Patents

Literature

103results about How to "Reduce agglomeration effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prepared reinforced elastomer, elastomer composite and tire having component thereof

InactiveUS6156822AReduction of mixing energySpeed up the processSpecial tyresWheelsPolymer scienceElastomer composites

Preparation of an elastomer which contains a dispersion of filler reinforcement by forming a filler reinforcement in-situ within the elastomer host, the resulting elastomer / filler composite and tire having component which contains such reinforced elastomer. The invention includes a rubber composition of at least two elastomers wherein one of said elastomers is a pre-formed composite of elastomer and in-situ formed filler reinforcement. A tire having a component of such rubber composition, particularly a tire tread, is specifically contemplated.

Owner:THE GOODYEAR TIRE & RUBBER CO

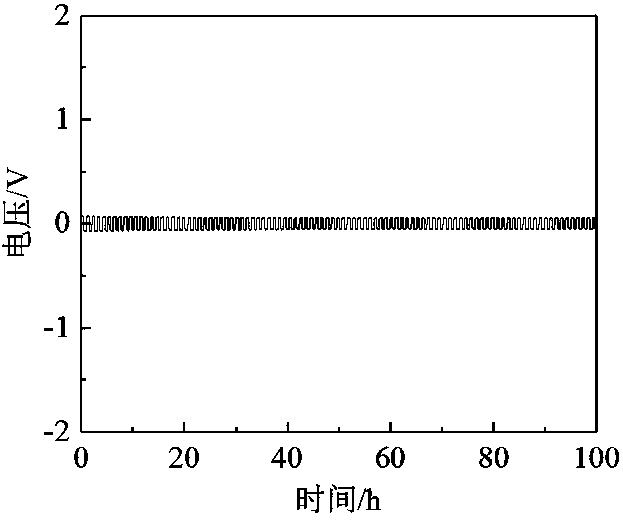

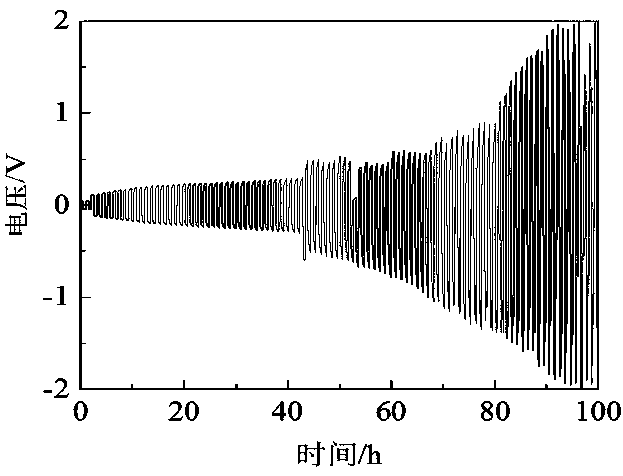

Solid electrolyte membrane as well as preparation process and application thereof

InactiveCN110212241AReduce agglomeration effectGood dispersionFinal product manufactureElectrolytesElectrical resistivity and conductivityInorganic filler

The invention discloses a solid electrolyte membrane as well as a preparation process and an application thereof. The solid electrolyte membrane is prepared from a polymer matrix, a modified inorganicfiller and a lithium salt. The inorganic filler is modified, so that the agglomeration effect of the inorganic filler in an organic solvent can be effectively reduced, and the inorganic solid polymerelectrolyte membrane with high dispersibility is obtained. The surface of the inorganic filler is grafted with a silane coupling agent through covalent bonds, so that the interaction between the polymer matrix and the inorganic filler can be enhanced, the interface affinity between the polymer electrolyte thin film and the electrode material is improved, and the inorganic solid polymer electrolyte membrane which is high in electrical conductivity, low in interface impedance, strong in mechanical property and the like can be obtained. The preparation method has the advantages that materials are easy to obtain, the preparation process is simple, the obtained inorganic solid state polymer electrolyte membrane is excellent in performance, and large-scale preparation is facilitated.

Owner:HARBIN INST OF TECH

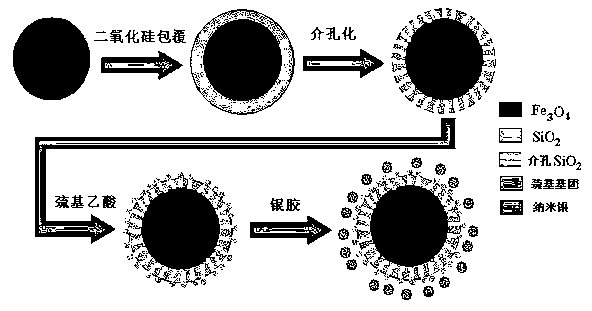

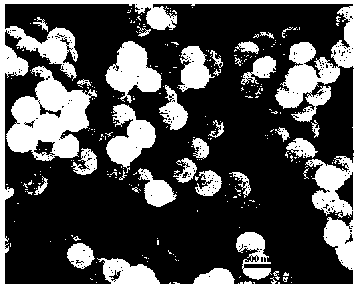

Preparation method of nanosilver and sulfydryl jointly modified magnetic microspheres

InactiveCN103223322AUniform particle size distributionReduce agglomeration effectMicroballoon preparationMicrocapsule preparationChemical reactionMagnetic bead

The invention belongs to the technical field of magnetic materials and in particular relates to a preparation method of nanosilver and sulfydryl jointly modified magnetic microspheres. The preparation method comprises the following steps of: 1) preparing Fe3O4 magnetic microspheres; 2) preparing SiO2 wrapped Fe3O4 magnetic microspheres; (3) preparing sulfydryl modified SiO2 wrapped Fe3O4 magnetic microspheres; and 4) preparing nanosilver and sulfydryl jointly modified SiO2 wrapped Fe3O4 magnetic microspheres. According to the method, nano Fe3O4 is wrapped by a silane coupling agent and the stability and the acid-base resistance are improved due to the safety and the stability of silica; and a functional sulfydryl group is introduced into the surface through chemical reaction, so that novel modified magnetic nanoparticles are obtained. Due to investment and development of biological technology industry, life science and diagnostic reagent industry, the development of biological magnetic bead products with the technological advantage and the cost performance advantage is greatly promoted.

Owner:LUOYANG NORMAL UNIV

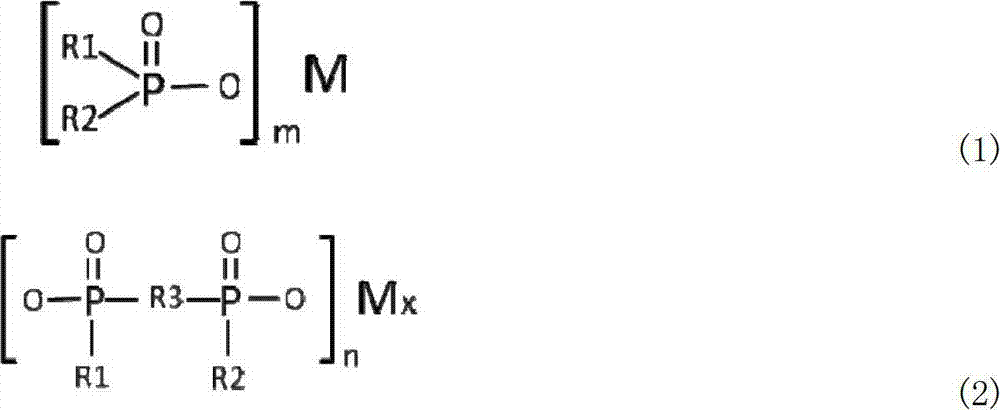

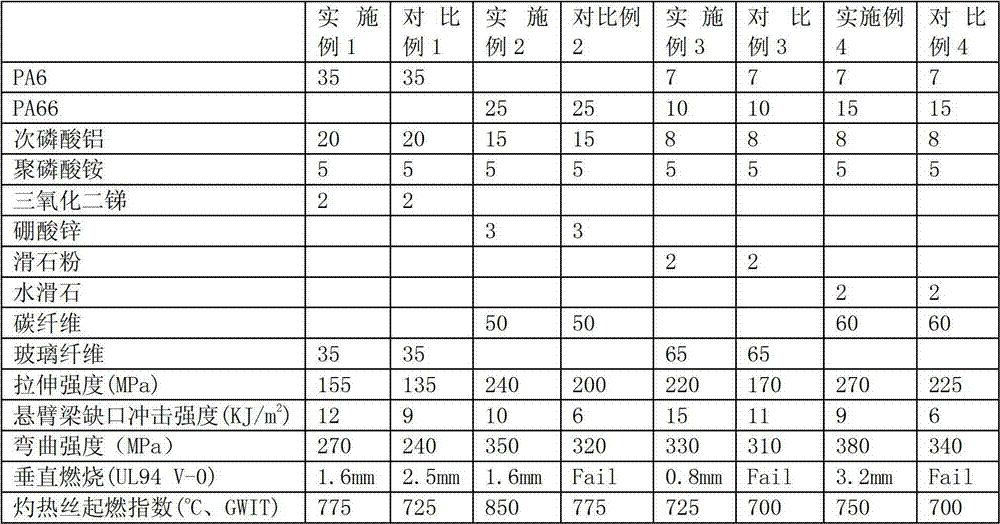

Nylon composition, preparation method and applications thereof

The present invention provides a nylon composition, a preparation method and applications thereof. The preparation method comprises: uniformly mixing a nylon resin, a maleic anhydride copolymer, a halogen-free red and phosphorus-free fire retardation agent, a fire retardation synergist, an antioxidant and a lubricant according to a certain ratio, placing the mixed material in a twin-screw extruder through a main material inlet of the extruder, and placing glass fibers or carbon fibers in the extruder respectively through different side material inlets of the twin-screw extruder. According to the halogen-free and red phosphorus-free fire retardation nylon composition preparation method, the glass fibers or the carbon fibers are added respectively through the different side material inlets of the twin-screw extruder, such that disadvantages of reduced fire retardation, not high strength, not high modulus retention rate and the like due to excessive fiber addition caused by a candlewick effect are overcome compared with the common preparation method, and the method is applicable for fire retardation electronic and electrical product fields with high strength requirements.

Owner:TIANJIN KINGFA NEW MATERIAL +1

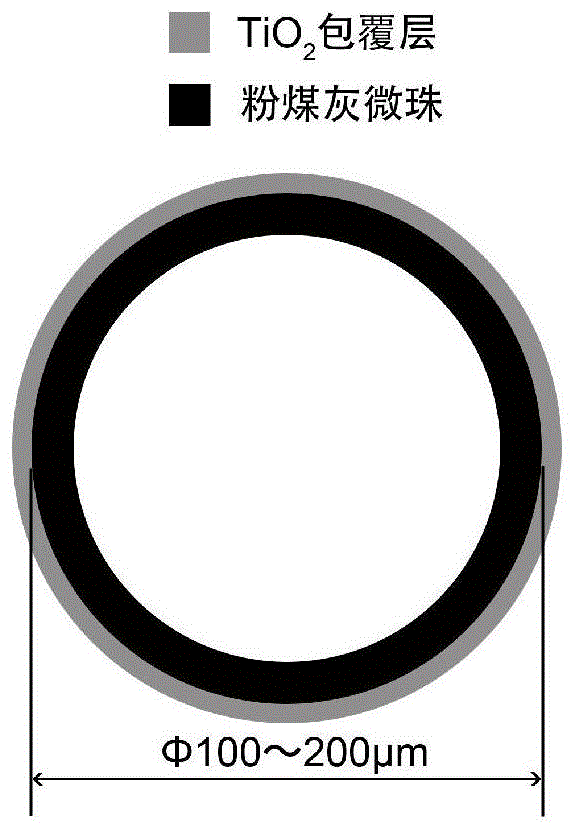

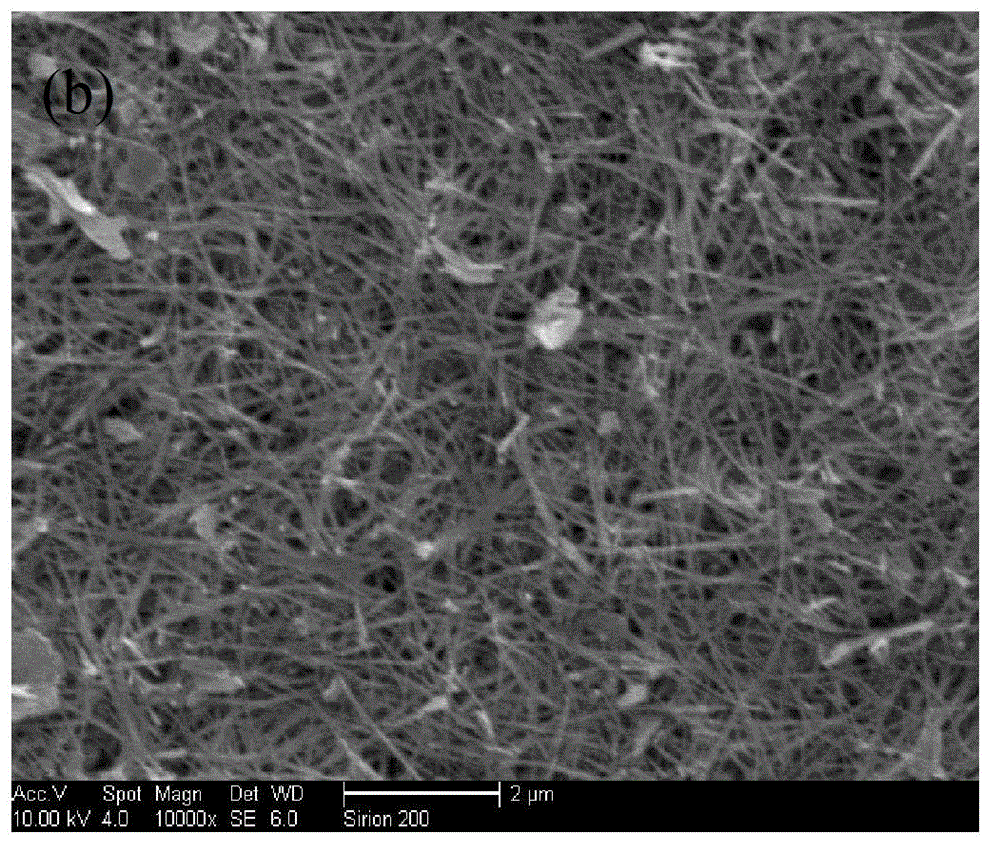

Coal ash microsphere loaded one-dimensional nanometer titanium dioxide (TiO2) composite photocatalyst and preparation method thereof

InactiveCN102872846AFully irradiatedWith heat insulationWater/sewage treatment by irradiationCatalyst activation/preparationLiquid mediumMicrosphere

The invention discloses coal ash microsphere loaded one-dimensional nanometer titanium dioxide (TiO2) composite photocatalyst and a preparation method thereof. The coal ash microsphere loaded one-dimensional nanometer TiO2 composite photocatalyst consists of a coal ash microsphere and a one-dimensional nanometer TiO2 film covered on the surface of the coal ash microsphere, wherein the coal ash microsphere is in a thin-wall hollow structure; the external diameter of the coal ash microsphere is 100-200 micrometers; the thickness of the wall is 2-6 micrometers; the thickness of the one-dimensional nanometer TiO2 film is about 0.5-3 micrometers; and the TiO2 is in the one-dimensional nanometer structure. The composite photocatalyst disclosed by the invention is easy to disperse, recover and use in liquid medium, has a higher reaction activity and has a wide application prospect on the water body purification aspect, and a purpose of effectively removing organic pollutants in the water body can be achieved.

