Method for measuring deformation of object in smoke under flame smoke environment

A measurement method and smoke technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve problems such as ambiguity, speckle image distortion on the surface of the test piece, deformation calculation, etc., to overcome the influence of blur and solve the deformation of the object surface measured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited thereby.

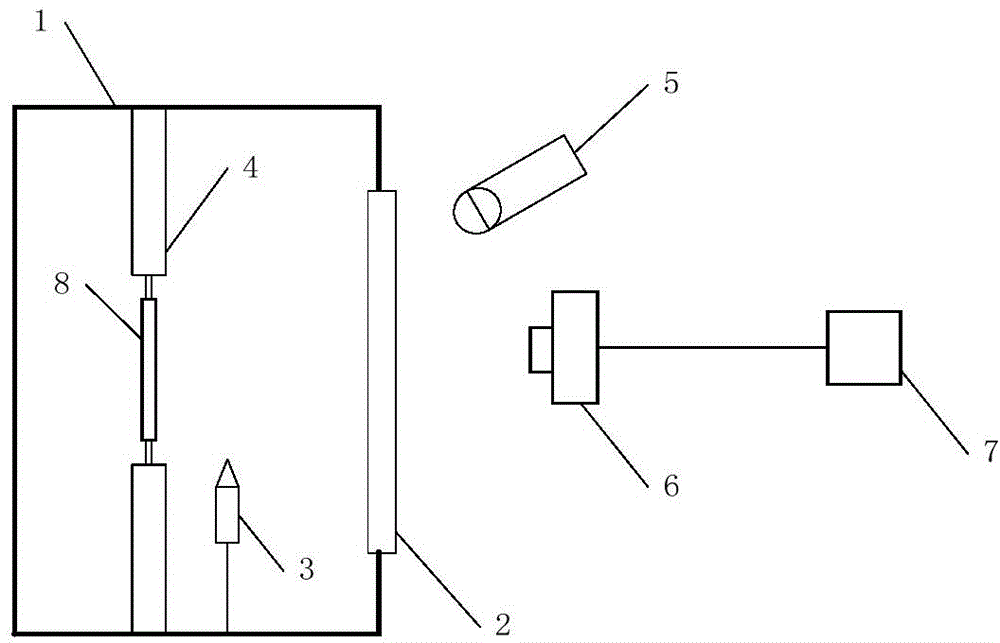

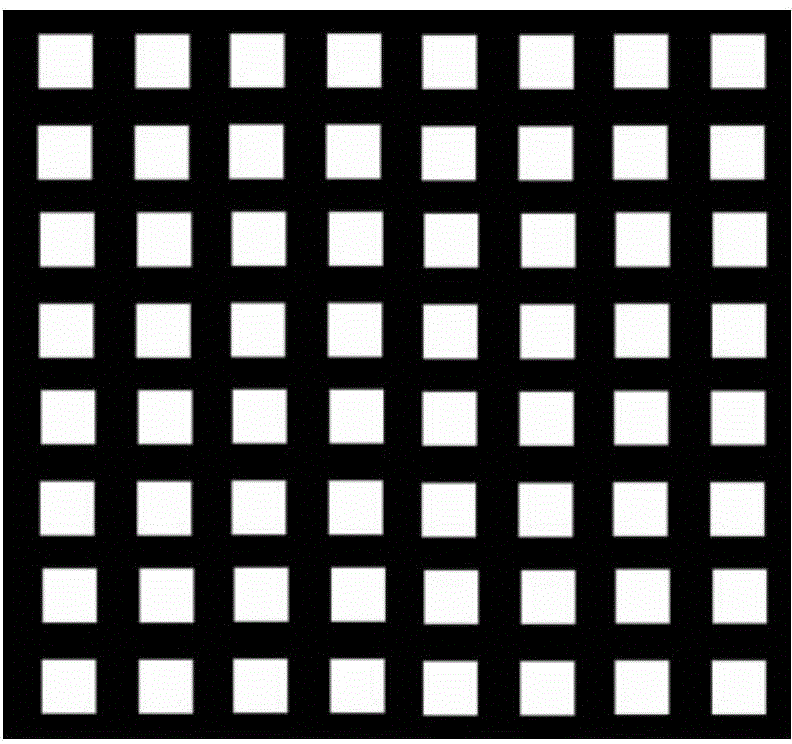

[0026] figure 1 A schematic structural view of an embodiment of a method for measuring deformation of an object passing through smoke under a flame and smoke environment provided by the present invention. Aluminum oxide or silver is used to make reflective light speckle speckles on the surface of the object to be measured. The speckle shape is square, rhombus or triangular. figure 2 An example of special shape speckle on the object surface used in this embodiment is shown.

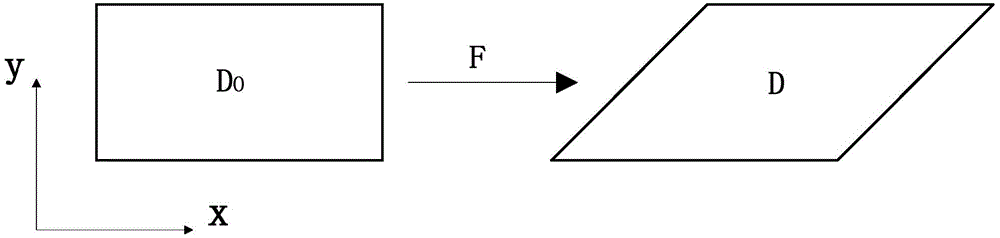

[0027] Put the object to be tested with mirror speckle on the surface into a test chamber filled with flame and smoke, and place it on the force-heat loading table. The object is deformed by force or heat on the loading platform, and a CCD camera with a filter is used to shoot t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com