Patents

Literature

492results about How to "Reduce torque fluctuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

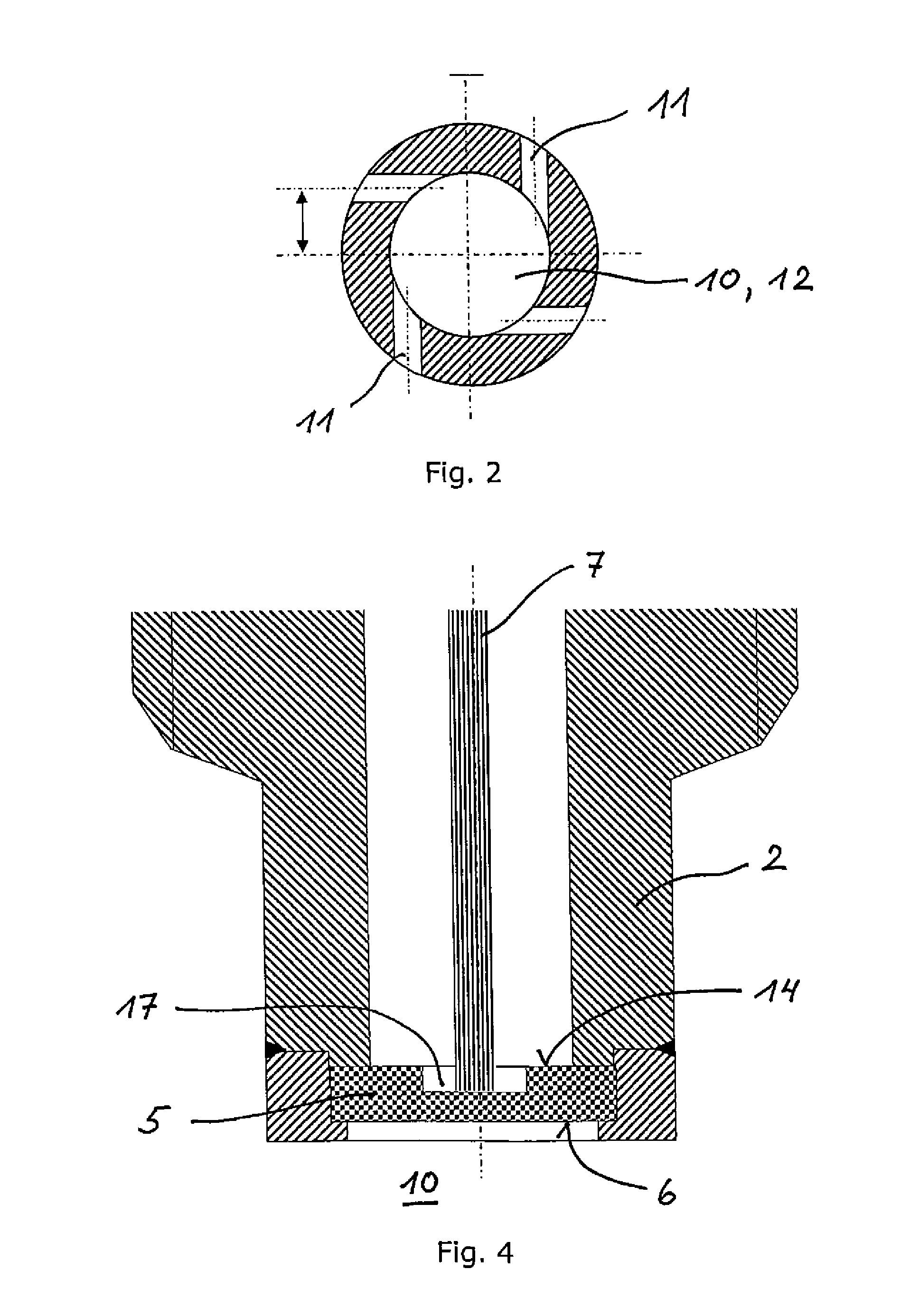

Sintered ring magnet

InactiveUS20060055266A1Reduce distortion problemsReducing cogging torqueMagnetic circuit rotating partsManufacturing dynamo-electric machinesMagnetic polesMaterials science

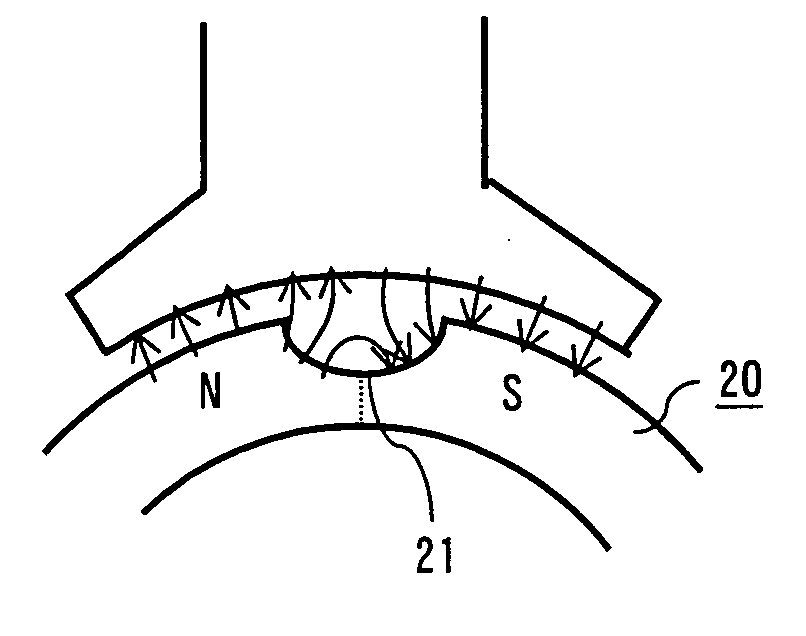

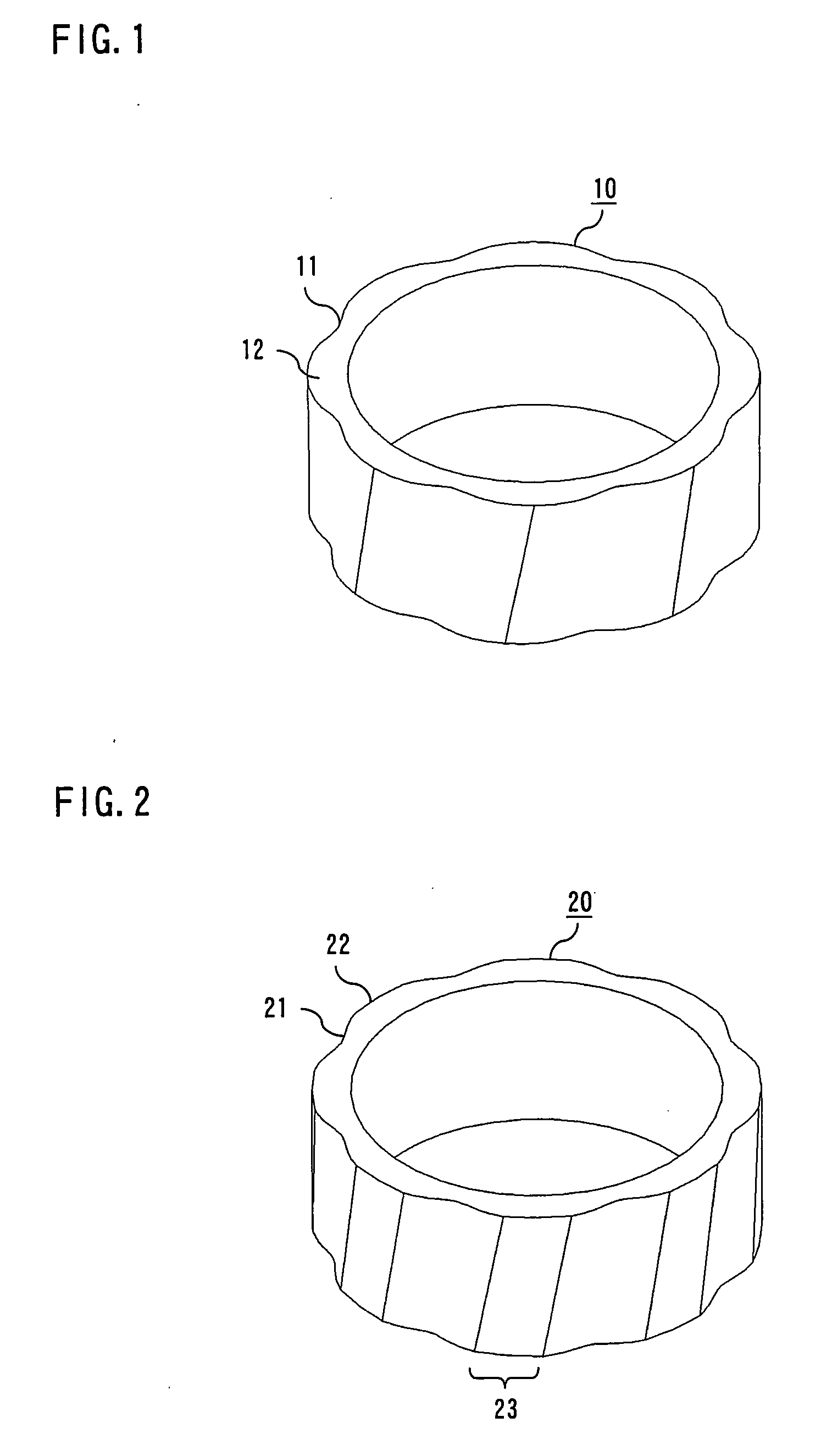

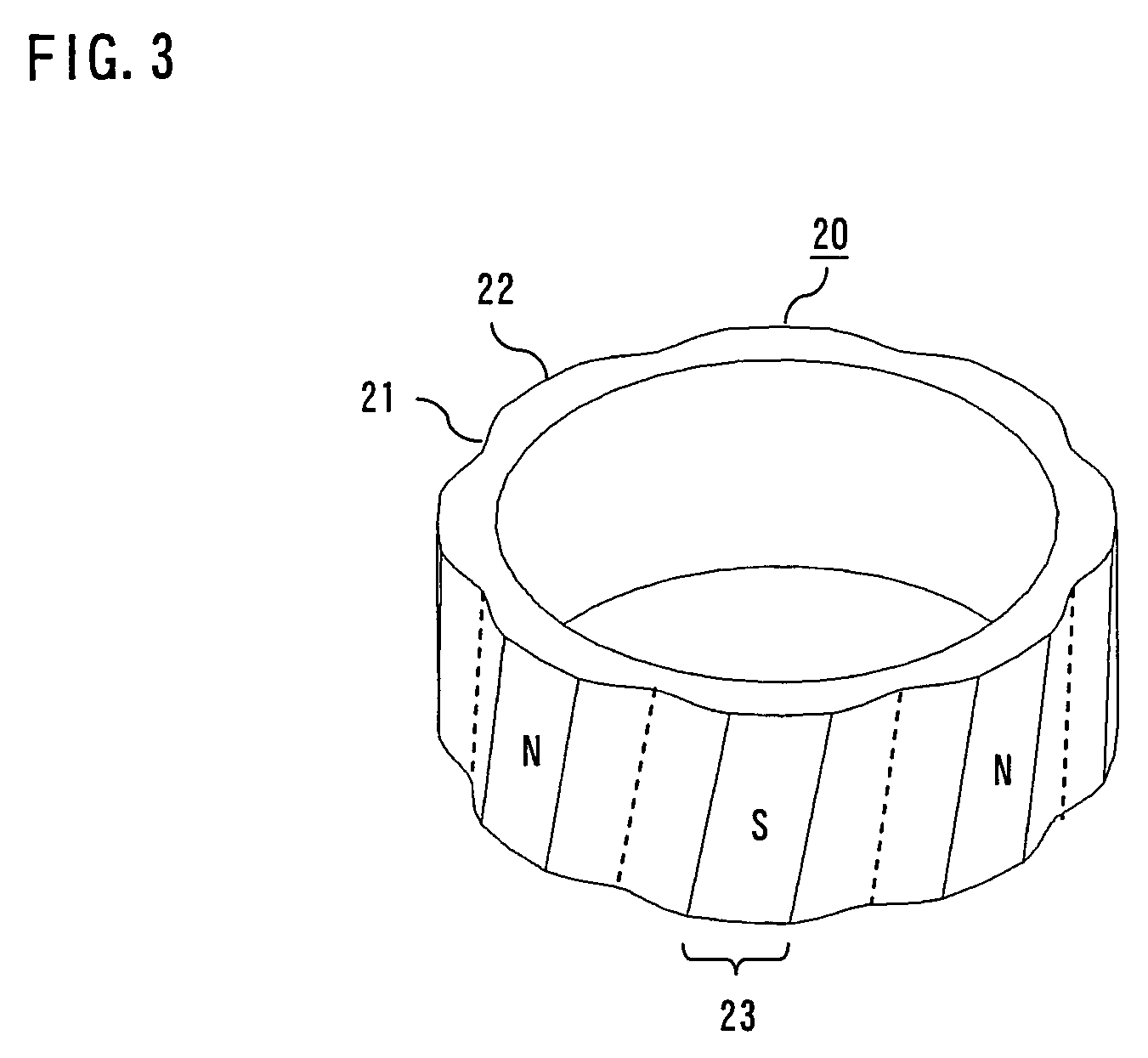

A sintered ring magnet (10) is produced through processes of magnetically orienting magnetic powder by applying a magnetic field, pressing the magnetic powder and sintering a ring-shaped powder compact (30) thus formed. The sintered ring magnet (10) has a generally cylindrical outer surface with surface corrugations formed by alternating hollows (11) and protrusions (12) at regular intervals around the sintered ring magnet (10) at least in part along an axial direction thereof, wherein the sintered ring magnet (10) varies in cross-sectional shape from one position to next along the axial direction, and magnetic poles are formed along the surface corrugations with boundaries of the magnetic poles located in the hollows (11). The hollows (11) and the protrusions (12) are skewed about a longitudinal axis of the sintered ring magnet (10). The surface corrugations are shaped into a wavy pattern expressed approximately by absolute values of a sine wave.

Owner:MITSUBISHI ELECTRIC CORP

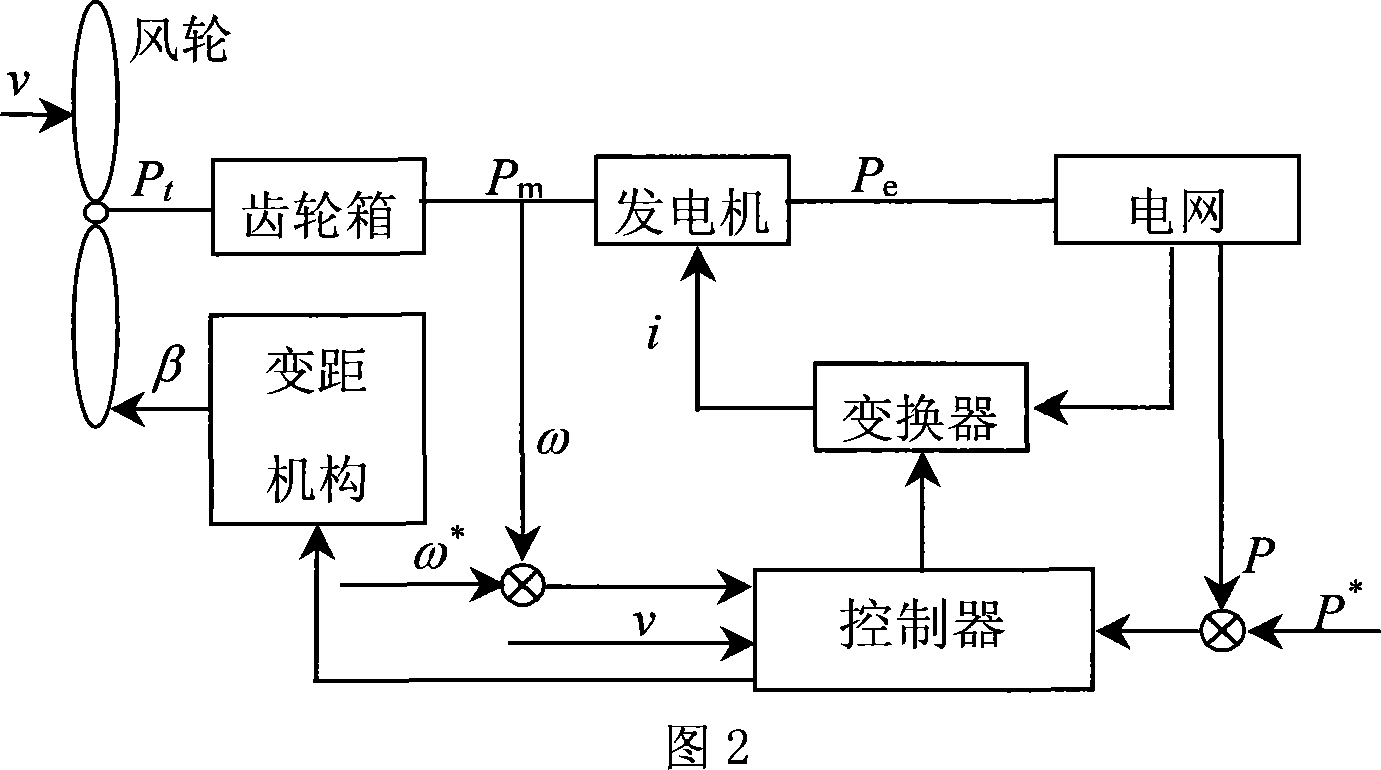

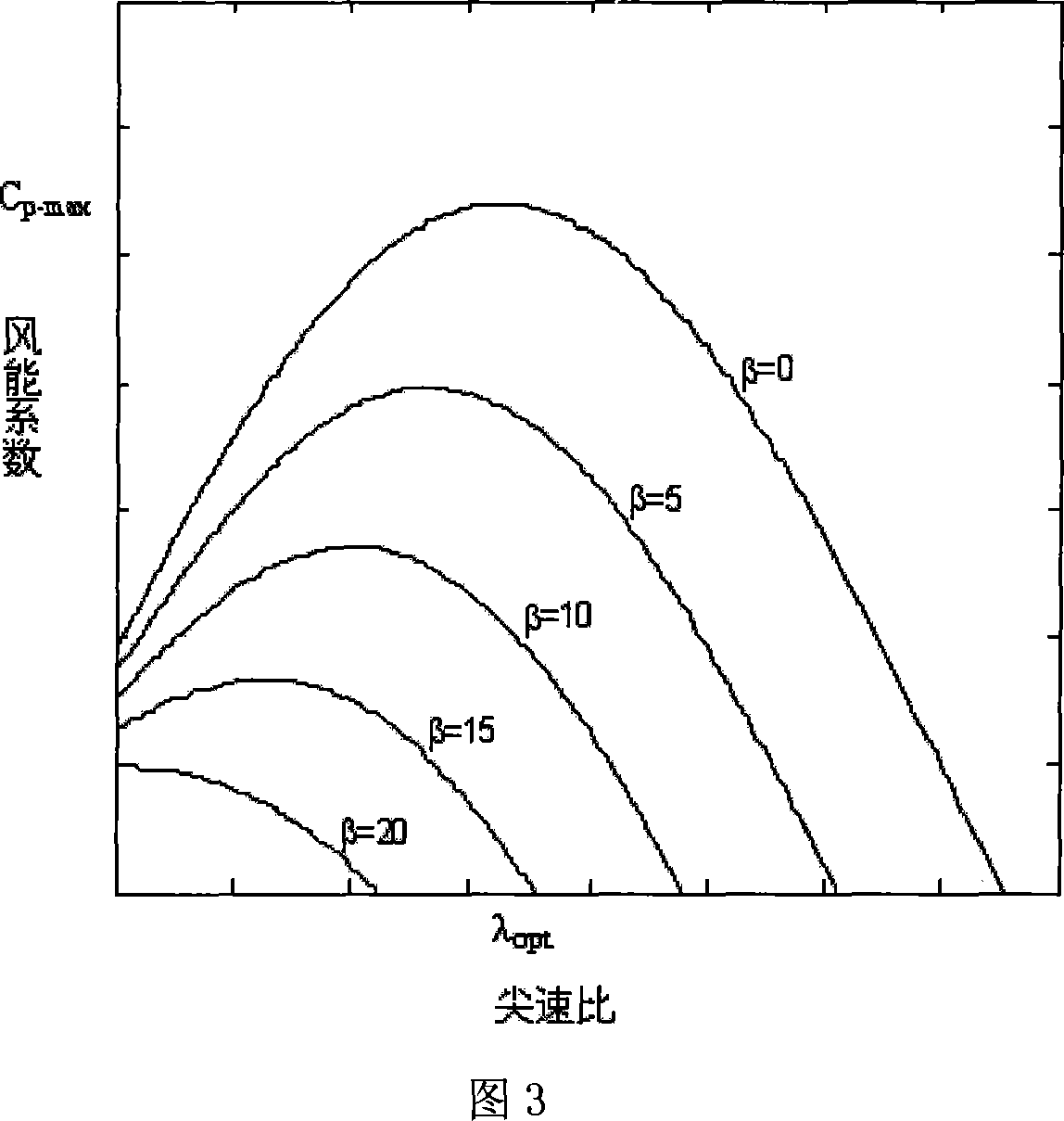

Large scale wind power machine control method based on maximum energy capture

InactiveCN101054951ASmall temperature changeImprove working characteristicsWind motor controlMachines/enginesMachine controlMaximum energy capture

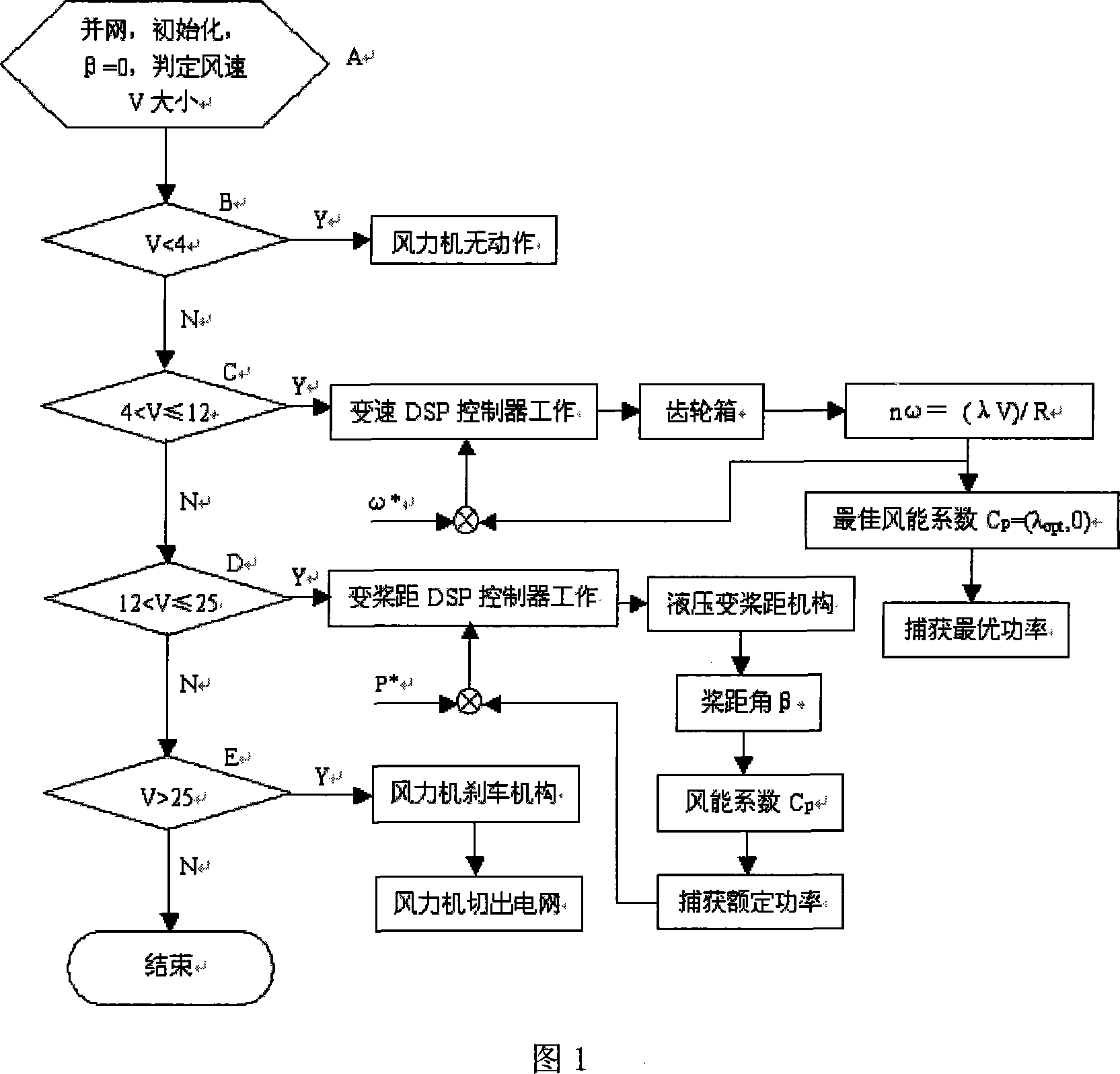

The present invention relates to method for controlling the output power of a wind turbine having maximum energy capture in wind power generation field. When the wind speed varies between a cut-in wind speed and a rating wind speed, a speed change control method is adopted to track the best power curve and to obtain maximum power; when the wind speed varies between the rating wind speed and a cut-out wind speed, a blade change control method is adopted to regulate the change of the blade distance angle for the blade and hold the rating power invariable. The present invention can select different control method based on the wind speed to realize the maximum power output for the wind turbine, thereby can improve the wind energy using efficiency for the generator unit and ensure the stability and reliability of running of the wind turbine.

Owner:SHANGHAI JIAO TONG UNIV

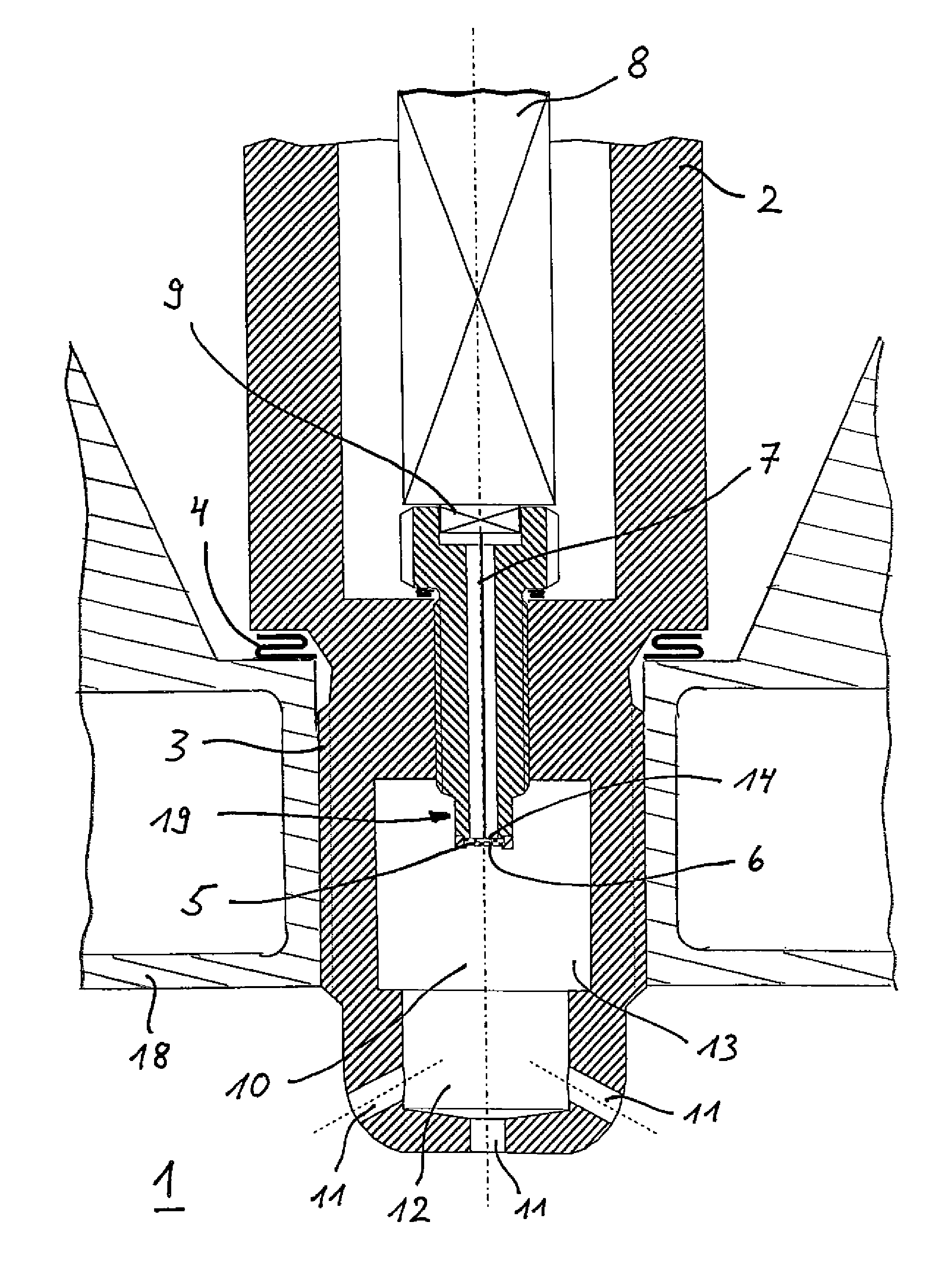

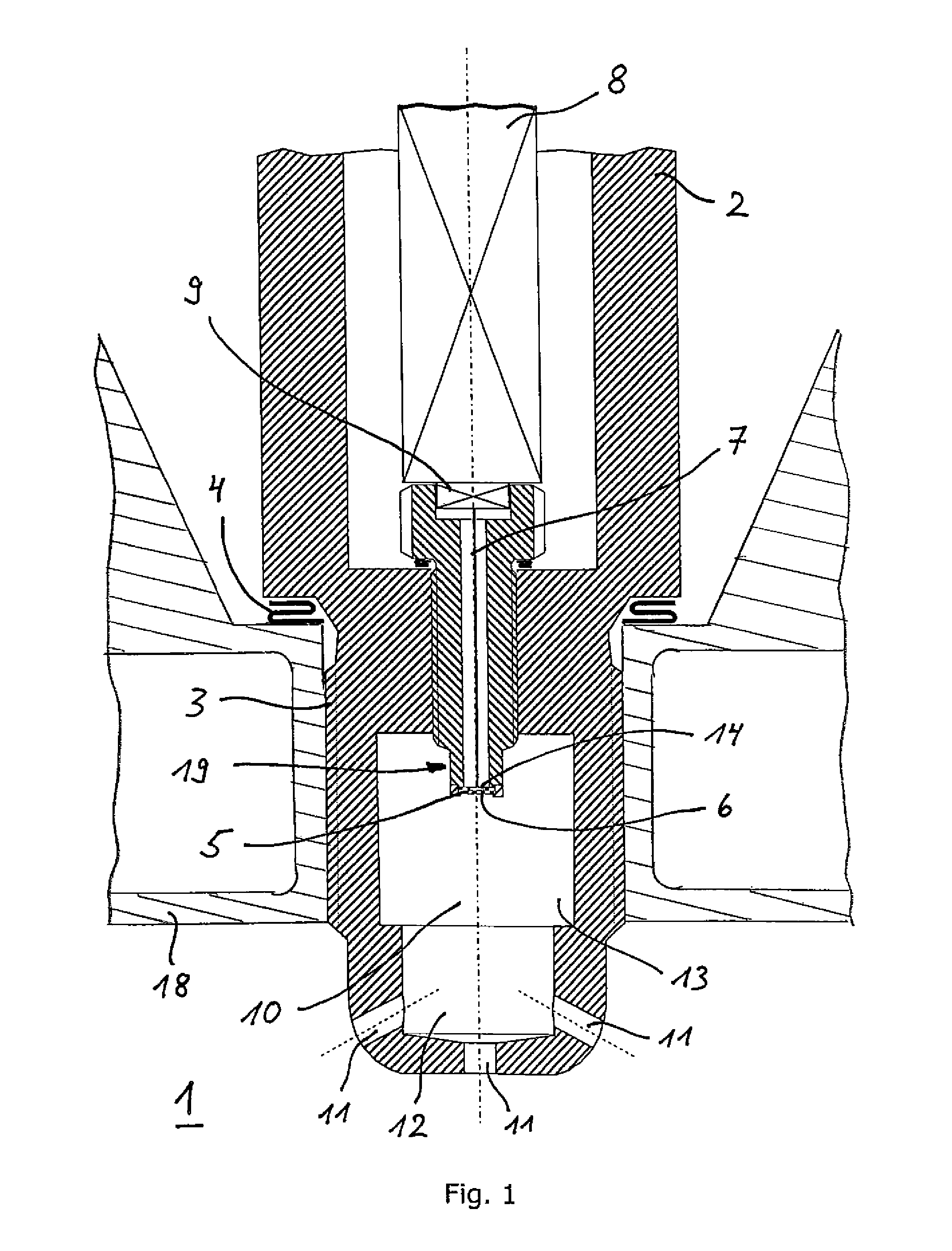

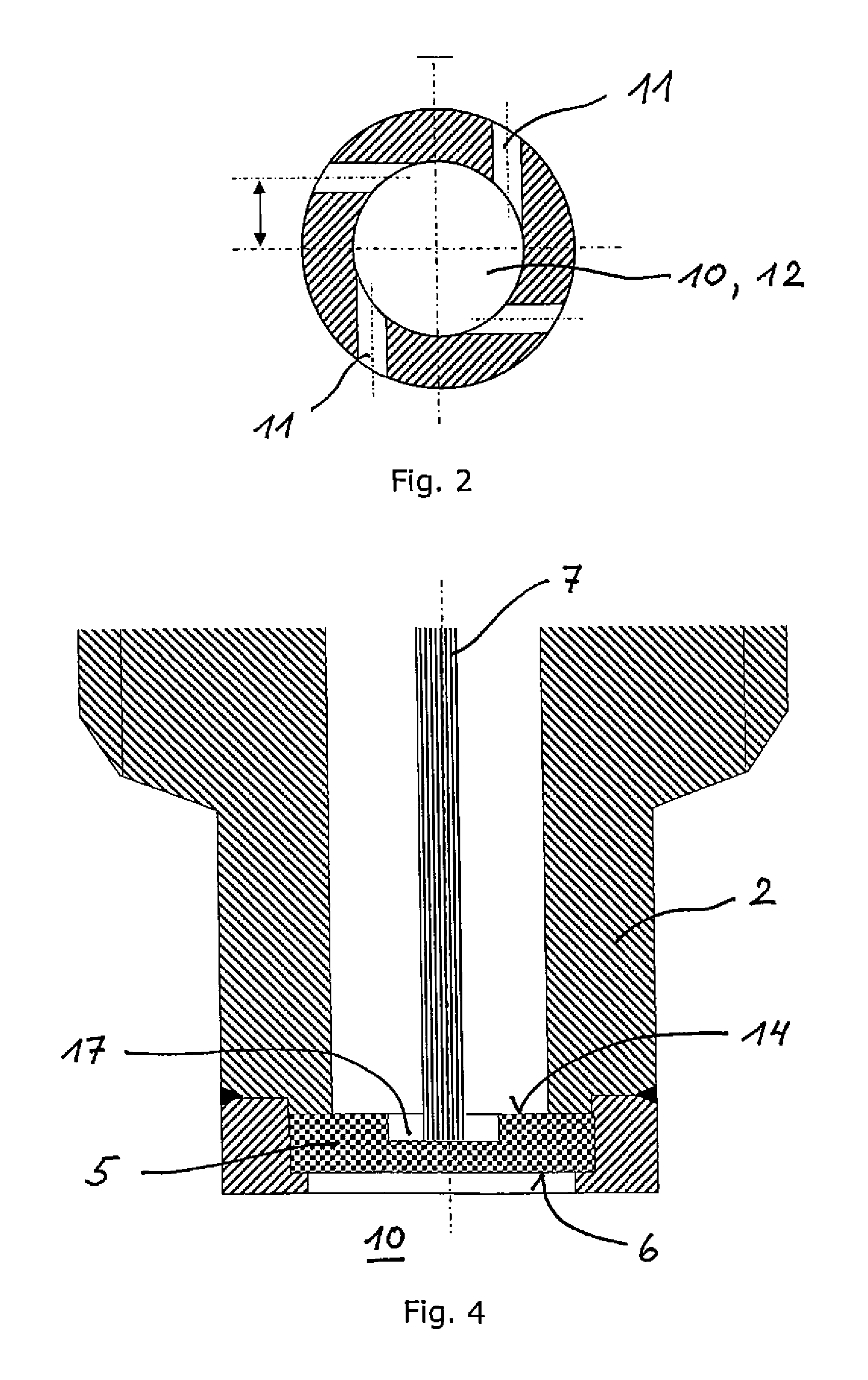

Laser ignition for gas mixtures

ActiveUS20100147259A1Reduce riskReliable ignitionCombustion enginesIgnition sparking plugsCombustion chamberInternal combustion engine

