Patents

Literature

31results about How to "Balance radial force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

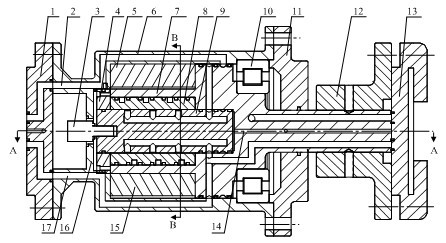

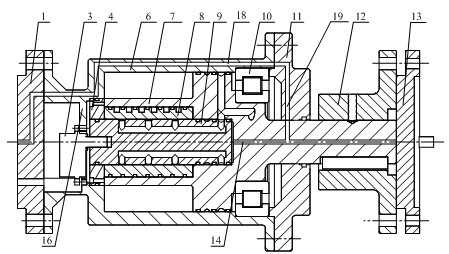

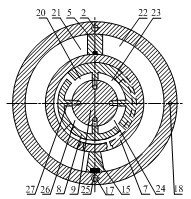

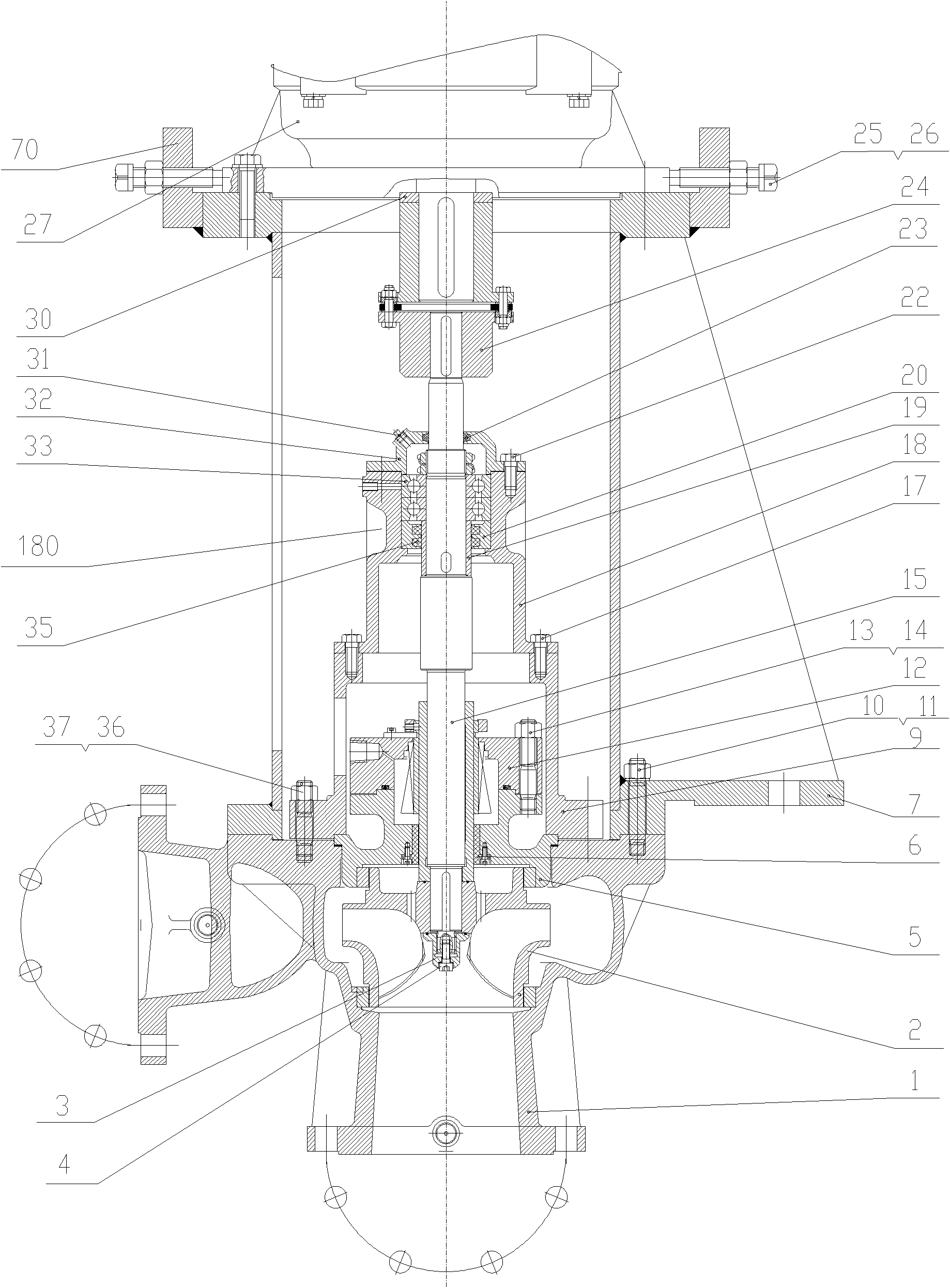

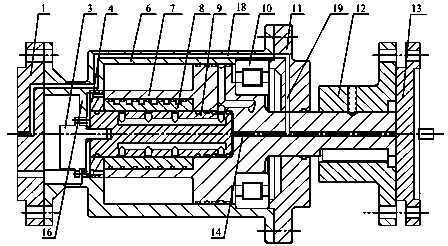

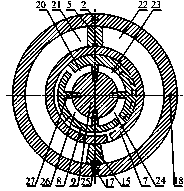

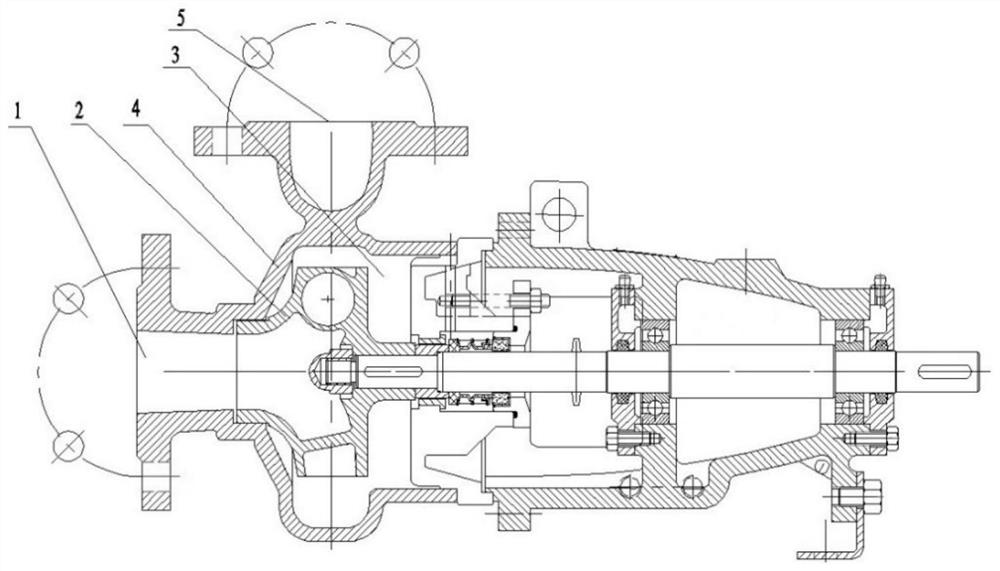

Easily controlling hydraulic corner self-servo valve

ActiveCN102562701ASmall resistance and hydraulic clamping forceGood dynamic characteristicsServomotor componentsPhysicsHollow cylinder

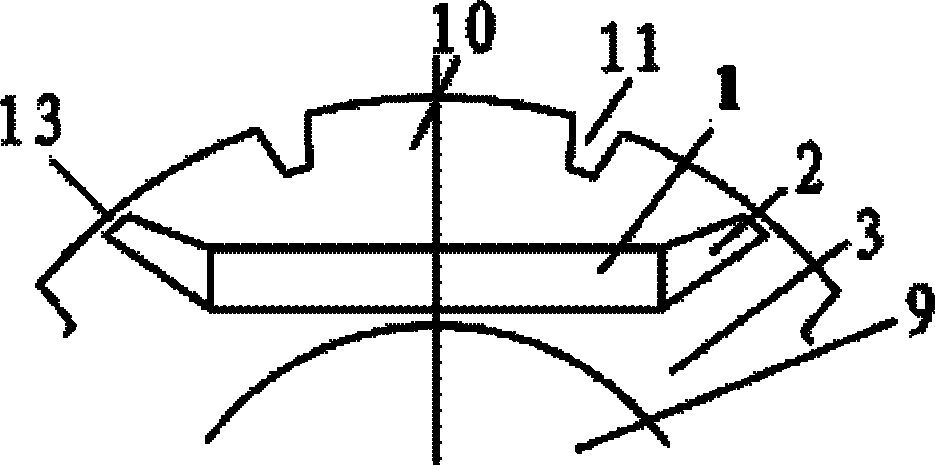

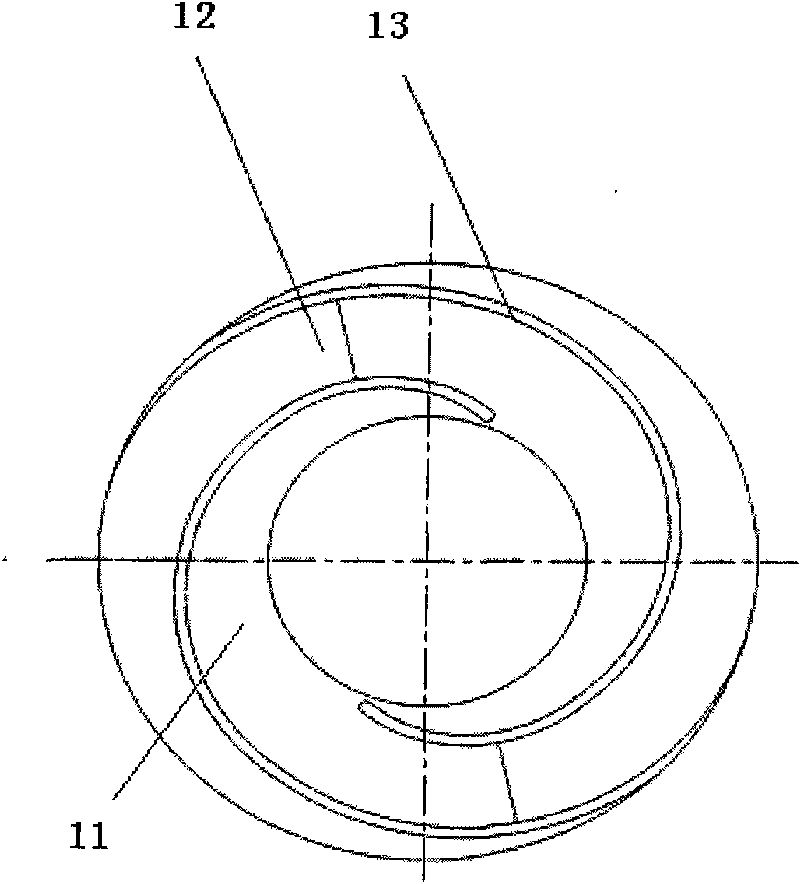

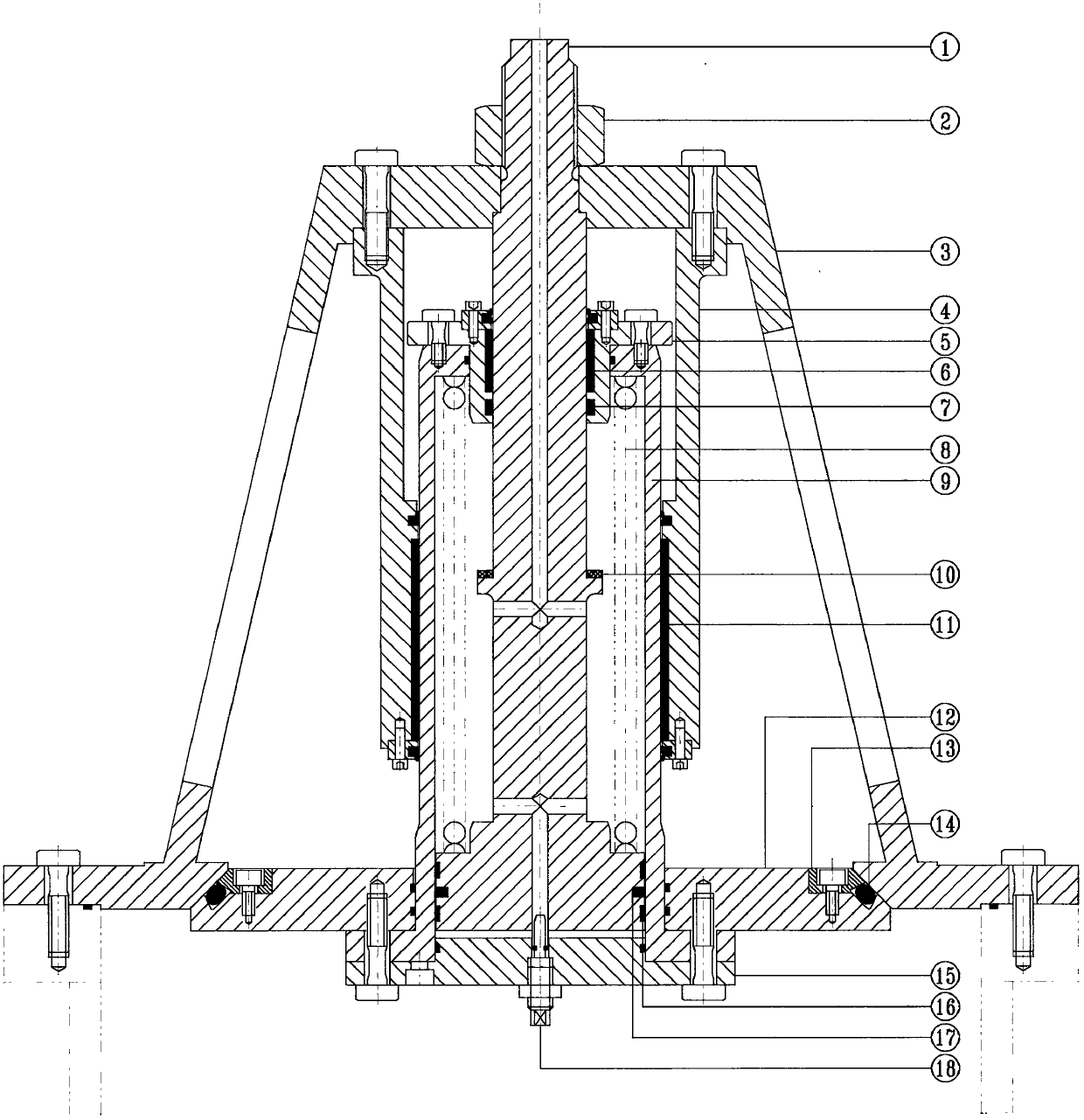

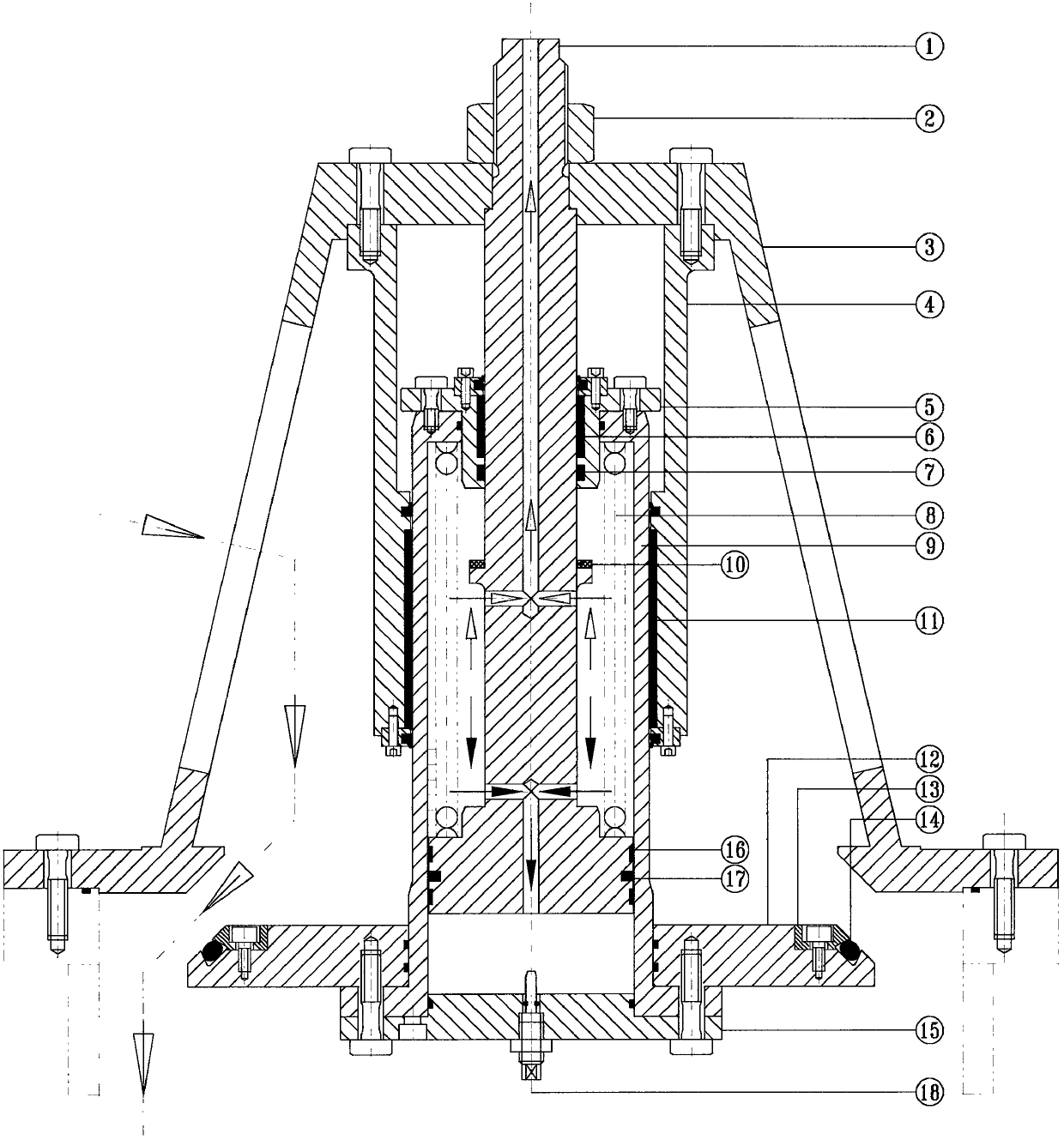

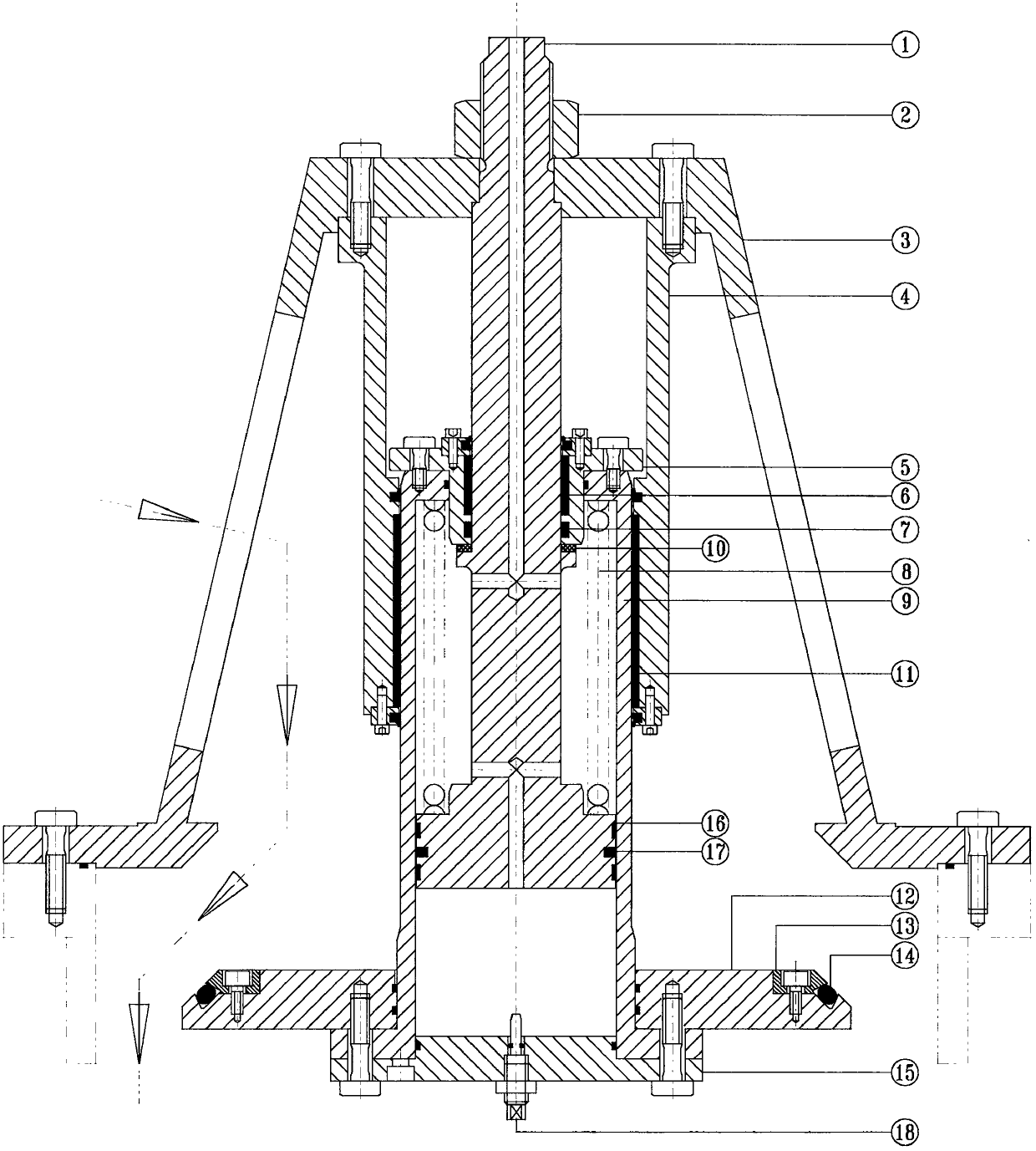

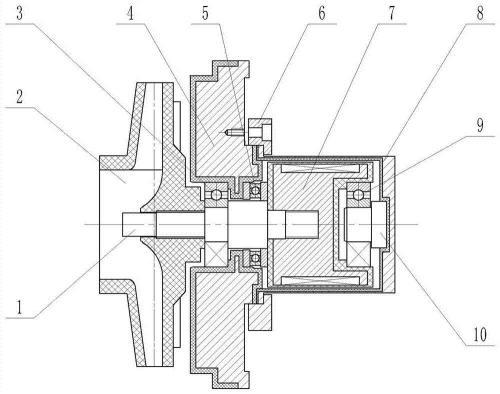

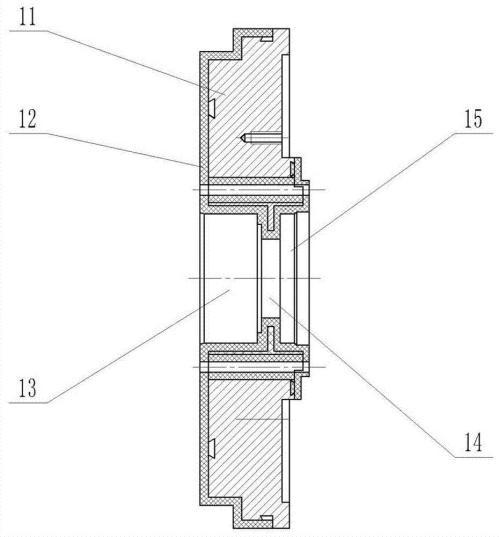

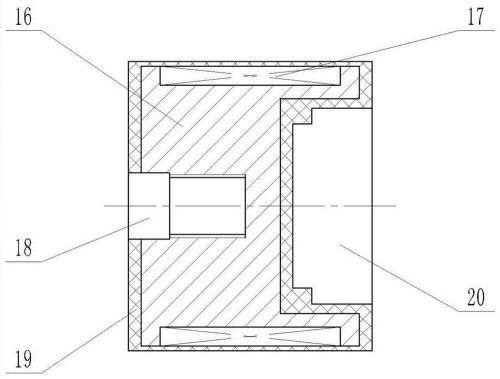

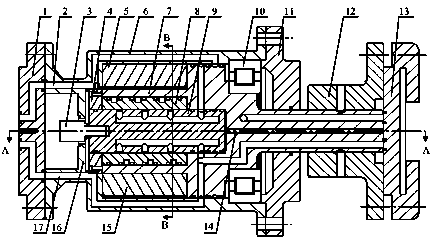

The invention relates to an easily controlling hydraulic corner self-servo valve which is characterized in that a blade (15) is arranged on the outer wall of a hollow column body (35) of a valve body (7); the initial assembly position of the blade (15) is in axis symmetric arrangement with that of a fixed baffle block (5); a valve sleeve (8) is arranged in a the hollow column body (35), and a valve core (8) is arranged in a small hollow circle (34) of the valve body (7); a high pressure oil inlet P and a low pressure oil outlet T of a left end cover (1) are respectively communicated with high and low pressure outer oil annular slots (31 and 28) of the valve body (7) correspondingly through high and low pressure oil channels (2 and 17) of a cylinder body (6); high and low pressure inner oil annular slots (32 and 30) of the valve body (7) are correspondingly communicated with core body high and low pressure oil annular slots (39 and 40) of the valve core (9); and core body high and low pressure oil channels (38 and 41) enter a first working chamber and a and second working chamber correspondingly through upper and lower semi-circle oil annular slots (36 and 37) of the valve sleeve (8). According to the invention, the easily controlling hydraulic corner self-servo valve has the characteristics that the preparation is convenient, the radial force and the axial force subjected by the valve core are both balanced, the resistance of the valve core is low, the dynamic characteristics are good, and the servo blind area is small.

Owner:武汉科技大学资产经营有限公司

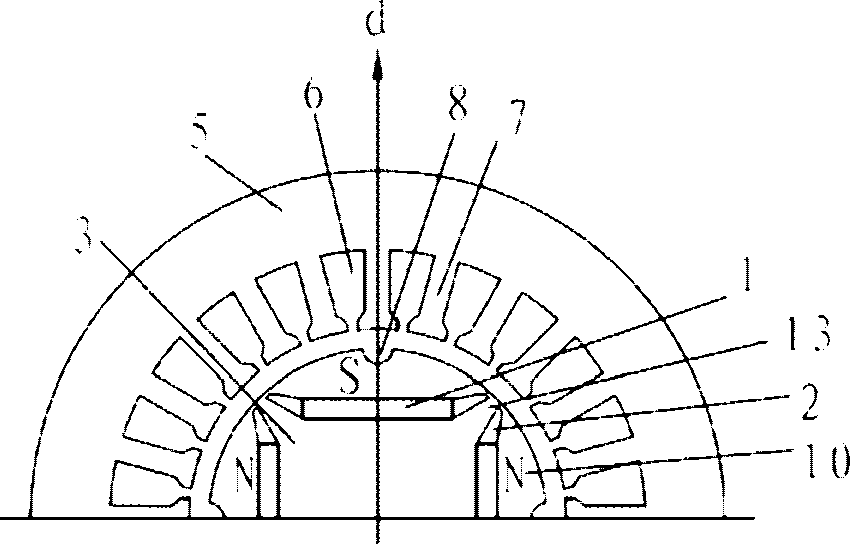

Built-in permanent-magnetic motor rotor and motor comprising same

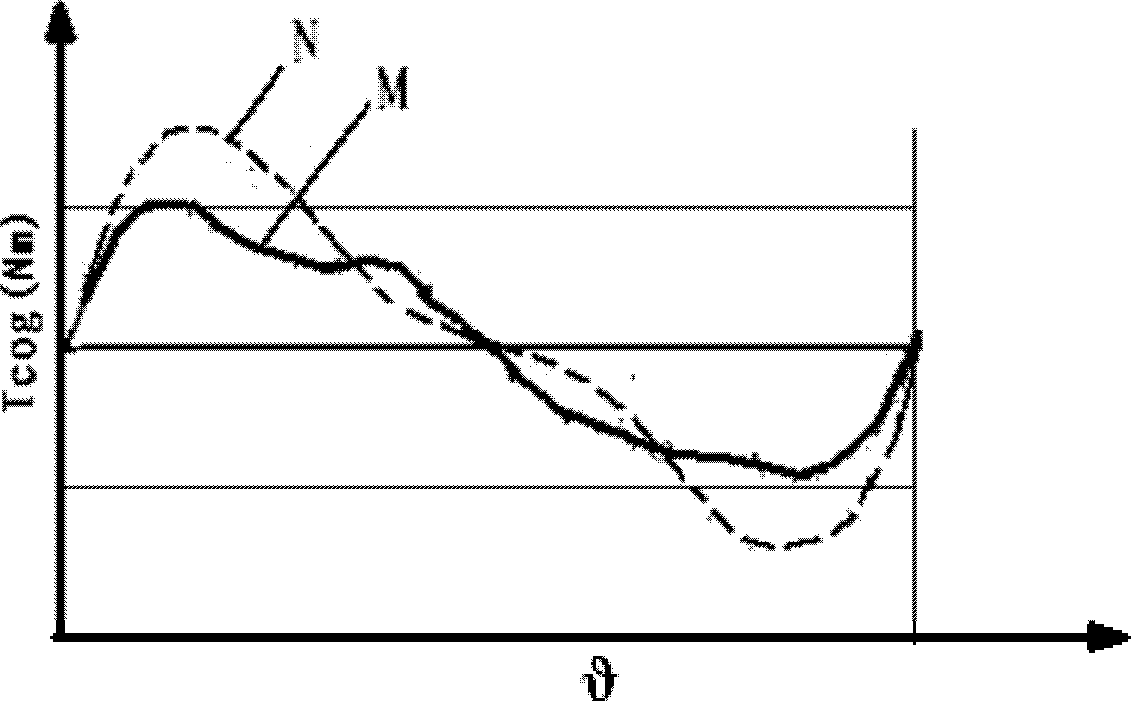

InactiveCN102355071AReduce noiseImproved air gap magnetic field waveformMagnetic circuit rotating partsSynchronous machinesWave shapeControl theory

The invention discloses a built-in permanent-magnetic motor rotor, which comprises a rotating shaft and a rotor iron core, wherein the rotor iron core comprises a pole shoe, at least one permanent magnet body is arranged inside the pole shoe, and the outer circle of the pole shoe is provided with a plurality of grooves. The invention also discloses a motor, which comprises a stator and the rotor. Due to the adoption of the built-in permanent-magnetic motor rotor, the waveform of an air gap field of the motor can be improved, fundamental wave times of the cogging torque fluctuation can be increased, the cogging fundamental wave and the ultra-harmonics torque amplitude can be reduced, and the torque fluctuation caused by the cogging can be reduced.

