Roughness coefficient prototype observation and determination method for long-distance water conveyance canals

A technology for long-distance water delivery and roughness prototyping, applied to measuring devices, instruments, etc., can solve problems such as unreliability, waste of manpower, material resources, and missing valuable opportunities for prototype observation, and achieve the effect of rapid setting and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

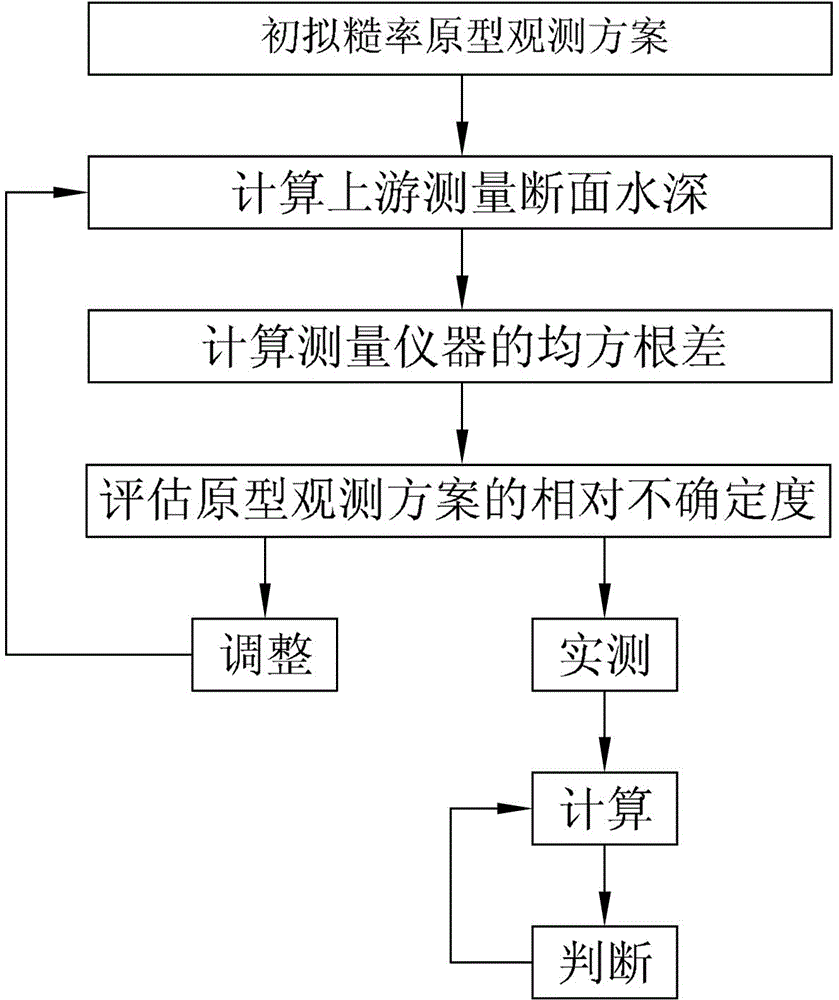

[0037] This embodiment is a prototype observation and measurement method for the roughness of a long-distance water delivery channel. The steps of the method are as follows, and the flow process of the method is as follows: figure 1 Shown:

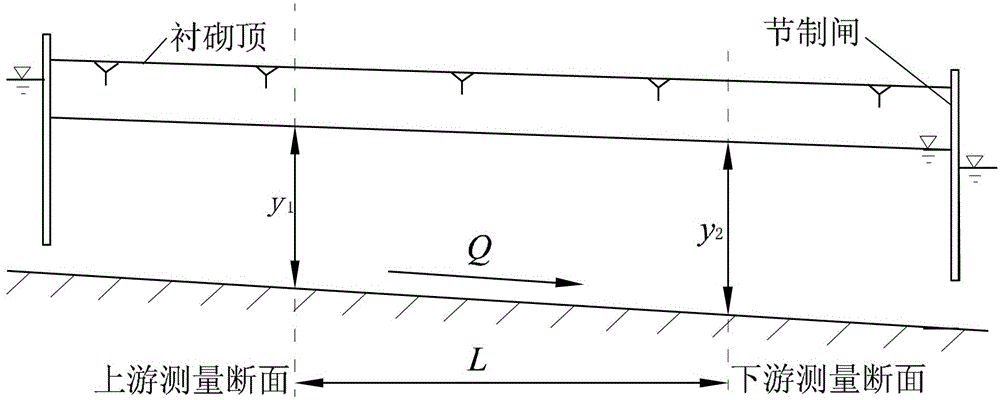

[0038] Steps for preliminary roughness prototype observation scheme: used for preliminary prototype observation flow Q 0 , determine the location of the downstream measurement section, and determine the water depth of the section y 20 , the preliminary measurement section spacing L 0 . Firstly, survey and observe the channel to be measured, and select its multi-year average water delivery flow as the prototype observation flow according to the channel’s years of operation. At the same time, select a canal section with a regular cross-section shape and a smooth channel direction, and set a measuring section downstream of it. The water depth of this section is measured, the distance between the sections is initially planned, and the u...

Embodiment 2

[0084] This embodiment is an improvement of Embodiment 1, and it is the allowable relative uncertainty of the measurement of roughness in Embodiment 1 K 1 The value range of is refined. The roughness measurement described in this embodiment allows relative uncertainty K 1 The value range is: 1%~5%.

[0085] K 1 The value reflects the level of people’s requirements for the accuracy of roughness measurement. For channel projects with sufficient water head and short distance, the influence of roughness error is relatively small, and people’s requirements for measurement accuracy can be lower. K 1 Take a large value; for channel projects with tight water head and long distance, the impact of roughness error is relatively large, and people have high requirements for measurement accuracy. K 1 Should take a small value.

Embodiment 3

[0087] This embodiment is an improvement of the first embodiment, and it is the lower boundary value of the roughness trial calculation of the first embodiment K 2 The refinement of the value range. The lower boundary value of roughness trial calculation described in this embodiment K 2 The value range is: 0.005~0.01.

[0088] K 2 The value reflects people's judgment on the deviation range between the roughness design value and the measured value, and is mainly affected by the channel design and construction level. For long-distance water delivery channels, the design unit usually has rich engineering experience, sufficient demonstration of the design scheme, high level of construction mechanization, strict quality control, and a small deviation between the roughness design value and the measured value, usually within 0.005, and a small value is desirable; for small and medium-sized For large-scale channels, the level of design and construction is relatively low, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com