Patents

Literature

333 results about "Surface matching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

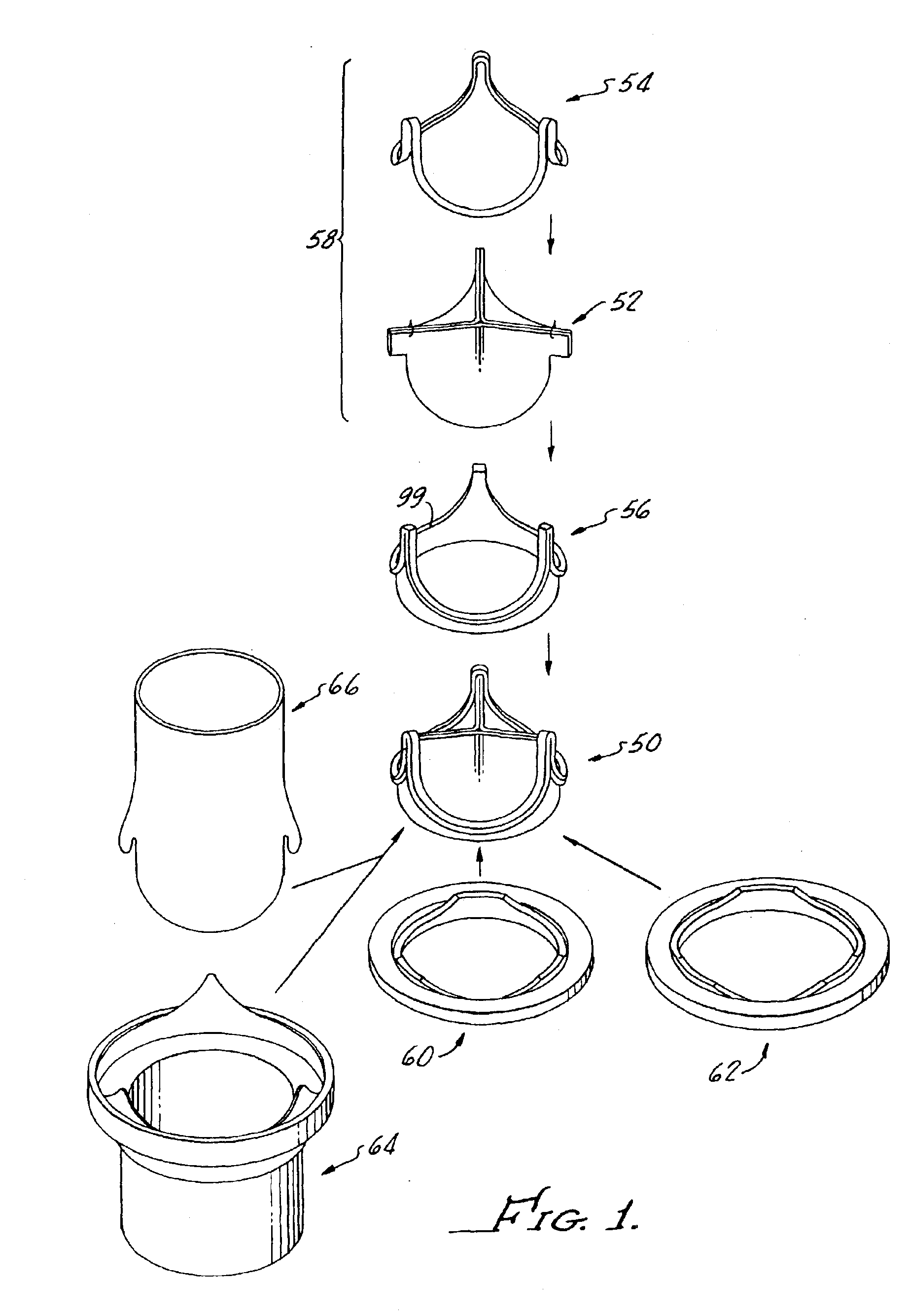

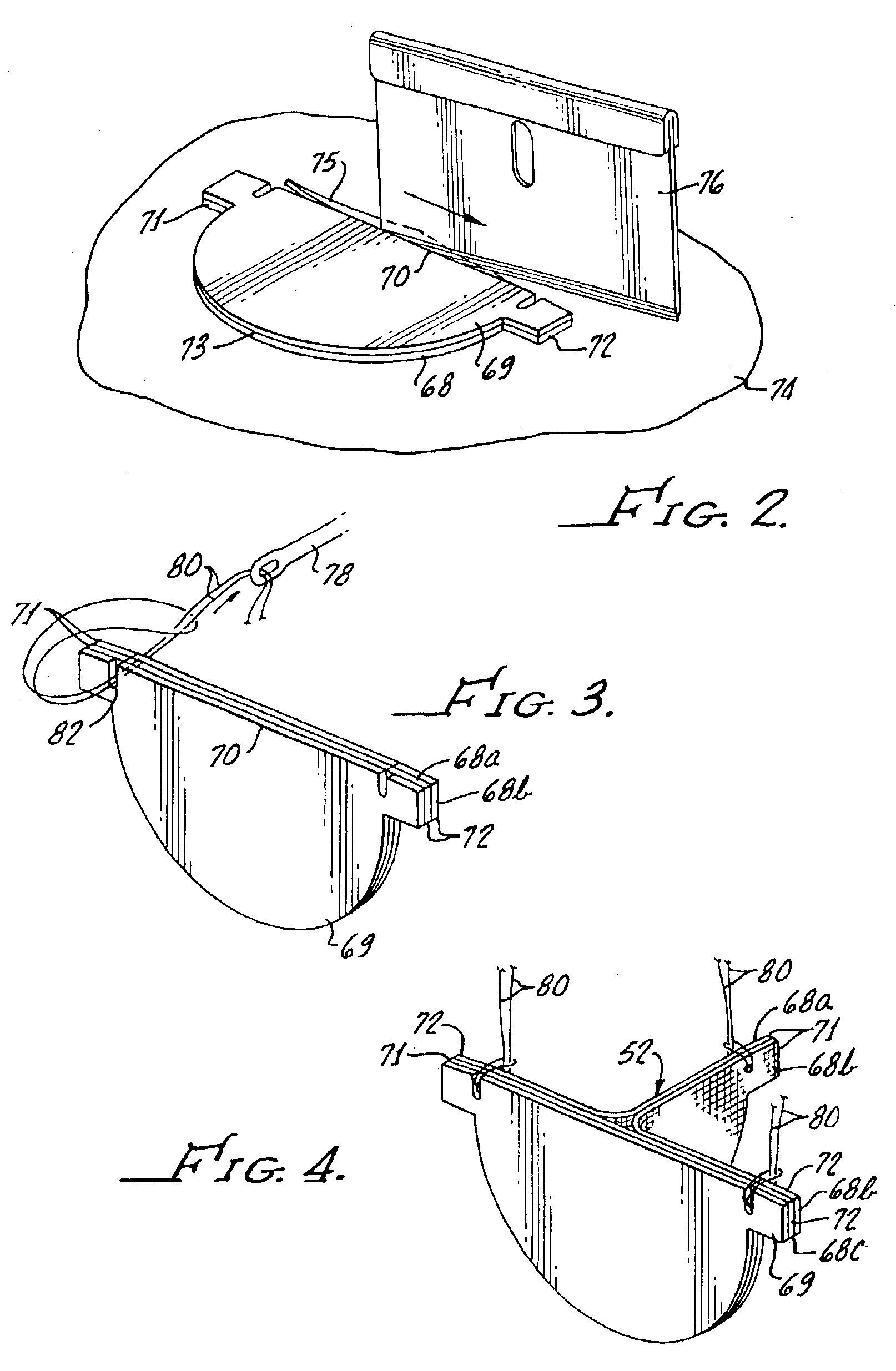

