Large thickness steel plate for hydrogenation reaction chamber reeling equipment and production method thereof

A technology of a hydrogenation reactor and a production method, which is applied in the field of steel smelting, can solve the problems that the strength, toughness and the sensitivity coefficient of tempering embrittlement cannot meet the requirements for the use of hydrogenation equipment, and the thickness is small, and achieve good tempering embrittlement. The effect of chemical sensitivity coefficient, high temperature tensile strength and yield strength, and internal compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

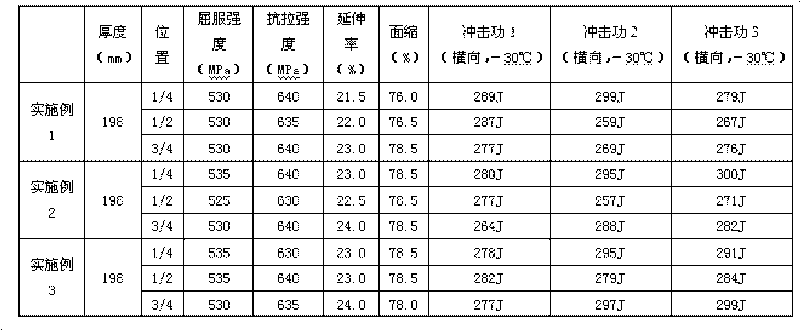

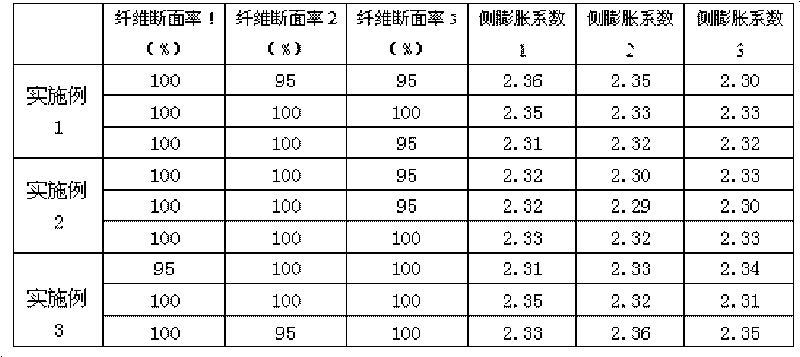

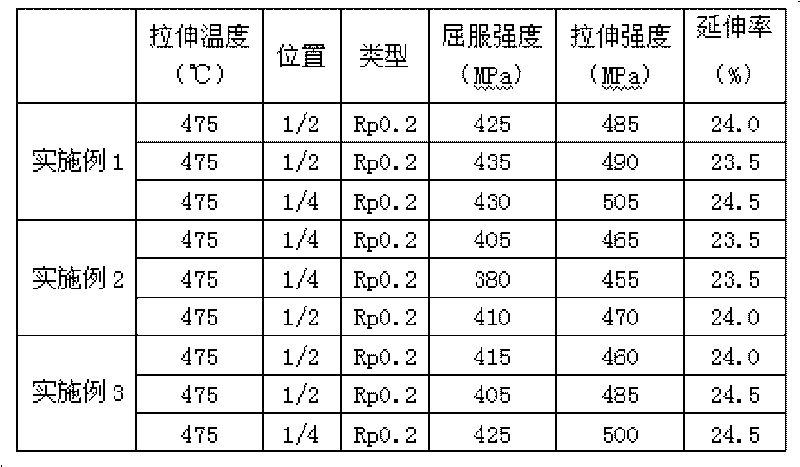

Examples

Embodiment 1

[0028] The steel plate for large-thickness hydrogenation reactor reel equipment, its composition mass percentage is: C: 0.17%, Si: 0.07%, Mn: 0.41%, P: 0.010%, S: 0.010%, Ni: 0.15%, Cr: 2.31%, Nb: 0.014%, Cu: 0.13%, Mo: 0.96%, Sb: 0.003%, Sn: 0.009%, As: 0.010%, V: 0.007%, Al: 0.042%, the rest is Fe and unavoidable impurities .

[0029] A method for producing a steel plate for large-thickness hydrogenation reactor reel equipment, comprising the following steps:

[0030] (1) The molten steel containing the above components is smelted in an electric furnace, and then sent to an LF refining furnace for refining for 45 minutes. During the refining process, when the molten steel is not exposed, the amount of argon blowing is increased, and the slag is sampled and analyzed according to the target. Value adjustment composition, white slag retention time 25 minutes, casting after refining, off-line stacking and slow cooling for 18 hours, cleaning with temperature, transfer to electro...

Embodiment 2

[0036] The steel plate for large-thickness hydrogenation reactor reel equipment, its composition mass percentage is: C: 0.12%, Si: 0.06%, Mn: 0.27%, P: 0.009%, S: 0.007%, Ni: 0.20%, Cr: 1.95%, Nb: 0.010%, Cu: 0.10%, Mo: 1.13%, Sb: 0.003%, Sn: 0.01%, As: 0.012%, V: 0.010%, Al: 0.050%, the rest is Fe and unavoidable impurities .

[0037] A method for producing a steel plate for large-thickness hydrogenation reactor reel equipment, comprising the following steps:

[0038] (1) The molten steel containing the above components is smelted in an electric furnace, and then sent to an LF refining furnace for refining for 60 minutes. During the refining process, when the molten steel is not exposed, the amount of argon blowing is increased, and the slag is sampled and analyzed according to the target. Value adjustment composition, white slag retention time 30 minutes, casting after refining, off-line stacking and slow cooling for 20 hours, cleaning with temperature, transfer to electros...

Embodiment 3

[0044] The steel plate for large-thickness hydrogenation reactor reel equipment, its composition mass percentage is: C: 0.15%, Si: 0.09%, Mn: 0.63%, P: 0.010%, S: 0.008%, Ni: 0.18%, Cr: 2.60%, Nb: 0.020%, Cu: 0.15%, Mo: 1.13%, Sb: 0.003%, Sn: 0.01%, As: 0.016%, V: 0.005%, Al: 0.040%, the rest is Fe and unavoidable impurities .

[0045] A method for producing a steel plate for large-thickness hydrogenation reactor reel equipment, comprising the following steps:

[0046] (1) The molten steel containing the above components is smelted in an electric furnace, and then sent to an LF refining furnace for refining for 50 minutes. During the refining process, when the molten steel is not exposed, the amount of argon blowing is increased, and the slag is sampled and analyzed according to the target. Value adjustment composition, white slag retention time 30 minutes, casting after refining, off-line stacking and slow cooling for 16 hours, cleaning with temperature, transfer to electros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com