Patents

Literature

143 results about "Roughness coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

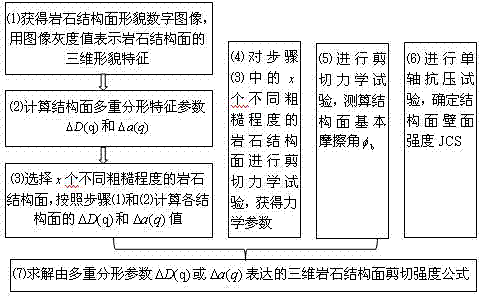

Multi-fractal evaluation method for three-dimensional rock structure surface shear mechanical behavior

InactiveCN103926156ABig subjectivityOvercome the pitfalls of artificial valuationMaterial strength using steady shearing forcesClassical mechanicsStructural engineering

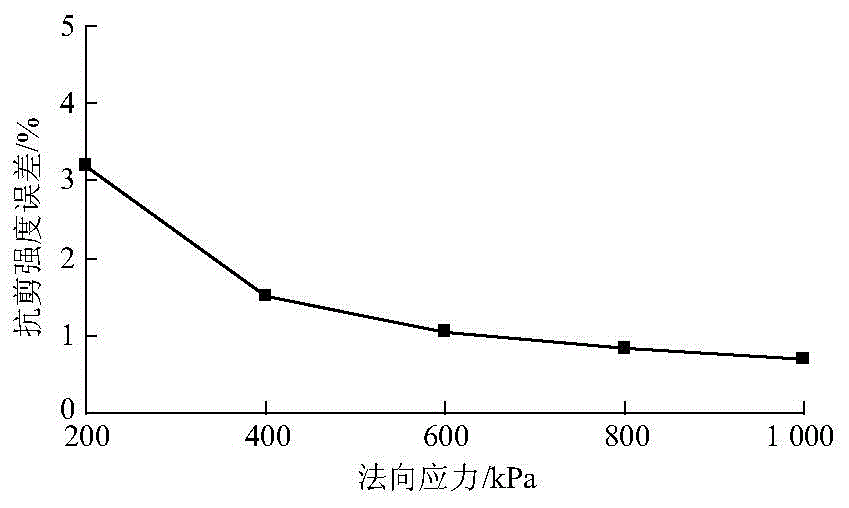

The invention provides a three-dimensional rock structure surface shear strength evaluation method. The method comprises the following steps of (1) acquiring three-dimensional topography data of a rock structure surface; (2) calculating multi-fractal characteristic parameters delta D (q) and delta a (q) of the structure surface according to a multi-fractal calculation formula, and representing the roughness of the three-dimensional rock structure surface by using the delta D (q) and the delta a (q); (3) carrying out a shear mechanics test on the rock structure surfaces with different roughness degrees to obtain shear mechanics parameters, and calculating the values of the delta D (q) and the delta a (q) of all the structure surfaces according to the step (1) and the step (2); and (4) testing a Barton shear formula improved by calculation data fitting by the step (3) to obtain the three-dimensional rock structure surface shear strength formula expressed by the delta D (q) or the delta a (q). Therefore, the rock structure surface shear strength can be evaluated by the three-dimensional rock structure surface shear strength formula in the engineering practice. The formula overcomes the defect that the Barton formula only considers about the two-dimensional characteristic and artificial estimation of joint roughness coefficient (JRC) of the structure surface, so that a method for comprehensively evaluating the shear strength characteristic of the rock structure surface is provided.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

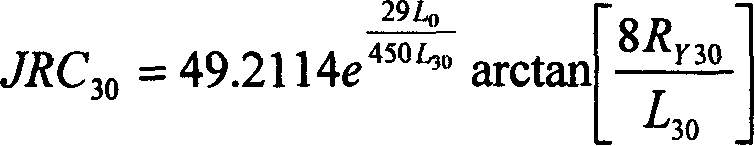

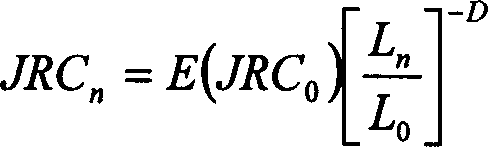

Method for determining dimensional size effects of toughness coefficients of typical stone structural surface

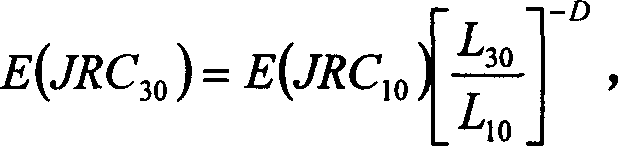

A method for confirming fractal dimension includes preparing section to be measured, drawing contour curve, measuring fluctuation amplitude Ry10 for 10 cm section contour curve and calculating out its roughness coefficient JRGo value solving out expected value E (JRC10) for JRC10; applying the same steps to obtain expected value E (JRC30) for 30cm section, utilizing formula E=(JRC30)=E(JRC10)[L30 / L10]-D to convert out fractal dimension D of JRC dimension effect for typical rock structural plane.

Owner:JINHUA VOCATIONAL TECH COLLEGE

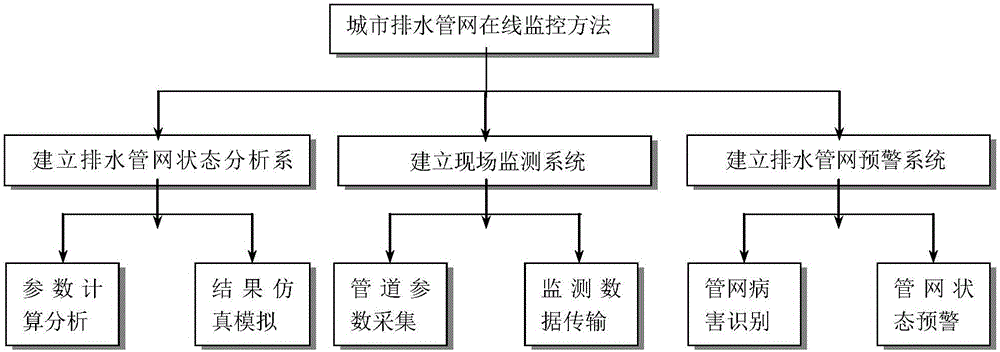

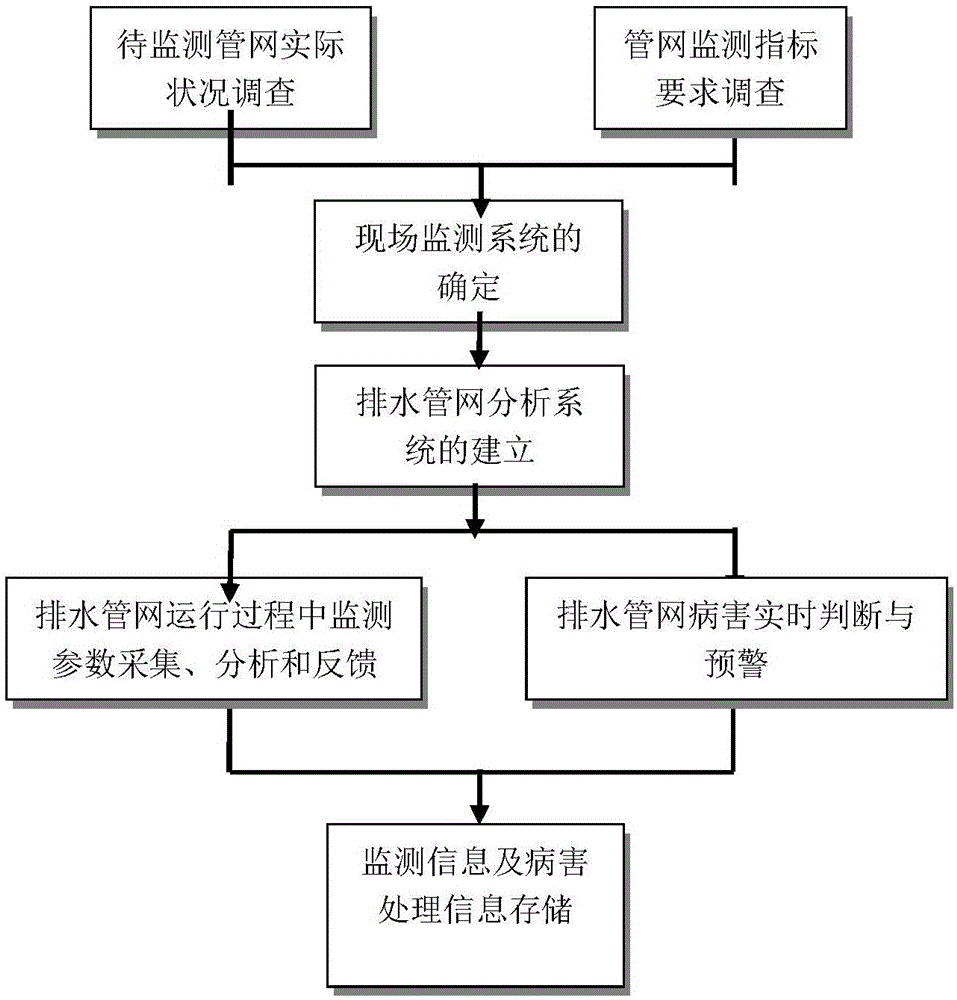

Urban drainage network online detection method

ActiveCN105065917AImprove management levelReduce security risksPipeline systemsDiseaseSite monitoring

The invention discloses an urban drainage network online detection method. The method includes the steps that S1, an on-site monitoring system of a drainage network is built, and pipeline liquid level parameters and pipeline displacement parameters of all monitoring points in the operation process of the drainage network are collected and stored in a pre-warning database; S2, according to the pipeline position, the elevation, the pipeline diameter, the gradient and pipeline roughness coefficient parameters of each monitoring point, a static database of the drainage network is built, and the static database is associated with the pre-warning database; S3, a state analysis system of the drainage network is built to obtain the operation state of the drainage network; and S4, a pre-warning system of the drainage network is built, pipeline disease problems in the operation process of the drainage network are judged in real time according to the state of the drainage network and pipeline displacement state analysis results, and real-time pre-warning is achieved. A whole set of monitoring method is disclosed for stable and safe operation of an urban drainage network to achieve informatization management of the urban drainage network, and bases are provided for urban drainage network planning and construction.

Owner:JSTI GRP CO LTD

Method for measuring and calculating roughness of field rock structural plane

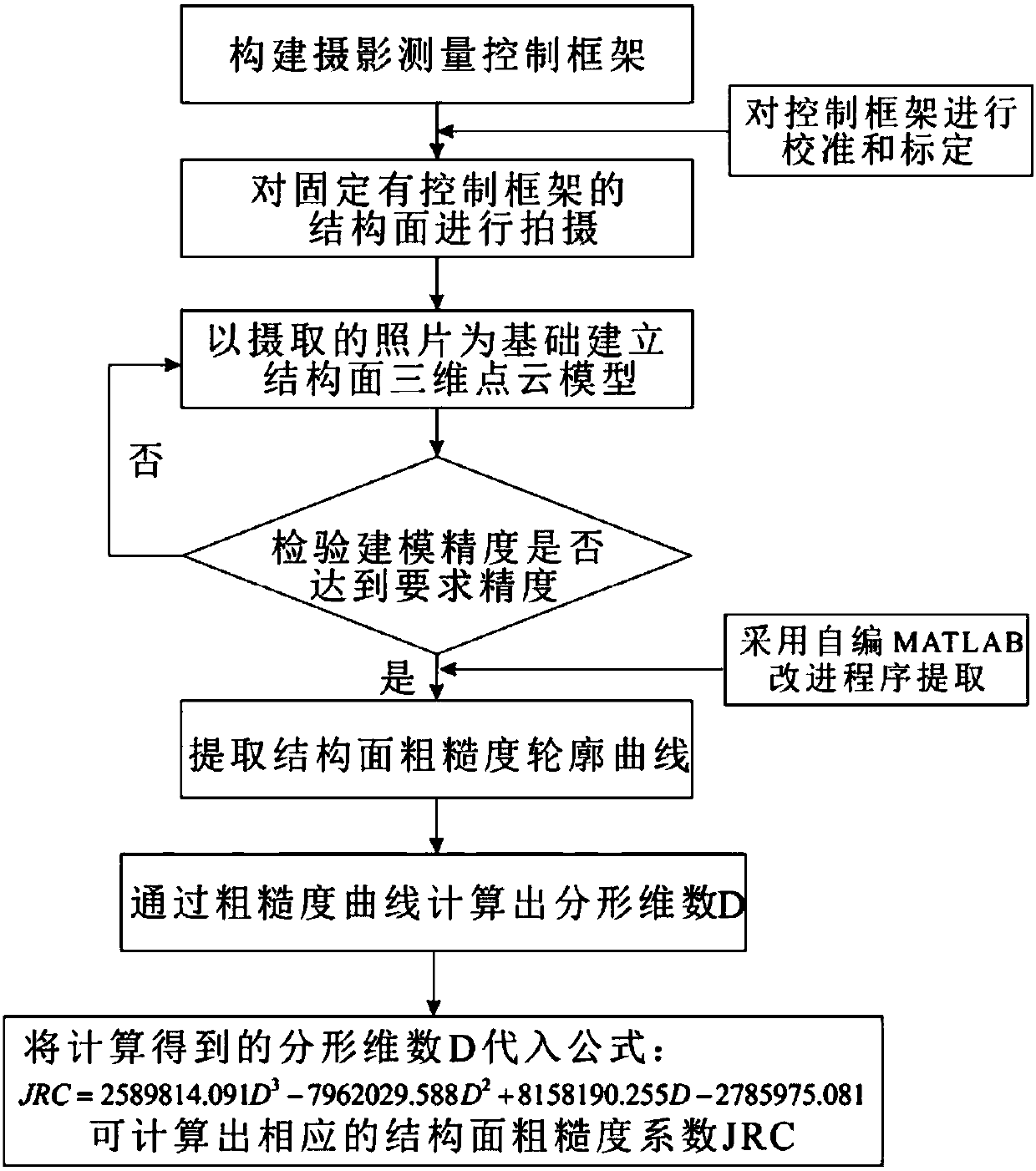

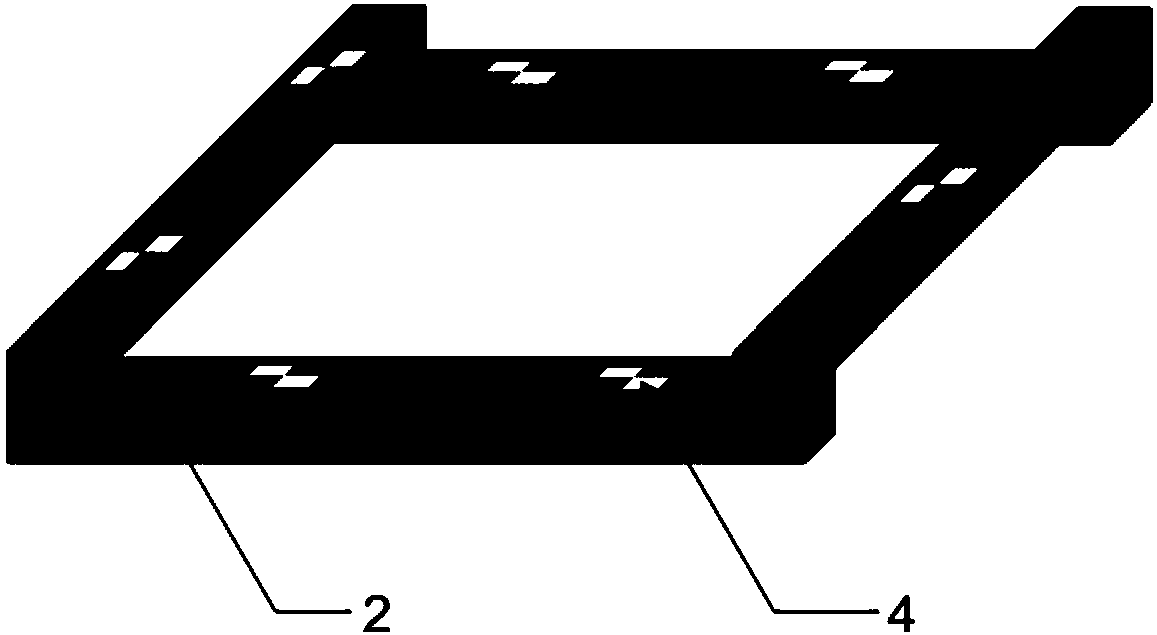

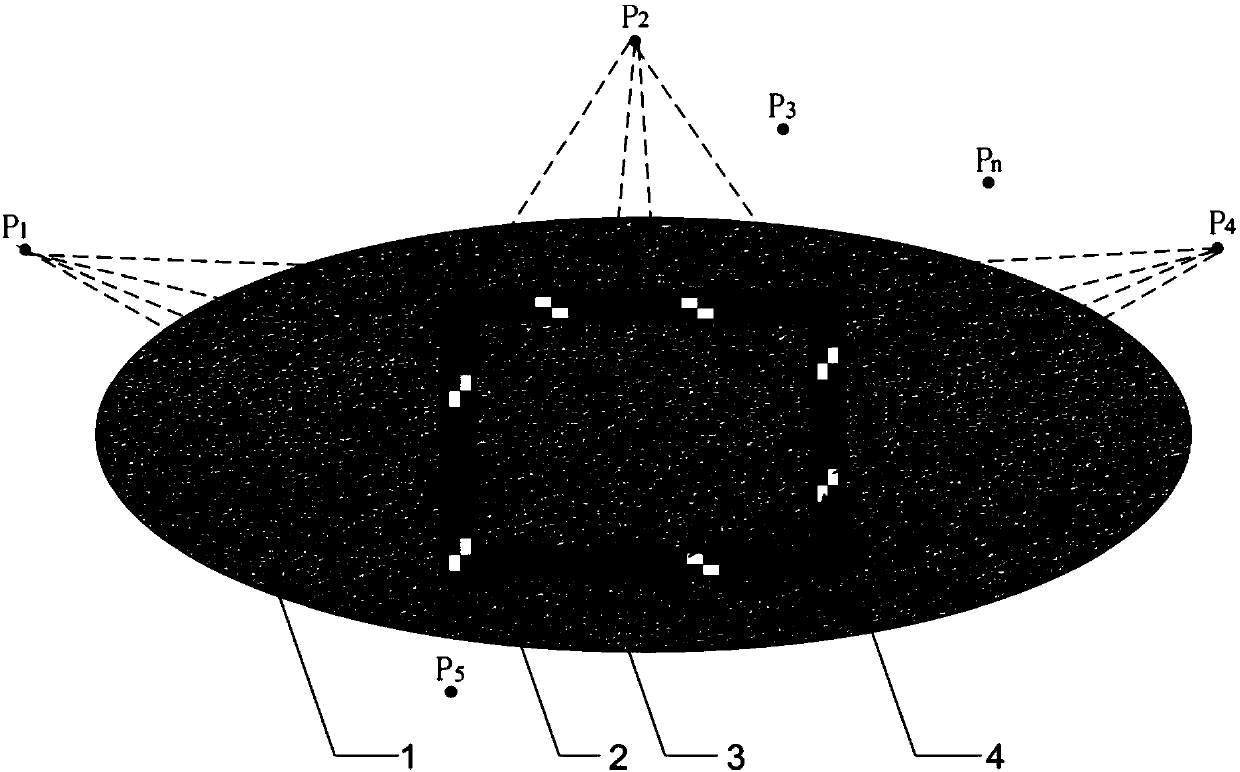

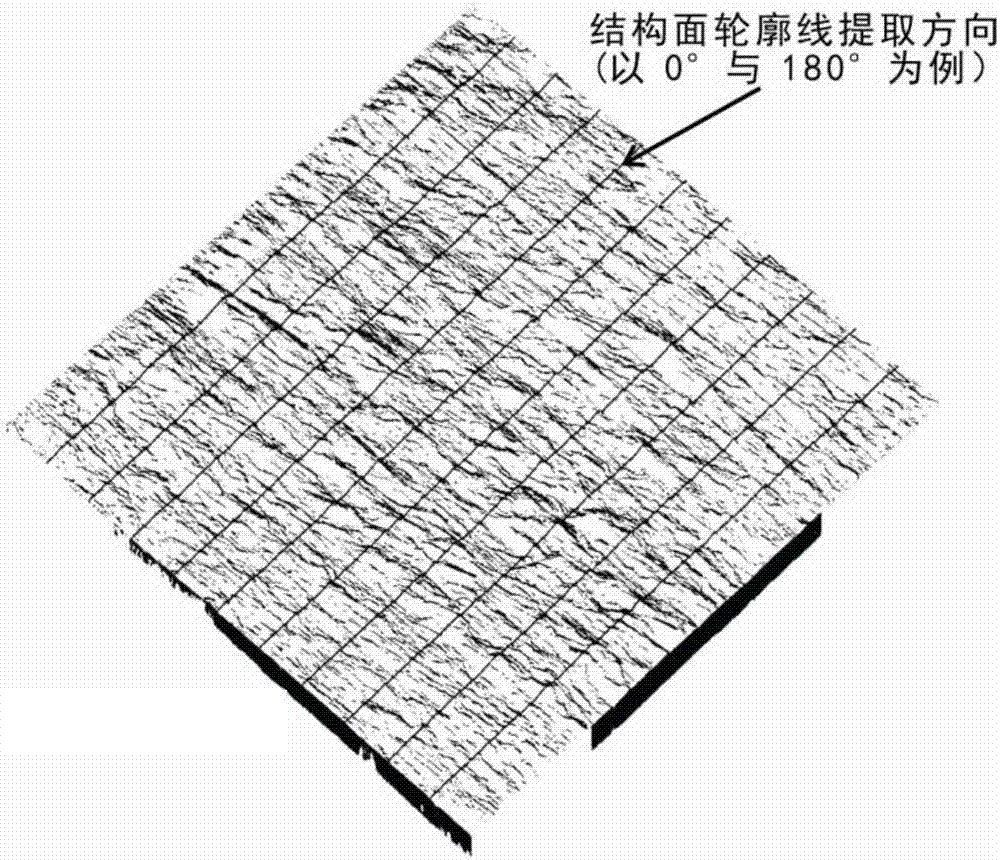

ActiveCN107655459AReduce biasImprove computing efficiencyPicture interpretationPoint cloudClassical mechanics

The invention discloses a method for measuring and calculating roughness of a field rock structural plane. The method comprises the following steps: constructing a closed control frame by straight battens, and aligning the control frame; fixing the aligned control frame on a to-be-measured structural plane, and photographing different positions of the to-be-measured structural plane, wherein the photographing range comprises the whole frame; establishing a three-dimensional point cloud model of the field rock structural plane by pictures; extracting a roughness profile curve in any direction of the structural plane by the three-dimensional point cloud model; calculating the roughness fractal dimension of the structural plane by the roughness profile curve of the structural plane; and calculating the corresponding roughness coefficient of the rock structural plane by the fractal dimension of the roughness of the rock structural plane. By the method, the calculation precision and efficiency are improved; and meanwhile, the method is suitable for indoor and field environments.

