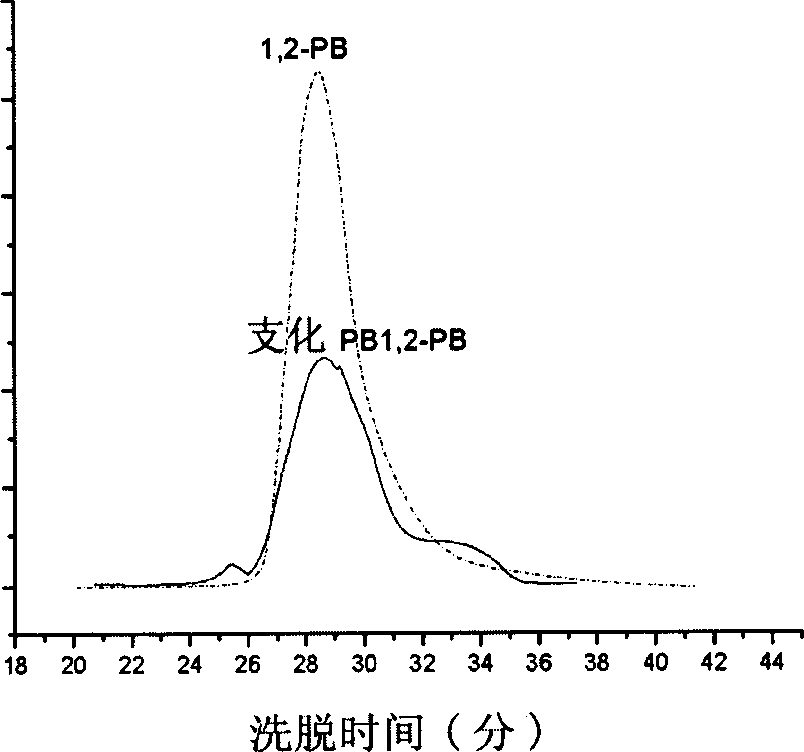

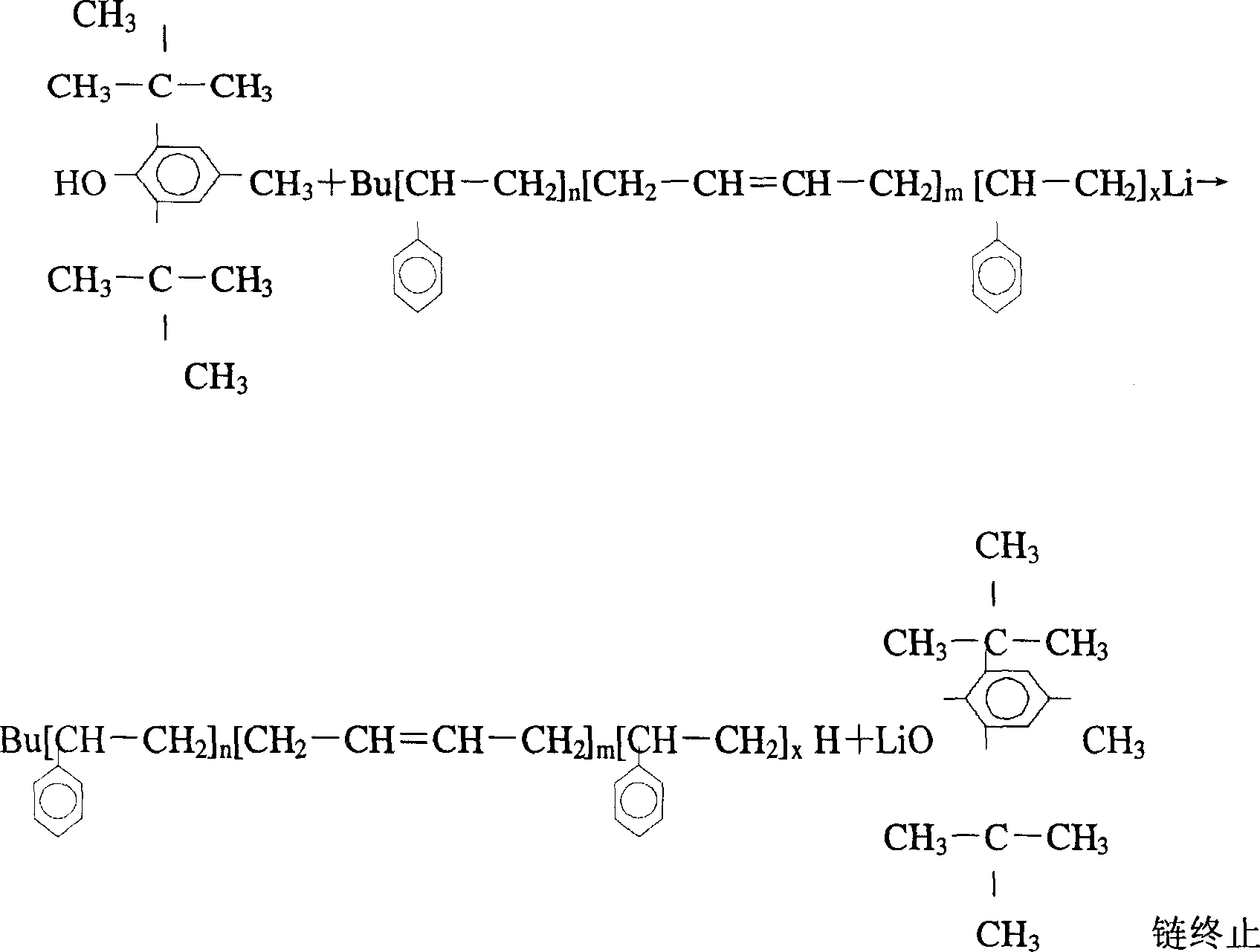

Method for preparing branched high vinyl polybutadiene rubber using molybdenum series catalysis

The invention relates to a method for preparing branched high ethenyl butadiene rubber with molybdenum catalyst, recombining macromolecular monomer prepared through polymerization of molybdenum catalyst butadiene atom free radical or butadiene anion initiated by organic lithium, naphthalene sodium, with coordinate polymerization of butadiene or original position polymerization, to prepare said product with controllable construction. The method is characterized by simple process, special construction of polymer, proper molecular weight and molecular distribution, more than 80% of ethenyl content, controllable property, length, distribution and degree of branching of branch chain in a certain range, good processing behavior and physical mechanics property and low production cost.

Owner:QINGDAO UNIV OF SCI & TECH

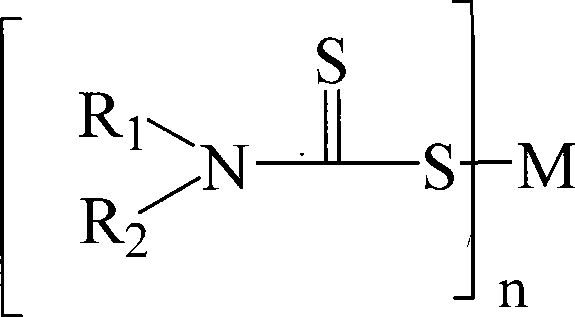

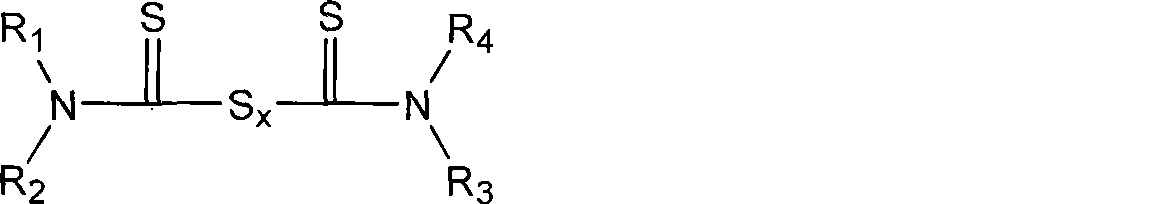

Preparation of high melt strength polypropylene

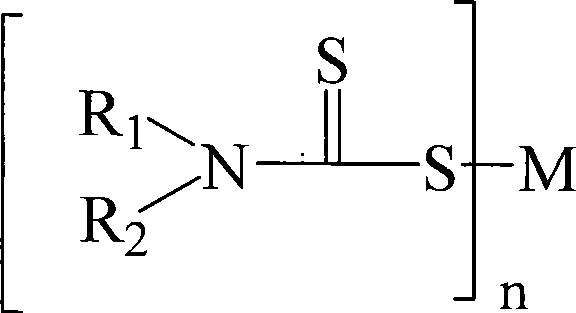

The invention discloses a method for preparing polypropylene with high melt strength, which comprises melt-blending polypropylene, monomer containing double bond, peroxide, dithiocarbamate series substance and antioxidant. The dithiocarbamate is added as adjuvant to inhibit the propylene degradation of the peroxide, improve the graft ratio, reduce monomer amount containing double bond, and save the cost. The obtained polypropylene with high melt strength has melt strength more than 2-15 times of that of raw material, and gel content smaller than 10%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

