Patents

Literature

335results about How to "Improve hydraulic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

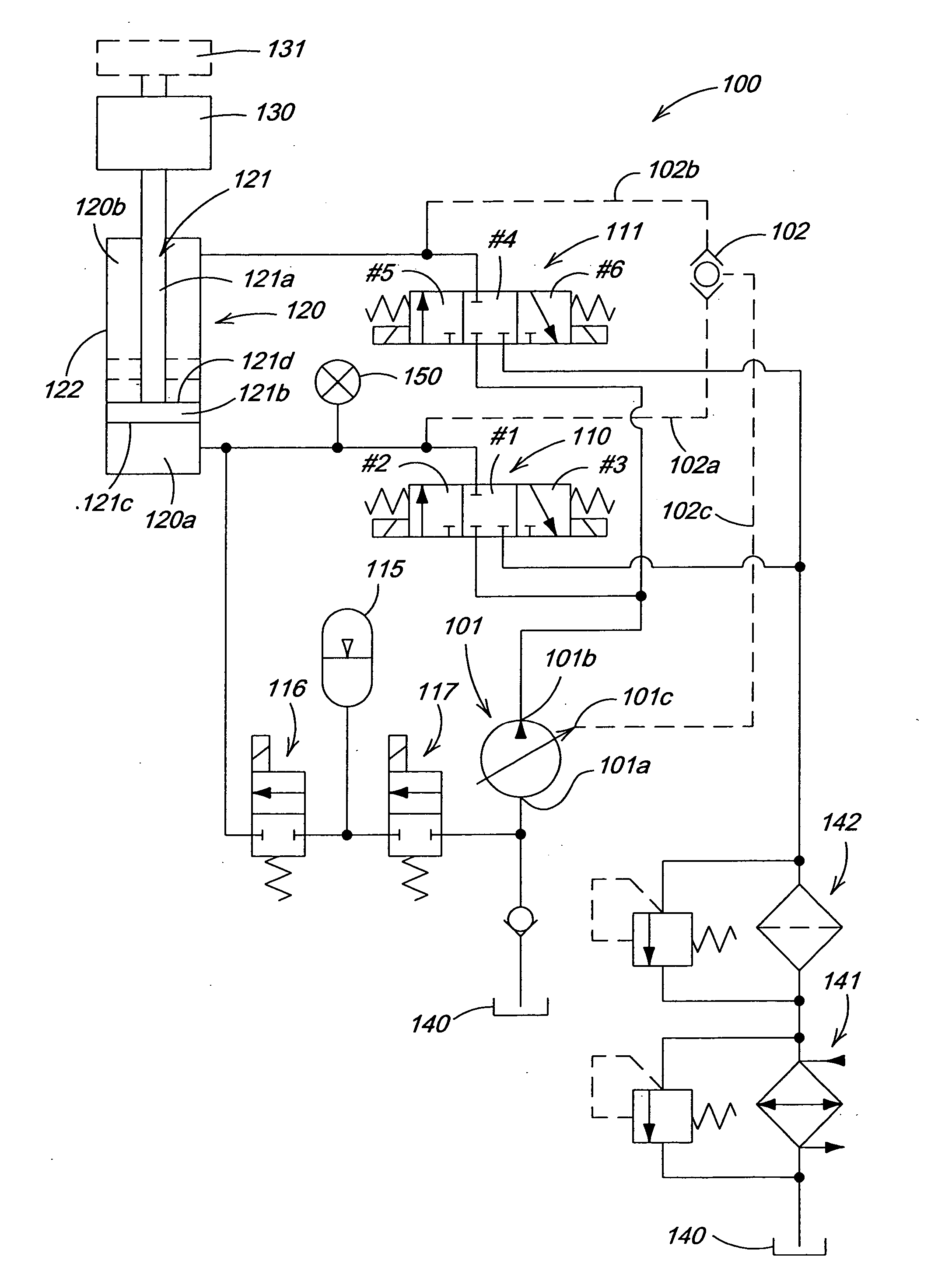

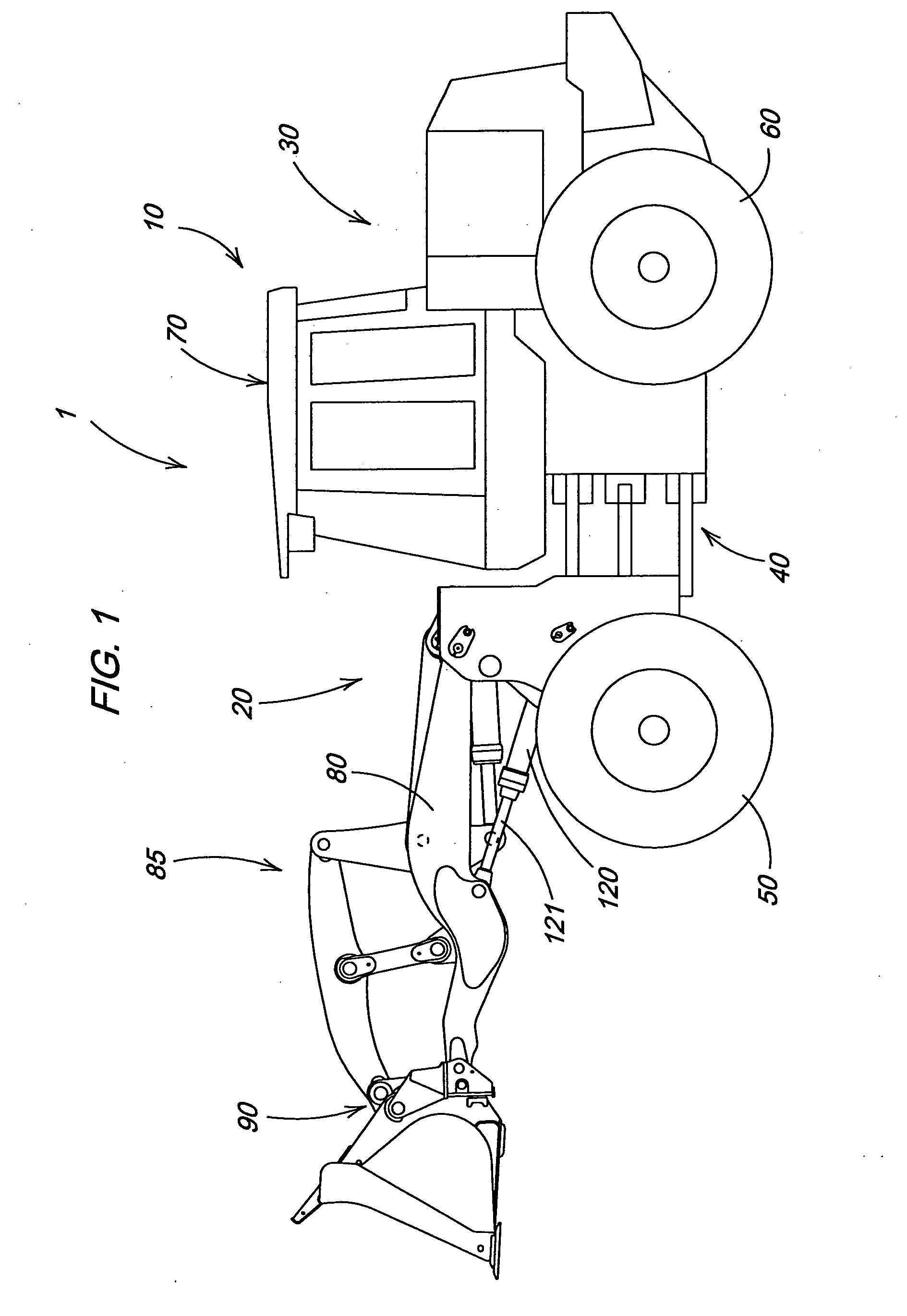

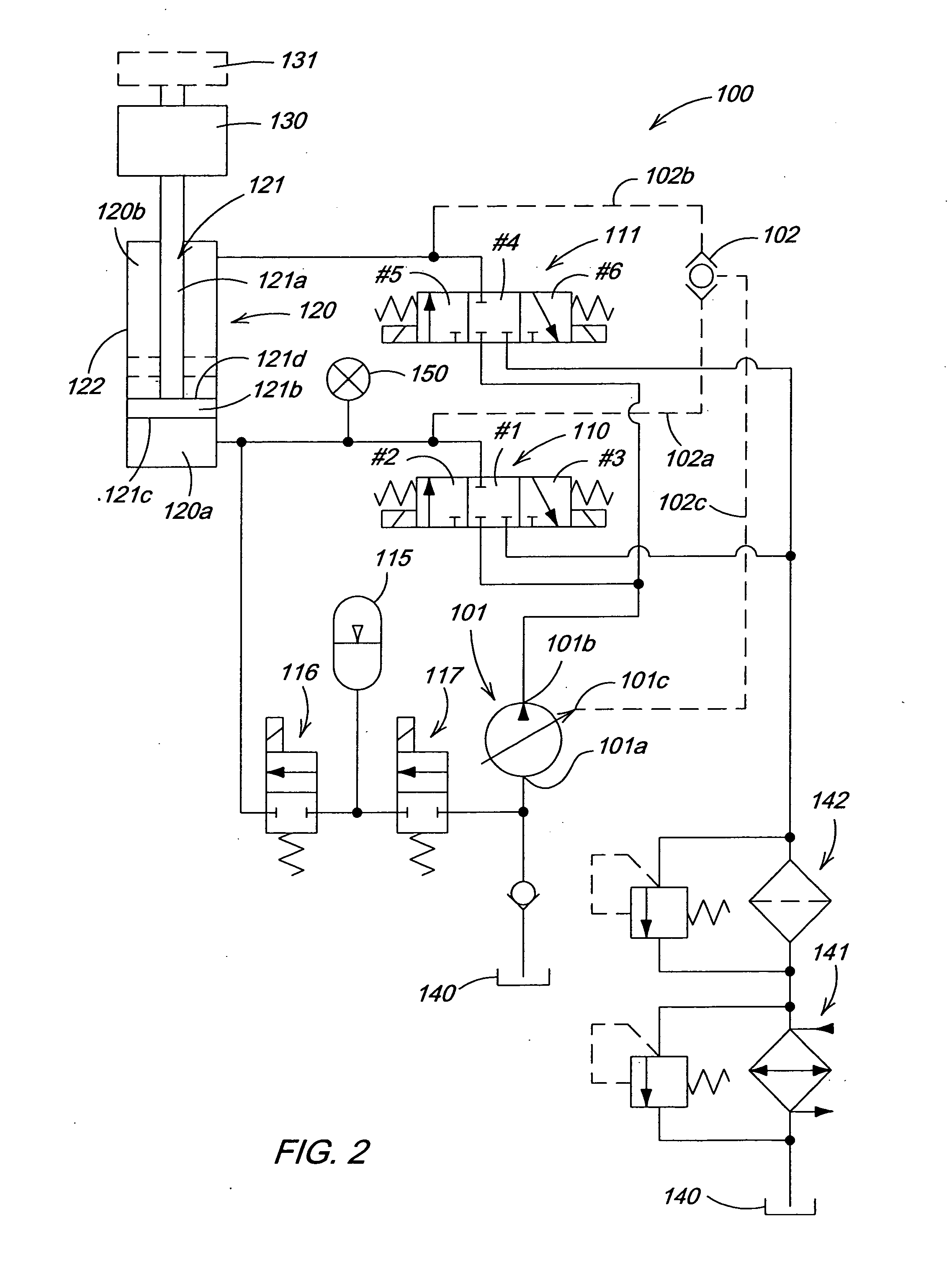

Hydraulic energy intensifier

InactiveUS20060075749A1Reduce energy loadHigh energyFluid couplingsAccumulator installationsHydraulic cylinderStored energy

Hydraulic circuits used to manipulate tools in, for example construction equipment, uses less power for a retraction of a hydraulic cylinder than for an extension of that cylinder. Provided is a hydraulic circuit that uses the stored energy from the low energy phase to lower the energy load on the hydraulic pump during the high energy phase. Energy from the hydraulic pump is increased during the low energy phase to increase the amount of stored hydraulic energy. The increased amount of stored energy is then used to intensify or add to the energy generated by the hydraulic pump for the high energy phase.

Owner:DEERE & CO

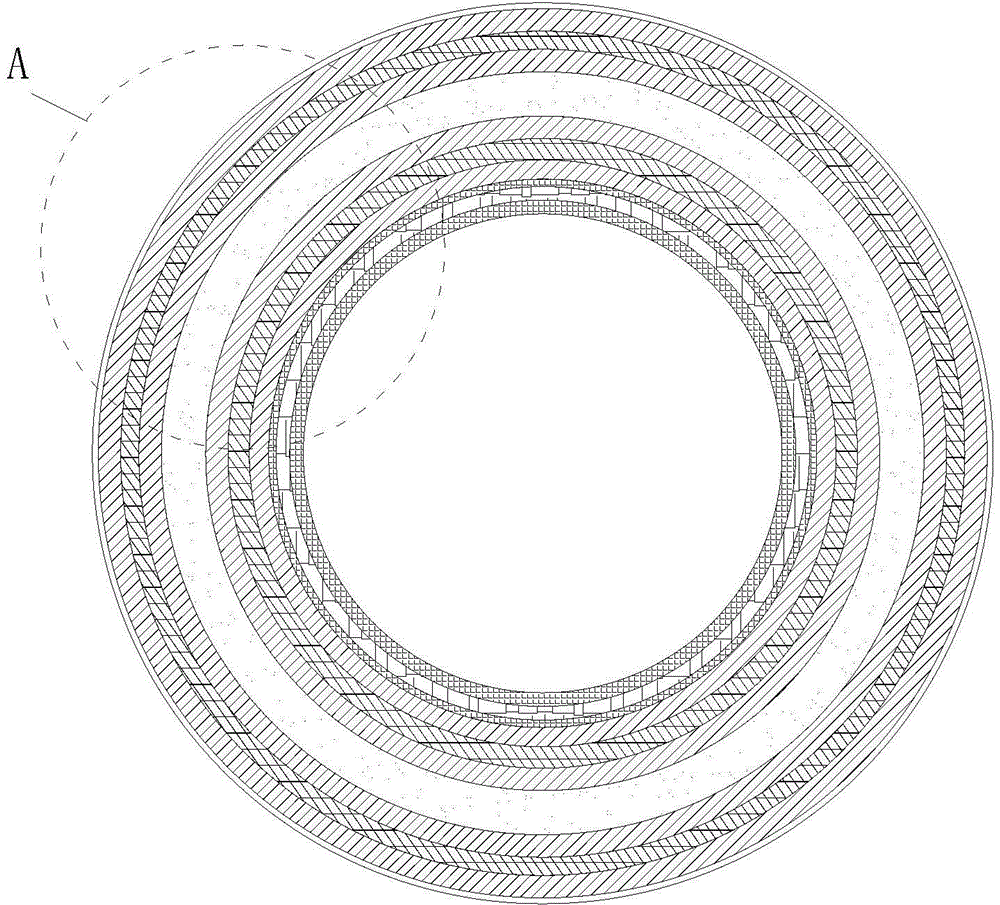

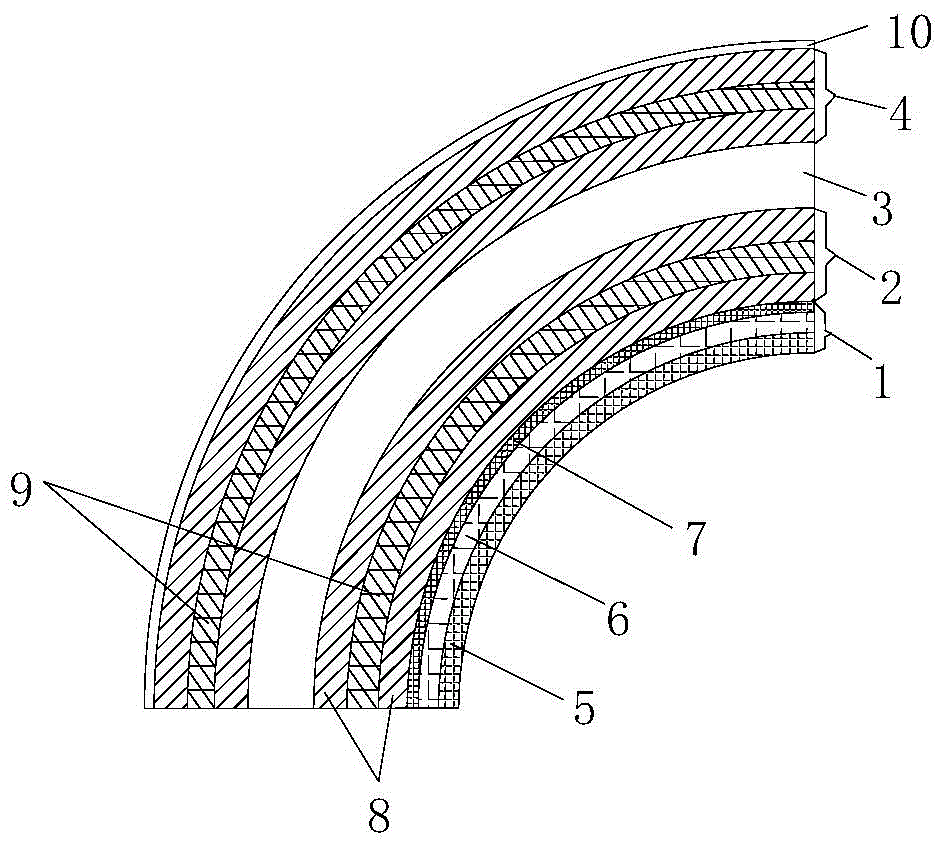

High-strength glass fiber-reinforced plastic pipeline and production method thereof

The invention discloses a high-strength glass fiber reinforced plastic pipeline and a production method thereof, and belongs to the technical field of glass fiber reinforced plastic pipelines and production methods thereof. The high-strength glass fiber reinforced plastic pipeline is a circular pipeline, and is characterized by comprising a lining layer, an inner structural layer, a middle sand inclusion layer and an outer structural layer, wherein the lining layer is formed by soaking and bonding a glass fiber surface felt layer, a glass fiber knitted felt layer and a grid cloth layer in sequence through lining resin from inside to outside; the inner structural layer and the outer structural layer are constructed by one or more glass fiber yarn annular winding layers and one or more glass fiber yarn crossed winding layers; the annular winding layers and the crossed winding layers are formed at intervals; the middle sand inclusion layer consists of upper layer sand inclusion cloth, lower layer sand inclusion cloth and a sand material compressed and clamped between the upper layer sand inclusion cloth and the lower layer sand inclusion cloth; the sand material is formed by mixing quartz sand and sand adhesion resin. The pipeline has the advantages of high compressive strength, high axial tensile strength, large pipe diameter span, light weight, high hydraulic performance, freeness from scaling, insulation, flame retardance and corrosion resistance.

Owner:HUNAN XIAOXIANGYUAN TECH DEV

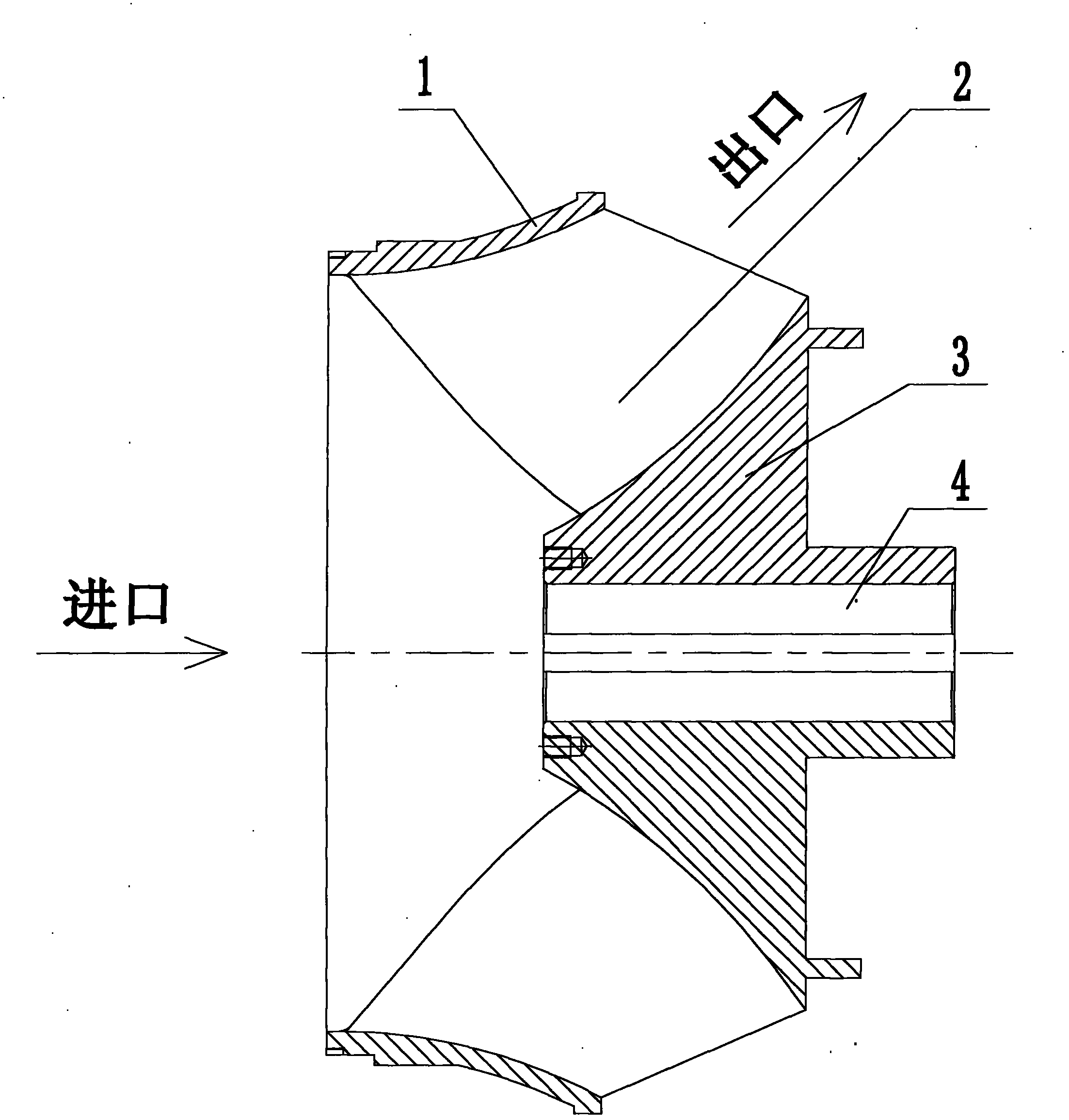

CFD (Computational Fluid Dynamics)-based modeling design method for nuclear main pump and designed million-kilowatt-grade nuclear main pump impeller

InactiveCN102207101AEasy to chooseImprove hydraulic performancePump componentsPumpsImpellerConversion coefficients

The invention discloses a CFD (Computational Fluid Dynamics)-based modeling design method for a nuclear main pump and a designed million-kilowatt-grade nuclear main pump impeller, belonging to the technical fields of design and manufacture of pumps. The CFD-based modeling design method for the nuclear main pump is characterized by comprising four steps of: 1, selecting a model pump impeller satisfying similar conditions with a pre-designed pump impeller according to the design parameters of a million-kilowatt-grade nuclear main pump; 2, calculating size conversion coefficients by utilizing a conventional modeling design formula, and selecting 3-4 different size coefficients within a certain range to convert the model pump impeller; 3, carrying out numerical simulation respectively on the 3-4 pump impellers obtained in the step 2, and carrying out logarithm fitting on a relation between the size coefficients and delivery lift to obtain the nuclear main pump impeller meeting requirements; and 4, optimizing the nuclear main pump impeller obtained in the step 3 to complete the design. The invention has the advantages that the design problem of the high-temperature and high-pressure large-flow million-kilowatt-grade nuclear main pump is solved, and a design process is concise, efficient and controllable.

Owner:DALIAN UNIV OF TECH

Chemical reactor system and process

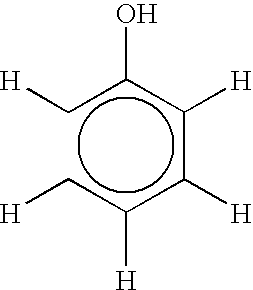

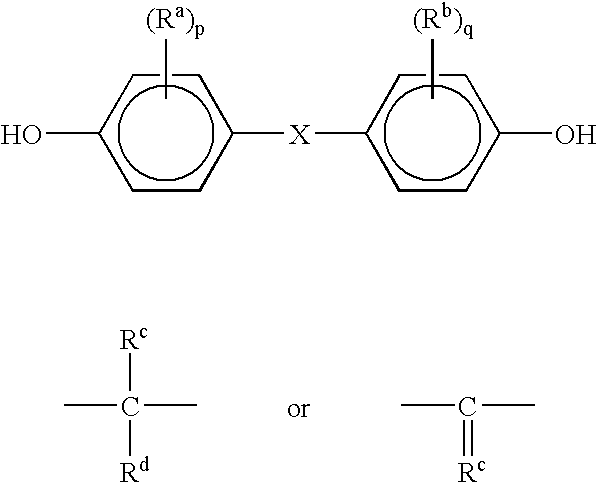

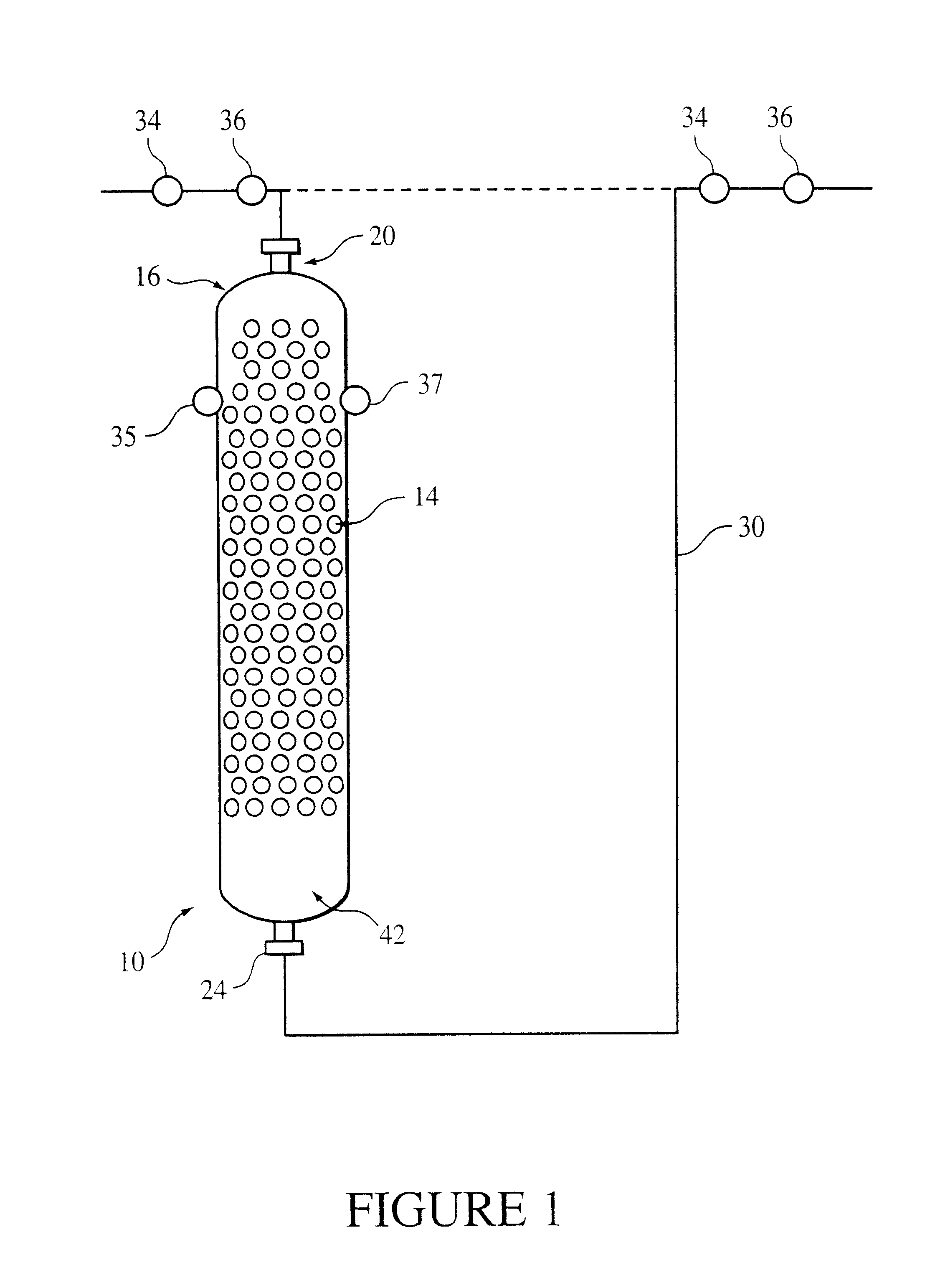

InactiveUS6703530B2Large effective void fractionLower overall pressure dropOrganic compound preparationOrganic chemistry methodsReactor systemChemical reactor

A method for producing bisphenol includes introducing a phenol and a ketone into a fixed, supported catalytic bed reactor system in a downflow mode, reacting the phenol and the ketone to form a reaction mixture, and recovering the bisphenol isomer from the reaction mixture. The preferred bisphenol isomer is bisphenol A, or p,p'-bisphenol A, produced from the reaction of phenol and acetone. The reactor for producing the bisphenol A from the reaction of phenol and acetone includes an ion exchange resin catalyst disposed in a bed and packing randomly distributed throughout the ion exchange resin catalyst to improve heat transfer efficiency and reduce compression of the catalyst bed.