Owner:NANJING UNIV OF SCI & TECH

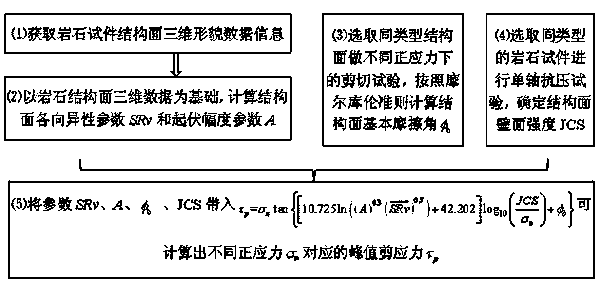

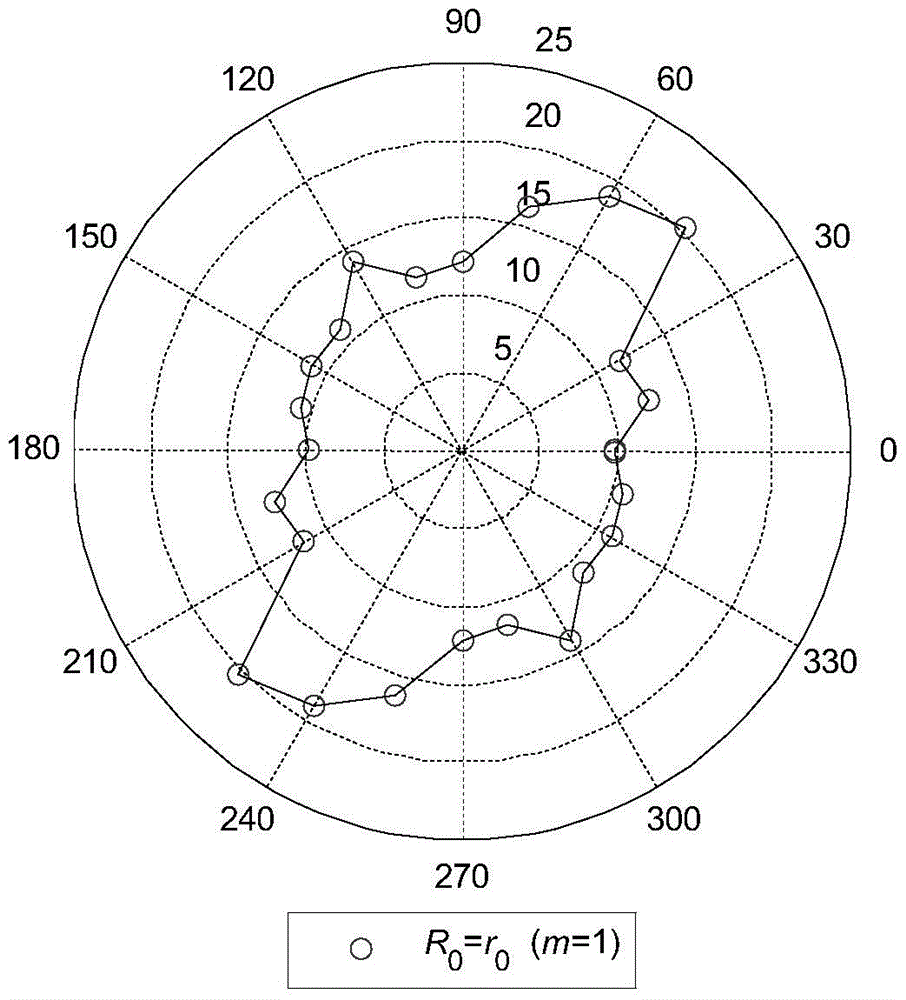

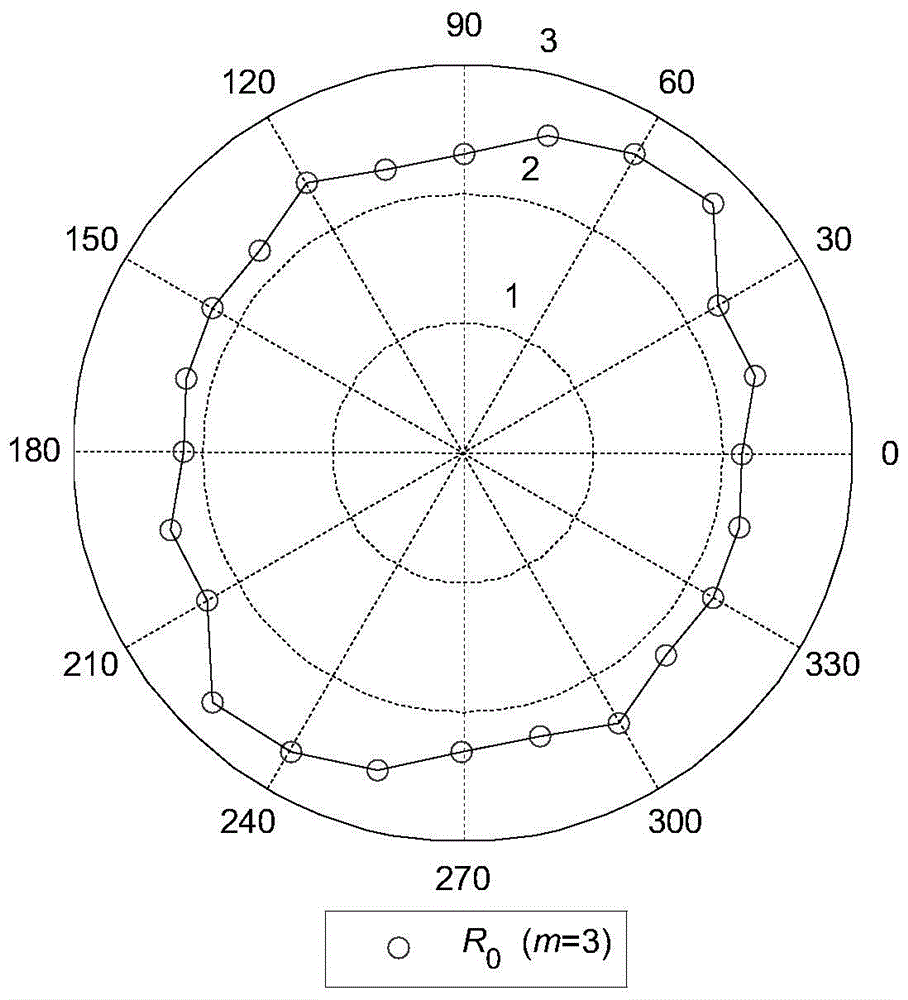

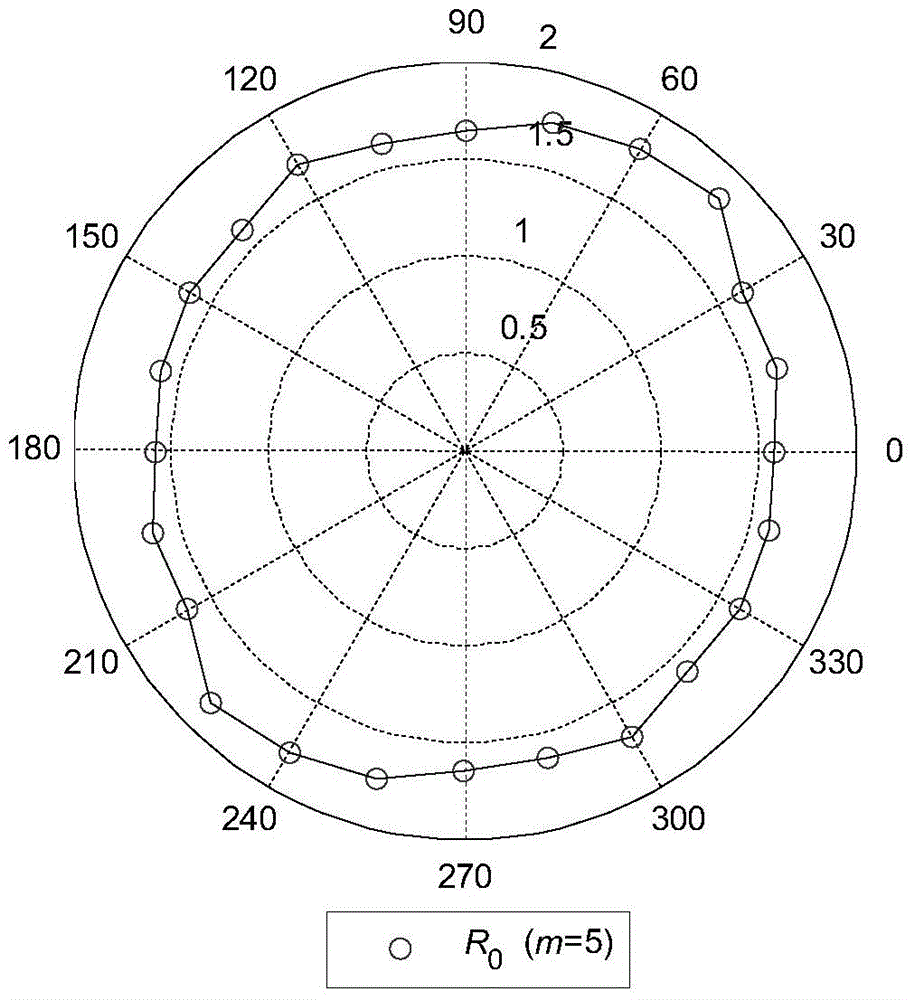

Evaluation method of shear strength of rock structural surface with anisotropic characteristics

InactiveCN105466790AOvercome the pitfalls of artificial valuationMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesPetrologyRoughness coefficient

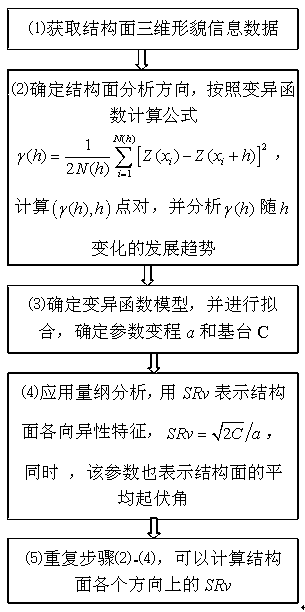

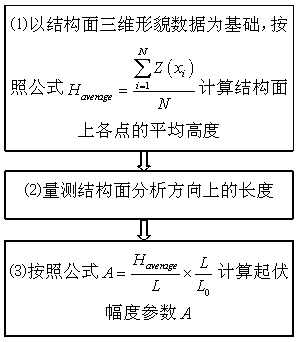

The present invention relates to evaluation method of shear strength of a rock structural surface with anisotropic characteristics. The method comprises the steps of: (1) acquiring three-dimensional morphology data of the rock structural surface; (2) calculating an anisotropic characteristic parameter SRv and a relief intensity parameter A of the structural surface, and expressing roughness in each direction of the three-dimensional rock structural surface by using the parameters SRv and A; (3) testing the wall strength JCS and basic friction angle of rock structural surfaces of the same type; and (4) substituting the structural surface parameters obtained in the steps (2) and (3) into a formula shown as below to obtain the peak shear strengths under different direct stress. The present invention focuses on the anisotropic characteristics of structural surface, overcomes the defect of artificial valuation of roughness coefficient JRC in Barton formula and realizes quick and accurate evaluation of shear strength of the rock structural surface on all directions.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

True object material quality reflecting attribute modeling approach based on linear light

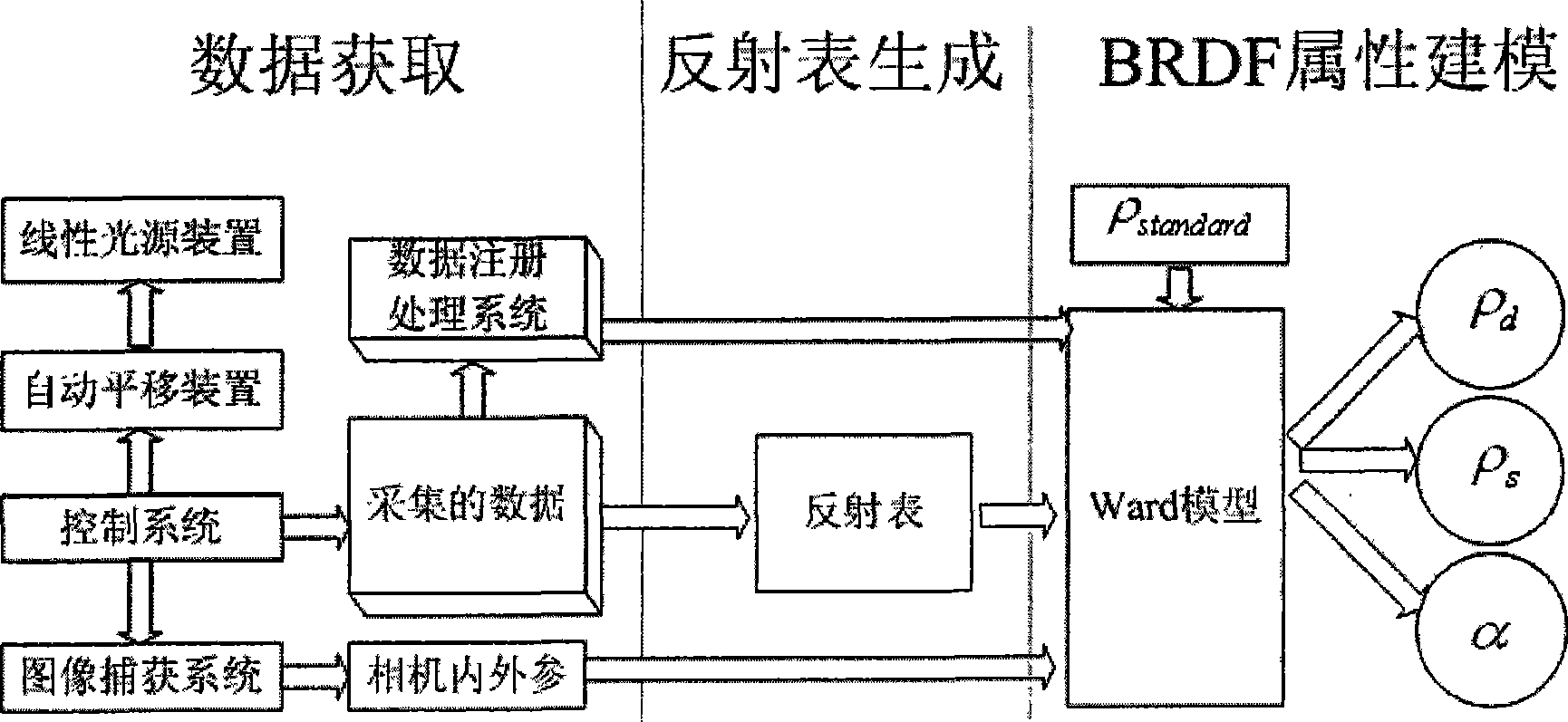

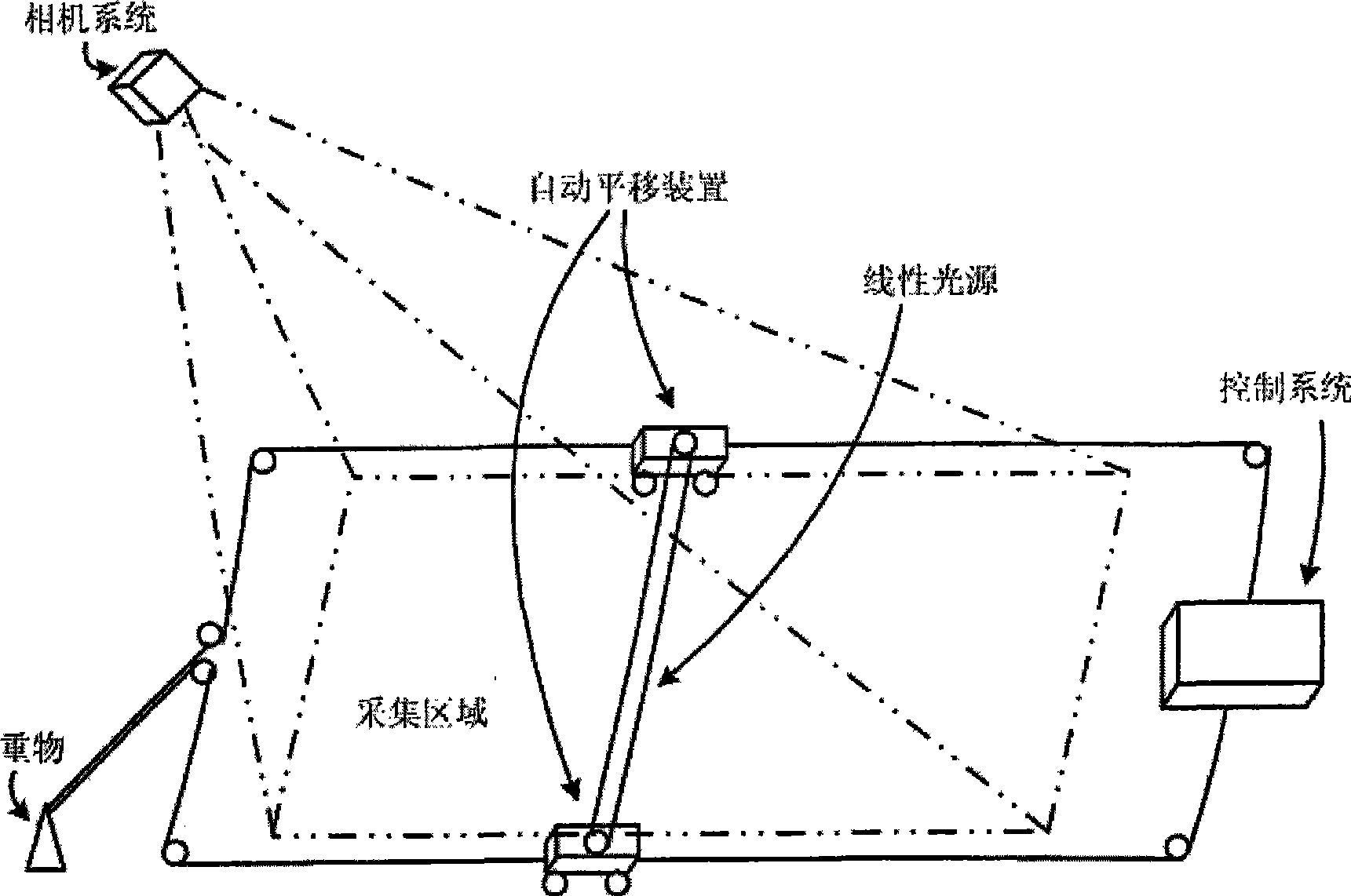

A method for modeling a reflection attribute of a real object material based on a linear light source comprises the following steps: (1) a data collection device based on the linear light source collects and process data; the linear light source is taken as a light source system of the data collection device; the linear light emitted by the linear light source shines a collected plane object, a control system drives an automatic translation system to move forwards; meanwhile, an industrial camera collects images of the collected plane object, a computer performs subsequent processing of the collected image data to obtain a trajectory curve of pixel values and store the trajectory curve; (2) a reflection table is generated; (3) BRDF attribute is modeled to obtain rhod of a Ward illumination model, and then obtain alpha, and finally obtain rhos according to the trajectory curve of the pixel values obtained in the step (1) and the reflection generated in the step (2), wherein, the rhod is a diffuse reflection parameter, the rhos is a mirror reflection parameter and the alpha is a material roughness coefficient. The method can efficiently collect data and quickly solve the parameters of the BRDF model, and is easy to be realized.

Owner:BEIHANG UNIV

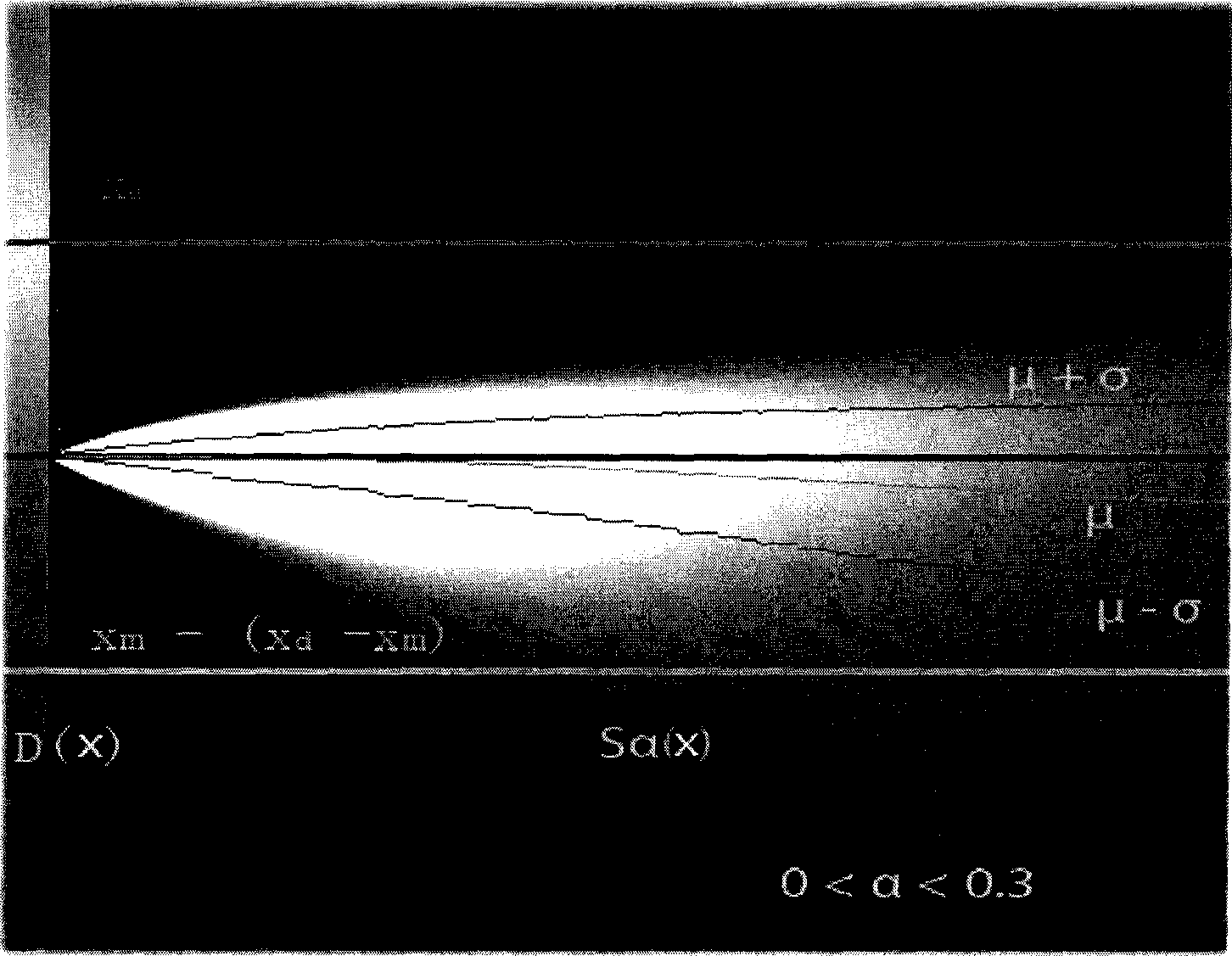

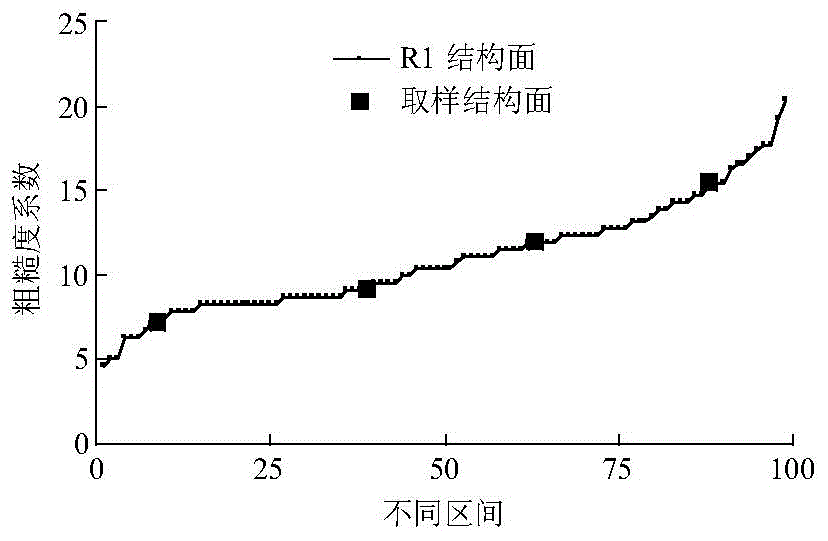

Joint roughness coefficient size effect sampling representativeness evaluation method

ActiveCN104834806ASolving Quantitative Evaluation ProblemsImprove reliabilitySpecial data processing applicationsNormal densityResearch Object

The invention discloses a joint roughness coefficient size effect sampling representativeness evaluation method. The method comprises the following steps: selecting a typical rock structural plane for serving as a research object of the roughness coefficient size effect, measuring a structural plane contour line with a maximum-size-effect research size in an oriented way through a profilograph, extracting the surface coordinate information of a series of size structural plane samples according to a field large-scale rock structural plane surface form element measuring result, calculating the roughness coefficients of the series of samples, and performing probability density function fitting on the overall distribution of standard size sample data; building a joint roughness coefficient size effect probability density function model; calculating a series scale joint roughness coefficient probability density function maximum value according to a maximum likelihood estimation principle; and determining the roughness coefficient representative value of each sample through relative deviation analysis of the roughness coefficient of each structural plane sample and a representative evaluation index. The quantitative evaluation problem of the joint roughness coefficient size effect sample representativeness is solved, and the reliability is high.

