Patents

Literature

55 results about "Deformation strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deformation | strain |. is that deformation is the act of deforming, or state of being deformed while strain is (obsolete) treasure or strain can be the act of straining, or the state of being strained.

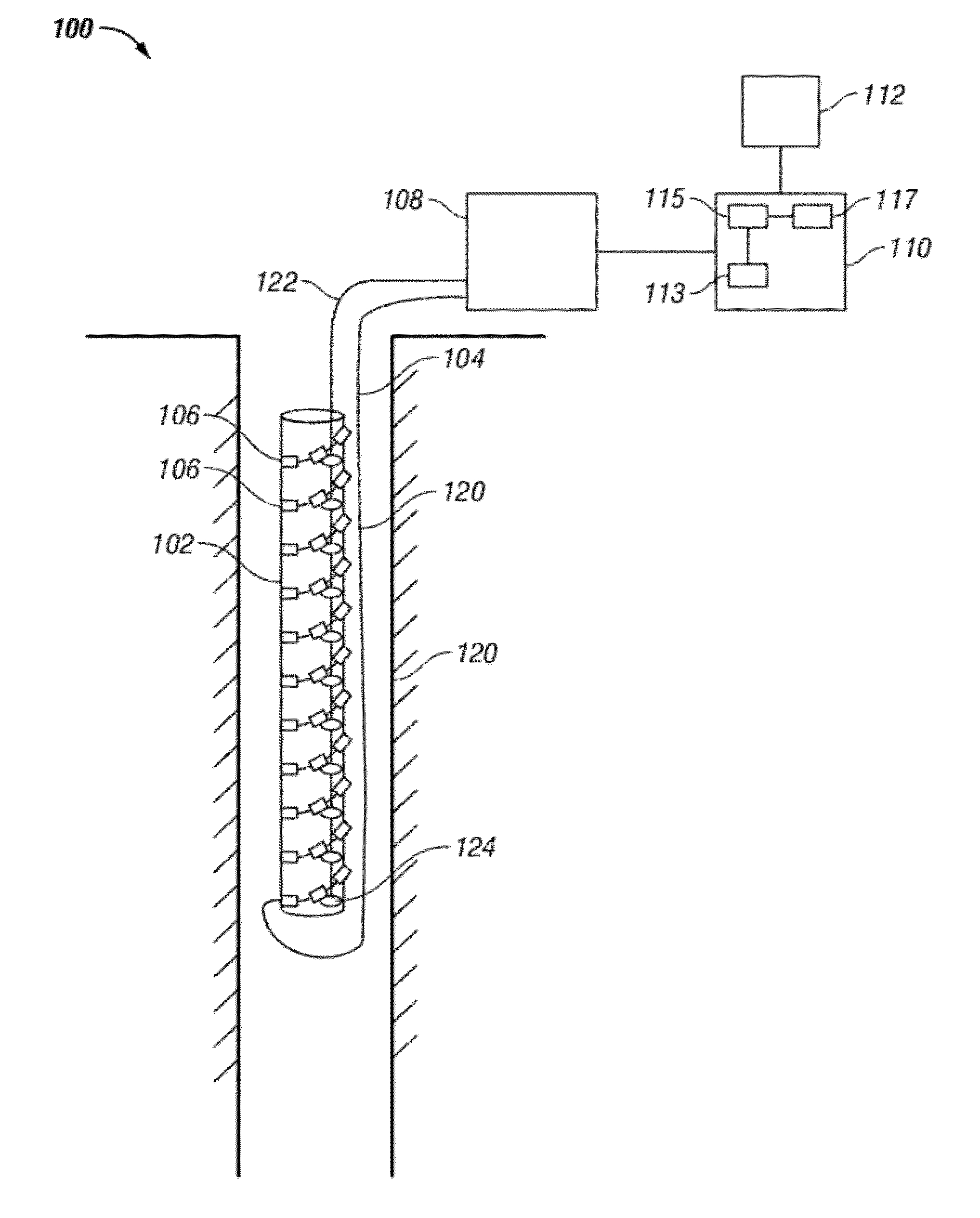

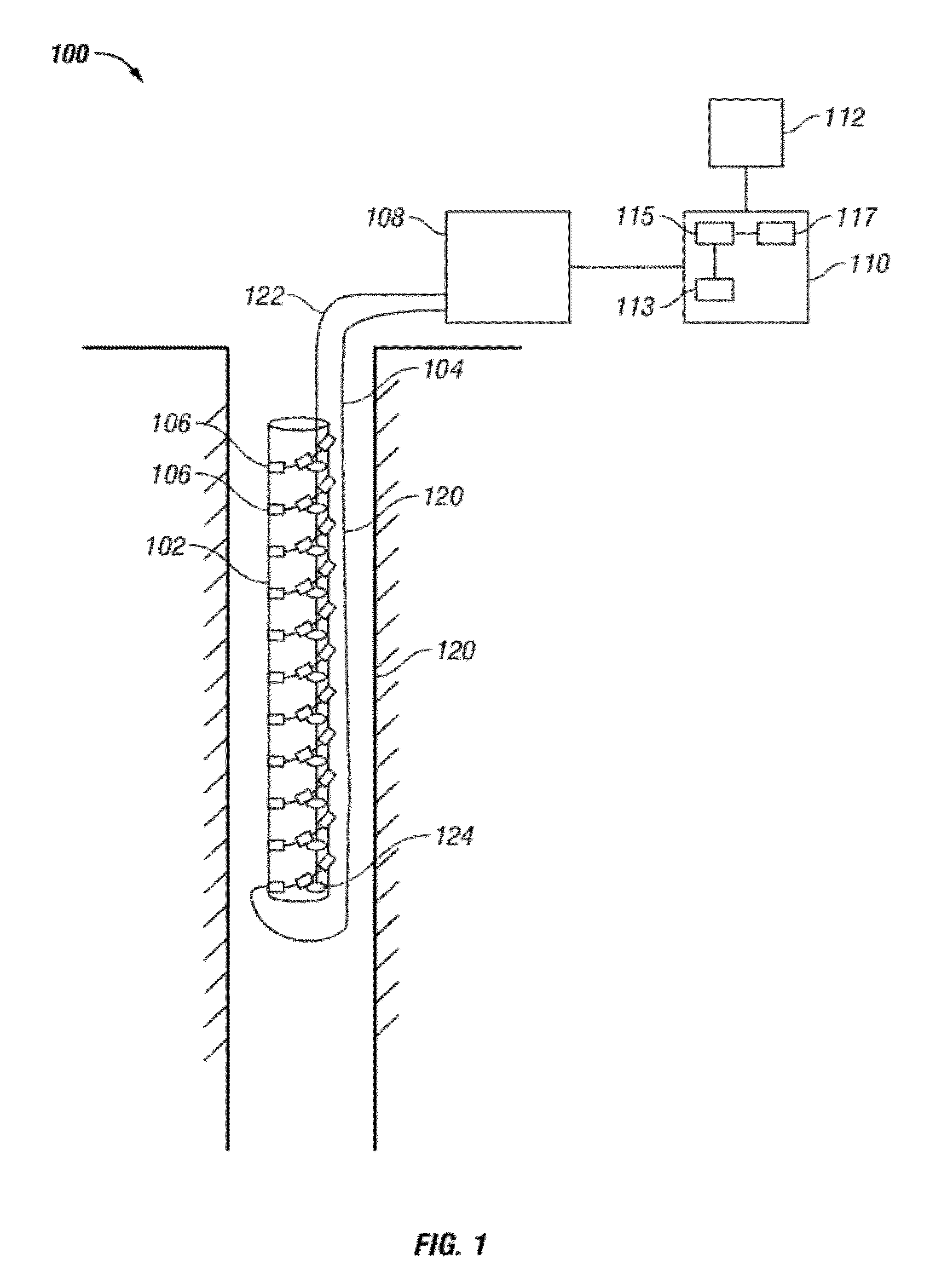

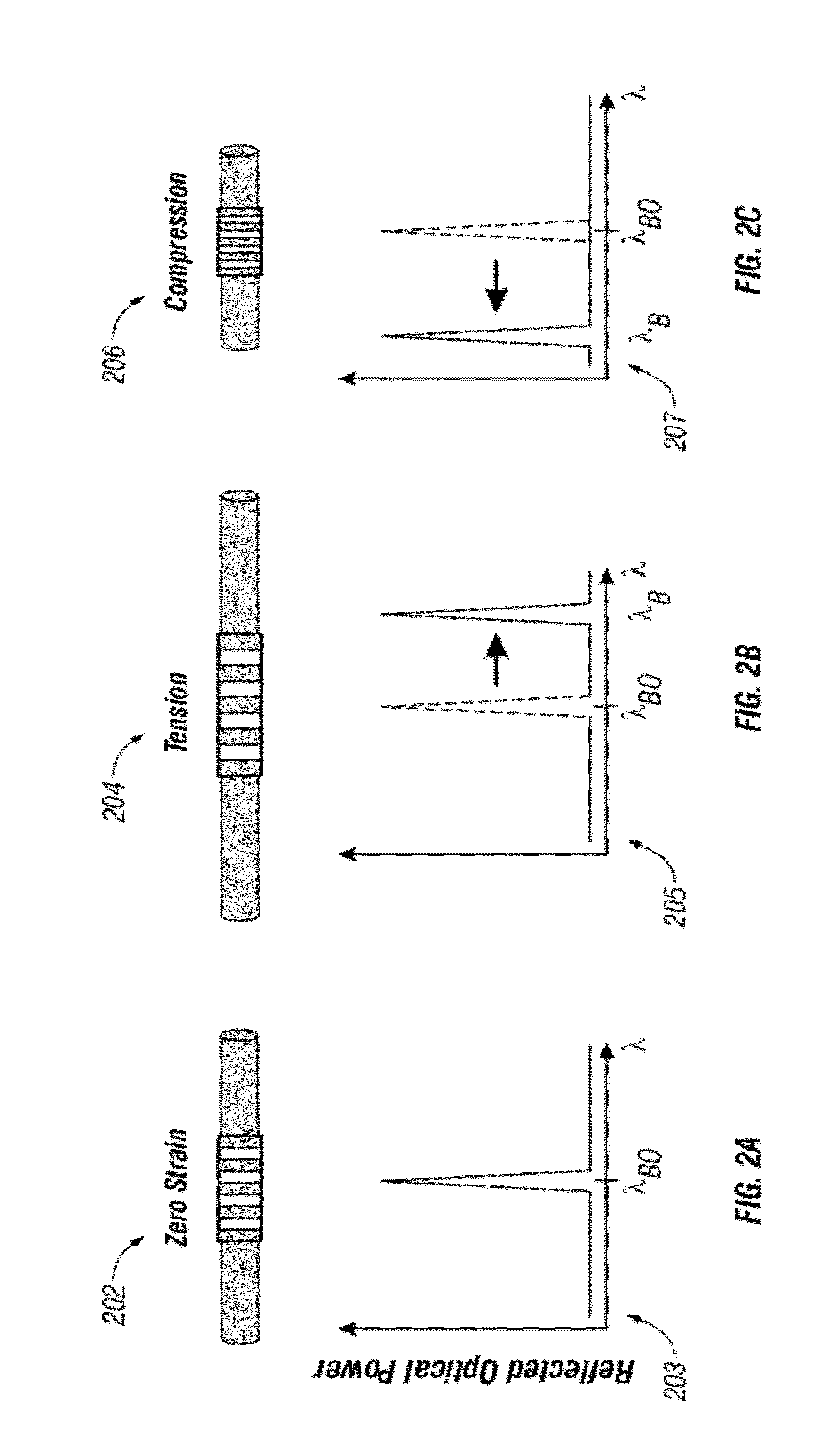

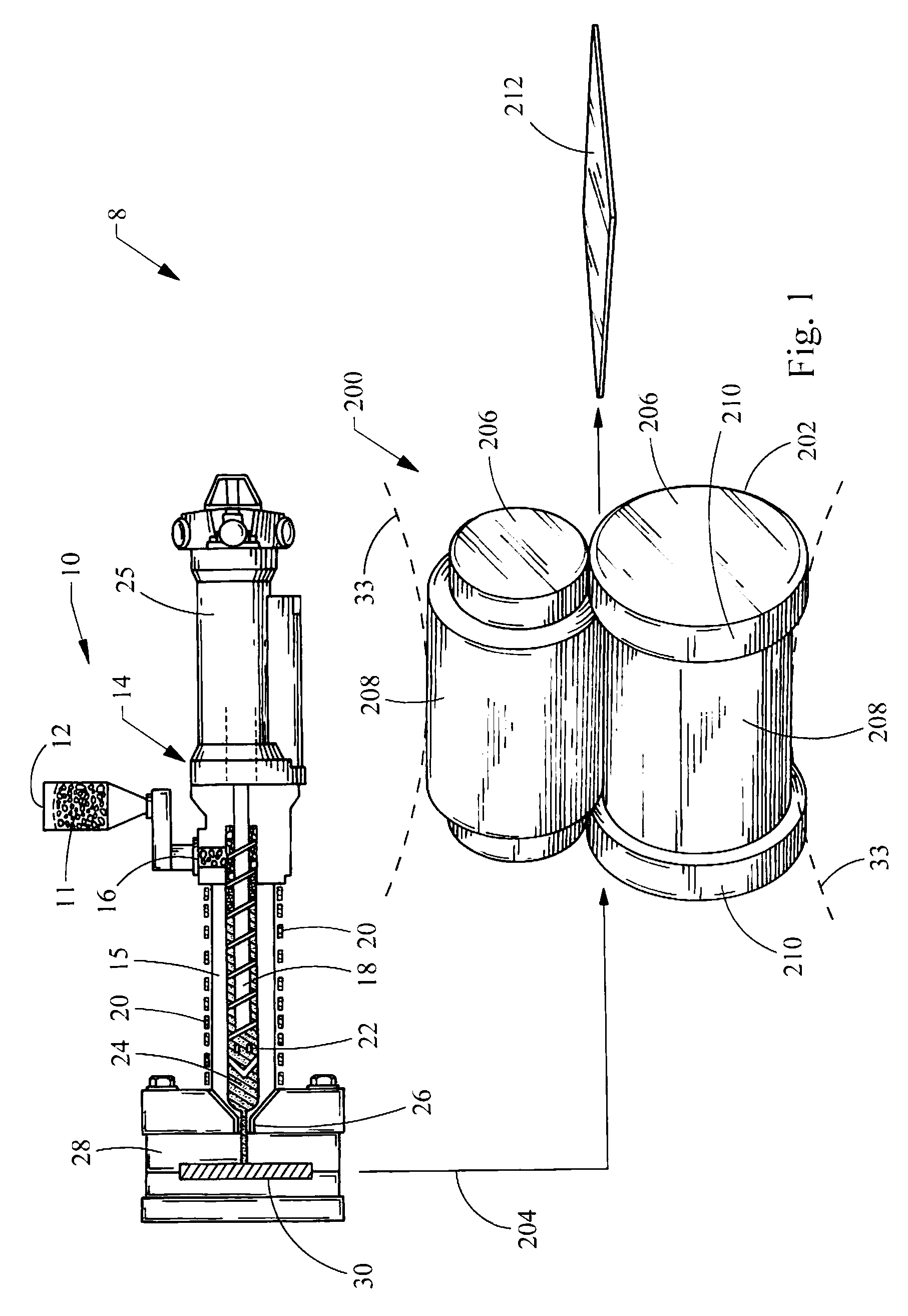

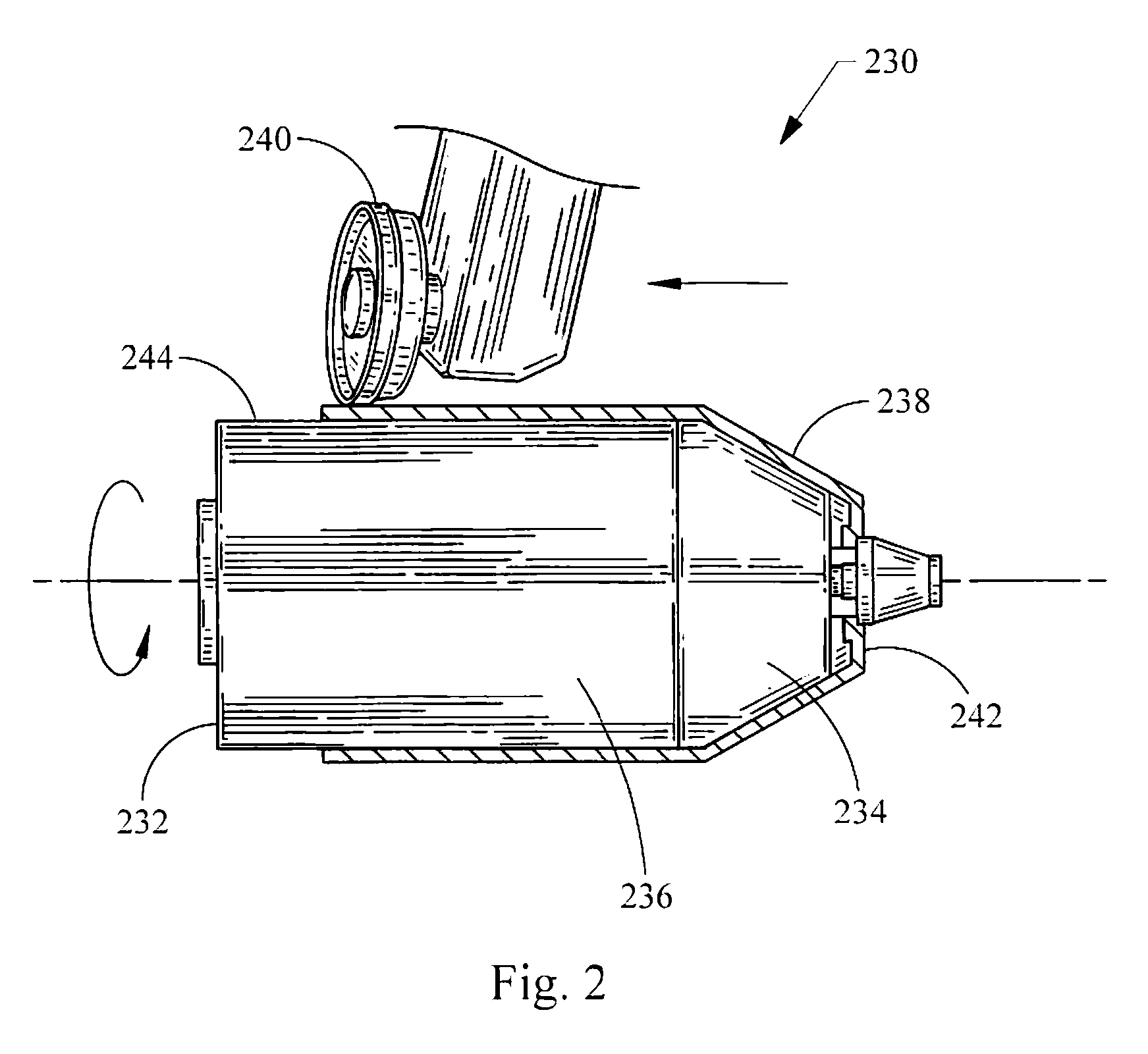

Interpretation of Real Time Compaction Monitoring Data Into Tubular Deformation Parameters and 3D Geometry

A method, apparatus and computer-readable medium for determining a deformation strain distribution of a member corresponding to a selected deformation mode is disclosed. Strain measurements are obtained at a plurality of sensors, wherein each strain measurement is related to a strain at a location of the member. A component of the strain related to a selected deformation mode for the obtained strain measurements is determined and a principal strain component and a secondary strain component for each of the determined components of the strain is determined. The determined principal strain component and secondary strain component are mapped to a surface of the member to determine the deformation strain distribution.

Owner:BAKER HUGHES INC

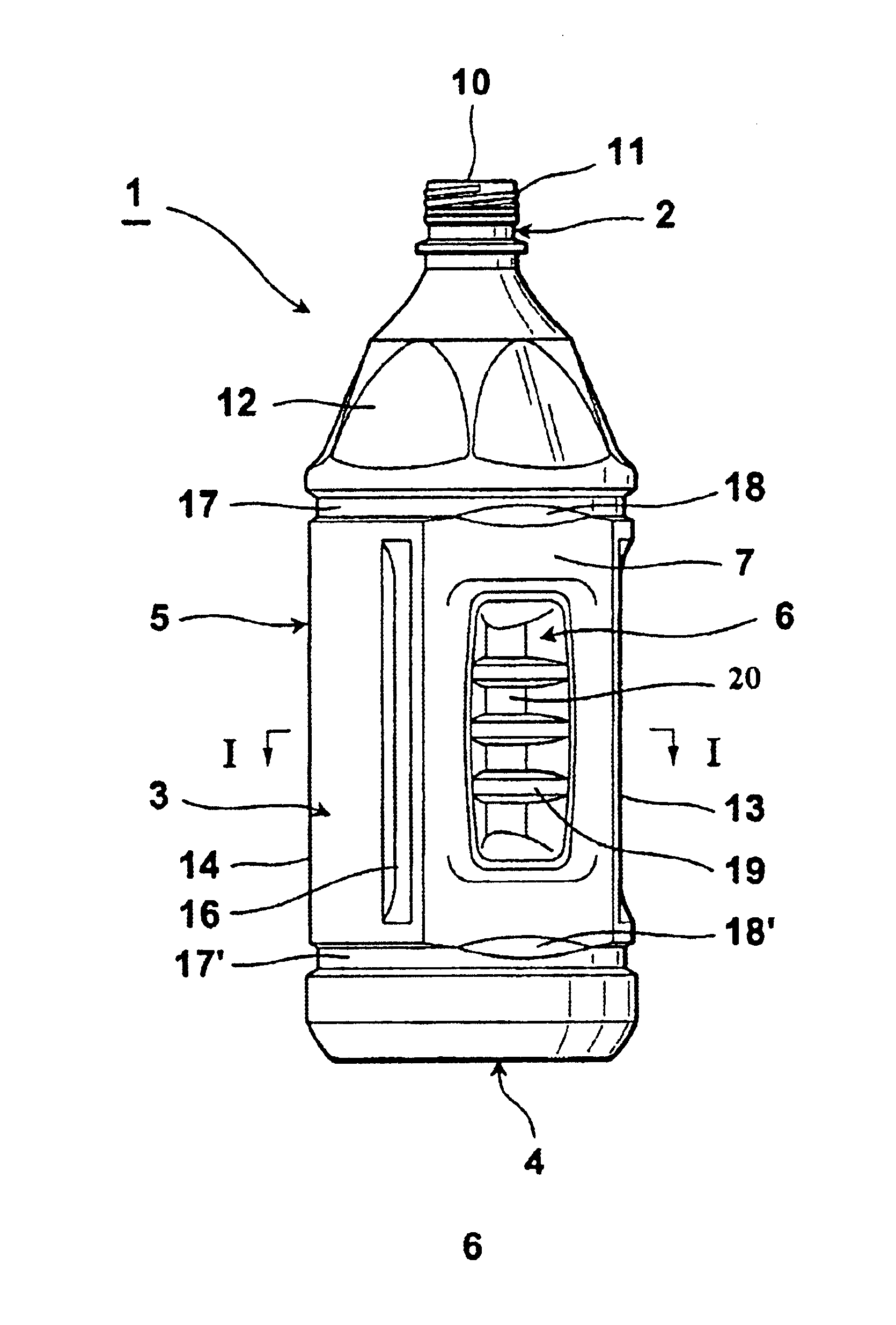

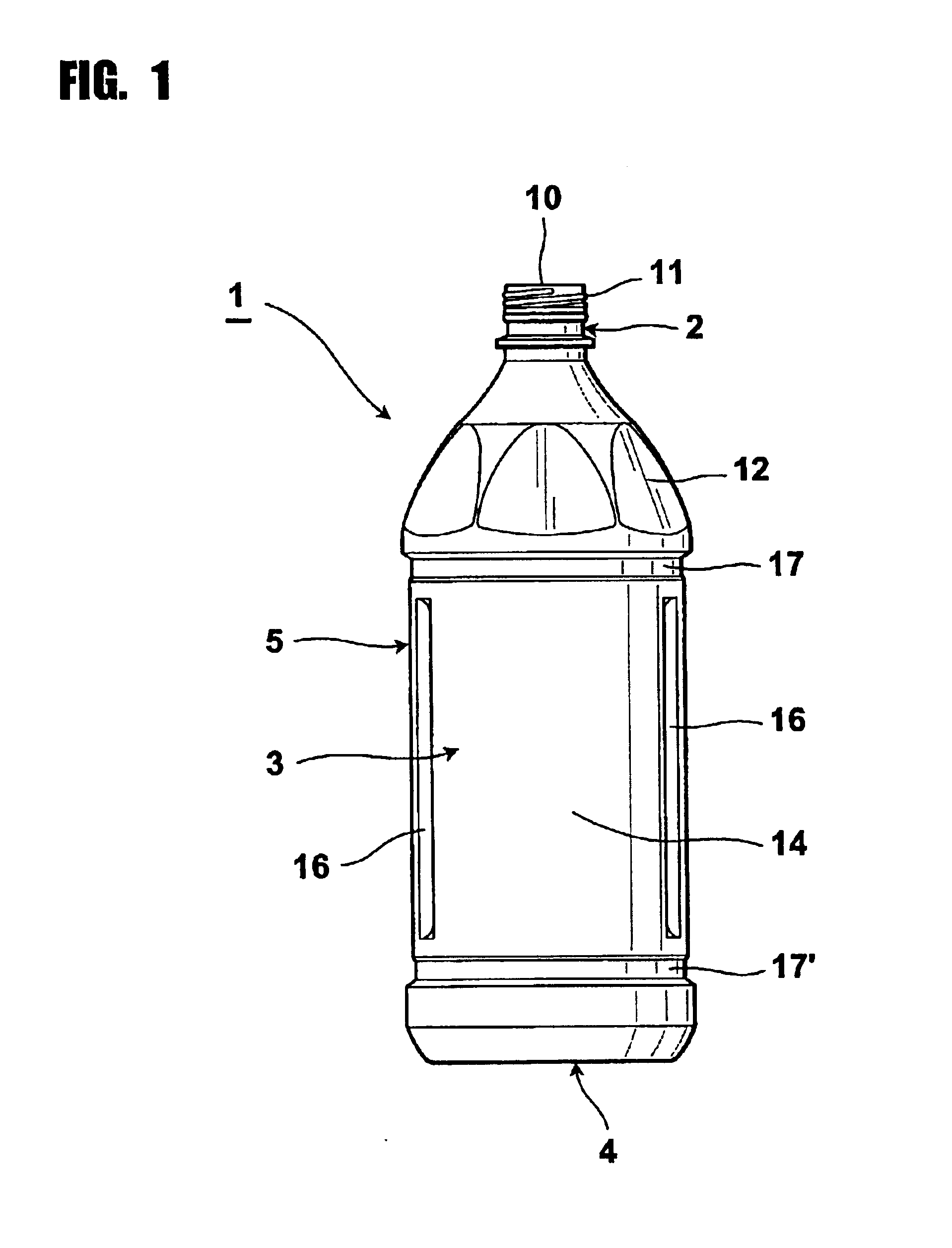

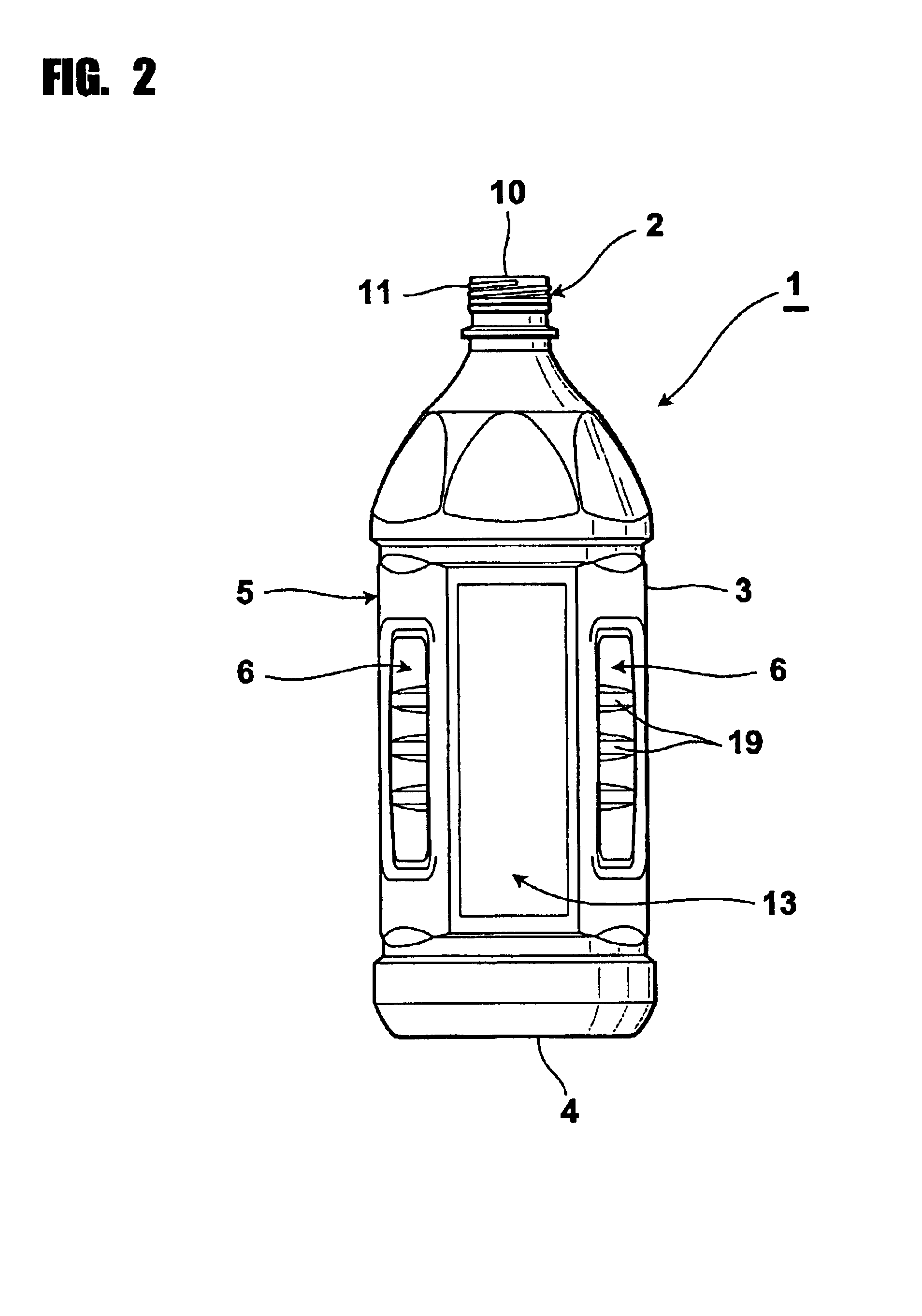

Handy bottle and process for manufacturing same

InactiveUS6964347B2Absorbs deformation strainMaintaining lightweight propertyBottlesLarge containersBlow moldingEngineering

