Multi-angle intelligent measurement instrument of rock structure surface roughness coefficient and measurement method of rock structure surface roughness coefficient

A technology of roughness coefficient and structural surface, which is applied to measurement devices, instruments, optical devices, etc., can solve the problems of simple measurement methods, inability to directly give the roughness coefficient of rock mass structural surface, and low mechanical measurement accuracy. Save work time and work intensity, easy to record and export data, comprehensive and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

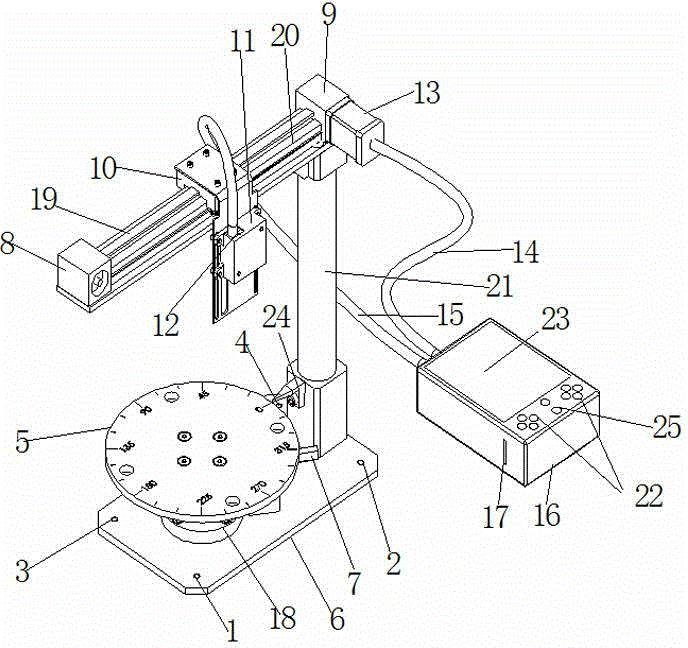

[0028] Such as figure 1 As shown, the bottom of the device base 6 of the present invention is equipped with adjustable legs, including the first leg 1, the second leg 2, the third leg 3, and the fourth leg 4; The device 7 has an angle engraved on the turntable, with a scale every 15°; the base 6 is welded to the guide rail 20 on the top of the support 21 through the support 21; The rear is connected with a transmission motor 13, and is pulled by a belt 19; a slide block 10 is installed on the guide rail 20, and the slide block 10 is fixed on the belt 19; 12; Microcontroller 16 is provided at the rear of the support, and microcontroller 16 is connected to transmission motor 13 through first wire 14, and is connected to distance sensor 12 through second wire 15; battery, button 22 are housed in microcontroller 16 , display screen 23, indicator light 25, memory card 17 and circuit board and are fixed by bolt.

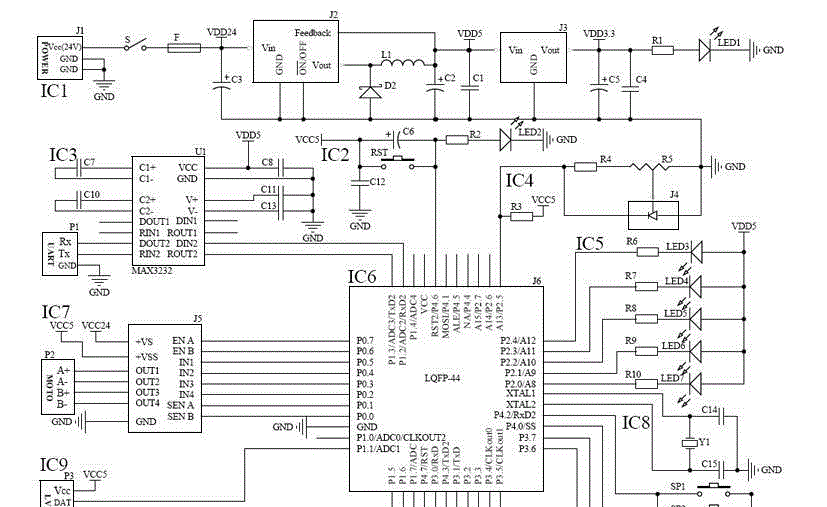

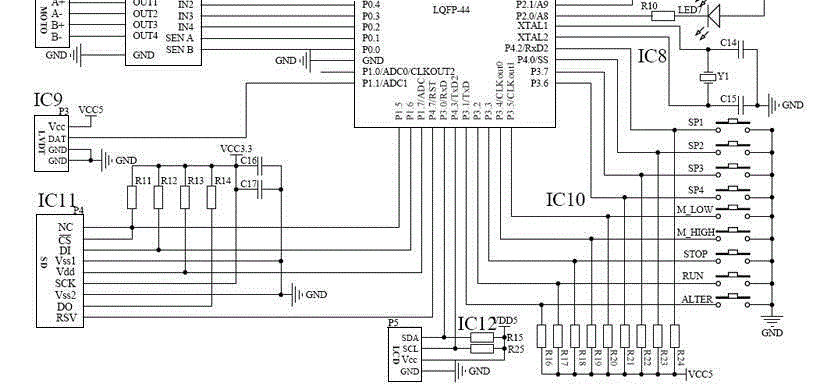

[0029] Such as figure 2 with image 3 As shown, the control circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com