Owner:苏州和鑫电气股份有限公司

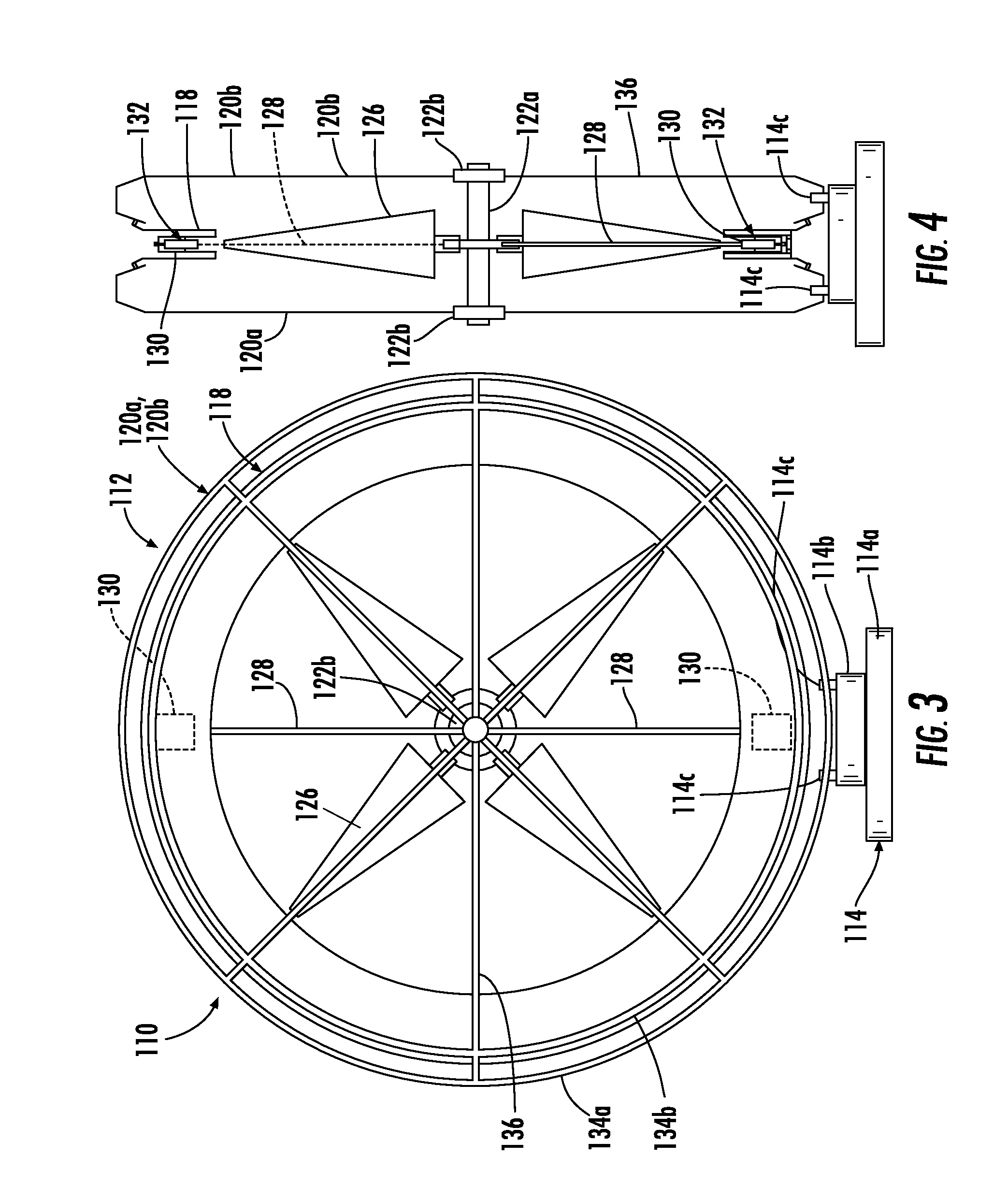

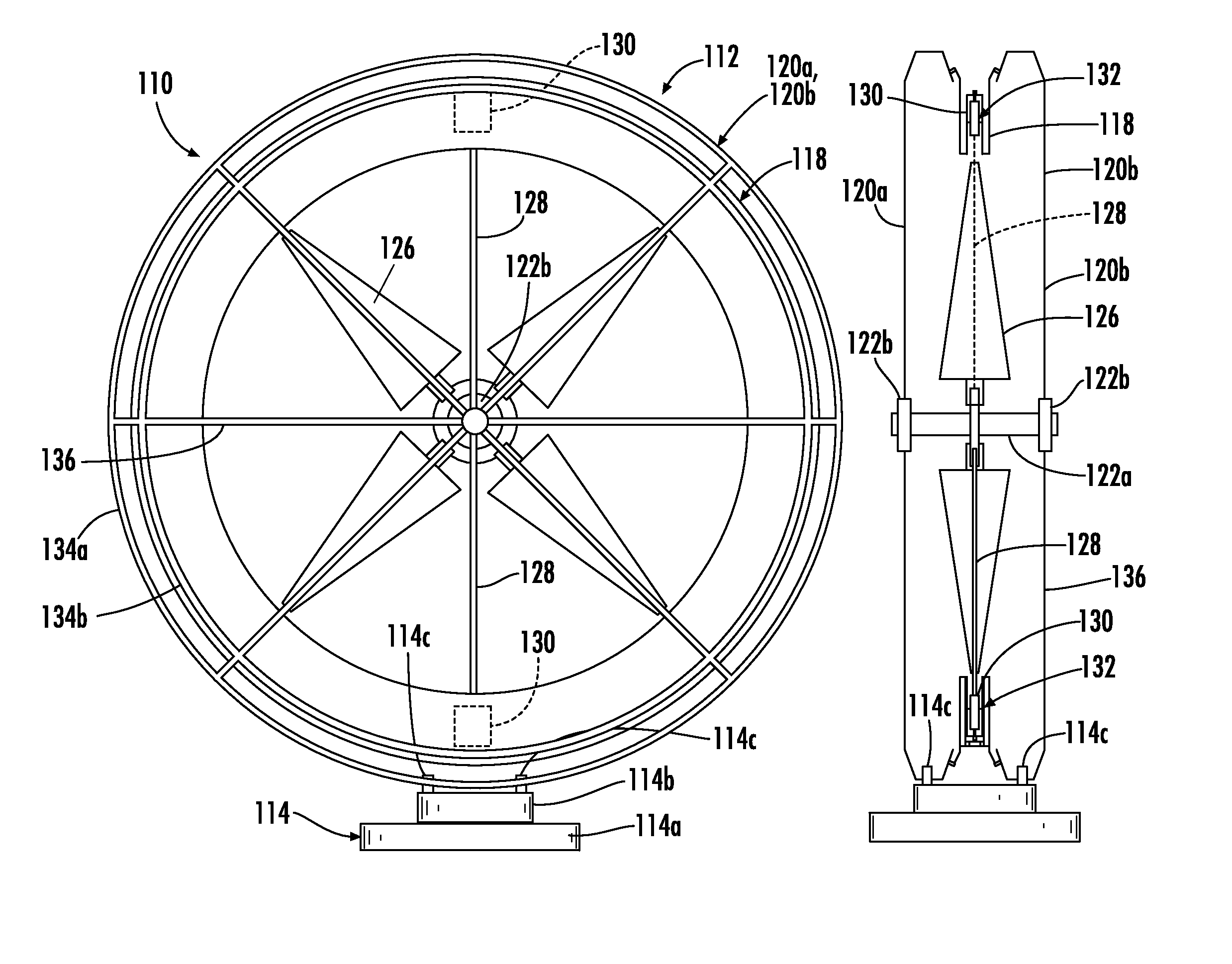

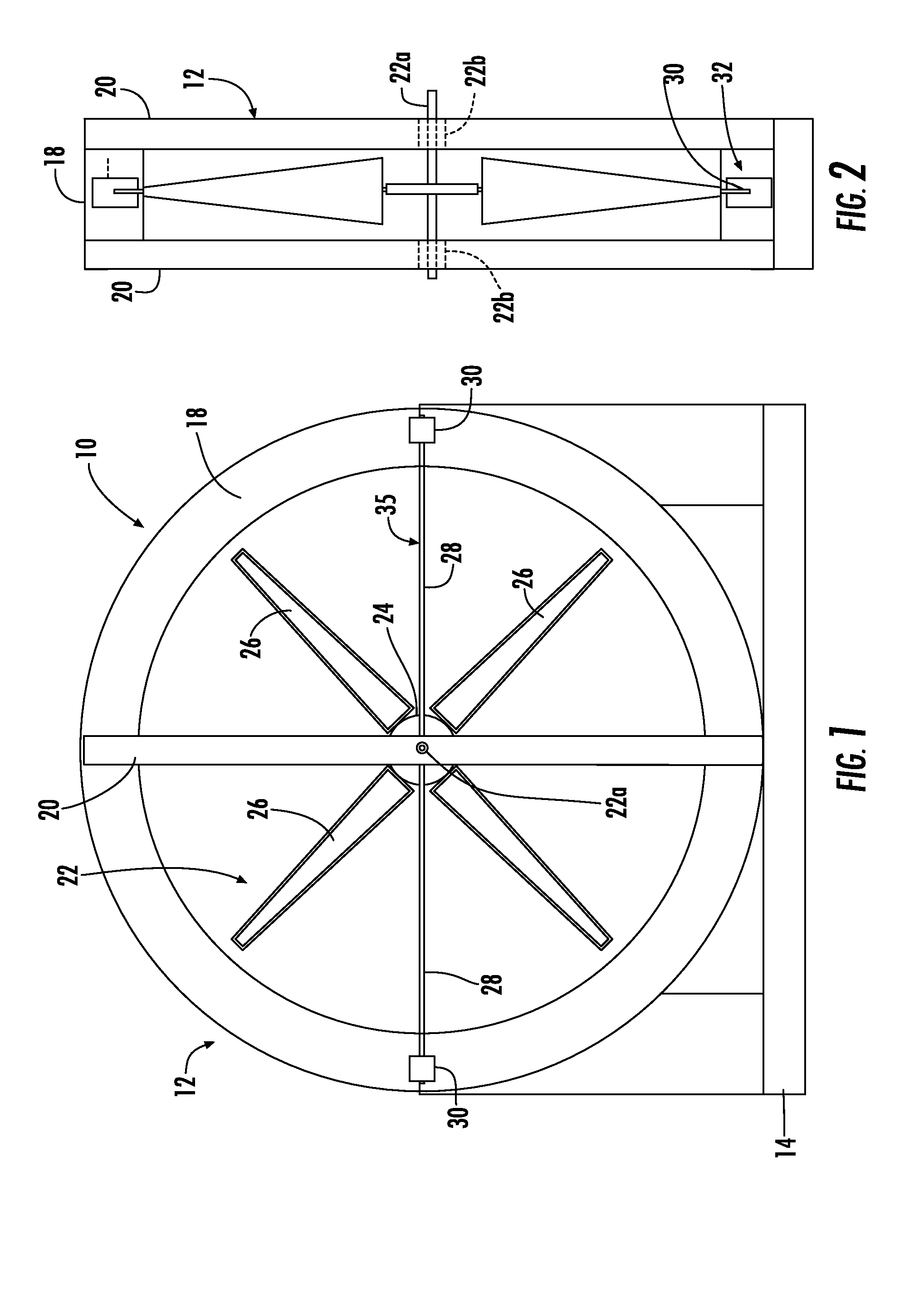

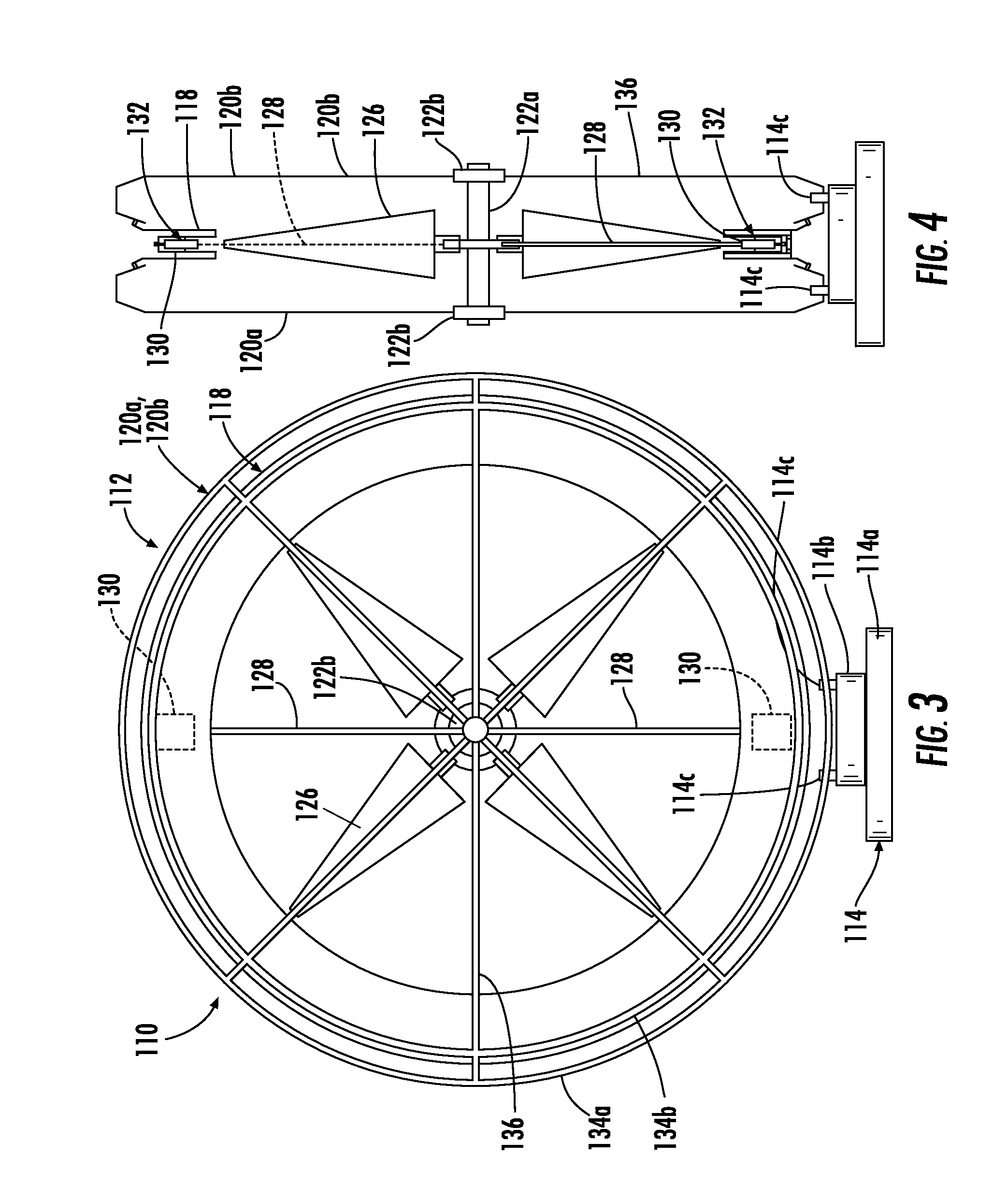

Wind turbine

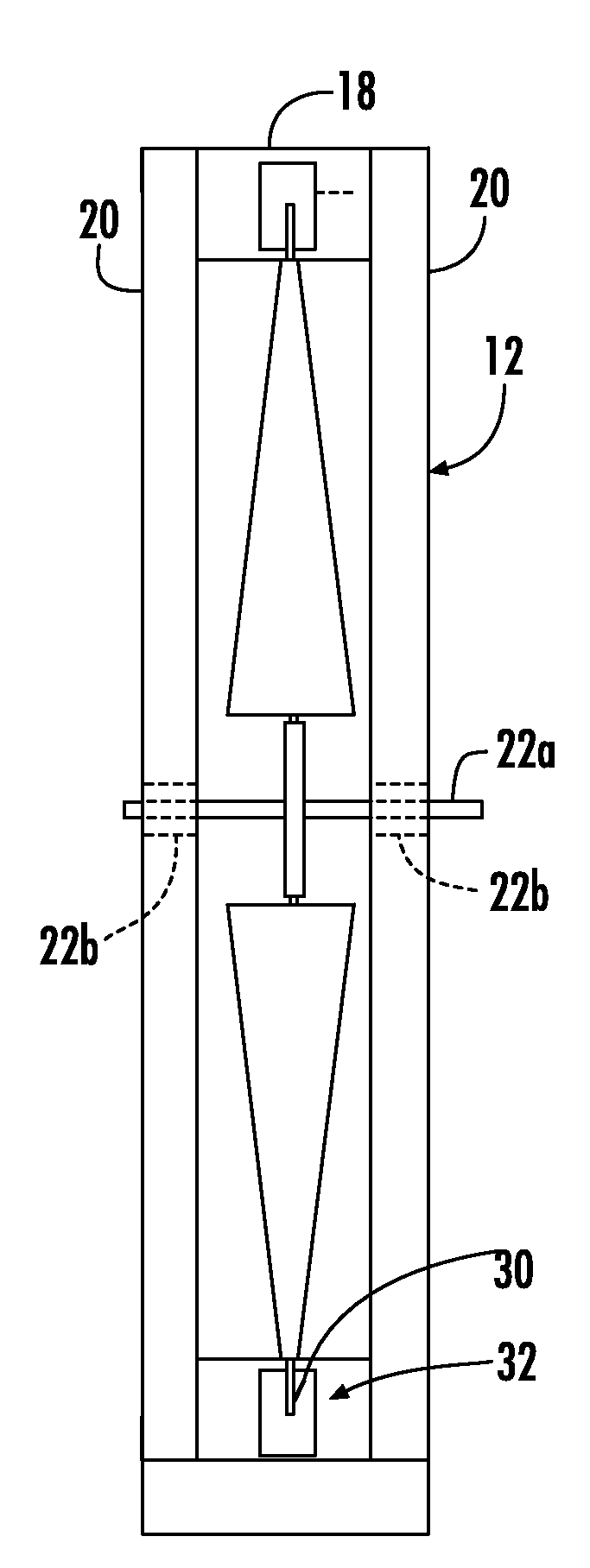

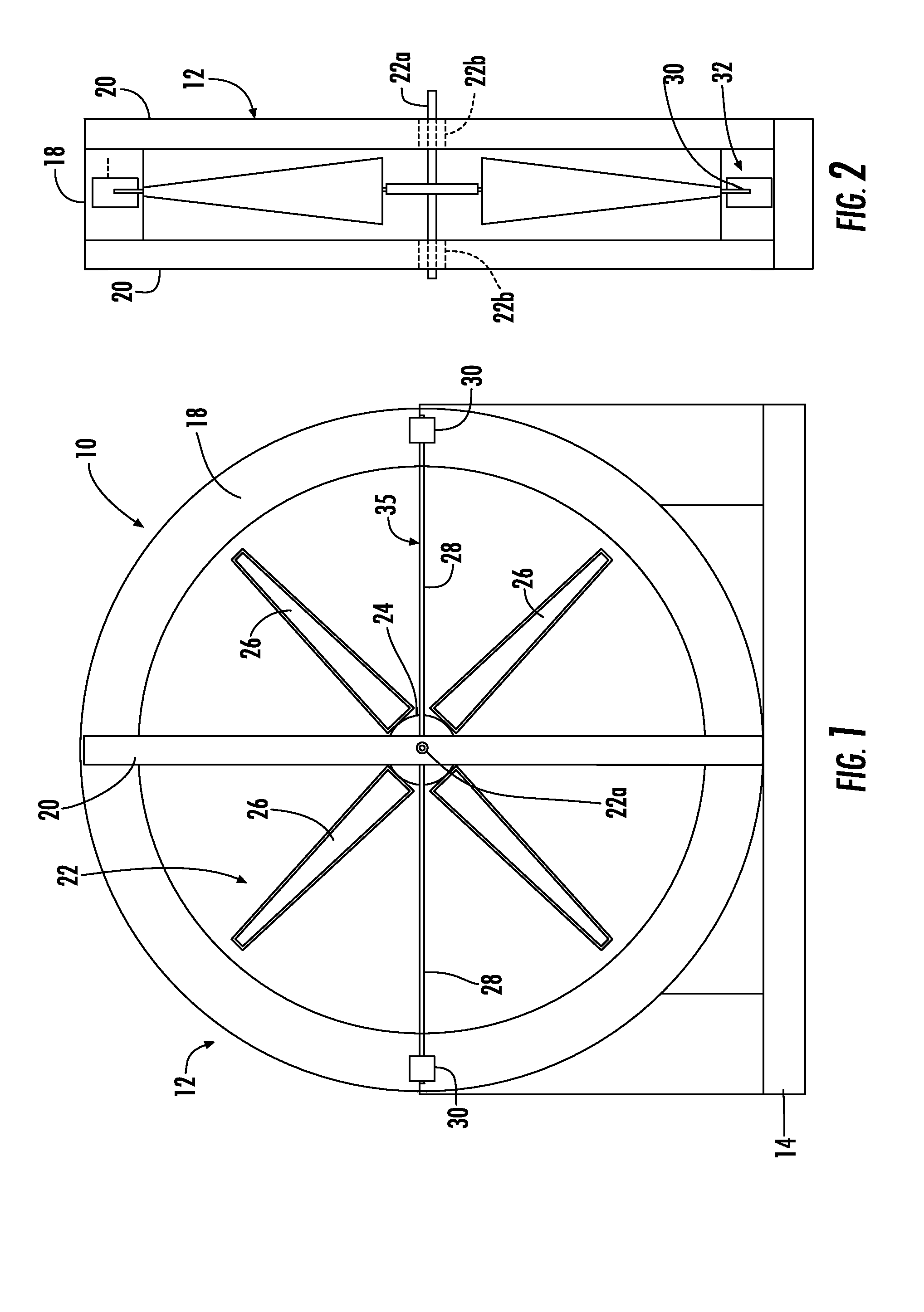

InactiveUS20100295317A1Simple and inexpensive componentReduce noiseWind motor controlWind motor supports/mountsRotational axisTurbine blade

A wind turbine includes a rotary shaft having an axis of rotation, a plurality of turbine blades supported for rotary motion by the shaft, and a plurality of magnets supported by and spaced outwardly from the rotary shaft. The blades are mounted to the shaft by a mount that is radially inward of the magnets wherein the magnets have an annular velocity of at least the annular velocity of the blades. The turbine also includes a conductive coil, which is located outwardly from the magnets and the blades, wherein the coil surrounds the magnets and the blades and which is sufficiently close to the magnets such that rotary movement of the magnets induces current flow in the coil.