A handy bottle is capable of absorbing deformation strain caused by variation of capacity, is easy to lift and carry because of its recessed portions for gripping and is excellent in dropping strength and capable of not buckling while maintaining moldability and lightweight property. Typically, the handy bottle has recessed portions for gripping on both sides of a body portion thereof and a shape in diametric cross section of the recessed portions is almost bilaterally symmetrical to a line connecting deepest portions of the recessed portions and a central axis of the body portion. The process for producing the handy bottle allows movable inserts capable of molding the recessed portions for gripping to be on standby in predetermined positions and allows the movable inserts to proceed toward the deepest portions of the recessed portions for gripping in the course of blow molding.

Owner:TOYO SEIKAN KAISHA LTD

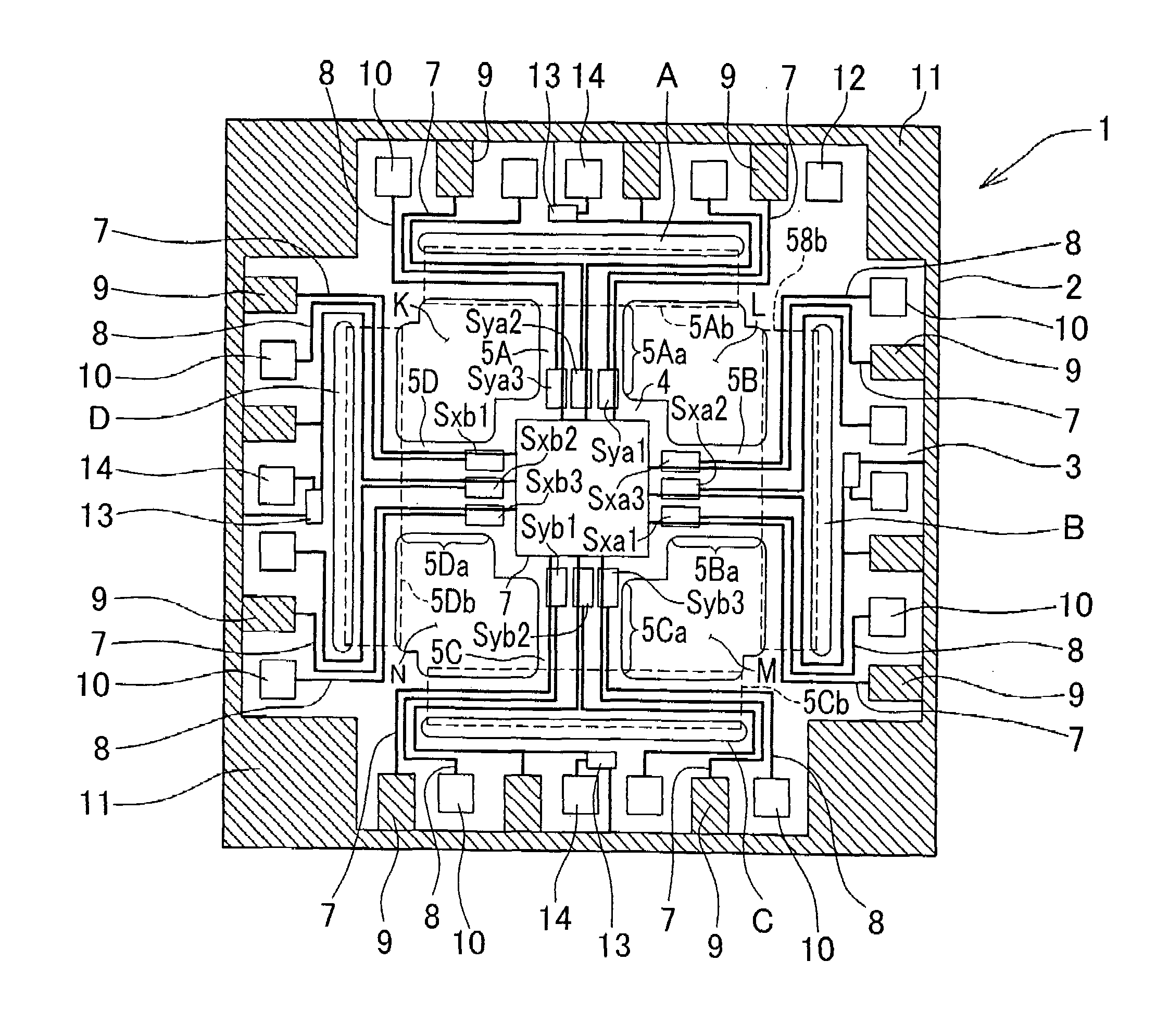

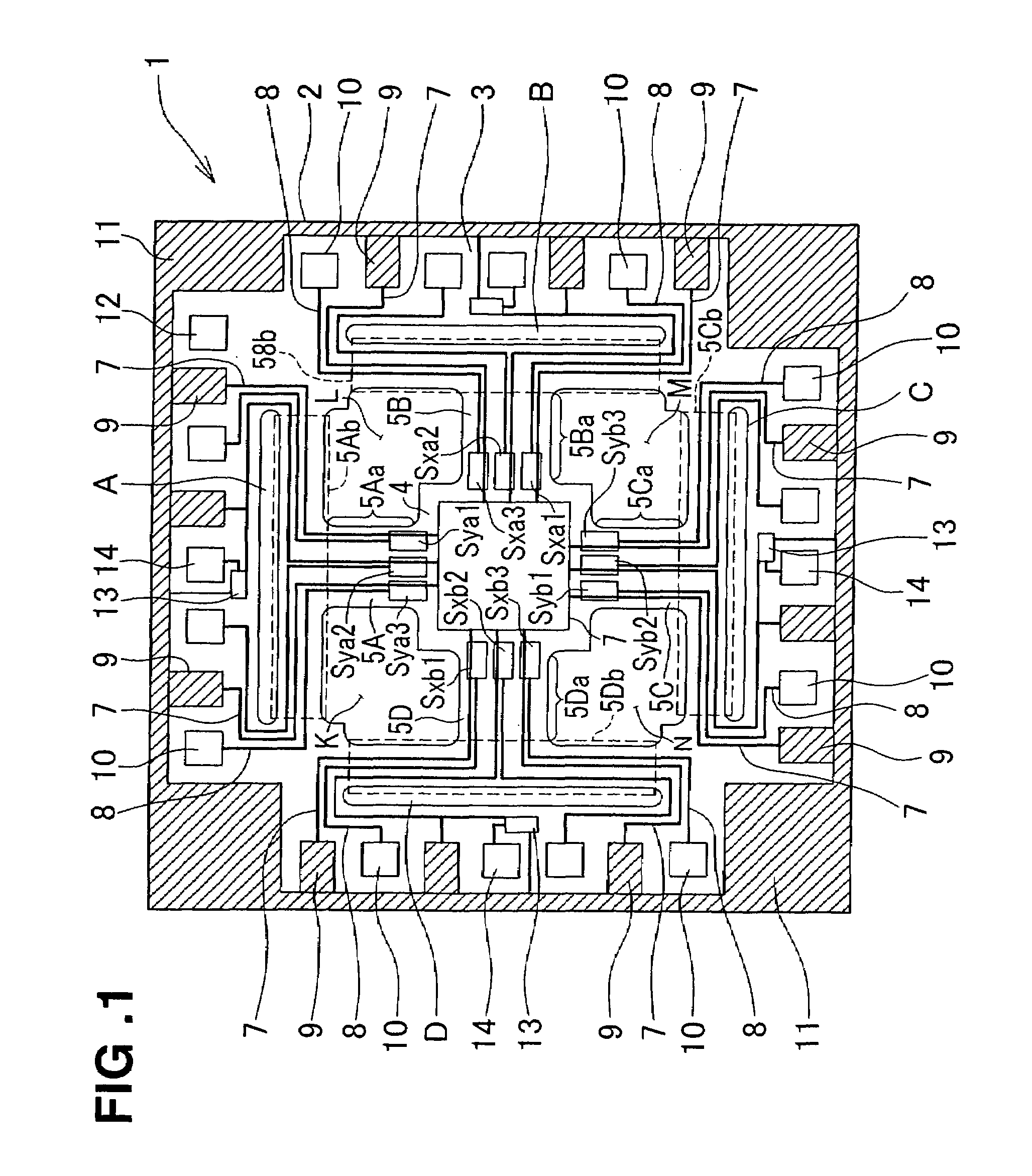

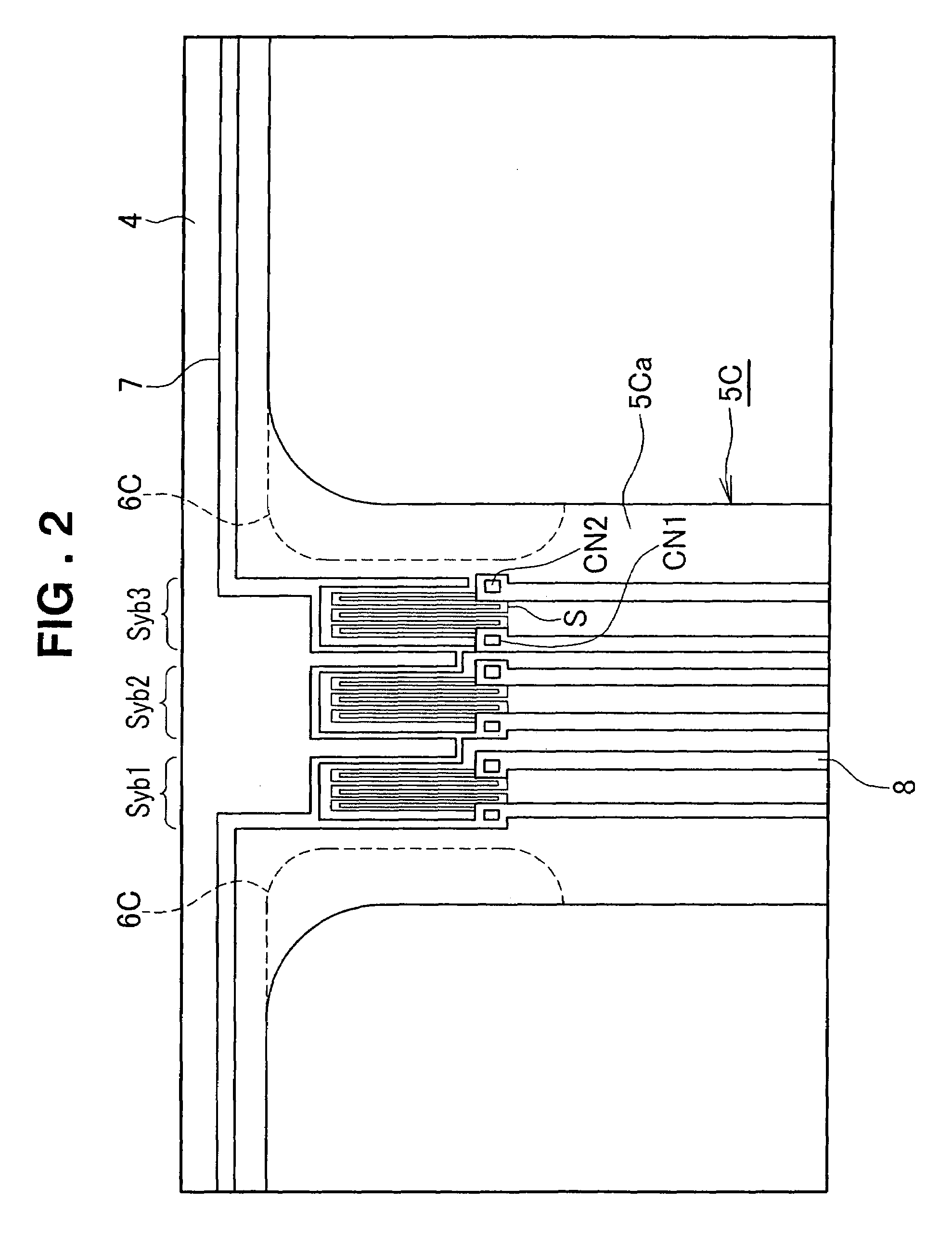

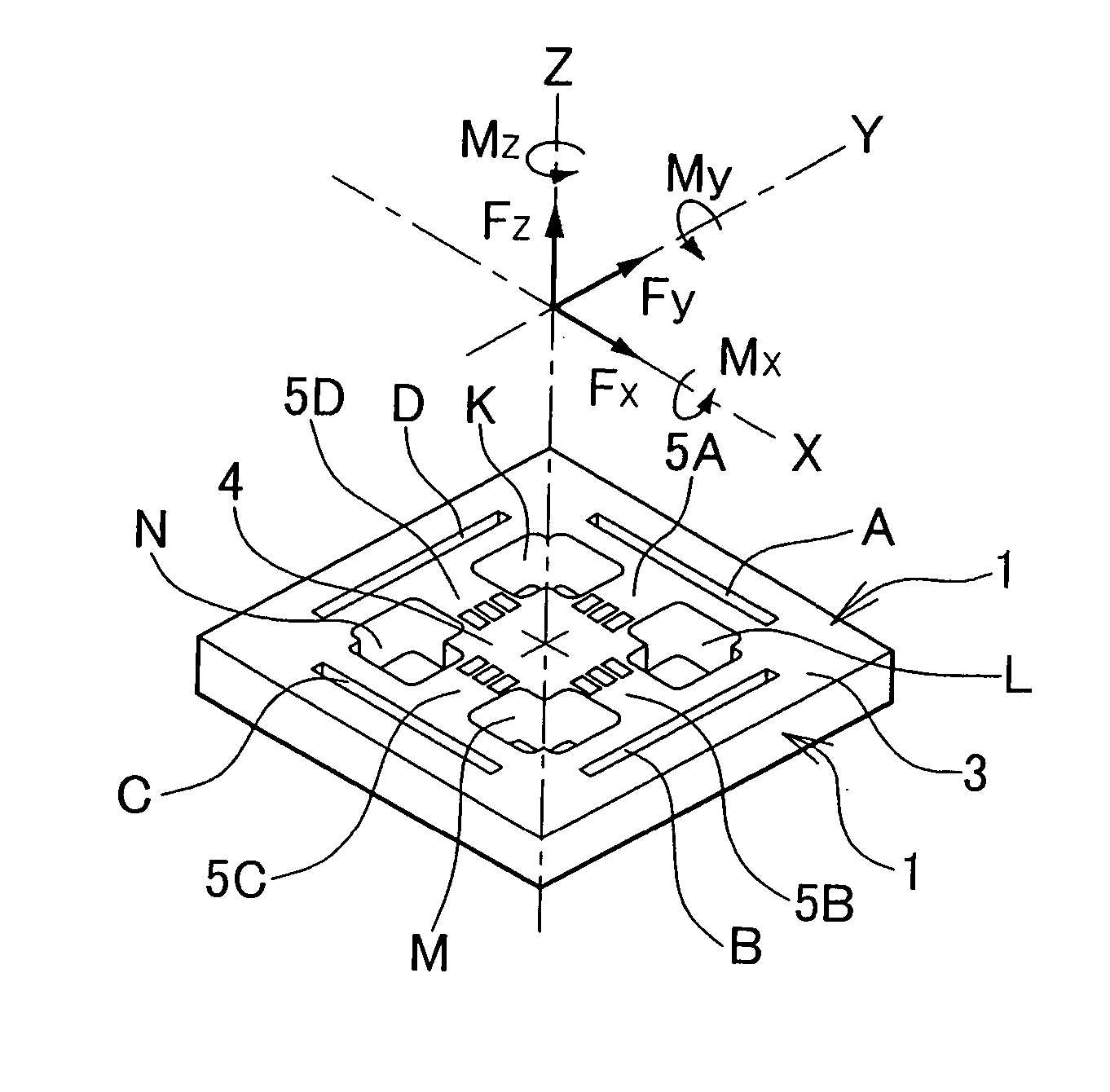

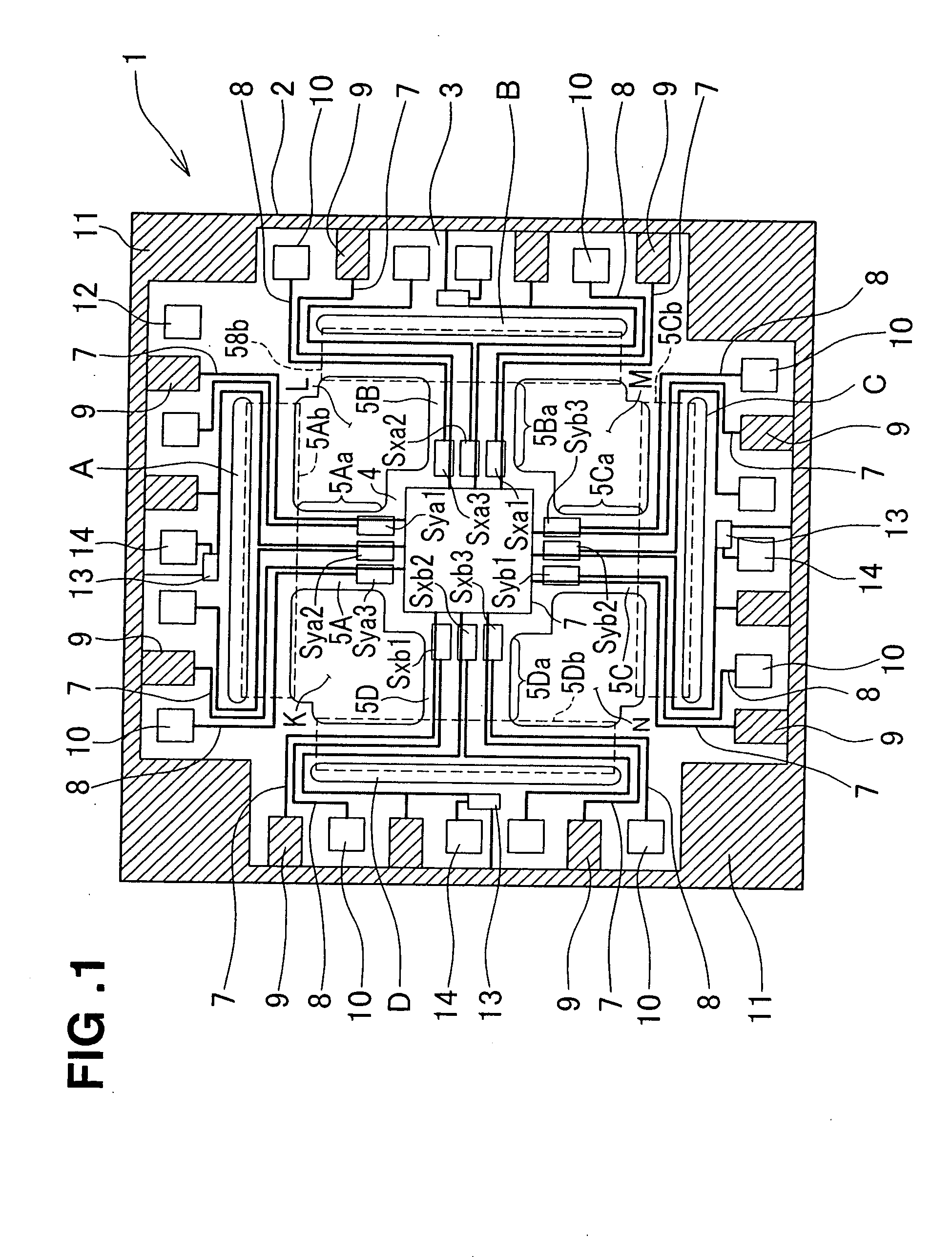

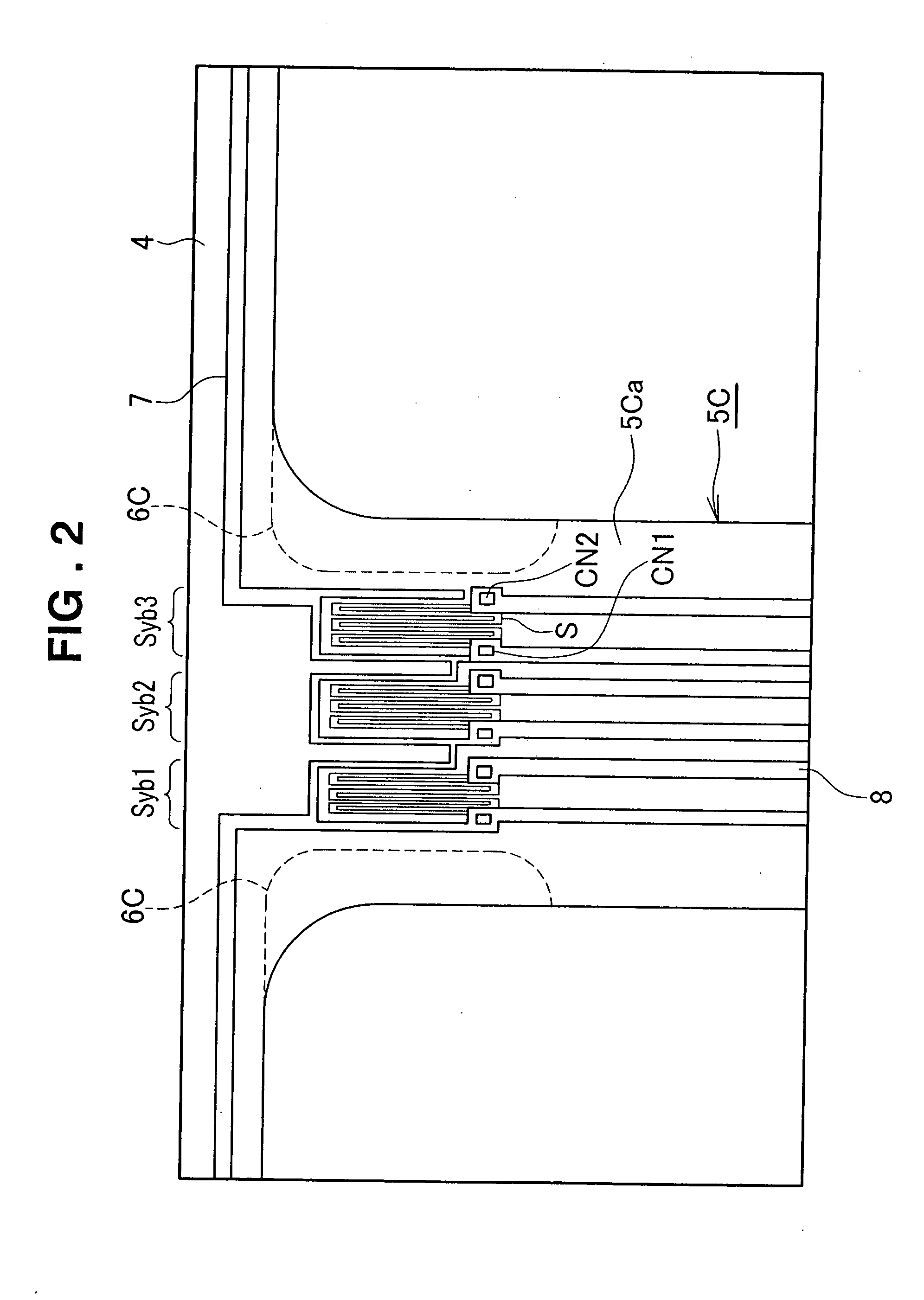

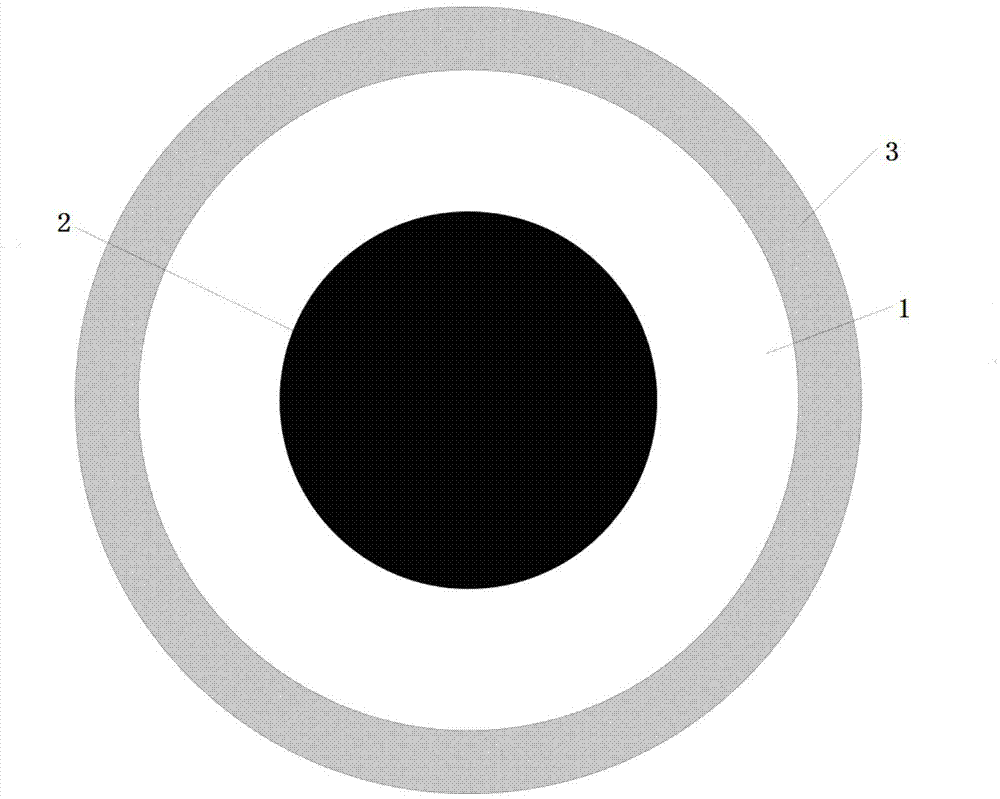

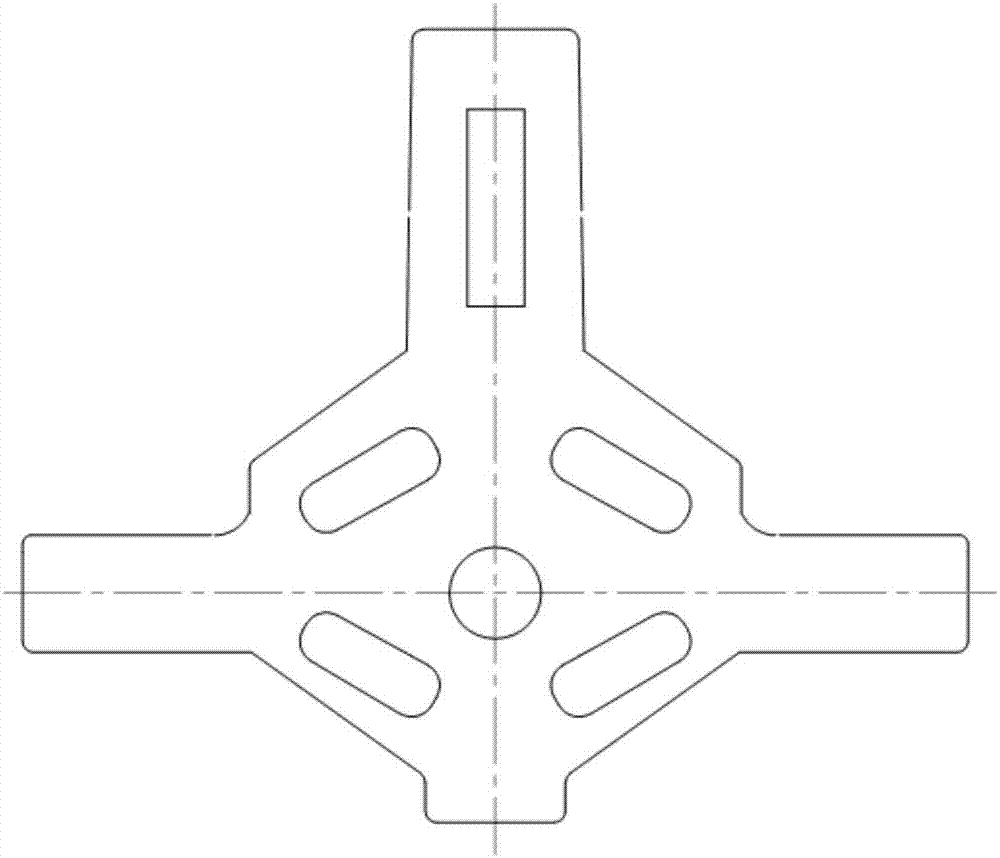

Six-axis force sensor chip and six-axis force sensor using the same

InactiveUS6951142B2Suppress mutual interferenceImprove accuracyForce measurementTension measurementEngineeringActive layer

Owner:HONDA MOTOR CO LTD

Six-axis force sensor chip and six-axis force sensor using the same

InactiveUS20050081645A1Suppress mutual interferenceImprove accuracyForce measurementTension measurementEngineeringActive layer

A thin plate-shaped six-axis force sensor chip comprising a semiconductor substrate formed by semiconductor film-forming processes, the sensor chip having through-holes formed therein and arranged so that the sensor chip is functionally divided by the through-holes into an action part to which an external force is applied, a support part to be fixed to an external structure, and a plurality of connecting parts each connecting together the action part and the support part and having a bridge portion of generally T-shaped configuration joined to the action part and an elastic portion joined to the support part. Each of the connecting parts has a plurality of strain resistance devices each comprising an active layer formed on at least one of front and rear faces thereof in an area thereof where deformation strain effectively occurs, the strain resistance devices being electrically connected to corresponding electrodes disposed in the support part.

Owner:HONDA MOTOR CO LTD

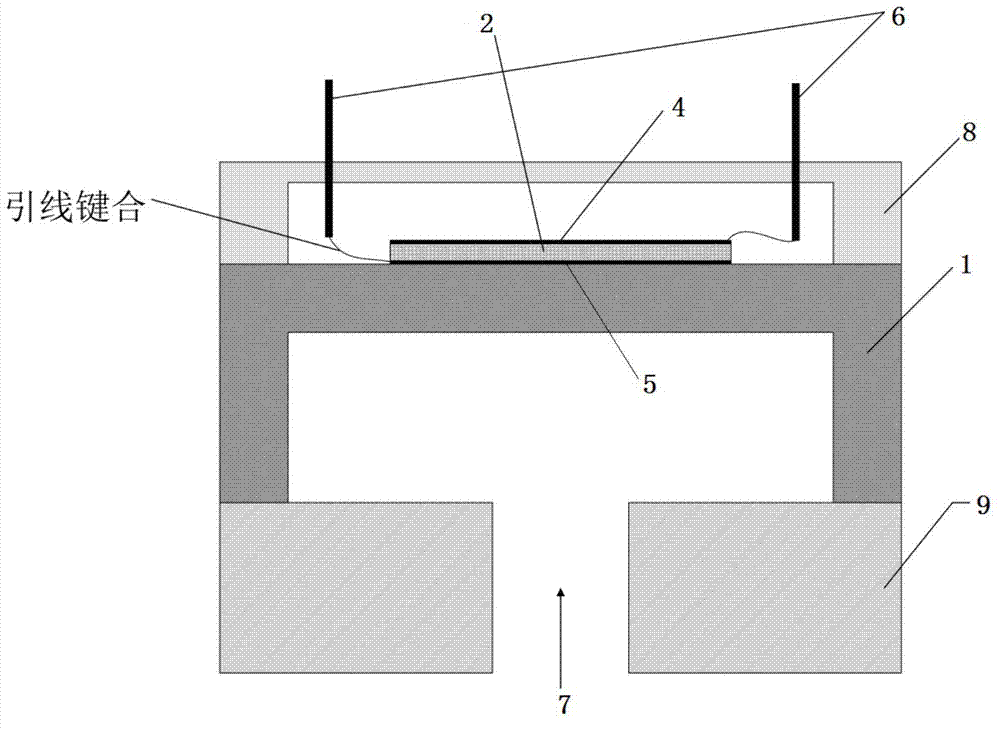

High-precision deflection electric type pressure sensor based on metal elastic element

InactiveCN103616098AWide selectionOvercome some deficiencies of strain measurement pressureForce measurement using piezo-electric devicesElectricityMetal electrodes

The invention discloses a high-precision deflection electric type pressure sensor based on a metal elastic element. The sensor comprises the metal elastic element for measuring mechanical vibration generated by micro pressure, a deflection electric dielectric film is pasted on the top of the metal elastic element, an insulation layer is arranged on the periphery of the metal elastic element, an upper metal electrode and a lower metal electrode are arranged on the upper surface and the lower surface of the deflection electric dielectric film respectively, the upper metal electrode and the lower metal electrode of the deflection electric dielectric film are connected with two output wires for measuring charge signals respectively, a pressure channel which is used for exerting pressure is formed below the metal elastic element, the deflection electric dielectric film, the upper metal electrode and the lower metal electrode are all arranged in an outer shell, and one end of each of two wires is led out from the outer shell. According to the sensor, the pressure on the film is measured through the linear relation between the exertion pressure and the mechanical deformation strain gradient of the metal elastic element, and the pressure measuring can be accurately and easily achieved.