Owner:SABIC GLOBAL TECH BV

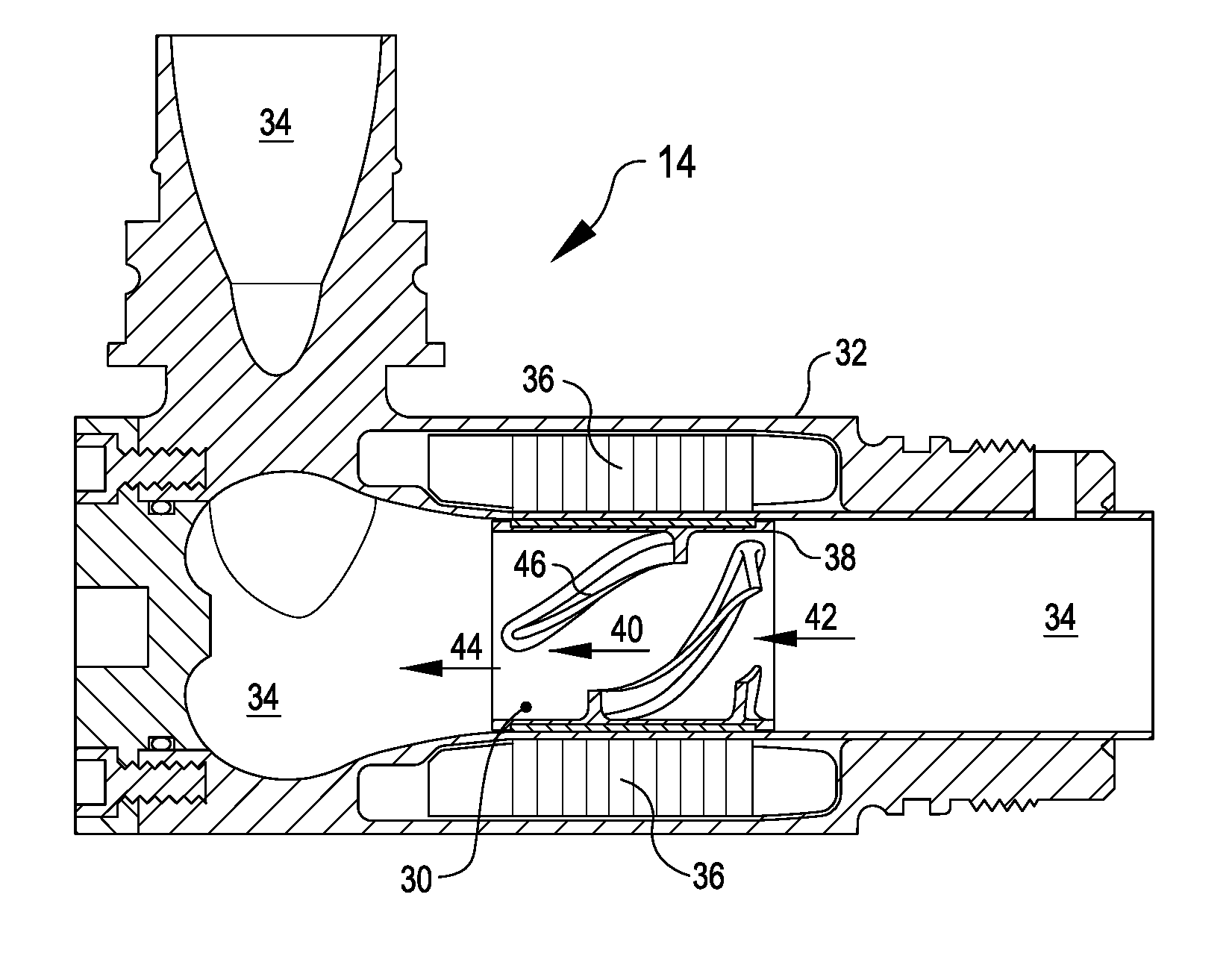

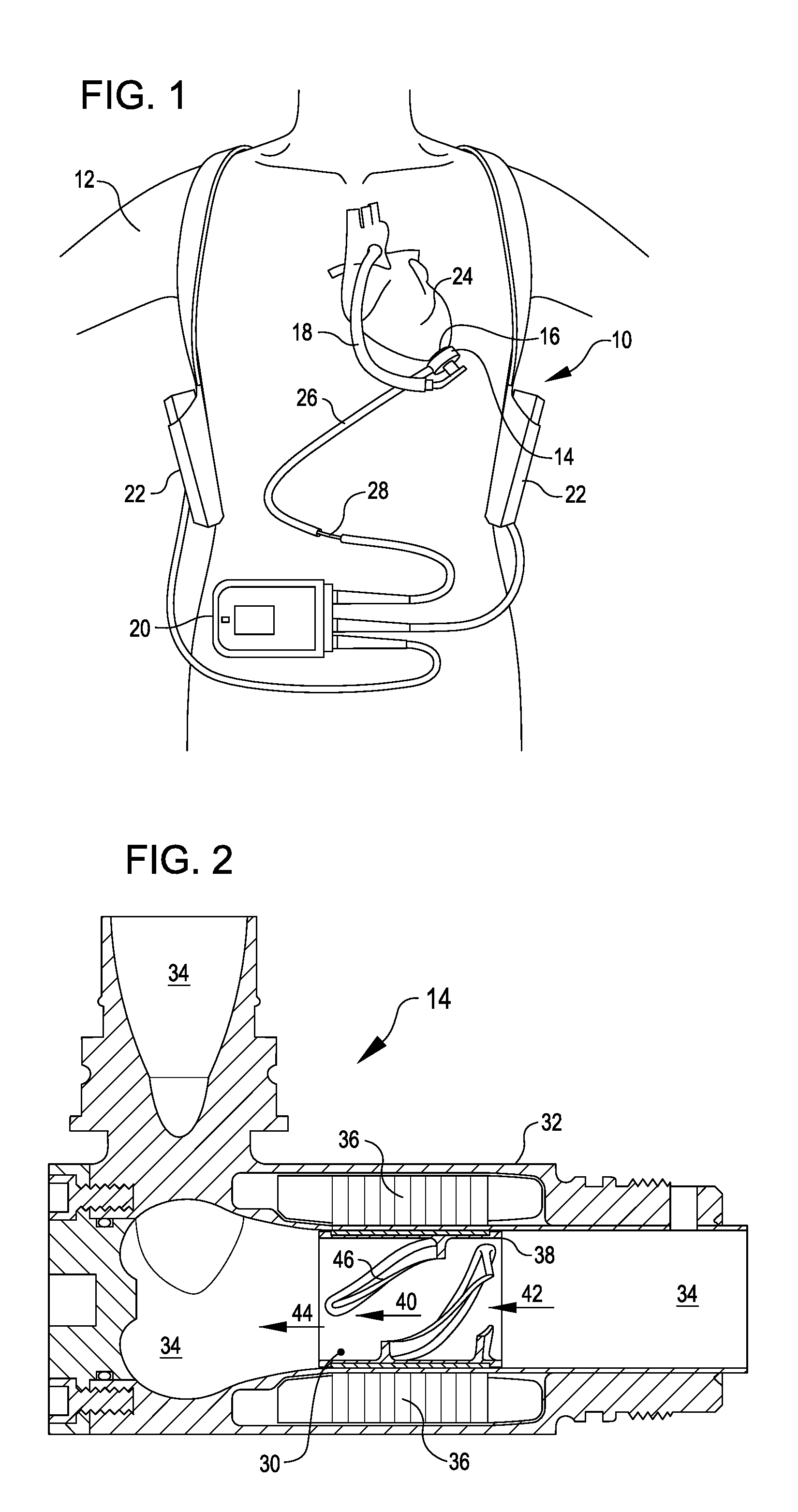

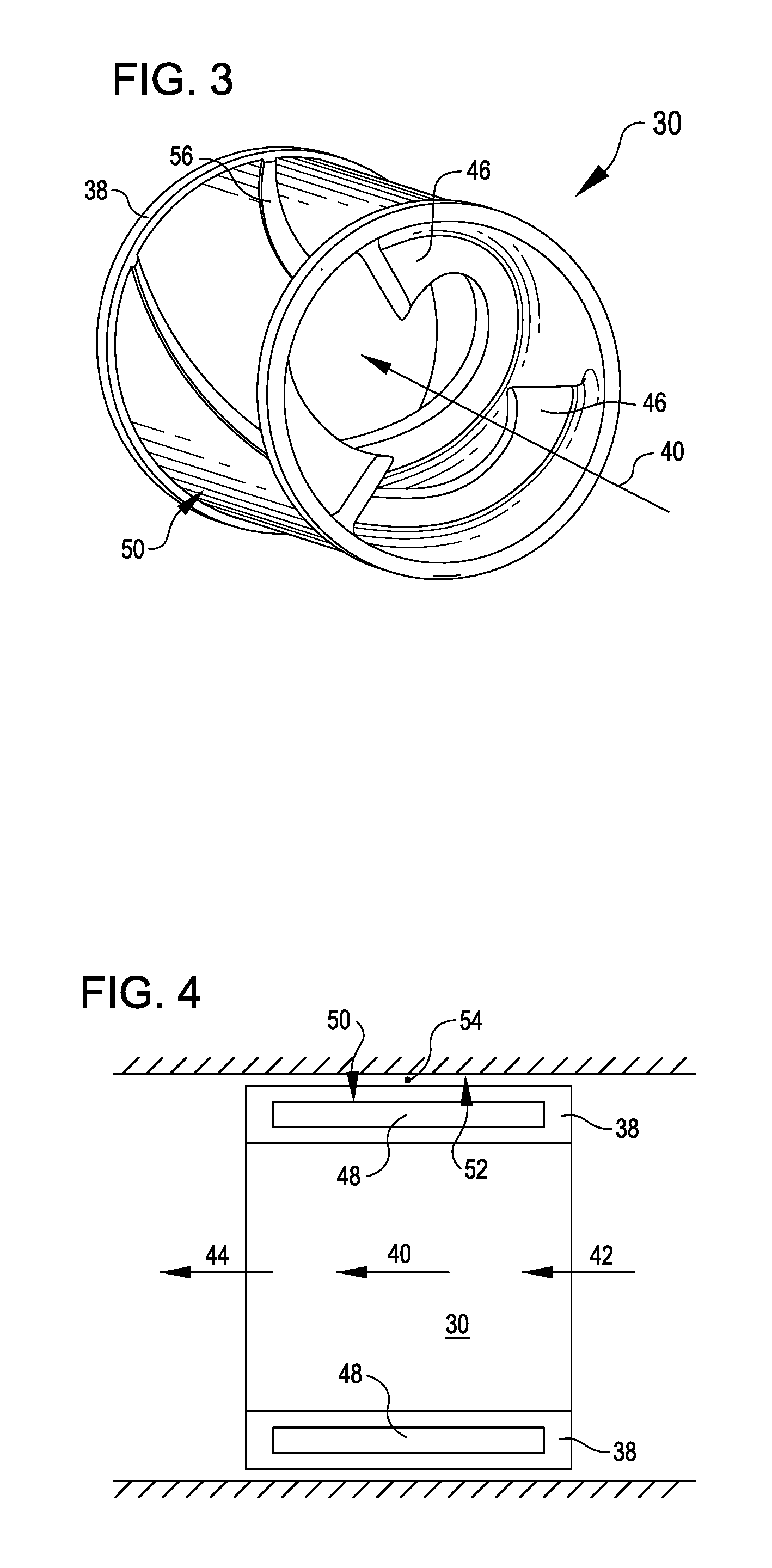

Ventricular assist devices having a hollow rotor and methods of use

ActiveUS20160375187A1Improve hydraulic performanceHemolysis rateControl devicesBlood pumpsBlood pumpEngineering

Blood pumps for ventricular assist devices employ a hollow rotor to impel blood through the blood pump. A blood pump includes a housing having a housing inlet, a housing outlet, and a housing blood flow channel through which the housing inlet and the housing outlet are in fluid communication. A motor stator is disposed around the housing blood flow channel and operable to generate a rotating magnetic field. A hollow rotor is disposed within the housing blood flow channel and rotated via the rotating magnetic field. The hollow rotor has a rotor circumferential wall enclosing a rotor blood flow channel. The hollow rotor has at least one rotor blade extending inwardly from the rotor circumferential wall. The at least one rotor blade is configured to impel blood through the rotor blood flow channel when the hollow rotor is rotated via the rotating magnetic field.

Owner:TC1 LLC

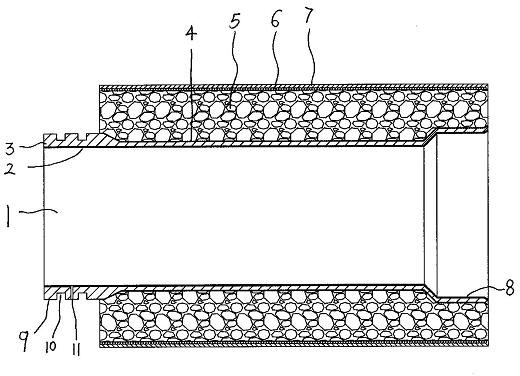

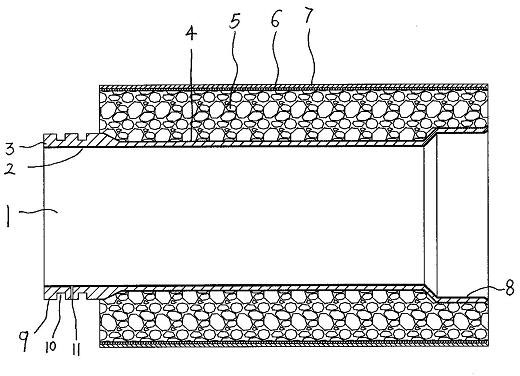

Prestressed concrete glass reinforced plastic composite pipe and preparation method thereof

The invention belongs to the technical field of water supply and drainage pipelines, and discloses a prestressed concrete glass reinforced plastic composite pipe and a preparation method thereof. The composite pipe is mainly technically characterized by comprising a pipe body, wherein the pipe body consists of a glass reinforced plastic lining layer, a glass reinforced plastic structural layer, a transition layer, a concrete structural layer, a glass reinforced plastic rib winding layer and an outer protective layer from inside to outside; the right ends of the glass reinforced plastic lining layer and the glass reinforced plastic structural layer are provided with sockets, and the left ends of the glass reinforced plastic lining layer and the glass reinforced plastic structural layer are provided with spigots; the outer wall of the glass reinforced plastic structural layer is coated with resin quartz sand granules except the spigot part to form the transition layer; the outer wall of the transition layer is cast with the concrete structural layer; the outer wall of the concrete structural layer is wound with the glass reinforced plastic rib winding layer; and the outer wall of the glass reinforced plastic rib winding layer is provided with the outer protective layer. The prestressed concrete glass reinforced plastic composite pipe has the characteristics of high rigidity, and good strength, corrosion resistance and hydraulic performance.