Owner:MULTIFLASHLIGHT

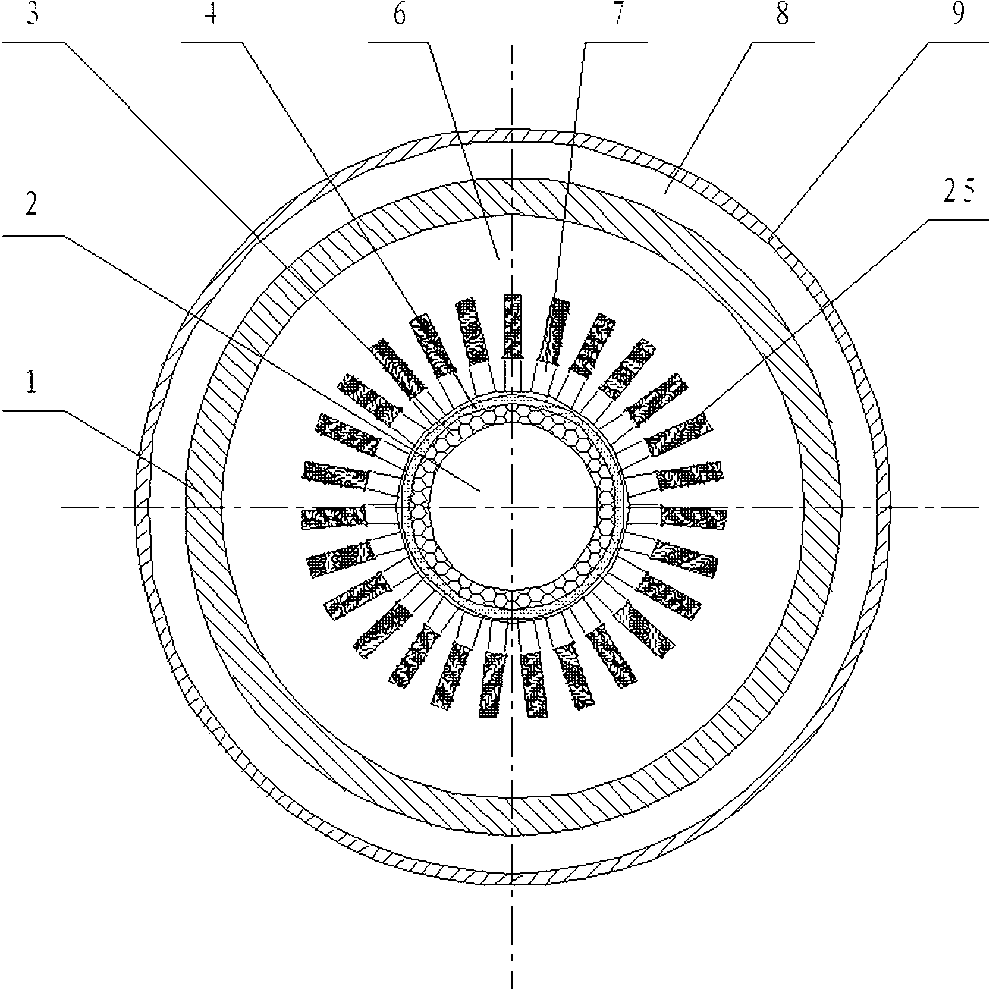

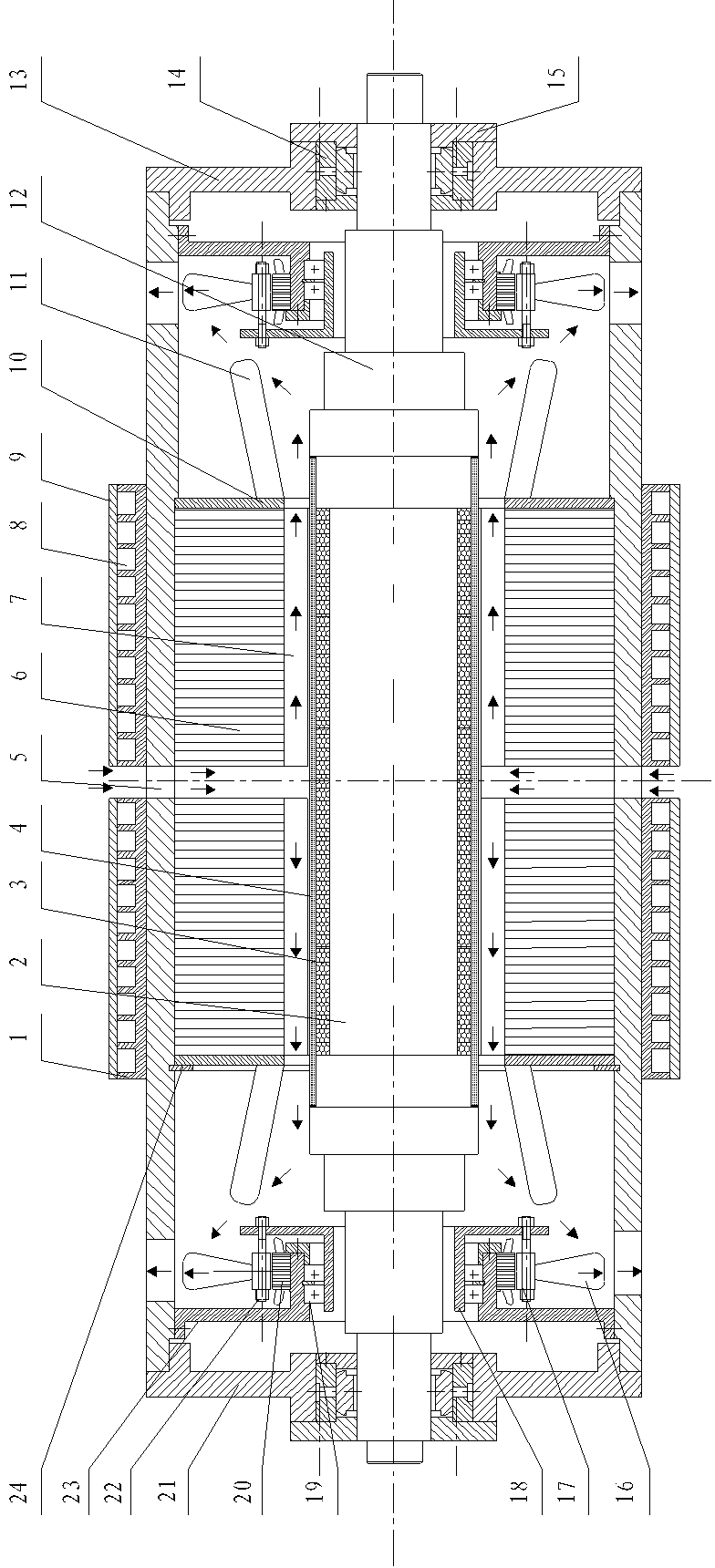

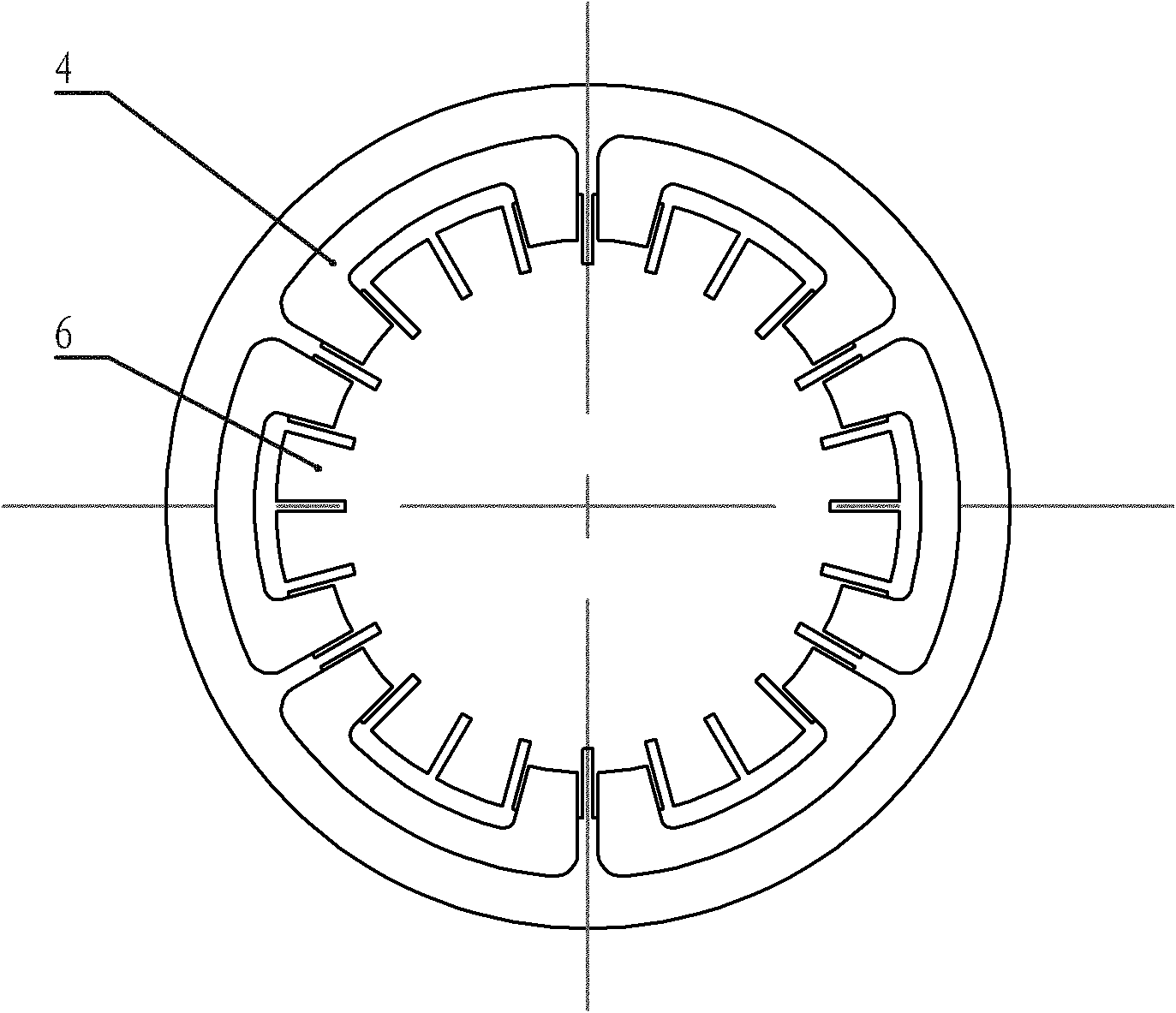

Air and water hybrid cooling high-speed permanent-magnet motor

InactiveCN102983680AReduce eddy current lossLow heat generationMagnetic circuit rotating partsMagnetic circuit stationary partsWater flowPermanent magnet motor

The invention discloses an air and water hybrid cooling high-speed permanent-magnet motor and belongs to the technical field of motors. The large-power high-speed permanent-magnet motor comprises a casing, a cooling water jacket, a stator core, a stator radial air duct, a stator inner air duct, a motor rotor, an outer rotor axial fan, an outer rotor fan fixing frame and two sliding bearings. The stator core is divided into two sections, the radial air duct is reserved in the middle, and the inner air duct is reserved in a stator slot close to the air gap position. The cooling water jacket is arranged outside the stator casing, a spiral water way is arranged in the water jacket, and water flows into the water way from the middle of the water way and flows out from a left spiral water outlet and a right spiral water outlet which are arranged at two ends of the water way. The air and water hybrid cooling high-speed permanent-magnet motor can mechanically solve the problem that a permanent magnet is broken when bearing large pulling stress during high-speed rotating, further solves the problems that the large-power high-speed motor is large in loss density, difficult in heat dissipation and over high in temperature rising, and prevents the permanent magnet from having irreversible demagnetization easily at high temperature.

Owner:SHENYANG POLYTECHNIC UNIV

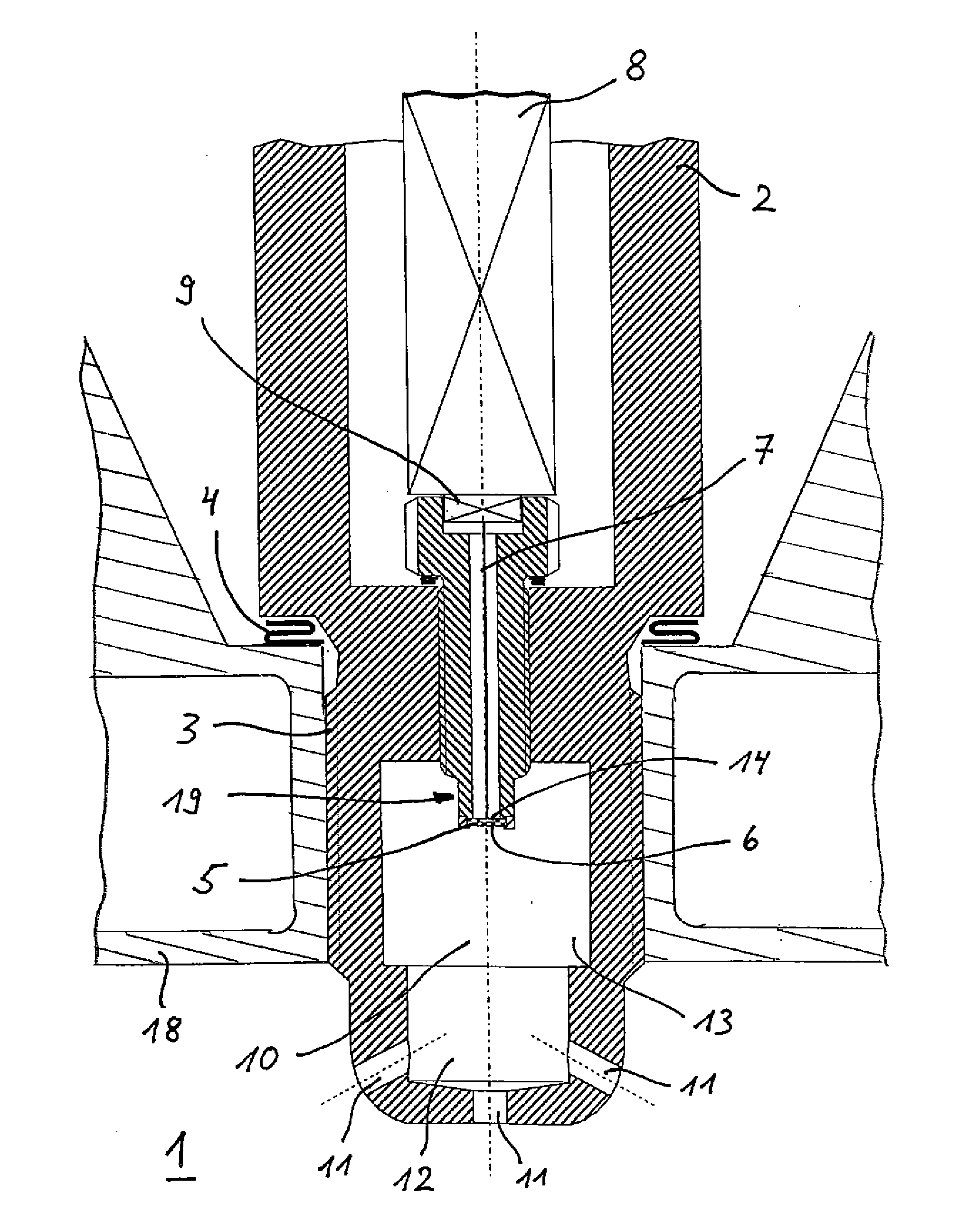

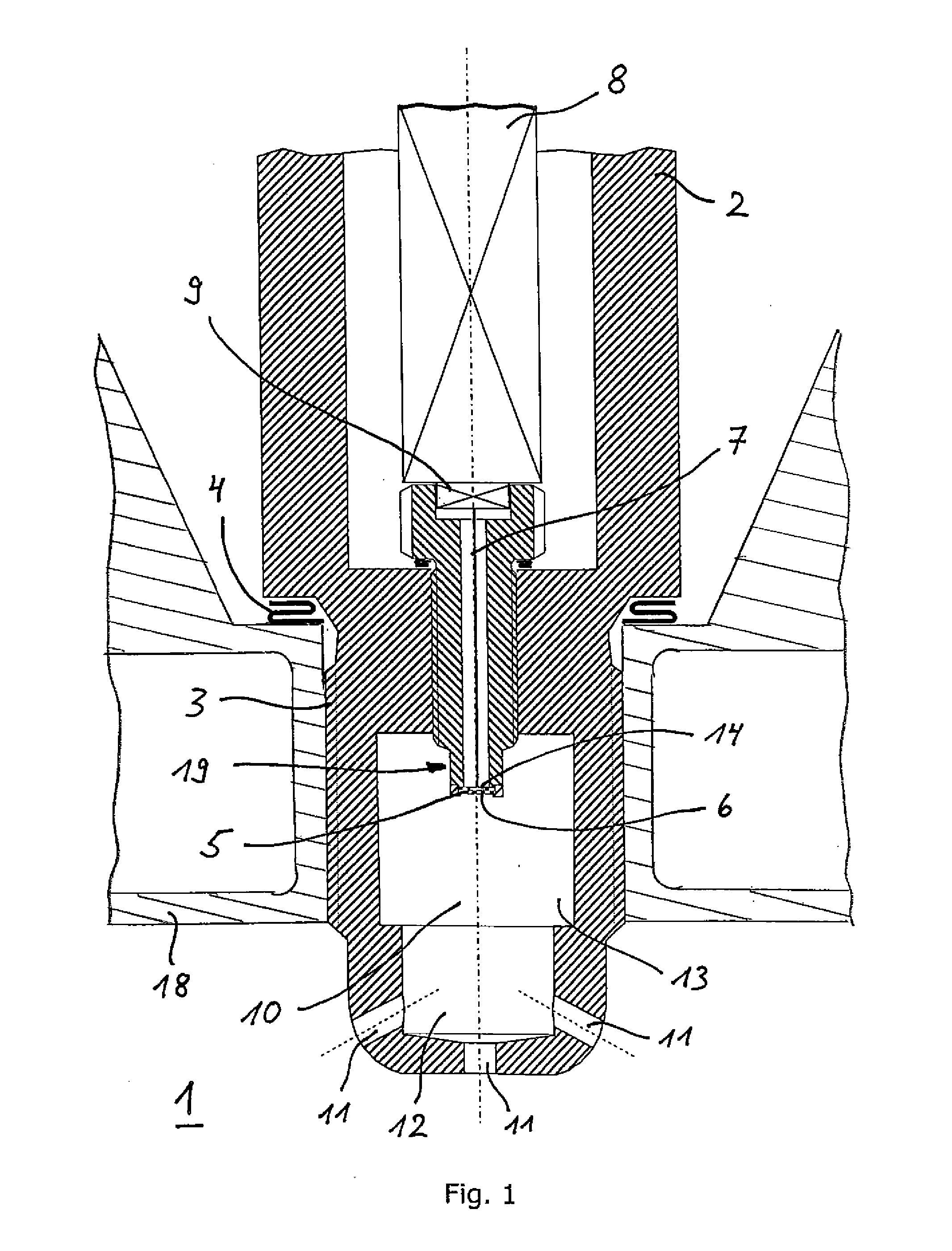

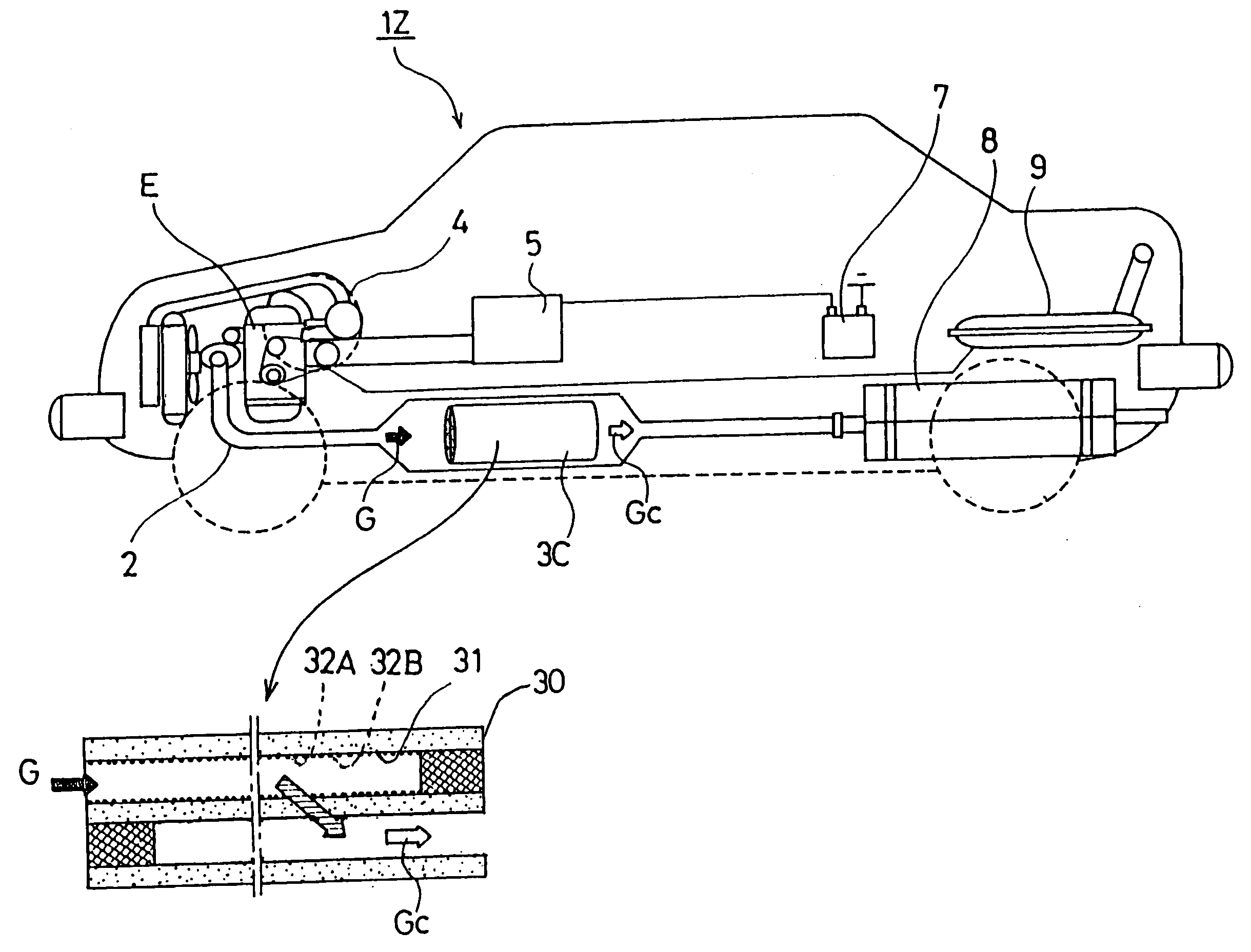

Laser ignition for gas mixtures

ActiveUS8181617B2Emission reductionReduce torque fluctuationCombustion enginesIgnition sparking plugsExternal combustion engineEngineering

An ignition device for the ignition of a gas mixture in a main combustion chamber (1), in particular of an internal combustion engine, is proposed, wherein the absorber body (5) is heated by means of a laser (8). A prechamber (10) is located upstream of the absorber body (5) on the combustion chamber inner side (6) in order to improve the ignition behavior.

Owner:MULTIFLASHLIGHT

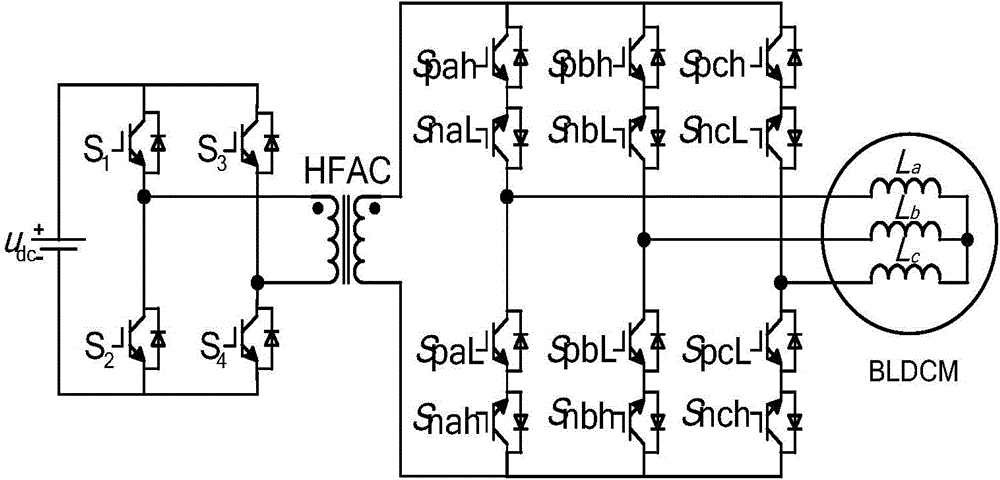

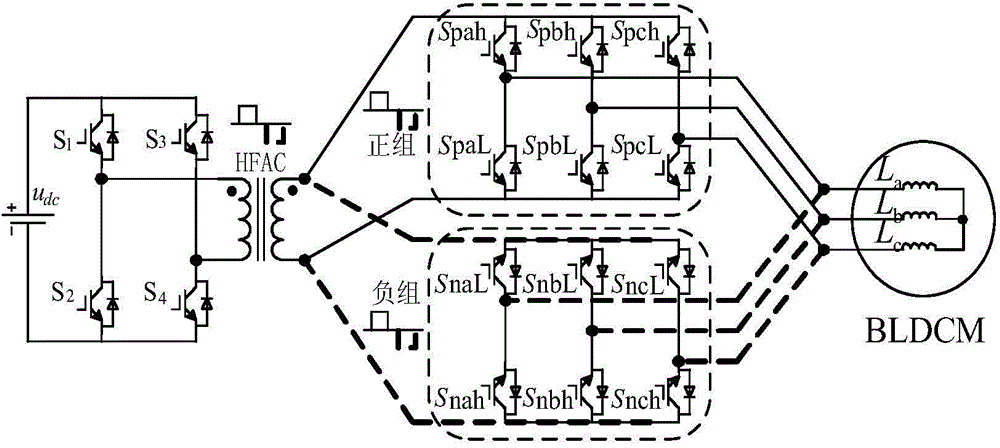

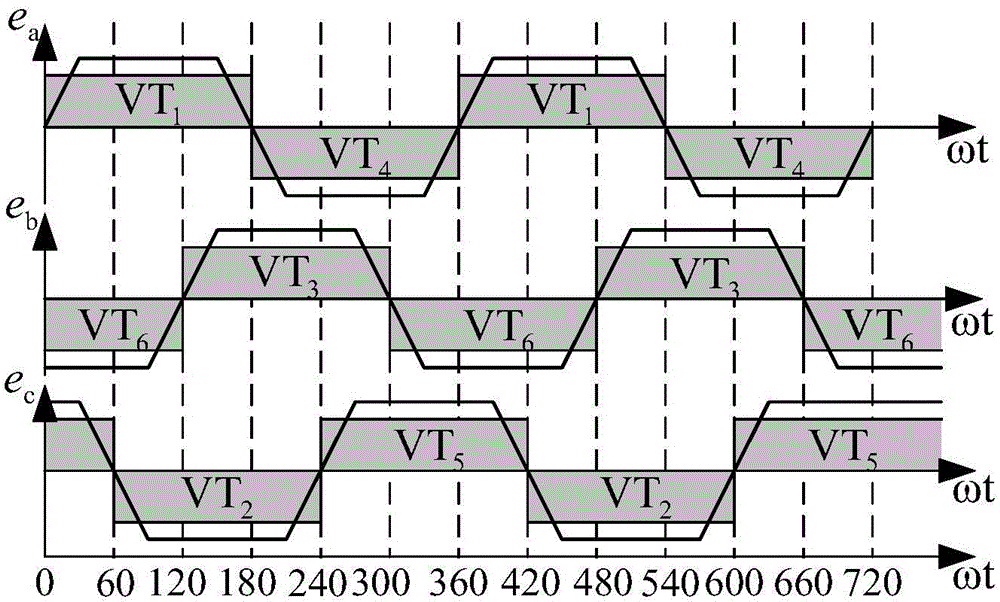

High-frequency-link driver for brushless motor of electric automobile

InactiveCN104579043AIncrease working frequencyReduce volumeTorque ripple controlAc-dc conversionBrushless motorsMatrix converters

The invention discloses a high-frequency-link driver for a brushless motor of an electric automobile and a 180-degree control method of a high-frequency-link driver. A high-frequency-link matrix converter is used in a driver of the electric automobile, so that the driver of the electric automobile has the capacity of a brushless direct-current motor. A high-frequency-link matrix converter decoupling thinking and circuit driving signals of a common full-bridge brushless direct-current motor 180-degree triangular conduction control mode are used together to obtain a novel modulation strategy of the high-frequency-link matrix converter with a brushless direct-current motor load, three windings of the motor can be controlled to operate together by a triangular conduction brushless motor control system, the use ratio of the windings is improved further, torque fluctuation is reduced, and the outputting power of the motor is increased. The high-frequency-link driver for the brushless motor of the electric automobile has a wide application prospect in the field of electric automobiles.

