Preparation method and application of polyhedral oligomeric silsesquioxane loaded substituted aryl heterocyclic phosphate or salt nucleating agent

A technology of silsesquioxane and heterocyclic phosphate, which is applied in the field of polypropylene modification, can solve the problems of reducing the nucleation efficiency of nucleating agents, poor compatibility and dispersion, and easy agglomeration of powder, so as to achieve full nucleation effect, promotion of dispersion, effect of nucleation efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

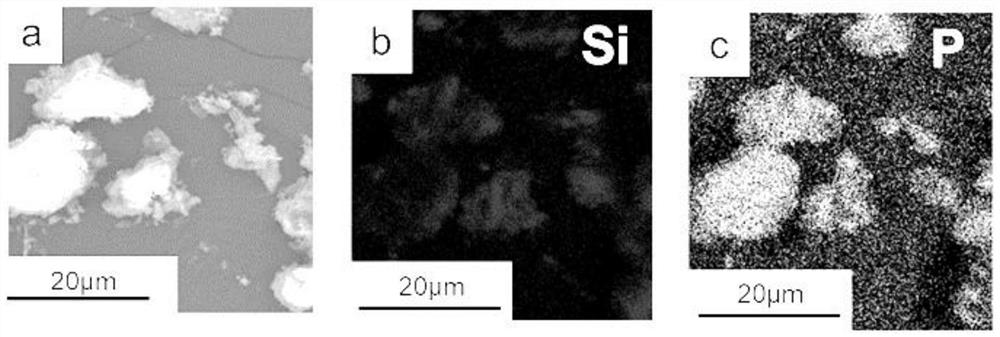

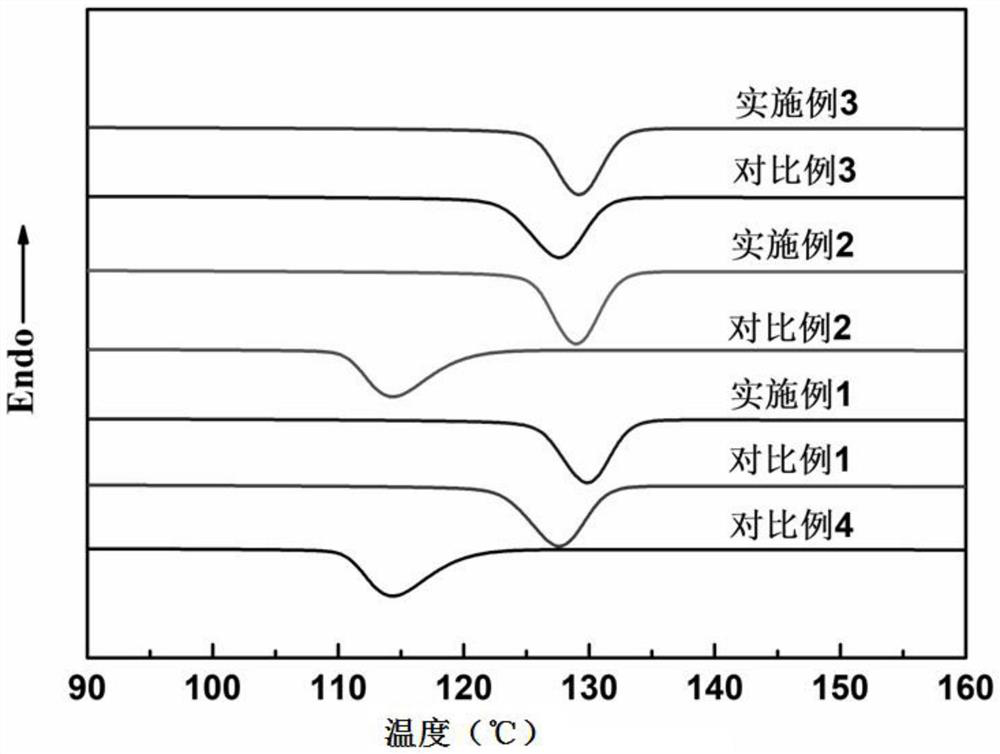

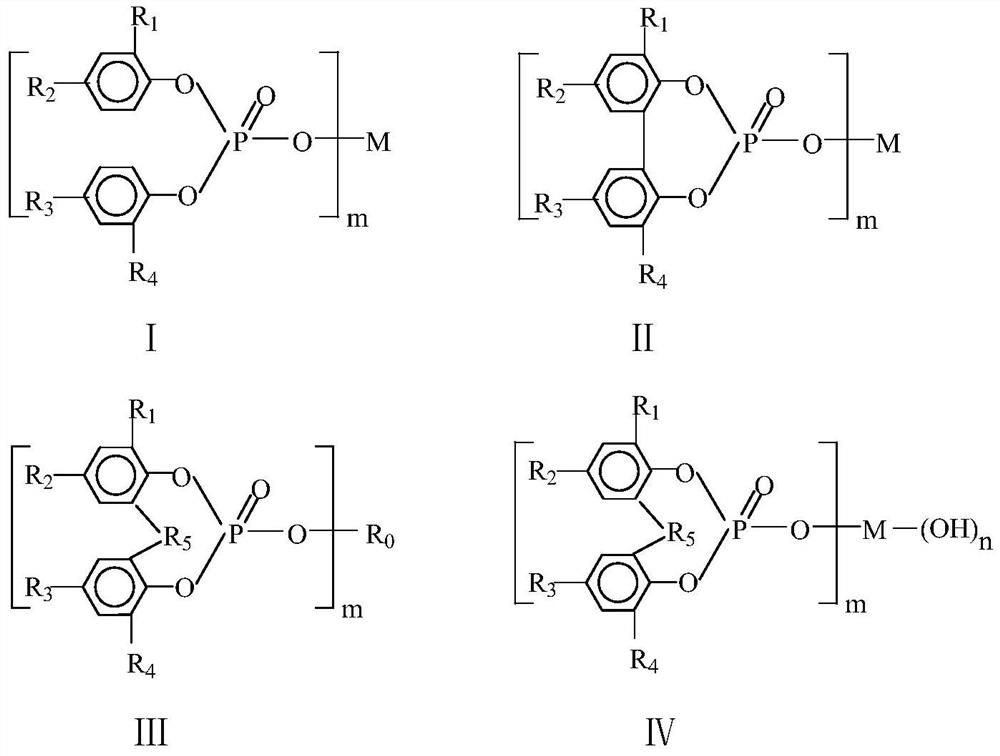

[0041] Dissolve 1g of bis(4-tert-butylphenyl)sodium phosphate nucleating agent in 40ml of absolute ethanol solution, then mix the absolute ethanol solution with octapolymethyl cage silsesquioxane evenly under ultrasonic . The temperature for ultrasonic mixing is 50°C, the time is 120 minutes, the frequency is 35kz, and the power is 100%. The mass ratio of the nucleating agent to POSS is 1:1, and then the mixture of the two is dried at 100°C for 24 hours and passed through a 200-mesh sieve to obtain the cage-type silsesquioxane-supported substituted aryl heterocyclic phosphoric acid The ester or salt nucleating agent is characterized by EDS (X-ray energy spectrometer) to prove that its loading is successful. Such as figure 1 as shown, figure 1 It is an X-ray energy spectrometer (EDS) schematic diagram of the cage silsesquioxane supported substituted aryl heterocyclic phosphate (ester) salt nucleating agent prepared in Example 1 of the present invention. It can be seen from ...

Embodiment 2

