Back-flushing pump of circulating water filtering system for nuclear power station

A technology for circulating water filtration and backwashing pumps, which is applied to the components, pumps, and pump devices of pumping devices for elastic fluids, which can solve the problems of inconvenient maintenance and maintenance, increased system complexity, and insufficient radial force. Balance and other issues, to achieve the effect of easy maintenance and maintenance, anti-reversal, high hydraulic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

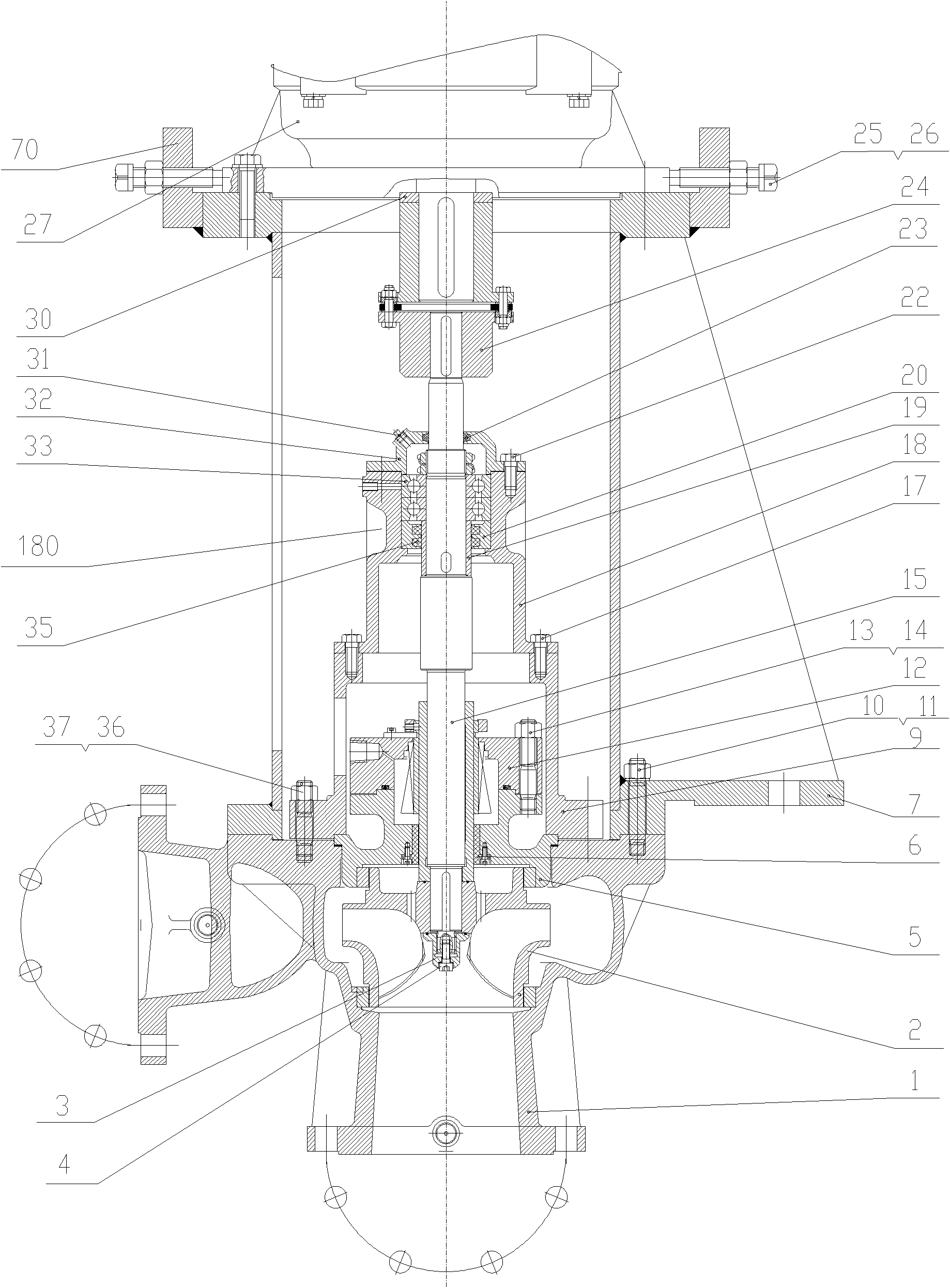

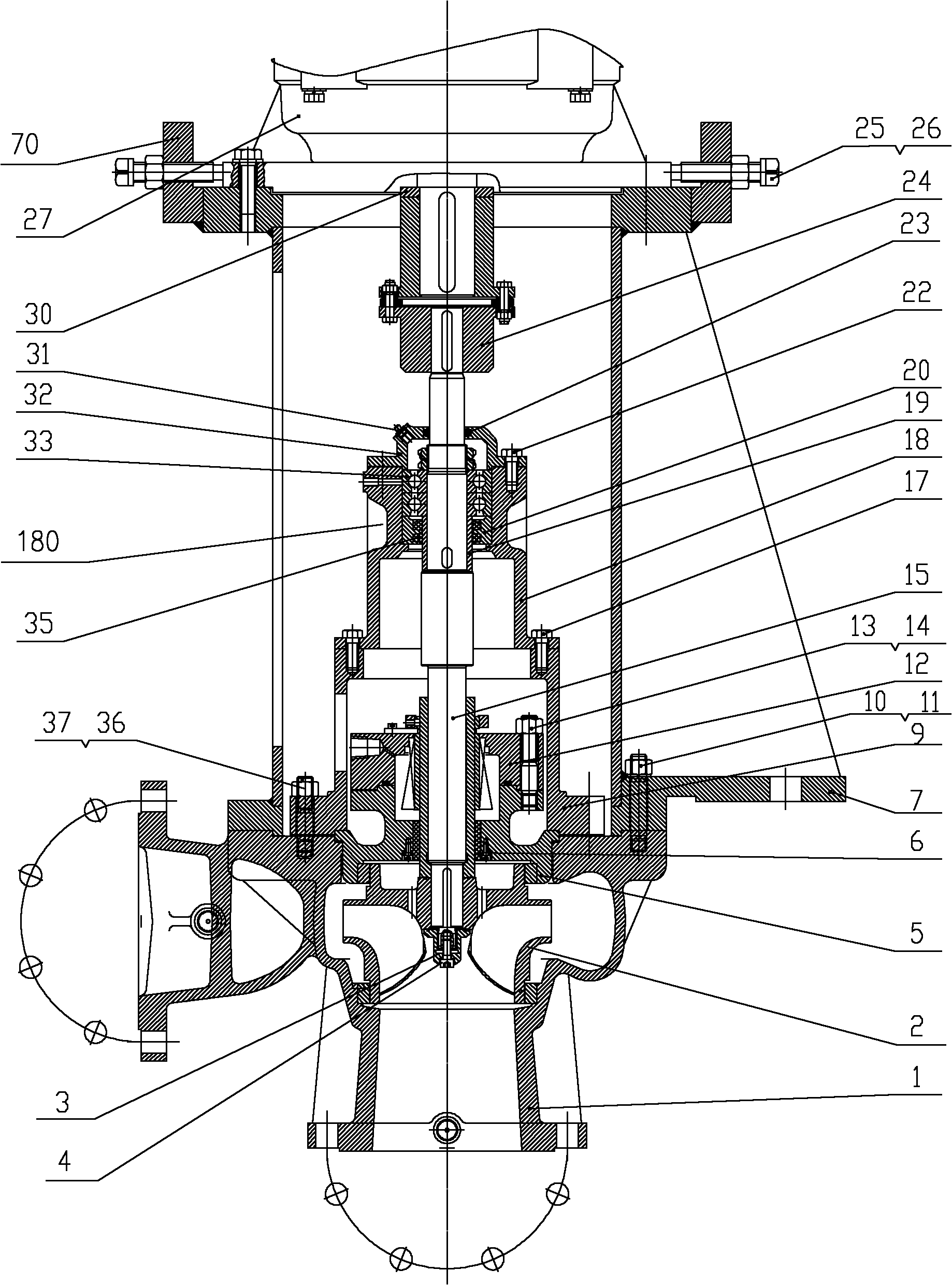

[0019] see figure 1 , the circulating water filtration system backwash pump for nuclear power plants of the present invention is a single-stage single-suction vertical centrifugal pump, which includes a stator assembly, a rotor assembly, a bearing assembly, a shaft seal assembly and a motor.

[0020] The stator assembly includes a pump body 1, a pump cover 5, a bearing bracket, and a motor frame 7, wherein the pump body 1 is a radially split double volute structure; the bearing bracket is composed of an intermediate bracket 9 and a bearing body 18, which is convenient for pumping. internal inspection and maintenance; the intermediate support 9 is connected to the upper end of the pump body 1 through twelve AM16×70 studs 36 and nuts 37, and the bearing body 18 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com