Wheel motor driver integrated with magnetofluid brake

A magnetic fluid, wheel motor technology, applied in the direction of hydraulic resistance brakes, electric components, brake types, etc., can solve problems such as lack and safety, and achieve the effect of reducing torque fluctuation, reducing stator thickness, and reducing the effect of magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

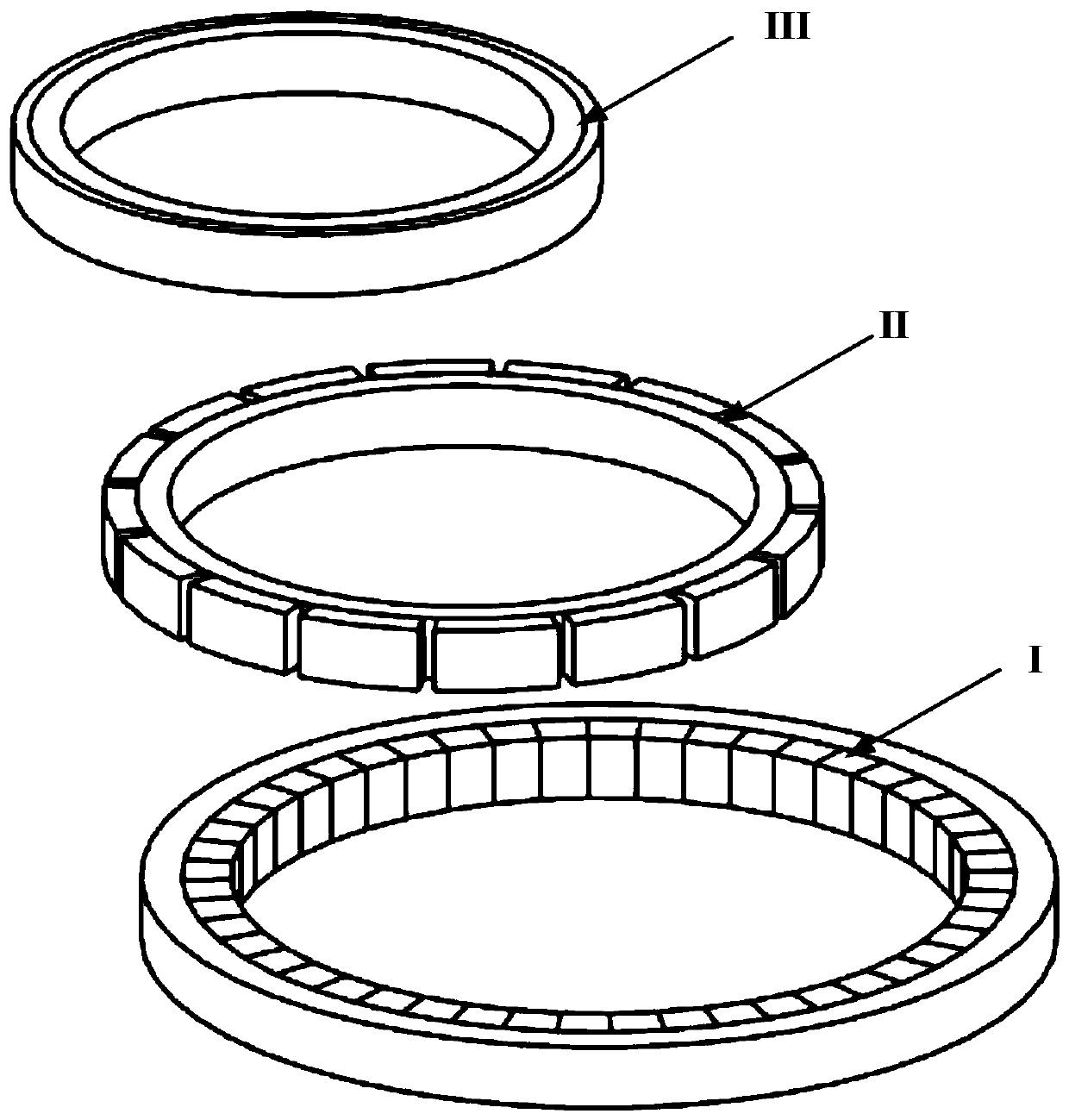

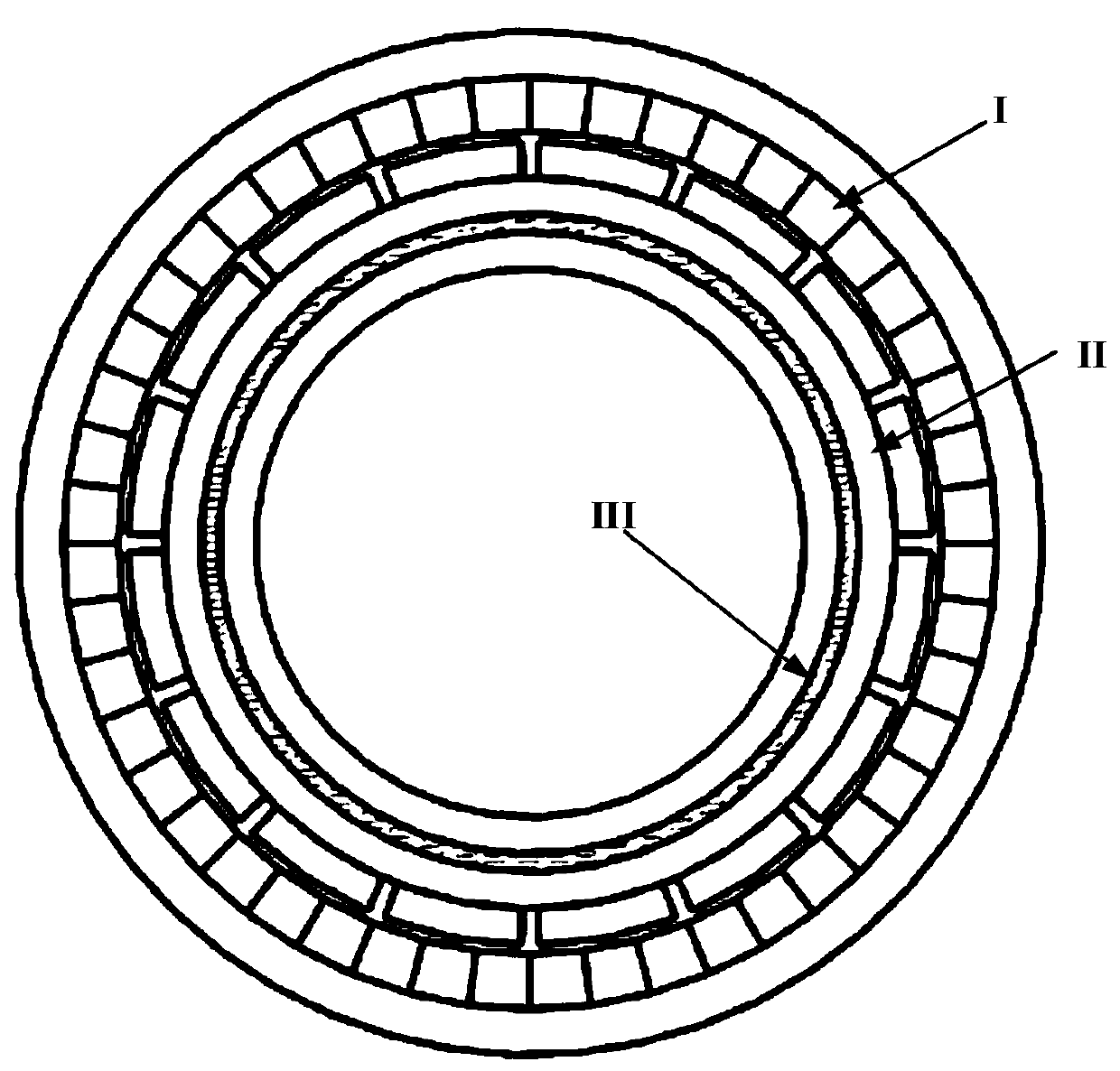

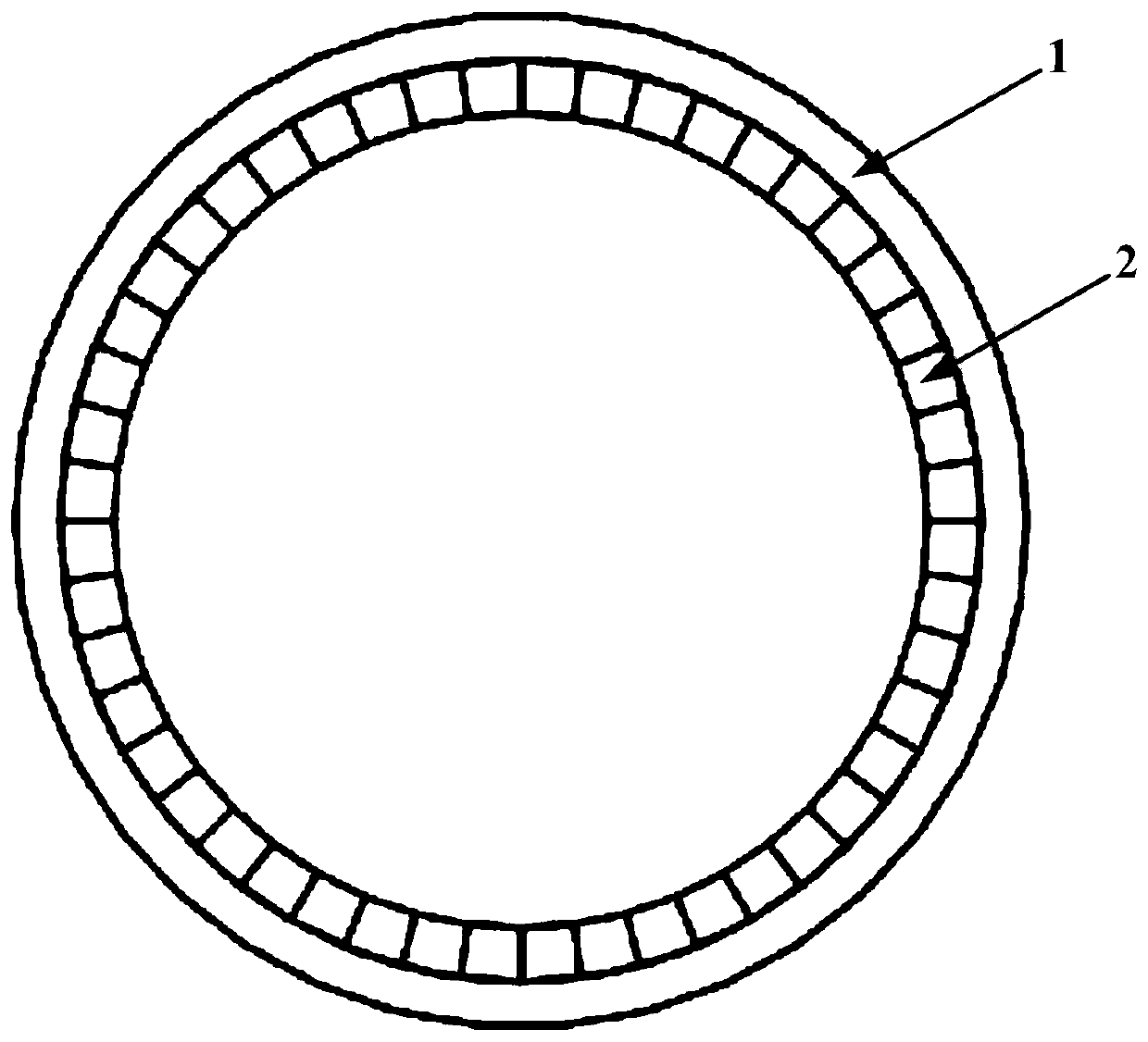

[0020] The wheel motor driver with integrated magnetic fluid brake disclosed by the invention is divided into three parts: a stator, a rotor and a magnetic fluid.

[0021] In the wheel motor driver with integrated magnetic fluid brake, the stator part adopts a cogging-free design, which reduces the thickness of the stator.

[0022] In the wheel motor driver with integrated magnetic fluid brake, the rotor adopts a large-radius multi-pole permanent magnet design to realize low-speed high-torque operation. The permanent magnet adopts Halbach Array, which increases the concentration effect of the magnetic field on one side of the magnet and reduces the magnetic flux leakage on the other side. With this design, in the normal operation mode of the motor, the magnetic field will be concentrated on the air gap side without changing the viscosity characteristics of the ferrofluid side. The permanent magnet adopts the design of combining soft magnetic and hard magnetic materials. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com