Owner:WUHAN UNIV OF TECH +1

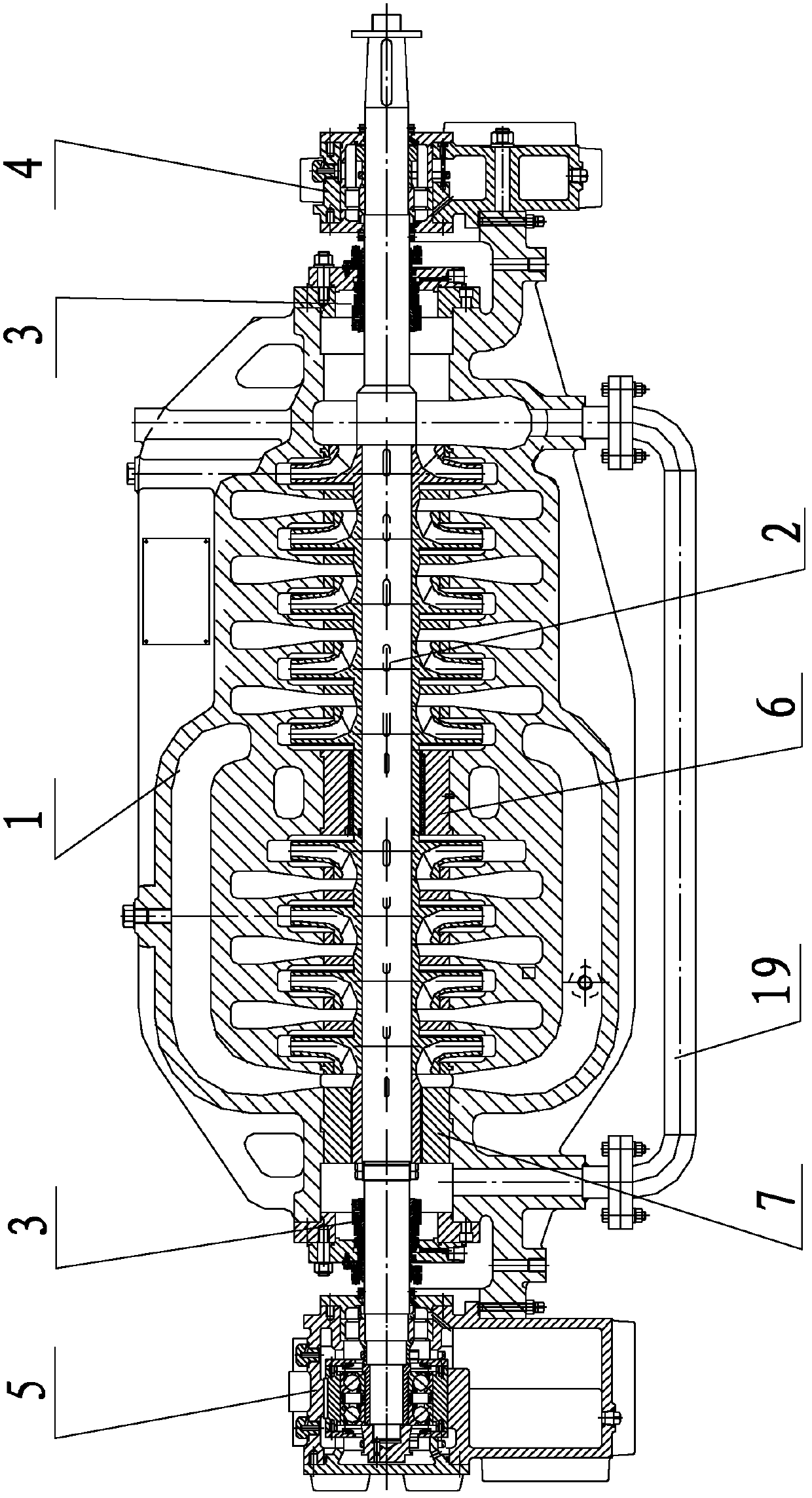

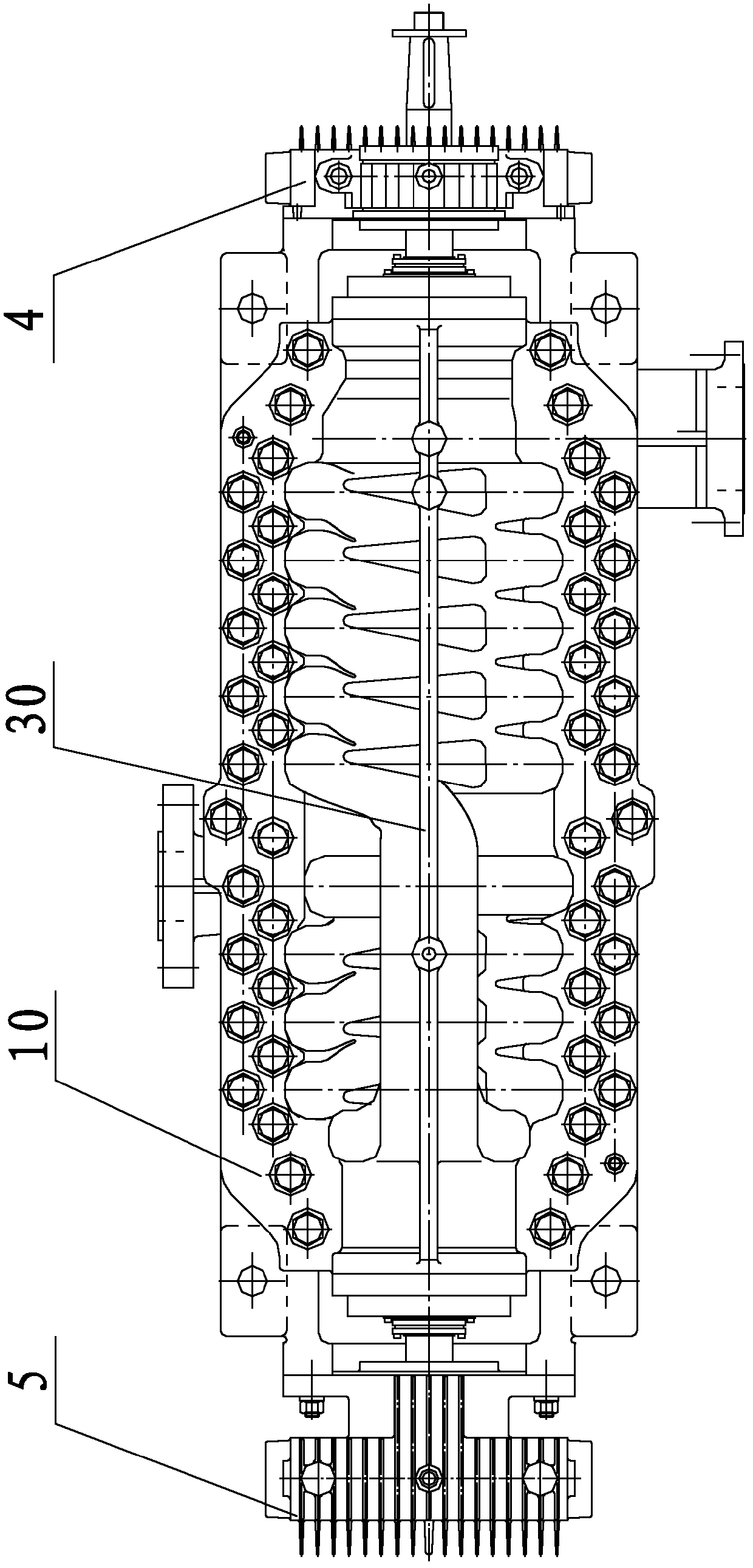

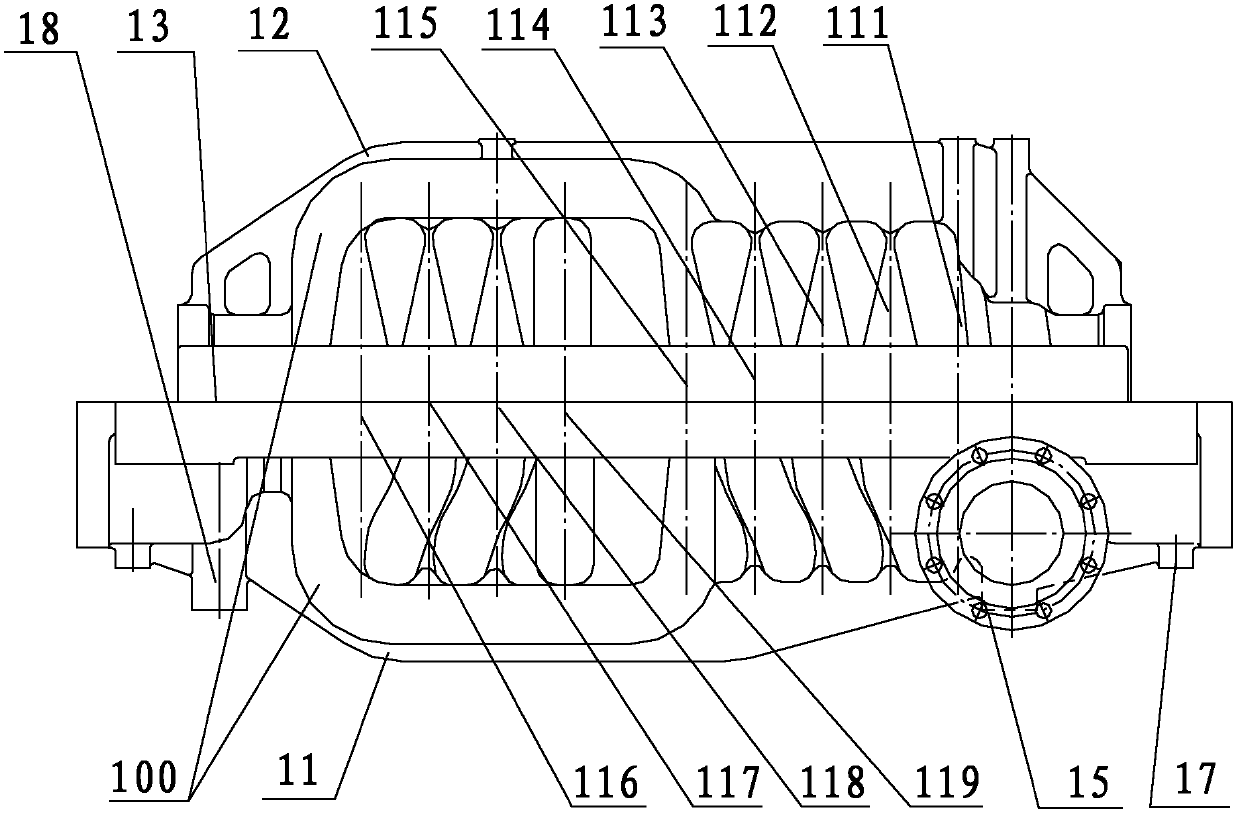

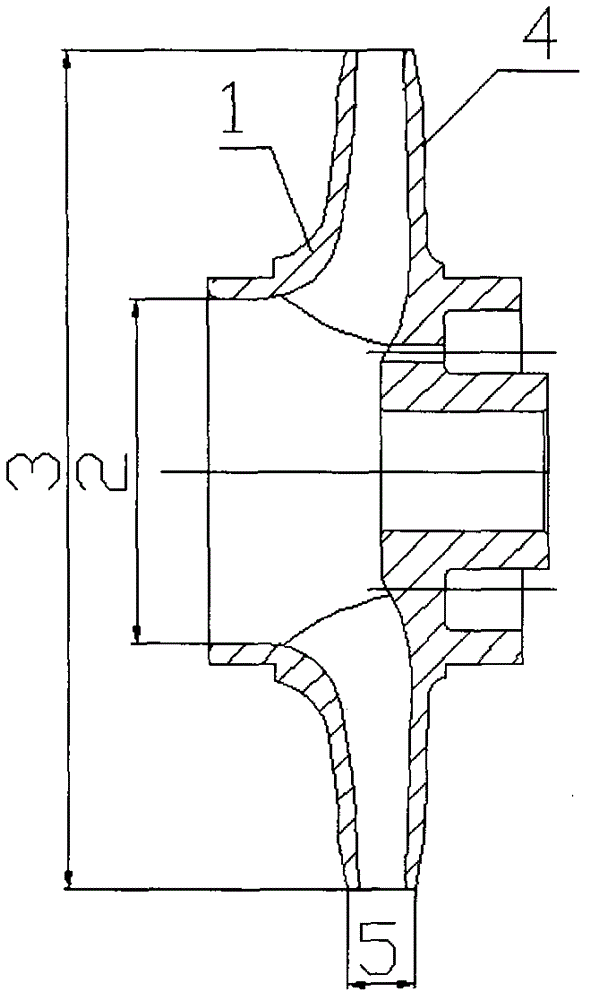

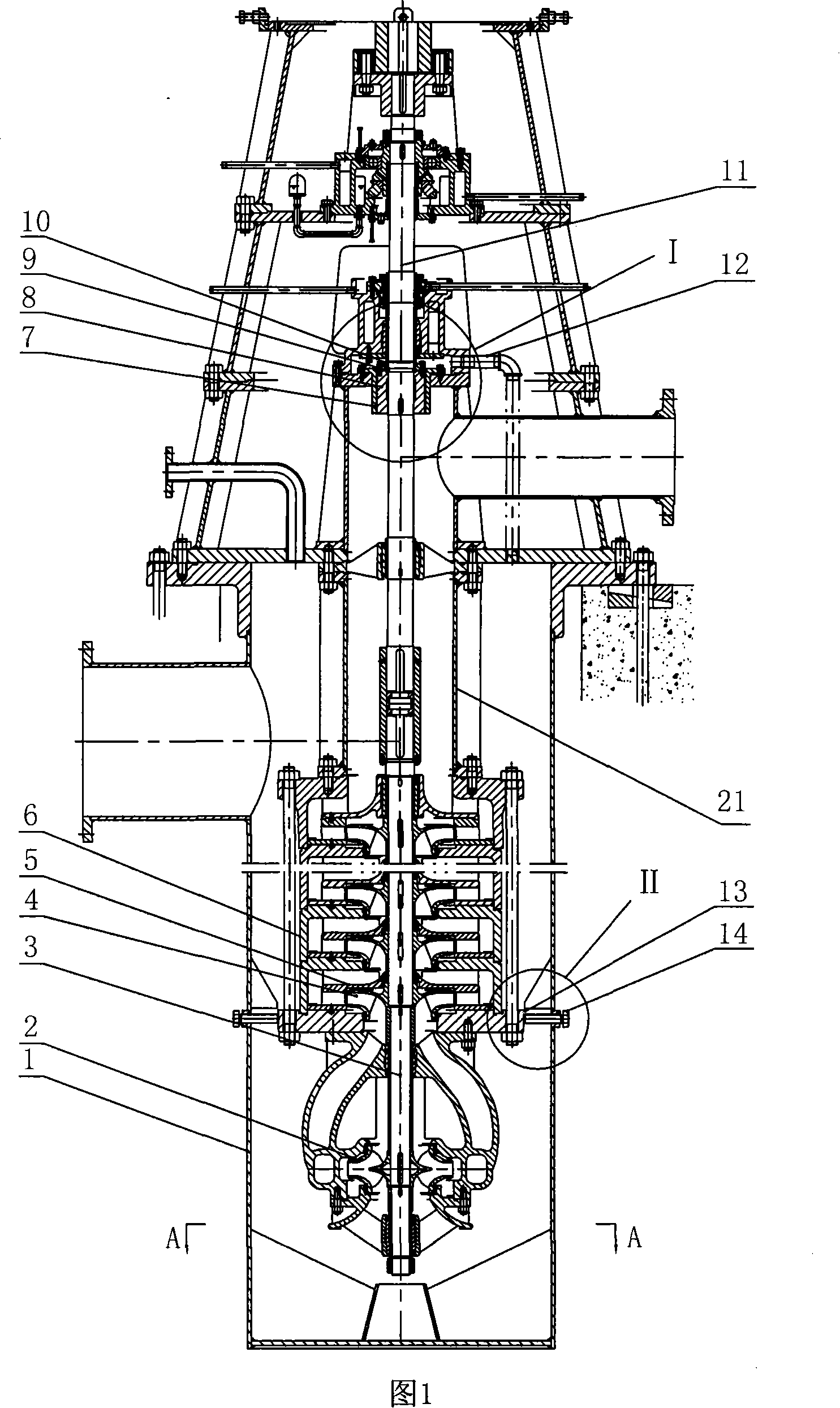

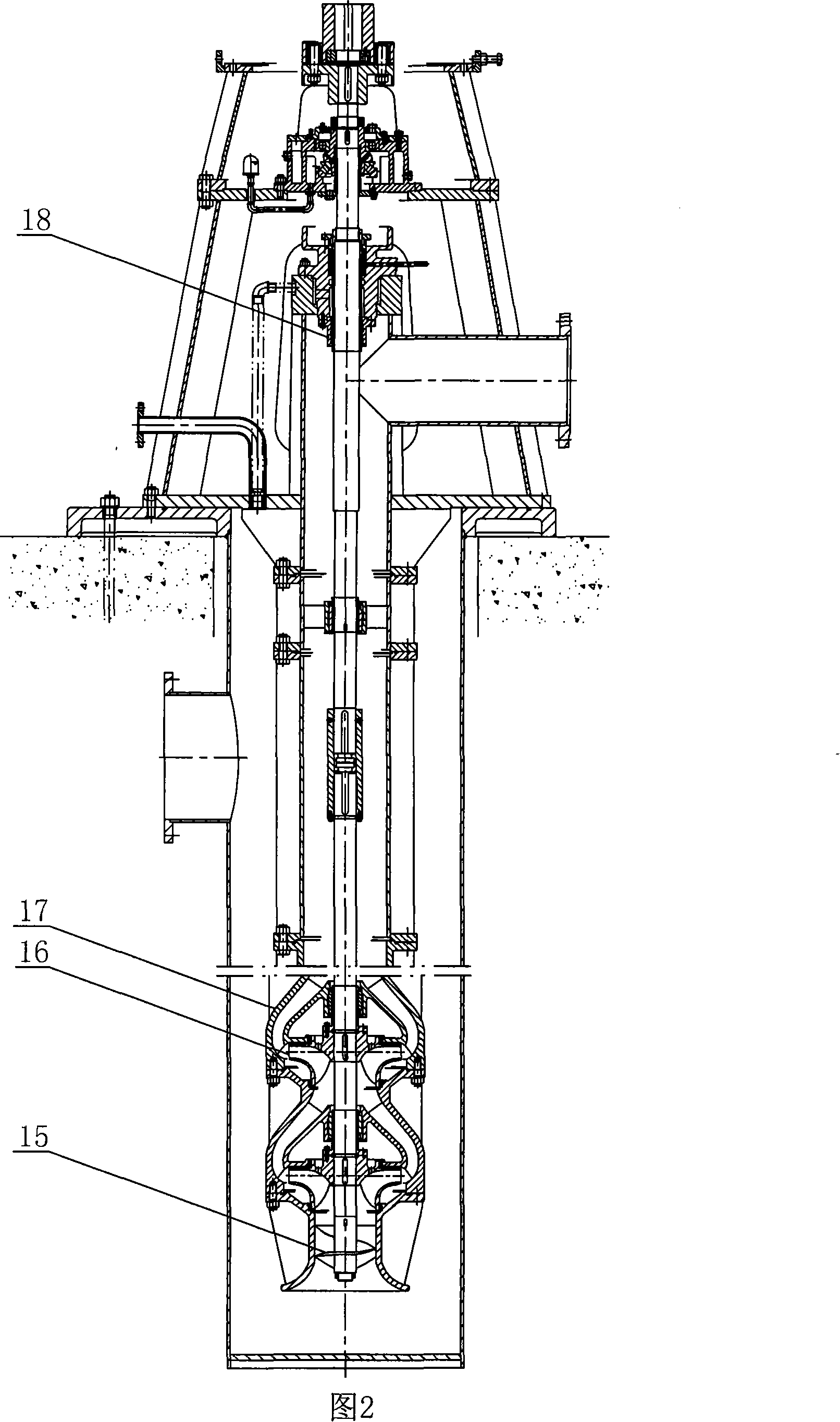

Startup water feed pump for nuclear power station

ActiveCN102606485ASimple structureGood hydraulic performancePump componentsRadial flow pumpsImpellerPump chamber

The invention discloses a startup water feed pump for a nuclear power station, which comprises a stator component, a rotor component, two sets of mechanism seals, a mechanism sealing washing tube and a bearing component. The rotor component comprises a pump body and a balance water pipe, the rotor component comprises a pump shaft, an impeller, a middle sealing shaft sleeve, a rear sealing shaft sleeve and a shaft sleeve nut, and the bearing component comprises a front bearing, a rear bearing, a middle throttling bush and a rear throttling bush. The pump body is of an axial section structure and is divided into a lower pump body at the lower portion and an upper pump cover at the upper portion through a horizontal split, the lower pump body and the upper pimp cover are integrally connected through a plurality of press bolts, and an inner cavity of the pump body comprises a low pressure zone containing a first water pumping chamber, a second water pumping chamber, a third water pumping chamber, a fourth water pumping chamber and a fifth water pumping chamber and a high pressure zone containing a sixth water pumping chamber, a seventh water pumping chamber, an eighth water pumping chamber and a ninth water pumping chamber. The balance water pipe is connected between an inlet and an outlet which are arranged at the front portion and the rear portion of the pump body, the impeller is composed of nine levels of impellers, the two sets of mechanical seals are respectively arranged at the front end and the rear end of the pump body, and the mechanical sealing washing pipe is led out of an outlet of the first water pumping chamber to be respectively connected on the two sets of mechanical seals.

Owner:SHANGHAI APOLLO MACHINERY

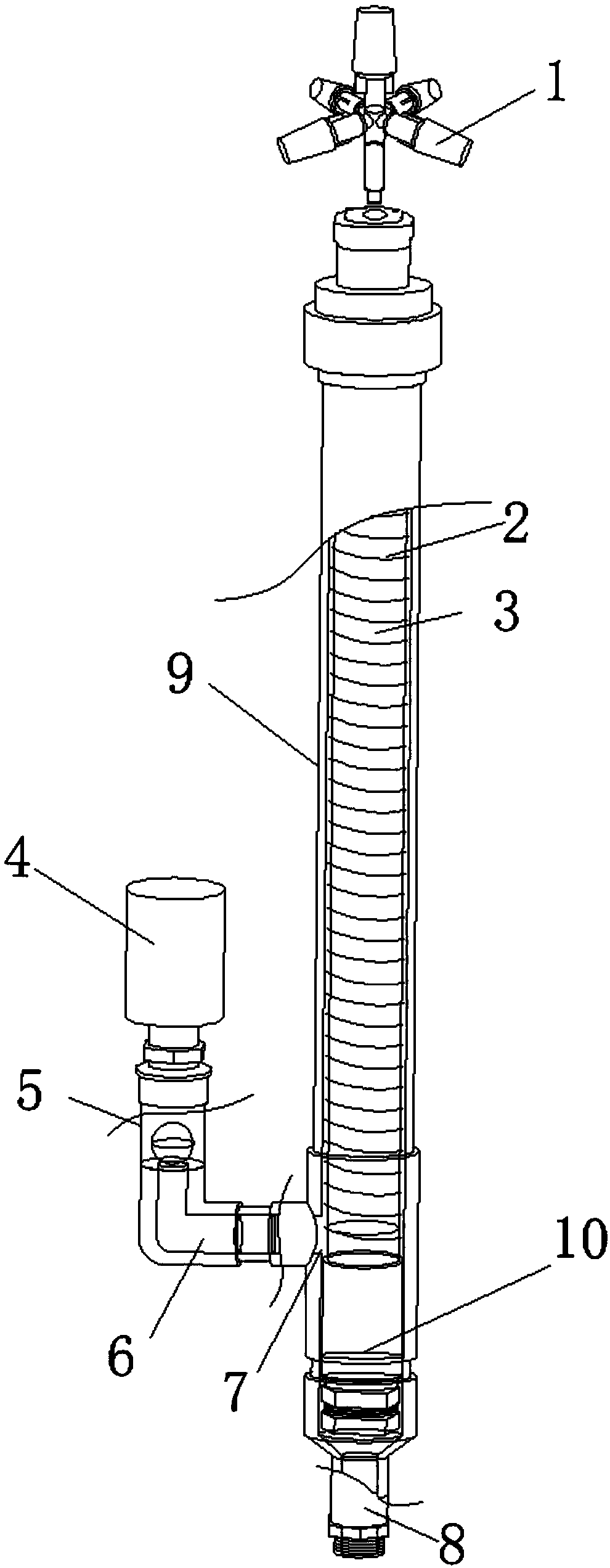

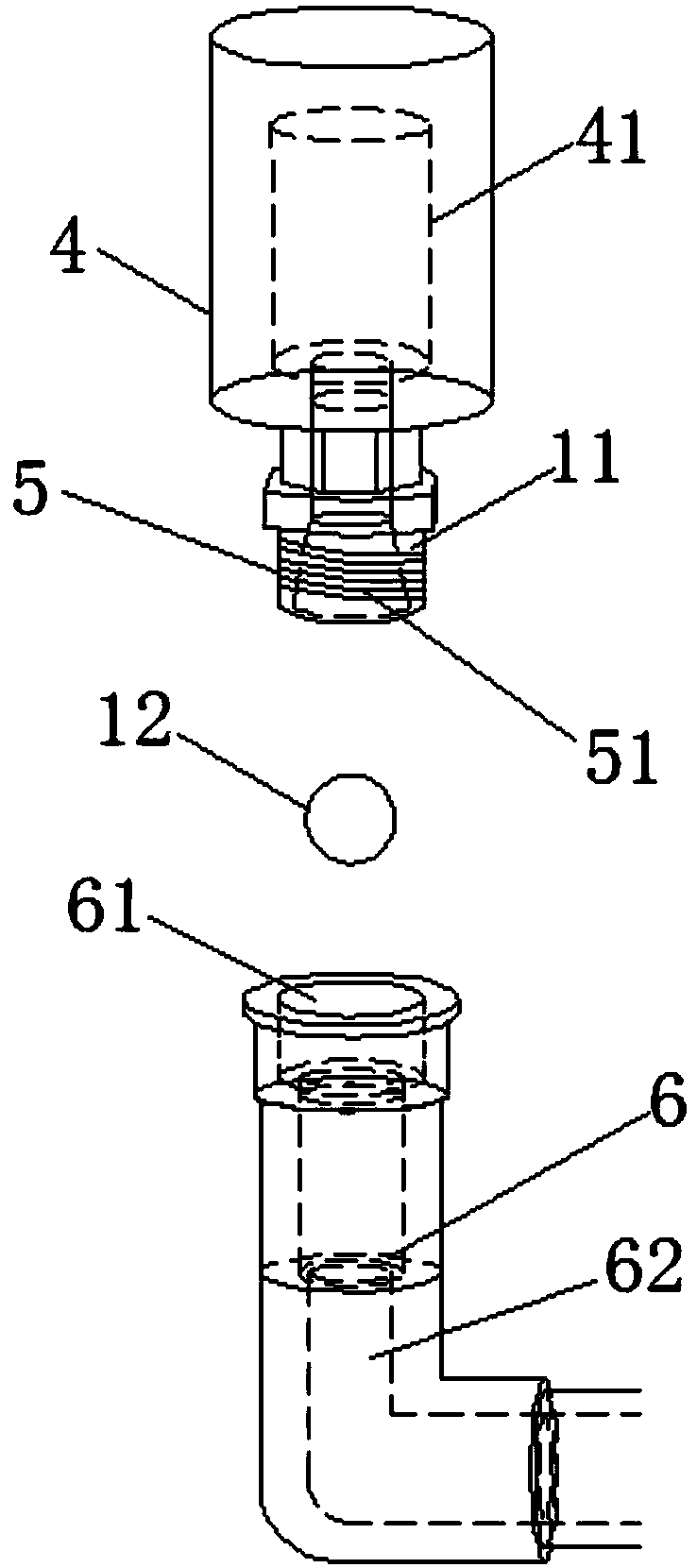

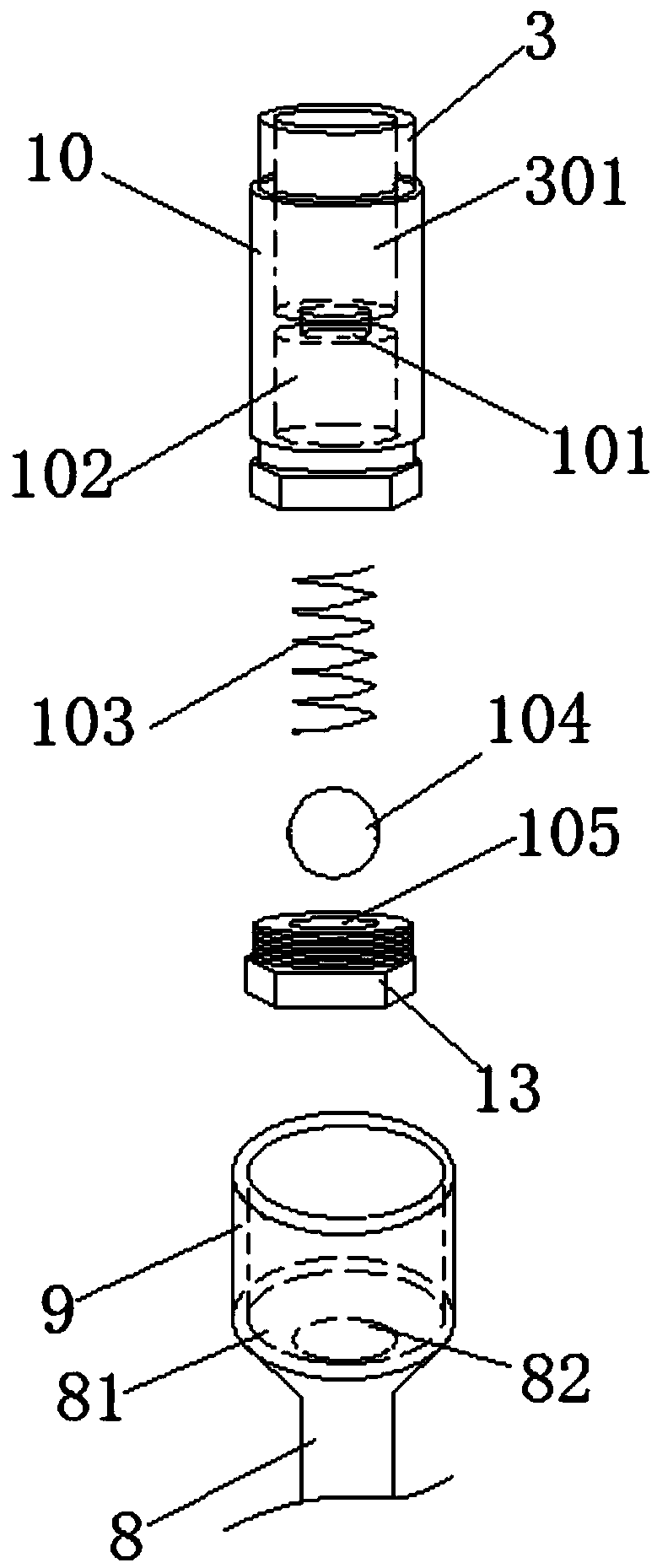

Ceramic root irrigation and microspray irrigation complemented irrigating device

ActiveCN109258409AEasy accessMeet irrigation water requirementsClimate change adaptationWatering devicesDrip irrigationWater flow

The invention discloses a ceramic root irrigation and microspray irrigation complemented irrigating device. The ceramic root irrigation and microspray irrigation complemented irrigating device comprises a tubular casing and a movable pipe, wherein the movable pipe is assembled in a slidingly sealing mode inside the casing, a gap is formed between the movable pipe and the casing, and the upper endof the movable pipe extends out of the casing and is provided with an atomizing nozzle; the side wall of the casing is connected with an irrigating unit through a by-pass pipe; the connected part between the irrigating unit and the by-pass pipe is provided with a first flow regulating valve, and the lower end of the movable pipe is provided with a second flow regulating valve; the opening degree of the first flow regulating valve and the second flow regulating valve is adjusted through water flow. Through a combined structure, the ceramic root irrigation and microspray irrigation complementedirrigating device combines spray irrigation and root irrigation within one irrigation device; by means of an internally arranged pressure compensating structure, a ceramic root irrigation and microspray irrigation combined manner can be applied to irrigation of different crops, so that the ceramic root irrigation and microspray irrigation complemented irrigating device can be high in utilization efficiency of irrigating water, simple in structure, good in hydraulic performance and high in channel blocking resistance.