Owner:SHAOXING UNIVERSITY

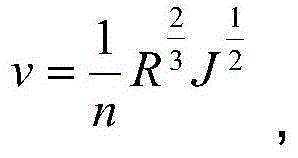

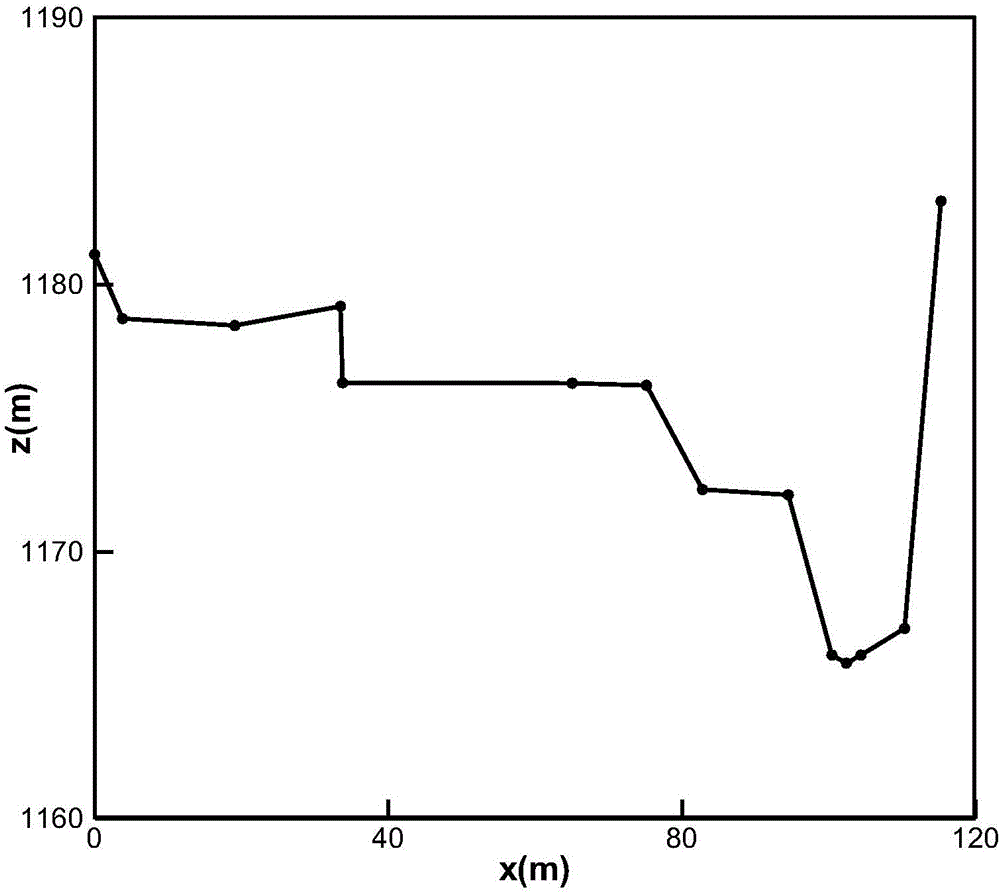

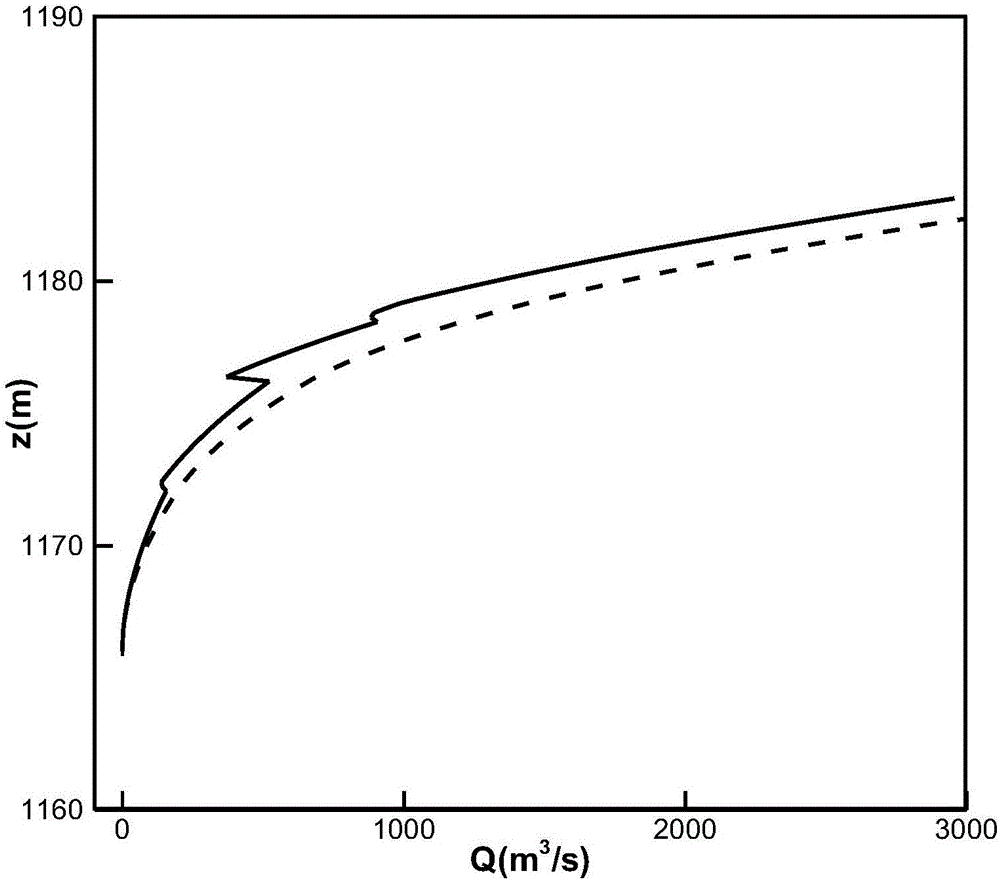

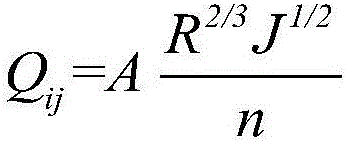

A natural river course cross section stage-discharge relation determining method

ActiveCN106021854AAvoid Double Value ProblemsInformaticsSpecial data processing applicationsHigh elevationDouble Value

The invention provides a natural river course cross section stage-discharge relation determining method. The method comprises the steps of firstly, obtaining actually-measured cross section data (xi, zi) of a target cross section, forming M subsections between the cross section x1 and xN equally (xni, xni+1), and obtaining the elevation value corresponding to a node of each subsection; secondly, determining the Manning roughness coefficients n of the different cross sections; thirdly, forming Nz layers equally between the lowest elevation and the highest elevation of the cross sections, calculating the discharge value Qij of each subsection of each elevation equal division layer, and calculating the sum of the discharge values Qij of all the subsections to obtain the total cross section discharge value Qj corresponding to the layer; obtaining a stage-discharge relation according to the total cross section flow value Qj of each layer and the stage corresponding to the layer. The method is based on subsection calculation of stage-discharge relations, performs segmentation calculation of corresponding discharges on the river course cross sections according to the roughness and thus obtains the stage-discharge relation corresponding to a whole cross section; the method can avoid the double value problem in conventional stage-discharge relation determination.

Owner:XIAN UNIV OF TECH

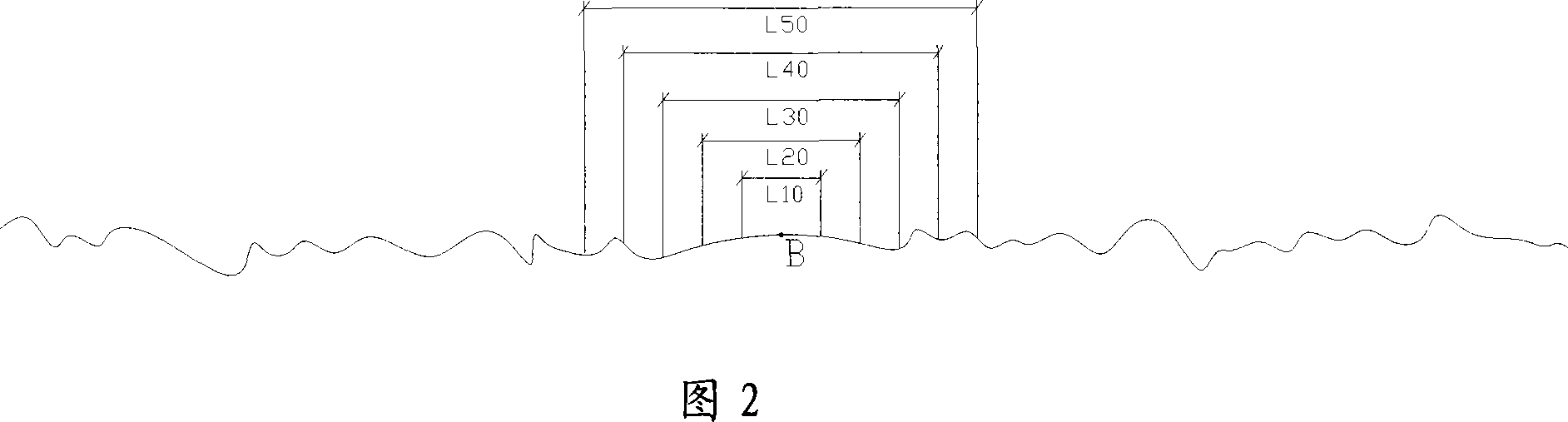

Measuring method for large size structure surface contour curve roughness coefficient

A method for measuring outline curve roughness coefficient of large dimension structure surface can realize effective measurement on outline curve roughness coefficient with different sampling length by confirming measurement reference point of outline curve roughness coefficient on large dimension structure surface.

Owner:ZHEJIANG COLLEGE OF CONSTR

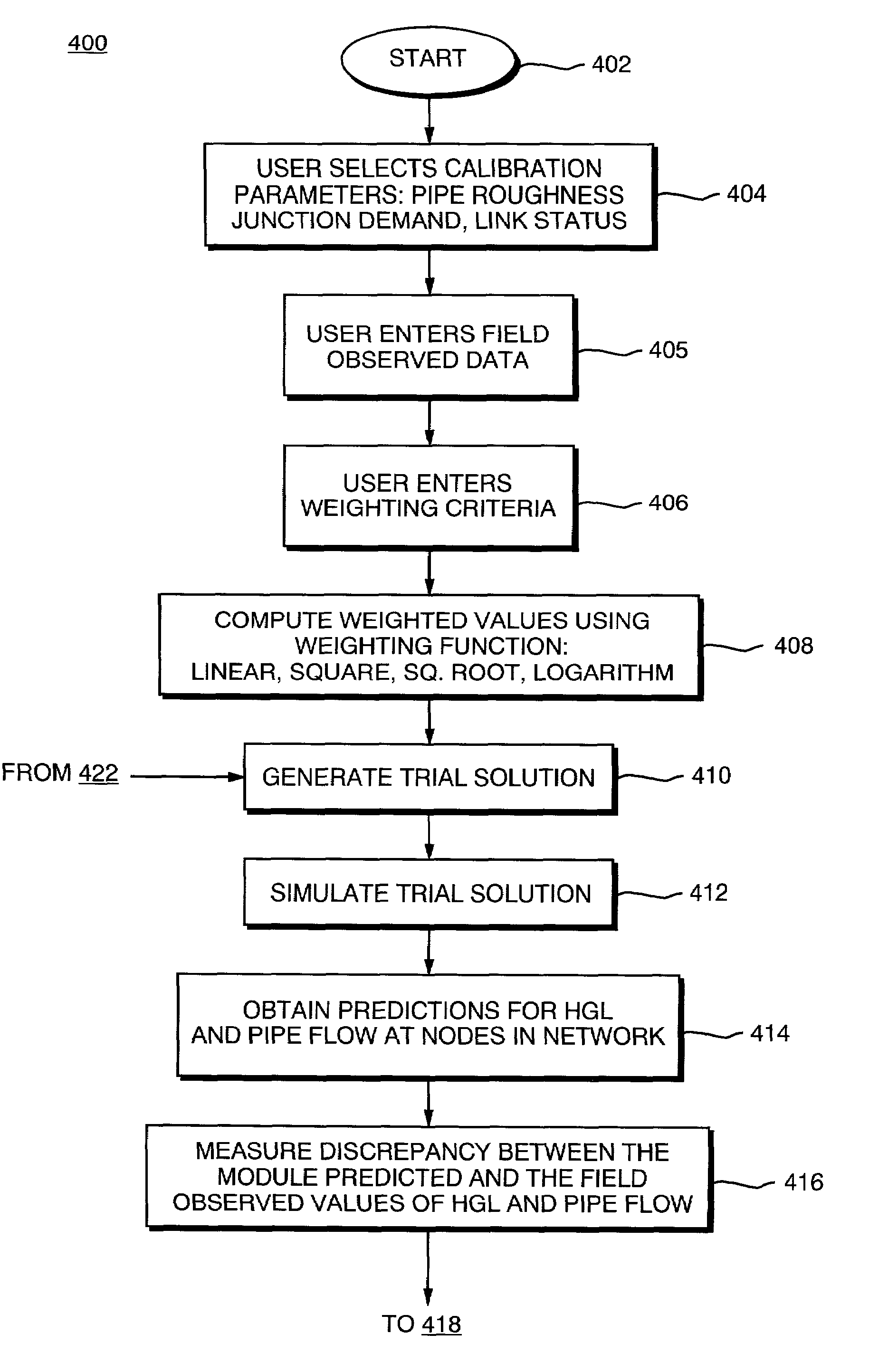

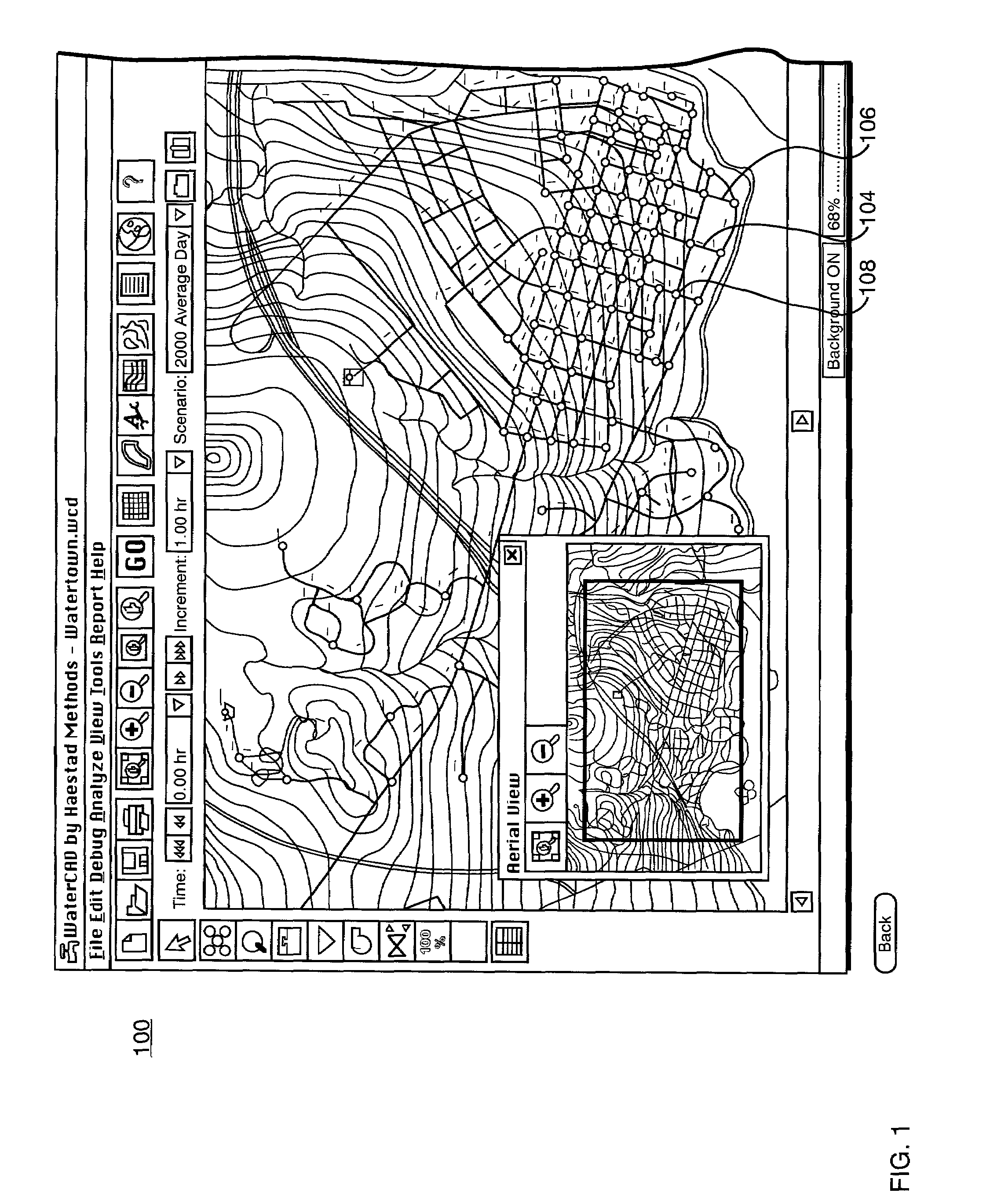

Method and system for automatic water distribution model calibration

ActiveUS7457735B2Improve accuracyImprove efficiencyStructural/machines measurementElectrical measurementsData setEngineering

A water distribution model calibration technique is provided that allows a user to design a calibration model by selecting several input parameters desired to be used for the calibration of a model that allows an engineer to collect a complete set of data to represent the overall system conditions at any given time of day. For example, several parameters may be chosen including link status, the pipe roughness coefficient, junction demand, and pipe and valve operational status. Trial solutions of the model calibration are generated by a genetic algorithm program. A hydraulic network solver program then simulates each trial solution. A calibration module runs a calibration evaluation program to evaluate how closely the model simulation is to the observed data.

Owner:BENTLEY SYST INC

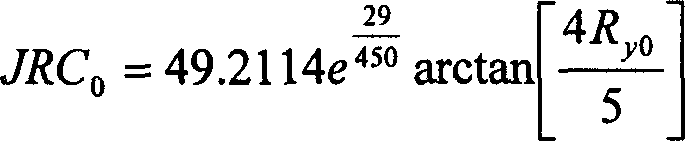

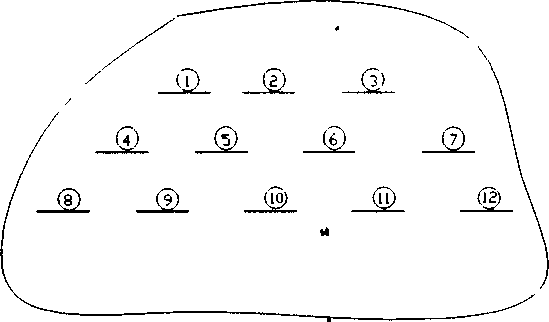

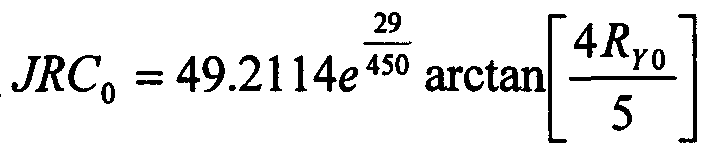

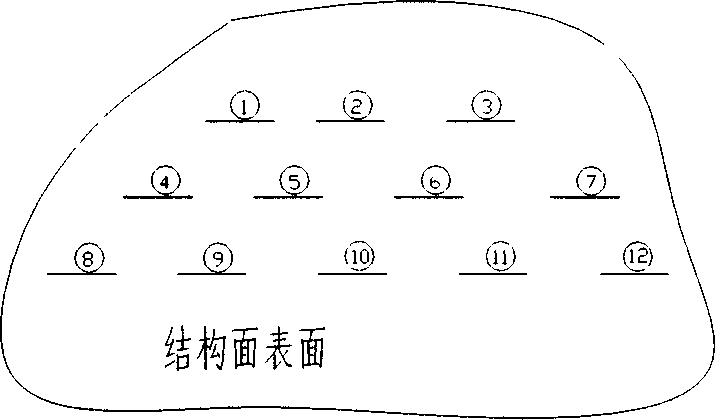

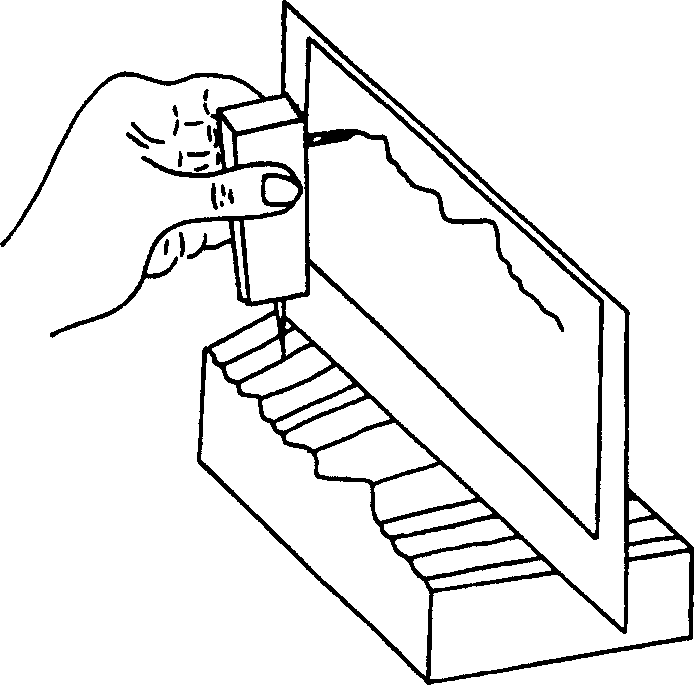

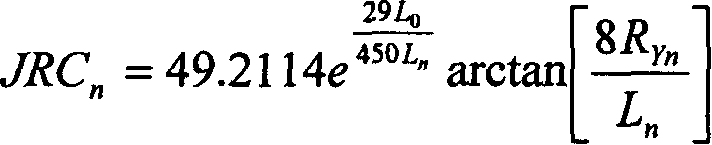

Determination of roughness coefficient of rock mass structural face

A method for determining roughness coefficient of rock mass structure surface includes sampling multiple measurement sections with length of 10 cm for each, plotting profilogram for said sections and measuring out fluctuation range Ryo of profilogram, applying formula of JRCo = 49.2114e 29 / 450arctan (4Ryo / 5) to calculate roughness coefficient JRCo value for each said section, obtaining expected value E(GRCo) by utilizing JRCo, using mode of JECn = E (JRCo)(Ln / Lo) ¿C D to convert out roughness coefficient JRCn value of rock mass structure surface.