Owner:E NET

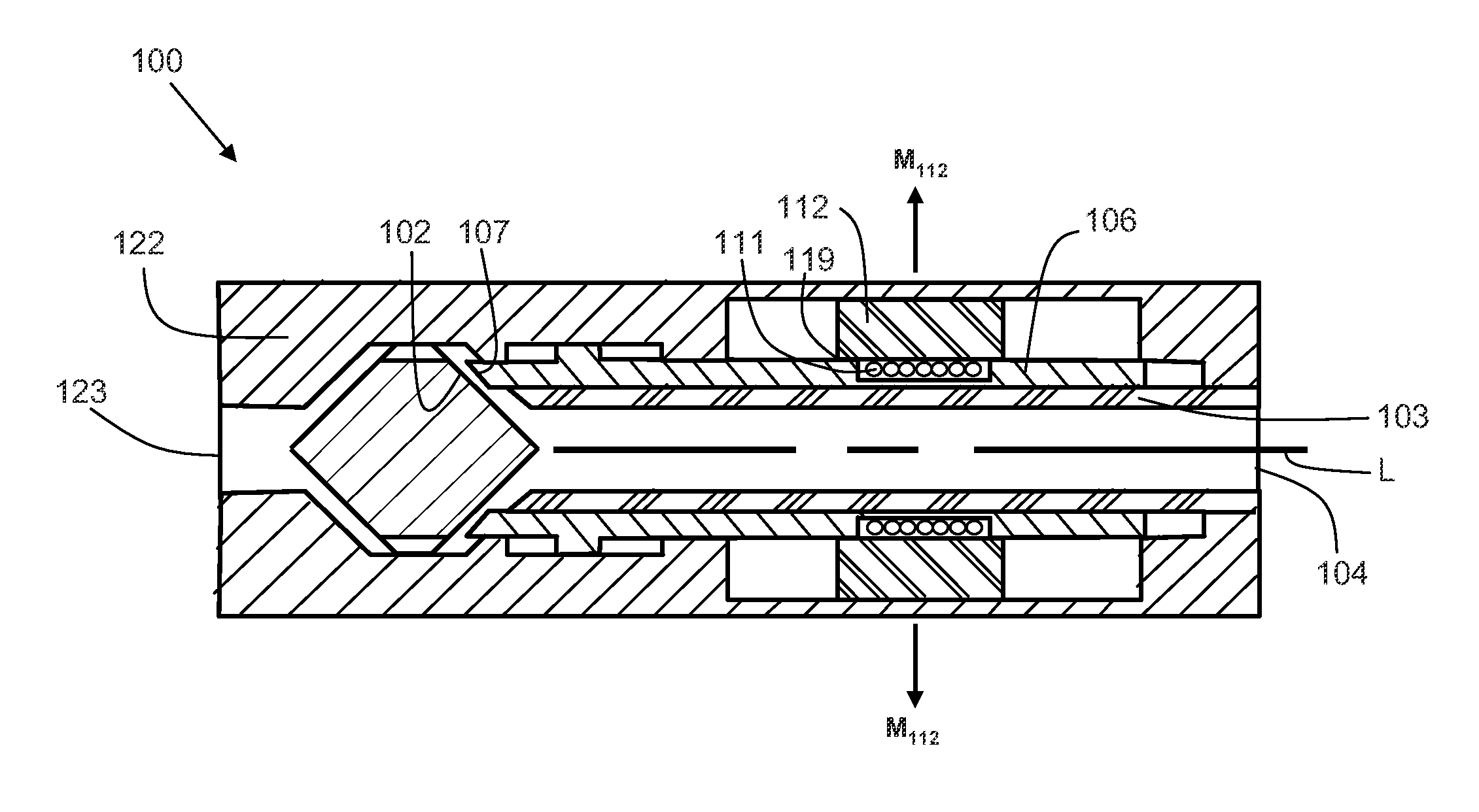

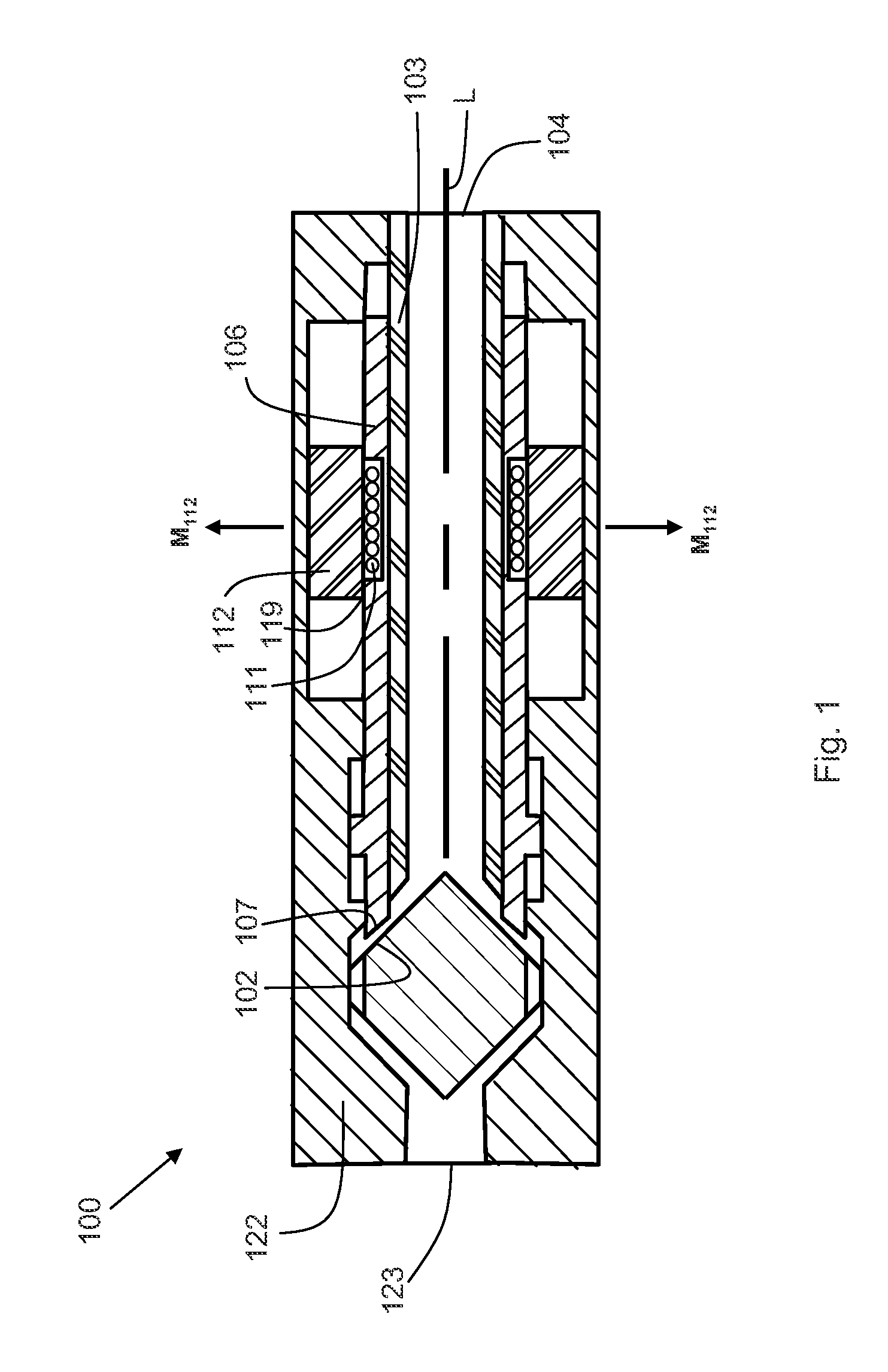

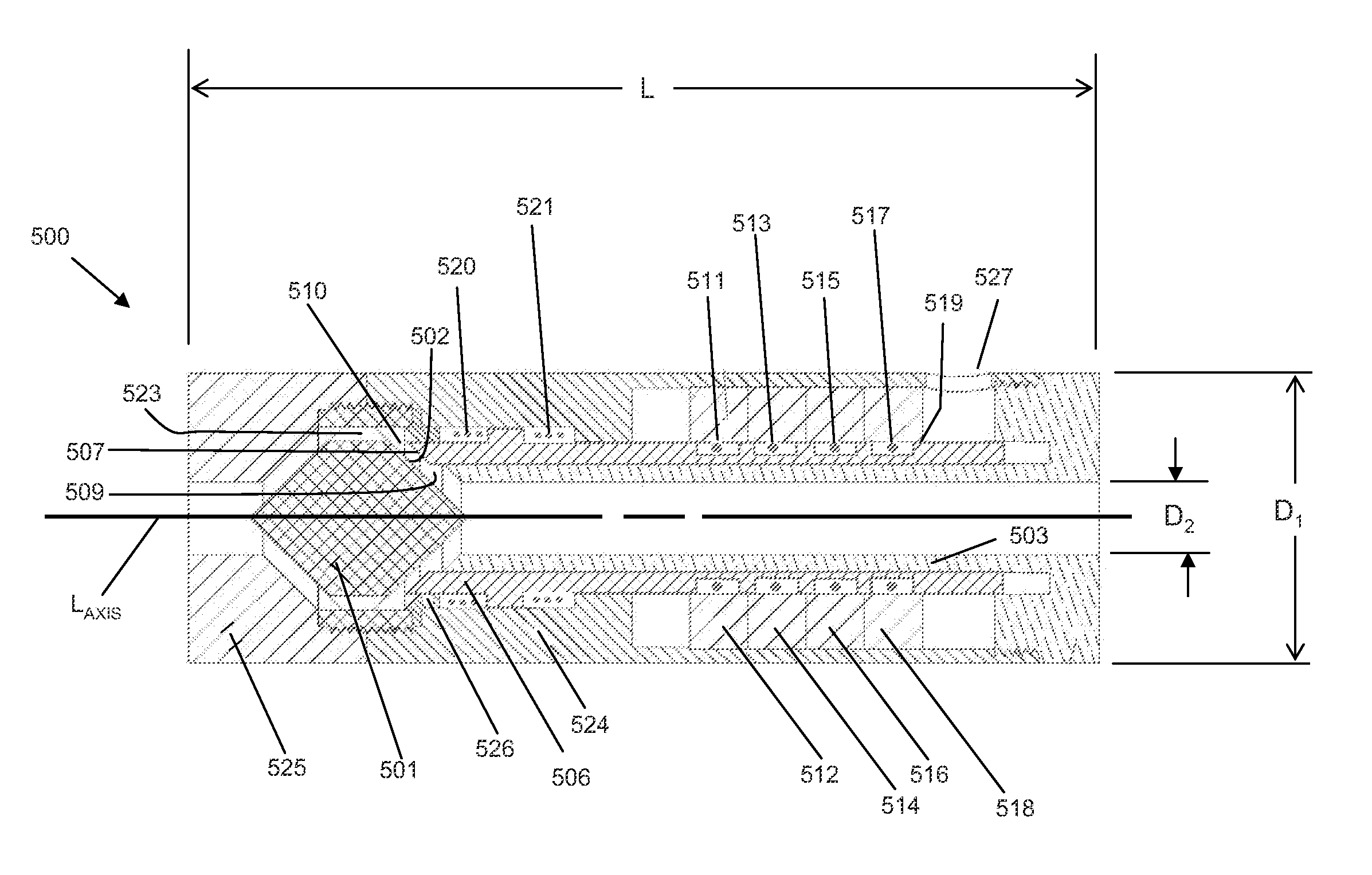

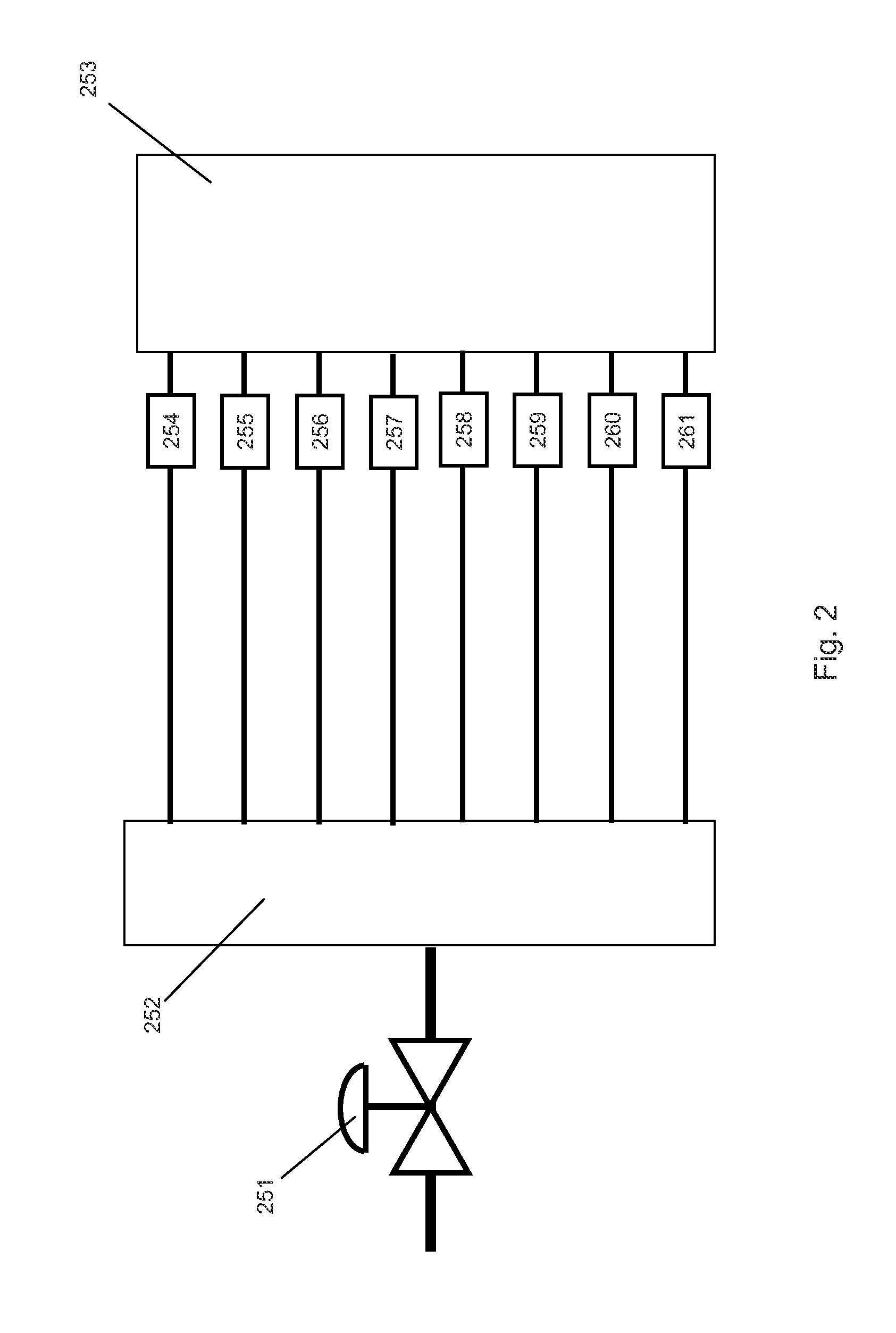

Active Combustion Flow Modulation Valve

ActiveUS20120061596A1Improve responseMovement is lowOperating means/releasing devices for valvesTurbine/propulsion fuel valvesPower flowHigh rate

A flow modulation valve has a slidably translating hollow armature with at least one energizable coil wound around and fixably attached to the hollow armature. The energizable coil or coils are influenced by at least one permanent magnet surrounding the hollow armature and supported by an outer casing. Lorentz forces on the energizable coils which are translated to the hollow armature, increase or decrease the flow area to provide flow throttling action. The extent of hollow armature translation depends on the value of current supplied and the direction of translation depends on the direction of current flow. The compact nature of the flow modulation valve combined with the high forces afforded by the actuator design provide a flow modulation valve which is highly responsive to high-rate input control signals.

Owner:UNIVERSITY OF PITTSBURGH

Wind turbine

InactiveUS8178987B2Simple and inexpensive componentImprove efficiencyWind motor controlWind motor supports/mountsTurbine bladeWind force

A wind turbine includes a rotary shaft having an axis of rotation, a plurality of turbine blades supported for rotary motion by the shaft, and a plurality of magnets supported by and spaced outwardly from the rotary shaft. The blades are mounted to the shaft by a mount that is radially inward of the magnets wherein the magnets have an annular velocity of at least the annular velocity of the blades. The turbine also includes a conductive coil, which is located outwardly from the magnets and the blades, wherein the coil surrounds the magnets and the blades and which is sufficiently close to the magnets such that rotary movement of the magnets induces current flow in the coil.

Owner:E NET

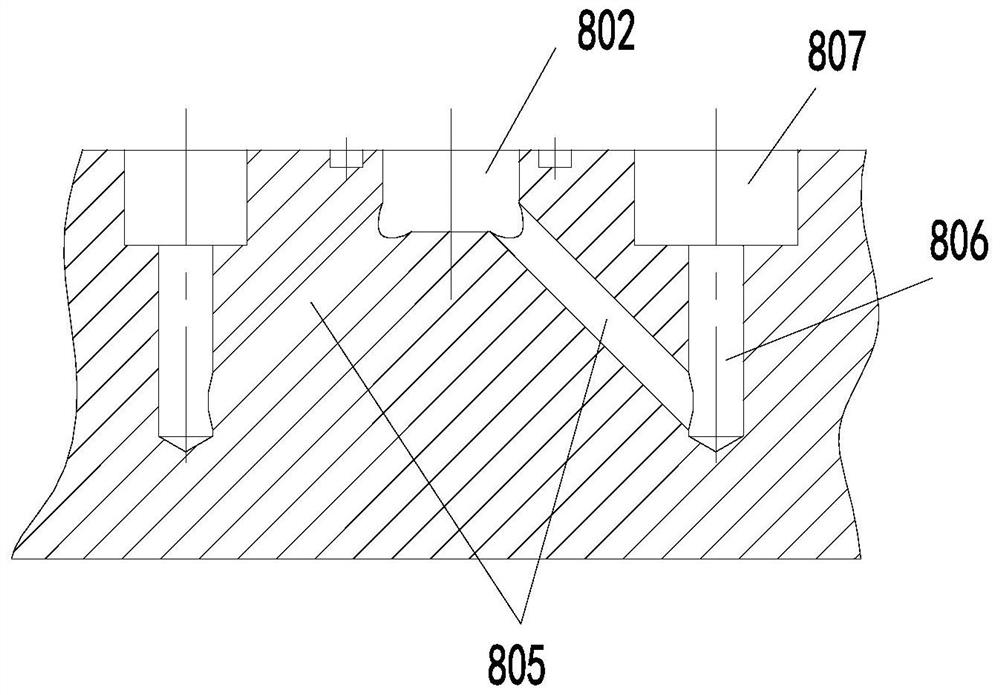

Back-flushing pump of circulating water filtering system for nuclear power station

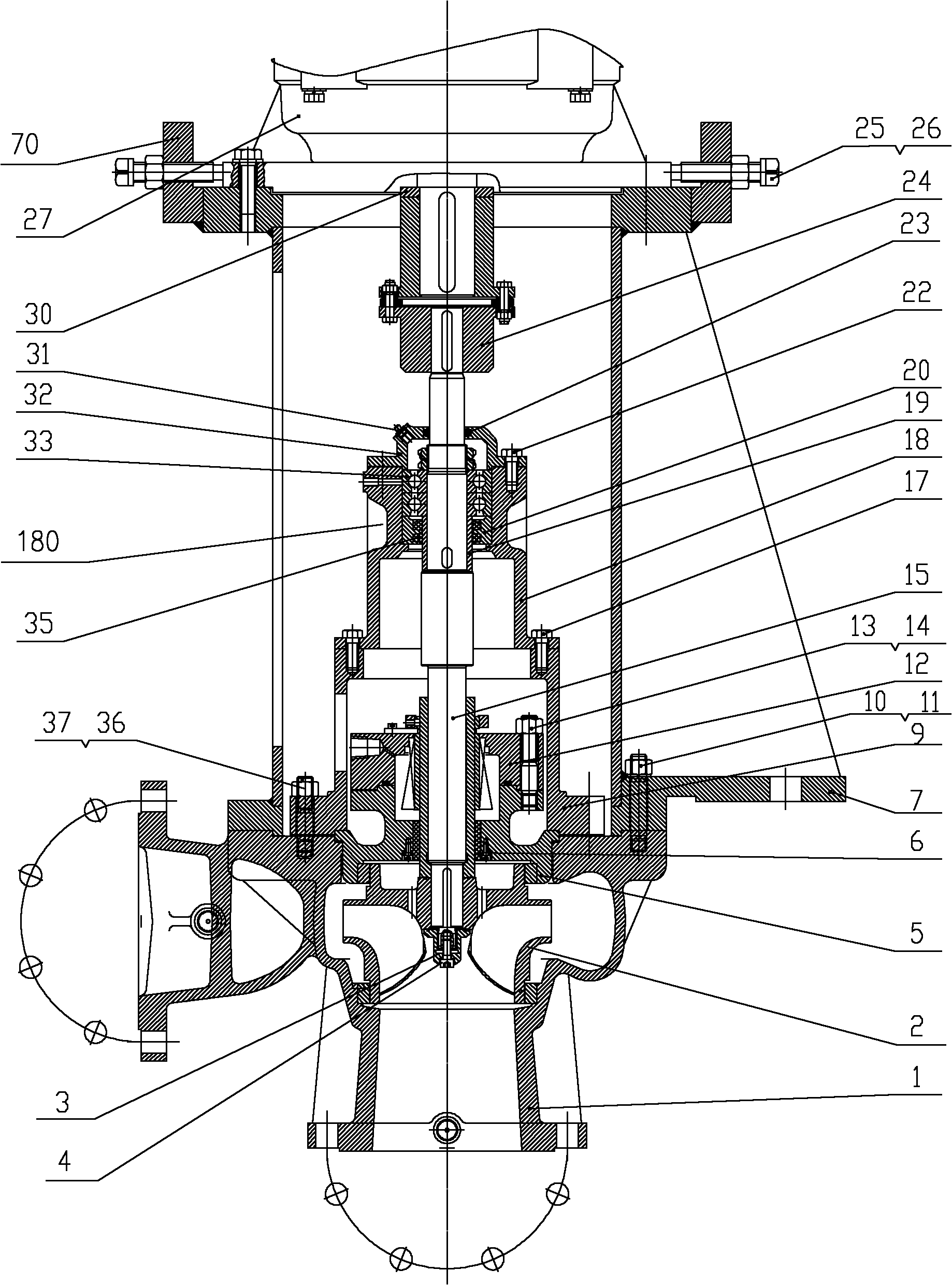

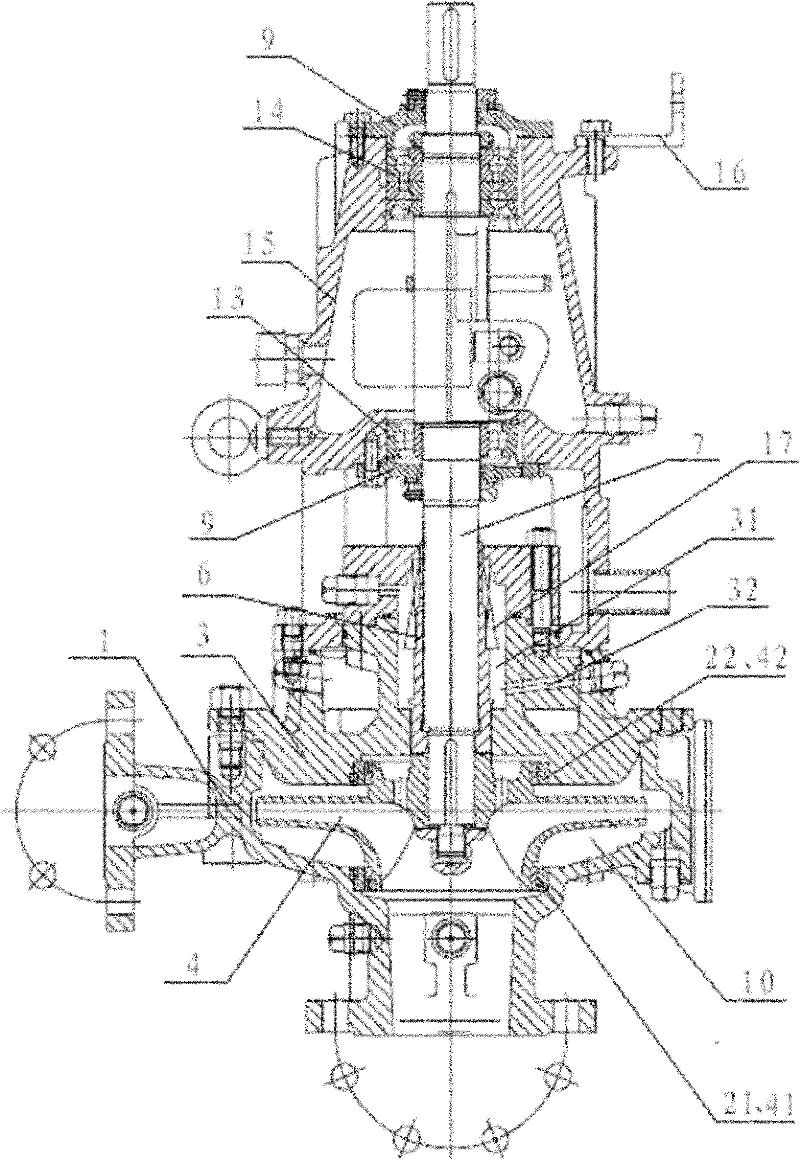

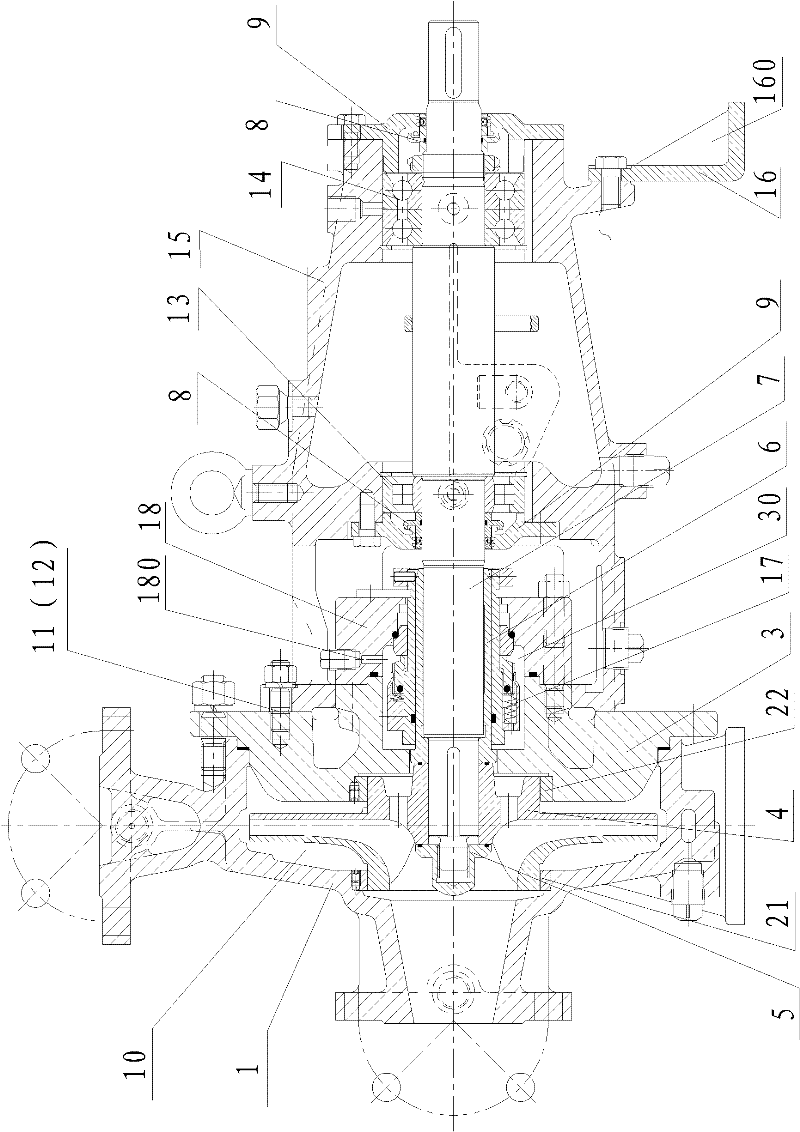

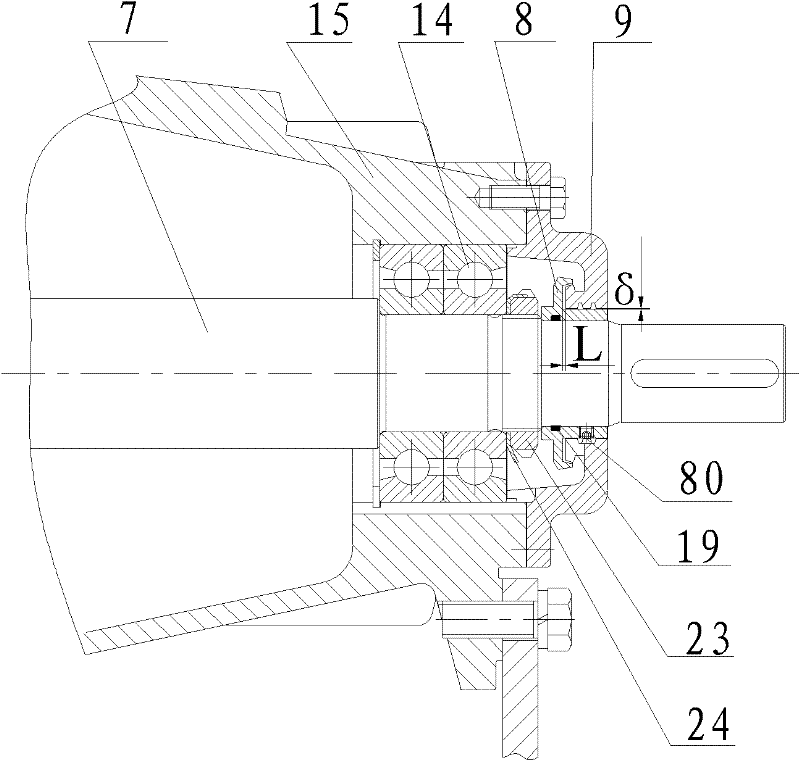

InactiveCN102116300ASmall sizeReduce axial sizePump componentsPump installationsSingle stageBall bearing

The invention discloses a back-flushing pump of a circulating water filtering system for a nuclear power station, which is a vertical single-stage single-suction centrifugal pump. The back-flushing pump comprises a stator assembly, a rotor assembly, a bearing assembly, a shaft seal assembly and a motor. The stator assembly comprises a pump body, a pump cover, a bearing bracket and a motor frame; the rotor assembly comprises an impeller, a pump shaft connected with the impeller through an impeller nut and a shaft sleeve sleeved at an upper middle part of the pump shaft; the pump body adopts a radial split type double-volute structure; the bearing bracket comprises an intermediate bracket and a bearing body; the outer edge of the pump cover is clamped between the upper end of the inner edge of the pump body and the lower end of the inner edge of the intermediate bracket; the bearing assembly comprises a pair of angular contact ball bearings installed in a cavity of the bearing body in a back-to-back mode and sleeved at the upper middle part of the pump shaft, a set of guide bearings arranged between the lower part of the pump shaft and the inner edge of the pump cover and an upper bearing cover; and the shaft sealing assembly comprises a pump body seal installed at the upper end of the pump cover and a bearing oil seal which is installed in the cavity of the bearing body and arranged at the lower ends of the angular contact ball bearings.

Owner:SHANGHAI APOLLO MACHINERY

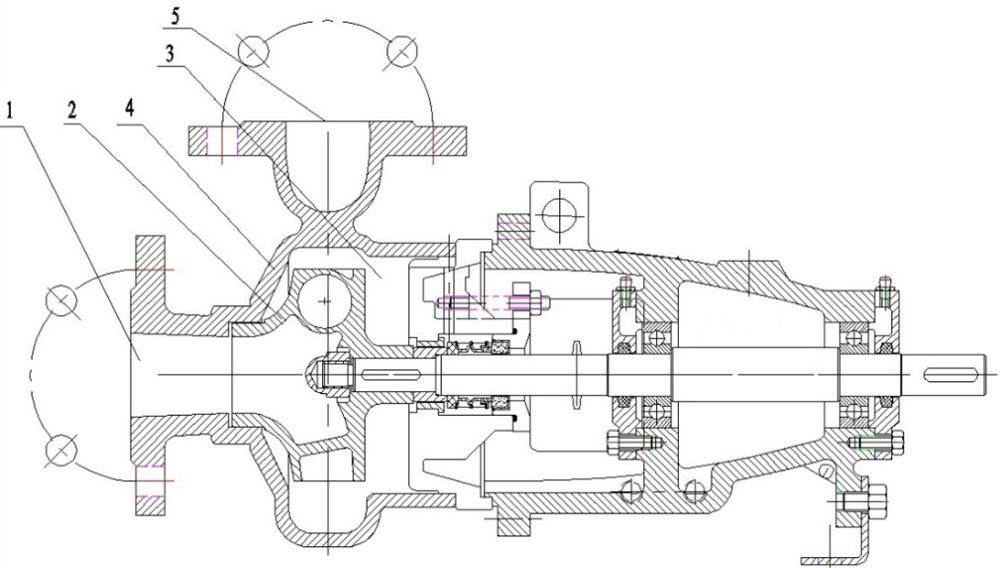

Component cooling water pump for nuclear power plant

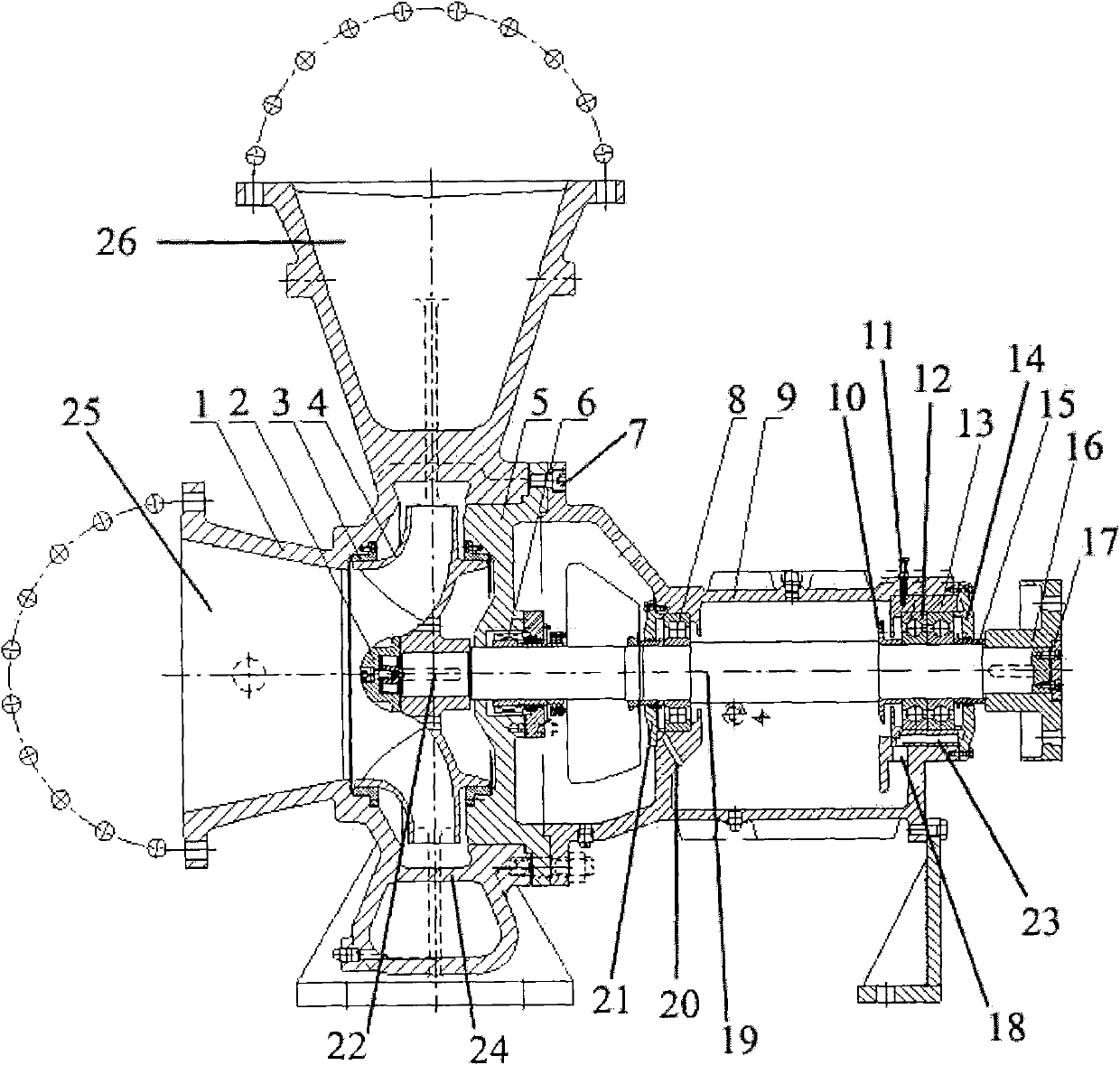

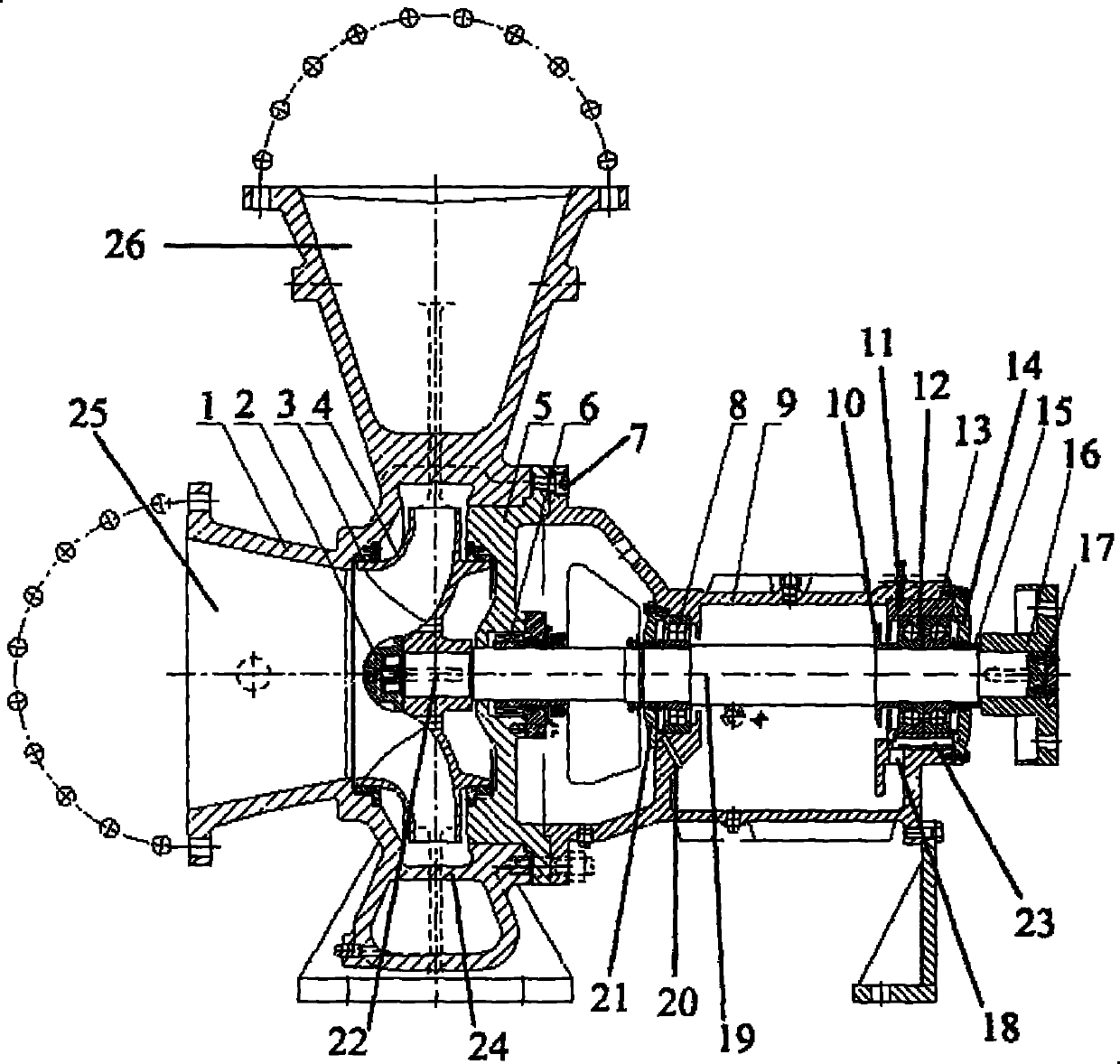

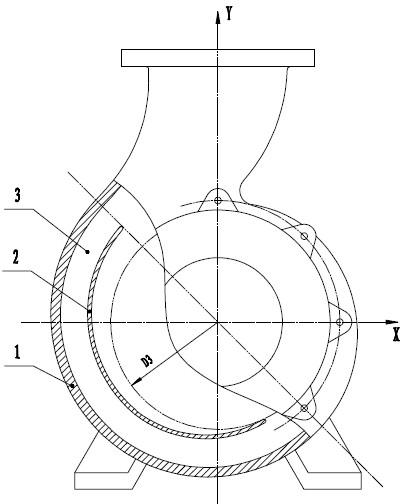

InactiveCN102022339AReduce volumeImprove running stabilityPump componentsRadial flow pumpsCentrifugal pumpLubrication

The invention discloses a component cooling water pump for a nuclear power plant, which is a single-stage, single-suction, double-volute and horizontal arm-hanging type centrifugal pump. The pump is characterized in that a pump body is in a radial split-casing double-volute structure, one end of the pump body is provided with a suction inlet, and a pump cover is fixedly connected to the other end of the pump body; the upper side of the pump body is provided with a discharge outlet, and the suction inlet is perpendicular to the discharge outlet; a pump shaft passes through the pump cover and a bearing body; and a shaft seal assembly is composed of box-type mechanical seal components. The component cooling water pump disclosed by the invention has the advantages that the pump body is in a radial split-casing double-volute structure, and the centre line of an impeller is coincide with the centre line of the pump body, therefore, the radial force of the pump in the process of operating can be reduced, the shock resistance is enhanced, the service life is prolonged, and the volume of the pump is reduced; and because a thin-oil self-lubricating system is adopted, the pump can directly start without pre-lubrication, thereby enhancing the operating stability of the pump.

