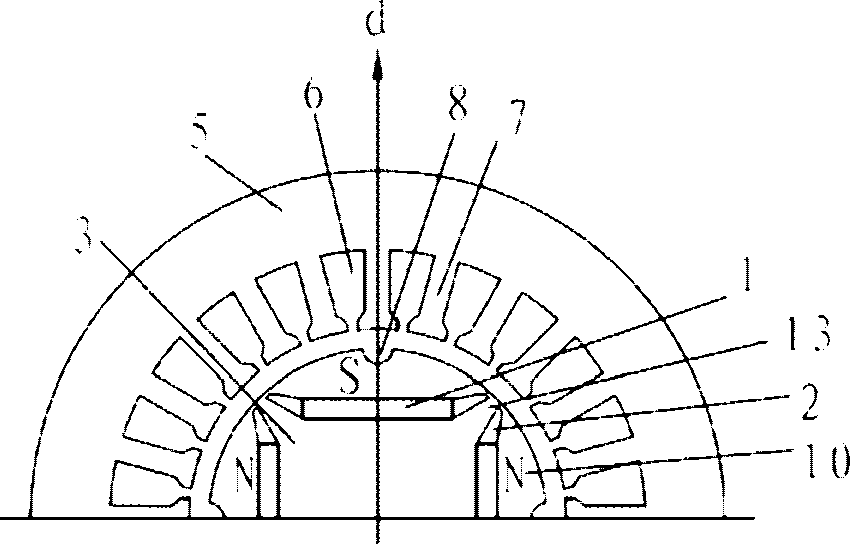

Built-in permanent-magnetic motor rotor and motor comprising same

A motor rotor and rotor technology, applied in the field of electric motors, can solve problems such as difficulty in meeting industrialization, low overload capacity, and low power density, and achieve the effects of improving overload capacity, reducing mechanical vibration, and increasing the number of fundamental waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

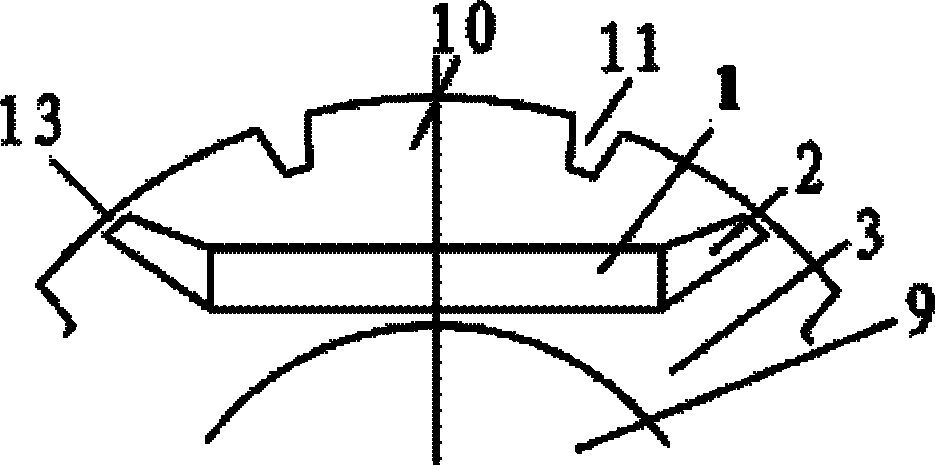

[0021] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

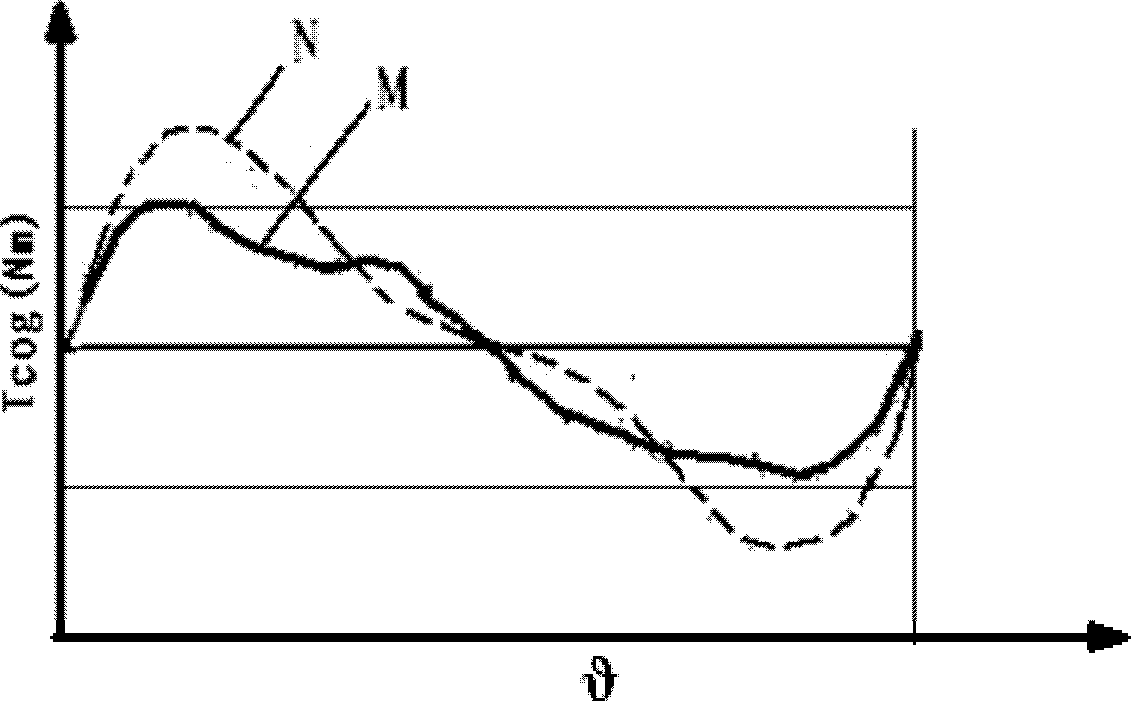

[0022] Torque fluctuations caused by electromagnetic causes produce mechanical and electromagnetic noise, which affect the smooth operation and reliability of the motor. The torque, which fluctuates periodically with the spatial position, has nothing to do with the stator current; the other is the ripple torque, which is the harmonic torque caused by the difference between the current and back EMF waveforms. The torque fluctuation of permanent magnet synchronous motor for vehicle is the superposition of cogging torque and ripple torque. The motor industry and research institutes all over the world are doing research to reduce the torque fluctuation of the motor, such as the use of fractional slot method, auxiliary slot method, auxiliary tooth method, inclined slot method, oblique pole method, closed slot method and magnetized slot wedge method,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com