Patents

Literature

496 results about "Sensitivity coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength weather resisting steel with Cu2-xS dispersed precipitates and manufacturing method thereof

ActiveCN101928894AReduce steelmaking costsInhibition of segregationTemperature control deviceManufacturing convertersChemical compositionHigh intensity

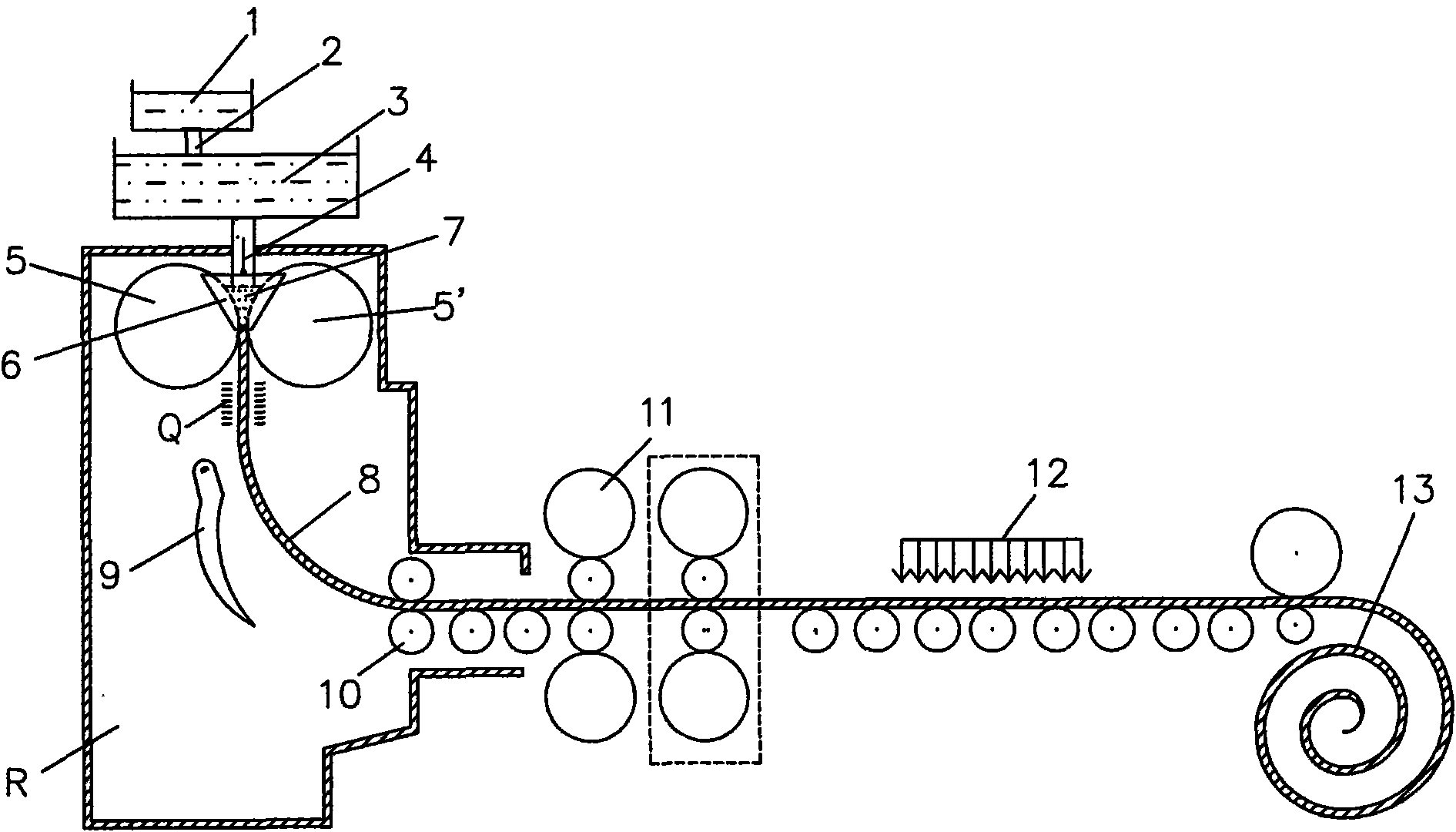

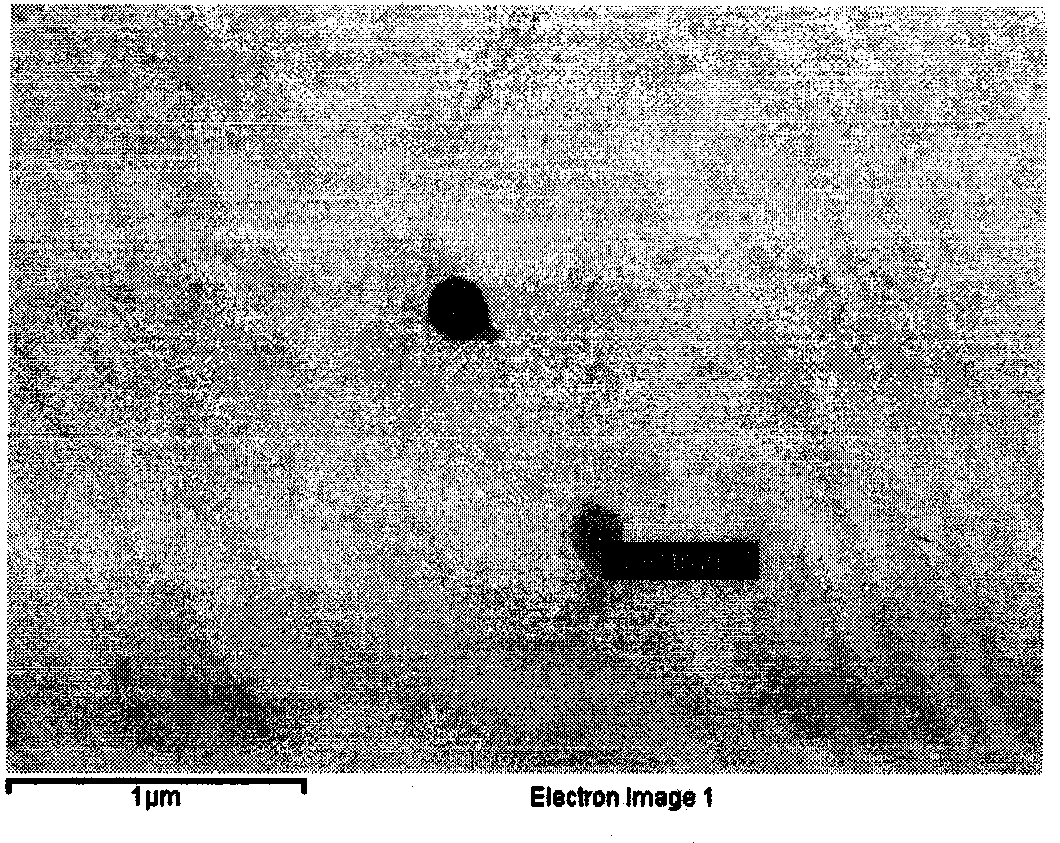

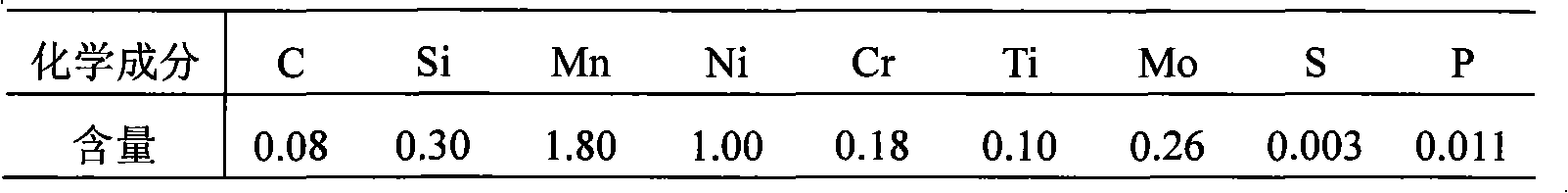

The invention relates to high-strength weather resisting steel with Cu2-xS dispersed precipitates, which comprises the following chemical components in percentage by weight: 0.04-0.08% of C, 0.20-0.40% of Si, 0.4-1.0% of Mn, 0.03-0.12% of P, not more than 0.2% of S, 0.01-0.06% of Al, 0.20-0.80% of Cu, 0.40-0.6% of Cr, 0.12-0.40% of Ni, 0.001-0.006% of Ca and the balance of Fe and inevitable impurities. The welding cold crack sensitivity coefficient Pcm is not more than 0.18%. A manufacturing method comprises the following steps of: acceleratedly cooling both sides of a cast belt formed by continuous casting by using a gas and adopting a thin belt continuous casting production technology, wherein the cooling rate is 150-200 DEG C / s; performing the entire double-roller continuous casting process in a closed chamber filled with protective atmosphere; and arranging one to two stands for online hot rolling, wherein the thickness of a finished steel belt reaches 0.6-2 mm. The desulfurization procedure in steel making process can be omitted, and the steel making cost is reduced. The segregation of copper elements is inhibited, meanwhile, a large quantity of dispersed Cu2-xS precipitates can be formed to achieve the effect of dispersion strengthening.

Owner:BAOSHAN IRON & STEEL CO LTD

High strength low yield ratio welding structure steel and production method thereof

The invention belongs to welded structural steel with high strength and low yield ratio and a production method thereof, aiming at solving the defects that a steel plate or a steel coil with the specification smaller than 25mm can only be produced, the process is long, and the like. The invention adopts the measures that the welded structural steel contains chemical components by weight that: 0.04-0.10 percent of C, 0.60-2.00 percent of Si, 1.50-2.50 percent of Mn, less than or equal to 0.030 percent of P, less than or equal to 0.010 percent of S, 0.20-0.50 percent of Cu, 0.40-0.80 percent of Cr, 0.35-0.80 percent of Ni, 0.0008-0.0030 percent of B, and at least three of the following components: less than or equal to 0.60 percent of Mo, 0.015-0.060 percent of Nb, 0.030-0.120 percent of V, less than or equal to 0.030 percent of Ti, less than or equal to 0.040 percent of Als and less than or equal to 0.010 percent of Zr, and the rest is Fe and unavoidable impurities; and meanwhile, Mn and Cr also need to satisfy the condition that Mn and Cr are equal to 2.20-2.80 percent, and the welding cold crack sensitivity coefficient Pcm is equal to C plus Si / 30 plus (Mn plus Cu plus Cr) / 20 plus Mo / 15 plus Ni / 60 plus V / 10 plus 5B and is less than or equal to 0.30 percent; the production method comprises the following steps of heating a steel billet, rough rolling, finishing rolling, relaxing and laminar cooling, and the laminar cooling comprises the following steps of slow cooling, quick cooling and natural cooling to room temperature.

Owner:武钢集团有限公司

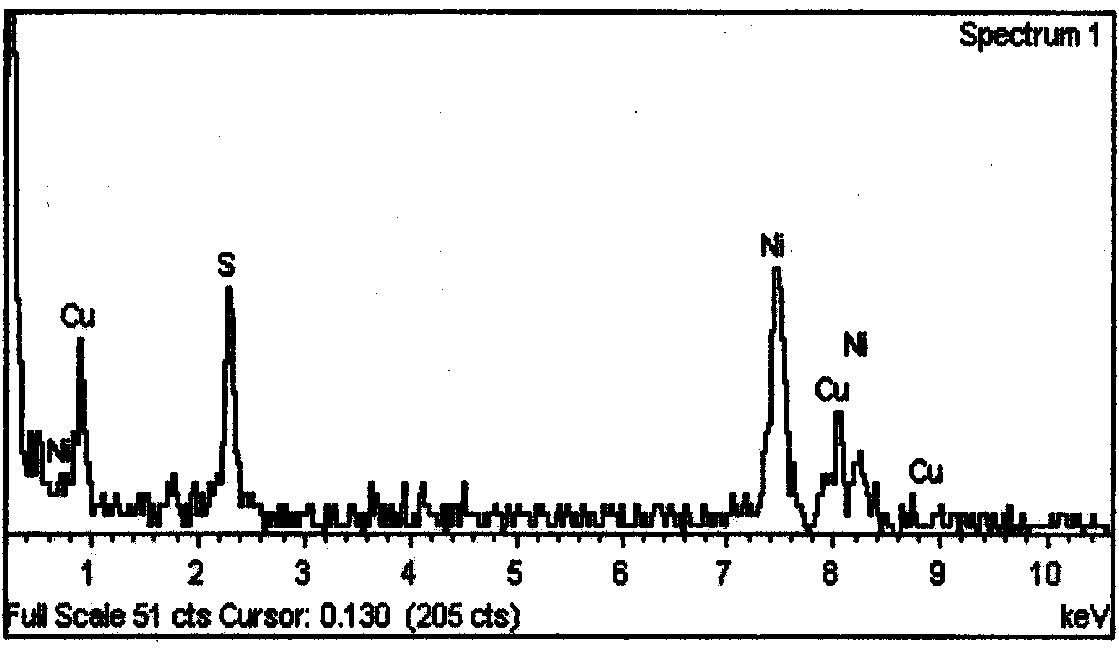

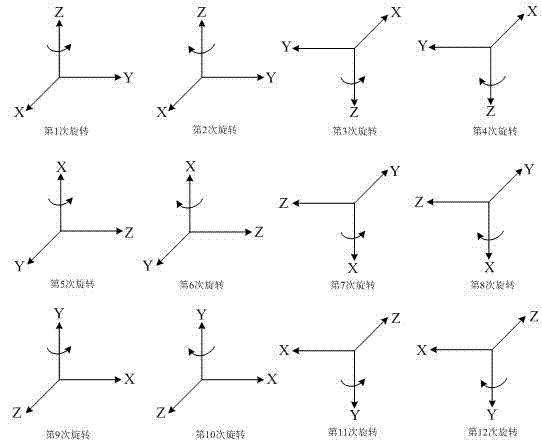

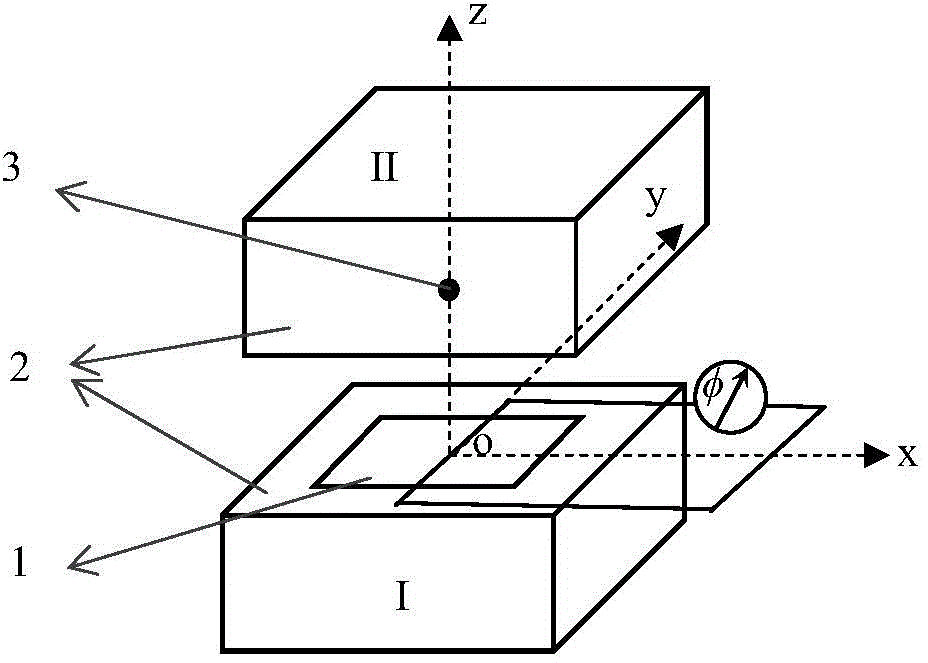

Triaxial MEMS gyroscope rotation integral calibration method based on uniaxial turntable

The invention discloses a triaxial MEMS gyroscope rotation integral calibration method based on a uniaxial turntable. According to the invention, first, a triaxial MEMS gyroscope error model is established; the triaxial MEMS gyroscope is fixed on the uniaxial turntable; MEMS gyroscope six-position rotary calibration is carried out; test data and sampling time of 12 times of rotation of the MEMS gyroscope at the 6 positions are tested and recorded; through the 12 times of rotation of the MEMS gyroscope at the 6 positions, a MEMS gyroscope error model is simplified, and an error model after gyroscope rotation is obtained; integral calculations are carried out upon two sides of the equation of the error model after gyroscope rotation, an error equation set is established, and MEMS gyroscope error coefficient is obtained by calculation. With the method provided by the invention, calibration precision is ensured; and fixed zero bias, scale factor, cross-coupling error coefficient, and acceleration sensitivity coefficient of the MEMS gyroscope can be solved rapidly, such that calibration efficiency is improved.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