Owner:闫朝阳 +1

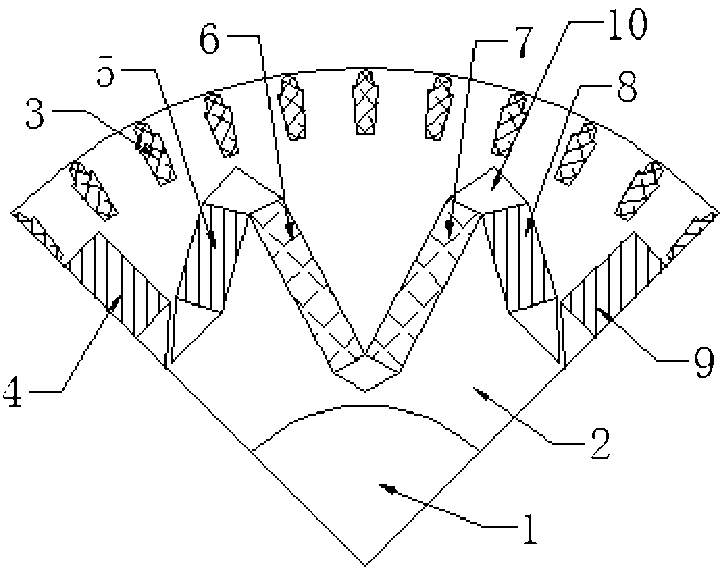

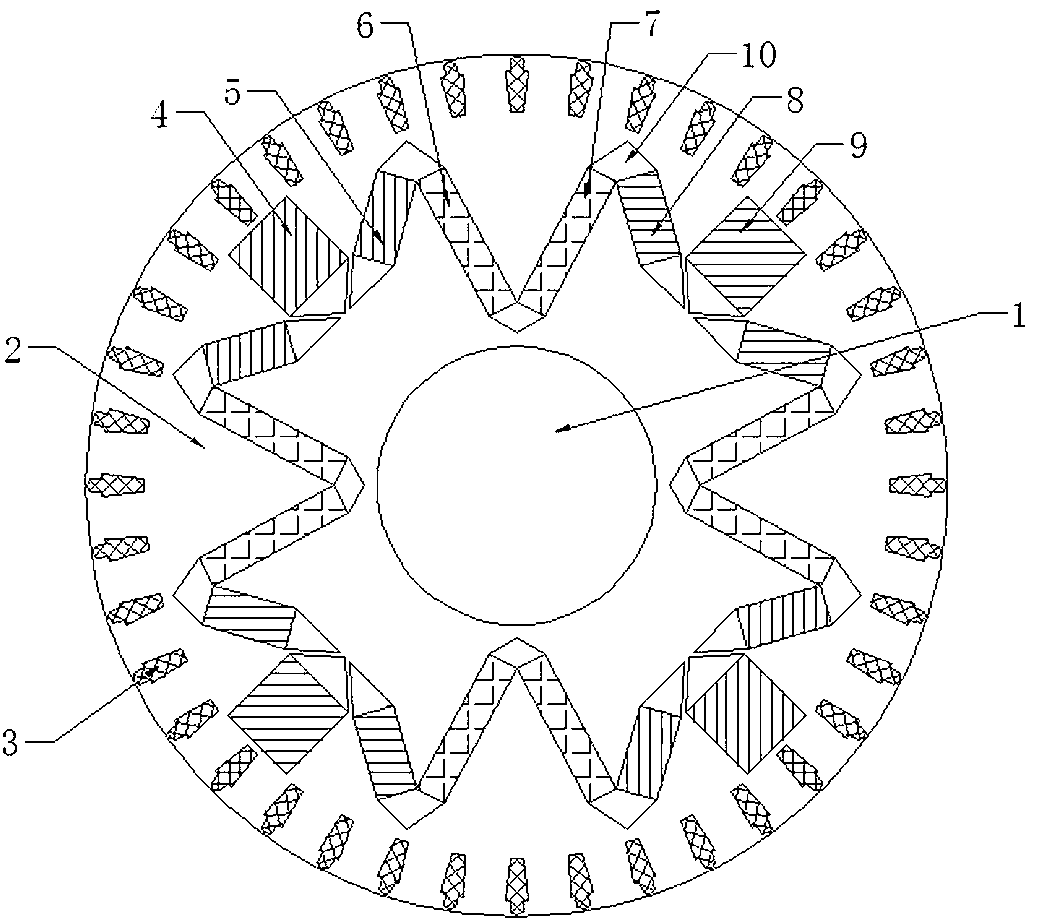

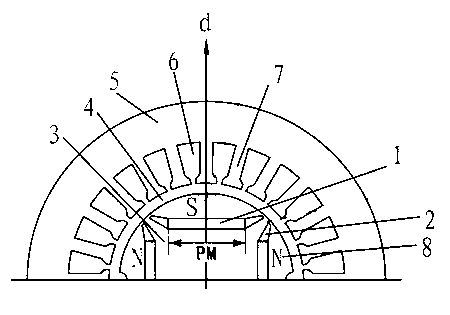

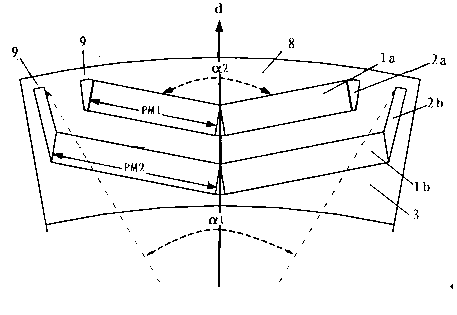

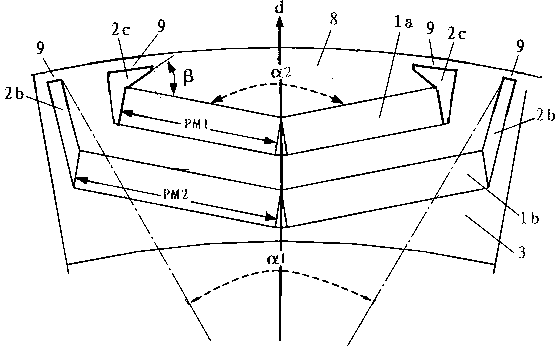

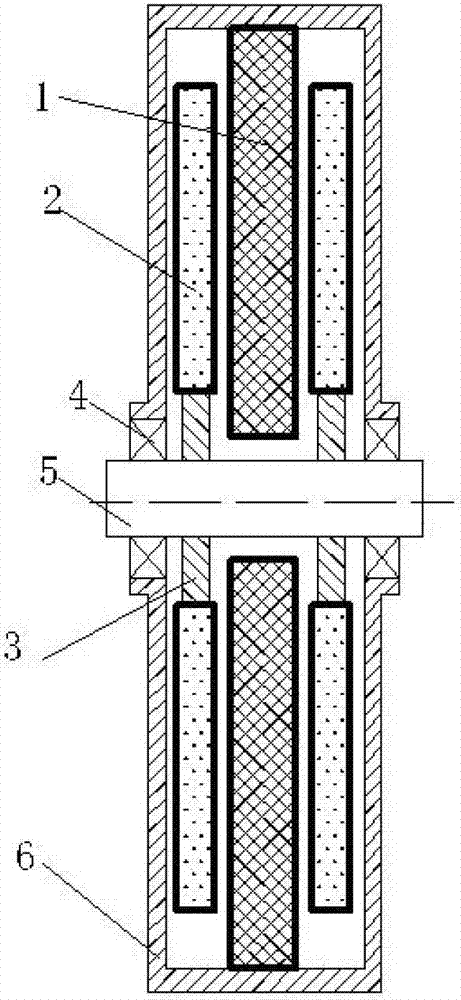

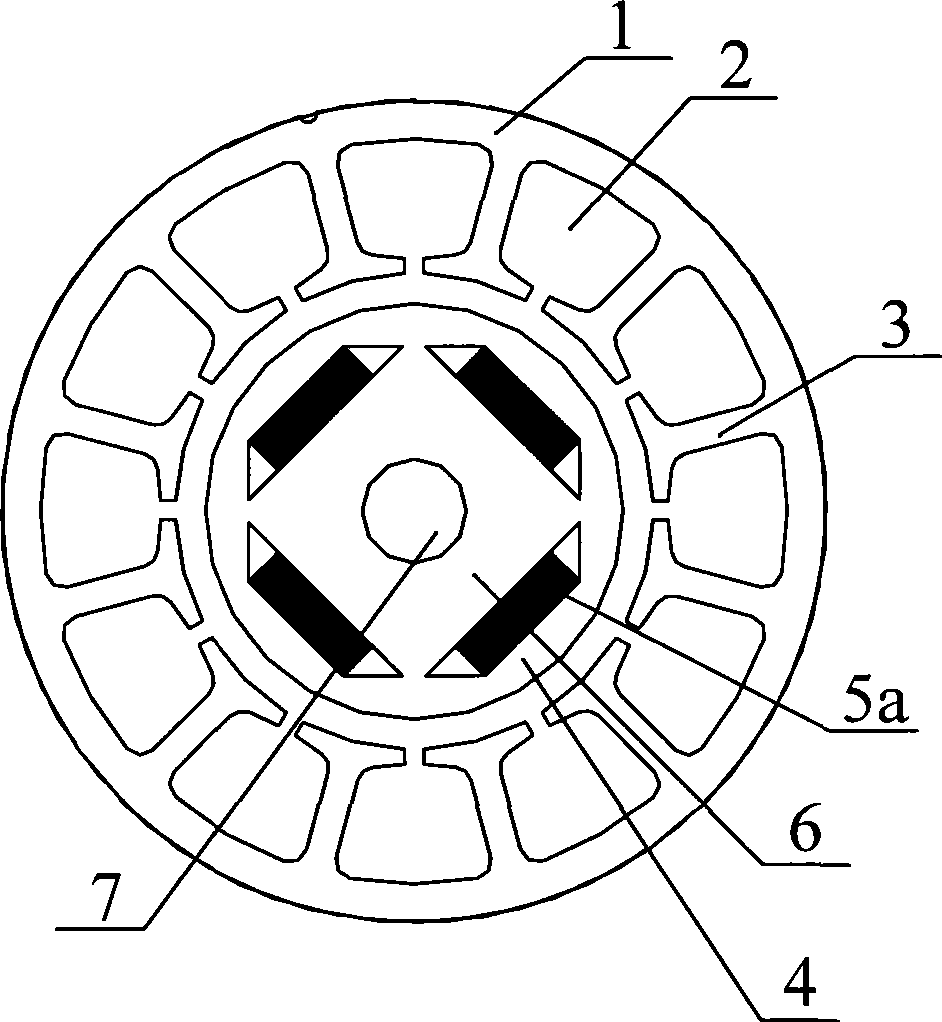

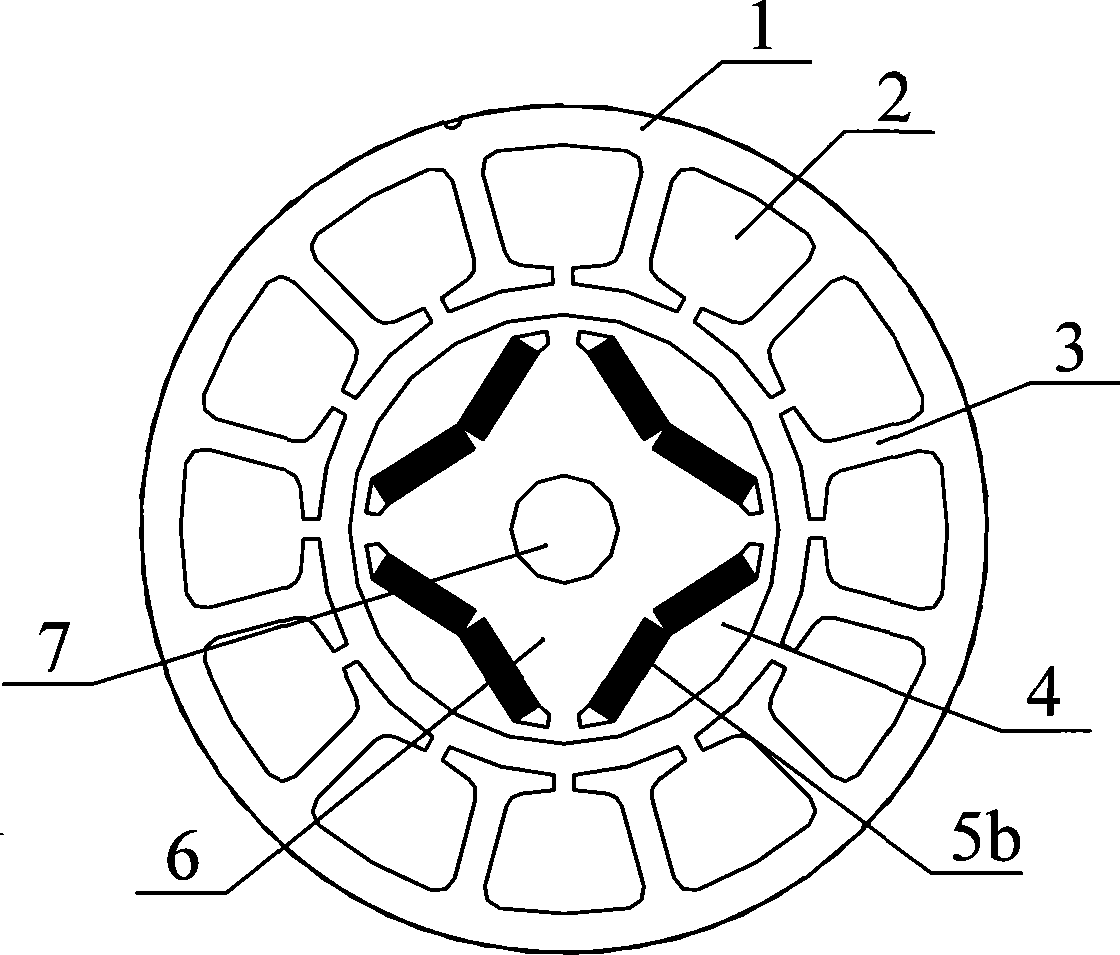

Asynchronous starting permanent magnet synchronous motor rotor based on permanent magnets with different residual magnetic densities

ActiveCN103219814ALow costReduce dosageMagnetic circuit rotating partsElectric machinePermanent magnet synchronous motor

The invention relates to an asynchronous starting permanent magnet synchronous motor rotor based on permanent magnets with different residual magnetic densities, and belongs to the field of permanent magnet motors. The asynchronous starting permanent magnet synchronous motor rotor comprises a rotating shaft, a starting cage, a rotor iron core and the permanent magnets, wherein 2p VVV-shaped permanent magnet slots encircling the rotating shaft are uniformly formed in the rotor iron core; a first permanent magnet and a second permanent magnet are arranged in a first V-shaped slot; a third permanent magnet and a fourth permanent magnet are arranged in a second V-shaped slot; a fifth permanent magnet and a sixth permanent magnet are arranged in a third V-shaped slot; and magnetism isolation slots are reserved between the permanent magnets. On the premise that the stable-state running performance is not reduced, the cost of an asynchronous starting permanent magnet synchronous motor is effectively reduced, and the no-load air gap magnetic density waveform sine distortion rate is reduced; harmonic waves are effectively suppressed; the efficiency of the motor is improved; the torque ripple is reduced; and the vibration noise is reduced.

Owner:SHENYANG POLYTECHNIC UNIV

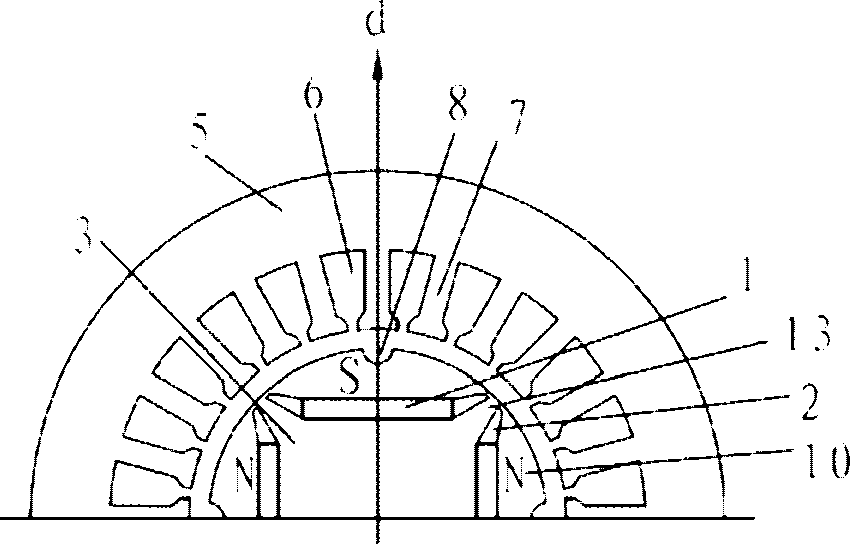

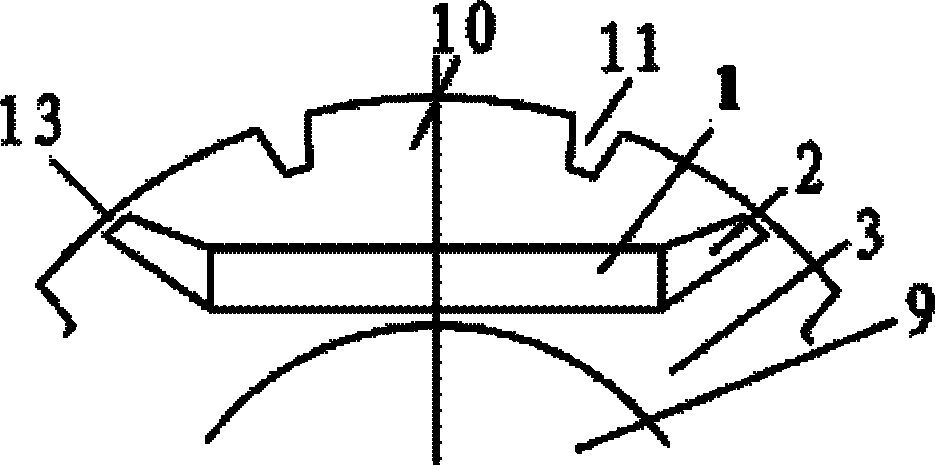

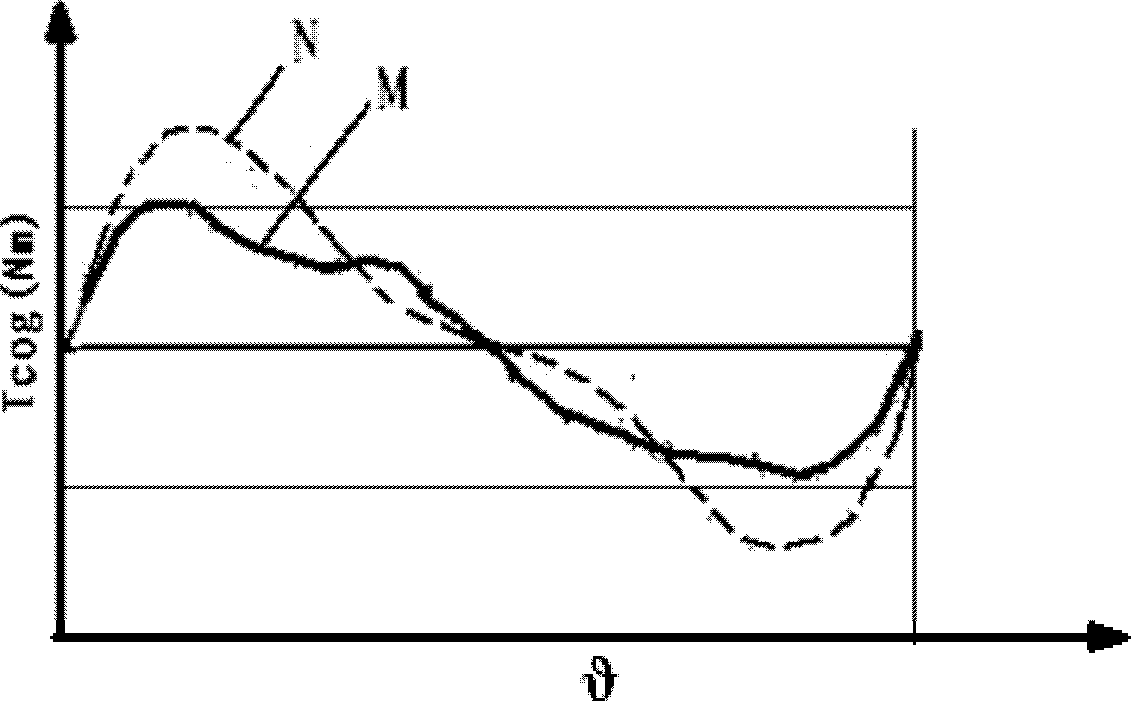

Built-in permanent-magnetic motor rotor and motor comprising same

InactiveCN102355071AReduce noiseImproved air gap magnetic field waveformMagnetic circuit rotating partsSynchronous machinesWave shapeControl theory

The invention discloses a built-in permanent-magnetic motor rotor, which comprises a rotating shaft and a rotor iron core, wherein the rotor iron core comprises a pole shoe, at least one permanent magnet body is arranged inside the pole shoe, and the outer circle of the pole shoe is provided with a plurality of grooves. The invention also discloses a motor, which comprises a stator and the rotor. Due to the adoption of the built-in permanent-magnetic motor rotor, the waveform of an air gap field of the motor can be improved, fundamental wave times of the cogging torque fluctuation can be increased, the cogging fundamental wave and the ultra-harmonics torque amplitude can be reduced, and the torque fluctuation caused by the cogging can be reduced.

Owner:苏州和鑫电气股份有限公司

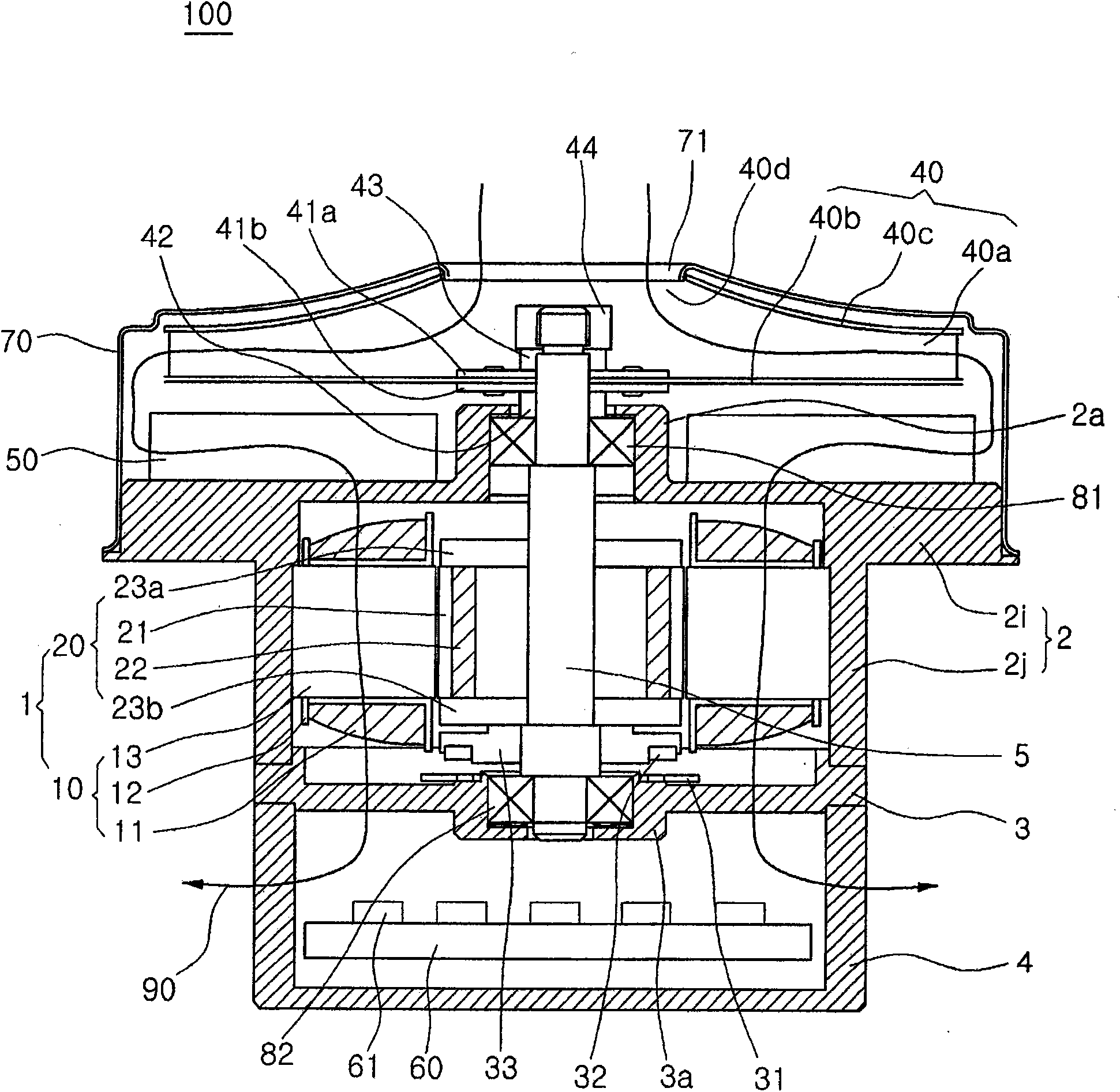

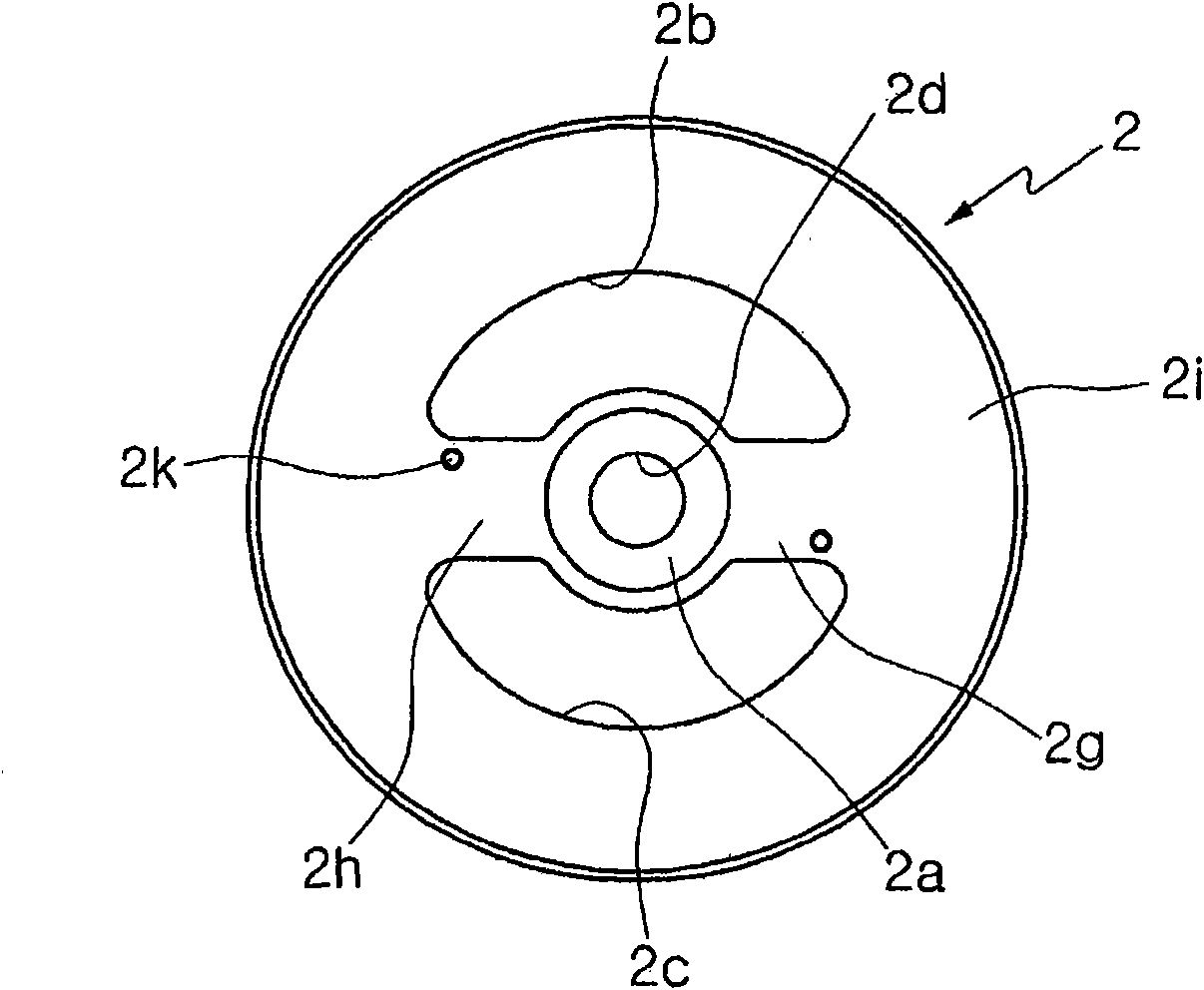

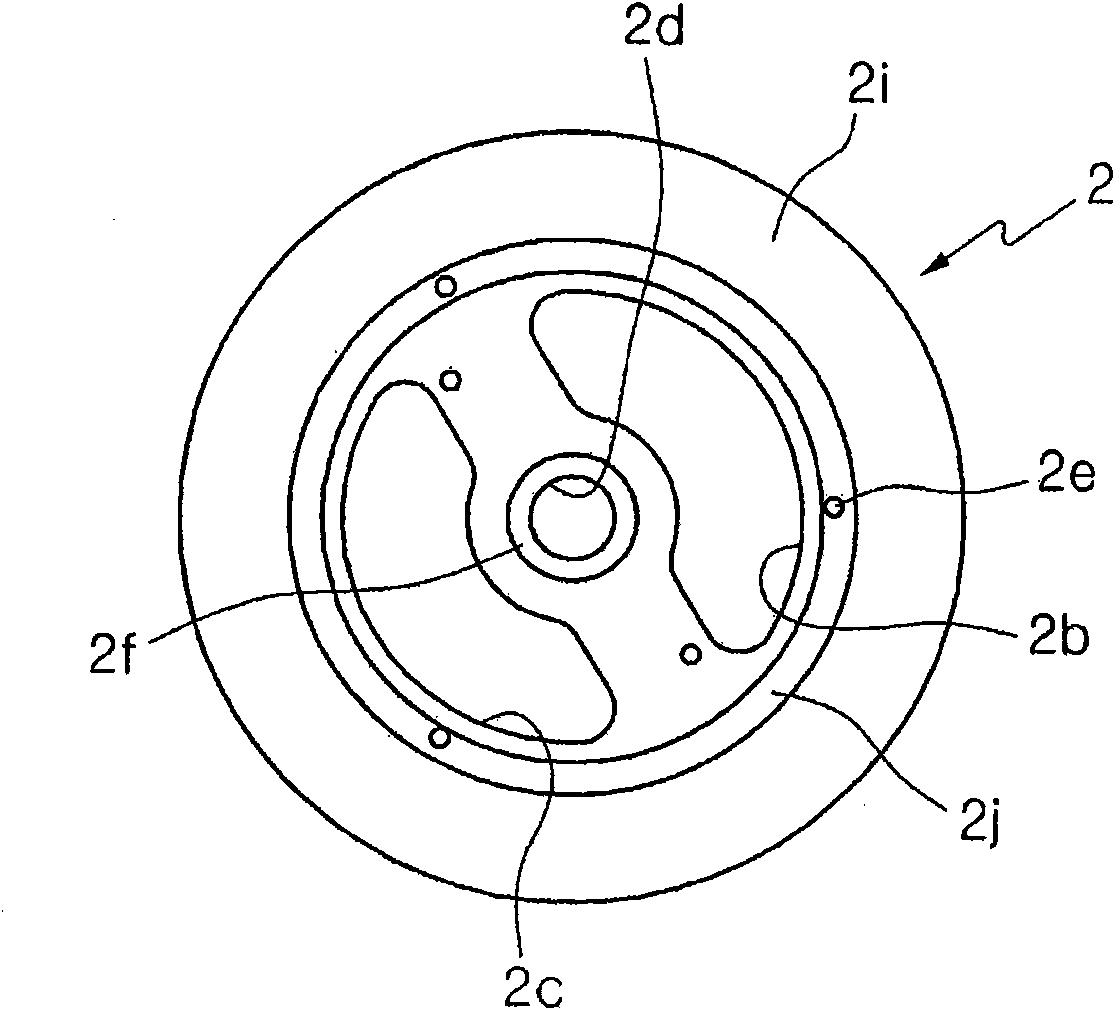

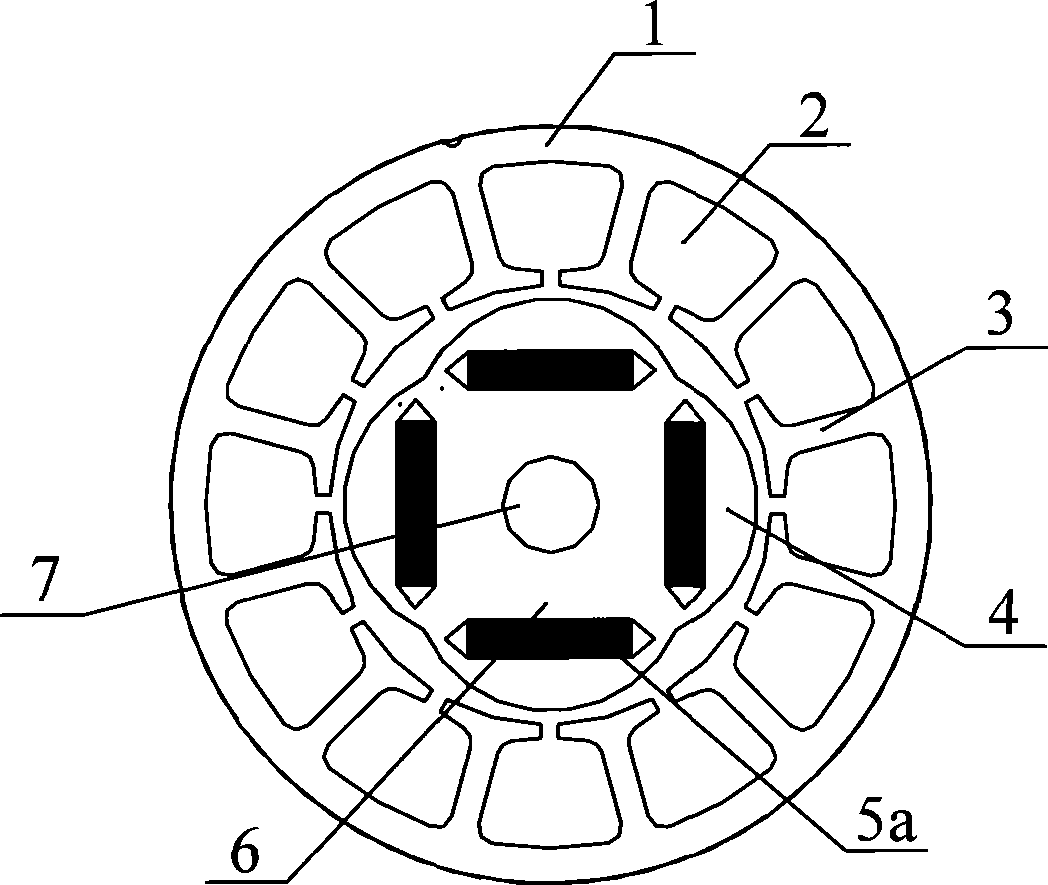

IPM motor and vacuum inhaling apparatus using the same

InactiveCN101802415AThe factor of frictional resistance is minimizedAchieve coolingPump componentsPiston pumpsRotational axisStator coil

Provided is a high speed and high efficiency IPM (Interior Permanent Magnet) motor and a slim type vacuum inhaling apparatus using the same, which establishes a passage path of introduced air into a path of air-cooling the inside of a stator and a circuit element to thus cool heat that is produced from the IPM motor without a special heat radiator. The IPM motor includes: a stator having a number of tees which are protruded so as to form a number of slots on the inner circumferential wall of a cylindrical body, and a stator coil which is partially wound around the slots; and an IPM type rotor having a rotor core at the central side of which a rotating shaft is mounted, and a number of permanent magnets which are fitted into a number of permanent magnet insertion holes which are formed on the identical circumference of the rotor core, and which is rotated by the stator. The permanent magnet includes a first group of permanent magnets and a second group of permanent magnets which wholly have two-pole magnetic pole structure and form a first spacer and a second spacer between the first group of permanent magnets and the second group of permanent magnets to prevent the leakage of magnetic flux in the circumference direction.

Owner:AMOTECH

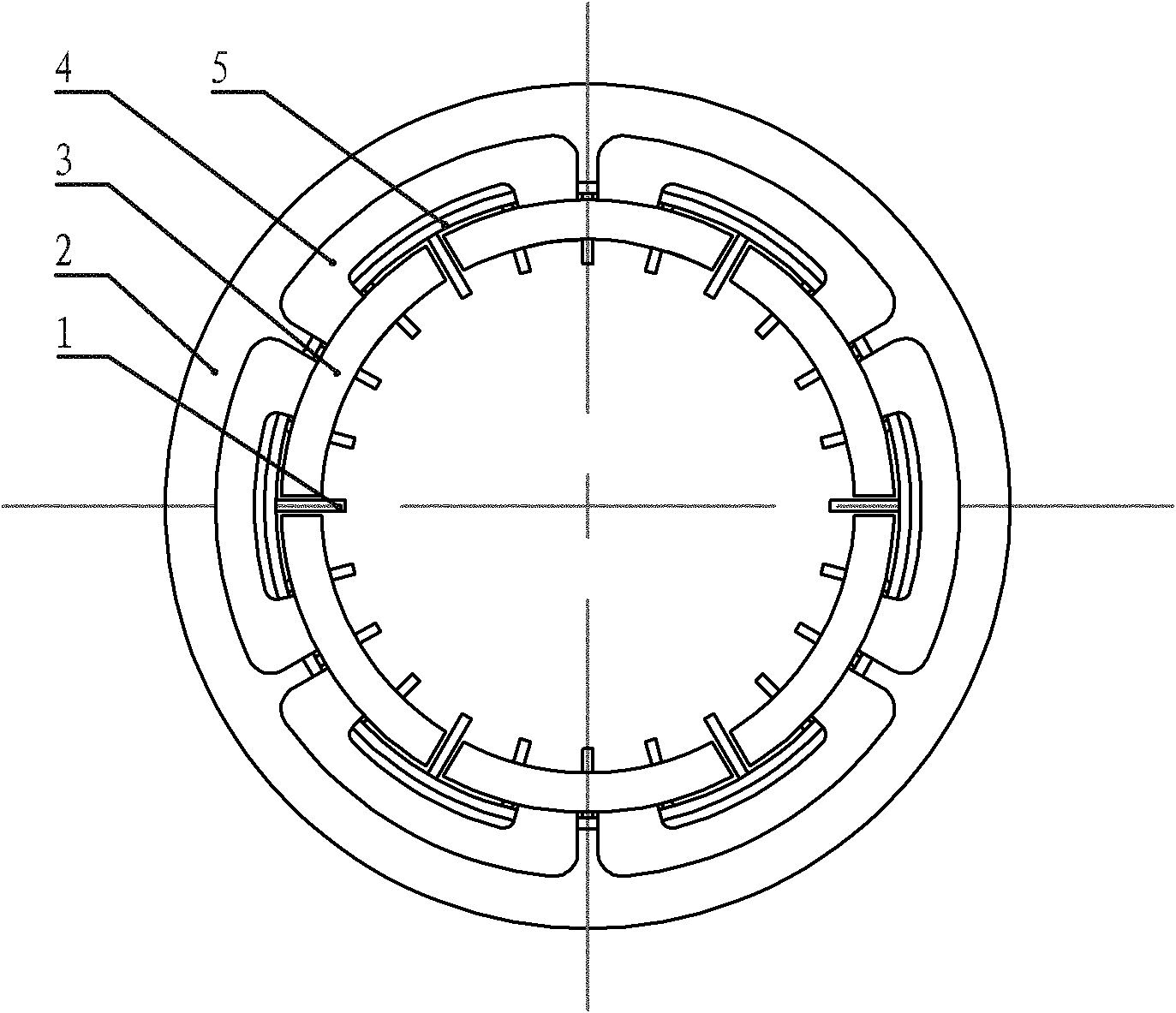

Double-layer V-shaped built-in permanent magnet motor rotor for electric automobile

InactiveCN103280904AImproved air gap magnetic field waveformImprove resultant torque rippleSynchronous machine detailsMagnetic circuit rotating partsConstant powerMagnet

The invention relates to a double-layer V-shaped built-in permanent magnet motor rotor for an electric automobile. Multiple groups of permanent magnet slots which are radially arranged in an inner layer and an outer layer are uniformly arranged on the iron core of the rotor at intervals along the circumferential direction; one or more V-shaped magnetized stripy magnetic steel is embedded in each permanent magnet slot. By virtue of the optimization of structures such as the angle of polar arc of inner-layer V-shaped magnetic steel, the included angle of outer-layer V-shaped magnetic steel, the width proportion of the inner-layer magnetic steel to the outer-layer V-shaped magnetic steel and the included angle of the outer-layer forcipated permanent magnet slot and the outer-layer magnetic steel, the air-gap flux density waveform is more approximate to the sinusoidal distribution, the harmonic component is reduced, the air-gap field waveform of the motor is improved, the fundamental wave frequency of spline torque fluctuation is improved, the spline fundamental wave and the ultraharmonics torque amplitude value are reduced, the torque fluctuation caused by splines is reduced, and the synthesis torque fluctuation of the motor is greatly reduced; and meanwhile, the reluctance torque is obviously increased, the salient pole rate and flux weakening speed expanding capability of the motor are improved, a constant-power speed range wider than that of a surface-mounted permanent magnet motor can be obtained, and the driving requirement of electric and hybrid automobiles can be met.