Owner:NORTHWEST A & F UNIV

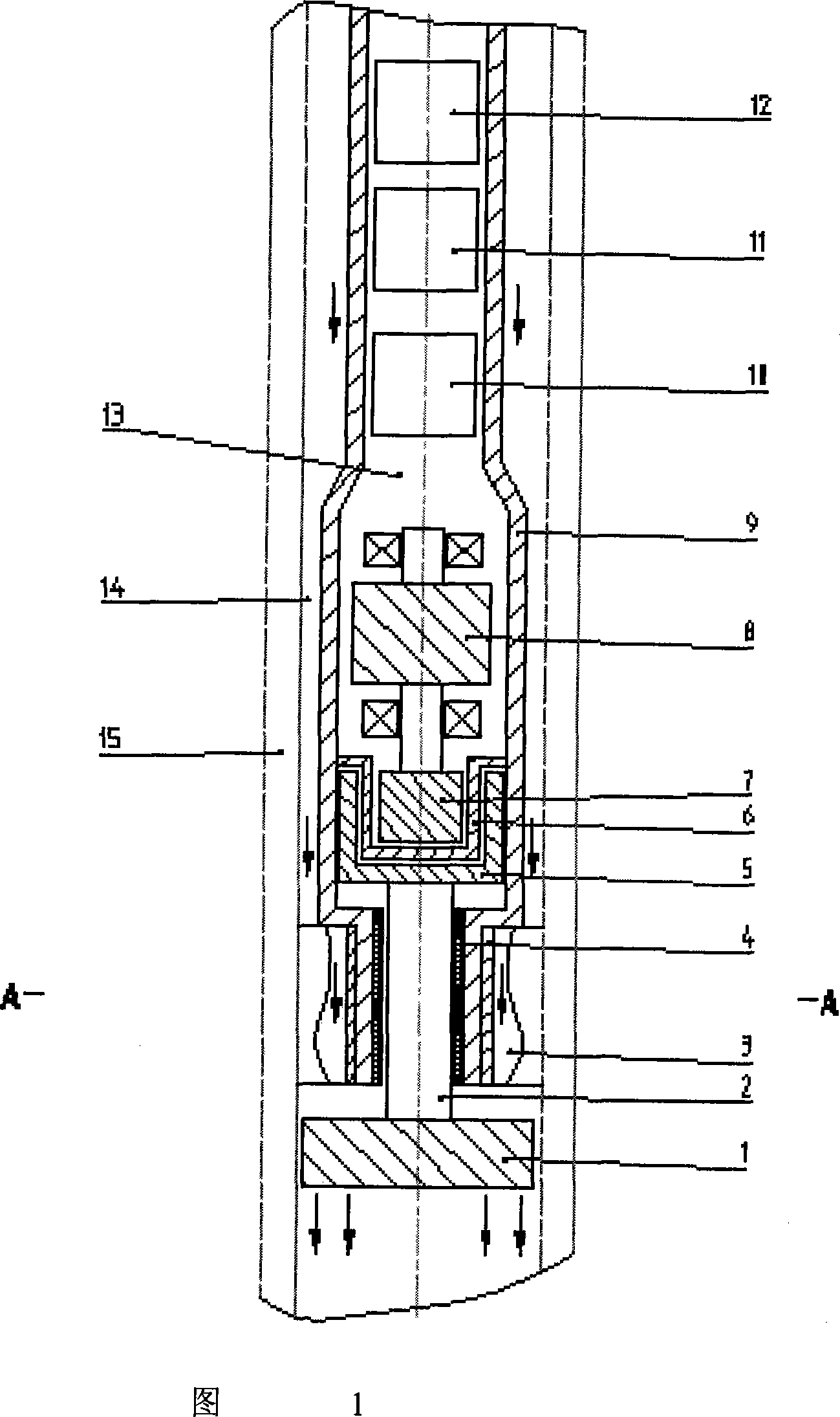

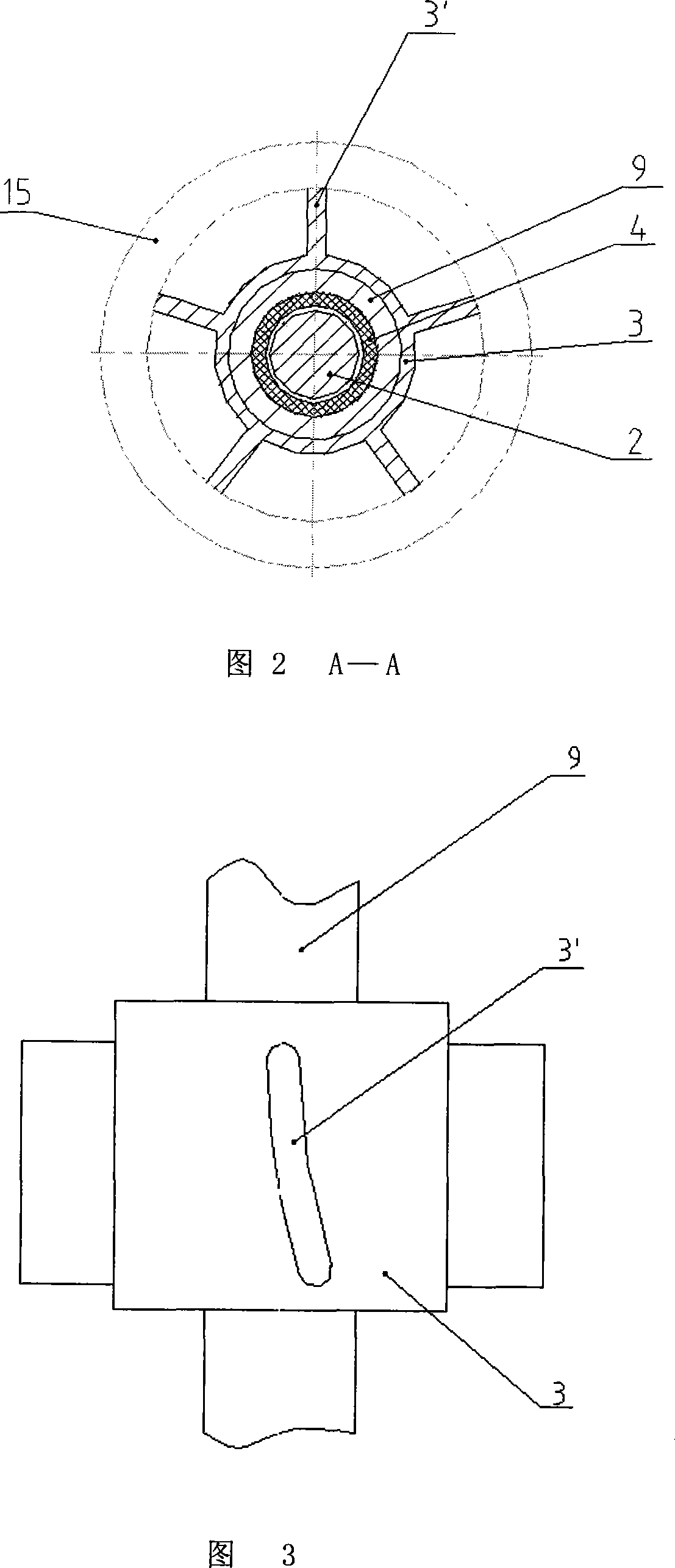

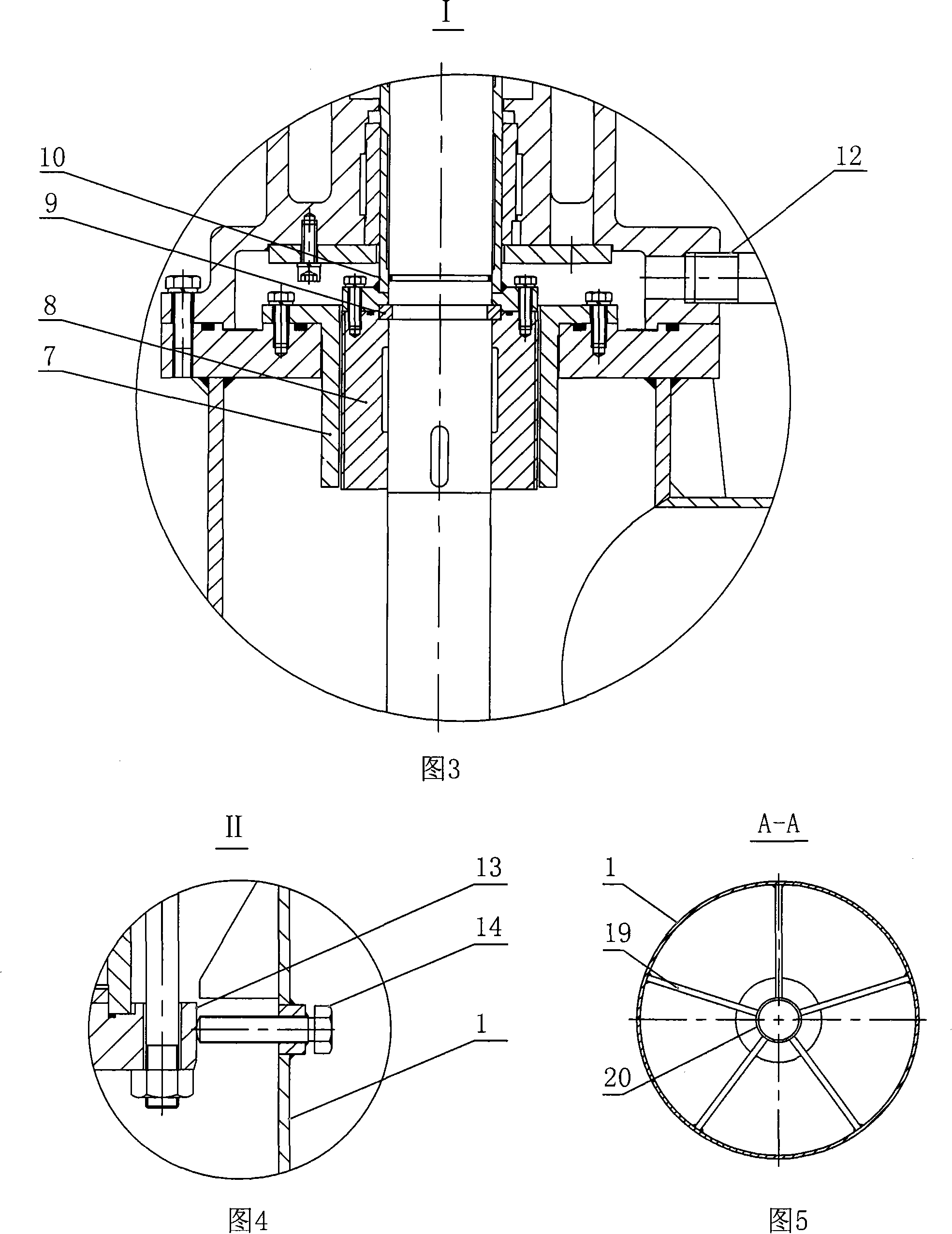

Slurry turbine alternating current generator

InactiveCN101126366AExtended service lifeGuaranteed flow rate and directionMachines/enginesEngine componentsElectric generatorInstrumentation

The invention relates to a mud turbo alternator, which is used for providing power supply for the drilling instruments in the mine and comprises a turbine, a turboshaft, a sliding bearing, a magnetic coupling outer magnet rotor, a shielding case, a magnetic coupling inner magnet rotor, a generator and a case; A guide pulley for guiding the mud is arranged above the turbine; the inner magnet rotor is arranged in the upper part of the magnetic coupling outer magnet rotor and is coaxially connected with the generator; the shielding case is arranged between the outer magnet rotor and the inner magnet rotor; A standby high-temperature battery which is used when the generator is in failure or the pump is stopped is arranged in the upper air cavity inside the case. The invention has the advantages that the device is the complete non-contact power transference, the complete static seal, the seal is safe and reliable, the hydraulic vibration is small, the pressure is even, the hydraulic performance of the worm wheel is good; additionally, the mud turbo alternator is provided with a standby battery, therefore,, the operation is stable and reliable, the service life of the generator is long and the technology capability is good and the cost is low.

Owner:武汉海阔科技有限公司

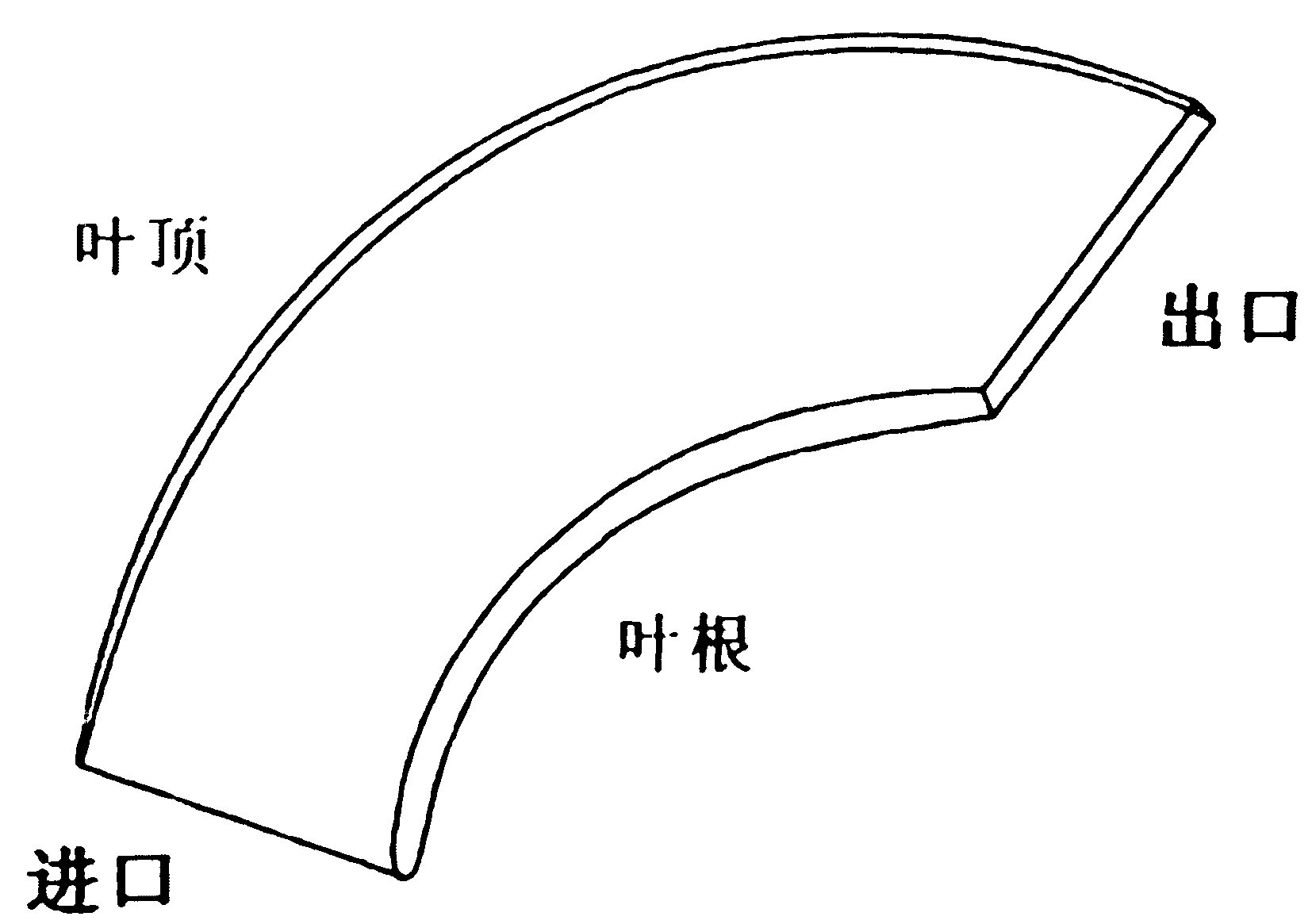

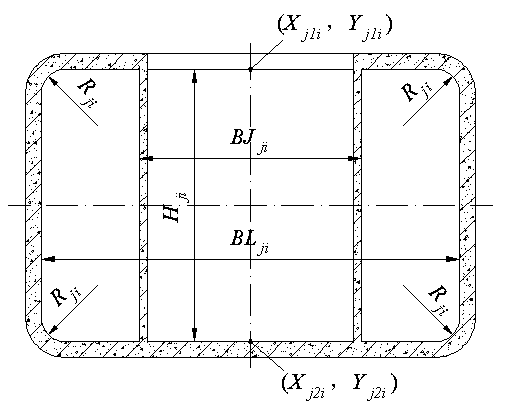

Design method for impeller of multiphase mixed transportation pump

InactiveCN102979759AImprove hydraulic performanceImprove efficiencyPump componentsPumpsImpellerLinearity

The invention relates to a design method for an impeller of a multiphase mixed transportation pump. With the adoption of the design method, hydraulic performance of the mixed transportation pump is improved, and the influences of gas content on the performances of the mixed transportation pump are reduced through controlling main geometrical parameters such as an inlet diameter, an impeller outlet diameter, an outlet width of each impeller blade; the thickness of a front cover plate side of each impeller blade is 25% less than the thickness of a rear cover plate side; the thickness of each blade is uniformly increased from the front cover plate side to the rear cover plate side according to linearity; the thickness of each blade is gradually increased along a filament line direction from an inlet edge to an outlet edge; the thickness of each inlet edge is about 40% of the thickness of the corresponding outlet edge; and the number of the blades of the impeller is 3 to 6.

Owner:JIANGSU UNIV

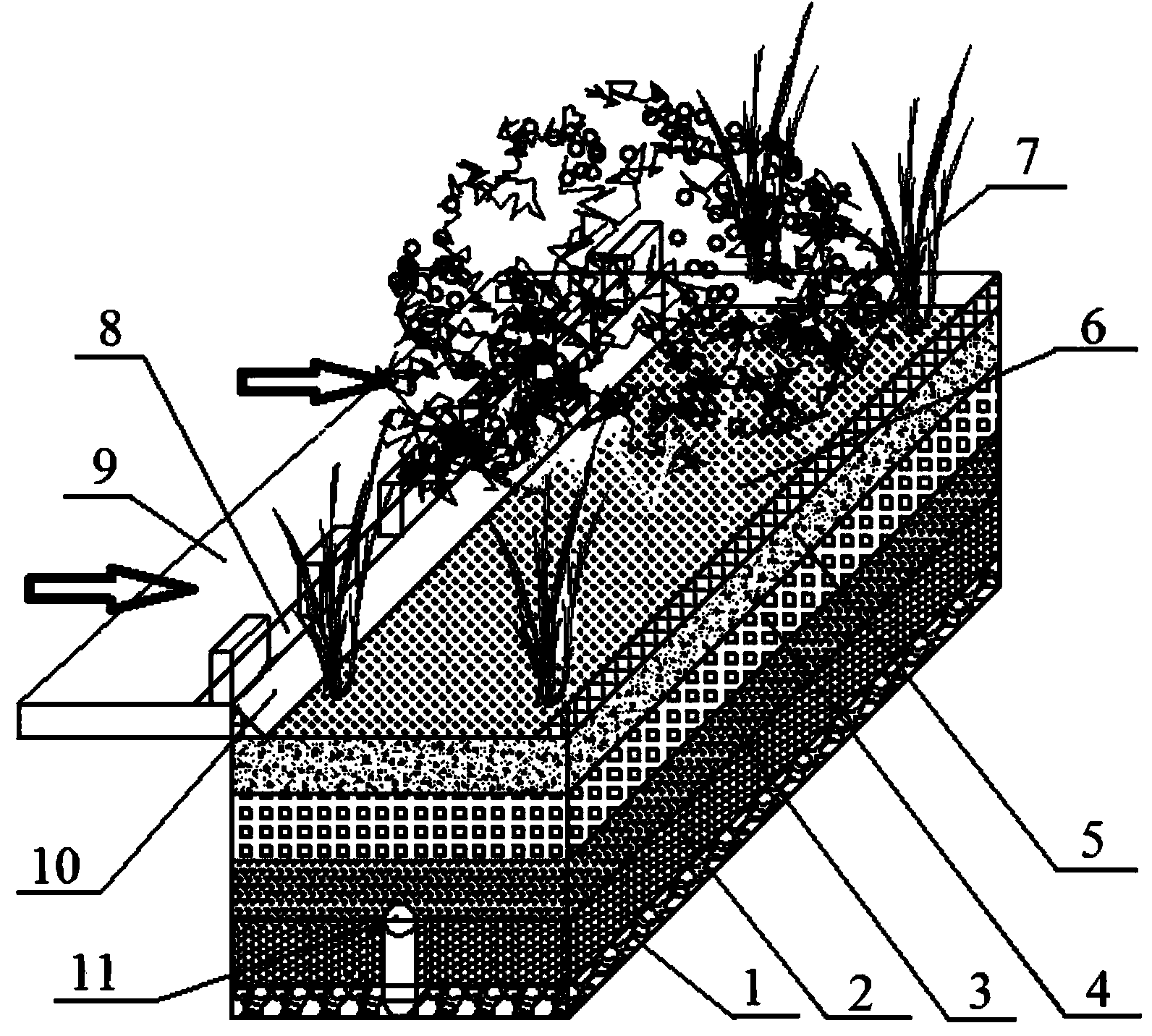

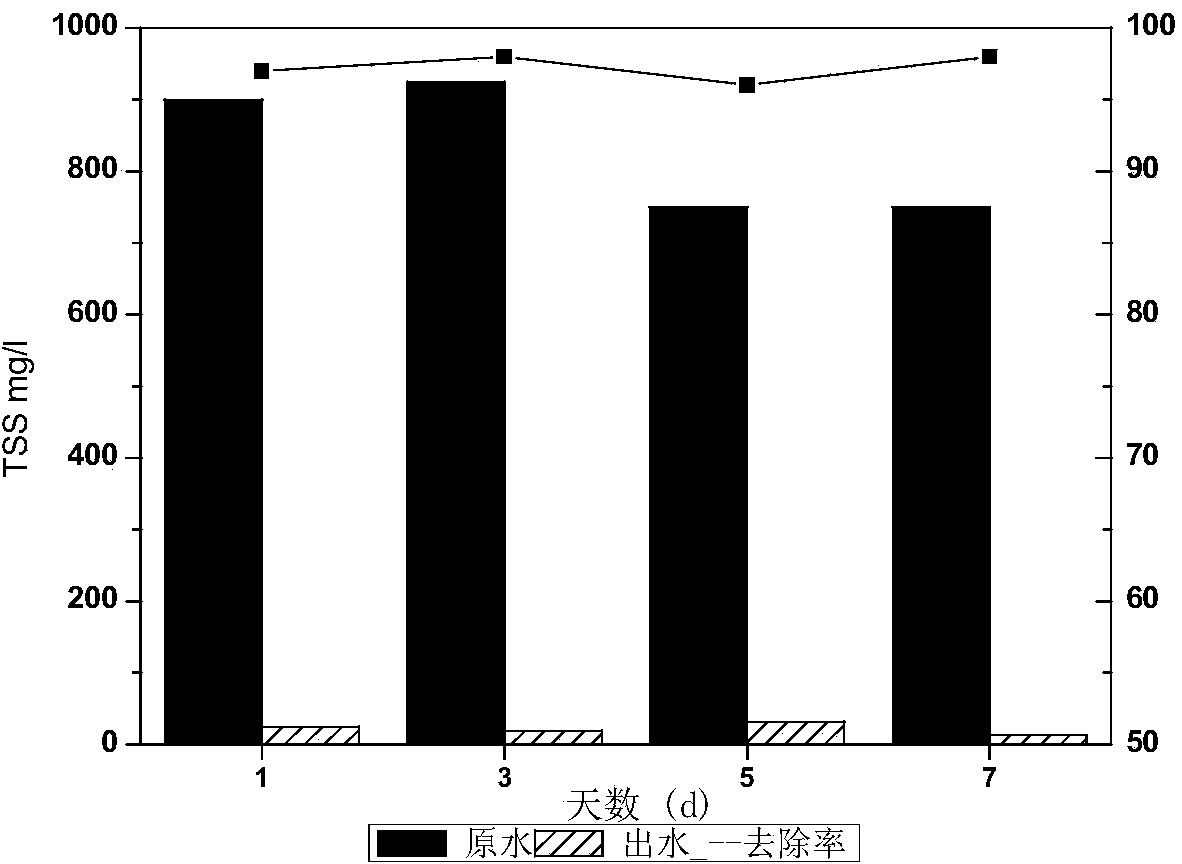

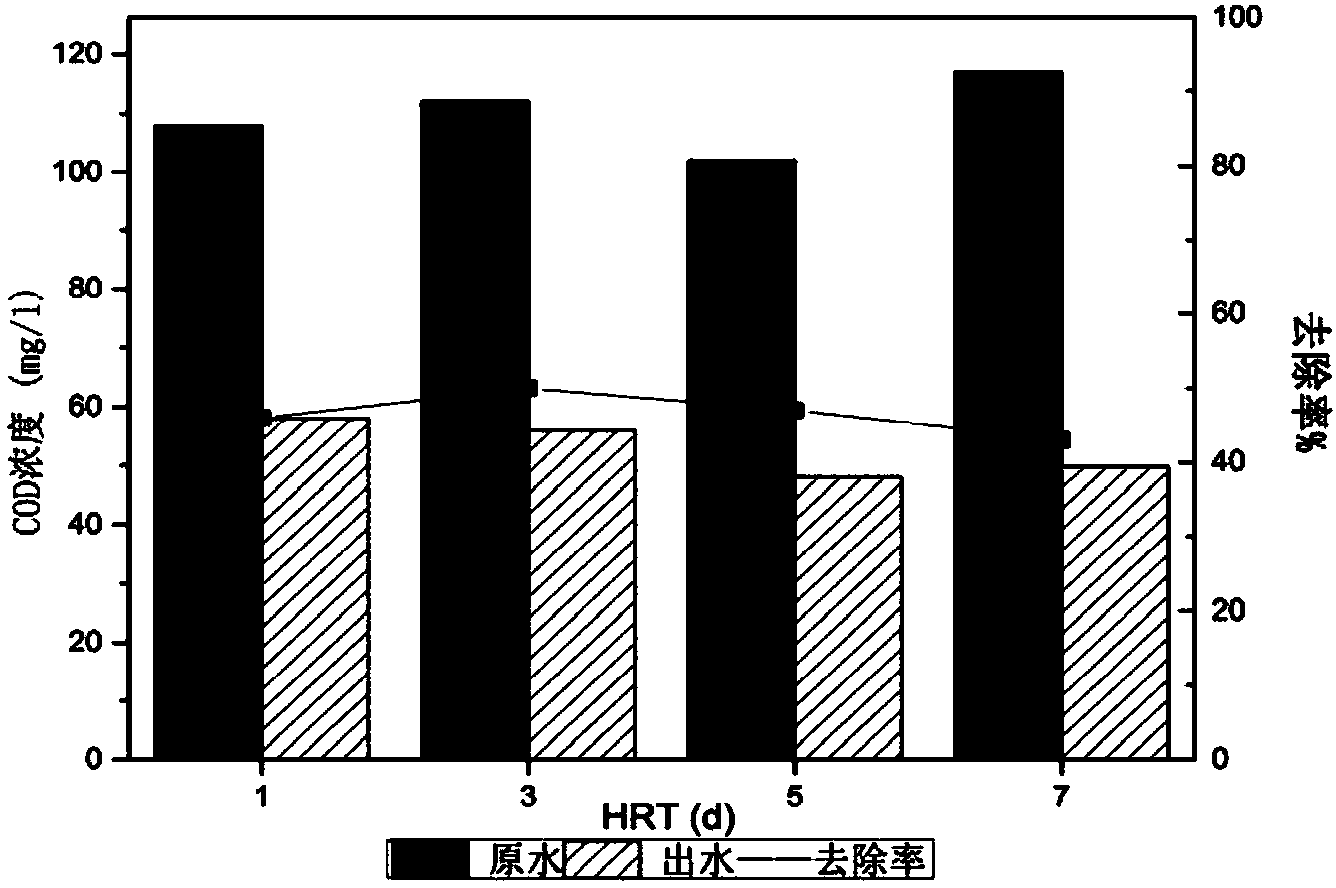

Ecological filter groove construction method for cutting urban runoff pollution

InactiveCN104110059APromote absorptionStrong penetrating powerFatty/oily/floating substances removal devicesSewerage structuresEngineeringSurface runoff

The invention relates to an ecological filter groove construction method for cutting urban runoff pollution. An ecological filter groove is constructed in an urban green belt, and a water distribution groove and an energy dissipation plate are connected to the front of the ecological filter groove; the ecological filter groove is sequentially divided into a gravel layer, a ceramsite layer, a zeolite layer, a quartz sand layer and a soil layer from bottom to top, and shrubs and herbs are planted in the soil layer. Compared with the prior art, the configuration method of soil, large-particle-size quartz sand, middle-particle-size zeolite, small-particle-size ceramsite and large-particle gravel is adopted, good growth of plants can be guaranteed, ground surface runoff pollutants can be effectively held back as well, meanwhile the shrubs and the herbs are planted in the ecological filter groove in a matched mode, the soil layer is covered by grass sod, the vegetation is developed in root system, has good absorption function to nitrogen and phosphorus, can beautify urban landscape, and can generate good landscape benefits. According to the ecological filter groove construction method, the urban runoff pollution is cut down by constructing the ecological filter groove, and the method has the advantages of being easy and convenient to operate, low in cost, easy to manage and the like.