Owner:HEFEI UNIV OF TECH

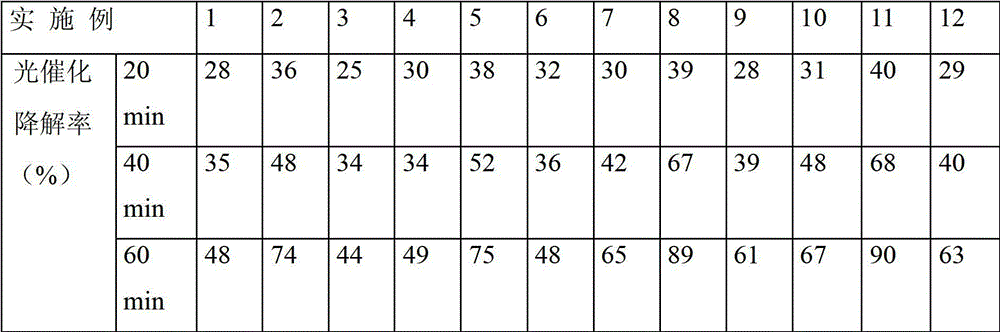

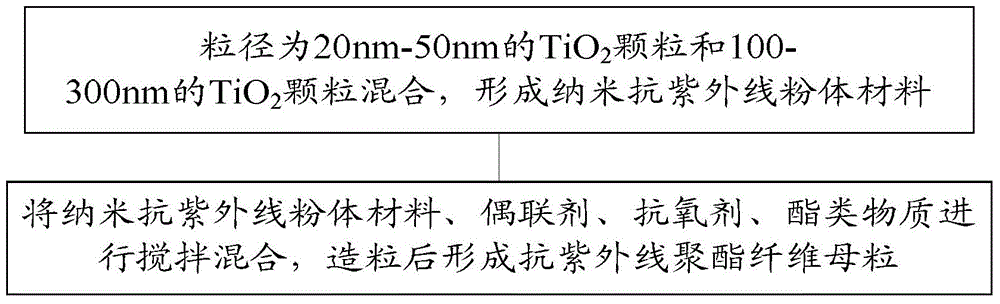

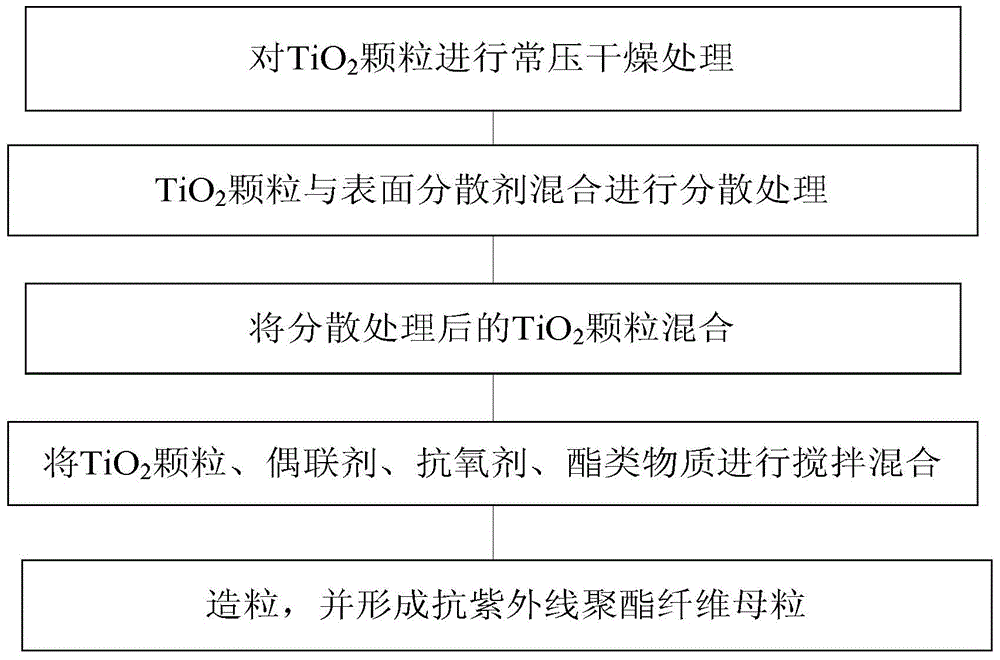

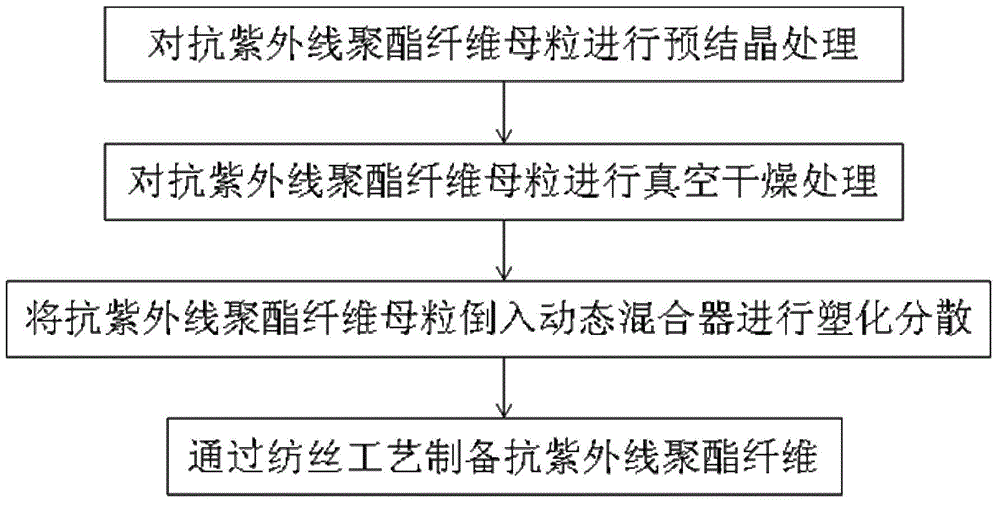

Ultraviolet resistant polyester fiber master batch and preparation method thereof, and production method of polyester fiber containing ultraviolet resistant polyester fiber master batch

ActiveCN103554847AReduce agglomeration effectGood spinning propertiesMonocomponent polyesters artificial filamentArtifical filament manufactureFiberPolyester

The invention provides an ultraviolet resistant polyester fiber master batch and a preparation method thereof, and a production method of polyester fibers. The preparation method of the ultraviolet resistant polyester fiber master batch comprises the following steps of: mixing TiO2 having the particle size ranging from 20nm to 50nm and TiO2 having the particle size ranging from 100nm to 300nm in the mass ratio of (25%-100%): (0%-75%) to form a nanometer ultraviolet resistant powder material; stirring and mixing the nanometer ultraviolet resistant powder material, a coupling agent, an antioxidant and an ester material together in the mass ratio of (20%-30%): (2.7%-2.85%): (0.15%-0.3%): (77%-67%), and then pelleting to form the ultraviolet resistant polyester fiber master batch. The production method of polyester fibers comprises the steps of putting the ultraviolet resistant polyester fiber master batch in a dynamic mixer in spinning equipment and preparing ultraviolet resistant polyester fibers through a spinning process. The production method of polyester fibers provided by the invention is simple and effective, low in cost, and suitable for preparing the ultraviolet resistant polyester fibers on large-scale chemical fiber equipment.

Owner:CHINESE TEXTILE ACAD

Bone repair composite for inducing mesenchymal stem cell differentiation and preparing method of bone repair composite

ActiveCN105999396AGood dispersionReduce agglomeration effectTissue regenerationProsthesisBiological propertyBioactive glass

The invention relates to a bone repair composite for inducing mesenchymal stem cell differentiation and a preparing method of the bone repair composite. The technical problem that existing materials are unsatisfactory in biological property is solved. The bone repair composite is formed by a graphene film and biologically-active glass, wherein the biologically-active glass is uniformly loaded on the surface of the graphene film and is in uniform spherical morphology. The bone repair composite and the preparing method can be applied to the field of bone repair.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

Rubber composition and tire having tread thereof

InactiveUS6160047ALow bulk densityHigh volumeSpecial tyresTyre tread bands/patternsCarbon blackElastomer

A rubber composition as a blend comprised of an elastomer(s), and particulate reinforcement provided as an intimate blend of carbon black particles and fumed silica particles, together with a coupling agent. A tire having a component of such rubber composition such as, for example, a tread, is specifically contemplated.

Owner:THE GOODYEAR TIRE & RUBBER CO

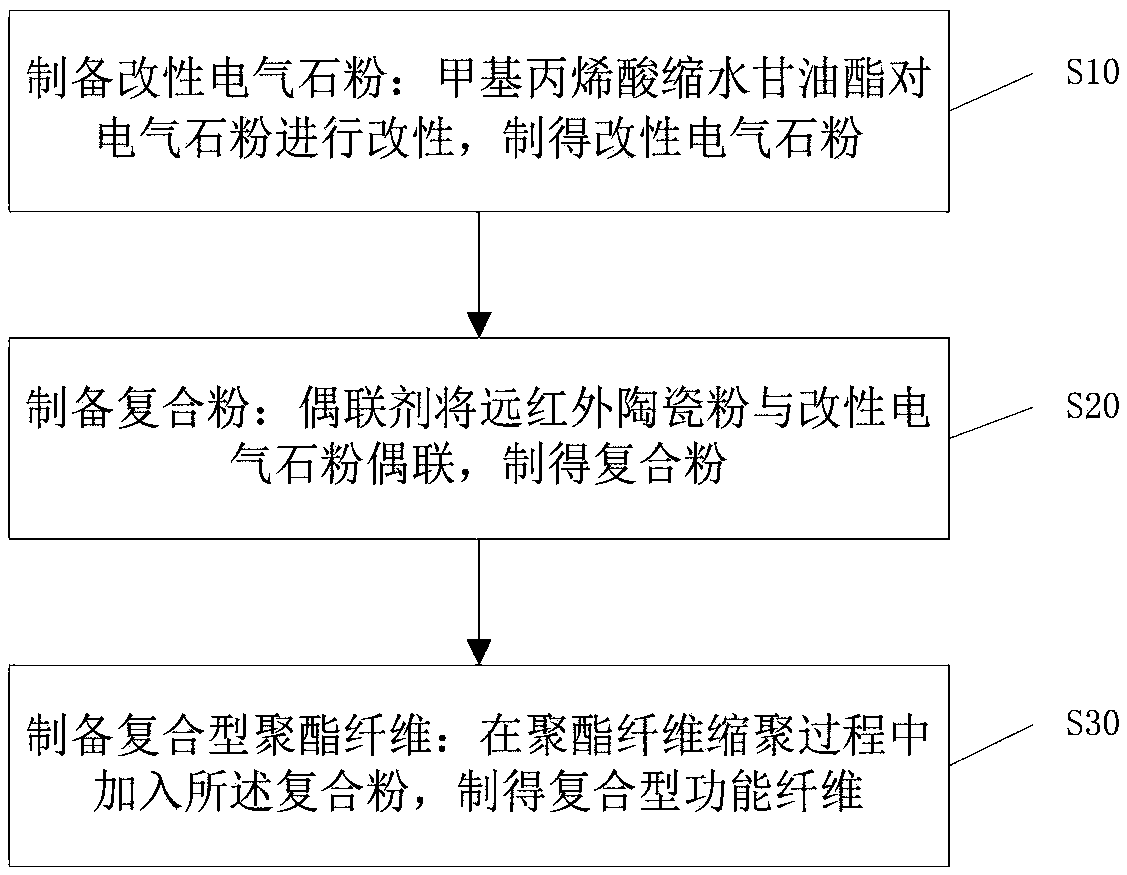

Antibacterial composite functional fiber and preparation method thereof

ActiveCN109295532AReduce agglomeration effectImprove dispersion stabilityMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention relates to the technical field of polyester fiber production, and concretely relates to an antibacterial composite functional fiber and a preparation method thereof. The preparation method comprises the following steps: modifying tourmaline powder with glycidyl methacrylate, coupling the modified tourmaline powder with a far-infrared ceramic powder to prepare a composite powder, andadding the composite powder in a polycondensation reaction of polyester fibers to prepare the composite fiber. The antibacterial composite functional fiber is prepared by the method, and has the composite functions of resisting bacteria, releasing negative ions and emitting far infrared rays. The tourmaline powder is modified to effectively reduce the coagulation effect of the tourmaline powder inthe fiber preparation process, increase the dispersion stability of the tourmaline powder and solve the problem of difficult spinning formation and the problems of uneven distribution and poor mixingeffect of the tourmaline powder in the fiber.