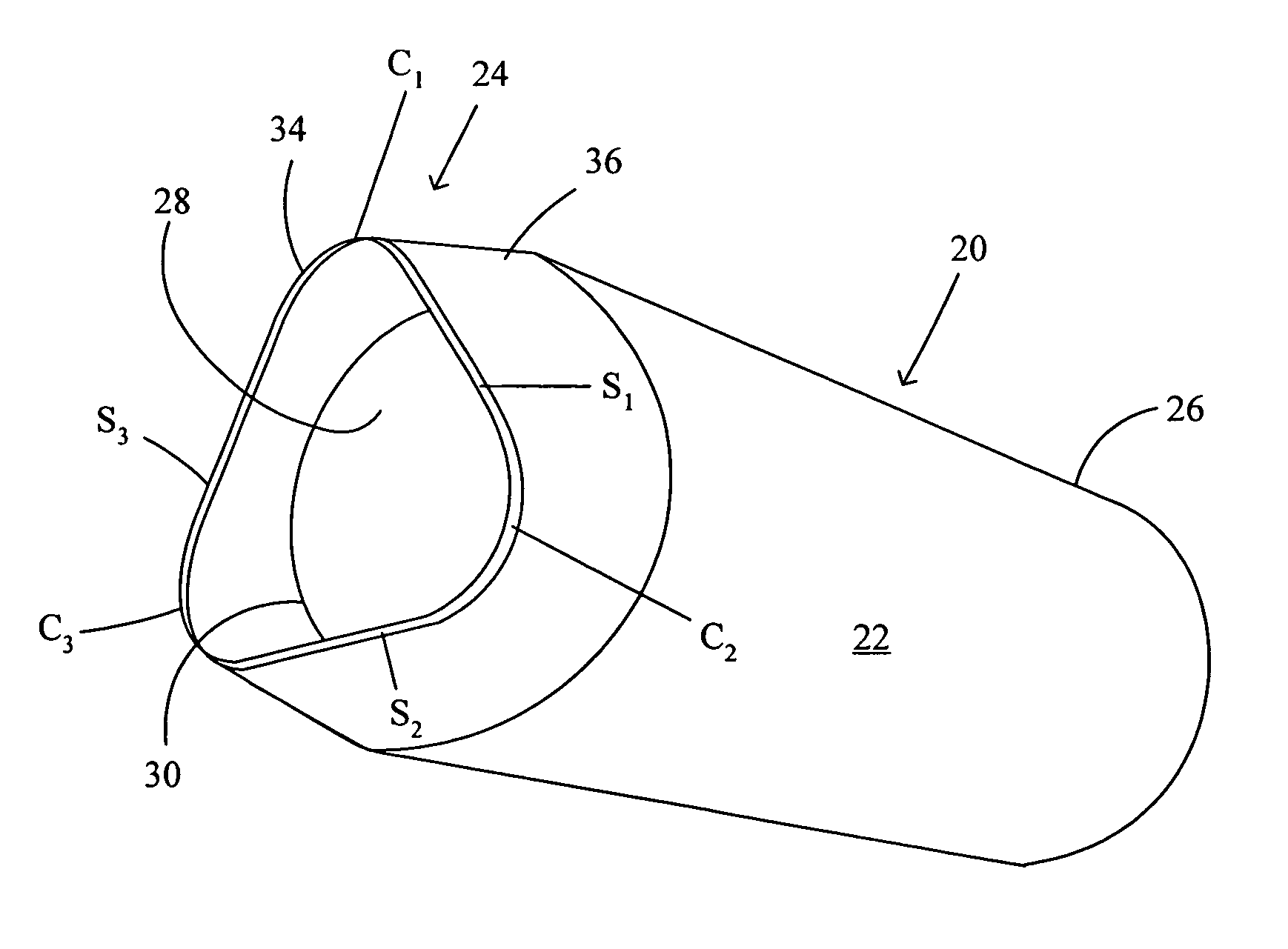

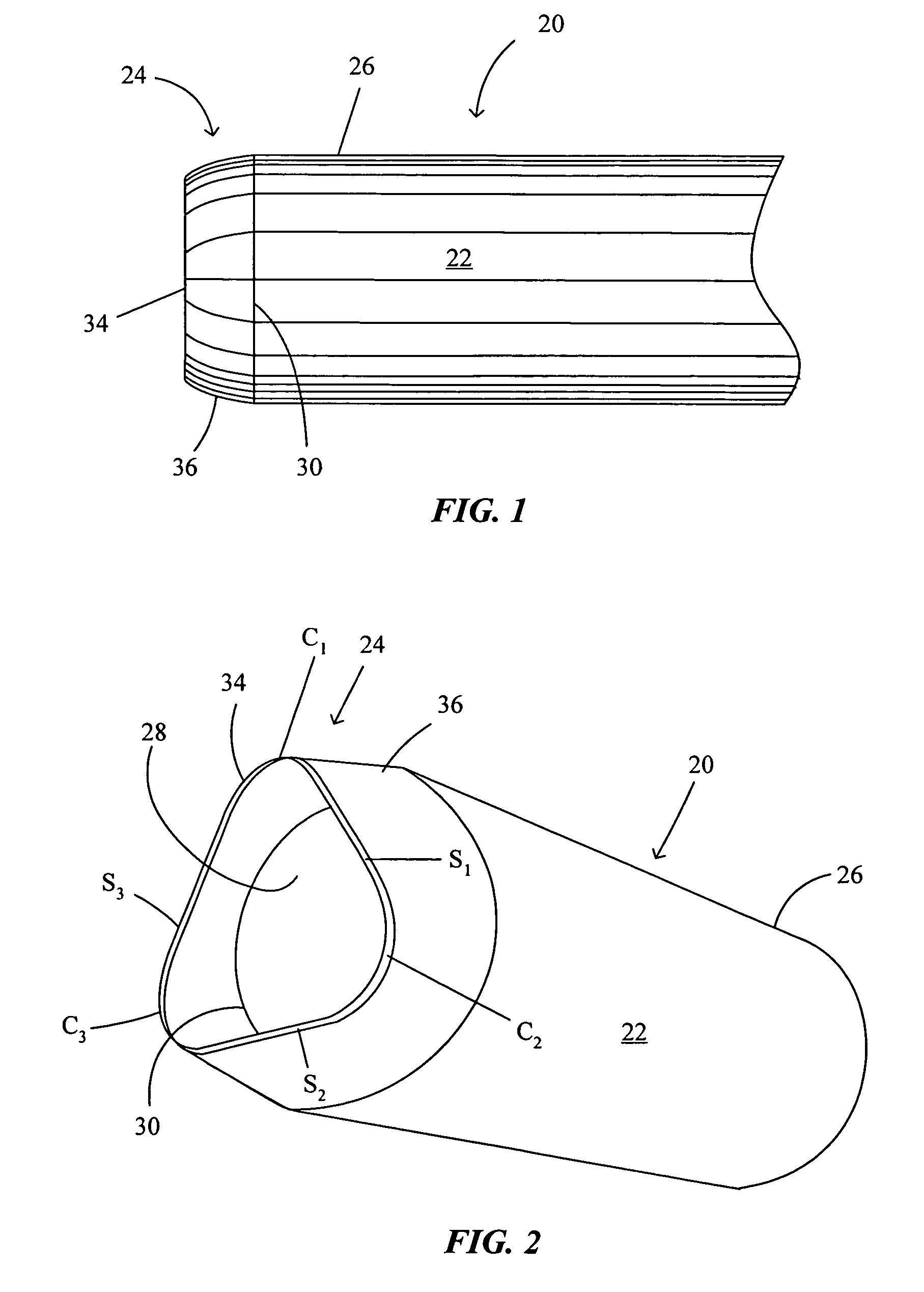

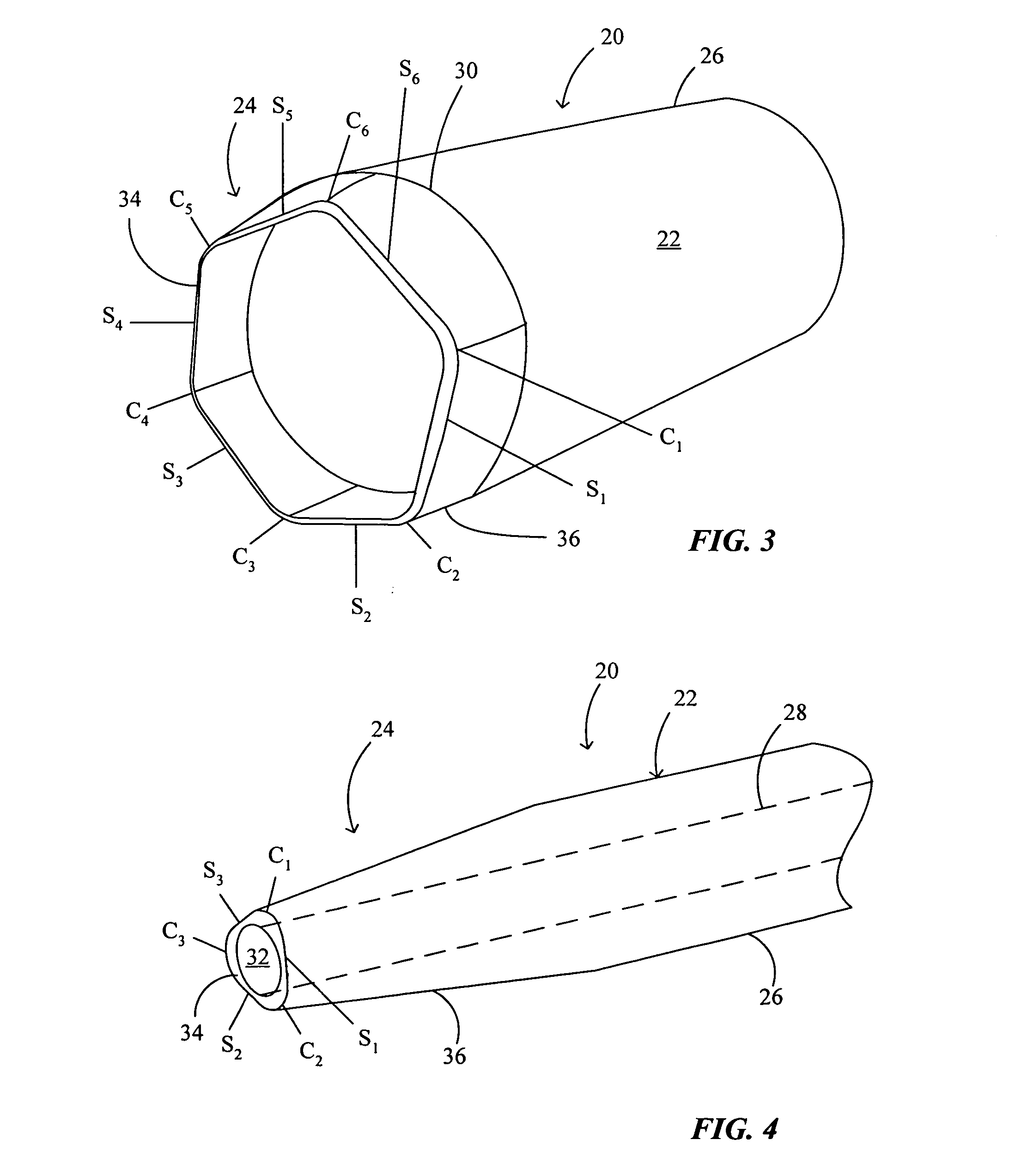

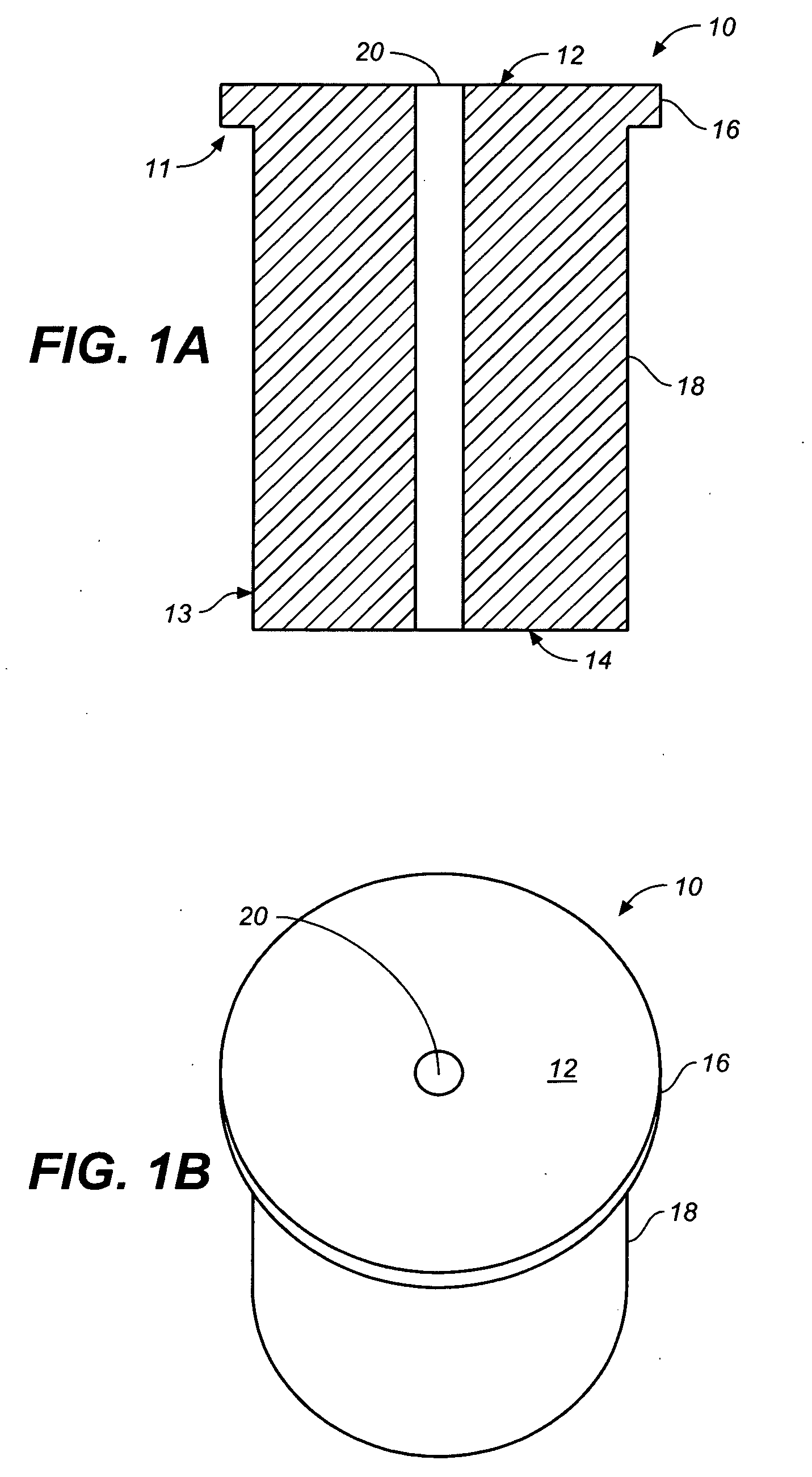

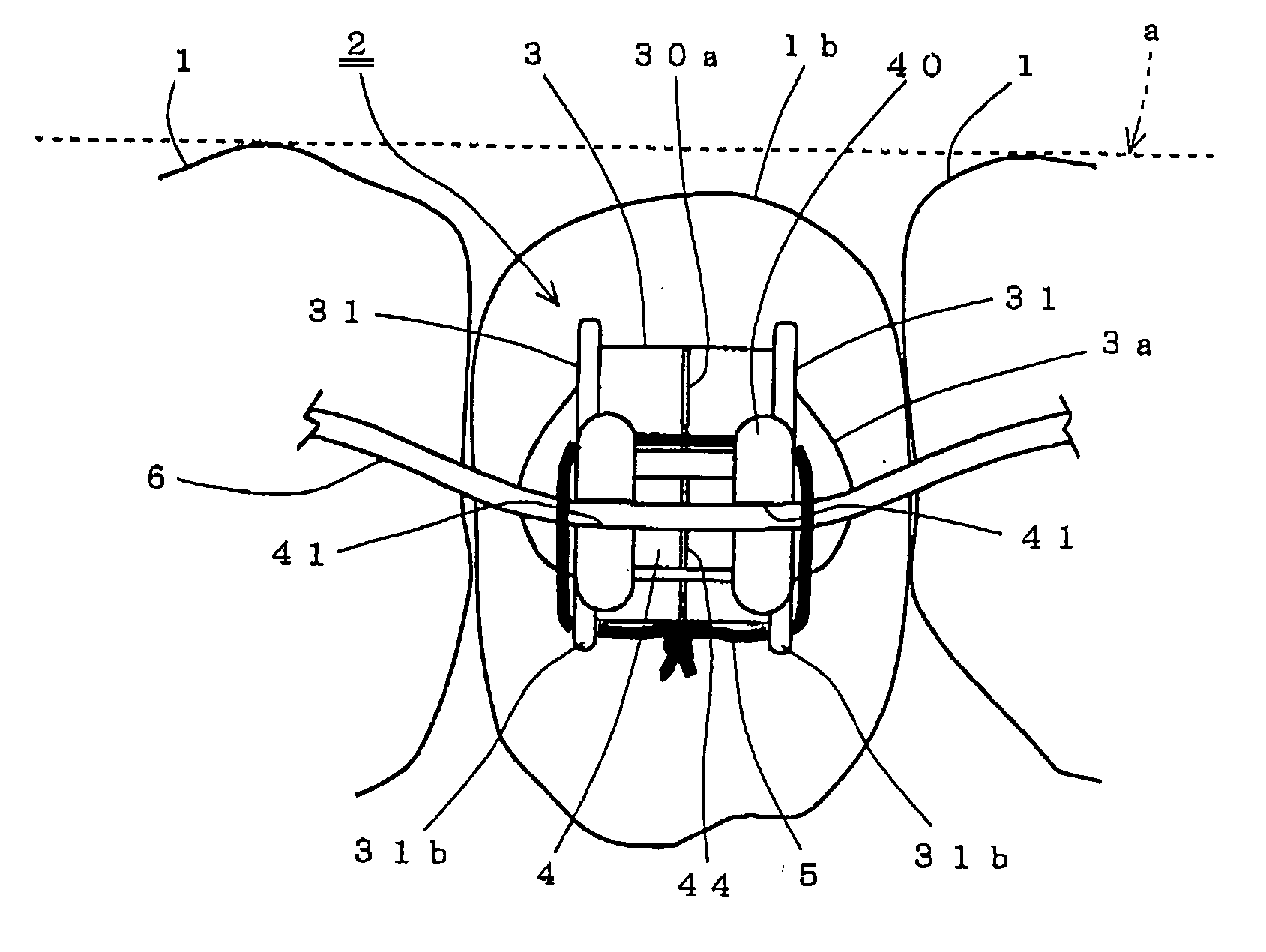