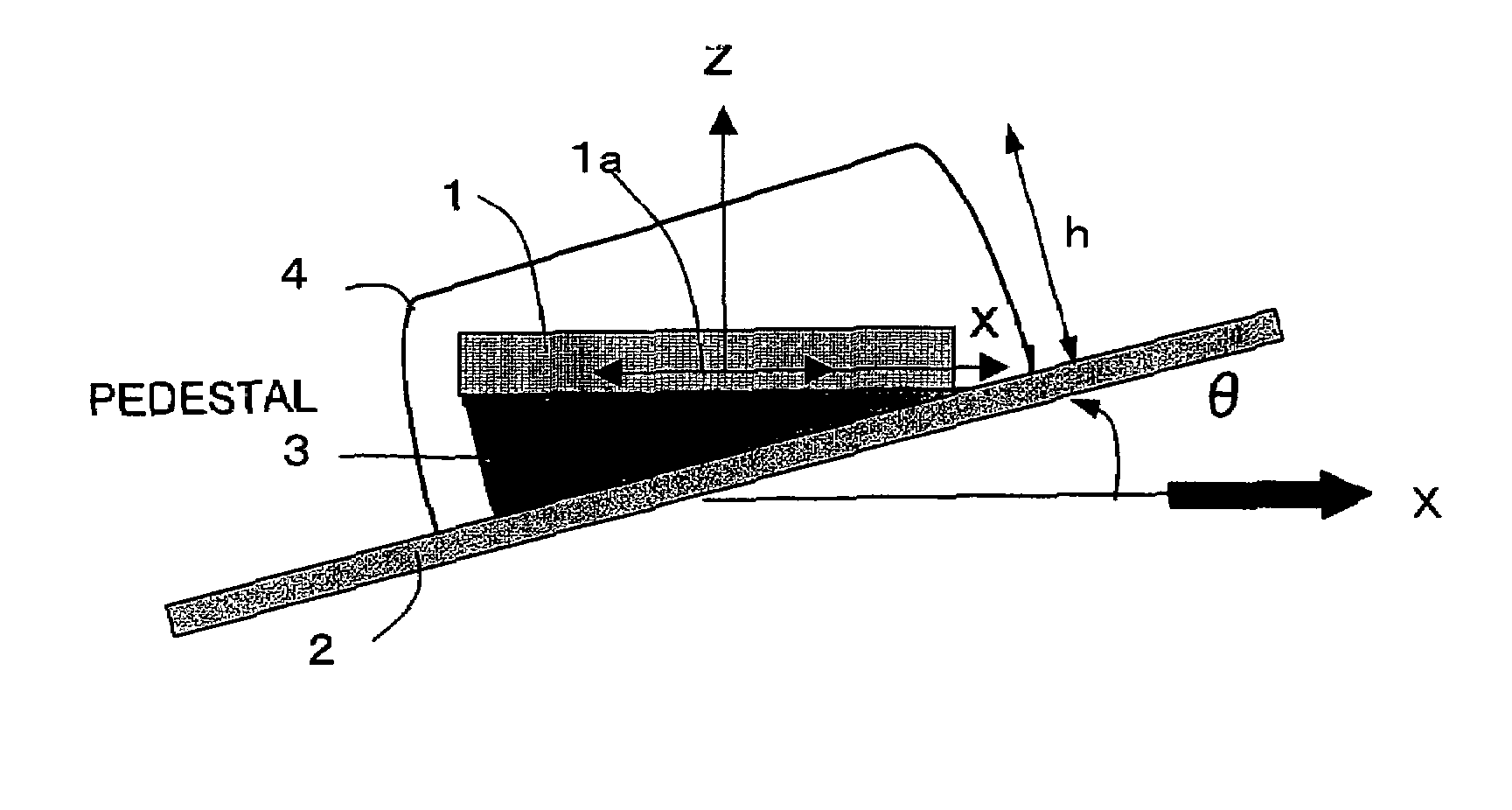

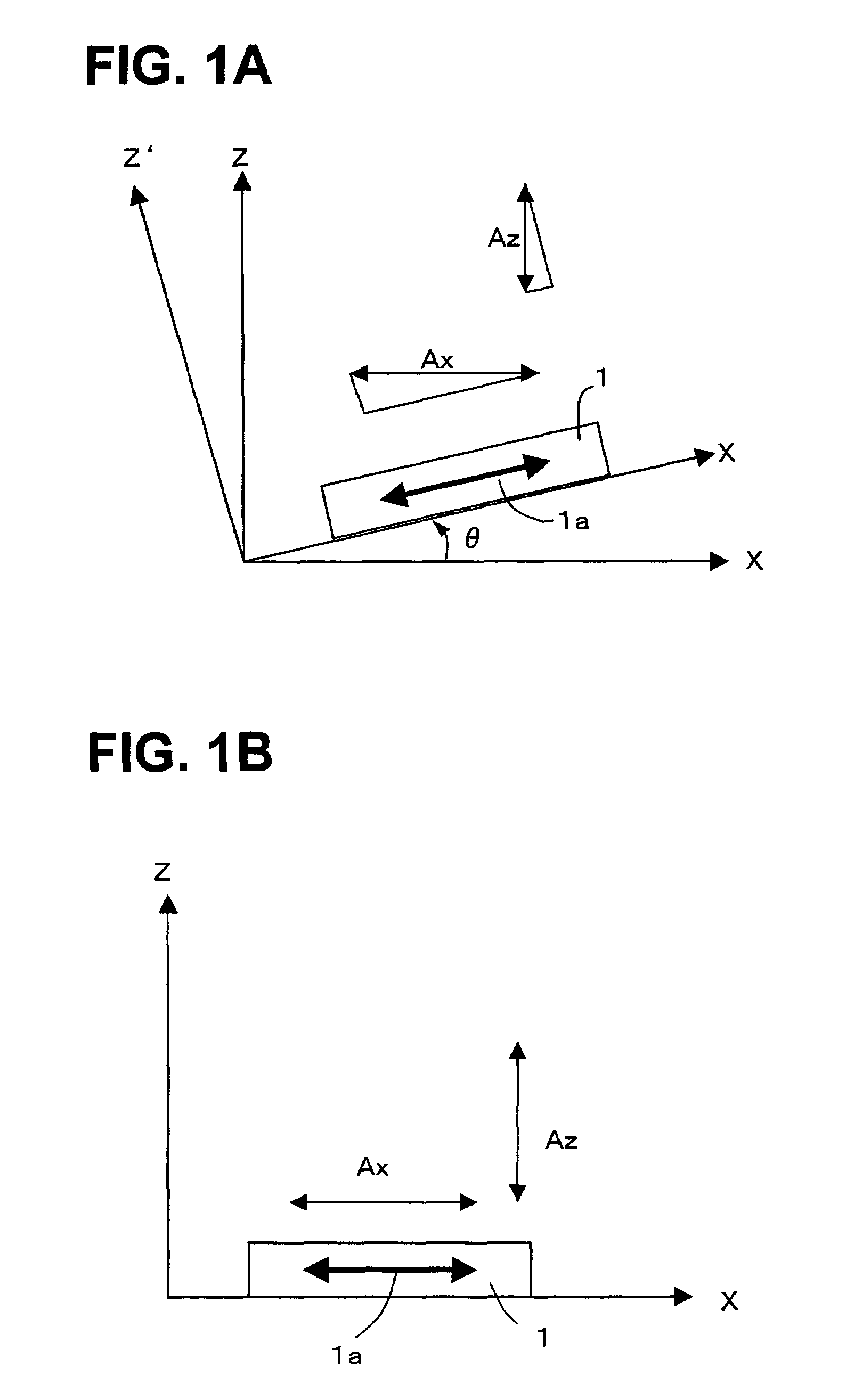

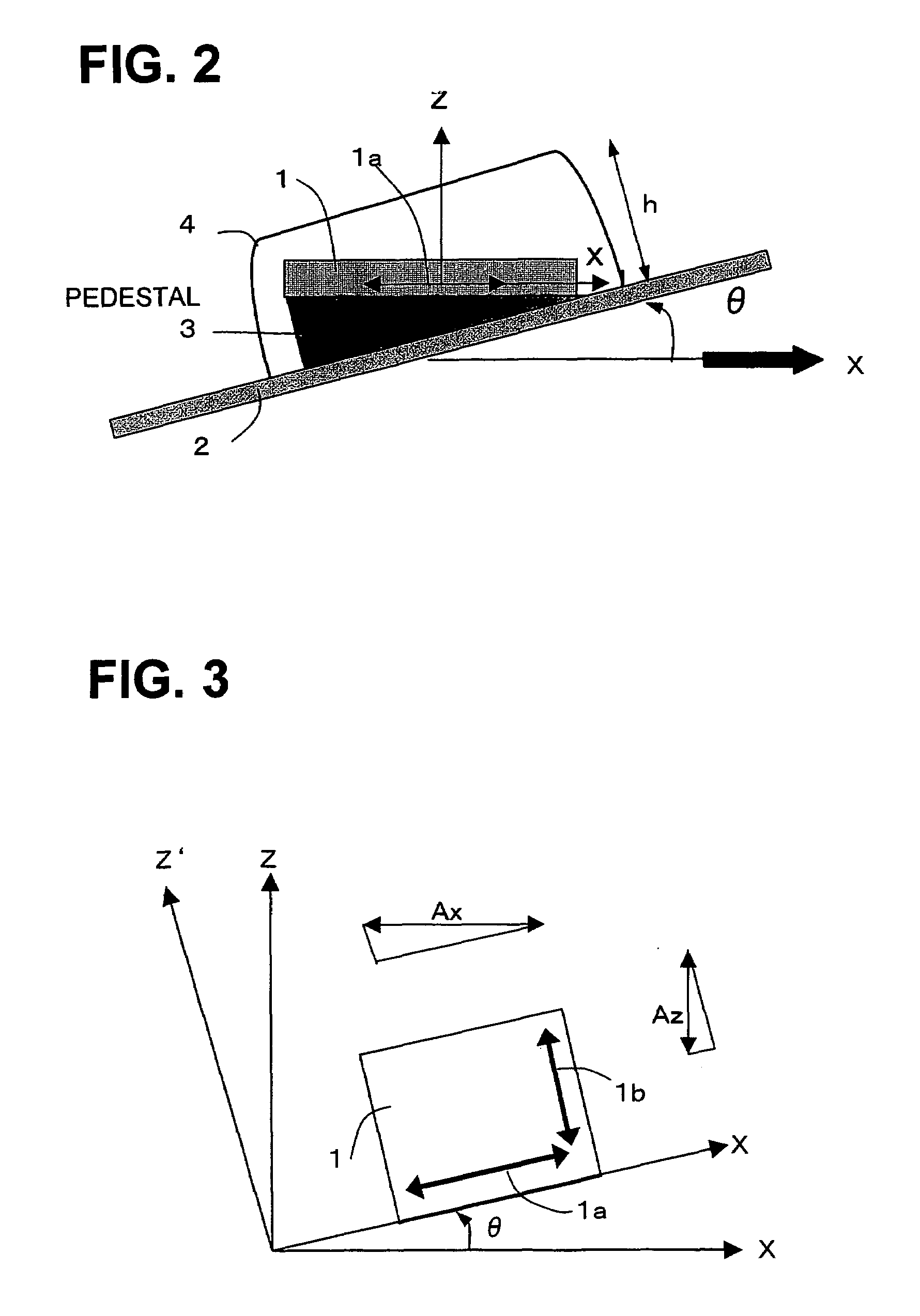

Stress detection method for sensor device with multiple axis sensor and sensor device employing this method

InactiveUS7320253B2Acceleration measurement using interia forcesForce measurementClassical mechanicsAPX

The present invention provides the stress detection method for force sensor device with multiple axis sensor device and force sensor device employing this method, whose installation angle is arbitrary. The stress detection method includes, first and second force sensors whose detection axes are orthogonal to each other. When the detection axis of first force sensor forms angle θ with direction of detected stress Ax, and the stress component of direction perpendicular to direction of the detected stress Ax is Az, output Apx of the axis direction of first force sensor is found as Apx=αx (Ax×cos θ+Az×sin θ), and output Apz of the axis direction of the second force sensor is found as Apz=αz (Ax×sin θ+Az×cos θ), and, when αx and αz are detection sensitivity coefficients of first and second force sensors respectively, the detection sensitivity coefficient αz of second force sensor is set as αz=αx tan θ, and the detected stress Ax is found as Ax=(Apx−Apz) / αx(cos θ−tan θ×sin θ).

Owner:TAMAGAWA SEIKI CO LTD

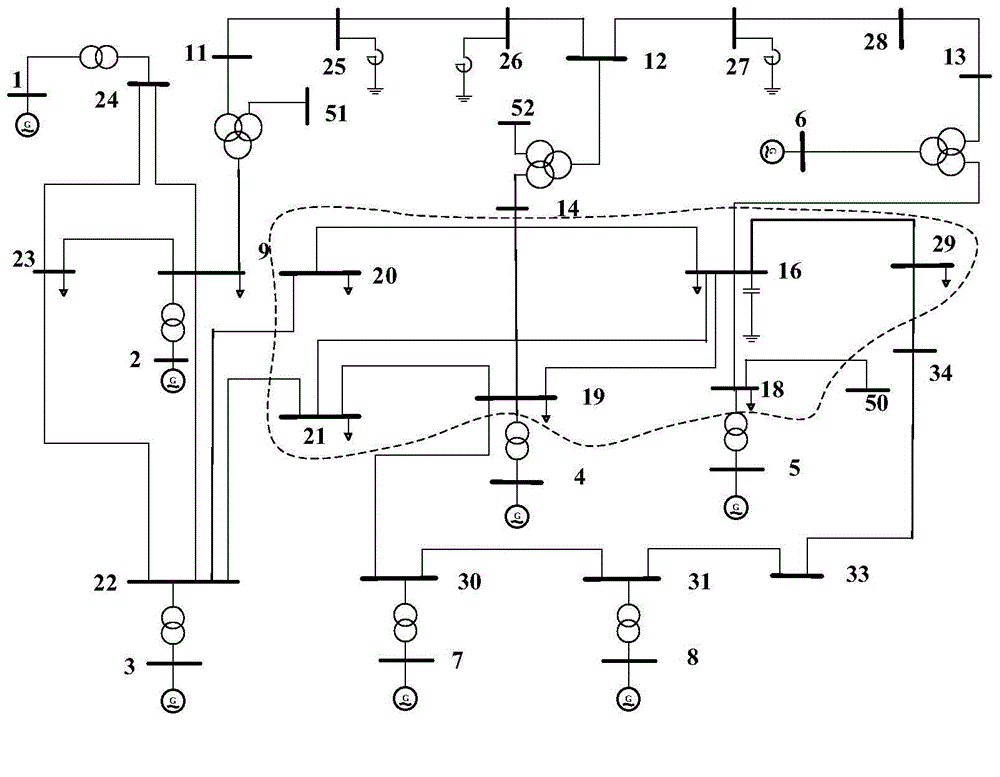

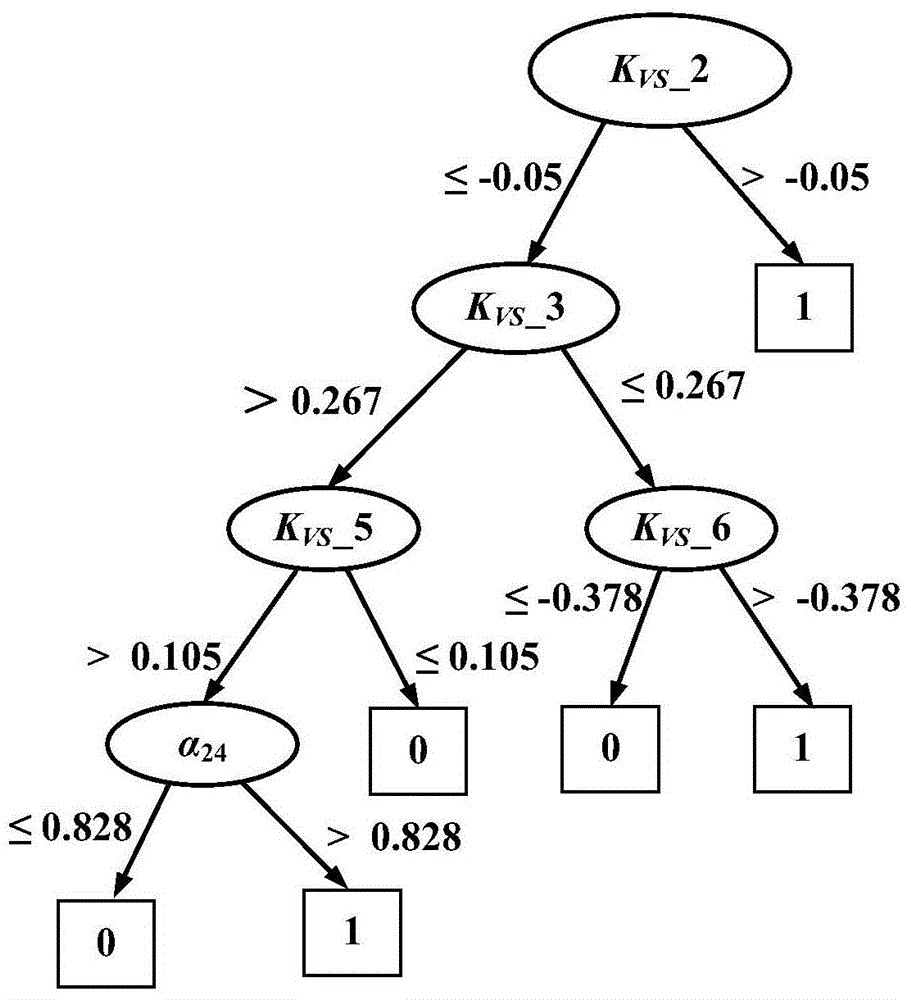

Assessment method for transient voltage stabilization of load area of electrical power system

ActiveCN104617574AAccurate classificationAccurate assessmentSystems intergating technologiesSpecial data processing applicationsDecision modelElectric power system

The invention relates to an assessment method for transient voltage stabilization of a load area of an electrical power system and belongs to the electrical power system stability analyzing and assessment field. The assessment method for the transient voltage stabilization of the load area of the electrical power system includes that using data measured by a synchronous phasor measurement unit as basis, and building an initial sample database for data mining through a lot of simulation samples; extracting characteristics for reflecting the stabilization degree of each node through the quantitative evaluation for each node in the area; identifying through a multiple linear regression method to obtain sensitivity coefficients for reflecting the mutual influence relations between the nodes in a local area network; using a semi-supervised clustering method to demarcate all the samples; using a decision tree algorithm to perform classified learning to obtain a decision tree model, and using the decision tree model for online monitoring to assess the global transient voltage stabilization state of the load area of the electrical power system.

Owner:TSINGHUA UNIV

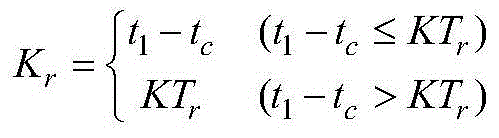

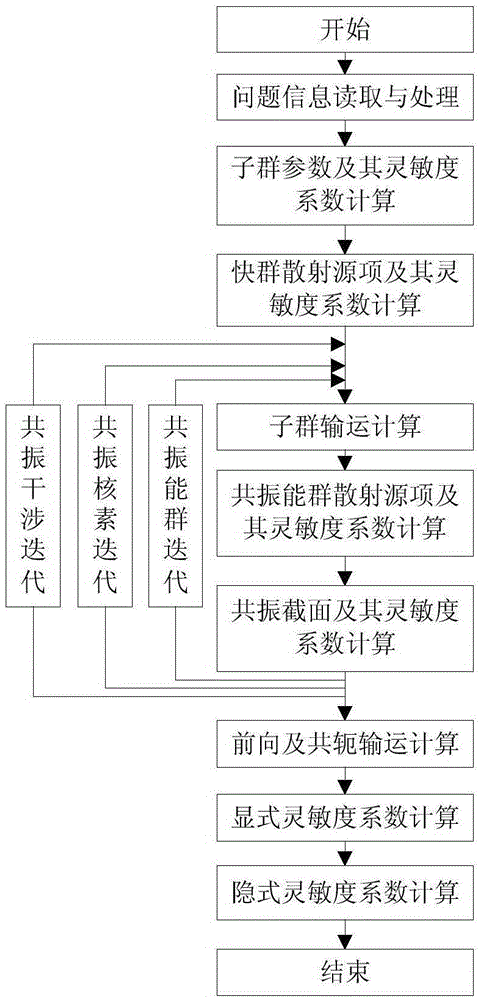

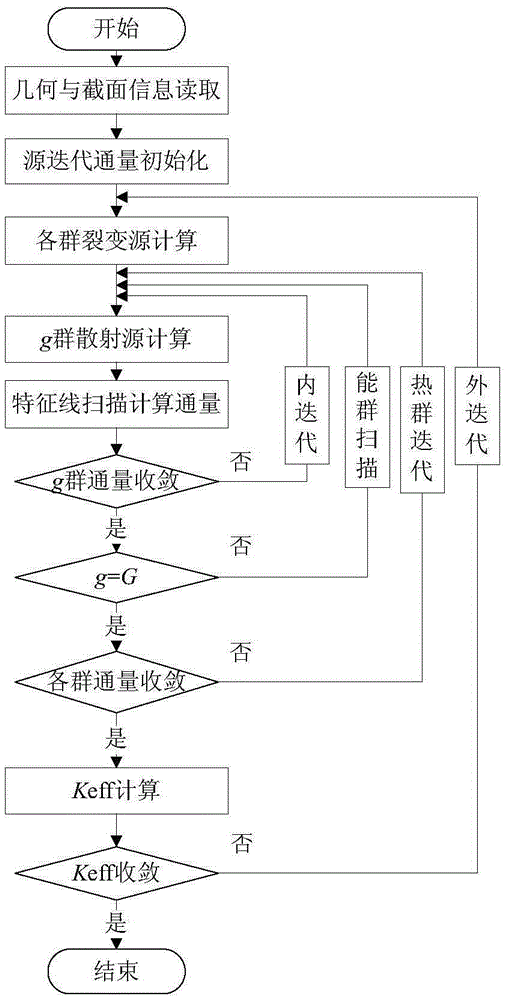

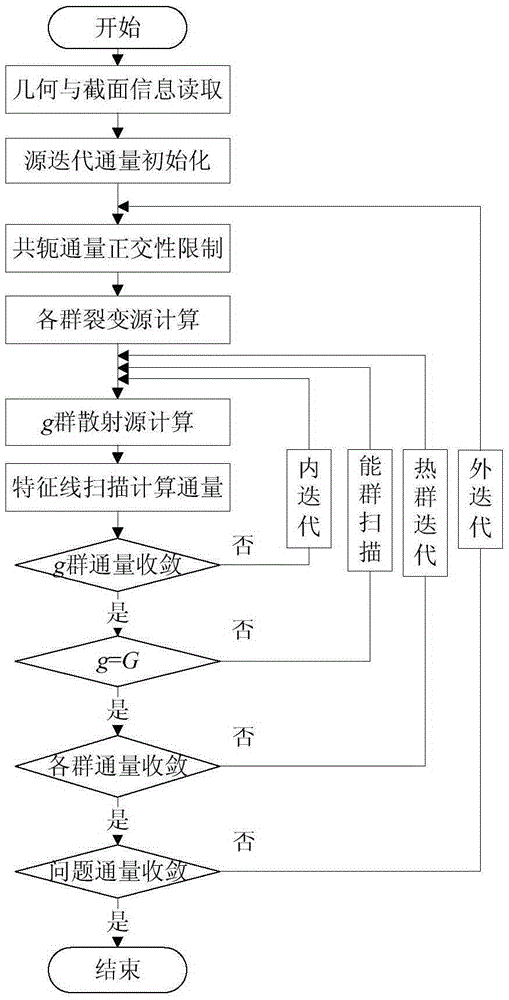

Method for acquiring sensitivity coefficient of important parameter of reactor physical grid computation

ActiveCN105426342ASensitivity calculations are fastImprove computing efficiencyComplex mathematical operationsGrid computationMethod of undetermined coefficients

The invention provides a method for acquiring a sensitivity coefficient of an important parameter of reactor physical grid computation. The method comprises: 1, establishing a computing model for a specific reactor physical computing problem; 2, adopting a subgroup resonance self-shielding method to perform resonance self-shielding computation, establishing a corresponding generalized conjugate equation for a fast group source term, a resonance energy group source term and a resonance self-shielding section, and solving the generalized conjugate equation to obtain a sensitivity coefficient of a resonance self-shielding section; 3, for an important parameter that needs to be computed, establishing and solving the generalized conjugate equation corresponding to the important parameter, so as to obtain an explicit sensitivity coefficient of the parameter; and 4, combining the sensitivity coefficient of the resonance self-shielding section and the explicit sensitivity coefficient of the resonance self-shielding section to obtain an implicit sensitivity coefficient, wherein a total sensitivity coefficient is equal to the sum of the explicit sensitivity coefficient and the implicit sensitivity coefficient. According to the method provided by the invention, the sensitivity coefficient of any parameter that can be represented as a flux or conjugate flux functional can be obtained quickly; an implicit effect is also considered; and thus the sensitivity coefficient is more accurate.