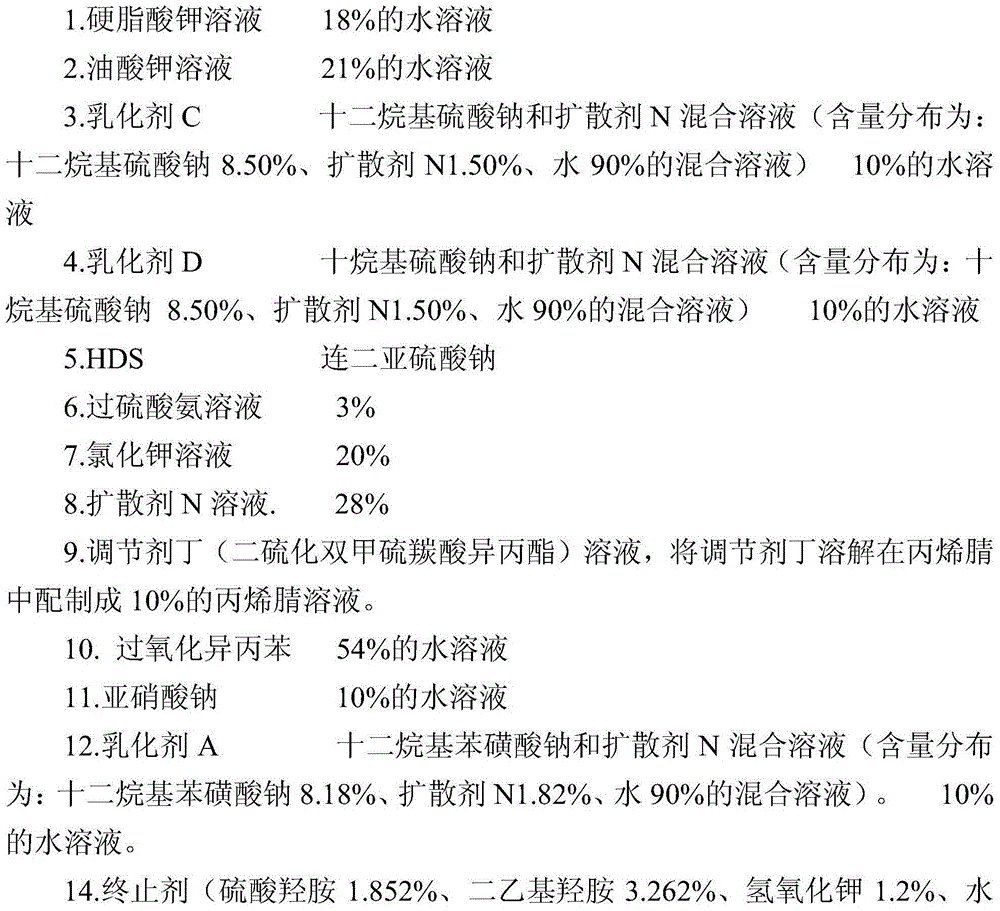

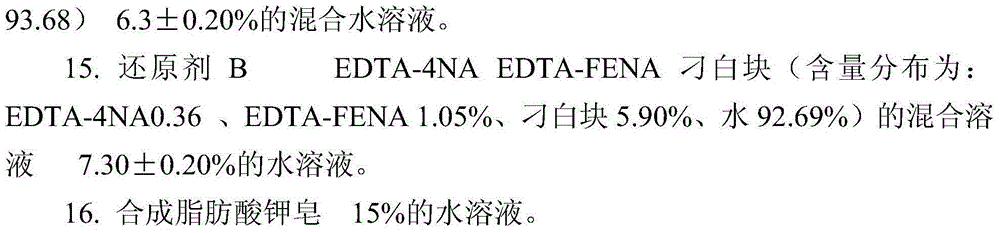

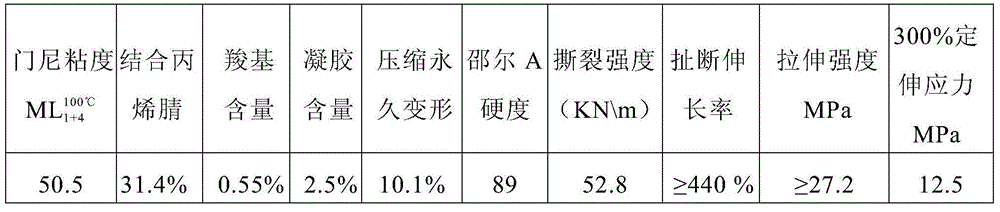

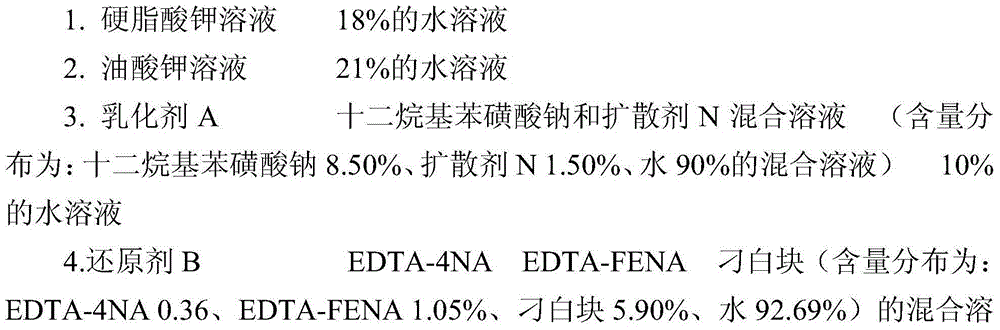

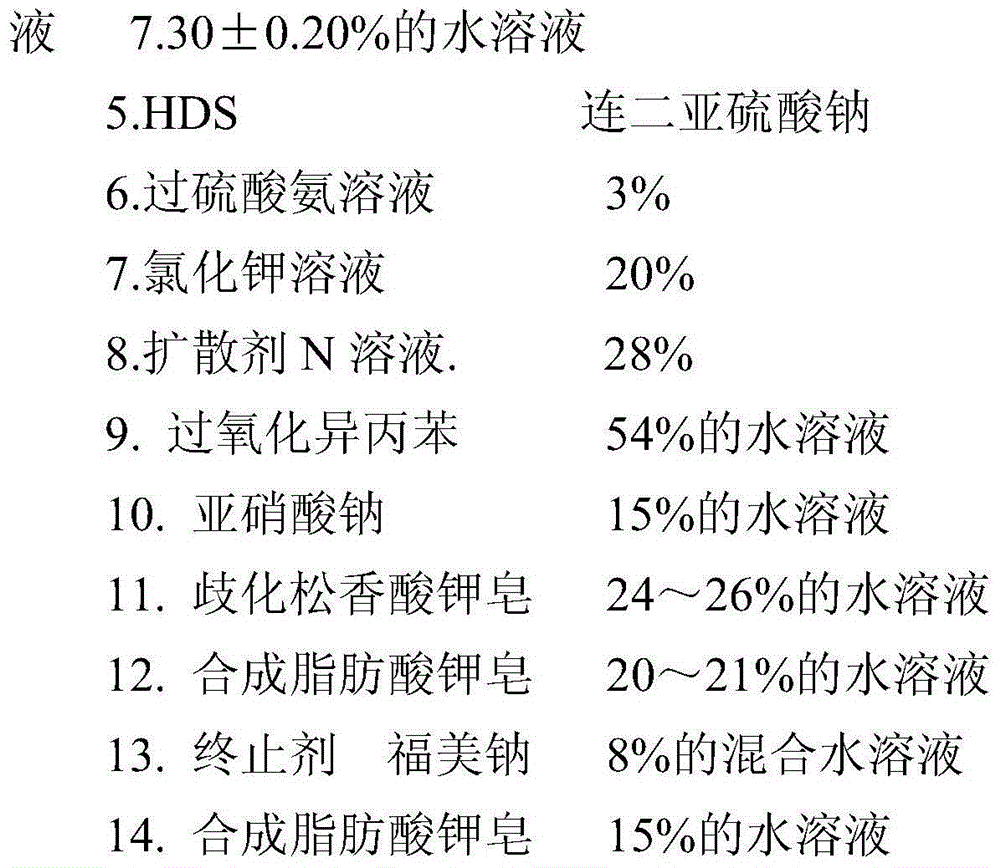

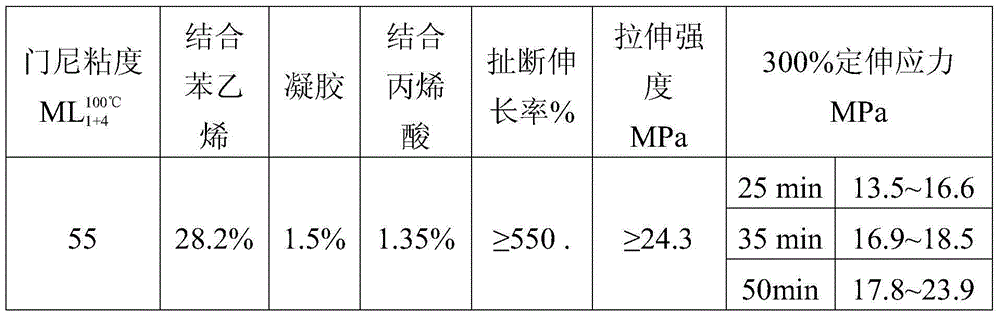

Preparation method of carboxyl nitrile rubber through emulsion polymerization

The invention relates to a preparation method of carboxyl nitrile rubber through emulsion polymerization. According to the preparation method, acrylonitrile, an emulsifier, an adjusting agent, and an initiator are added into a polymerization kettle, then butadiene is added, emulsion polymerization is carried out under stirring, and in the late phase of emulsion polymerization, unsaturated carboxylic acid and / or anhydride thereof is added into the polymerization kettle. The obtained carboxyl nitrile rubber has a low content of gel and a two-layer molecular structure, the index of conjugated acid is controllable; during the processing process, a three-dimensional network structure can be easily formed, thus the mechanical and physical properties of rubber products made of the carboxyl nitrile rubber are good; after processing, the Mooney viscosity is increased, the crosslinking degree of finished products is good, and especially, the elongation at break is prominently improved.

Owner:PETROCHINA CO LTD

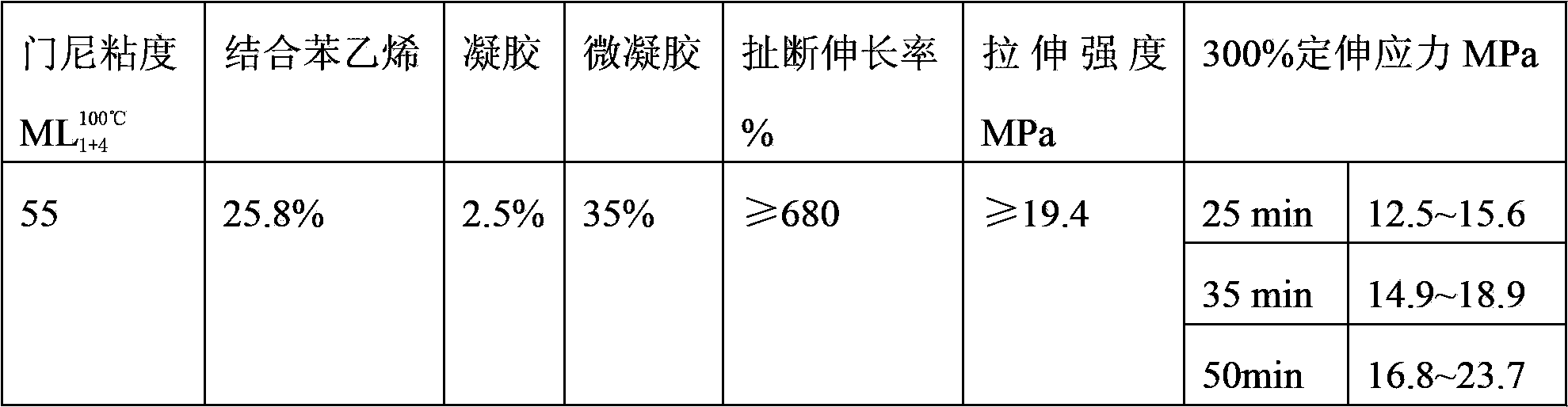

Method of preparing carboxyl styrene butadiene rubber through emulsion polymerization

The invention relates to a method of preparing carboxyl styrene butadiene rubber through emulsion polymerization. According to the method, styrene, an emulsifier, a conditioning agent, and an initiator are added into a polymerization kettle, then butadiene is added to carry out emulsion polymerization under stirring, and in the later period of reactions, unsaturated carboxylic acid and / or unsaturated carboxylic anhydride are added into the polymerization kettle. The prepared carboxyl styrene butadiene rubber has a low gel content, a controllable combined acid index, and a dual layer molecular structure; during the processing process, a three dimensional net-like structure can be formed easily; the mechanical and physical properties of rubber product are good, after processing, Mooney viscosity is increased, the crosslinking degree of finished product is good, and especially, the elongation at break is obviously improved.

Owner:PETROCHINA CO LTD

In-situ hydrogenation method of acrylonitrile-butadiene rubber latex

InactiveCN101704909AOvercoming the problem of low degree of hydrogenationImprove hydrogenation performancePolymer scienceAcrylonitrile

The invention belongs to the field of hydrogenation of acrylonitrile-butadiene rubber latex. The hydrogenation of acrylonitrile-butadiene rubber latex is realized through the technical scheme as follows: the mixture of acrylonitrile-butadiene rubber latex and hydrazine hydrate is heated to 30 to 70 DEG C, and then constant temperature is kept for 2 to 8 h, and in the process with constant temperature, aqueous solution of sodium periodate is dripped into the mixture, the dripping rate is controlled, and the dripping is accomplished within 2 to 6 hours. The method has the advantages of simple process flow, low cost, less pollution, high hydrogenation rate, low cross linking level of the prepared hydrogenated acrylonitrile-butadiene rubber latex, and good processing property.

Owner:BEIJING UNIV OF CHEM TECH

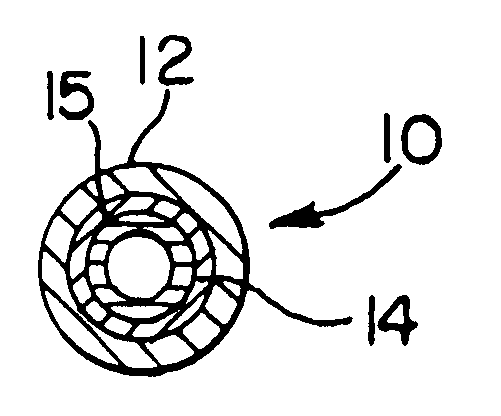

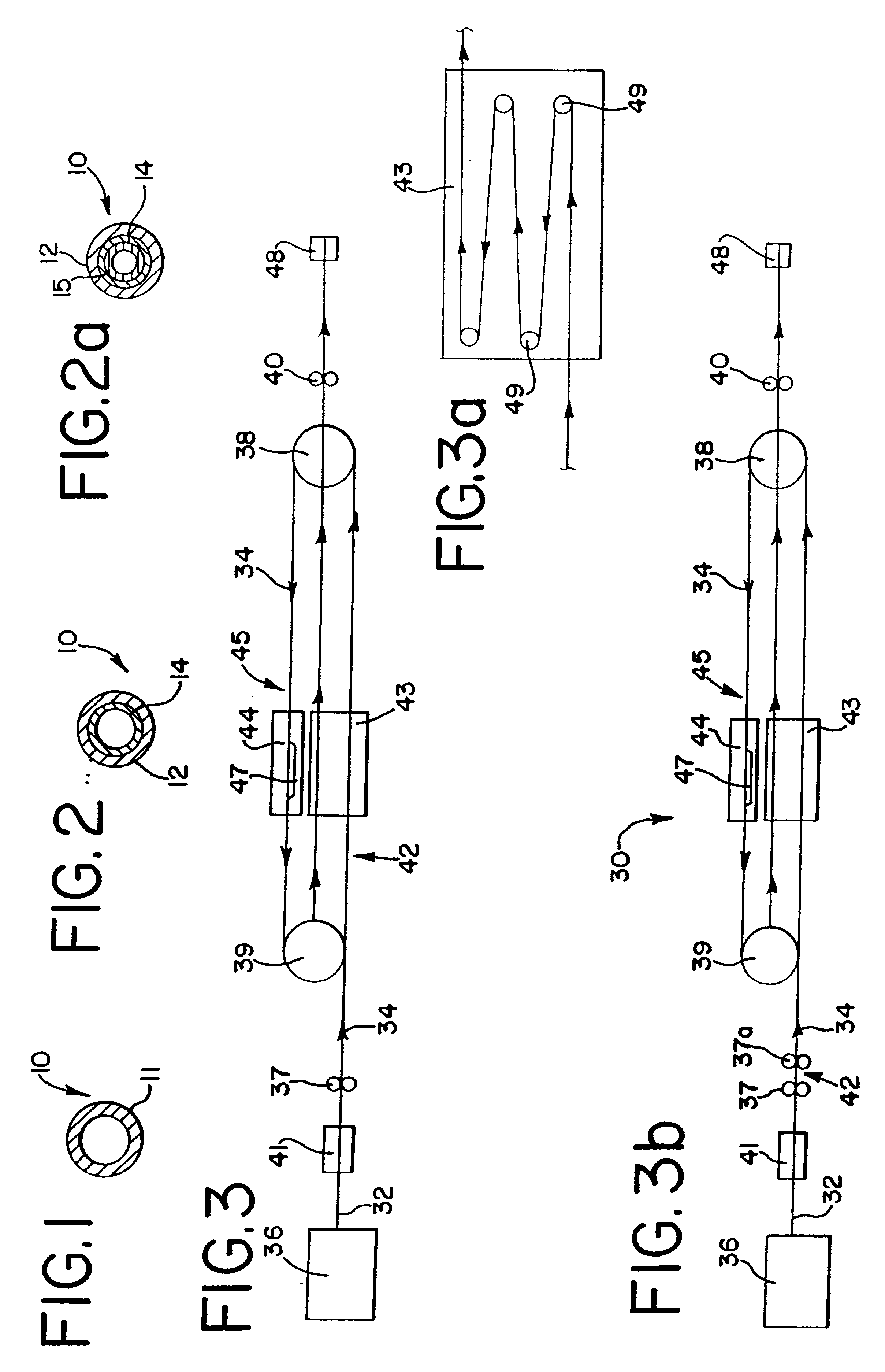

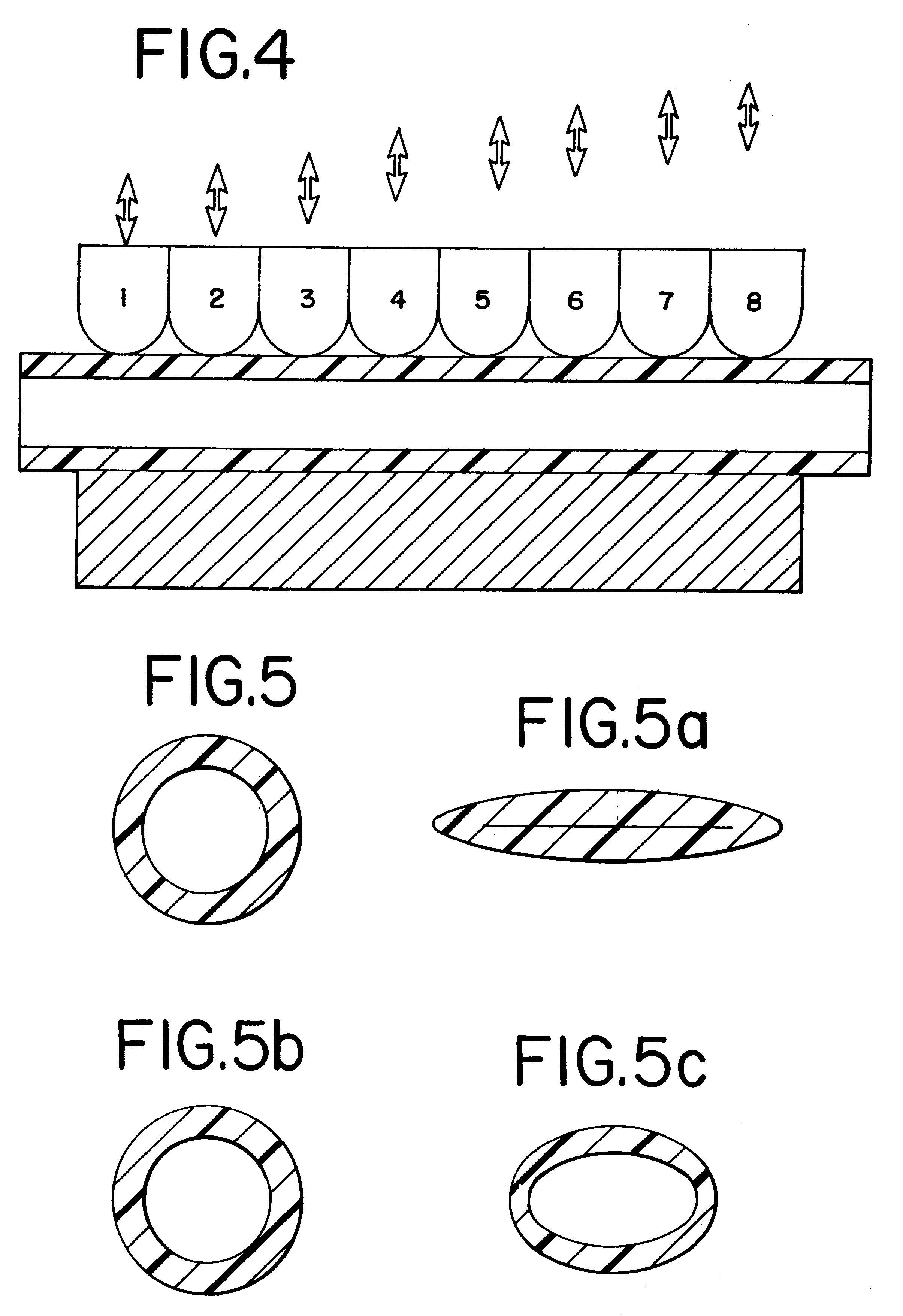

Medical tubing and pump performance enhancement by ionizing radiation during sterilization

InactiveUS6187400B1Improve performanceIncrease elasticitySurgeryMedical devicesPerformance enhancementCarboxylic acid

The present invention provides a method of using a medical tubing with a pump for administering measured amounts of a beneficial fluid over time to a patient comprising the steps of providing a tubing having a first layer selected from the group consisting of ethylene homopolymers and ethylene copolymers, wherein the copolymers of ethylene are an ethylene monomer copolymerized with at least one monomer selected from the group consisting of lower alkyl olefins, lower alkyl esters of a carboxylic acid, and lower alkene esters of a carboxylic acid, the lower alkyl and lower alkene having from 3 to 18 carbons, the tubing having been exposed to a sterilization dosage of radiation of from about 15 to about 45 kGys; and pumping fluid through the tubing with the pump.