Owner:XI AN JIAOTONG UNIV

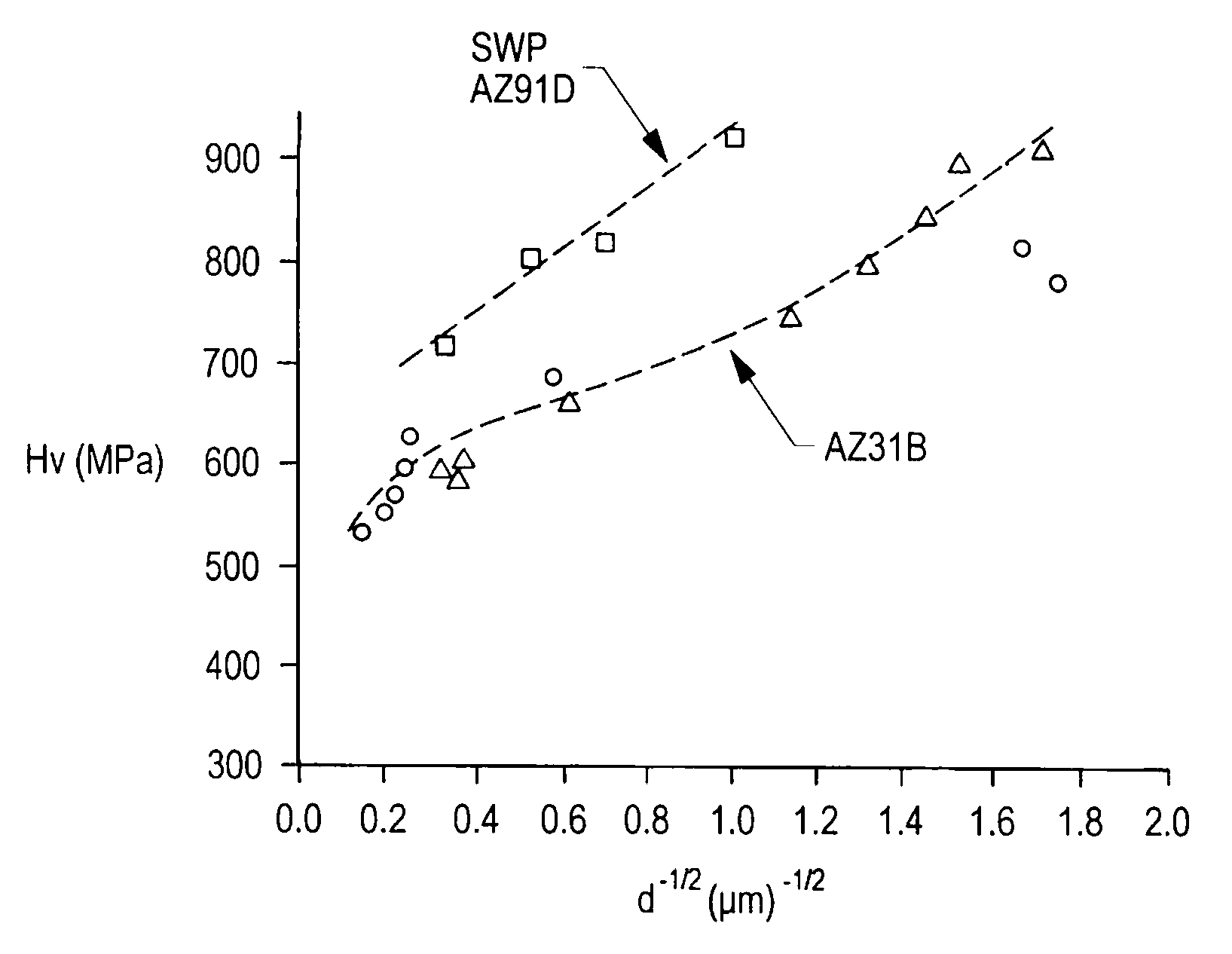

Apparatus and method of producing a fine grained metal sheet for forming net-shape components

InactiveUS20080000557A1Reduce assemblyLow costMelt-holding vesselsFurnace typesMetal alloyUltra fine

A method and apparatus for producing ultra-fine grained magnesium metal alloy material sheets. The apparatus molds and rapidly solidifies a metal alloy material to form a fine grain precursor. The precursor is then subjected to deformation strains that alter the grain structure of the precursor so as to form a ultra fine grained structure in sheet form. The sheet form may then be subjected to superplastic forming to form a net shaped article.

Owner:THIXOMAT

An optical fiber sensing system temperature compensating method

The invention provides an optical fiber sensing system temperature compensating method comprising the following steps: 1, temperature calibrating is carried out on an optical sensor to obtain a temperature sensitivity coefficient K[T1]; 2, temperature calibrating is carried out the optical sensor attached in an adhesive mode to the surface of a test piece, of which the materials is same with a to-be-measured piece so as to obtain a material uniform thermal expansion coefficient K[T2]; 3, strain calibrating is carried out on the optical sensor to obtain a strain sensitivity coefficient K [Epsilon]; and 4, in strain and deformation measurement carried out on the to-be-measured piece, strain applied to the to-be-measured piece is measured by an optical fiber strain sensor, and an optical fiber temperature sensor is used to make temperature compensating for the strain sensor; and influences by uniform thermal expansion are rejected to obtain effective deformation strain data. The invention is mainly used for occasions such as strain and deformation caused by fore bearing and non-uniform thermal expansion in optical fiber sensing network measurement, and difficulties in measuring by the optical fiber sensor with regard to deformation and uniform thermal expansion of the measured piece and strain and temperature cross sensitivity are overcome.

Owner:山东双测安全信息技术产业研究院有限公司

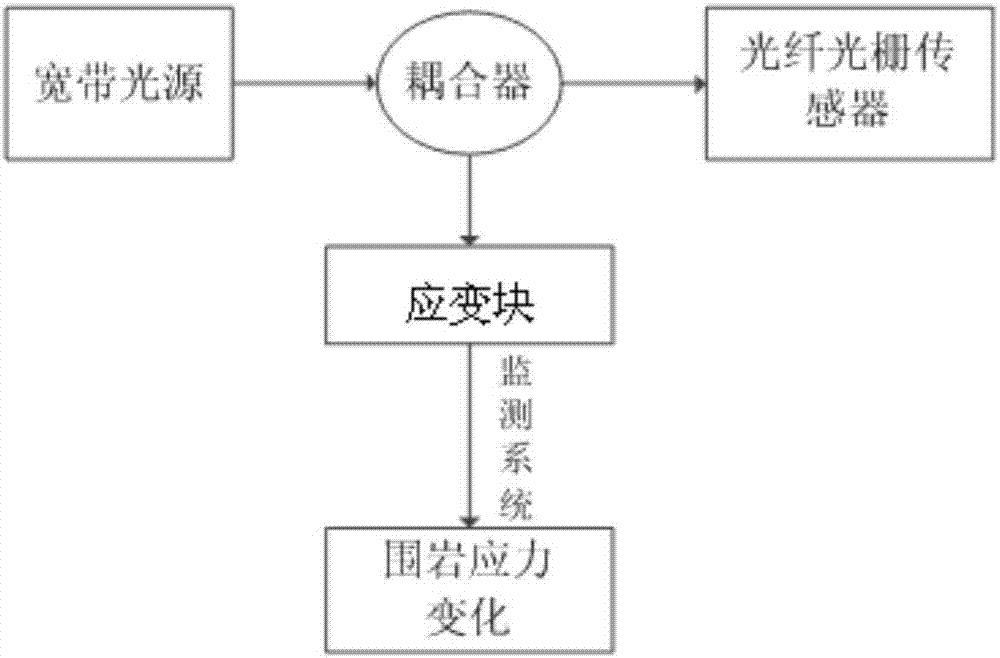

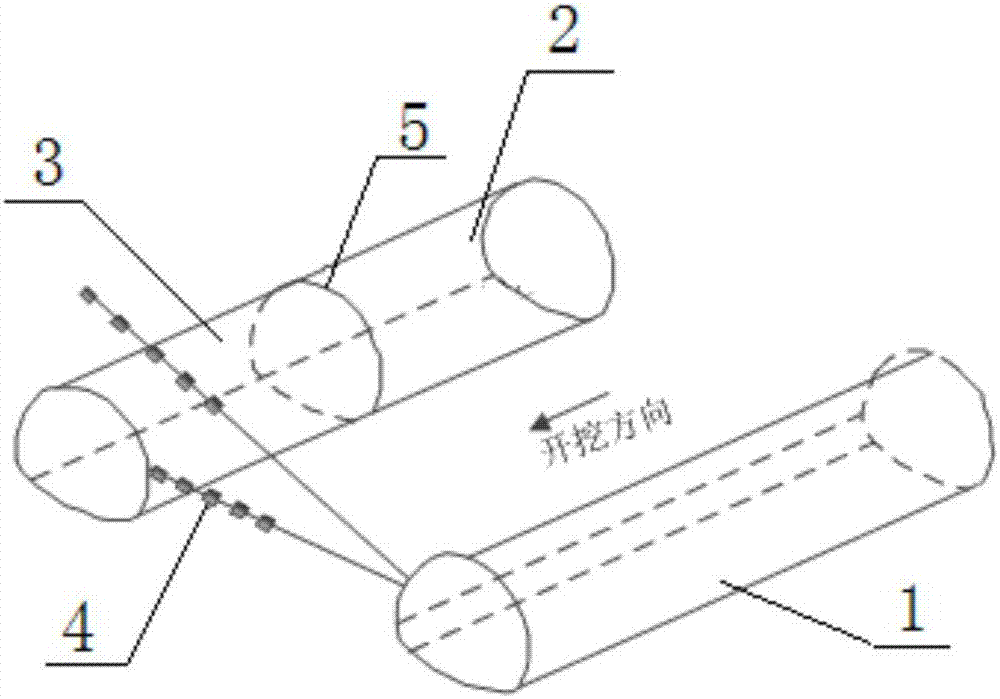

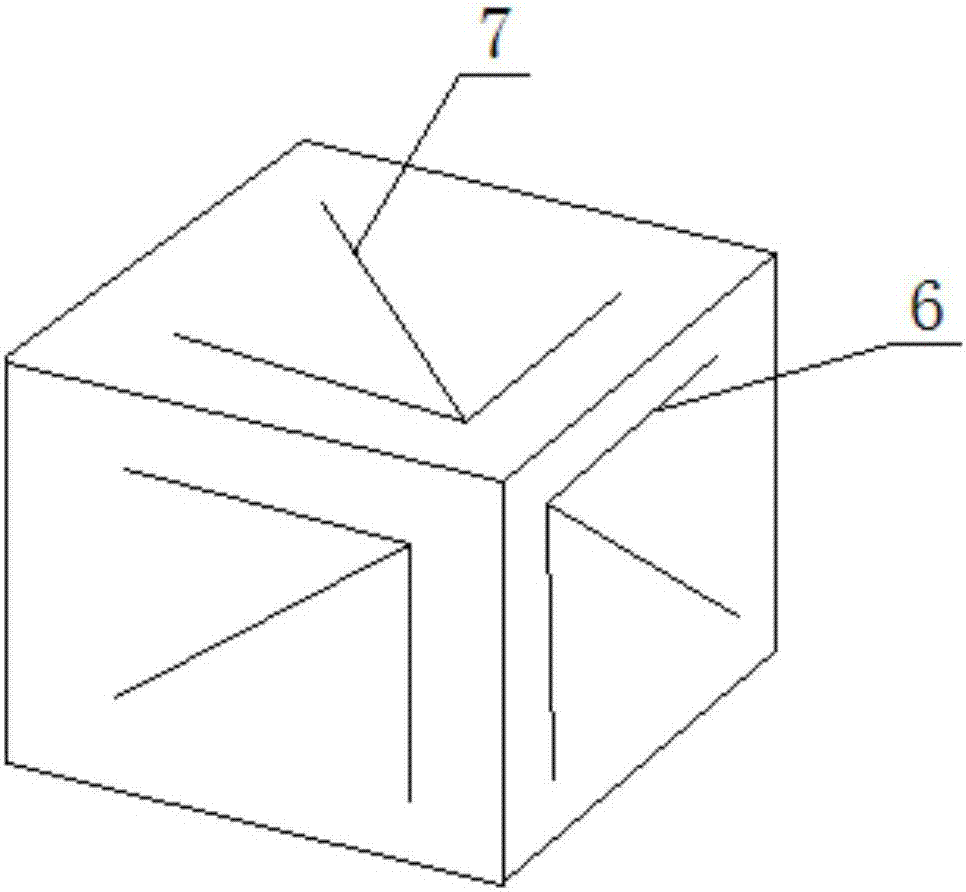

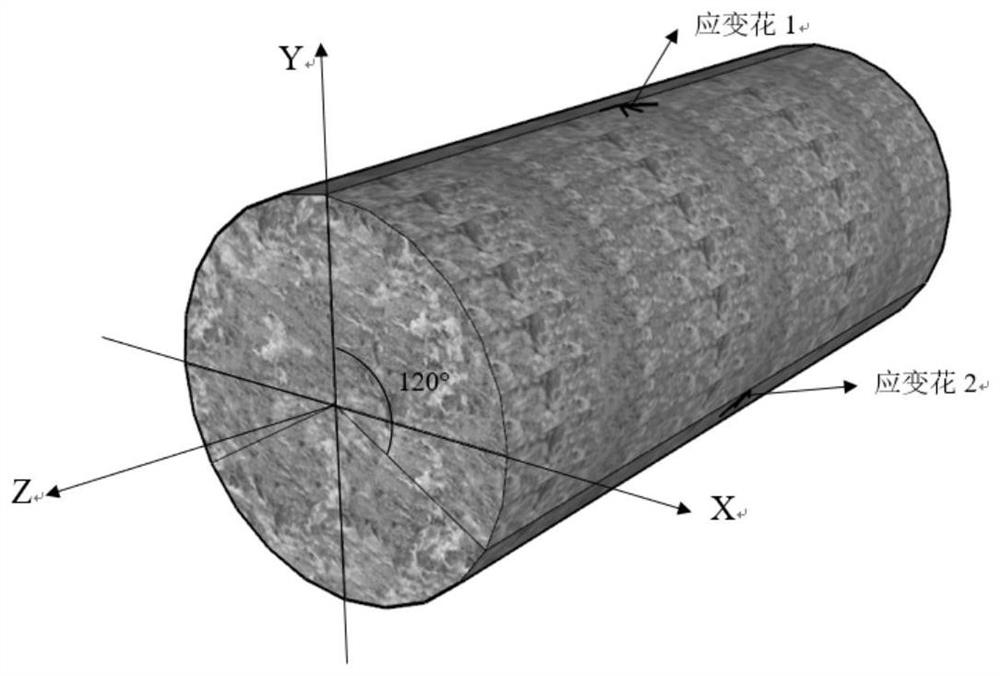

Dynamic test method for surrounding rock disturbed stress field during tunnel construction process

InactiveCN107144380AReduce construction costsClarify the law of changeForce measurement by measuring optical property variationStrain sensorElastic modulus

The invention relates to a dynamic test method for the surrounding rock disturbed stress field during the tunnel construction process. The method includes the following steps of constructing an anteriorly arranged excavation body adjacent to a to-be-monitored tunnel, wherein the anteriorly arranged excavation body is provided with at least one monitoring space and the monitoring space is located in front of the excavating surface of the to-be-monitored tunnel; in the anteriorly arranged excavation body, arranging at least one monitoring drilling hole in front of the excavating surface of the to-be-monitored tunnel, wherein the monitoring drilling hole is substantially parallel to the excavating surface of the to-be-monitored tunnel; arranging a strain block at a measuring point inside the monitoring drilling hole, wherein the strain block is provided with a plurality of strain sensors for monitoring the three-dimensional strained condition of the measuring point; grouting into the drilling hole to drive the strain block to closely cling to the surrounding rock; during the tunnel excavation process, generating the disturbance deformation by the surrounding rock, transmitting displacement data signals monitored by the strain sensors to a monitor, and converting the displacement data into stress data by the monitor according to the elasticity modulus and the poisson 's ratio of the strain block. In this way, the three-dimensional strained condition of the measuring point can be obtained.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