[0044] 3g of 2,2'-methylene bis(4,60 di-tert-butylphenyl)phosphate was dissolved in 40ml of anhydrous methanol solution, and then the prepared solution was mixed with octapolyphenyl cage silsesquioxane Mix well under ultrasound. The temperature for ultrasonic mixing is 30°C, the time is 30 minutes, the frequency is 53kz, and the power is 100%. The mass ratio of nucleating agent to POSS is 1:1. Subsequently, the mixture of the two was dried at 100° C. for 24 hours, and passed through a 200 mesh sieve to obtain the cage-type silsesquioxane supported substituted aryl heterocyclic phosphate or salt nucleating agent, which was passed through EDS (X-ray energy spectrometer) to prove its successful loading.

[0045] 0.14 parts by weight of the cage-type silsesquioxane-supported substituted aryl heterocyclic phosphate or salt nucleating agent, 0.1 parts by weight of antioxidant 1010, 0.1 part by weight of antioxidant 168, and 99.66 parts by weight of polypropylene in a twin-screw M...

Embodiment 3

[0047] Dissolve 2g of 2,2'-methylene-bis(4,6-di-tert-butylphenyl)sodium phosphate nucleating agent in 40ml of absolute ethanol solution, and then mix the prepared solution with octaisobutyl The cage silsesquioxane was mixed homogeneously under ultrasound. The temperature for ultrasonic mixing is 40°C, the time is 100 minutes, the frequency is 53kz, and the power is 100%. The mass ratio of the nucleating agent to cage silsesquioxane is 1:7.5. Subsequently, the mixture of the two was dried at 100° C. for 24 hours, and passed through a 400 mesh sieve to obtain the cage silsesquioxane supported substituted aryl heterocyclic phosphate or salt nucleating agent, which was passed through EDS (X-ray energy spectrometer) to prove its successful loading.

[0048] The cage silsesquioxane loaded substituted aryl heterocyclic phosphate or salt nucleating agent 0.34 parts by weight, 0.1 parts by weight antioxidant 1010, 0.1 parts by weight antioxidant 168, 99.46 parts by weight polypropyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com