Owner:BAXTER INT INC

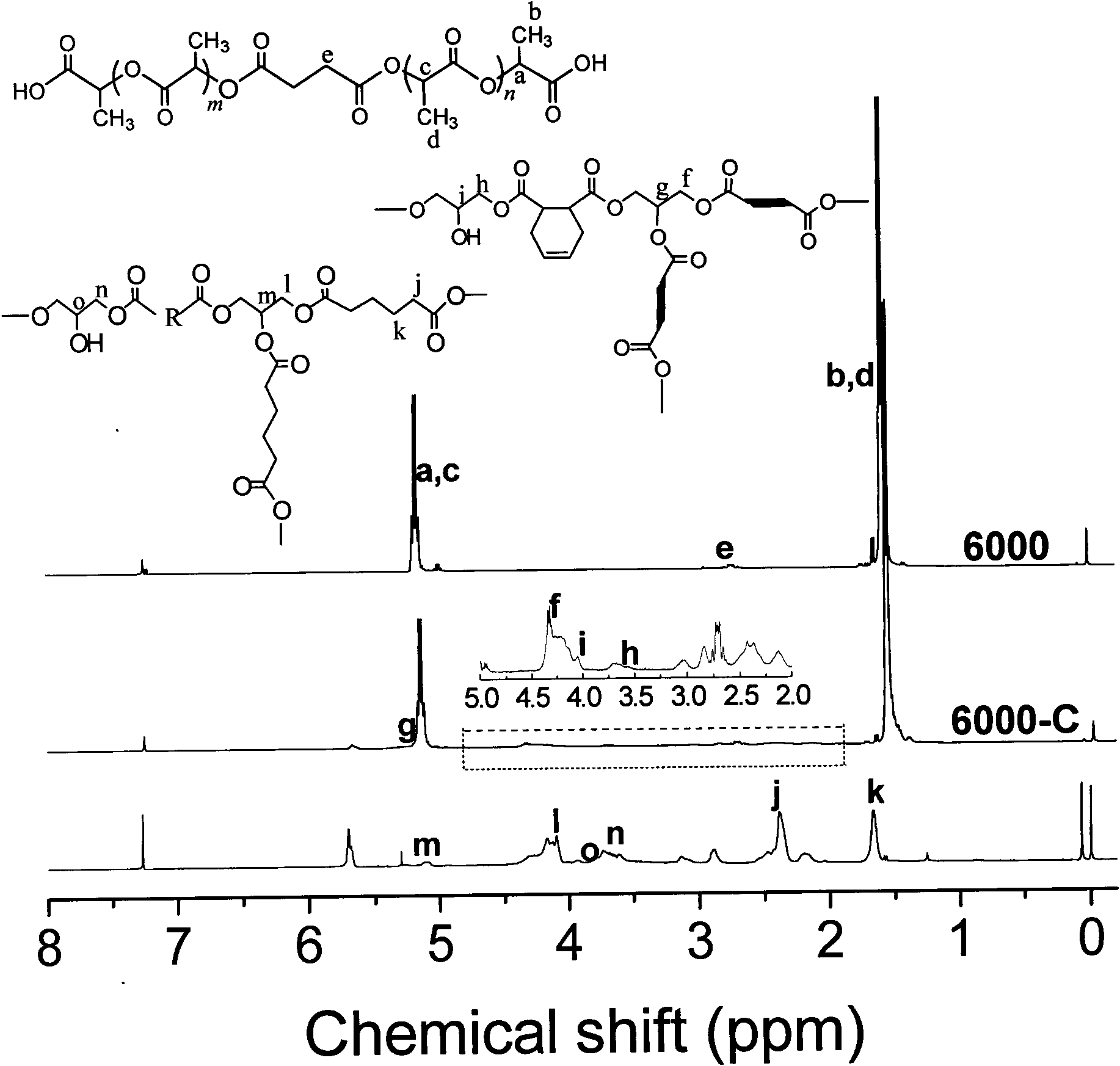

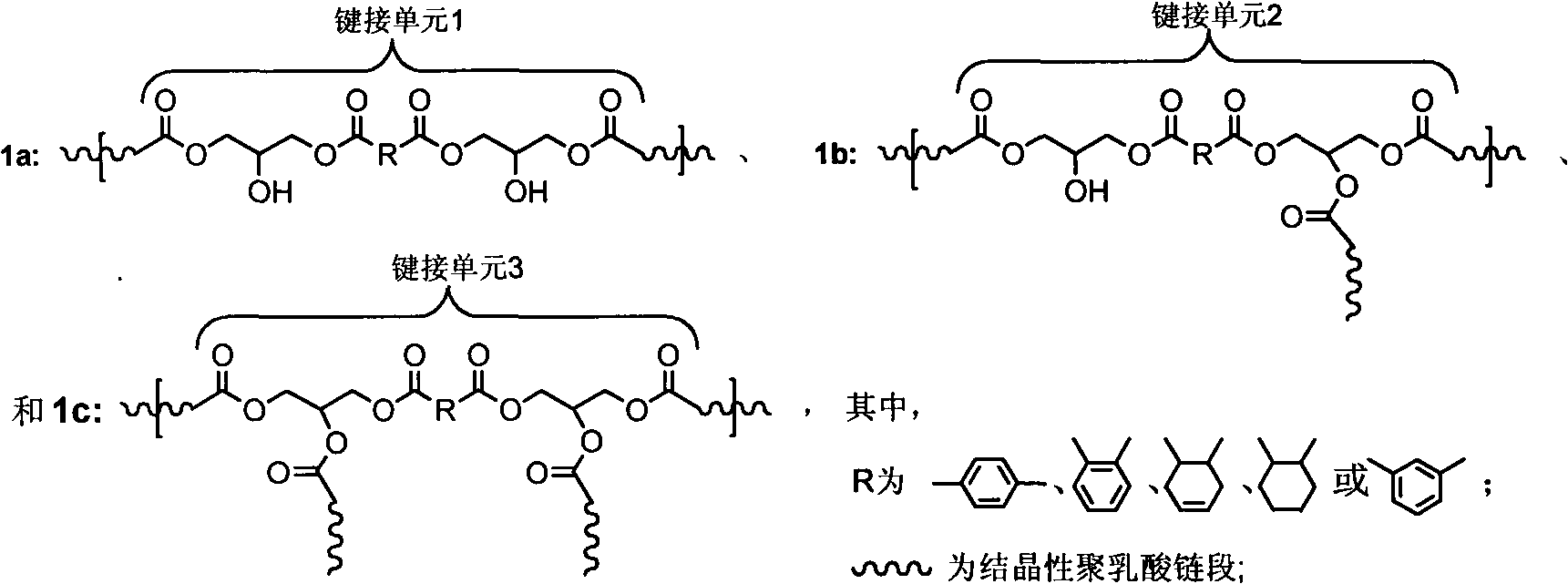

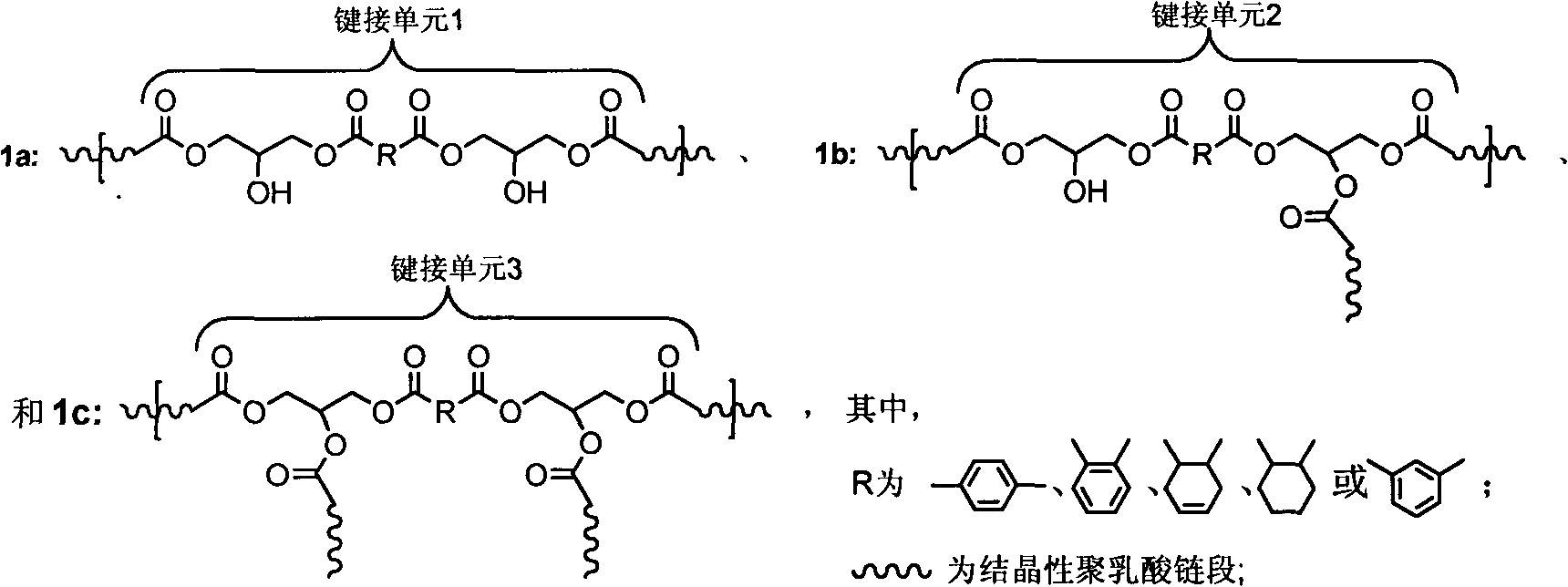

High-molecular weight long-chain branched crystalline polylactic acid material and preparation method thereof

The invention discloses a high-molecular weight long-chain branched crystalline polylactic acid material and a preparation method thereof. The preparation method comprises the following steps of: 1) adding 0.1 to 1 percent of protonic acid catalyst into aqueous solution of lactic acid or mixed solution of the aqueous solution of the lactic acid and silicon dioxide nano particle silica sol containing 0.1 to 10 weight percent of lactic acid, and dehydrating to obtain a product I; 2) adding 0.4 to 2 molar percent of dibasic acid or anhydride into the product I, and reacting to obtain a product II; 3) adding 0.1 to 1 weight percent of lewis acid catalyst into the product II, performing melt polycondensation, and adding 0.1 to 5 weight percent of crystallization accelerator to obtain terminal carboxyl group crystalline polylactic acid prepolymers; and 4) reacting diglycidyl ester and the terminal carboxyl group crystalline polylactic acid prepolymers in a molar ratio of 0.8:1-1.2:1 to obtain the high-molecular weight long-chain branched crystalline polylactic acid material. The preparation method has the advantages of simplicity, short reaction time, high efficiency, low cost and environmental friendliness and capability of contributing to realizing commercialization.

Owner:ZHEJIANG UNIV

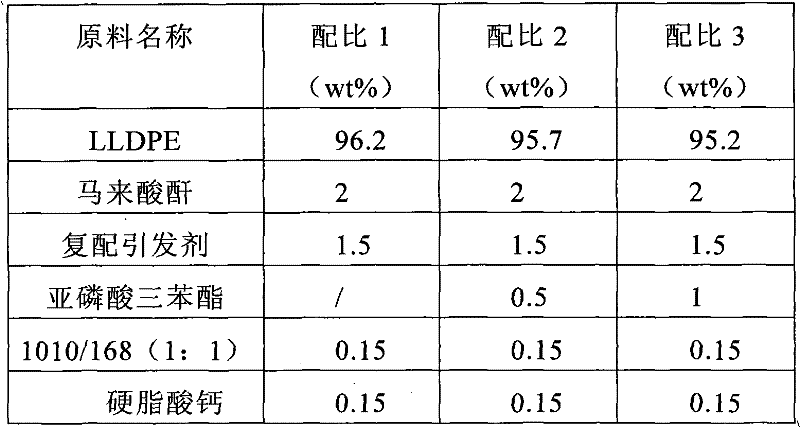

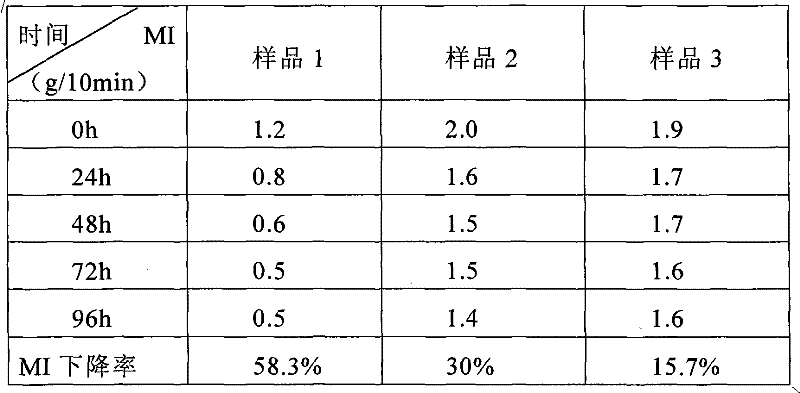

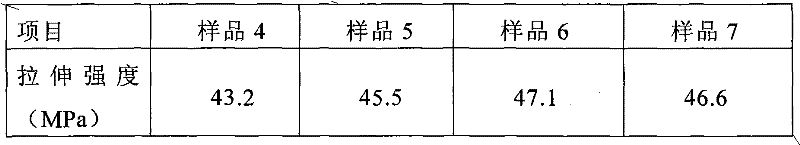

High-efficiency ultra-low-smell maleic anhydride graft composition

The invention relates to a preparation method of a high-performance ultra-low-odor maleic anhydride grafted composition by reaction extrusion. The maleic anhydride grafted composition is characterized in that the composition comprises 90wt%-97wt% of polymeric resin, 1wt%-5wt% of maleic anhydride, 0.5wt%-2wt% of initiator, 0.5wt%-1.5wt% of second monomer, 0.5wt%-2wt% of odor absorbent and 0.1wt%-1wt% of antioxidant. The preparation method comprises the steps as follows: weighing the raw materials; mixing in a high speed mixer for 2-5 minutes; discharging; and carrying out fusion reaction and extruding in a twin-screw extruder at a rotation speed of 180-600rpm at 150-225 DEC C. The maleic anhydride grafted composition has the characteristics of high grafting ratio, light color, low gel content and low maleic anhydride residue, and can be widely applied in a high molecular material processing industry.