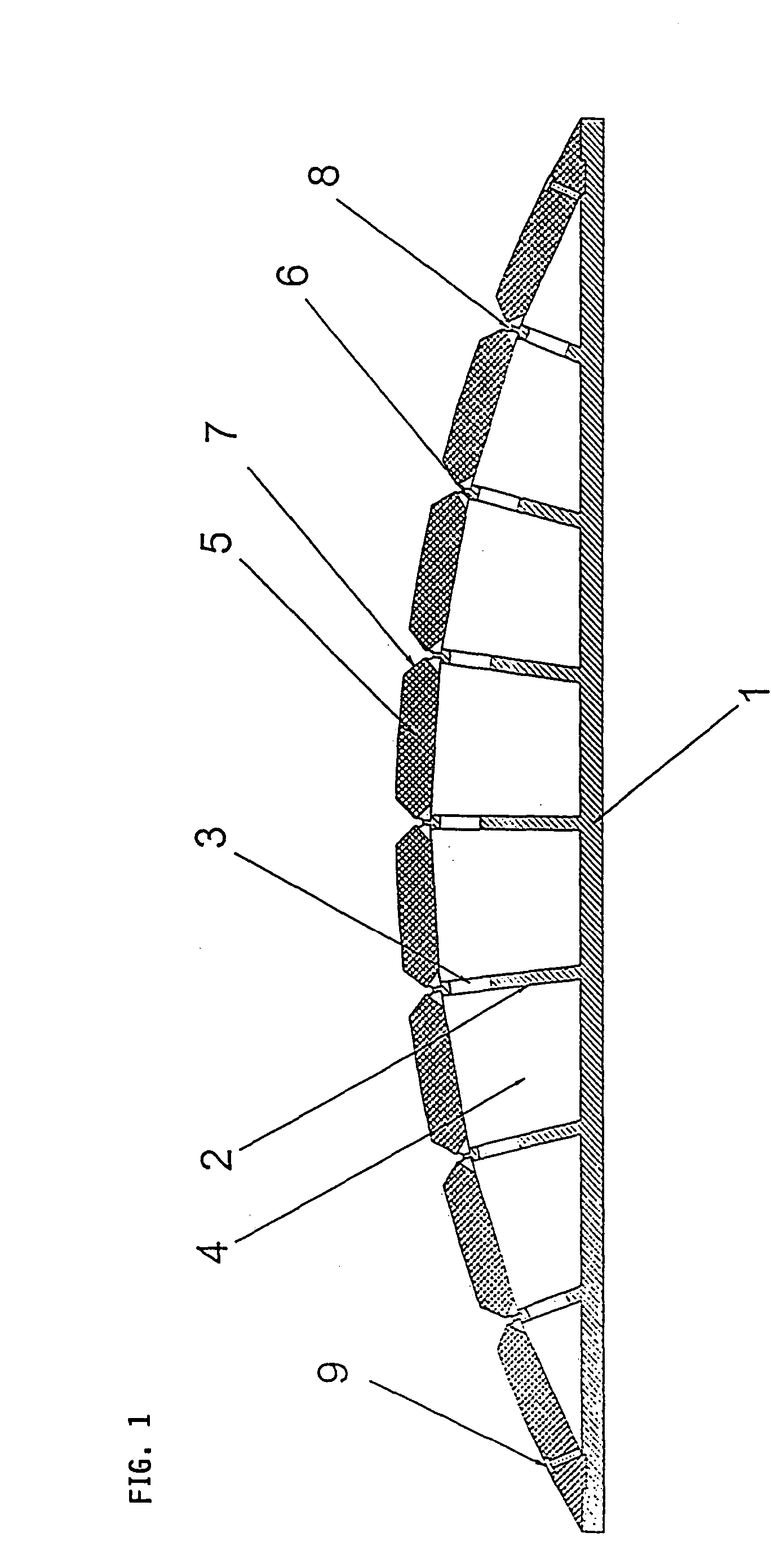

Contoured heart valve suture rings

InactiveUS20060009842A1Improving long-term functionalityReduce pointsHeart valvesInsertion stentCatheter