Owner:HEYE HEALTH TECH CO LTD

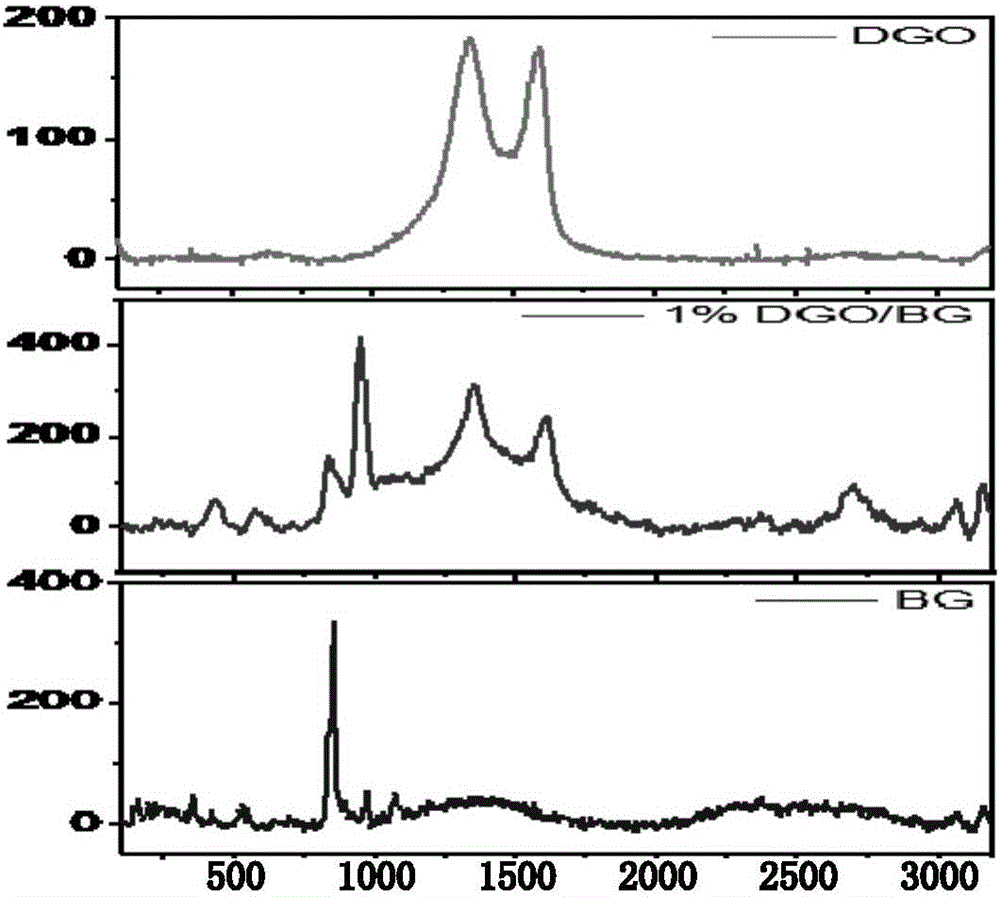

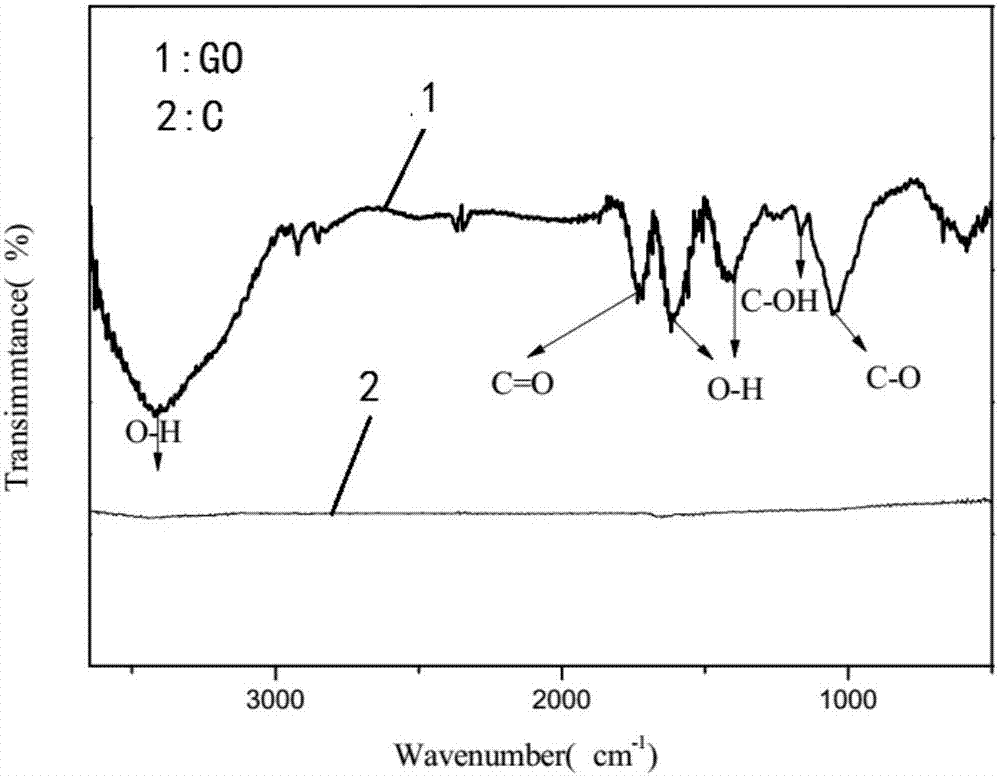

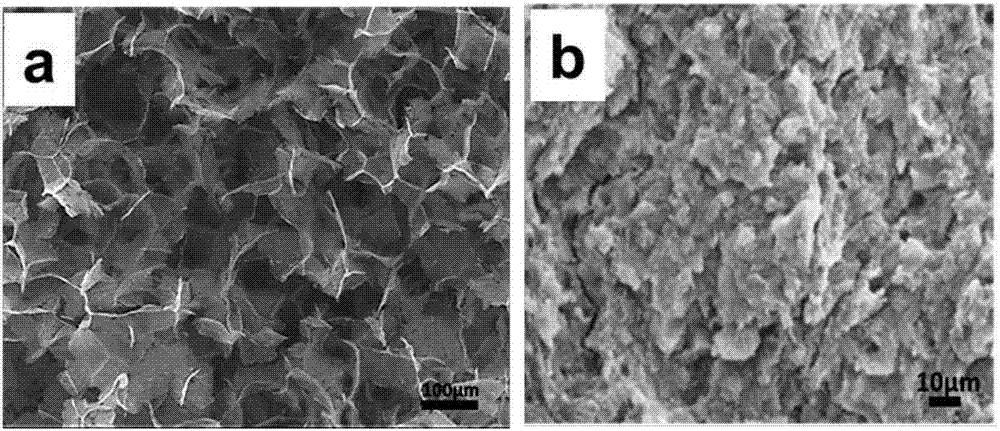

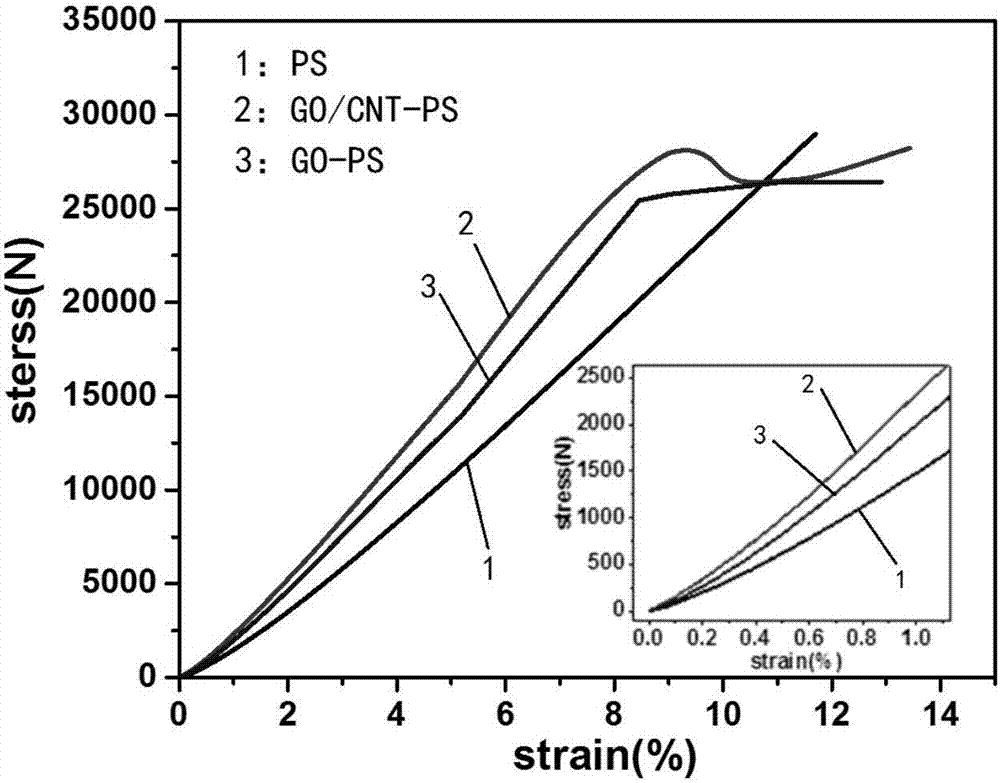

High-performance carbon nano-tube/graphene oxide aerogel/polystyrene composite material and preparation method thereof

The invention discloses a preparation method of a high-performance carbon nano-tube / graphene oxide aerogel / polystyrene composite material. The method includes the steps: firstly, preparing graphene oxide suspension liquid by an improved Hummers method, and performing mixing and freeze drying on the prepared graphene oxide suspension liquid and carbon nano-tubes to prepare carbon nano-tube / graphene oxide aerogel; secondly, filling gaps of the aerogel with mixtures with styrene monomers by a vacuum-assisted impregnation method, and performing in-situ polymerization reaction to obtain a carbon nano-tube / graphene oxide / polystyrene composite material; finally, performing heat treatment on the obtained composite material. The preparation method is simple in process and green and environmentally friendly in process, prepared framework aerogel has the advantages of low density, high porosity and the like, the aerogel and polystyrene are compounded to obtain the composite material, and the composite material has higher strength and modulus as compared with pure polystyrene.

Owner:QINGDAO UNIV

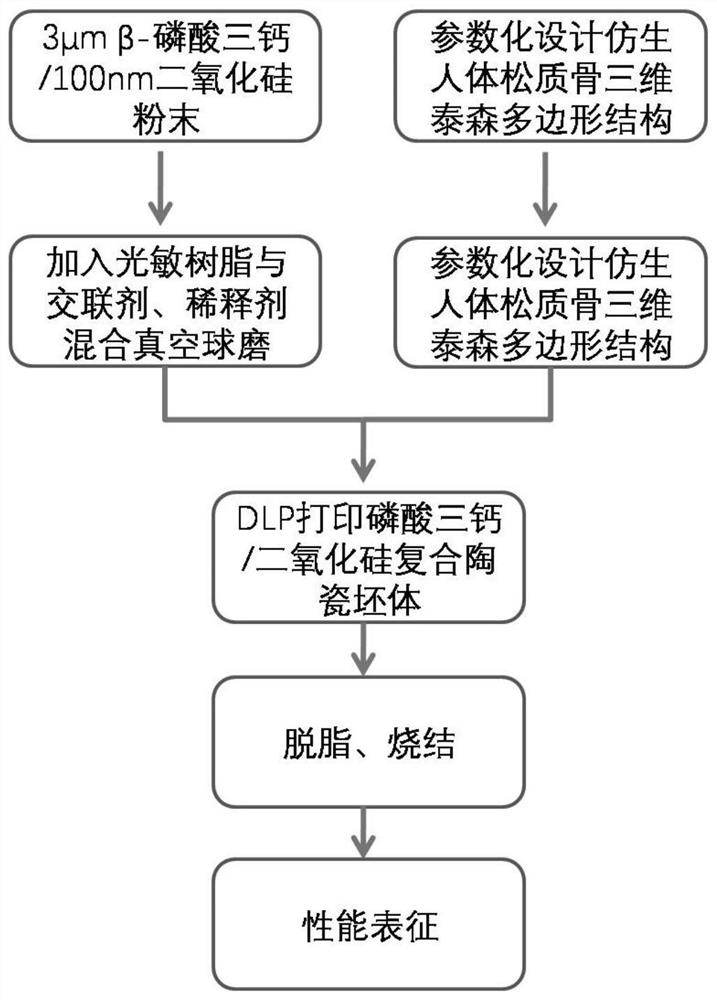

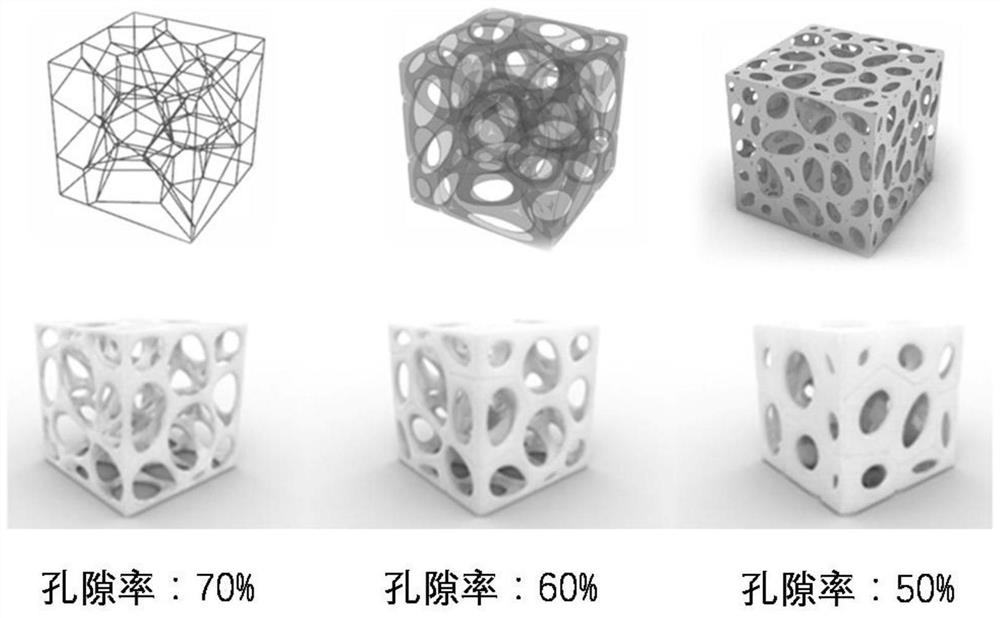

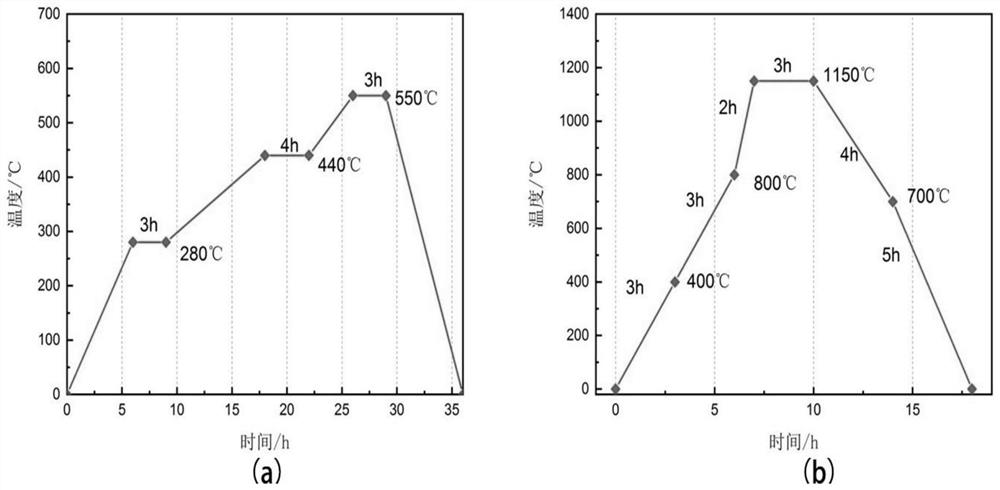

Preparation method of light-cured 3D printing Thiessen polygon bionic structure tricalcium phosphate/silicon dioxide composite biological ceramic

InactiveCN111825443AImprove crystal qualityMeet the mechanical performance requirements of cancellous boneAdditive manufacturing apparatusAuxillary shaping apparatus3d printHuman body

The invention discloses a preparation method of a light-cured 3D printing Thiessen polygon bionic structure tricalcium phosphate / silicon dioxide composite biological ceramic, and belongs to the fieldof 3D printing ceramic and bionic structure design. The composition provided by the invention is prepared from tricalcium phosphate powder with an average particle size of 30-50microm, silicon dioxidepowder with a particle size of less than or equal to 100nm, 405nm waveband photosensitive resin, a cross-linking agent 3, 3-dimethylacrylic acid resin and a diluent polypropylene glycol according toa certain ratio. Through the printing forming and degreasing sintering process, the tricalcium phosphate / silicon dioxide bionic porous biological ceramic bone tissue engineering scaffold with compactgrain combination, porosity adjustable between 50% and 80% and compression resistance between 3MPa and 8MPa can be obtained, meets the compressive property requirement of human body cancellous bone and has the structural characteristic of bionic human body cancellous bone.

Owner:BEIJING UNIV OF TECH

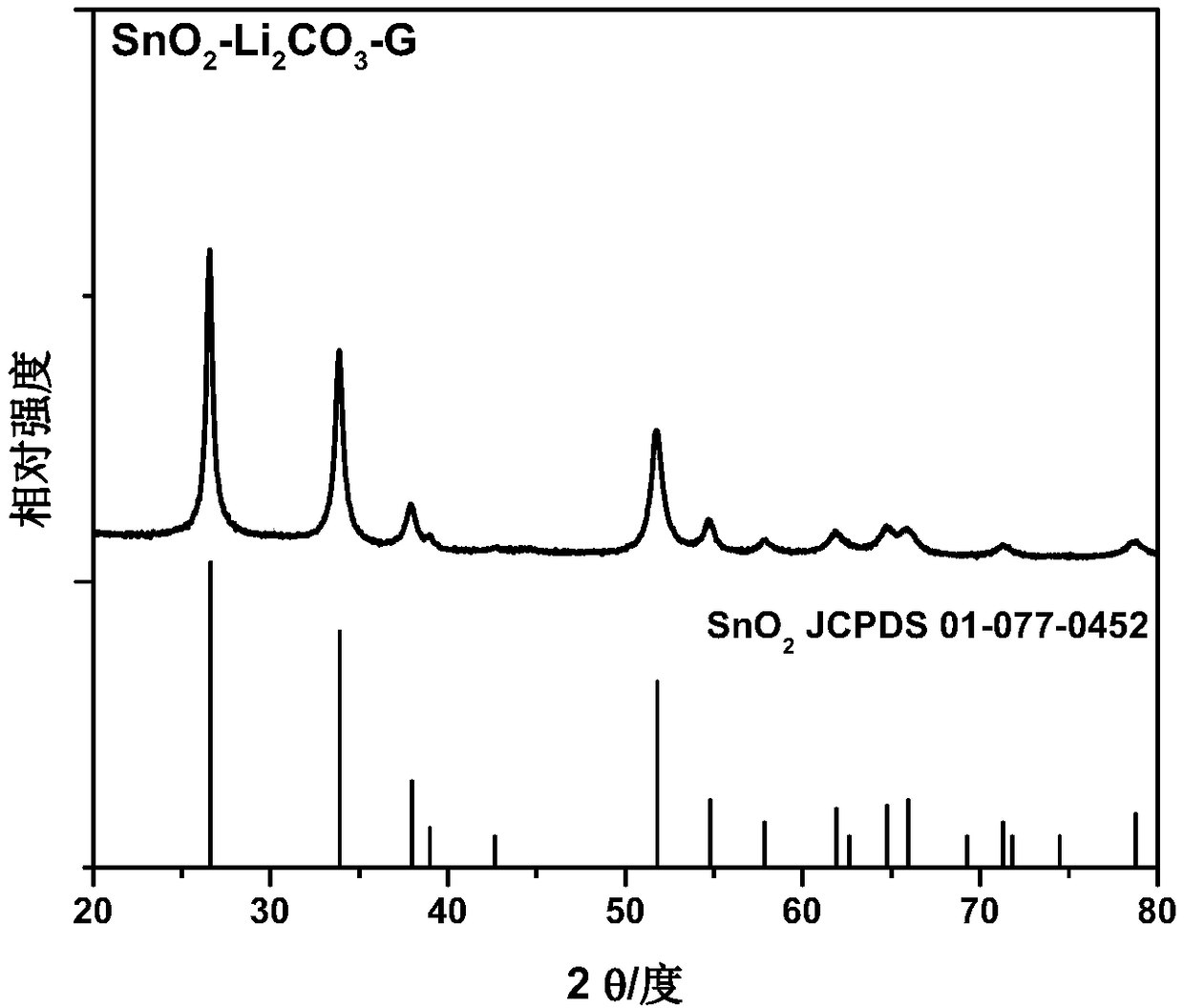

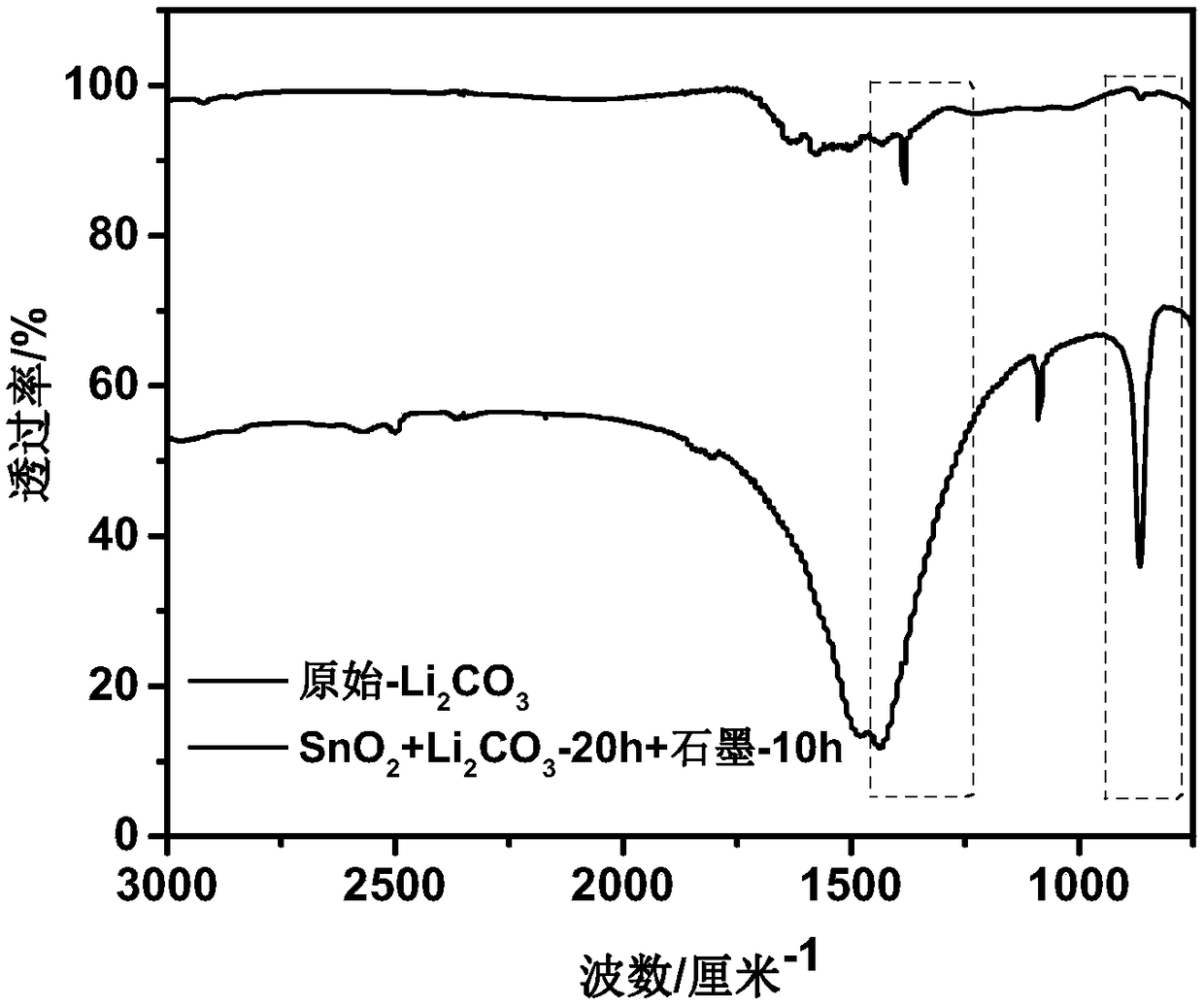

Pre-lithiatedanode material with high reversible capacity and preparation method of pre-lithiatedanode material

InactiveCN109411717AEasy to separateGood effectNegative electrodesSecondary cellsLithium carbonateGraphite

The invention relates to a pre-lithiatedanode material with the high reversible capacity and a preparation method of the pre-lithiatedanode material. The pre-lithiatedanode material comprises a graphite-like carbon material, metallic oxide or silicon uniformly distributed on the pre-lithiatedanode material, and lithium carbonate; the first coulomb efficiency of the anode material is 5%-10% higherthan that of the corresponding pure metallic oxide or silicon anode material, and the capacity retention rate of the anode material is no less than 85% after cycling for 100-350 times. The preparationmethod includes the steps that the metallic oxide or silicon powder, lithium carbonate powder, the graphite-like carbon material and a grinding agent are stirred,mixed and subjected to ball-milling.According to the pre-lithiatedanode material with the high reversible capacity and the preparation method of the pre-lithiatedanode material, by adding the lithium carbonate, the irreversible capacityof the anode material in the initial charging and discharging process is lowered, and thus the first coulomb efficiency is improved; by adding the graphite-like carbon material, structural stabilityof the material in the reaction process and conductivity of an electrode material are improved; and according to the ball-milling method, the size of the anode material particlescan be refined in a short time, and the volume change of the anode material is buffered.