Owner:JINHUA VOCATIONAL TECH COLLEGE

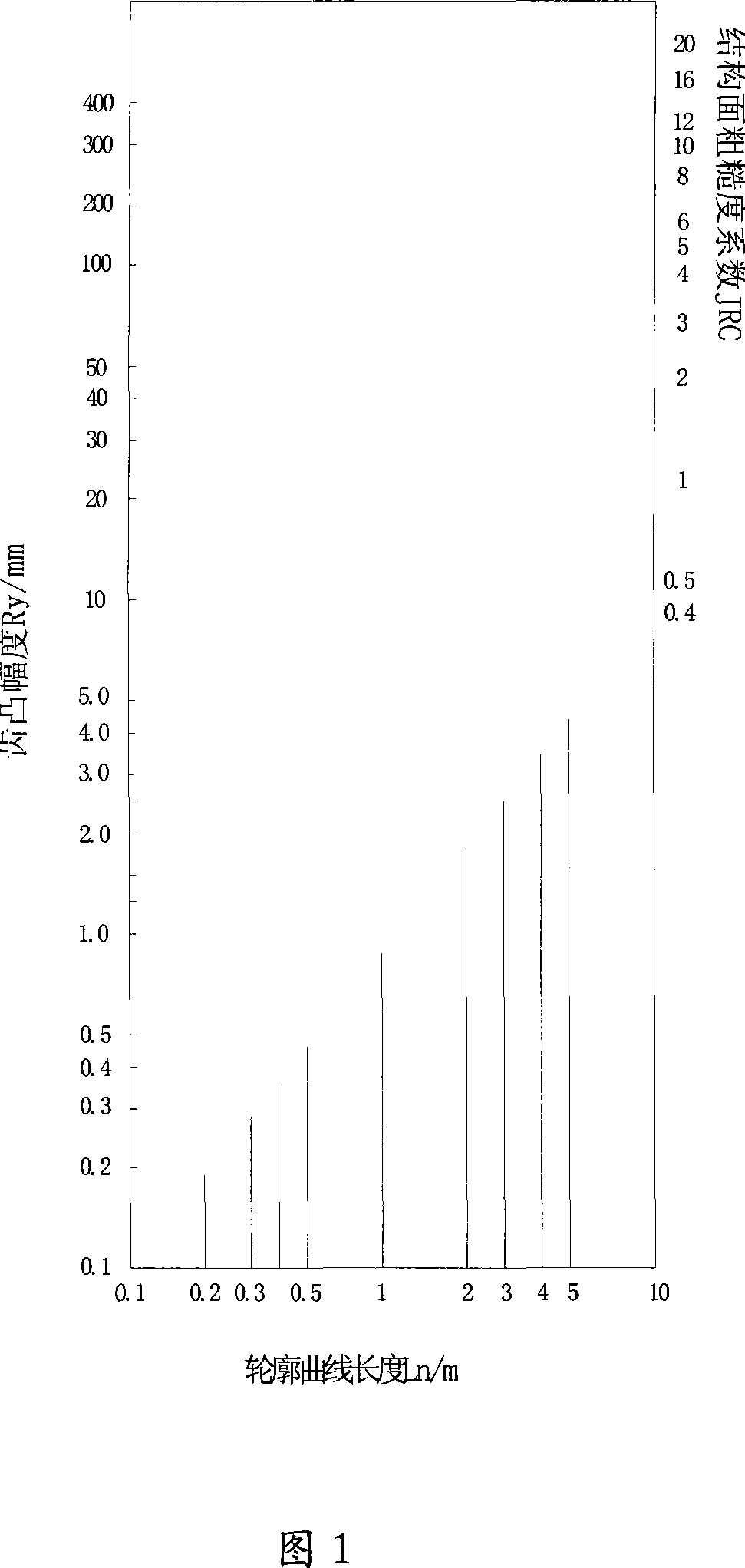

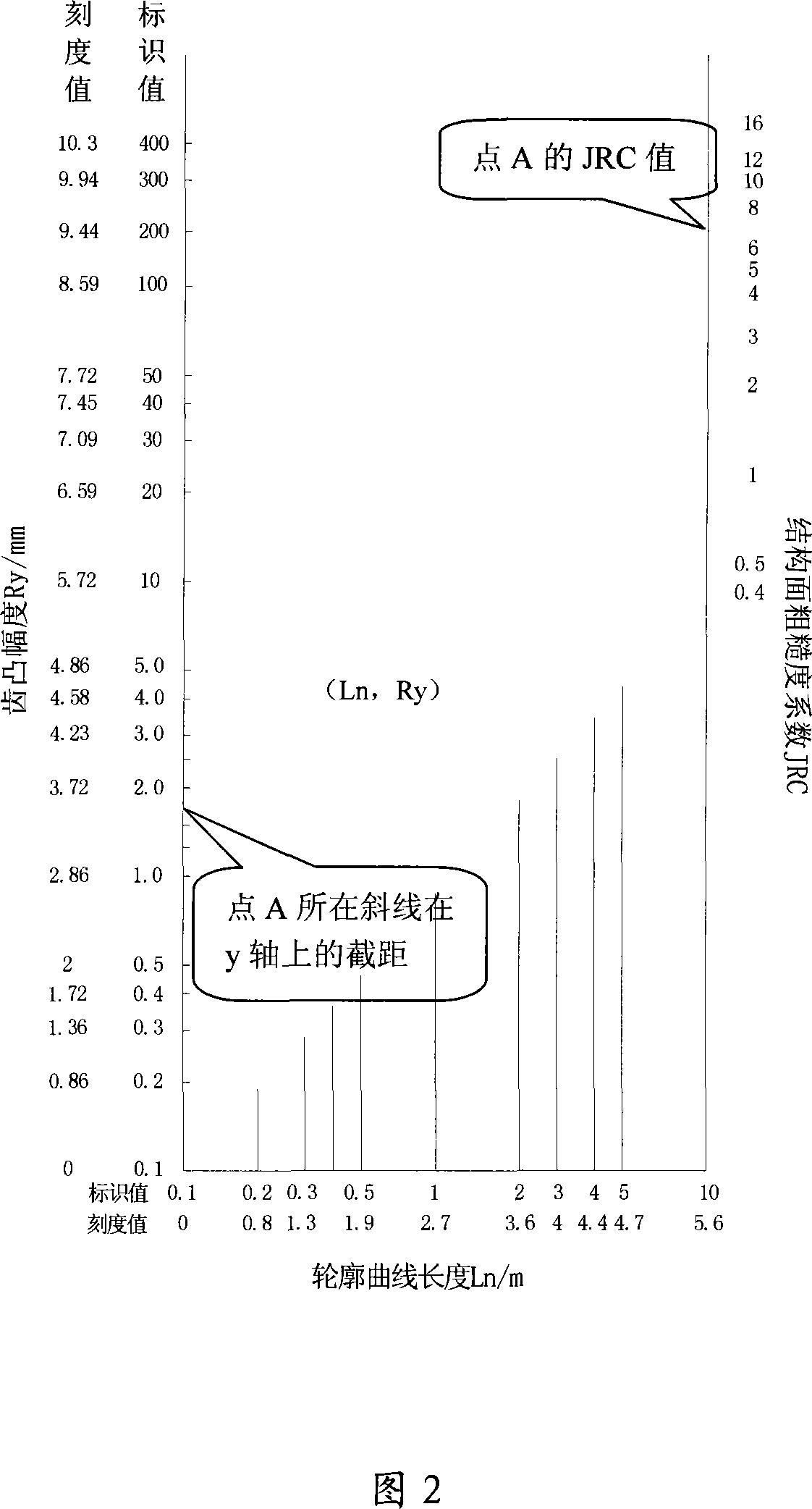

Simple measurement method for rock structural plane roughness coefficient

The invention relates to a simple method for measuring roughness coefficient of rock structure surface, including the following steps of: measuring convex tooth amplitude Ryn of rock structure surface; calculating the relative convex tooth amplitude value RA of rock structure surface profile curve with sampling length Ln using the formula RA=RYn / Ln; obtaining the roughness coefficient of rock structure surface profile curve with sampling length Ln by substituting the RA into the formula JRCn=400RA. The method which is simple and convenient for operation and calculation quickly can be performed without the influence of human factor and have great value and social economical benefit with satisfied precision.

Owner:ZHEJIANG COLLEGE OF CONSTR

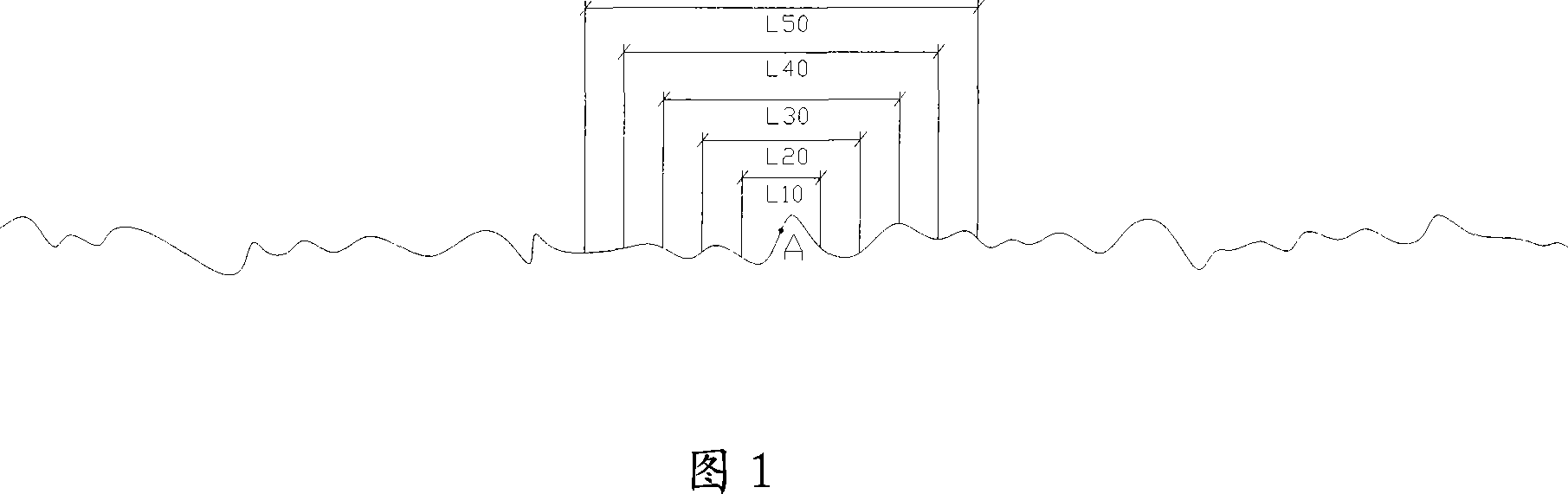

Juding method for for measuring effictiveness of large size structure surface contour curve roughness coefficient

A method for judging measurement effectiveness of outline curve roughness coefficient on large dimension structure surface includes selecting measurement reference point on outline curve of large dimension structure surface, setting the sampling length interval to be 10cm; separately measuring roughness coefficient of JRC10, JRC20, JRC30, JRC40 and JRC50 of structure surface outline curve as per sampling length of 10cm, 20cm, 30cm, 40cm and 50cm; carrying out measurement effectiveness judgment according to measured result and confirming that measurement is effective when JRC10>JRC30 JRC20>JRC40 and JRC30>JRC50 or otherwise confirming that measurement is not effective.

Owner:ZHEJIANG COLLEGE OF CONSTR

Determination of roughness coefficient of rock mass structural face

InactiveCN1779415AEasy to operateFast measurementMeasurement devicesStatistical analysisClassical mechanics

A method for measuring roughness coefficient of rock mass structure surface includes arranging multiple measurement sections at potential sliding direction on engineering rock mass structure surface uniformly, plotting profilogram for each of said sections and measuring fluctuation range Ryn of each profilogram, using formula of JRCn = 49.2114e 29Ln / 450Loarctan (8Ryn / Ln) late out roughness coefficient JRCn, counting up JRCn value to obtain expected value of JRCn being used as roughness coefficient of rack mass structure surface.

Owner:JINHUA VOCATIONAL TECH COLLEGE

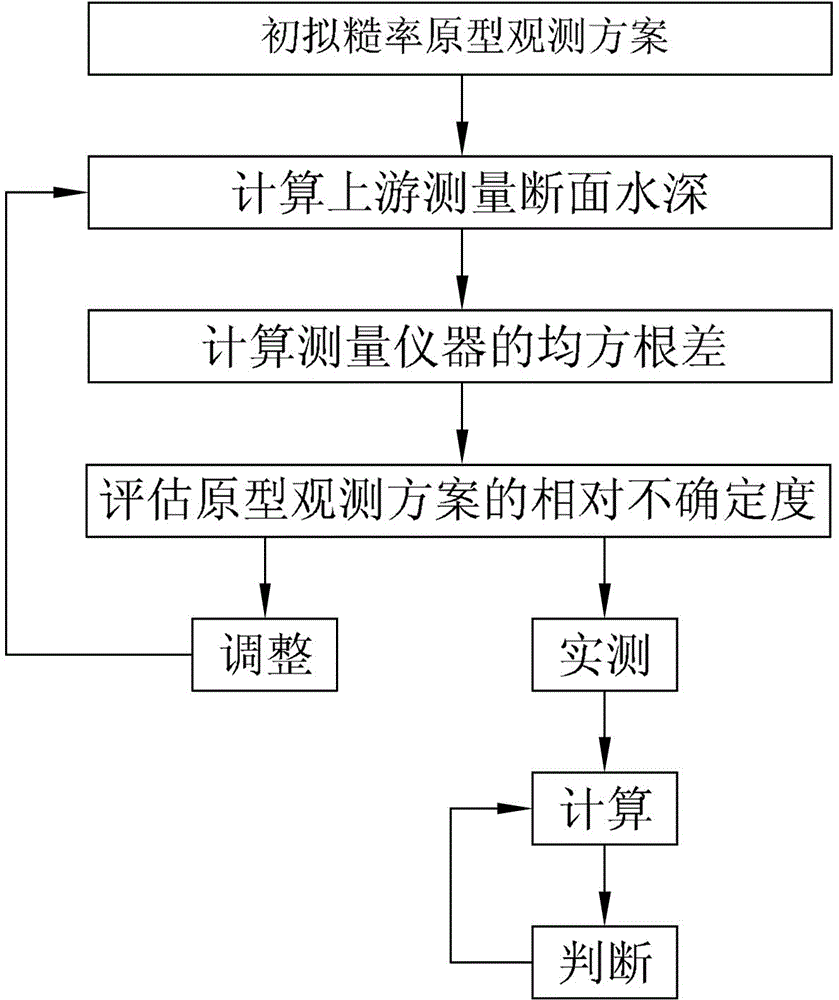

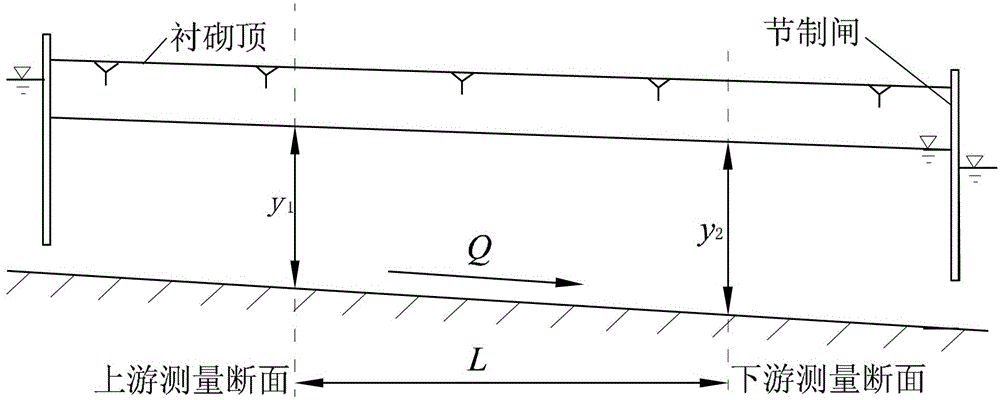

Roughness coefficient prototype observation and determination method for long-distance water conveyance canals

ActiveCN105091838AScientific settingQuick SetupMeasurement devicesMeasuring instrumentMaterial resources

The invention relates to a roughness coefficient prototype observation and determination method for long-distance water conveyance canals, and the method comprises steps of initially drafting a roughness coefficient prototype observation scheme, calculating the water depth of an upstream measuring section, calculating the sensitivity coefficient, calculating the root-mean-square deviation of a measuring instrument, assessing the relative uncertainty of the prototype observation scheme, adjusting, actually measuring, calculating and determining. The method adopts the measurement uncertainty theory, so that the scientificity of the prototype observation scheme can be assessed, the comprehensive influences of the water level, the precision of a flow measuring instrument, the flow, the separation distance of the measuring sections on the uncertainty of the roughness coefficient measured results can be analyzed, the reasonable value can be determined according to the set relative uncertainty; and the roughness coefficient prototype observation is made accordingly. In the calculating process, the change along the canal of the structure and the hydraulic characteristics of the long-distance water conveyance canal is seriously considered, the roughness coefficient is solved by adopting a constant gradually varied flow equation in a differential form, the prototype observation scheme can be scientifically and quickly set, the work efficiency is improved, and waste of unnecessary labor and material resources can be avoided.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

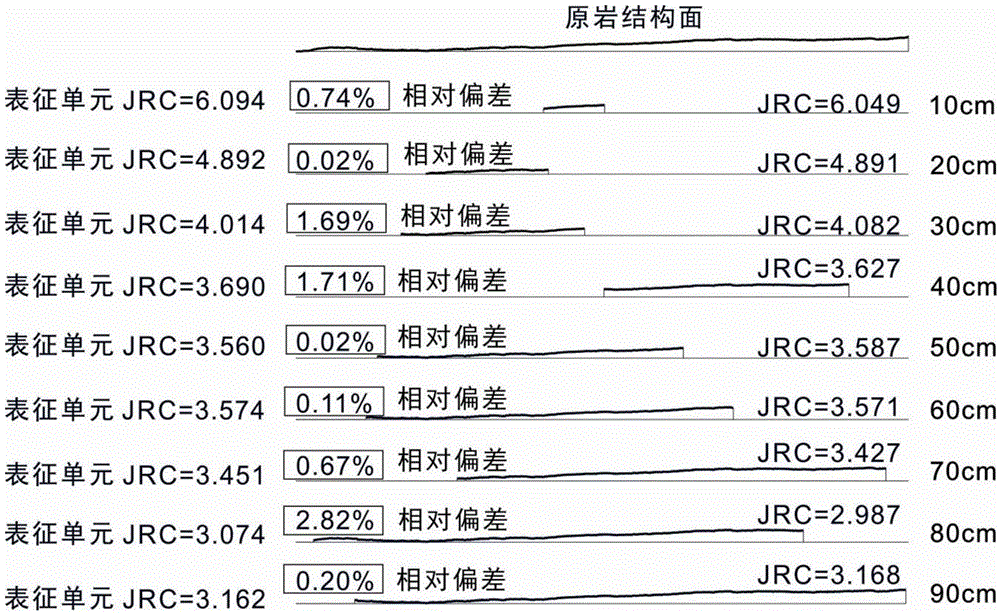

Method for determining structural surface roughness coefficient dimension effect sample characterization unit

ActiveCN104833333AGuaranteed repeatabilityAvoid uniquenessMeasurement devicesResearch ObjectNormal density

The invention provides a method for determining a structural surface roughness coefficient dimension effect characterization unit. The method comprises the steps of selecting a typical rock mass structural plane which is well exposed as a research object, by means of a surface shape factor measurement result for a field large-dimension rock mass structural surface, calculating an overlapping length of an adjacent structural surface roughness sample according to a sample dimension and number of samples, and performing iteration for extracting surface coordinate information of a series of dimension structural surface samples; computing the roughness coefficients of the series of samples, performing Weibull distribution probability density function fitting on overall distribution of sample data of different dimensions, and constructing a structural surface roughness coefficient dimension effect probability density function model; and through relative deviation analysis on the roughness coefficient and a representative evaluation index of each structural surface sample, searching a minimal value of a sample roughness coefficient characterization value on each dimension condition, and determining the structural surface roughness coefficient characterization unit. The method of the invention effectively settles a problem of ensuring uniqueness in selecting a structural surface roughness coefficient dimension effect research sample and ensuring repeatability of a test result.

Owner:SHAOXING UNIVERSITY

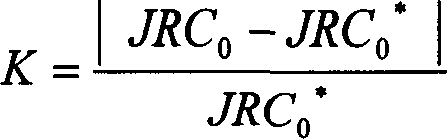

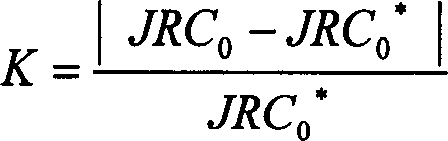

Evaluation method for representitiveness of rock structural fece sample

InactiveCN1815183AThe principle is simpleEasy to operateMaterial strength using steady shearing forcesSpecial data processing applicationsTest sampleSurface roughness

Present invention relates to a rock mass structure surface test sample representativity evaluation method. It includes following steps: calibrating test direction respectively on selected rock mass structure surface test sample and in situ rock mass structure surface to make rock mass structure surface test sample direction concordance with in situ rock mass structure surface roughness coefficient measurement, to proceed orient statistics measuring to rock mass structure surface test sample according to calibrating direction to obtain rock mass structure surface test sample roughness coefficient eigenvalue JRC 0, uniformly distributing not less than 30 strip measuring line along calibrating direction according to rock mass structure surface test sample length, to proceed orient statistics measuring to obtain sample size in situ rock mass structure surface roughness coefficient eigenvalue JRC 0 * evaluating structural plane test sample representativity by k=|JRC 0-JRC 0 * | / JRC 0 *. If K=0-0.15, means fine structural plane test sample representativity, if K=0.15-0.4, means better structural plane test sample representativity, if K=0.4-0.7, means intermediate structural plane test sample representativity, if K=0.7-1, means bad structural plane test sample representativity, if K>=1, means very bad structural plane test sample representativity.