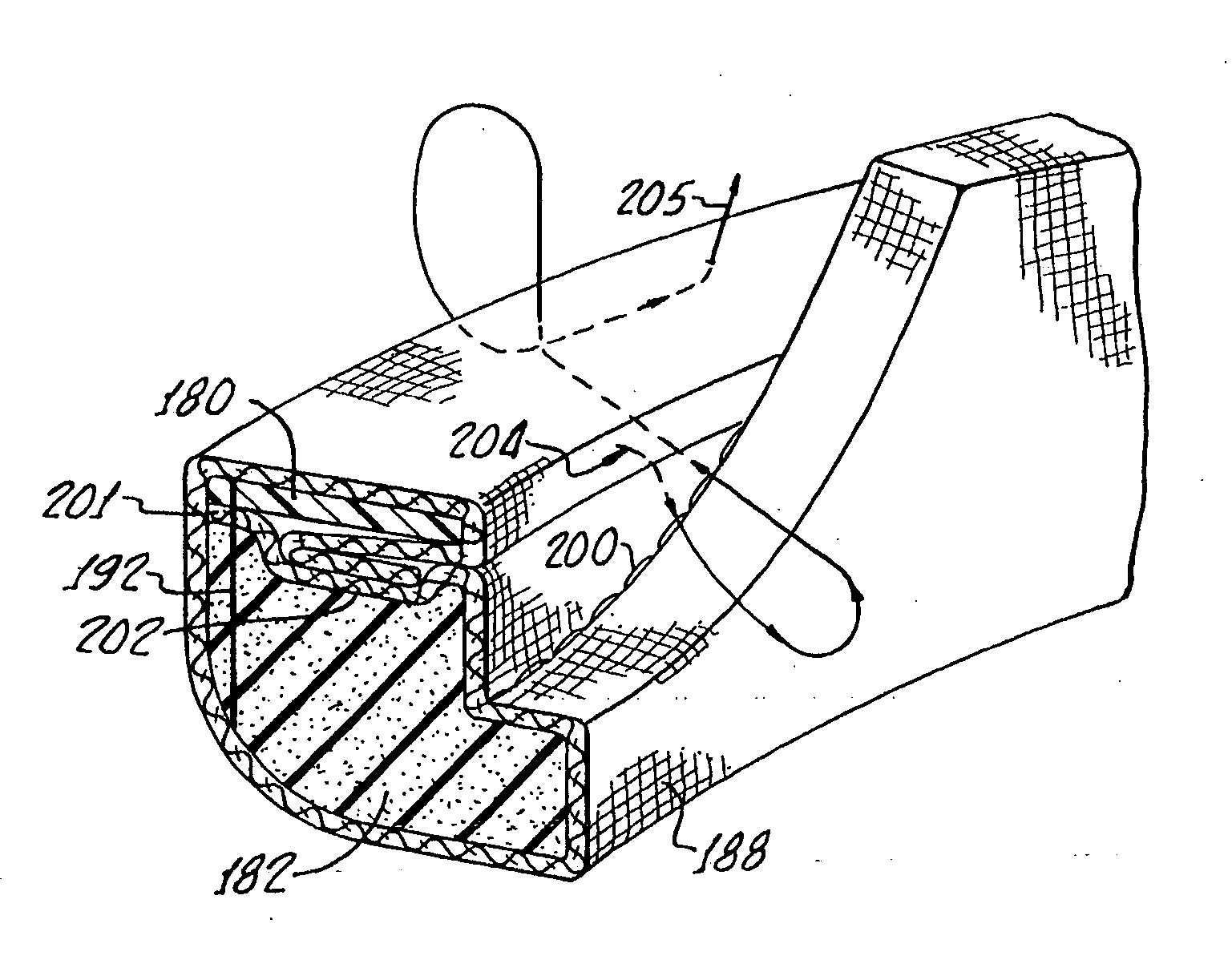

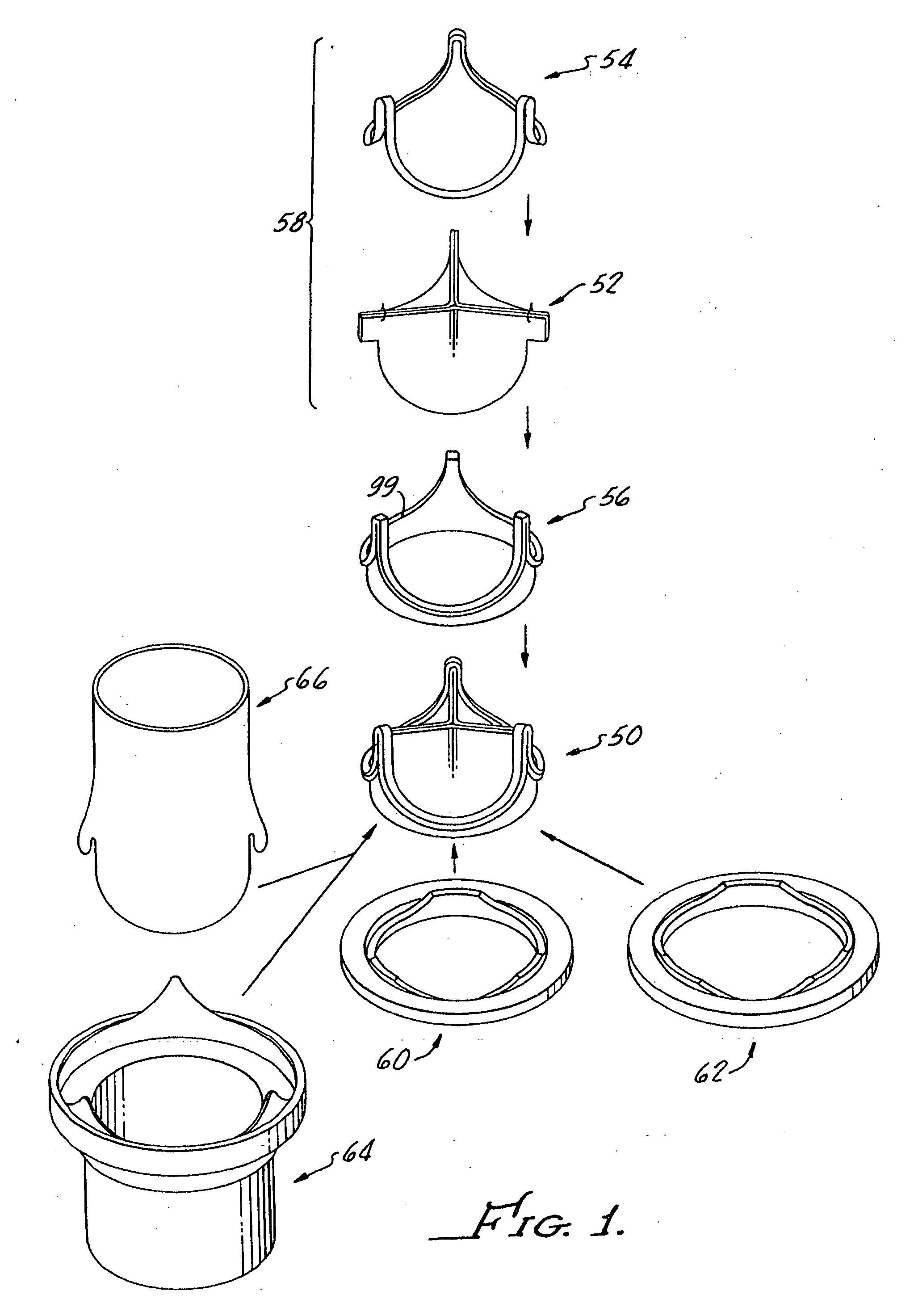

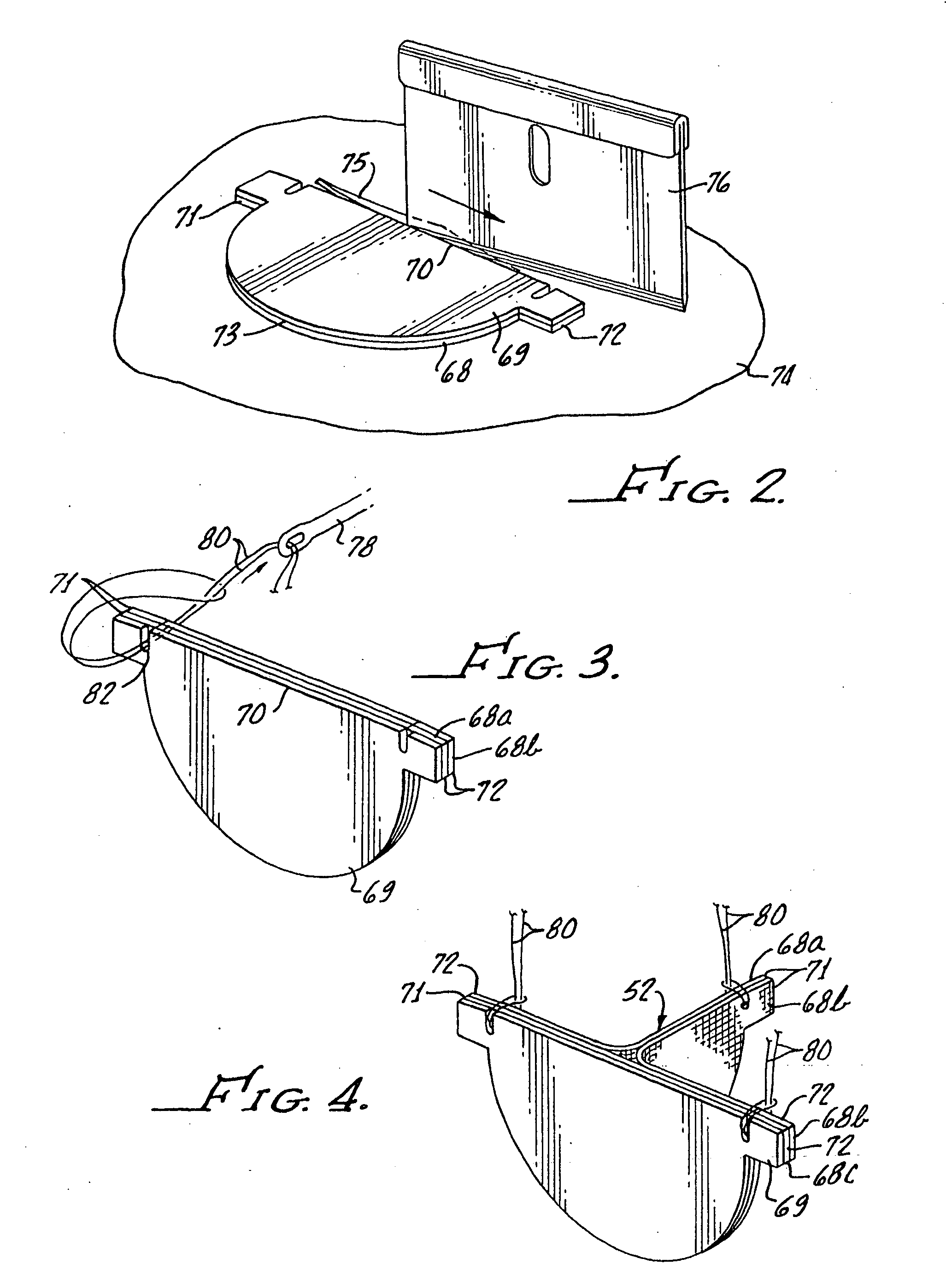

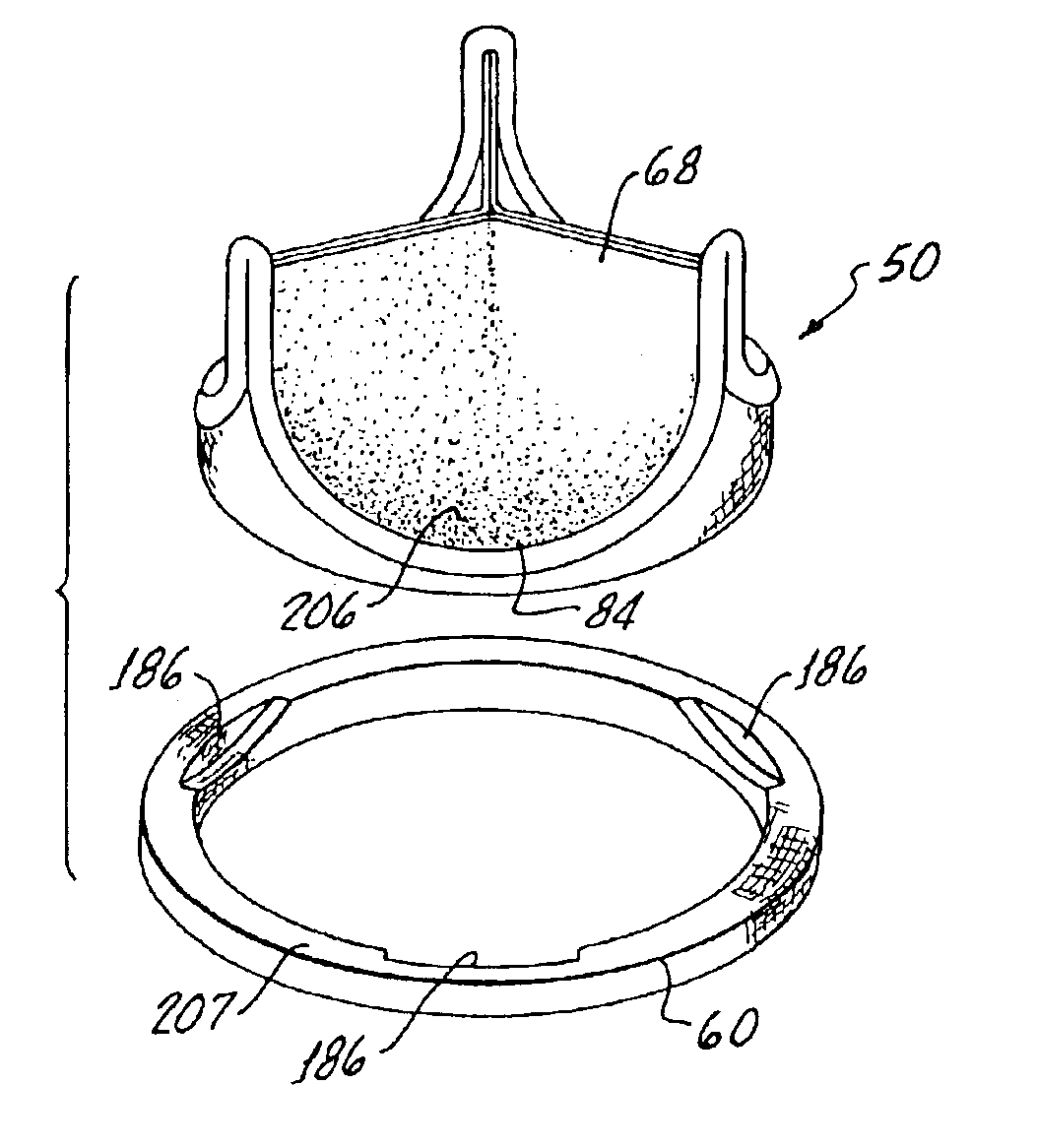

Improved, adaptable tissue-type heart valves and methods for their manufacture are disclosed wherein a dimensionally stable, pre-aligned tissue leaflet subassembly is formed and its peripheral edge clamped between and attached to an upper shaped wireform and a lower support stent. A variety of adaptable structural interfaces including suture rings, flanges, and conduits may be attached to the support stent with or without an outlet conduit disposed about the wireform to provide a tissue-type heart valve adaptable for use in either a natural heart or in mechanical pumping devices. The methods include forming individual leaflets with a template and using the template to attach the leaflets together to form a tissue leaflet subassembly. The template and leaflets include a straight edge terminating in oppositely directed tabs, and a curvilinear cusp edge extending opposite the straight edge. The template may include a guide slot in its straight edge and the assembly includes aligning two leaflet tabs with the template and passing sutures through the guide slot and through the leaflet tabs. The leaflet subassembly is mated to a wireform with the tabs extending through commissure posts of the wireform. A support stent having an upper surface matching the lower surface of the wireform sandwiches the edges of the leaflet subassembly therebetween. Separated tabs on the leaflet subassembly are passed through the wireform commissures and attached to adjacent stent commissures so as to induce clamping of the leaflet tabs between the stent commissures and wireform commissures upon a radially inward force being applied to the leaflets.