Owner:SOUTH CHINA UNIV OF TECH

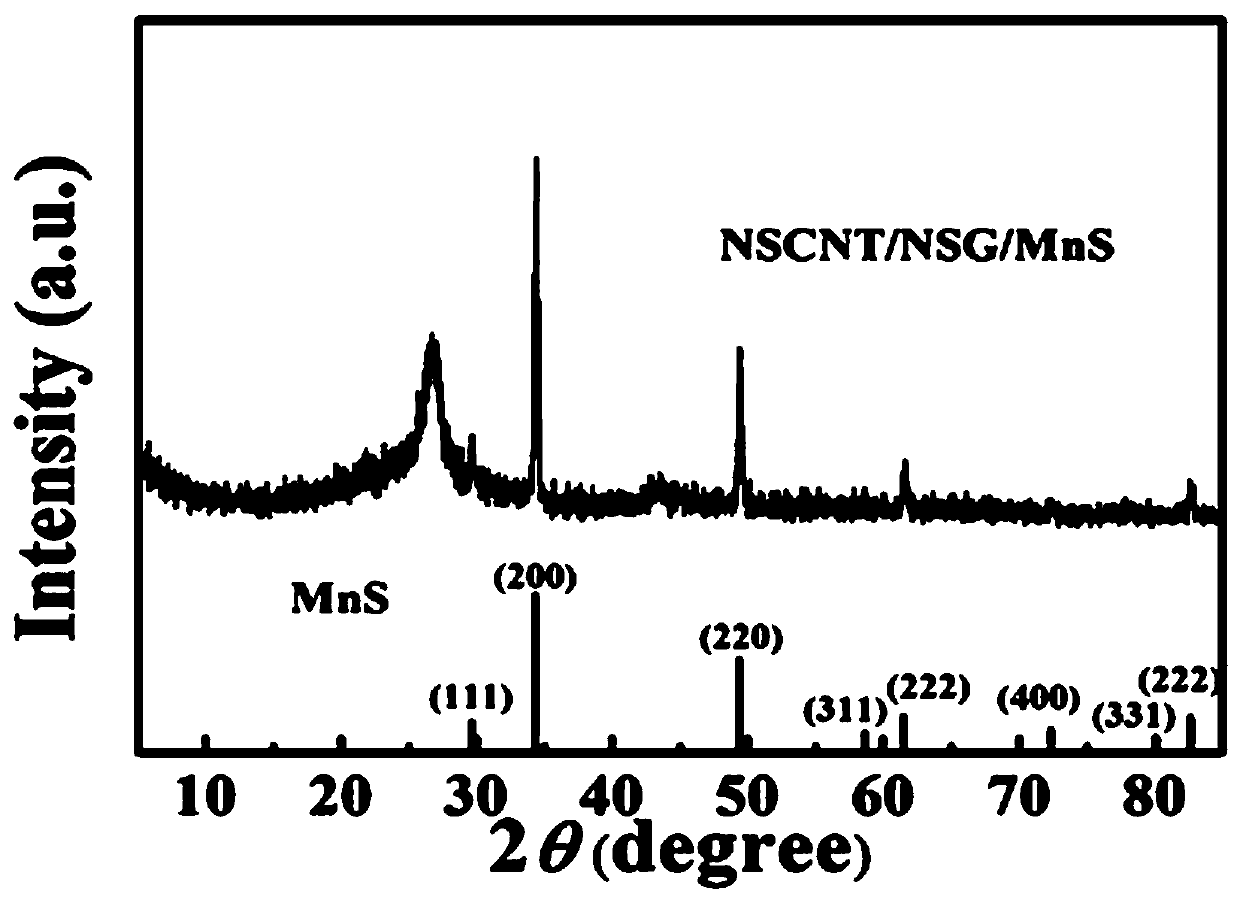

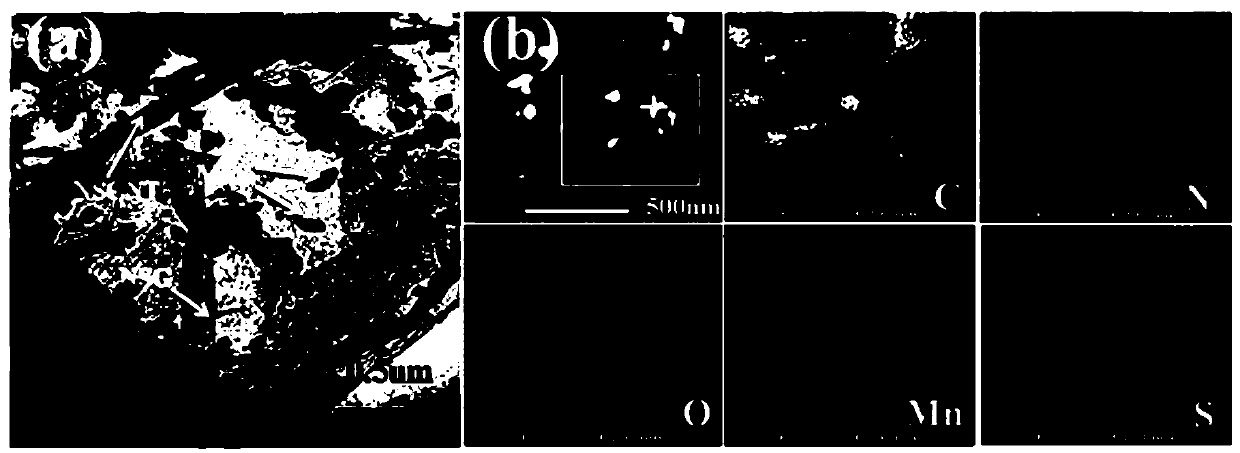

Doped-type carbon/manganese sulfide composite material preparation method

ActiveCN110474050ASimple preparation processIncrease profitMaterial nanotechnologySecondary cellsStrong acidsReducing agent

The invention relates to the manganese sulfide composite material technology field and especially relates to a doped-type carbon / manganese sulfide composite material preparation method. The method comprises the following steps of dissolving inorganic nitrate in an acid solution containing a concentrated sulfuric acid, and then adding an original carbon material and permanganate separately to carryout an oxidation reaction; after the reaction is finished, successively adding a reducing agent and a non-oxidizing strong acid to the reaction solution, thoroughly stirring and then carrying out static layering to obtain a lower layer precipitate; and adding a heteroatom-containing molecular source to the precipitate, carrying out high-temperature heat treatment and finally preparing a doped-type carbon / manganese sulfide composite material. The method has advantages that based on a raw material optimum utilization idea, in a carbon material oxidizing and doping process, manganese / sulfur particles remaining in the oxidation reaction of the carbon material are fully used, and the doped-type carbon / manganese sulfide composite material is obtained through direct heat treatment so that resource wastes and environmental pollution are reduced; and during a whole preparation process, a technology is simple, a reaction raw material utilization rate is high, components of the composite material are uniformly dispersed and quality is better.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Preparation method of nano silicon dioxide reinforced nylon 6 composite

The invention belongs to the technical field of polymeric nanocomposites and particularly relates to a preparation method of a nano silicon dioxide reinforced nylon 6 composite. The preparation method comprises the following steps: through a sol-gel reaction process of silicate compounds, performing hydrolysis, dehydration and condensation polymerization of the silicate compounds in the presence of a catalyst to generate nanoscale silicon dioxide in situ; performing ring-opening hydrolysis and condensation polymerization of caprolactam to obtain a precursor of certain molecular weight; adding a chain extender and a molecular weight regulator; and preparing an in-situ nano silicon dioxide reinforced nylon 6 composite by a reactive extrusion method of a twin-screw extruder. In the invention, the problem of dispersion of nanoscale additives in a polymer melt is solved, so the molecular weight of nylon 6 is adjustable; and the nanoparticle reinforced nylon 6 composite has excellent comprehensive performance and good industrial application prospects.

Owner:GUANGDONG JUHANG INST FOR ADVANCED MATERIALS CO LTD +1

Modified red mud for coating and preparation method of modified red mud

ActiveCN110079130AReduce manufacturing costReduce occupancyFireproof paintsPowdery paintsRed mudFilter press

The invention discloses a preparation method of modified red mud for a coating. The preparation method comprises the following steps: firstly, washing the red mud, detecting a pH value of the washed red mud, carrying out filter pressing treatment to obtain clean red mud and drying the clean red mud; secondly, carrying out superfine grinding on the dried clean red mud and sieving to obtain clean red mud powder; thirdly, adding a modifier I into the clean red mud powder, controlling the temperature and the speed, and stirring to obtain a mixture I; fourthly, adding the mixer I and the modifier II into a stirrer, controlling the temperature and the speed, and stirring to obtain a mixer II; fifthly, drying the mixture II, then carrying out superfine grinding and sieving to obtain the modifiedred mud for the coating. According to the preparation method disclosed by the invention, the red mud is modified, then is filled into the coating for preparing indoor powder as filler and reaches thefilling volume as high as 48.3 percent or above; compared with filler such as conventional barium sulfate, the modified red mud has good filling performance and high filling volume, so that the production cost can be greatly reduced.

Owner:广西福宝信科技有限公司

Preparation method for polyimide three-layer composite film with electromagnetic shielding function

InactiveCN106939518AWith electromagnetic shielding functionReduce agglomeration effectFilament/thread formingNon-woven fabricsComposite filmElectrospinning

The invention provides a preparation method for a polyimide three-layer composite film with an electromagnetic shielding function. When carbon nanotubes are employed for modification of a polyimide film, the resistivity of the polyimide film can be effectively reduced; however, with increase of the content of the carbon nanotubes, the carbon nanotubes are substantially agglomerate in polyimide, which leads to drastic decrease of the mechanical properties of the polyimide film. The preparation method provided by the invention comprises the following steps: (1) preparation of a carbon nanotube-modified polyamide acid solution; (2) preparation of a carbon nanotube-modified polyamide acid microporous film by using an electrostatic spinning method; (3) preparation of a polyamide acid solution; (4) coating of two sides of the microporous film with the polyamide acid solution; and (5) thermal imidization of a prepared carbon nanotube-modified polyimide acid three-layer composite film. The polyimide three-layer composite film prepared in the invention is mainly applied to broaden the application scope of polyimide films in the field of electromagnetic shielding materials.

Owner:HARBIN UNIV OF SCI & TECH

Modifier I and method of applying the same in preparation of coating

ActiveCN110093095AReduce agglomeration effectHigh glossPowdery paintsEpoxy resin coatingsEpoxyAdhesion force

The invention discloses a modifier I, which is composed of diethanolamide stearic acid monoglyceride and N,N'-ethylenebis[N-(sodium ethylenesulfonate)-dodecanamide]; and a method of applying the samein preparation of coating. The method includes adding the modifier I into clean red mud powder, stirring the mixture at a controlled temperature in a controlled speed to obtain a mixture I, subjectingthe mixture I to a second time of modification to obtain a mixture II, and applying the mixture II to preparation of indoor powder coating after the mixture II is dried and crushed. The diethanolamide stearic acid monoglyceride and N,N'-ethylenebis[N-(sodium ethylenesulfonate)-dodecanamide] are utilized for surface modification of the red mud so as to introduce long-chain fatty acid, amino, sulfoand other groups onto the surfaces of red mud particles, thus improving dispersibility and processing fluidity of the modified red mud powder, allowing the modified red mud to be more compatible withother raw materials of the coating such as epoxy resin and polyester resin, improving adhesion force of a coating layer interface, and further improving coating film apparent performance and gloss ofthe indoor powder coating.