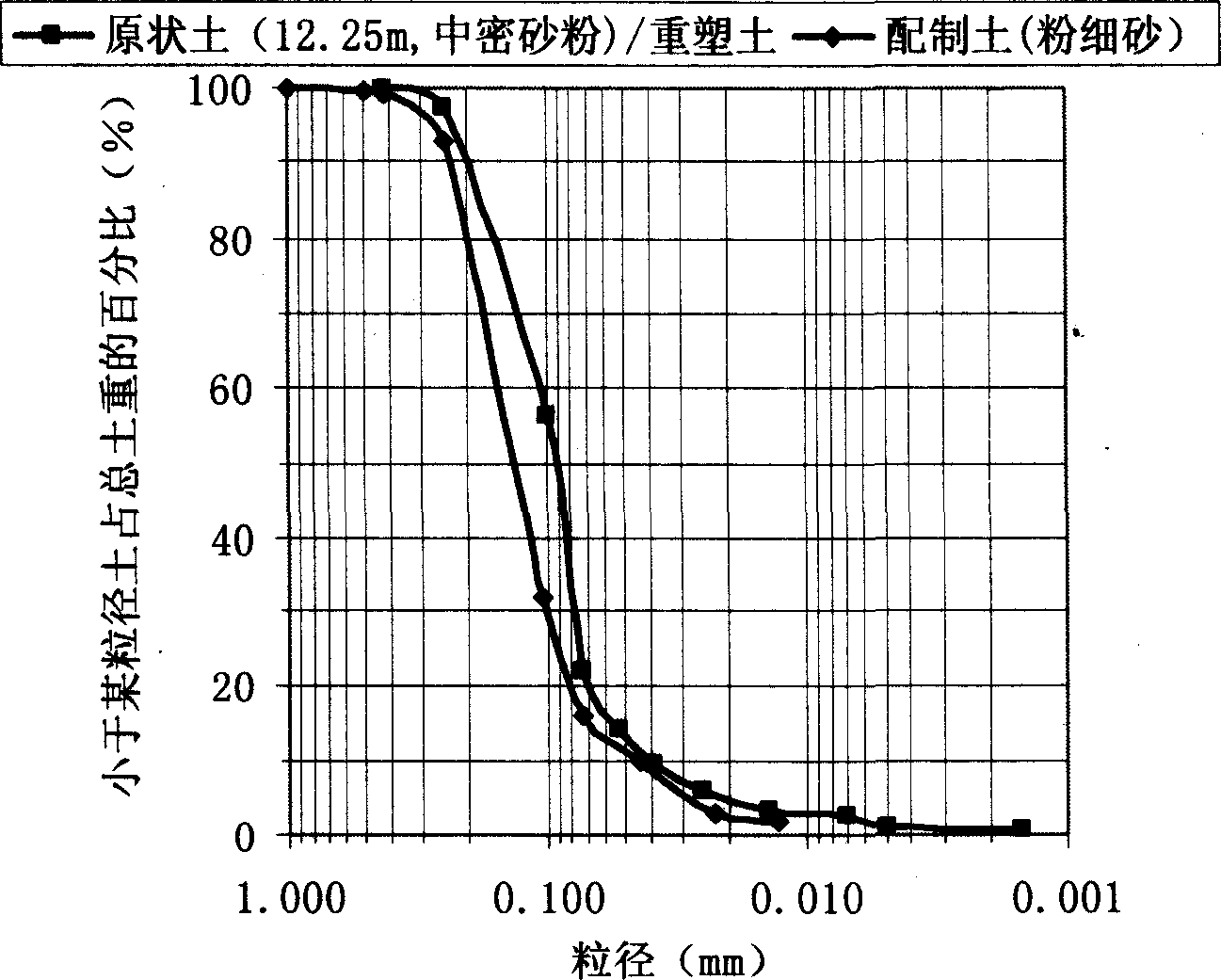

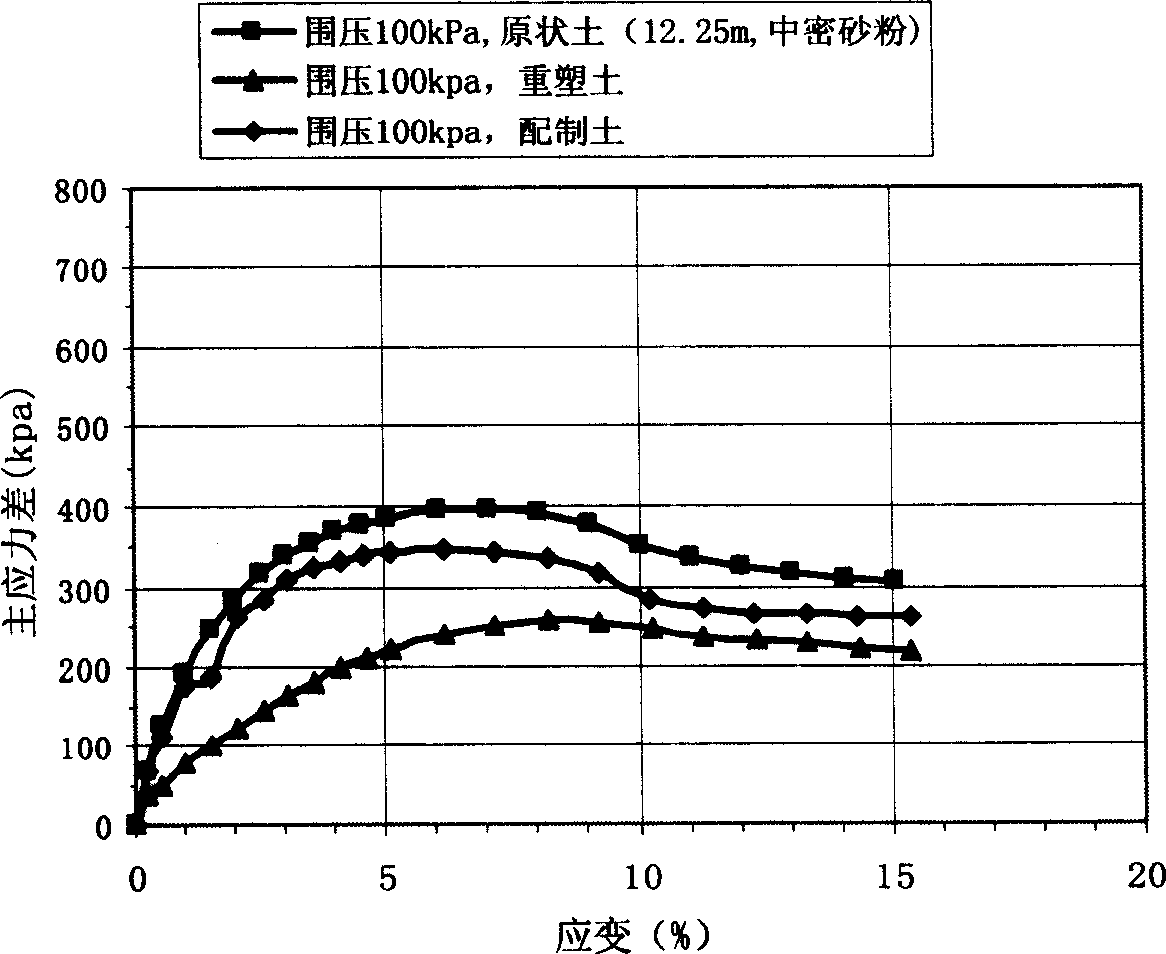

Method for preparing soil for analogue test

InactiveCN1851443AMeet the needs of practical engineering designSave research moneyPreparing sample for investigationEarth material testingPermeability coefficientMechanical property

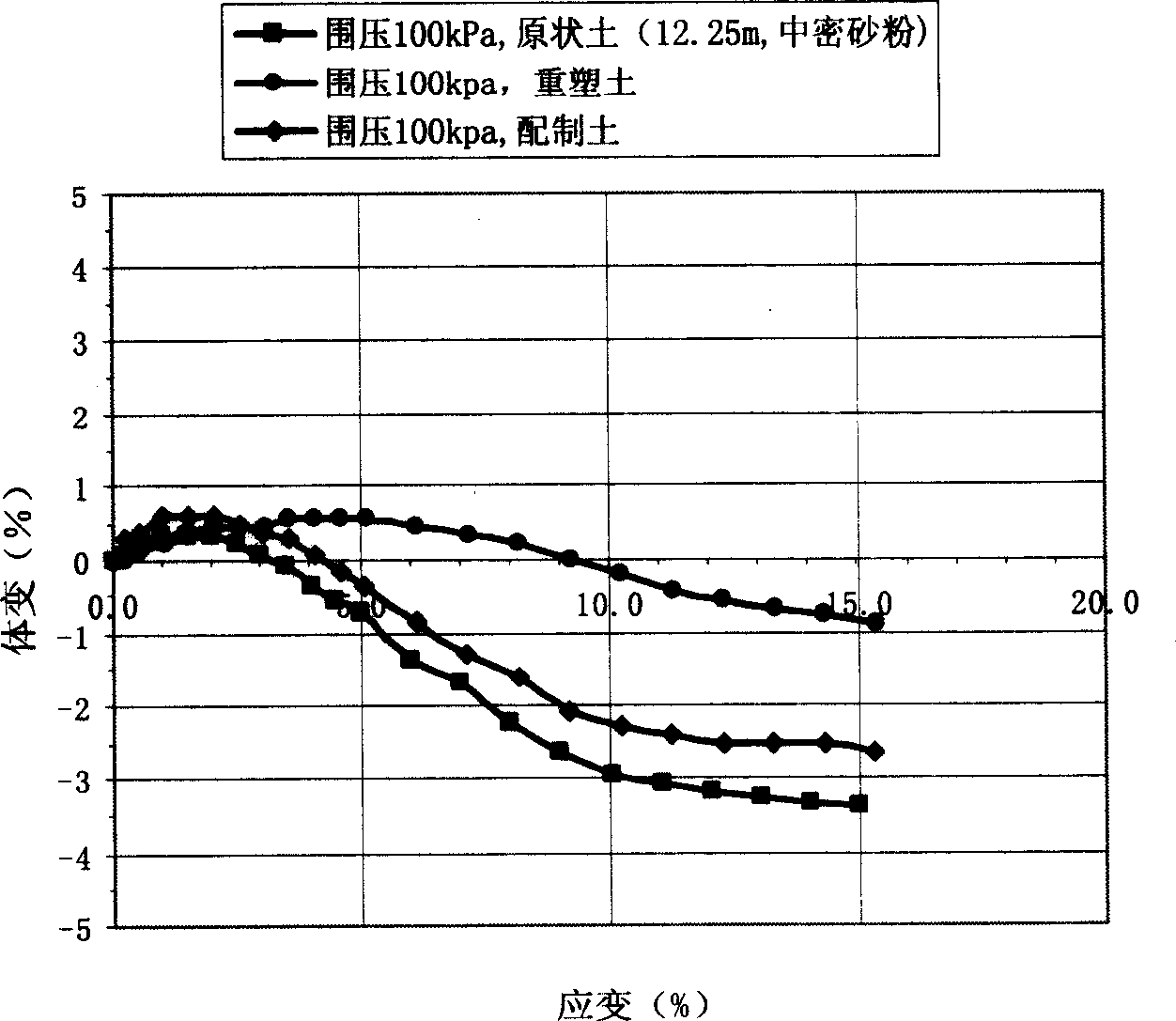

The invention discloses a manufacture method for analysis earth that includes the following steps: taking physical characteristic analysis to parent soil and the matter properties experiment of particle, proportion, density, unit weight and permeability coefficient; gaining the particle class curve, density, penetrating parameter from the experiments; fetching sample earth to make it close to the particle class curve; taking mechanical property and analysis of triaxiality compression shear; when the sample earth has the corresponding stress-strain, deformation-strain and penetrating parameter, taking large quantity matching according to the sample earth. The invention has close statics feature as undisturbed sand that could sharply save research outlay and shorten research process.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

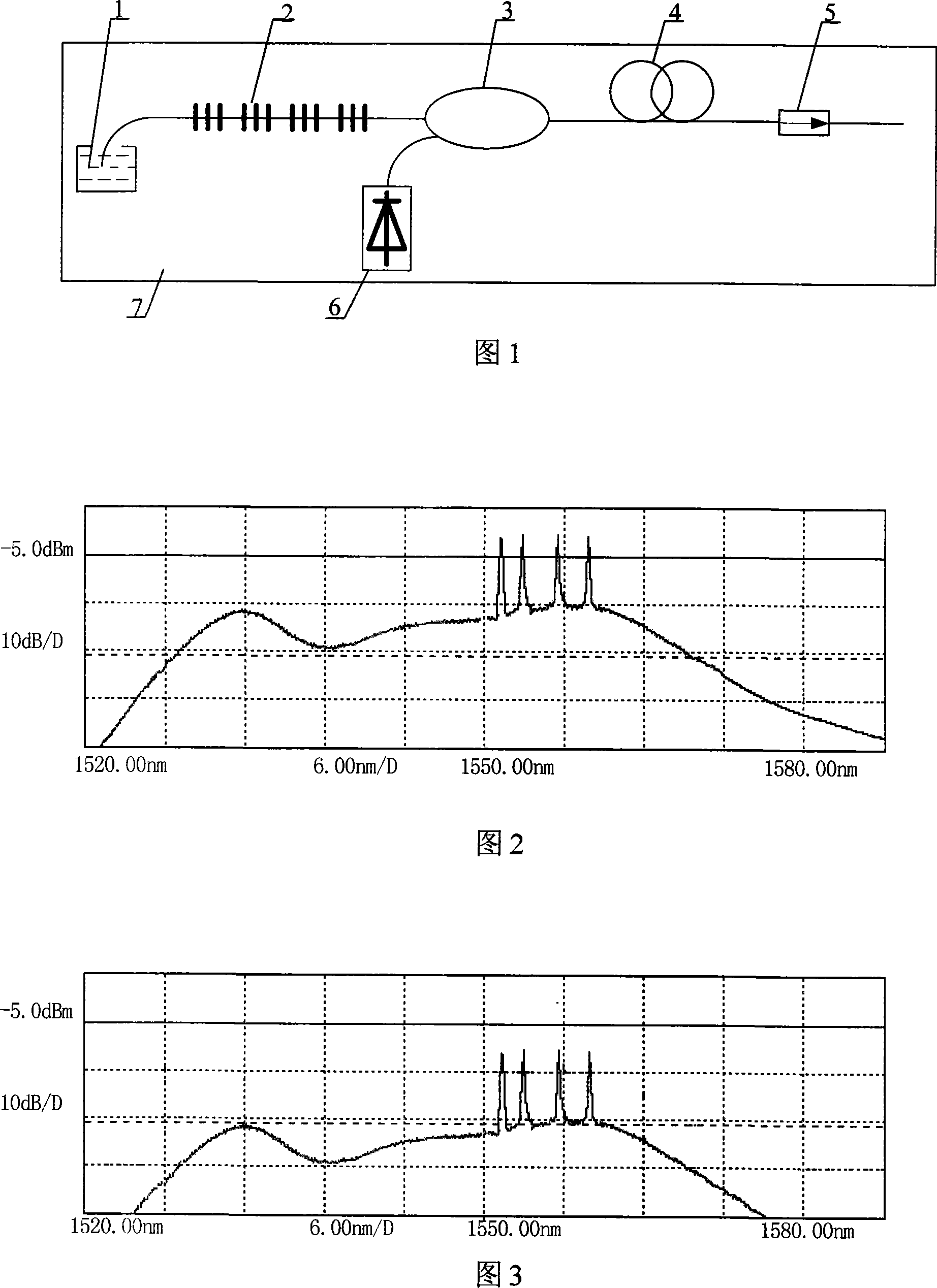

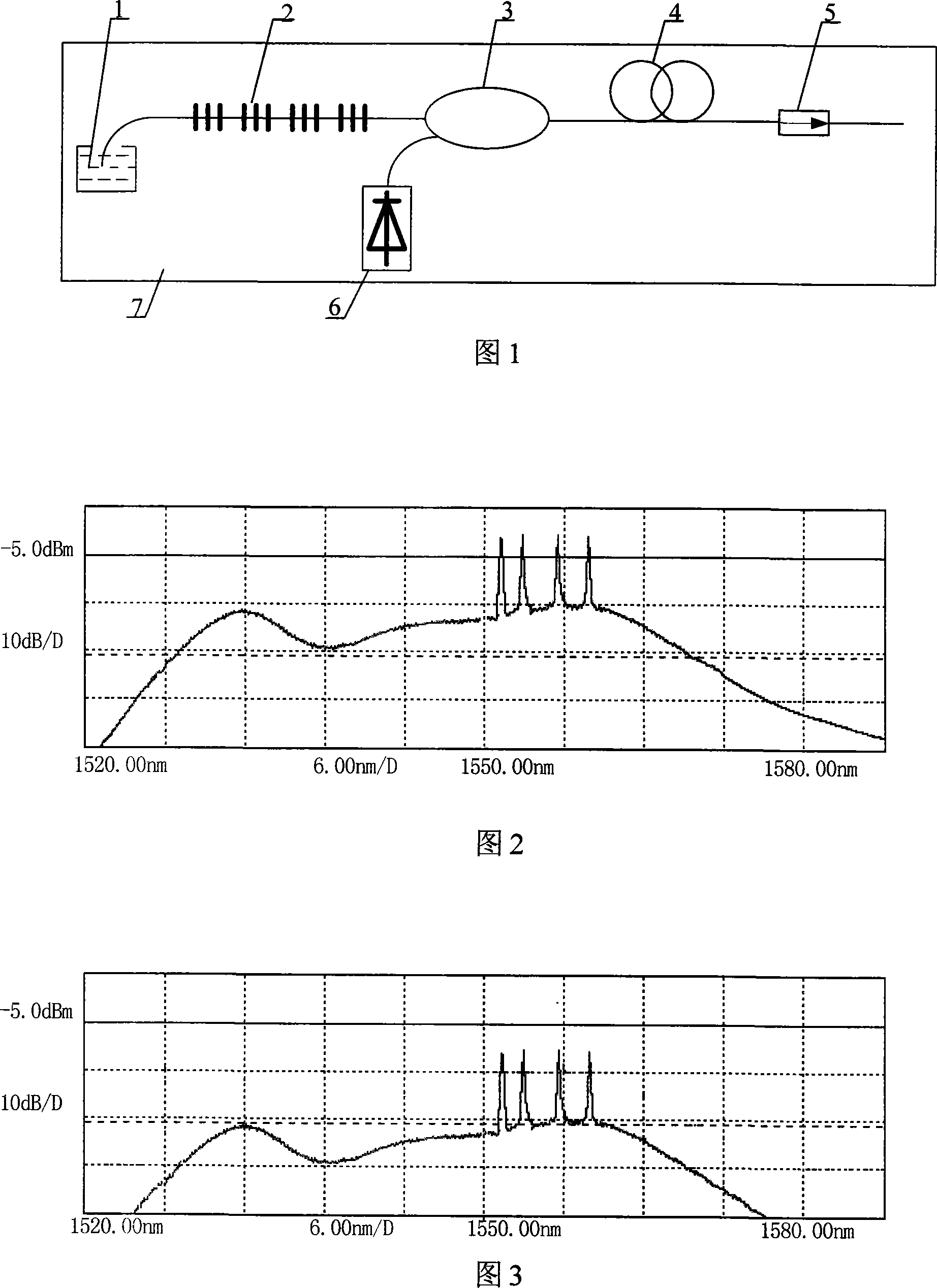

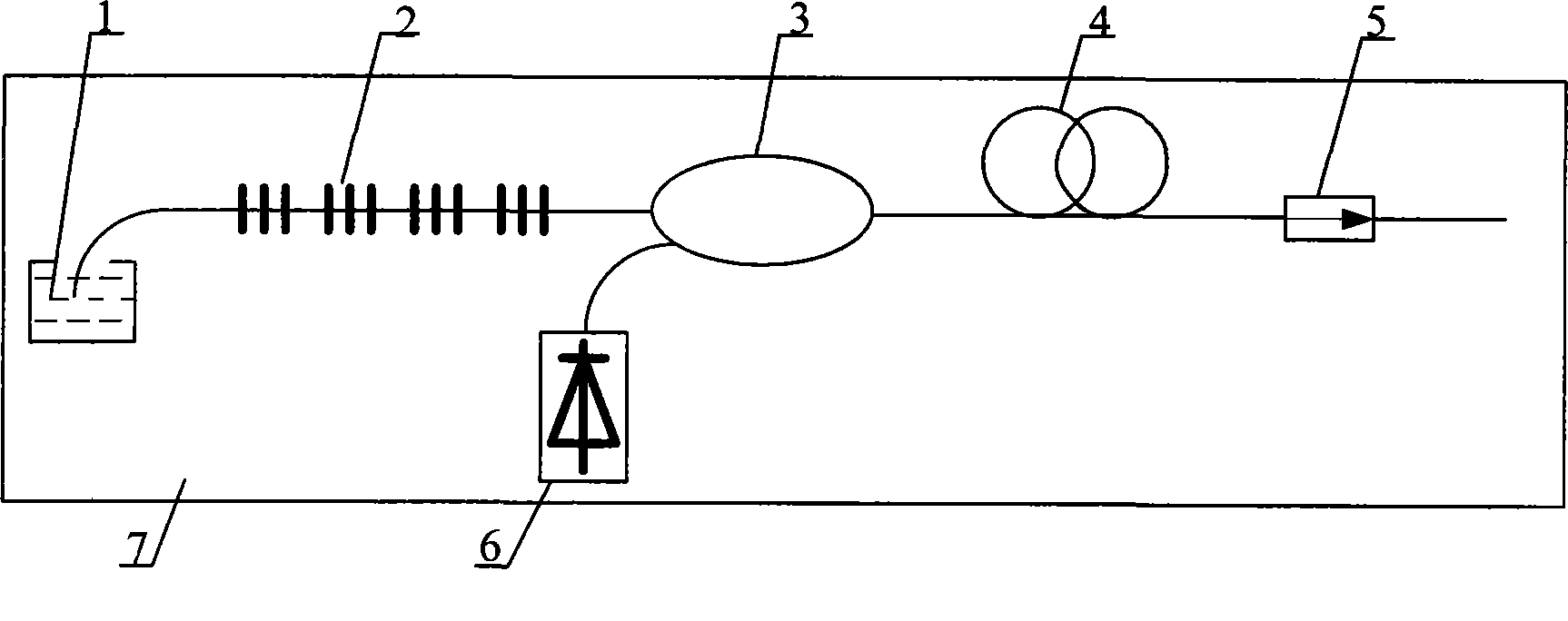

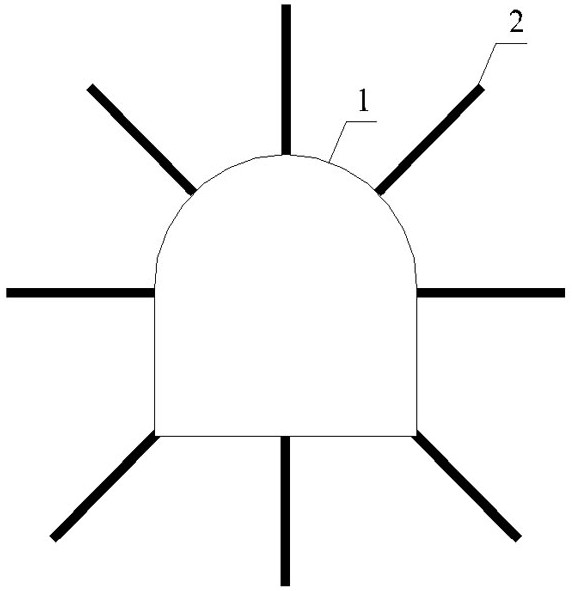

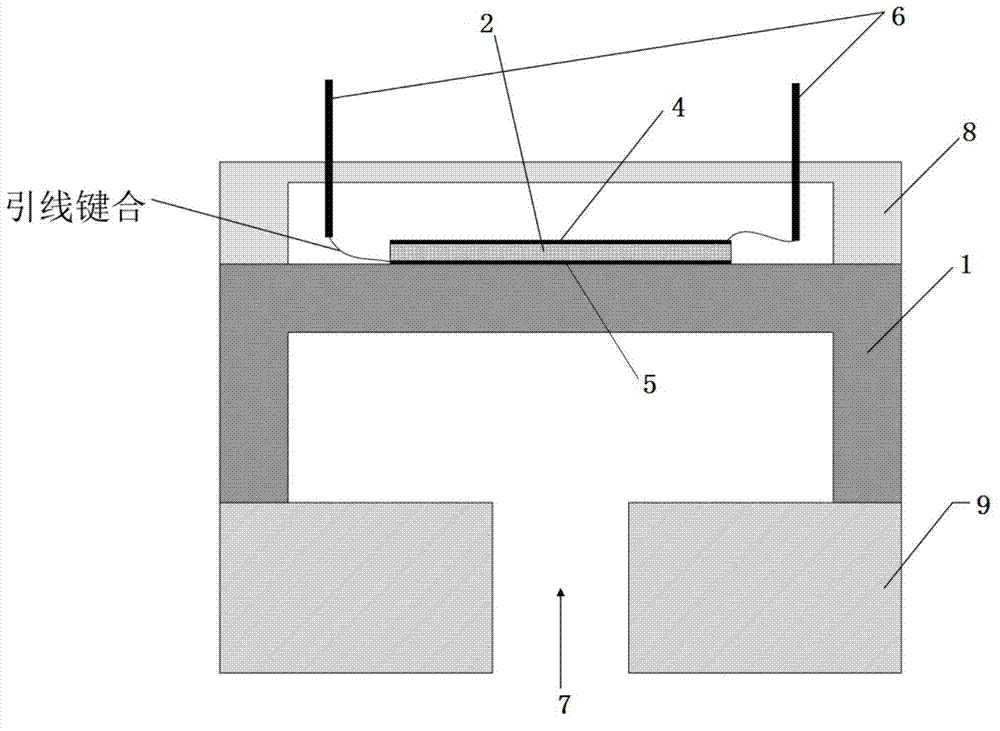

Long distance optical fiber grating sensing and transmitting device

InactiveCN101216326AHigh-resolutionHigh measurement accuracyCoupling light guidesConverting sensor output opticallySensor arrayFiber

The invention relates to a long-distance optical fiber grating sensing transducer. An optical fiber end surface matching fluid container, an optical fiber sensor array, a wavelength division multiplexer, an erbium-doped fiber, an optical isolator are sequentially disposed in the upper part of a mounting plate from left to right, an optical fiber end surface matching fluid is filled in the optical fiber end surface matching fluid container, one end of the optical fiber sensor array is disposed inside the optical fiber end surface matching fluid, the other end of the optical fiber sensor array is connected with one input end of the wavelength division multiplexer via an optical fiber, a pumping laser is disposed in the lower part of the mounting plate, the output end of the pumping laser is connected with the other input end of the wavelength division multiplexer via an optical fiber, the output end of the wavelength division multiplexer is connected with one end of the erbium-doped fiber, and the other end of the erbium-doped fiber is connected with one end of the optical isolator with an optical fiber. The invention has the advantages of high signal-to-noise ratio, wide detection range, high resolution and measurement accuracy, long transmission distance, good reliability, and low production cost; and can be used for long-distance detection of temperature, pressure, pipeline deformation strain in oil and gas pipelines.