Owner:苏州和鑫电气股份有限公司

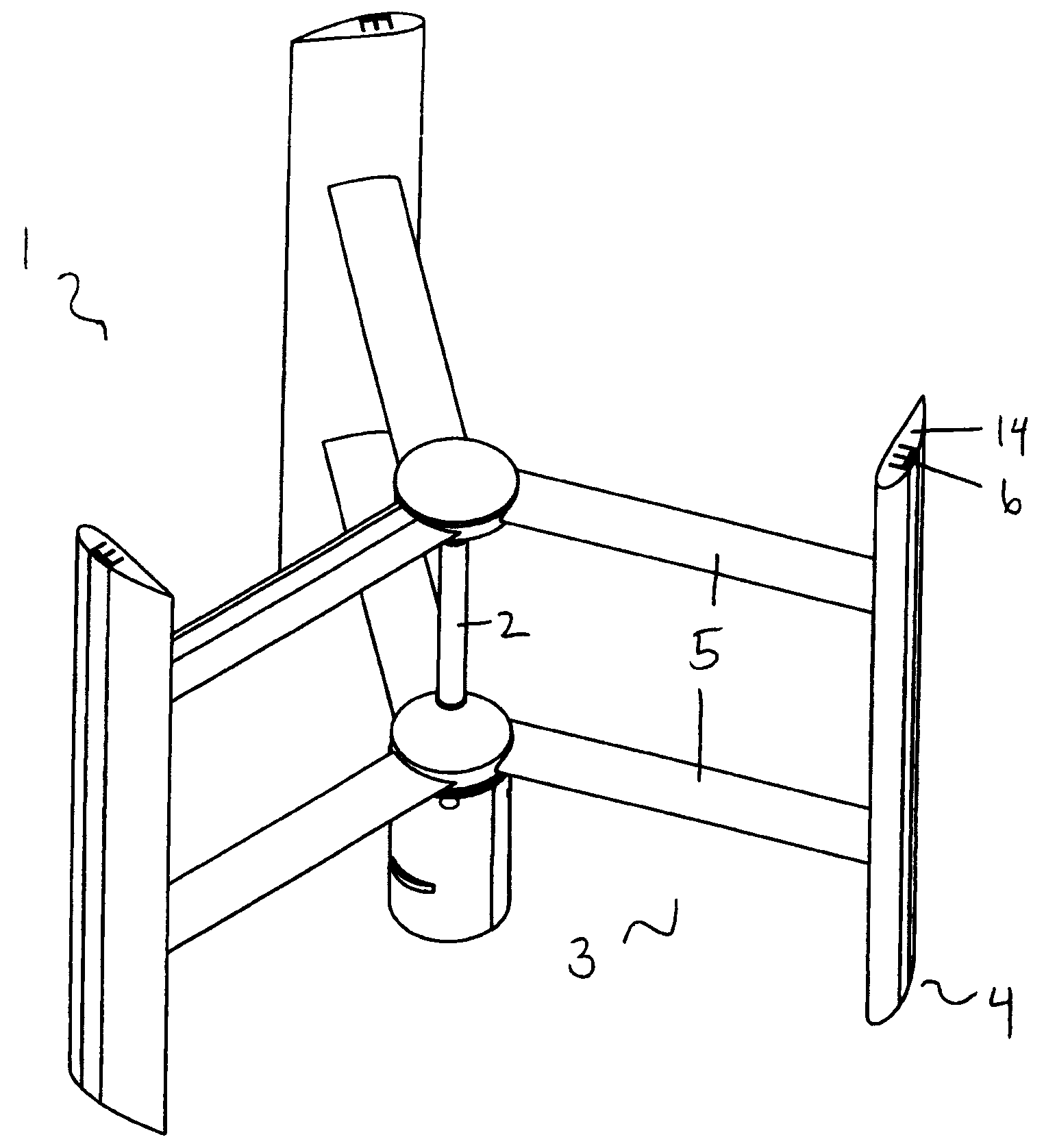

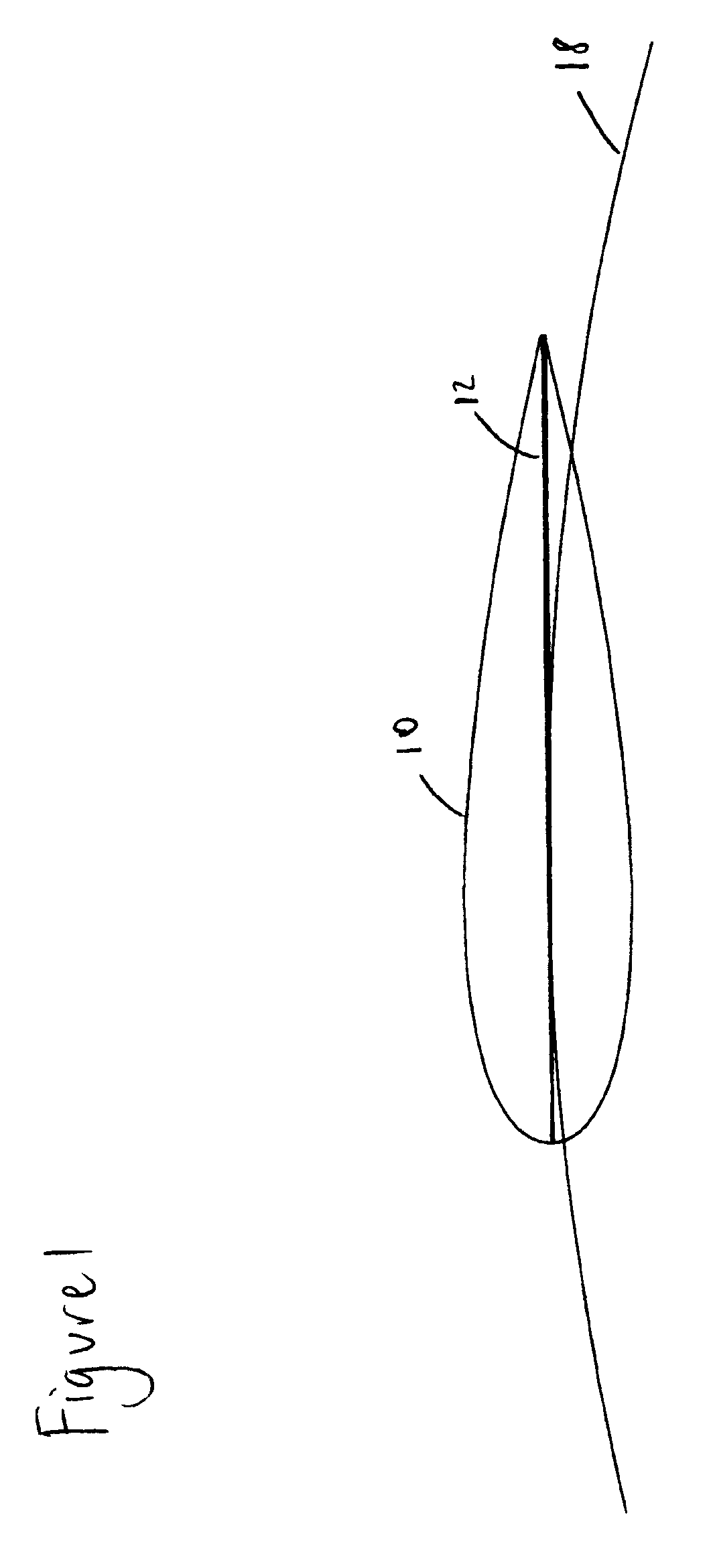

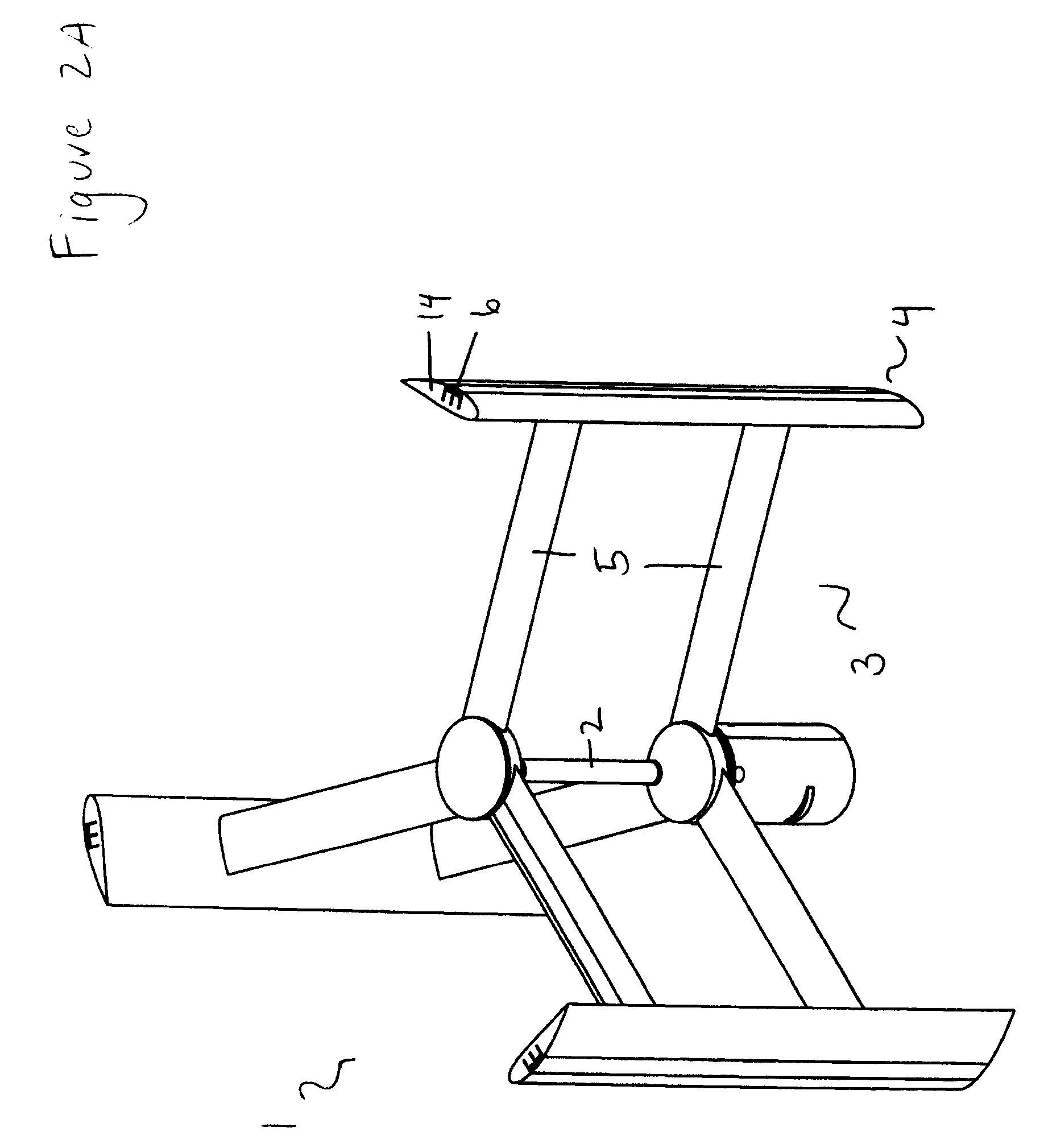

Wind turbine blade having curved camber and method of manufacturing same

InactiveUS20080256795A1Reduce torque fluctuationRotary propellersFinal product manufactureTurbine bladeVertical axis wind turbine

A wind turbine blade for a vertical axis wind turbine (VAWT) having a curved camber and a method of manufacturing same is disclosed. The method of manufacturing a turbine blade comprises determining the profile of an airfoil of the blade and forming the blade having the airfoil with the translated profile. The step of determining the profile of an airfoil of the blade comprises selecting a symmetrical airfoil having a straight mean camber line and a desired chord length; selecting a circular segment having the same radius as a path traveled by the blade around a hub of the VAWT and locating the circular segment to contact the mean camber line at at least one point; translating the mean camber line of the symmetrical airfoil such that it overlaps with the circular segment; and determining the profile of the airfoil blade by translating the profile of the symmetrical airfoil to correspond with the translated mean camber line of the symmetrical airfoil.

Owner:WINDTERRA SYST

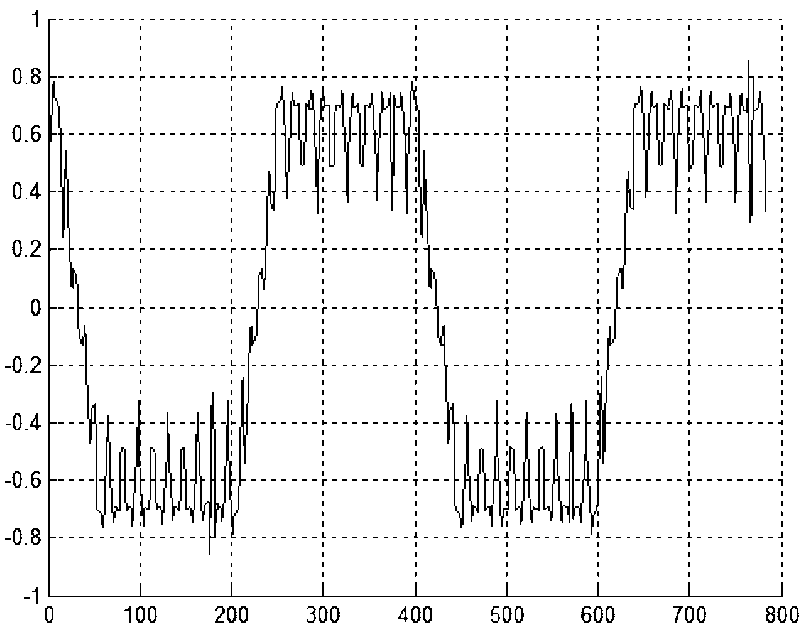

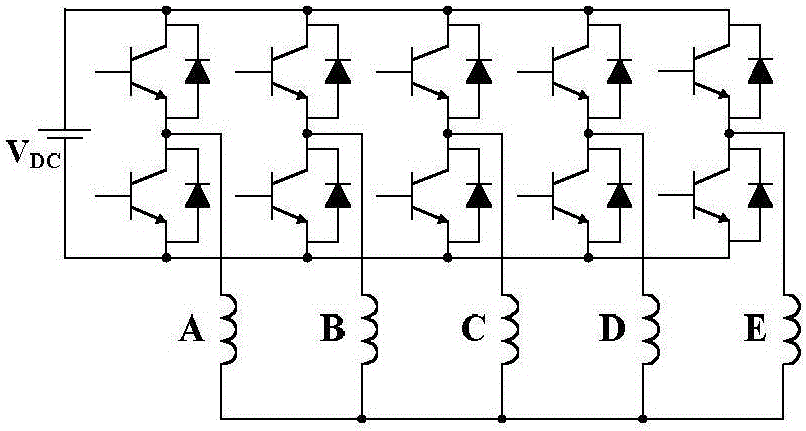

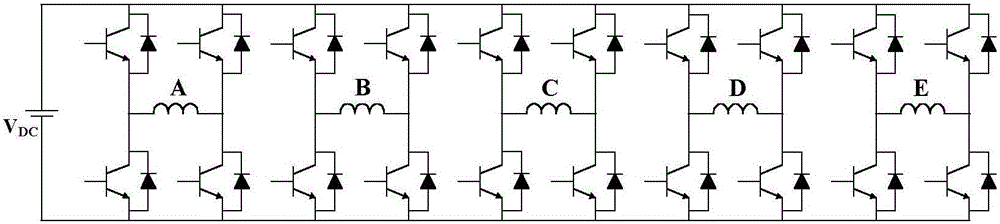

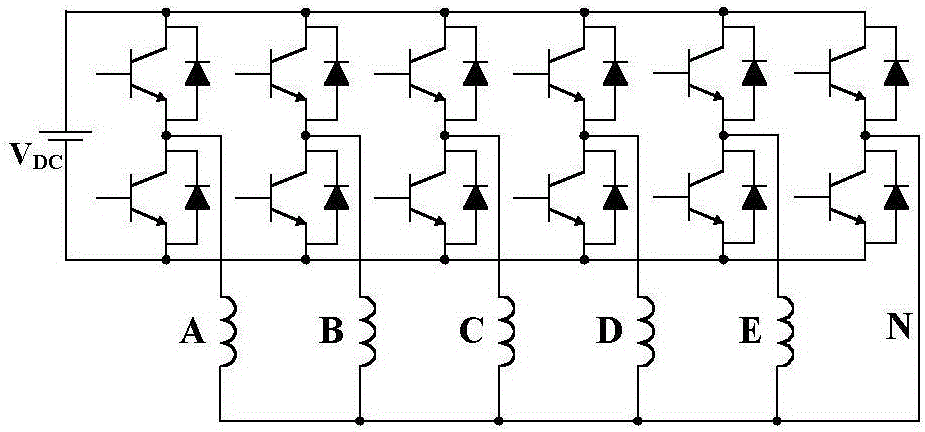

Current setting method for open-circuit fault tolerance control of five-phase permanent magnet synchronous motor

ActiveCN105743398AIncreased torque output capabilityHigh torqueTorque ripple controlPreconditionElectrical current

A current setting method for open-circuit fault tolerance control of a five-phase permanent magnet synchronous motor belongs to the field of motor control. The current setting method settles a problem of low motor torque output capability in fault tolerance control of routine five-phase permanent magnet synchronous motor open-circuit faults. The current setting method is characterized in that a five-phase permanent magnet synchronous motor is powered by a five-phase full-bridge or five-phase six-bridge inverter; on condition that one-phase, two-phase or three-phase winding open-circuit fault of the motor occurs, for making the motor output a highest smooth torque, maximizing of amplitude of a forward rotation component is required under a precondition that a forward rotation component in a synthetic magnetomotive force is zero; and a positive circular rotating magnetic field with highest amplitude is generated in an air gap. The input current of each residual winding phase is adjusted. Compared with a traditional winding open-circuit fault tolerance control method, the current setting method can improve torque output capability of the five-phase permanent magnet synchronous motor on the condition of winding open-circuit fault, realizing higher output torque and smaller torque fluctuation.

Owner:黑龙江省工研院资产经营管理有限公司

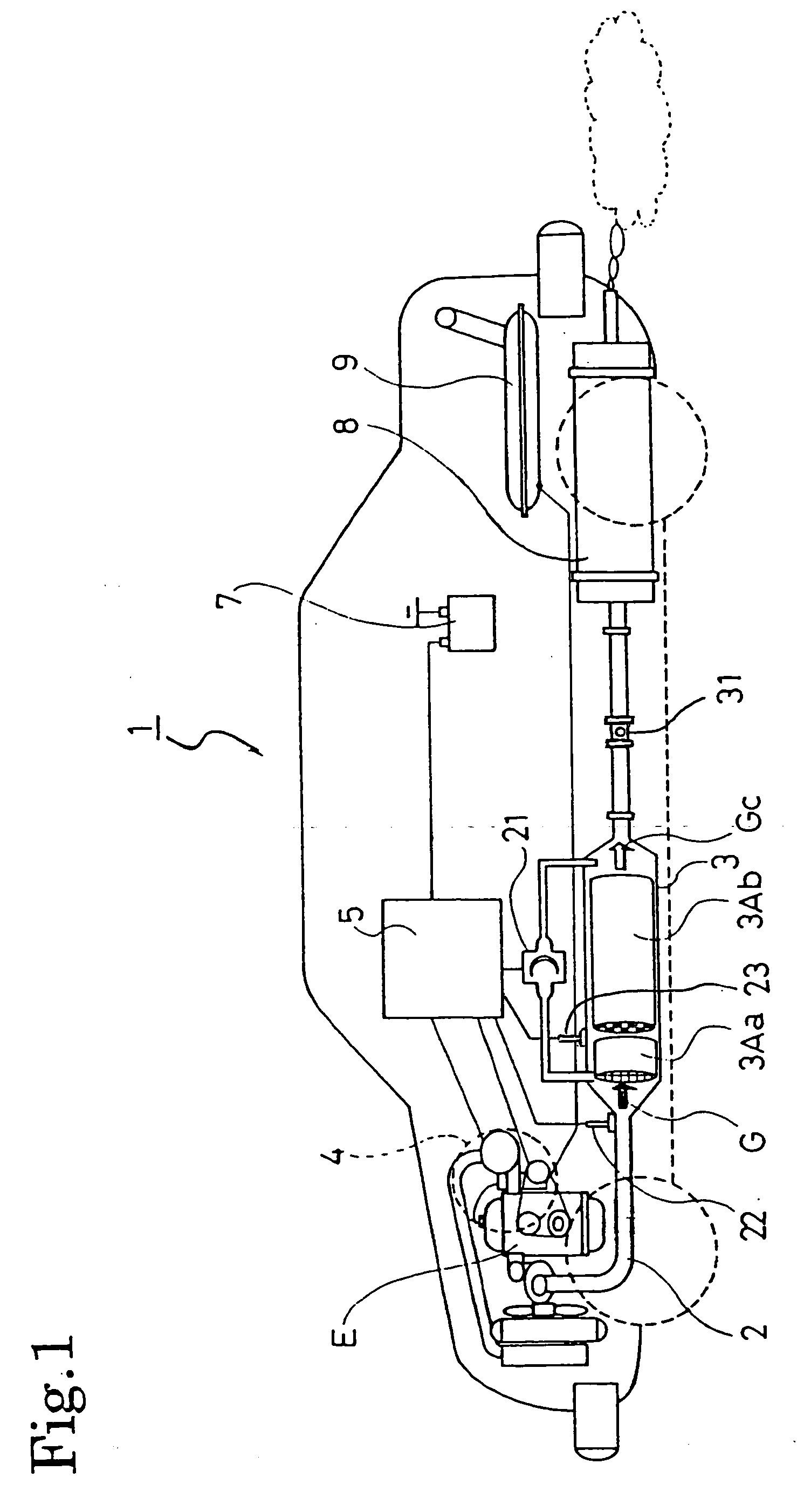

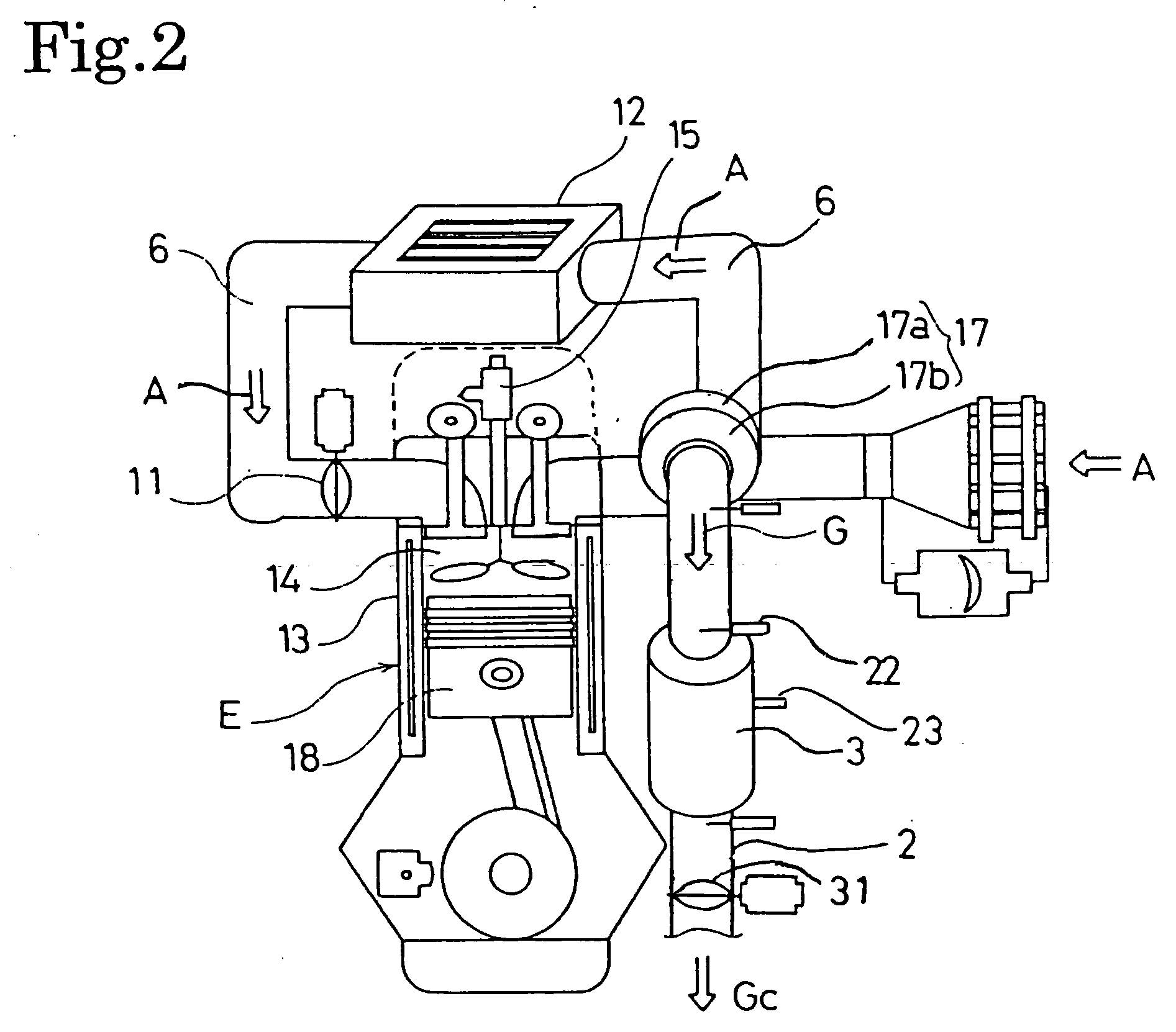

Exhaust gas cleaning system

ActiveUS20060201144A1Improve fuel efficiencyReduce exhaust temperatureElectrical controlInternal combustion piston enginesLower limitCombustion

An exhaust gas purifying system causes less torque fluctuation and is capable of preventing the occurrence of white smoke in a regeneration control operation for regenerating a continuous regeneration DPF 3. When the continuous regeneration DPF 3 with an oxidation catalyst 3Aa on the upstream side of a filter 3Ab is controlled to regenerate, an exhaust throttle valve 31 provided in an exhaust passage 2 is closed and a delay multi-step injection control is performed to increase the temperature of the exhaust gas if an exhaust temperature T1 at the inlet of the oxidation catalyst 3Aa is less than the activation temperature Ta of the oxidation catalyst. After the exhaust temperature T1 at the inlet of the oxidation catalyst 3Aa has risen to the activation temperature Ta of the oxidation catalyst or higher, the exhaust throttle valve 31 is opened in a stepwise or continuous manner so that the exhaust temperature T2 at the inlet of the filter 3Ab rises to a lower limit temperature of PM forced combustion Tb1 or higher.

Owner:ISUZU MOTORS LTD

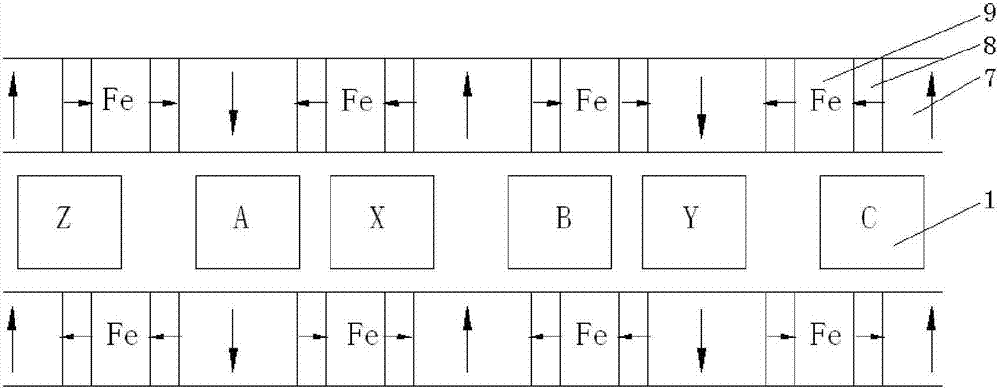

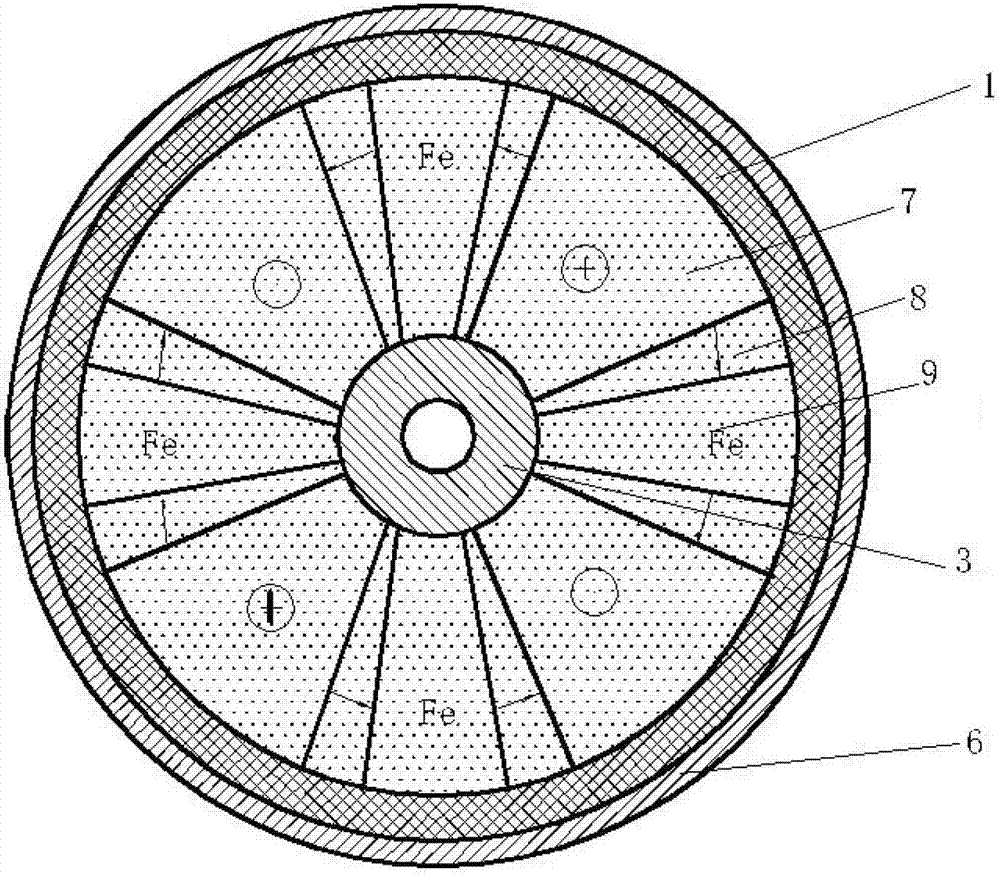

Halbach-structure-based iron-core-free axial magnetic field brushless direct-current electromotor

InactiveCN102904404AEliminate cogging torque and core lossEliminate axial magnetic forceMagnetic circuit rotating partsElectric machinesPhysicsTorque density

The invention discloses a Halbach-structure-based iron-core-free axial magnetic field brushless direct-current electromotor which comprises a stator iron-core-free armature disc, a permanent magnet, a rotor disc, a shaft, a bearing and a rotor outer shell, wherein two symmetrical rotor discs are arranged at two sides of the stator iron-core-free armature disc; the stator iron-core-free armature disc and the rotor disc are installed on the shaft; the shaft is installed in the rotor outer shell through the bearing; the permanent magnet is pasted on the rotor disc, and is pasted on the inner surface of the rotor outer shell; a Halbach magnet structure with axial magnetizing and tangential magnetizing is adopted for the permanent magnet, and an enclosed magnetic circuit is formed automatically; and a soft magnetic material is placed at the middle of the permanent magnet with tangential magnetizing. According to the invention, on the basis that more permanent magnets are not used, flux density with great air clearance can be obtained, and are is in sine distribution; the output torque is high; the torque density is large; the efficiency is high; the structure is simple; the assembly is simple; and the Halbach-structure-based iron-core-free axial magnetic field brushless direct-current electromotor is suitable for relevant driving occasions with compact structures for electric automobile hub motors and the like.

Owner:SOUTHEAST UNIV

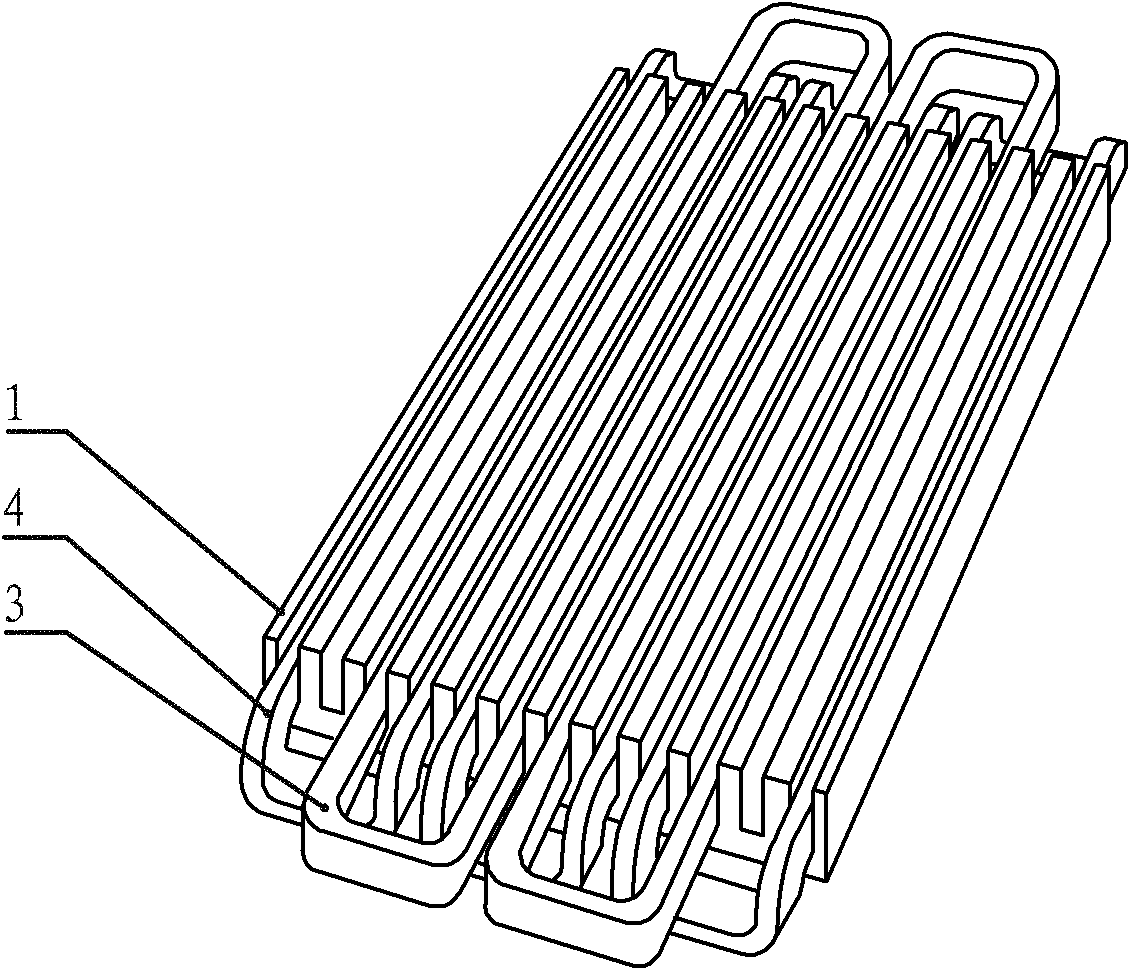

Efficient three-phase slot-free permanent magnet motor

ActiveCN101982930AImprove winding factorHigh positioning accuracyPropulsion systemsSynchronous machines with stationary armatures and rotating magnetsThin walledWinding factor

The invention provides an efficient three-phase slot-free permanent magnet motor, belonging to the field of a motor, which solves the shortcomings of low winding factor, low power density, high loss and high temperature rise of the existing slot-free motor. When the motor is a cylinder type rotary motor, an armature iron core is circular; a coil framework fixed at the side of the armature iron core close to the rotor is formed by a thin-wall cylinder and thin clapboards; a plurality of thin clapboards are evenly and fixedly distributed in the thin-wall cylinder in a radial pattern by taking the axis of the armature iron core as a symmetrical axis; a wiring slot is formed between two adjacent thin clapboards; the pitch of each coil in the winding is the distance between the adjacent four thin clapboards in the coil framework; half of end portion bending coils in 3p coils are orderly and adjacently embedded in the wiring slot formed by the thin clapboards; and the two ends both bend towards the stator iron core side; and the other coils are orderly and adjacently embedded in the wiring slot formed by the other thin clapboards, wherein effective sections of the adjacent coils in the adjacent two flat coils are positioned in two effective sections of the same end portion bending coil.