Owner:广西福宝信科技有限公司

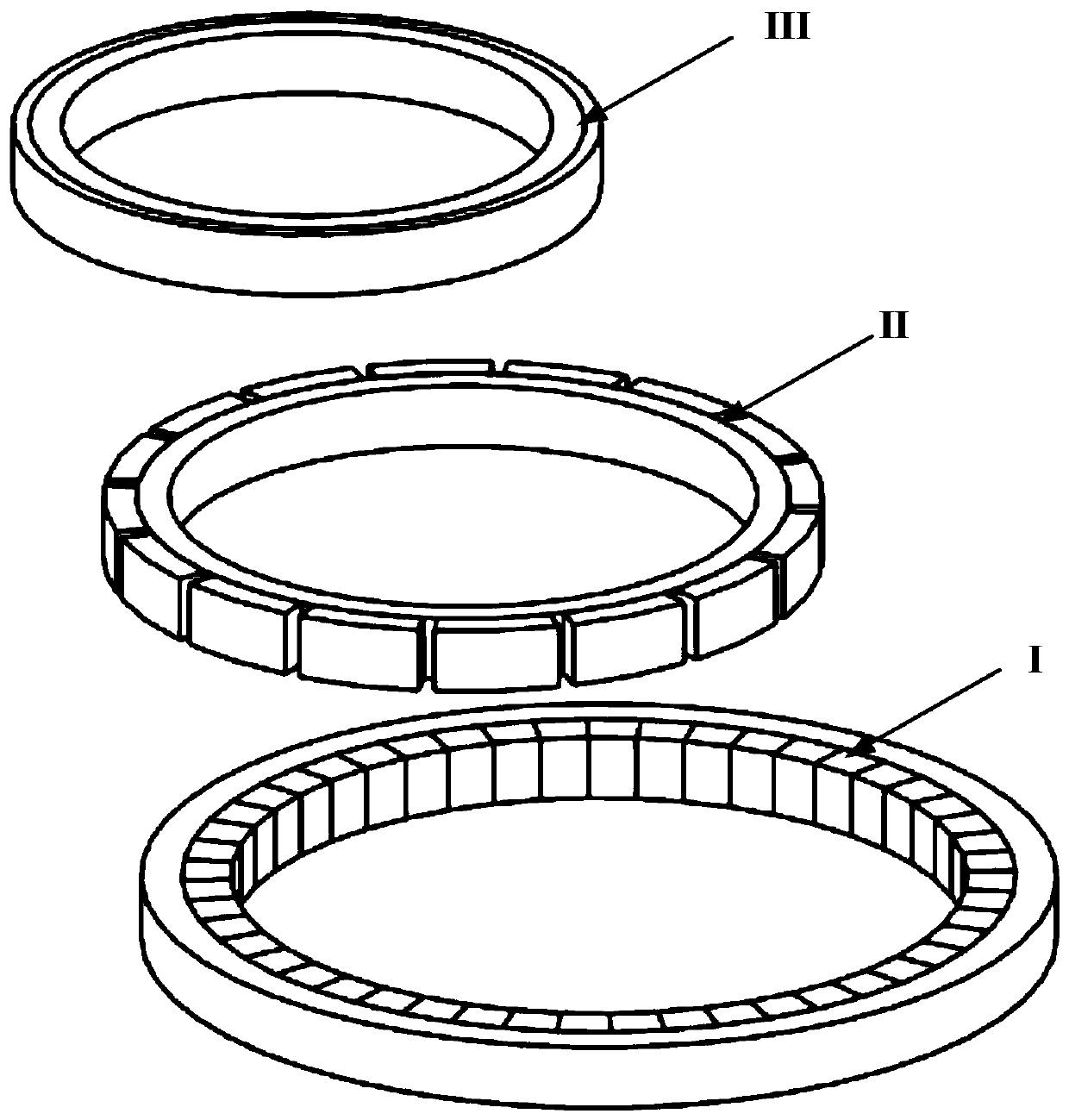

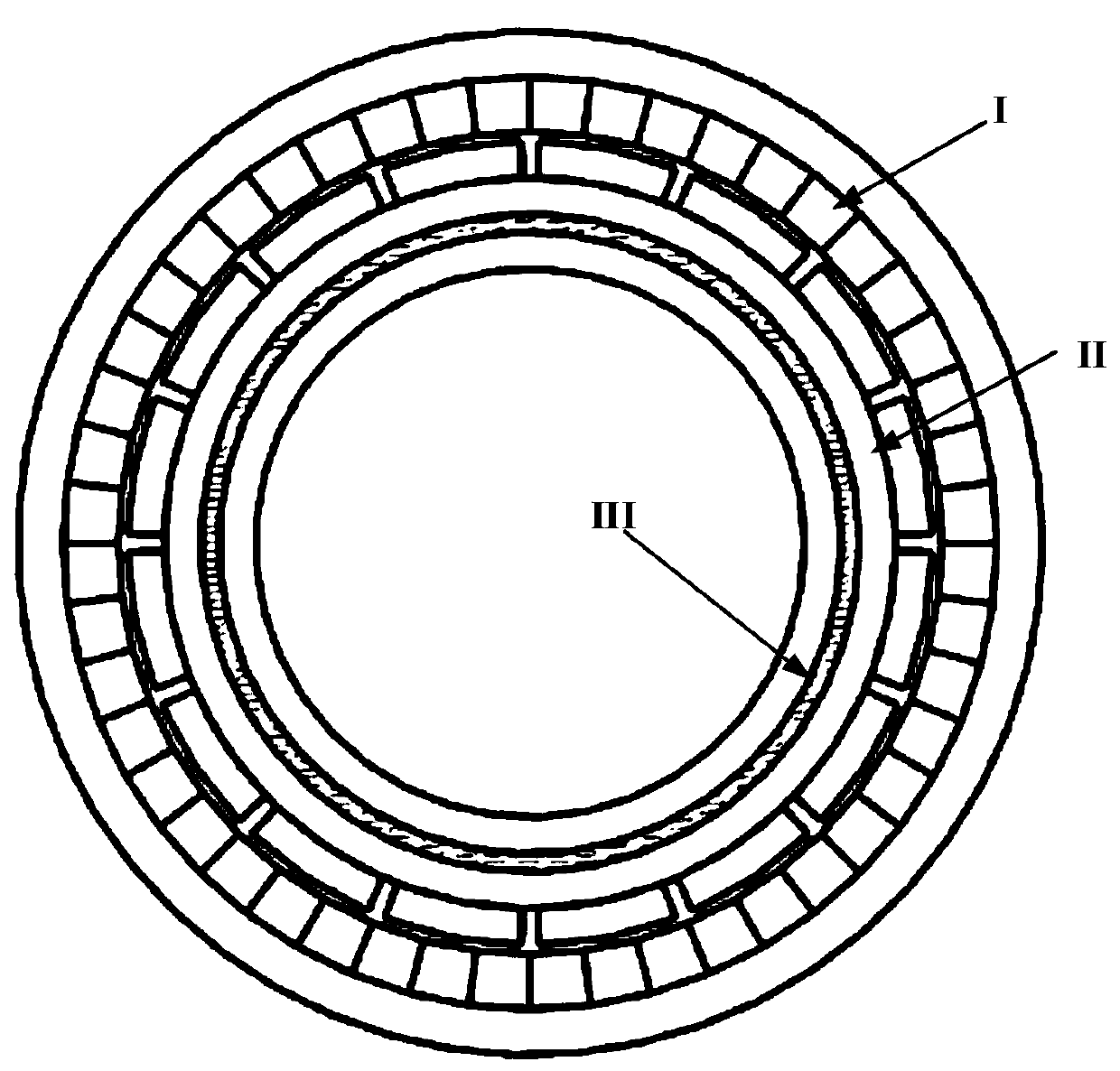

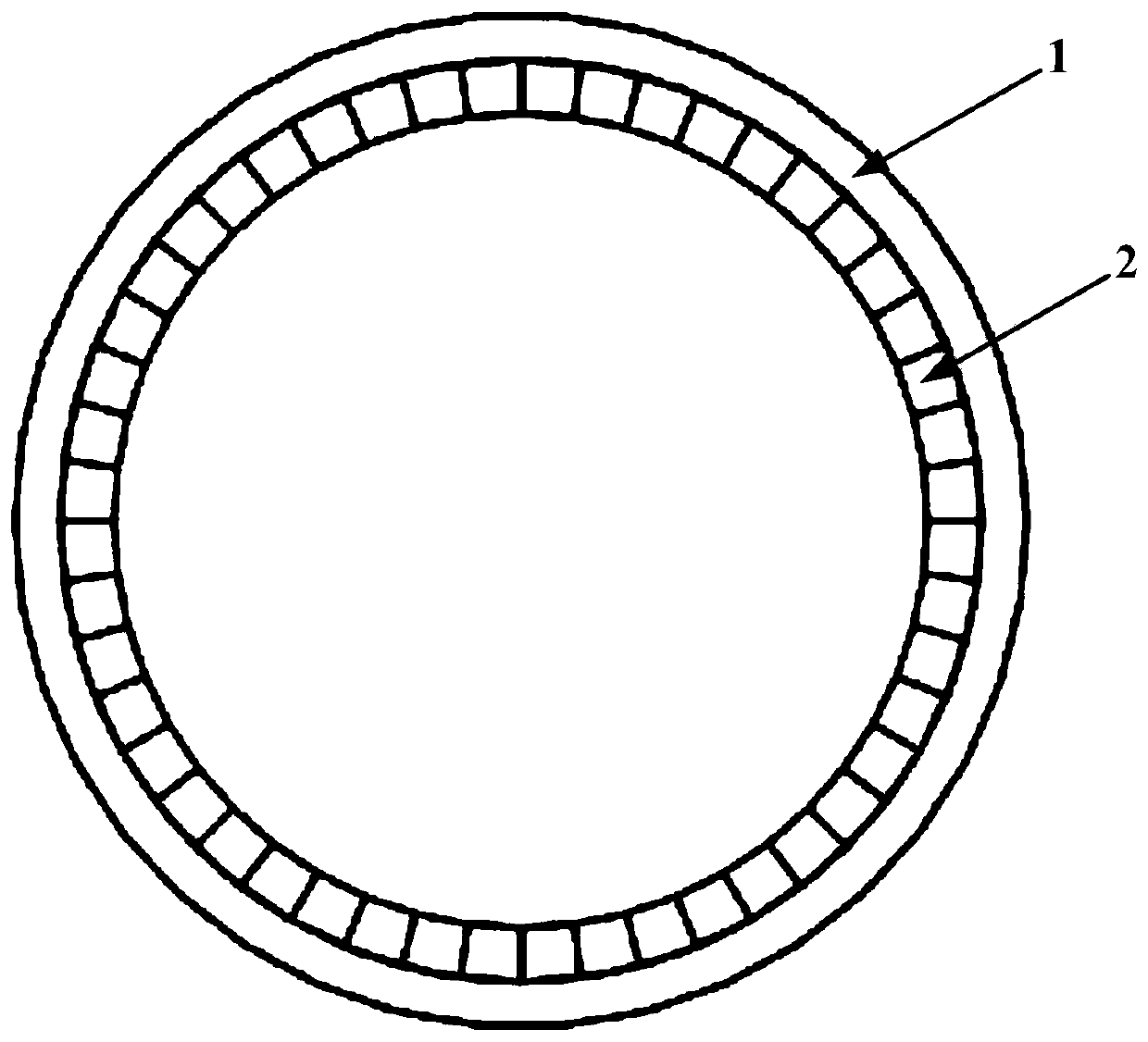

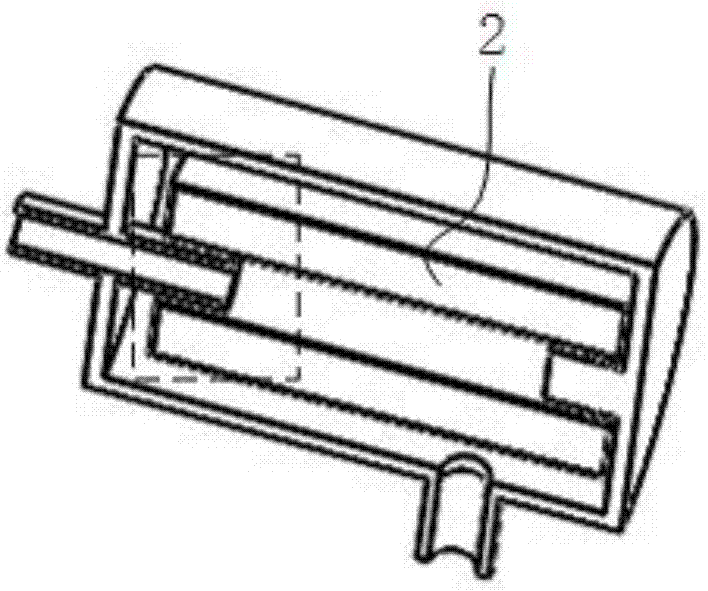

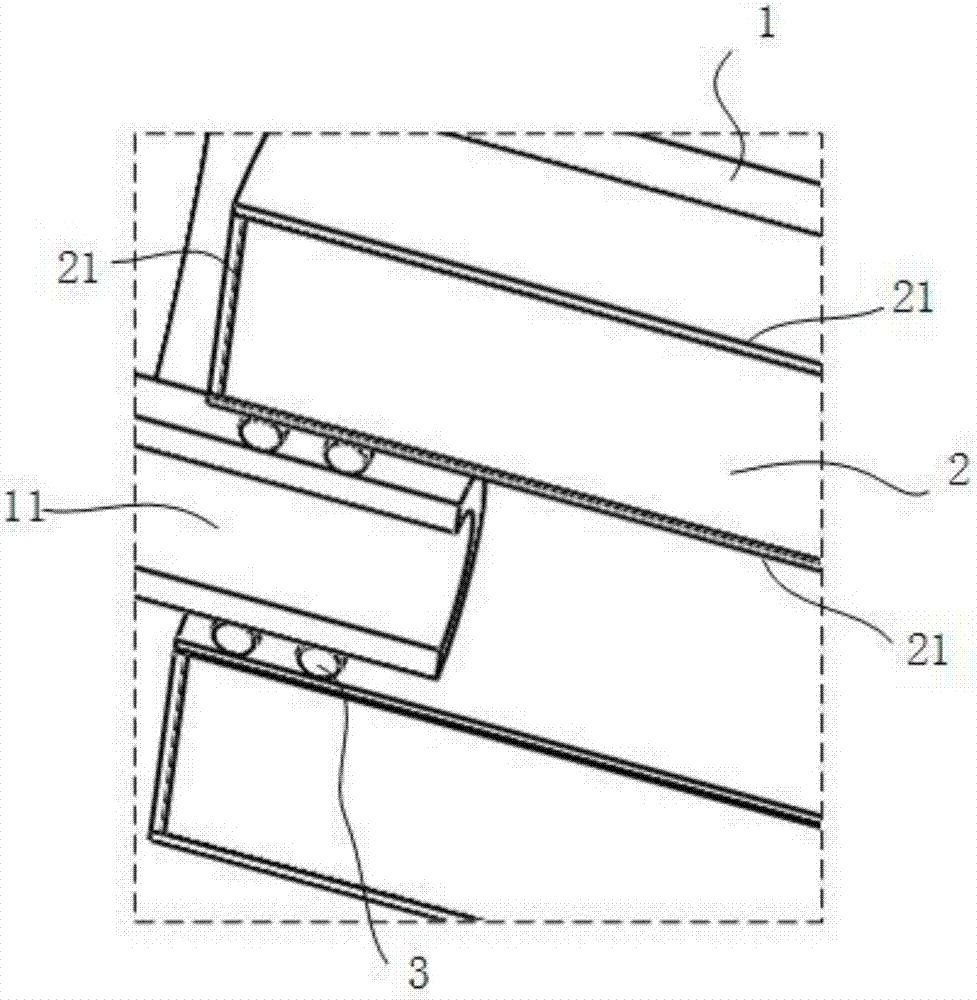

Wheel motor driver integrated with magnetofluid brake

ActiveCN110714997AReduce torque fluctuationReduce agglomeration effectLiquid resistance brakesMechanical energy handlingStator coilElectric machinery

The invention discloses a wheel motor driver integrated with a magnetofluid brake. The wheel motor driver comprises a stator (I), a rotor (II) and a magnetofluid structure (III). The stator (I) is located on the outermost circle, the magnetofluid structure (III) is located in the middle, and the rotor (II) is located between the stator (I) and the magnetofluid structure (III). A permanent magnet is composed of a hard magnetic material and a soft magnetic material. The direction change of the magnetic field of the soft magnetic material can be controlled through pulse currents of a stator coil,and the normal operation mode of a motor and the damping operation mode of the magnetofluid brake are switched. The magnetofluid part is located on the other side of the main rotor to form the similar single-stator double-rotor structure, and the magnetofluid changes the fluid characteristics under the common effect of a magnet and the magnetic field of the magnetic coil and has the damping and braking effects. By means of the whole novel motor, the integrated design and control of the active damping brake and the wheel motor are realized, and the number of parts and the weight and size of awhole system are reduced.

Owner:SOUTHEAST UNIV

Production process for preparing alkali cementing material from coal gangue

The invention relates to the field of solid waste resource utilization, and provides a production process for preparing an alkali cementing material from coal gangue, which comprises the following steps: (1) crushing, ball-milling and sieving coal gangue to obtain coal gangue powder; (2) putting the coal gangue powder into the mixed acid solution, uniformly stirring, standing for several days, carrying out suction filtration, and drying; (3) mixing the coal gangue powder obtained in the step (2) with salty mud, calcining at high temperature, cooling, carrying out secondary ball milling, and sieving to obtain mixed powder; (4) weighing the following raw materials in parts by weight: 50-80 parts of the mixed powder, 20-40 parts of slag powder, 4-8 parts of an exciting agent and 24-36 parts of water; (5) uniformly mixing the raw materials to obtain alkali gelling slurry; and (6) injecting the alkali gelling slurry into a mold, carrying out vibration molding, curing at normal temperature until demolding, and carrying out steam curing at 66-72 DEG C for 8 hours. According to the preparation method, the problems of resource waste and environmental pollution of the coal gangue waste are solved, and the alkali cementing material with excellent performance is prepared.