Owner:ZHEJIANG COLLEGE OF CONSTR

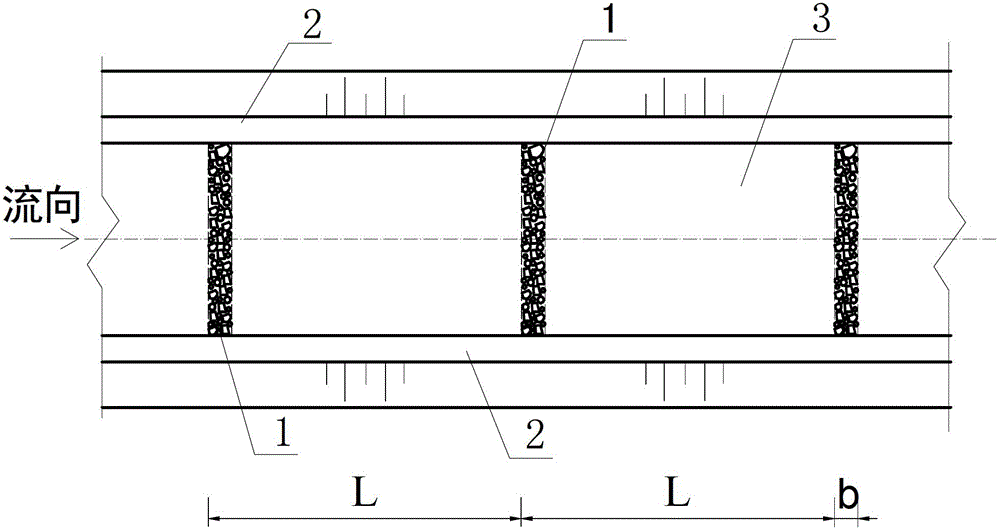

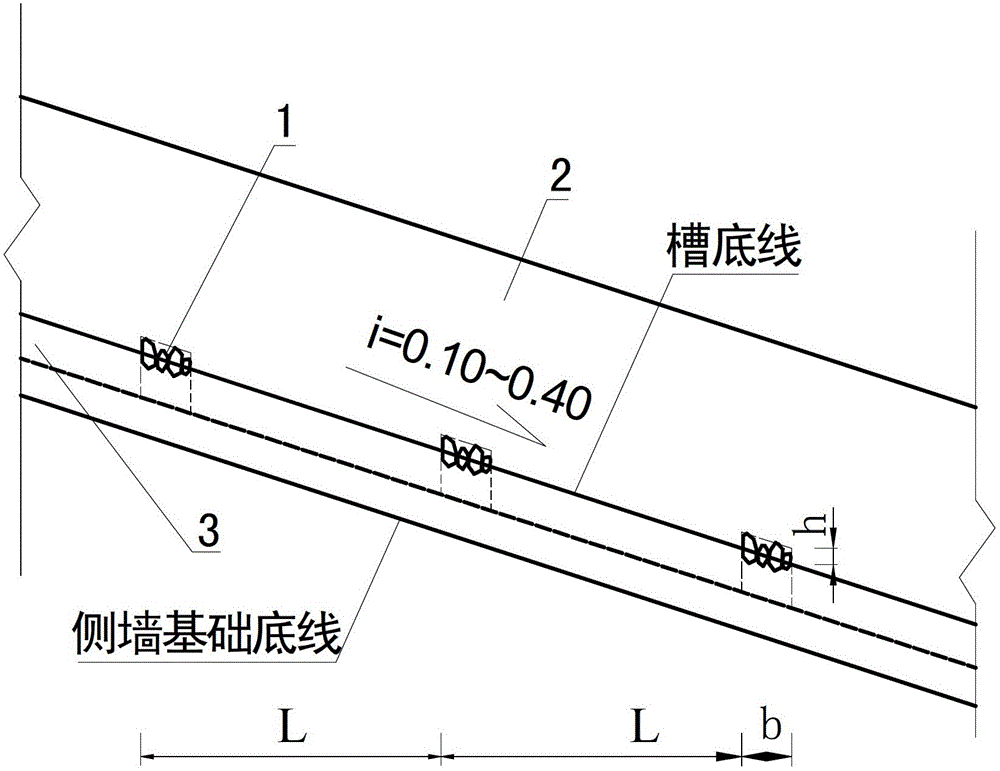

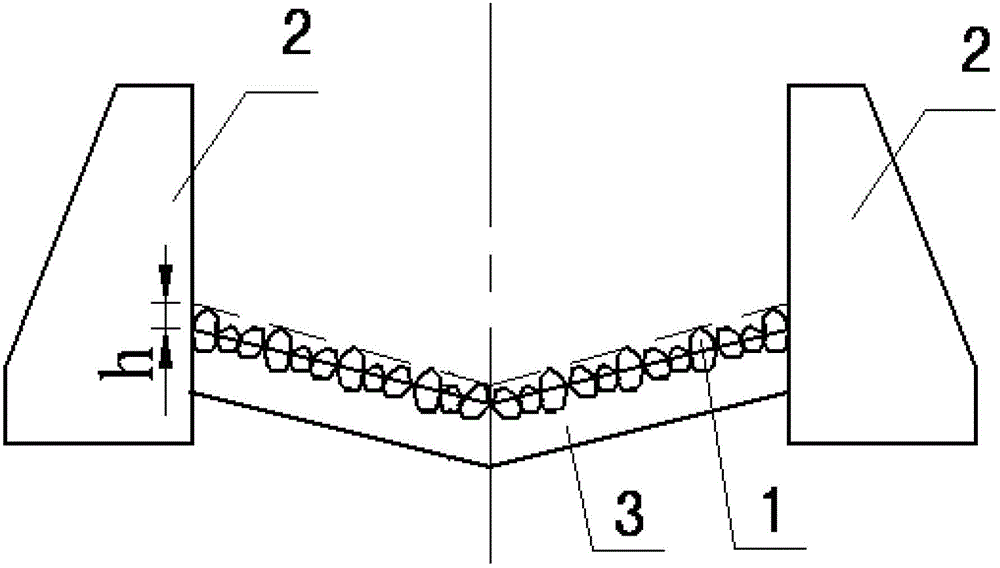

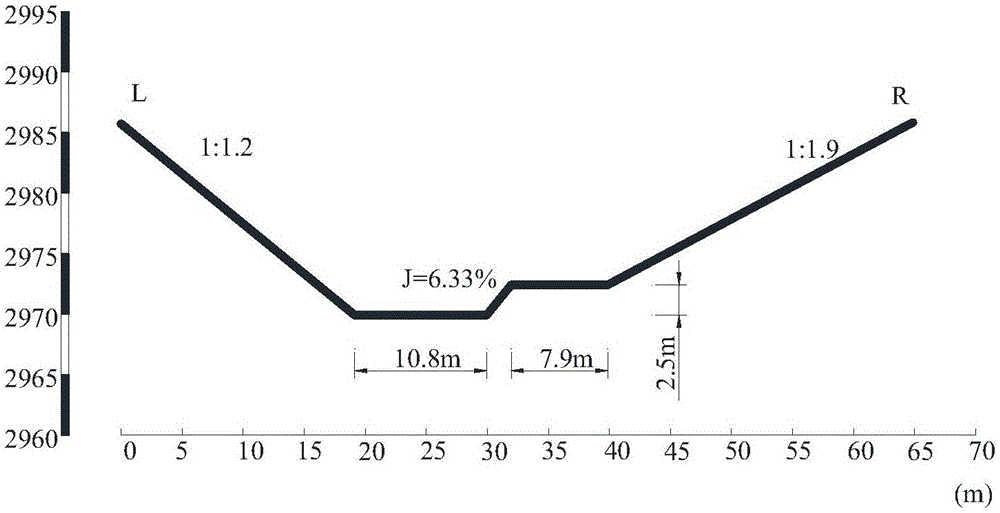

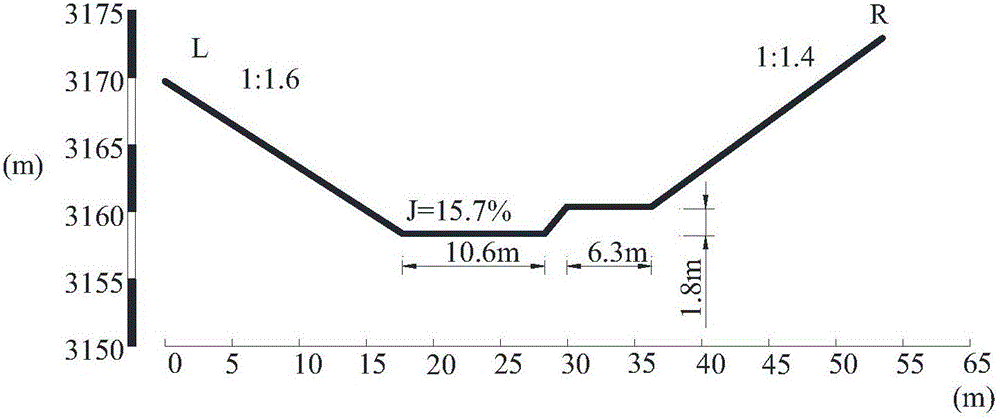

All-lining debris flow draining and guiding groove with roughened groove bottom and application thereof

The invention discloses an all-lining debris flow draining and guiding groove with a roughened groove bottom and an application thereof. The draining and guiding groove comprises an all-lining bottom plate of the draining and guiding groove and side walls of the draining and guiding groove which are arranged at two sides. A plurality of roughened belts with a certain width and convex height are arranged above the bottom plate of the draining and guiding groove. The roughened belts transversely penetrate along the draining and guiding groove, are connected with the bottom plate of the draining and guiding groove and are distributed at a certain interval. A plurality of roughened bodies with different convex heights are distributed at random to constitute the roughened belts. The top surface of the roughened belts is uneven. Compared with the prior art, the draining and guiding groove provided by the invention fully utilizes the characteristic that the roughened belts can improve the roughness coefficient of the draining and guiding groove to reduce the flow speed of debris flow and then the abrasion kinetic energy of debris flow. Thus, the safety of the draining and guiding groove is greatly improved, the project maintenance cost is greatly lowered and the draining and guiding groove can well adapt to large-gradient longitudinal slopes of valleys. Compared with traditional draining and guiding grooves, the project operating maintenance cost can be saved by 50-80% by adding 2-5% of project investment and the project safety is greatly improved.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

Method for representatively sampling subsize rock model structural surface sample sampled based on layering probability

ActiveCN103558094AReduce in quantityLow costMaterial strength using steady shearing forcesStatistical precisionErrors and residuals

A method for representatively sampling a subsize rock model structural surface sample sampled based on layering probability comprises the following steps of: (1) orientationally counting and measuring fluctuation amplitude of a raw rock structural surface sample, respectively calculating a roughness coefficient characteristic constant JRC and a statistic average value of each measuring segment of the scale by a formula; (2) calculating based on quartile division to obtained JRC average values and variances of three intervals: P0-25, P25-75 and P75-100; and (3) setting a relative permissible error of an average value of samples and an ensemble average value to be gamma, and setting confidence to be 95%. The said calculated data is substituted into a layeredly sampling formula to obtain a total sample size, and the sample size of each layer is determined based on the layer weight: W0-25=1 / 4, W25-75=1 / 2 and W75-100=1 / 4. The method provided by the invention can effectively satisfy statistic precision requirement of the shear strength dimension effect of the rock model structural surface, and can raise test statistic precision.

Owner:SHAOXING UNIVERSITY

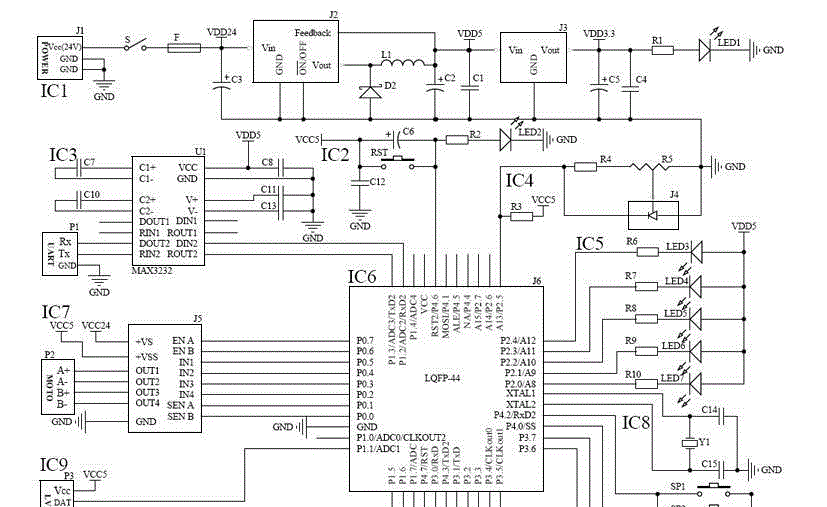

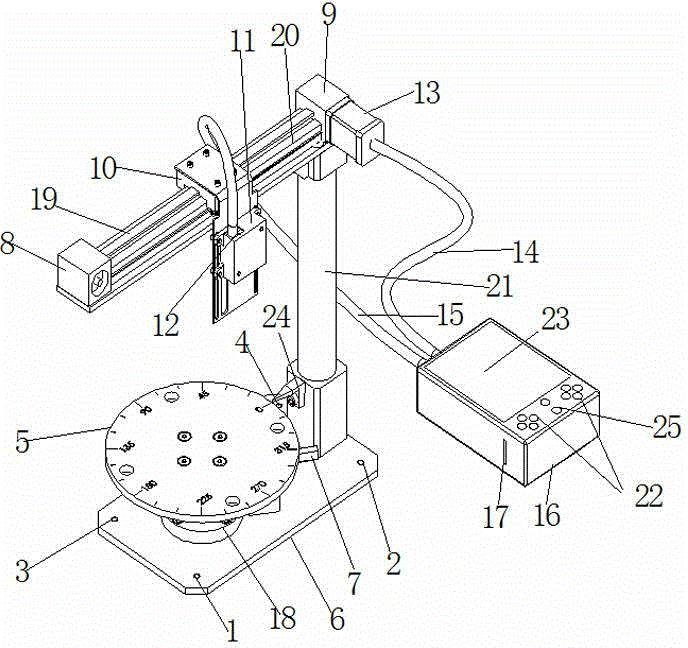

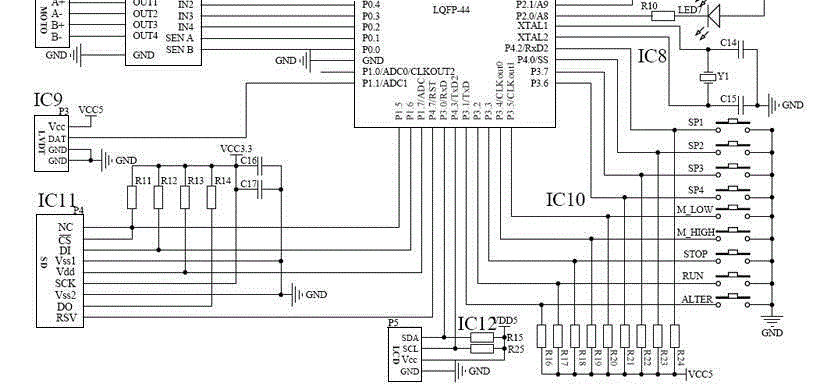

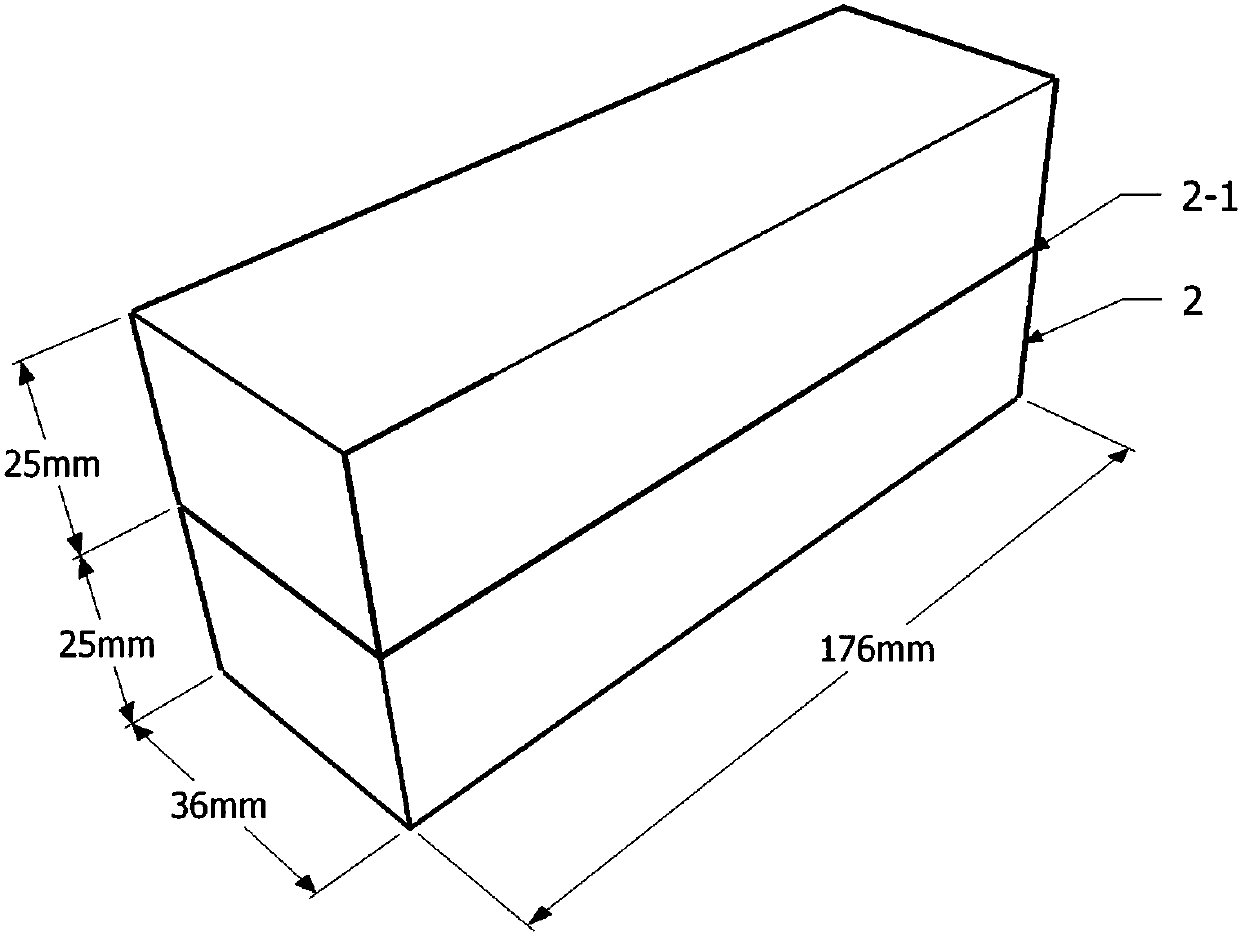

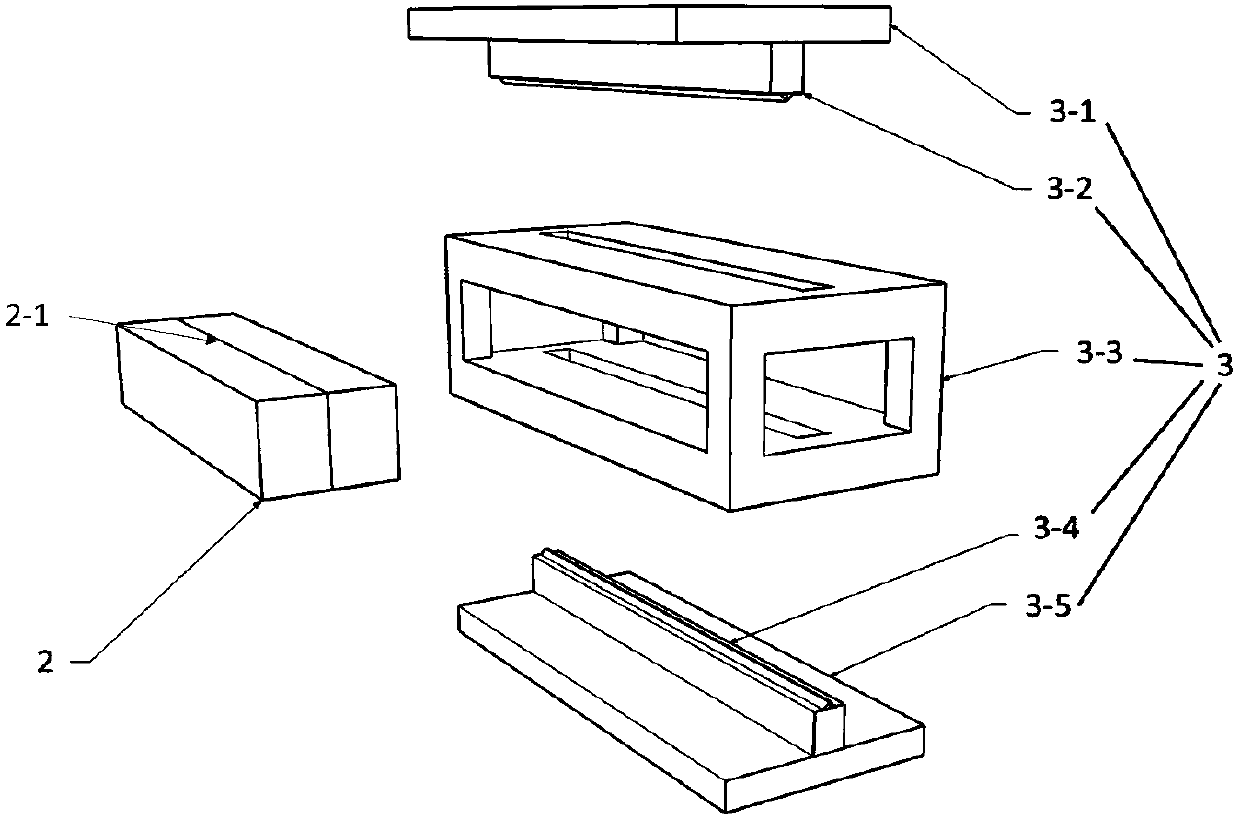

Multi-angle intelligent measurement instrument of rock structure surface roughness coefficient and measurement method of rock structure surface roughness coefficient

InactiveCN104677313AEasy to measureEasy to recordUsing optical meansStructure of the EarthSurface roughness

The invention relates to the field of measurement of rock structure surface roughness coefficient, in particular to a multi-angle intelligent measurement instrument of rock structure surface roughness coefficient and a measurement method of the rock structure surface roughness coefficient. The multi-angle intelligent measurement instrument comprises a turntable, a base, a bracket, a driving motor, a guide rail, a belt, a distance sensor, a micro-controller and a control circuit. The invention further relates to the intelligent measurement of the rock structure surface roughness coefficient with adoption of the measurement instrument. The instrument and the method are suitable for the indoor and outdoor measurement of roughness coefficients of various forms of rock structure surfaces; a user can measure the roughness coefficient of the rock structure surface from different directions, and take the average of multiple results as the finally measured roughness coefficient value of the rock structure surface; the roughness of the entire rock structure surface can be measured as much as possible through multidirectional measurement, so that the measurement results are more comprehensive and accurate.