Owner:HARBIN INST OF TECH

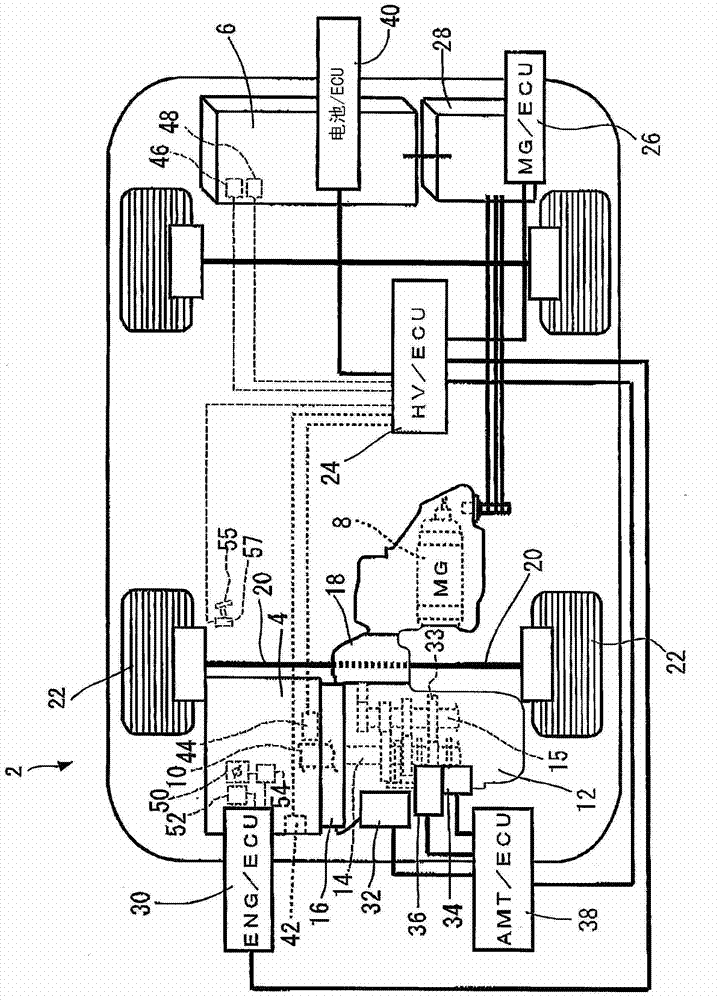

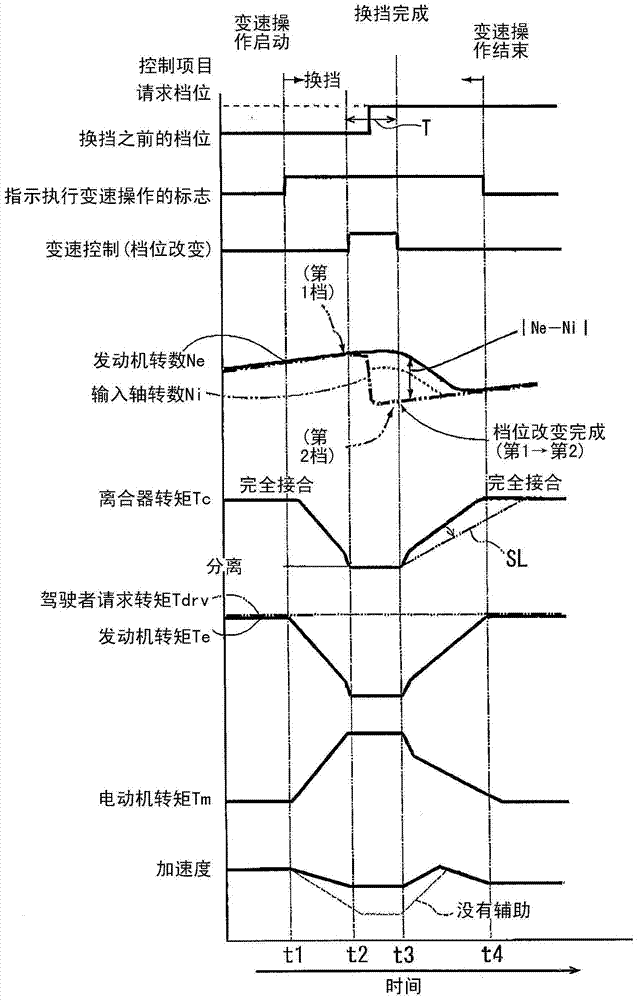

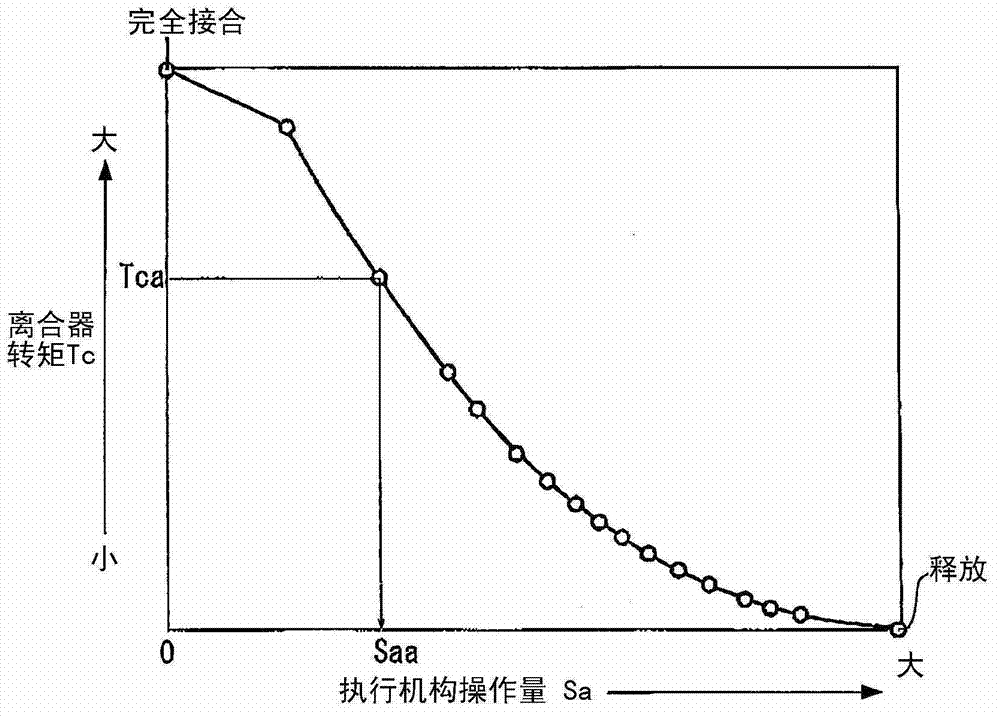

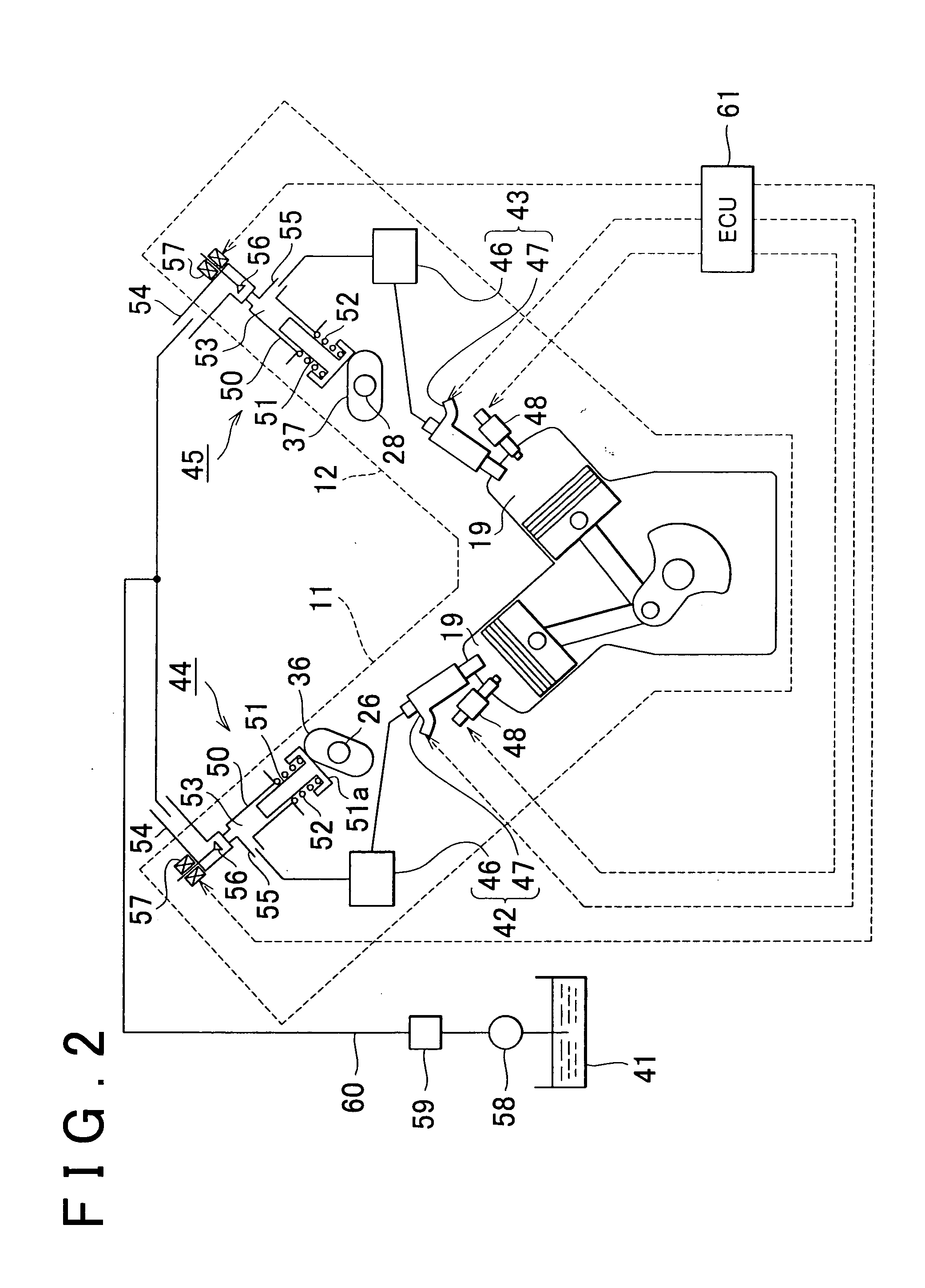

Control apparatus of hybrid vehicle

InactiveCN103010206AReduce power consumptionReduce torque fluctuationHybrid vehiclesPropulsion using engine-driven generatorsSeparated stateAutomatic transmission

A control apparatus of a hybrid vehicle includes an automatic transmission (12), a clutch (16), a motor (8), a battery (6), a driving assist control device (26) performing a driving assist control by driving the motor to generate an assist torque, a gear shift assist control device (26) performing a gear shift assist control by driving the motor in response to a decrease of the engine torque caused by the disengagement state of the clutch, an SOC value detection device (48) detecting an SOC value, and a first mode switch device (24) switching an operation mode of the hybrid vehicle from a normal mode in which the driving assist control and the gear shift assist control are performed to a battery power preserving mode in which the driving assist control is prohibited and the gear shift assist control is permitted in a case where the SOC value is equal to or smaller than a first predetermined value.

Owner:AISIN SEIKI KK +1

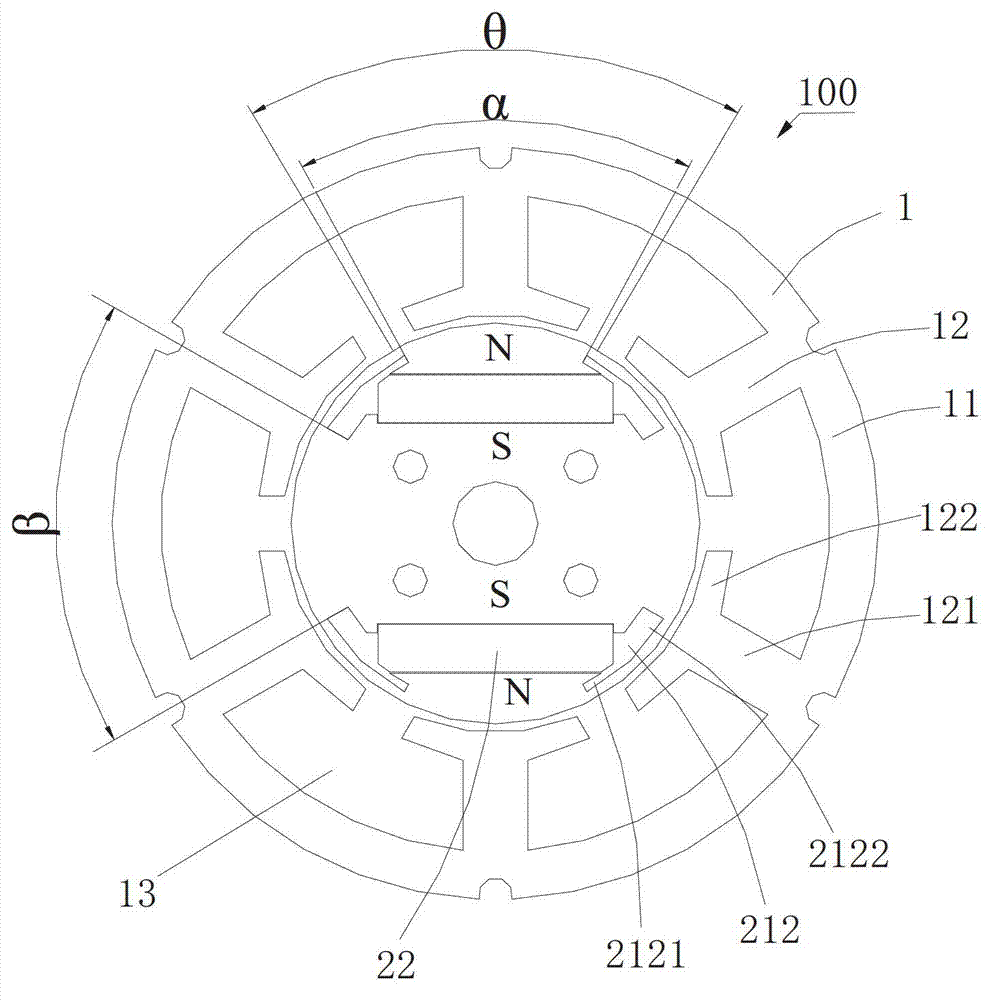

Permanent magnet motor

ActiveCN103117611AGuaranteed electromagnetic torqueIncrease electromagnetic torqueMagnetic circuit rotating partsPermanent magnet motorElectromagnetic torque

The invention discloses a permanent magnet motor comprising a rotor. The rotor comprises a rotor core and permanent magnets. The rotor core comprises at least two accommodating slots, and the permanent magnets are respectively accommodated in the accommodating slots. Grooves are respectively arranged at two ends of the accommodating slots. Magnetic field of each permanent magnet does not penetrate through other permanent magnets. An angle, defined as alpha, is formed between the tail ends of the grooves disposed on two sides of the same accommodating slot and the center of the rotor. An angle, defined as delta, is formed between the tail ends of the adjacent grooves disposed on two different accommodating slots and the center of the rotor. Alpha is 80%-120% of delta. Other permanent magnets assisting the permanent magnets of the permanent magnet motor can be omitted. On the premise of guaranteeing electromagnetic torque of the permanent magnet motor, torque ripple is remarkably reduced. According to relation between alpha and delta, the electromagnetic torque of the permanent magnet motor is greatly increased.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

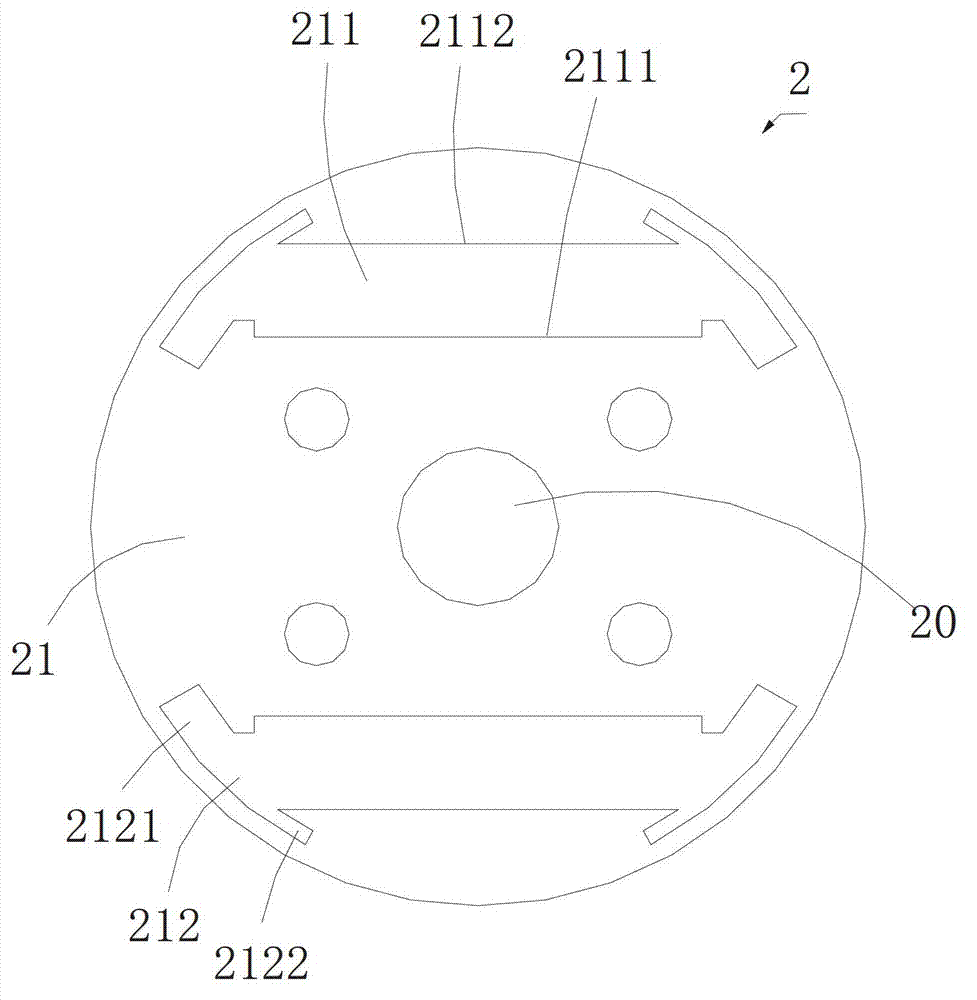

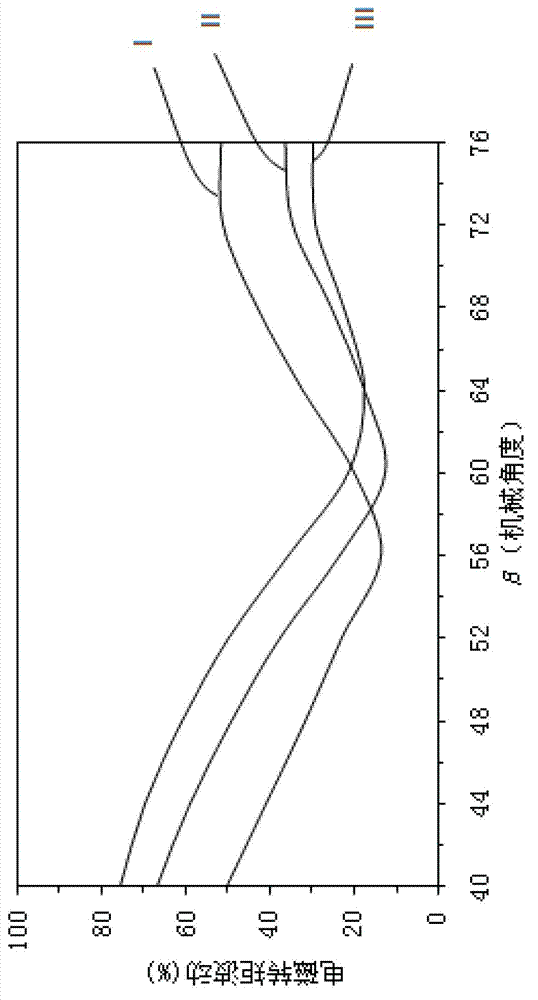

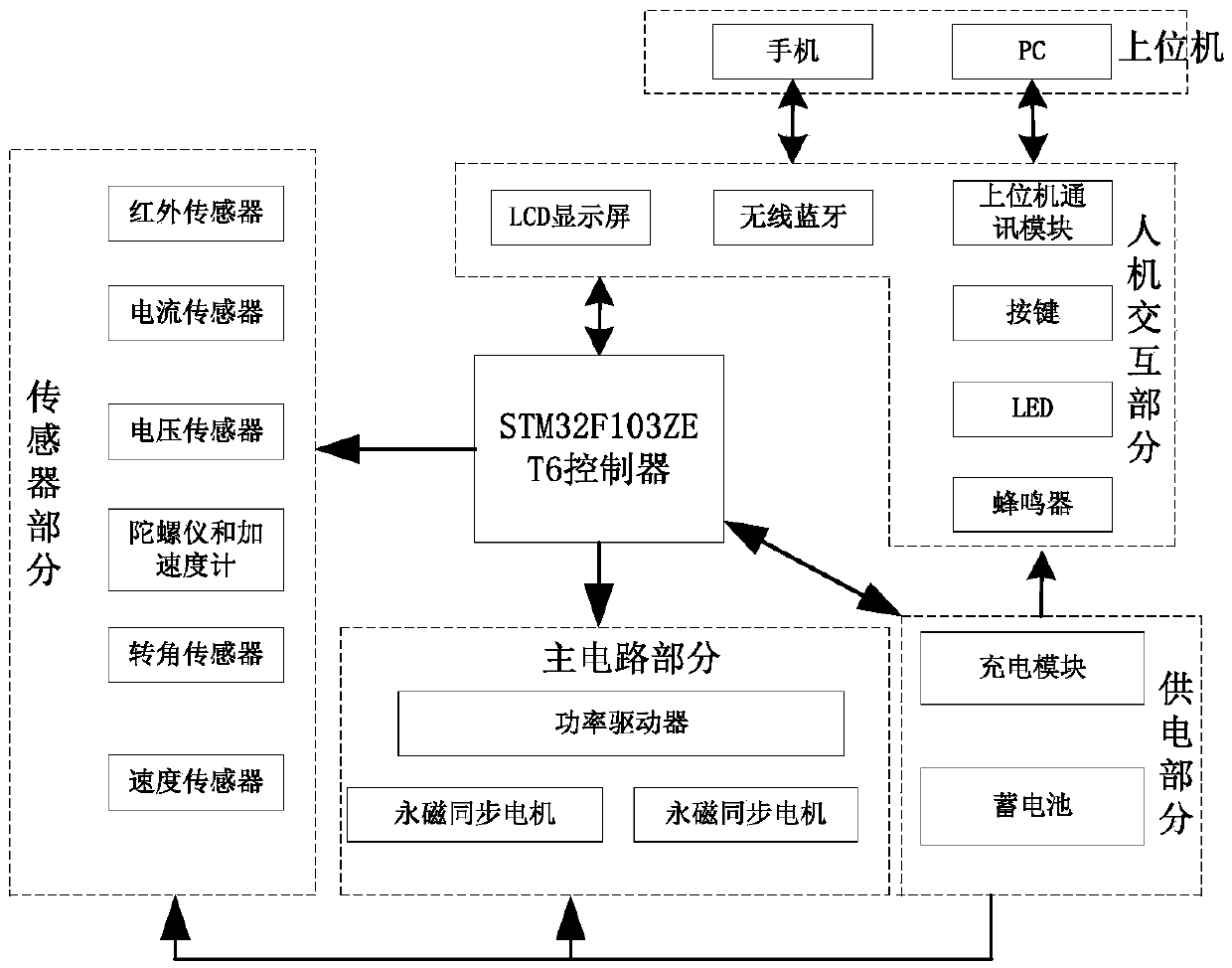

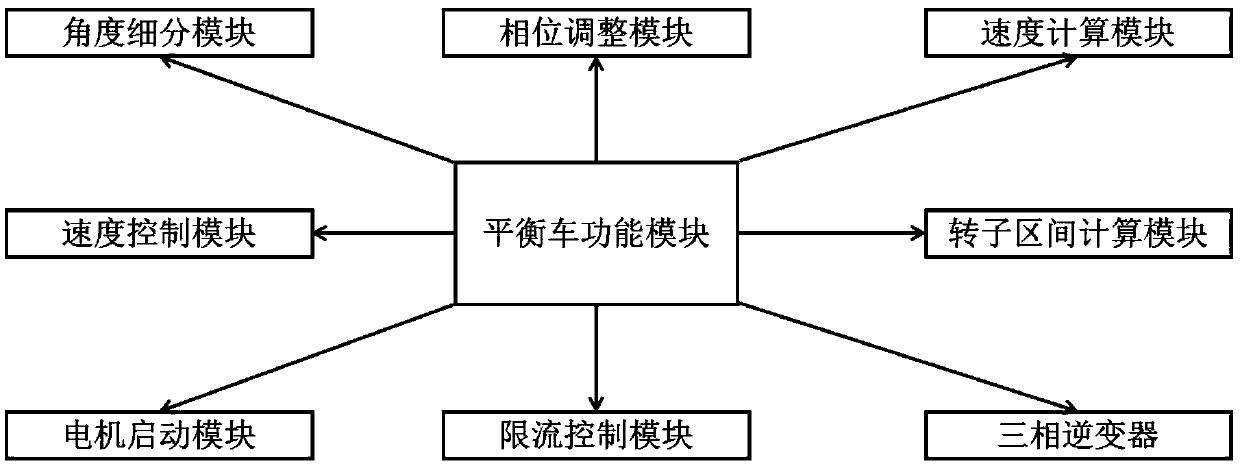

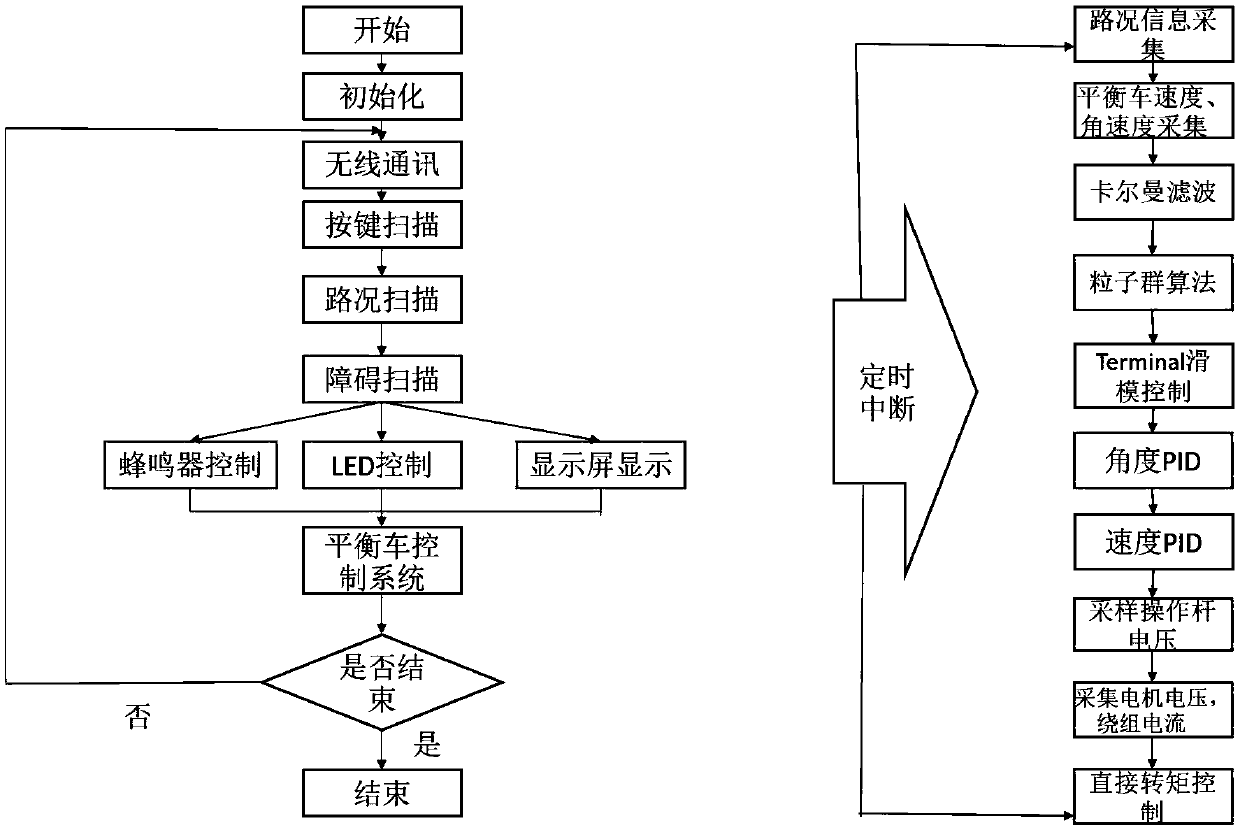

A system for balancing a vehicle and a control method thereof

ActiveCN109067264AStrong battery lifeReduce loss rateTorque ripple controlMultiple motor speed/torque controlMathematical modelParticle swarm algorithm

The invention discloses a balancing vehicle system and a control method thereof. According to a difference equation model and a drift error model of attitude signals of the balancing vehicle system, astate equation of an extended Kalman filter and a mathematical model of a permanent magnet linear motor are established. A second-order dynamic Terminal sliding film is used to drive permanent magnetsynchronous motor. Particle Swarm Optimization (PSO) is used to optimize the parameters of tracking controller, synchronization controller, clearance elimination controller and switching function ina two-motor system. The invention realizes that the signal collected by the sensor of the balancing vehicle has large noise and zero drift error, and solves the problem of poor robustness and the problem that the Brush motor structure is complex, fault, maintenance workload, short life, commutation spark easy to produce electromagnetic interference, as well as in the balance of the car in the process of running jitter, deviation is too large, and low security.

Owner:汇佳网(天津)科技有限公司

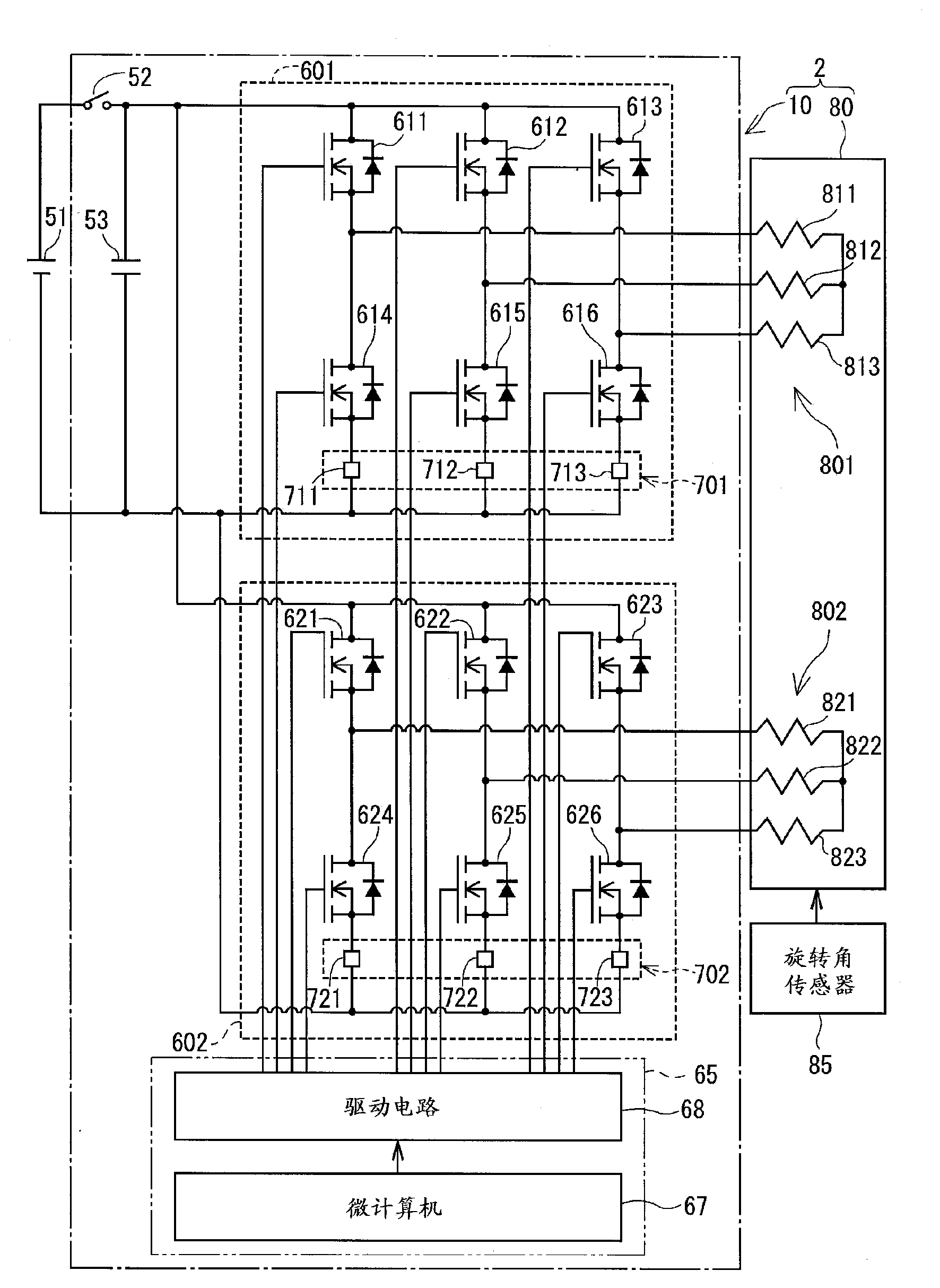

Control device for a three-phase rotating machine

ActiveCN103378790AReduce the soundReduce/or vibrationTorque ripple controlVector control systemsThree-phaseAlternating current

In a control device for a three-phase rotating machine with first and second winding sets, a current feedback computing section includes a current sum controller and a current difference controller. The current sum controller multiplies, by a sum gain, an error between a sum of current command values for alternating currents output from first and second inverters and a sum of sensed current values and computes a sum of voltage command values. The current difference controller multiplies, by a difference gain, an error between a difference of the current command values and a difference between the sensed current values, and computes a difference of voltage command values. In a variable-responsiveness mode, a gain ratio between the sum gain and the difference gain is varied according to a reference frequency such that the current sum controller and the current different controller are different in responsiveness.

