A Characterization Method for Intrinsic Sensory Quality of Tobacco Leaf Raw Materials

A sensory quality, tobacco leaf technology, applied in the direction of removing certain components, weighing, data processing applications, instruments, etc., to achieve the effect of simple and easy method, high reliability and accuracy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

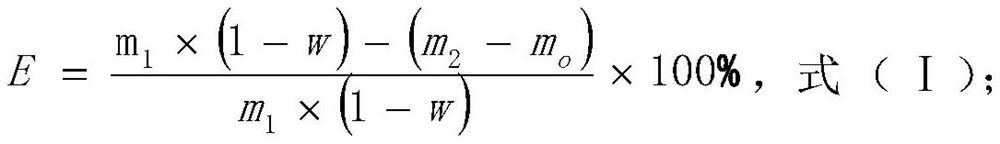

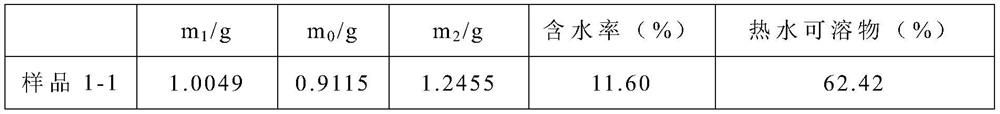

[0066] Weigh a certain amount of tobacco leaf shredded tobacco sample m 1 Put it in the solvent cup of the Soxhlet extractor, add distilled water according to the ratio of solid to liquid at 1:25, set the cycle number of the Soxhlet extractor to 10 times, the extraction temperature to 100°C±1°C, and the cooling water circulation device to 2°C. Extraction, the extraction time is 2.3h, uncap the weighing bottle and bottle cap and put it in the oven for 3h, add the cap and take out the weighing bottle, cool to room temperature, weigh the mass of the dry weighing bottle and bottle cap m 0 After the extraction, take out the sample, transfer it to a dried weighing bottle, put it in an oven, and bake it at 105°C±1°C until it reaches a constant weight, then cover it and take it out of the weighing bottle, cool it to room temperature, and cover it. Weigh the lid and weigh the total mass of the bottle and sample after drying m 2 According to YC / T31, the water content of the tobacco sam...

Embodiment 2

[0071] Weigh a certain amount of tobacco leaf shredded tobacco sample m 1 Put it in the solvent cup of the Soxhlet extractor, add distilled water according to the ratio of solid to liquid at 1:35, set the cycle number of the Soxhlet extractor to 13 times, the extraction temperature to 100°C±1°C, and the cooling water circulation device to 2°C for Extraction, the extraction time is 2h, uncap the weighing bottle and bottle cap and put it in the oven for 3h, add the cap and take out the weighing bottle, cool to room temperature, weigh the mass of the dry weighing bottle and bottle cap m 0 After the extraction, take out the sample, transfer it to a dried weighing bottle, put it in an oven, and bake it at 105°C±1°C until it reaches a constant weight, then cover it and take it out of the weighing bottle, cool it to room temperature, and cover it. Weigh the lid and weigh the total mass of the bottle and sample after drying m 2 According to YC / T31, the moisture content of the tobacco...

Embodiment 3

[0075] Weigh a certain amount of tobacco leaf shredded tobacco sample m 1 Put it in the solvent cup of the Soxhlet extractor, add distilled water according to the ratio of solid to liquid at 1:30, set the cycle number of the Soxhlet extractor to 15 times, the extraction temperature to 100°C±1°C, and the cooling water circulation device to 2°C for Extraction, the extraction time is 3h, uncap the weighing bottle and bottle cap and put it into the oven for 3h, add the cap and take out the weighing bottle, cool to room temperature, weigh the mass of the dry weighing bottle and bottle cap m 0 After the extraction, take out the sample, transfer it to a dried weighing bottle, put it in an oven, and bake it at 105°C±1°C until it reaches a constant weight, then cover it and take it out of the weighing bottle, cool it to room temperature, and cover it. Weigh the lid and weigh the total mass of the bottle and sample after drying m 2 According to YC / T31, the water content of the tobacco ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com