Owner:SHANGHAI SUNNY

Preparation method of natural rubber with constant viscosity

InactiveCN101864004AInhibition of cross-linking reactionLow gel contentPolymer scienceMooney viscosity

The invention discloses a preparation method of natural rubber with constant viscosity which relates to the technique of mooney viscosity control of natural rubber. The method comprises the steps of adding the mercaptan compounds into the natural rubber, mixing evenly, and then performing the conventional processes of solidification, tabletting, prilling and drying. The natural rubber with constant viscosity of the invention has the storage hardening value of smaller than 2 represented by the Wallace initial plasticity, and has the storage hardening value of smaller than 5 represented by the mooney viscosity, thereby significantly improving the processing characteristics.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Environment-friendly polyethylene compatilizer and preparation method thereof

The invention relates to an environment-friendly polyethylene compatilizer and a preparation method thereof. The environment-friendly polyethylene compatilizer comprises the following components in percentage by weight: 75 to 98 percent of polyethylene, 1 to 10 percent of functional monomer, 0.1 to 10 percent of initiator, 0.1 to 9 percent of anti-crosslinking agent, 0.1 to 3 percent of antioxidant and 0.1 to 3 percent of lubricating agent. The preparation method comprises the following steps of: placing the components in a highly mixing machine in a ratio; mixing; feeding the mixture into a double-screw extruder in a side feeding manner; extruding by using the double-screw extruder; and performing ultrasonic treatment to obtain the product. Compared with the prior art, the environment-friendly polyethylene compatilizer and the preparation method thereof have the advantages that: the polyethylene compatilizer with high grafting ratio is obtained by a compound initiating system and an ultrasonic technology; the problems of high monomer residual amount and serious gelling phenomenon are solved; emission of toxic substances is reduced; and the environment and healthiness of users are protected.

Owner:SHANGHAI SUNNY

High-strength heat-resistant modified silicon rubber power cable sheath material

InactiveCN104292836AHigh strengthImprove heat resistanceRubber insulatorsInsulated cablesPolymer scienceBenzoyl peroxide

The invention discloses a high-strength heat-resistant modified silicon rubber power cable sheath material which is prepared from the following raw materials in parts by weight: silicone rubber, fluorine rubber, nano calcium carbonate, modified silica, potassium titanate whiskers, aluminum hydroxide, ferric oxide, tin oxide, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, methyltris(methylethylketoximino)silane, benzoyl peroxide, hydroxyl silicone oil, an amino silane coupling agent, dibutyltin dilaurate, magnesium oxide, a hydroxy stearic acid, an accelerant, an antiager, and a plasticizer. The high-strength heat-resistant modified silicon rubber power cable sheath material disclosed by the invention is high in strength and good in heat resistance, and a cable sheath prepared by using the high-strength heat-resistant modified silicon rubber power cable sheath material is good in comprehensive performance and long in service life.

Owner:ANHUI CONSTANT CRYSTAL CABLE GROUP

Catalyst system and method for polymerizing butadiene

The invention relates to a catalyst system and a method for polymerizing butadiene by using the catalyst system. The catalyst system comprises soluble nickel compounds, organic aluminum compounds and boron triflouride complexes, wherein ligands are mixtures of any two compounds of oxide compounds including alcohols, esters, ketones and ethers. The catalytic system is high in activity, can catalyze the polymerization of 1,3-butadiene in an alkaline solvent at a temperature of between 20 DEG C below zero and 90 DEC G to synthesize cis-rich polybutadiene rubber having little gel but a cis-content of over 97 percent, even up to 99 percent. The system and the method can realize stable production with low energy consumption in a polymerization process, light rubber sticking in a polymeric kettle and pipes and convenient operation.