Owner:XI'AN PETROLEUM UNIVERSITY

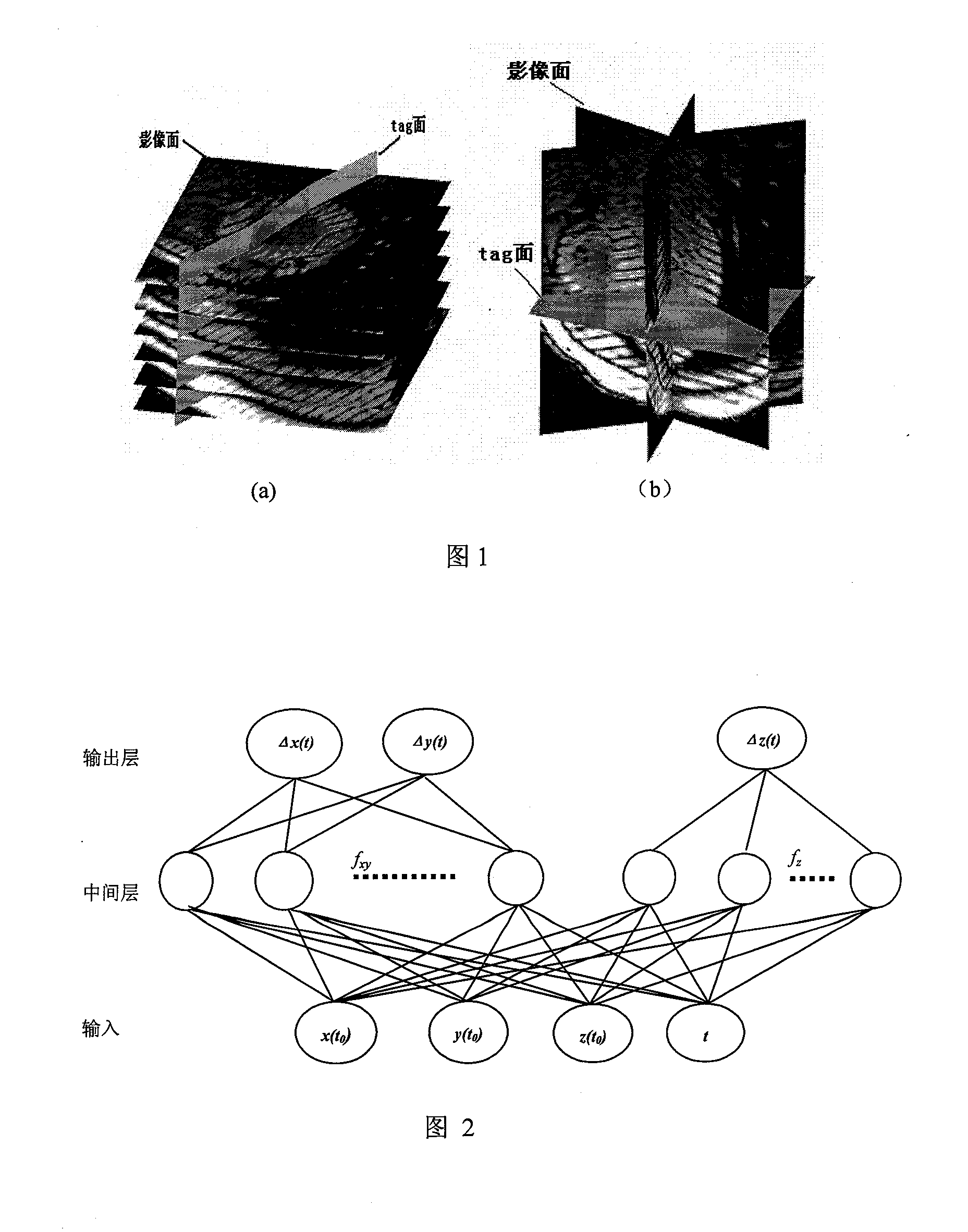

Three-dimension cardiac muscle straining computing method

InactiveCN101224110ACalculation speedImage analysisDiagnostic recording/measuringSonificationIterative method

The invention discloses a three-dimensional myocardial deformation strain calculation method. The invention divides the myocardium into a plurality of local (sub) regions according to the time and space coordinates on the basis of completing the segmentation processing of the marked cardiac magnetic resonance image sequence, a feed forward neural network (BPNN) and a polynomial or support vector machine (SVM) are used for fitting a local displacement field, the calculation of the established local continuous displacement field is done by the Newton iterative method, the motion parameters of the myocardial particle are calculated and the non-linear interpolation technology is used for calculating the myocardial strain parameters. The invention has clear physical significance and simple and effective algorithm, a model is applicable to parallel calculation, which can calculate the forward and backward motion of arbitrary myocardial particle; and the strain calculation results can be used as the judgment criteria of the three-dimensional cardiac ultrasound strain measurement results.

Owner:NANJING UNIV OF SCI & TECH

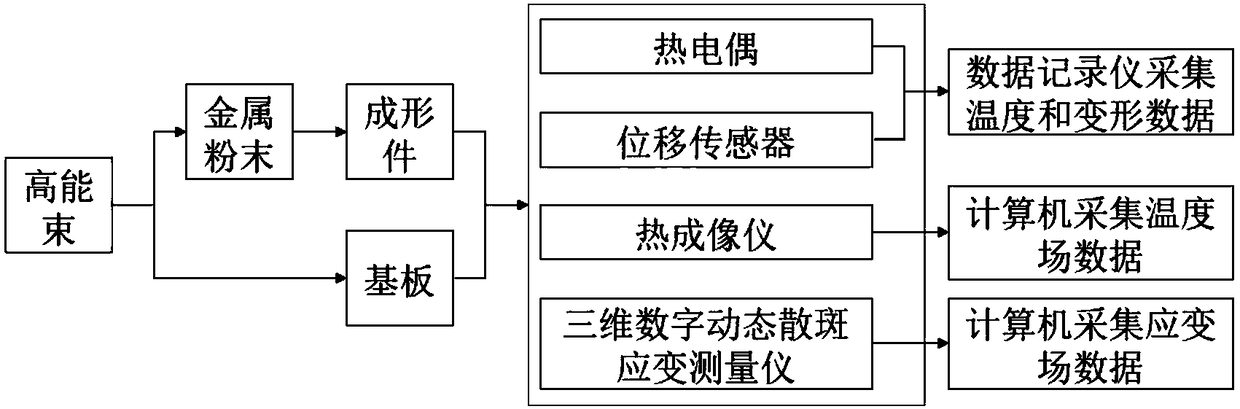

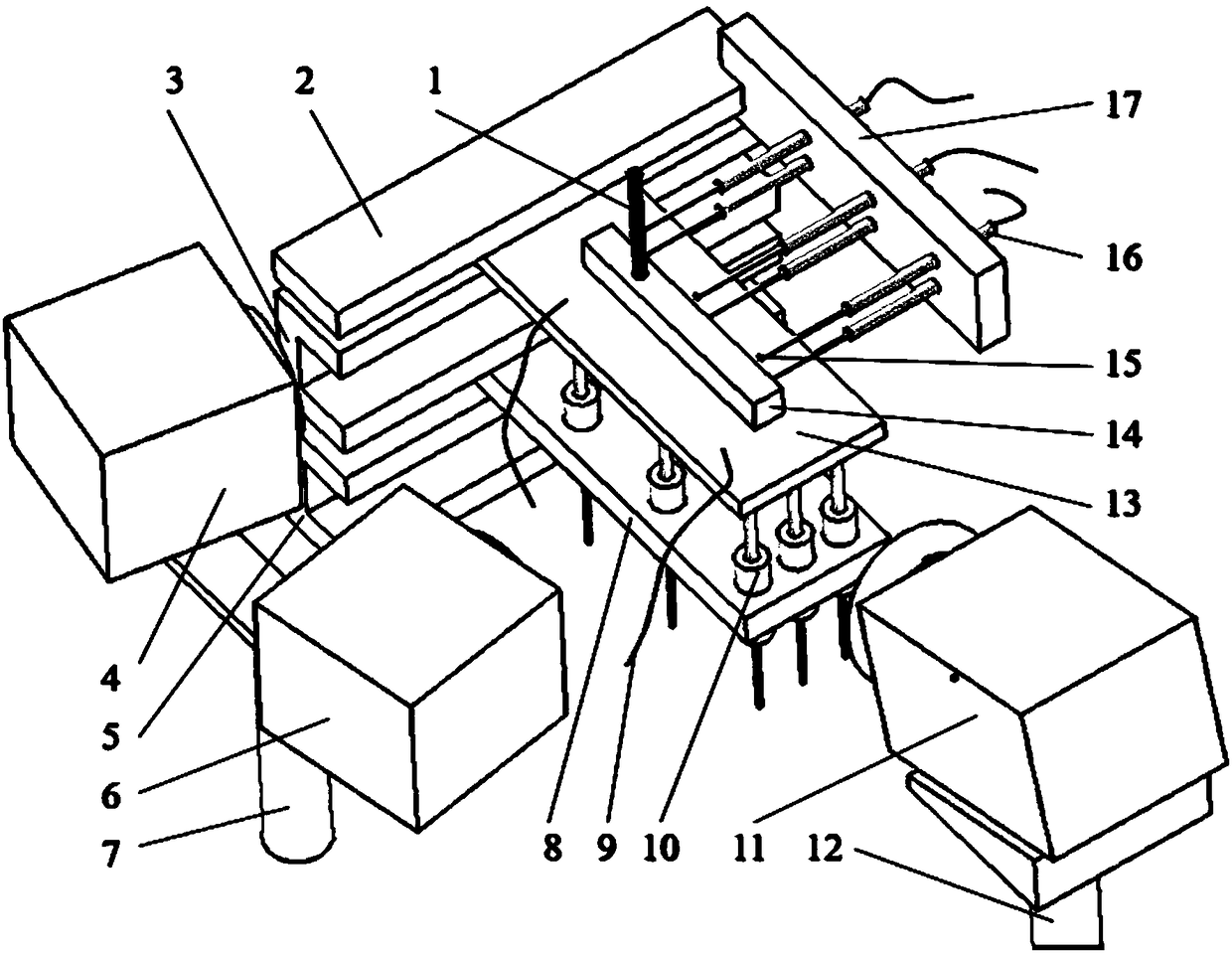

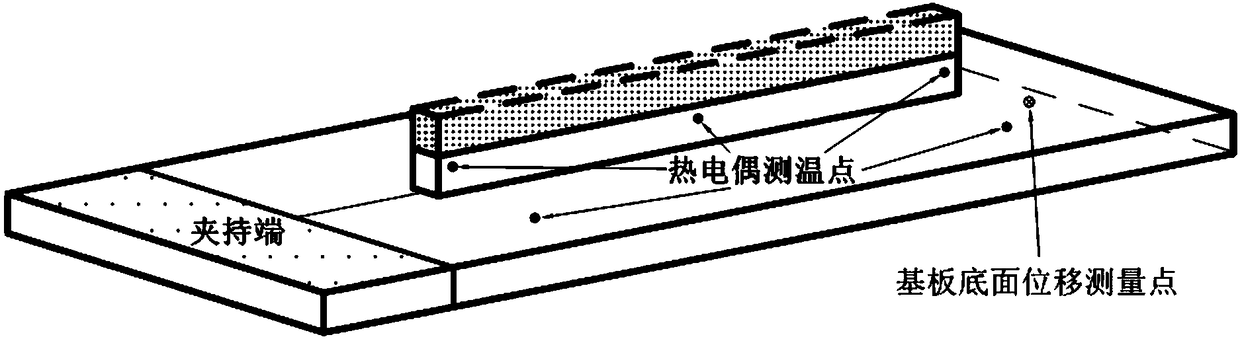

Checking method and checking data measurement apparatus of high-energy-beam additive-manufacturing finite-element thermal coupling model

ActiveCN108132075AReal-time synchronous temperature monitoringReal-time and synchronous monitoring of strain in the whole fieldMeasurement devicesSpecial data processing applicationsMeasurement deviceManufacturing technology

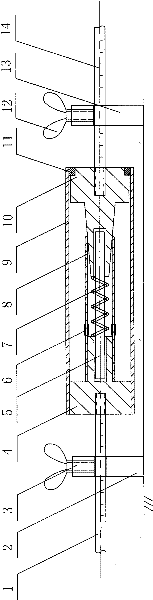

The invention shows a checking method and checking data measurement apparatus of a high-energy-beam additive-manufacturing finite-element thermal coupling model. The apparatus comprises a workbench, afixture system and a data acquisition system, wherein the fixture system and the data acquisition system are installed on the workbench. In addition, the checking method includes: step one, carryingout real-time experiment measurement on a fusion covering process and heat-deformation-strain during high-energy-beam additive-manufacturing processing; step two, establishing a model framework, inputting a material property, and dividing a grid, and completing calibration of a finite-element temperature field; and step three, setting a force field boundary condition and using a calibrated temperature field results as an initial condition, obtaining a substrate deformation and strain field results, completing calibration of a finite-element force field, and thus completing calibration of a high-energy-beam additive-manufacturing finite-element thermal coupling model. According to the invention, reliable experiment data are provided for simulation of the high-energy-beam additive manufacturing; the scientific guidance is provided for establishing a process method for controlling deformation of the substrate and finished elements effectively; and thus application of the additive-manufacturing technology is prompted.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

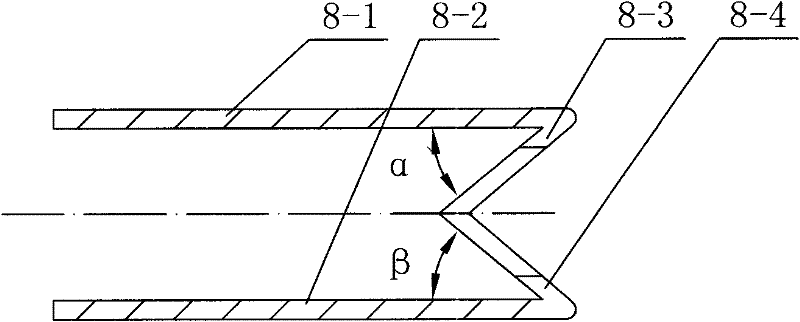

Double cantilever large deformation strain measurement sensor

InactiveCN102261889AHigh sensitivityImprove anti-interference abilityElectrical/magnetic solid deformation measurementFull bridgeEngineering

The invention relates to a two-cantilever large-deformation strain measurement sensor. A left end holder is provided with a left end connecting rod, a right end holder is provided with a right end connecting rod, the right end of the left end connecting rod is provided with a fixing body mounted at the left end in a sleeve, the left end of the right end connecting rod is provided with a wedge-shaped body mounted at the right end in the sleeve, the right end of the fixing body in the sleeve is provided with a spring leaf and a centering / spacing slide rod positioned in the spring leaf, the centering / spacing slide rod is externally provided with a compensating spring, the right end of the centering / spacing slide rod is arranged on the wedge-shaped body, the spring leaf is provided with even-numbered (at least four) resistance strain gages, and all the resistance strain gages form a full bridge which uses a lead wire for output. By using the W-shaped spring leaf, the invention greatly improves the sensitivity; and as both ends of the spring leaf are fixed, the two-cantilever large-deformation strain measurement sensor can still have high antijamming capability and stability even if the external loading force changes a lot. The two-cantilever large-deformation strain measurement sensor provided by the invention has the advantages of high sensitivity, easy calibration process, less linearity error, high antijamming capability, good stability and the like, and can be used as a large-deformation displacement sensor.

Owner:CHANGAN UNIV

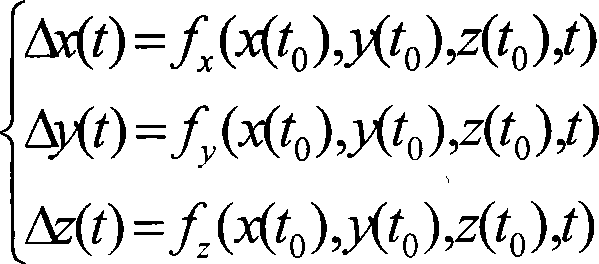

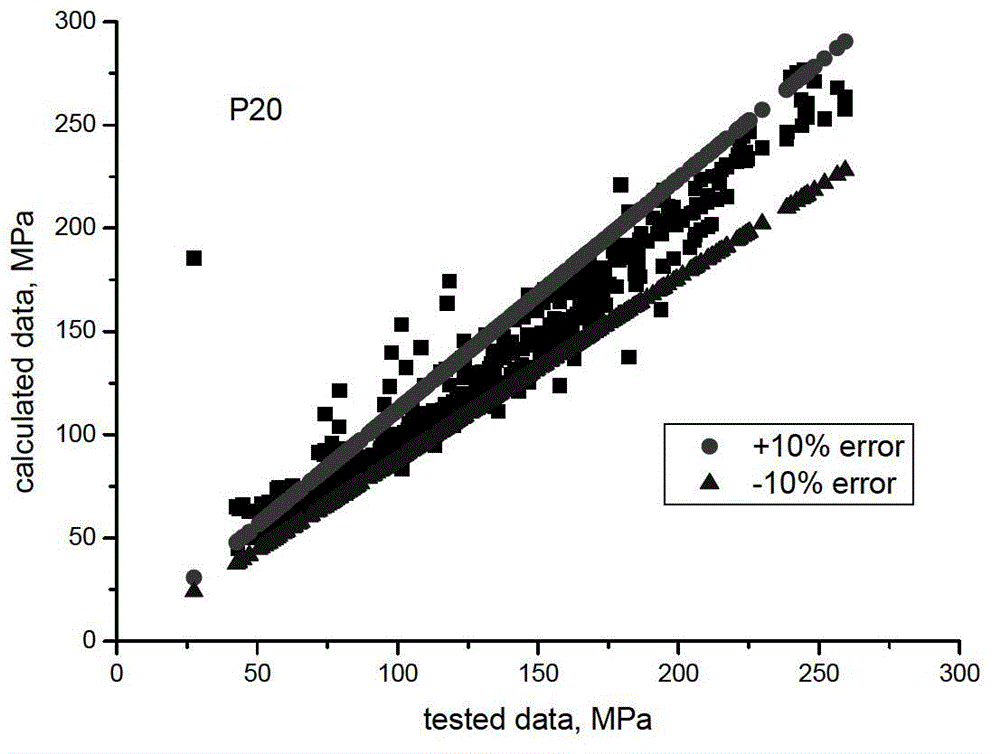

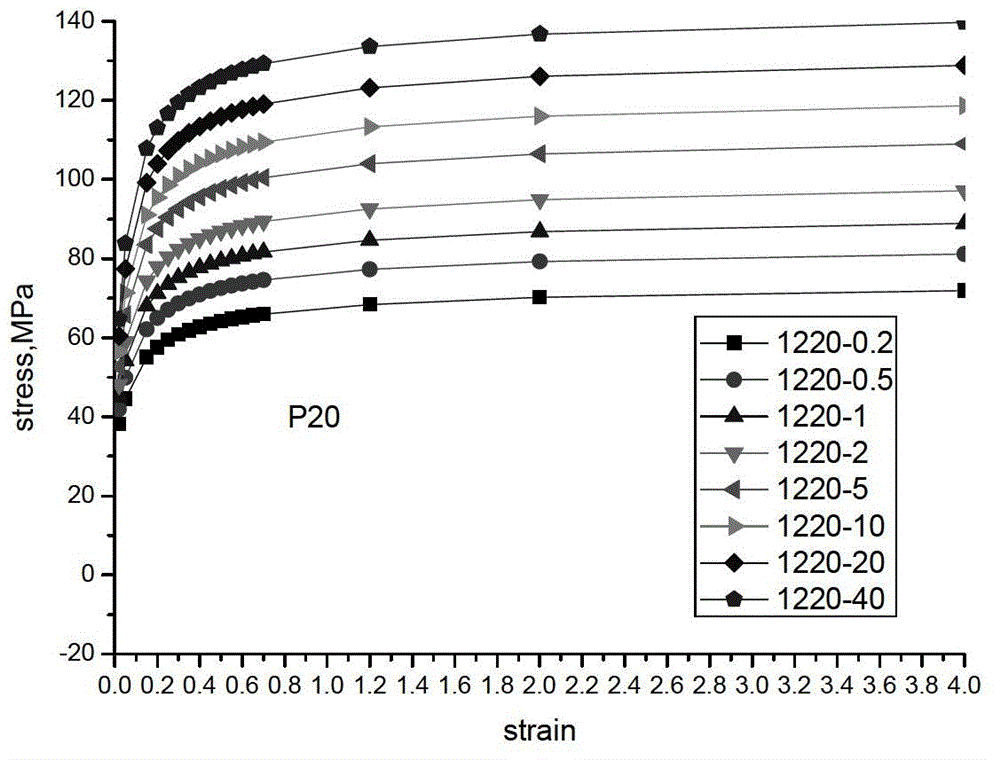

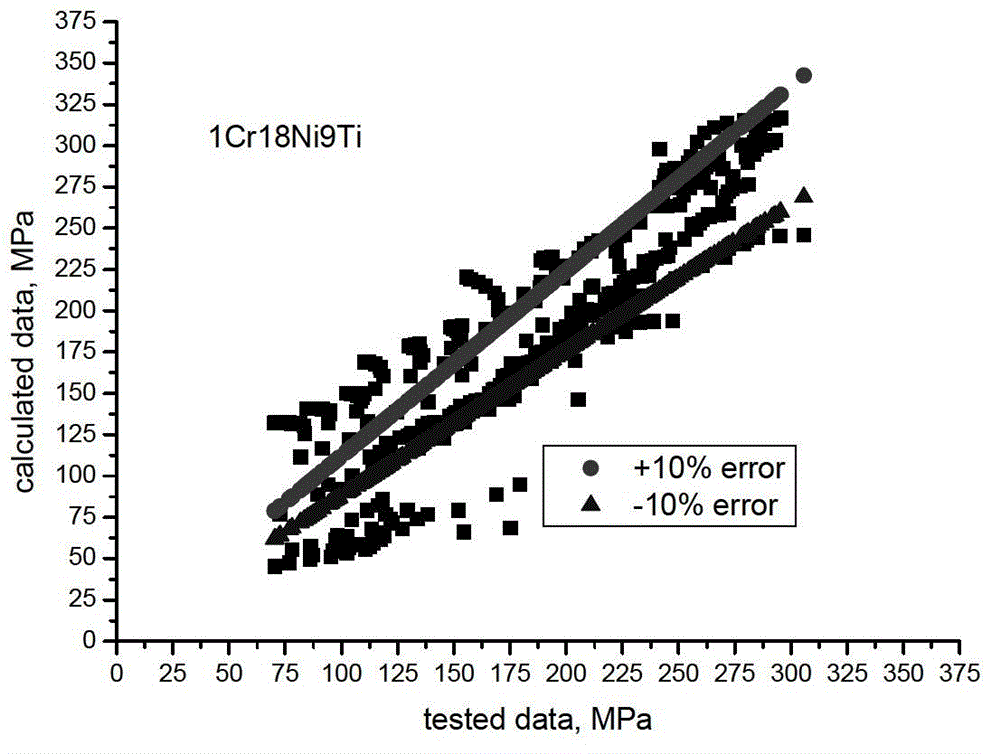

Construction method of material deformation resistance unified model for rolling mill design

InactiveCN102750453AImprove engineering applicabilityAdd equipmentSpecial data processing applicationsComputer Aided DesignProduction line

The invention provides a construction method of a material deformation resistance unified model with extrapolation stability in the rolling mill design process. According to the method, a large number of heat processing simulation experiment data is used as basis, and through nonlinear fitting analysis, the material deformation resistance is expressed into heat processing parameters such as deformation temperature T, deformation strain velocity and deformation quantity nonlinear function. The model is suitable for the rolling process design and a rolling production line design system of rod wires, plates and pipes in steel grades such as structure steel, pipeline steel, mold steel, and heat resistant steel, the model can precisely represent the nonlinear function relationship between deformation strain and deformation parameters of each kind of steel, meanwhile, high data extrapolation capability is also realized, and the model can be applied to the roller intensity design in a rolling production line and the computer aided design of a heat processing process.