Owner:EDWARDS LIFESCIENCES CORP

Heart valves and suture rings therefor

InactiveUS6945997B2Reduce stress pointImproving long-term functionalityHeart valvesInsertion stentTissues types

Improved, adaptable tissue-type heart valves and methods for their manufacture are disclosed wherein a dimensionally stable, pre-aligned tissue leaflet subassembly is formed and its peripheral edge clamped between and attached to an upper shaped wireform and a lower support stent. A variety of adaptable structural interfaces including suture rings, flanges, and conduits may be attached to the support stent with or without an outlet conduit disposed about the wireform to provide a tissue-type heart valve adaptable for use in either a natural heart or in mechanical pumping devices. The methods include forming individual leaflets with a template and using the template to attach the leaflets together to form a tissue leaflet subassembly. The template and leaflets include a straight edge terminating in oppositely directed tabs, and a curvilinear cusp edge extending opposite the straight edge. The template may include a guide slot in its straight edge and the assembly includes aligning two leaflet tabs with the template and passing sutures through the guide slot and through the leaflet tabs. The leaflet subassembly is mated to a wireform with the tabs extending through commissure posts of the wireform. A support stent having an upper surface matching the lower surface of the wireform sandwiches the edges of the leaflet subassembly therebetween. Separated tabs on the leaflet subassembly are passed through the wireform commissures and attached to adjacent stent commissures so as to induce clamping of the leaflet tabs between the stent commissures and wireform commissures upon a radially inward force being applied to the leaflets.