Owner:王庆乐

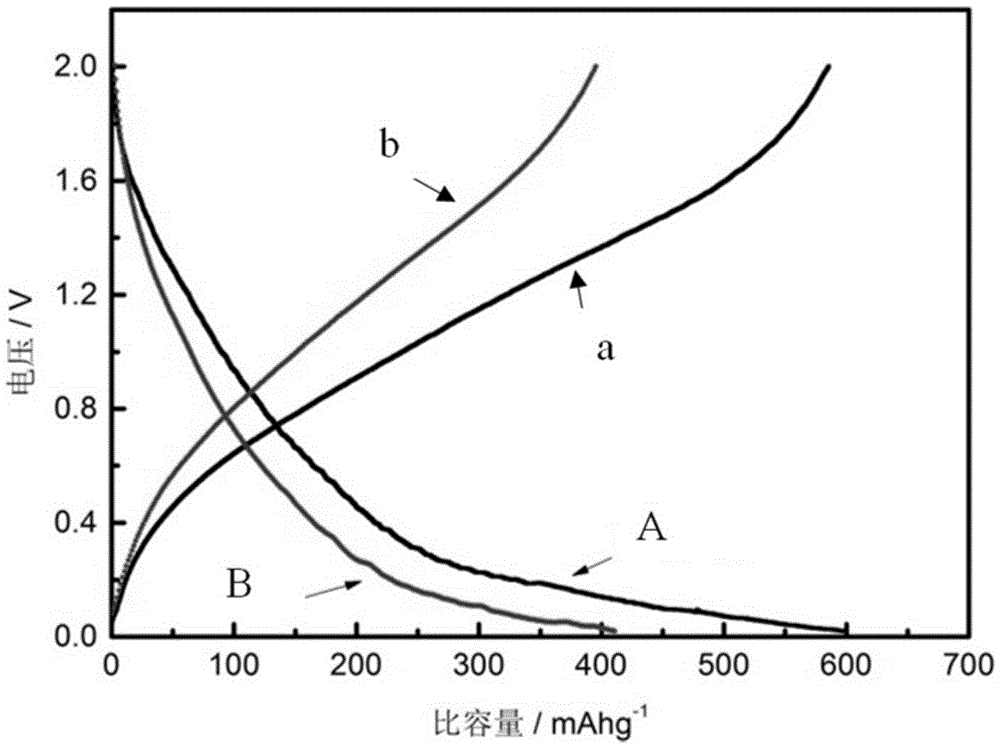

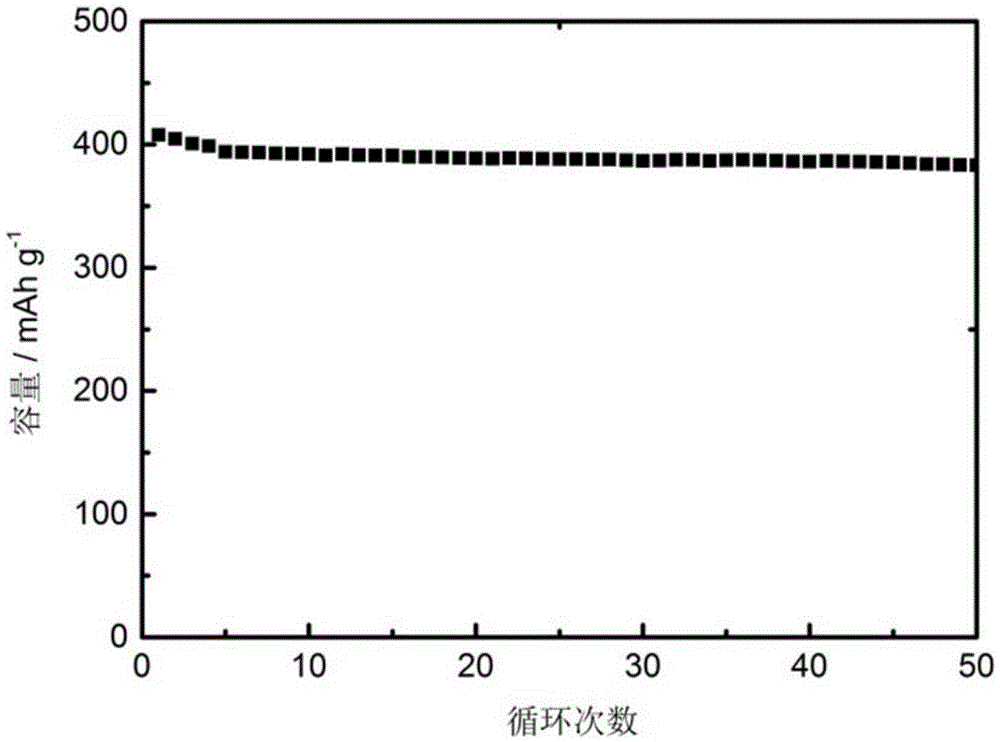

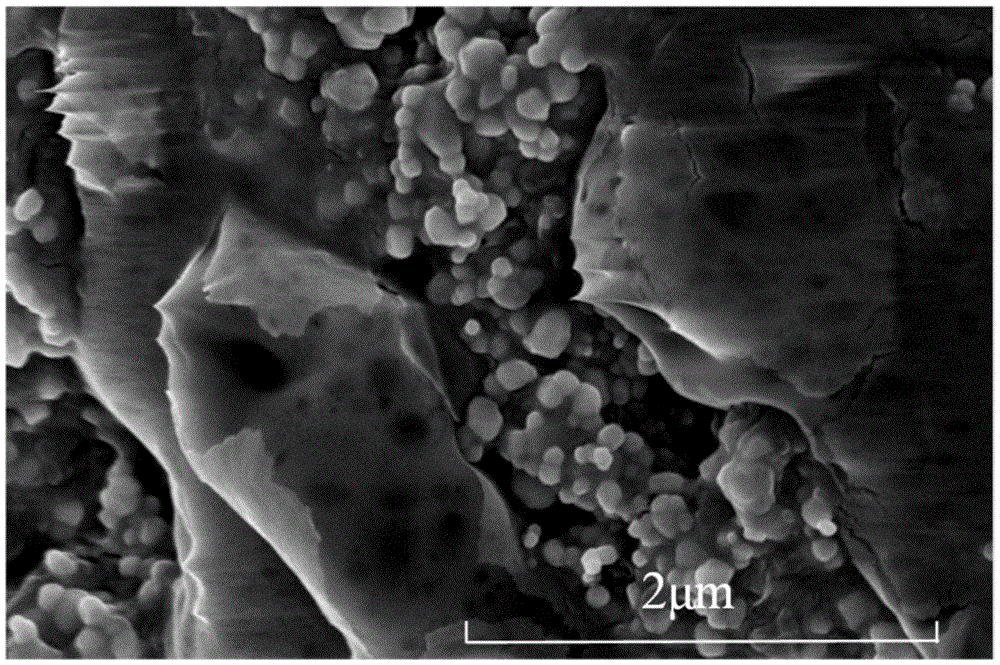

Negative material for sodium-ion battery and preparation method for negative material and sodium-ion battery

ActiveCN105552347ARandom combinationTaking into account the cycle performanceCell electrodesSecondary cellsCharge dischargeAlloy

The invention discloses a negative material for a sodium-ion battery and a preparation method for the negative material and the sodium-ion battery. The method comprises the steps as follows: a precursor is cooled in a reducing atmosphere after being sintered; the precursor is a solid obtained by mixing and reacting of a mixed solution containing graphene, titanium dioxide, a tin salt and a copper salt and a precipitant; the molar ratio of a tin element to a copper element to a titanium element is x to (1-x) to 1; and x is less than or equal to 0.5 and more than 0. The preparation method disclosed by the invention is simple and convenient. According to the prepared material, various raw material components cooperate with one another, so that the aggregation effect of tin-copper particles is effectively reduced; the volume effect of an alloy formed by tin and sodium in the discharge process is suppressed; the cycle performance, the stability, the conductivity and the charge-discharge capacity of the material can be considered; the negative material for the sodium-ion battery can be applied to preparation of a soft package sodium-ion battery; and compared with a lithium-ion battery, the sodium-ion battery is green, safe and low in price, and has great advantages as an energy storage application.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH +1

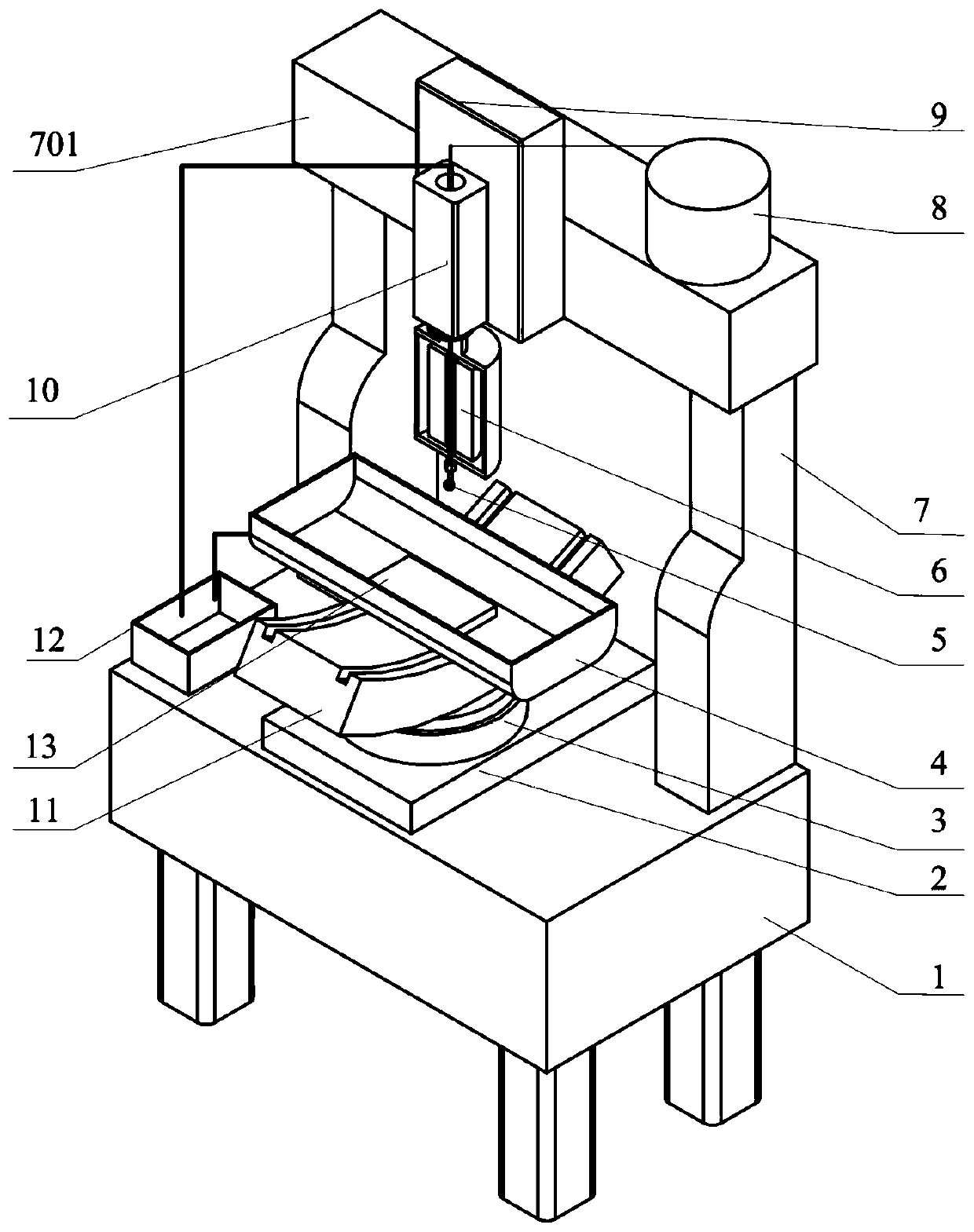

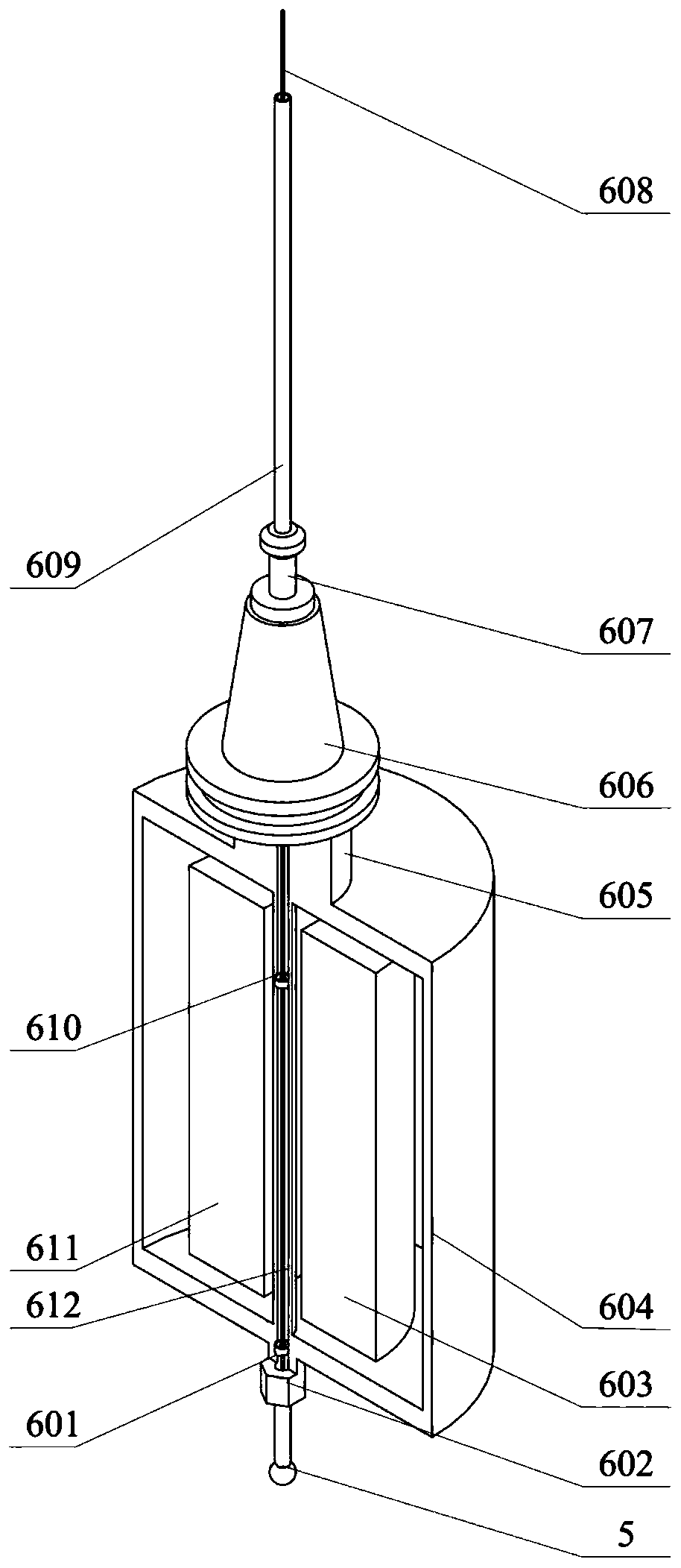

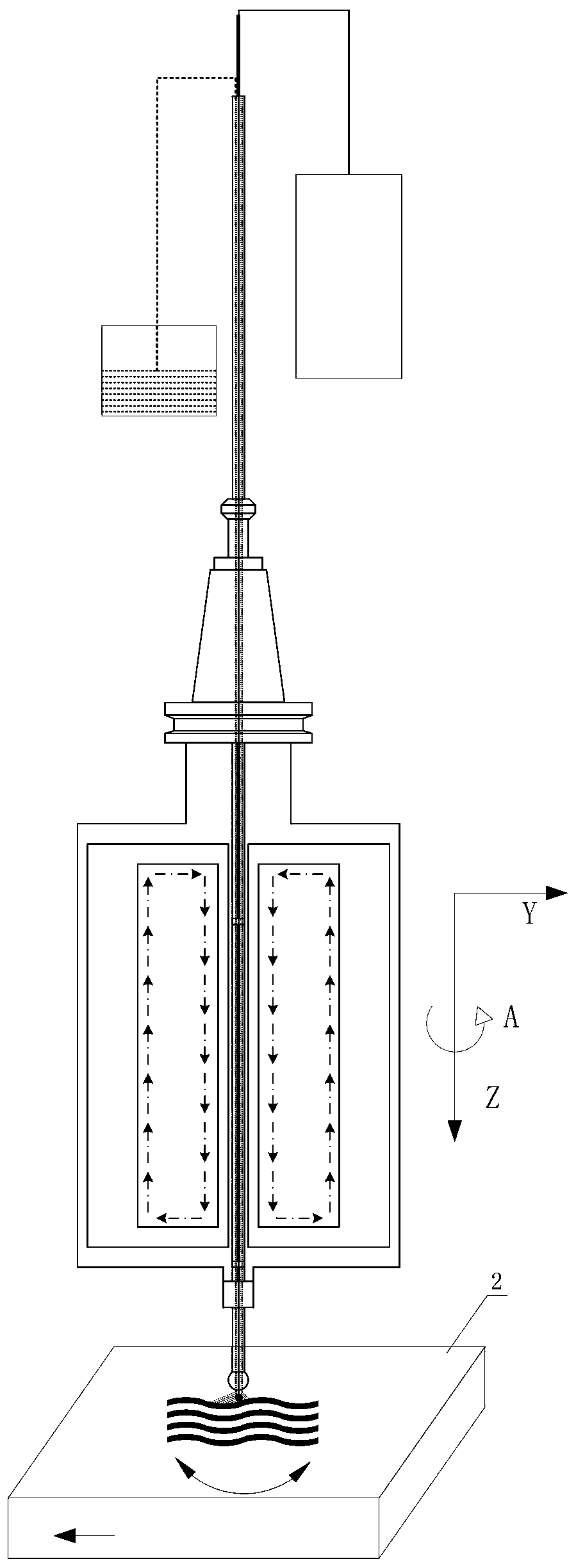

Five-axis linkage laser magnetorheological composite polishing machining device and using method thereof

ActiveCN109746813AAvoid damageReduce agglomeration effectGrinding carriagesPolishing machinesSurface modificationOptoelectronics

The invention discloses a five-axis linkage laser magnetorheological composite polishing machining device and a using method thereof, and belongs to the technical field of composite polishing machining. Five-axis linkage laser magnetorheological composite polishing provided by the invention is a novel machining method, the advantages of magnetorheological polishing and laser surface modification are combined, a positive effect in addition to the combination of the advantages of magnetorheological polishing and laser surface modification is achieved, and thus the purposes of reducing surface cracks, subsurface damage and the agglomeration effect of magnetorheological liquid, and improving the machining quality and machining efficiency are achieved. At the moment, central laser irradiation can achieve the effects of machining dead zones, softening the part surface, reducing cutting resistance and tool damage and the like, lase also can achieve the functions of eliminating carrier liquid,magnetic particles and a stabilizer in the magnetorheological fluid and the agglomeration effect between machined material residues and chips, thus, the magnetic particles are dispersed on the to-be-machined surface more discretely, the machining efficiency is improved, and the better surface machining quality is achieved.