Owner:UNIV OF SCI & TECH BEIJING

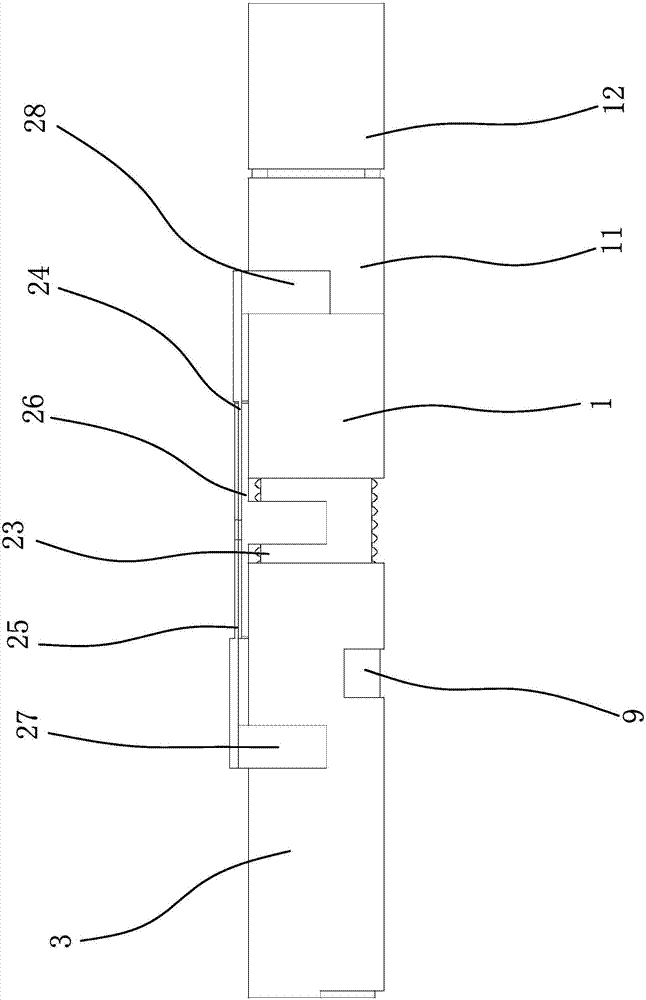

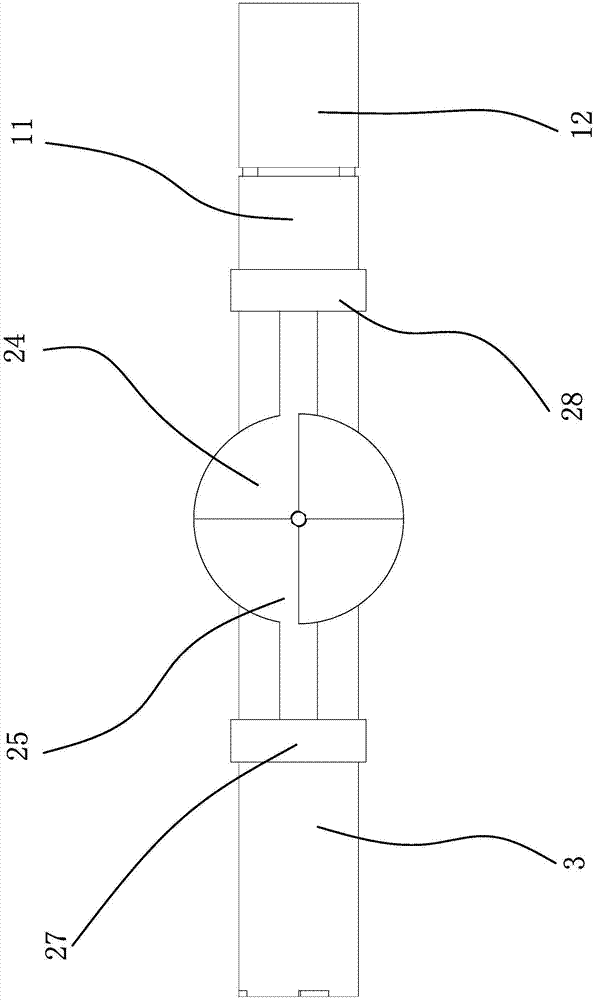

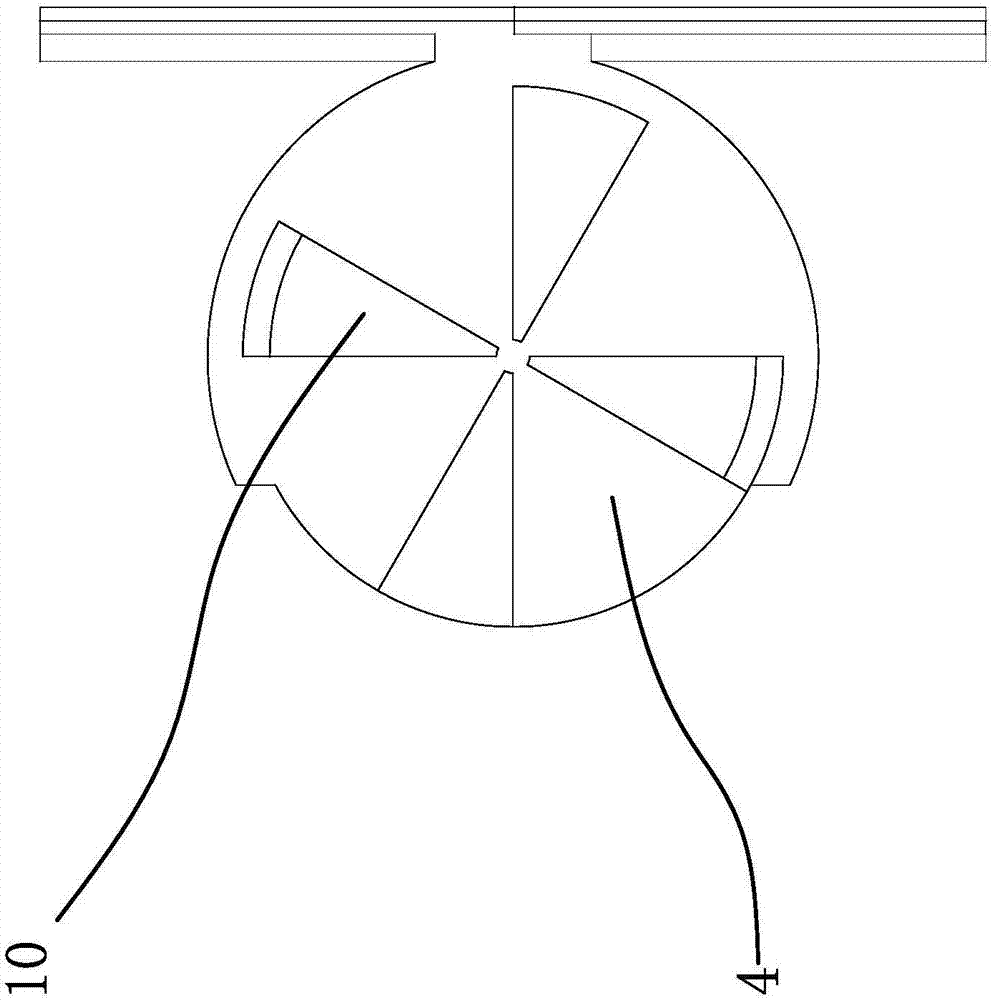

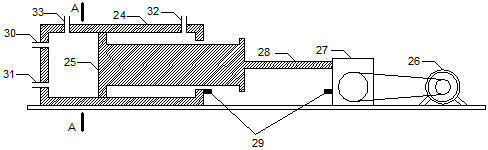

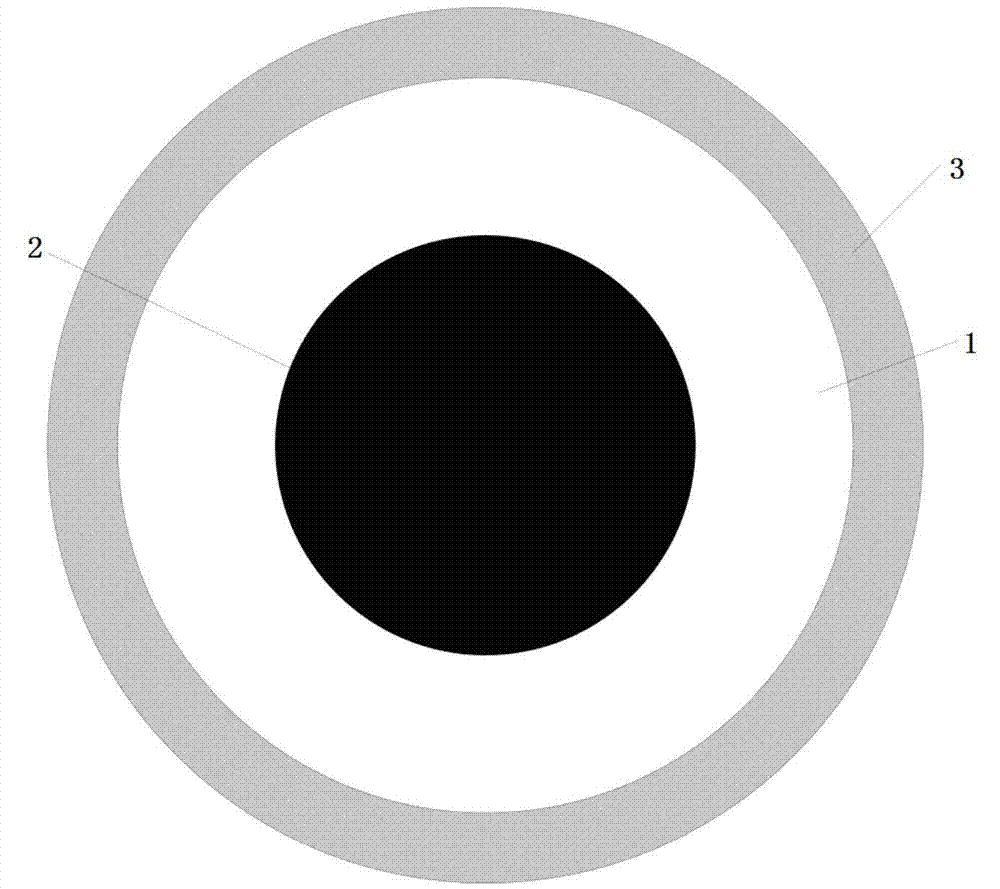

Strength of materials deformation strain demonstration teaching tool

The invention provides a strength of materials deformation strain demonstration teaching tool and belongs to the field of teaching tools. The teaching tool herein includes teaching tool pole pieces which refer to a pole piece 1, a pole piece 2, and a pole piece 3. The pole piece 3 is fixedly provided with a covering tray. The pole piece 2 is fixedly provided with a spring fixing piece 1 which is provided with a circle groove thereon. The circle groove is fixedly provided therein with a bearing which is fixedly provided with a shaft 1. The pole piece 3 is fixedly provided with a spring fixing piece 2 which is provided with a penetration hole thereon. The pole piece 1 is provided with a shaft 2. The shaft 1 and the shaft 2 are sleeved with adjusting springs. The shaft 2 has one end which protrudes from the spring fixing piece 2 is fixedly provided with a torsion dial. The pole piece 1 and the pole piece 2 are provided therebetween with a bending stress demonstration assembly which can demonstrate bending stress. The other end of the pole piece 2 is provided with a shearing stress demonstration assembly which can demonstrate shearing stress. According to the invention, the teaching tool can demonstrate stretching, or compression, shearing, torsion and bending.

Owner:QUZHOU UNIV

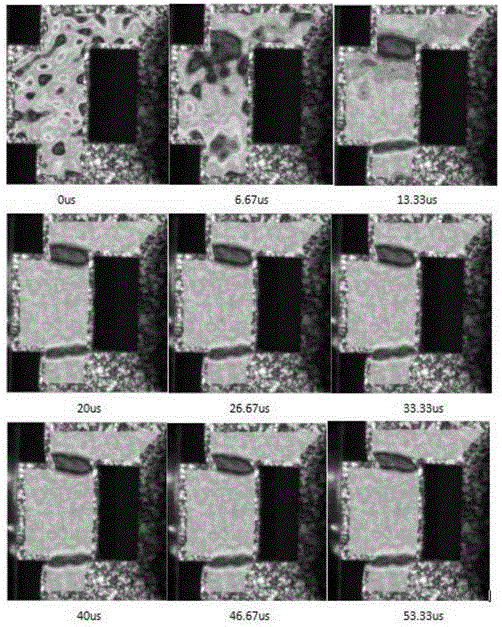

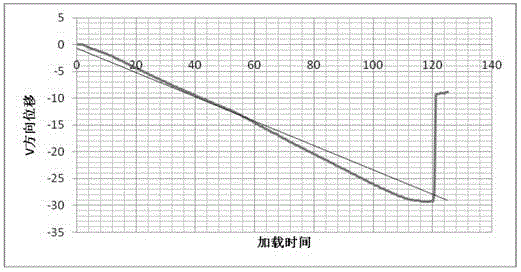

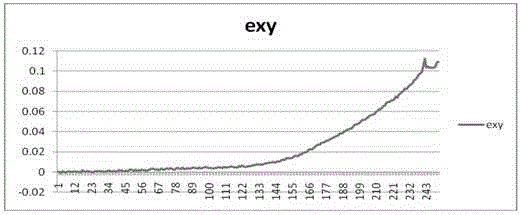

Testing device for static/dynamic metal shearing behavior

InactiveCN104677752ALow costEasy to makeMaterial strength using steady shearing forcesTest sampleReference image

The invention discloses a testing device for static / dynamic metal shearing behavior. A prepared convex test sample is applicable to dynamic and static shearing behavior testing both, speckle spots can be manufactured on the surface of the convex test sample, acquired data can be calculated by using a digital image relevant method, and then relevant data of a test sample deformation strain field can be obtained. By adopting the method, the operation test sample area shearing and the whole process of shearing deformation can be directly observed. The data calculation process comprises the following steps: by taking a first speckle spot image without deformation as a reference image and other images as deformation images, selecting an area of which the strain is required to be calculated from the reference image, and at the same time selecting a relevant calculation window in the area of which the strain is required to be calculated; determining an appropriate calculation step length according to the resolution of the image, and moving the relevant window to a relatively small strain influence area in the area of which the strain is required to be calculated as a calculating starting point, and starting displacement calculation; after the calculation is completed, selecting points, lines and shearing areas for data analysis according to experiment requirements.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

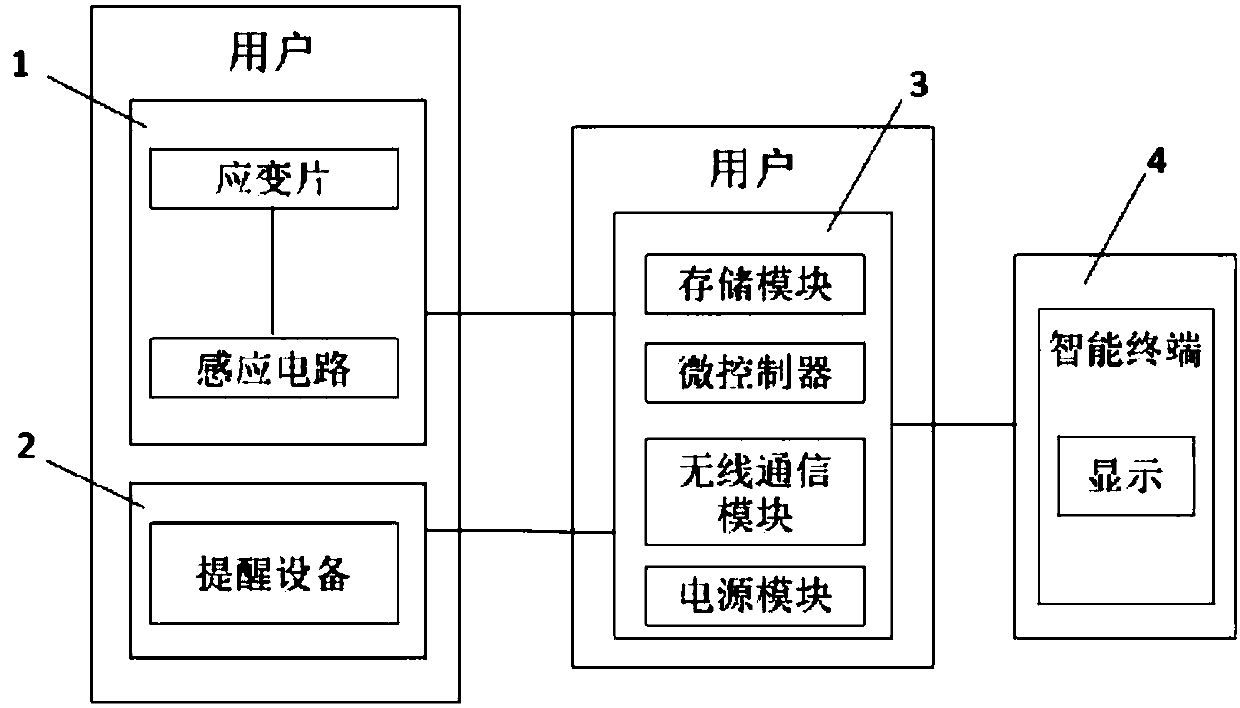

High-deformation strain sensor based baby sleep respiration monitoring device

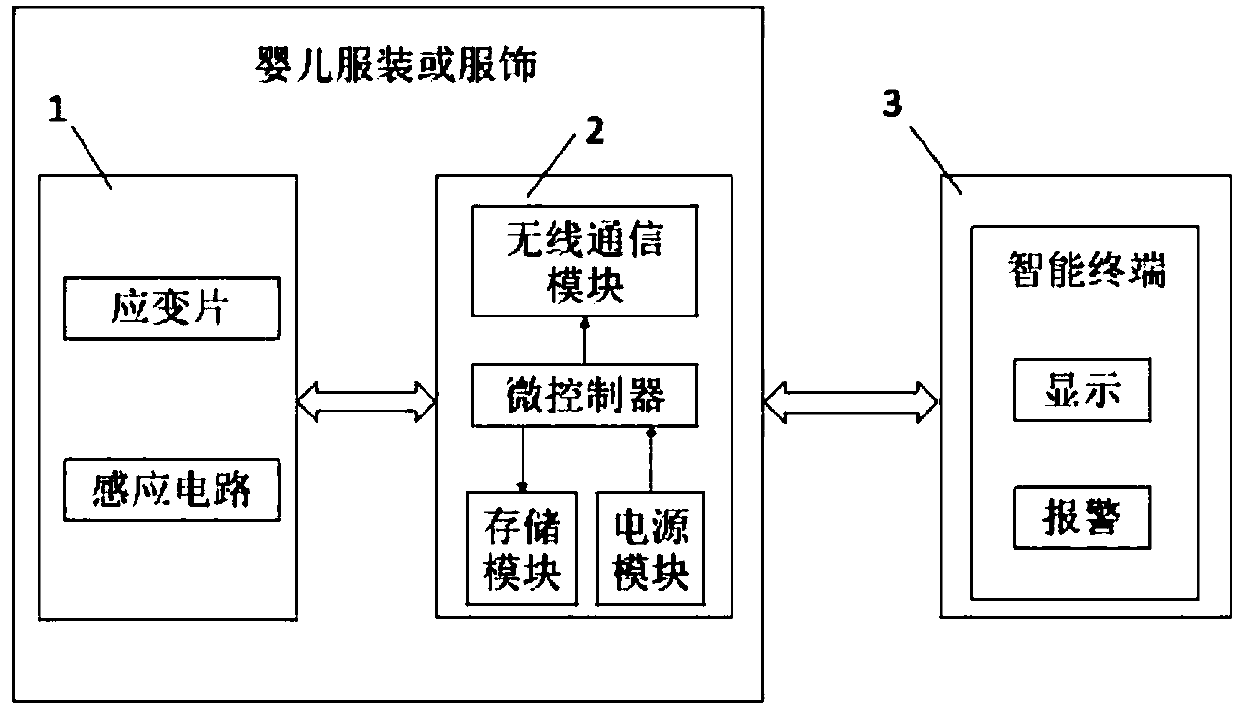

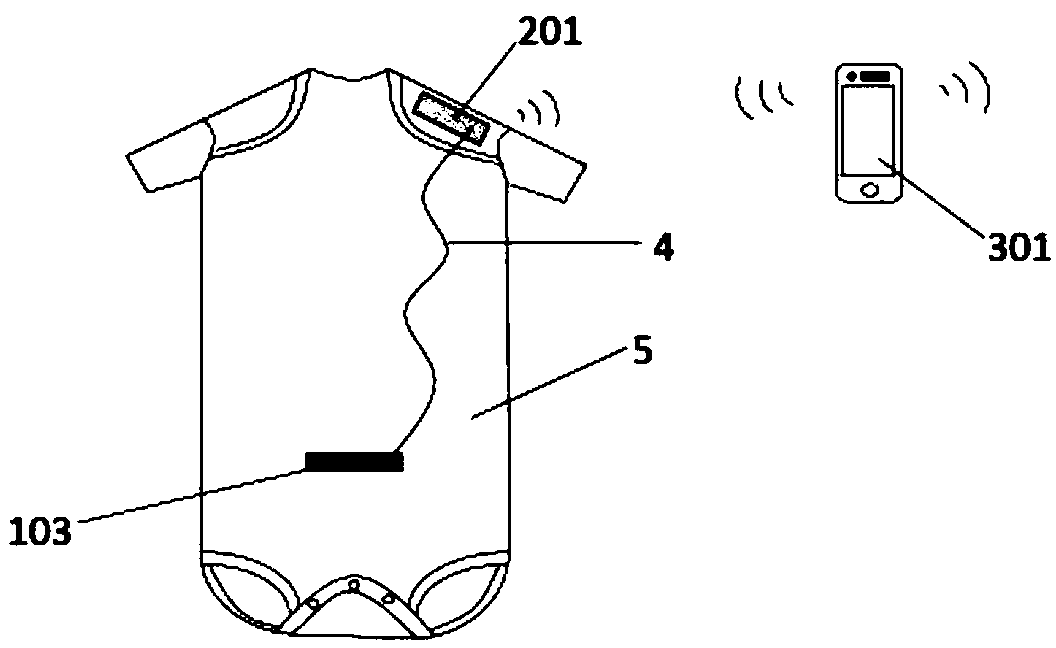

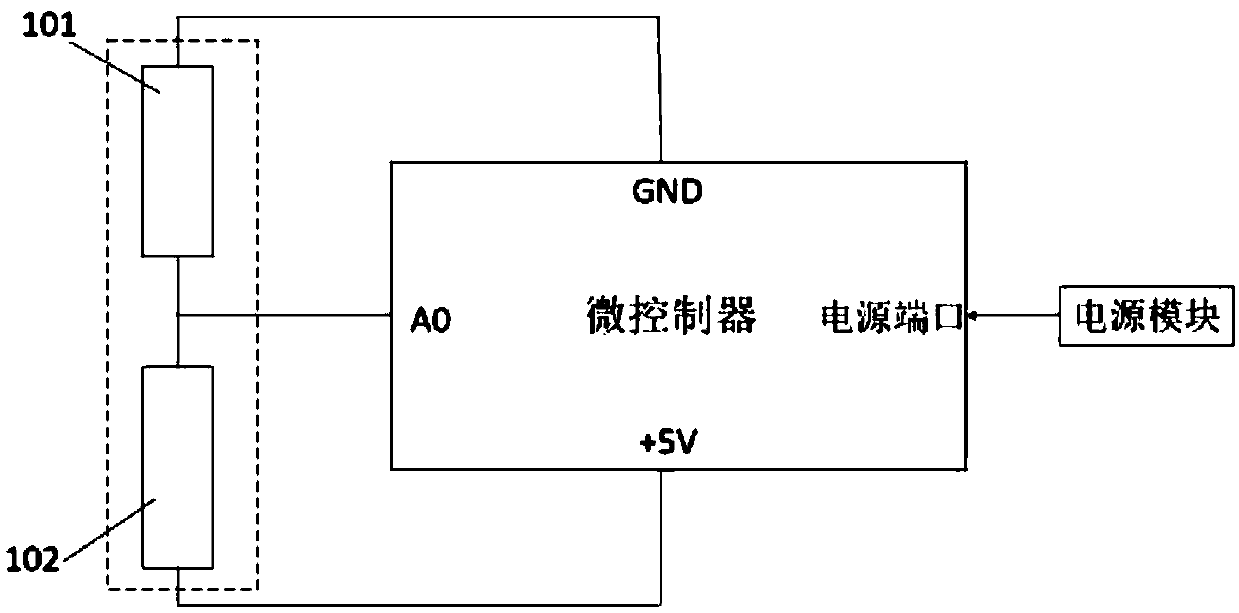

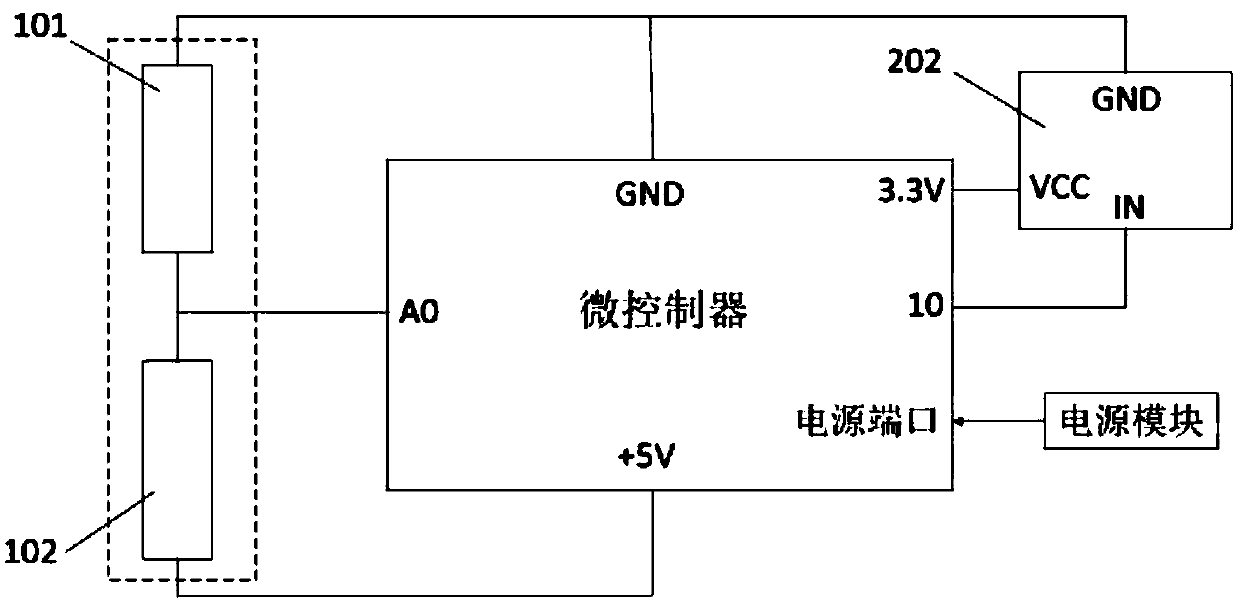

InactiveCN107693023AEasy to cleanReal-time understanding of sleep conditionsSensorsAlarmsMicrocontrollerComputer module

The invention provides a high-deformation strain sensor based baby sleep respiration monitoring device. The monitoring device includes three portions: a data acquisition unit, a data processing unit,and an intelligent terminal unit; the data acquisition unit is formed by a high-deformation strain sensor is integrated on a baby clothing or garment, and is used for acquiring abdomen deformation data while a baby breathes; the data processing unit includes a microcontroller, a storage module, a wireless communication module, and a power supply module, is integrated on the baby clothing or garment, and is used for processing the acquired data and sending the data to the intelligent terminal of a guardian; and the intelligent terminal unit can display real-time baby respiration conditions andsend an alarm to the guardian through threshold determination. The monitoring device can monitor the sleep respiration condition of a baby in real time, can prevent emergencies while the baby has a sleep, and can relieve the pressure that the guardian takes care of the baby.

