Prestressed concrete glass reinforced plastic composite pipe and preparation method thereof

A glass fiber reinforced plastic, prestressed technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of high roughness coefficient of concrete inner wall, poor concrete crack resistance, influence of pipeline flow, etc., to achieve excellent hydraulic performance, good hydraulic performance, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] When the prestressed concrete fiberglass composite pipe provided by the present invention is manufactured,

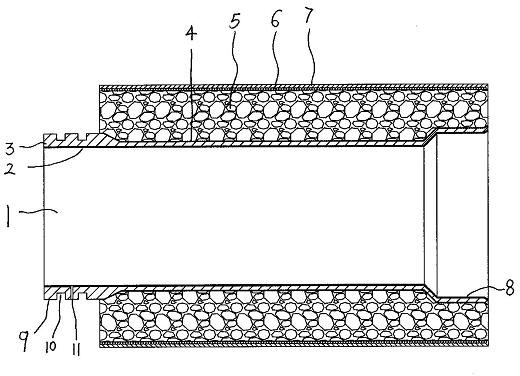

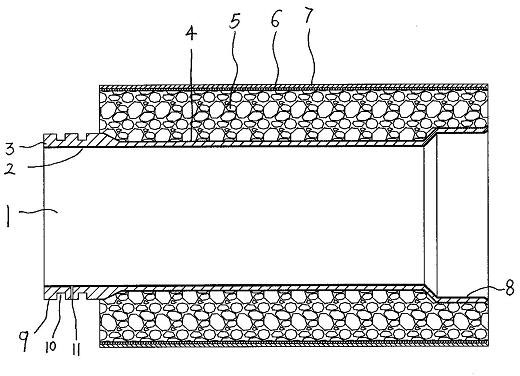

[0024] The first step is to use the winding process to make the FRP lining layer 2 on the cylindrical inner mold, and then wind the FRP structure layer 3 on the FRP lining layer 2. The right end of the FRP structure layer 3 is the socket 8, and the left end is the socket 9 , and coat resin quartz sand particles on the outer wall of the FRP structure layer 3 except for the socket 9 to form a transition layer 4;

[0025] In the second step, after the FRP structure layer 3 is solidified, the inner mold is removed, and the outer mold is placed on the outer mold; a pipe ring cavity is formed between the transition layer 4 and the outer mold, and ordinary concrete is poured in this cavity, and vertical vibration is adopted. Or horizontal centrifugal pouring process to form concrete structure layer 5;

[0026] The third step takes off the outer mold, and winds the pres...

Embodiment 2

[0030] When the prestressed concrete fiberglass composite pipe provided by the present invention is manufactured,

[0031] The first step is to use the winding process to make the FRP lining layer 2 on the cylindrical inner mold, and then wind the FRP structure layer 3 on the FRP lining layer 2. The right end of the FRP structure layer 3 is the socket 8, and the left end is the socket 9 , and coat resin quartz sand particles on the outer wall of the FRP structure layer 3 except for the socket 9 to form a transition layer 4;

[0032] In the second step, when the FRP structure layer 3 is solidified, the inner mold is removed, and the outer mold is placed on the outer mold; a pipe ring cavity is formed between the transition layer 4 and the outer mold, and ordinary concrete is poured in this cavity, and vertical vibration is adopted. Or a horizontal centrifugal pouring process to form a concrete structure layer 5, and place glass reinforcement cages in the concrete structure laye...

Embodiment 3

[0037] When the prestressed concrete fiberglass composite pipe provided by the present invention is manufactured,

[0038]The first step is to use the winding process to make the FRP lining layer 2 on the cylindrical inner mold, and then wind the FRP structure layer 3 on the FRP lining layer 2. The right end of the FRP structure layer 3 is the socket 8, and the left end is the socket 9 ;

[0039] The second step is to take off the inner mold after the glass fiber reinforced plastic structure layer 3 is solidified, and put the outer mold on its outer jacket; a pipe ring cavity is formed between the glass fiber reinforced plastic structure layer 3 and the outer mold, and resin concrete is poured in this cavity, and the vertical mold is adopted. Vibration or horizontal centrifugal pouring process to form concrete structure layer 5;

[0040] The third step takes off the outer mold, and winds the prestressed glass reinforcement outside the concrete structure layer 5 to form the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com