Multi-fractal evaluation method for three-dimensional rock structure surface shear mechanical behavior

A three-dimensional rock and structural plane technology, applied in the field of rock mechanics, can solve problems such as insufficient comprehensiveness, difficulty in wide application, and many parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

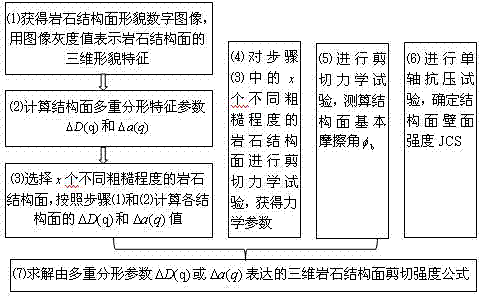

[0046] See figure 1 It is a multi-fractal description flow chart of the shear mechanics behavior of the three-dimensional rock structural plane.

[0047] Image Acquisition of Structural Surface and Representation of 3D Shape of Structural Surface by Gray Value

[0048] The topography of the gypsum structure surface obtained by Canon 60D digital camera (see image 3 ), perform image grayscale conversion on the topography image of the structural surface, and scale, and then store the processed data. The flow chart of the gray value of the image representing the three-dimensional shape characteristics of the rock discontinuity plane is shown in Figure 4 . The specific steps of the scaling determination process in this process are as follows:

[0049] (1) After actual measurement, the difference between the highest point and the lowest point of the structural surface ( ) is 9mm;

[0050] (2) According to the statistical results of the gray value of the structural surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com