Owner:SHANGHAI APOLLO MACHINERY

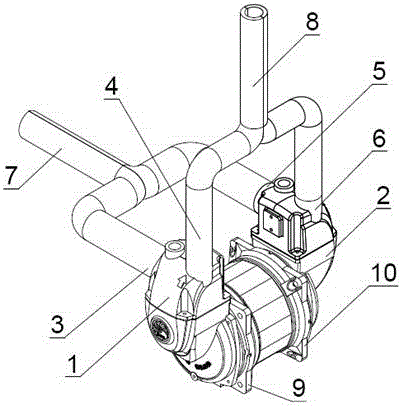

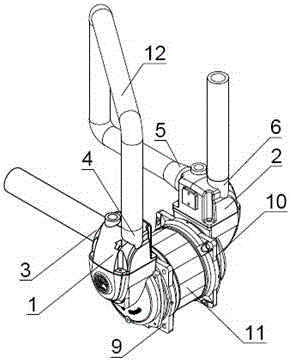

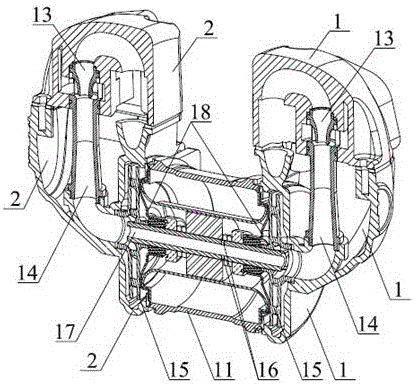

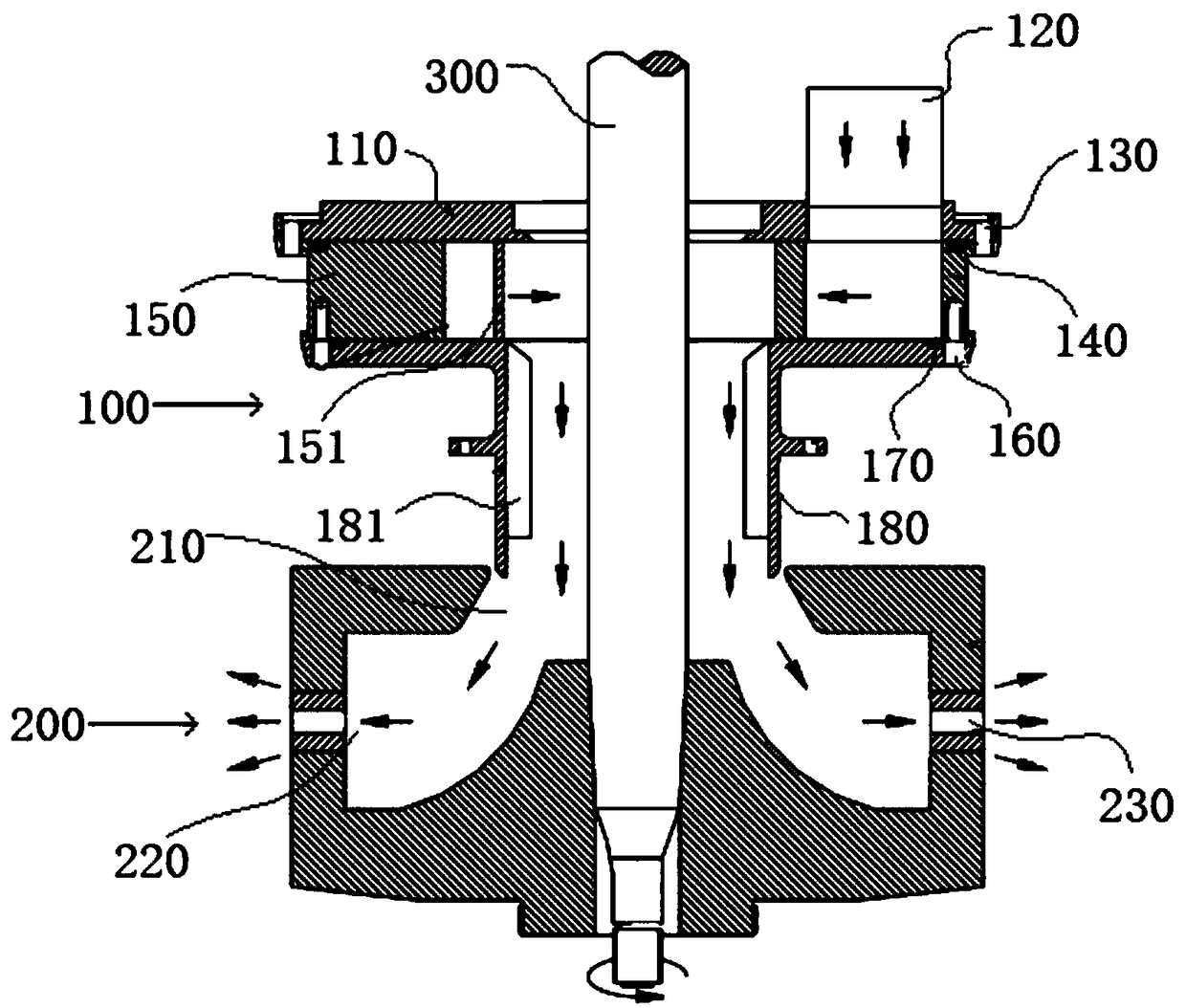

Low noise double-body self-priming combination pump

The invention discloses a low noise double-body self-priming combination pump. The low noise double-body self-priming combination pump comprises a motor, pump body connecting supports installed at the two ends of a motor shaft, a first pump body and a second pump body. The first pump body is provided with a first inlet and a first outlet, and the second pump body is provided with a second inlet and a second outlet. The motor is located between the two symmetrically installed pump bodies, and the motor shaft stretches out of a motor shell from the two sides of the two ends of the motor to drive the two pump bodies. The single motor is used for driving the two combination pump bodies on the two sides of the motor at the same time to balance radial force at the ends of the motor shaft, and the double-body combination pump which is low in noise, high in machine pump efficiency and excellent in comprehensive work performance such as flow, lift and suction head lift is provided.

Owner:ZHEJIANG SINCONTROL PUMP IND

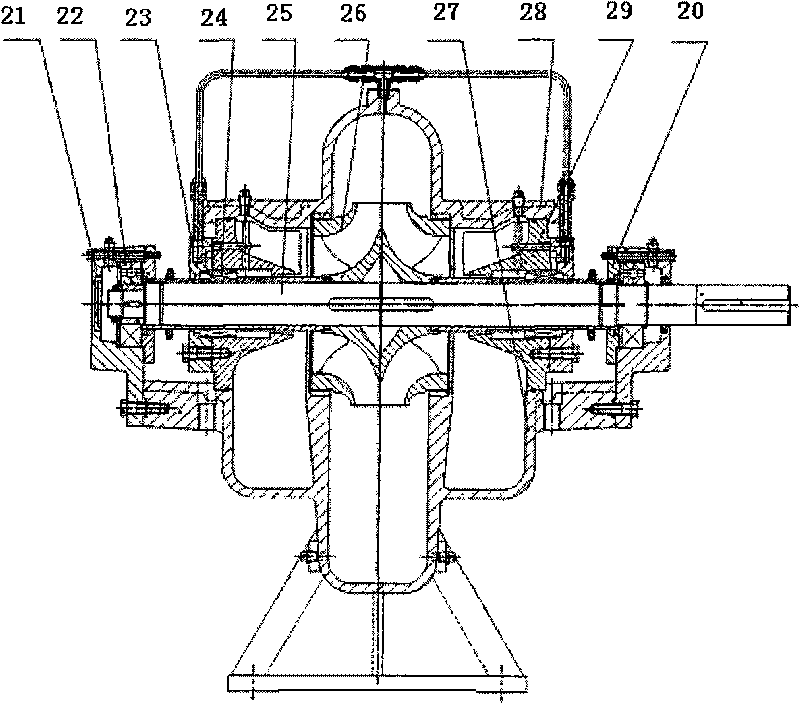

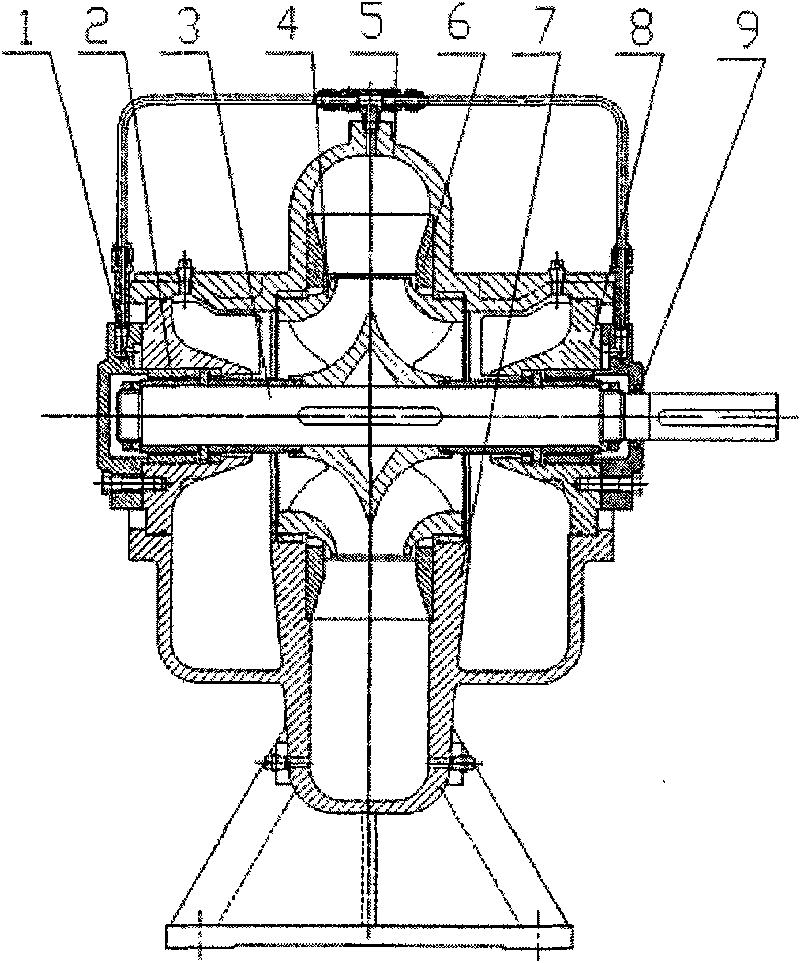

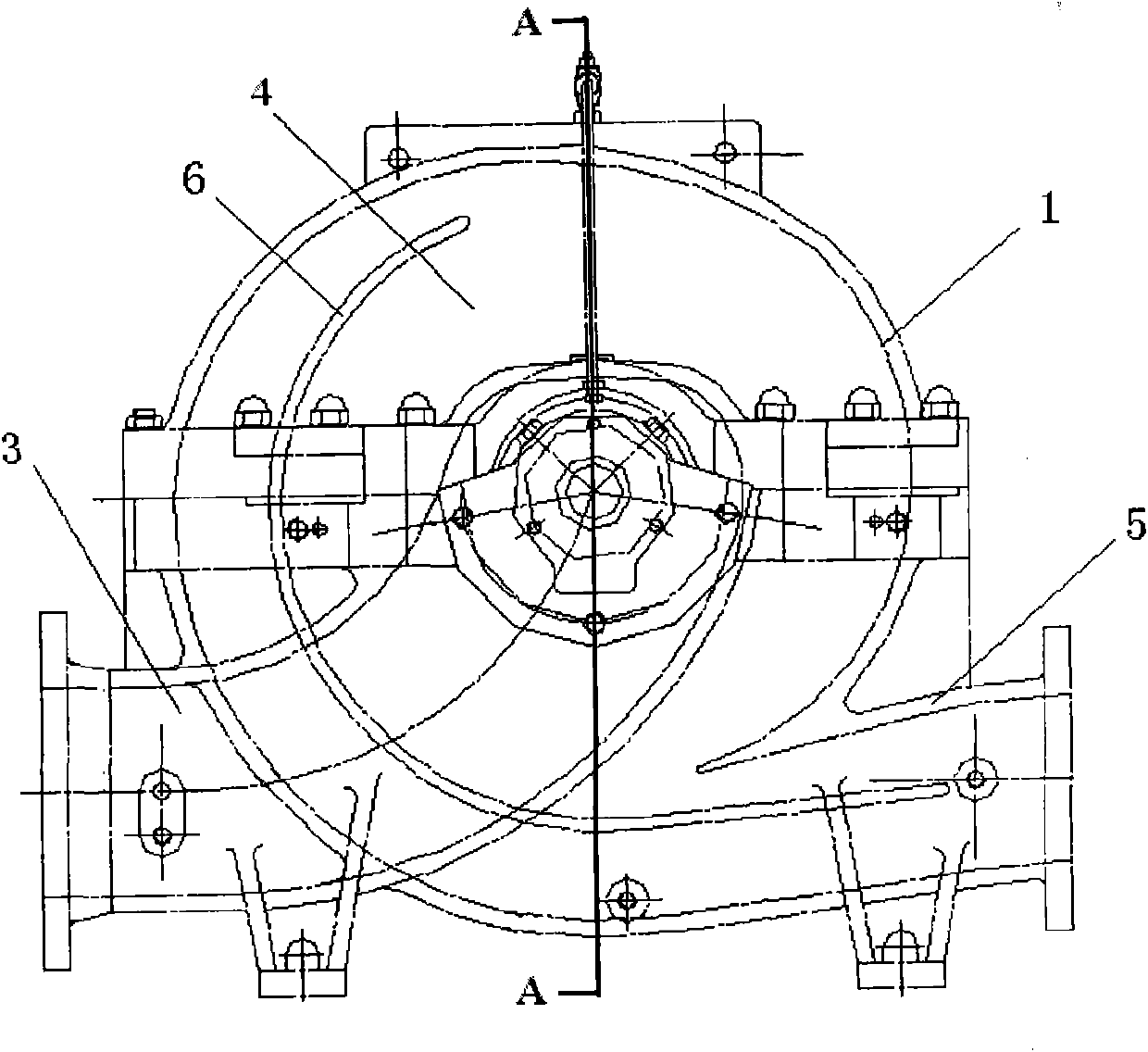

Novel double-suction pump with flow channel type guide blade

The invention relates to a novel double-suction pump with a flow channel type guide blade, which comprises a slide bearing gland, a slide bearing, a shaft, an impeller, a pump cover, a pump body, a slide bearing body and an auxiliary seal element. The double-suction pump is characterized in that a flow channel type guide blade is additionally arranged in a pressing chamber of the pump. The flow channel type guide blade comprises a guide blade cover plate, two flow channels and guide blades, wherein the two guide blades are spiral and are distributed on the symmetrical positions with an angle of 180 degrees. The invention balances the radial force generated when the pump runs, reduces easily damaged parts and cost, improves the reliability of the pump, prolongs the service life of the pump and ensures that the double-suction pump has wide efficient area when meeting a large flow and lifting capacity range.

Owner:SHANGHAI LIANCHENG(GRP) CO LTD

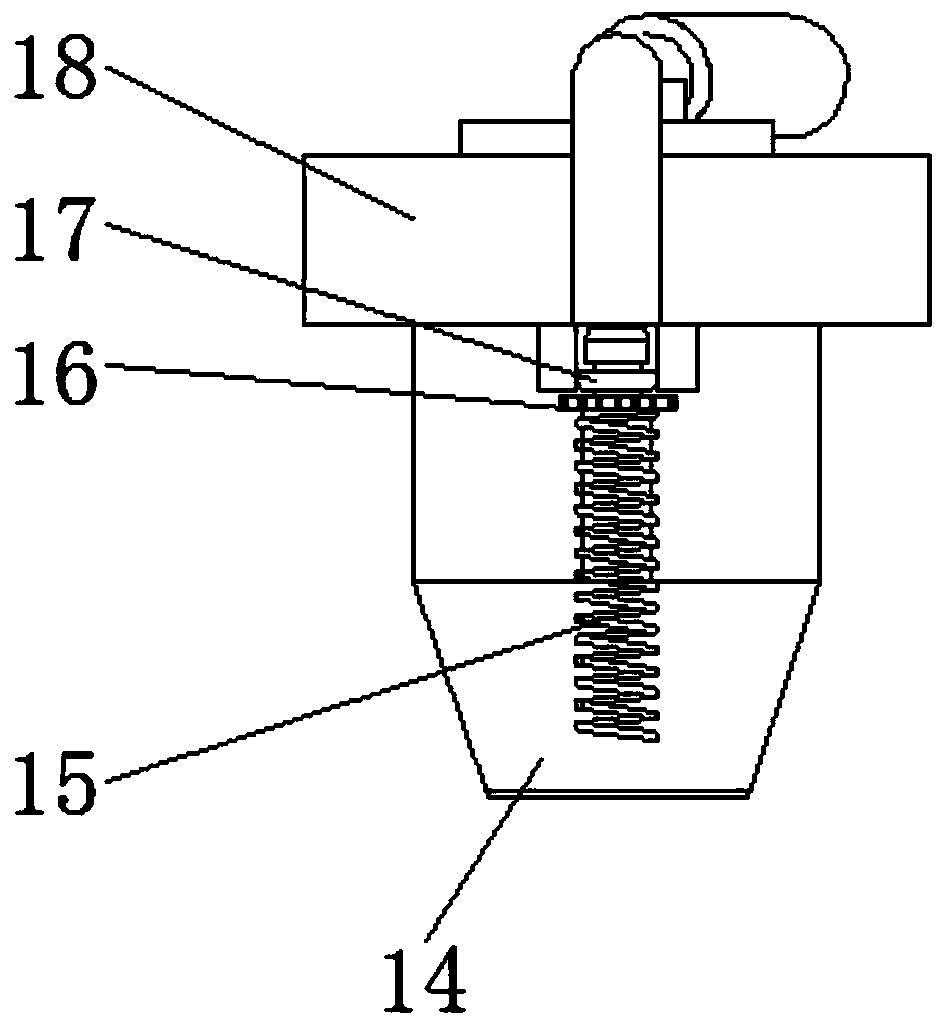

Leakage-free hydraulic buffering vacuum breaker valve

PendingCN110056690AGuaranteed sealing performanceExtended service lifeEqualizing valvesHydro energy generationHydraulic cylinderWater turbine

The invention provides a leakage-free hydraulic buffering vacuum breaker valve. According to the vacuum breaker valve, a hydraulic cylinder and the valve plate are arranged, wherein the hydraulic cylinder is installed on the valve plate and acts together with the valve plate, a sliding seal between the bottom of the hydraulic cylinder and a valve rod is located inside a hydraulic buffering cavity,so that complete sealing in the hydraulic cylinder is guaranteed, hydraulic buffer oil is in a completely sealed state, sealing abrasion leakage is avoided, and the service life of the vacuum breakervalve is prolonged; moreover, a throttling valve is arranged, the buffering effect of the valve plate in the closing position is improved, noise generated through collision of the valve plate and a valve seat is reduced, a supporting sleeve plays a role in supporting the hydraulic cylinder, and further balances radial force of opening and closing of the valve plate so as to prolong the fatigue life of the vacuum breaker valve, meanwhile, a spring is arranged, so that axial force is balanced; and in addition, the vacuum breaker valve is simple in structure, reasonable in design, safe and reliable, and potential safety hazards during operation of a water turbine are effectively reduced.

Owner:秦皇岛森润滋科技有限公司

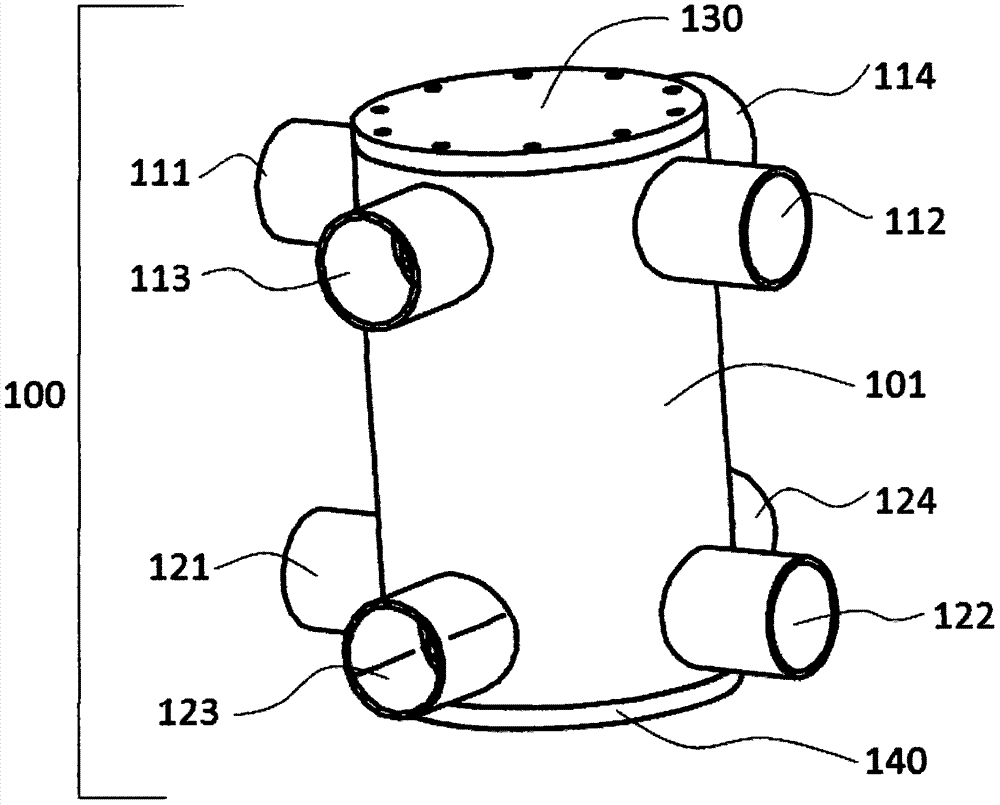

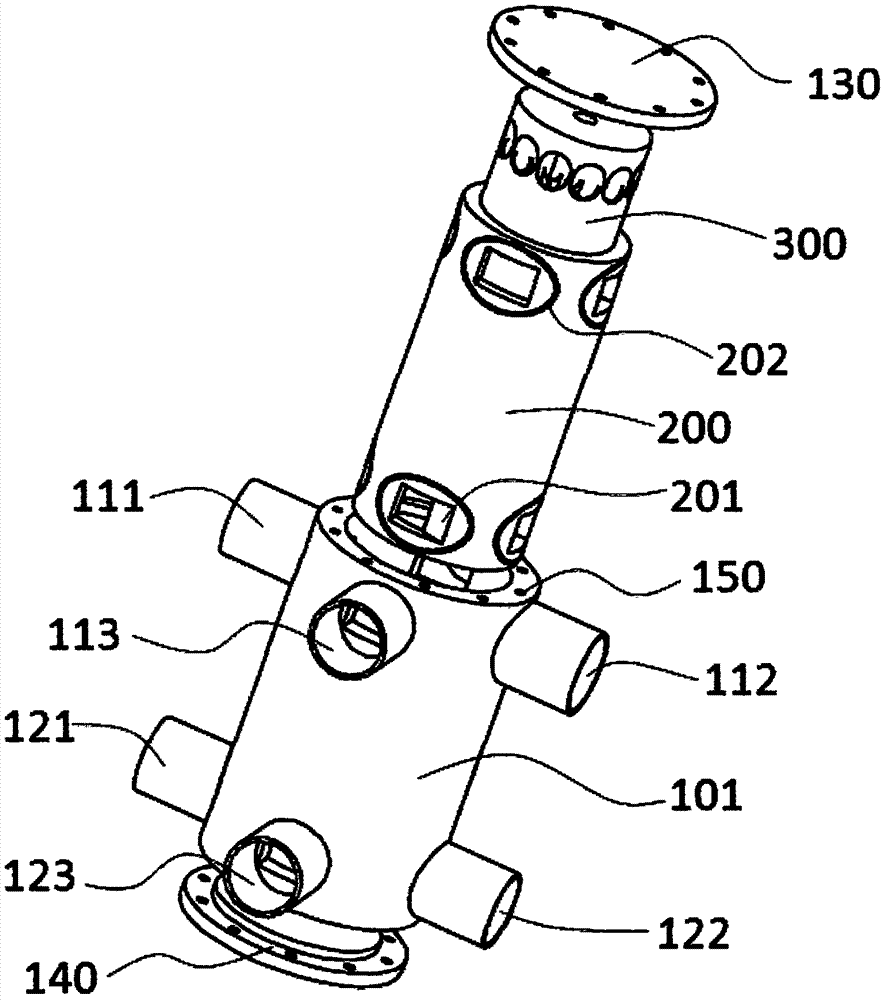

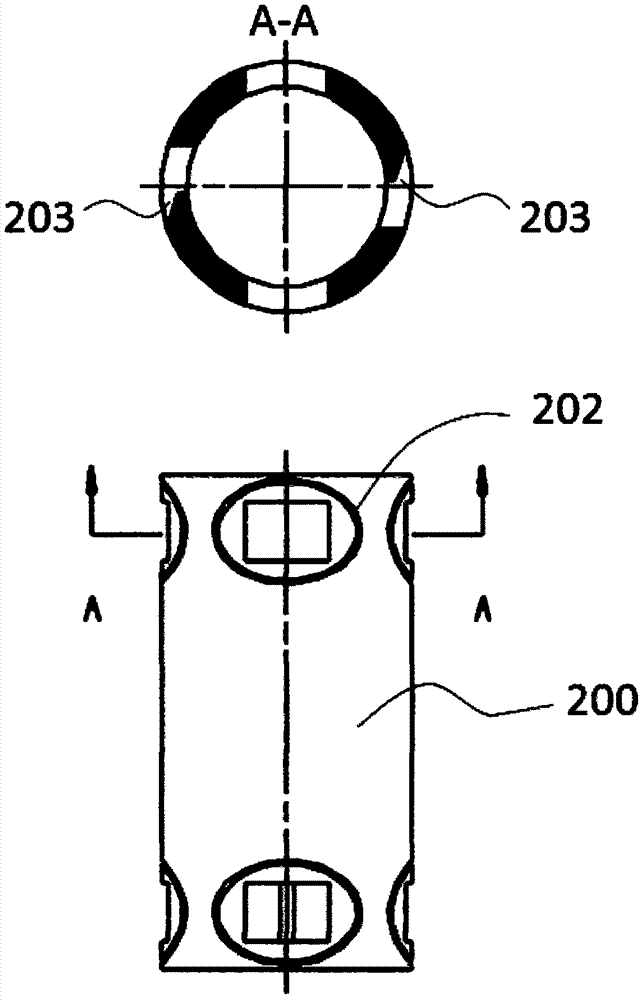

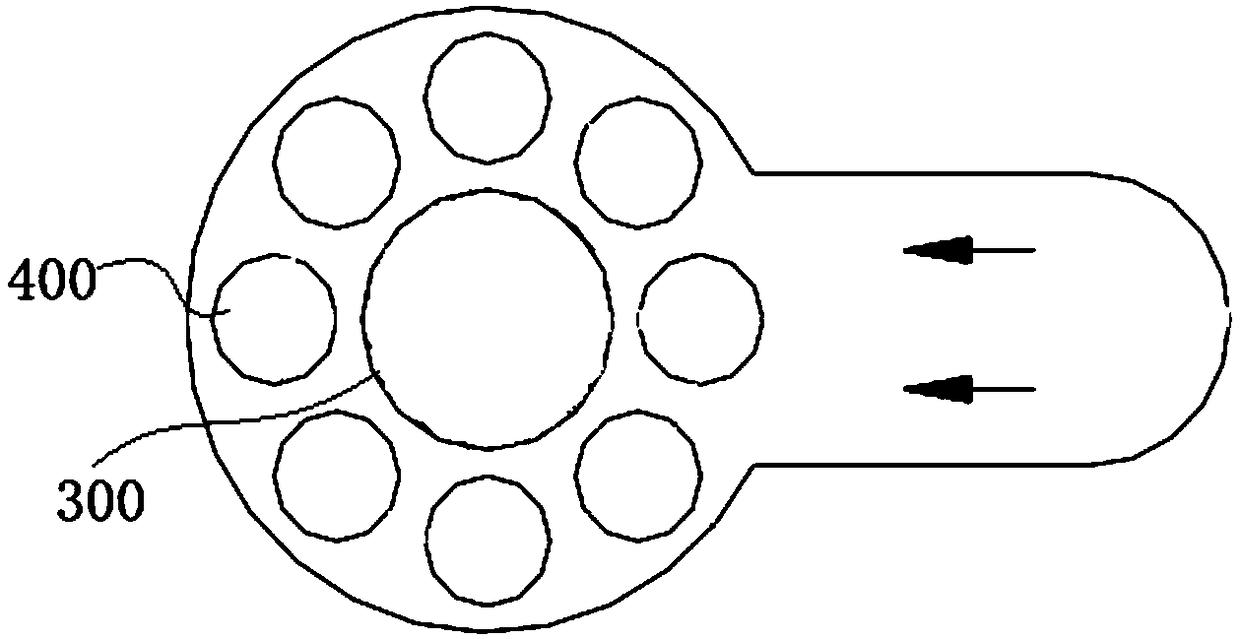

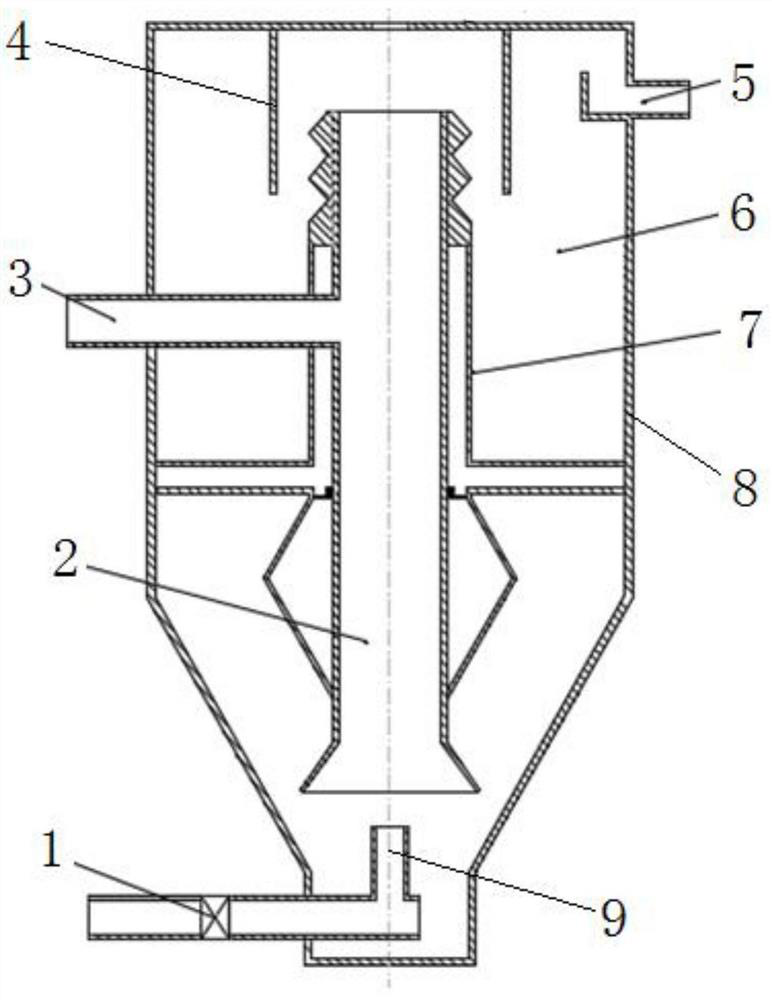

Multiple-in and multiple-out type pressure exchanger

InactiveCN107542705AReduce processing difficultyIncrease exchange frequencySeawater treatmentReverse osmosisEngineeringFluid pressure

A multiple-in-multiple-out pressure exchanger, the pressure exchanger is used for transferring pressure energy from a high-pressure first fluid to a low-pressure second fluid to provide a pressurized second fluid, the pressure exchanger is characterized by comprising: a body , a sleeve disposed within the body and a rotor rotating within the sleeve; the rotor having a plurality of passages extending generally axially through the rotor, the passages having a first opening at one end of the rotor , having a second opening at the other end of the rotor, the openings being spaced apart from each other along the length of the rotor; the sleeve having four or more internally distorted inlet passages and four or more a discharge passage, the sleeve passage is arranged such that when the end opening of the first passage of the rotor is aligned with the inlet passage on one of the sleeves, the other end opening of the passage is also aligned with the discharge passage on the sleeve allow.