Owner:XI AN JIAOTONG UNIV

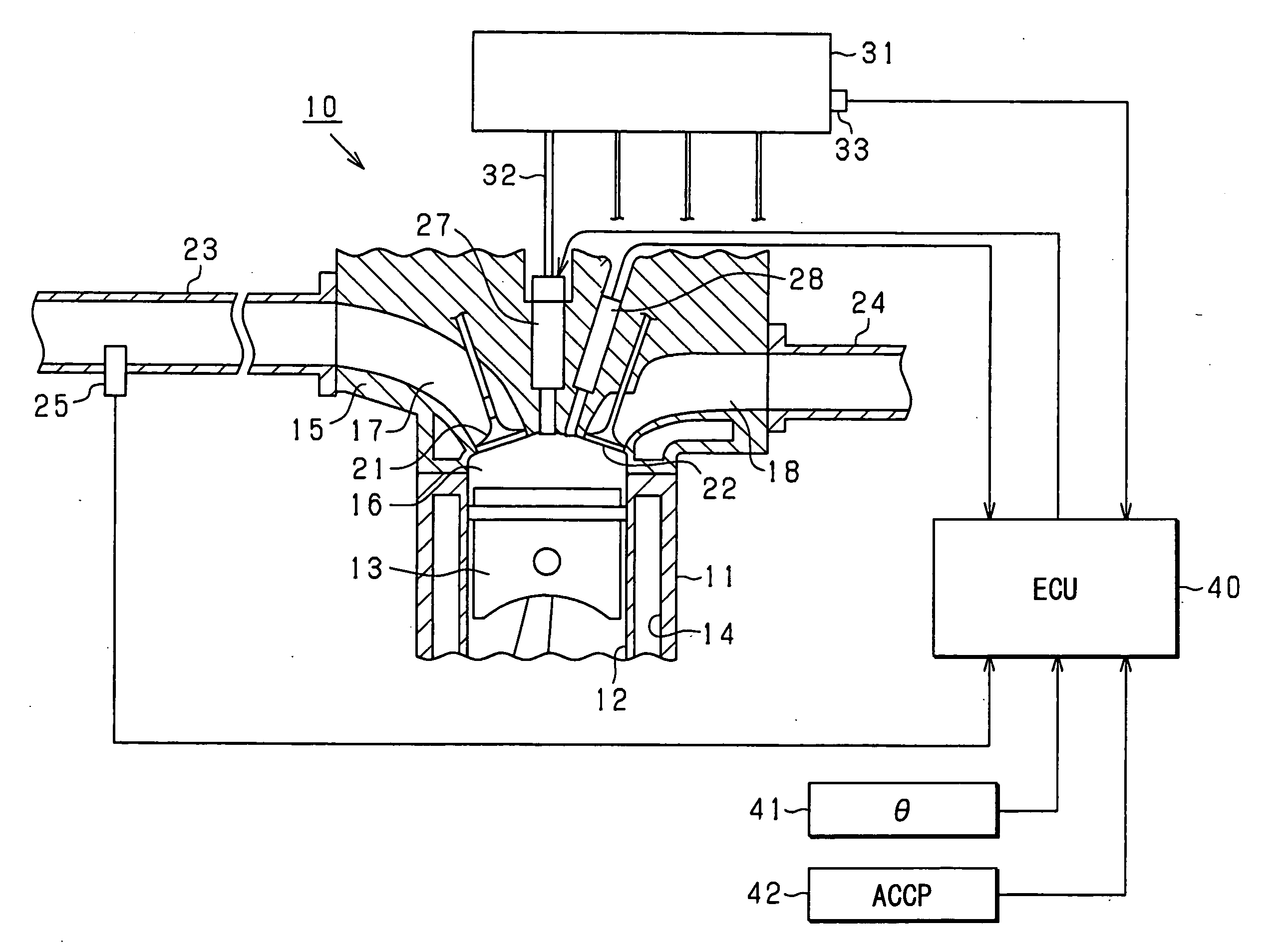

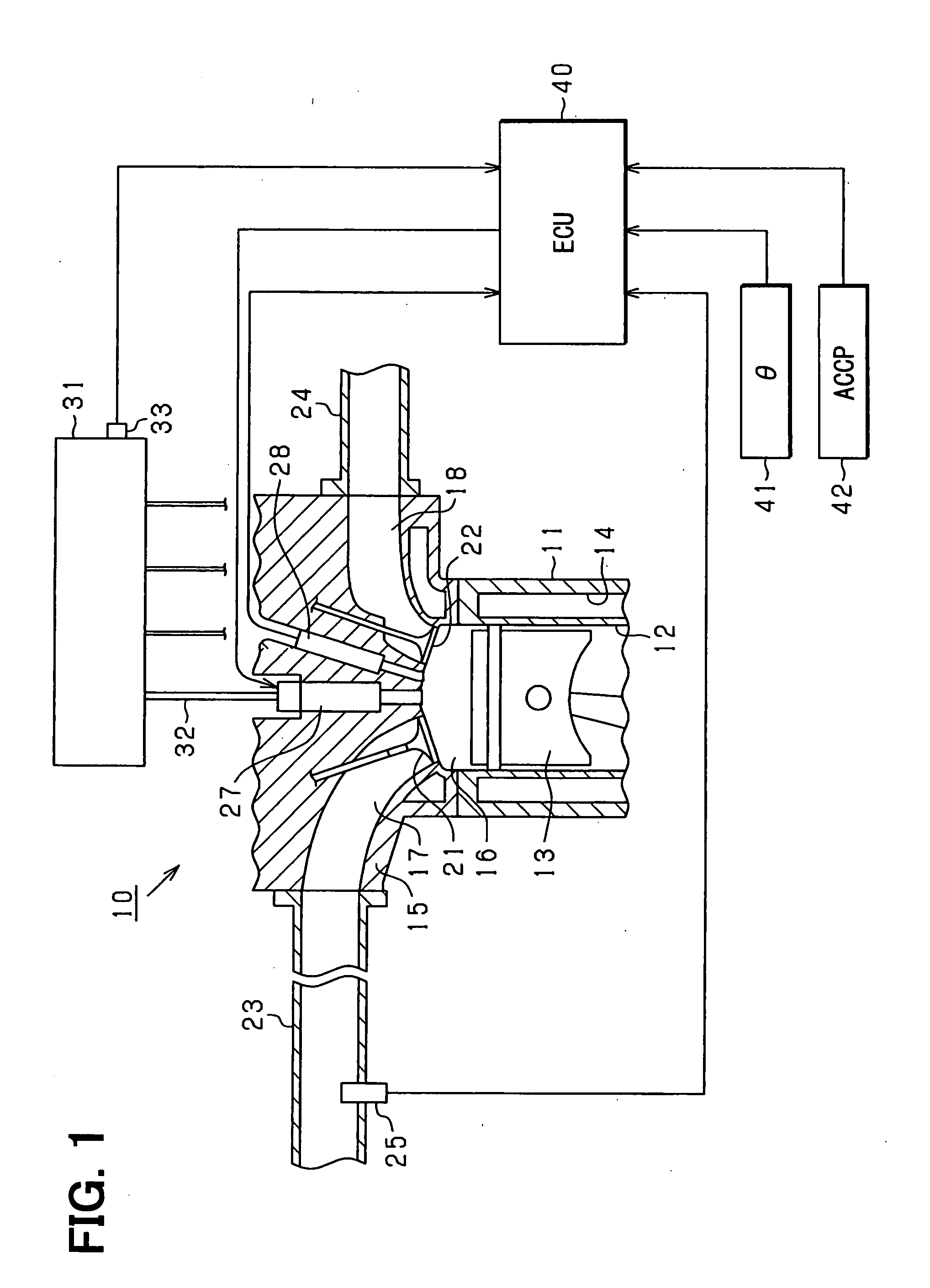

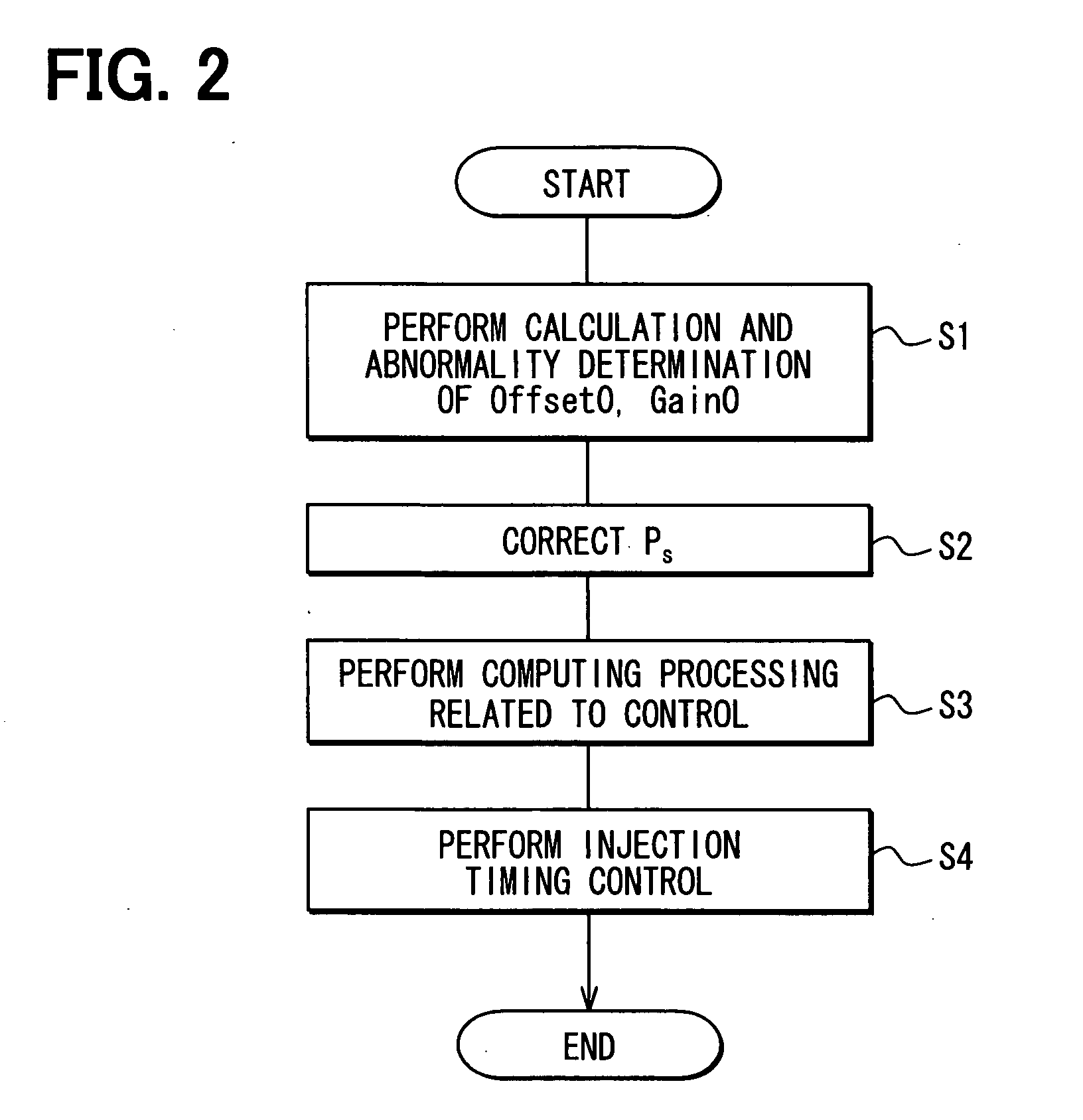

Abnormality determination device of cylinder pressure sensor

InactiveUS20070277591A1Reduce the possibilityAnalogue computers for vehiclesElectrical controlEngineeringBiomedical engineering

An abnormality determination device of a cylinder pressure sensor calculates a gain (sensing sensitivity coefficient) and an offset (bias) indicating an output characteristic of the cylinder pressure sensor. The device determines existence or nonexistence of an abnormality in the gain and the offset respectively. When the device determines that the abnormality exists, the device performs failsafe processing set in modes different from each other between the case of the abnormality in the gain and the case of the abnormality in the offset. As the failsafe processing in the case of the abnormality in the gain, the device performs processing for substantially prohibiting usage of a sensor value of the cylinder pressure sensor in control (fuel injection timing control) by using an alternative value (specified value) instead of the sensor value of the cylinder pressure sensor.

Owner:DENSO CORP

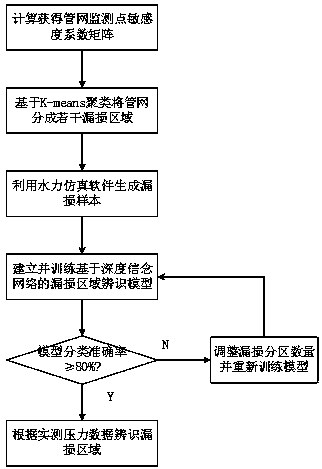

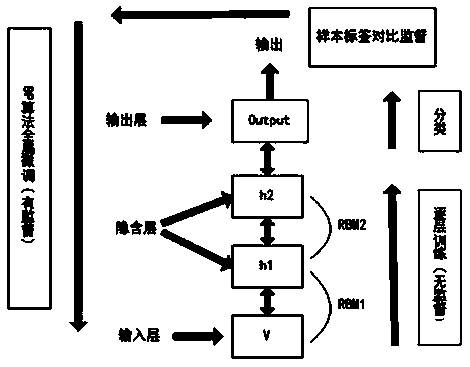

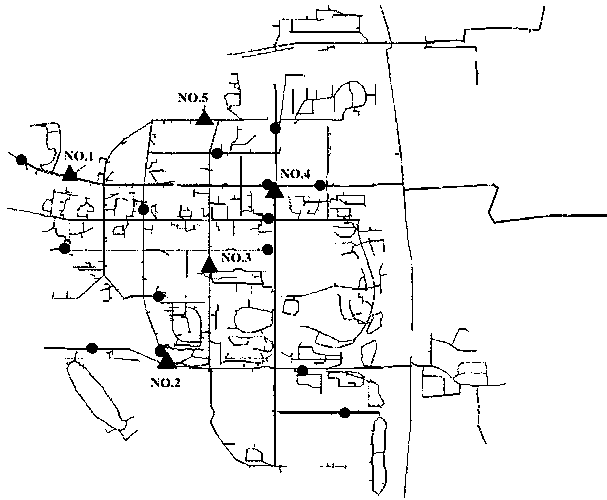

Clustering and deep belief network-based leakage initial locating method

ActiveCN108647470ASolve problems that are easy to converge to a local optimumGood initial valueGeneral water supply conservationPipeline systemsDeep belief networkOperability

The invention discloses a clustering and deep belief network-based leakage initial locating method. The method comprises the steps of firstly performing calculation to obtain a pipe network monitoringpoint sensitivity coefficient matrix; secondly dividing a pipe network into multiple leakage regions based on K-means clustering, and generating a leakage sample by utilizing hydraulic simulation software; thirdly building and training a deep belief network-based leakage region identification model; and finally identifying the leakage regions according to actually measured pressure data. The method solves the problem of leakage sample scarcity during modeling, realizes quick locating of the leakage regions in an initial leakage stage, and has relatively high identification precision and relatively strong operability.

