Device for integrating baffling denitrification and dephosphorization and COD degradation

A denitrification phosphorus removal and integrated device technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the impact of denitrification phosphorus accumulation bacteria, baffle reactor Stir unevenly and other problems to reduce impact, avoid excessive phosphorus absorption and excessive phosphorus release under anaerobic conditions, and achieve low equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

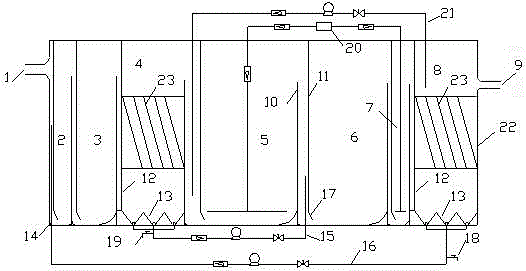

[0030] The petrochemical wastewater after air flotation treatment (CODcr is 330mg / L, ammonia nitrogen concentration is 30mg / L, TP is 5mg / L) enters the first anaerobic compartment (2) through the water inlet (1), and is mixed with the return sludge The pH is around 7 to degrade COD and remove refluxed nitrate nitrogen. Then flow into the second anaerobic compartment (3) and adjust the pH to about 7.5 by adding lye, and the denitrifying phosphorus-accumulating bacteria perform anaerobic phosphorus release and degrade COD to synthesize energy and store it in the body. After the separation of mud and water in the middle sedimentation compartment (4), the sludge overflows to the anoxic compartment (6), with an excess ratio of 30%; while the supernatant enters the nitrification compartment (5). The pH of the supernatant entering the nitrification cell (5) is adjusted to about 8.0, and the nitrifying bacteria oxidize the ammonia nitrogen in the supernatant to nitrate nitrogen, etc., ...

Embodiment 2

[0035] Processing method is as embodiment 1. .The specific operating indicators are:

[0036] The CODcr of petrochemical wastewater after air flotation treatment is 230mg / L, the concentration of ammonia nitrogen is 20mg / L, the concentration of TP is 3mg / L, the water temperature is 30°C, and the pH value is 7.0.

[0037] The measured COD of the effluent is 40mg / L, the concentration of ammonia nitrogen is only 1mg / L, the concentration of TN is 3.5mg / L, and the concentration of TP is 0.3mg / L. The removal rates of COD, ammonia nitrogen and TP are respectively 83%, 95%, and 90%. , the effluent reaches the first-class A standard stipulated by the state.

Embodiment 3

[0039] Processing method is as embodiment 1. .The specific operating indicators are:

[0040] The CODcr of petrochemical wastewater after air flotation treatment is 430mg / L, the concentration of ammonia nitrogen is 44mg / L, the concentration of TP is 7mg / L, the water temperature is 30°C, and the pH value is 7.0.

[0041] The measured COD of the effluent is 48mg / L, the concentration of ammonia nitrogen is only 2mg / L, the concentration of TN is 6.5mg / L, and the concentration of TP is 0.4mg / L. The removal rates of COD, ammonia nitrogen and TP are respectively 89%, 95%, and 94%. , the effluent reaches the first-class A standard stipulated by the state.

[0042] This device adopts the theory of denitrification phosphorus removal, which not only solves the problem of insufficient carbon source caused by substrate competition in the traditional biological phosphorus removal process, but also avoids the contradiction between the sludge age mismatch between nitrifying bacteria sludge a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com