Owner:宁波淡海智能科技有限公司

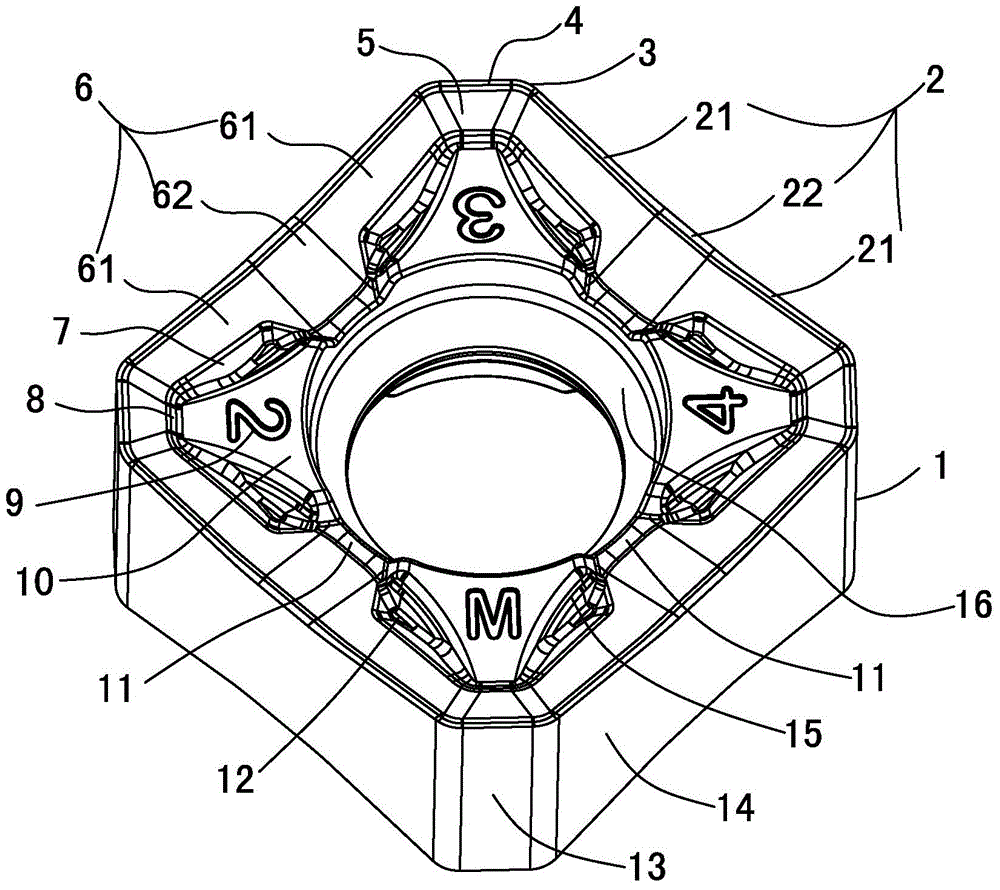

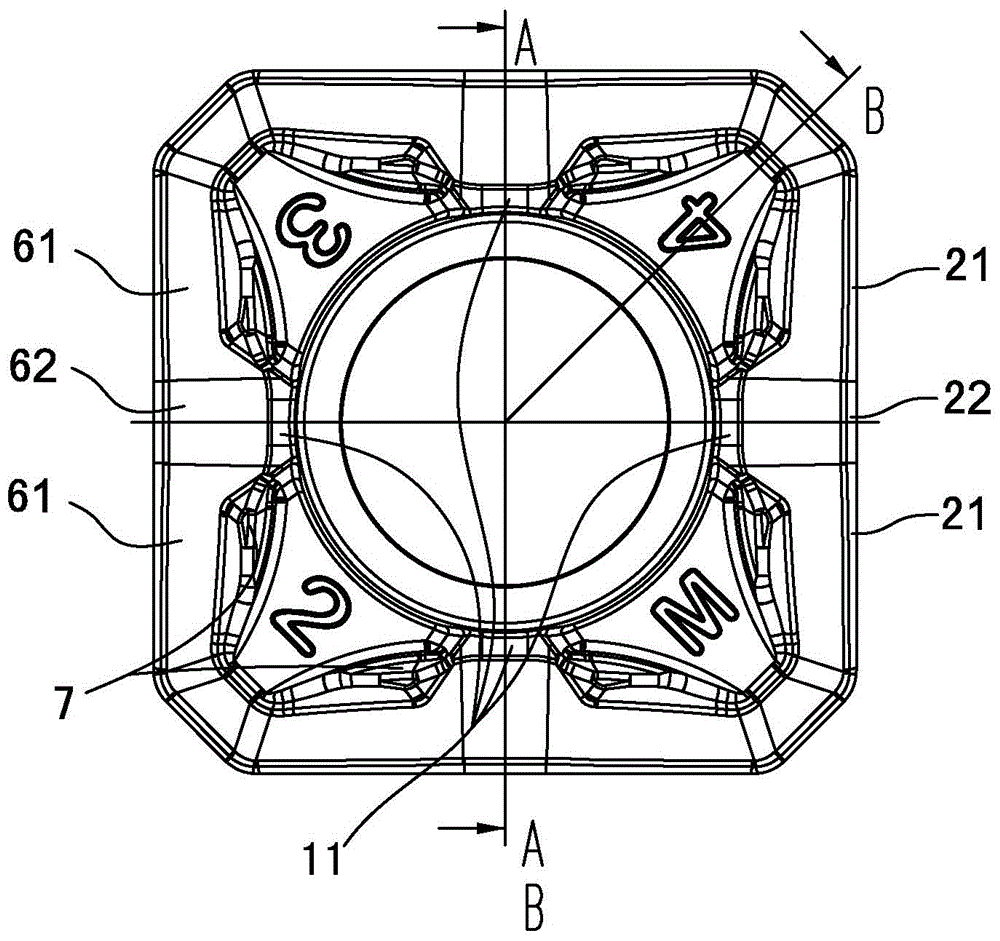

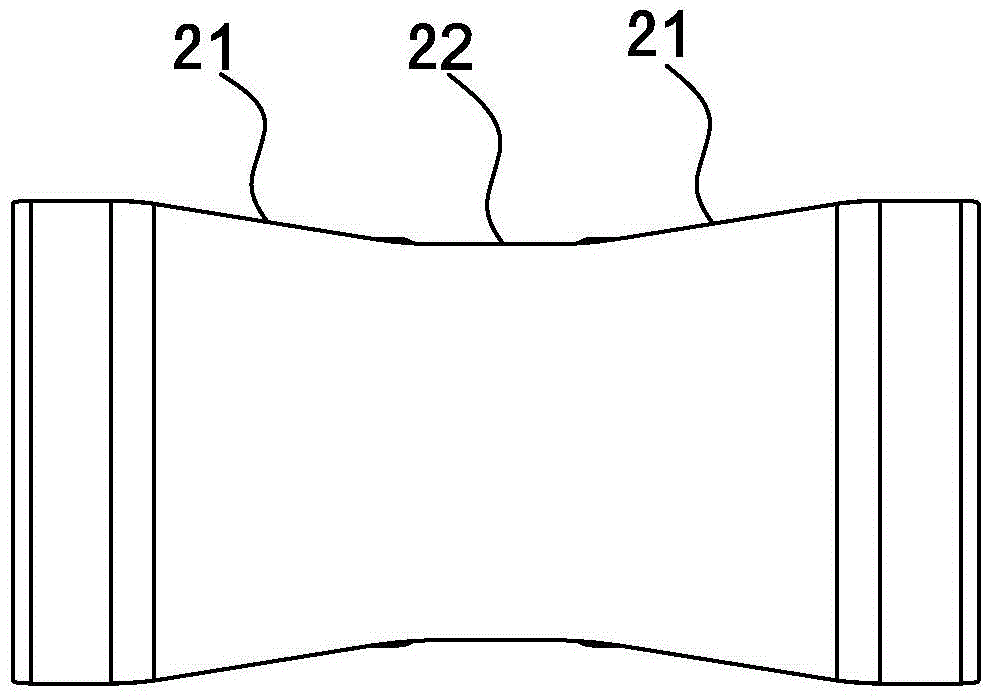

Negative-type milling blade

ActiveCN104439461AAvoid rough cuttingImprove economyTransportation and packagingMilling cuttersBearing surfaceSwarf

The invention discloses a negative-type milling blade comprising a blade body, wherein the blade body has an upper surface, a lower surface and a quadrangular peripheral surface and is also provided with a through hole and bosses around the through hole, and a main cutting edge and a smoothing edge are alternately arranged on the peripheral surface in sequence; the main cutting edge has a concave structure and gradually tilts close to opposite surfaces of the upper and lower surfaces from two ends respectively, and a non-tilting smooth middle part of the main cutting edge is formed at a position which is 1 / 6-1 / 3 of the length of the edge on the main cutting edge; and the front tool face of the non-tilting smooth middle part of the main cutting edge of the negative-type blade body is connected to the through hole perpendicular to the upper and lower surfaces by extending at a positive angle gently, and an open scrap accommodating groove leading to the through hole is formed at the bosses. According to the negative-type milling blade disclosed by the invention, by designing of the concave structure of the main cutting edge of the cutting blade and combining the design of a special opening structure groove at a bearing surface chip breaker groove of the blade, cutting force distribution and cutting flowing can be optimized, processing of self breaking scraps can be performed, and the processability and stability of a cutter are improved.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

Rotary atomizer system

PendingCN108296038AReduce wearExtended service lifeMovable spraying apparatusLiquid spraying apparatusSpray nozzleEngineering

The invention discloses a rotary atomizer system, and belongs to the technical field of atomizers. The system comprises a feed liquid distributor, a rotary atomizing wheel and a rotary main shaft, wherein the discharge pipe of the feed liquid distributor corresponds to the atomizing wheel inlet of the rotary atomizing wheel, and second guiding blades are uniformly arranged in the circumferential direction of the inner wall of the discharge pipe at intervals; a nozzle is arranged at the atomizing wheel outlet of the rotary atomizing wheel, an inlet hole is formed in the inner circle inlet section of the nozzle, and the inlet hole is an eccentric variable-diameter hole. The invention aims at overcoming the defects of severe abrasion and nonuniform distribution of feed liquid of atomizers inthe prior art, and provides the rotary atomizer system; the system can ensure that the feed liquid enters the discharge pipe and the atomizing wheel with uniform distribution, so that the feed liquidis atomized uniformly, the nozzle is not easily blocked, and the service life of the atomizer is prolonged.

Owner:ANHUI XINCHUANG ENERGY SAVING & ENVIRONMENTAL PROTECTION SCI & TECH +1

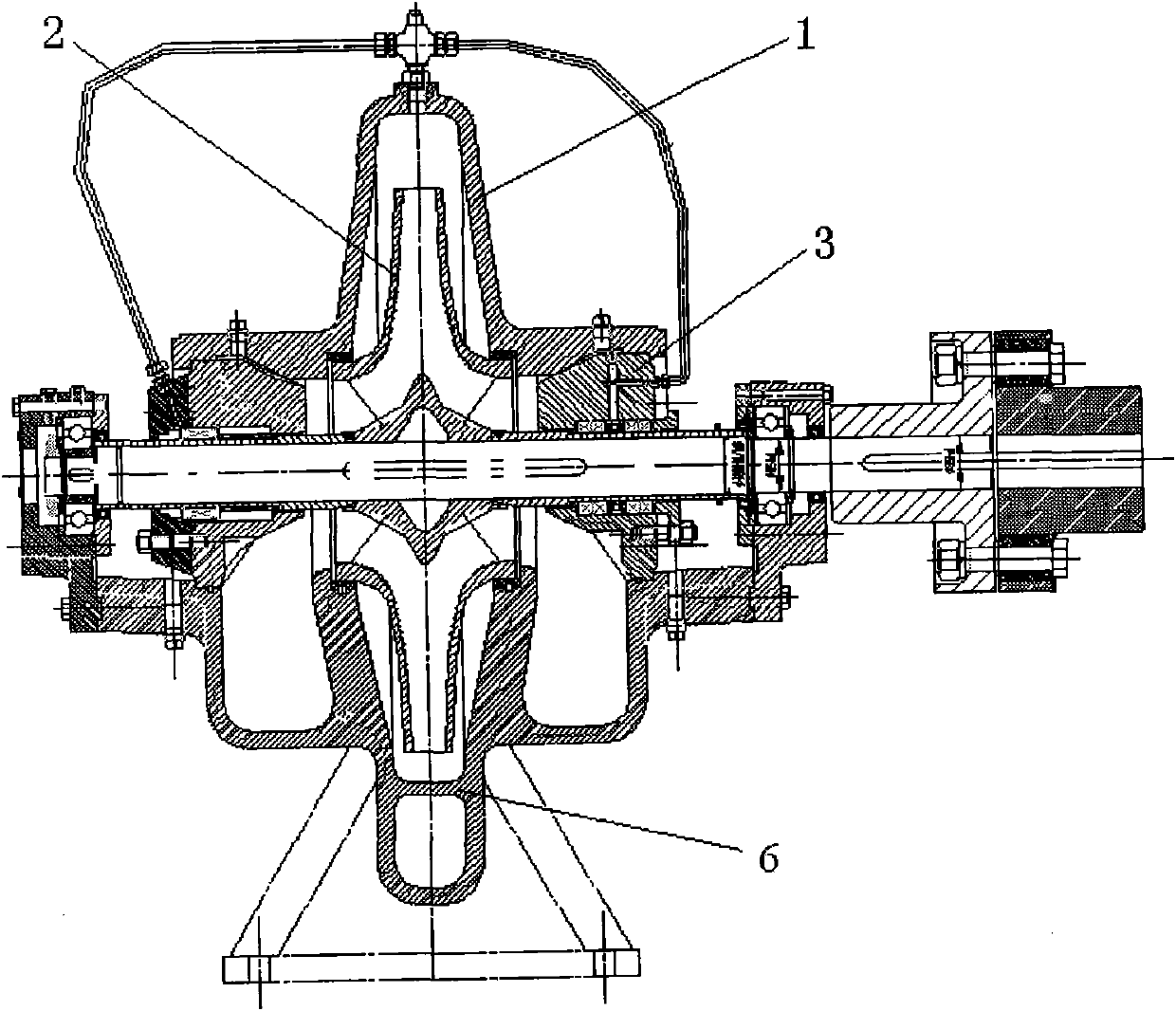

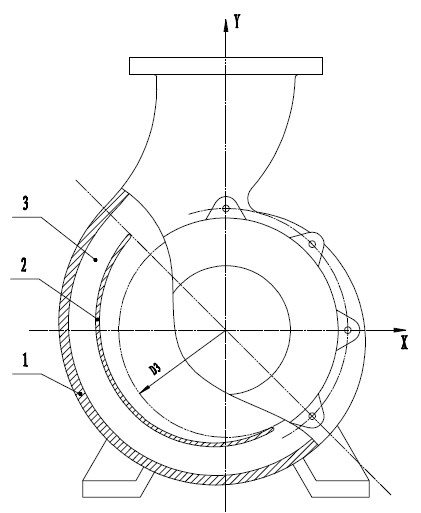

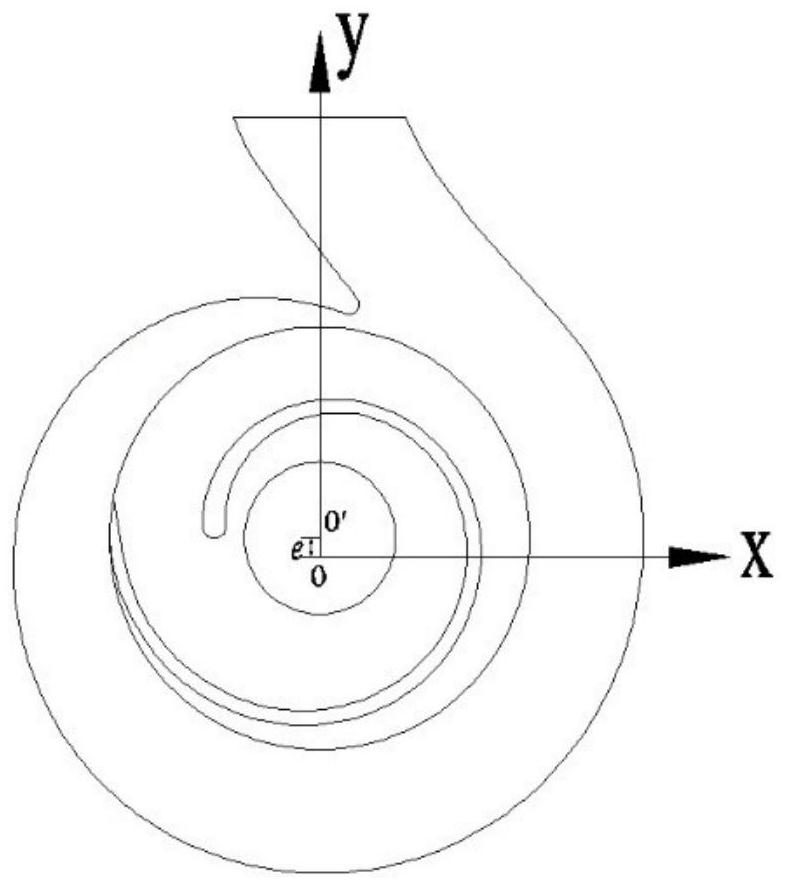

Method for optimizing dummy plate of double-volute type double-suction pump and product produced with same

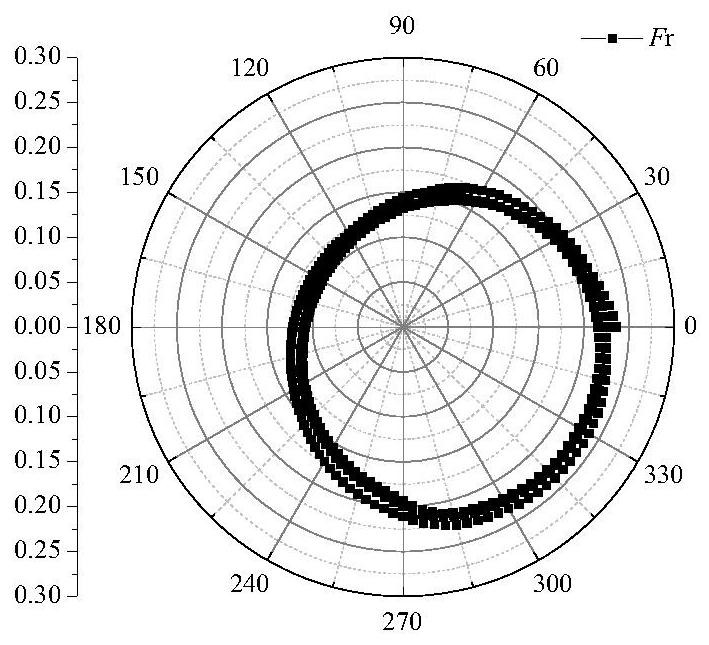

InactiveCN102032217BBalance radial forceReduce headPump componentsPumpsEngineeringDimensional modeling

The invention relates to a method for optimizing a dummy plate of a double-volute type double-suction pump and a product produced with the same. The method comprises the following steps of: respectively carrying out three-dimensional modeling and grid dividing by selecting the double-volute type double-suction pump formed by a plurality of starting positions and stopping positions of the dummy plate; guiding the divided grid model into ANSYS-CFX software to carry out numerical simulation to obtain a flux-lift and flux-efficiency curve graph of the double-volute type double-suction pump and a single-volute pump and a flux-dependent impeller radial force distribution graph under each starting position and each stopping position; by analyzing the curved graph and the distribution graph, selecting the starting position and the stopping position which correspond to the curve representing the minimum impeller radial force as the starting position and the stopping position of the dummy plateof the double-volute type double-suction pump correspondingly, wherein the curve representing the minimum impeller radial force is one curve of all flux-lift and flux-efficiency curves of the double-volute type double-suction pump, which is very similar to a flux-lift and flux-efficiency curve of the single-volute pump; and adopting arc transition between the starting position and the stopping position, wherein the curvilinear equation for the arc transition is a log spiral equation, thus the optimization is finished.

Owner:CHINA AGRI UNIV

Active combustion flow modulation valve

ActiveUS8540209B2Improve responseMovement is lowOperating means/releasing devices for valvesTurbine/propulsion fuel valvesPower flowHigh rate

Owner:UNIVERSITY OF PITTSBURGH

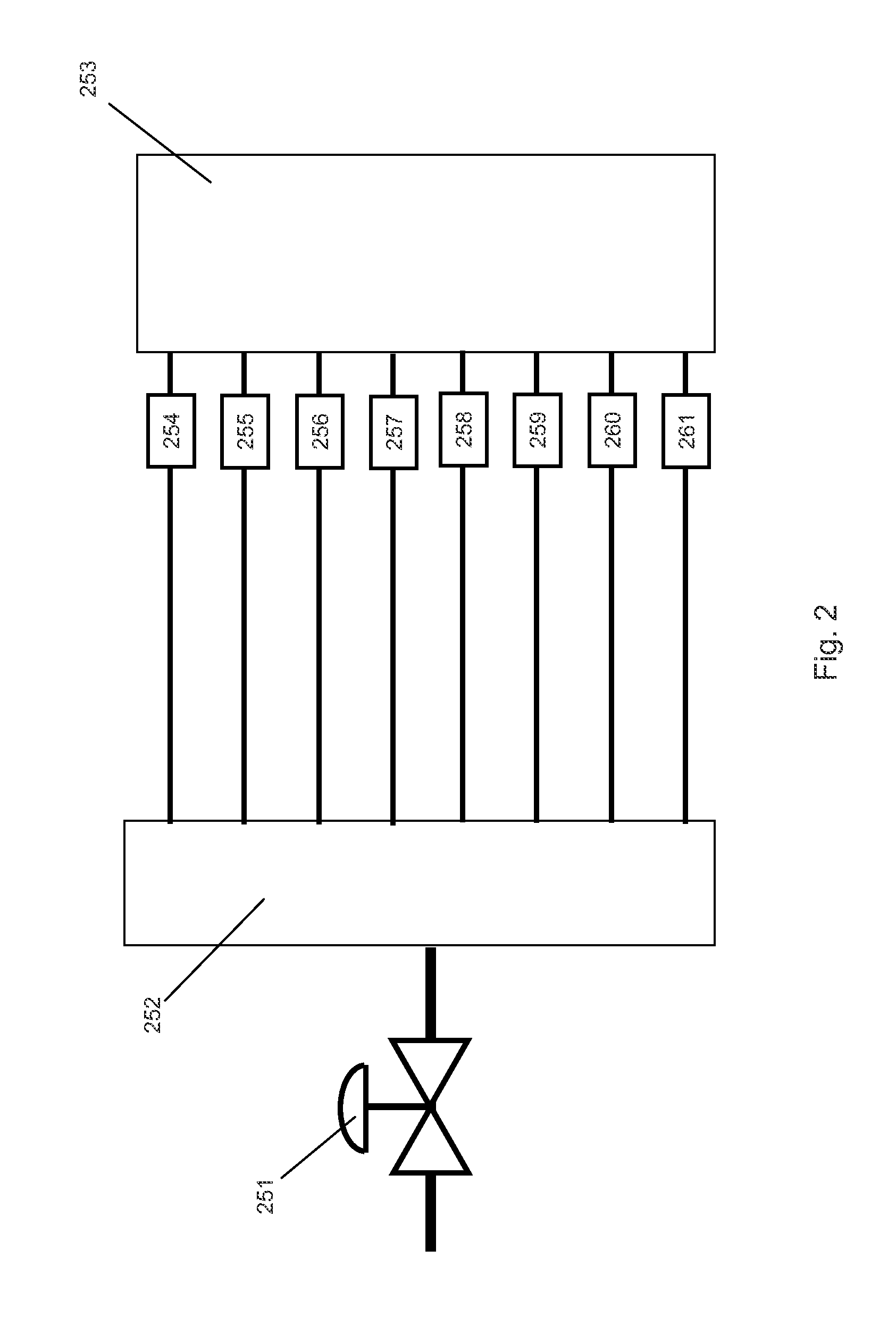

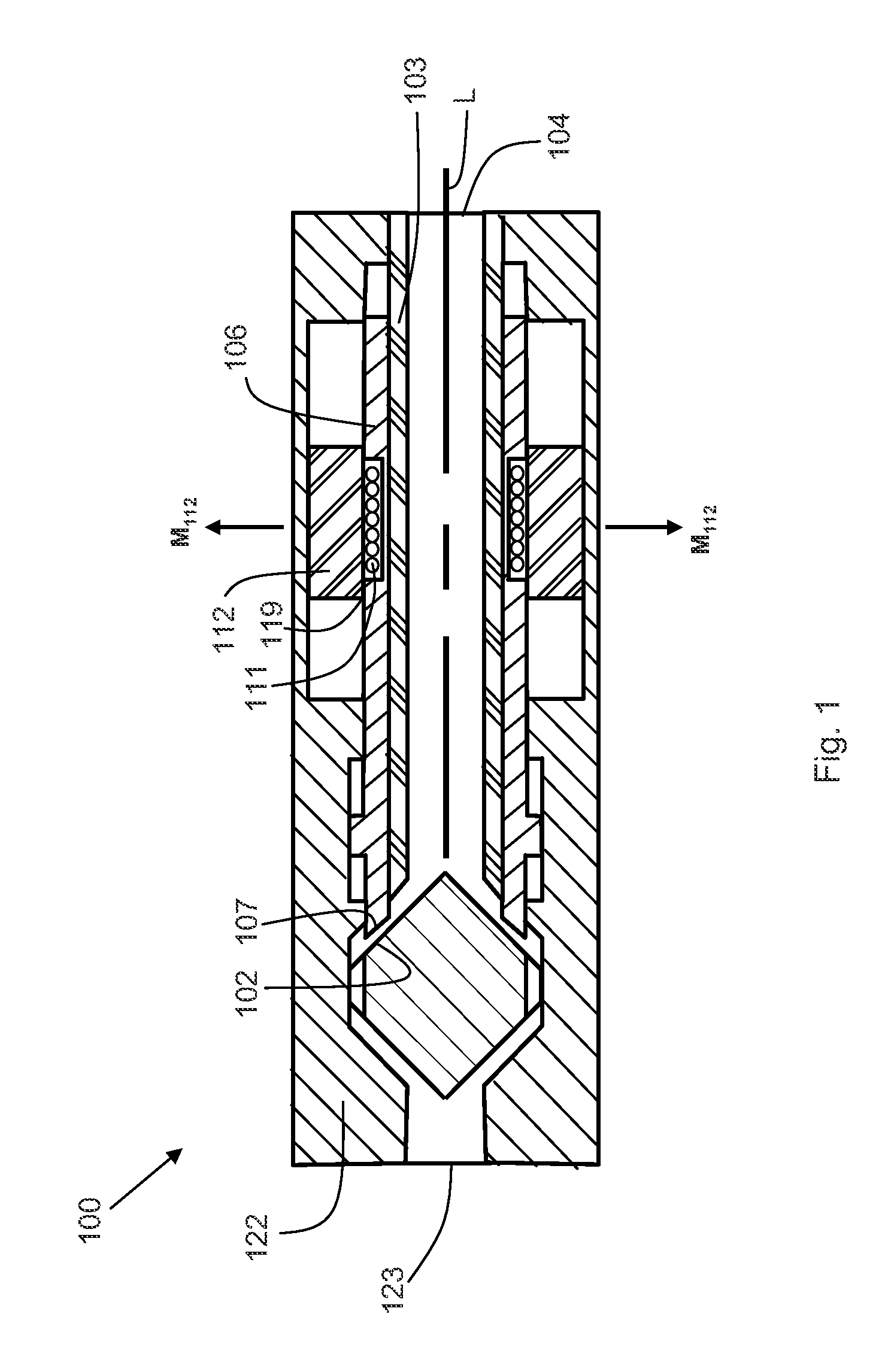

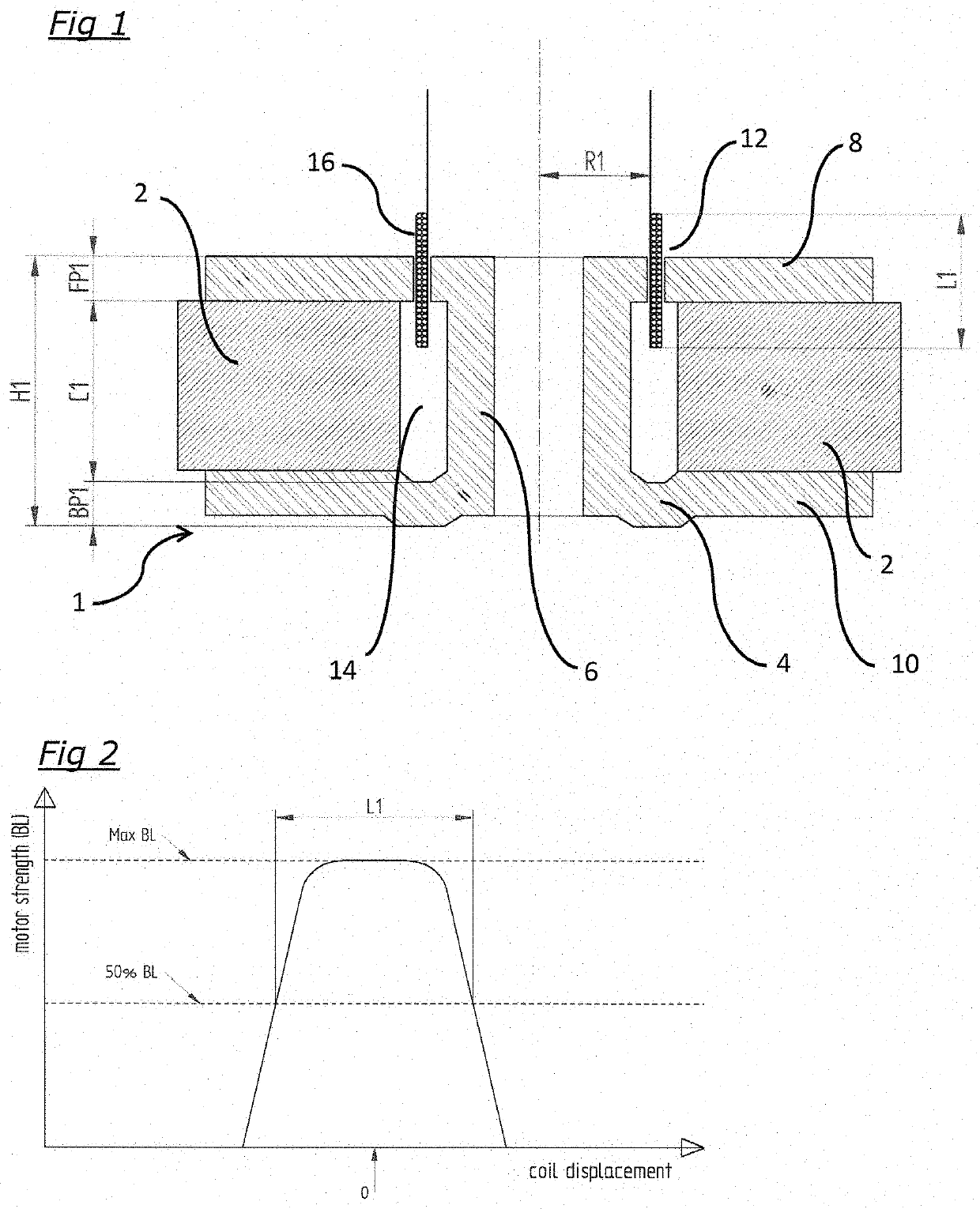

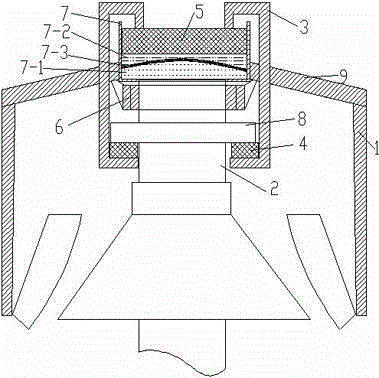

Loudpseakers

ActiveUS20210227331A1Increasing the thicknessImprove sound qualityLoudspeaker signals distributionReciprocating motionEngineering