Owner:CHINA PETROLEUM & CHEM CORP

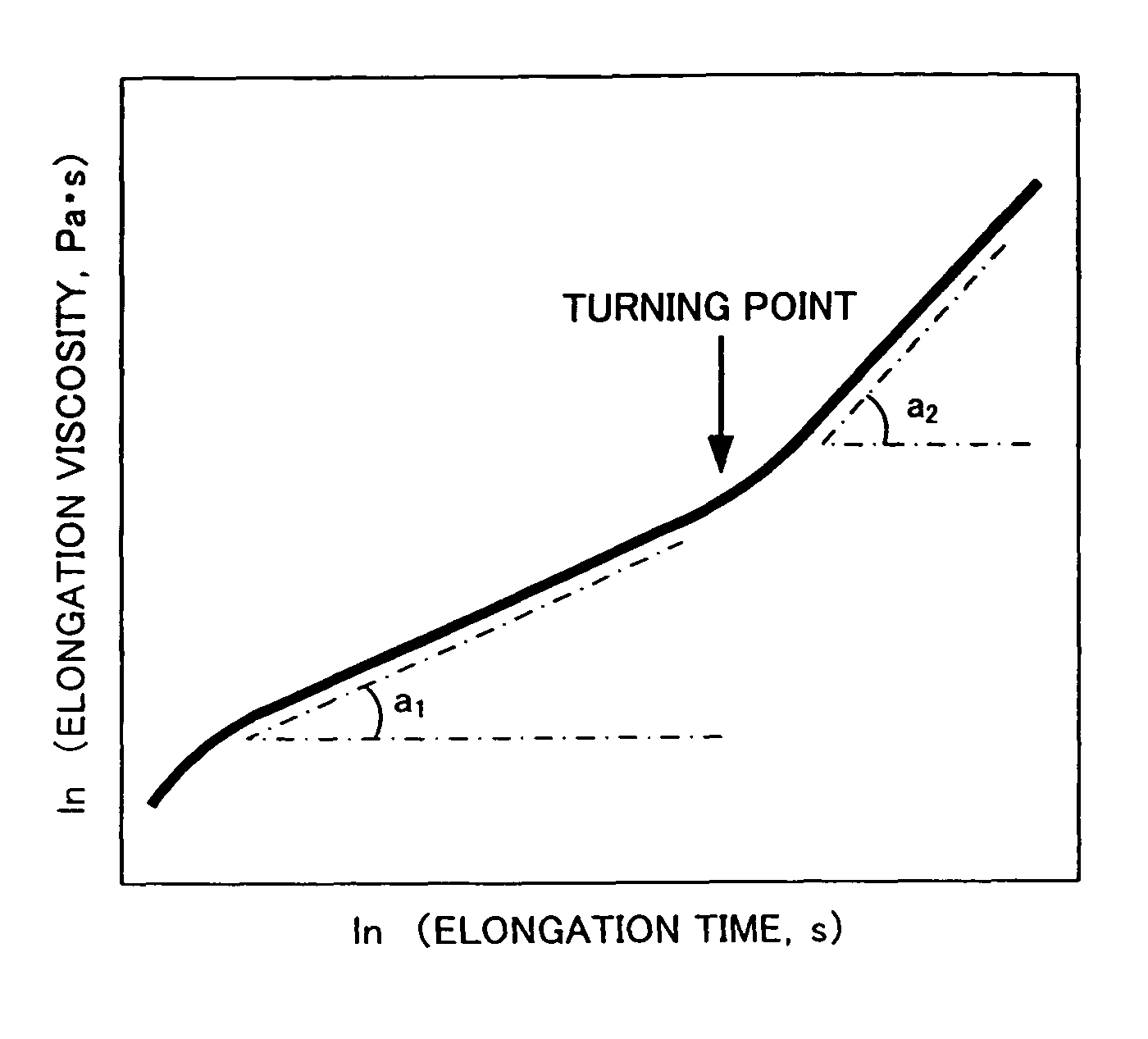

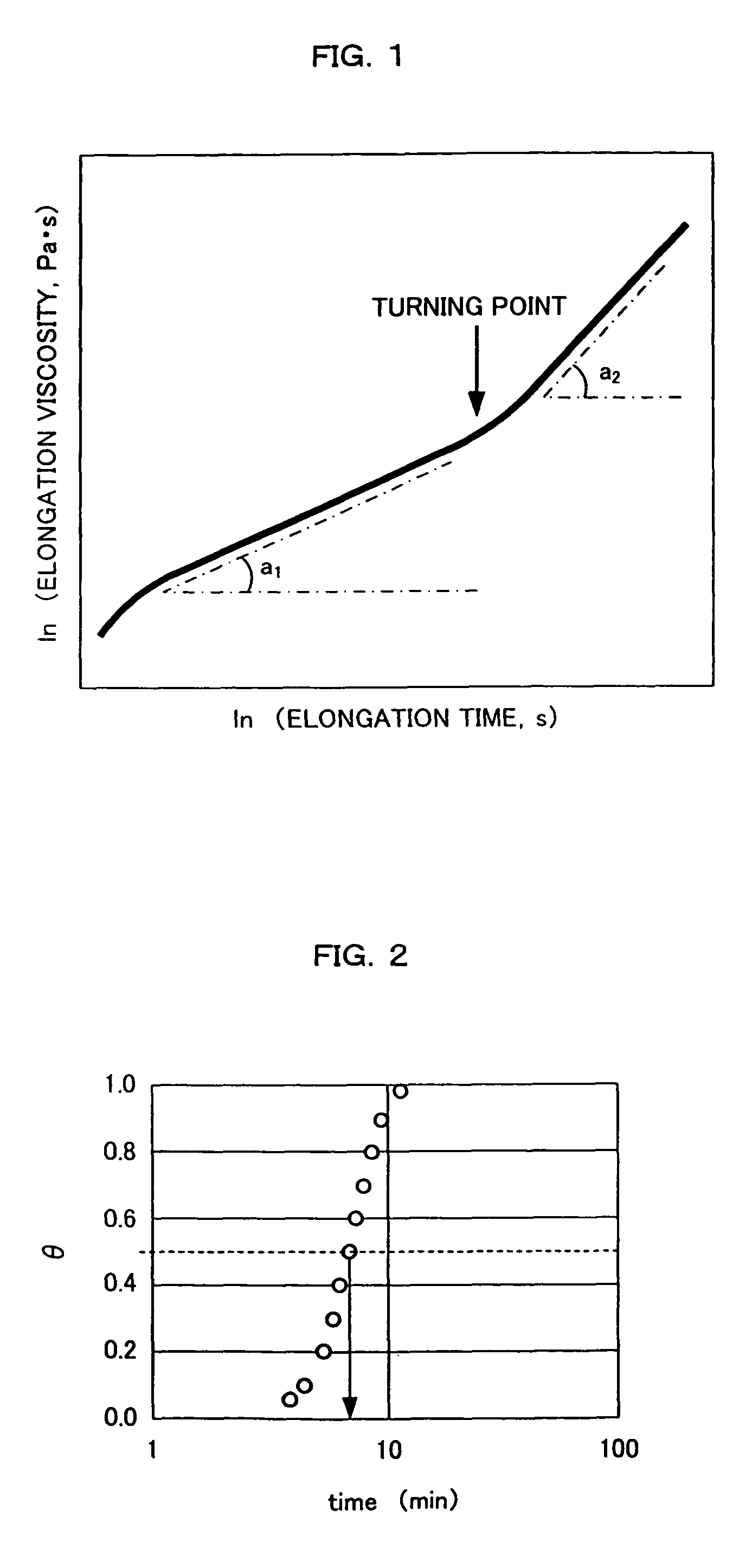

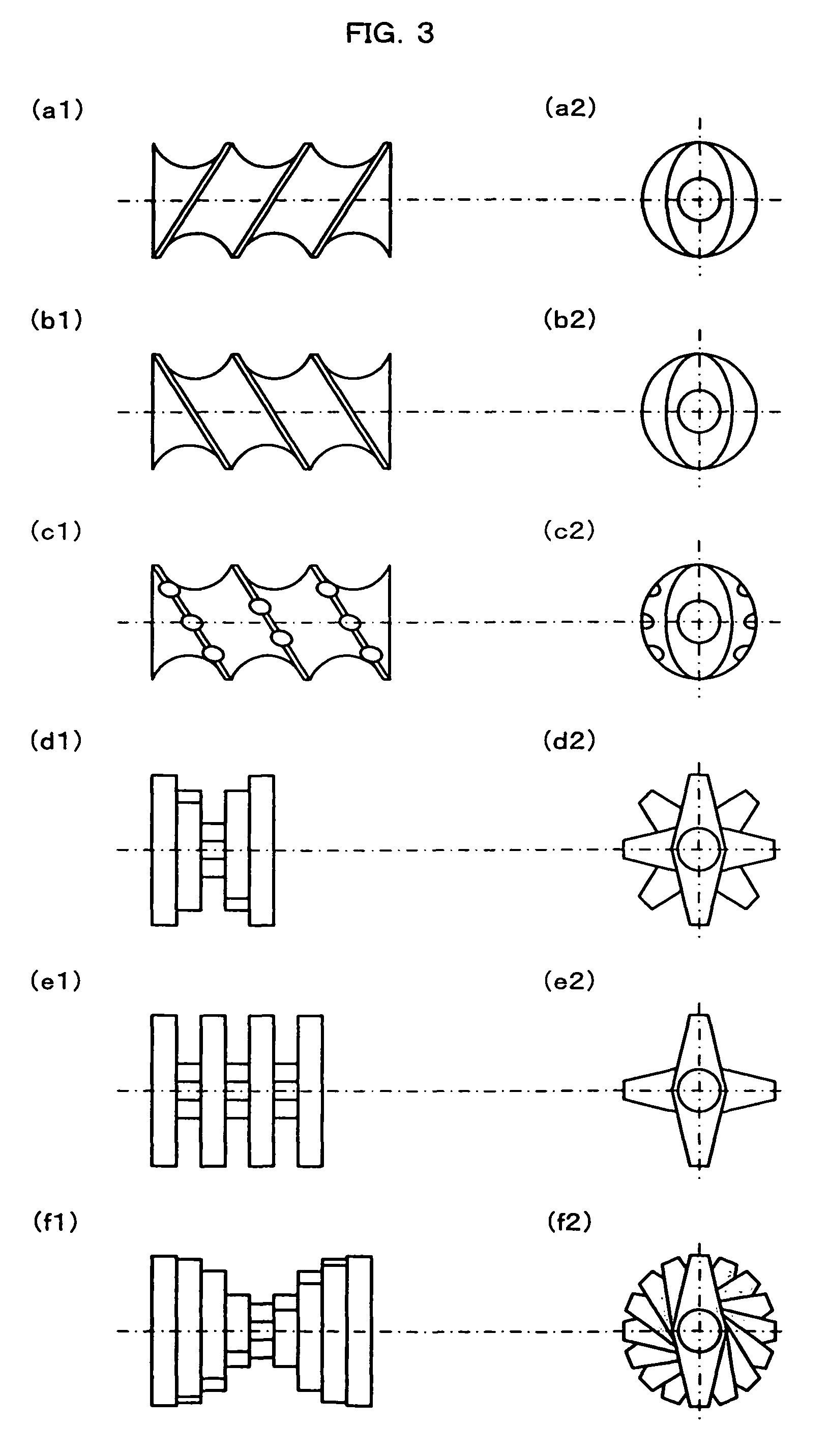

Polypropylene for foam and polypropylene foam

The present invention is concerned with a polypropylene composition comprising a polypropylene base resin, the polypropylene composition having—a XHU content of less than 1.25 wt. %;—a F30 melt strength of at least 30 cN, determined in the Rheotens test at 200° C.; and—a melt extensibility v30 of at least 200 m / s, determined in the Rheotens test at 200° C. In another aspect the present invention is concerned with a polypropylene composition having an MFR (2.16 kg, 230° C., ISO 1133) of 1.0 to 5.0 g / 10 min comprising a polypropylene base resin, the polypropylene base resin being obtainable by producing an intermediate polypropylene having an MFR (2.16 kg, 230° C., ISO 1133) of 0.5 to 2.5 g / 10 min in the presence of an asymmetric catalyst; mixing the intermediate polypropylene with peroxide and at least one diene at a temperature of 20 to 90° C. for at least 2 minutes to form a pre-mixed material; melt mixing the pre-mixed material in a melt mixing device at a barrel temperature in the range of 180 to 300° C., whereby the melt mixing device is a melt mixing device includes a feed zone, a kneading zone and a die zone, whereby an initial barrel temperature T1 is maintained in the feed zone, a barrel temperature T2 is maintained in the kneading zone and a die barrel temperature T3 is maintained in the die zone, whereby the barrel temperatures T1, T2, and T3 satisfy the following relation: T1<T3<T2. In yet another aspect the present invention is concerned with a process for the production of a polypropylene composition having—a XHU content of less than 1.25 wt. %;—a F30 melt strength of at least 30 cN, determined in the Rheotens test at 200° C.; and—a melt extensibility v30 of at least 200 m / s, determined in the Rheotens test at 200° C. whereby an asymmetric catalyst derived intermediate polypropylene having an MFR (2.16 kg, 230° C., ISO 1133) of 0.5 to 2.5 g / 10 min is mixed with peroxide and at least one diene at a temperature of 20 to 90° C. for at least 2 minutes to form a pre-mixed material; and the pre-mixed material is melt mixed in a melt mixing device at a barrel temperature in the range of 180 to 300° C. In yet another aspect the present invention is concerned with foam comprising the polypropylene composition according to the present invention. The present invention is further concerned with the use of the polypropylene composition for producing foamed articles.

Owner:BOREALIS AG

Preparation method of acrylonitrile copolymer spinning solution

InactiveCN102747452ALow gel contentImprove technical effectMonocomponent synthetic polymer artificial filamentFilament-forming treatmentCarbon fibersItaconic acid

The invention relates to a preparation method of an acrylonitrile copolymer spinning solution to mainly solve a problem of easy gel generation of solutions in the prior art. The preparation method comprises the following steps: 1, adding a solvent, acrylonitrile, itaconic acid and an initiator azo-bis-iso-heptonitrile to a reactor, and reacting at 30-45DEG C for 24-50h under the protection of a gas inert to the reacting substances to obtain an acrylonitrile copolymer spinning solution I; and 2, carrying out pressure reduction on the spinning solution I to remove residual monomers and bubbles to obtain the novel acrylonitrile copolymer spinning solution. The method well solves the problem through above technical scheme, and can be applied to the industrial production of carbon fiber precursors.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of polyether ketone/sulfone high-temperature resistant material

The invention discloses a preparation method of a polyether ketone / sulfone high-temperature resistant material, which comprises the following steps that: firstly, a reactive monomer, a solvent and an inorganic alkali are put into a first reactor, are mixed at a temperature of 40 to 90 DEG C by stirring, and are dissolved; secondly, the mixture is transferred to a second reactor, is added with a water-carrying agent, and is stirred at a temperature of 150 to 280 DEG C to be subjected to salt formation dehydration; and a material after being subjected to salt formation dehydration is introducedinto a third reactor, and is stirred at a temperature of 230 to 330 DEG C to be subjected to polymerization to obtain a product. The synthesis process of the polyether ketone / sulfone material is reacted in three reactors with different temperatures, so that an intermediate product prepared in each step is more sufficient and uniform, the obtained product has a gel content reduced to less than 3% and molecular weight distribution which is more reasonable and reaches the range of 2.42 to 2.45 without changing the comprehensive performance of the product, and thereby the quality of the resin product is improved; and the preparation method is suitable for continuous production, and production cost reduction, energy consumption reduction in a production process and stable quality of the obtained product are achieved.

Owner:KINGFA SCI & TECH CO LTD +2

Emulsion polymerization method for preparing tractable butadiene styrene rubber

The invention relates to an emulsion polymerization method for preparing a tractable butadiene styrene rubber. The polymerization method comprises at least the following steps: adding part of styrene (an oil phase) and part of an emulsifier (an aqueous phase), a regulator and an initiator into a polymerization kettle; adding butadiene; carrying out emulsion polymerization with stirring; and when conversion rate of the polymerization reaction in the middle stage reaches 30-60%, refilling the emulsifier, the crosslinking agent, styrene and the regulator by one or more times. The styrene butadiene rubber prepared by the method provided by the invention has high micro gel content and low gel content; coupled with the electron cloud effect of the pi bonds in the benzene ring of the molecular chain, a three-dimensional net shape structure is easy to form in the processing process; and the rubber product has good physical and mechanical properties, increased Mooney viscosity, and correspondingly increased tensile strength and 300% stretching strength.

Owner:PETROCHINA CO LTD

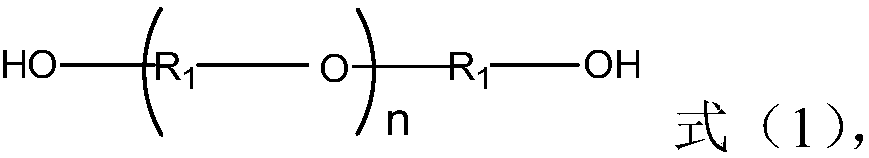

Method for preparing monoolefine-conjugated diene copolymer solution for halogenating

The present invention relates to a method for preparing monoolefine-conjugated diene copolymer solution for halogenating. The method comprises: (1) mixing a terminant solution which has been cooled tobe below 35 DEG C with monoolefine-conjugated diene copolymer slurry, wherein the terminator solution contains C1-C2 haloalkanes and saturated aliphatic alcohols A and optionally C5-C8 aliphatic alkanes, the saturated aliphatic alcohols A is one or several kinds of C1-C5 saturated mono fatty alcohol, one or several kinds of C2-C4 saturated dihydric fatty alcohol and one or several kinds of saturated fatty alcohols shown in the formula (1), (2) replacing the halogenated alkane in the solution by at least one replacement solvent and removing the unreacted monomer, wherein the replacement solvent is selected from C5-C8 aliphatic alkanes. The halogenating butyl rubber obtained by the method has the characteristic of low gel content, and the low molecular weight oligomer content in the halogenated butyl rubber having a weight average molecular weight of less than 20,000 is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Natural rubber produced from latex and composition comprising same

The present invention provides a natural rubber obtained by drying collected natural rubber latex without coagulation, wherein the drying is performed using a drum dryer and / or a belt dryer. In addition, there is provided a method of forming a natural rubber-filler mixture by adding at least one of carbon black and an inorganic filler to natural rubber latex, and adding a compound containing acyl to these natural rubber and natural rubber-filler mixture. A natural rubber of a viscosity stabilizer of a hydrazine compound or an ester of an aromatic or aliphatic polycarboxylic acid derivative, and a rubber composition prepared using the above natural rubber and having excellent productivity, abrasion resistance and fracture resistance.

Owner:BRIDGESTONE CORP

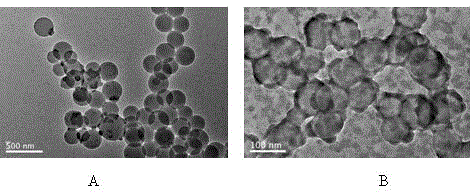

Method for synthesizing Pickering-type emulsion through semi-continuous polymerization

The invention discloses a method for synthesizing a Pickering-type emulsion through semi-continuous polymerization, and belongs to the field of high molecule polymerization. The method comprises the following steps: preparing a water phase, preparing a dropping component for semi-continuous emulsion polymerization, and preparing the Pickering-type emulsion through the semi-continuous emulsion polymerization, namely obtaining the Pickering-type emulsion. By the method, the using proportion (0.1-2.0wt%) of solid particles can be obviously reduced, latex particles with the size being about 100 nm can be formed, the coating form of the solid particles on the surfaces of the latex particles is intact, and the stability of the emulsion is high.

Owner:CHANGZHOU UNIV

Method of terminating polymerization reaction containing conjugated diolefin polymer

InactiveCN1919881AGuarantee product qualityDoes not increase macromolecular contentPolymer scienceEmulsion

The invention discloses a method to terminate polymerization reaction of polymer with conjugated olefin, which is characterized by the following: the polymer with conjugated olefin is polybutadiene rubber, poly-emulsion butadiene styrene rubber, poly-solution butadiene styrene rubber,styrene thermo plasticity elastic body SBS, SIS, SEBS, SEPS, isoprene rubber, low cis-form polybutadiene rubber, K-pitch; adding phenols material being measured into autoclave as terminal catalyst; stirring fully; reacting at least 1min.

Owner:CHINA PETROCHEMICAL CORP +1

Method for preparing nickel series low-mooney high cis-1,4-polybutadiene rubber

The invention provides a method for preparing nickel series low-mooney high cis-1,4-polybutadiene rubber. A solution polymerization reaction is performed by 1,3-butadiene in a polymerization solvent. The preparation method has the beneficial effect that a low-mooney cis rubber with the mooney viscosity between 25 and 40 can be prepared stably, and the prepared low-mooney cis rubber can be kept in a higher tensile strength, achieves the same strength as that of butadiene rubber with mooney viscosity between 40 and 50, and has a low gel content which is less than 0.5 percent.

Owner:万达集团股份有限公司

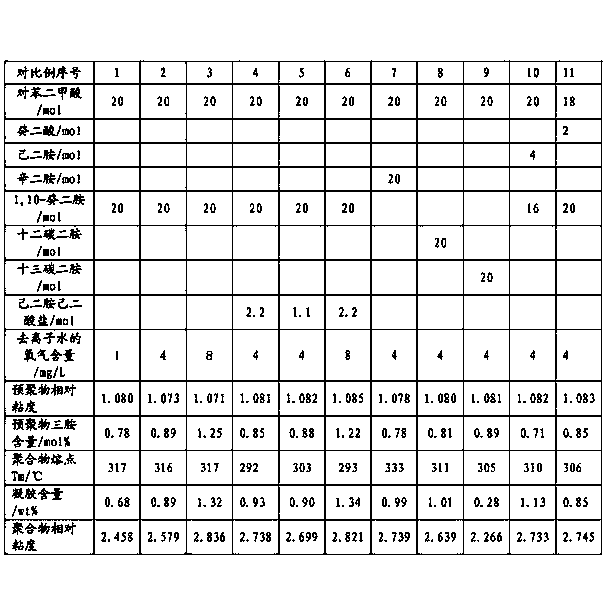

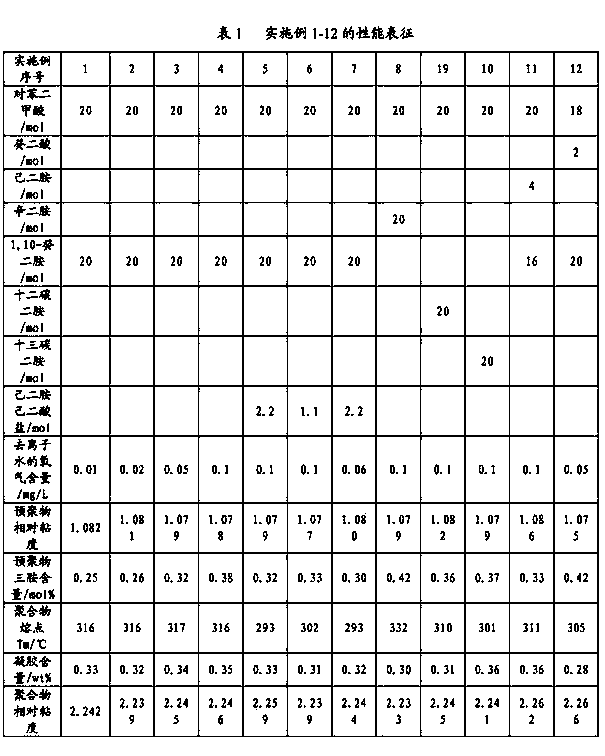

Polyamide, and preparation method and application thereof

The invention relates to a polyamide, and a preparation method and an application thereof. The preparation method of the polyamide comprises the following steps: 1, charging: adding a dicarboxylic acid monomer, a diamine monomer, deionized water, an optional nylon salt and other reaction assistants to a reaction vessel, wherein the oxygen content of deionized water is less than 0.05-0.1mg / L; 2, filling with a protection gas; and 3, pre-polymerization: heating the reaction vessel to pre-polymerize a mixture in the reaction vessel. The gel content of polyamide polymerized through the preparation is lower than that of polyamide polymerized through the prior art because of the low triamine content of a pre-polymerized product, and polyamide prepared in the invention has a high use temperature and a good hot-working performance.

