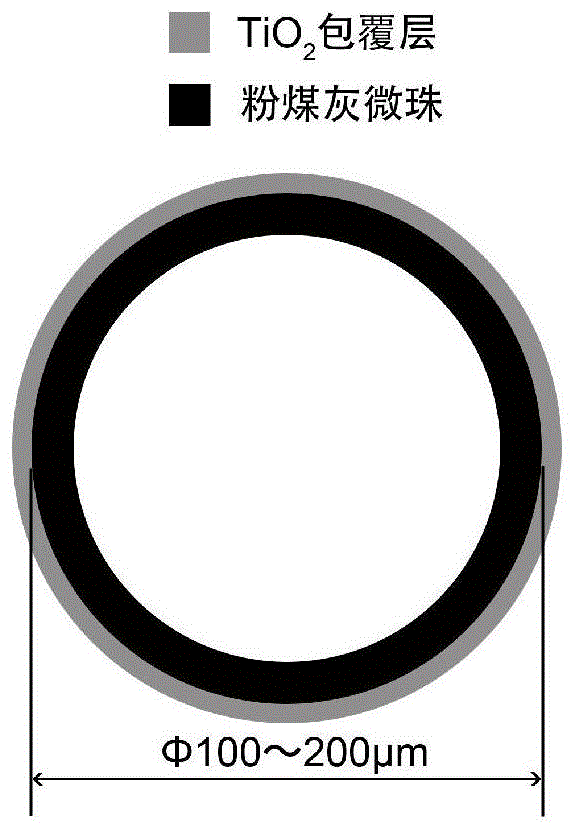

Coal ash microsphere loaded one-dimensional nanometer titanium dioxide (TiO2) composite photocatalyst and preparation method thereof

A technology of nano-titanium dioxide and fly ash microbeads, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the problems of difficult powder, difficult liquid medium separation, and limited practical application. Achieve easy recycling, reduce agglomeration effect, and improve recycling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

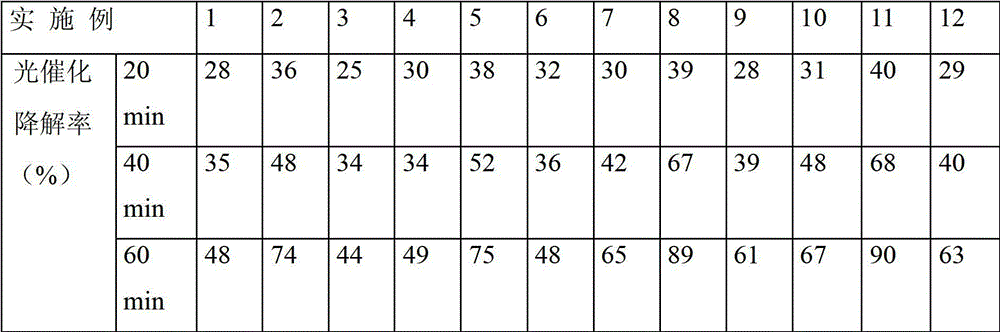

Examples

Embodiment 1

[0030] 1. Wash the fly ash microbeads 3 times with distilled water to remove impurities, and then dry them at 60°C for use.

[0031] 2. Get 5g of cleaned fly ash microbeads and place them in a beaker, add 100mL of distilled water, take a water bath at 85°C, and control the mechanical stirrer at 350 rpm to stir evenly to obtain a microbead suspension.