Owner:FOSHAN SHUNDE SUN YAT SEN UNIV RES INST +2

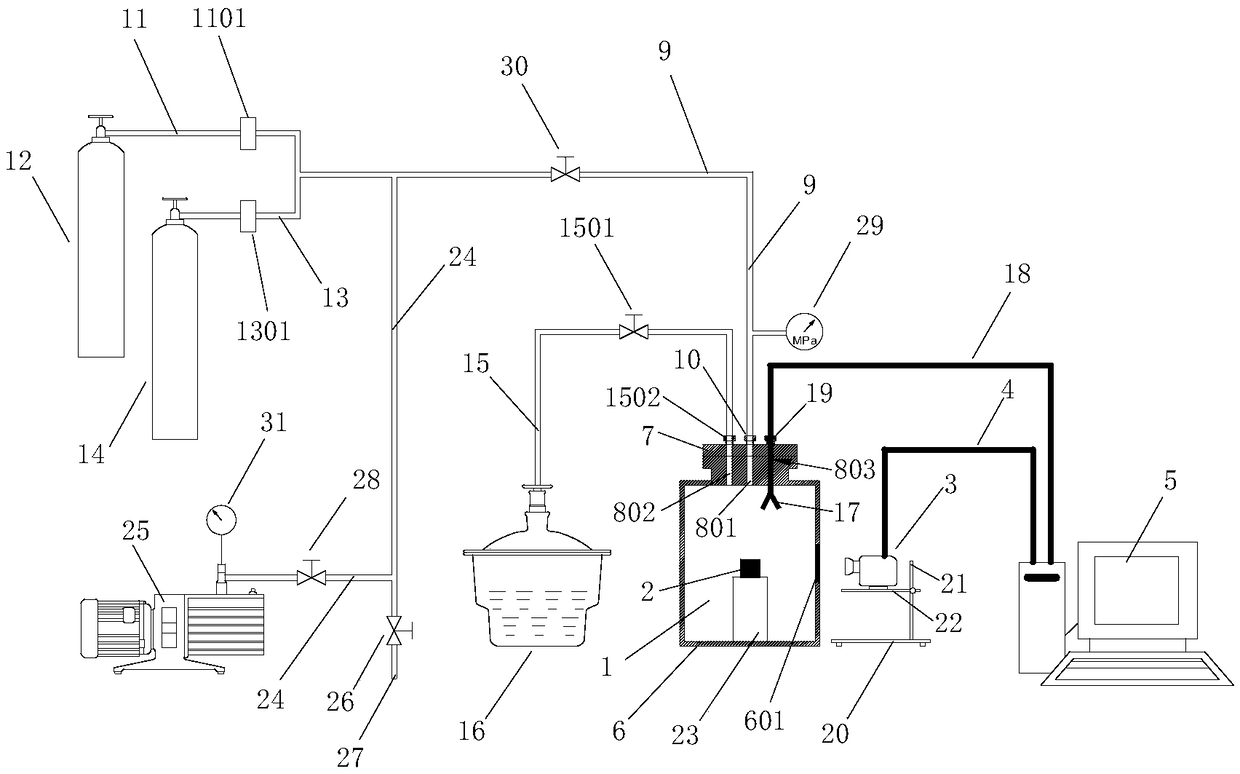

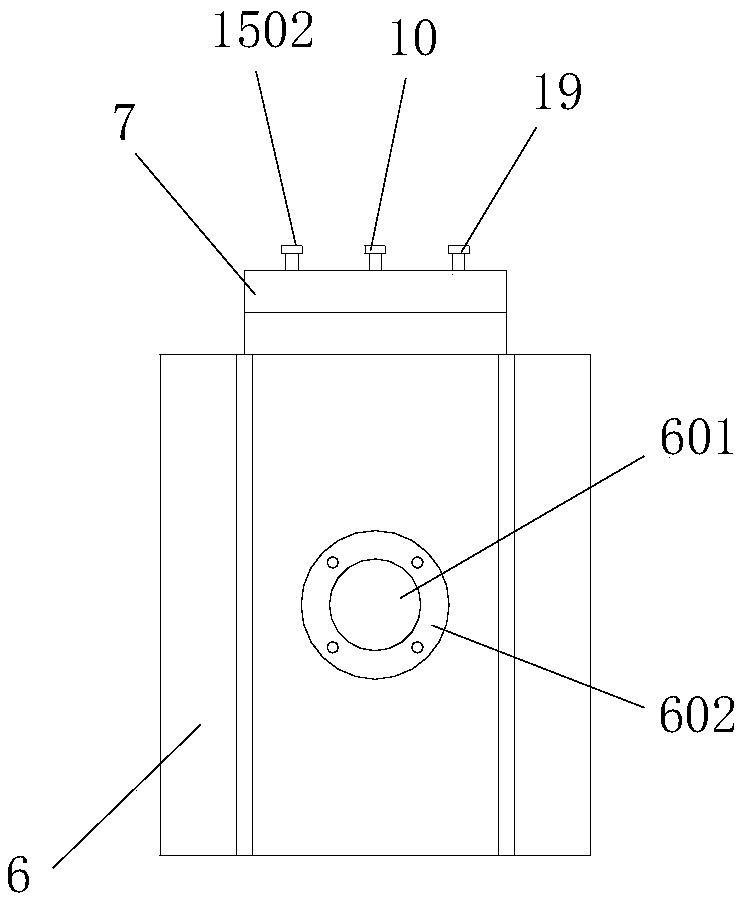

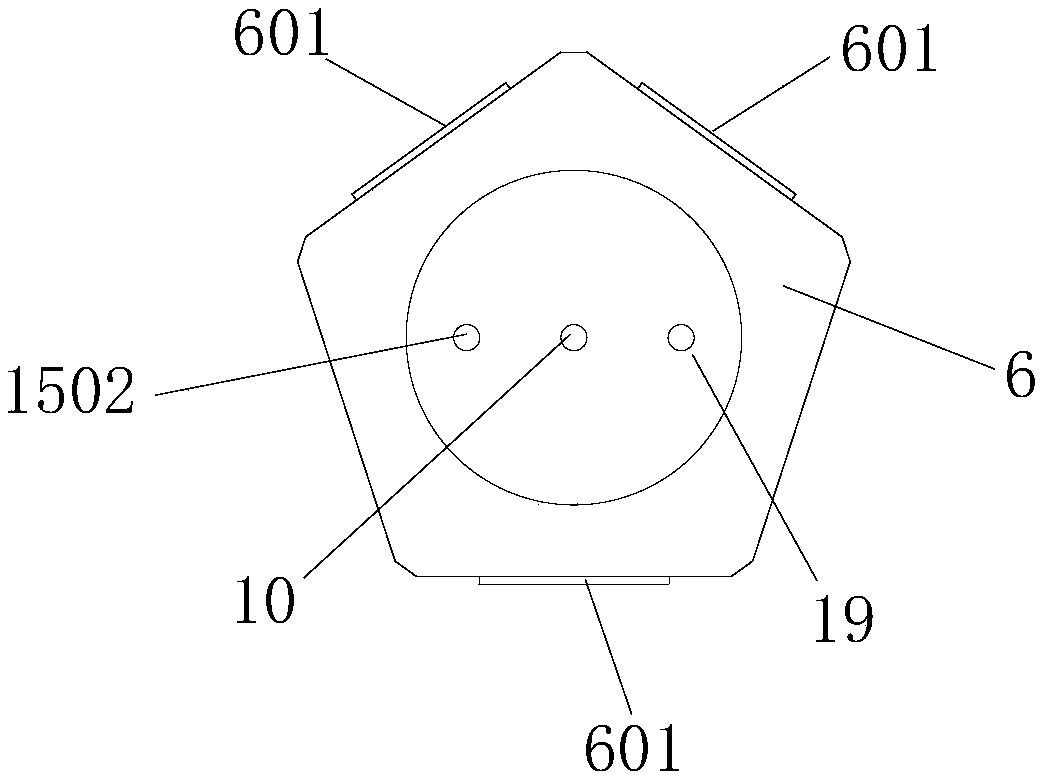

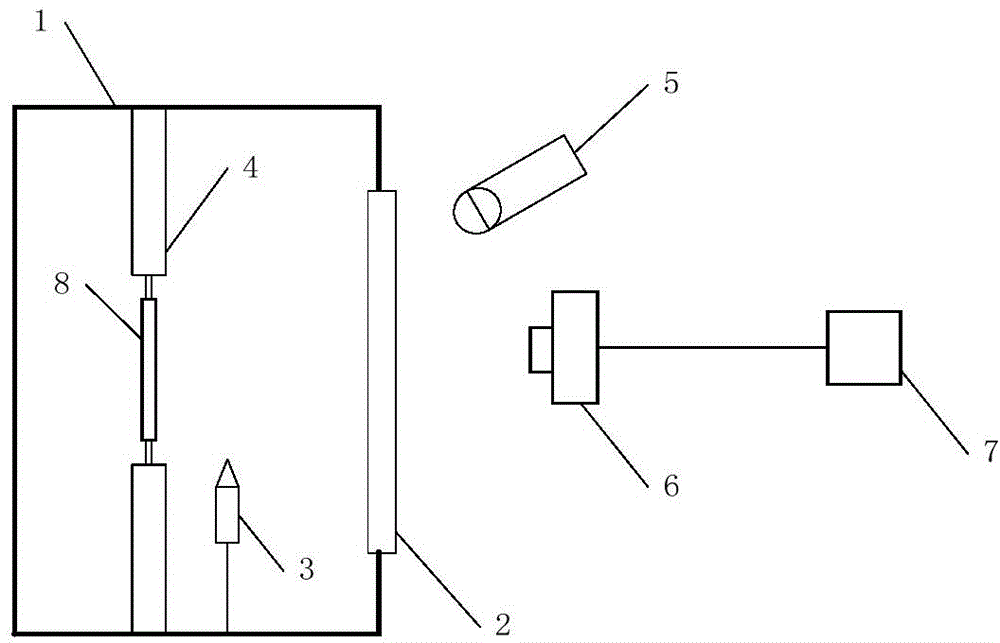

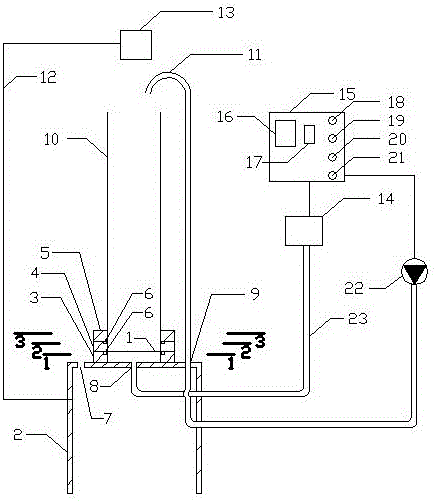

Coal-rock adsorption and desorption deformation visualization testing system and method under combined action of water and gas

InactiveCN109470834ASimple structureSimple test methodFuel testingDeformation strainProcess engineering

The invention provides a coal-rock adsorption and desorption deformation visualization testing system and method under the combined action of water and gas. The system comprises a testing tank provided with a sealing cavity and a gas supply mechanism for inflating the sealing cavity. The system also comprises an industrial high speed camera for carrying out image shooting on the deformation strainof a coal sample, and the gas supply mechanism comprises a methane gas supply mechanism and a vapor supply mechanism which are connected with the sealing cavity respectively so that deformation strain can be performed on the coal sample under the coexisting condition of water and methane. According to the coal-rock adsorption and desorption deformation visualization testing system under the combined action of water and gas provided by the invention, vapor is introduced into the sealing cavity, and then water adsorption treatment can be carried out on the coal sample in advance, the testing for a gas adsorption and desorption deformation characteristic can be carried out, a gas adsorption and desorption deformation characteristic evolution law including a coal body under the influence of water can be reflected, and a gas adsorption and desorption deformation mechanism of an in situ coal reservoir coal body can be developed more deeply.

Owner:SHIJIAZHUANG TIEDAO UNIV

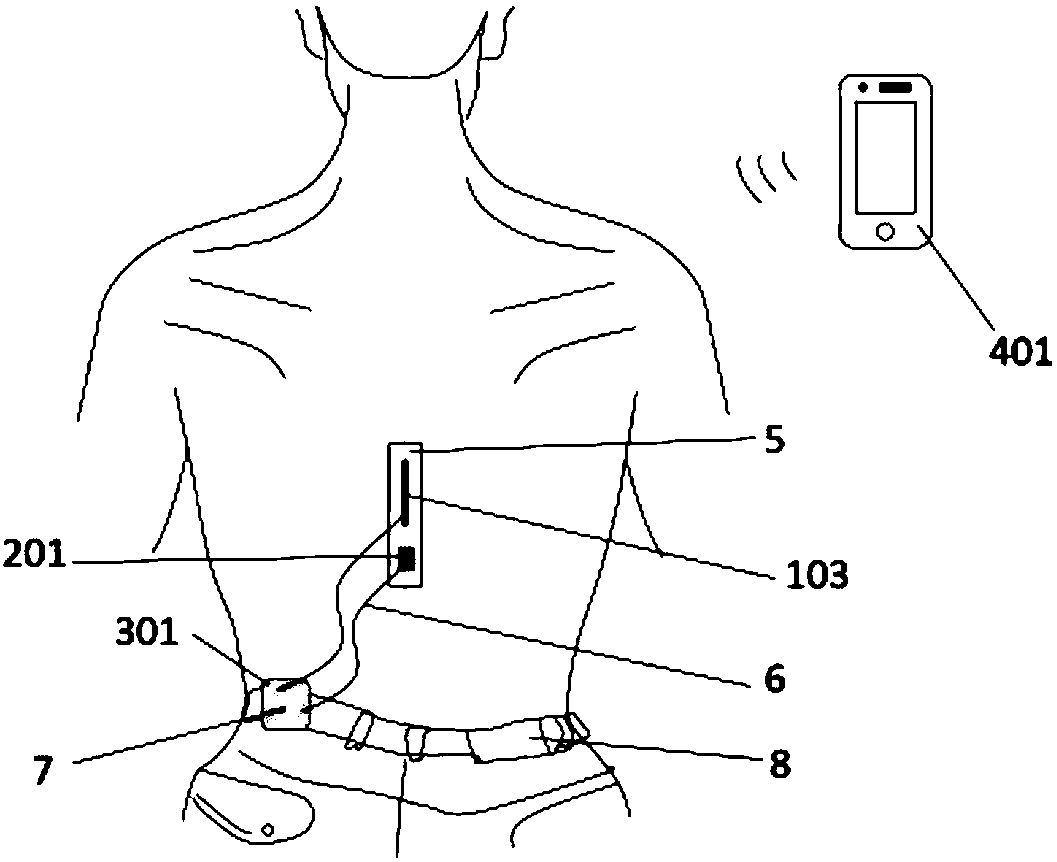

Posture monitoring device based on high deformation strain sensor

InactiveCN107610427AReduce power consumptionSmall sizeElectrical/magnetic solid deformation measurementAlarmsMicrocontrollerEngineering

The present invention provides a posture monitoring device based on a high deformation strain sensor. The device comprises a detection unit, a reminding unit, a control unit and a display unit. The detection unit is formed by the high deformation strain sensor and is fixed to the back of a user to collect bending data of the back of the user. The reminding unit is formed by a reminding device andis fixed to the back of the user to remind the user to correct a posture. The control unit comprises a microcontroller, a storage module, a wireless communication module and a power module and is wornon the user, and the control unit is used for processing received data, controlling the reminding unit to remind the user to correct a wrong posture, and carrying out wireless communication with a smart terminal of the user through the wireless communication module. The display unit can display a real-time posture condition and provide an analysis advice to the user. The monitoring device provided by the invention has the advantages of comfortable wearing, a compact size and low cost, real-time monitoring is achieved, and the user is reminded to correct the wrong posture.

Owner:FOSHAN SHUNDE SUN YAT SEN UNIV RES INST +2

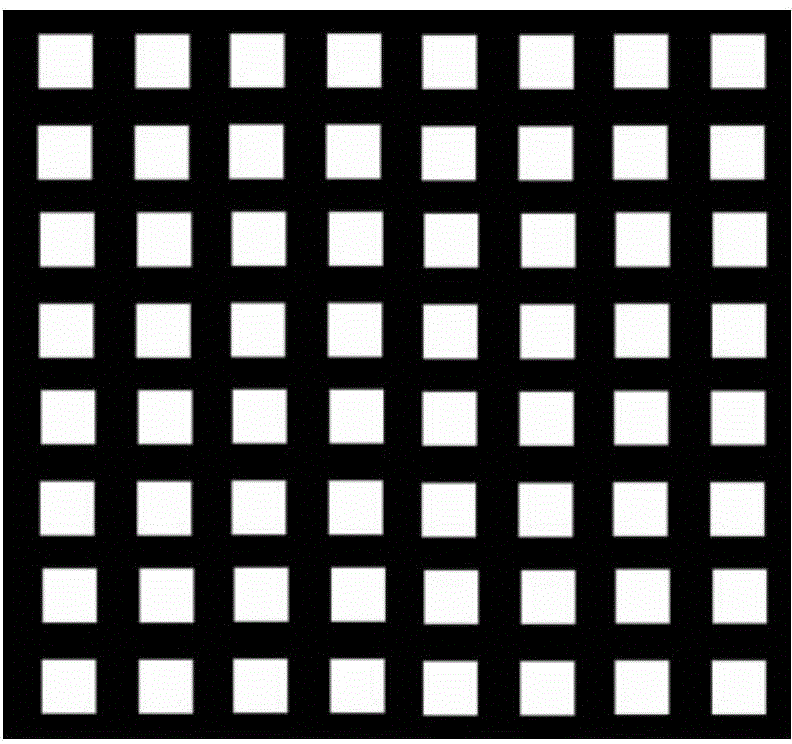

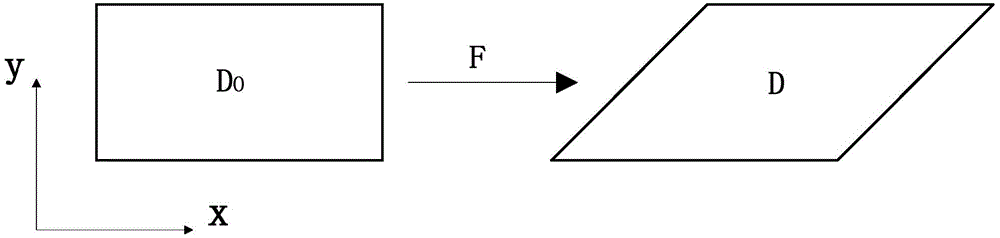

Method for measuring deformation of object in smoke under flame smoke environment

ActiveCN104613888AOvercoming ambiguitySolving Surface Deformation MeasurementsUsing optical meansStructural deformationCcd camera

The invention provides a method for measuring deformation of an object in smoke under a flame smoke environment, and belongs to the technical field of structural deformation measuring and optical measuring mechanics measurement. The method comprises the steps of irradiating the surface through a laser source or a narrow-band light source to separate a measured object surface with high temperature reflector speckle pots; shooting the surface of the object to be measured through a CCD camera with a filter film on a lens by passing through the flame smoke to obtain a fuzzy image of the speckle pots on the object surface; recovering the clear original image of the speckle pots on the surface of the measured object without being fuzzed by the flame smoke by the phase recovering algorithm; calculating the object surface deformation according to the variation of the shape and appearance of the speckles on the object surface during heat deforming, so as to measure the deformation strain of the surface of the measured object and the displacement in the whole field on real time. With the adoption of the method, the object deformation can be measured in the whole field on real time by passing through the flame smoke; the real-time whole-field deformation measurement can be performed for the object which is deformed and even damaged due to stressing or heating in the flame smoke environment.

Owner:TSINGHUA UNIV

Short process preparation method of high-strength high-conductivity deformation-processed Cu-Cr-Ag in-situ composite material

The invention discloses a short process preparation method of a high-strength high-conductivity deformation-processed Cu-Cr-Ag in-situ composite material. The short process preparation method comprises the following steps: (1) a Cu-Cr-Ag ternary alloy cast ingot is cast by adopting a method combining medium-frequency induction melting and graphite mould pouring; (2) the cast ingot is placed in a zone melting-directional solidification furnace for directional solidification treatment, so that Cr dendritic crystals form directionally arrayed micro nanoscale fiber in the axial direction; (3) a material subjected to the directional solidification treatment is subjected to multipass cold drawing deformation, so that the micro nanoscale fiber formed in a directional solidification process is further refined to be nanoscale fiber; and (4) comprehensive regulation on the strength, the conductivity, the elongation percentage, and the like of the material is carried out by adopting final aging heat treatment. The continuous directionally arrayed micro nanoscale fiber is formed through as-cast structure control, with the combination of the cold drawing deformation, alloying and the final aging heat treatment, the preparation technological process is shortened, the cold deformation strain capacity is reduced, the size of the final material is increased significantly, the final material can acquire stable and good use comprehensive performances, and the application scope of the deformation-processed Cu-based in-situ composite material can be widened in the field of high and new technologies.

Owner:NANCHANG INST OF TECH +1

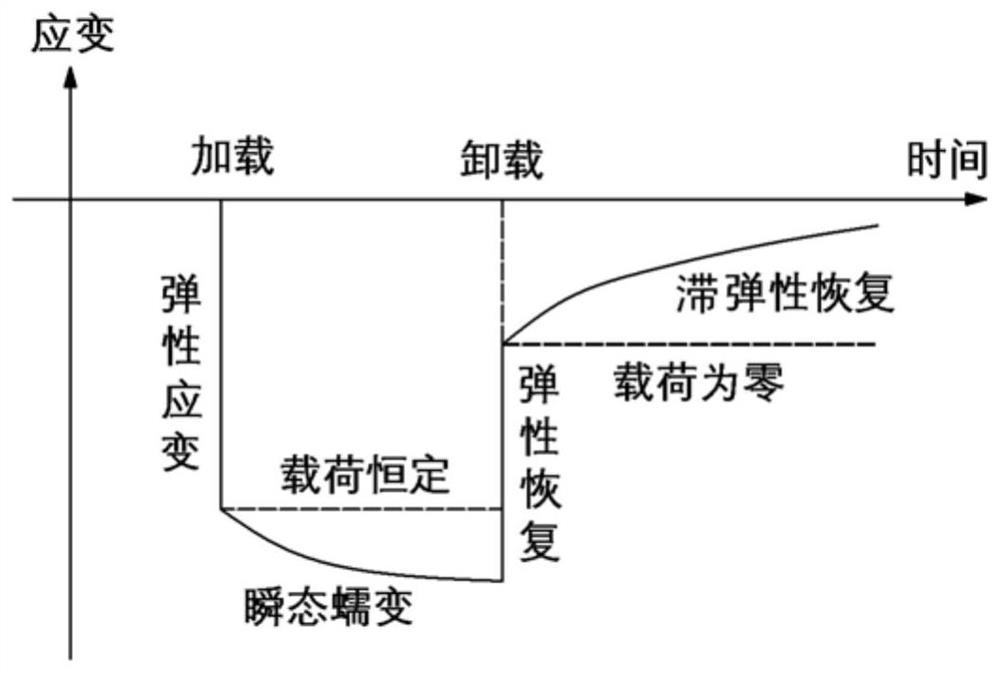

Method for measuring ground stress by using rock core hysteretic elasticity recovery deformation

InactiveCN112129448AAdaptableImprove economyMeasurement of force componentsRock coreClassical mechanics

The invention provides a method for measuring ground stress by using rock core hysteretic elasticity recovery deformation. The method is used for effectively obtaining reliable ground stress data, andis higher in adaptability and efficiency. The method comprises the following steps of rock core drilling, strain gauge pasting, hysteretic elasticity deformation strain testing, temperature calibration, hysteretic elasticity flexibility measurement and data analysis processing. Compared with a traditional method, the method has higher adaptability and economic efficiency; particularly, under thecomplicated geological conditions of deep hole drilling and stratum crushing, when a stress relief method, a hydraulic fracturing method and the like are difficult to implement, the method can still possibly obtain the reliable ground stress data; and the adaptability is higher.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

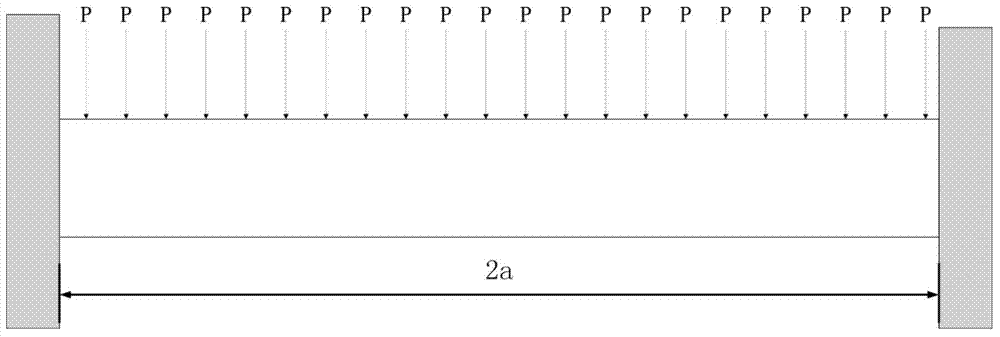

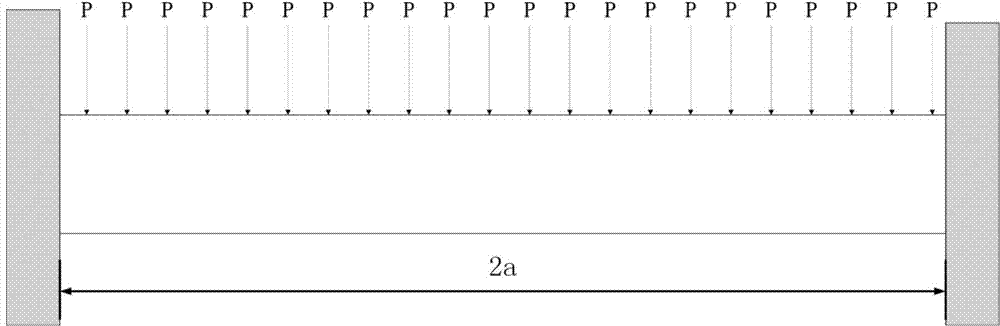

Continuous stable pressurization type geomembrane liquid expansion deformation mechanical testing device

The invention relates to test equipment applicable to measurement of the liquid expansion deformation mechanical property of geomembranes in membrane-paving seepage-proofing projects in the fields of water conservancy plain reservoirs, municipal refuse landfills and the like. The test equipment is characterized in that the liquid expansion deformation mechanical property test of the geomembranes under the overburden pressure can be carried out, the hydraulic pressure and the expansion breakage pressure of the geomembranes in a container can be measured, the overburden hydraulic pressure can be supplied for the geomembranes, the crown height of the liquid expansion deformation of the geomembranes can be automatically measured by virtue of a laser displacement sensor, and then a strain relation curve of liquid expansion deformation strain of the geomembranes can be obtained. A continuous stable pressurization type geomembrane liquid expansion deformation mechanical testing device comprises a pressurization system, a liquid expansion sealing device, a burden pressure device and a measurement and control system. An original pump type hydraulic pressure supply manner is abandoned in the pressurization system of the device, and an autonomously designed continuous stable pressure supplying device is adopted. The liquid expansion sealing device mainly consists of an upper flange disc, a lower flange disc and a horizontal operation platform, and a hydraulic sealing space is formed. The burden pressure device consists of an organic glass cylinder and a flange disc. The measurement and control system consists of a precise digital display pressure sensor and the laser displacement sensor.