Owner:KINGFA SCI & TECH CO LTD +1

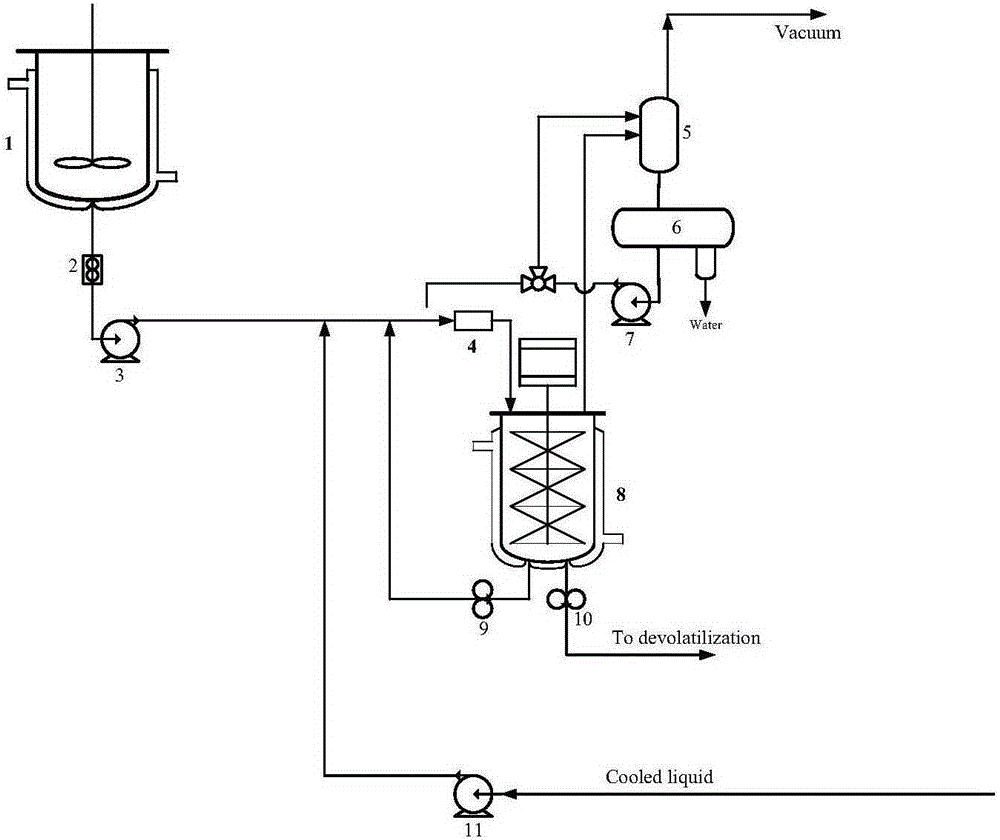

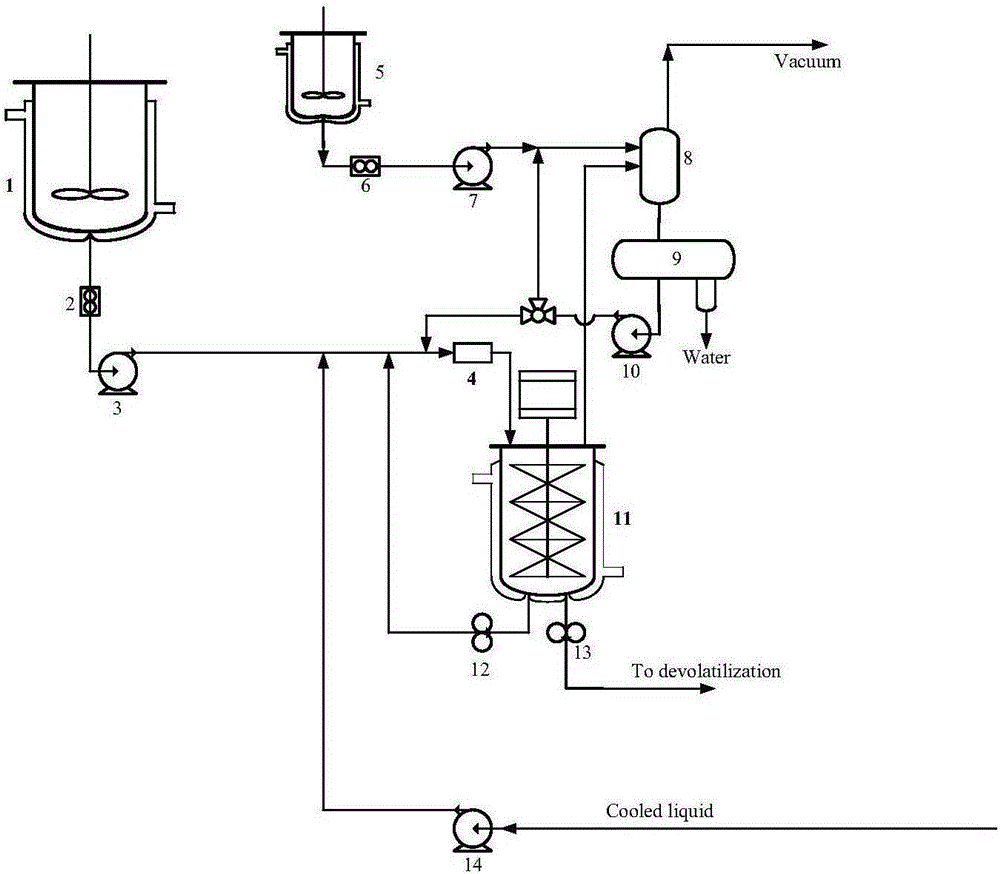

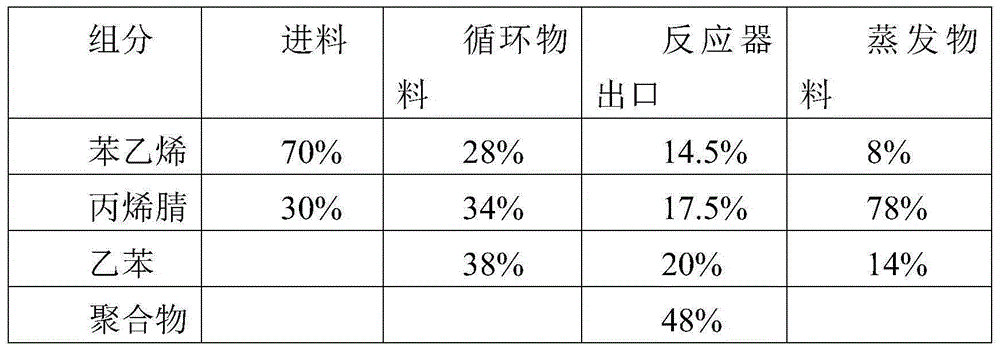

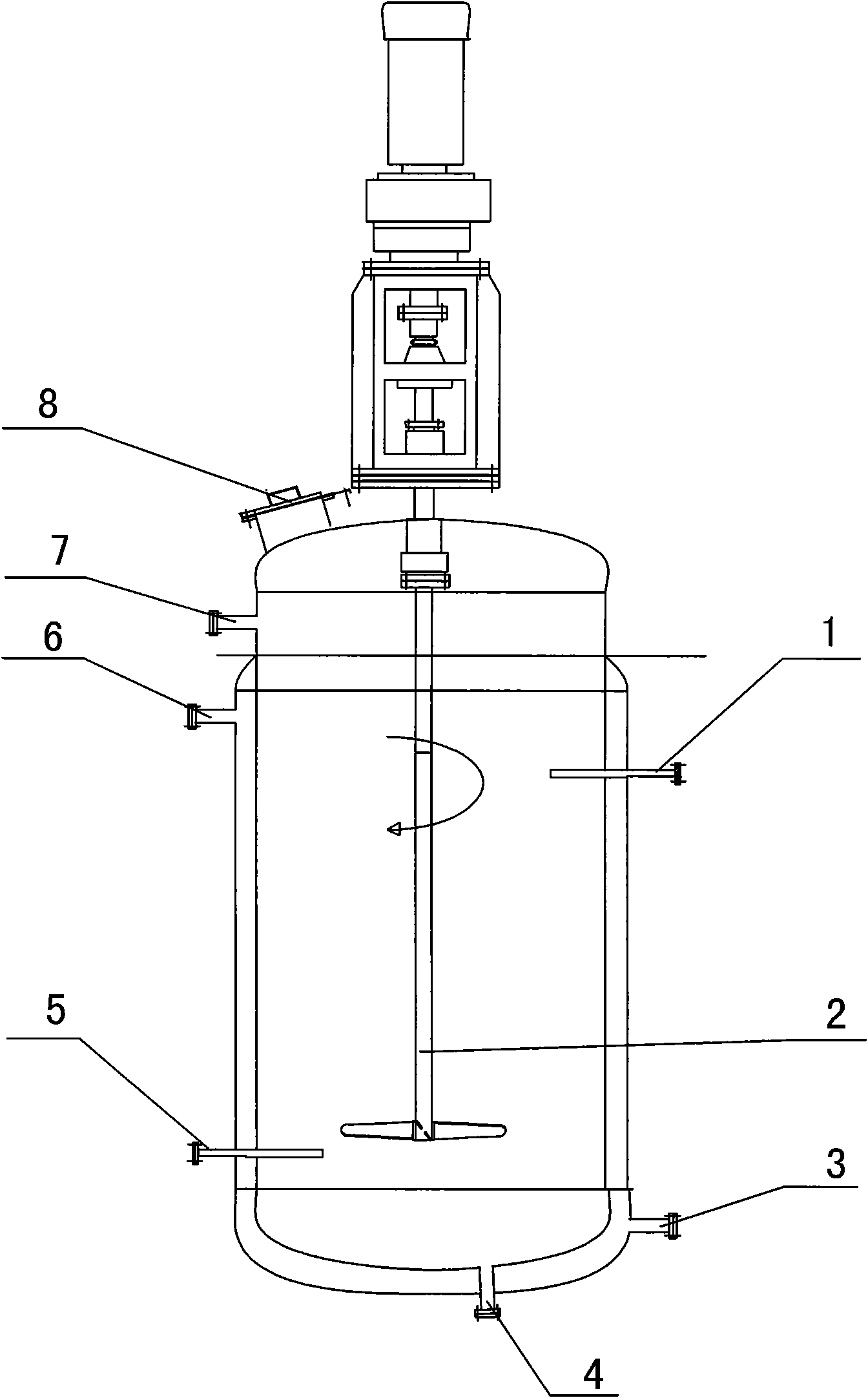

High-nitrile SAN resin and production method thereof

InactiveCN106188374ANarrow molecular weight distributionReduce yellow indexAcrylonitrileMelt flow index

The invention relates to a production method of high-nitrile SAN resin. The method comprises the specific steps of (a) mixing acrylonitrile with part of styrene cinnamene to obtain a mixture A, then mixing the mixture A with a circulating material and a condensation circulating material outside a reactor in a static mixer through a metering pump so as to obtain a mixture B, and then continuously leading the mixture B to the reactor; and enabling the rest of the styrene to be pumped into a steam condenser at the top of a reaction kettle through the metering pump, to be in contact with steaming air flows of the reactor, and to be mixed with condensation steam to become a condensation circulating material, and enabling the condensation circulating material to enter the reactor through a static mixer ; (c) polymerizing a reaction mixture at 140-160 DEG C in the reactor for 1.5-2.5 hours so as to obtain an SAN copolymer; and (d) performing two-stage devolatilization in a devolatilization machine, and performing pelleting in a pelletizer, so as to obtain the high-nitrile SAN resin with narrow distribution. According to the high-nitrile SAN resin produced by the method disclosed by the invention, the percentage by mass of acrylonitrile is greater than or equal to 32%, the melt indexes of products are smaller than 6g / 10min(230 DEG C, 2.16Kg), and the yellow index of the products is smaller than 12.