Owner:CHANGCHUN UNIV OF SCI & TECH

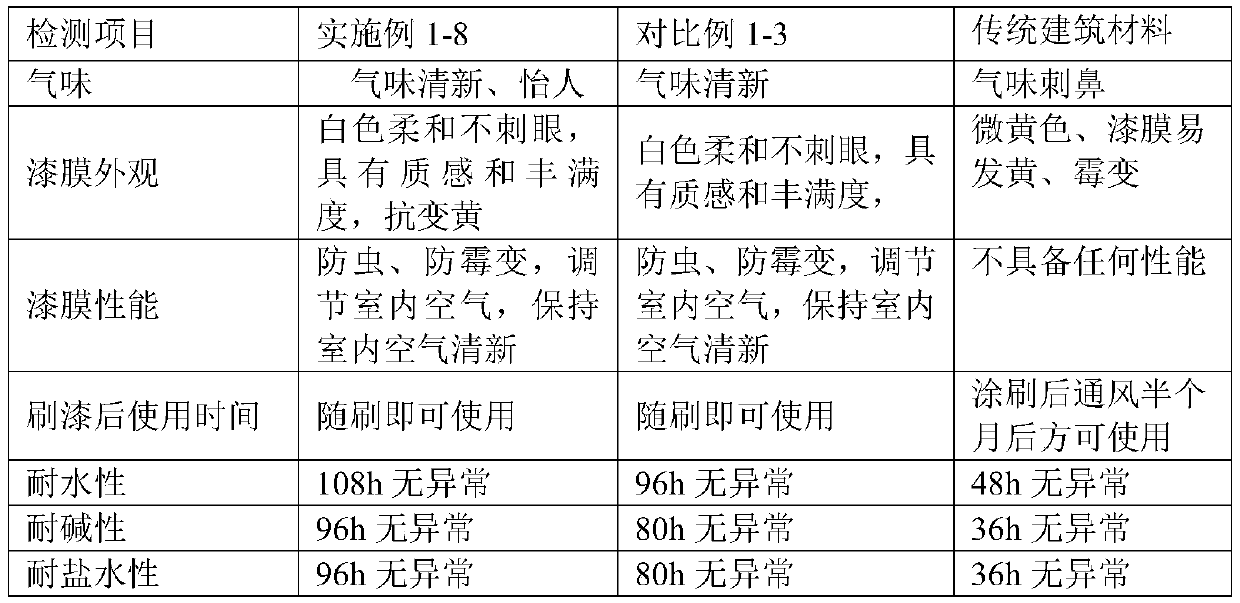

Bacteriostatic paint and production method thereof

InactiveCN110373082AAnti-agingGood for healthAntifouling/underwater paintsPaints with biocidesMicrosphereHuman health

The invention discloses bacteriostatic paint and a production method thereof. The paint comprises the following components, in parts by weight, of 100-150 parts of phenolic resin, 100-150 parts of silicon dioxide aerogel, 50-80 parts of plant extracts, 50-60 parts of negative ion powder, 20-30 parts of nanometer titania, 30-40 parts of modified carbon nanotubes, 30-40 parts of graphene oxide, 20-30 parts of vitrified microspheres, 10-15 parts of chitosan, 3-5 parts of a surfactant, 3-5 parts of a bacteriostatic agent, 1-2 parts of a silane coupling agent and 1-2 parts of a levelling agent. Thepaint has the characters of being ageing-resistant, free from peeling and discoloration, high in weather resistance, non-toxic, odourless, good in levelling property and easy to apply, and is scrub-resistant, the original strength and quality of the paint can still be maintained after other functional components are added moderately, and the paint not only can release negative air ions for a longterm to purify air and to benefit human health, but also can restrain and sterilize bacteria.

Owner:HENAN YUQIAN TECH TRANSFER CENT CO LTD

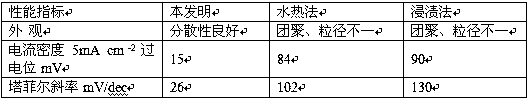

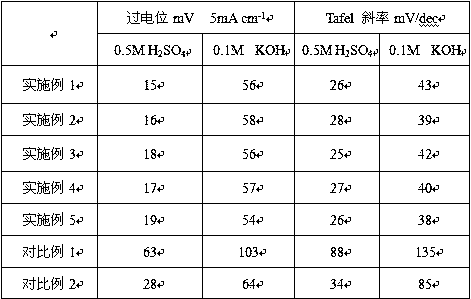

Preparation method for preparing tin bisulfide catalyst of hydrogen for fuel cell

InactiveCN108479807AGood effectGood dispersionPhysical/chemical process catalystsElectrodesBisulfideThiourea

The invention provides a preparation method for preparing a tin bisulfide catalyst of hydrogen for a fuel cell. The method comprises the steps that modified porous organic silicon is adopted as a substrate, molten metal tin and thiourea are subjected to an evaporation source reaction, evaporated tin atoms preferentially enter nanometer gaps of organic silicon to be combined with a modified group and react with thiourea to generate tin bisulfide nanoparticles, organic silicon loaded with the tin bisulfide nanoparticles is immersed in hydrofluoric acid for etching, a carbon-covering layer is deposited, the tin bisulfide nanoparticles are fixed in the gaps, and a high-dispersion carbon-covering tin bisulfide nanoparticle catalyst is obtained; therefore, the aggregation effect in the preparation method is lowered, and the defects that the tin bisulfide nanoparticle catalyst is serious in aggregation, and the catalytic performance is affected are overcome. Accordingly, the organic silicon on the surface is etched with hydrofluoric acid, a carbon source uniformly wraps the surface of tin bisulfide at high temperature, corrosion of electrolyte on tin bisulfide can be inhibited, and the stability of the catalyst in the electrolyte is improved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

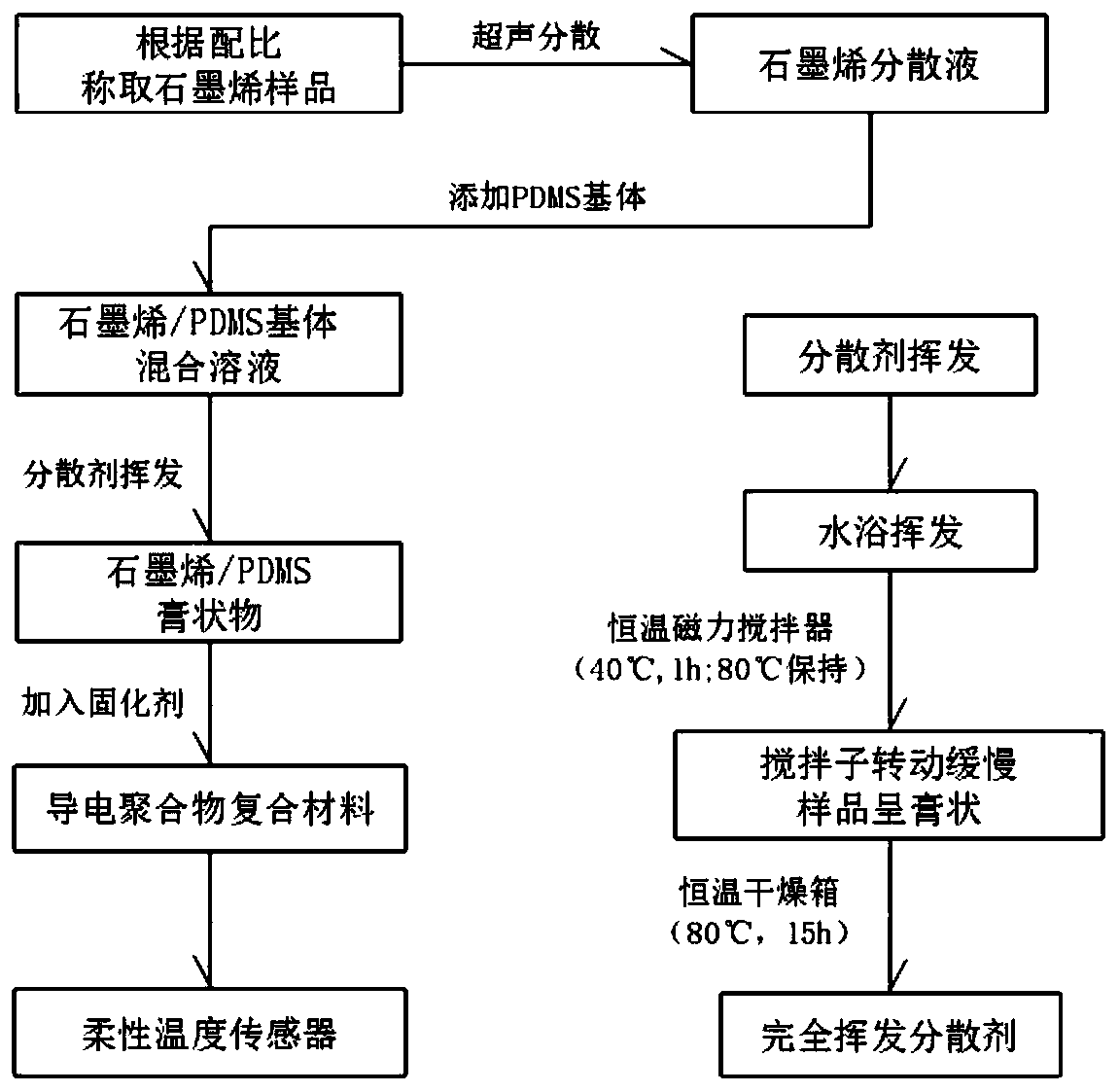

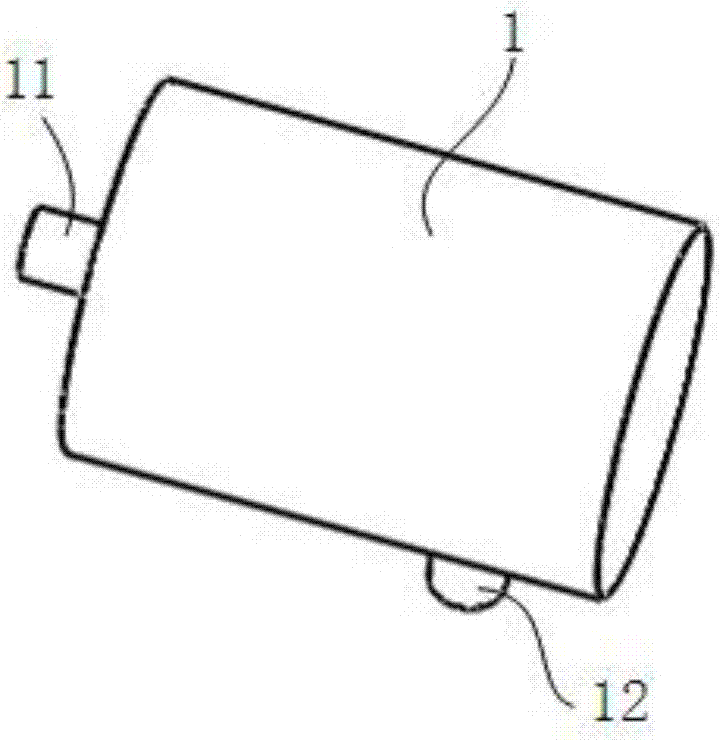

Flexible temperature sensor and preparation method thereof

InactiveCN110423469AReduce van der Waals forcesIncrease electrostatic repulsionBody temperature measurementRepulsion forceGraphene

The invention discloses a flexible temperature sensor and a preparation method thereof. Before graphene is mixed with PDMS, van der Waals force among graphene particles is reduced through ultrasonic dispersion treatment of the graphene, and electrostatic repulsion force between particle surfaces is increased to increase the distance between graphene sheets, thereby weakening agglomeration effect,thereby solving the technical problems that the graphene cannot form a cross-linking network with the PDMS, conductive paths are blocked, and the flexible temperature sensor cannot quickly sense environmental temperature changes and has poor sensitivity.

Owner:CENT SOUTH UNIV

Preparation method of meteorolite white wine

InactiveCN106947677AReduce agglomeration effectIncrease surface areaAlcoholic beverage preparationActivated carbonHydrogen

The invention discloses a method for preparing meteorite liquor, which mainly comprises the steps of hydrogen explosion treatment of meteorites into powder, and then making filter elements together with meteorite powder and activated carbon according to a conventional method, and then activating the liquor through the filter elements. Compared with the prior art, the present invention hydrogen-explodes the meteorite into powder, and the surface area in contact with the liquor is increased by more than one million times, so the activation speed is rapidly increased, no soaking is required, and high-efficiency continuous production can be carried out. Meteorite powder and activated carbon have a synergistic effect after being mixed together. The microporous structure of activated carbon reduces the agglomeration effect of meteorite powder and expands the surface area. In addition, it can activate the wine body while filtering out odor impurities in the wine, killing two birds with one stone.

Owner:烟台弘辰百诺酒业有限公司

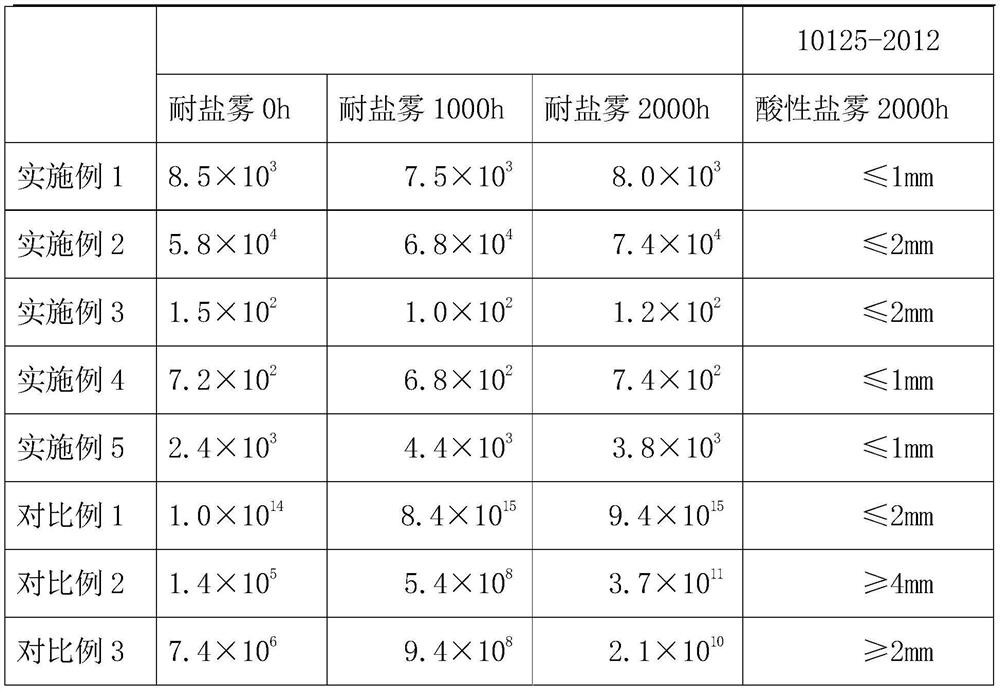

Antistatic powder coating and preparation method thereof

PendingCN112724776AReduce agglomeration effectUniform adsorptionAnti-corrosive paintsPowdery paintsOrganic acidPolymer science

The invention relates to the field of preparation methods of high polymer materials, and particularly discloses an antistatic powder coating and a preparation method thereof. The coating is prepared from a component A and a component B according to the weight percentage of 200-20: 1. wherein the component A is prepared from the following raw materials in percentage by weight: 30.0-75.0 percent of resin; 3.0-30.0% of a curing agent; 0.8-1.5% of a leveling agent; 1.0-5.0% of a coupling agent; 0.3-1.0% of a defoaming agent; 0.2-1.0% of an electricity increasing agent; 0.5-5.0% of other auxiliary agents; and 10.0-45.0% of a pigment and filler; wherein the sum of the weight percentages of the raw materials is 100%. The component B is prepared from the following raw materials in percentage by weight: 40.0-85.0 percent of a composite conductive additive; 10.0-58.0% of an organic acid modified stabilizer; 0.5-8.0% of a coupling agent; and 0.2-5.0% of a dispersing agent; wherein the sum of the weight percentages of the components is 100%. The invention also discloses a preparation method for preparing the antistatic powder coating. According to the antistatic powder coating disclosed by the invention, the application efficiency of a conductive material can be improved, the cost of the coating is reduced, and the corrosion resistance and the conductive stability of a coating layer are remarkably improved.