Owner:TAIYUAN UNIV OF TECH

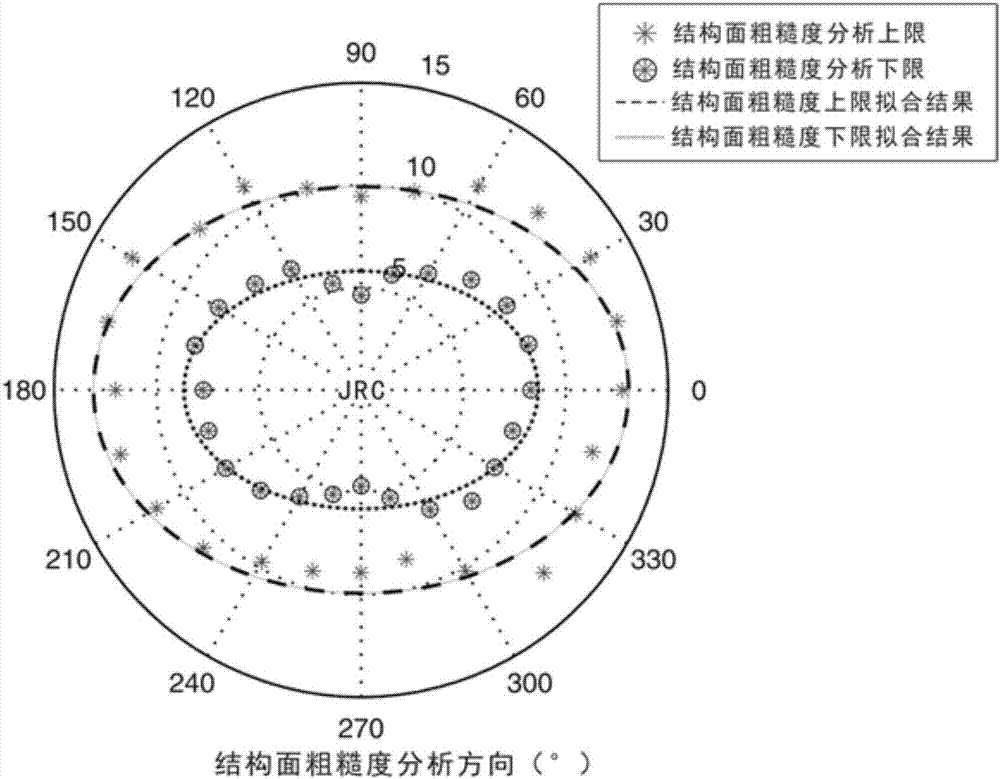

Quantitative evaluation method of structural surface roughness coefficient anisotropy

The present invention provides a quantitative evaluation method of structural surface roughness coefficient anisotropy. The method comprises: selecting an engineering rock structural surface required to be analyzed; uniformly distributing structural surface segments of survey at different directions; drawing the contour curve of each segment of survey through adoption of a contour curve instrument; measuring the structural surface roughness coefficient of each segment of survey; calculating the statistical average value of the structural surface roughness coefficient at each direction in the condition with the same size, and obtaining the roughness coefficient sequence at each direction; performing transformation of each item in the roughness coefficient sequence; fitting the processed structural surface roughness coefficient through adoption of an anisotropy ellipse; and determining the long shaft a and a short shaft b of the anisotropy ellipse at each direction, wherein [Theta] shows the rotation direction, the ratio of the long shaft and the short shaft shows the difference of the max and the min of the roughness coefficient on the anisotropy ellipse at each direction, and the [Theta] shows the predominant direction of the growth of the structural surface roughness. The quantitative evaluation method of structural surface roughness coefficient anisotropy is able to effectively and quantificationally determine the degree of the structural surface roughness coefficient anisotropy.

Owner:SHAOXING UNIVERSITY

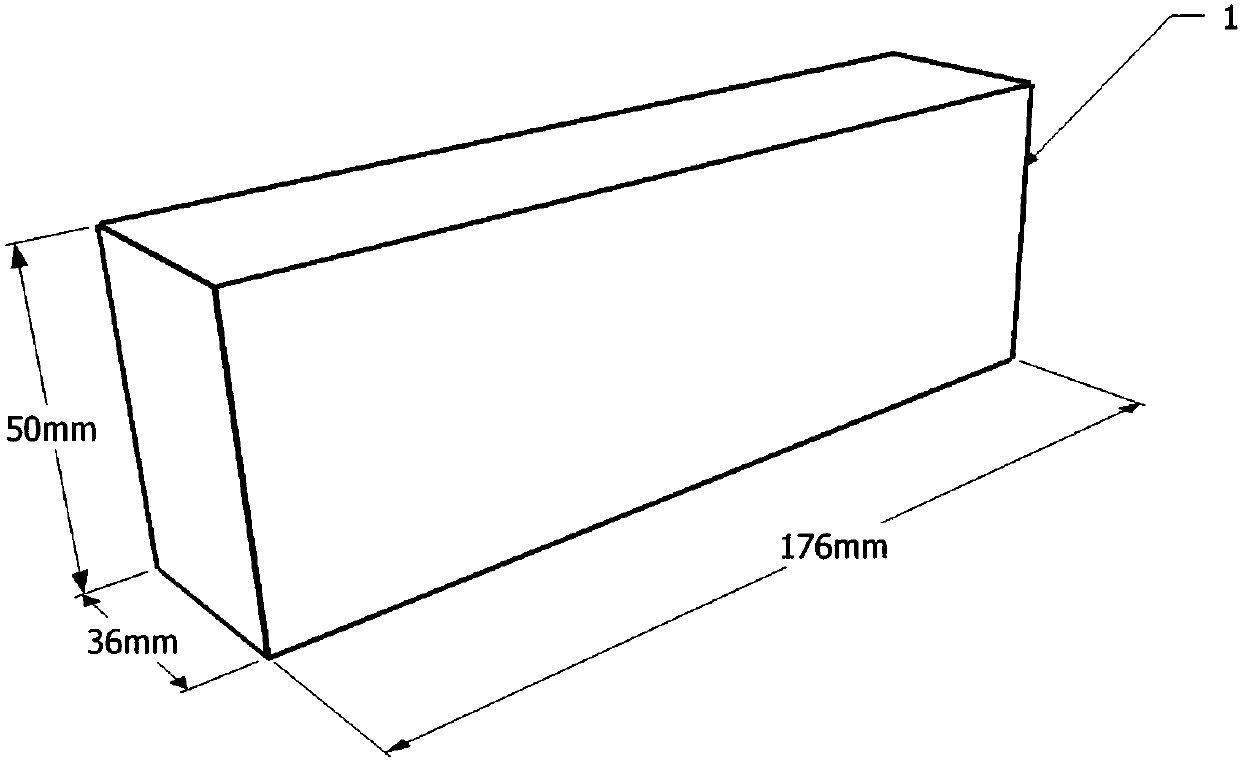

Manufacturing method for manmade rock sample for simulating real form of hydraulic fracturing crack

InactiveCN110388201AConsistent mechanical propertiesSolve the problem of large shape differenceSurveyData processing applicationsRock coreSurface roughness

The invention discloses a manufacturing method for a manmade rock sample for simulating the real form of a hydraulic fracturing crack. An original square rock plate is manufactured through an underground rock core or same-layer-position outcrop rock of an oil gas reservoir section; the rock plate is split in the length direction through a rock plate splitting device, and a three-dimensional laserscanner is used for obtaining split rock sample surface rough feature data; the rock sample surface roughness coefficient after splitting is calculated, and a pair of split rock samples capable of most representing the reservoir hydraulic fracturing crack surface feature are selected according to the roughness coefficient; according to the surface roughness feature data, a 3D printer is used for manufacturing a manmade rock sample manufacturing die; manmade rock sample manufacturing materials are prepared according to reservoir section rock mineral components, and a manmade rock sample for simulating the real form of the hydraulic fracturing crack is formed through pressing. According to the manufacturing method, the principle is simple, adopted equipment facilitates machining and manufacturing, rock samples consistent to reservoir rock mineral in component and real and uniform in surface rough feature can be manufactured in batches, and testing is conveniently conducted.

Owner:SOUTHWEST PETROLEUM UNIV

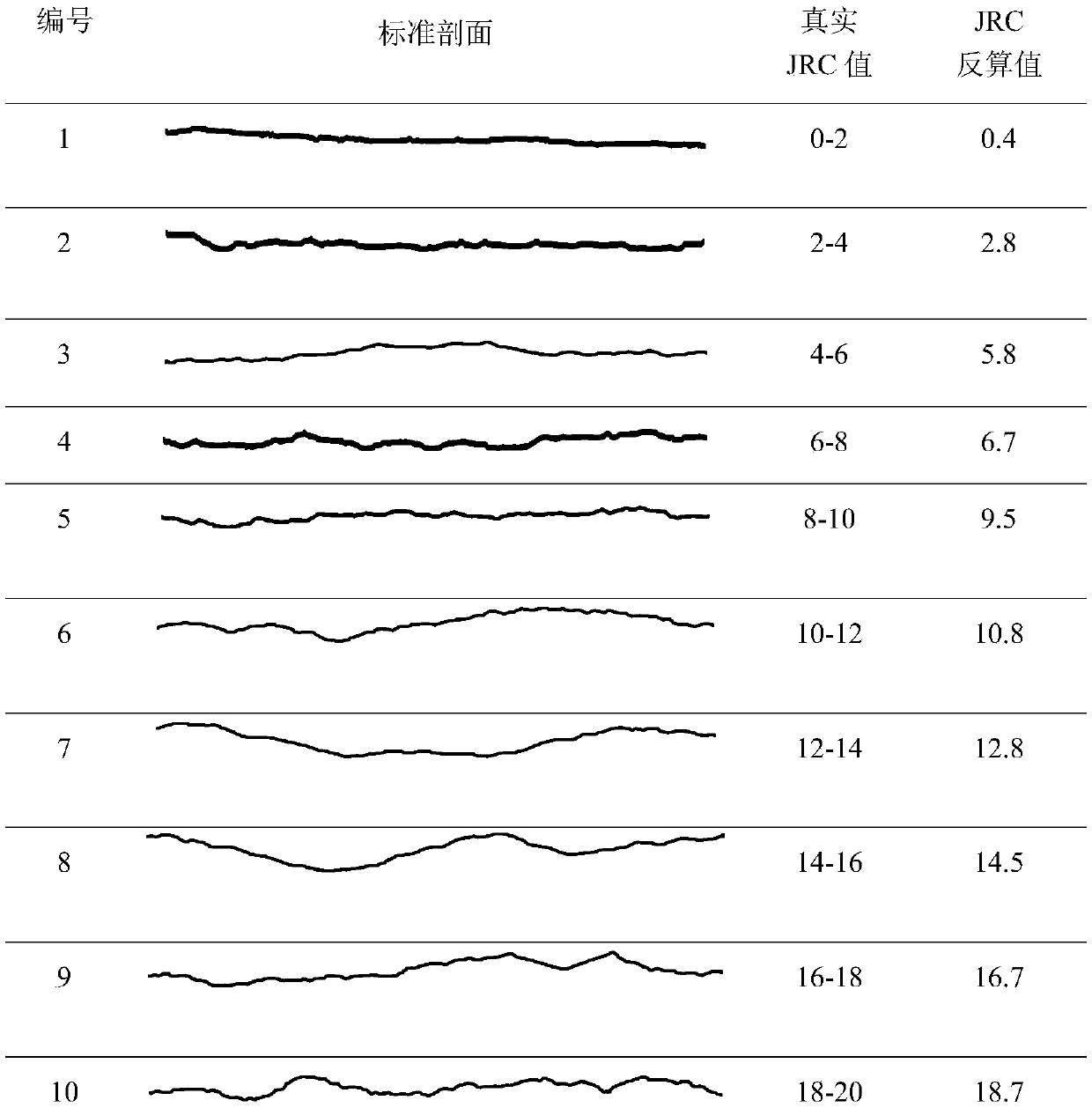

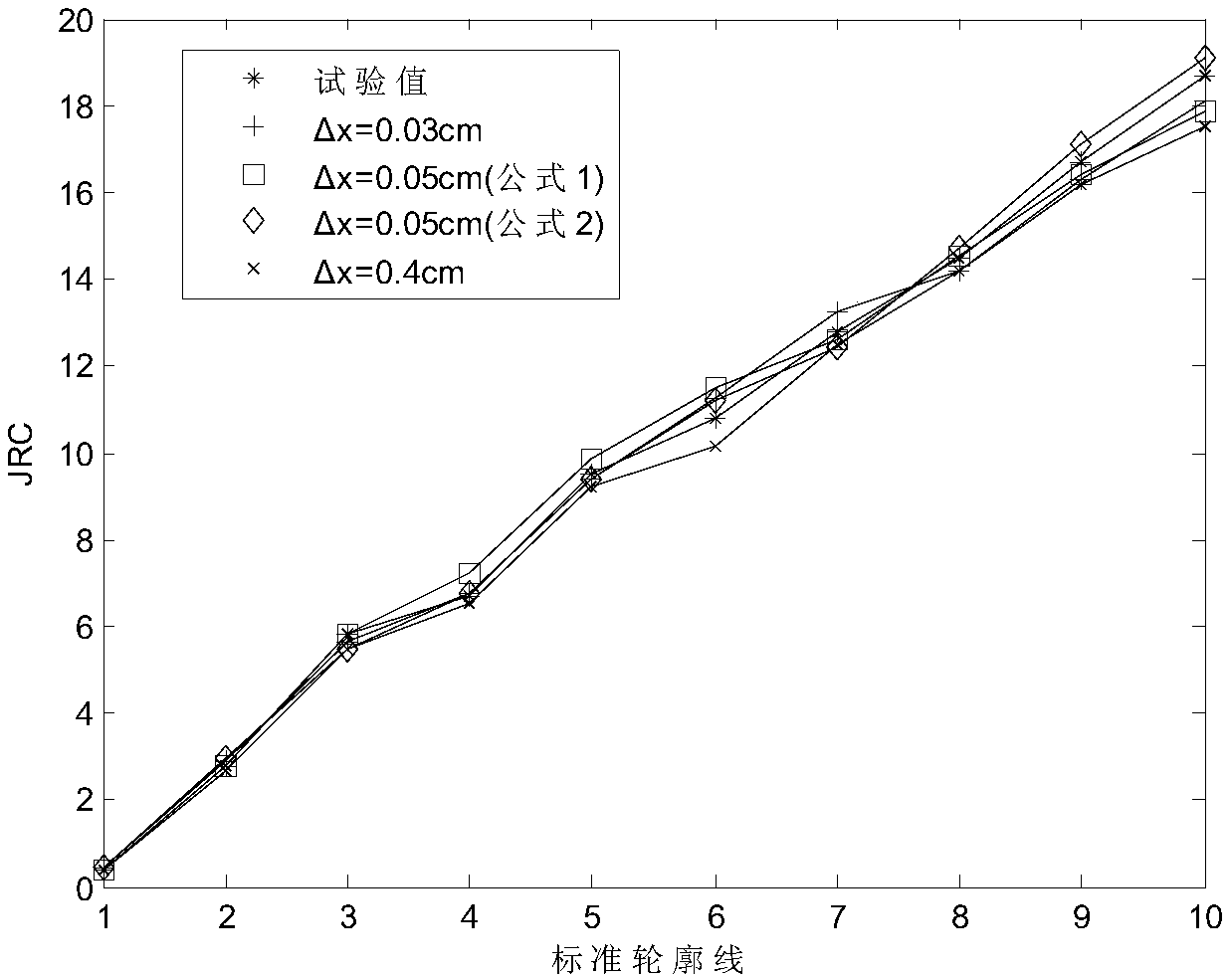

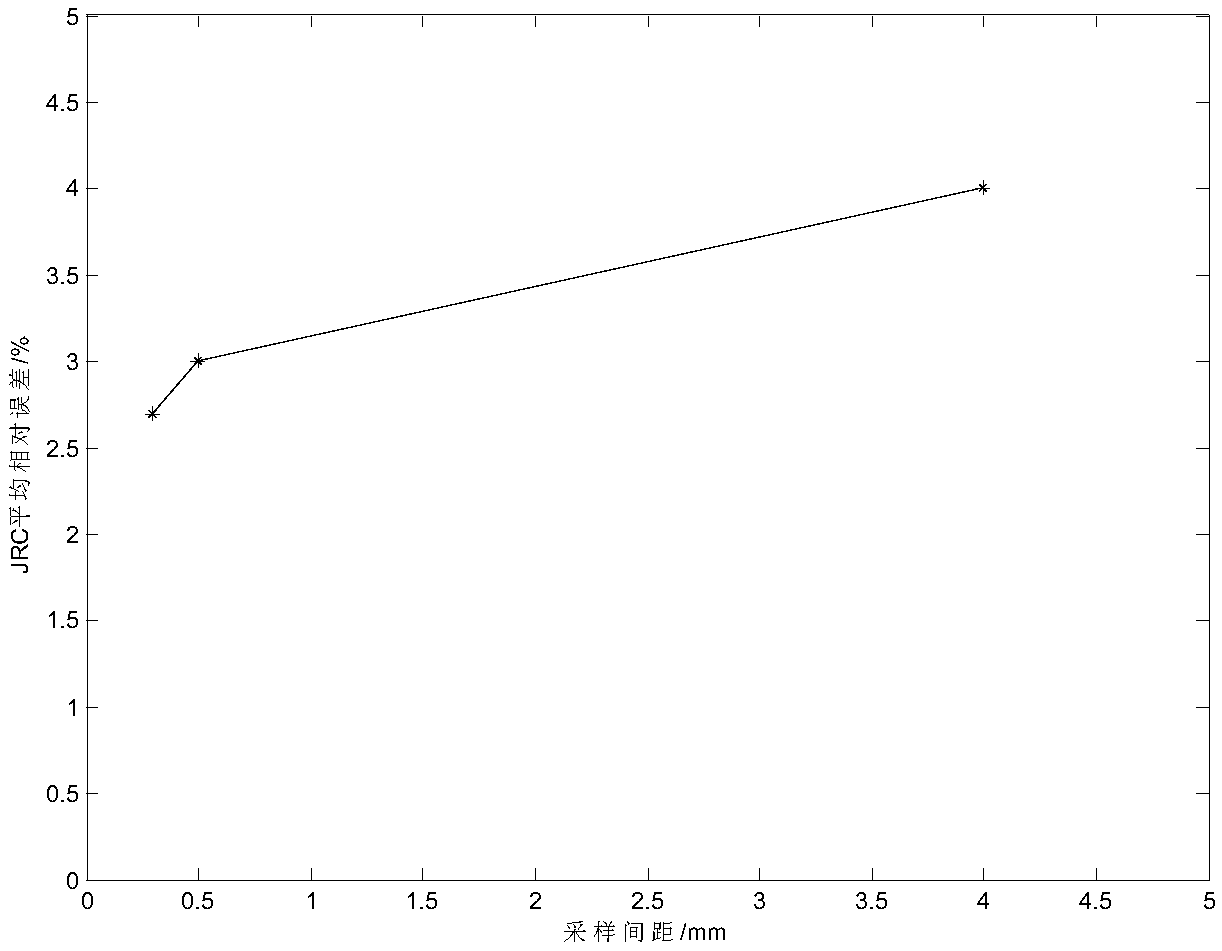

Structural plane roughness coefficient statistical method at different sampling intervals

ActiveCN107656902AImprove applicabilityAvoid errorsComplex mathematical operationsComputer scienceRoot mean square

The invention relates to a structural plane roughness coefficient statistical method at different sampling intervals, which comprises the following steps of: 1, selecting an engineering rock mass structural plane which needs to be analyzed, drawing N two-dimensional outline section lines in parallel mutually along a testing direction, and respectively acquiring two-dimensional data parameters of the n curves; 2, selecting an ith two-dimensional section line, and then calculating a one-order derivative root-mean-square Z2 of the two-dimensional section line at a sampling interval delta x; 3, when a value of the delta x is between 0.005 and 0.05cm, calculating a roughness coefficient feature value JRC1i corresponding to the ith two-dimensional section line, and when the value of delta x is between 0.05 and a maximum value of the sampling interval, calculating a roughness coefficient feature value JRC2i corresponding to the ith two-dimensional section line; and 4, then carrying out processing on other n-1 curves also according to the step 1 to the step 3, and finally, calculating out a roughness coefficient mean (with reference to the specification) or (with reference to the specification) of the structural plane along the testing direction at the sampling interval delta x. The structural plane roughness coefficient statistical method disclosed by the invention is high in accuracy.