Owner:TONGJI UNIV

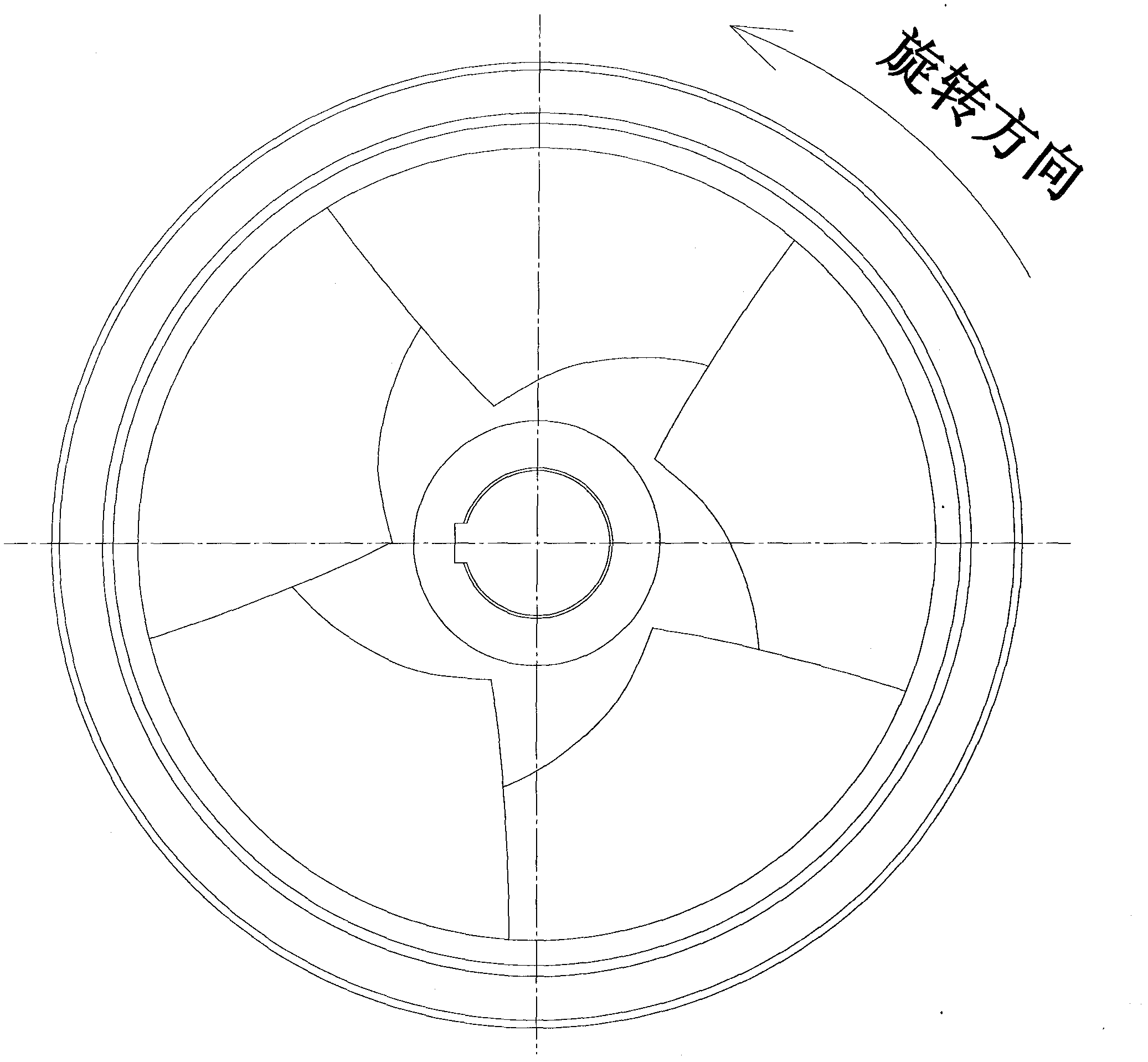

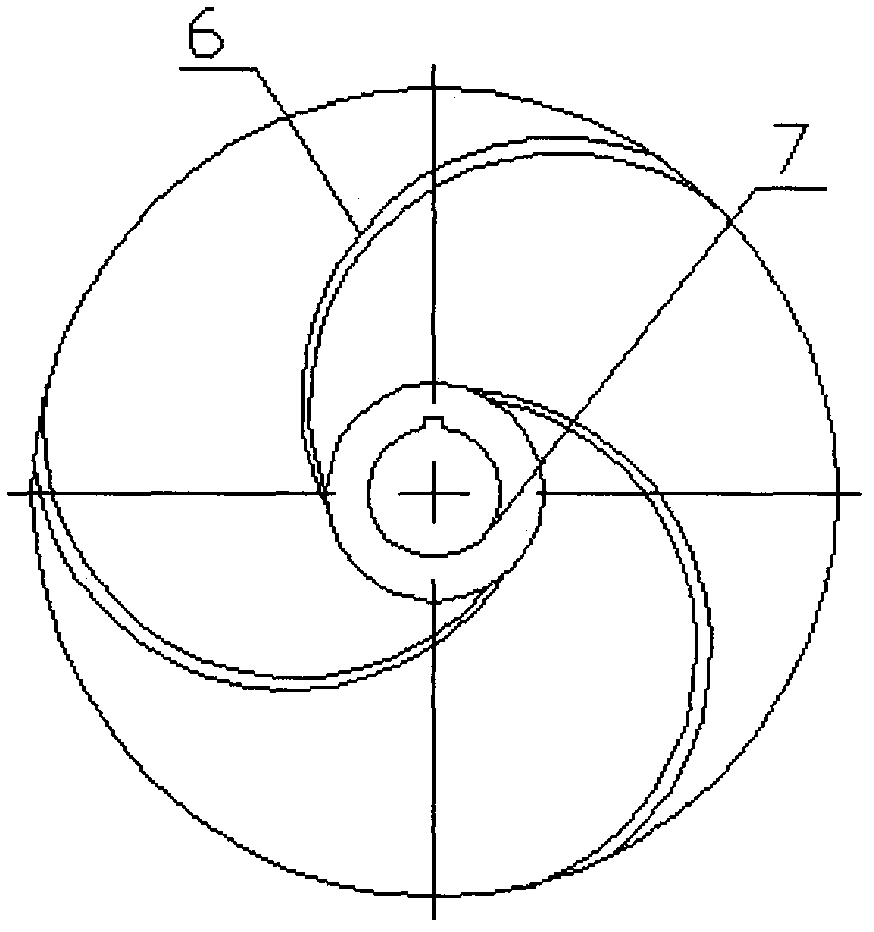

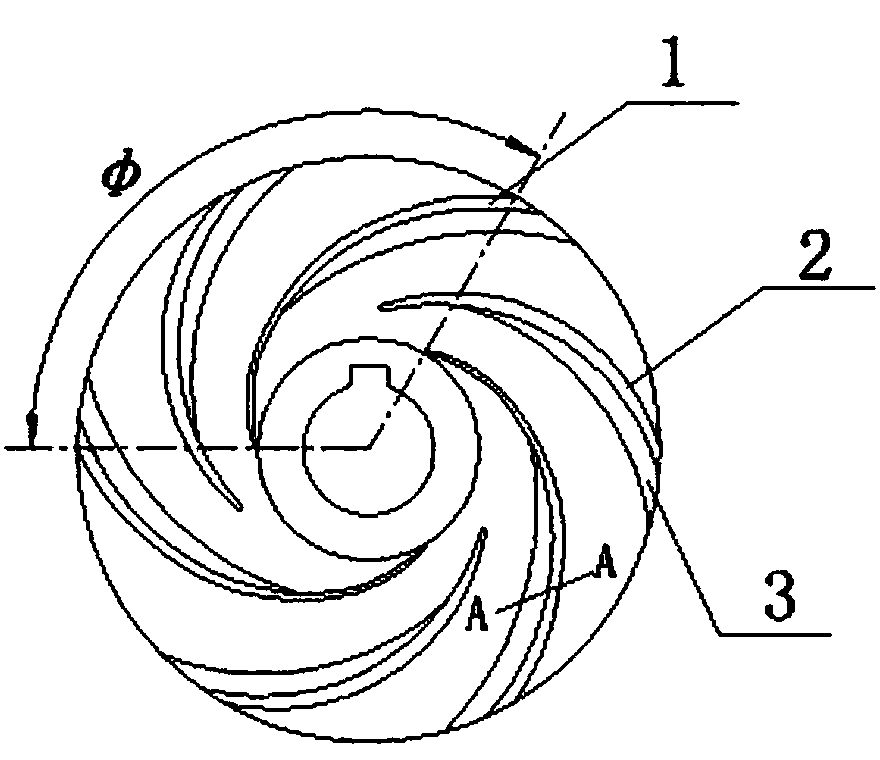

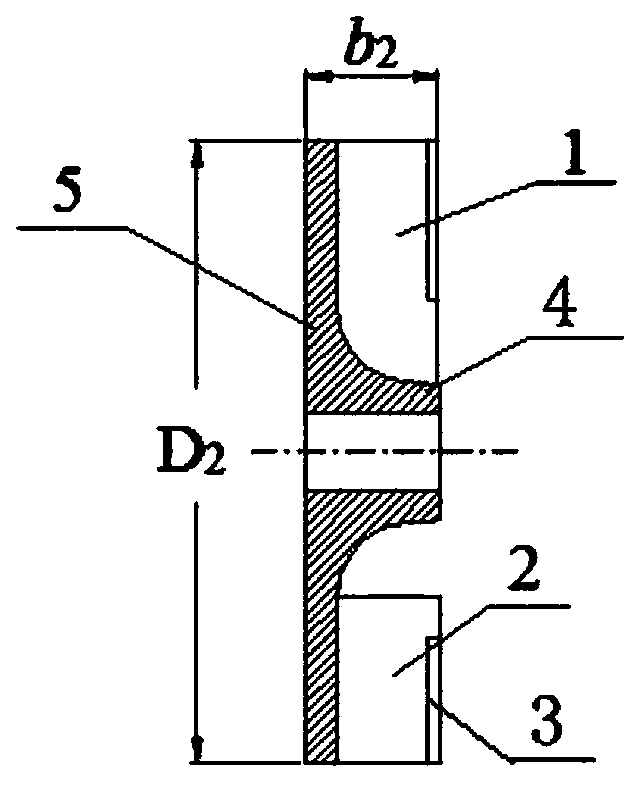

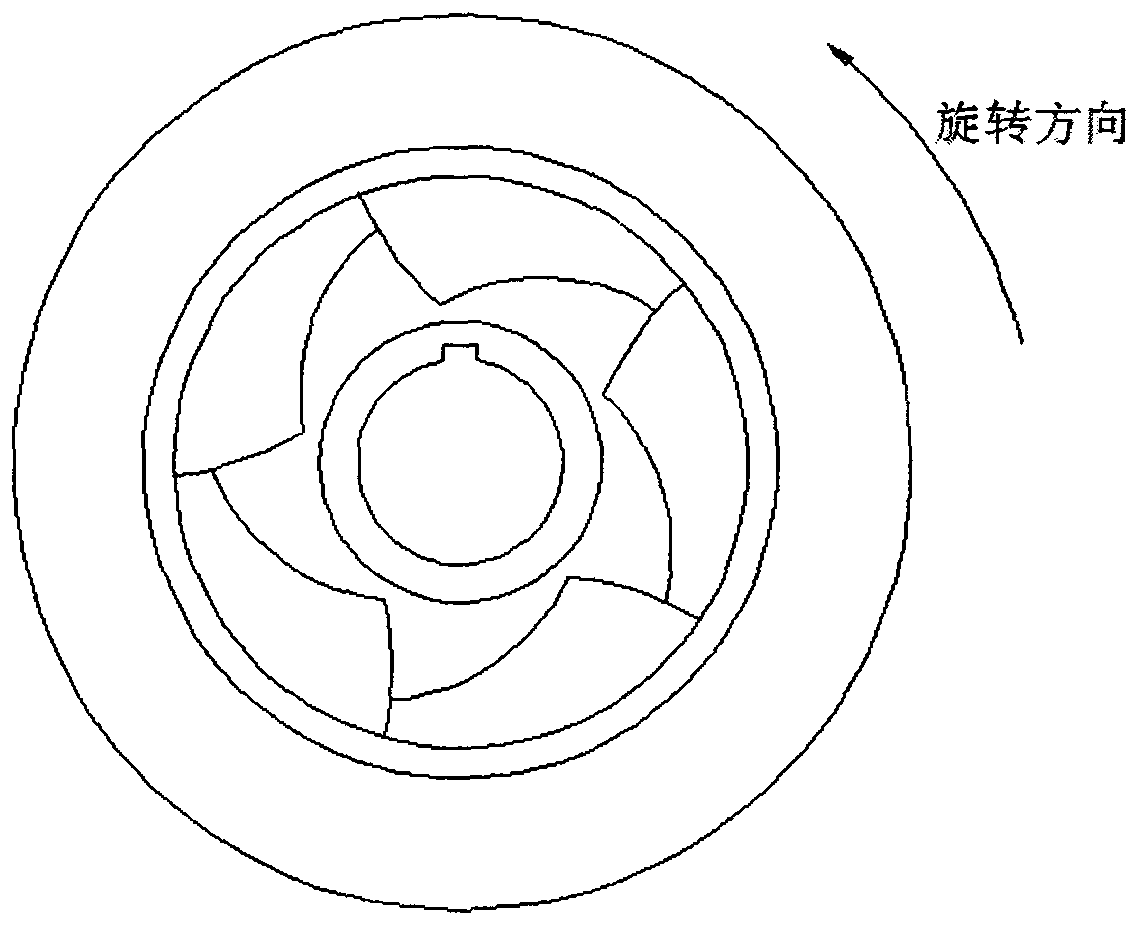

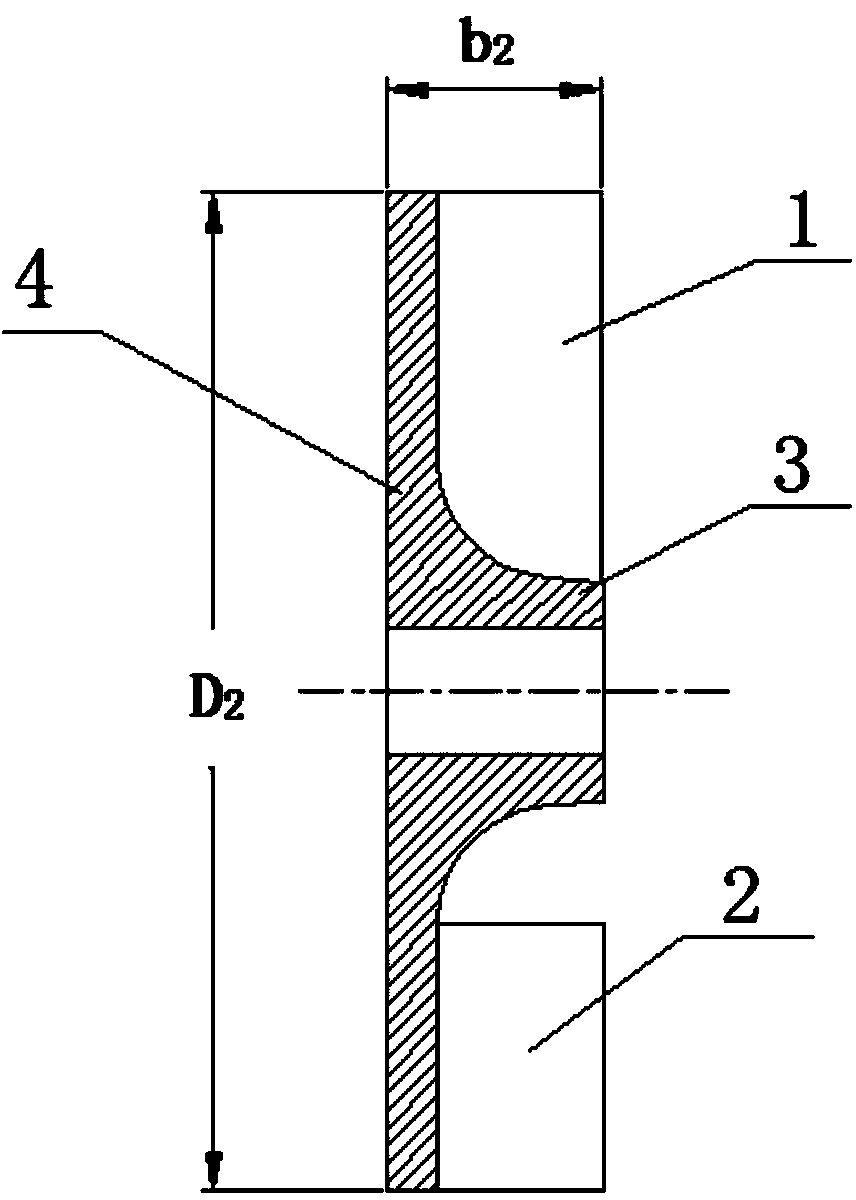

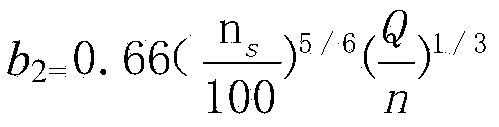

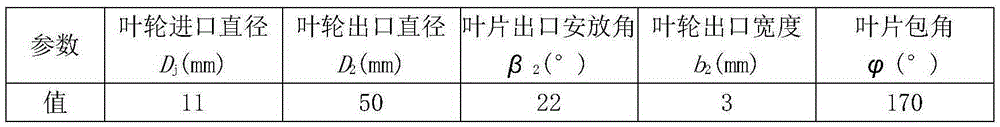

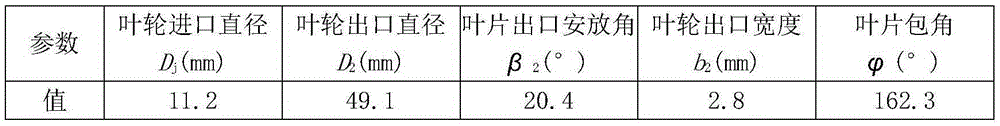

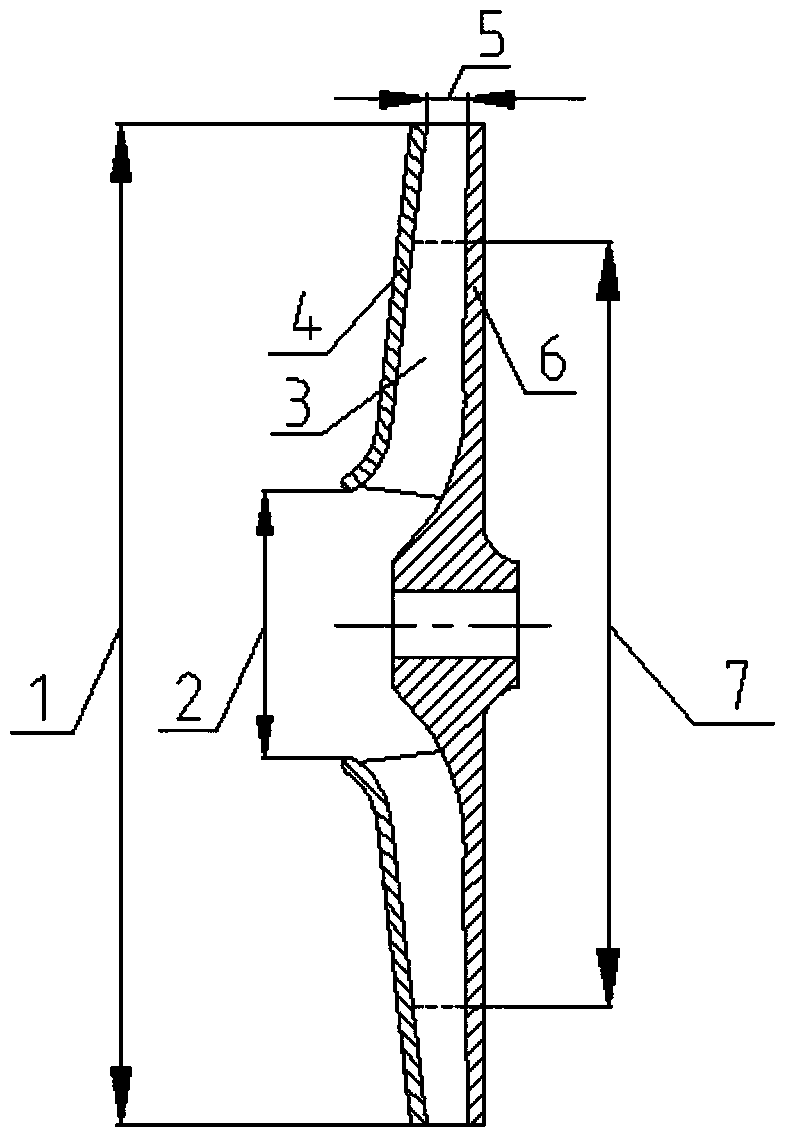

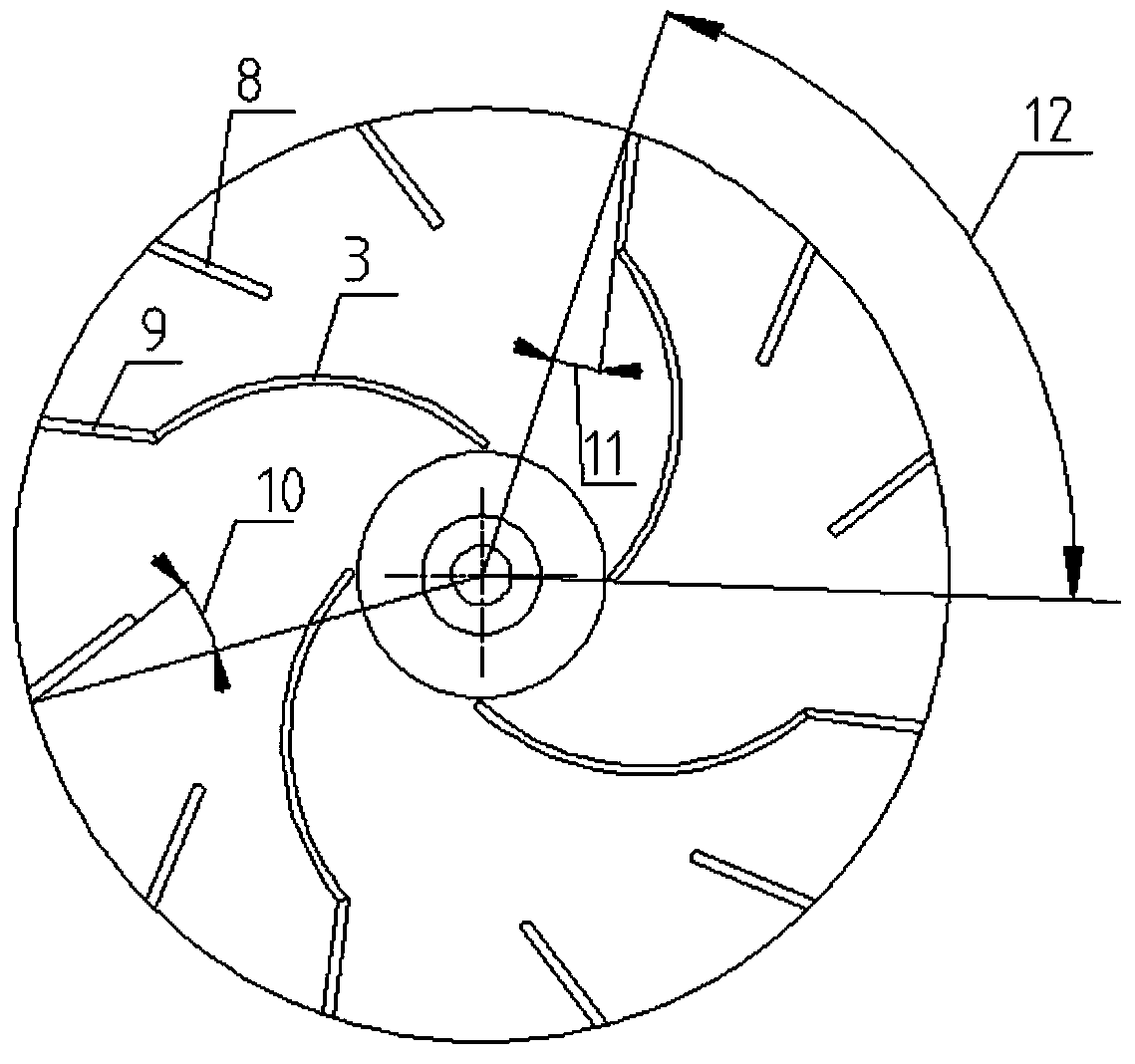

Design method for non-clogging vortex-pump impeller with long and short edgefold blades

InactiveCN104358707AImprove hydraulic performanceImprove efficiencyPump componentsPumpsImpellerSemi open

The invention provides a design method for a non-clogging vortex pump impeller with long and short edgefold blades. The design method is characterized in that the impeller is a semi-open impeller; the blades of the impeller comprise long blades and short blades with different lengths; edgefolds extending in the direction opposite to the rotating direction of the impeller are arranged on the long blades and short blades; the impeller outer diameter of the vortex pump impeller is D2, the impeller outlet width is b2, the impeller inlet diameter is D1, the total number of the blades is Z, the volute bladeless cavity width is L, the edgefold width is b0, and the wrap angle of each blade is phi. The non-clogging vortex pump impeller with long and short edgefold blades, which is designed according to the design method provided by the invention has good hydraulic performance, can effectively reduce energy loss of circulation flow in a pump cavity, increase the passing rate of conveyed solid medium, and improve the efficiency of a vortex pump, and has a good reaction effect after trial use by a user, so that investment and energy sources can be effectively saved.