Owner:DENSO CORP

Electromagnetic rotary drive and rotational device

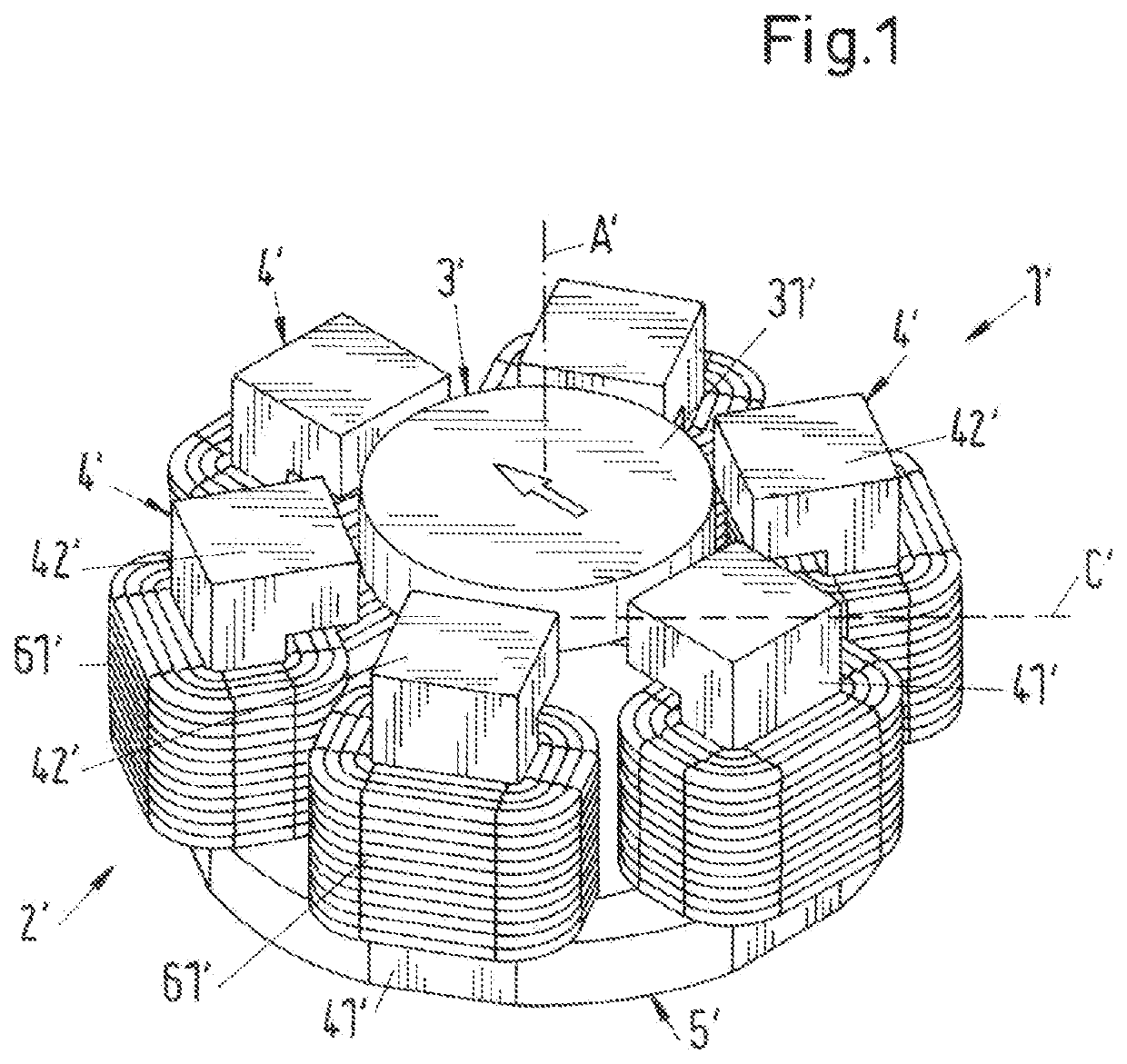

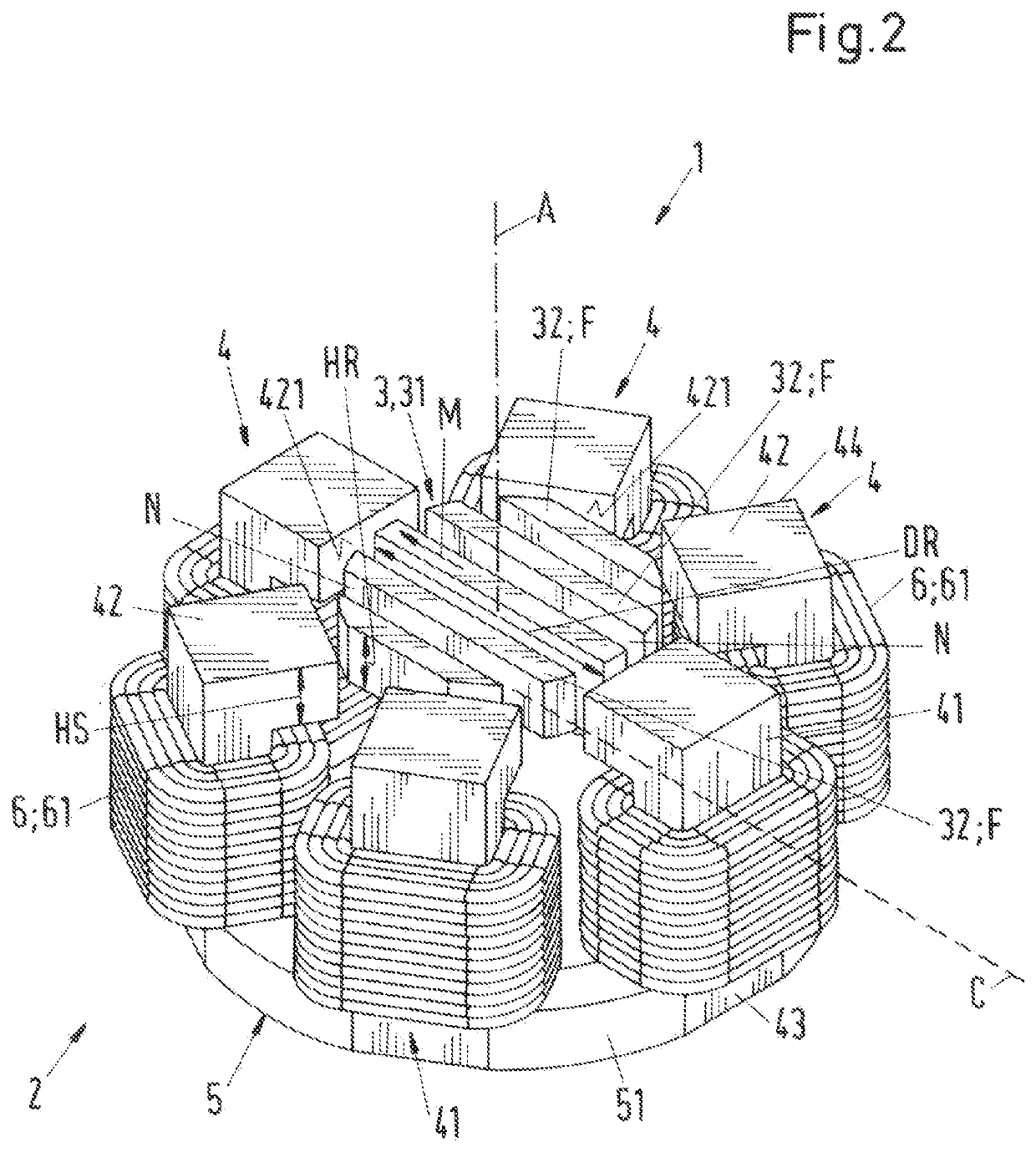

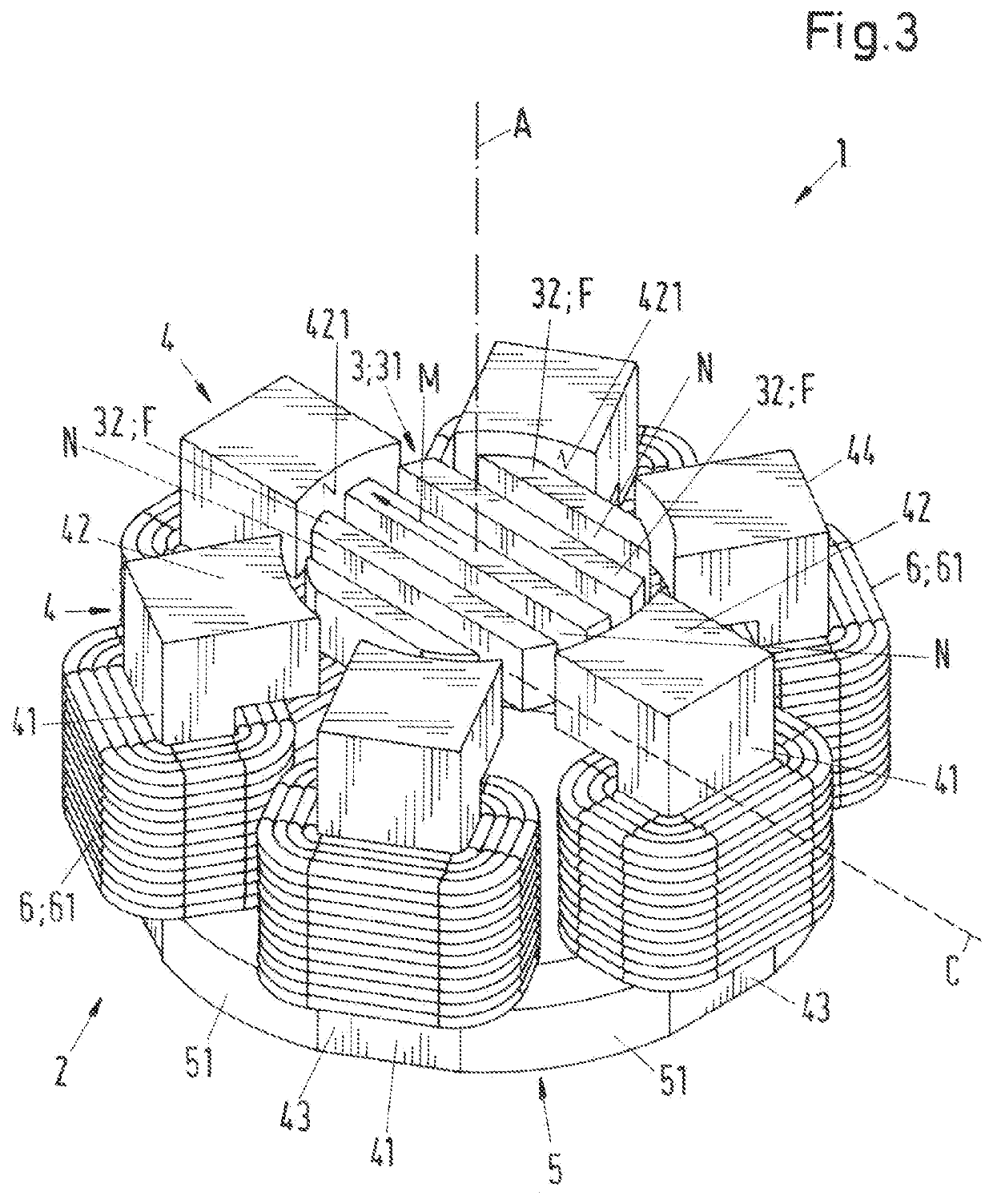

ActiveUS20190356195A1Minimize eddy current lossLarge heightPump componentsSynchronous motorsMagnetic reluctanceClassical mechanics

An electromagnetic rotary drive includes a rotor, a stator and windings. The rotor includes a magnetically effective core. The rotor is contactlessly magnetically drivable about an axis of rotation and the rotor is contactlessly magnetically levitatable. The stator has coil cores, each with a longitudinal limb parallel with the axis and a transverse limb extending radially, the transverse limb being perpendicular to the axis. The windings generate an electromagnetic rotational field, each winding surrounding one longitudinal limb, such that the stator is free of permanent magnets. The rotor is ferromagnetic or ferrimagnetic with one preferential magnetic direction extending radially, and the core of the rotor has a magnetic resistance in the preferential magnetic direction, the magnetic resistance at most half as large as the magnetic resistance in a direction, which is perpendicular to the preferential magnetic direction and perpendicular to the axial direction.

Owner:LEVITRONIX

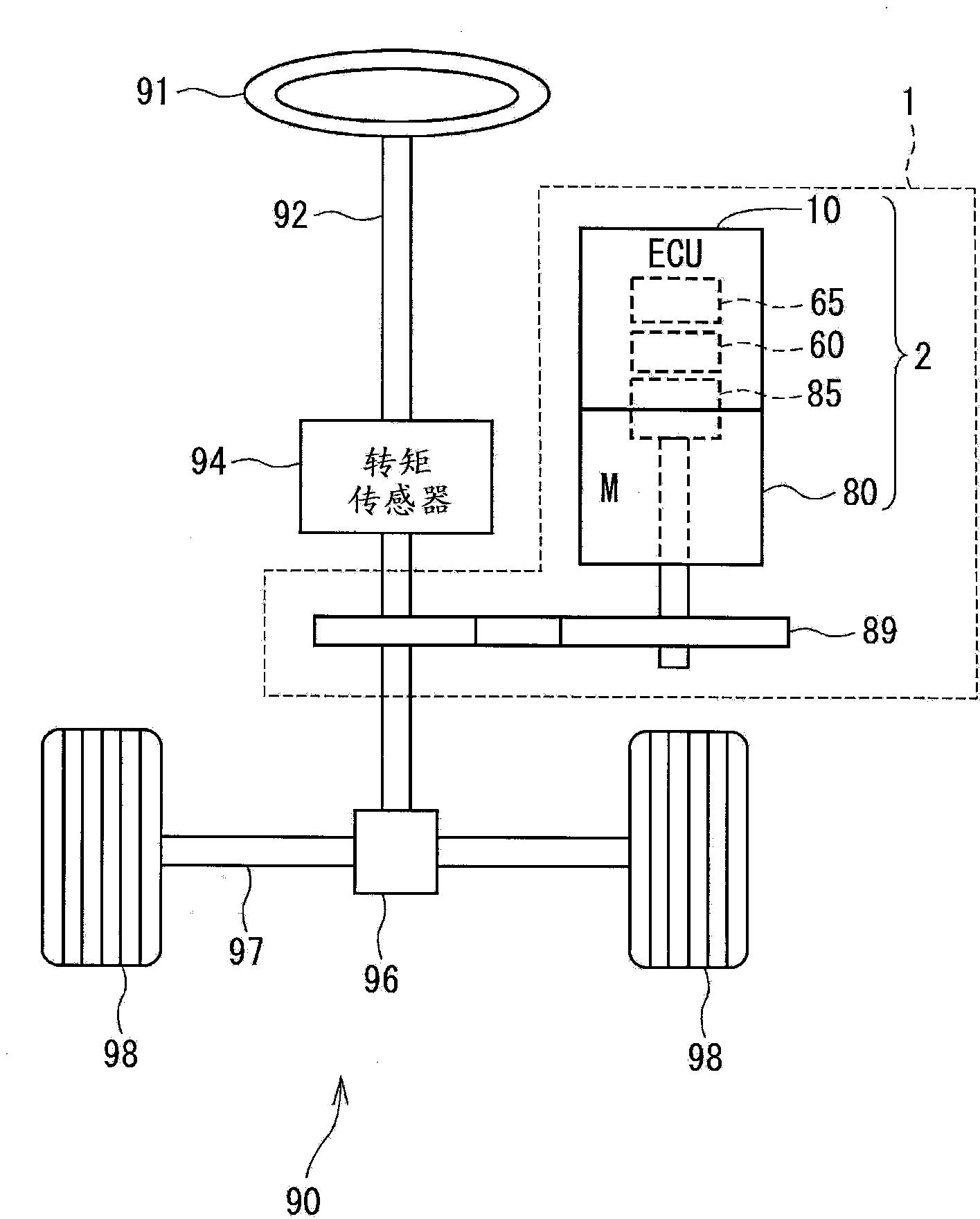

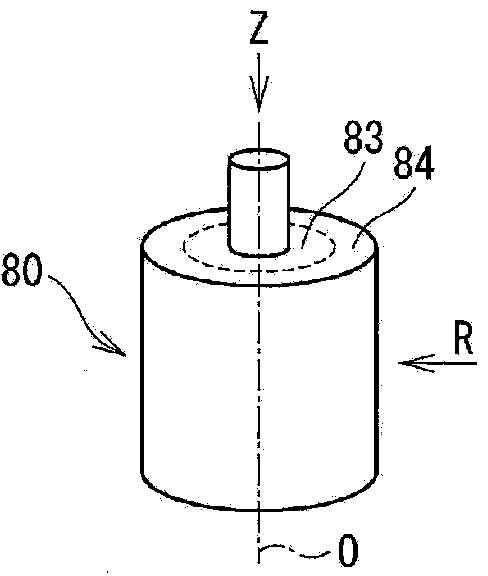

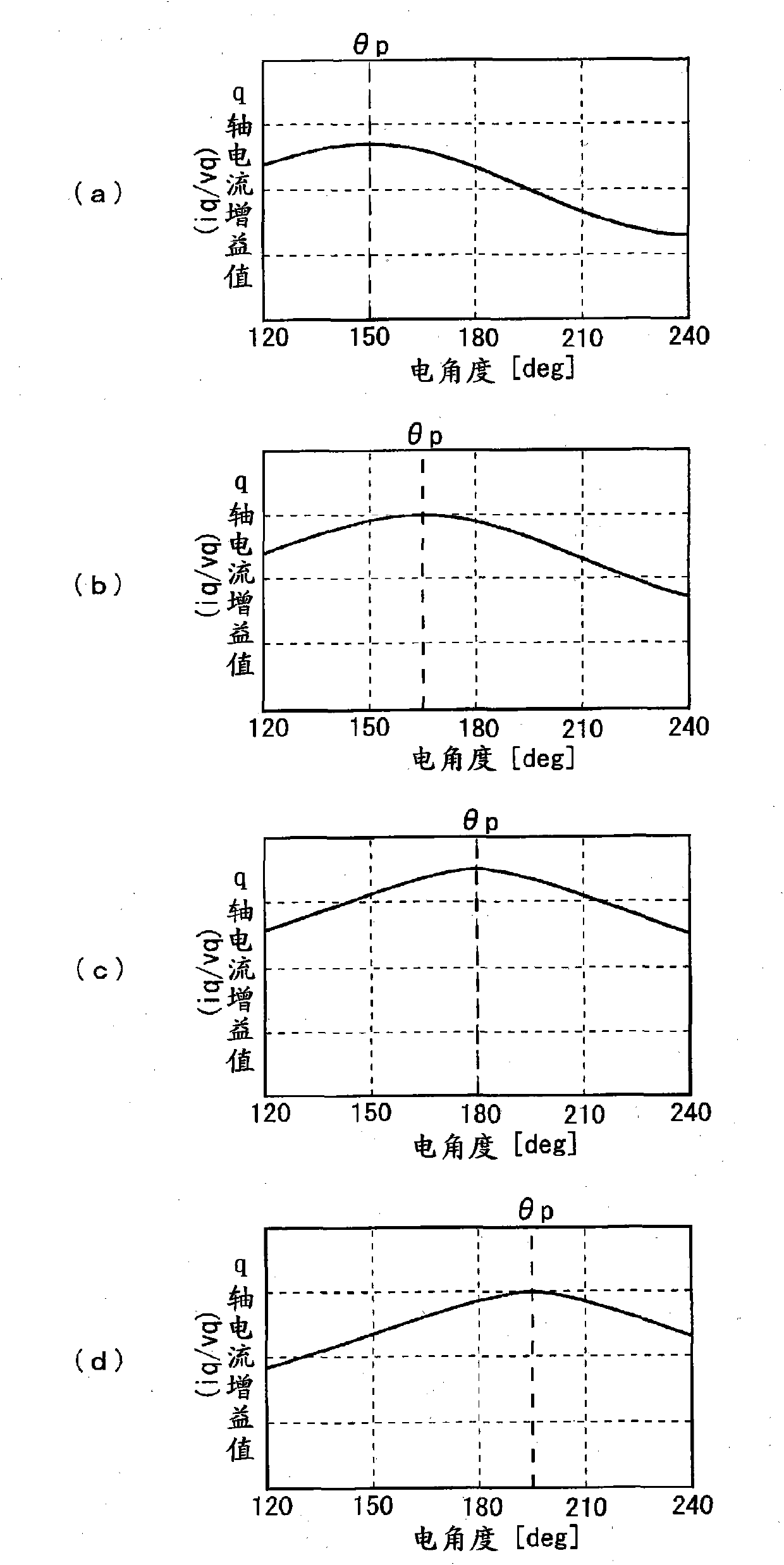

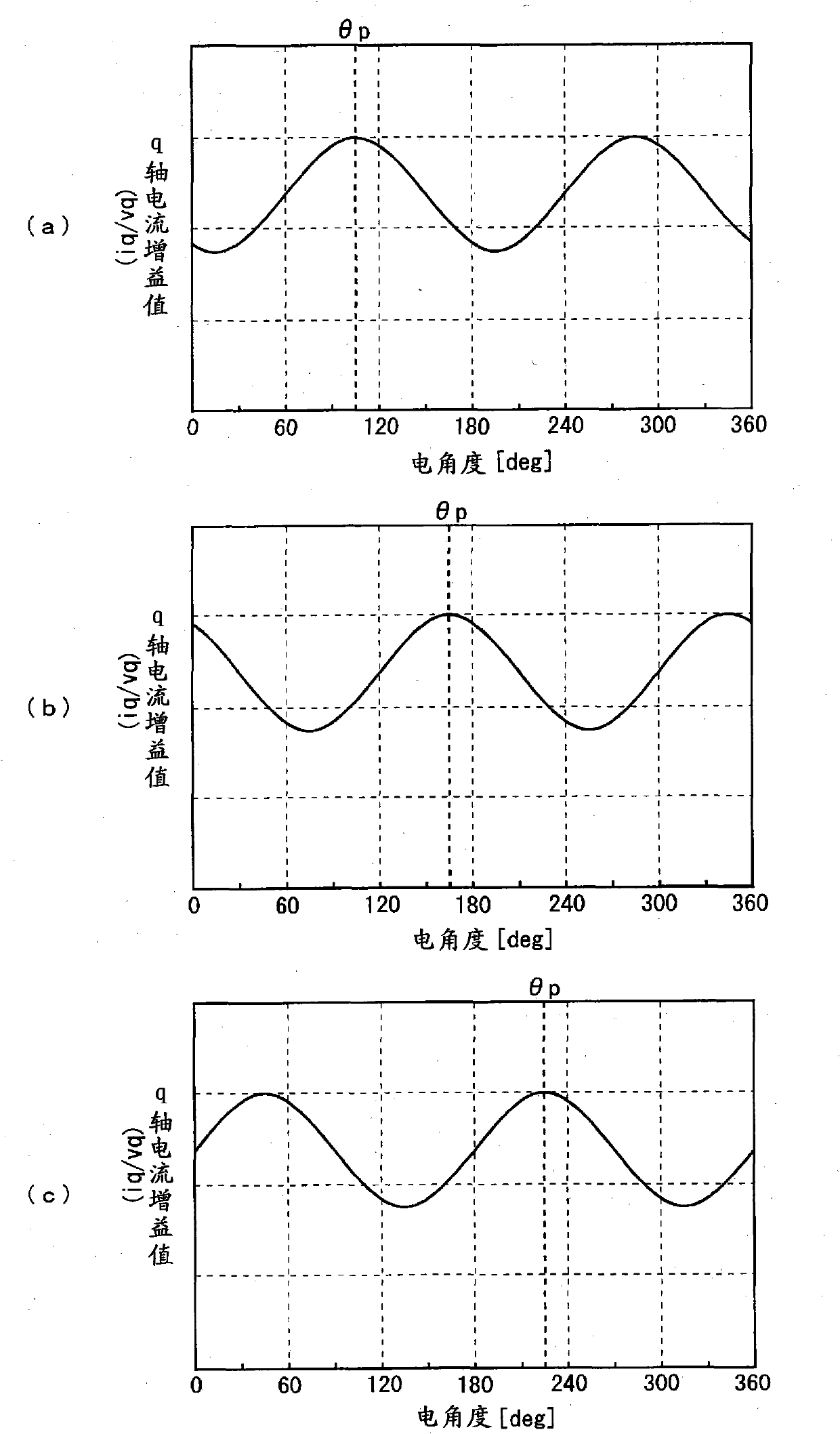

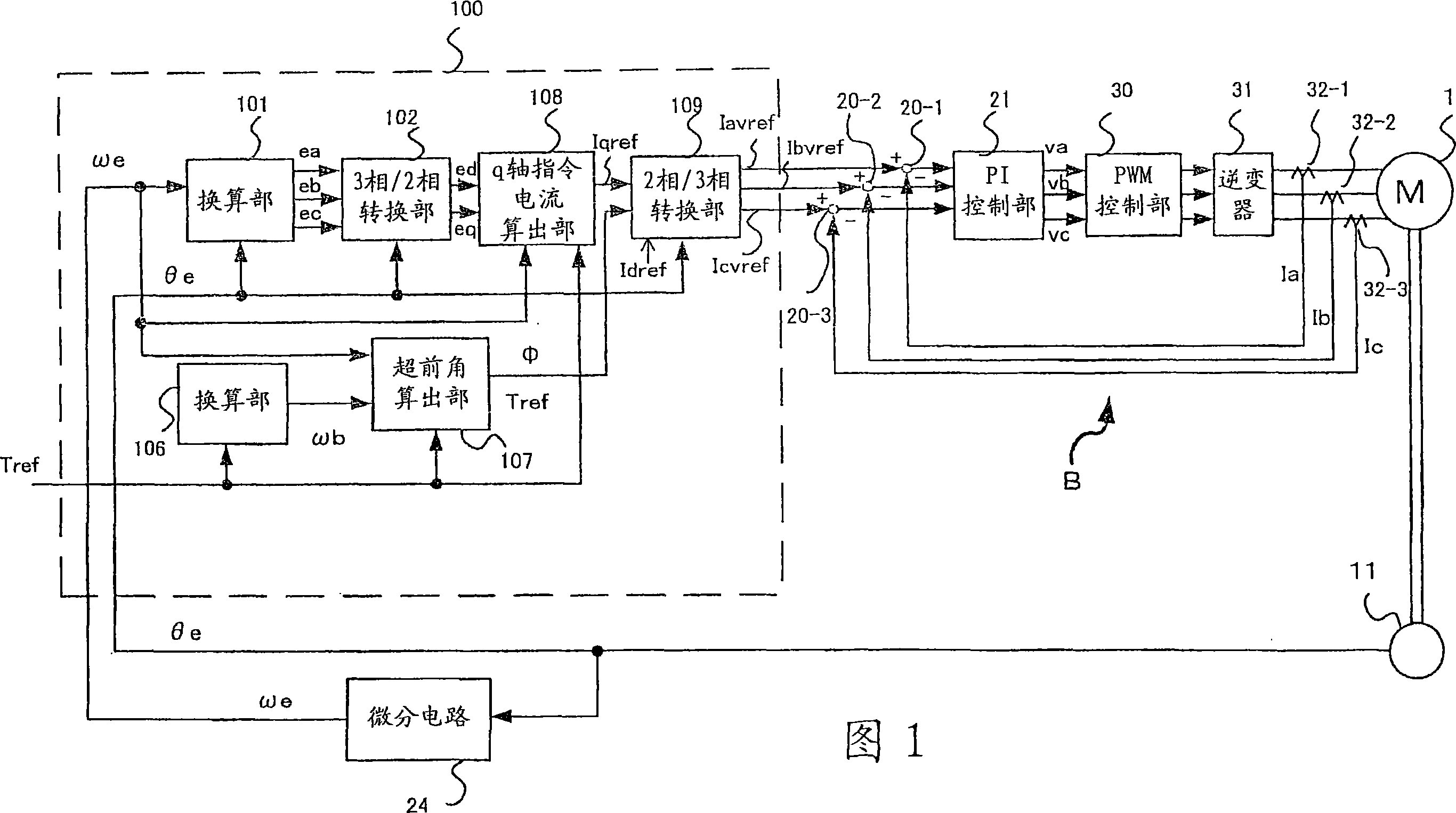

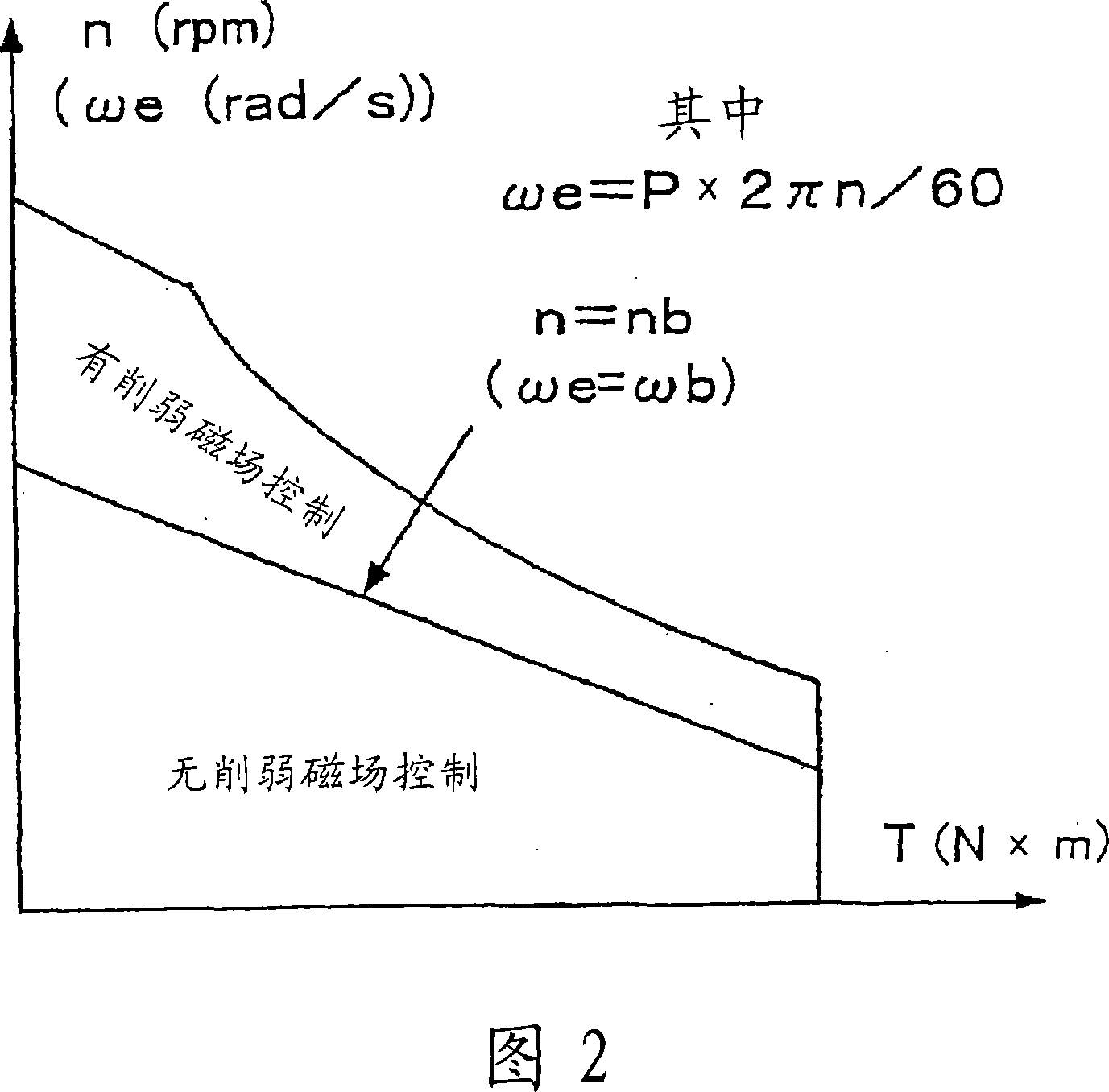

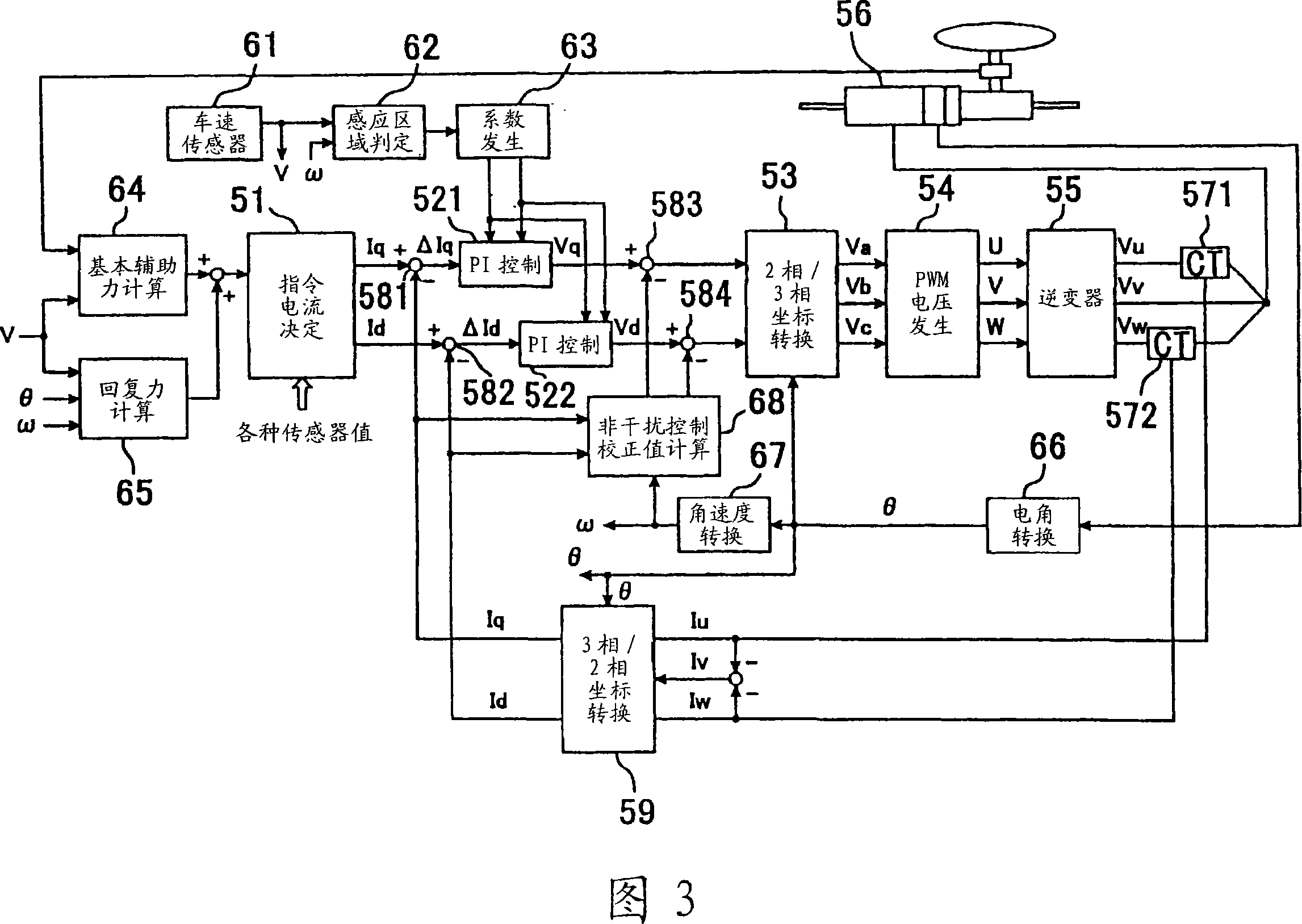

Motor control device and electric power steering device

InactiveCN101911467ASuppression of torque rippleAccurate compensationTorque ripple controlAC motor controlPower steeringMagnetic flux

A motor control device includes control calculation means formed by an open loop control unit and a dq-axis / 3-phase conversion unit. The open loop control unit obtains voltage instruction values vd, vq on the d-axis and q-axis according to current instruction values id*, iq* on the d-axis and q-axis, the armature winding interlinking magnetic flux quantity f, and the rotor angular velocity omega e in the motor. The dq-axis / 3-phase conversion unit converts the voltage instruction values vd, vq into phase voltage instruction values Vu, Vv, Vw. On the other hand, a data acquisition unit acquires angle-dependency data indicating dependency on the electric angle indicated by a secondary higher harmonic component concerning the electric angle of the d-axis or the q-axis component of the motor current according to the current detection value ia and the electric angle theta. A correction coefficient decision unit decides a correction coefficient for correcting the phase voltage instruction value so as to reduce the dependency according to the angle-dependency data. A correction execution unit corrects the phase voltage instruction values Vu, Vv, Vw obtained by the dq-axis / 3-phase conversion unit, according to the decided correction coefficient.