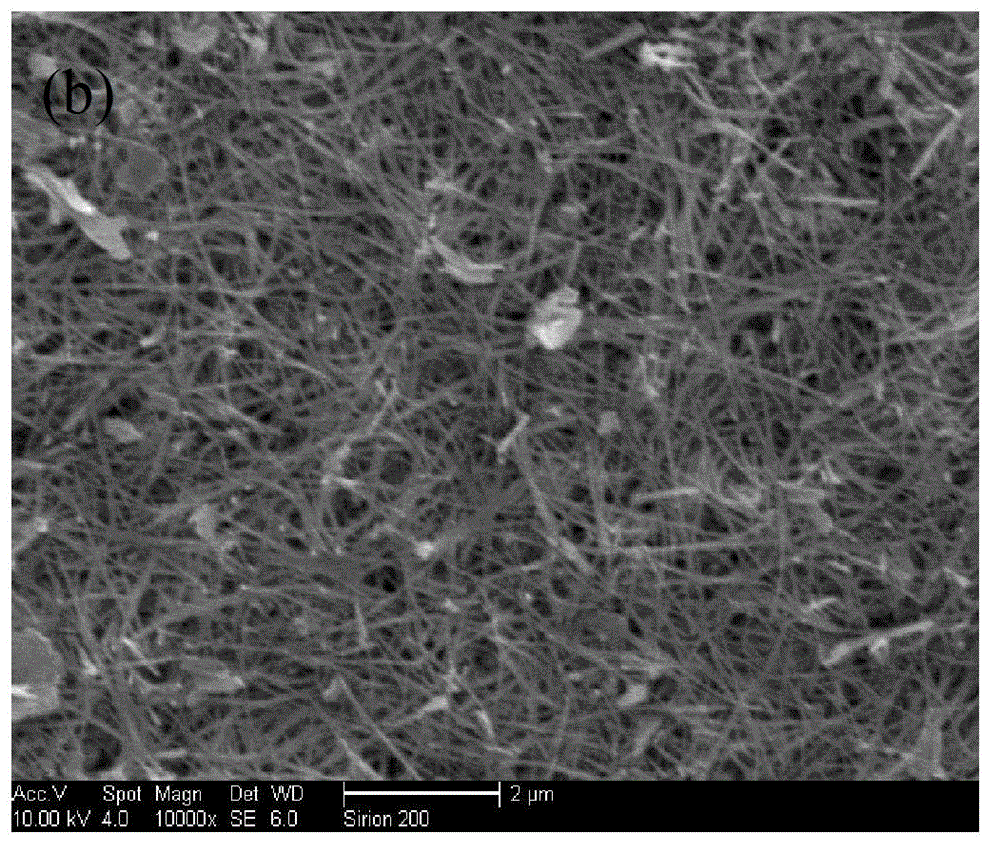

[0032] 3. Prepare 250mL of 0.1mol / L TiCl in an ice-water bath 4 solution; adjust microbead suspension pH to be 2.5, add 40g urea as slow-release precipitating agent, the TiCl 4 The solution was added dropwise into the continuously stirring microbead suspension at a rate of 1mL / min. After the dropwise addition was completed, continue to stir at 85°C for 30min, filter with suction, wash repeatedly with distilled water and ethanol, dry at 75°C, and then dry at 400°C. Calcined for 2 hours, the nano-TiO 2 / fly ash microbeads composite photocatalytic material.

[0033] 4. Weigh 0.5g nano-TiO 2 / The fly ash microbead composite pho...

Embodiment 2

[0035] 1. Use distilled water to wash the fly ash microbeads 3 times to remove impurities therein, then dry at 60°C to obtain the cleaned fly ash microbeads.

[0036] 2. Get 5g of cleaned fly ash microbeads and place them in a beaker, add 100mL of distilled water, take a water bath at 85°C, and stir with a mechanical stirrer controlled at 350 rpm to obtain a microbead suspension.

[0037] 3. Prepare 250mL of 0.1mol / L TiCl in an ice-water bath 4 solution; adjust microbead suspension pH to be 2.5, add 40g urea as slow-release precipitating agent, the TiCl 4 Add the solution dropwise into the continuously stirring microbead suspension at a rate of 2mL / min. After the dropwise addition, continue to heat and stir for 30min, filter with suction, wash repeatedly with distilled water and ethanol, dry at 75°C, and then calcinate at 400°C for 2h , that is, the nano-TiO 2 / fly ash microbeads composite photocatalytic material.

[0038] 4. Weigh 0.5g nano-TiO 2 / The fly ash microbead ...

Embodiment 3

[0040] 1. Use distilled water to wash the fly ash microbeads 3 times to remove impurities therein, then dry at 60°C to obtain the cleaned fly ash microbeads.

[0041] 2. Get 5g of cleaned fly ash microbeads and place them in a beaker, add 100mL of distilled water, take a water bath at 85°C, and stir with a mechanical stirrer controlled at 350 rpm to obtain a microbead suspension.

[0042] 3. Prepare 250mL of 0.1mol / L TiCl in an ice-water bath 4 solution; adjust microbead suspension pH to be 2.5, add 40g urea as slow-release precipitating agent, the TiCl 4 Add the solution dropwise into the continuously stirring microbead suspension at a rate of 1mL / min. After the dropwise addition, continue to heat and stir for 30min, filter with suction, wash repeatedly with distilled water and ethanol, dry at 75°C, and then calcinate at 400°C for 2h , that is, the nano-TiO 2 / fly ash microbeads composite photocatalytic material.

[0043] 4. Weigh 0.5g nano-TiO 2 / The fly ash microbead ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com