Owner:JIANGSU UNIV

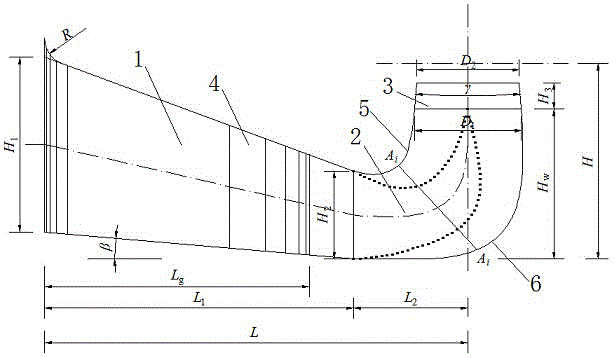

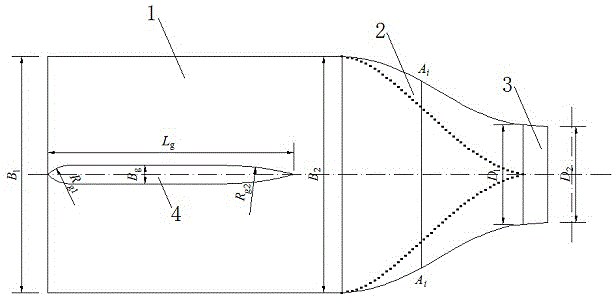

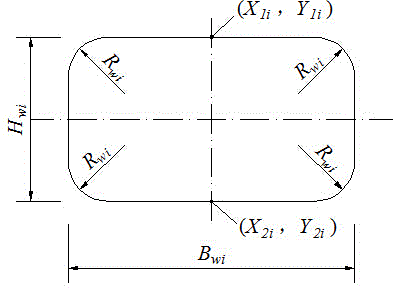

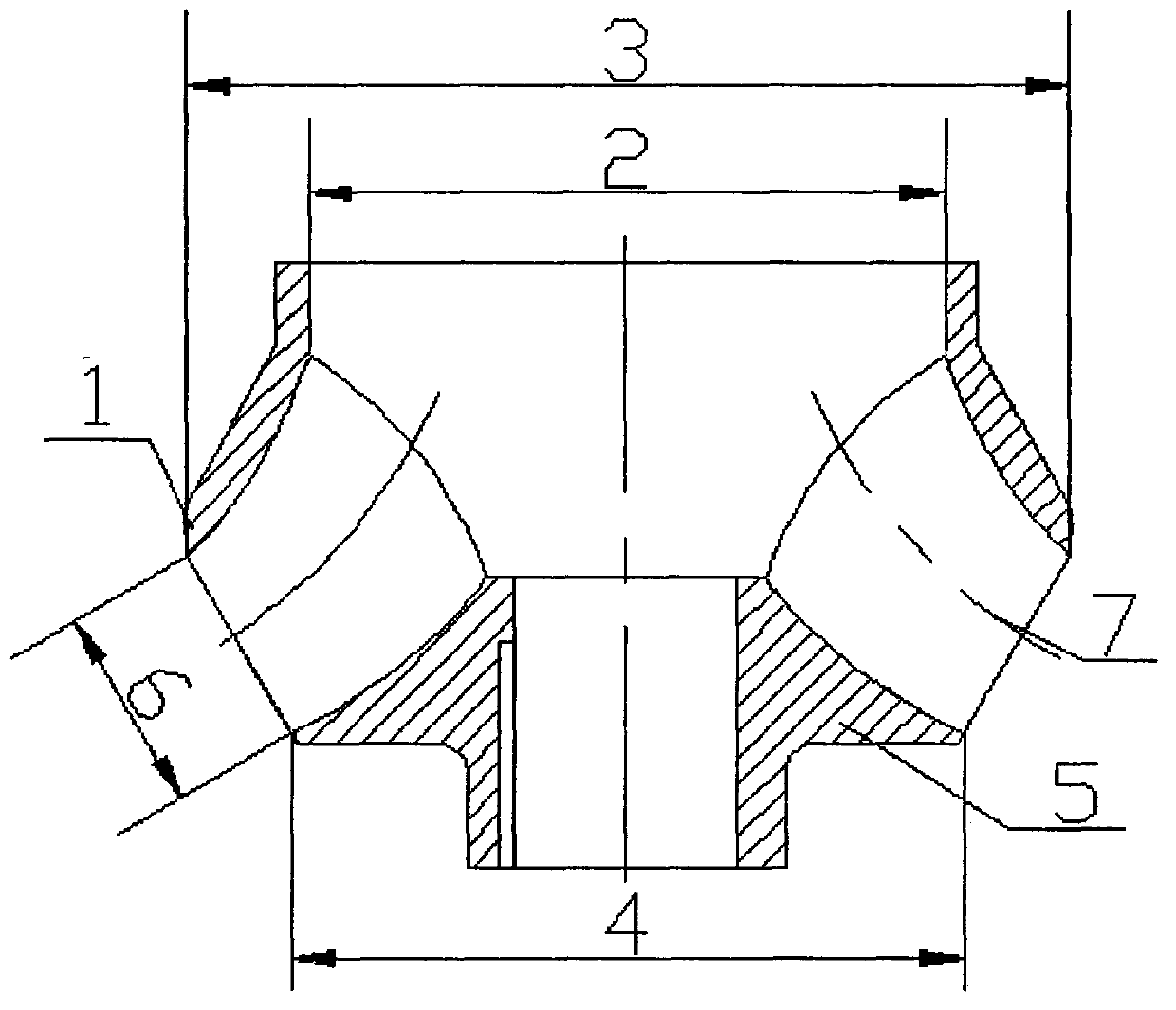

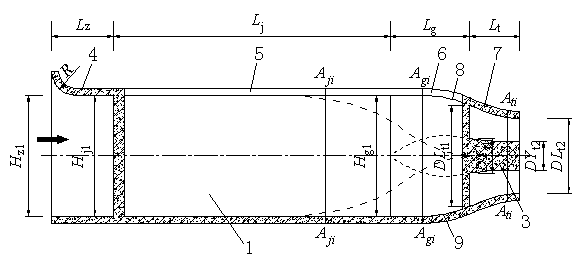

Elbow-shaped water inlet conduit with excellent hydraulic performance and application method thereof

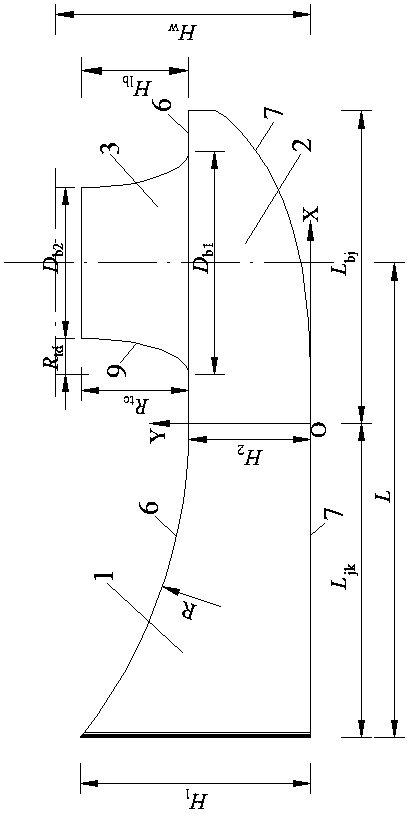

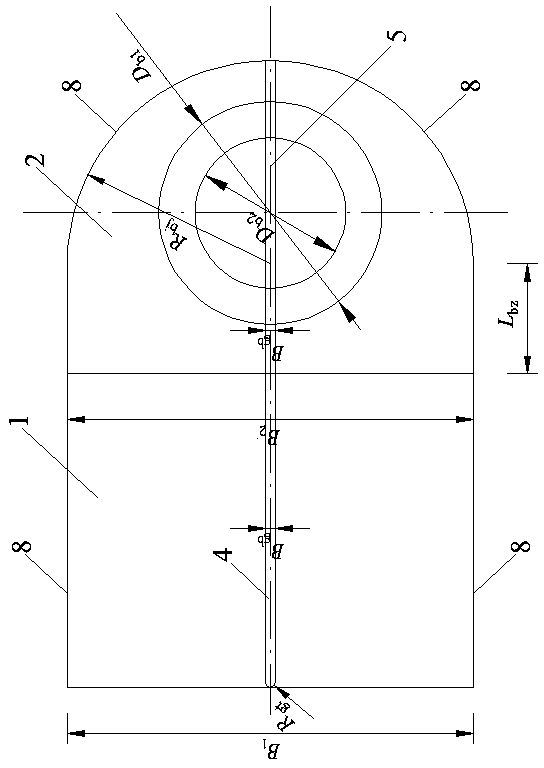

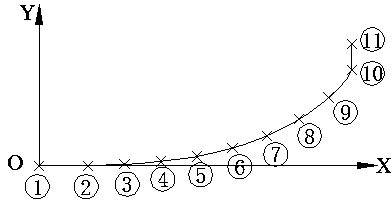

ActiveCN104132000AImprove hydraulic performanceEasy to usePump componentsPumpsImpellerQuality by Design

The invention provides an elbow-shaped water inlet conduit with excellent hydraulic performance and an application method of the elbow-shaped water inlet conduit with excellent hydraulic performance, and belongs to the technical field of a pump station in a water conservancy project. The elbow-shaped water inlet conduit is geometrically characterized by comprising a linear segment, an elbow bending segment and a circular truncated cone segment. Middle separation piers are arranged in the linear segment. A value range is provided for a straight segment, the linear segment and the circular truncated cone segment which are geometrically simple, and detailed section position and section data are provided for the geometrically complex elbow bending segment. All dimensions of the elbow-shaped water inlet conduit are expressed with relative values, the actual required dimensions of the water inlet conduit of the pump station can be obtained as long as the relative values are multiplied by the diameter of a water pump impeller to be adopted in the pump station, and the parameters of the linear segment and the circular truncated cone segment can be adjusted within a certain range according to actual requirements of the pump station so that the different requirements of different pump stations for main geometrical parameters such as conduit length, conduit height and bottom edge inclination angle can be met. The elbow-shaped water inlet conduit with excellent hydraulic performance and the application method of the elbow-shaped water inlet conduit with excellent hydraulic performance can guarantee that the elbow-shaped water inlet conduit of each pump station is excellent in design quality and hydraulic performance, wide in application range and convenient to use, thereby having significance in guaranteeing safety, stability and efficient operation of medium and large pump stations.

Owner:YANGZHOU UNIV

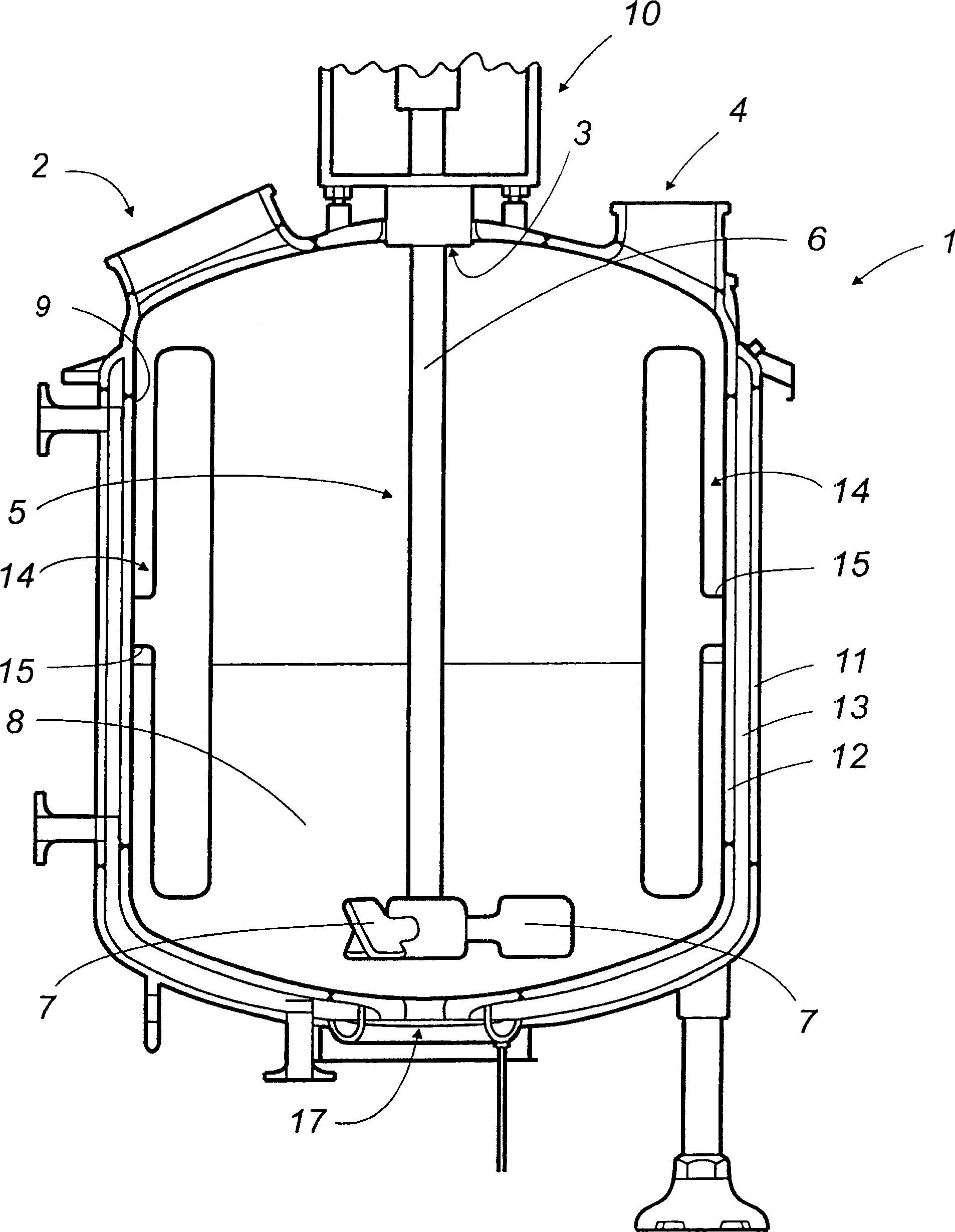

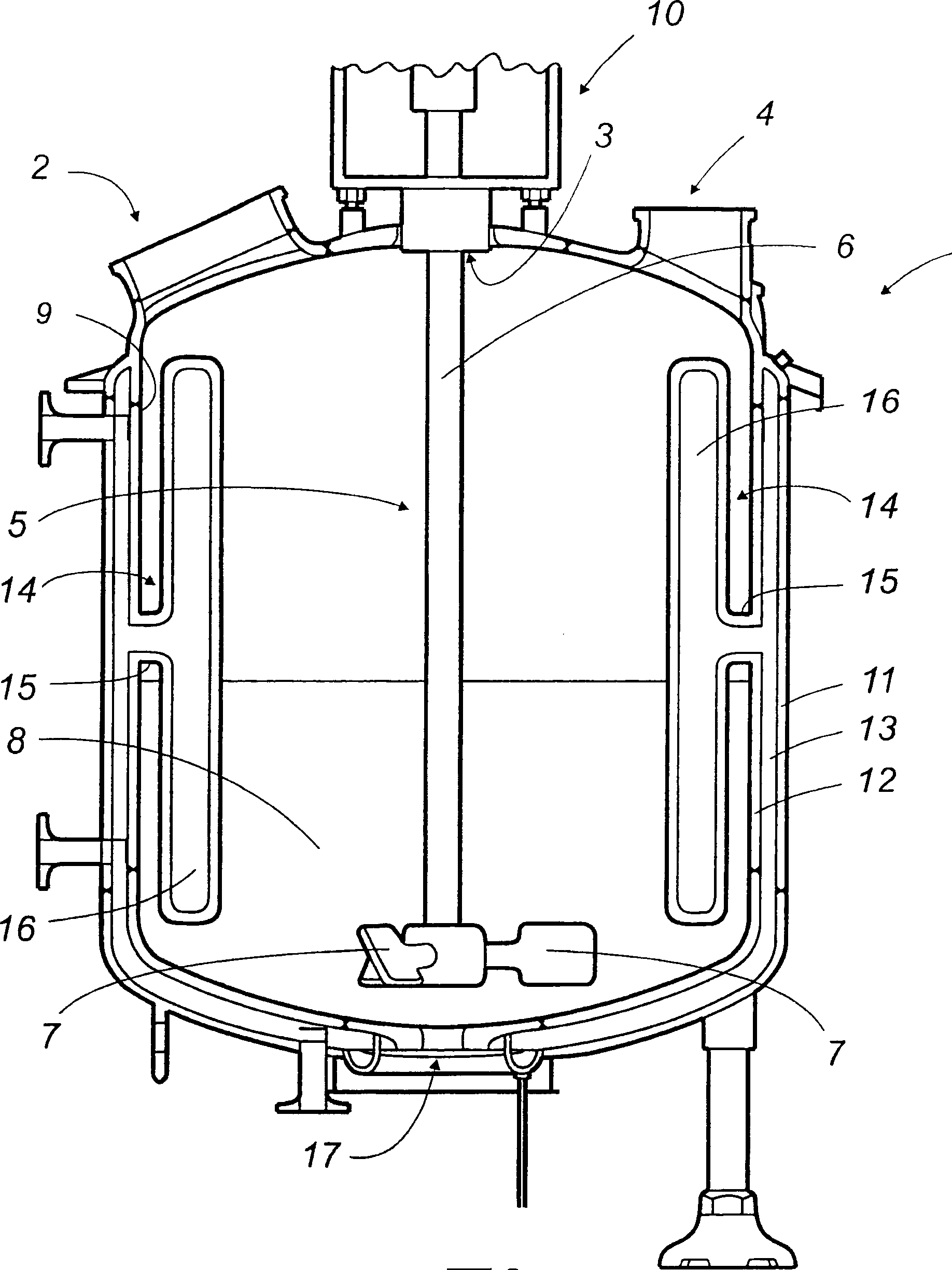

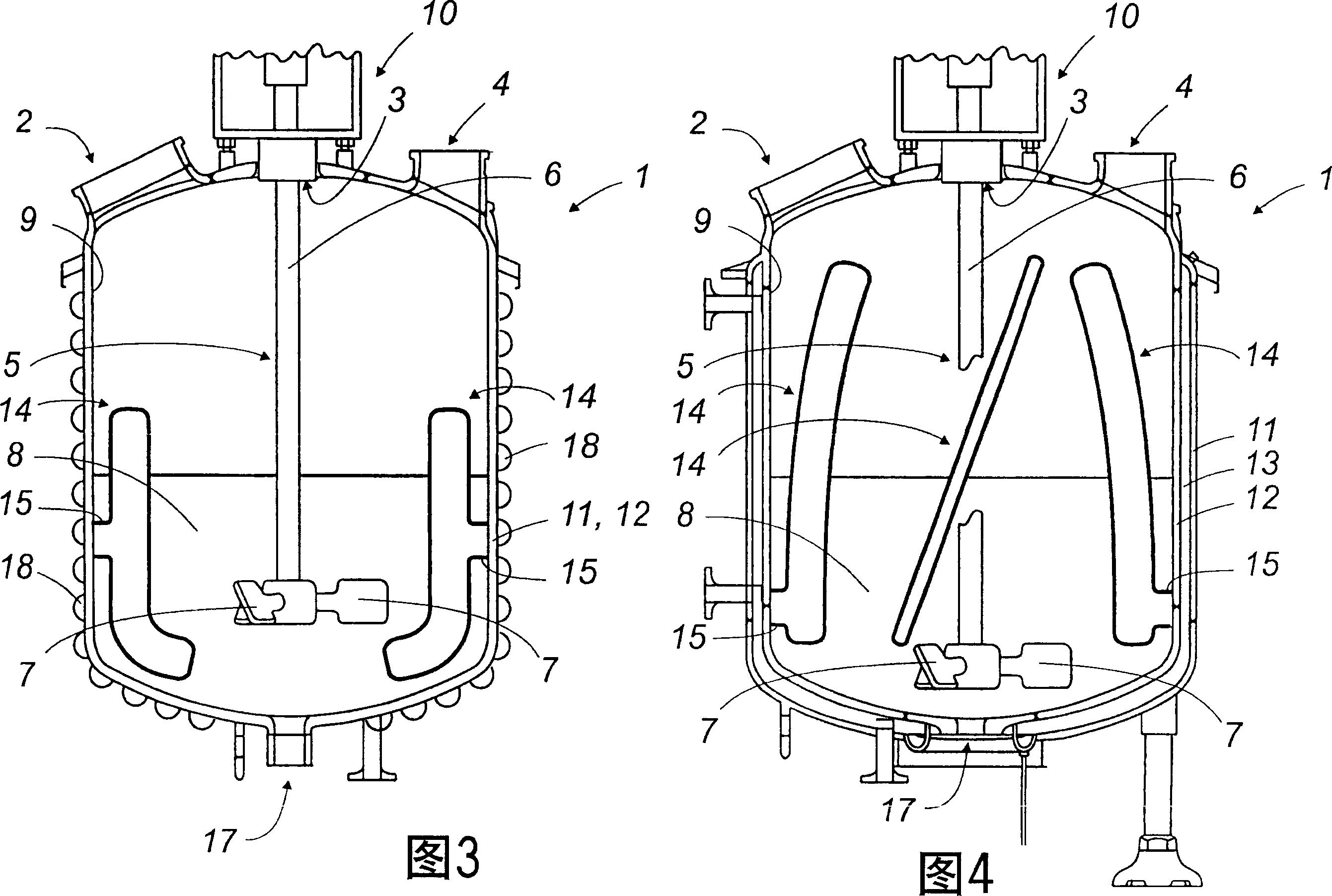

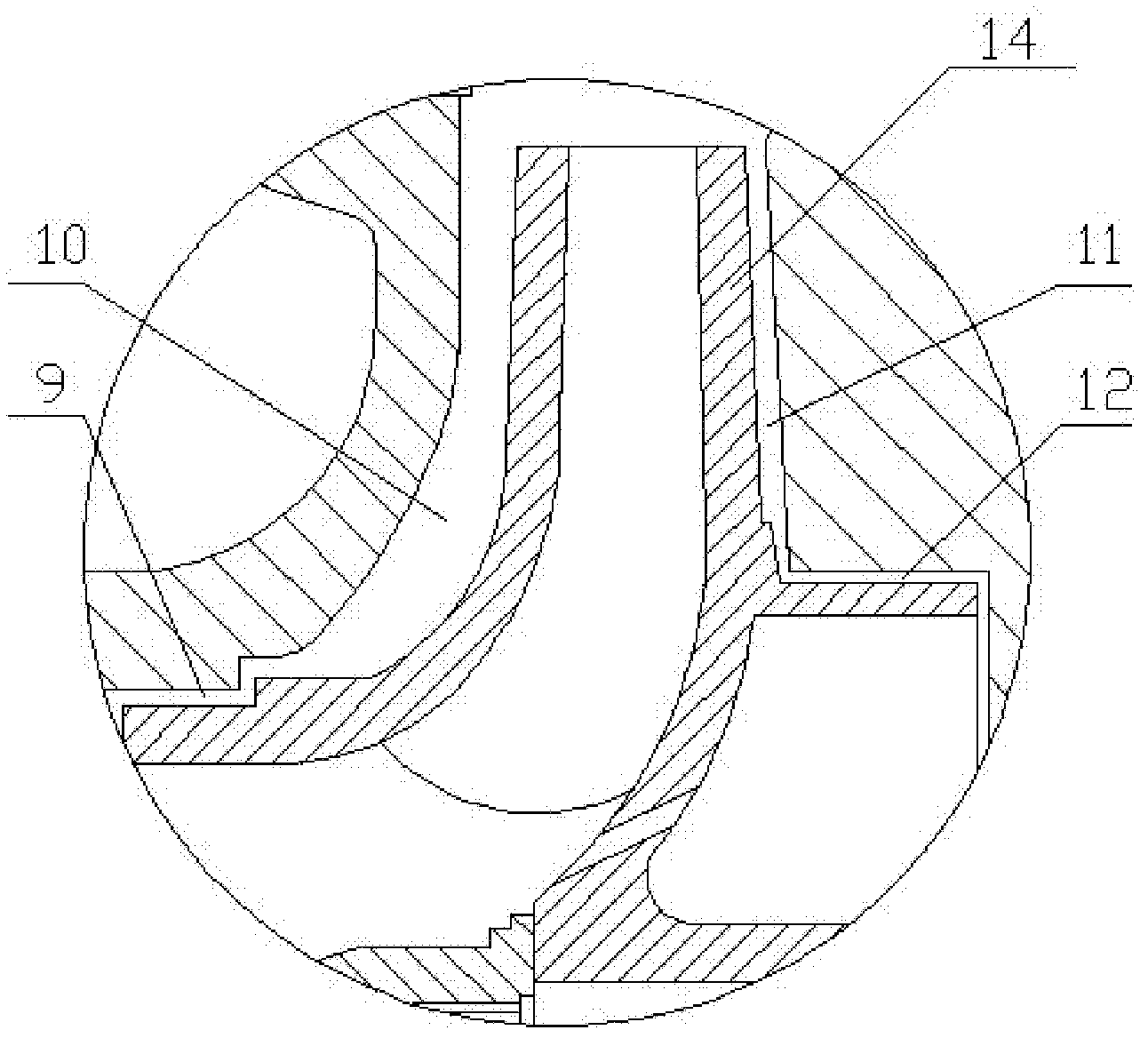

Baffle fixed at a separation from the internal wall of an enamelled container by means of a local connection

InactiveCN1735453AEasy to cleanImprove hydraulic performanceTransportation and packagingRotary stirring mixersChemical reactorEngineering

The baffle (14) is fixed at a distance from the opposite inner wall (12) of the container (1) intended to be enameled, such as a chemical tank or container, and is held in place by at least one contact connection (15) Stay away from that inner wall. The baffles can be solid or hollow. In the case of hollows, the baffles can be equipped with connecting fluid channels, which lead through the contact connections of the baffles to the space enclosed between the inner wall (12) and the outer wall (11) of the container (11). 13). The invention also relates to a container comprising one or more baffles of this type. The present invention is of interest to the chemical and pharmaceutical industries, particularly to manufacturers and users of baffles.