Owner:JTEKT CORP

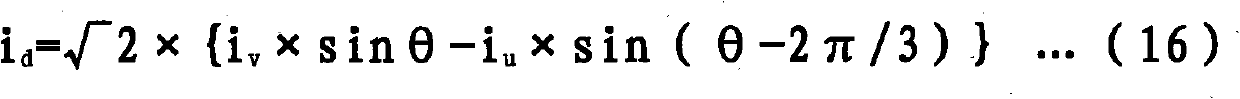

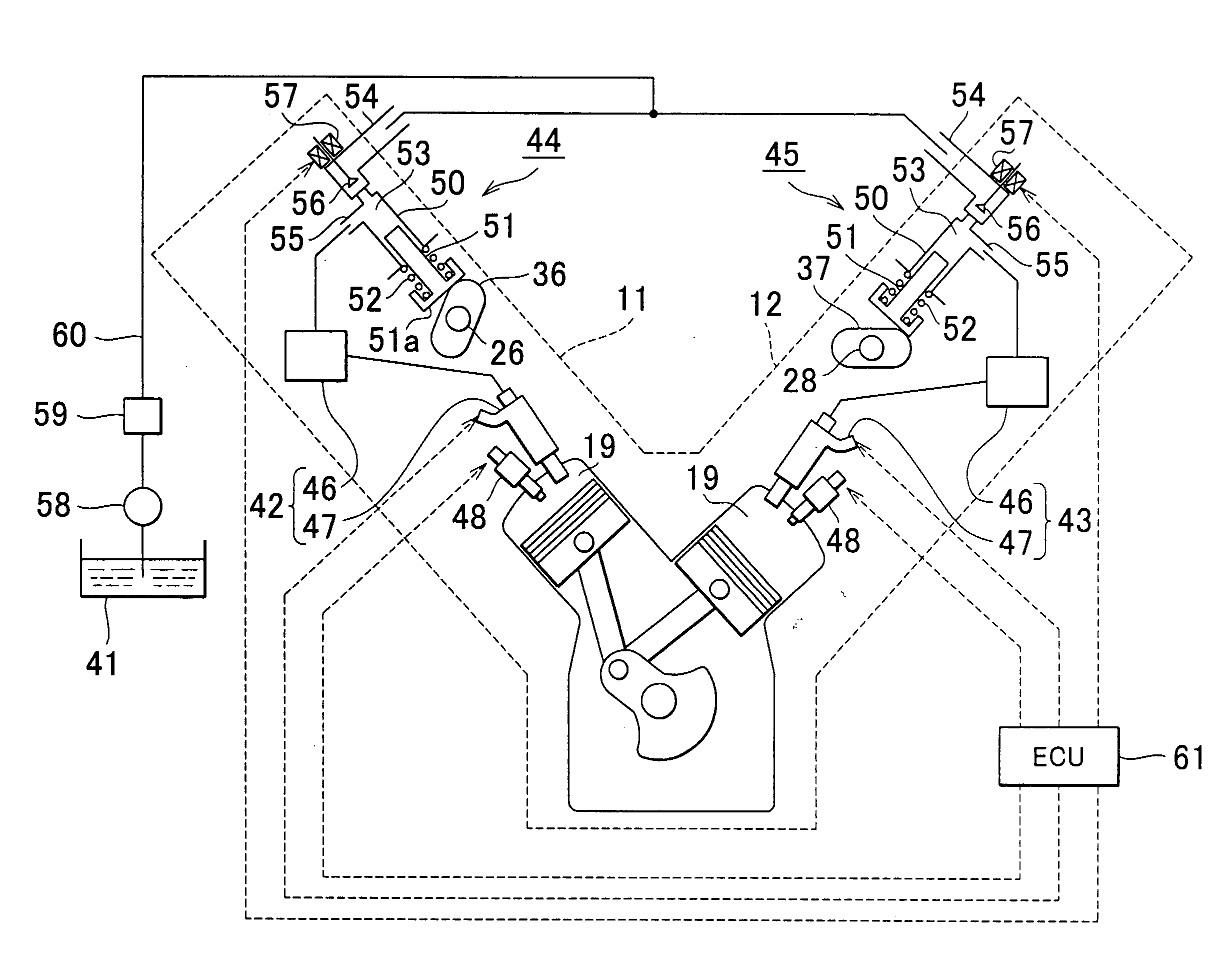

Valve system of V-type engine

ActiveUS20070193541A1Suppress fluctuationsSignificant valueValve drivesMachines/enginesEngineeringCam

A valve system of a V-type engine in which a camshaft provided in each bank is formed with valve cams that open and close engine valves and a pump cam for driving a fuel pump, the phase of the pump cam relative to the valve cams is set such that the crank angle at which driving torque of the pump cam is maximized does not coincide with the crank angle at which driving torque of each of the valve cams is maximized.

Owner:TOYOTA JIDOSHA KK

High power wide velocity modulation built-in permanent magnet brushless wheel motor for electric automobile

InactiveCN101436793AIncrease powerRun at high speedMagnetic circuit rotating partsElectric machinesInsertion depthMagnetic poles

The invention relates to a high-power wide-speed adjustment built-in permanent magnet brush wheel-free motor for an electric automobile, which comprises a shell, and a rotor and a stator arranged in the shell. The rotor comprises a stator core and a stator winding which are fixed on the inner wall of the shell. The stator core comprises a stator yoke, a stator slot and a stator tooth. The rotor comprises a rotating shaft and a rotor core. An inner circle of the rotor core is uniformly embedded with radical magnetizing rectangular magnetic steel strips or cracked radical magnetizing rectangular steel strips along the circumferential direction. The radical magnetizing rectangular magnetic steel strips or the cracked radical magnetizing rectangular steel strips form permanent magnetic poles. An external circle of a pole shoe of a rotor is of a non-concentric arc-shaped curved surface and provided with non-uniformly symmetric radial air gaps. Magnet-shielding magnetic bridges are arranged between the magnetic poles and the high saturation of a magnetic circuit at a cross section of the magnet-shielding magnetic bridges is ensured. The radical insertion depth of the magnetic steel strips in the core, the width of an empty groove of a magnet-embedding steel groove, the angle of the empty groove of the magnet-embedding steel groove, the angle of polar arc and so on are adjusted to realize smooth operation with high efficiency, high power output, wide speed adjustment and quick response.

Owner:苏州和鑫电气股份有限公司

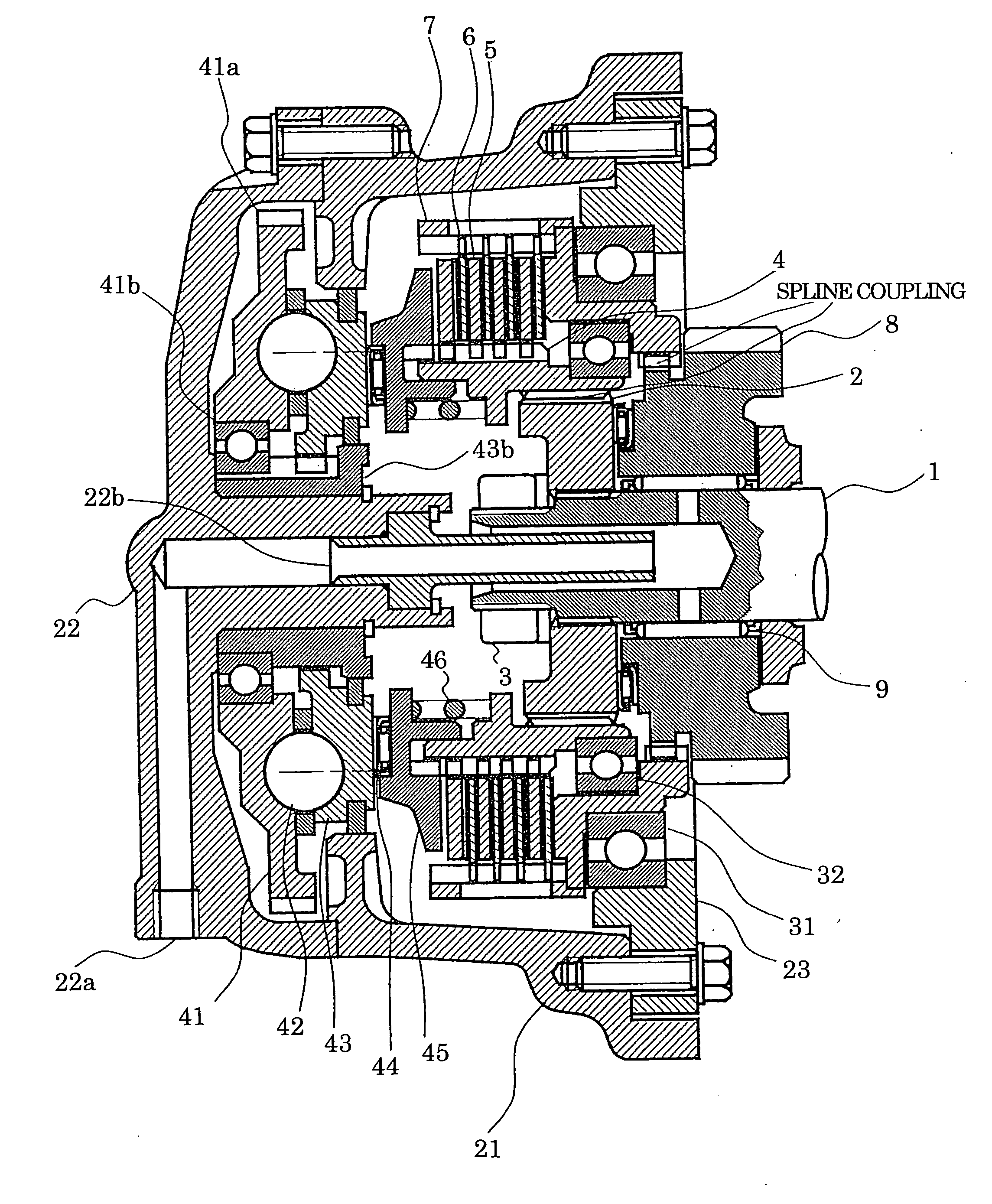

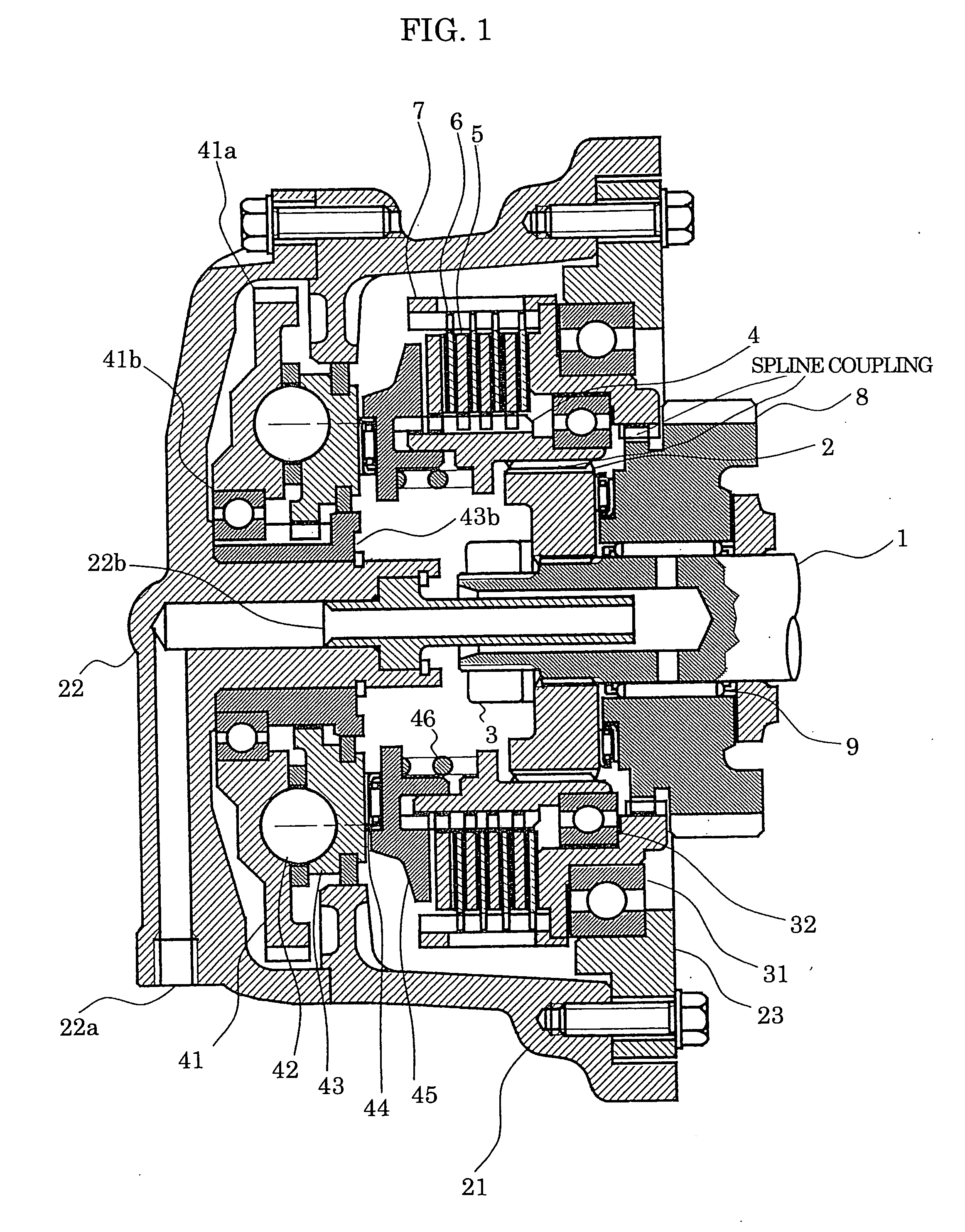

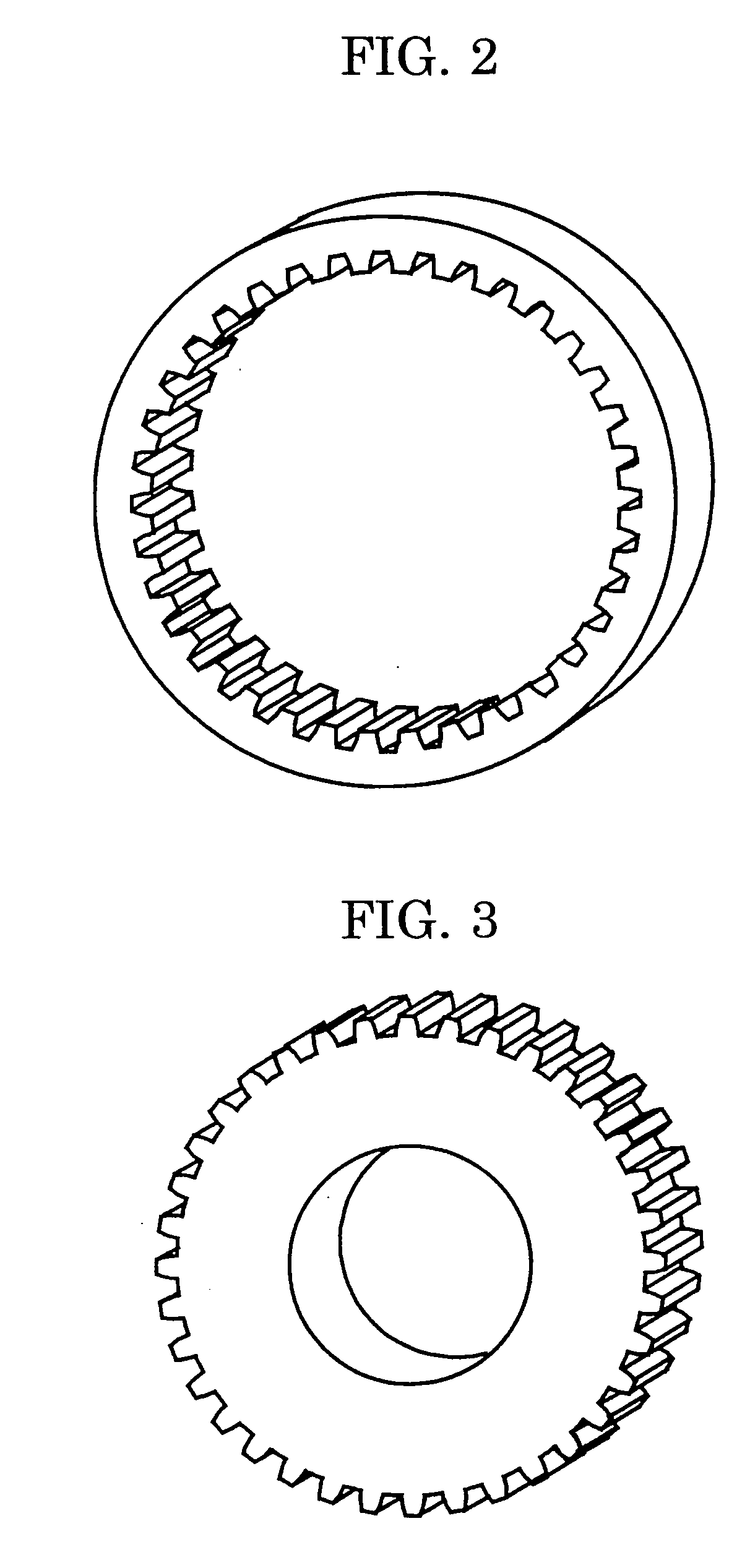

Clutch mechanism free from influence of axial displacement of rotary member

InactiveUS20070144861A1Suppress mutual interferenceEliminating and reducing undesirable vibratory fluctuationGear lubrication/coolingMagnetically actuated clutchesAxial displacementCoupling

A clutch mechanism includes: an input rotary member for receiving an input torque; a hub for receiving the torque from the input rotary member; first friction discs held by the hub; second friction discs arranged to be pressed against the first friction discs to achieve a torque-transmitting engagement therebetween; a drum supporting the second friction discs and stopped by the drum support bearing against movement in one axial direction; and an output rotary member for receiving the torque from the drum. Transmission of the torque from the drum to the output rotary member is achieved by a spline coupling therebetween. Axial movement of the drum in one direction is stopped by an end surface of a drum support bearing mounted in a housing. The hub is splined to the input rotary member for axial movement relative to the rotary input member.

Owner:HITACHI LTD

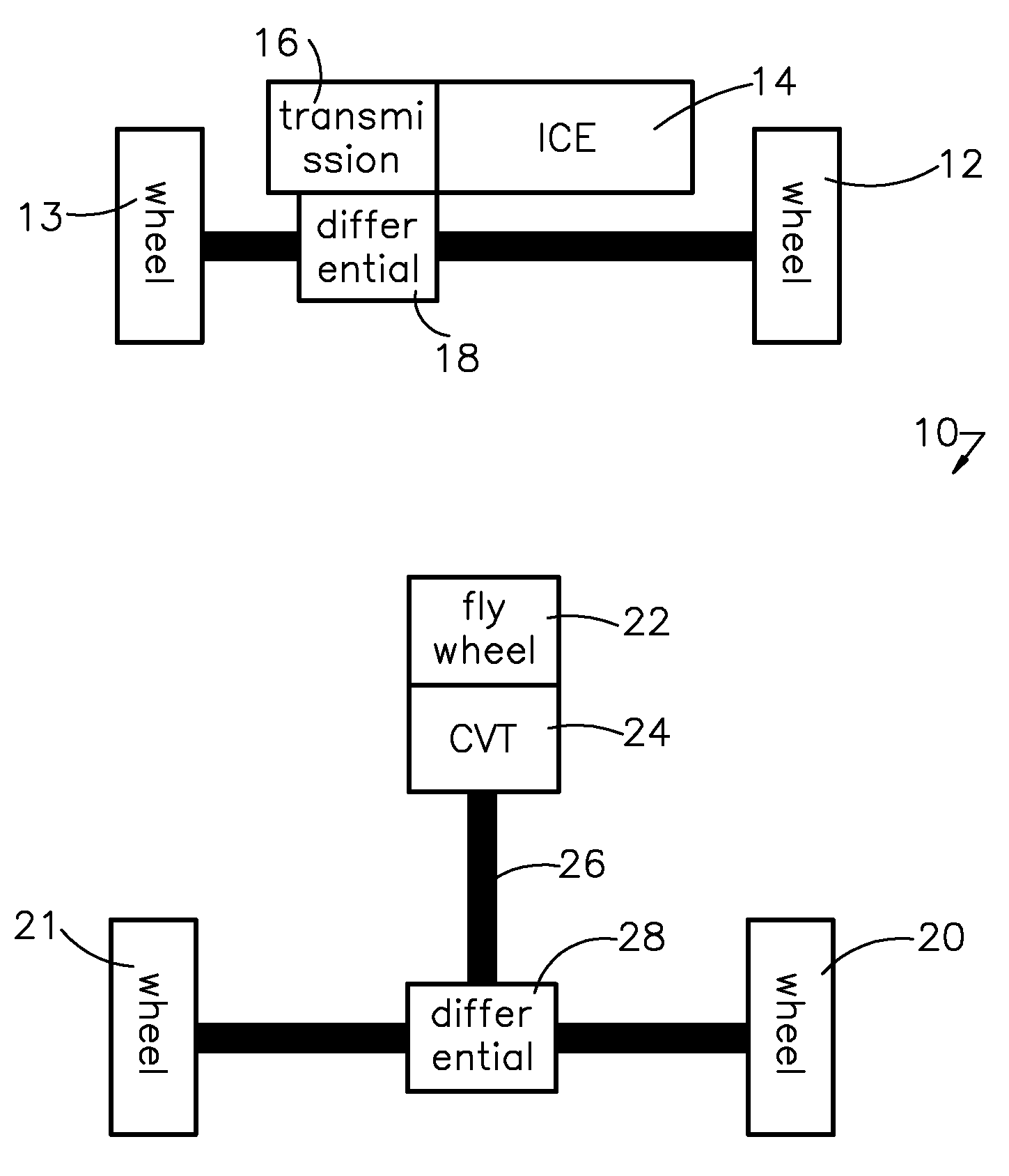

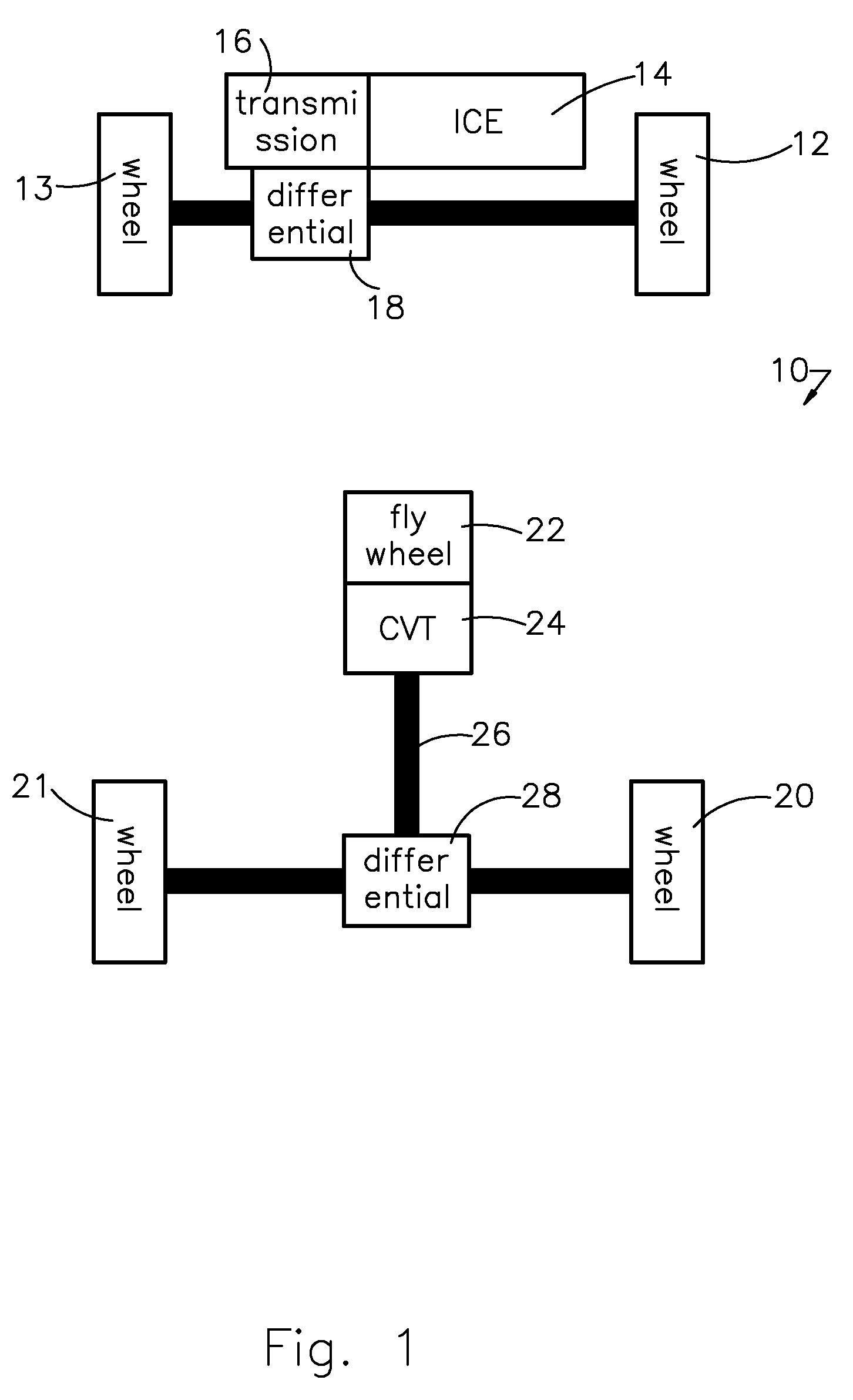

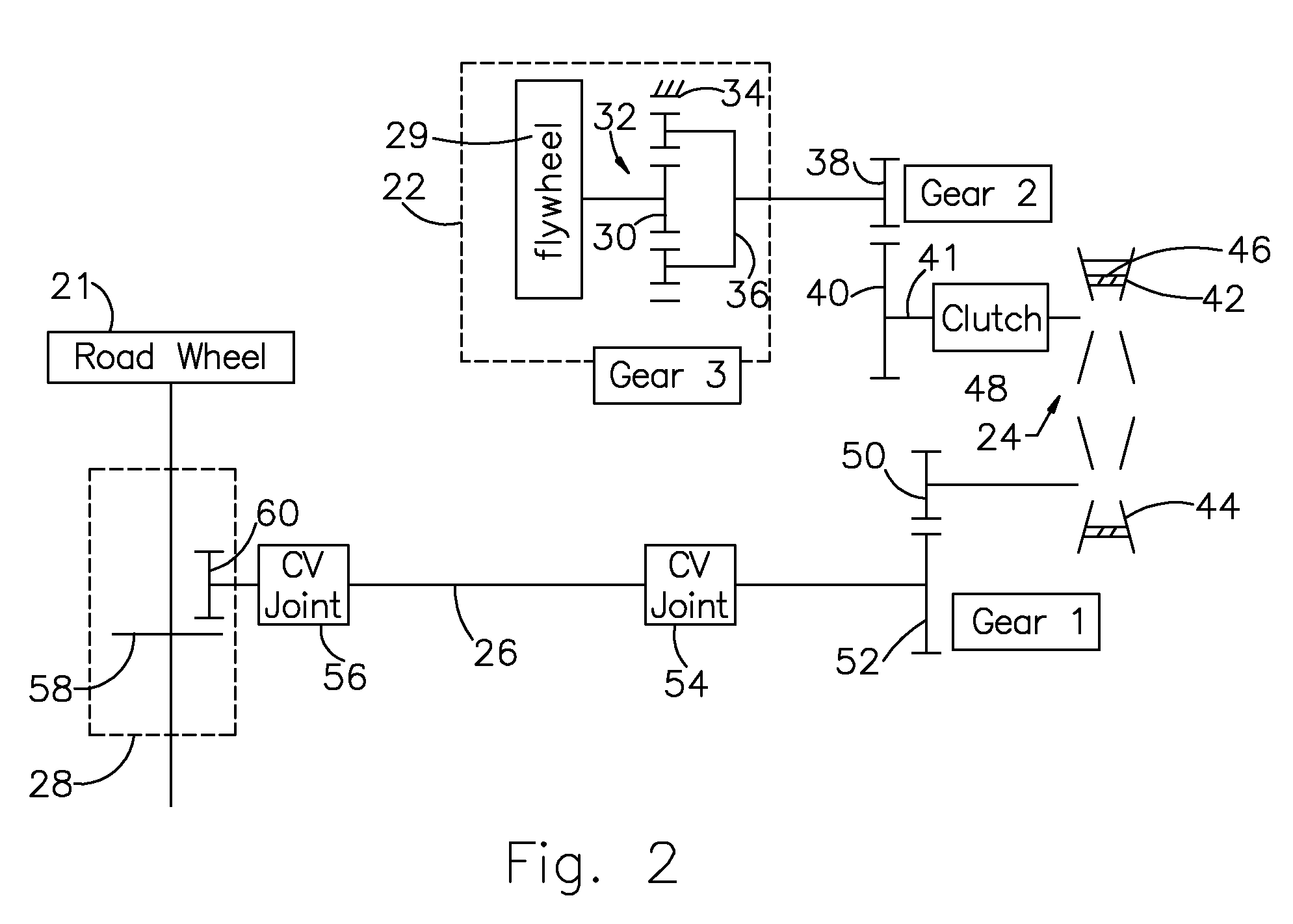

Controlling torque in a flywheel powertrain

InactiveUS8142329B2Reduce errorsEasy to measureAuxillary drivesGas pressure propulsion mountingFreewheelFlywheel

A method for controlling a powertrain for an automotive vehicle includes determining a desired flywheel torque, determining, with reference to the desired flywheel torque, a desired torque capacity torque of a clutch through which torque is transmitted between the flywheel and wheels of the vehicle, operating the clutch to produce the desired clutch torque capacity, determining a slip error across the clutch, and changing a gear ratio of a continuously variable transmission located in a drive path between the clutch and said wheels to a gear ratio that reduces the slip error.