Owner:UNIV OF JINAN

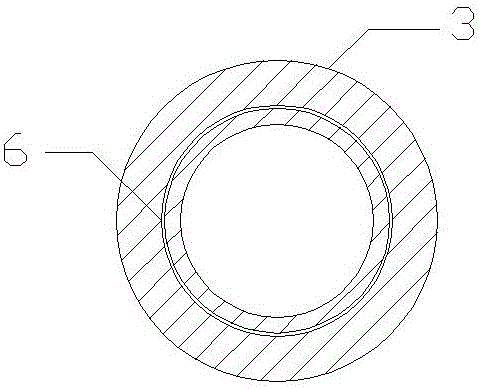

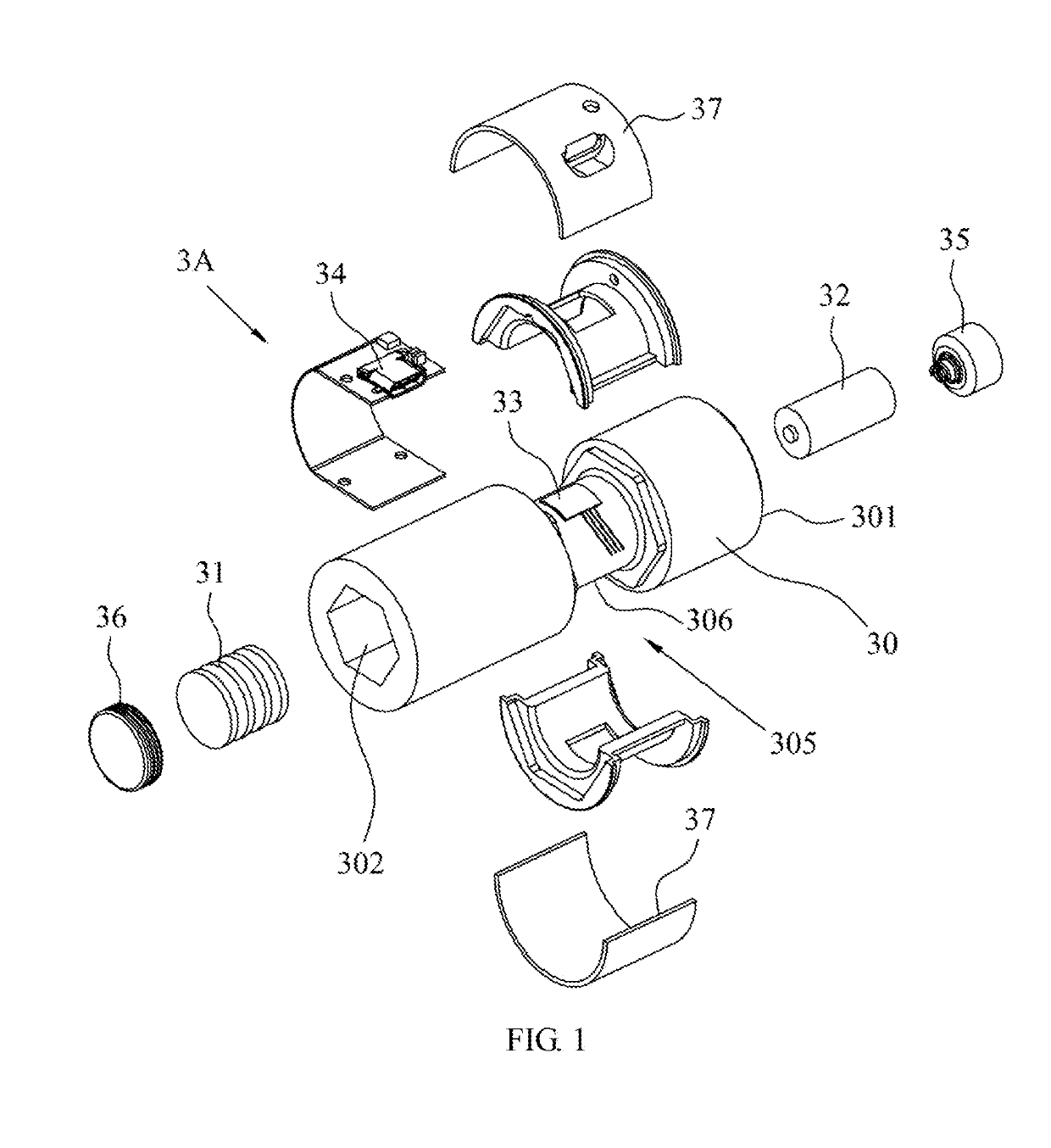

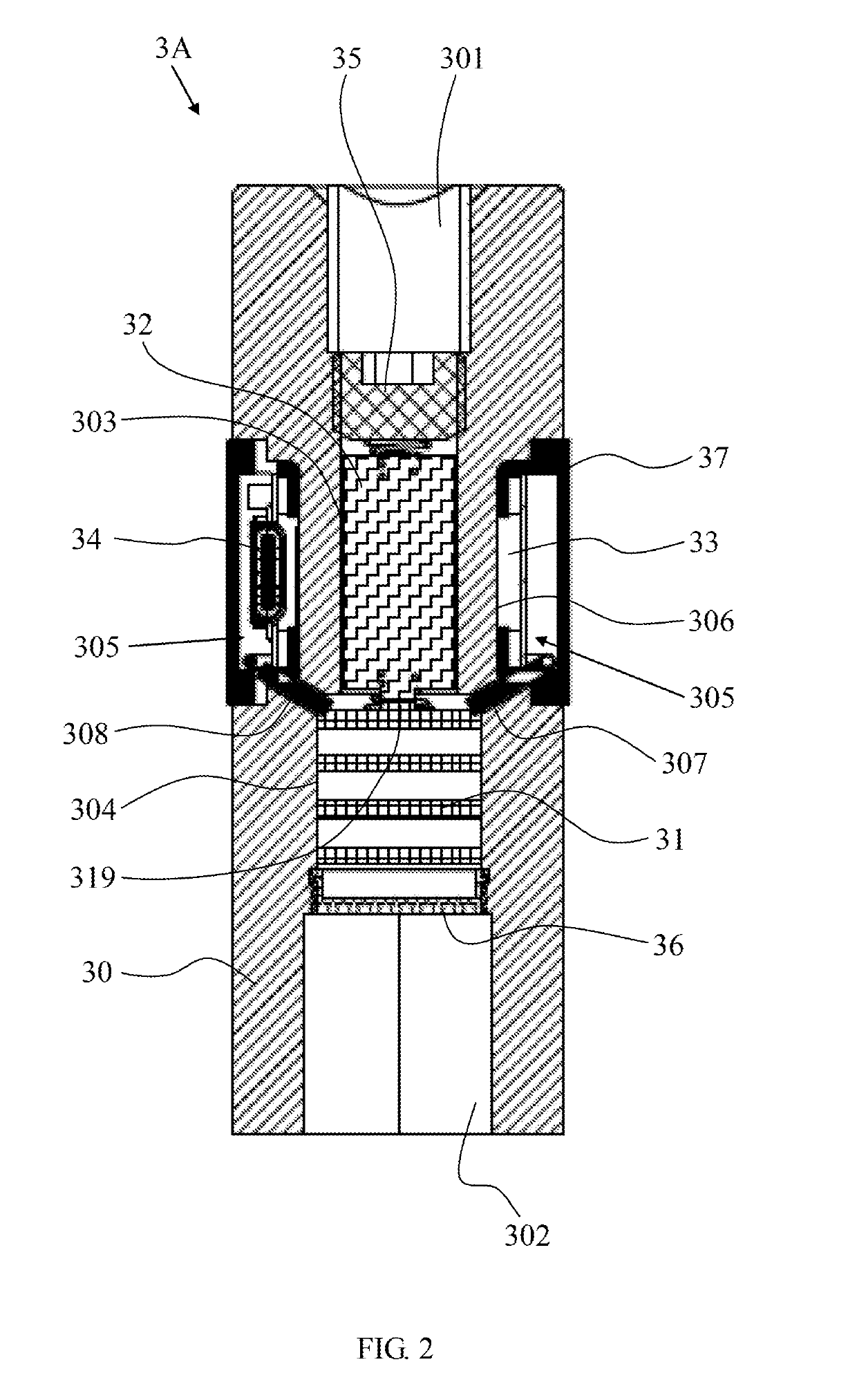

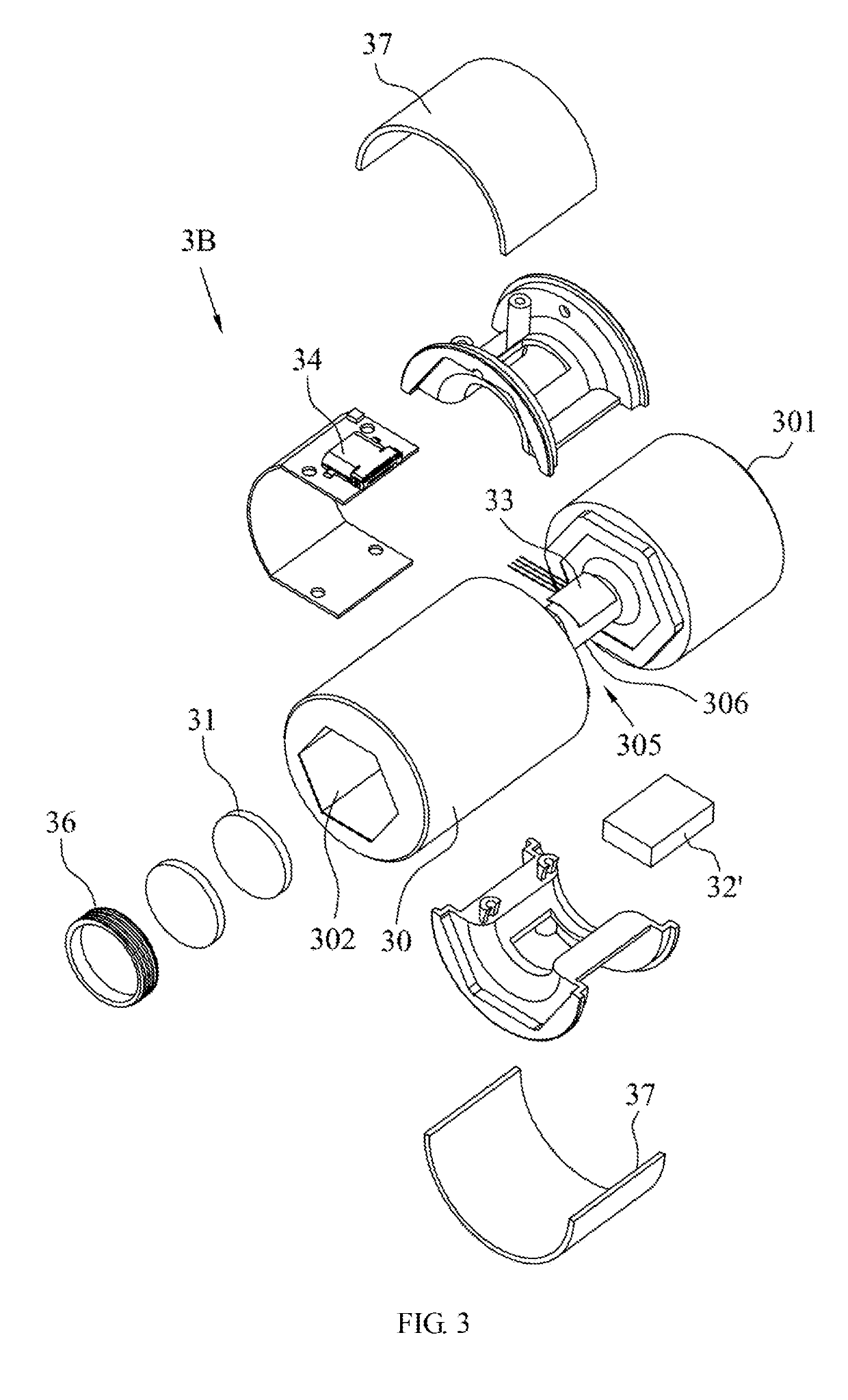

Socket having functions of torque sensing, angle sensing and signal transmitting

ActiveUS20190126448A1Efficient readingImprove practicalityWork measurementSpannersComputer moduleEngineering

A socket having functions of torque sensing, angle sensing, and signal transmitting is provided. The socket includes a socket body, a circuit board module, a deformation strain sensing unit, an output / input module, a power supply module, and a protection device. Wherein, the socket body has variable structures to accommodate the circuit board module, the deformation strain sensing unit, the power supply module and the output / input module, and to protect the accommodated elements by the protection device. Accordingly, the socket has the functions of torque sensing, angle sensing, and signal transmitting.

Owner:CHINA PNEUMATIC CORP

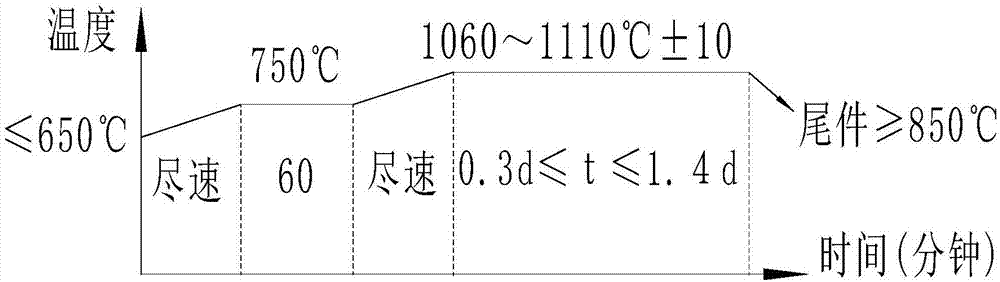

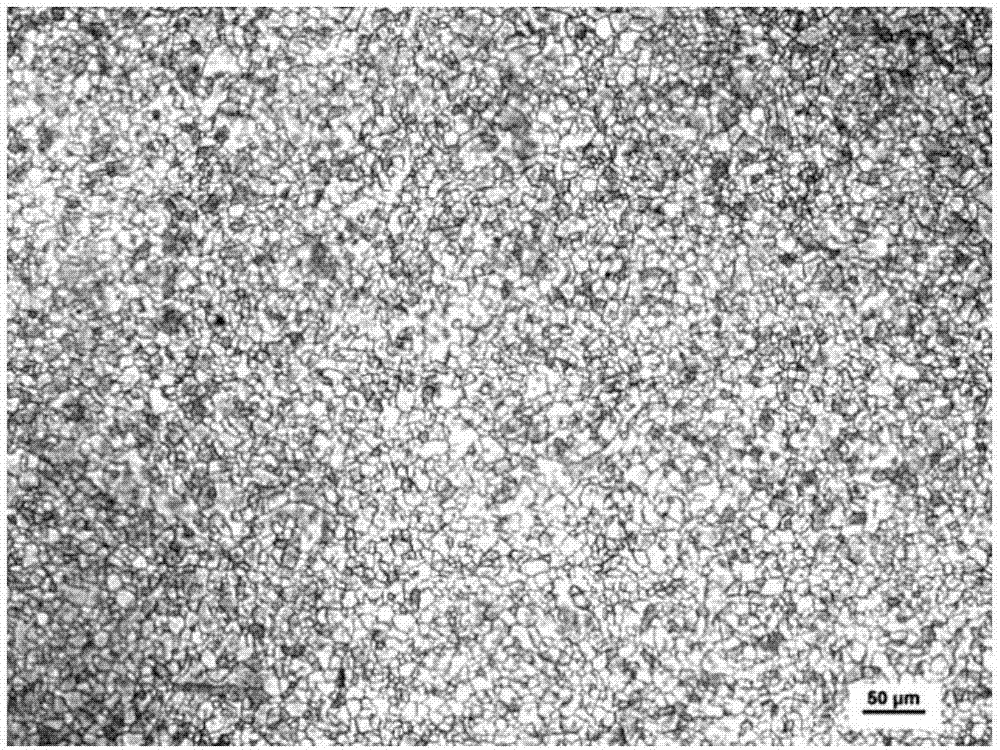

Forging method of large-sized die forging part of fine-grain AF1410 steel

InactiveCN107175306ARefine the grain sizeIncrease grain size gradeMetal-working apparatusProduction rateHeating time

The invention relates to the technical field of forging, and discloses a method for forging fine-grained AF1410 steel large die forgings. The heating temperature of the forging method is 1060°C-1110°C, the maximum heating time is ≤1.4 times of the effective thickness of the billet, the deformation speed of the press is 5-15mm / s, and the deformation amount is ≥30%. The method adopts new forging process parameters, reasonably reduces the heating temperature, reduces the heating time, increases the deformation amount of the die forging fire, can refine the grain size of the forging, and increases the grain size grade of the forging to 10-11. The comprehensive properties such as tensile strength, plasticity, impact toughness and fatigue life have been significantly improved. While improving the quality of forgings, it can effectively reduce production costs and increase productivity.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

Long distance optical fiber grating sensing and transmitting device

InactiveCN101216326BHigh-resolutionHigh measurement accuracyCoupling light guidesConverting sensor output opticallySensor arrayFiber

The invention relates to a long-distance optical fiber grating sensing transducer. An optical fiber end surface matching fluid container, an optical fiber sensor array, a wavelength division multiplexer, an erbium-doped fiber, an optical isolator are sequentially disposed in the upper part of a mounting plate from left to right, an optical fiber end surface matching fluid is filled in the opticalfiber end surface matching fluid container, one end of the optical fiber sensor array is disposed inside the optical fiber end surface matching fluid, the other end of the optical fiber sensor array is connected with one input end of the wavelength division multiplexer via an optical fiber, a pumping laser is disposed in the lower part of the mounting plate, the output end of the pumping laser isconnected with the other input end of the wavelength division multiplexer via an optical fiber, the output end of the wavelength division multiplexer is connected with one end of the erbium-doped fiber, and the other end of the erbium-doped fiber is connected with one end of the optical isolator with an optical fiber. The invention has the advantages of high signal-to-noise ratio, wide detection range, high resolution and measurement accuracy, long transmission distance, good reliability, and low production cost; and can be used for long-distance detection of temperature, pressure, pipeline deformation strain in oil and gas pipelines.

Owner:XI'AN PETROLEUM UNIVERSITY

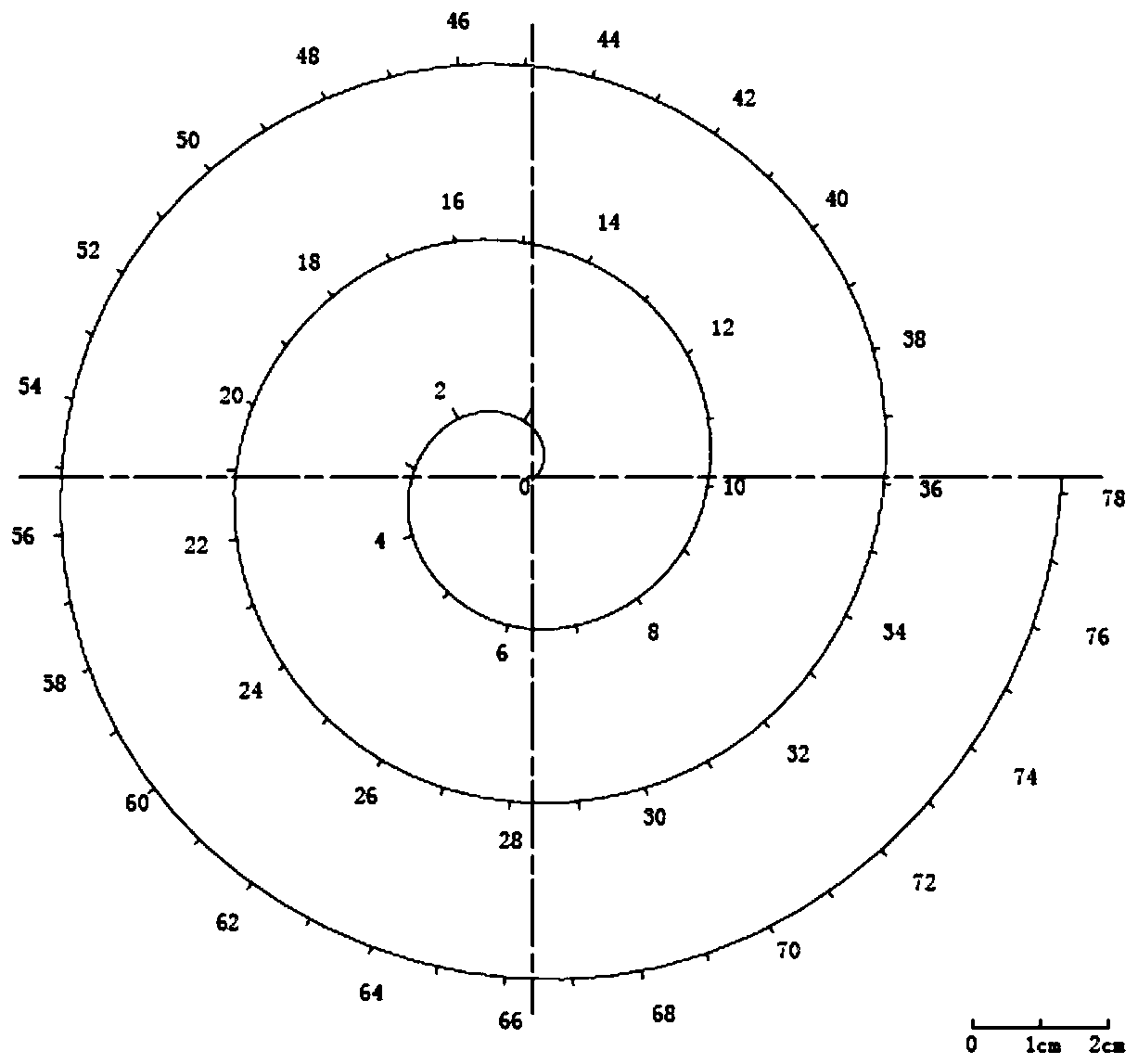

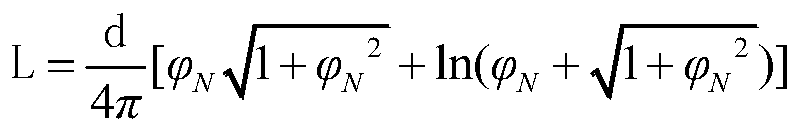

Strain gauge pasting and positioning method in oil and gas pipeline concave deformation strain field measurement

ActiveCN109780987ASolve the problem that the measurement and positioning of the strain field in the depression area cannot be carried out on the inner wall of the pipelineReal-time acquisition of sag stress field changesElectrical/magnetic solid deformation measurementAdhesiveStrain gauge

The invention discloses a strain gauge pasting and positioning method in oil and gas pipeline sunken deformation strain field measurement, which comprises the following steps: positioning the sunken center of the inner wall of a pipeline, drawing a spiral scale, and manufacturing a spiral strain gauge positioning mold according to the spiral scale; fixing a strain gauge and coating an adhesive; and pasting the strain gauge, and finally taking out the spiral strain gauge positioning mold to complete strain gauge pasting and positioning. According to the invention, a plurality of strain gauges can be simultaneously adhered to specified positions of the inner walls of pipelines with various inner diameters, and meanwhile, pasting devices for the strain gauges can be adjusted according to testrequirements, so that real-time measurement of pipeline inner wall concave strain field response is realized while an oil and gas pipeline concave defect prefabrication test is realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

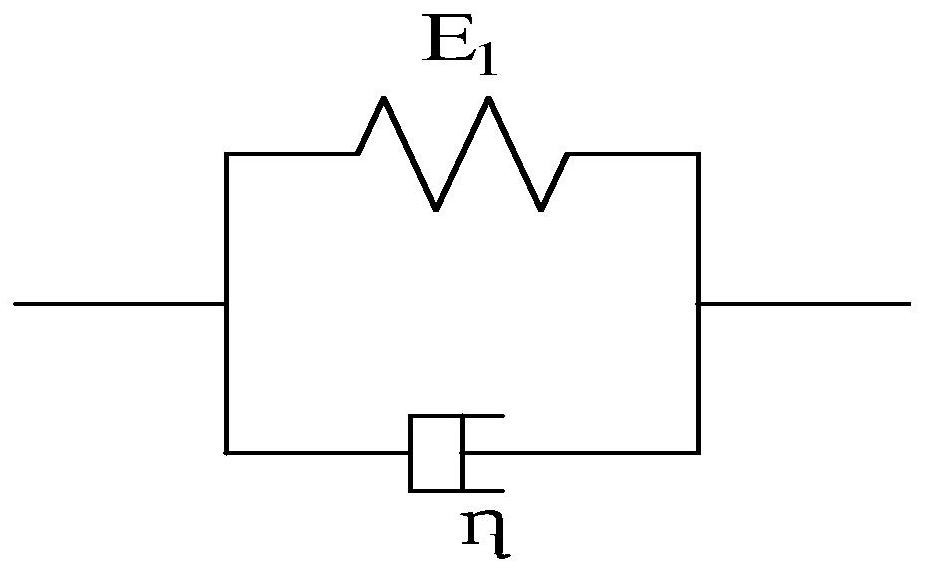

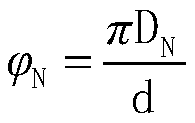

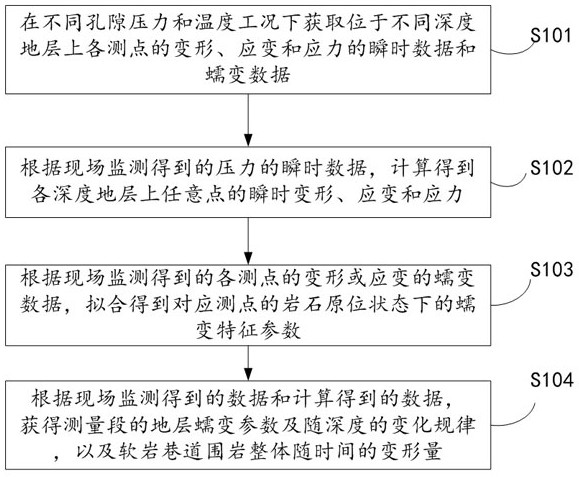

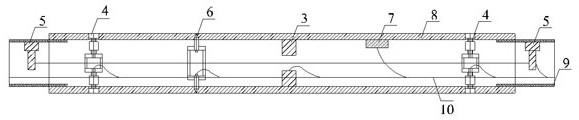

Soft rock creep in-situ monitoring analysis method and system

ActiveCN113340359AUnderstand the law of destruction developmentRealize targeted designMeasurement devicesDesign optimisation/simulationTransient deformationPressure data

The invention discloses a soft rock creep in-situ monitoring analysis method and a system. The method comprises the following steps: acquiring instantaneous data and creep data of deformation, strain and stress of each measuring point on stratums at different depths under different pore pressure and temperature working conditions; according to instantaneous pressure data obtained through field monitoring, obtaining instantaneous deformation, strain and stress of any point on the stratum of each depth through calculation; according to creep data of deformation or strain of each measuring point obtained by field monitoring, fitting to obtain creep characteristic parameters of the corresponding measuring point in a rock in-situ state; and according to the data obtained through field monitoring and the data obtained through calculation, obtaining the stratum creep parameters of the measurement section, the change rule along with the depth and the overall deformation amount of the surrounding rock of the soft rock roadway along with time. Therefore, by adopting the scheme provided by the invention, the overall deformation characteristics and rules in the supporting process of a soft rock roadway heading machine can be effectively researched in time, the targeted design of roadway supporting parameters is realized, and the optimal supporting opportunity is effectively grasped.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Characterization method for dynamic fracture performance of metal material

PendingCN113049358AAvoid problems with inaccurate measurementsAvoid interferenceMaterial strength using repeated/pulsating forcesMetallic materialsReflected waves

The invention discloses a characterization method for the dynamic fracture performance of a metal material, and belongs to the technical field of material dynamic mechanical experiments. The characterization method comprises the step of dynamically loading a standard three-point bending sample by using a split Hopkinson pressure bar, wherein a characterization parameter is an energy value consumed when the standard three-point bending sample is dynamically fractured, the split Hopkinson pressure bar is a split Hopkinson pressure bar, the loading air pressure is 2-4 atm, the deformation strain rate ranges from 10<3>s<-1> to 10<4>s<-1>, punches are arranged at the tail end of an incident bar and the front end of a transmission bar of the split Hopkinson pressure bar and are used for loading and supporting a sample, strain gauges are attached to the incident bar and the transmission bar, and stress-time curves of incident waves, transmitted waves and reflected waves in the loading process are obtained through using a signal acquisition system. The characterization method provided by the invention can quantitatively characterize the dynamic fracture performance of the metal material under the strain rate of 10<3>s<-1>-10<4>s<-1>.

Owner:GRIMAT ENG INST CO LTD

A high-precision flexoelectric pressure sensor based on metal elastic elements

InactiveCN103616098BWide selectionOvercome some deficiencies of strain measurement pressureForce measurement using piezo-electric devicesDielectricInsulation layer

The invention discloses a high-precision deflection electric type pressure sensor based on a metal elastic element. The sensor comprises the metal elastic element for measuring mechanical vibration generated by micro pressure, a deflection electric dielectric film is pasted on the top of the metal elastic element, an insulation layer is arranged on the periphery of the metal elastic element, an upper metal electrode and a lower metal electrode are arranged on the upper surface and the lower surface of the deflection electric dielectric film respectively, the upper metal electrode and the lower metal electrode of the deflection electric dielectric film are connected with two output wires for measuring charge signals respectively, a pressure channel which is used for exerting pressure is formed below the metal elastic element, the deflection electric dielectric film, the upper metal electrode and the lower metal electrode are all arranged in an outer shell, and one end of each of two wires is led out from the outer shell. According to the sensor, the pressure on the film is measured through the linear relation between the exertion pressure and the mechanical deformation strain gradient of the metal elastic element, and the pressure measuring can be accurately and easily achieved.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com