Owner:EDWARDS LIFESCIENCES CORP

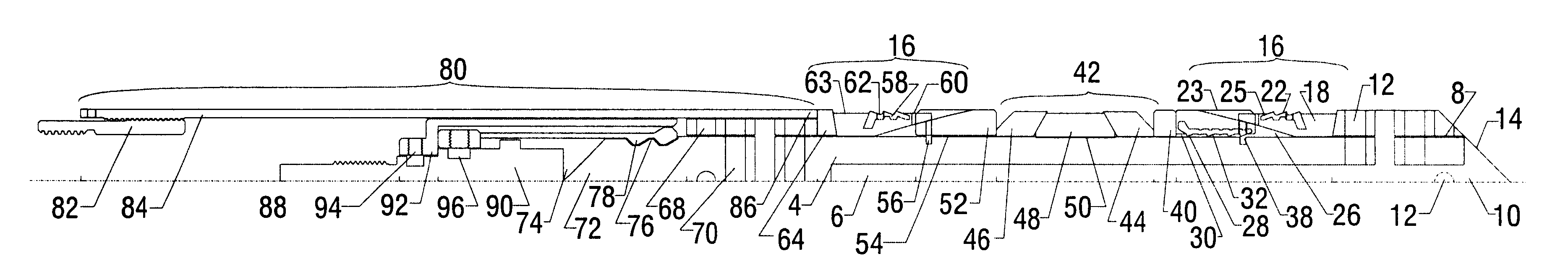

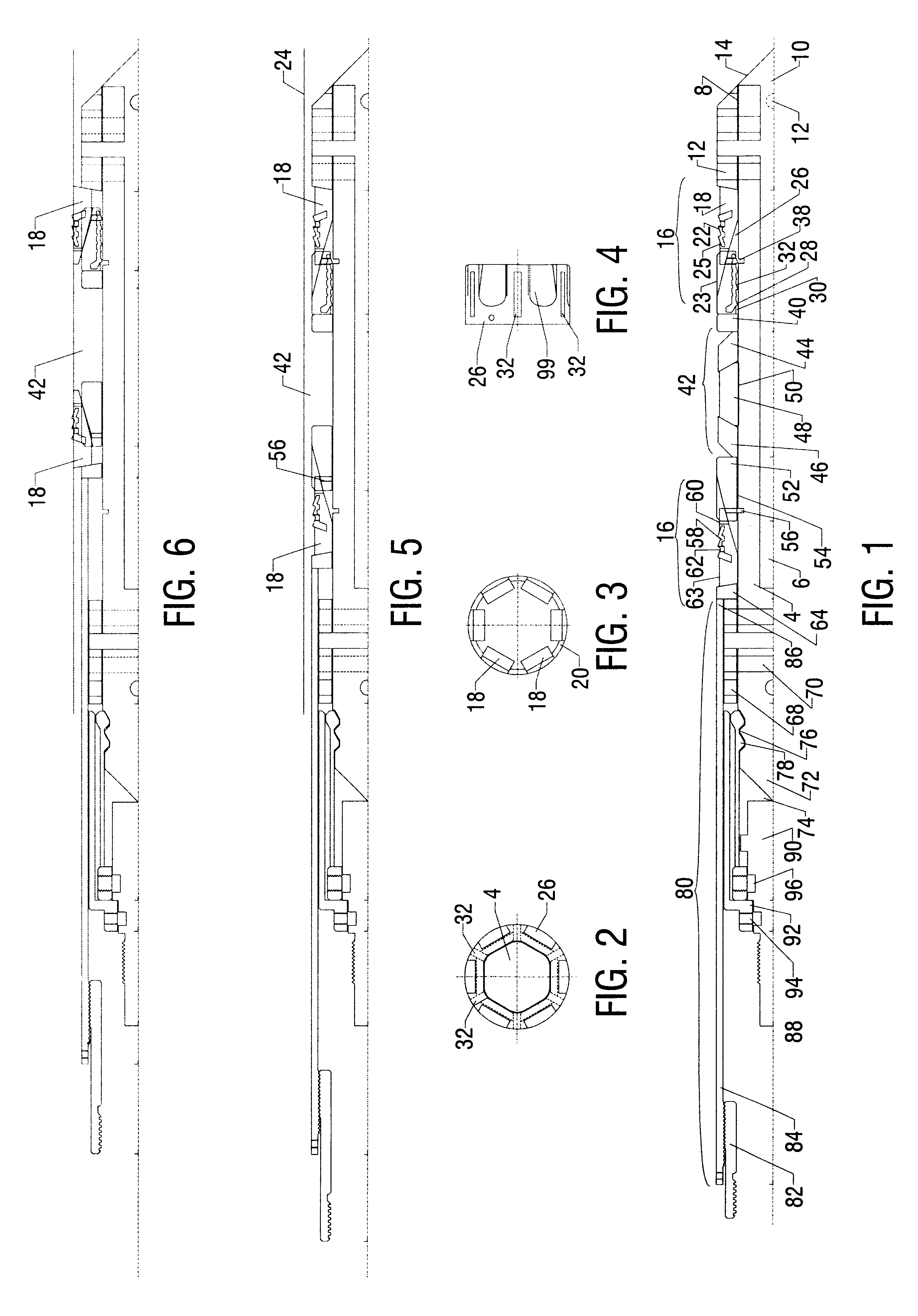

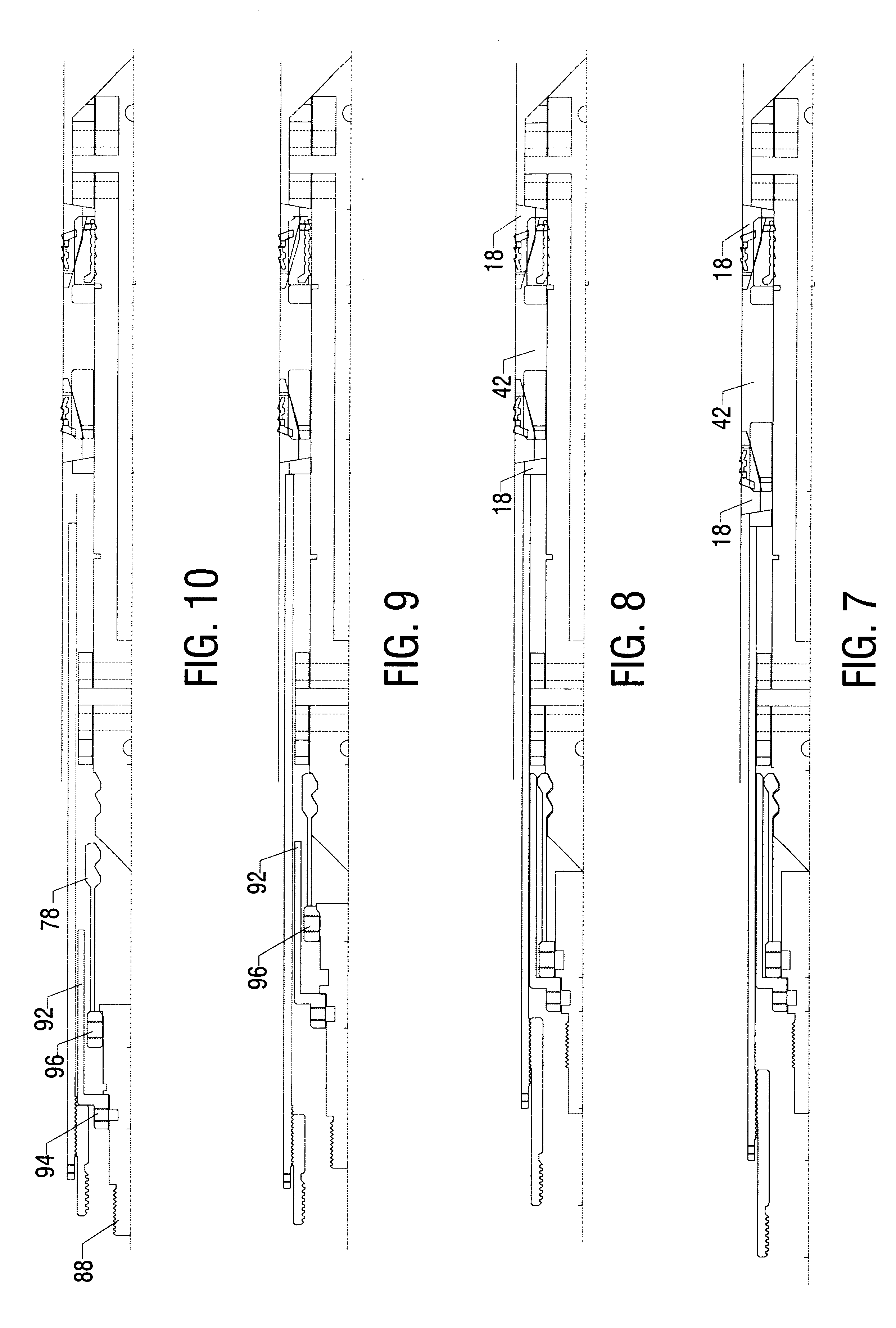

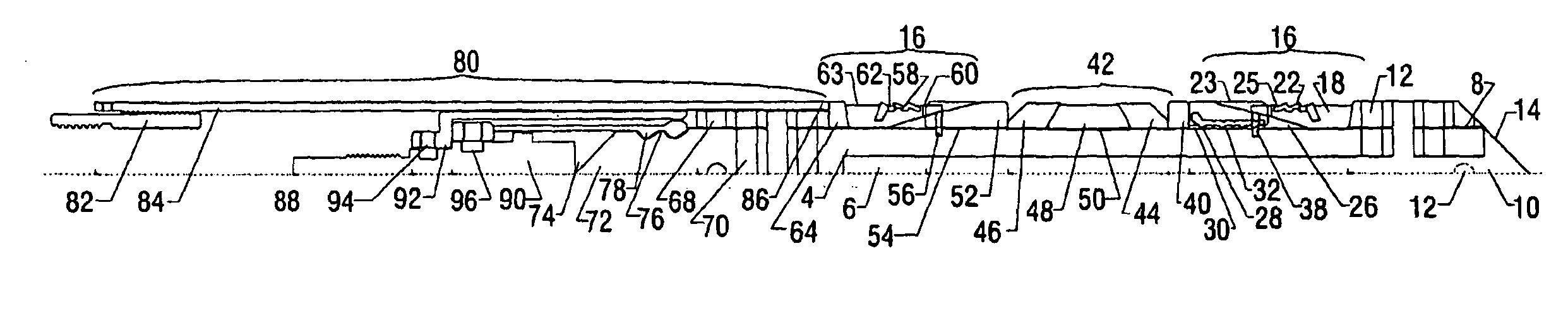