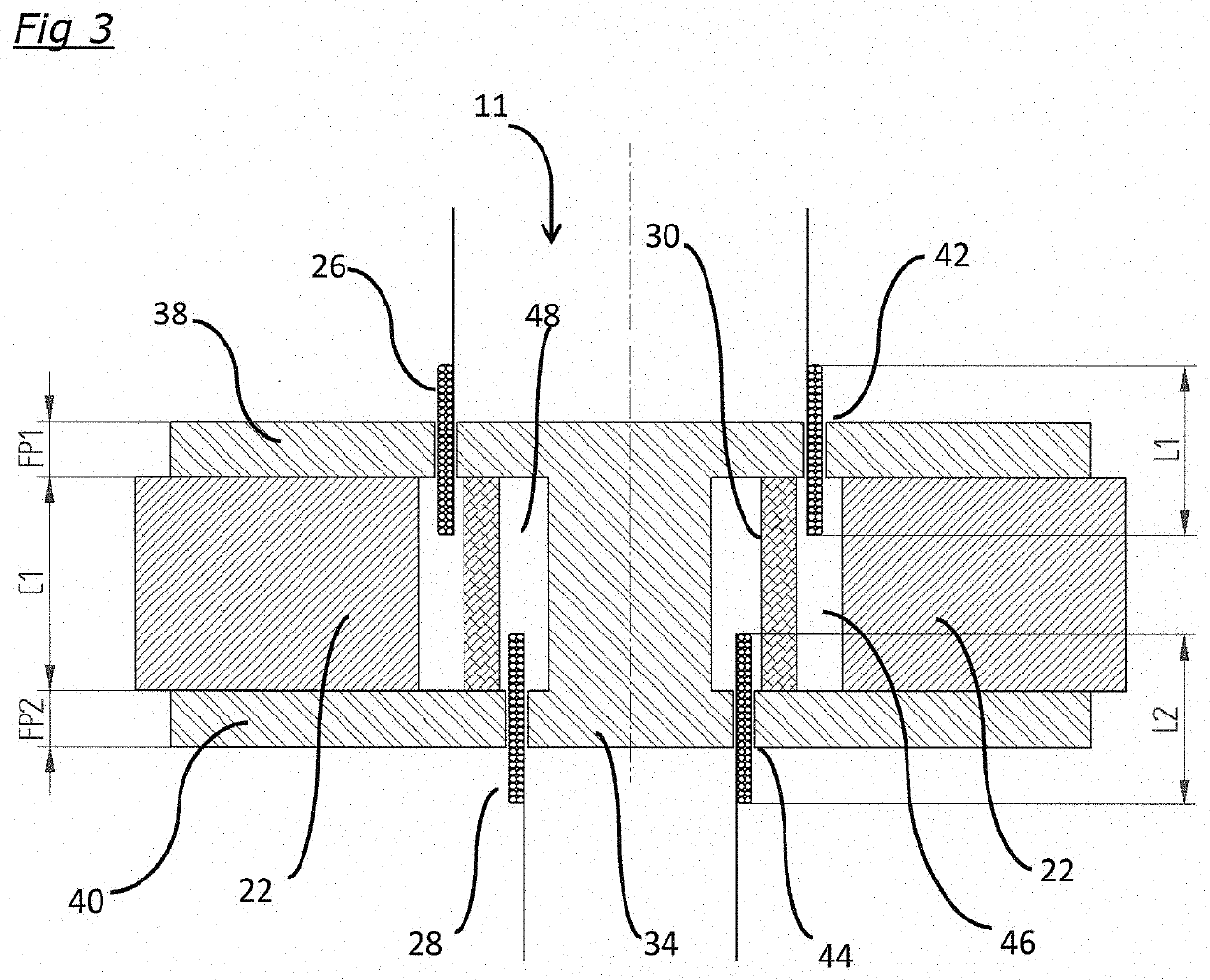

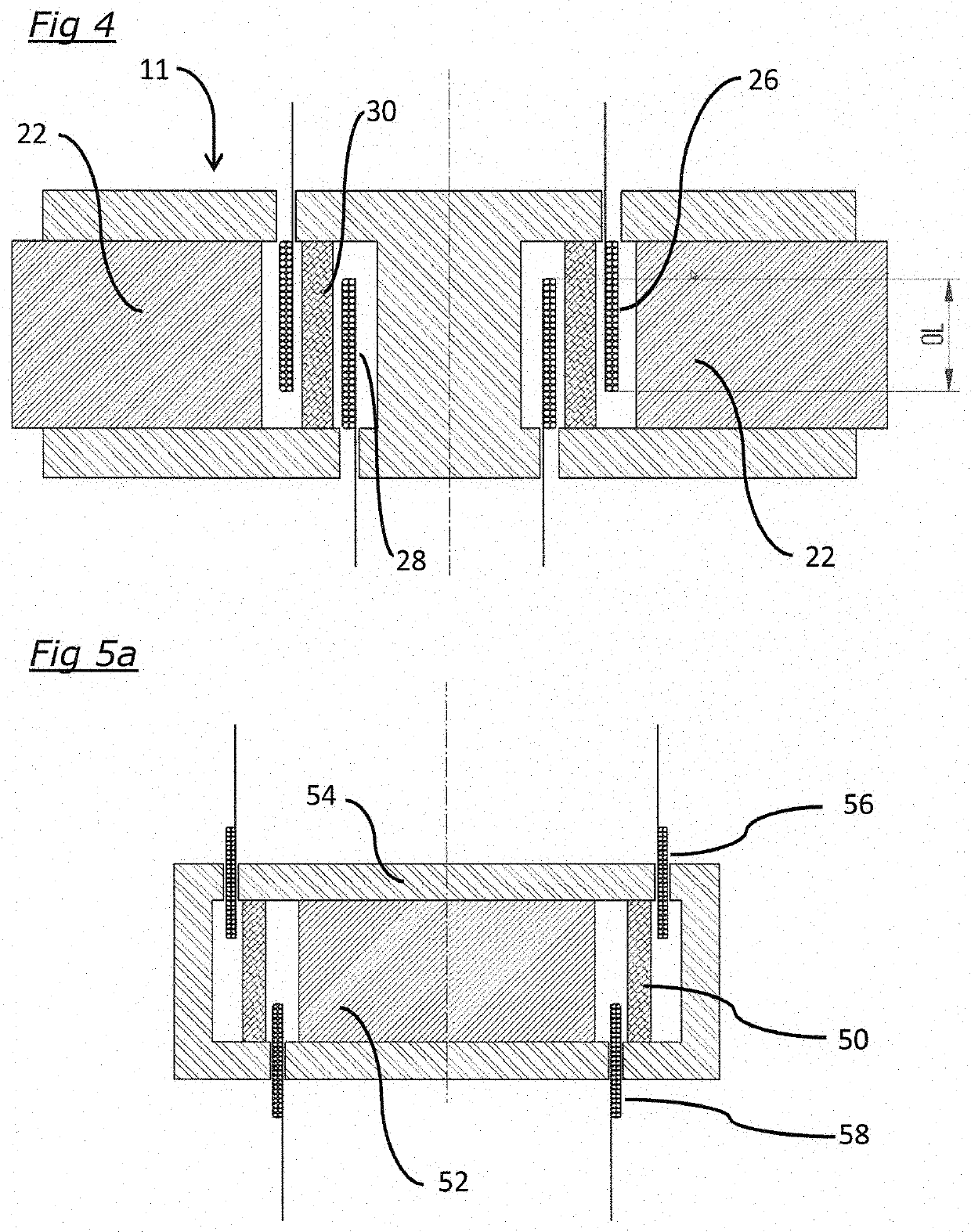

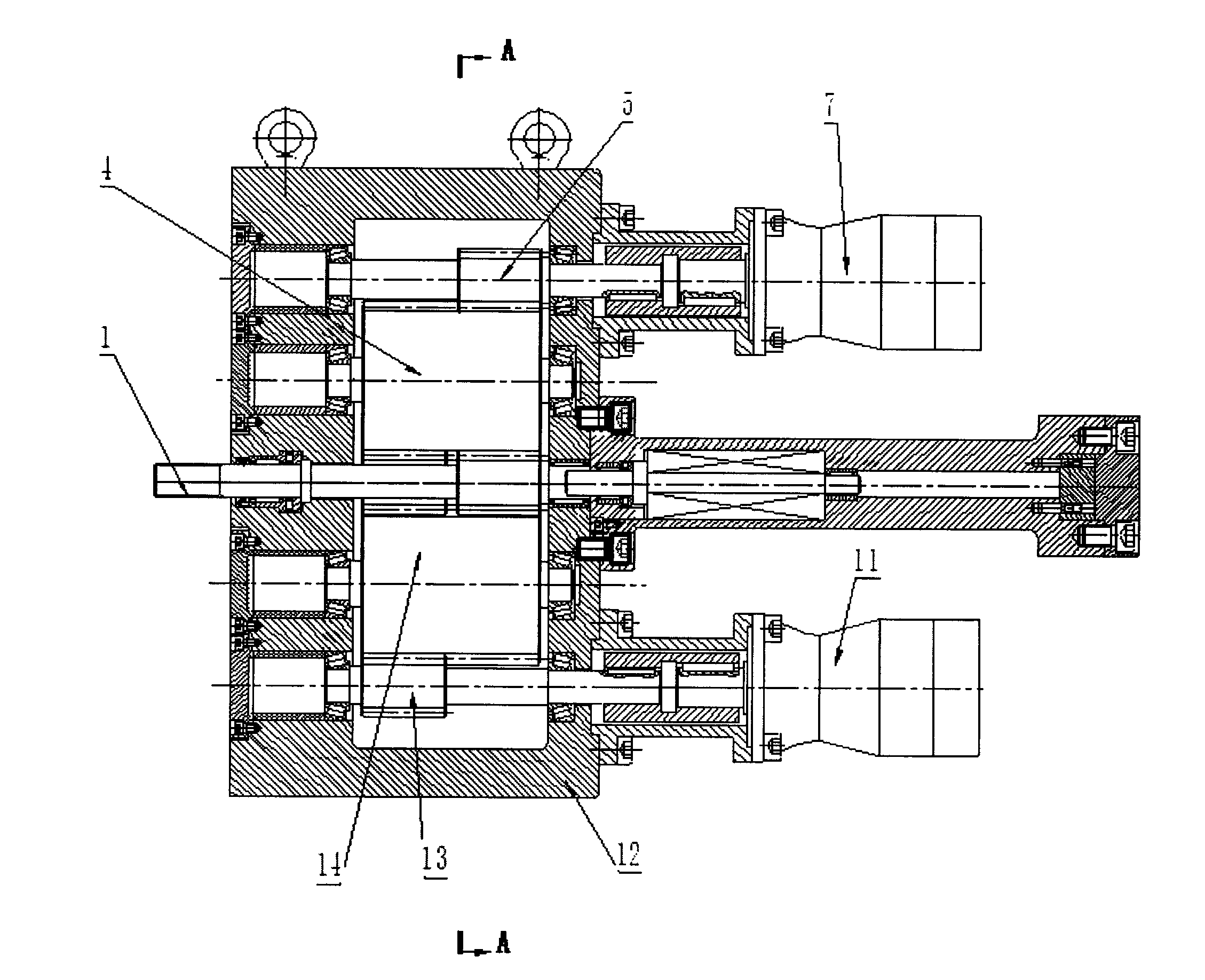

A loudspeaker comprising two acoustic diaphragms mounted to face in axially-opposed directions, two voice coils each having an axis and an axial length and being configured to reciprocate along its axis to drive one of the diaphragms, the axes being substantially parallel and both axes passing through both diaphragms, and at least one magnet forming part of a chassis assembly configured to provide two axially-extending gaps, one for each of the voice coils to reciprocate within, wherein the at least one magnet and the chassis assembly are adapted so that magnetic flux flows across the gaps in opposite directions, and wherein when in use the diaphragms are at their predetermined maximum negative excursions the voice coils overlap in the axial direction by between 10% and 90% of their average axial length, and wherein when in use the diaphragms are in a relaxed position, between their maximum negative and positive excursions, the voice coils do not overlap in the axial direction.

Owner:GP ACOUSTICS INT

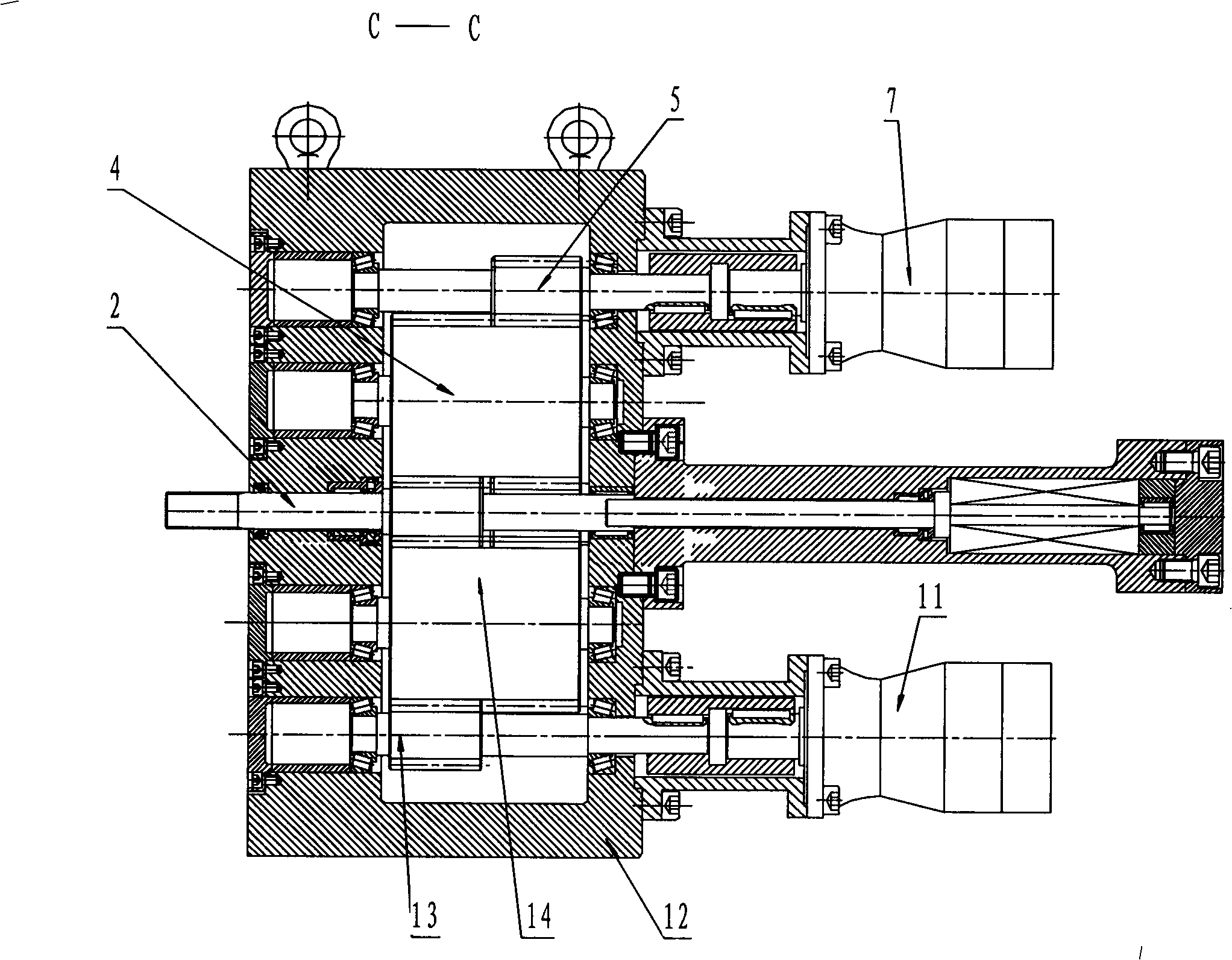

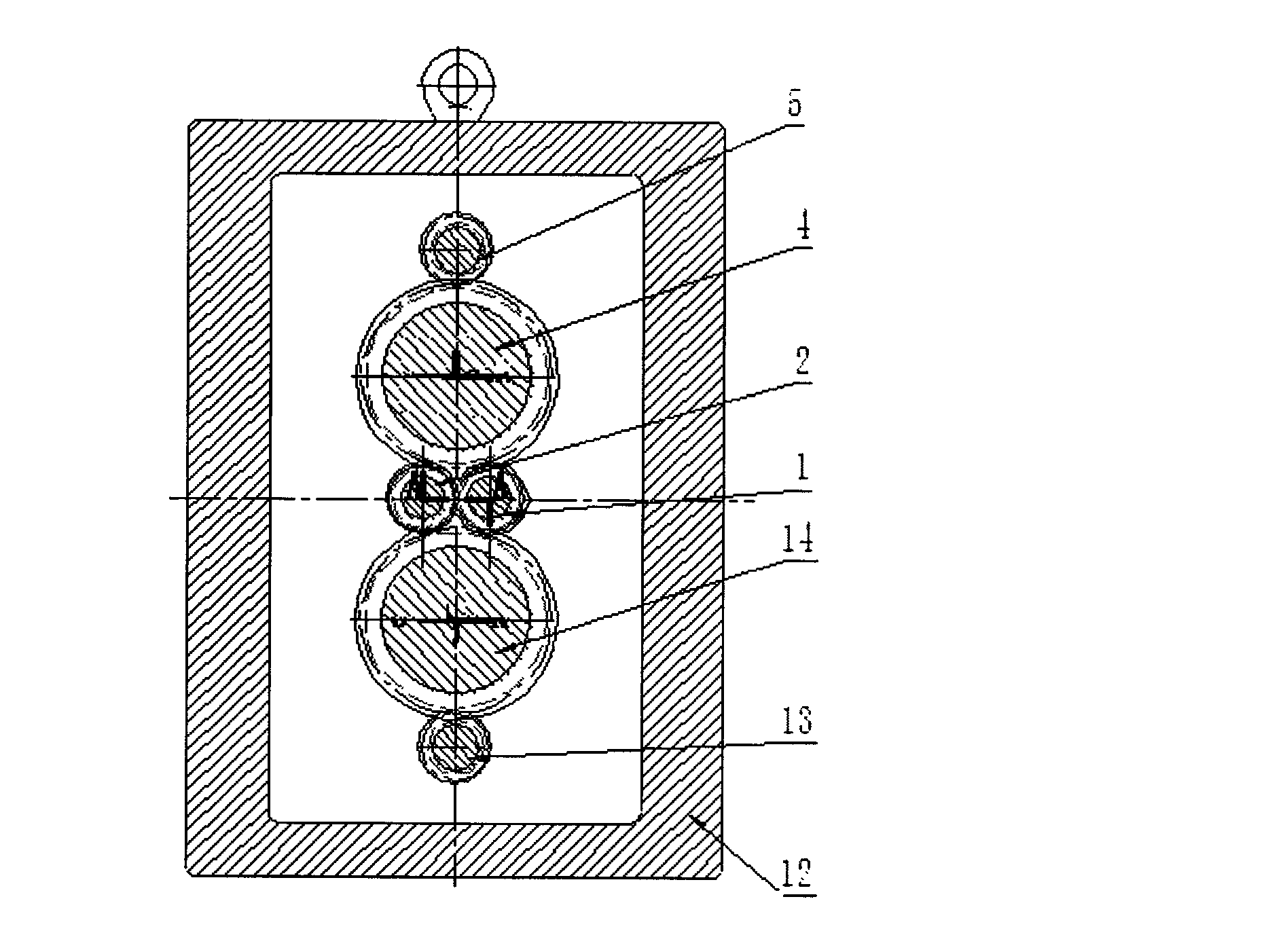

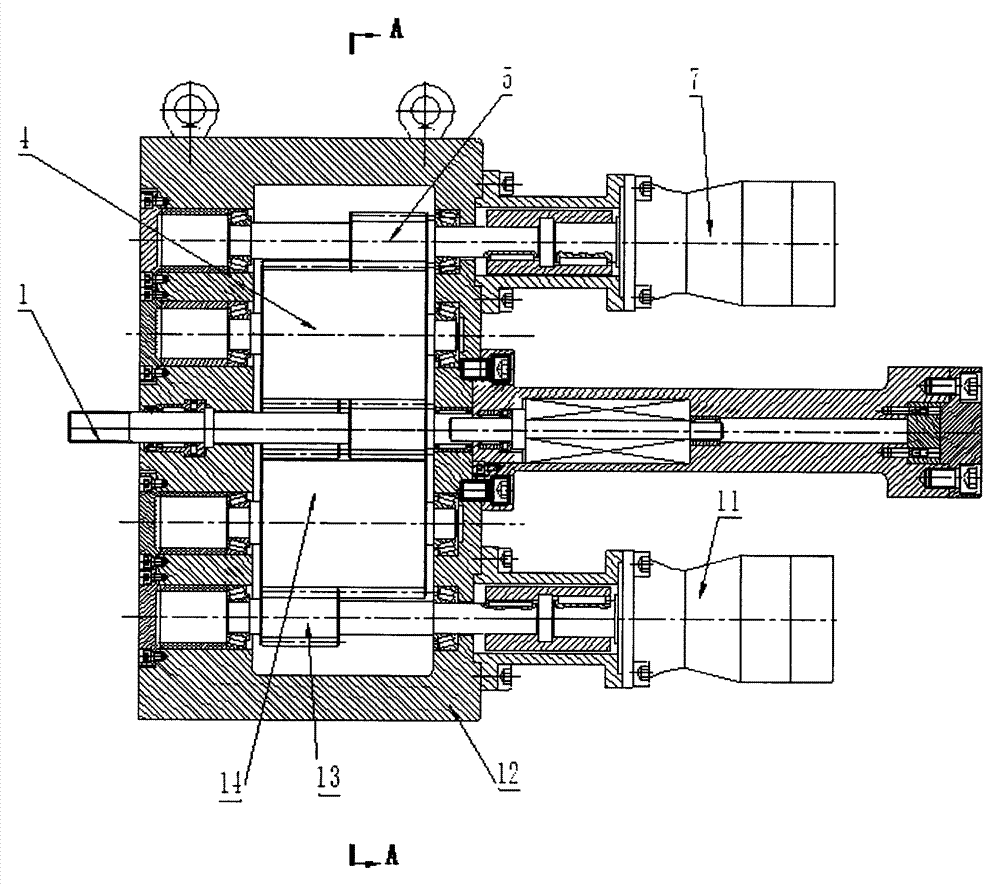

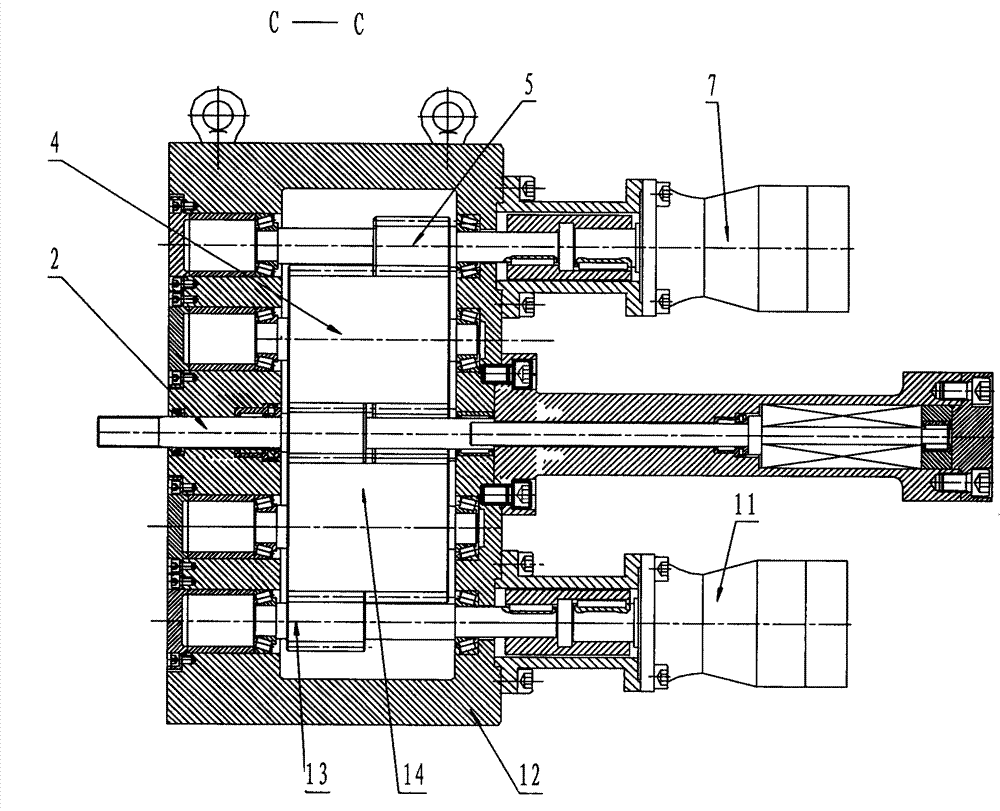

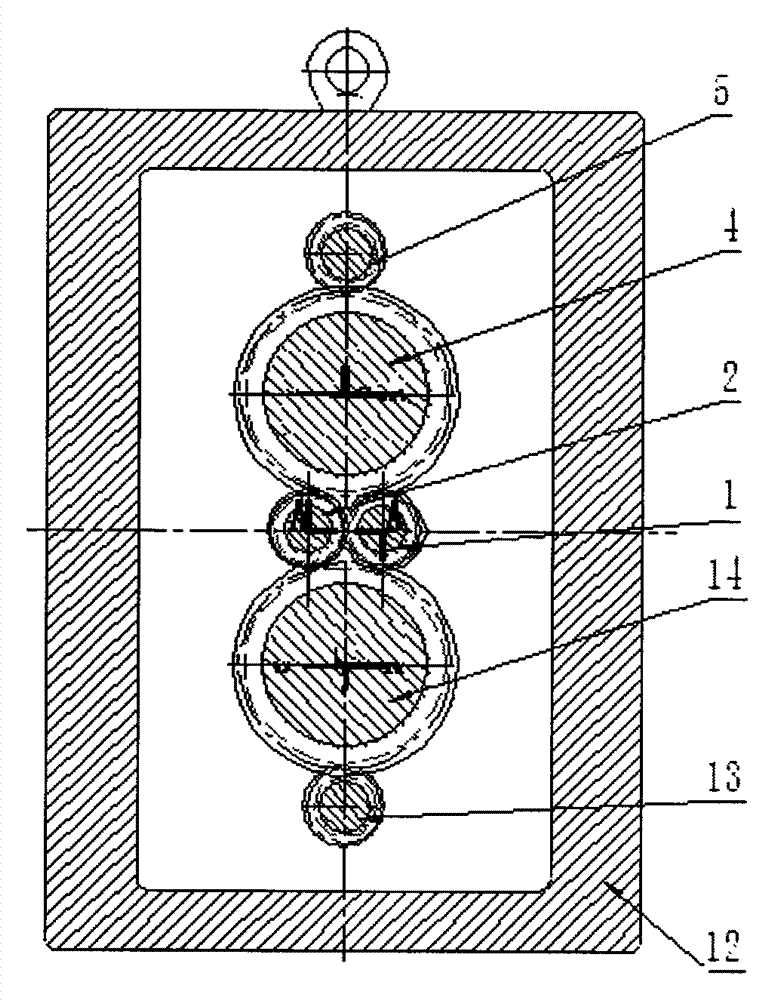

Same-direction double-screw transmission with oil motors

InactiveCN103256340AIncrease torqueBalance radial forceToothed gearingsGearing detailsGear driveDrive shaft

The invention relates to a same-direction double-screw transmission with oil motors, and belongs to the field of plasticizing extrusion molding. The same-direction double-screw transmission is characterized in that two output gear shafts of the same-direction double-screw transmission are transversely parallelly arranged in the center of a transmission case, transmission gears on the output gear shafts are arranged in a front-back dislocation manner, and front ends of the two output gear shafts are used as driving shafts of double screws; two transitional gear shafts are respectively arranged on two sides of the output gear shafts in the vertical direction, a front transmission gear and a rear transmission gear are fixed onto each transitional gear shaft, the two front transmission gears of the two transitional gear shafts are simultaneously meshed with the transmission gear of one output gear shaft, the two rear transmission gears of the two transitional gear shafts are simultaneously meshed with the transmission gear of the other output gear shaft, and two input gear shafts are respectively in gear transmission with the two transitional gear shafts via the oil motors. The same-direction double-screw transmission has the advantages that the double screws can rotate in the same direction, torque born by each output shaft can be greatly increased, and radial force on the output shafts is balanced.