Owner:HANGZHOU DIANZI UNIV

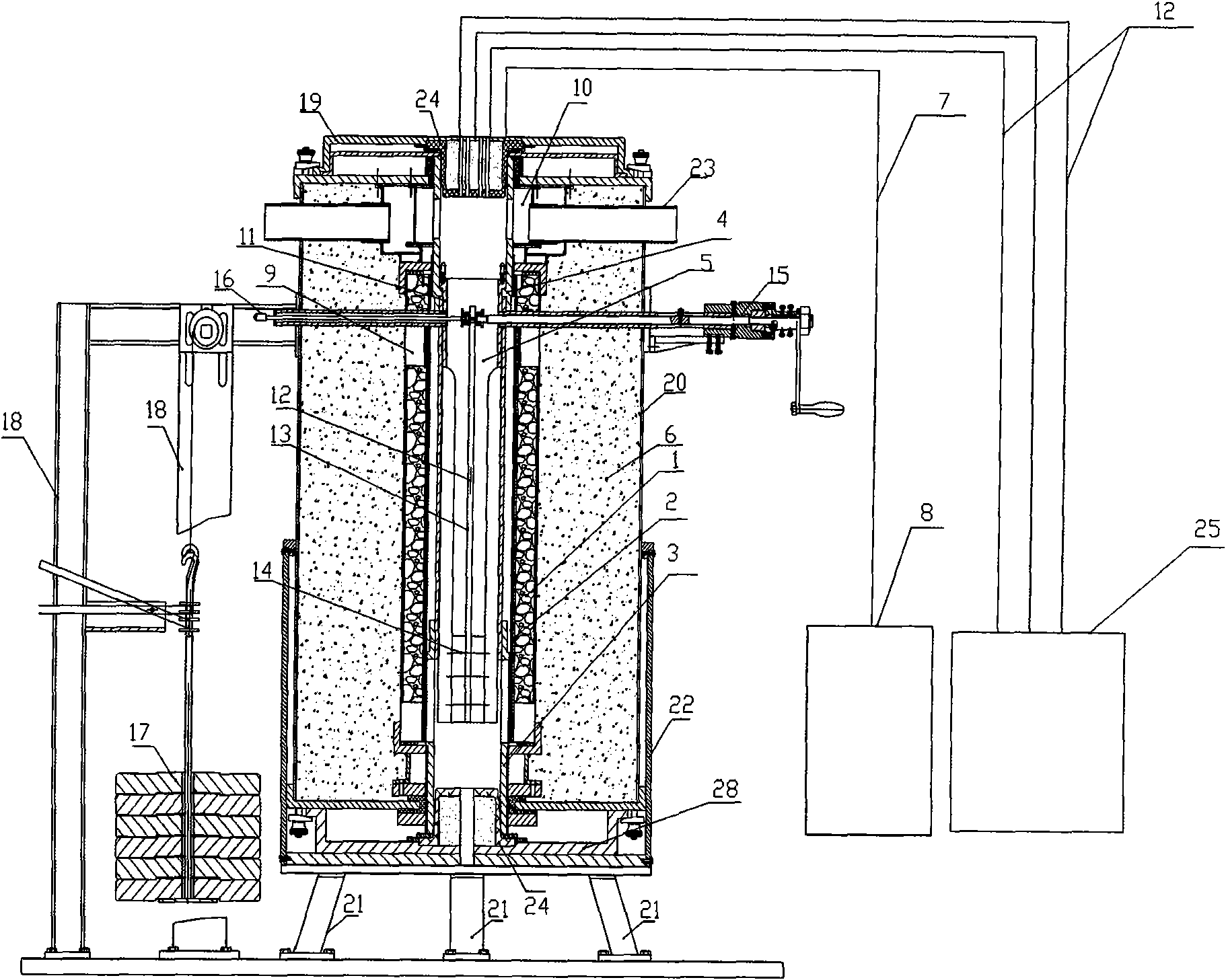

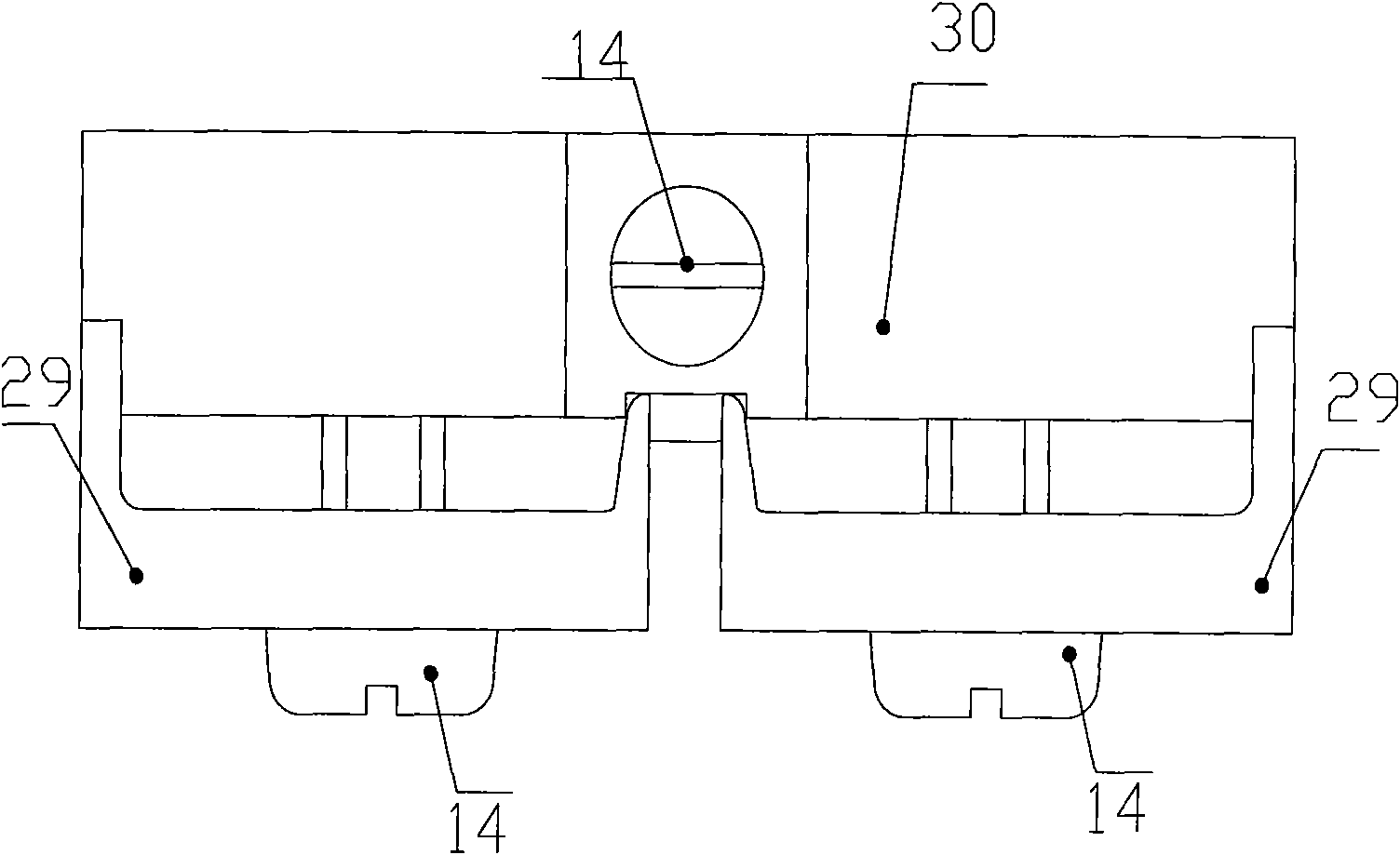

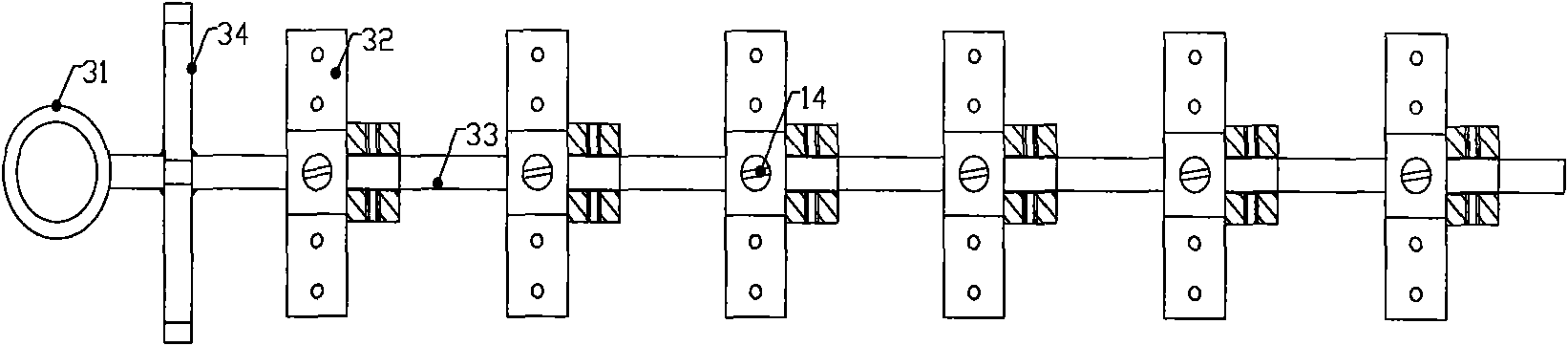

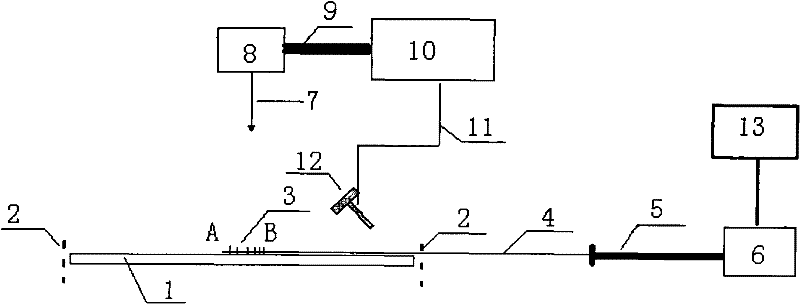

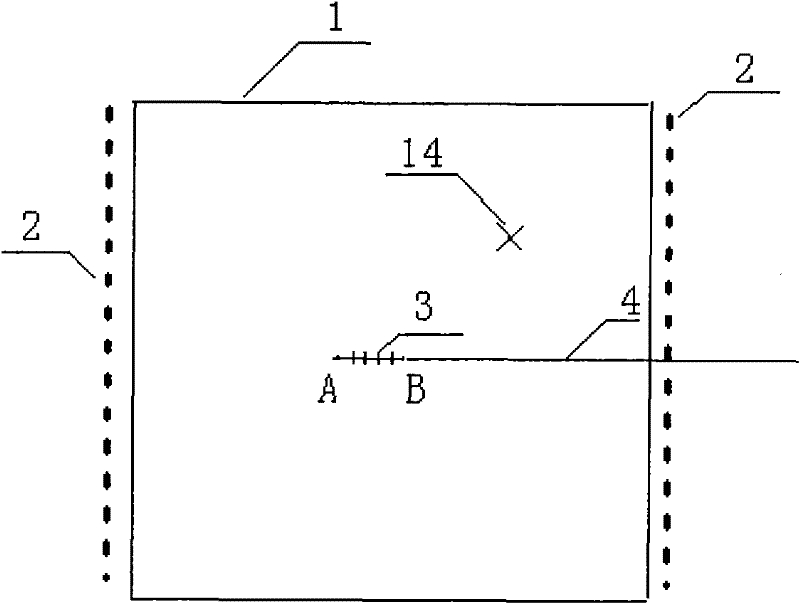

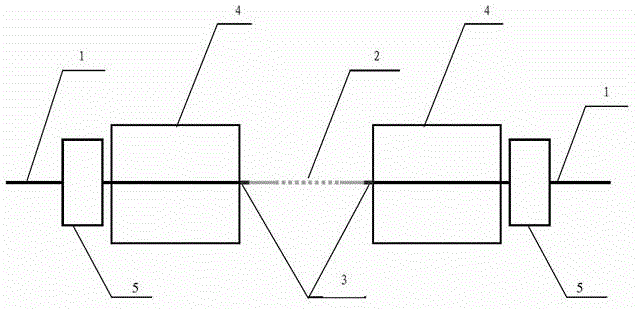

High temperature strain foil performance parameter tester and test method thereof

ActiveCN101614640AGood high temperature repeatabilityImprove test accuracyMaterial strength using tensile/compressive forcesSupporting systemTemperature control

The invention provides a high temperature strain foil performance parameter tester and a test method thereof. The high temperature strain foil performance parameter tester is composed of a heating system, a heat preservation system, a temperature control system, a circulation system, a support system and a loading system. The tester and the test method of the invention can test technical parameters of the high temperature strain foil such as null shift, thermal output, thermal delay, mechanical delay, change of sensitivity coefficient with temperature, creep deformation of the high temperature strain foil, creep deformation of constant strength calibration beams made of measured target material and the like. The tester and the test method of the invention feature high test precision, good high temperature repeatability and reliable test results, thus providing data correction for long-term high temperature strain monitoring.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

High-property super-thick steel plate for 500 MPa-level engineering structure and manufacturing method thereof

The invention belongs to the technical field of low alloy steels and production processes thereof, and particularly relates to a high-property super-thick steel plate for a 500 MPa-level engineering structure and a manufacturing method thereof. The high-property super-thick steel plate comprises the following components in percentage by weight: 0.020%-0.070% of C, 0.30%-0.60% of Si, 1.35%-1.60% of Mn, 0.010%-0.020% of P, S<=0.005%, 0.030%-0.060% of Nb, 0.010%-0.030% of Ti, 0.020%-0.050% of Als, 0.35%-0.45% of Cu, 0.20%-0.40% of Cr, 0.30%-0.60% of Ni, 0.05%-0.10% of Mo and the balance of Fe and inevitable impurities. In addition, the high-property super-thick steel plate disclosed by the invention meets the requirements that the welding cold cracking sensitivity coefficient Pcm is less than or equal to 0.20% and the ASTMG101-01 corrosion-resistant index I is more than 6.0. The manufacturing method disclosed by the invention adopts the low-C Cu-Ni-Cr-Mo-Nb-Ti component system, prevents the grain in an HAZ (Welding Heat Affected Zone) from being growingn because a grain refining effect achieved by compositely adding Nb-Ti is higher than the grain refining effect achieved by independently using V, enhances the obdurability of a steel plate base body and HAZ and is contributivee to enhancinge the welding line energy.

Owner:JIGANG GRP

Automatic control method of width of hot continuous rolling and finish rolling strip steel

ActiveCN103286141AReduce Width FluctuationImprove width precisionMetal rolling stand detailsAutomatic controlTime changes

The invention relates to the field of strip steel hot rolling, in particular to a control method of the width of hot rolling strip steel. An automatic control method of the width of hot continuous rolling and finish rolling strip steel comprises the steps as follows: a temperature change model of the strip steel in a finish rolling process is built, sensitivity coefficients are calculated, and temperature reference values of the strip steel at rack outlets are calculated; temperature modification values of the strip steel at the rack outlets are calculated, and temperature prediction values are obtained in combination of the temperature reference values and the temperature modification values; real-time change values of the width of the strip steel are calculated; feedback deviation values of the width of the strip steel are obtained through comparison, and the feedback deviation values are distributed to racks, so that feedback deviation values of the width of the strip steel, which are required to be adjusted by the racks, are obtained; and tension of loops among the racks are adjusted in combination of the real-time change values of the width of the strip steel and the feedback deviation values of the width of the strip steel, so that the width of the steel strip is controlled. The method can well guarantee that the width of the strip steel after finish rolling can fluctuate nearby set values, the width accuracy of a strip product is finally improved, and accordingly, the utilization rate of a material by a downstream user is remarkably increased.

Owner:BAOSHAN IRON & STEEL CO LTD

High intensity gas shielded welding wire, wire rod and application thereof

ActiveCN101288925ASimple designReduce dosageArc welding apparatusWelding/cutting media/materialsCrack resistanceChemical element

The invention provides a gas protection welding wire rod and a welding wire thereof. Both the wire rod and the welding wire comprises the following elements (according to the weight percent): C is 0.03 to 0.12, Si is 0.30 to 0.80, Mn is 1.2 to 2.2, S is equal to or less than 0.015, P is equal to or less than 0.020, Ni is 0.4 to 1.0, Cr is 0.1 to 0.5, Mo is 0.2 to 0.6, Ti is 0.06 to 0.2, and the rest is Fe and inevitable impurity elements. The welding wire provided by the invention has the advantages of simple chemical element design, small content of the precious alloy elements and low crack sensitivity coefficient, and the deposited metal has the advantages of high intensity, excellent crack resistance and low-temperature shock toughness and excellent dynamic performance. The welding wire of the invention is suitable for the welding of low alloy structure steel with 600 to 800MPa tensile strength, which is applicable to engineering mechanics, heavy trucks, hydraulic power, coal power and other industries.

Owner:BAOSHAN IRON & STEEL CO LTD

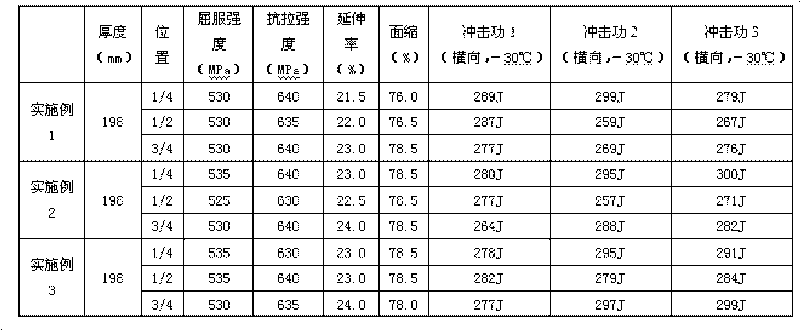

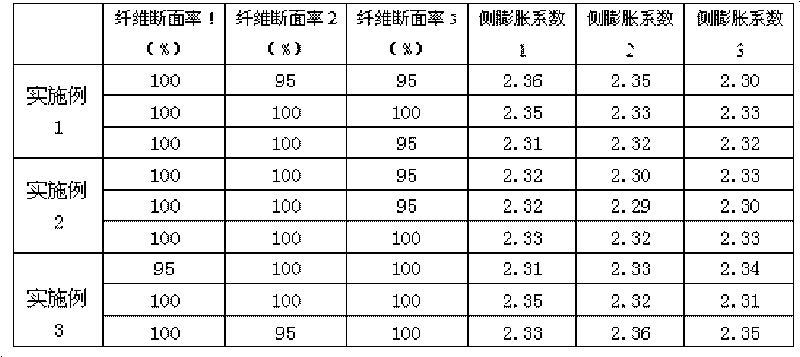

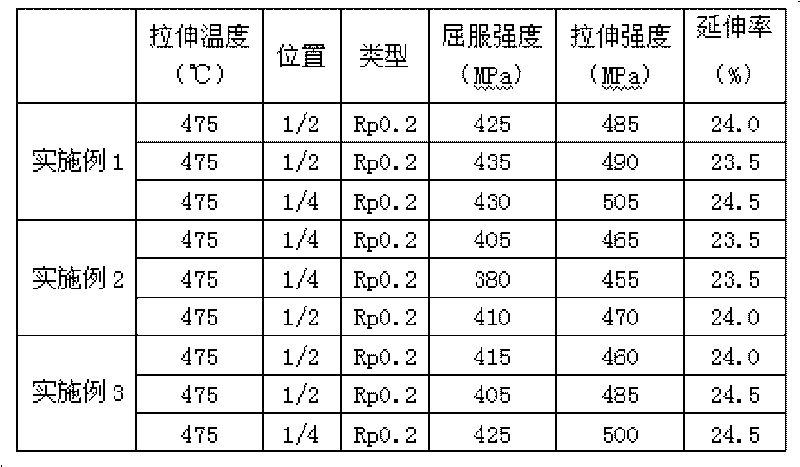

Large thickness steel plate for hydrogenation reaction chamber reeling equipment and production method thereof

InactiveCN101713054AImprove purityUniform compositionProcess efficiency improvementElectric furnaceSheet steelHydrogenation reaction

The invention discloses a large thickness steel plate for hydrogenation reaction chamber reeling equipment and a production method thereof. The steel plate takes Cr-Mo steel as the base, an amount of alloying elements, such as Ni, Cu, Al, Nb, Mn, Cr and the like are added, the contents of harmful elements, such as Sn, Sb, As, P, S and the like are controlled, and the finished large thickness steel is prepared by adopting the processes of electric furnace smelting, LF refining furnace refining, throwing down line stacking for slow-cooling, electroslag remelting, rolling and product forming, diffusion hydrogen annealing, normalizing and tempering heat treatment and the like. The thickness of the steel plate reaches 198 mm, the weight of single steel plate reaches 25 tons, the high temperature tensile strength and yield strength of the steel plate are good, the lower temperature toughness at minus 30 DEG C is good, the steel plate has good tempering embrittlement sensitivity coefficient, and the purity of the produced steel plate is high, the component is uniform, the inner part is compact, and the mechanical property is uniform. The steel plate can meet the operation requirement of hydrogenation reaction chamber reeling equipment, and is suitable for the production of the main structural parts of all hydrogenation reaction chamber reeling equipment.

Owner:WUYANG IRON & STEEL +1

Exposure method and apparatus

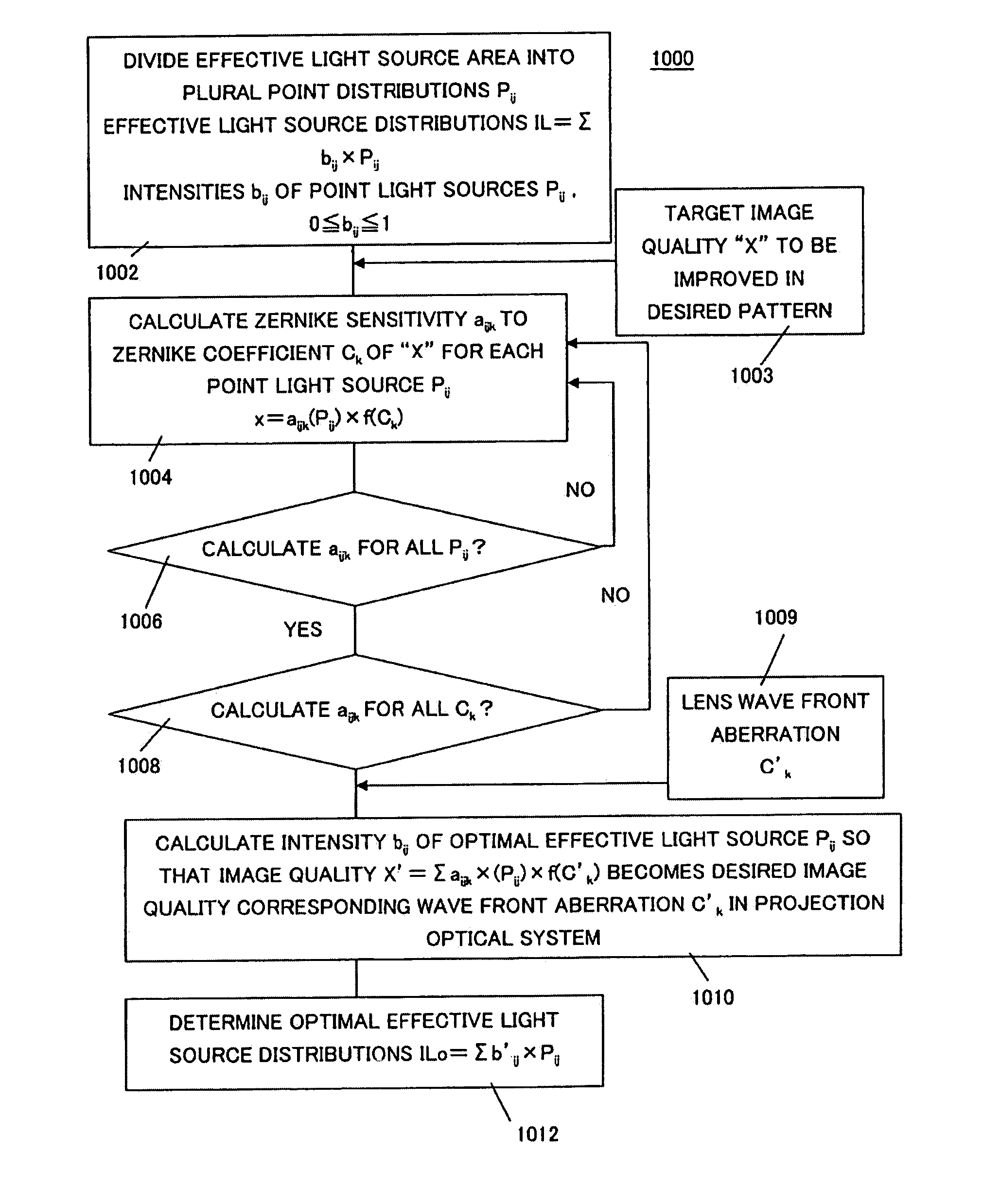

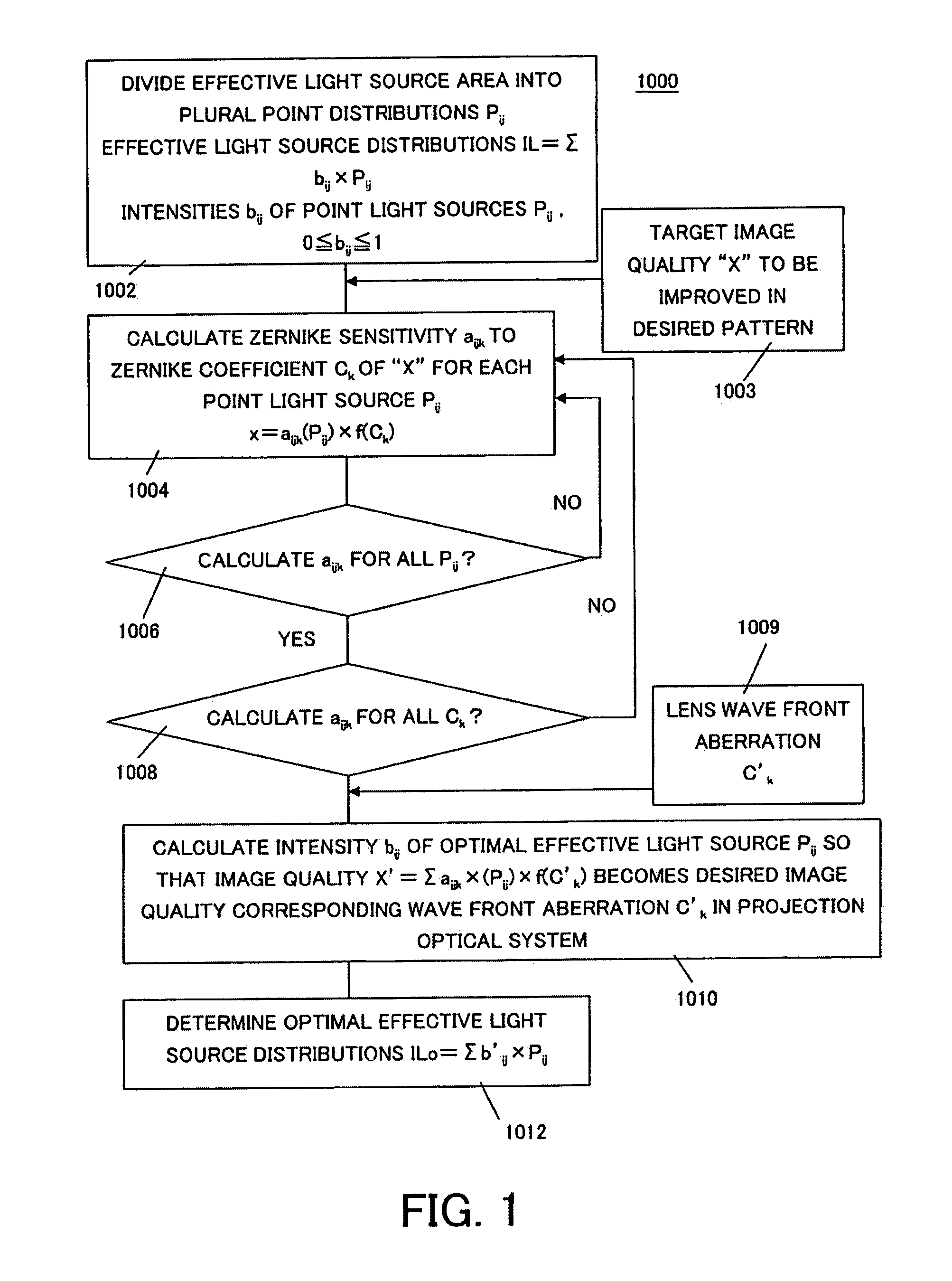

InactiveUS7095481B2High resolutionReduce image quality degradationSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPoint lightImaging quality

An exposure method for projecting, through a projection optical system, a predetermined pattern formed on a mask onto an object to be exposed. The exposure method includes the steps of dividing an effective light source area for illuminating the mask into plural point light sources, calculating a Zernike sensitivity coefficient that represents a sensitivity of a change of image quality of the predetermined pattern to a change of a Zernike coefficient, when wave front aberration in the projection optical system is developed into a Zernike polynomial for all divided point light sources, determining an effective light source distribution based on a combination of Zernike sensitivity coefficient of all divided point light sources, and forming the effective light source distribution by intensity of each point light source.