Owner:SHAOXING UNIVERSITY

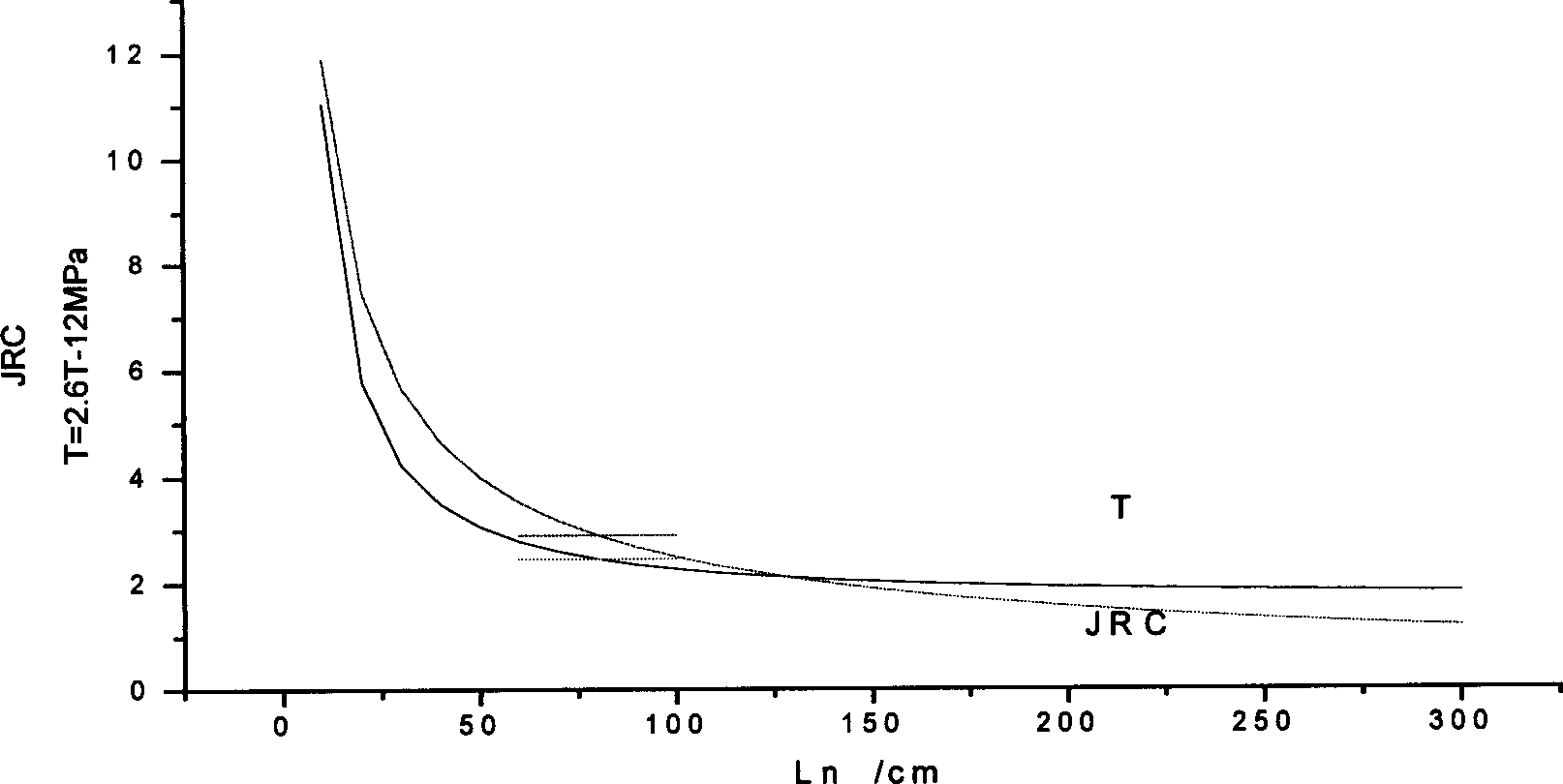

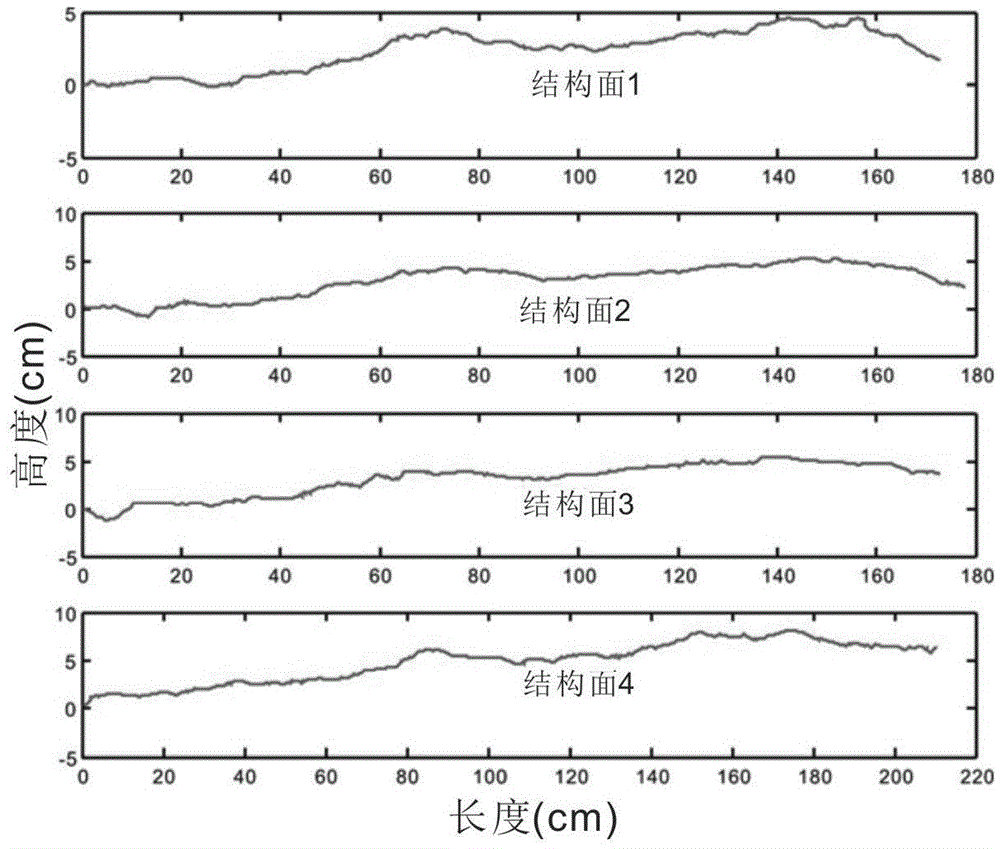

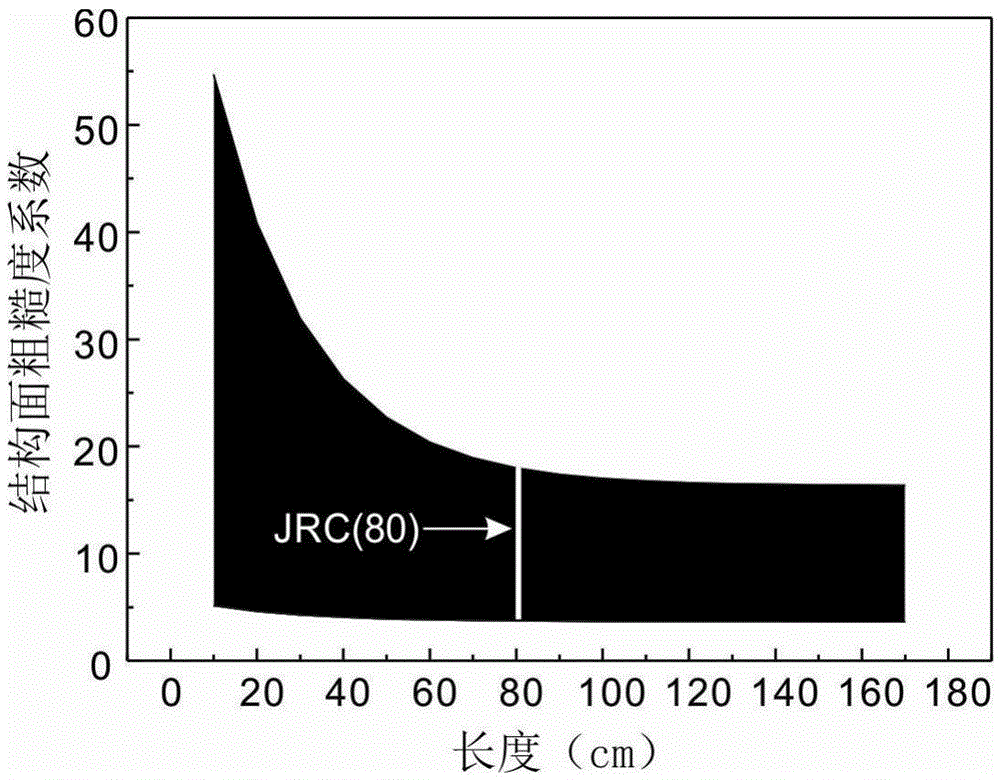

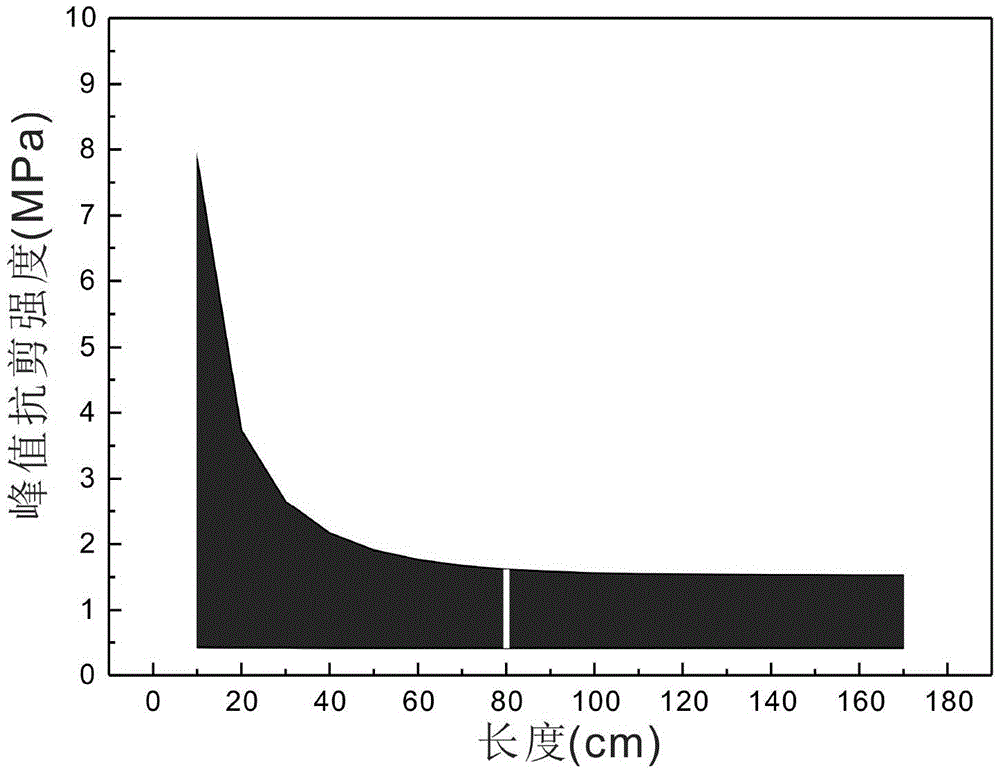

Comprehensive structural surface shearing strength evaluation method for rock mass based on mean value function

ActiveCN105606463AImprove accuracyMaterial strength using steady shearing forcesImaging processingStatistical analysis

The invention discloses a comprehensive structural surface shearing strength evaluation method for a rock mass based on a mean value function. The method comprises the following steps: selecting a structural surface of an engineering rock mass to be analyzed, and judging a potential sliding direction; uniformly distributing structural surface measurement sections in the potential sliding direction; drawing a contour curve of each measurement section with a contour curve instrument; extracting coordinate data on the contour curves with an image processing method, and thereby measuring a structural surface roughness coefficient of each measurement section; performing statistical analysis on the coordinate data of the structural surface under a condition of each size L independently to determine a minimum value and a maximum value of the roughness coefficient; fitting the distribution rule of the maximum values and the minimum values of the roughness coefficients of the structural surface under different size conditions respectively adopting exponential functions to obtain an interval function; combining the interval function of the structural surface shearing strength and an experimental structural surface shearing strength formula of Barton to obtain the mean value function expression of a structural surface shearing strength tao (JRC). According to the method, the accuracy of surface shearing strength evaluation for the rock mass can be effectively improved.

Owner:SHAOXING UNIVERSITY

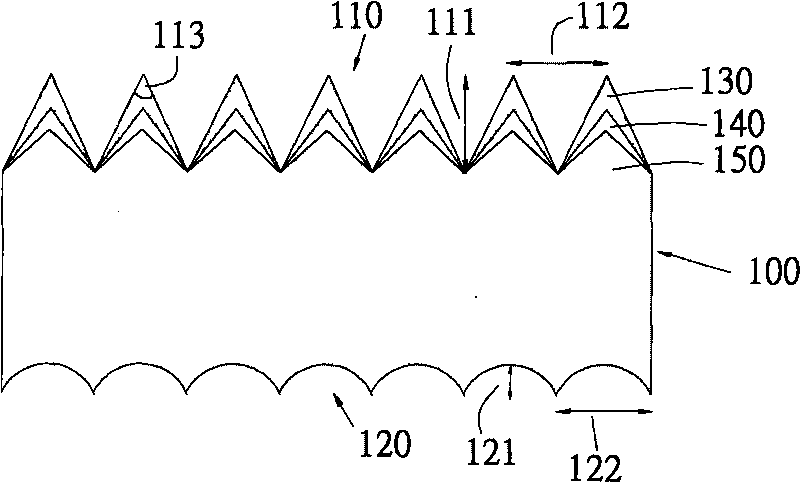

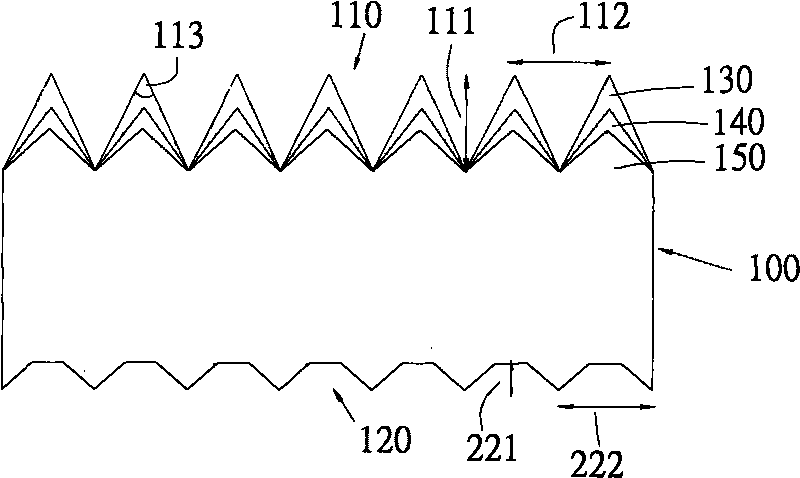

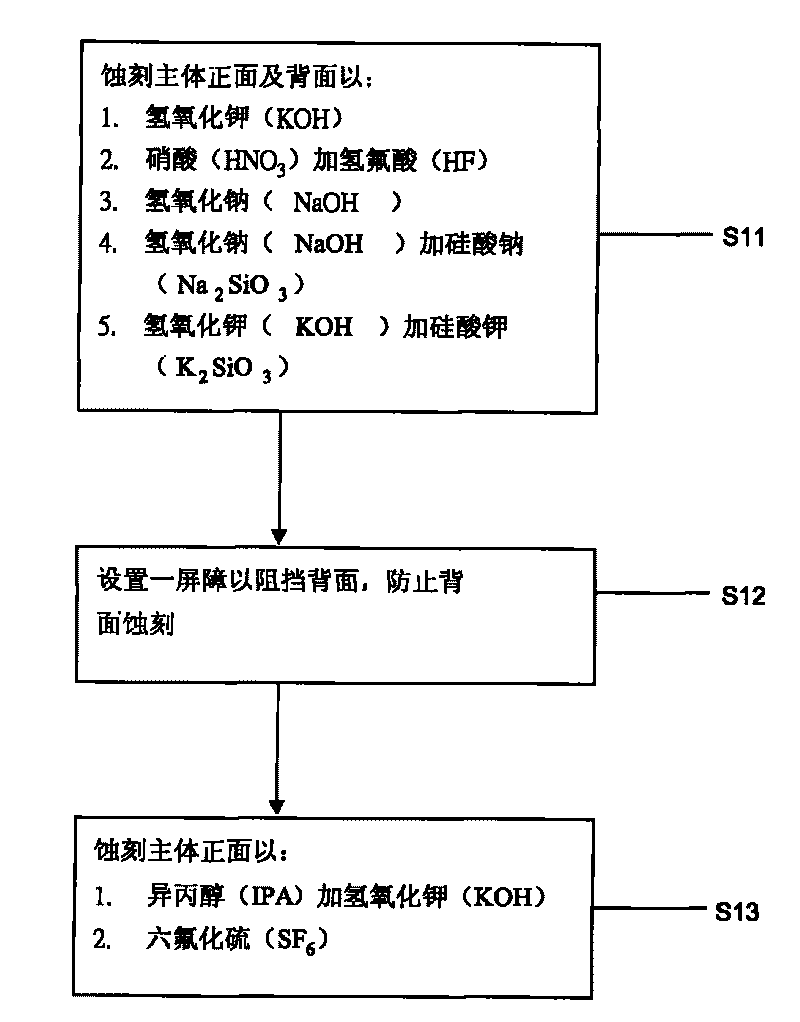

Surface structure of silicon crystal cell and manufacturing method thereof

InactiveCN101707222AAdvantages of surface structureImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationCrystal cellSurface structure

The invention discloses a surface structure of a silicon crystal cell and a manufacturing method thereof. The surface structure of the silicon crystal cell comprises a main body, the main body is provided with a front surface and a back surface, wherein the roughness coefficient of the front surface of the main body is larger than that of the back surface of the main body; the surface morphology of a front surface microstructure comprises a plurality of tapering bodies; and the surface morphology of a back surface microstructure comprises a plurality of arc bodies or polygonal bodies. The invention enables the back surface of the surface structure of the silicon crystal cell to be flatter than the front surface of the same, thereby enhancing the photoelectric conversion efficiency and reducing the fragmenting probability in the manufacture process.

Owner:MOTECH INDUSTRIES

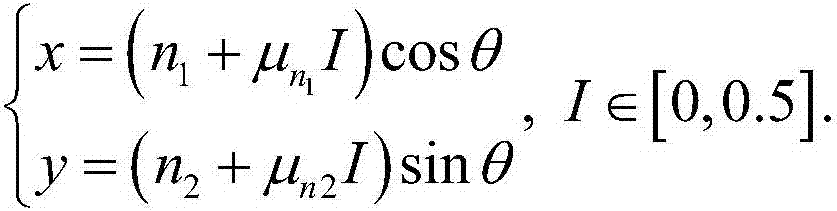

Approximate expression method for anisotropy of structural surface roughness based on median number function

The invention provides an approximate expression method for anisotropy of structural surface roughness based on median number function. The method comprises: obtaining the three-dimensional point cloud coordinate data of a structural surface; extracting the contour lines of structural surfaces in different sizes in different measuring directions and the coordinate data of the contour lines; measuring the structural surface roughness coefficient of each measurement section; in the condition of different sizes, making statistics and analysis of the structural surface roughness coefficients in the directions; calculating the statistical average value of the obtained structural surface roughness coefficients and the standard differences; using the sum of the statistical average value and the standard differences as the upper limit values and the differences as the lower limit values; drawing the anisotropy diagrams under the conditions of different sizes; fitting the upper limit values and the lower limit values in different directions through the use of an elliptic equation to obtain the expression of the median number function for the polar coordinates of the structural surface roughness coefficients; calculating and obtaining the interval range under different angle conditions; and obtaining the interval ranges of the roughness coefficients in all directions of the structural surfaces under conditions of different sizes. The method of the invention is capable of approximately expressing the uncertainty of the anisotropy of structural surface roughness.

Owner:SHAOXING UNIVERSITY

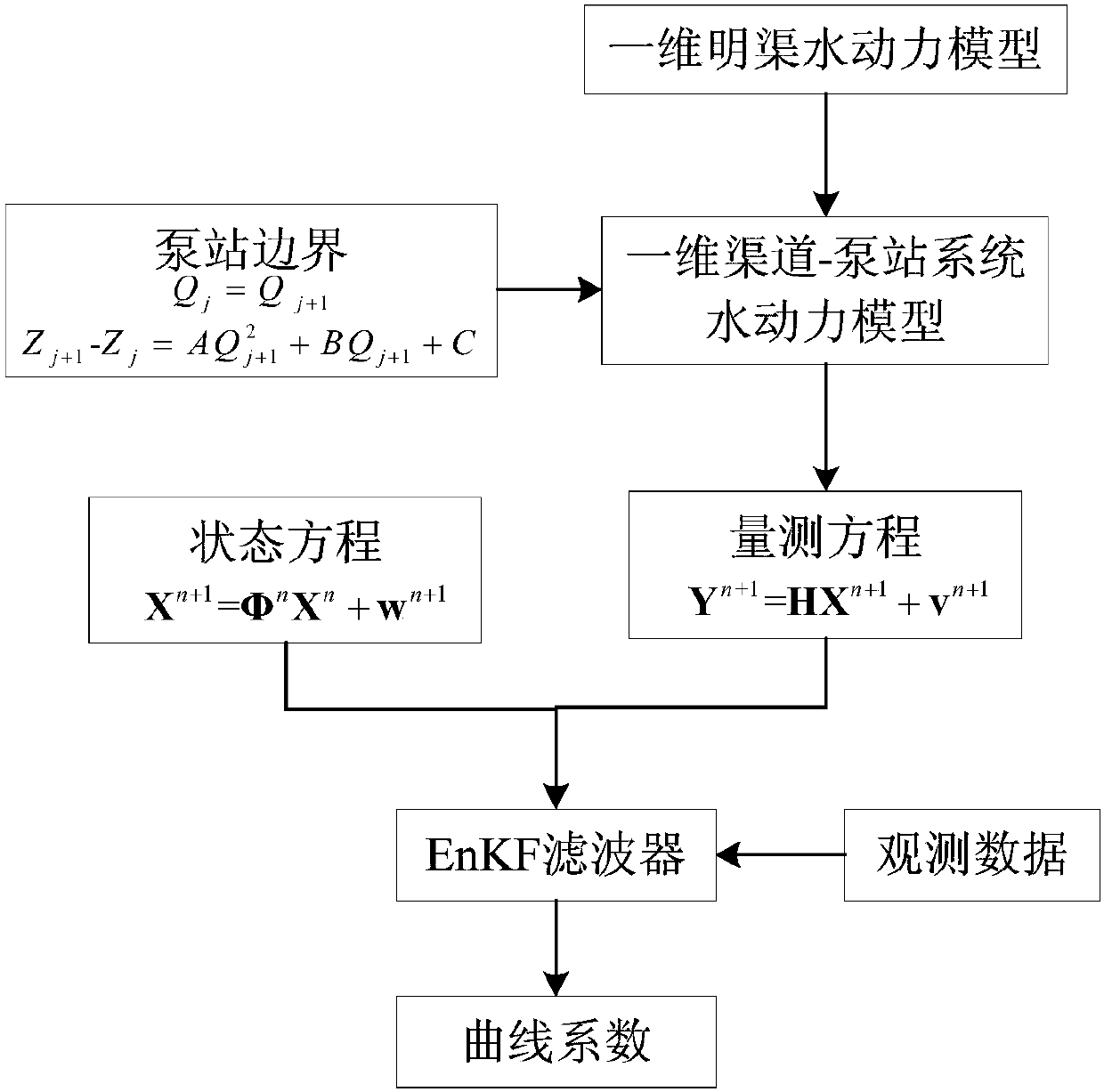

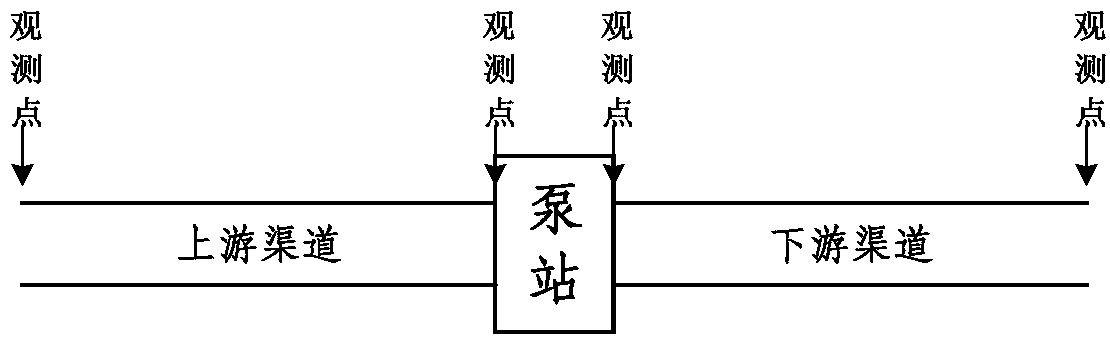

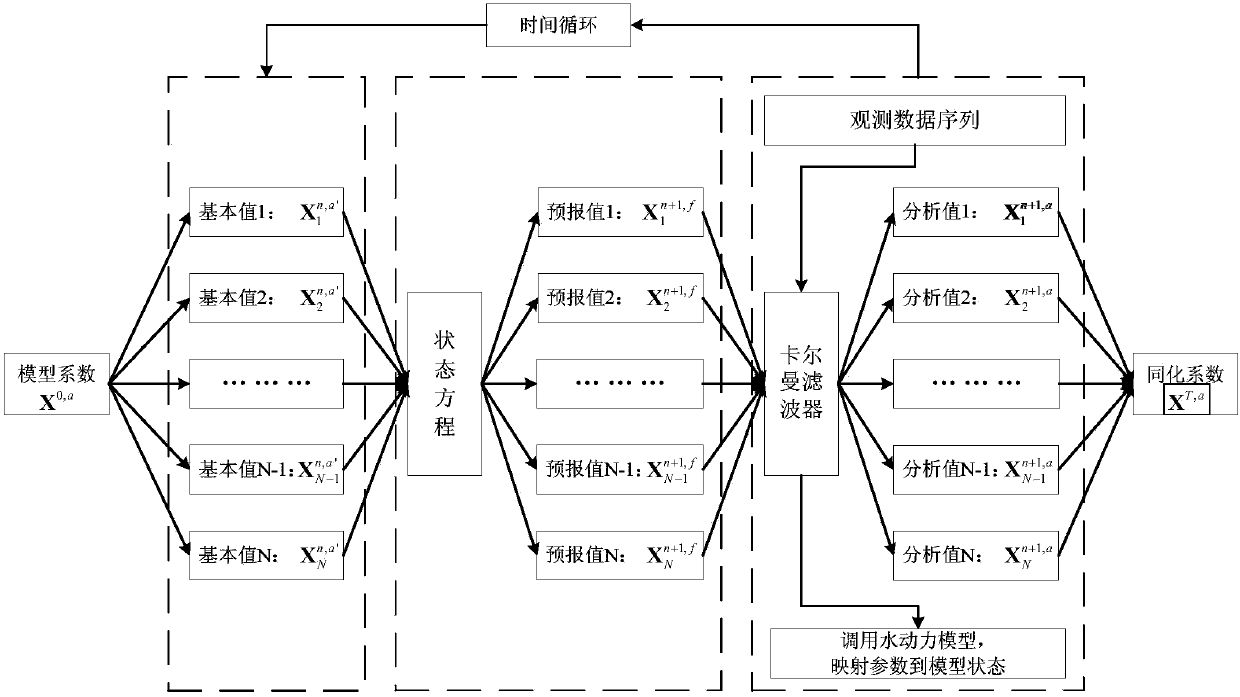

Identification method for pump station characteristic curve coefficients of one-dimensional hydrodynamic model