Owner:WESDON RIVER POWDER PAINT SCI RES CO LTD

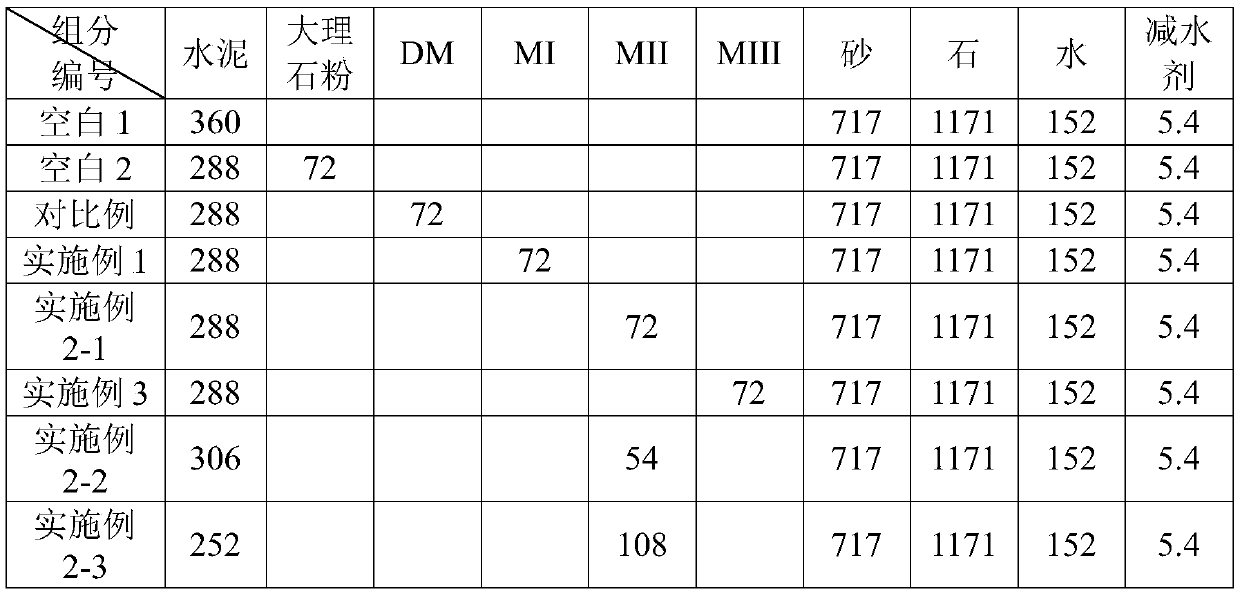

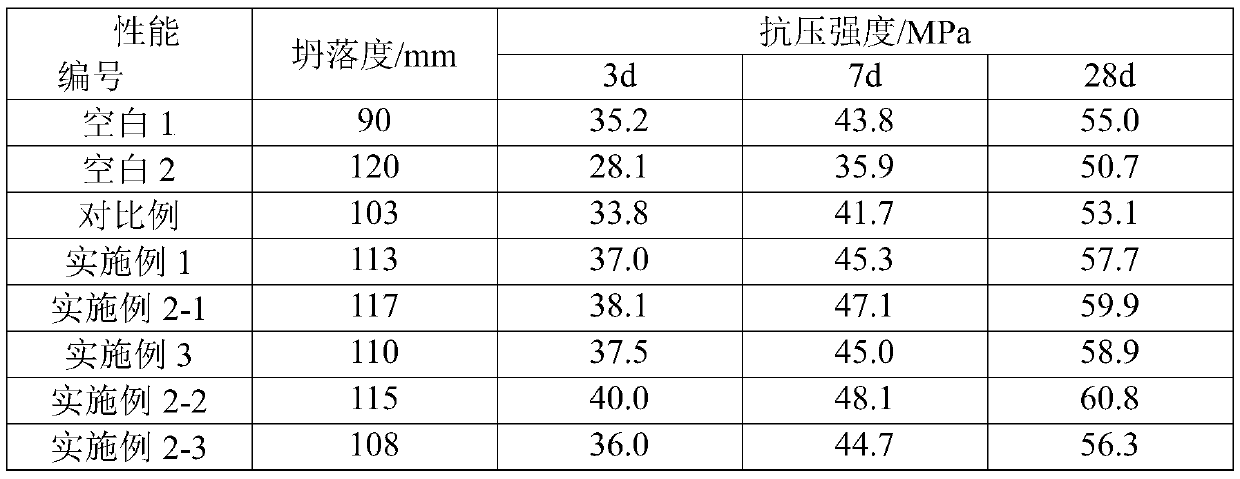

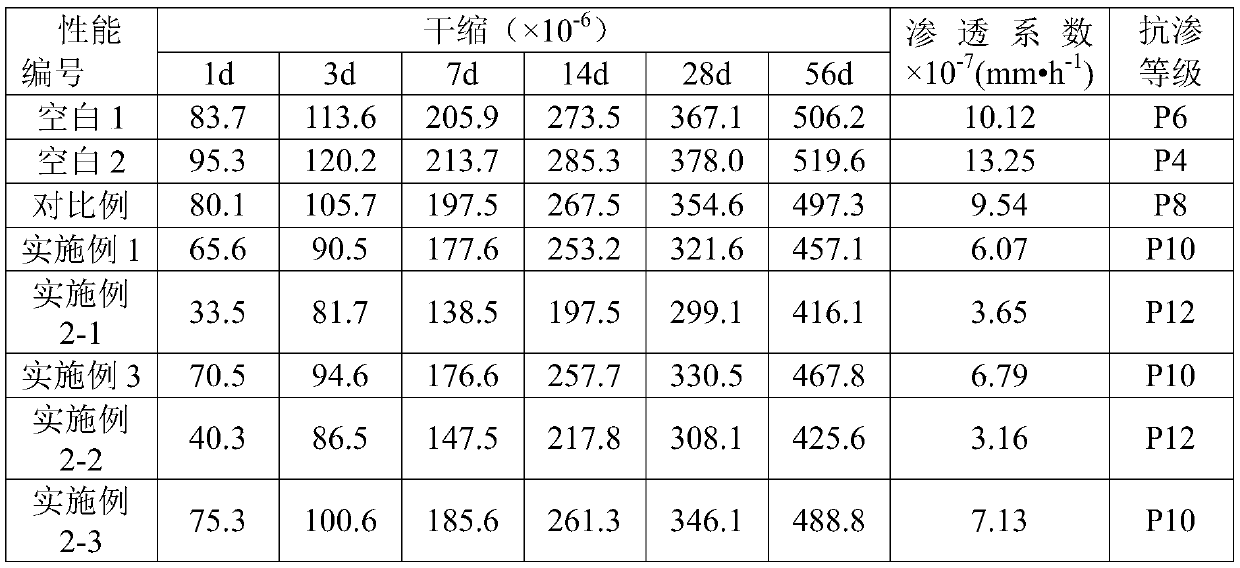

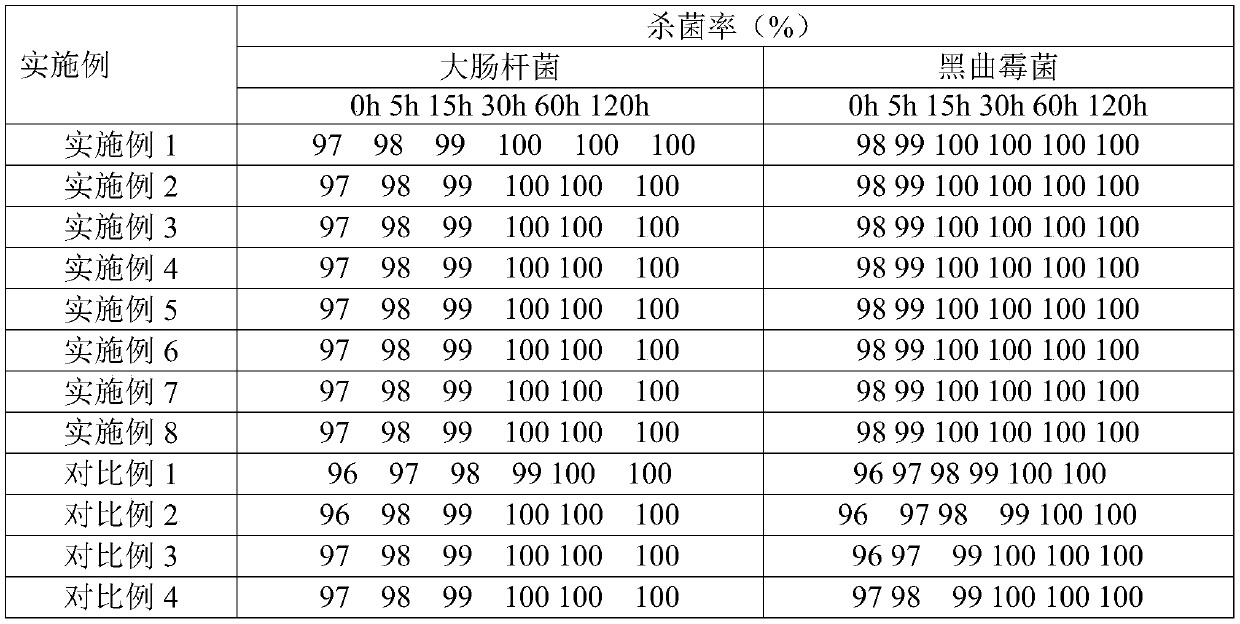

Impervious marble powder compound admixture and application thereof

ActiveCN110041007AReduce agglomeration effectImprove mechanical propertiesNetwork structureFour component

The invention provides an impervious marble powder compound admixture and an application thereof. The impervious marble powder compound admixture is prepared from following components in parts by weight: 75-90 parts of modified marble powder, 10-25 parts of modified metakaolin, 2-6 parts of rubber powder and 0.5-1.5 parts of basalt fiber. According to the impervious marble powder compound admixture, the marble powder and metakaolin are modified and then compounded with the rubber powder and the basalt fiber, the admixture for concrete is prepared, reaction activity of the impervious marble powder compound admixture and cement is greatly improved under the synergistic effect of the four components, an organic-inorganic three-dimensional interpenetration network structure which is stacked and staggered can be formed in the concrete when the admixture is applied to preparation of the concrete, so that pore structure distribution of the concrete is greatly improved, compactibility of the concrete is improved, and the prepared concrete has higher mechanical property and durability.

Owner:WUHAN UNIV OF TECH

Anion environment-friendly coating and preparation method thereof

InactiveCN110330889AStrong weather resistanceGood for healthStarch dervative coatingsAntifouling/underwater paintsWeather resistanceSilicon dioxide

The invention discloses anion environment-friendly coating and a preparation method thereof. The anion environment-friendly coating comprises the following ingredients in parts by weight: 100-150 parts of fluorosilicon resin, 50-60 parts of amino resin, 40-50 parts of hydroxyalkyl starch, 15-30 parts of diatom ooze, 30-40 parts of plant extract, 50-60 parts of anion powder, 20-30 parts of nano-titanium dioxide, 30-40 parts of modified CNTs (carbon nano tubes), 20-30 parts of nano-silicon dioxide, 3-5 parts of amber sand, 15-25 parts of ceramic carbon balls, 1-2 parts of isopropyl triisostearoyltitanate and 1-2 parts of carboxymethylcellulose. The coating has the characteristics of being anti-aging, non-scaling and non-discoloring, being strong in weather resistance, being non-toxic and tasteless and being good in flatting and easy in construction, is resistant to washing, is non-toxic and harmless, is fresh in smell and has a health-care effect.

Owner:HENAN YUQIAN TECH TRANSFER CENT CO LTD

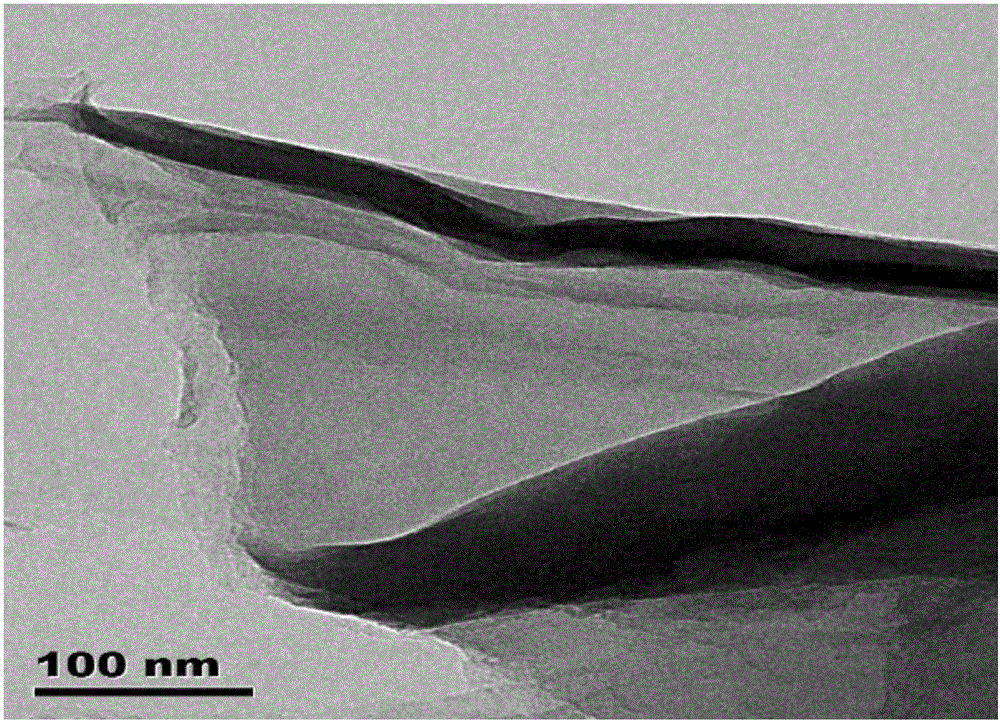

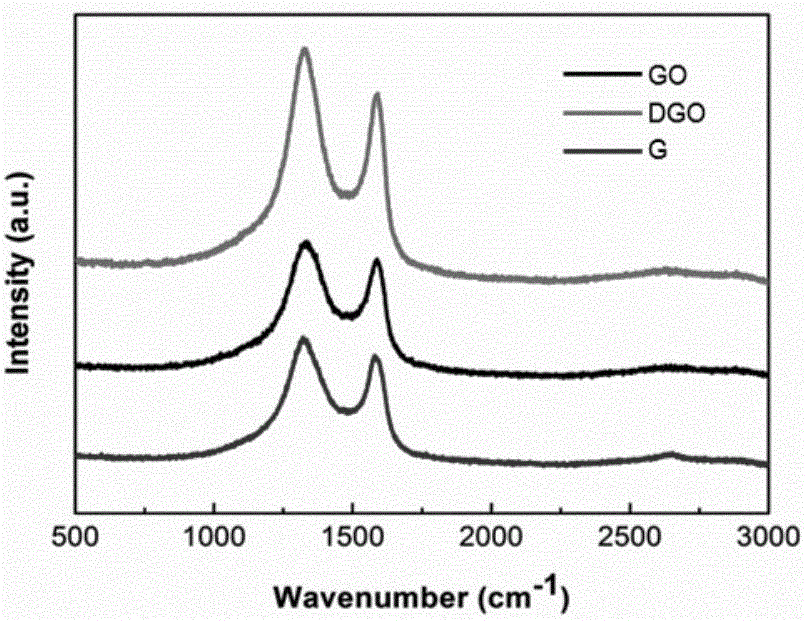

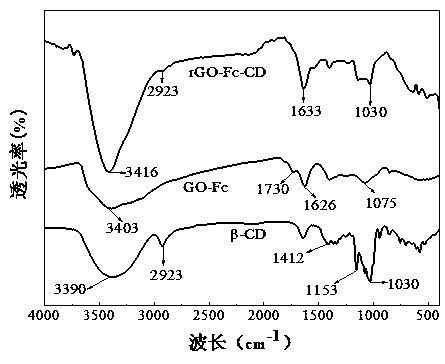

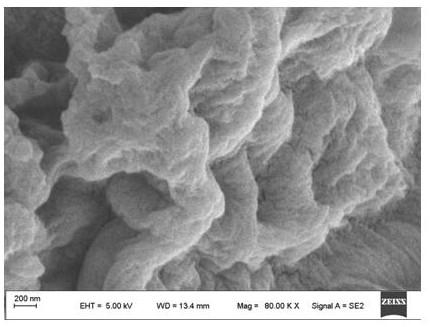

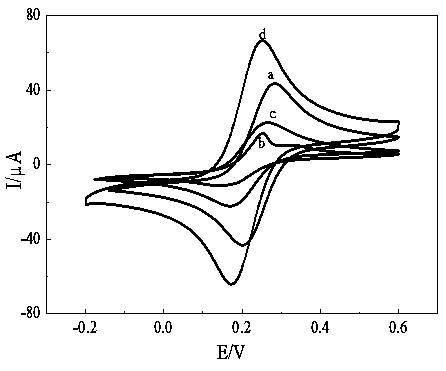

Preparation and application of graphene-ferrocene functionalized cyclodextrin chiral compound material

InactiveCN109251369AReduce agglomeration effectIncrease layer spacingMaterial electrochemical variablesD-PhenylalanineFerrocene

The invention discloses preparation and application of a graphene-ferrocene functionalized cyclodextrin chiral compound material. Firstly, graphene oxide (GO) is exfoliated by using ferrocene (Fc) through pi-pi action to reduce an aggregation effect of the GO and to increase interlayer spacing of the GO, so that functionalized GO-Fc is obtained; then under an alkaline condition, the GO-Fc and beta-cyclodextrin (beta-CD) are subjected to one-pot reaction to prepare the chiral compound material rGO-Fc-CD. A surface of a glassy carbon electrode (GCE) is modified with the chiral compound materialrGO-Fc-CD to form an electrochemical chiral sensing interface (rGO-Fc-CD / GCE), and the electrochemical chiral sensing interface (rGO-Fc-CD / GCE) has excellent conductivity. The chiral recognition material modified electrode rGO-Fc-CD / GCE is placed in a phenylalanine isomer solution, differential pulse voltammetry is used for scanning, and due to the fact that when L-phenylalanine and D-phenylalanine interact with the rGO-Fc-CD / GCE, peak current magnitude is different, a phenylalanine isomer can be identified fast and sensitively.

Owner:NORTHWEST NORMAL UNIVERSITY

Sandwich-shaped flexible temperature sensor and preparation method thereof

ActiveCN110487438AIncrease the temperature change rate of resistanceReduce van der Waals forcesThermometers using electric/magnetic elementsUsing electrical meansPliabilityCvd graphene

The invention discloses a sandwich-shaped flexible temperature sensor and a preparation method thereof. A conductive layer is independently prepared through the graphene dispersion liquid, the conductive layer is embedded between an upper substrate and a lower substrate which are made of PDMS materials so that the Van der Waals' force among graphene particles is reduced, electrostatic repulsion between particle surfaces is increased to increase a distance between graphene sheet layers, the agglomeration effect is further weakened, so the resistance temperature change rate of the flexible sensor is increased, the sensitivity of the flexible sensor to temperature change is improved, and thereby technical problems that a flexible sensor is small in resistance temperature change rate and not high in temperature sensitivity in the prior art are solved, the PDMS materials are utilized as the upper substrate and the lower substrate, the graphene material is independently prepared into the conductive layer, and thereby the flexible sensor prepared by the method has excellent performance of graphene and flexibility of PDMS.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com