Owner:德迪耶特里克公司

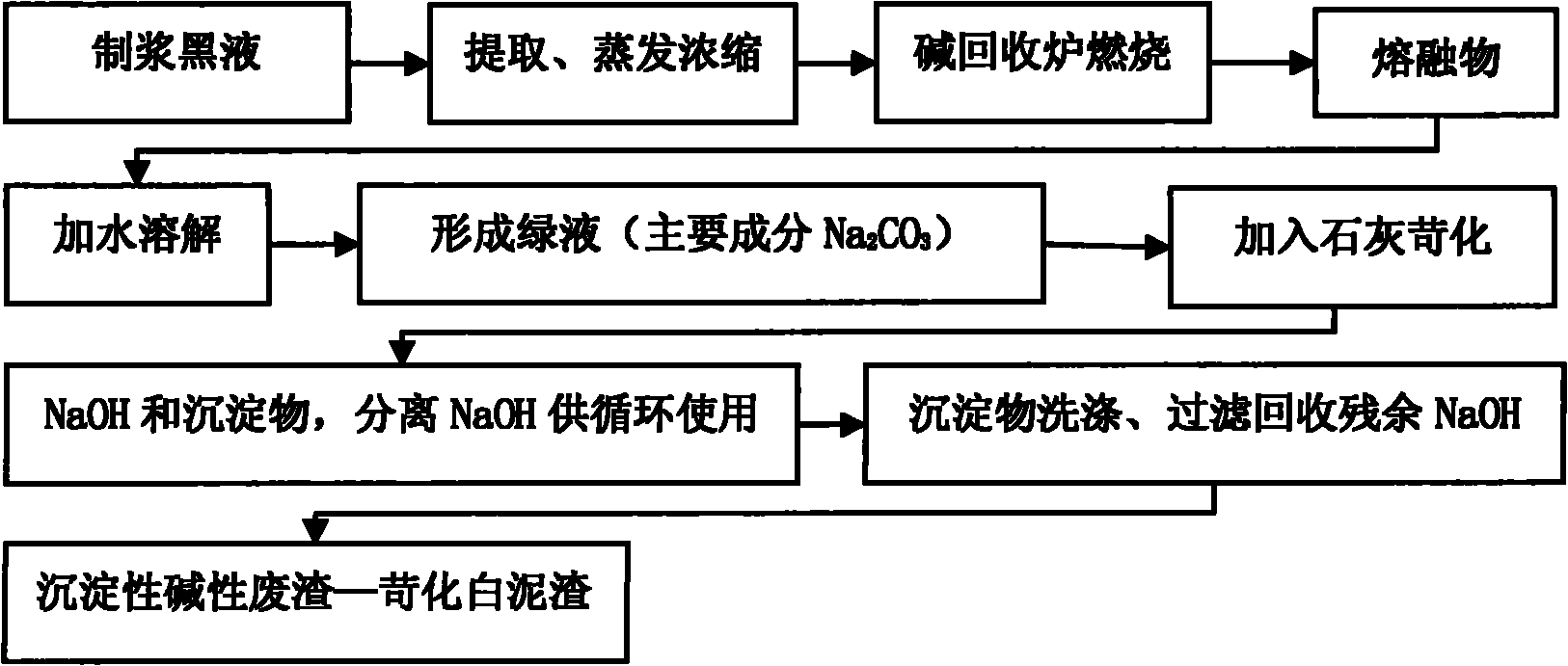

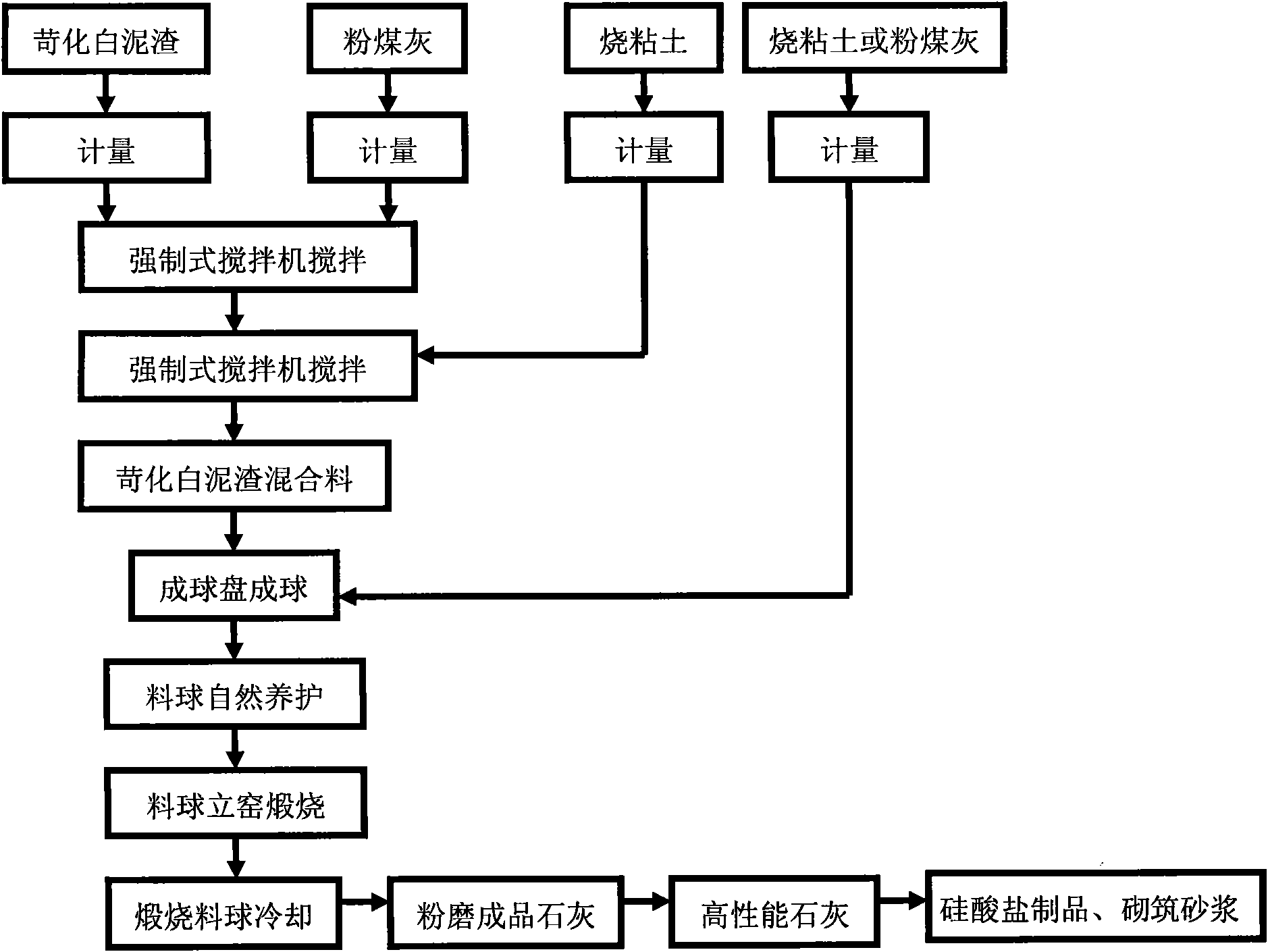

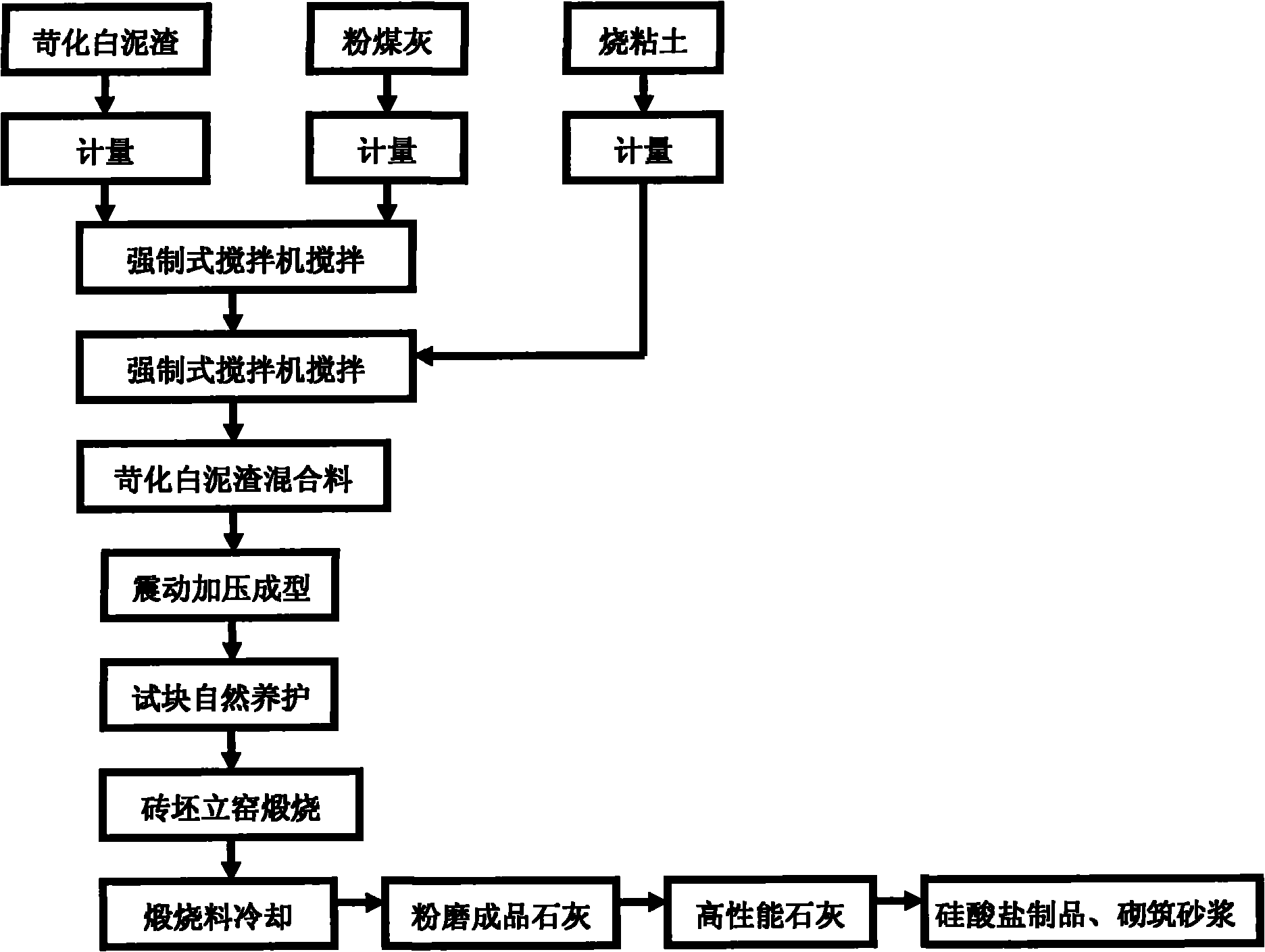

Method for preparing hydraulic calcium oxide through papermaking alkali recycling causticized white sludge

InactiveCN102070309AReduce dust pollutionReduce moisture contentSolid waste managementPapermakingSludge

The invention discloses a method for preparing hydraulic calcium oxide through papermaking alkali recycling causticized white sludge. The method comprises the following steps: preparing a mixture: putting papermaking causticized white sludge and pulverized fuel ash into a forced type stirrer for stirring, and putting burnt clay into the forced type stirrer for evenly stirring to obtain the mixture; molding the mixture: molding by adopting a centrifugal rolling balling method or shaking pressurization method; naturally curing the mixture: putting the molded mixture balls into the natural environment with good ventilation conditions for stacking and curing, and putting adobes into the natural environment with good ventilation conditions for stacking and curing for 7-14 days until the quality of the adobes can not be further reduced and the primary compression strength of the adobes is more than 1MPa; and calcining the material: conveying the cured and dried material balls or adobes intoa shaft kiln for calcining and insulating, then naturally cooling to the room temperature, and milling the calcined products to be used for preparing silicate products. The invention reduces the dustpollution and solves the problem of treatment of pulverized fuel ash.

Owner:NANJING UNIV OF SCI & TECH

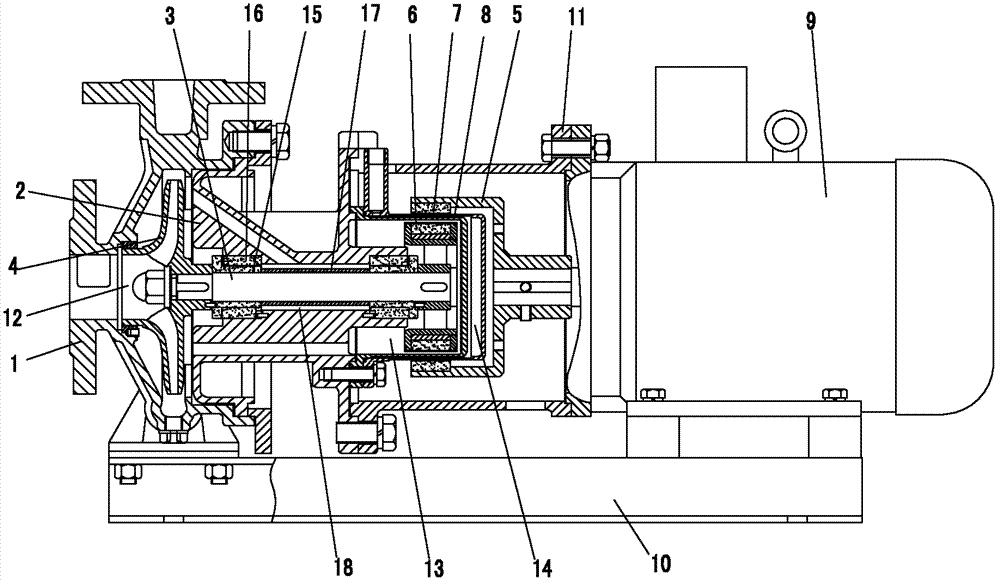

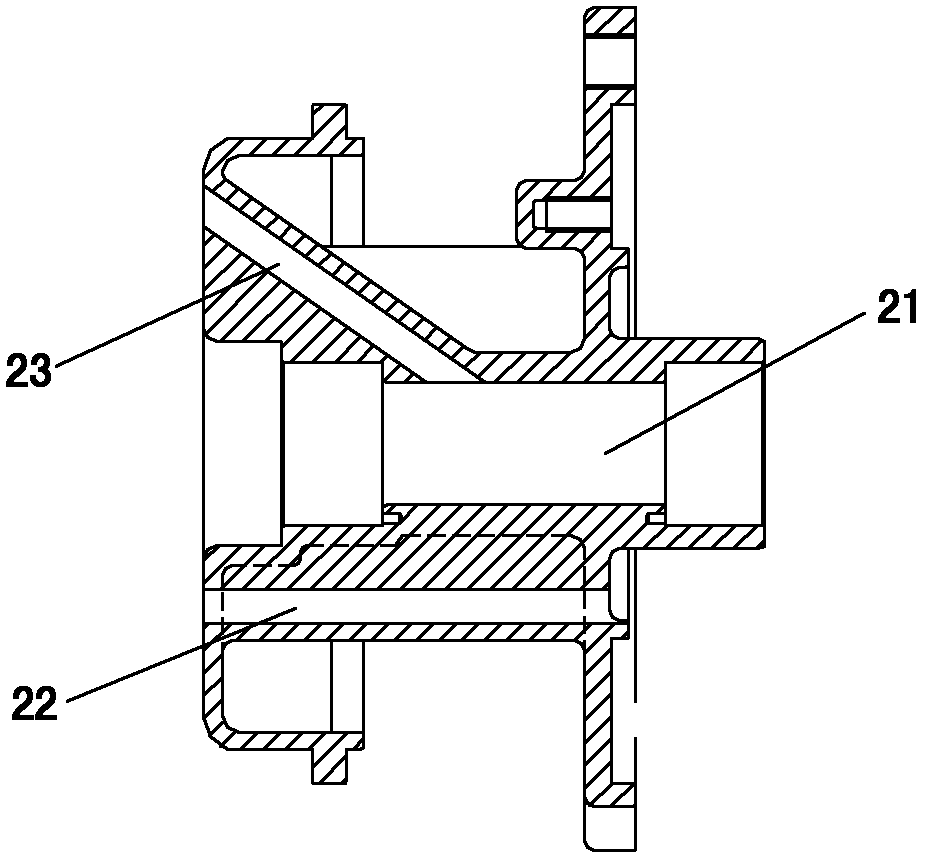

Magnetic driving pump

ActiveCN102954003ARunner is clean and freshExcellent comprehensive hydraulic performancePump installationsNon-positive displacement fluid enginesInner loopImpeller

A magnetic driving pump comprises a pump body, a pump cover, a pump shaft, an impeller, an outer magnetic rotor, an inner magnetic rotor, an isolation sleeve and a motor. The isolation sleeve comprises a primary isolation sleeve and a second isolation sleeve, the primary isolation sleeve is arranged on one side close to the inner magnetic rotor, the secondary isolation sleeve is arranged on one side close to the outer magnetic rotor, and an interval is reserved between the primary isolation sleeve and the secondary isolation sleeve to form an isolation sleeve cavity. One side of the pump cover is provided with a through hole communicating a pump cavity with an inner cavity, and the other side of the pump cover is provided with a diagonal circulating hole. The front end of the circulating hole is communicated with the pump cavity at the front end of the pump cover, and the rear end of the circulating hole is communicated with a shaft hole. When a medium delivered by the pump is to be heated or cooled, an external heater / cooler is directly transmitted to the pump cavity, a sliding bearing pair and the inner cavity of the isolation sleeve to heat or cool the medium owing to the pump cover and the double-layer isolation sleeve. By the aid of the reasonable structural design, sufficient pressure and flow of all internal circulating and lubricating systems can guarantee stable running of the pump.

Owner:上海佰诺泵阀有限公司

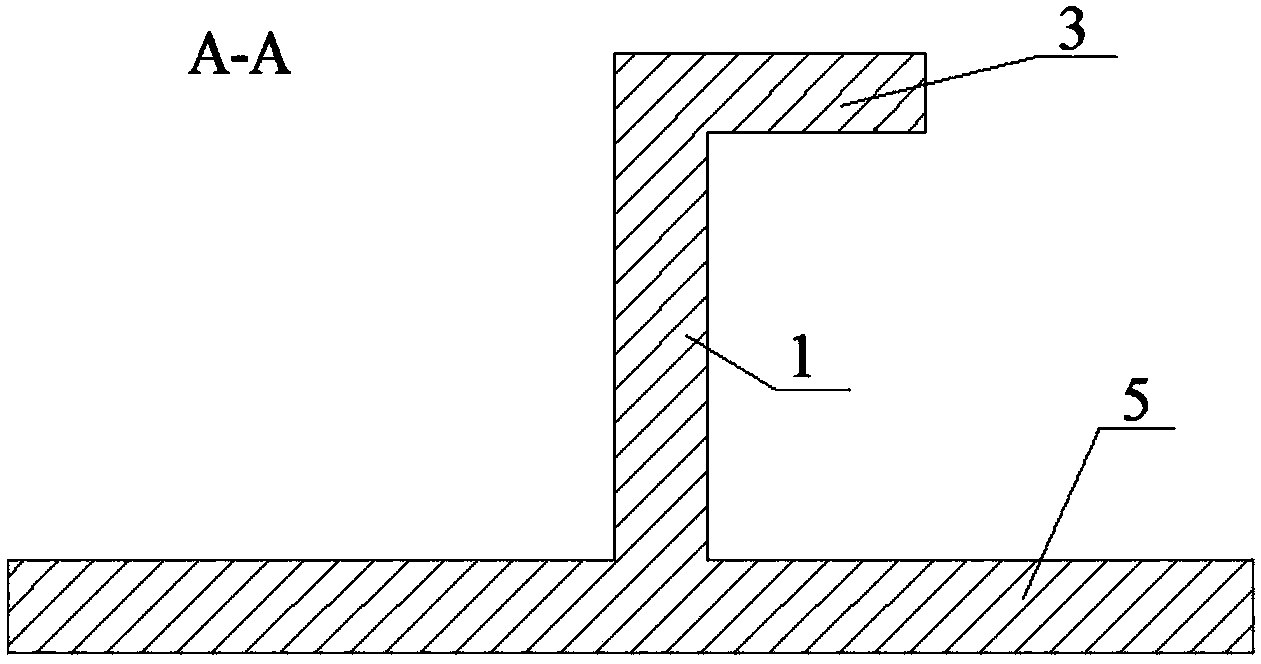

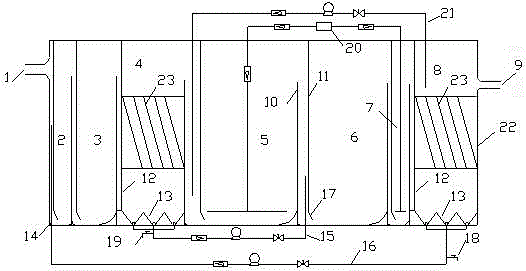

Dustpan-shaped inflow channel with excellent hydraulic performance and application method of dustpan-shaped inflow channel

ActiveCN104895145AImprove hydraulic performanceAdaptableArtificial water canalsPumping plantsReinforced concreteWater flow

The invention discloses a dustpan-shaped inflow channel with excellent hydraulic performance and an application method of the dustpan-shaped inflow channel, and belongs to the technical field of hydraulic engineering pump station. The dustpan-shaped inflow channel comprises three sections, namely a straight inlet section, a dustpan-shaped steering section and a trumpet pipe rectifying section, which are arranged in the water flow direction, wherein all the sections have different geometrical characteristics and effects; a rectifying separator plate is arranged in the middle of the straight inlet section, and an anti-vortex separator plate is arranged in the middle of the dustpan-shaped steering section; the straight inlet section, the dustpan-shaped steering section, the trumpet pipe rectifying section as well as the rectifying separator plate of the straight inlet section and the anti-vortex separator plate of the dustpan-shaped steering section are independent prefabricated reinforced concrete components, are manufactured in a factory, and then are transported to the pump station field for field assembly to form a complete dustpan-shaped inflow channel. The dustpan-shaped inflow channel provided by the invention is excellent in hydraulic performance, simple in application method and suitable for small and medium vertical pump stations, ensures the construction quality of the pump station inflow channel and greatly lowers the requirements for the field construction technology level of the inflow channel.

Owner:YANGZHOU UNIV

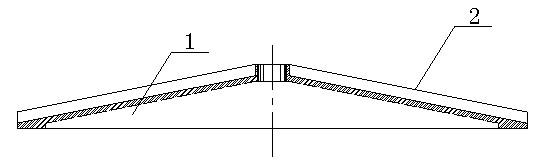

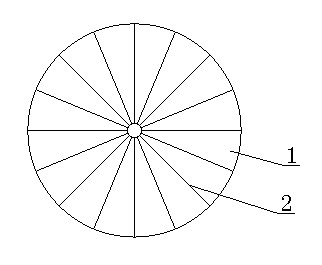

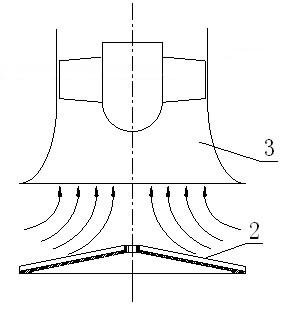

Novel vortex-preventing cone for water feeding of water pump

The invention relates to a novel vortex-preventing cone for water feeding of a water pump, belonging to the technical field of hydraulic engineering. The vortex-preventing cone is arranged under a suction flared pipe nozzle of the water pump, the tip of the vortex-preventing cone is just opposite to the center of the suction flared pipe nozzle of the water pump, vortex-preventing teeth are arranged on the conical surface of the vortex-preventing cone, and the plane area of the vortex-preventing cone is more than the area of the suction flared pipe nozzle of the water pump. The uneven vortex-preventing teeth are arranged on the conical surface of the vortex-preventing cone, and the section shape of a rack of the vortex-preventing teeth is rectangular or triangular or trapezoidal. A cone axial line of a flat cone and a pipe core line of a suction flared pipe of the water pump are arranged on the same straight line. The invention has the advantages of simple and scientific structure and reasonable design; the primary basis of a vortex strip is destroyed from the starting point of the vortex strip, circular quantity of water flow in a water inlet region can not accumulate, and the condition of generating high-intensity vortexes is deprived, the water flow in the water inlet region is smooth, the pressure fluctuation is reduced, and the pump vibration is avoided. The invention is suitable for inlets of various water pumps, ensures no vortex or corresponding hydraulic vibration, reduces hydraulic loss and improves properties of pumps.

Owner:YANGZHOU UNIV

Design method of nuclear main pump impeller

InactiveCN103104546AGood hydraulic performanceImprove efficiencyPump componentsPumpsImpellerNuclear engineering

The invention relates to a design method of a nuclear main pump impeller. Through controlling main geometric parameters such as the inlet diameter, and the impeller outlet diameter of the impeller, the outlet width of an impeller blade, and selecting appropriate specific speed and rotating speed, a nuclear main pump has relatively high effect under a liquid-phase condition, especially in gas phase and liquid-phase operating conditions, thus reducing the probability of nuclear safety accidents in the operating condition of water loss accidents of the nuclear main pump. The thickness of the front cover plate side of each impeller blade is about 15% smaller than the thickness of the rear cover plate side of each impeller blade, and the thickness of each blade uniformly increases from the front cover plate side to the rear cover plate side in a linear manner. The thickness of the blade gradually increases from an inlet edge to an outlet along a streamline direction, wherein the thickness of the inlet edge is about 35% that of an outlet edge; the number of blades of the impeller is 5; and the rotating speed of the nuclear main pump is above 1750r / min, and the specific speed is within 380-430r / min.

Owner:JIANGSU UNIV

Hydraulic design method of no-jam cyclone pump

The invention provides a hydraulic design method of a no-jam cyclone pump. An impeller of the cyclone pump is a semi-opening-type impeller, blades of the impeller include long blades and short blades, the lengths of the blades are different, due to the facts that the diameter of an outlet of the impeller of the cyclone pump, the width of the outlet of the impeller, the specific value range of the long blades and the short blades of the impeller are optimized and hydraulic design is carried out by controlling F8 section area selection and increasing the volute throat area, conveyed solid media are easy to pass, the passing rate of the conveyed solid media are improved, the blocking phenomena are prevented, meanwhile, loss of circulation flow in the cyclone pump is reduced, and accordingly efficiency of the cyclone pump is improved, and economic efficiency is good in production practices.

Owner:JIANGSU UNIV

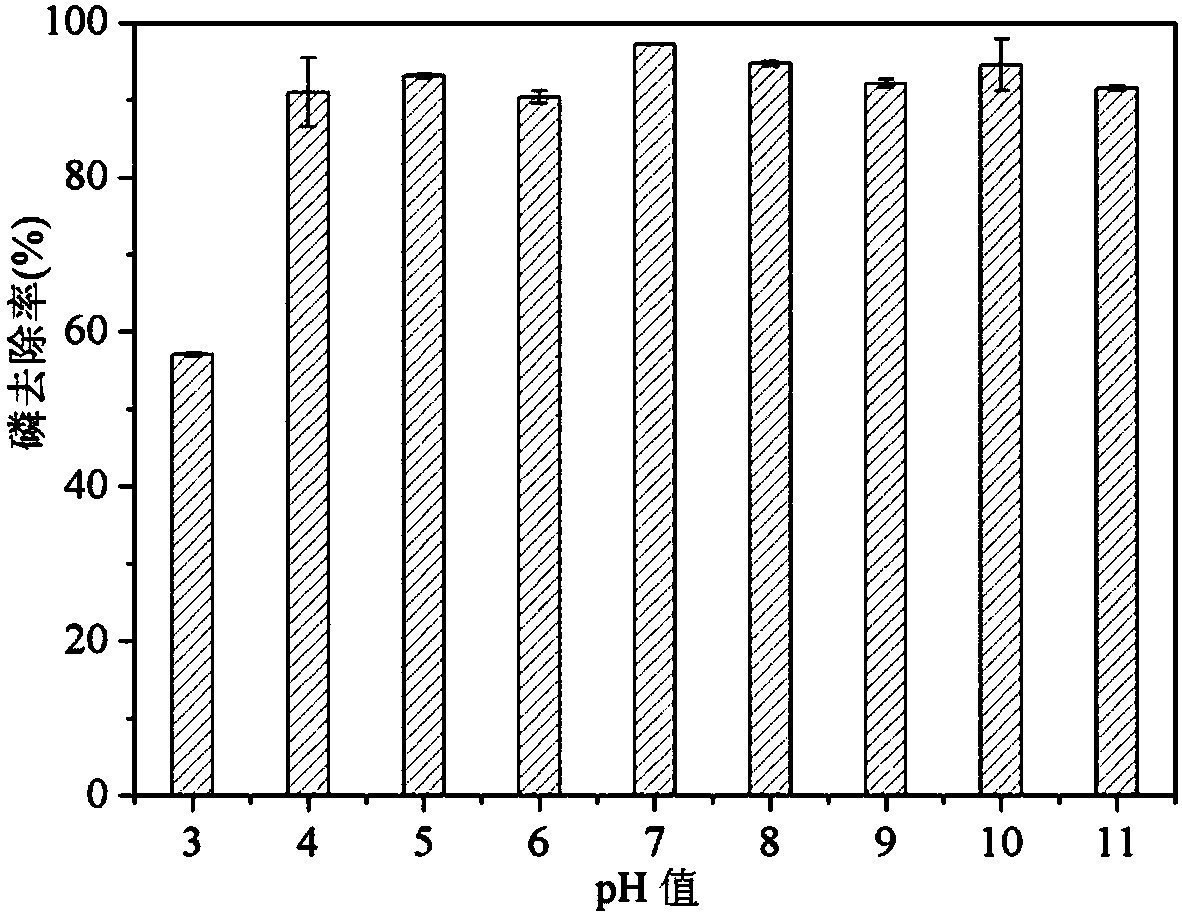

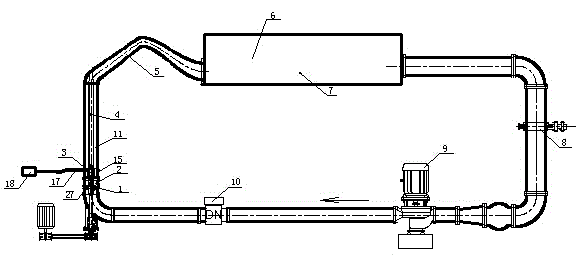

Modified anion resin material and preparation method and application thereof

ActiveCN107583673ALarge adsorption capacityImprove adsorption capacityOther chemical processesOrganic anion exchangersSorbentAdsorption effect

The invention provides a modified anion resin material as well as a preparation method and an application thereof. The preparation method comprises the steps as follows: a strong base type anion resinmaterial is washed and dried, and a dried strong base type anion resin material is obtained; a hydrochloric acid solution of ferric chloride and a hydrochloric acid solution of zirconium oxychlorideare mixed, a mixed solution is obtained, then, the dried strong base type anion resin material is added to a mixed solution to be treated, and the modified anion resin material is obtained. The modified anion resin material can be used as a phosphorus removal adsorbent. Iron oxide and zirconium oxide are successfully loaded on the strong base type anion resin material, so that the modified anion resin material retains the adsorptive property of the iron oxide and the zirconium oxide for phosphorus and provides a fixed environment of good mechanical strength and excellent hydraulic performance,and the excellent adsorption effect of the iron oxide and the zirconium oxide for phosphorus is played.

Owner:TONGJI UNIV

Axial flow pump device guide vane body hydraulic optimization method based on tests

ActiveCN104454564AImprove hydraulic performanceHydraulic optimizationPump componentsPump controlAxial-flow pumpHydraulic machinery

The invention discloses an axial flow pump device guide vane body hydraulic optimization method based on tests and belongs to the technical field of hydraulic machinery. The axial flow pump device guide vane body hydraulic optimization method based on the tests overcomes the defects that a pump device can not be matched with the hydraulic performance of a water outlet passage by the adoption of an existing axial flow pump guide vane body design method. According to the method, a model test device representing the influence of the average velocity circulation at a guide vane body outlet of an axial flow pump device on the hydraulic performance of the water outlet passage is designed and established, the guide vane body outlet circulation and the head loss of the water outlet passage in a group of tests containing seven schemes are tested and calculated respectively, and hydraulic optimization of a guide vane body of the axial flow pump device is achieved on the basis of clarifying the law of how the guide vane body outlet circulation of the axial flow pump device influences the head loss of the water outlet passage, so that the axial flow pump device is matched with the water outlet passage optimally, and the hydraulic performance of the axial flow pump device is further improved. The method is applicable to hydraulic optimization of guide vane bodies in axial flow pump devices composed of different types of axial flow pumps and different types of water outlet passages.