ActiveCN107633141AHigh precisionLow simulation accuracyResourcesSpecial data processing applicationsKaiman filterRiver network

The invention discloses an identification method for pump station characteristic curve coefficients of a one-dimensional hydrodynamic model, and relates to the technical field of hydrodynamic model parameter identification. The method comprises the steps that a one-dimensional open channel hydrodynamic model of a target open channel is built on the basis of a Saint-Venant equation, and roughness coefficients of a front connection channel and a back connection channel of a to-be-identified pump station are calibrated; the to-be-identified pump station boundary takes a continuity equation and apump station characteristic curve as consistency equations to be coupled with the Saint-Venant equation in the step 1 to form a one-dimensional channel-pump station hydrodynamic model containing the to-be-identified pump station boundary; state-space equations including the state equation X<n+1>=phi<n>X<n>+w<n+1> and the measurement equation Y<n+1>=HX<n+1>+v<n+1> which take the three pump stationcharacteristic curve coefficients of the to-be-identified pump station as state vectors are constructed; and observation data obtained in the time period when the angle or rotating speed of a pump station unit is invariable is selected, and a Kalman filter set is called to assimilate the curve coefficients. According to the method, the curve coefficients under any working conditions are automatically identified, and therefore the value simulation precision and adaptability of the river network hydrodynamic model are effectively improved.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

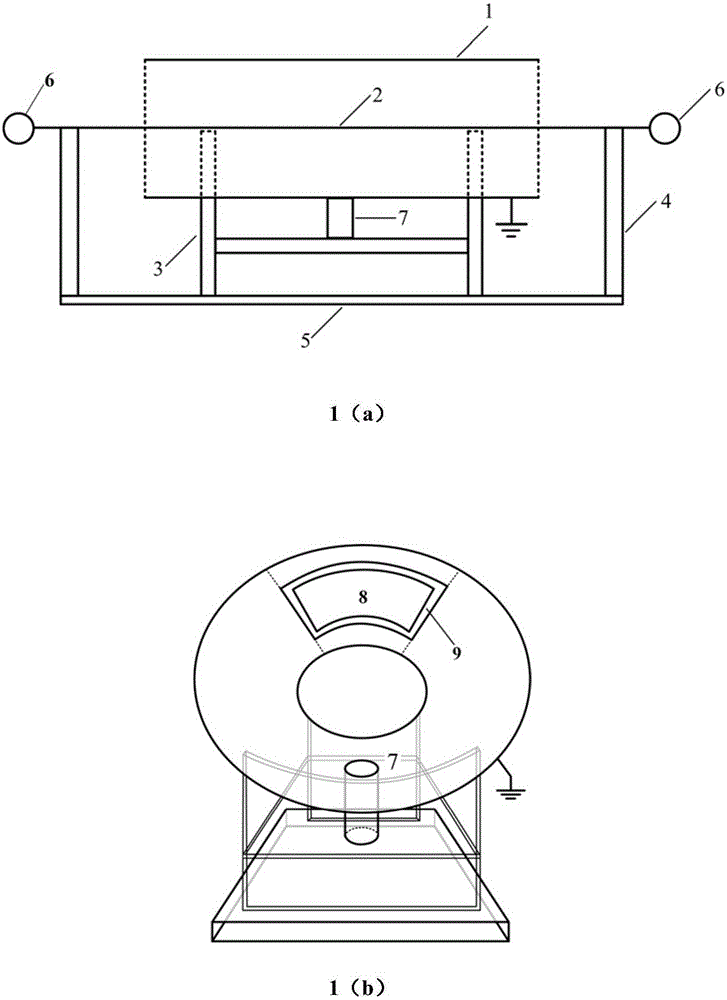

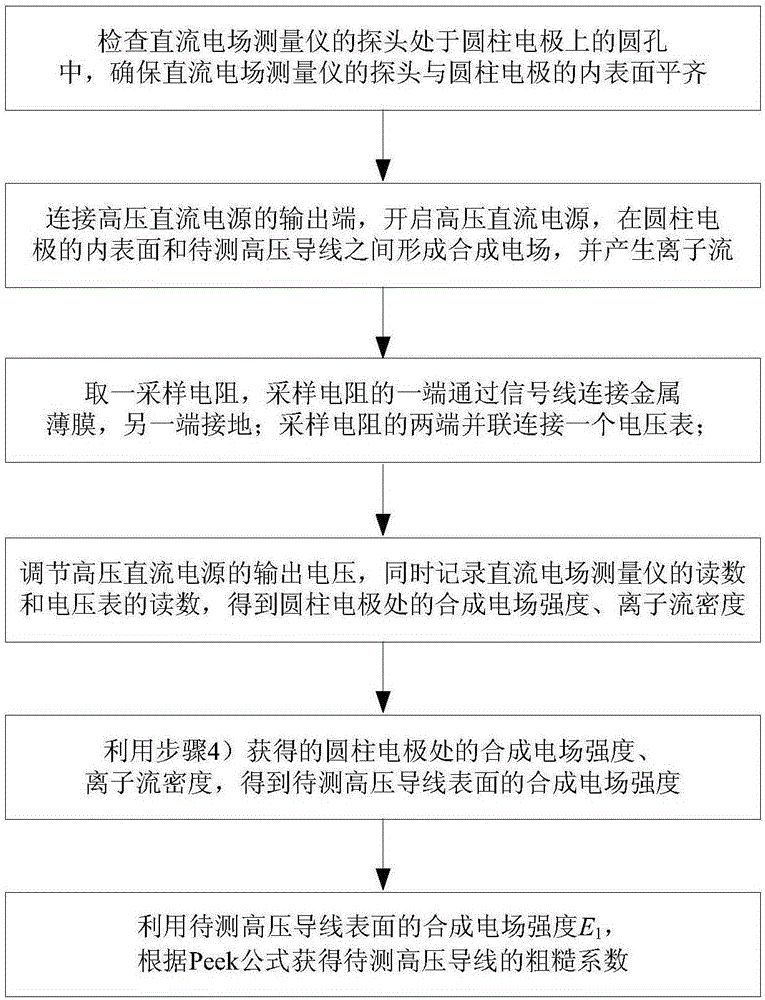

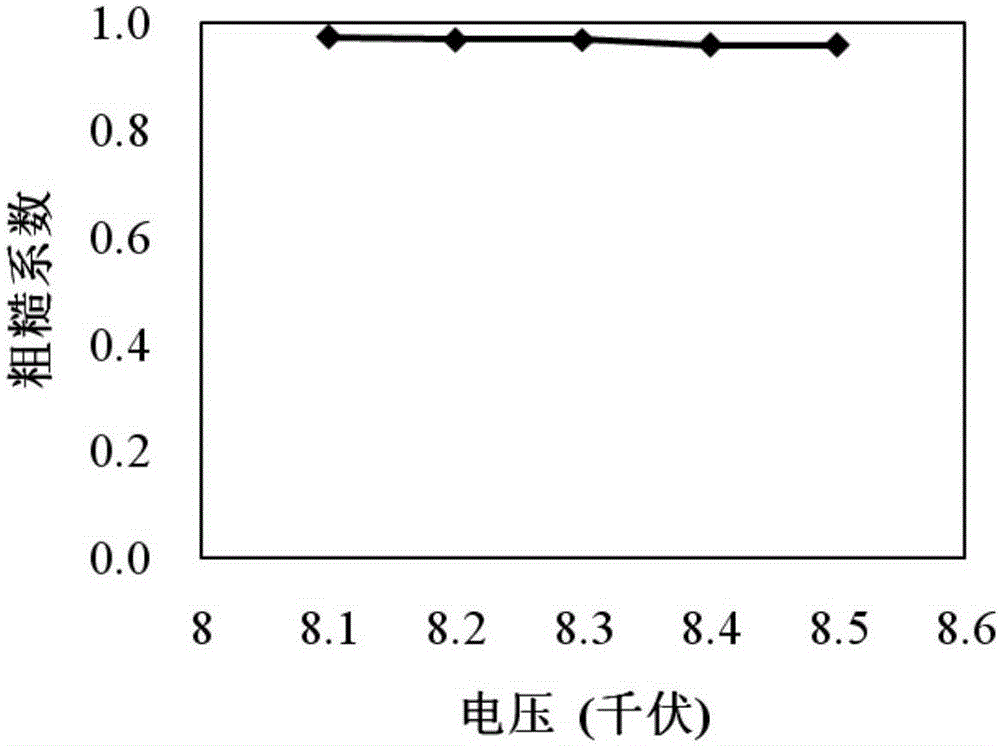

Measuring device and method of roughness coefficient of high-voltage conducting wire

ActiveCN105203021AAccurate measurementThe actual measurement is closely relatedElectric/magnetic roughness/irregularity measurementsMeasurement deviceHigh-voltage direct current

The invention belongs to the technical field of measurement of high pressure gas discharge electromagnetism, and discloses a measuring device and method of roughness coefficient of a high-voltage conducting wire. The measuring device is characterized in that: a cylindrical electrode is horizontally placed on a bracket, and is electrically grounded; the to-be-tested high-voltage conducting wire is horizontally fixed on support rods, and is coaxial with the cylindrical electrode; the probe of a direct-current electric field measuring device is placed in a circular hole in the cylindrical electrode, and is parallel and level with the inner surface of the cylindrical electrode; the to-be-tested high-voltage conducting wire is connected with the output end of a high-voltage direct current power supply, a synthesis electric field is formed between the inner surface of the cylindrical electrode and the to-be-tested high-voltage conducting wire, and ion current is generated; one end of a sample resistance is connected with a metal thin film, and the other end of the sample resistance is grounded; a voltmeter is connected with the two ends of the sample resistance in parallel; the output voltage of the high-voltage direct current power supply is adjusted, so as to obtain the synthesis electric field intensity at the cylindrical electrode, the ion current density and the synthesis electric field intensity of the surface of the be-tested high-voltage conducting wire; the roughness coefficient of the to-be-tested high-voltage conducting wire is obtained according to the Peek formula. According to the measuring device and method of roughness coefficient of the high-voltage conducting wire, accurate measurement of the roughness coefficient of the to-be-tested high-voltage conducting wire can be achieved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

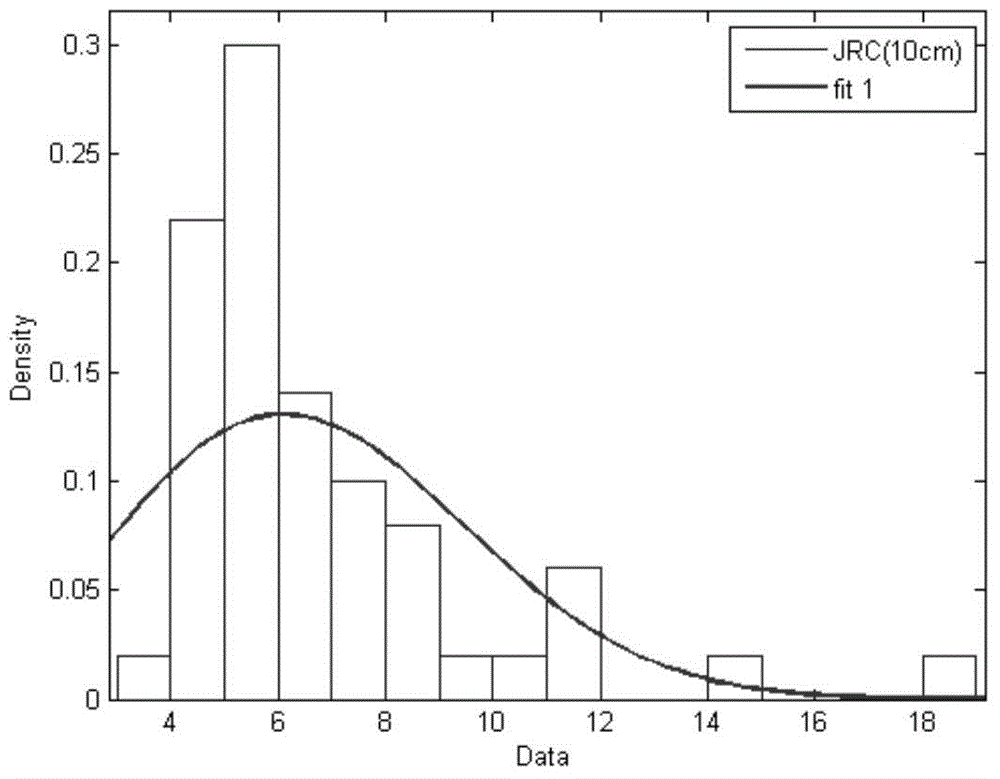

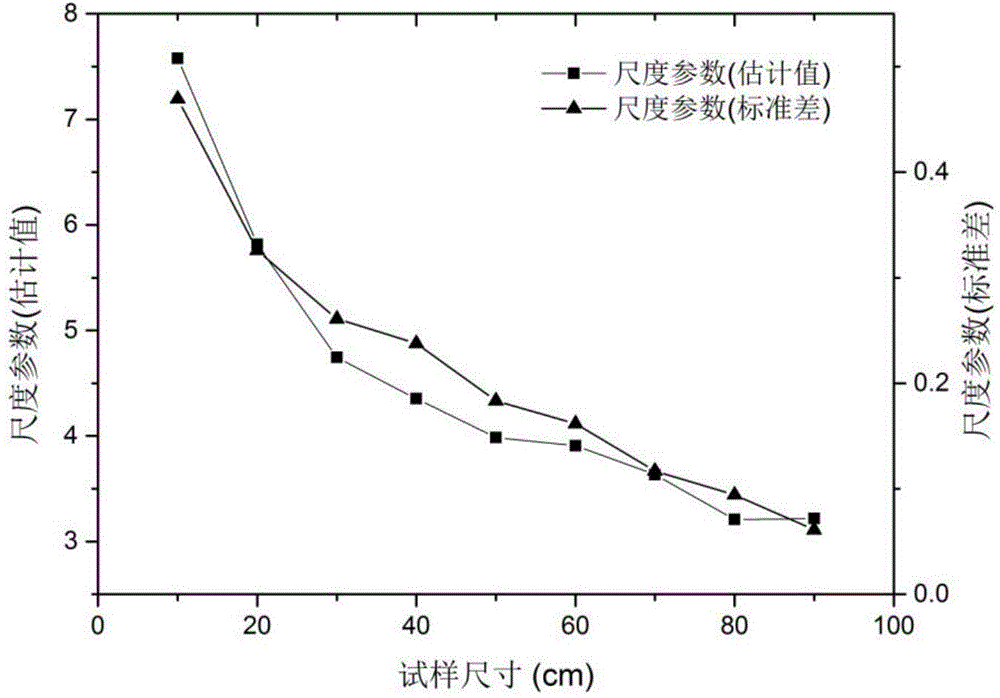

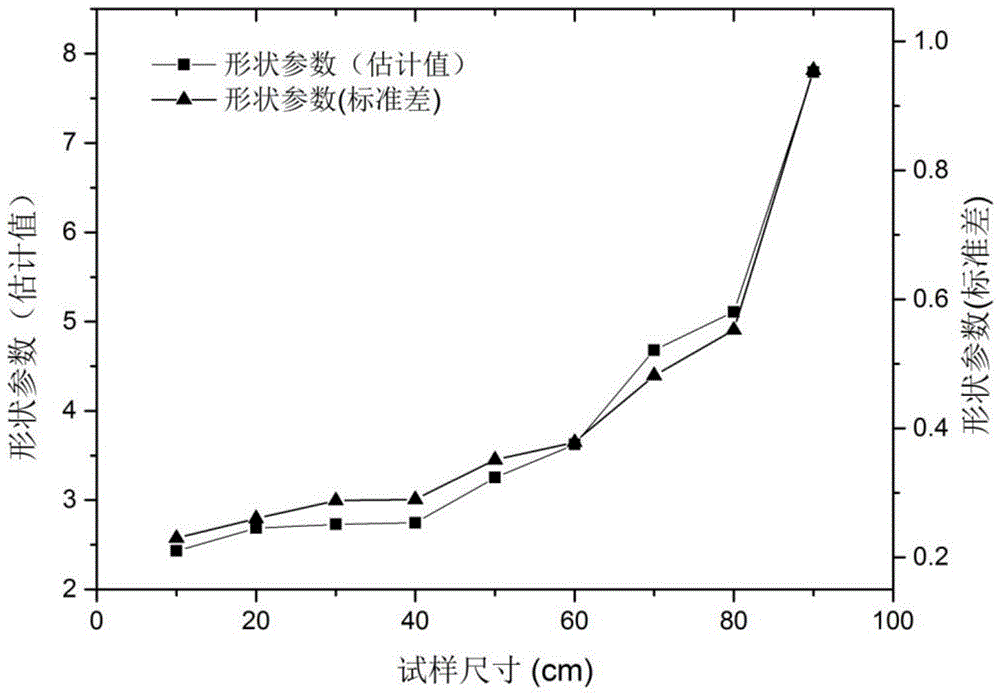

Establishing method of joint roughness coefficient size effect probability density function model

ActiveCN104881564AGood estimateQuick estimateSpecial data processing applicationsNormal densityFunctional relation

The invention relates to an establishing method of a joint roughness coefficient size effect probability density function model. The method includes the following steps: according to a joint contour line directional measurement result, adopting a large scanner to scan a drawing recording a joint contour line, and converting the drawing into picture format text; according to surface coordinate information of joint samples, adopting a Barton straight-edge simple formula to calculate roughness coefficient of a series of samples; based on phenomenological and significance test, respectively performing Weibull probability density function fitting (1) on general distribution of all size sample data; discovering functional relation among scale parameters a, shape parameter b and sample size 1 in Weibull distribution, and further establishing the joint roughness coefficient size effect probability density function model (2). By the method, influences of size effect on statistical laws of joint roughness coefficients can be described accurately, so that shear strength of joints in a series of sizes can be estimated conveniently and quickly.

Owner:SHAOXING UNIVERSITY

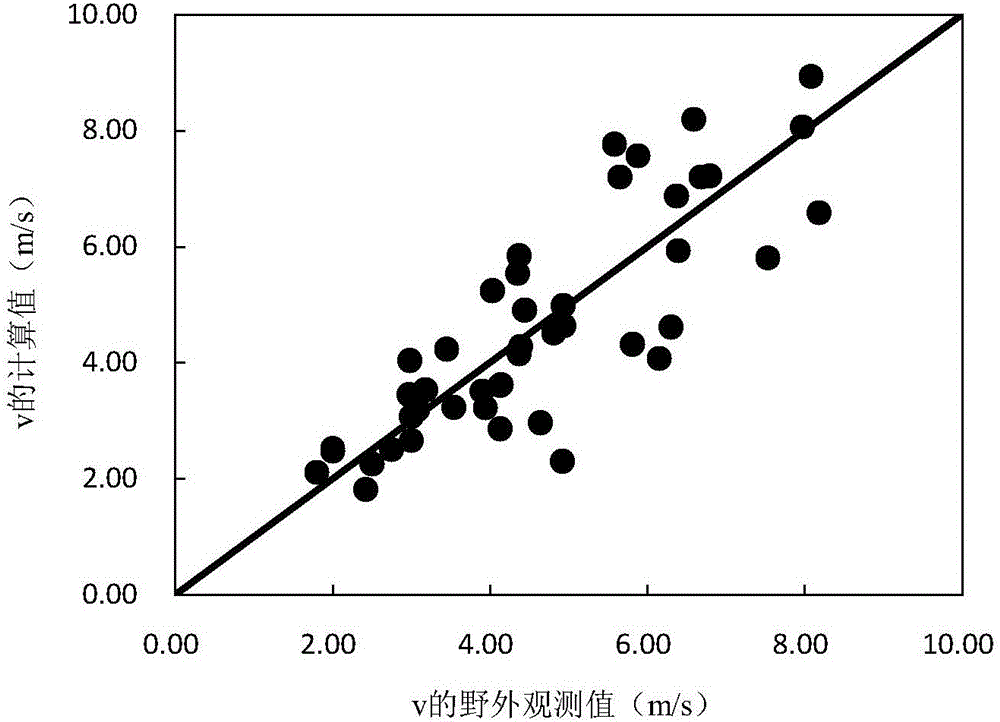

Method for measuring and calculating average flow velocity at cross section of viscous debris flow

ActiveCN107179419APrinciples of scientific calculationHigh precisionFluid speed measurementDebris flowMechanics

The invention discloses a method for measuring and calculating the flow velocity of a viscous debris flow. In allusion to defects existing in the prior art that influences imposed on the roughness coefficient, the flow velocity coefficient and the debris flow velocity by grain composition of the debris flow, the ratio of debris flow volume to sand content and the like are not considered and some variables are difficult to be accurately determined through table look-up or investigation, the invention provides a method for calculating the average flow velocity at the cross section of the debris flow with influences imposed on the flow velocity by the grain composition of the debris flow being sufficiently considered. According to the method, grain composition parameters (mu, Dc) are introduced into measurement and calculation for the flow velocity of the debris flow, dual influences imposed for the flow velocity of the debris flow by the ratio of debris flow volume to sand content are sufficiently considered, the influences imposed on the flow velocity of the debris flow by the ratio of debris flow volume to sand content are comprehensively represented by adopting Sv(1-Sv), and finally a formula model of v=f(exp(mu), H / Dc, Sv(1-Sv), H, J) for the flow velocity of the viscous debris flow can be acquired by taking a Manning formula as a prototype. The method disclosed by the invention is reliable in principle, scientific, simple and convenient in calculation process, high in precision of a measurement and calculation result and applicable to requirements of the engineering field.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com