Owner:SHANXI BEIFANG XINGAN CHEM IND

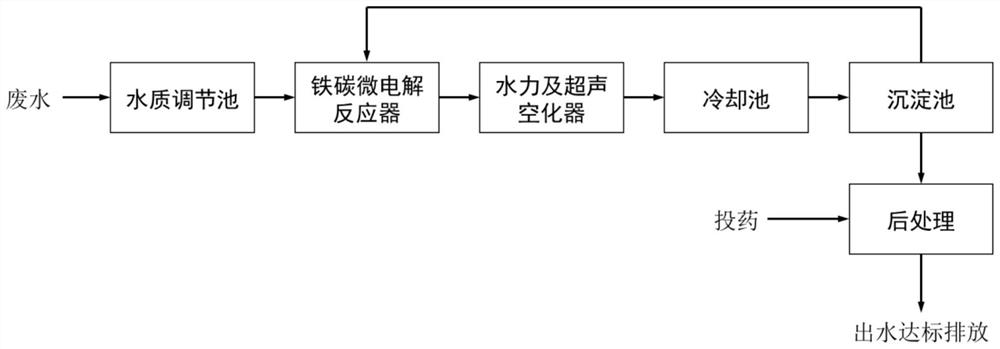

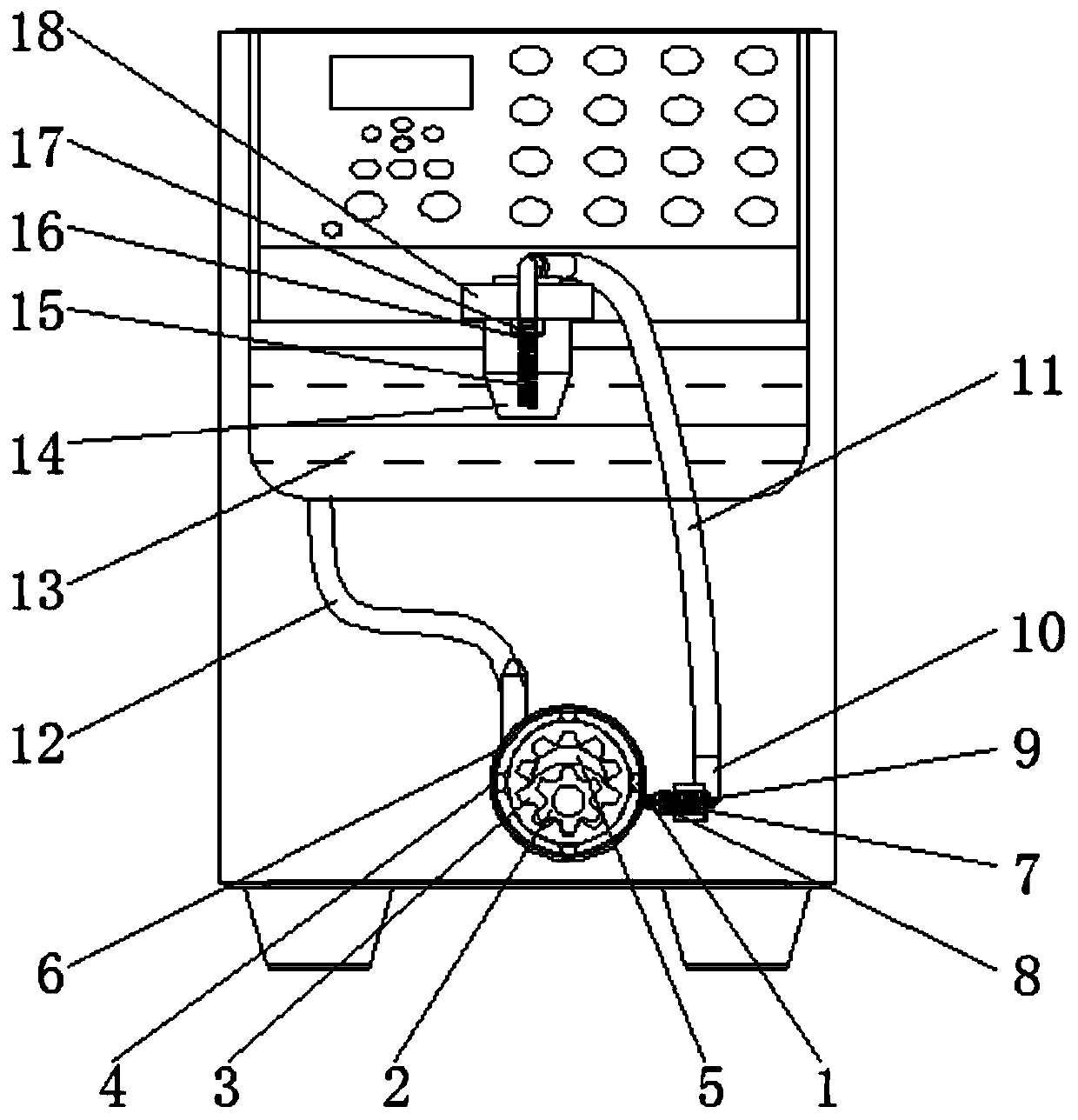

Antibiotic wastewater degradation method and device based on combined action of electrolysis and cavitation

InactiveCN111807583APromote degradationImprove efficiencyWater treatment compoundsWater contaminantsUltrasonic cavitationElectrolysis

The invention discloses an antibiotic wastewater degradation method and device based on the combined action of electrolysis and cavitation. The method comprises the following steps: (1) wastewater homogenization treatment; (2) carrying out iron-carbon micro-electrolysis reaction, and carrying out catalytic pretreatment on the antibiotic wastewater; (3) carrying out hydraulic and ultrasonic cavitation degradation to degrade antibiotics; (4) cooling and precipitating; (5) post-treatment; the device comprises an iron-carbon micro-electrolysis reactor and a hydraulic and ultrasonic cavitator, wherein a water outlet of the iron-carbon micro-electrolysis reactor is connected with a wastewater inlet of the hydraulic and ultrasonic cavitator. According to the method, the antibiotic wastewater is degraded by utilizing a method of combining iron-carbon micro-electrolysis pretreatment and hydraulic power and ultrasonic cavitation; compared with a single method, a better degradation effect and higher degradation efficiency can be obtained, secondary pollution caused by adding chemicals is avoided, the whole degradation process of the antibiotic wastewater is simplified, the structure is simple, maintenance is convenient, the energy utilization rate is greatly increased, and industrialization is easy to achieve.

Owner:SHANDONG UNIV

Adjustment device of cone crusher

InactiveCN106807486AThe adjustment device is safe and reliableGood welding performanceGrain treatmentsPistonPneumatic cylinder

The invention discloses an adjustment device of a cone crusher. The frame is provided with a support arm, and the top of the main shaft is provided with a shaft shoulder. The top of the main shaft is equipped with a radial force bearing. On the thrust bearing, the thrust bearing is installed on the lower part of the lock arm, the upper part of the lock arm is installed on the piston, the piston is arranged in the working cylinder, and the working cylinder is fixed on the support arm of the frame , the working cylinder includes a pneumatic cylinder, a hydraulic cylinder, and a diaphragm, the diaphragm separates the pneumatic cylinder from the hydraulic cylinder, and the hydraulic cylinder is arranged on the pneumatic cylinder. The technical purpose of the present invention is to provide an adjustment device for a cone crusher which is easy to adjust the distance between the movable cone and the fixed cone, and does not need to be provided with an oil tank and an accumulator for oil and gas adjustment.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

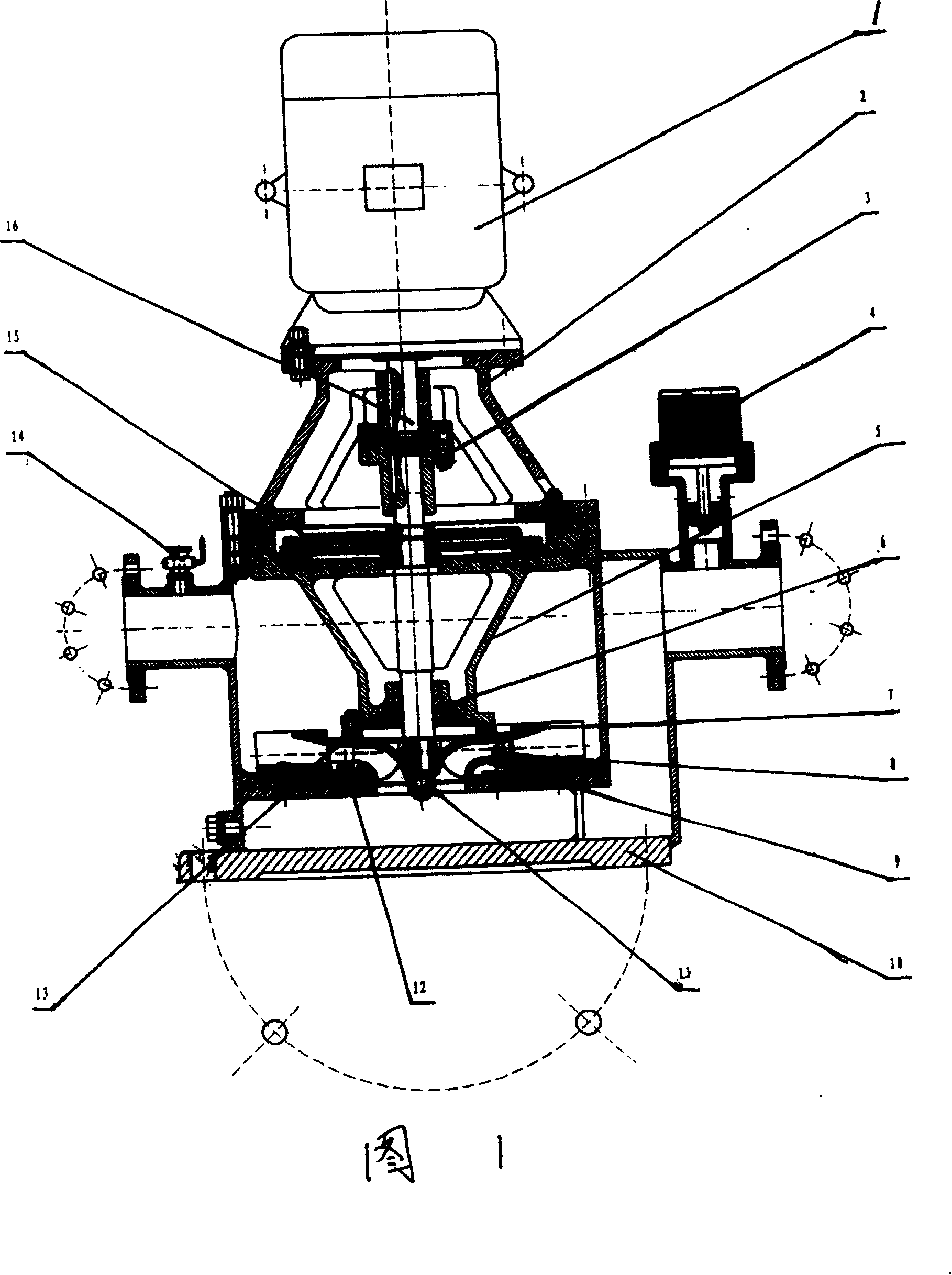

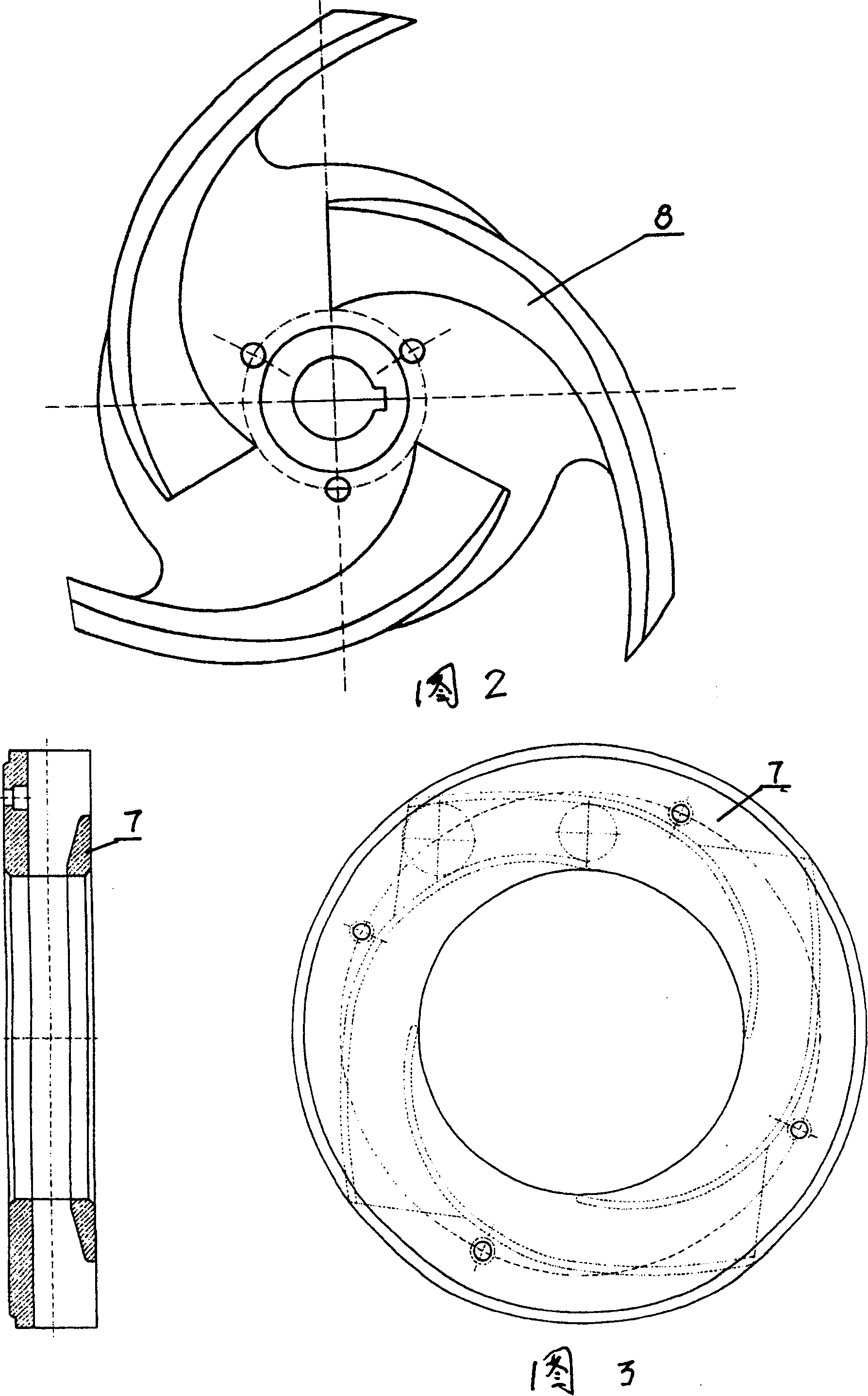

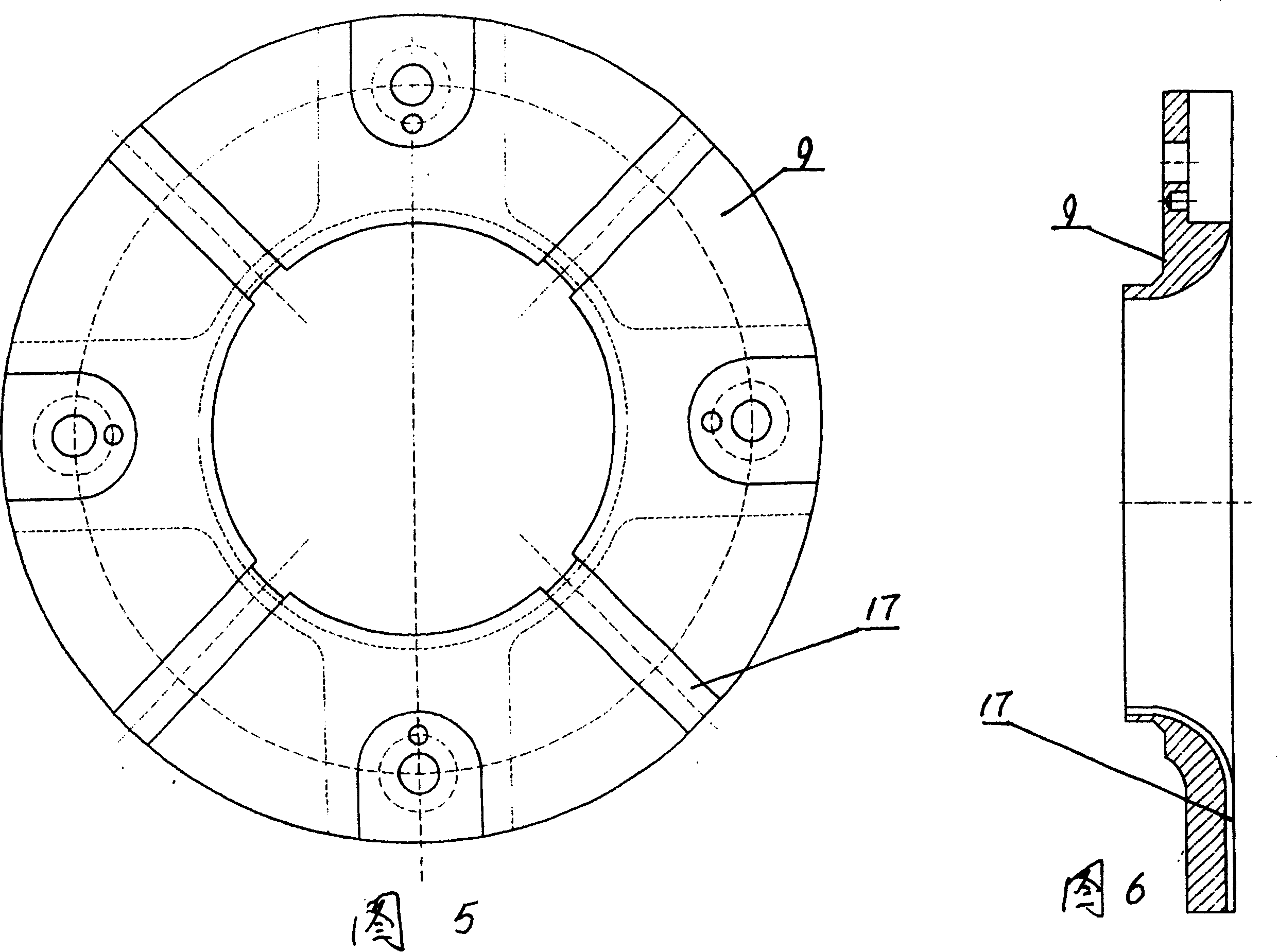

Vertical disintegratable self-suction dredge pump

InactiveCN100374729CImprove passabilityEfficient crushingSpecific fluid pumpsNon-positive displacement fluid enginesSiphonFiber

Present invention relates to dredge pump for sewage treatment, especially a vertical type disintegrable self-suction dredge pump. It features designing impeller as wide-open type structure for increasing pump ability and raising engine efficiency, said wide-open type impeller combined with blade effectively balancing axial force and radial force, topping mechanism set in pump body effectively disintegrating blocky-shaped particle and long fiber substance, setting exhaust valve on pump outlet for exhausting out vapour generated in separating vapour and liquid, setting solenoid valve on pump body suction inlet for preventing siphon affect sucking up water in pump body. Said invention has reasonable structure, compactness, reliable operation, combining disintegrating, exhausting, siphon prevention, and pumping function, and can be widely used in sewage treatment, sewage transference containing easy disintegrating solid particles and long fiber, and ship.

Owner:江苏迎浪科技集团有限公司

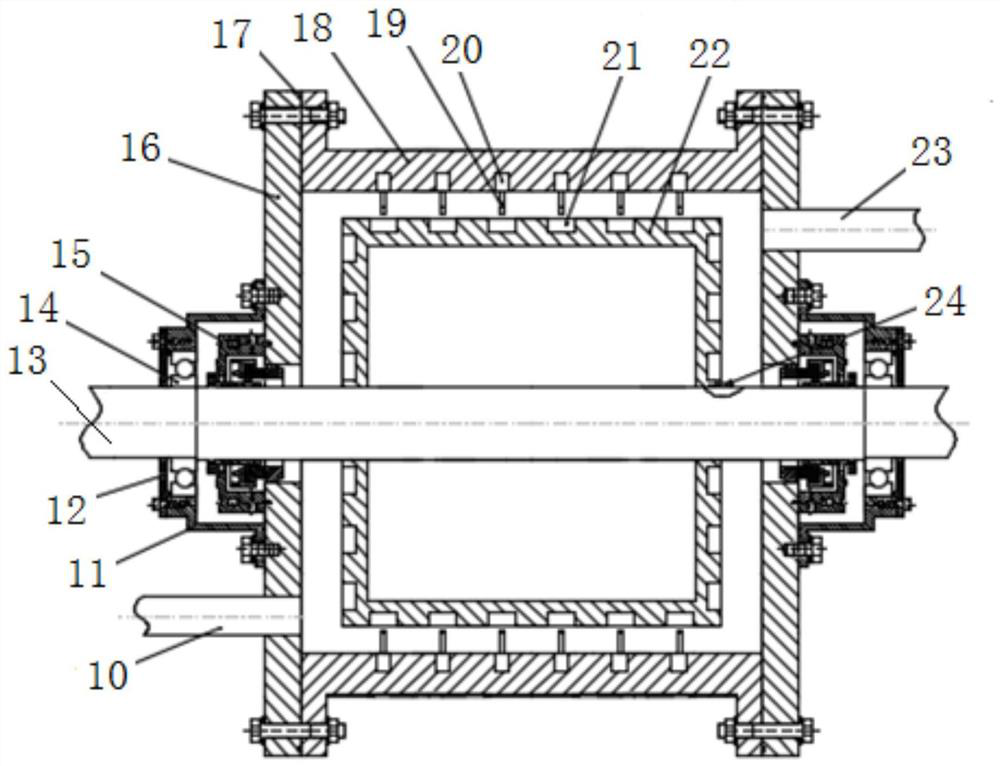

Ceramic bearing fluoroplastic magnetic drive pump

PendingCN114593070ABalance radial forceSolve the throwing eccentricityPump componentsPump installationsImpellerBall bearing

A fluoroplastic magnetic drive pump with a ceramic bearing solves the problems that an existing magnetic drive pump is complex in structure, large in vibration, high in noise, frequent in maintenance and large in application limitation. Which comprises a main pump shaft with an impeller at one end, and is characterized in that inner magnetic steel is arranged at the other end of the main pump shaft; a main ceramic ball bearing is arranged on the side, close to the impeller, of the middle of the main pump shaft, and a ceramic thrust bearing is arranged on the side, close to the inner magnetic steel, of the middle of the main pump shaft. A magnetic pump cover is arranged between the impeller and the inner magnetic steel and on the outer side of the middle part of the main pump shaft; a sealing cover seat arranged outside the inner magnetic steel is connected with a pump cover of the magnetic drive pump through a pressing plate; a secondary pump shaft is arranged on the inner side of the end of the sealing cover seat, and a secondary ceramic ball bearing is arranged between the secondary pump shaft and the inner magnetic steel. The motor is reasonable in design, compact in structure, stable in operation, free of vibration, low in noise, long in service life and low in maintenance cost, and can operate for a long time without lubrication.

Owner:虞淞

Easily controlling hydraulic corner self-servo valve

ActiveCN102562701BImprove dynamic characteristicsEasy to controlServomotor componentsEngineeringAxial force

The invention relates to an easily controlling hydraulic corner self-servo valve which is characterized in that a blade (15) is arranged on the outer wall of a hollow column body (35) of a valve body (7); the initial assembly position of the blade (15) is in axis symmetric arrangement with that of a fixed baffle block (5); a valve sleeve (8) is arranged in a the hollow column body (35), and a valve core (8) is arranged in a small hollow circle (34) of the valve body (7); a high pressure oil inlet P and a low pressure oil outlet T of a left end cover (1) are respectively communicated with high and low pressure outer oil annular slots (31 and 28) of the valve body (7) correspondingly through high and low pressure oil channels (2 and 17) of a cylinder body (6); high and low pressure inner oil annular slots (32 and 30) of the valve body (7) are correspondingly communicated with core body high and low pressure oil annular slots (39 and 40) of the valve core (9); and core body high and low pressure oil channels (38 and 41) enter a first working chamber and a and second working chamber correspondingly through upper and lower semi-circle oil annular slots (36 and 37) of the valve sleeve (8). According to the invention, the easily controlling hydraulic corner self-servo valve has the characteristics that the preparation is convenient, the radial force and the axial force subjected by the valve core are both balanced, the resistance of the valve core is low, the dynamic characteristics are good, and the servo blind area is small.

