Method for synthesizing Pickering-type emulsion through semi-continuous polymerization

A semi-continuous, emulsion technology used in the field of polymer polymerization to improve nucleation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

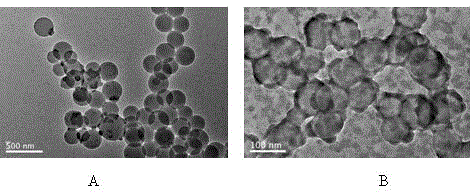

Image

Examples

Embodiment 1

[0023] The aggregation steps are as follows:

[0024] (1) Preparation of water phase:

[0025] 100 g of deionized water and 0.1 g of acrylic acid monomer were used to form a mixed solution, and 2.0 g of commercially available gas-phase solid silica particles with a particle size of 15 nm were added, and pulverized by a 450w ultrasonic crusher for 60 minutes to mix the silica evenly.

[0026] (2) Preparation of dripping components for semi-continuous emulsion polymerization:

[0027] Add 1.0 g of styrene monomer to 10 g of the water phase prepared in step (1), and disperse the monomer by ultrasonic crushing and emulsification. The dispersion process is cooled with ice water to avoid polymerization during the dispersion process.

[0028] (3) Preparation of Pickering type emulsion by semi-continuous emulsion polymerization:

[0029] Put the remaining 90g of the water phase prepared in step (1) into the reactor, start stirring, and use a two-leaf folding paddle (θ=45°, paddle di...

Embodiment 2

[0032] The aggregation steps are as follows:

[0033] (1) Preparation of water phase:

[0034] 100 g of deionized water and 5.0 g of acrylic acid monomer were mixed to form a mixed solution, 0.1 g of commercially available fumed silica particles with a particle size of 15 nm were added, and the silica was pulverized by a 450w ultrasonic crusher for 30 minutes to mix the silica evenly.

[0035] (2) Preparation of dripping components for semi-continuous emulsion polymerization:

[0036] Add 180.0g of styrene monomer to 90g of the water phase prepared in step (1), and disperse the monomer by means of ultrasonic crushing and emulsification. The dispersion process is cooled with ice water to avoid polymerization during the dispersion process.

[0037] (3) Preparation of Pickering type emulsion by semi-continuous emulsion polymerization:

[0038] Put the remaining 10g of the water phase prepared in step (1) into the reaction kettle, start stirring, and use a two-leaf folding paddl...

Embodiment 3

[0040] The aggregation steps are as follows:

[0041] (1) Preparation of water phase:

[0042] 100 grams of deionized water, 1.0 g of acrylic acid and 1.0 g of N,N-dimethylaminoethyl methacrylate monomers are mixed to form a mixed solution, and 0.5 g of commercially available gas-phase solid silica particles with a particle size of 15 nm are added. Stir and shear at 6000r / min to disperse and emulsify for 30 minutes to mix the silica evenly.

[0043] (2) Preparation of dripping components for semi-continuous emulsion polymerization:

[0044] Mix 10.0 g of 5.0 g of methyl methionate monomer and 5.0 g of styrene monomer for later use.

[0045] (3) Preparation of Pickering type emulsion by semi-continuous emulsion polymerization:

[0046] Put 100g of the water phase prepared by step (1) in the reaction kettle, start stirring, and use a two-leaf folding paddle (θ=45°, paddle diameter / kettle body diameter=0.7, paddle thickness / blade diameter= 0.2), the stirring rate is 90 r / min. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com