Owner:PETROCHINA CO LTD

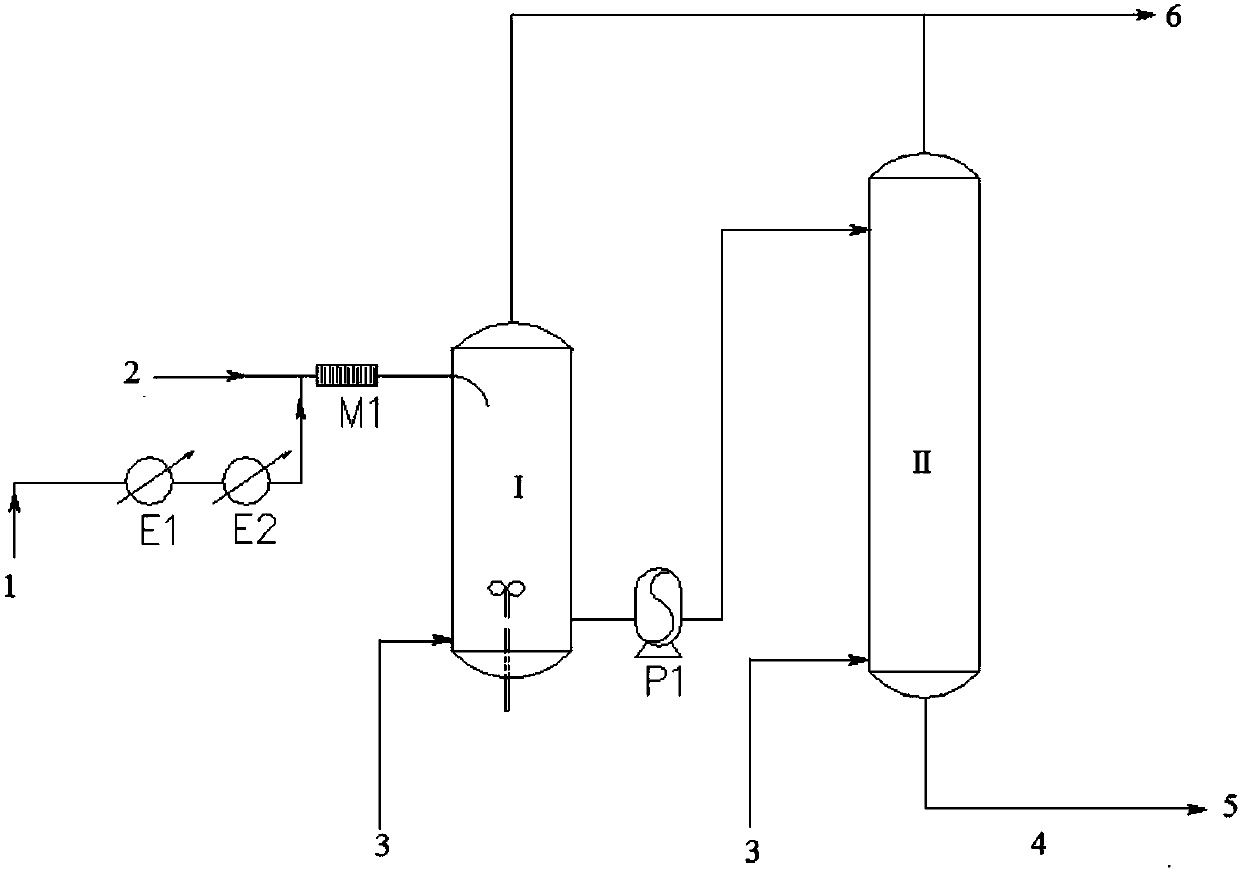

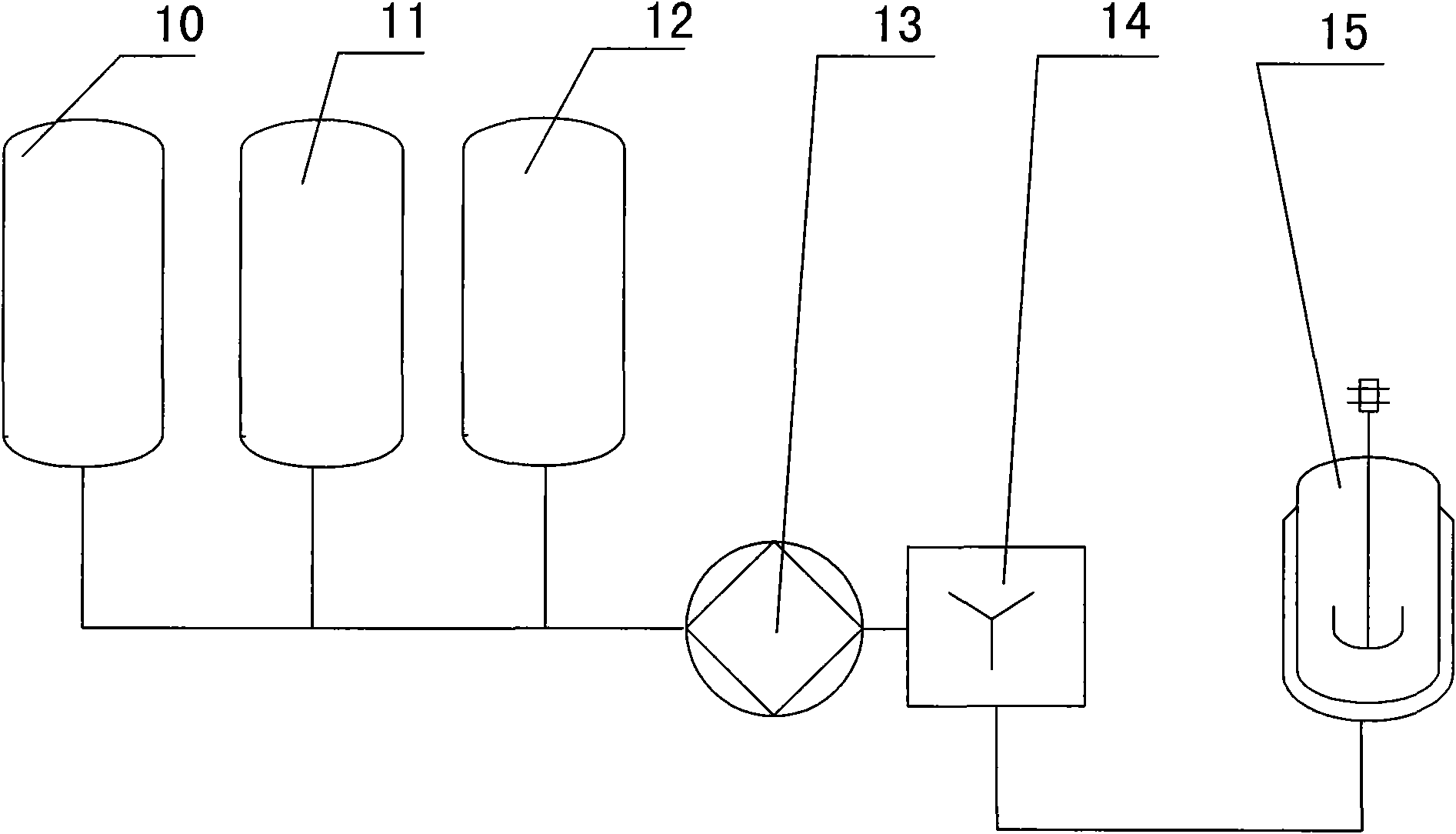

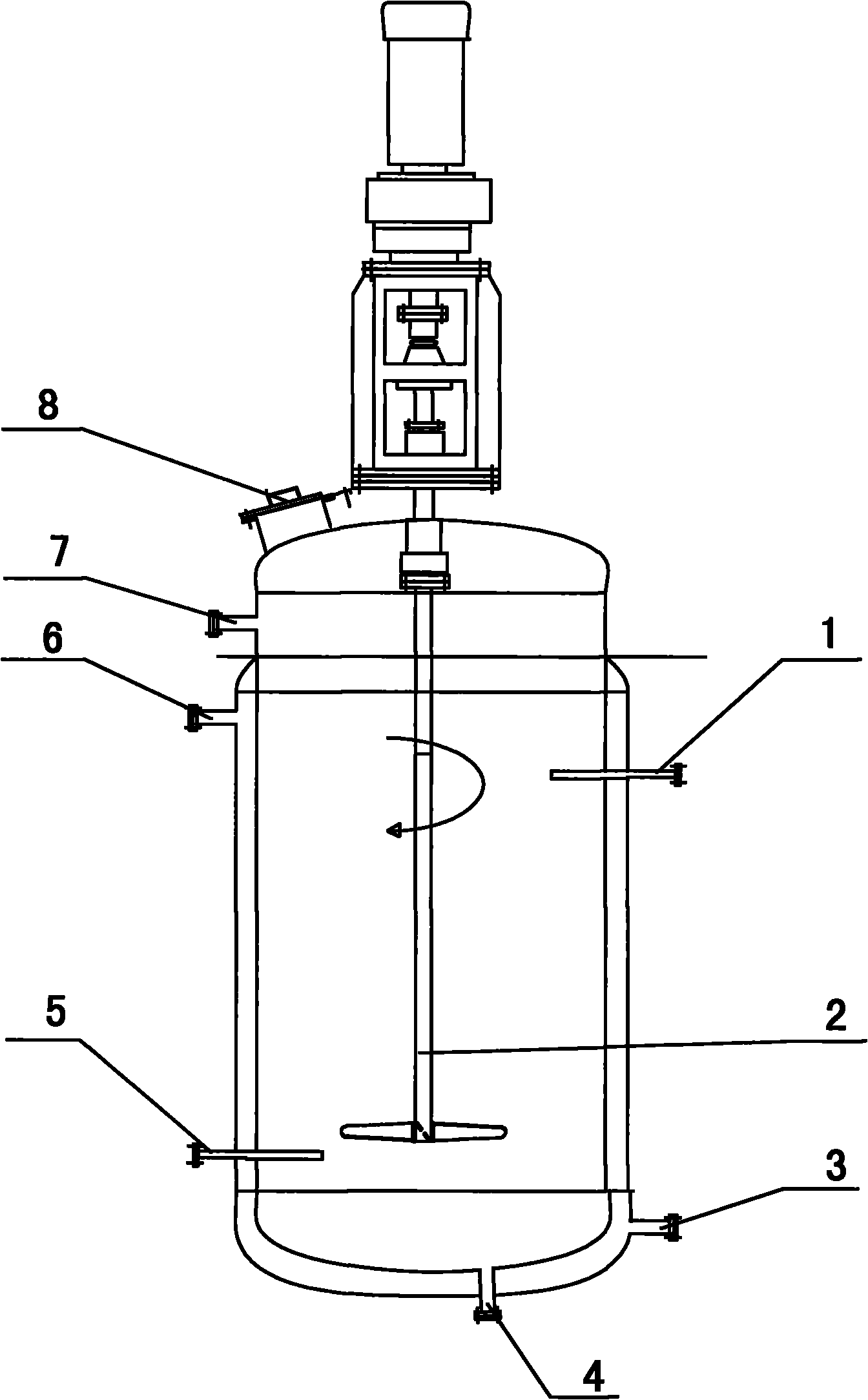

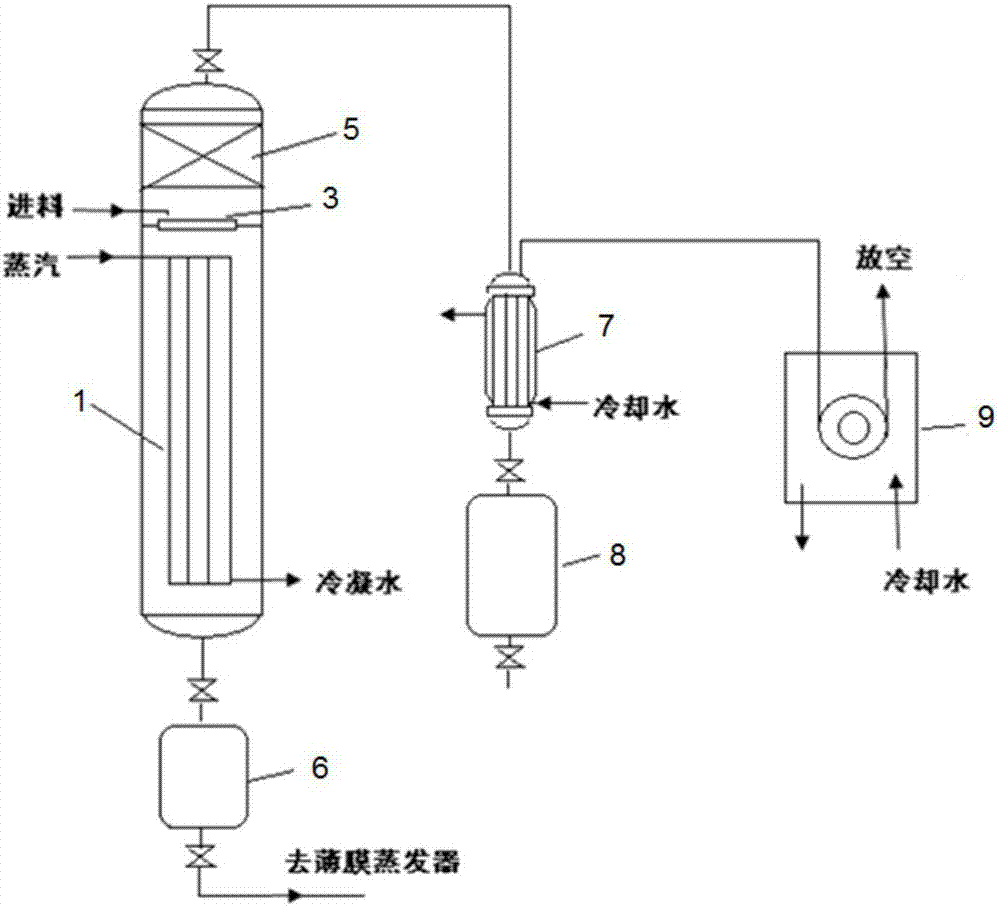

Pre-mixing process in rare-earth isoprene rubber production process

The invention relates to a pre-mixing process in a process for producing rare-earth isoprene rubber through isoprene solution polymerization by using a rare-earth catalyst. The pre-mixing process is characterized by comprising the following steps of: pre-mixing the rare-earth catalyst, an isoprene monomer and a solvent in a pre-mixing device consisting of a pipeline high-speed mixer and a pre-mixing kettle (14), and then injecting the mixture into a polymerization kettle. Aiming at the problems of poor dispersion of the catalyst, the monomer and the solvent during the isoprene solution polymerization, the process realizes efficient pre-mixing reaction of the rare-earth isoprene rubber. The rare-earth isoprene rubber can be widely applied to tyres and other rubber products, can be mixed with other rubbers, is particularly suitable for food and medicament industries such as artificial respiratory organs and the like, and is more suitable on the sanitation aspect compared with natural rubber and titanium rubber.

Owner:ZIBO LUHUA HONGJIN NEW MATERIAL CO LTD

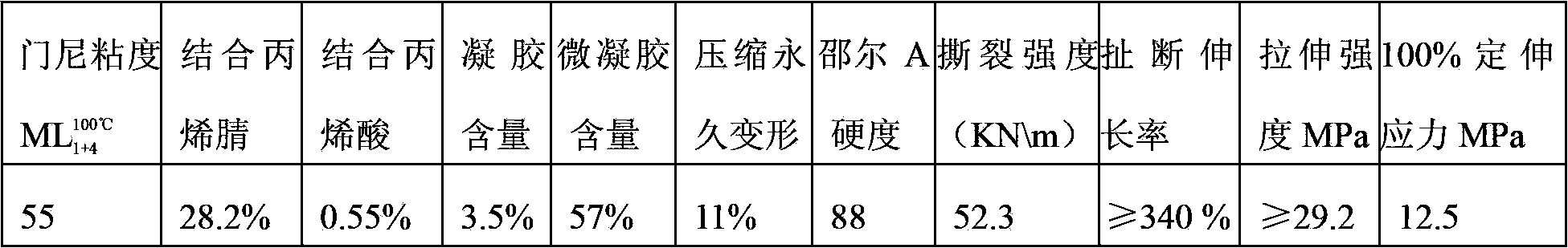

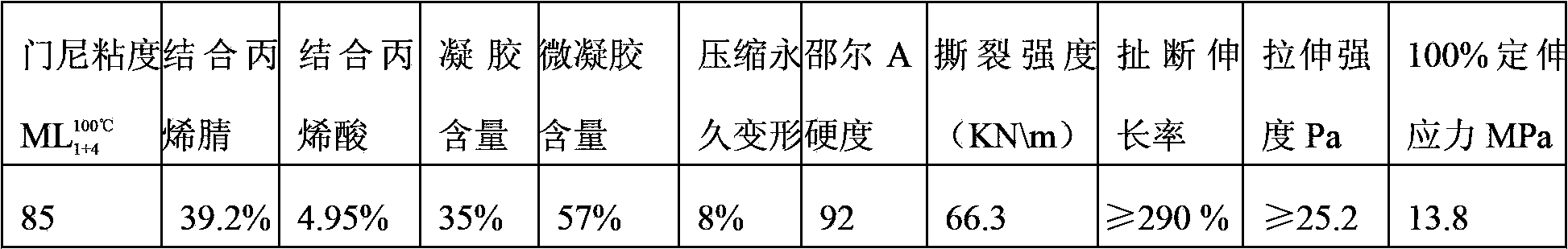

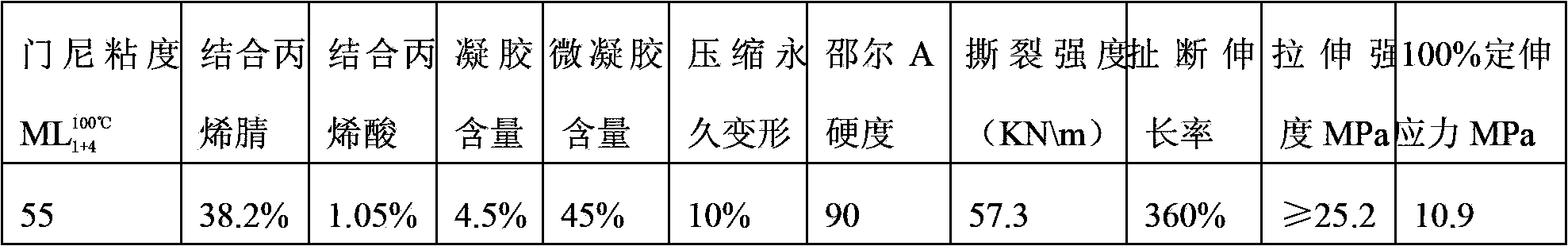

Process for preparing carboxylic acrylonitrile butadiene rubber through emulsion polymerization method

The invention relates to a process for preparing carboxylic acrylonitrile butadiene rubber through an emulsion polymerization method. An emulsifier and an adjusting agent are added in batch, and a crosslinking agent and a pre-crosslinking agent titanate are added at different times, so the carboxylic acrylonitrile butadiene rubber has the characteristics of high content of a microgel, low content of a gel, controllable combined acid index, easy formation of a stereo netted structure in the processing process, uniform distribution of carboxylic groups on a molecular chain, uniform structure formed in the vulcanizing and product processing processes, slight stress relax phenomenon, and good dimension stability. The rubber obtained through adopting the method has good physical and mechanical properties and an improved Mooney viscosity, and has corresponding better compression set, Shore A hardness, tearing strength, tensile strength, elongation at break and 100% stress at definite elongation than common carboxylic rubber.