Owner:CANON KK

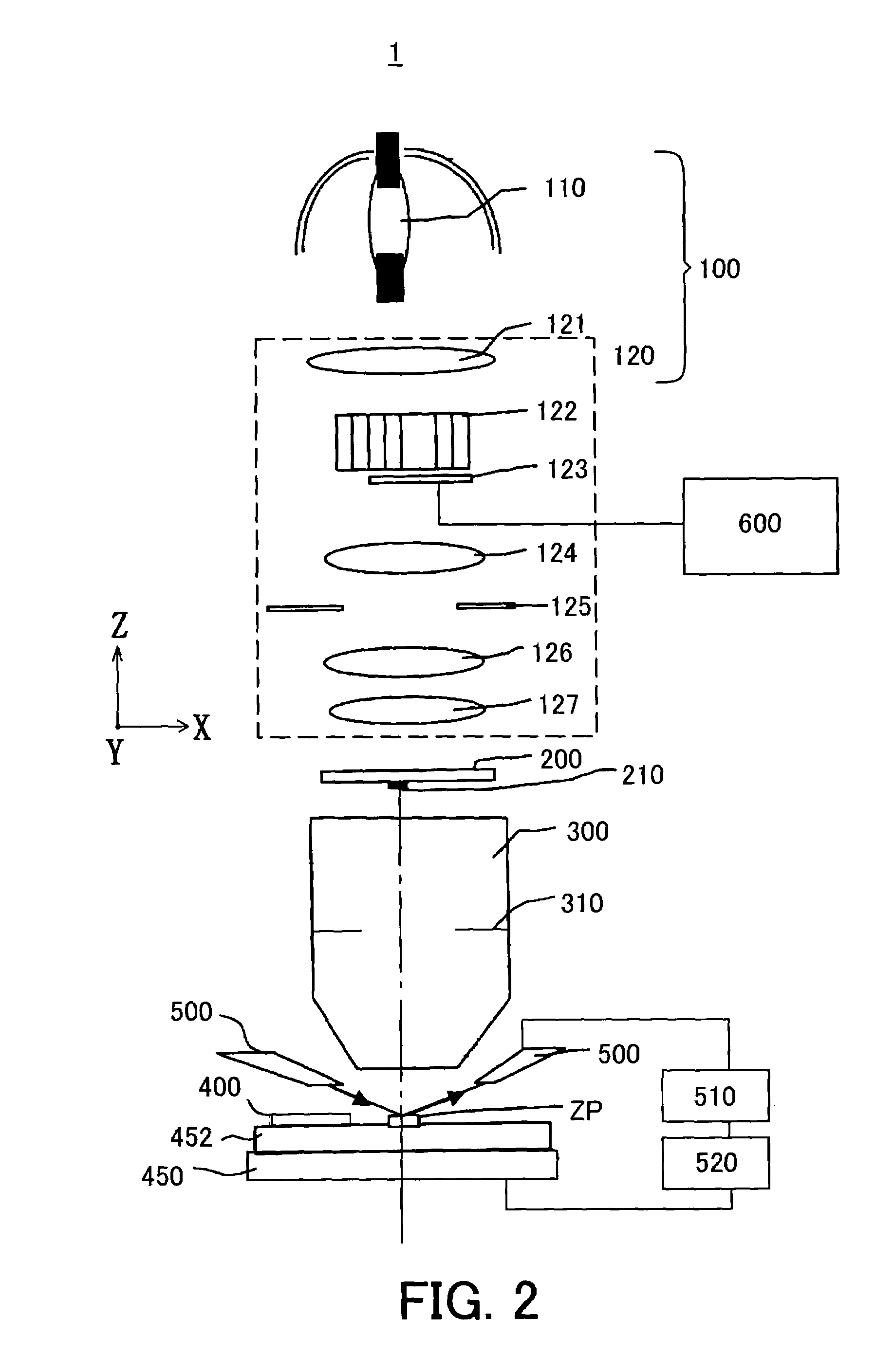

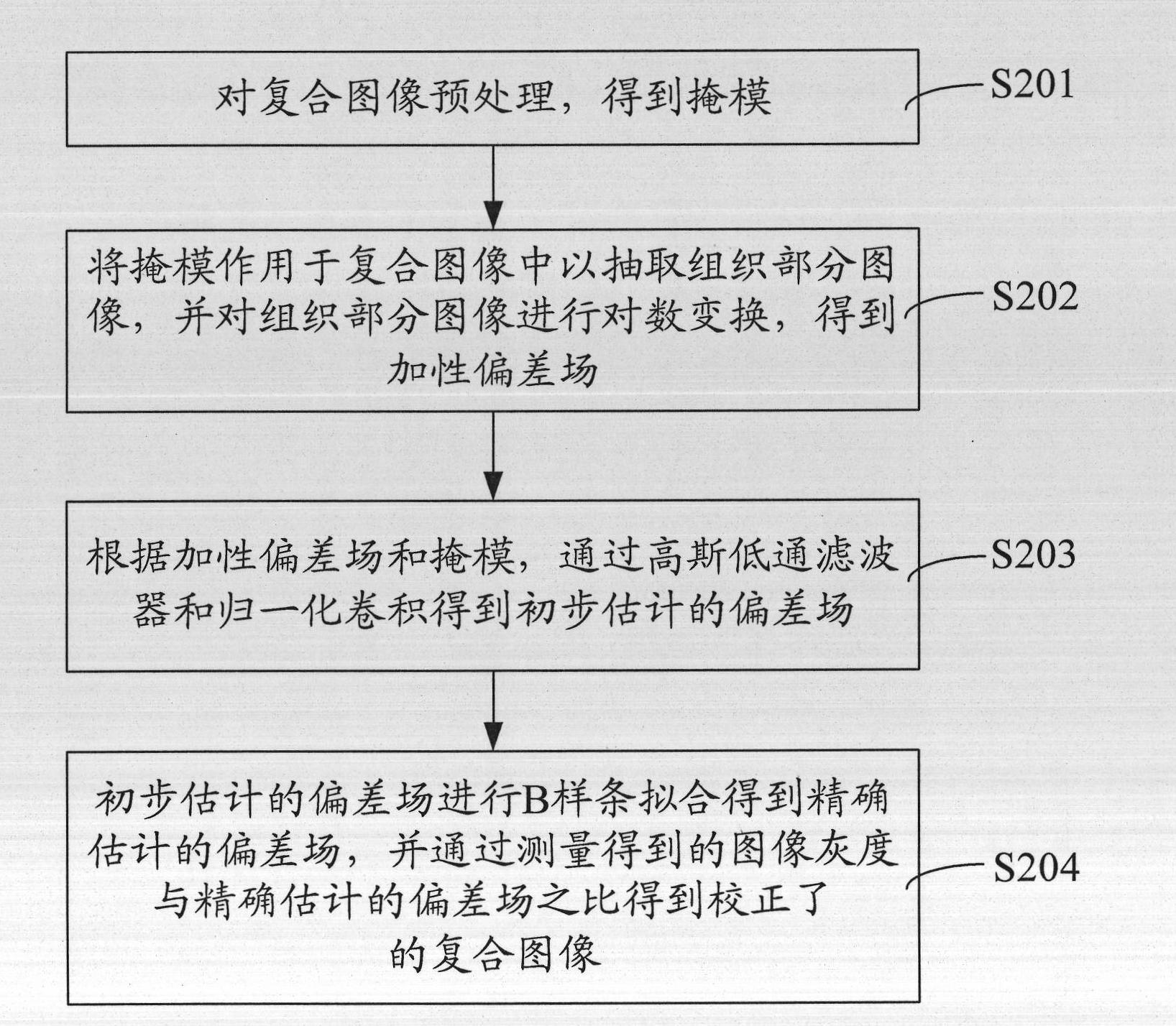

Magnetic resonance imaging method and device

InactiveCN101915901AUniform brightnessImprove accuracyMeasurements using NMR imaging systemsVisual field lossImage resolution

The invention relates to a magnetic resonance imaging method comprising the following steps of: correcting and scanning a visual field to obtain a plurality of composite images, summing the absolute values of the plurality of composite images to obtain a summation image, and computing a sensitivity coefficient according to the plurality of composite images and the summation image; and correcting the sensitivity coefficient, and generating a reconstructed image. The magnetic resonance imaging method and device sum the absolute values of the plurality of composite images to obtain the summation image and compute the sensitivity coefficient through the summation image, thereby effectively enhancing the uniformity of the sensitivity coefficient; and after the sensitivity coefficient is corrected, the reconstructed image is generated, thereby effectively eliminating artifacts caused by a motion factor and other factors on the images in the scanning process, enhancing the resolution of the artifact-free composite images generated after reconstruction and reinforcing the robustness of the reconstructed image.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

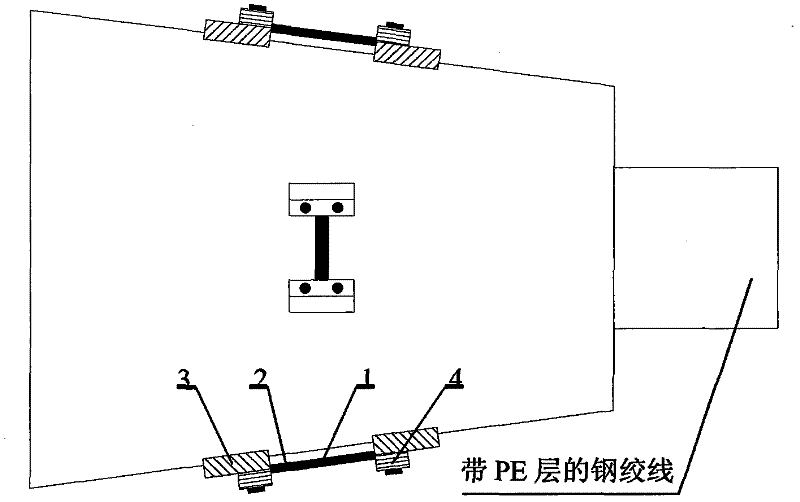

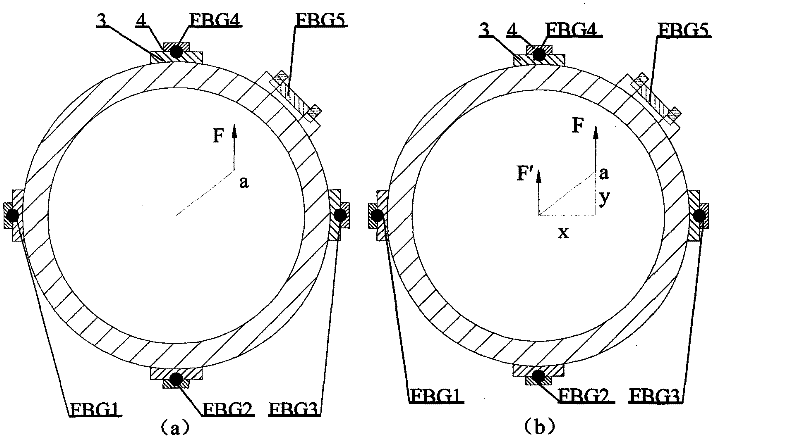

An online calibration device and method for fiber grating strain sensor

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

High-strength and high-toughness steel plate for 630MPa-grade tempered low-temperature spherical tank and manufacture method thereof

ActiveCN104789866AImprove mechanical propertiesLow weld cold crack susceptibilityUltimate tensile strengthTransition temperature

The invention discloses a high-strength and high-toughness steel plate for a 630MPa-grade tempered low-temperature spherical tank and a manufacture method thereof. The high-strength and high-toughness steel plate comprises the following components by weight percent: 0.07-0.09% of C, 0.15-0.25% of Si, 1.40-1.50% of Mn, less than or equal to 0.008% of P, less than or equal to 0.001% of S, 0.30-0.40% of Ni, 0.16-0.20% of Mo, 0.015-0.025% of Nb, 0.02-0.06% of V, 0.007-0.015% of Ti, less than or equal to 0.0030% of O, less than or equal to 0.0040% of N, 0.020-0.040% of Al, 0.0005-0.0030% of Ca, and the balance of Fe and unavoidable impurities, wherein the welding cold crack sensitivity coefficient Pcm value is 0.16-0.20% and the hot crack sensitivity coefficient Psr is less than or equal to 0.00%. By adopting the high-strength and high-toughness steel plate, the safety of the spherical tank integral structure is guaranteed, the yield strength of the steel plate is greater than or equal to 510 MPa, the tensile strength is greater than or equal to 630 MPa, the ductility is greater than or equal to 18%, the Charpy notch ballistic work average value in the plate thickness 1 / 4 part at -50 DEG C is greater than or equal to 2000 J, the single value is greater than or equal to 150 J, the Charpy notch ballistic work average value in the plate thickness 1 / 2 part at -50 DEG C is greater than or equal to 150 J, the single value is greater than or equal to 100 J, and the steel plate nil ductility transition temperature (NDTT) is less than or equal to -50 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

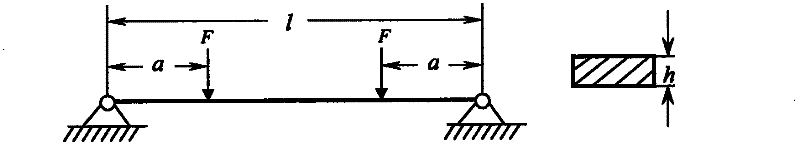

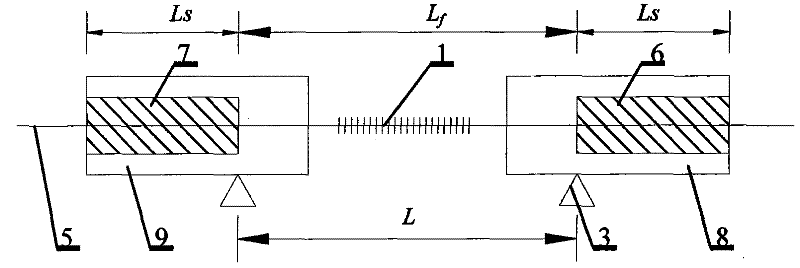

Sensitivity calibration method of fiber Bragg grating strain sensor

The invention, which belongs to the measuring technology, relates to a sensitivity calibration method of a fiber Bragg grating strain sensor. In the invention, a four-point-bending equal-strength beam is used to calibrate a fiber Bragg grating strain sensor sensitivity. The method is characterized by: determining a position where the fiber Bragg grating is pasted on a standard beam; installing the standard beam on a fixed platform and using a standard beam fulcrum to support the standard beam on the platform; adjusting loading points of a loading beam so as to achieve uniform force on the standard beam; connecting the fiber Bragg grating sensor with a fiber Bragg grating demodulation device; applying a transverse force which is perpendicular to an axis on a midpoint of the loading beam, wherein an effect direction of the transverse force is superposed with a longitudinal symmetrical plane of the standard beam; applying load on the standard beam; using the fiber Bragg grating demodulation device to record wavelength change of the fiber Bragg grating; then calculating the strain of a beam surface and a sensitivity coefficient of the fiber Bragg grating so as to realize calibration. By using the method of the invention, uniform loading can be achieved; the uniform and stable force of the fiber Bragg grating can be guaranteed; a reliable parameter can be provided for technology research and measurement of the fiber Bragg grating sensor.