Owner:YANGZHOU UNIV

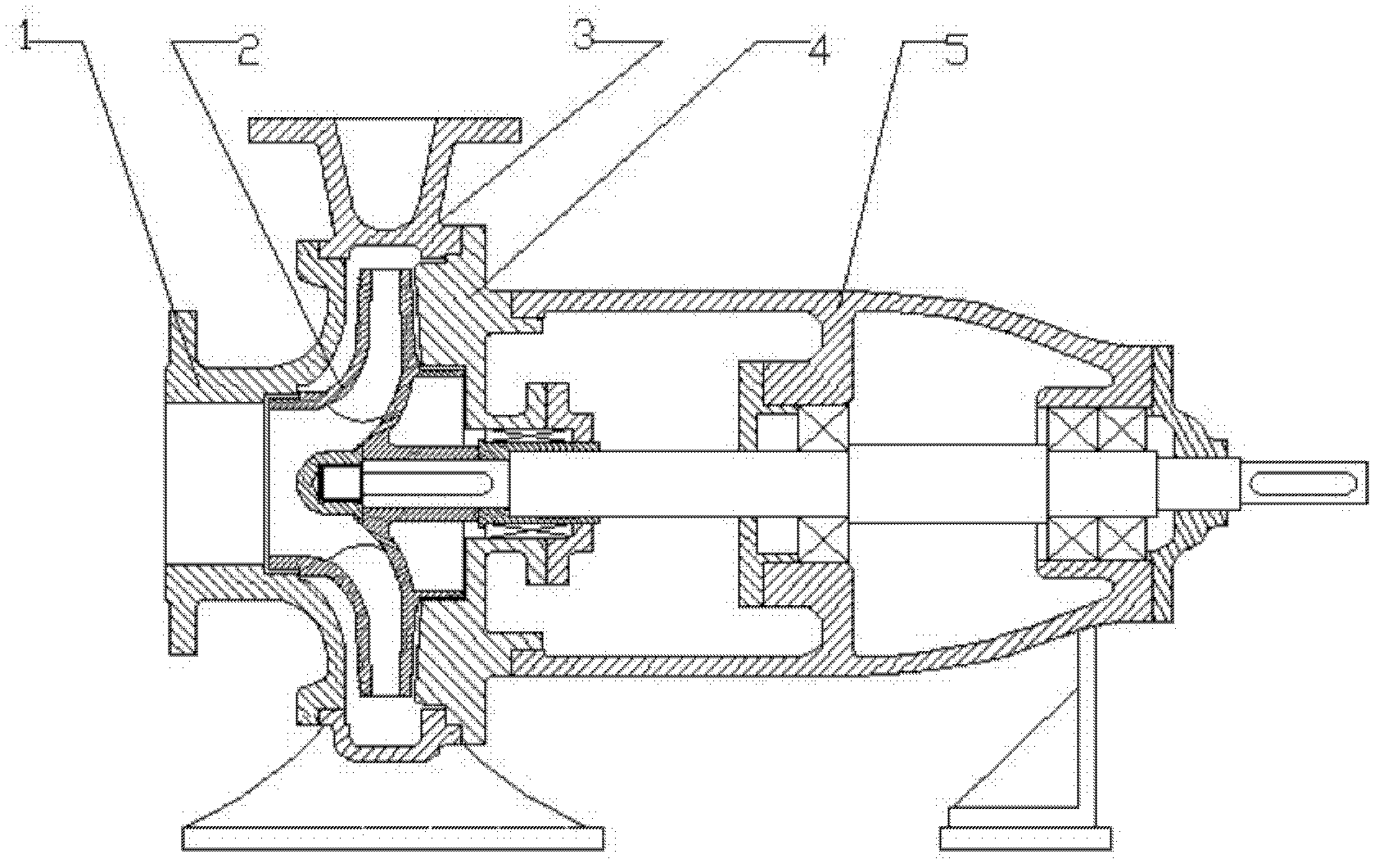

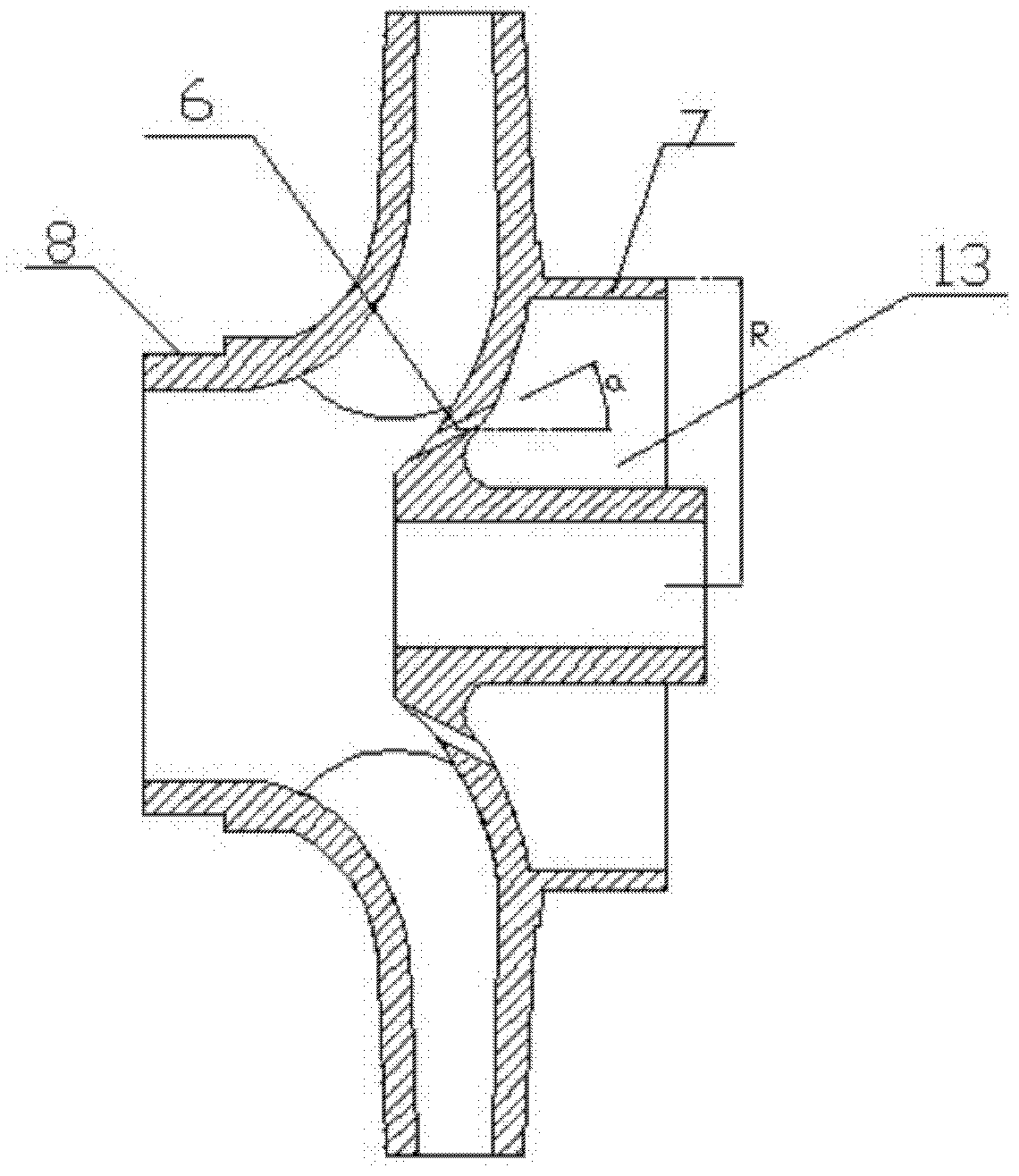

Single-stage centrifugal pump with balanced axial force

The invention discloses a single-stage centrifugal pump with a balanced axial force, which comprises a pump body, a front pump cover, an impeller, a rear pump cover, a rear cover plate opening ring and a bearing body, wherein a balancing chamber is formed by the rear part of a rear cover plate; the balancing chamber of the rear cover plate is communicated with an impeller suction port; the impeller is provided with an inclined balancing hole; one end of the balancing hole, which is positioned at the impeller suction port, is close to the position of a hub; one end of the balance hole, which is positioned on the balance chamber, is away from the position of the hub; an angle is formed by a center line of the balancing hole and the axial line of the hub; the diameter of a rear opening ring of the impeller is greater than that of a front opening ring of the impeller; and the length of the rear opening ring is greater than that of the front opening ring. According to the single-stage centrifugal pump disclosed by the invention, the balance of the axial force can be better achieved.

Owner:ZHEJIANG UNIV OF TECH

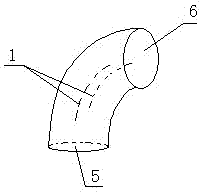

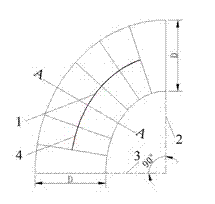

Novel 90-degree variable-curvature bent pipe

InactiveCN102410421AImprove flow characteristicsSimple and scientific structureFluid dynamicsSiphonsEngineeringCircular surface

The invention provides a novel 90-degree variable-curvature bent pipe, belonging to the technical field of fluid engineering. The central arc line of the bent pipe is a variable-curvature arc line with a gradually increased curvature or a quarter elliptic type line, each cross section perpendicular to the central arc line is a circular cross section, the circular cross section is a circular surface the diameter (D) of which is equal to that of an inlet orifice and an outlet orifice of the bent pipe, two side of the inner wall of the bent pipe are symmetrically provided with ribs, the thickness of the ribs is 0.005D, the height is 0.05D, the molded lines of the ribs and the central line of the bent pipe are arranged in the same curved surface, and the distance from the two ends of the ribs to the inlet and outlet orifices are respectively the length of the diameter (D) of 0.33-0.36 orifices. The novel 90-degree variable-curvature bent pipe provided by the invention has a scientific and simple structure and reasonable design, can restrain dean vortex, reduce the resistance loss by 4-8% caused by the dean vortex and improve the hydraulic efficiency of the whole pipeline or mechanical equipment system.

Owner:YANGZHOU UNIV

Device for integrating baffling denitrification and dephosphorization and COD degradation

ActiveCN105084637AReduce shockAvoid bringing inMultistage water/sewage treatmentSludgeReaction chamber

The invention discloses a device for integrating baffling denitrification and dephosphorization and COD degradation. The device comprises a reaction chamber, a transmission module and an oxygen supply module, wherein the reaction chamber comprises a first anaerobic cell, a second anaerobic cell, a mid-sedimentation cell, a nitrification cell, an anoxic cell, an aerobic cell and an end-sedimentation cell; the cells are separated by overflow partition plates; the transmission module comprises a sludge surpassing member and a sludge return member; and the oxygen supply module is composed of aerating equipment and two gas distributing pipes. The device disclosed by the invention has the benefits that as double anaerobic cells are designed with buffer functions, the impact effect of inflow abnormality and overhigh nitric nitrogen of return sludge on denitrifying phosphate-accumulating organisms is reduced, oxygen brought into a water inflow process is avoided, absolute anaerobism of the second anaerobic cell is ensured, and the stability and efficiency of the device disclosed by the invention in the treatment process are improved.

Owner:SINOPEC YANGZI PETROCHEM +1

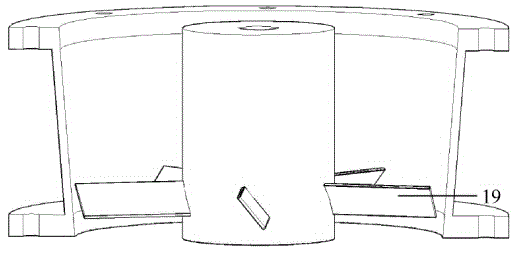

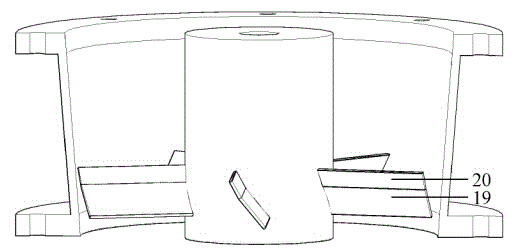

Vertical barrel pocket type extraction pump

InactiveCN101225833AReduce axial sizeLow installation accuracy requirementsPump componentsPumpsImpellerCavitation

The invention discloses a vertical bag type condensate pump, which is characterized in that a first stage impeller is a double suction impeller (2); the impeller (4) is closed; a radial guide vane (5) is positioned in an middle section (6); a balance drum (8) integrated with an upper shaft sleeve (10) is positioned on an upper main shaft (11); a balance drum sleeve (7) is positioned in an inner tube body (21); a narrow gap is formed between the balance drum (8) and the balance drum sleeve (7); a cavity above the balance drum (8) is communicated with an outer tube body (1) by a balance pipe (12); a guiding sheet (19) and a diversion cone (20) are positioned at the bottom part of the outer tube body (1), corresponding to the double suction impeller. The vertical bag type condensate pump has the advantages of compact structure, high efficiency, smooth operation, excellent anti-cavitation performance, and strong practicality and popularization value.

Owner:利欧集团湖南泵业有限公司

Front-located shaft type tubular pump water inlet flow passage with excellent hydraulic performance and application method thereof

ActiveCN104294883AGood hydraulic performanceEasy to useWater-power plantsHydro energy generationImpellerEngineering

The invention discloses a front-located shaft type tubular pump water inlet flow passage with excellent hydraulic performance and an application method thereof and belongs to the technical field of pump stations of water conservancy projects. The front-located shaft type tubular pump water inlet flow passage is divided into a linear inlet segment, a shaft flow passage segment, a through confluence segment and a round table rectifying segment along the water flow direction, and each segment has different geometrical characteristics; the shaft flow passage segment, through confluence segment and round table rectifying segment are complex in geometrical shape, and the shaft flow passage segment, through confluence segment and round table rectifying segment provide detailed section location drawings and section data lists; all sizes of the front-located shaft type tubular pump water inlet flow passage are represented by relative values, and the actually needed size of the pump station water inlet flow passage is obtained through multiplying the relative values by the diameter of a tubular pump impeller to be used for the pump station; parameters of the linear inlet segment can be regulated in a certain range according to the actual demands of the pump station so as to adapt to actual demands of different pump stations for such main geometrical parameters as flow passage length and width. The front-located shaft type tubular pump water inlet flow passage is significant for guaranteeing the safe, stable and effective running of the pump station.

Owner:YANGZHOU UNIV

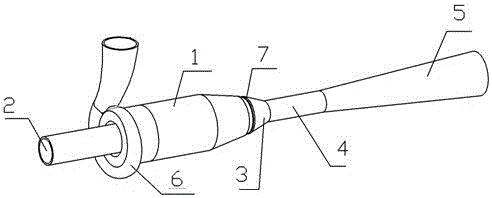

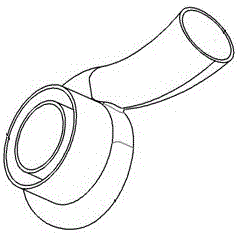

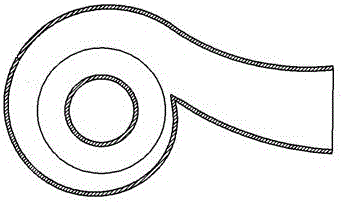

Jet pump with volute type flume

InactiveCN106224302AImprove flow statusJet pump efficiency improvementJet pumpsMachines/enginesStraight tubeWater flow

The invention provides a jet pump with a volute type flume. The jet pump comprises a fluid pipeline B, a fluid pipeline A arranged outside the fluid pipeline B in a sleeving mode, a constricted tube, a throat tube and an expansion tube, wherein the constricted tube, the throat tube and the expansion tube are sequentially connected with the water outlet end of the fluid pipeline A. The volute type flume arranged outside the fluid pipeline B in a sleeving mode is arranged at the inlet end of the fluid pipeline A. The diameter of the water outlet end of the fluid pipeline A is decreased gradually in the water flowing direction. The constricted tube is a round tube with the diameter being decreased gradually. The throat tube is a straight tube. The expansion tube is a round tube with the diameter being increased gradually. The jet pump is easy to manufacture and install, the symmetry of internal flow of the jet pump is good, flowing is more stable, and hydraulic performance is improved; the flow losses are reduced, mixing of two fluids is promoted, and the efficiency is improved advantageously; the frictional hydraulic losses are reduced; and the jet pump is suitable for an annular jet pump as well as a central jet pump.

Owner:WUHAN UNIV

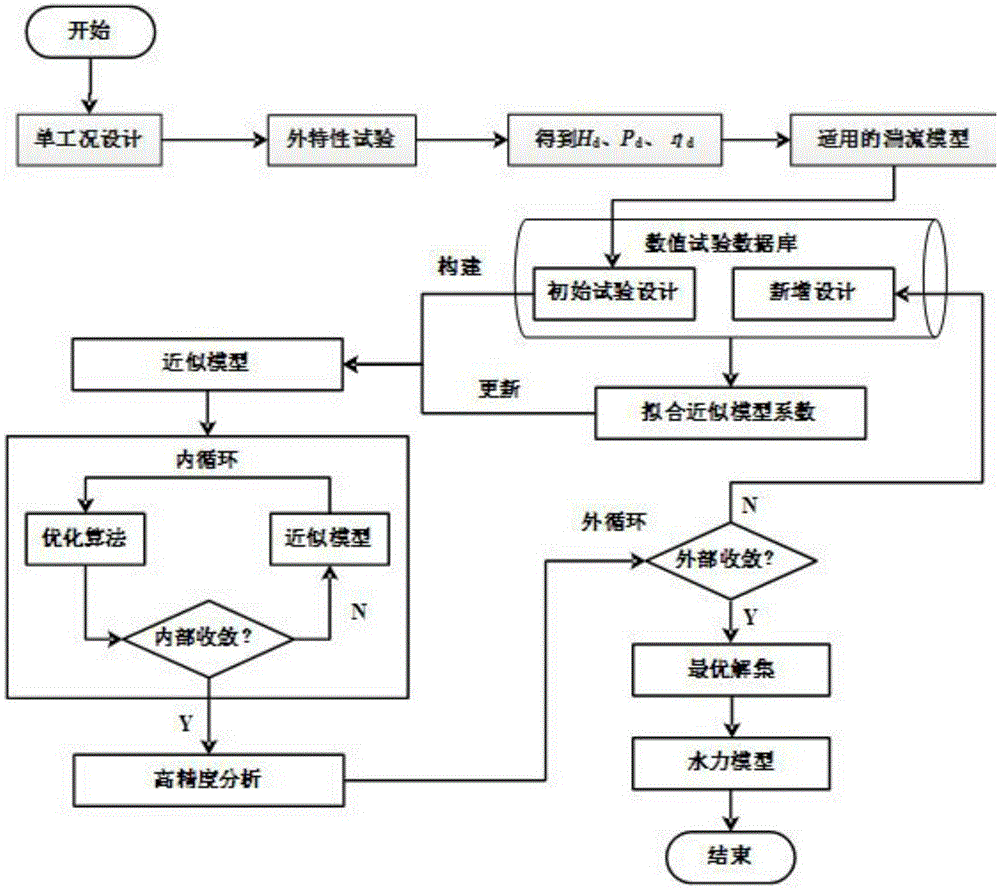

Multi-working-condition multi-target hydraulic optimization method for impeller of centrifugal pump with ultralow specific speed

ActiveCN105275867AEffective combinationImprove computing efficiencyPump componentsPumpsMinimum weightEngineering

The invention discloses a multi-working-condition multi-target hydraulic optimization method for an impeller of a centrifugal pump with the ultralow specific speed. The method comprises the specific steps that the lift, the power and the efficiency of the centrifugal pump with the ultralow specific speed under various working conditions are measured; a turbulence model with the smallest error between an experiment value and worked-out values of the centrifugal pump with the ultralow specific speed under various working conditions is found out; an objective function is obtained through the combination of the maximum weighted average efficiency or the minimum weighted average power under the multiple working conditions, the minimum weighted average radial force in the impeller under the multiple working conditions and the lowest weight of the impeller, a multi-working-condition multi-target optimization model of the impeller of the centrifugal pump with the ultralow specific speed is solved on the basis of a variable complexity method-multidisciplinary feasible (VCM-MDF) optimization strategy with internal and external double-circulation structures, and an impeller overall optimal solution set is obtained; and a hydraulic model of the impeller is designed according to the impeller overall optimal solution set obtained through optimization. By means of the method, multi-working-condition multi-target hydraulic optimization can be carried out on the impeller of the centrifugal pump with the ultralow specific speed, so that the hydraulic performance of the pump is improved, and the radial force in the impeller and the weight of the impeller can also be reduced.

Owner:JIANGSU UNIV

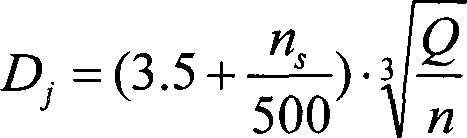

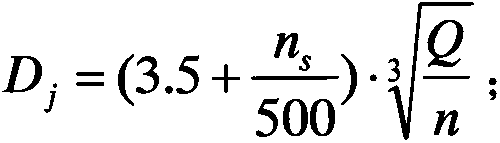

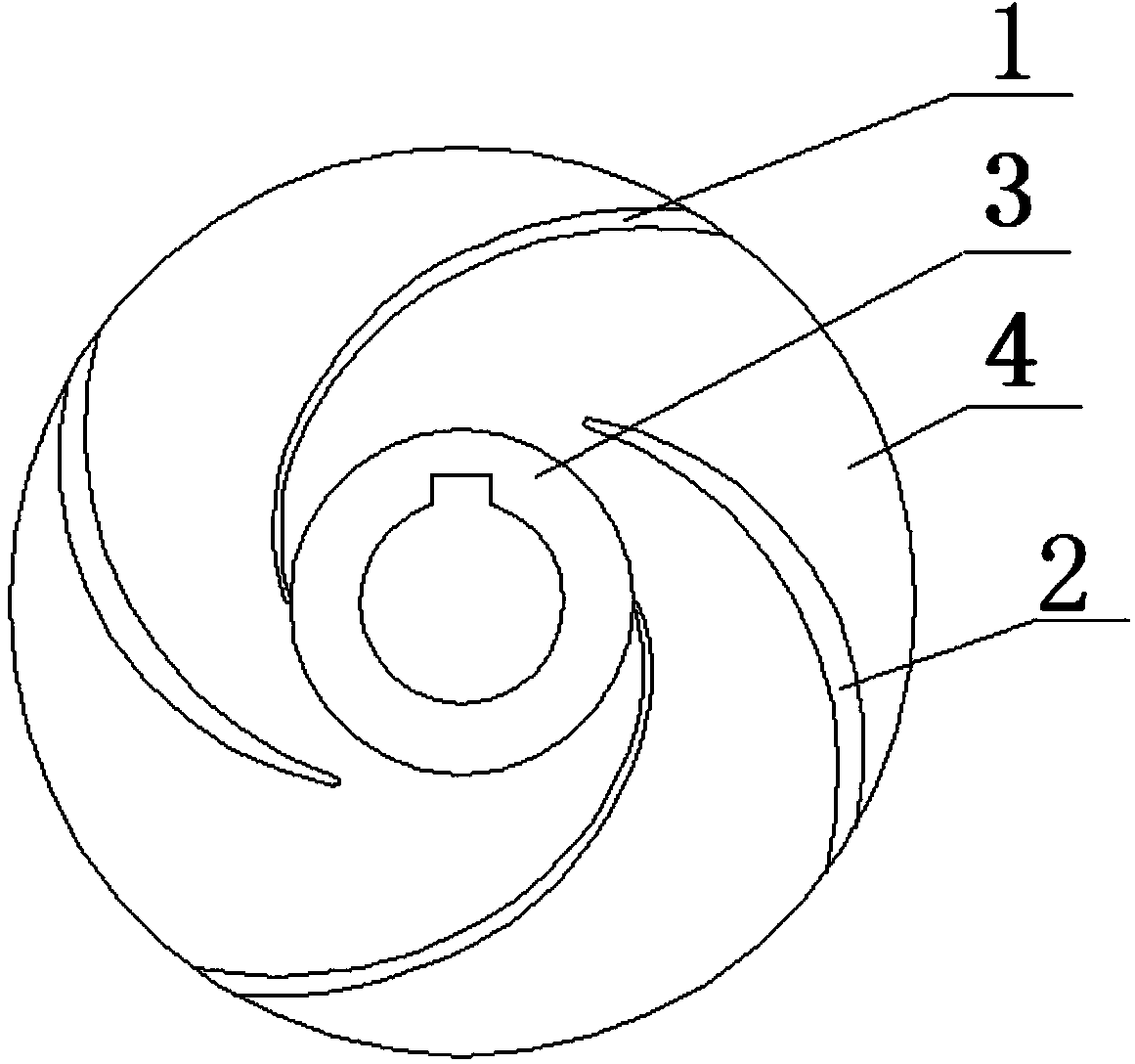

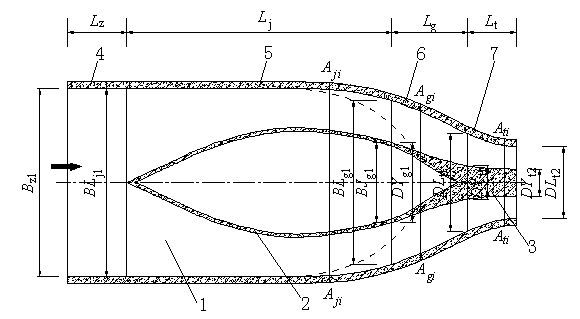

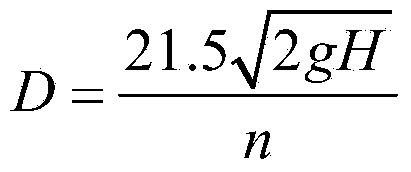

Combined type method for designing variable-camber low-specific-speed centrifugal pump impeller

ActiveCN103994099AImproved hydraulic performance and conveying capacityHigh liftPump componentsPumpsSpecific speedSize parameter

The invention provides a combined type method for designing a variable-camber low-specific-speed centrifugal pump impeller. The impeller is suitable for the fields such as pipe pressurization, high-lift water supply and municipal engineering. The design formula of main physical dimension parameters, including the impeller outer diameter D, the impeller inlet diameter Dj, the impeller outlet width b, the front bending blade inner diameter Db, the splitter blade slant angle alpha1, the front bending blade slant angle alpha2 and the blade wrapped angle phi, of the impeller is given. By means of the combined type method for designing the variable-camber low-specific-speed centrifugal pump impeller, flowing inside the impeller can be improved, and the lift and the stability of the impeller on large-flow working condition points can be improved.

Owner:JIANGSU YAMEI PUMP IND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com