Owner:武汉科技大学资产经营有限公司

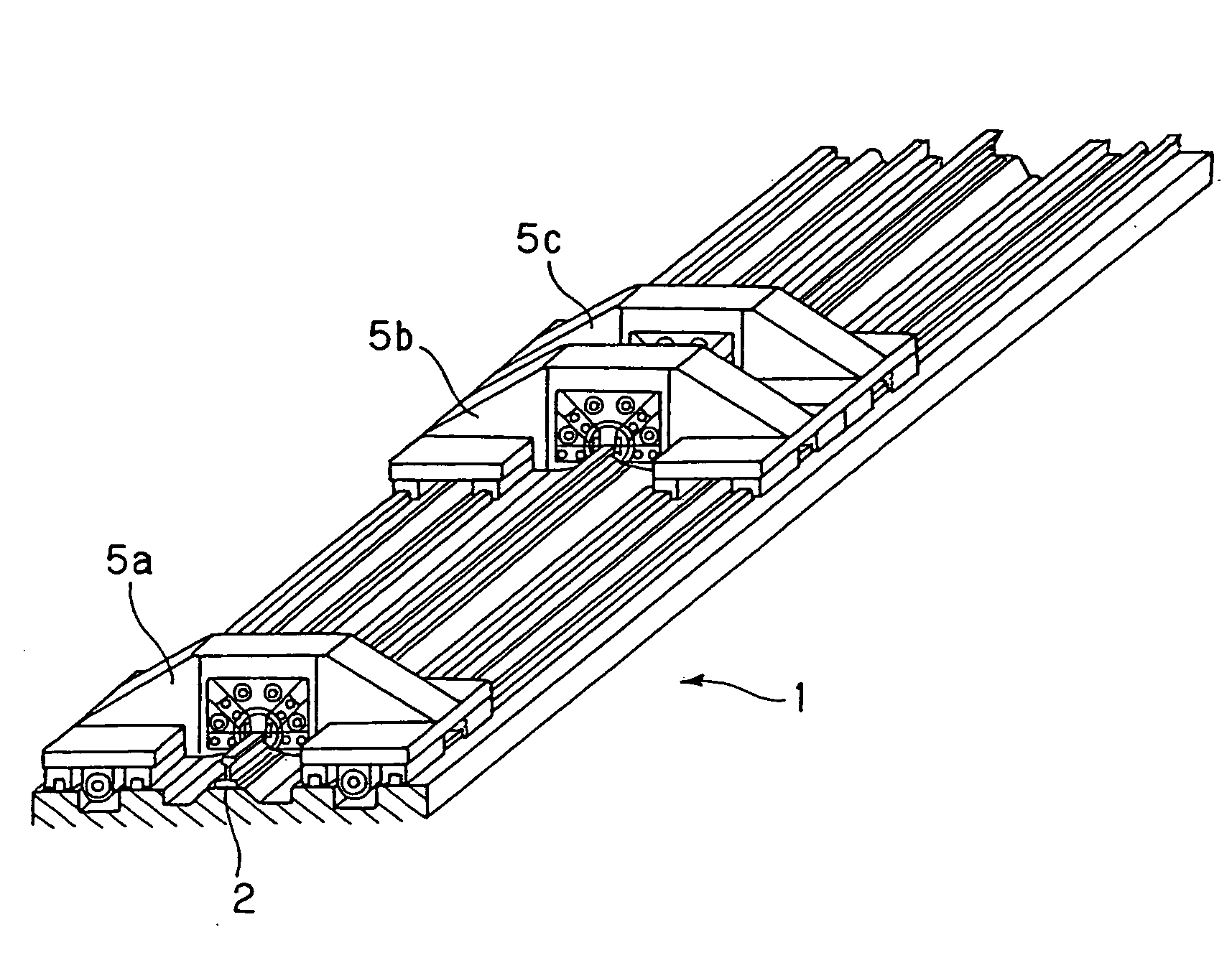

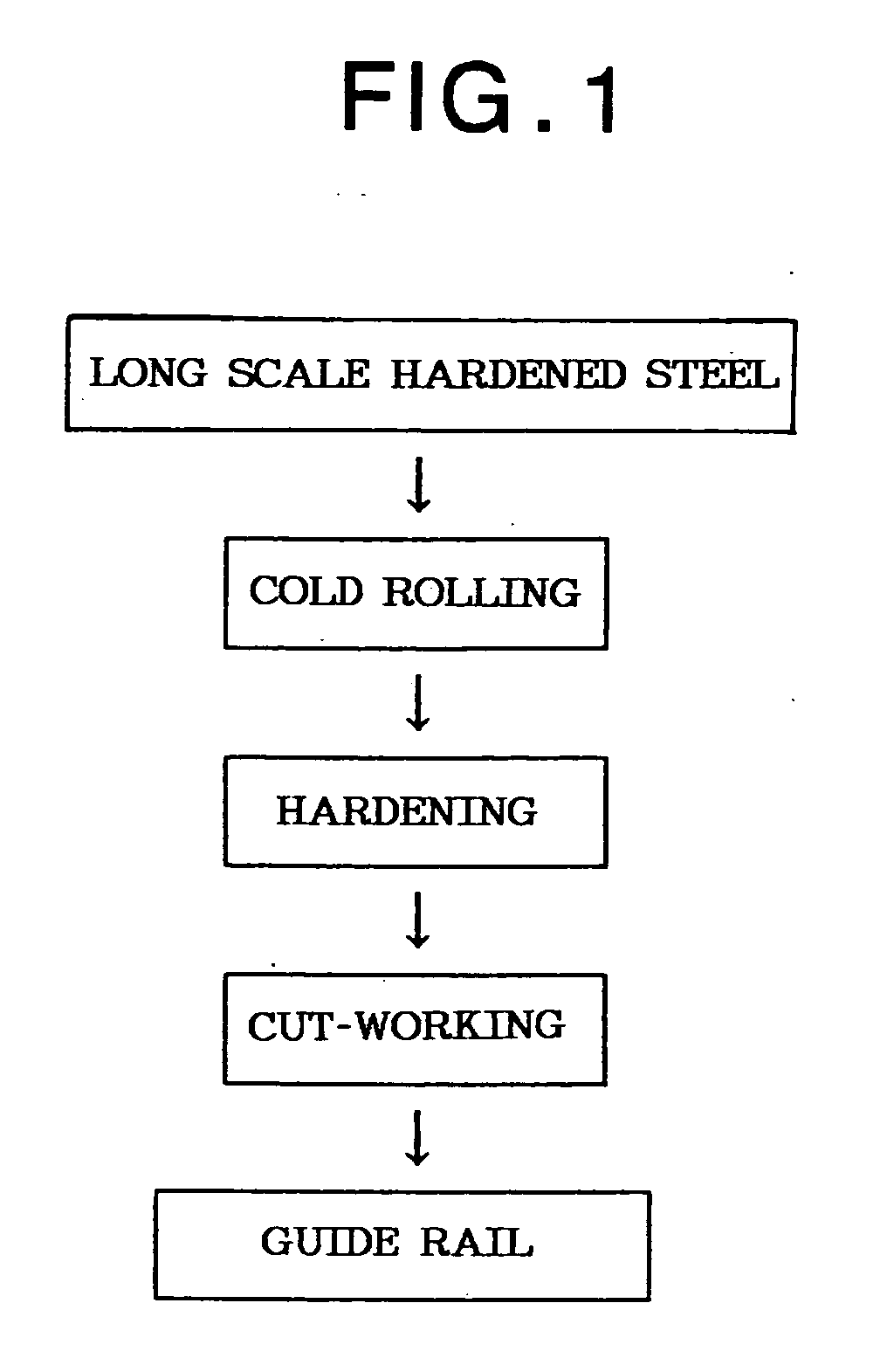

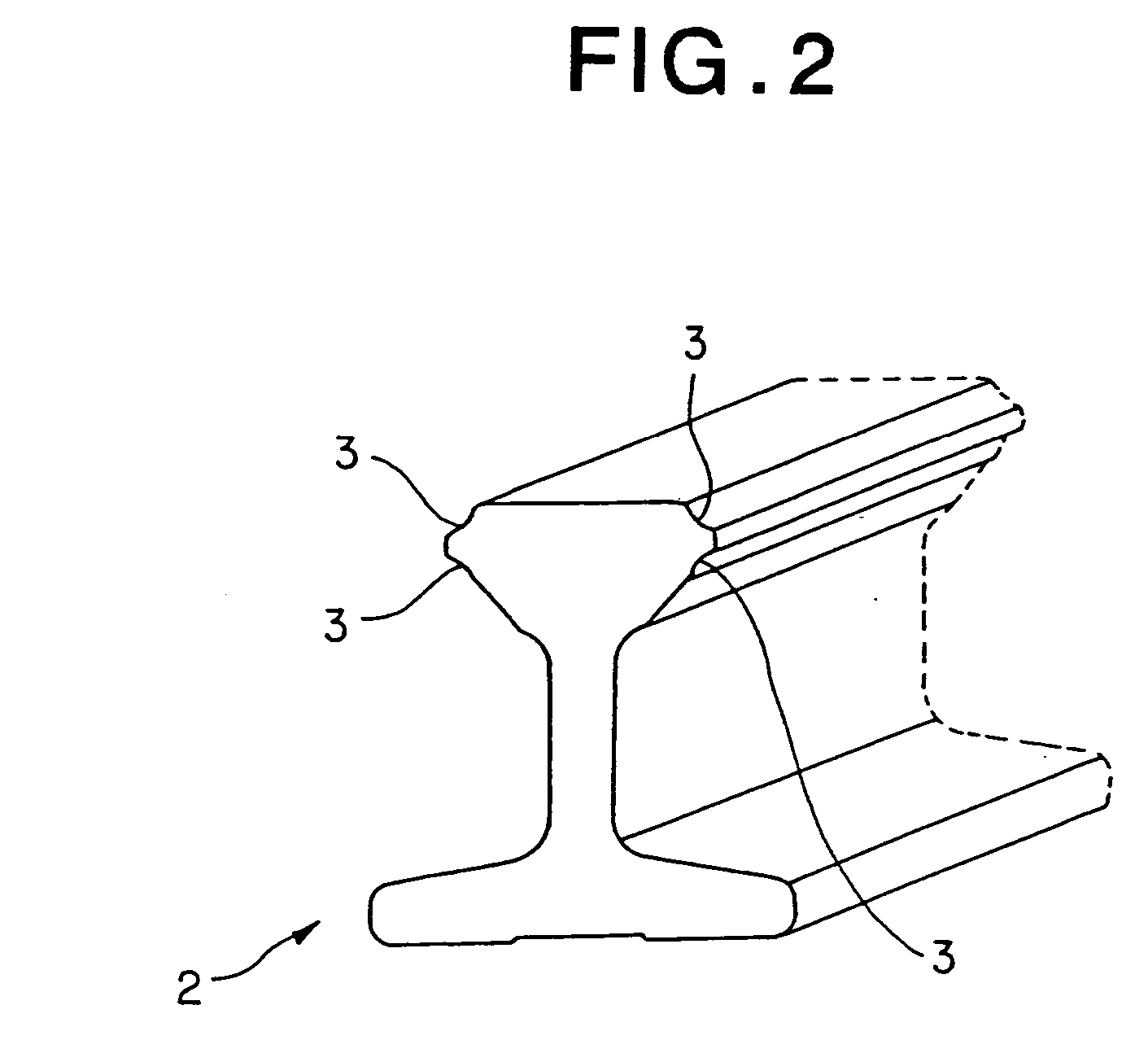

Method and apparatus for cutting long scale hardened steel

InactiveUS20050042054A1Equipment miniaturizationDrive stabilityLinear bearingsWorkpiecesEngineeringMechanical engineering

The present invention mainly aims to provide cutting method and cutting apparatus for manufacturing a guide rail of a rolling guide device by efficiently cut-working a long scale hardened steel. In order to achieve such object, there is provided a cutting method of linearly cutting a work surface (3) of the long scale hardened steel (2) along the longitudinal direction thereof. In this process, it is desired to arrange a plurality of CBN tools (7) along the longitudinal direction of the long scale hardened steel (2) to thereby sequentially cut the work surface (3). Furthermore, a cutting apparatus of the present invention comprises a fixing device (4) for fixing the long scale hardened steel (2), a tool rest (5) which is guided by a guide device (6) disposed along the longitudinal direction of the fixing device (4) and the CBN tool (7) cut-working the work surface (3) of the long scale hardened steel (2) held by the tool rest (5).

Owner:THK CO LTD

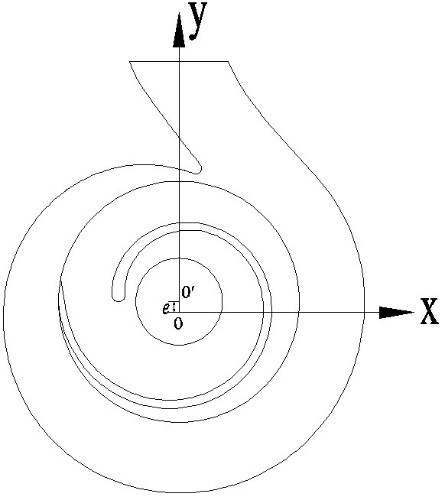

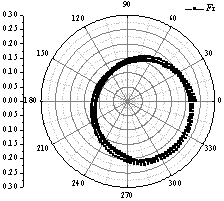

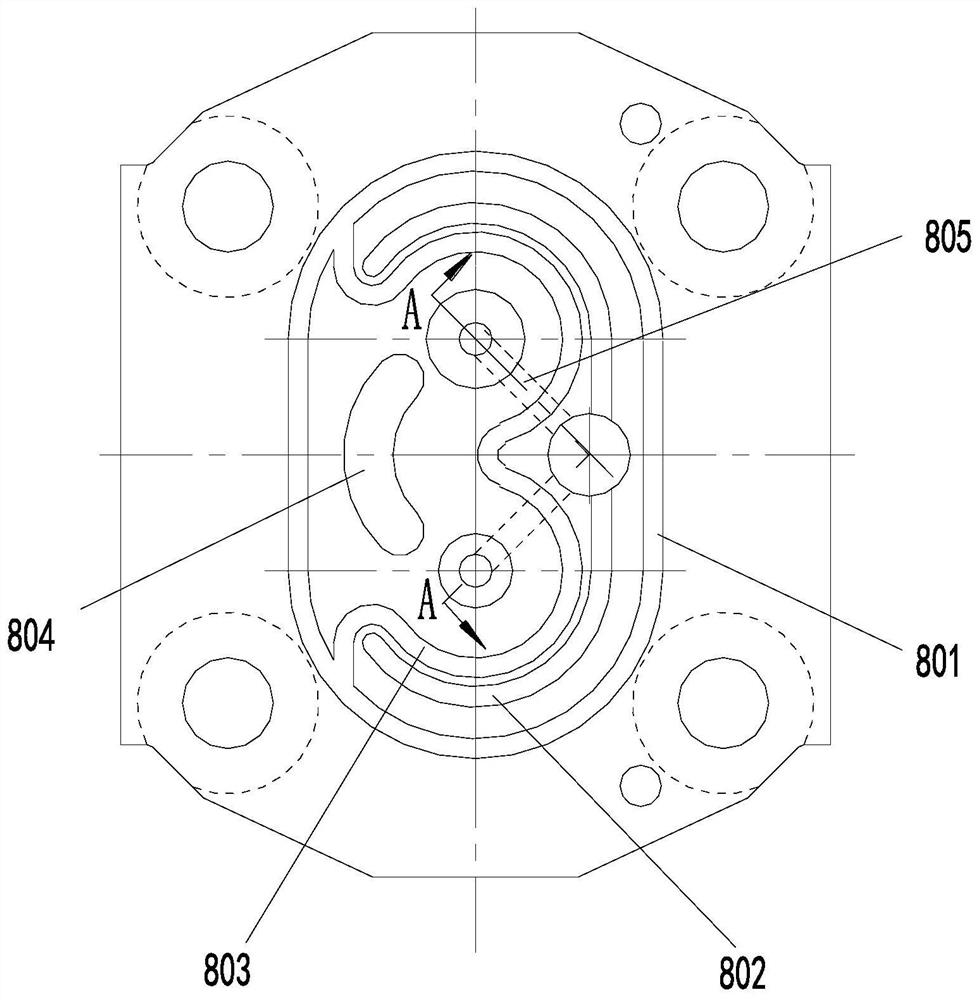

Method for self-balancing radial force of a single-blade centrifugal pump

ActiveCN112483461AReduce radial forceBalance radial forcePump componentsPump controlTest measurementGravity center

The invention discloses a method for self-balancing radial force of a single-blade centrifugal pump. The method comprises the following steps that S1, the circumferential distribution symmetry of a flow field inside the single-blade centrifugal pump is improved by adopting an impeller rotation center eccentricity method according to CFD numerical simulation, and meanwhile, the magnitude and position of eccentricity of the impeller rotation center are determined based on the CFD numerical simulation and test measurement; and S2, the position of the gravity center and the required centrifugal force are determined in combination with CFD numerical simulation and test measurement, and according to the calculated centrifugal force, the appropriate centrifugal force generated when the gravity center deviates from the rotation center is adopted and used for balancing the radial force. The method balances the radial force generated during operation of the pump, and improves the operation stability and reliability of the pump; and the method is adopted, is quick and convenient, can shorten the time consumed in the impeller balance weight machining process greatly, and improves the balance weight efficiency.

Owner:NANTONG UNIVERSITY

Boric acid delivery pump for nuclear power station

The invention discloses a boric acid delivery pump for a nuclear power station. A volute chamber has a double volute structure, so that radial force generated during the operation of an impeller is effectively balanced; a pump cover seal has a single-end-face containerization type mechanical seal structure, is convenient to assemble, disassemble and maintain and can effectively prevent media fromleaking outwards; a bearing oil seal has a labyrinth seal structure, so that an ideal sealing effect is achieved; a cooling cavity on a pump cover is eliminated, and the axial length of the pump cover is shortened, so that the integral pump set has a compact structure, and the space for installation and maintenance is effectively reduced; a sealing structure formed by combining a pump seal with an impeller seal is changed into a single pump body sealing structure, so that the delivery pump has a simple and reliable structure and is convenient to mount and maintain; and a supporting rib plate is arranged on a bearing bracket, so that the stability of the pump set is improved.

Owner:SHANGHAI APOLLO MACHINERY

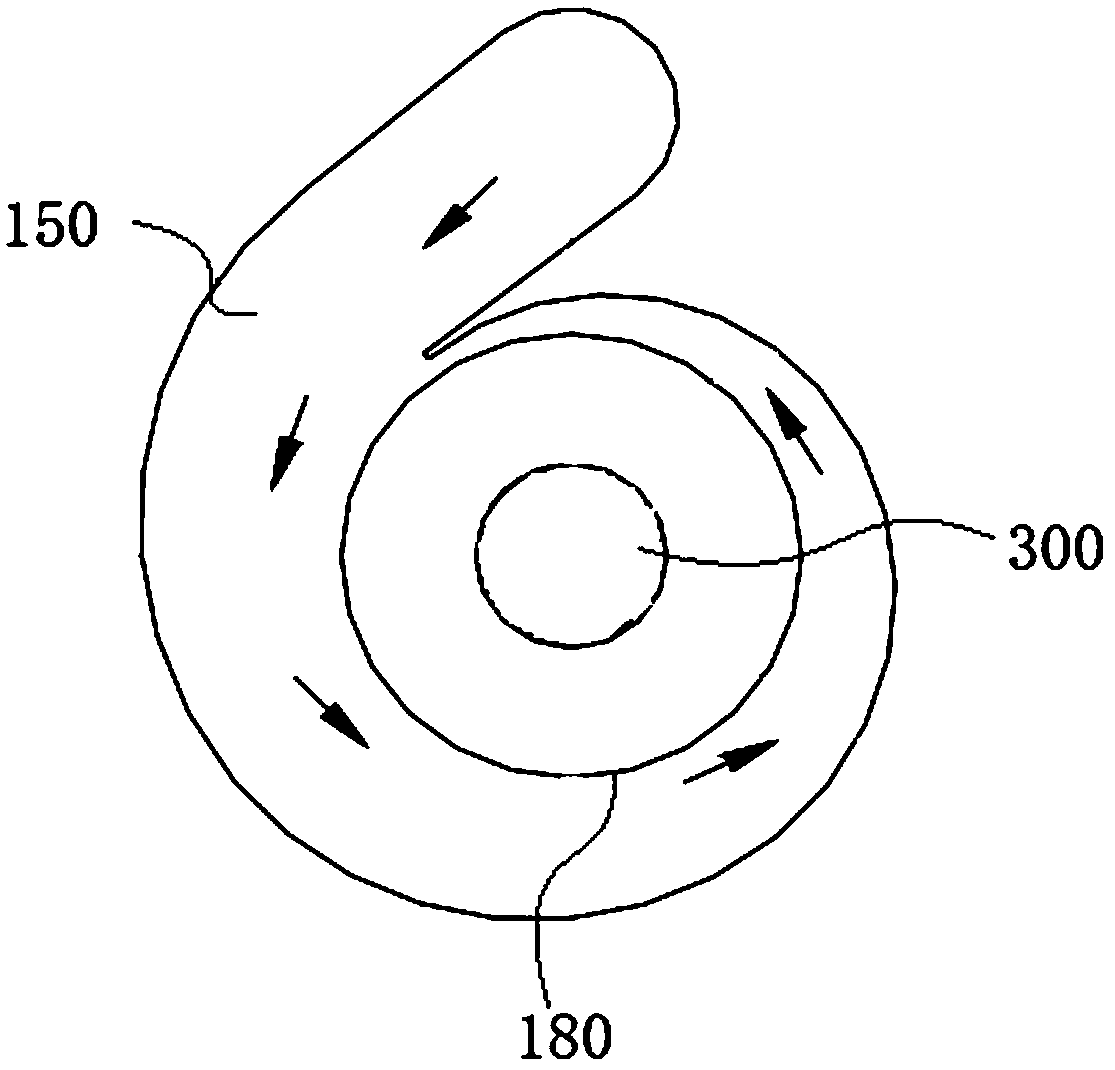

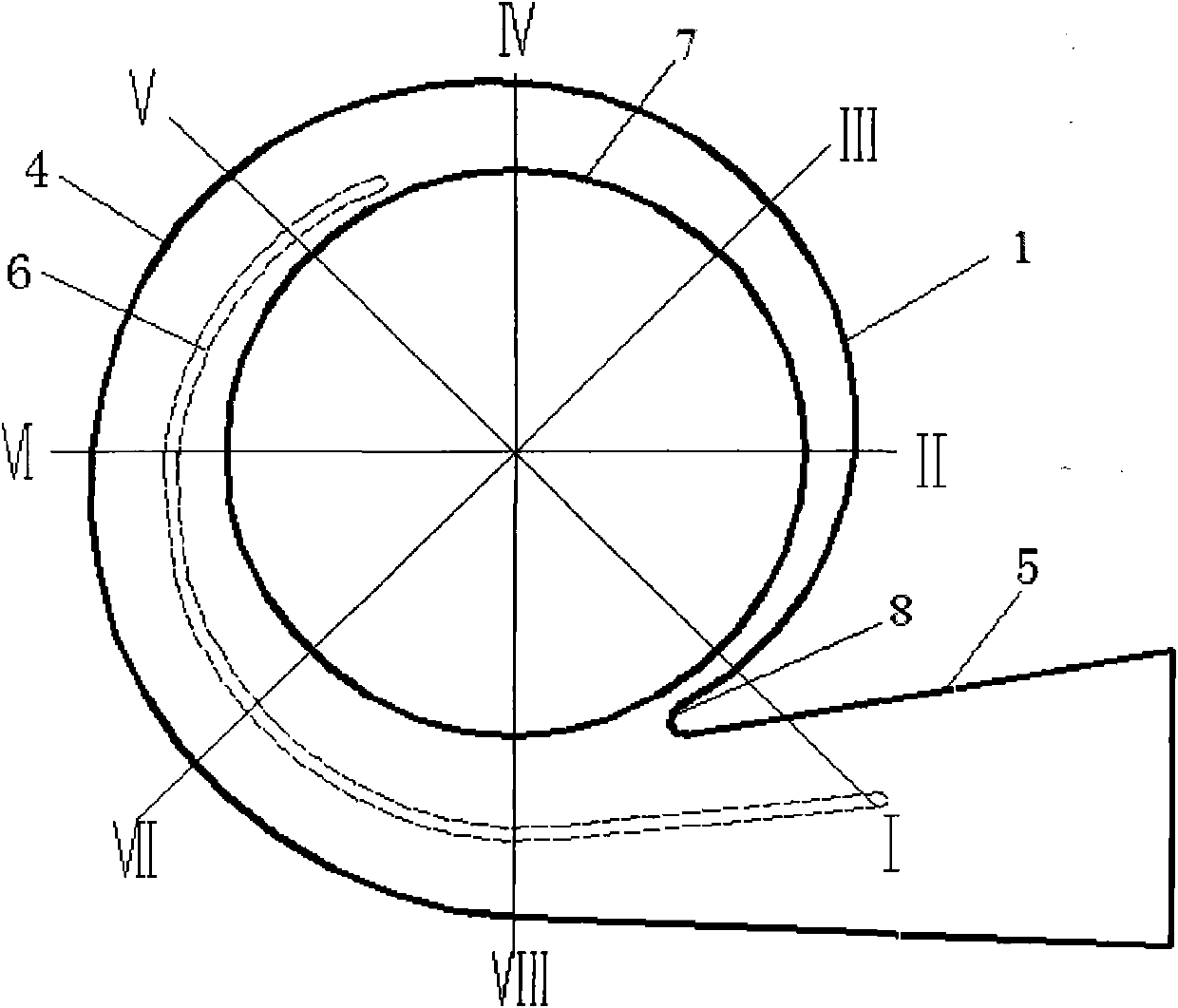

Volute chamber structure of horizontal pump

The invention discloses a volute chamber structure of a horizontal pump. A water allocation piece is arranged in a spiral flow channel formed between an impeller and a pump body; the water allocation piece is spirally shaped and arranged along the flow channel; and the starting end of the water allocation piece in the water flow direction in the flow channel is tangential with the base circle of the pump. With the technical proposal, according to the volute chamber structure of the horizontal pump, the water allocation device is additionally arranged in an appropriate position of the spiral flow channel of the large-flow horizontal pump body; in other words, the spiral flow channel is divided into two parts; in this way, noise generated due to great centrifugal force is reduced, the radial force is greatly balanced and the service life of a motor bearing is prolonged; therefore, the operation of the pump is reliable, the fault possibility of the pump is reduced and the efficiency of the pump is improved; and as a result, the service life of the pump is prolonged.

Owner:ZHANGJIAGANG ENDA PUMP IND

A co-rotating twin-screw transmission device using an oil motor

InactiveCN103256340BIncrease torqueBalance radial forceToothed gearingsGearing detailsGear driveDrive shaft

The invention relates to a co-rotating twin-screw transmission device using an oil motor, which belongs to the field of plasticizing extrusion molding. The two output gear shafts of the present invention are horizontally and parallelly arranged in the center of the transmission box body, and the transmission gears on it are arranged in a front and rear misalignment, and the front ends of the two output gear shafts are used as the drive shafts of the twin screws; Two transition gear shafts are respectively arranged on both sides, and each transition gear shaft is fixed with two front and rear transmission gears. The last two transmission gears of the transition gear shaft are engaged with the transmission gears of the other output gear shaft at the same time; the two input gear shafts drive the two transition gear shafts respectively through the oil motor; the present invention enables the twin screws to rotate in the same direction, In addition, the torque received by the output bearing is greatly improved, and the radial force of the output shaft is balanced.

Owner:SHANXI BEIFANG XINGAN CHEM IND

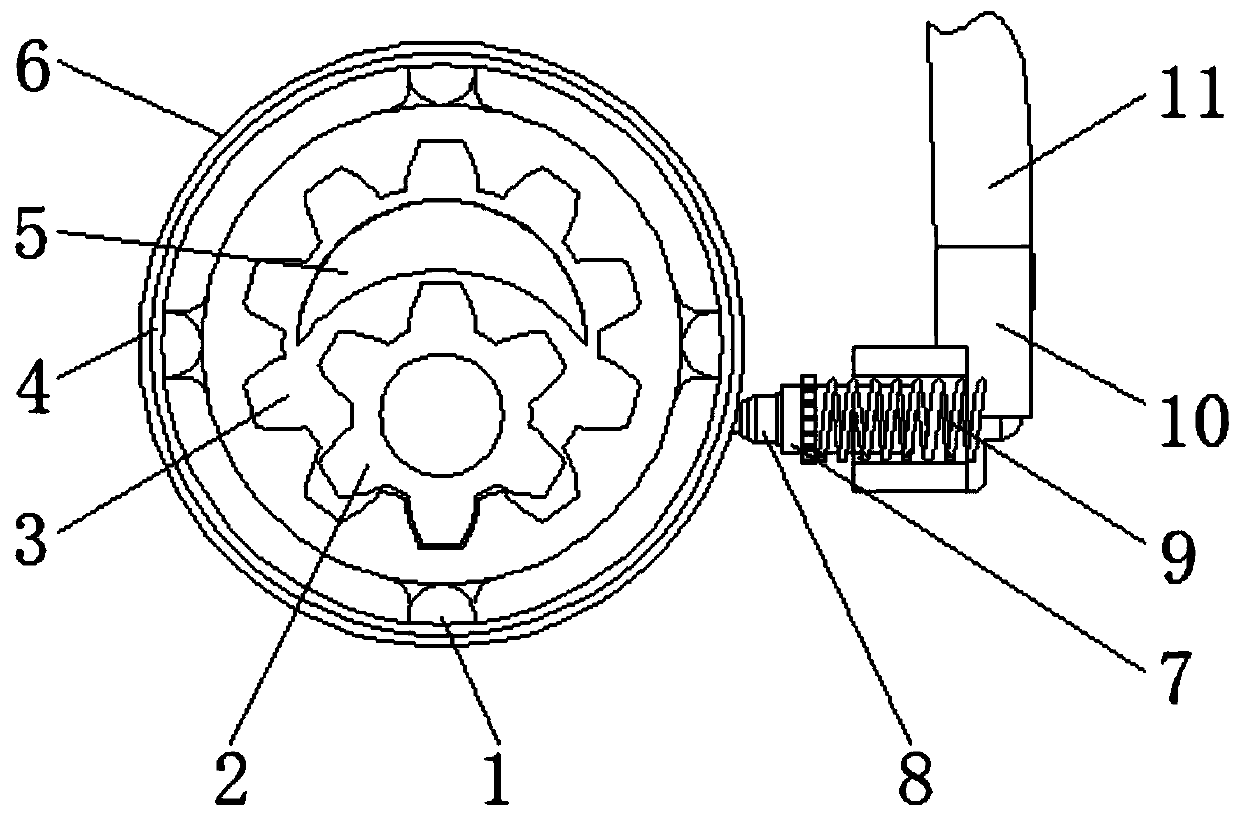

Internal gear pump with built-in brake deceleration locating columns and check valve

PendingCN109899283AWear-resistantHigh temperature resistantRotary piston pumpsRotary piston liquid enginesGear pumpDrive wheel

The invention discloses an internal gear pump with built-in brake deceleration locating columns and a check valve. The internal gear pump with the built-in brake deceleration locating columns and thecheck valve comprises a pump body and the brake deceleration locating columns. A seal ring is arranged in the pump body. A driven wheel is installed outside the seal ring. The front side of the drivenwheel is fixedly provided with a driving wheel. A swing link is installed on the upper side of the drive wheel to be attached to the surface of the driven wheel. A sugar discharge nozzle fixing seatis arranged on the upper surface of a liquid storage container. A check valve seal ring is arranged below the sugar discharge nozzle fixing seat. A second check valve plug head is installed below thecheck valve seal ring. The lower side of the second check valve plug head is connected with a second check valve plug head. A sugar discharge nozzle is installed outside the second check valve plug head. According to the internal gear pump with the built-in brake deceleration locating columns and the check valve, the installed first check valve plug head and the second check valve plug head can prevent fructose in a fructose feeding pipe from flowing back into the pump body and prevent the pump body against internal leakage and air leakage.

Owner:广东乐创电器有限公司

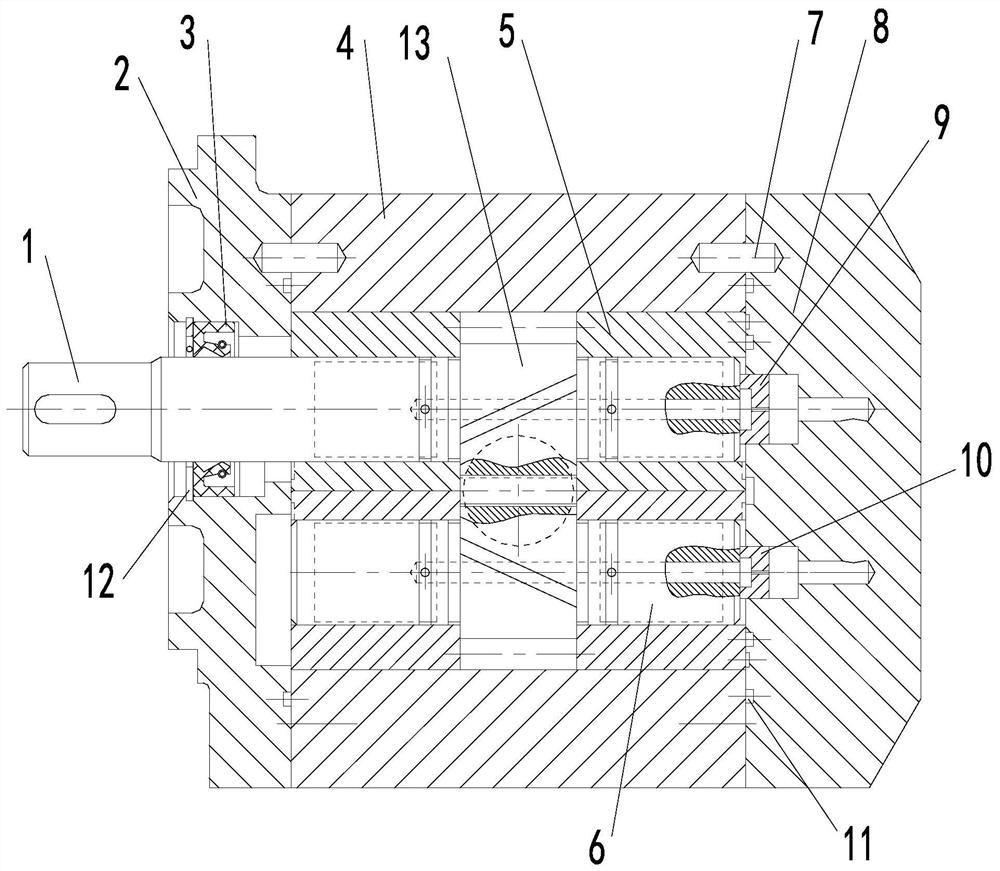

Axial and radial hydrostatic gear pump with helical teeth and double arc teeth

ActiveCN110594150BBalance axial forceBalance radial forceRotary piston pumpsRotary piston liquid enginesGear pumpSlider bearing

Owner:SHANDONG UNIV

A method for self-balancing radial force of single-vane centrifugal pump

ActiveCN112483461BReduce radial forceBalance radial forcePump componentsPump controlCentre of rotationCentrifugal force

The invention discloses a method for self-balancing radial force of a single-blade centrifugal pump, comprising the following steps: S1. According to CFD numerical simulation, a method of eccentricity of the rotation center of the impeller is used to improve the symmetry of the circumferential distribution of the flow field in the single-blade centrifugal pump, At the same time, the size and position of the eccentricity of the rotation center of the impeller determined based on CFD numerical simulation and experimental measurement; S2, combined with CFD numerical simulation and experimental measurement to determine the position of the center of gravity and the required centrifugal force, according to the calculated centrifugal force, use the center of gravity Off-centre of rotation produces a suitable centrifugal force, which is used to balance the radial forces. The method of the invention balances the radial force generated when the pump is running, and improves the running stability and reliability of the pump; the method is fast and convenient, can greatly reduce the time consumed in the processing of the impeller counterweight, and improve the counterweight efficiency.

Owner:NANTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com