Owner:CHINA AIRPLANT STRENGTH RES INST

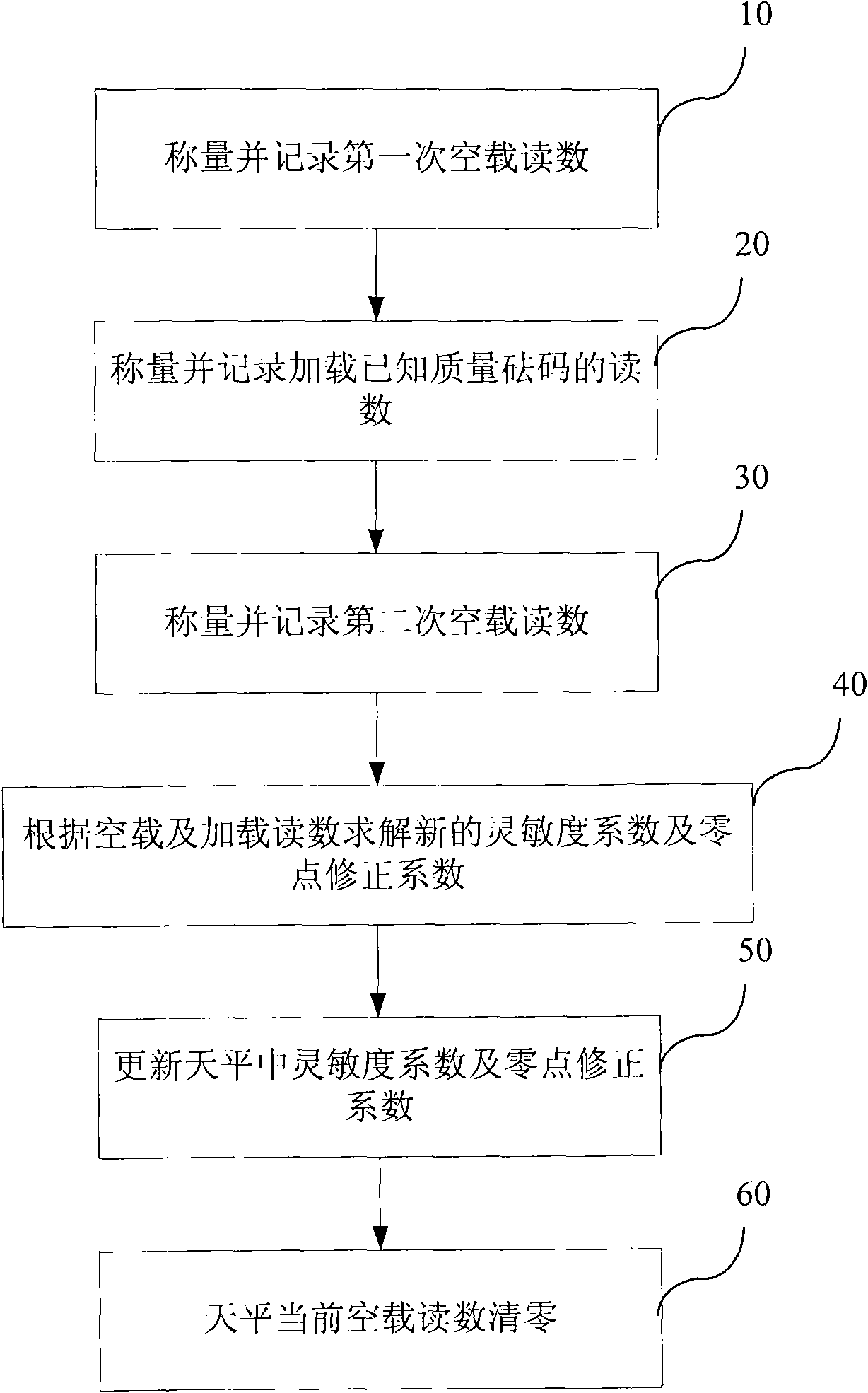

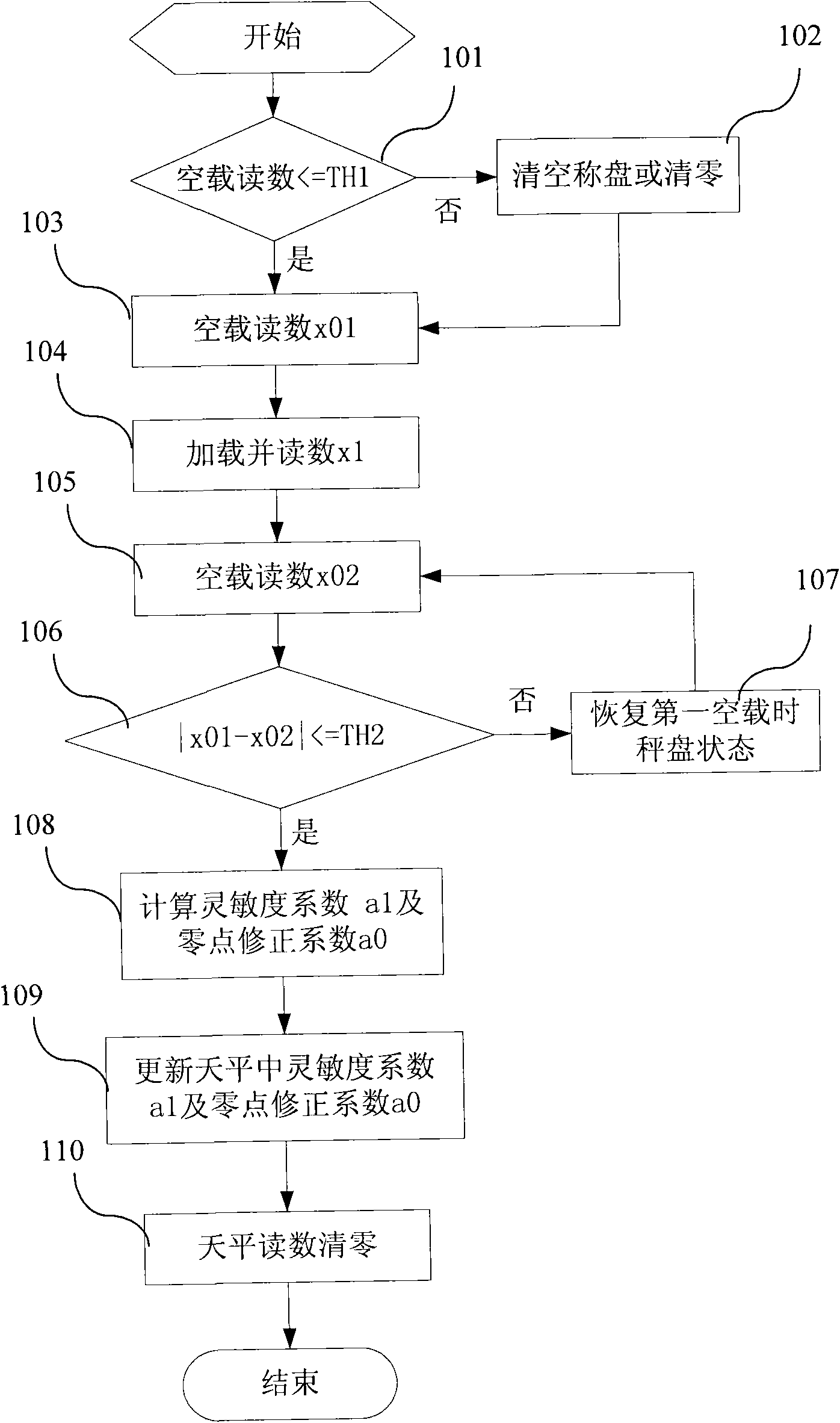

Method for calibrating measuring range of electronic balance

ActiveCN101650215AImprove calibration accuracyWeighing apparatus testing/calibrationComputer scienceZero drift

The invention relates to a method for calibrating the measuring range of an electronic balance. The method comprises the following steps: a) weighing and recording a first unloaded read number of theelectronic balance; b) weighing and recording the read number of the electronic balance loaded with weights in known mass; c) weighing and recording a second unloaded read number of the electronic balance; d) calculating a new sensitivity coefficient and a zero correction coefficient according to the first and second unloaded read numbers and the loaded read number; and e) updating the sensitivitycoefficient and the zero correction coefficient of the electronic balance. The method for calibrating the measuring range of the electronic balance can simultaneously solve the problems of measuringrange drift and zero drift, and improve the calibration accuracy.

Owner:METTLER TOLEDO INSTR SHANGHAI +1

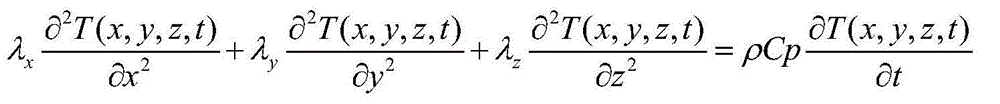

Method for measuring anisotropic material heat conductivity based on small-plane heat source

InactiveCN104597078AEasy to implementSimple stepsMaterial heat developmentTime domainLinear correlation

The invention discloses a method for measuring anisotropic material heat conductivity based on a small-plane heat source. The method comprises the following steps: building a three-dimensional heat transfer model of a measured sample in a right-angle coordinate system in a special form under the action of thermal interference; obtaining an analytical solution of temperature change in anisotropic material in a time domain by adopting Laplace transformation, variables separation, transcendental equation solving and inverse Laplace transformation methods; through sensitivity calculation, analyzing linear correlation of sensitivity coefficients of normal heat conductivity and tangential heat conductivity and the effects of parameters on temperature change; building an experiment measurement system, and collecting transient response data of the temperature; and simultaneously determining the normal heat conductivity and the tangential heat conductivity of the measured anisotropic material by an improved Gauss Newton parameter estimation method. The method has the advantages that the transient measurement method which is convenient to implement, fast in measurement and wide in application range and adopts simple steps is provided, and the normal heat conductivity and the tangential heat conductivity of the rectangular anisotropic material can be obtained by once measurement.

Owner:UNIV OF SCI & TECH BEIJING

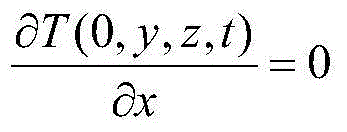

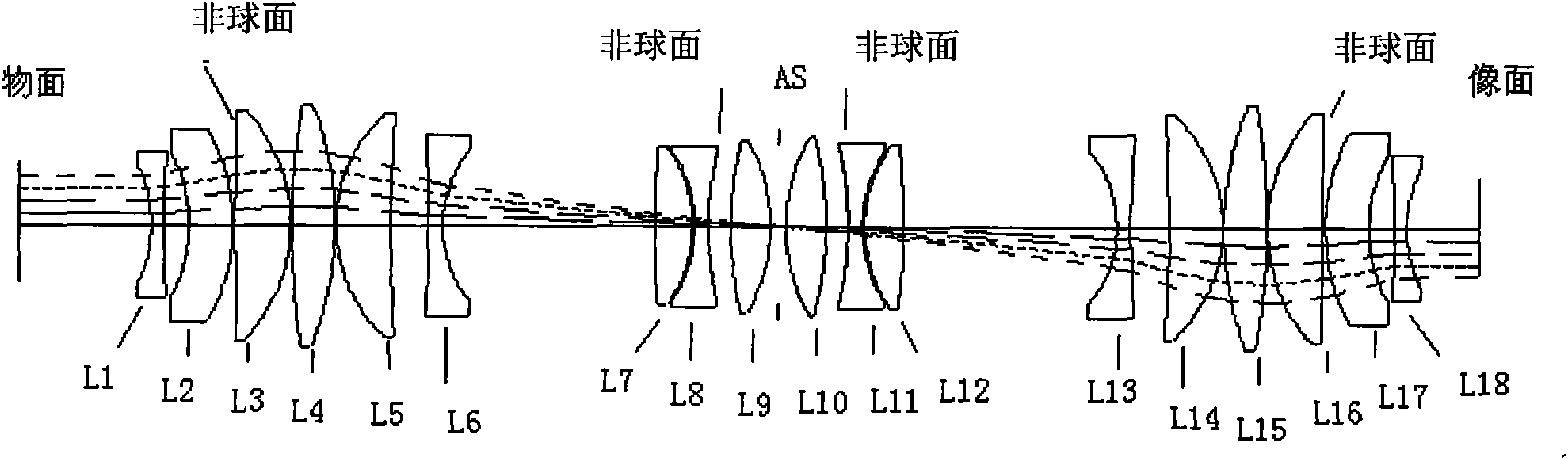

Low thermal effect projection objective

InactiveCN101571622AReduce adverse effectsPhotomechanical exposure apparatusMicrolithography exposure apparatusClassical mechanicsLens plate

The invention provides a low thermal effect projection objective. The projection objective consists of lenses with different low thermal effect sensitivity coefficients KLT / LH, and the lens with higher KLT / LH consists of materials with smaller thermal effect property, wherein the thermal effect sensitivity coefficient KLT / LH is equal to (D / ) ( / CA); D expresses the thickness of a single lens; CA expresses the effective light pass caliber of each lens; expresses average center thickness of N lenses; and expresses average light pass caliber of the N lenses. The lens selects the material with small thermal effect property according to the thermal effect sensitivity coefficient of the lens, and the adverse effect of the thermal effect on a projection optical system is reduced.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

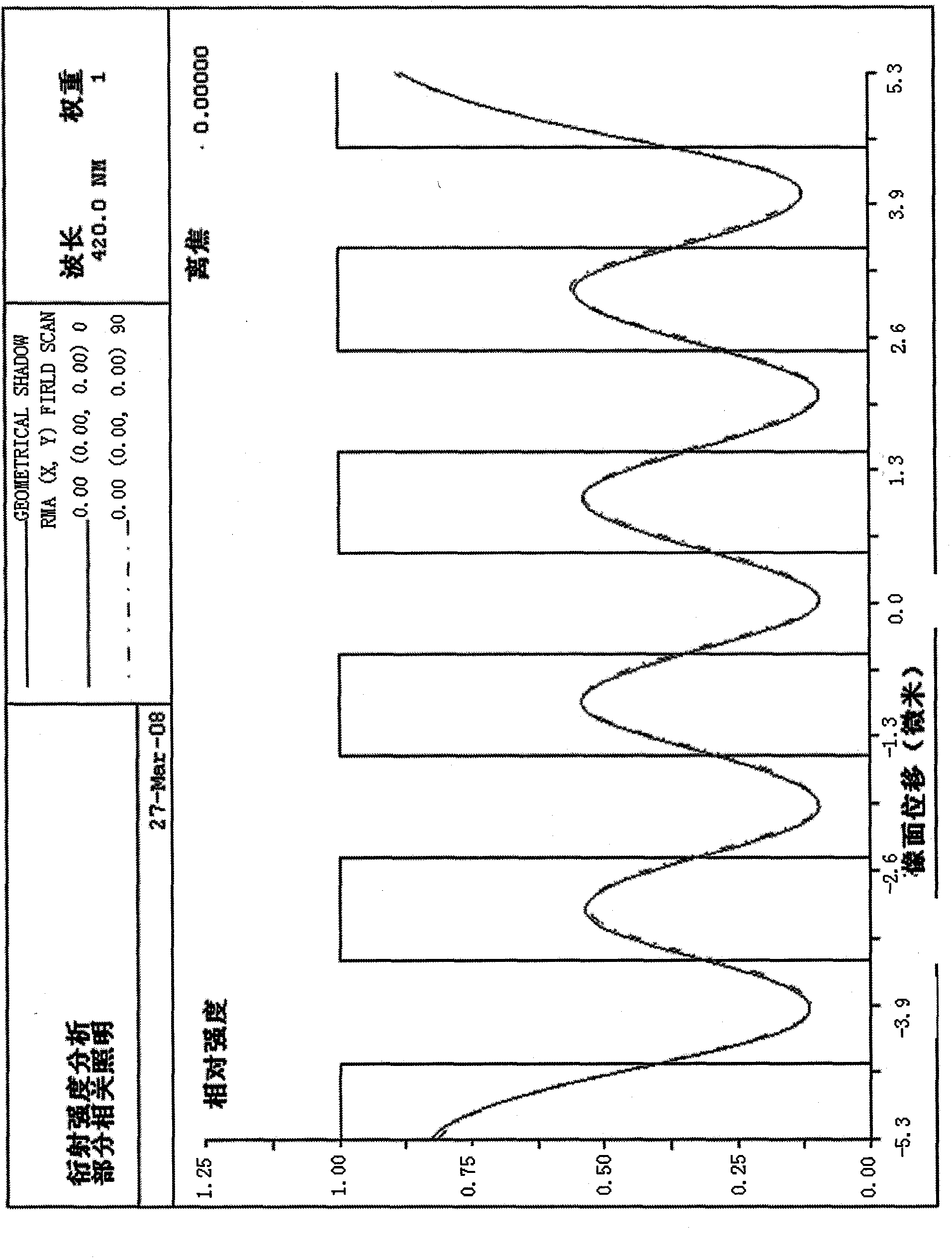

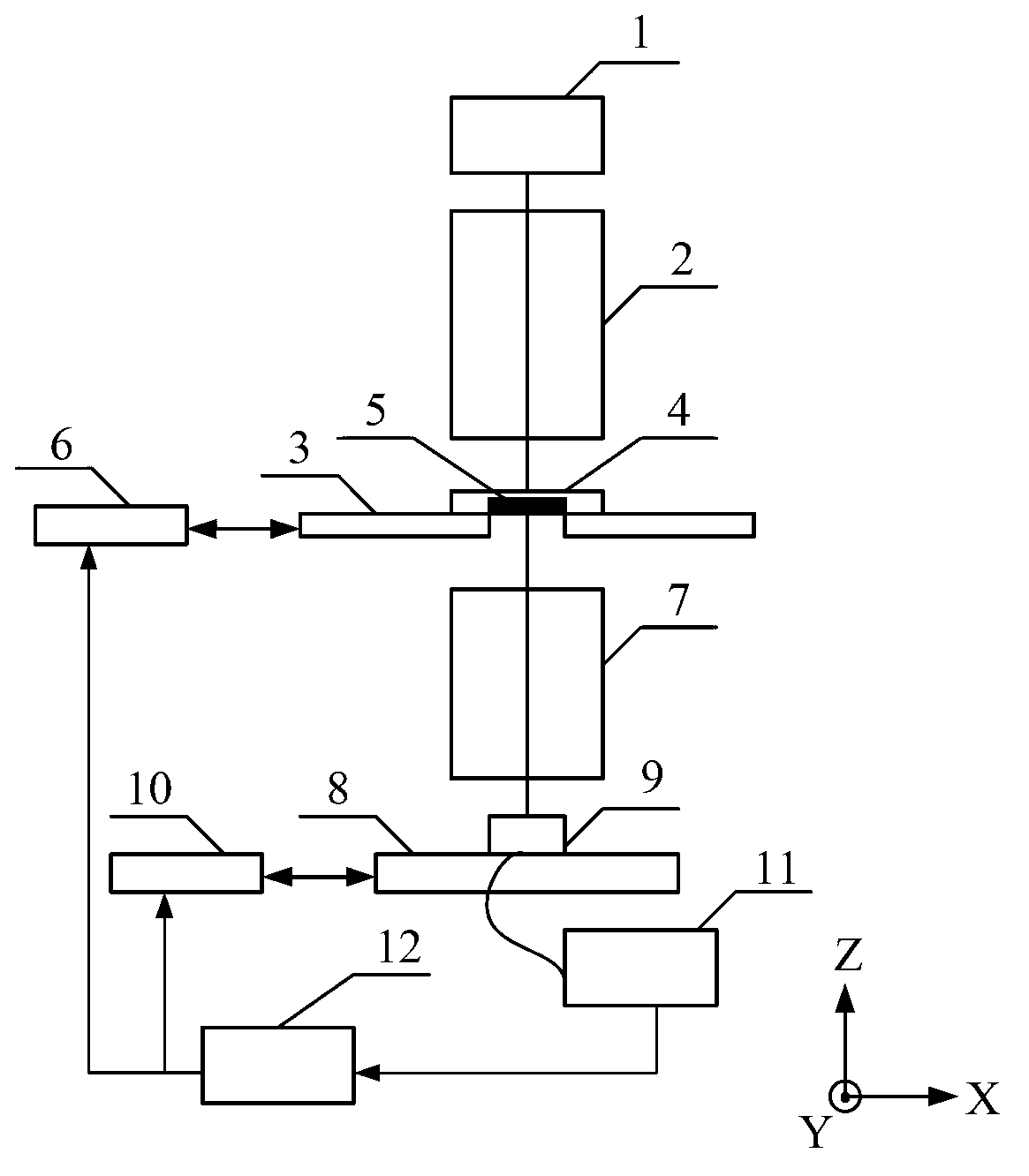

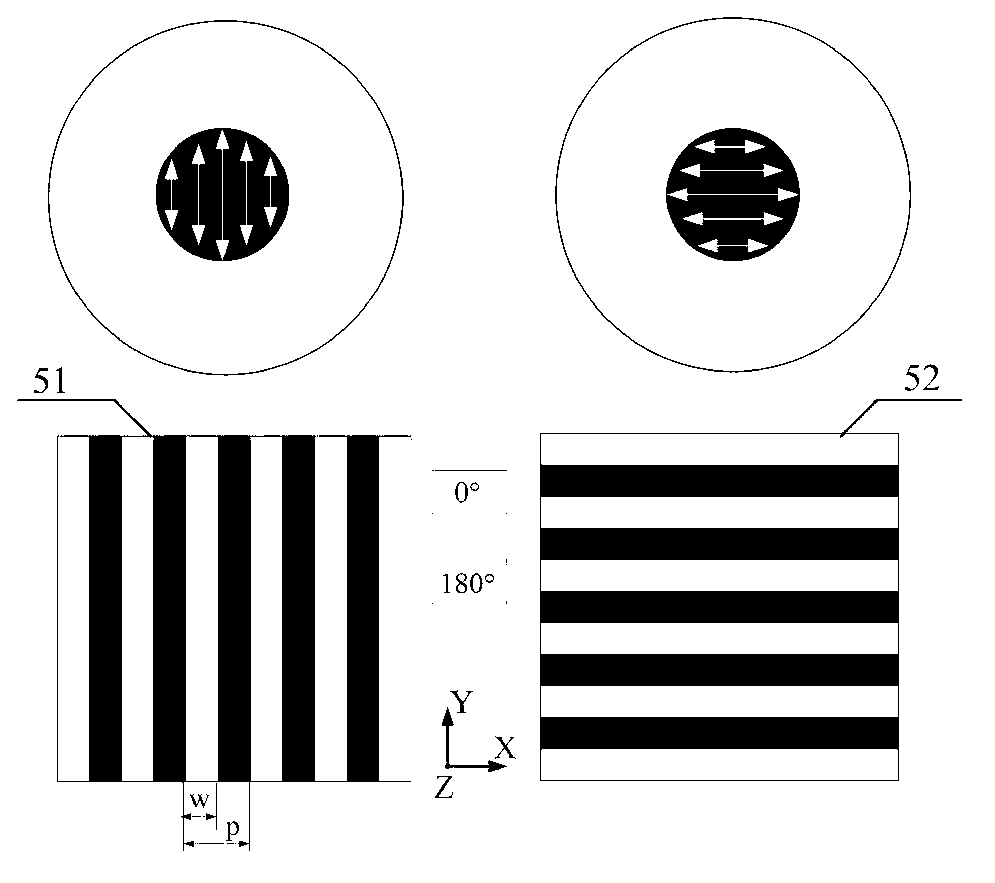

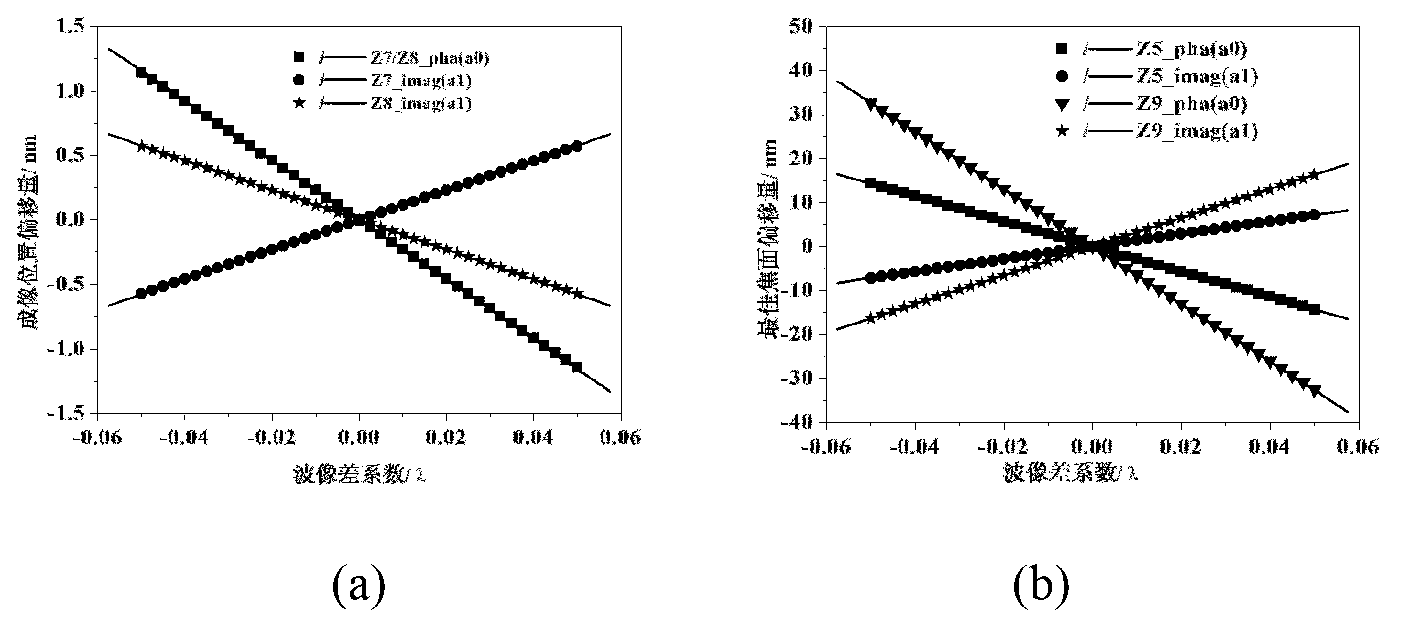

Projection lens polarization aberration in-situ detection method of photoetching machine