Owner:FORD GLOBAL TECH LLC

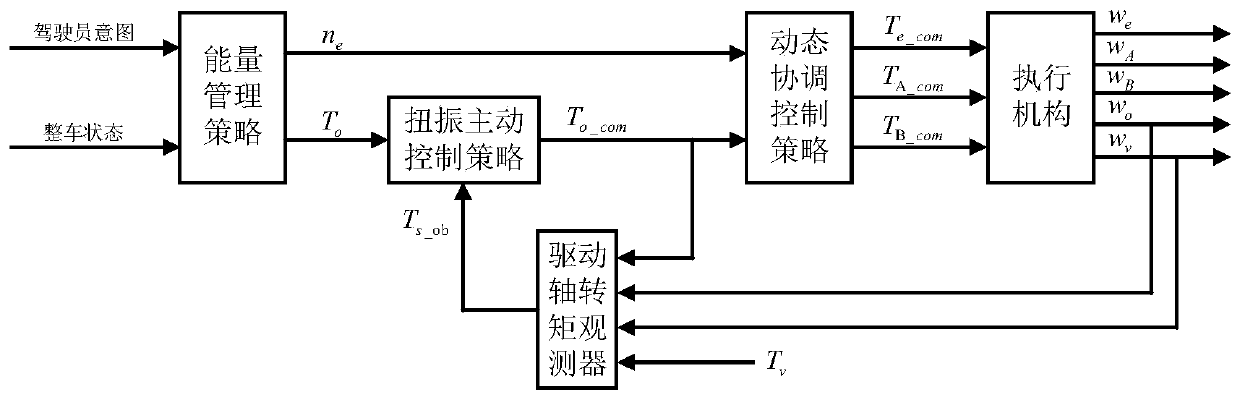

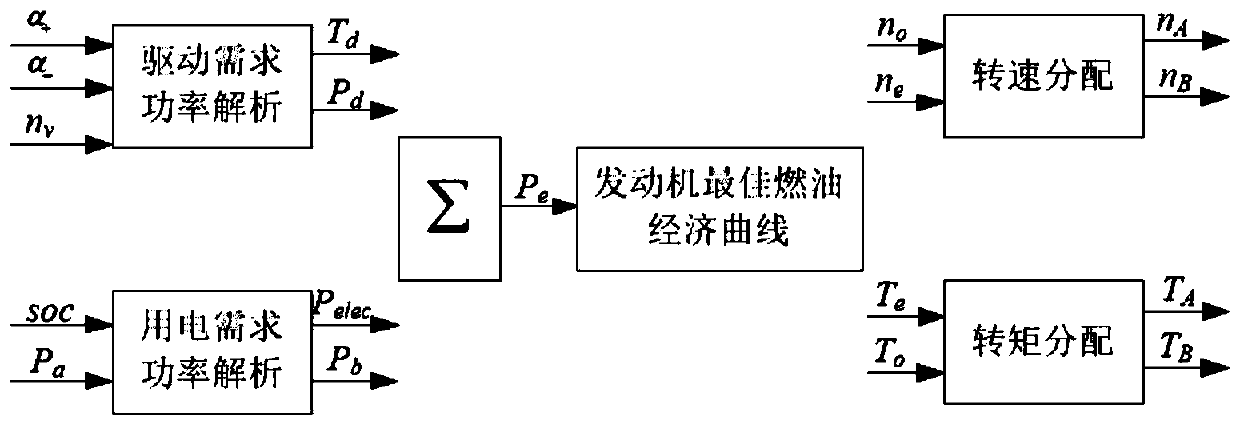

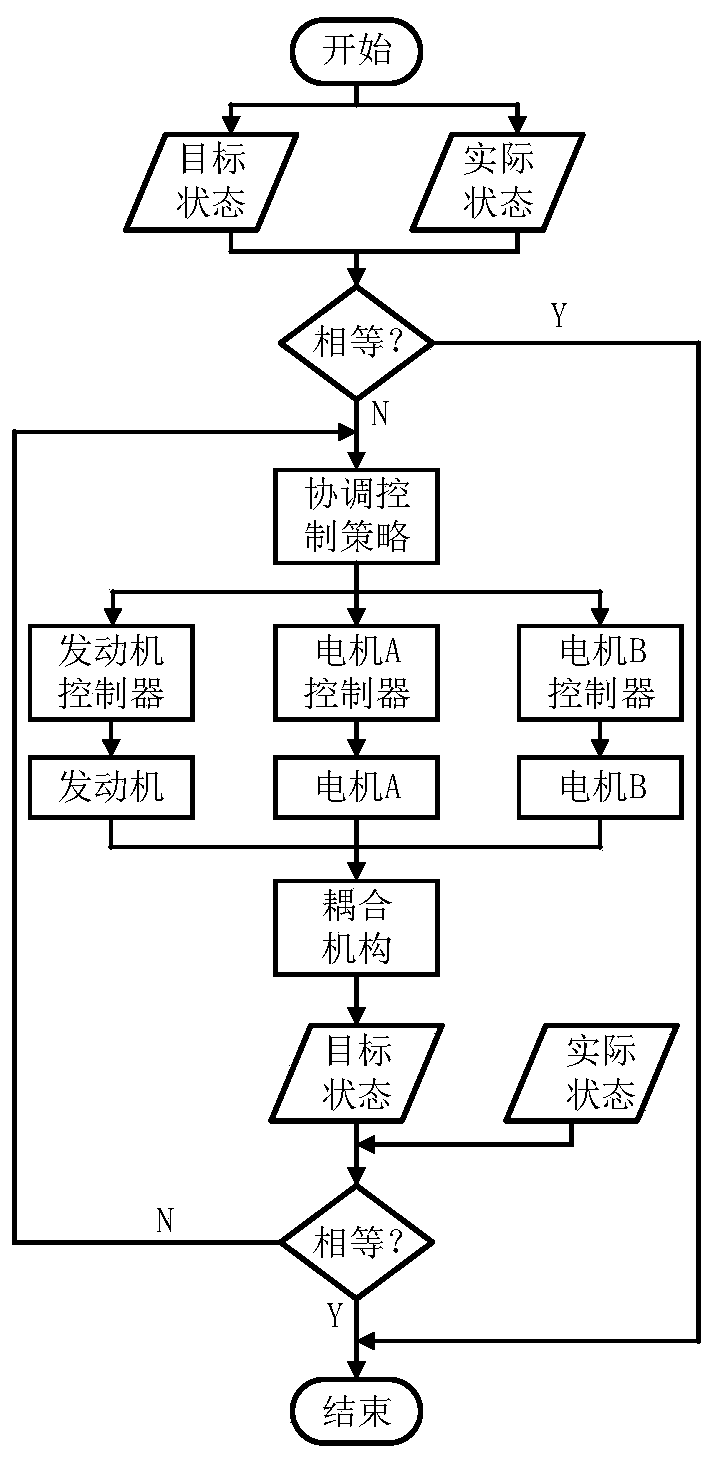

Low frequency torsional vibration reduction control system construction method based on hybrid drive

ActiveCN110304043AImprove securityImprove driving comfort performanceHybrid vehiclesDriver input parametersTorsional vibrationState switching

The invention discloses a low frequency torsional vibration reduction control system construction method based on hybrid drive. The low frequency torsional vibration reduction control system construction method based on hybrid drive comprises the following steps of 1, constructing a vehicle energy management strategy to determine a target state point of a vehicle; 2, constructing a dynamic coordinated control strategy, and using a motor A and a motor B to assist an engine to perform dynamic adjusting; 3, constructing a model reference self-adaptive control system; and 4, connecting a model reference self-adaptive controller between an energy management module and a dynamic coordinated control module to adjust an actual state of the vehicle to track a target state. According to the low frequency torsional vibration reduction control system construction method based on hybrid drive, after fuel economy and power performance of the engine and the remaining capacity of a power battery are comprehensively considered, the dynamic coordinated strategy is reasonably set so that the actual state of the vehicle can stably track the target state; the vehicle state switching process is fast andstable; the damage of low frequency torsional vibration to a torque transmission system is reduced; the service life of a vehicle part is prolonged; and the comfort and safety of the vehicle are enhanced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

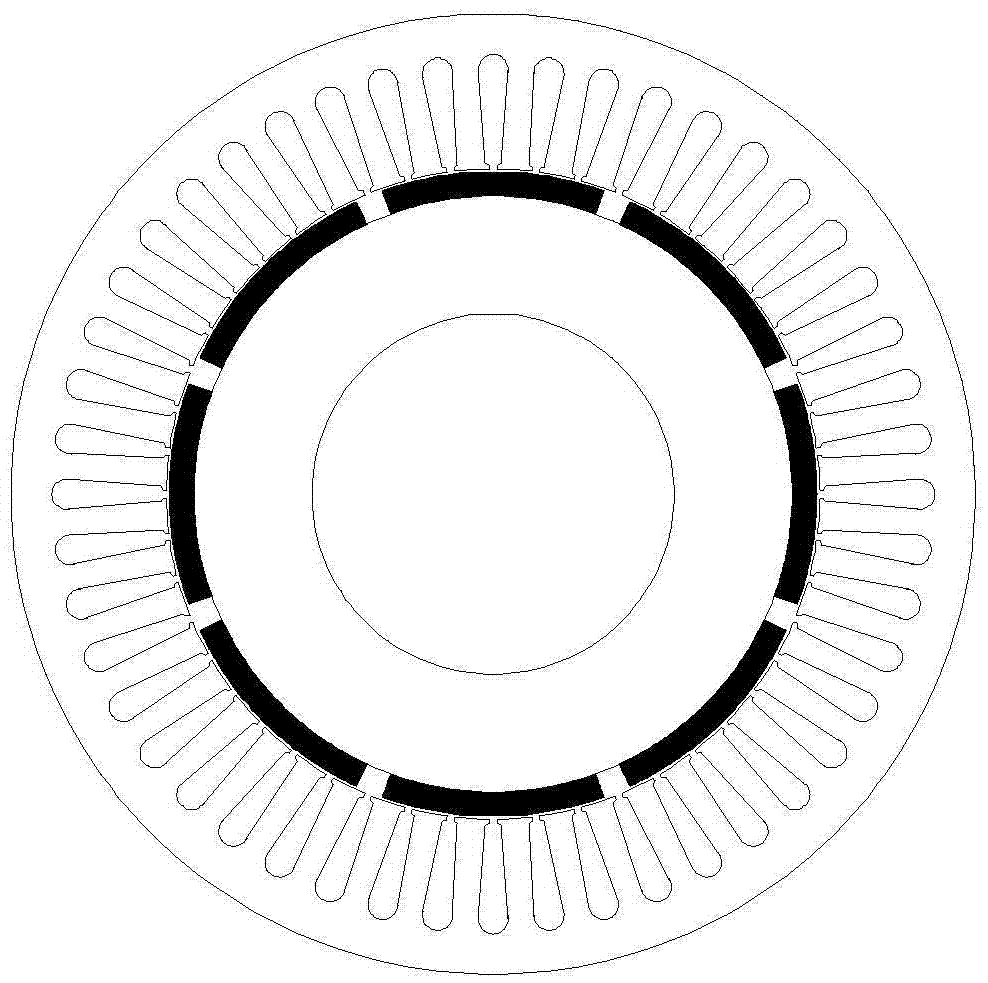

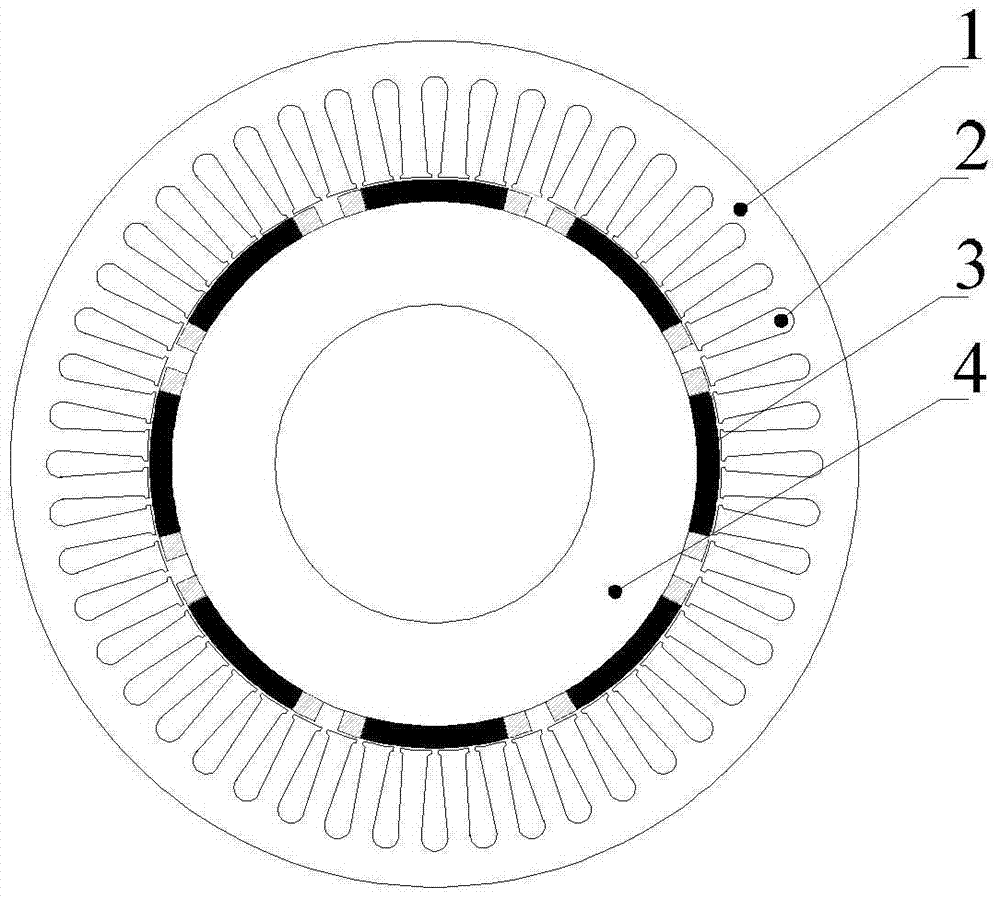

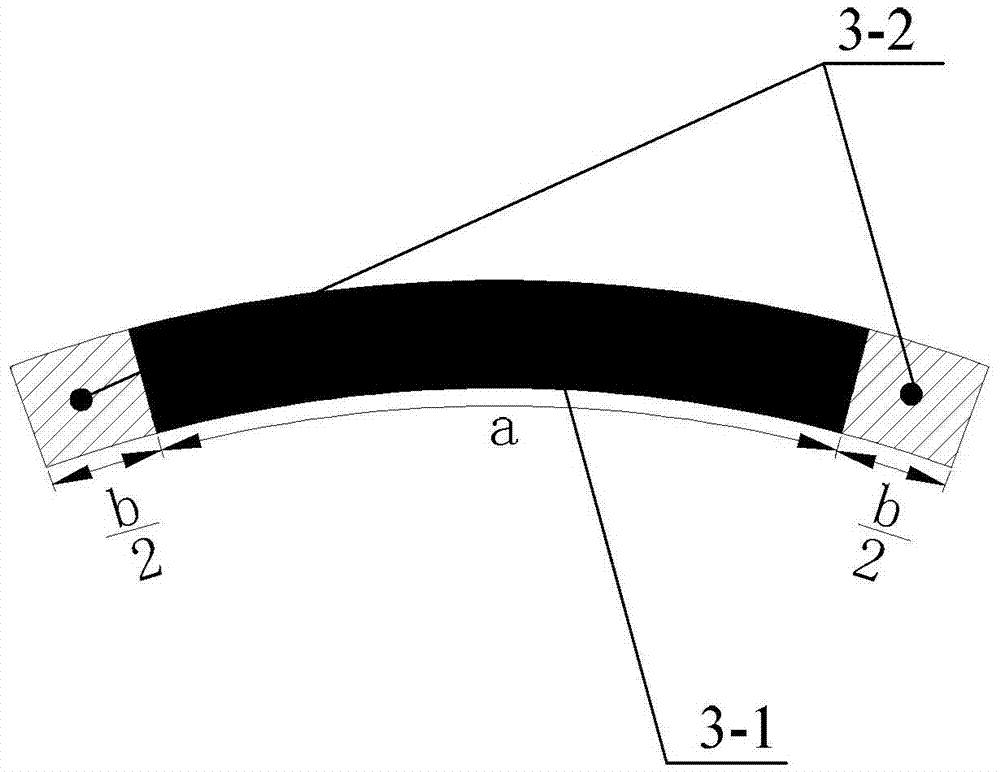

Composite magnetic pole type surface-mounted permanent magnet synchronous motor

ActiveCN105449968AAir gap magnetic density waveform distortion rate is smallIncrease axial lengthMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsSurface mountingPermanent magnet synchronous motor

The invention discloses a composite magnetic pole type surface-mounted permanent magnet synchronous motor, which belongs to the field of permanent magnet motors. The composite magnetic pole type surface-mounted permanent magnet synchronous motor aims to solve the problems that harmonic wave is in the presence in a sinusoidal-current-driven rare earth permanent magnet synchronous motor air gap magnetic field and local irreversible demagnetization always happen. The composite magnetic pole type surface-mounted permanent magnet synchronous motor comprises a rotor and a stator, wherein the rotor is arranged in the stator; a radial air gap is formed between the rotor and the stator; the excircle surface of the a rotor iron core is evenly provided with a plurality of rotor magnetic pols in a surface-mounted way; each rotor magnetic pole comprises a rare earth permanent magnetic pole and two ferrite permanent magnetic poles, wherein the left end surface and the right end surface of the rare earth permanent magnetic pole are independently provided with one ferrite permanent magnetic pole; the rare earth permanent magnetic pole and two ferrite permanent magnetic poles form a continuous circular-arc magnetic pole structure; and the magnetization directions of the rare earth permanent magnetic pole and two ferrite permanent magnetic poles are all radial magnetization and are the same. The permanent magnet synchronous motor of the structure causes the harmonic content of the air gap magnetic field to be lowered, motor efficiency is improved, the ferrite permanent magnet material is low in price, and cost is lowered.

Owner:HARBIN INST OF TECH

Brushless DC motor

InactiveCN101102090AReduce torque fluctuationReduce noiseElectronic commutation motor controlAC motor controlPhase currentsElectricity

The invention provides a motor for a brushless DC motor, which has small torque ripple even if a trapezoidal wave current is supplied and has a small size and reduced motor noise. Respective phase current command values are calculated on the basis of vector control. Pseudo-vector control for controlling respective phases separately is used as current feedback control.

Owner:NSK LTD

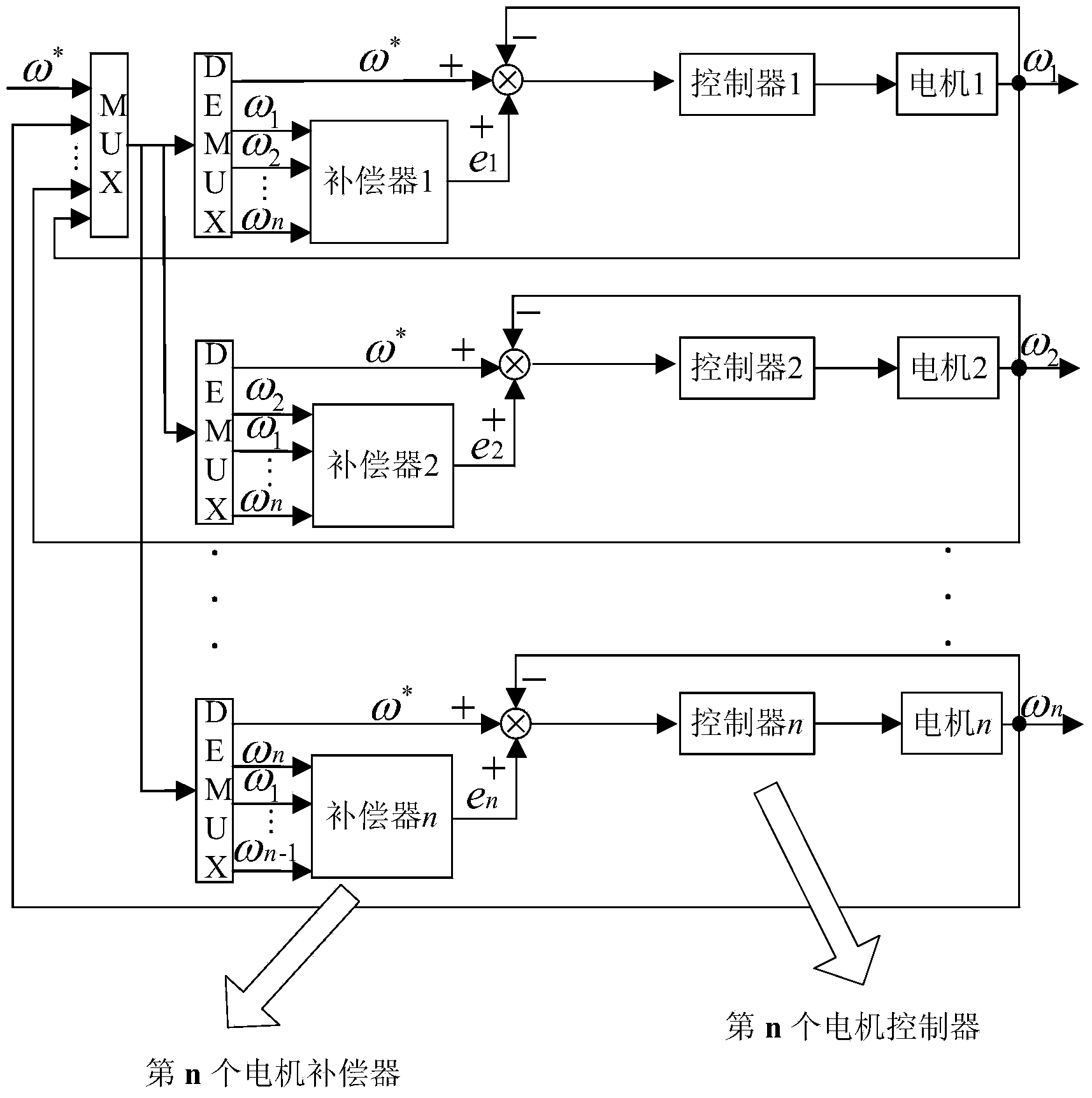

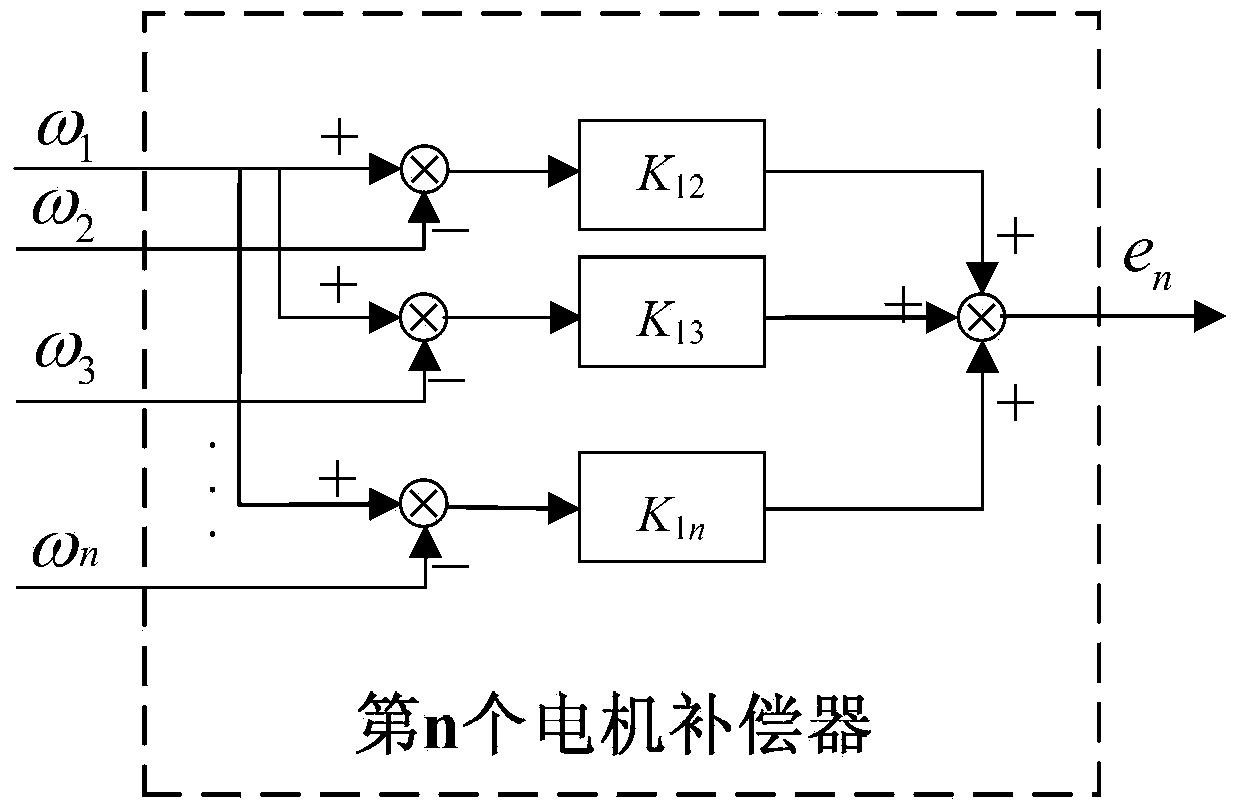

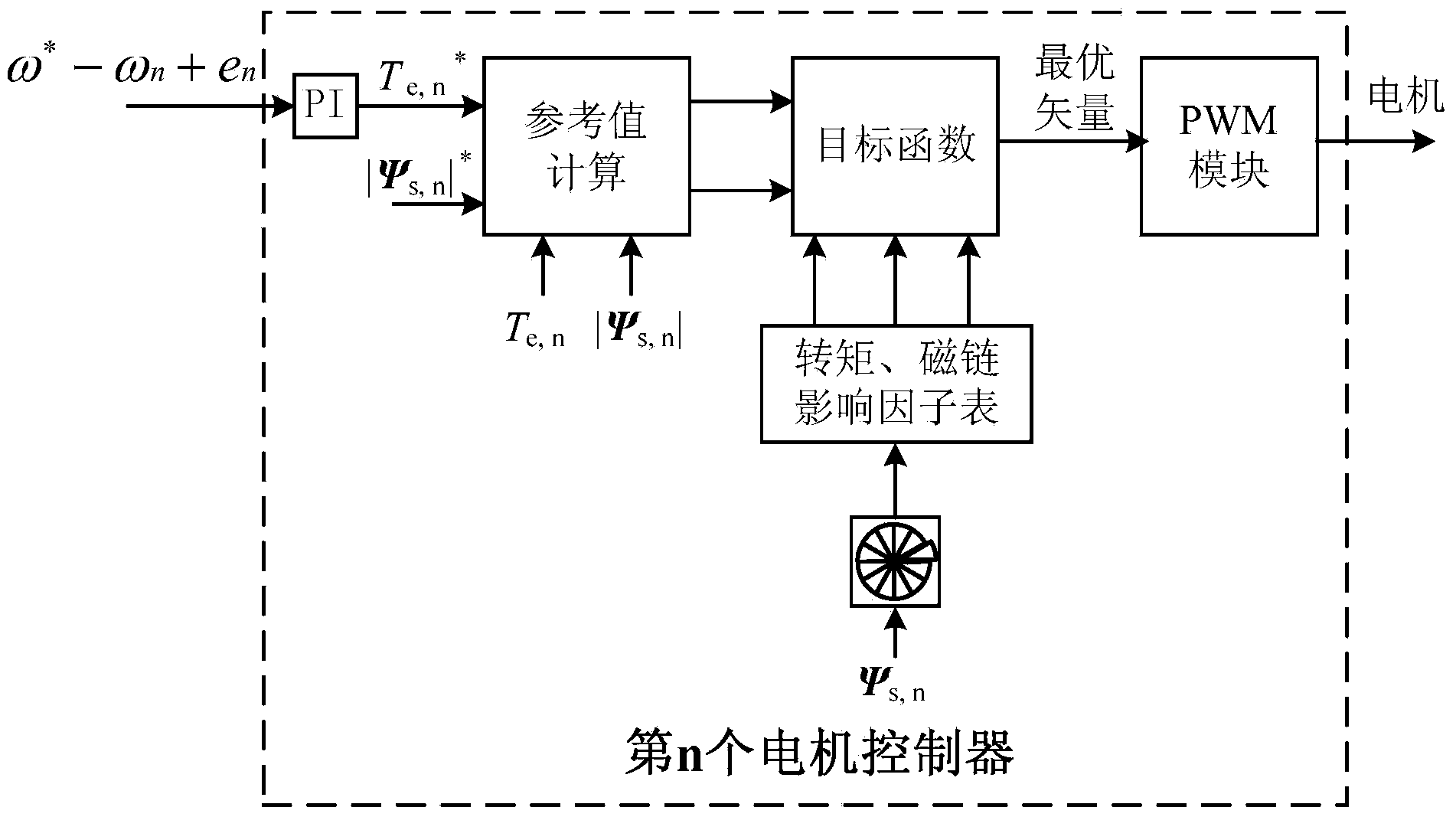

Direct torque control method suitable for multi-motor system

ActiveCN103944459AFast torque responseReduce torque fluctuationElectronic commutation motor controlVector control systemsVoltage vectorEqualization

The invention discloses a direct torque control method suitable for a multi-motor system. Firstly, a torque and flux linkage evaluating function of the multi-motor system is established; a torque and flux linkage impact factor table is obtained through the discretization and equalization processing on the evaluating function; then, the torque reference value of a single motor is generated through a deviation coupling controller of the multi-motor system; lastly, a torque impact factor reference value p Tau* and a flux linkage impact factor reference value p Lambada* are calculated, an objective function is established, and an inverter voltage vector enabling the value of the objective function to be minimum is selected according to the torque and flux linkage impact factor table and is used for controlling the multi-motor system. According to the direct torque control method, fast torque responses of the multi-motor system can be achieved, and torque ripples in steady-state operation can be lowered; the impact degrees of different inverter voltage vectors on the electromagnetic torque and the motor stator flux linkage amplitude of the multi-motor system under the action of different duty ratios can be comprehensively, directly and finely reflected through the established torque and flux linkage impact factor table.

Owner:TIANJIN UNIV

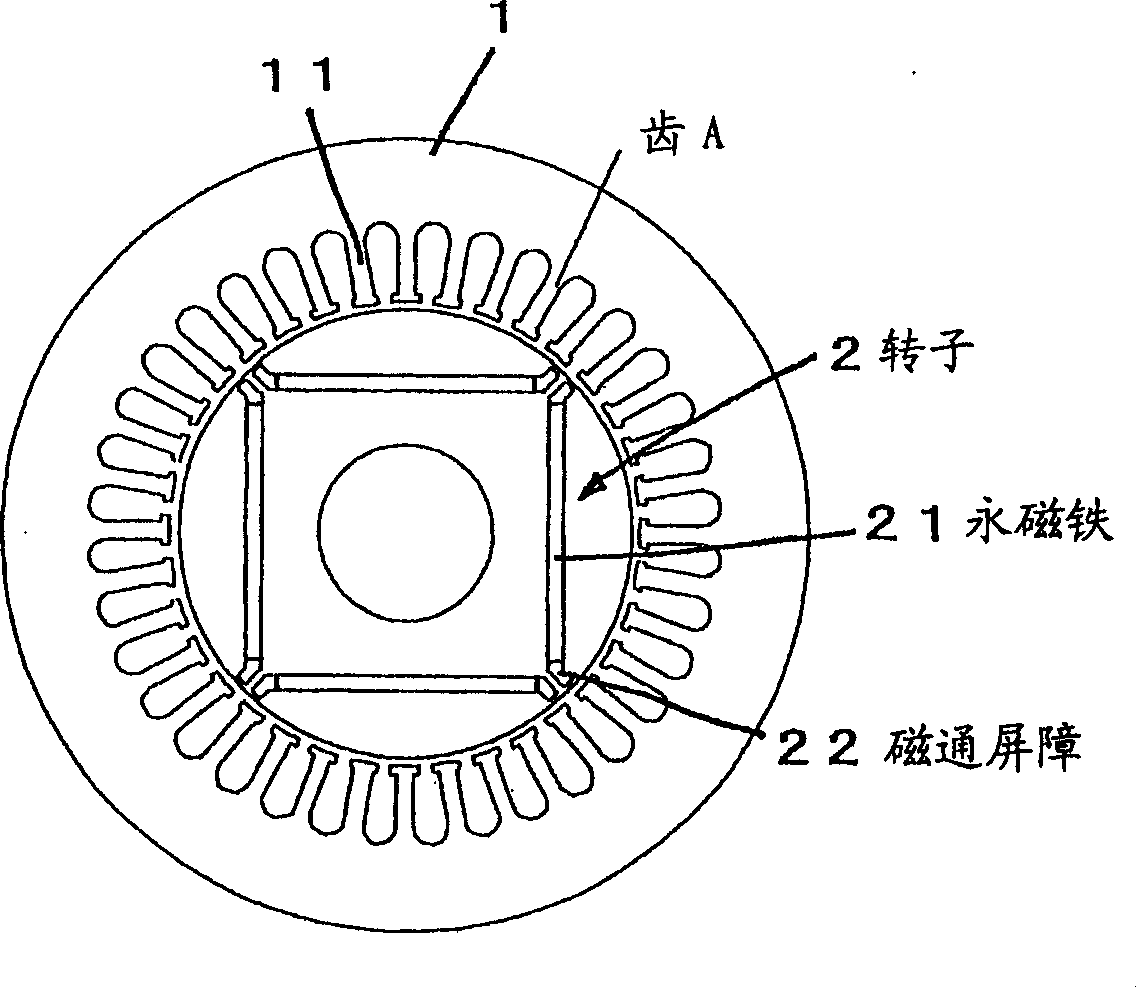

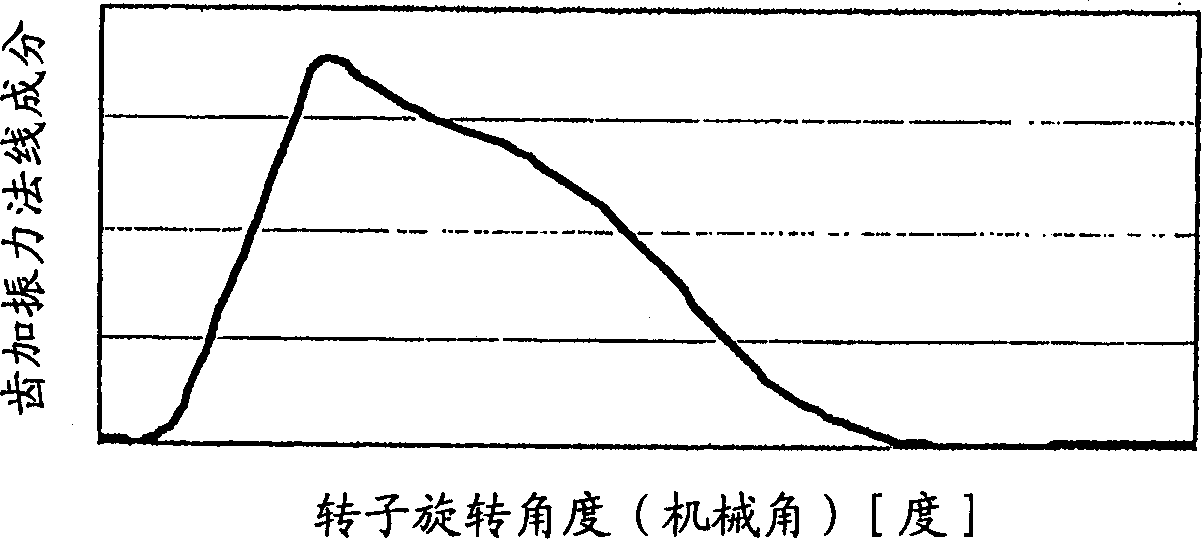

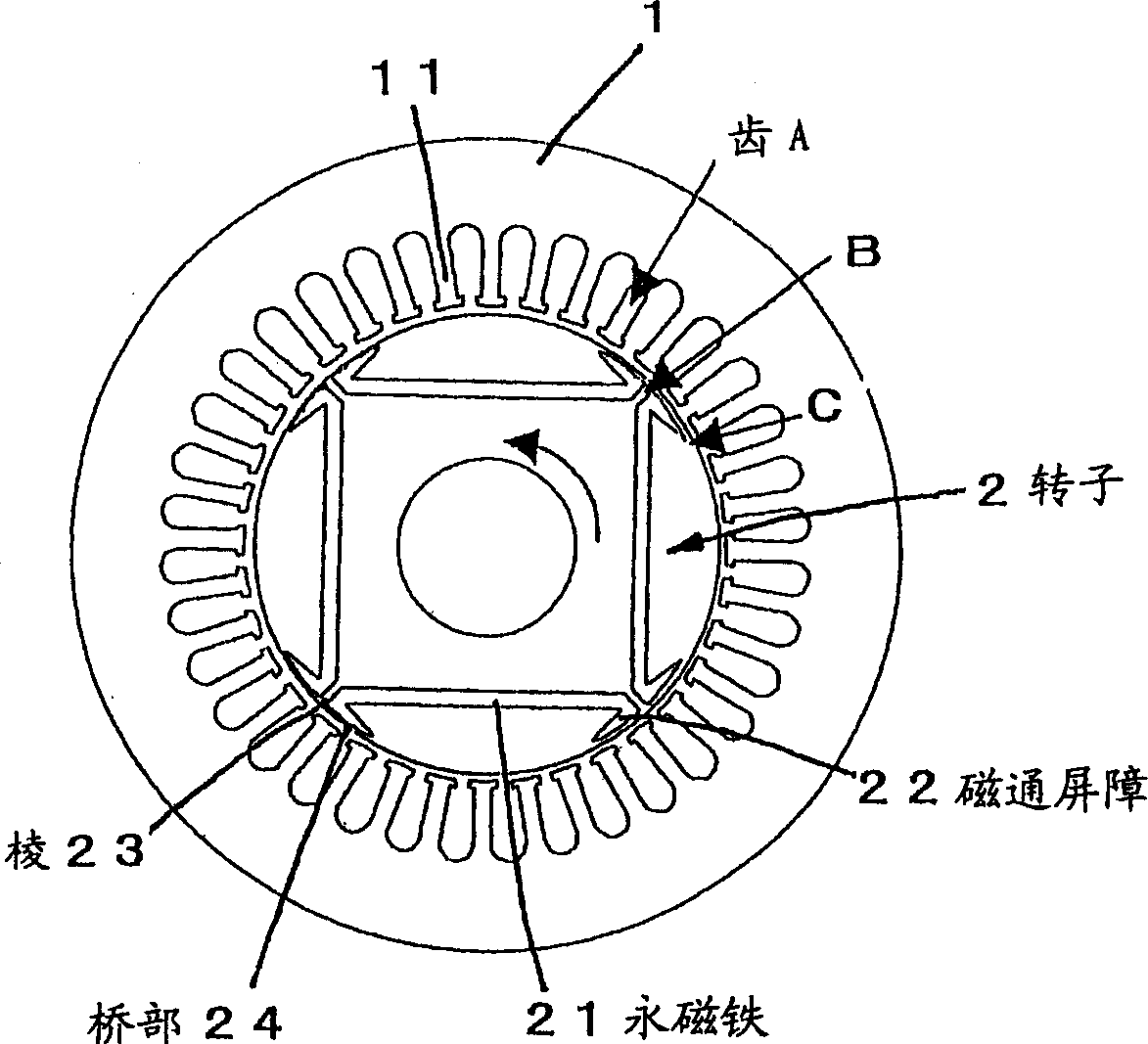

Blushless DC motor and blushless DC motor controller

InactiveCN1717853AReduce vibrationImprove efficiencyDC motor speed/torque controlMagnetic circuit rotating partsMotor speedLow noise

Let (theta0) be the angle formed between the end on the magnetic pole center side of a magnetic flux barrier (22) and the end of an adjacent magnetic flux barrier (22) on the side contacting a rib 23 with respect to the rotor center, f be the oscillation frequency desired to be reduced, Pn be the number of pole pairs, f0 = Pn * N be the electric angle frequency, N be the motor rpm, m = 1, 3, 5,..., and thetar be the angle formed by ribs with respect to the rotor center. The angle is set such that the relation theta0 = 180 DEG * m / (Pn * f / f0), (where, 2 theta0 - thetar < 90 DEG ) is satisfied, whereby high efficiency and low noise can be easily made compatible.

Owner:DAIKIN IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com