Owner:PETROCHINA CO LTD

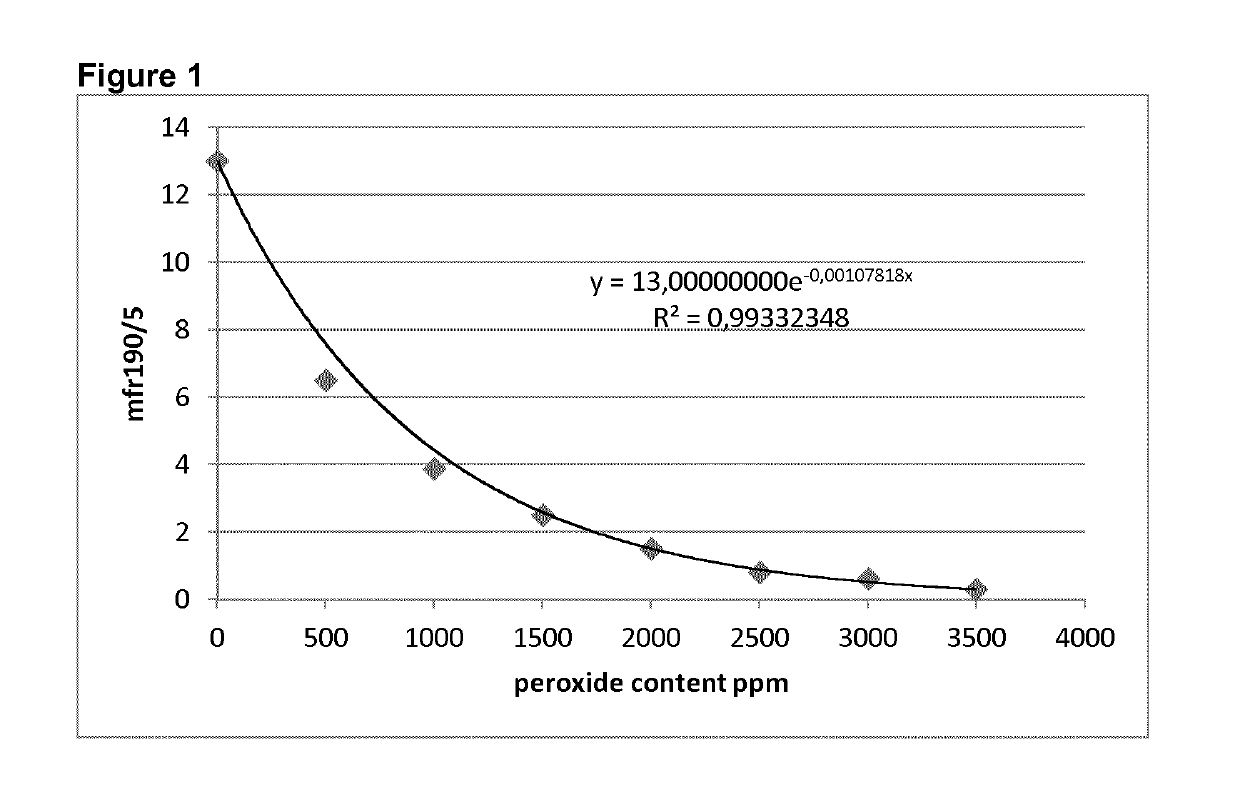

Molecular modification of polyethylene resin

ActiveUS20190177448A1MFR is also loweredLow melt flow ratePlastic recyclingPolymer scienceControl manner

The invention is related to a process for producing modified polyethylene having decreased melt flow rate (5 kg, 190° C.) (MFR). In particular, the present invention is directed to a process in a controlled manner for producing modified polyethylene recyclates having low MFR and low gel content directly by reactive extrusion processing.

Owner:BOREALIS AG

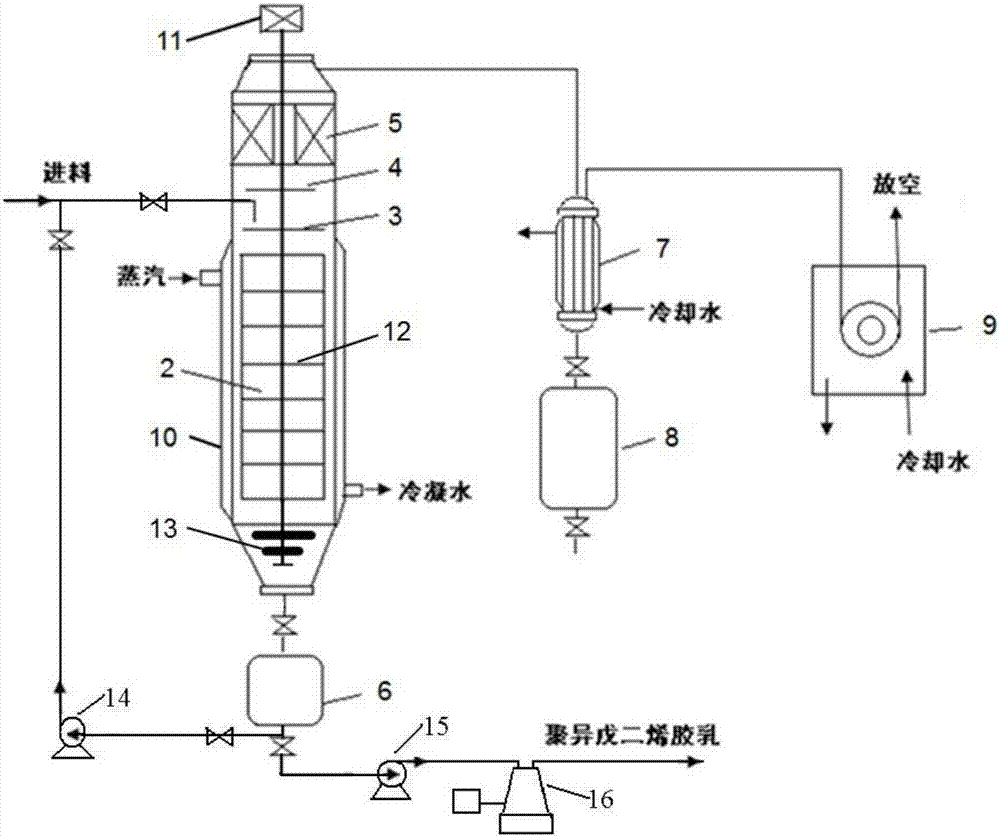

Method for preparing polyisoprene rubber latex

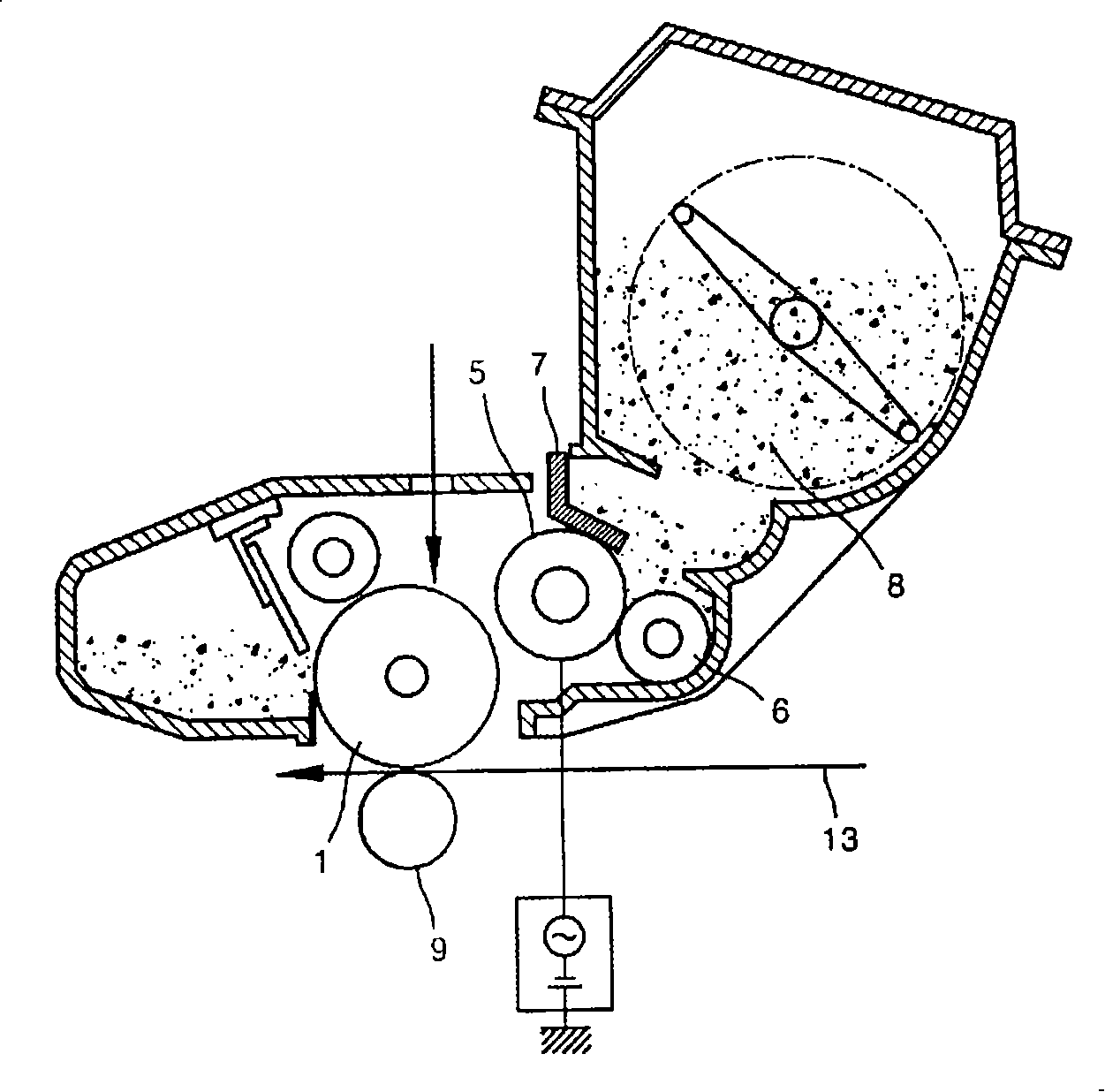

The invention relates to the field of rubber, particularly a method for preparing polyisoprene rubber latex. The method for preparing polyisoprene rubber latex comprises the following steps: (1) synthesizing an organic-solvent-containing polyisoprene rubber solution; (2) adding water, an emulsifier and a pH buffering agent, and emulsifying the obtained mixed solution under the action of mechanical force while controlling the pH value of the emulsion at 9-13, thereby obtaining a polyisoprene rubber emulsion; and (3) enabling the polyisoprene rubber emulsion to continuously pass through a concentrator and a scraper-bearing film evaporator, wherein the inside of the concentrator is provided with a static skimmer and / or a dynamic skimmer, the inside of the scraper-bearing film evaporator is provided with both a static skimmer and a dynamic skimmer, and in addition, at least part of the obtained polyisoprene rubber emulsion is circulated to the inlet of the film evaporator. The method can greatly enhance the latex preparation efficiency, and can obtain the polyisoprene rubber latex with stable performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

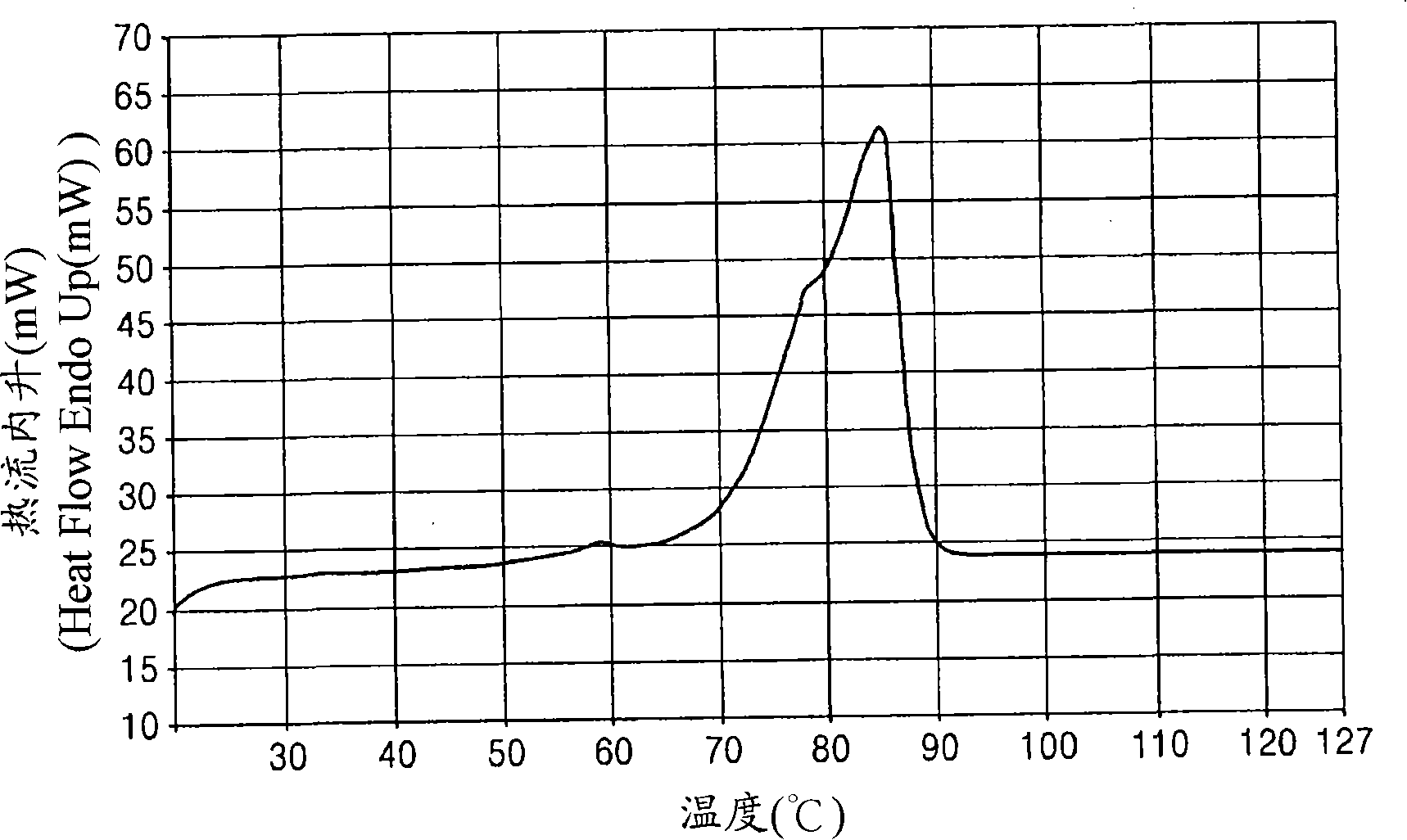

Electrophotographic developing agent

A non-magnetic one-component electrophotographic developing agent is provided having improved properties. The electrophotographic developing agent includes parent toner particles comprising a binder resin, a releasing agent, a colorant, and a charge control agent, and an external additive which is added to a surface of the parent toner particles, wherein the binder resin comprises a high viscosity polyester resin having a weight average molecular weight of about 90,000-140,000 and a gel content of less than about 5% and a low viscosity polyester resin having a weight average molecular weight of about 52,000-65,000 and a gel content of less than about 2%. According to an embodiment of the present invention, an electrophotographic developing agent having improved image gloss and fusing property, while ensuring durability may be prepared by using a blended combination of a high viscosity polyester resin and a low viscosity polyester resin.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com