ActiveCN103197512ASimple structureShort measurement timePhotomechanical exposure apparatusMicrolithography exposure apparatusData processing systemControl system

The invention discloses a projection lens polarization aberration in-situ detection method of a photoetching machine. A detection system used for the detection method comprises a light source, an illumination system, a mask bench, a mask comprising a detection mark, a projection lens, a working bench, an image sensor, a positioning system for the mask bench and a workpiece bench, a data processing system and a feedback control system; a polarization illumination mode is adopted for the detection method, and a large projection lens numerical aperture is selected for detection; then the imaging position deviation amount and the best focal plane deviation amount of the detection mark are measured by utilizing the image sensor; and the polarization aberration of the projection lens is calculated according to a calibrated polarization aberration flexibility coefficient. The projection lens polarization aberration in-situ detection method of the photoetching machine provided by the invention has the characteristics of simple structure of the detection system, short polarization aberration measurement time and large measurement range.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

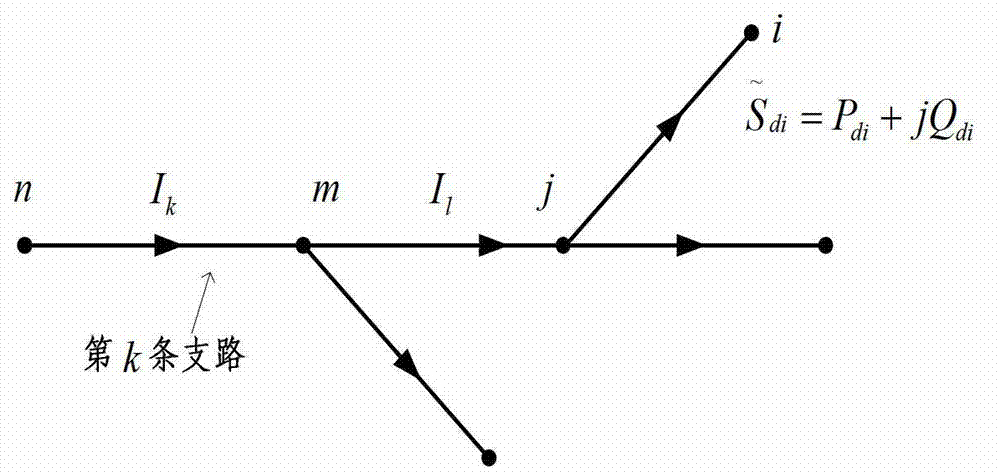

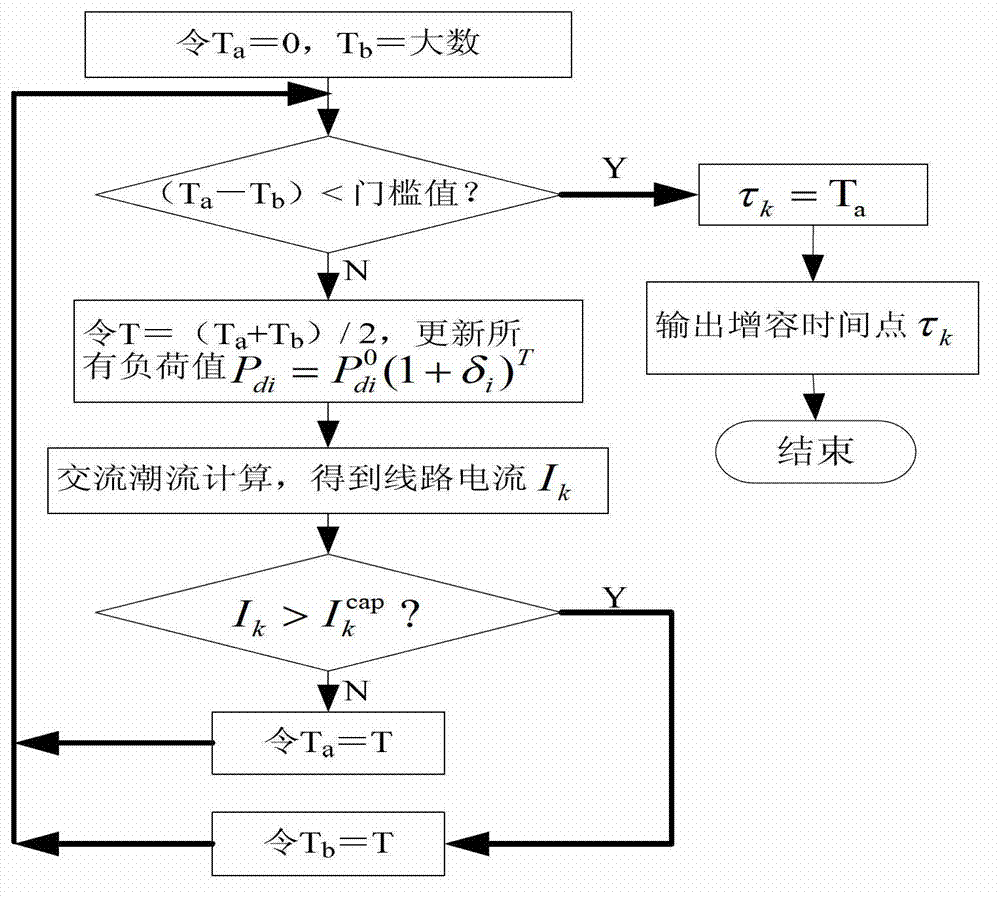

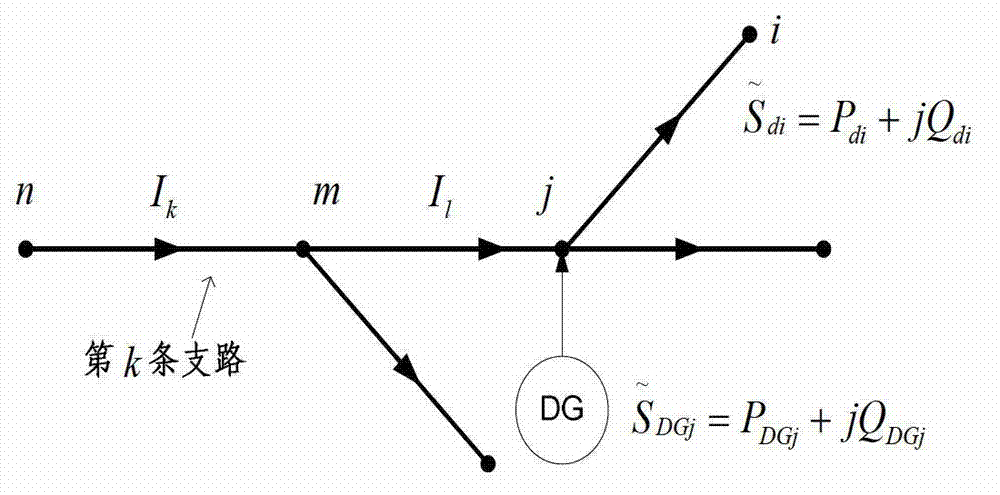

Distributed power generation planning method

The invention provides a distributed power generation planning method and belongs to the technical field of power energy saving. The method is mainly used for coordinating relation between power grid planning and distributed power supply configuration. The method includes first introducing a node sensitivity coefficient array and a unit loading increment cost array, building a power grid node / branch margin capacity cost model and a calculation method thereof, quantizing effect of the distributed power supply grid tying on the power grid node / branch margin capacity cost and finally conducting benefit calculation and evaluation on two distributed power supply property right models owned by a user and a power grid company based on a quantization model of effect of the distributed power supply grid tying to the power grid node / branch limit capacity cost.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

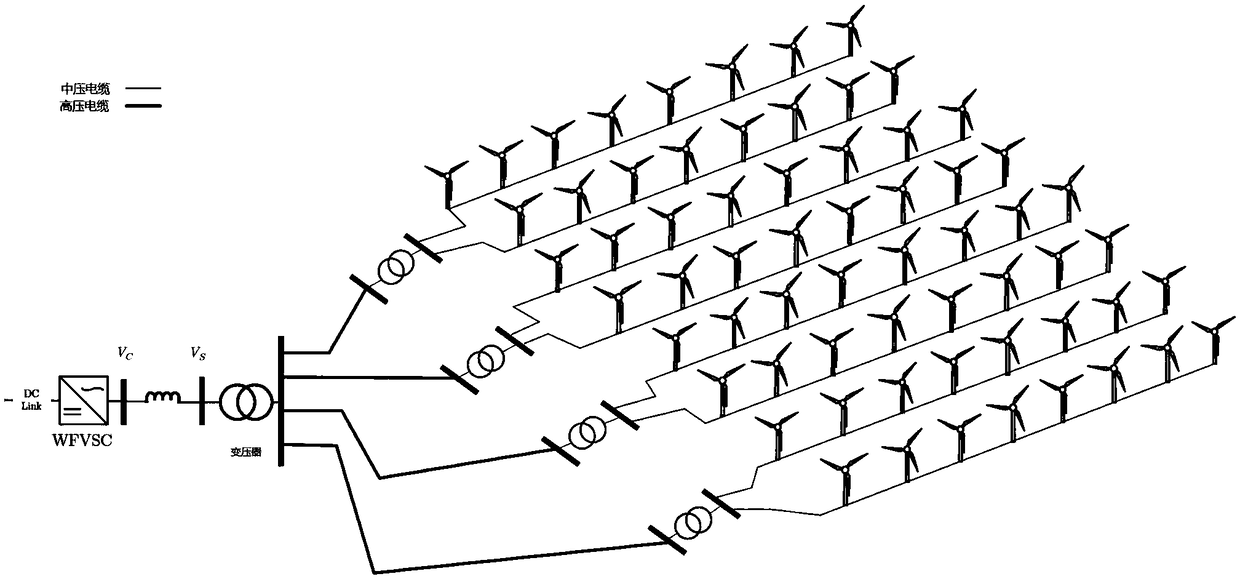

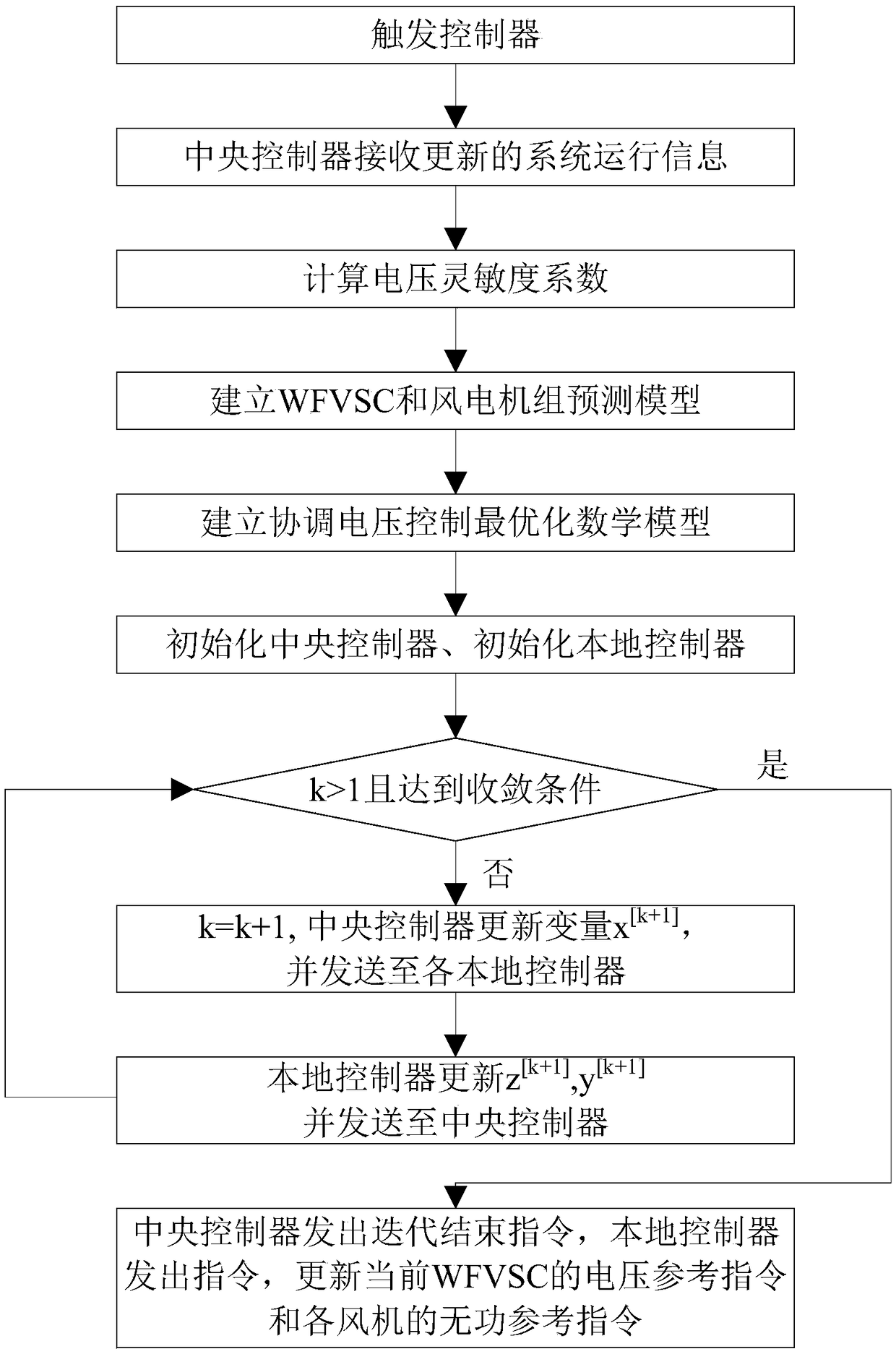

Distributed coordinated voltage control method and system for VSC-HVDC grid-connected wind farm based on MPC and ADMM algorithm

ActiveCN109149638ALighten the computational burdenOptimal control appliesSingle network parallel feeding arrangementsWind energy generationMathematical modelVoltage reference

The invention discloses a distributed coordinated voltage control method and system for a VSC-HVDC grid-connected wind farm based on an MPC and ADMM algorithm, which includes acquiring system operation state information, calculating voltage sensitivity coefficient, establishing predictive model of wind farm side converter, predictive model of reactive power linearization control of wind turbine generator system and linearized state space model of whole system; Aiming at minimizing the voltage offset and the reactive power fluctuation of wind turbine generator system, taking the reactive powerof wind turbine generator system and the voltage reference value of wind farm converter as decision variables, an optimized mathematical model for coordinated voltage control of the VSC-HVDC grid-connected wind farm based on MPV is established; The optimal mathematical model is solved. The invention disassembles the large-scale constrained optimization problem into an unconstrained optimization problem and a plurality of parallel small-scale constrained optimization problems, reduces the calculation burden of the central controller, and is more suitable for the optimization control of a large-scale offshore wind farm.

Owner:SHANDONG UNIV +1

Fiber grating cable tension transducer with temperature self-compensation function

InactiveCN102230834AWith online real-time cable force monitoringRealize online real-time cable force monitoringForce measurement by measuring optical property variationGratingSelf compensation

The invention provides a fiber grating cable tension transducer with a temperature self-compensation function, belonging to the field of transducer technologies. The transducer provided by the invention is characterized by comprising a metal baseplate, a clamping piece, a micro fiber grating strain transducer and a cable component of fiber transmission. The measuring sensitivity of the transducer can be adjusted by changing sizes of elements of the transducer in accordance with actual requirements, thus being suitable for monitoring cable tension of the different cables in real time. The fiber grating cable tension transducer can measure the cable tension of the cables indirectly by measuring an anchor head structure and utilize the properties of the fiber grating to improve the cable tension sensitivity coefficients of the transducer, and is not influenced by structural materials and external environments. The fiber grating cable tension transducer can eliminate influences of eccentric forces on measuring values, realize the temperature self-compensation and overcome the defects that a traditional electric transducer is subjected to electromagnetic interference easily and is poor in long-term stability, and has the advantages of high accuracy, light weight, low influences on the properties of the structure and the like.

Owner:DALIAN UNIV OF TECH

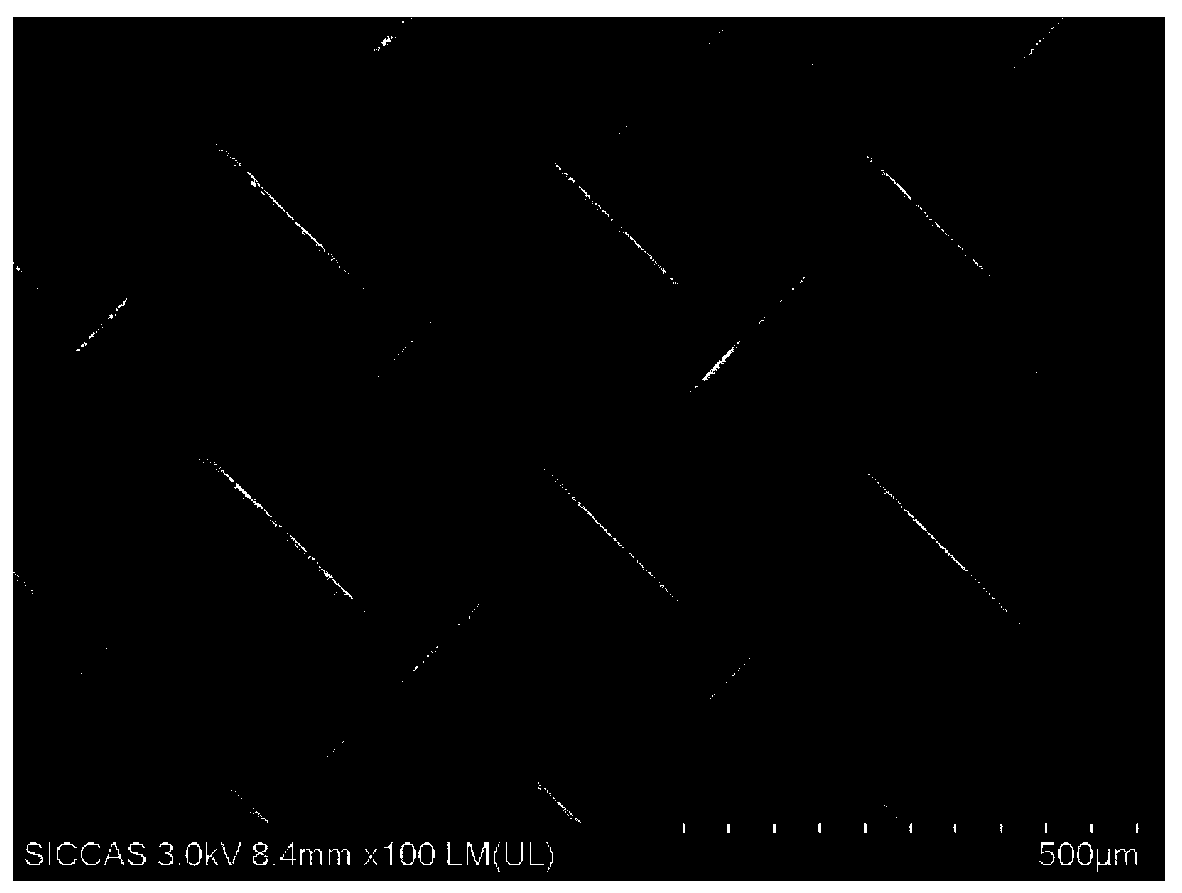

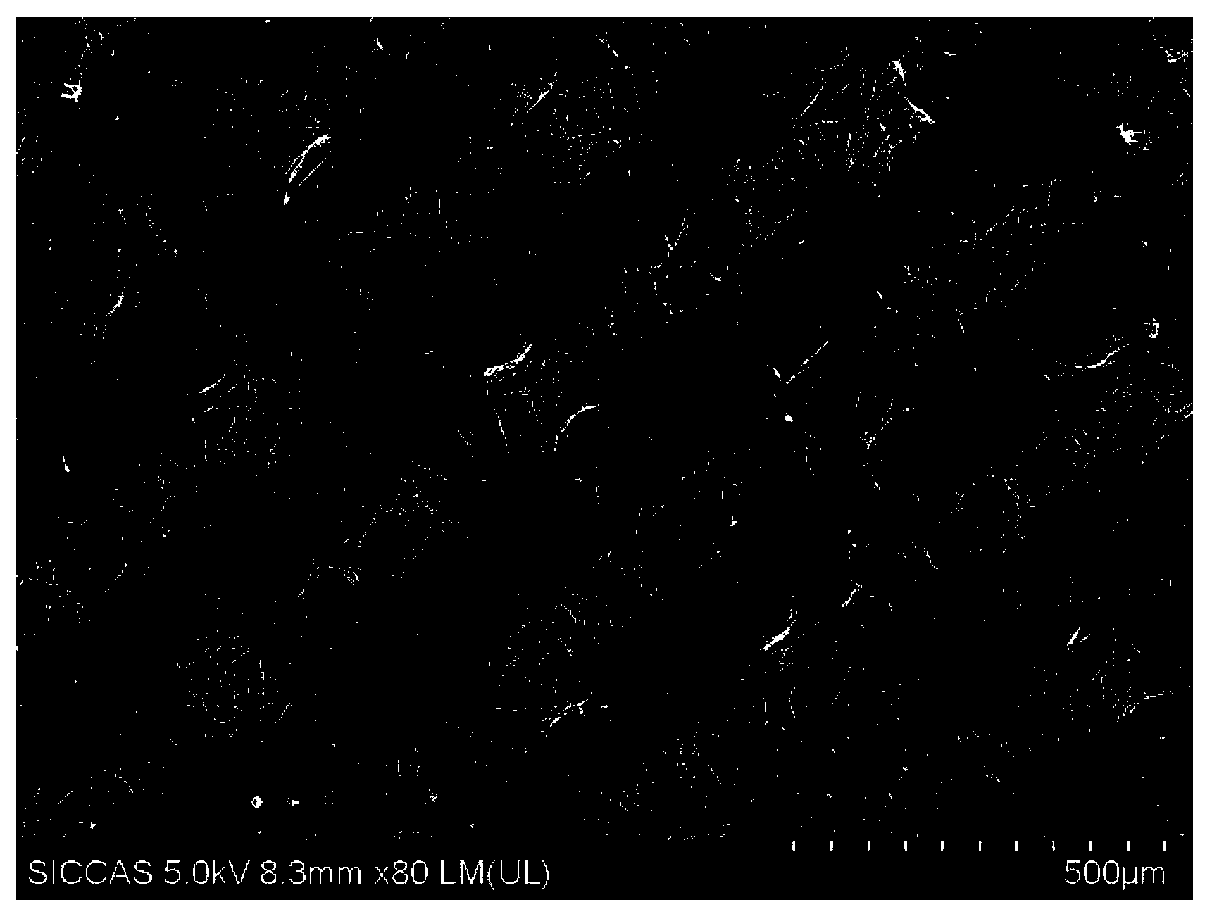

Multi-functional graphene flexible sensor having high resistance strain sensitivity coefficient and high deformation capability and preparation method thereof

ActiveCN107655397AHigh resistance strain gage coefficientEasy to prepareGrapheneElectrical/magnetic solid deformation measurementHigh resistanceFiber

The invention relates to a multi-functional graphene flexible sensor having a high resistance strain sensitivity coefficient and high deformation capability and a preparation method thereof. The graphene flexible sensor comprises a flexible substrate, a sensitive material attached onto the surface of the flexible substrate and electrodes distributed at the two ends of the sensitive material. The sensitive material is at least one layer of pleated braided mesh graphene film; the pleated braided mesh graphene film is braided by graphene fibers, preferably, is braided alternately in longitude andlatitude directions; and the graphene fiber internally has a graphene nano-sheet stack structure. The preparation method is simple to operate and low in cost, and have the potential of being widely applied to fields of daily human body motion sensing, health monitoring, an intelligent robot and man-machine interaction and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Mounting method of fiber Bragg grating sensor

The invention belongs to the fiber Bragg grating sensor application technology and relates to a mounting method of a fiber grating sensor. The mounting method of the fiber grating sensor obtains a fiber grating sensor adhering process which has ideal strain transmitting effects, good repeatability and high stability by combining analysis results of a strain transmitting theory of a sensor, selecting a variety of adhesives, using different processes for adhering the sensor and verifying the adhering effects through a standard beam test. Further, the fiber grating sensor is adhered by controlling key factors such as the elastic modulus of the adhesives, the adhering length and the adhering layer thickness which affect the strain transmitting rate of the fiber grating sensor, so that the obtained fiber grating sensor has high strain transmitting rates, good repeatability and stable strain sensitivity coefficients, can accurately measure the true strain of monitoring sites and ensures the effectiveness and reliability of the monitoring results.

Owner:CHINA AIRPLANT STRENGTH RES INST

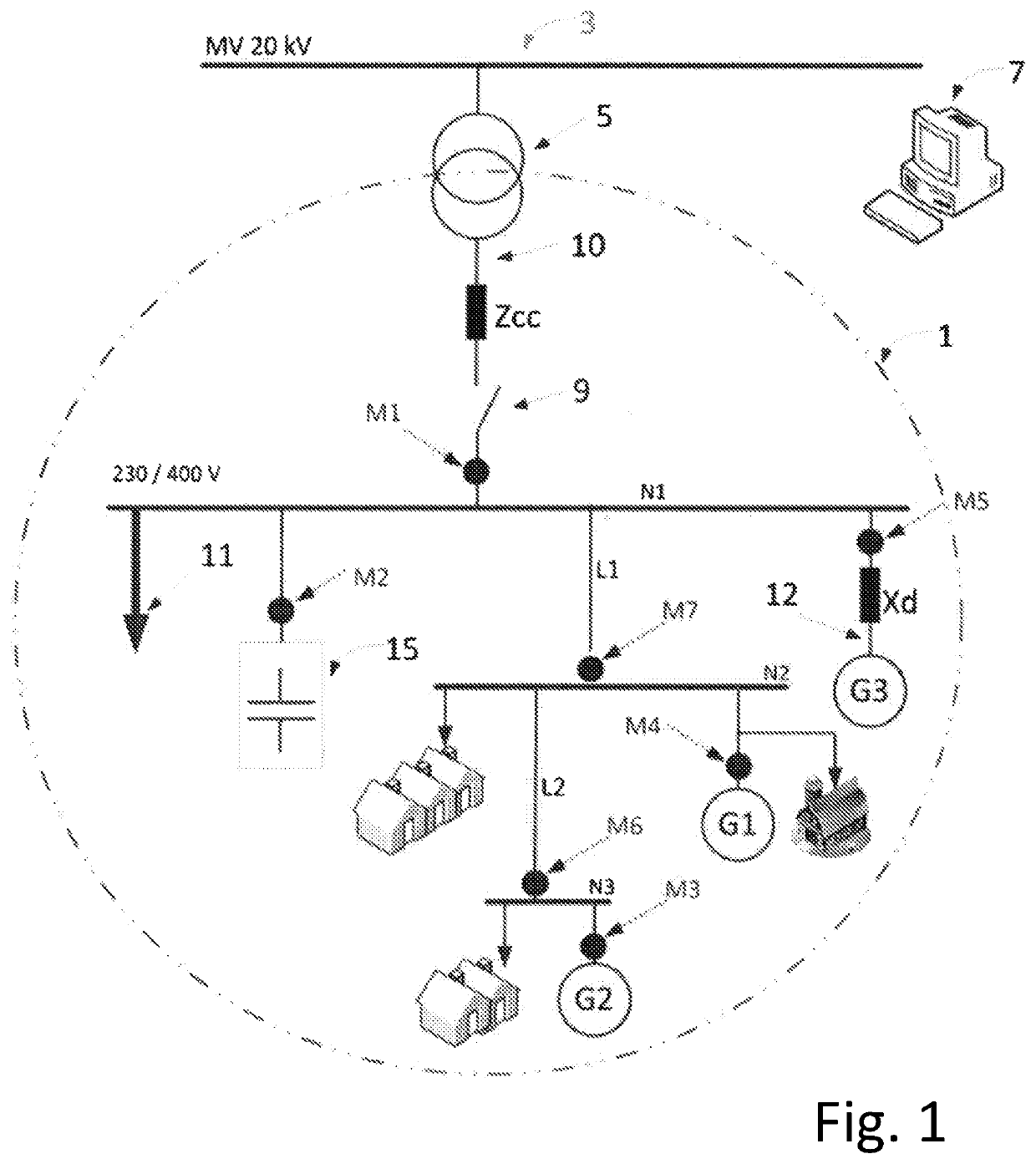

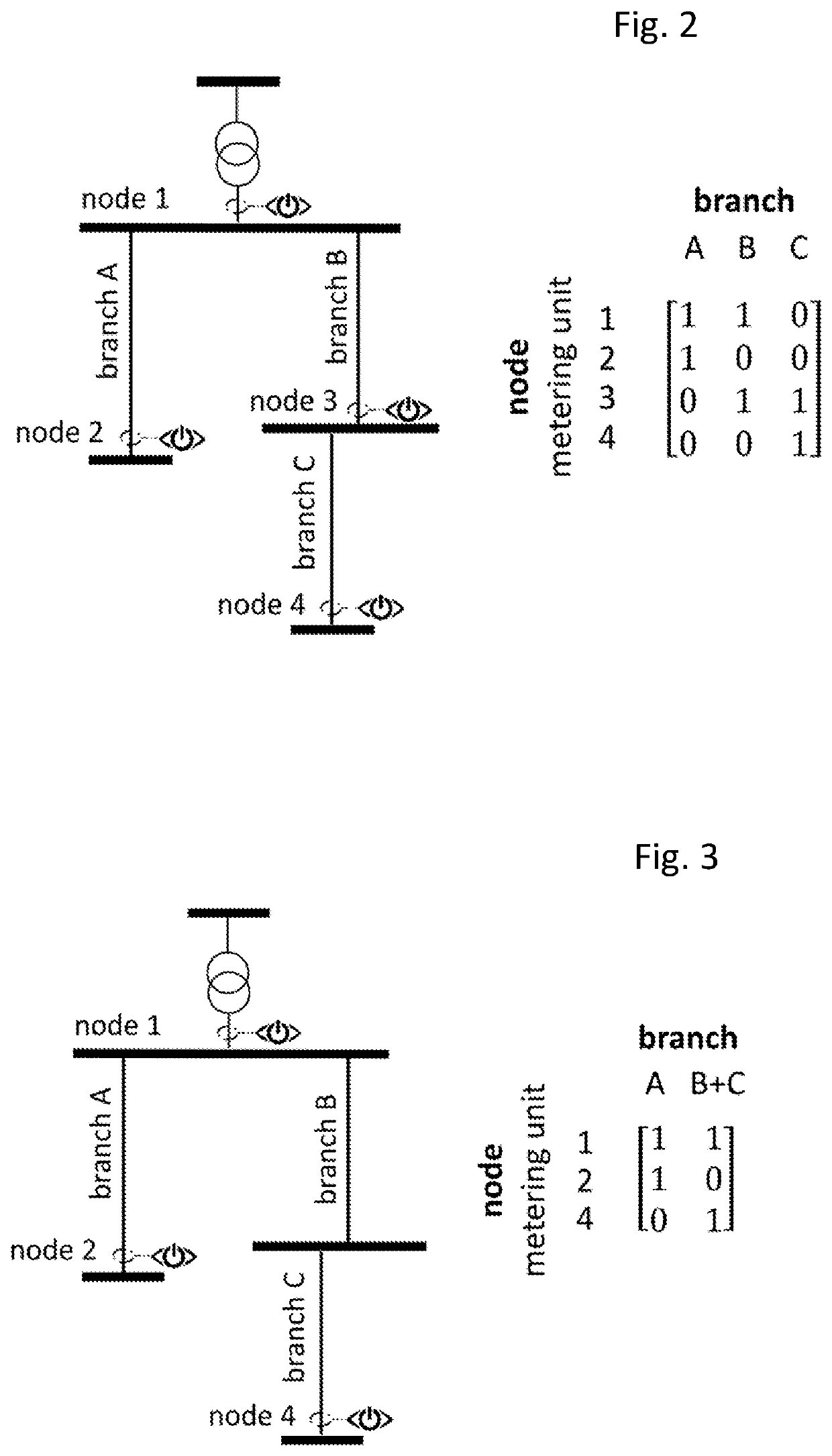

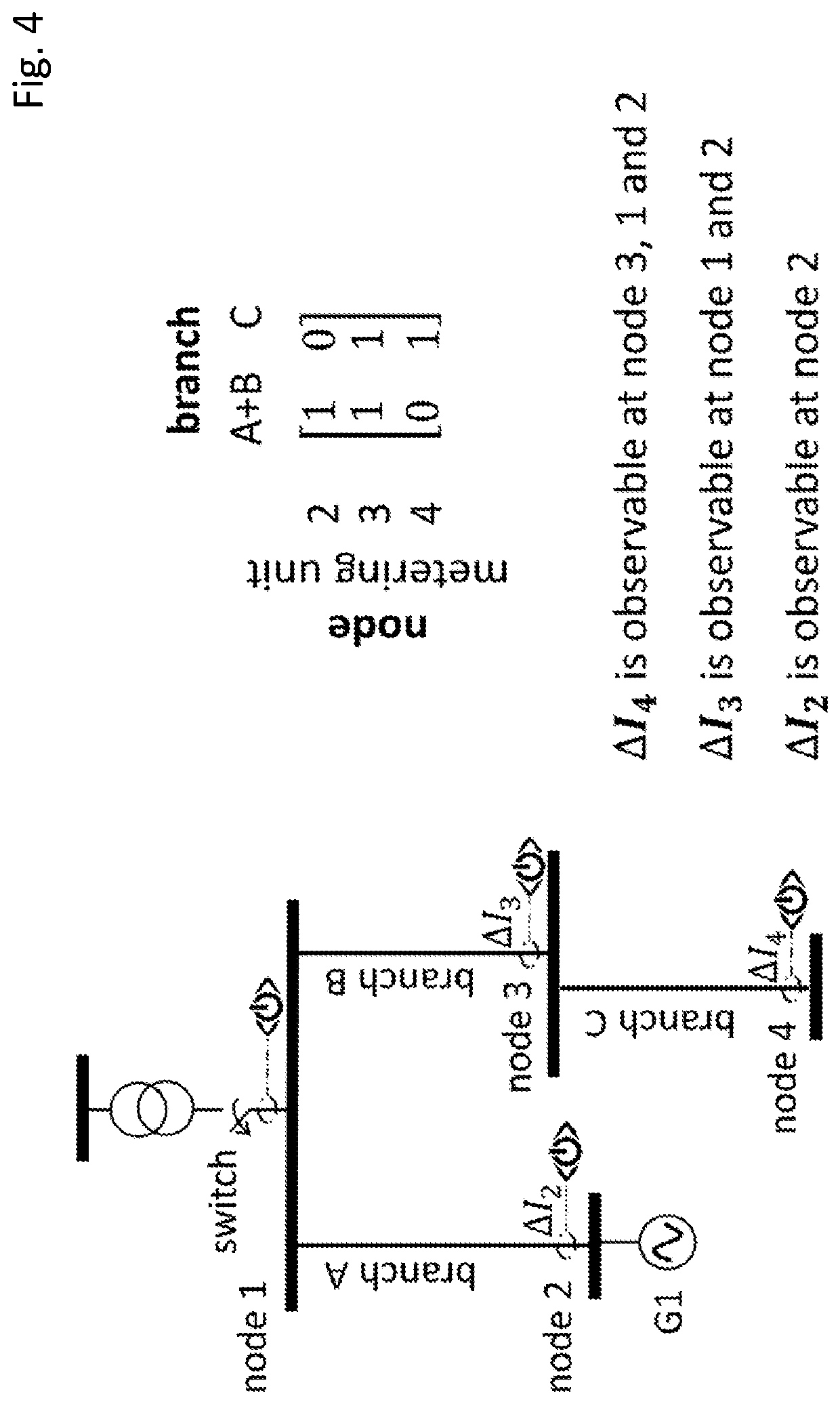

Method for estimating the topology of an electric power network using metering data

ActiveUS20200287388A1Single network parallel feeding arrangementsSystems intergating technologiesAlgorithmEngineering

Disclosed is a method for identifying the topology of an electric power network allows for the automatic and efficient identification of network topology without the knowledge of network parameters. The method is based on the estimation of mutual current sensitivity coefficients and on an algorithm to obtain the network incidence matrix from the estimated sensitivity coefficients. This algorithm is based on the general assumption that the metering unit that is the most sensitive to the variations of the measured current in a branch connected to a particular node is the metering unit that is arranged at the physical node immediately upstream form the particular node. The method effectively considers the presence of noise in the measurements and its time correlation.

Owner:KRAKENFLEX LTD

An optical fiber sensing system temperature compensating method

The invention provides an optical fiber sensing system temperature compensating method comprising the following steps: 1, temperature calibrating is carried out on an optical sensor to obtain a temperature sensitivity coefficient K[T1]; 2, temperature calibrating is carried out the optical sensor attached in an adhesive mode to the surface of a test piece, of which the materials is same with a to-be-measured piece so as to obtain a material uniform thermal expansion coefficient K[T2]; 3, strain calibrating is carried out on the optical sensor to obtain a strain sensitivity coefficient K [Epsilon]; and 4, in strain and deformation measurement carried out on the to-be-measured piece, strain applied to the to-be-measured piece is measured by an optical fiber strain sensor, and an optical fiber temperature sensor is used to make temperature compensating for the strain sensor; and influences by uniform thermal expansion are rejected to obtain effective deformation strain data. The invention is mainly used for occasions such as strain and deformation caused by fore bearing and non-uniform thermal expansion in optical fiber sensing network measurement, and difficulties in measuring by the optical fiber sensor with regard to deformation and uniform thermal expansion of the measured piece and strain and temperature cross sensitivity are overcome.

Owner:山东双测安全信息技术产业研究院有限公司

Large-wall-thickness X52MS acid-resistant pipeline steel plate produced by LF-RH refining process and manufacturing method thereof

The invention relates to a large-wall-thickness X52MS acid-resistant pipeline steel plate produced by an LF-RH refining process. The steel plate is characterized by being manufactured from the following chemical component percentage by weight: 0.03%-0.07% of C, 0.2%-0.4% of Si, 1.0%-1.4% of Mn, 0.02%-0.04% of Al, 0.02%-0.05% of Nb, less than or equal to 0.02% of V, 0.004%-0.012% of Ti, 0.1%-0.4% of Cr, 0.1%-0.2% of Mo, less than or equal to 0.0005% of B, less than or equal to 0.012% of P, less than or equal to 0.001% of S, less than or equal to 0.005% of [N], less than or equal to 0.005% of [O], less than or equal to 0.0015% of [H] and the balance being Fe and inevitable impurities, wherein the cold crack sensitivity coefficient Pcm is less than or equal to 0.19. The manufacturing method comprises the sequential steps of KR molten iron pretreatment, converter smelting, LF and RH refining, plate blank continuous casting, plate blank heating, rough rolling, intermediate blank cooling, finish rolling, ACC cooling and the like. The manufactured steel plate has thickness being 35.1-44.2 mm, yield strength being 380-440 MPa, tensile strength being 490-570 MPa, and elongation being greater than or equal to 33%, yield ratio being less than or equal to 0.09; an average shear plane ratio of drop hammer under the temperature of minus 5 DEG C is 85% or more; and the large-wall-thickness X52MS pipeline steel can meet the requirement of being used in an acidic environment, and has good HIC resistance and low-temperature toughness.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com