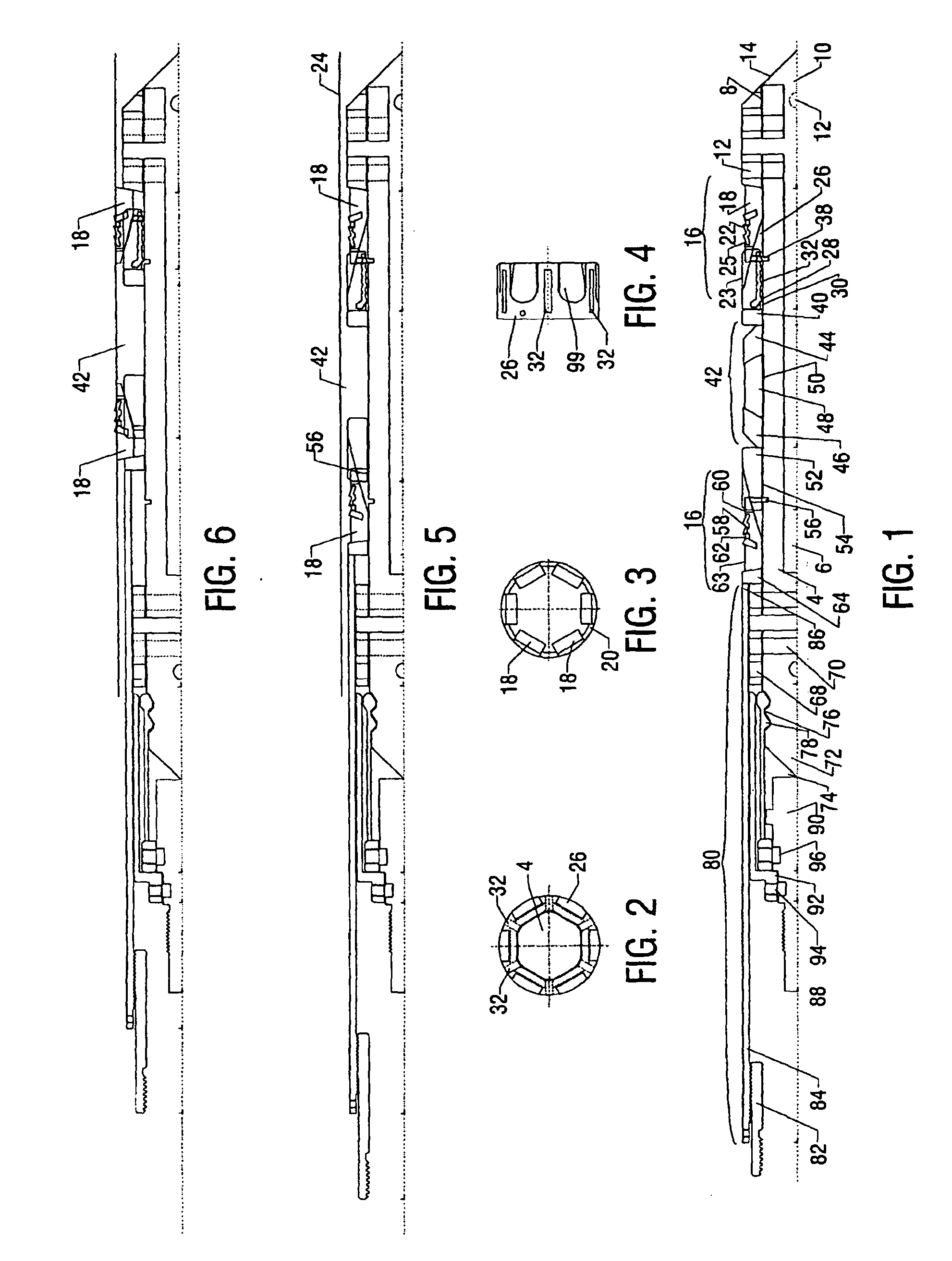

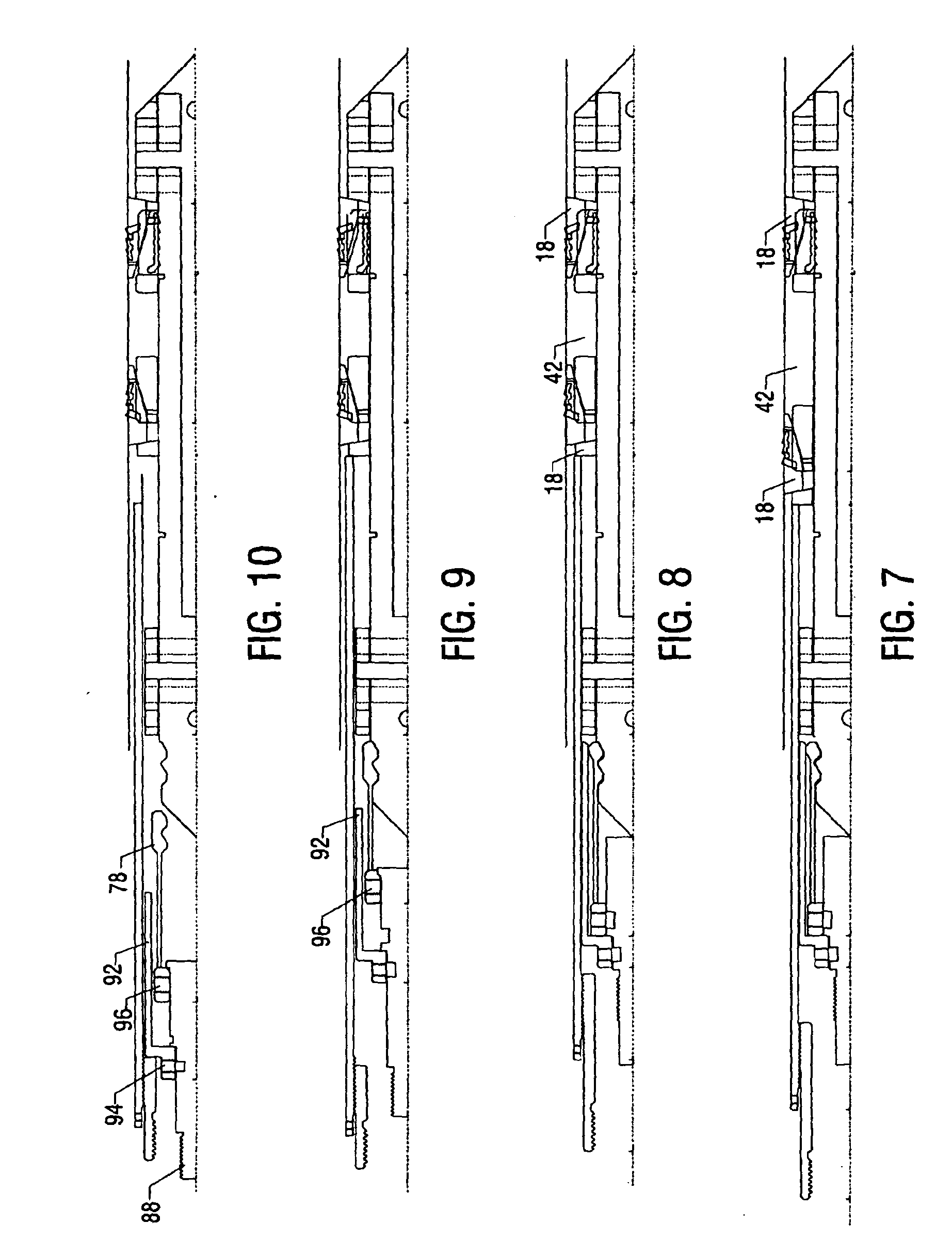

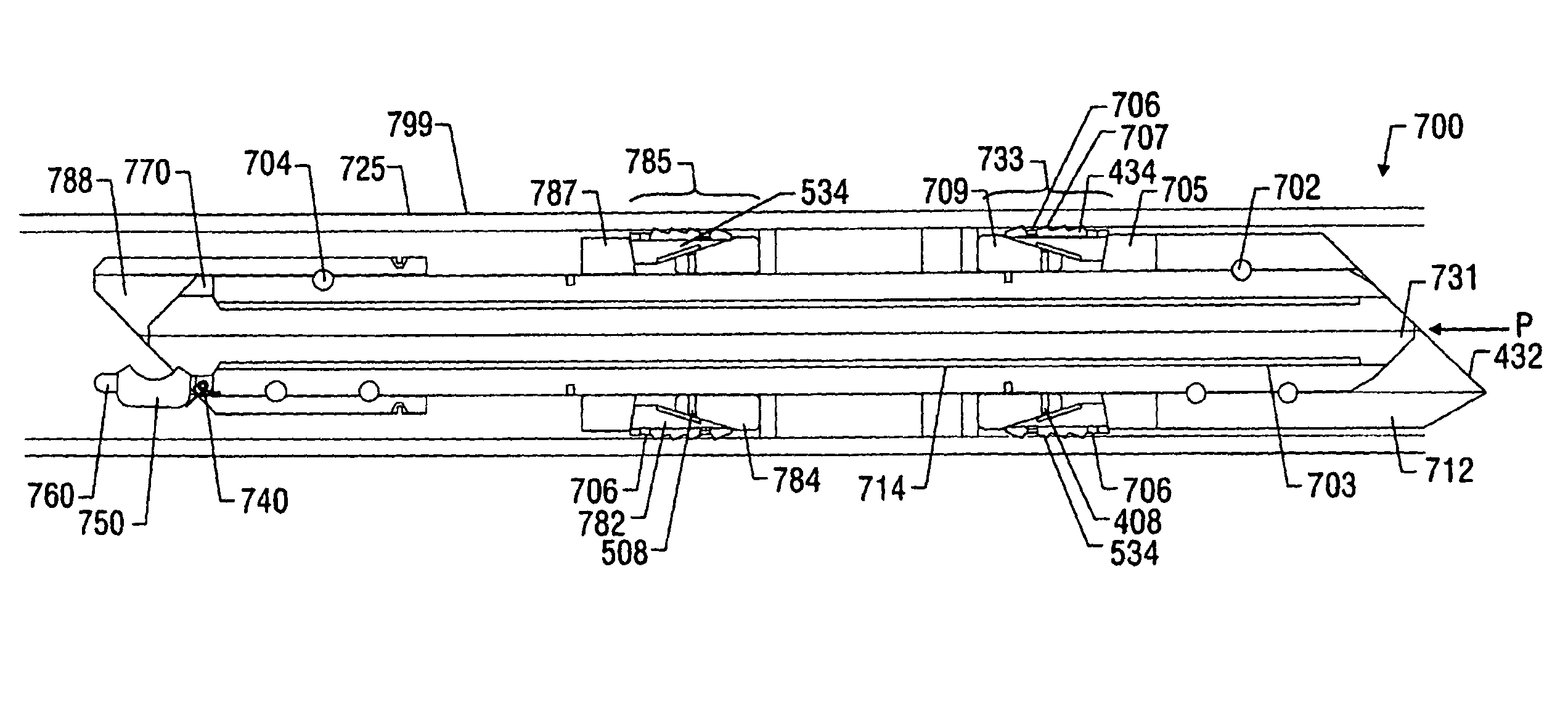

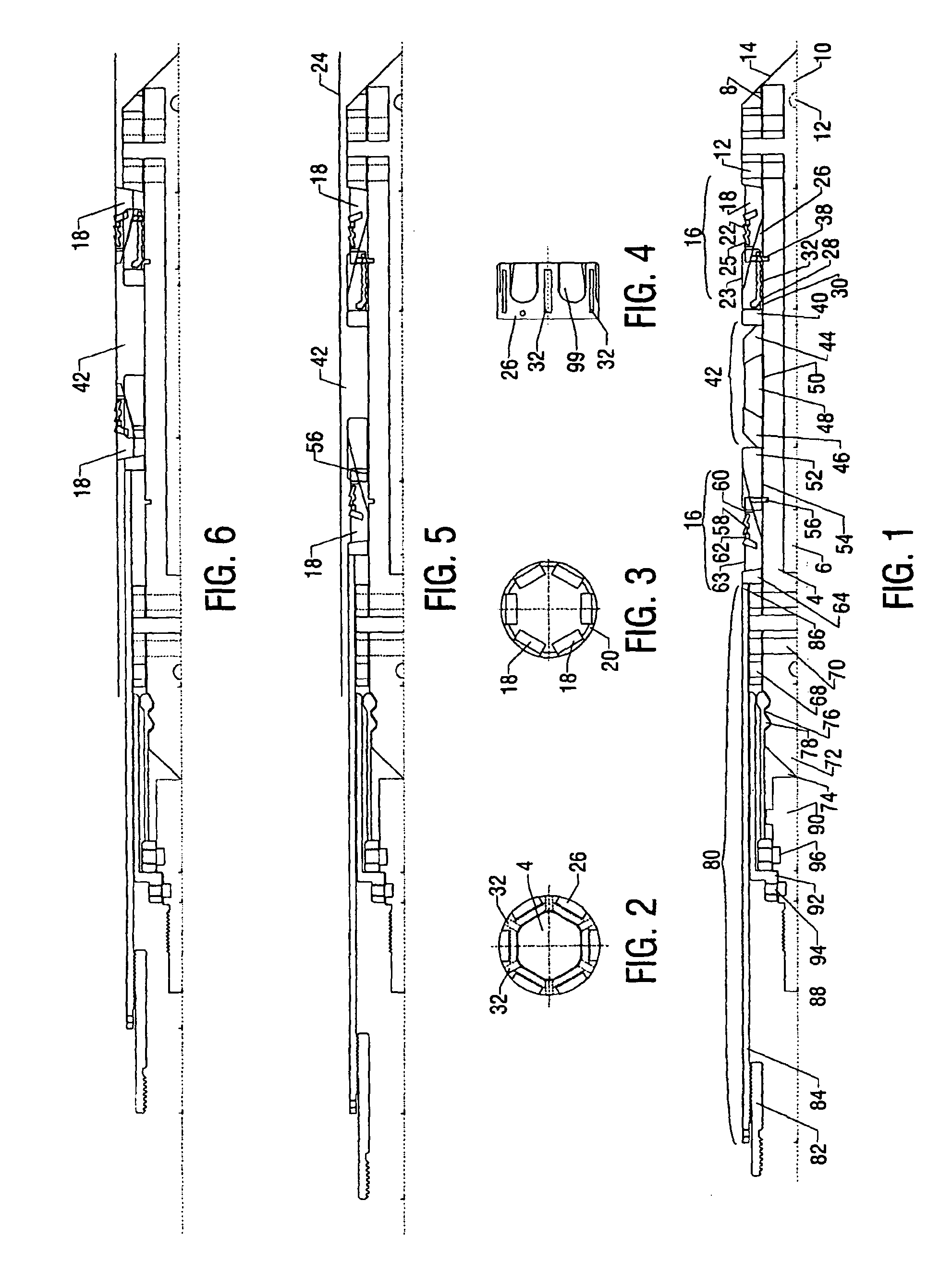

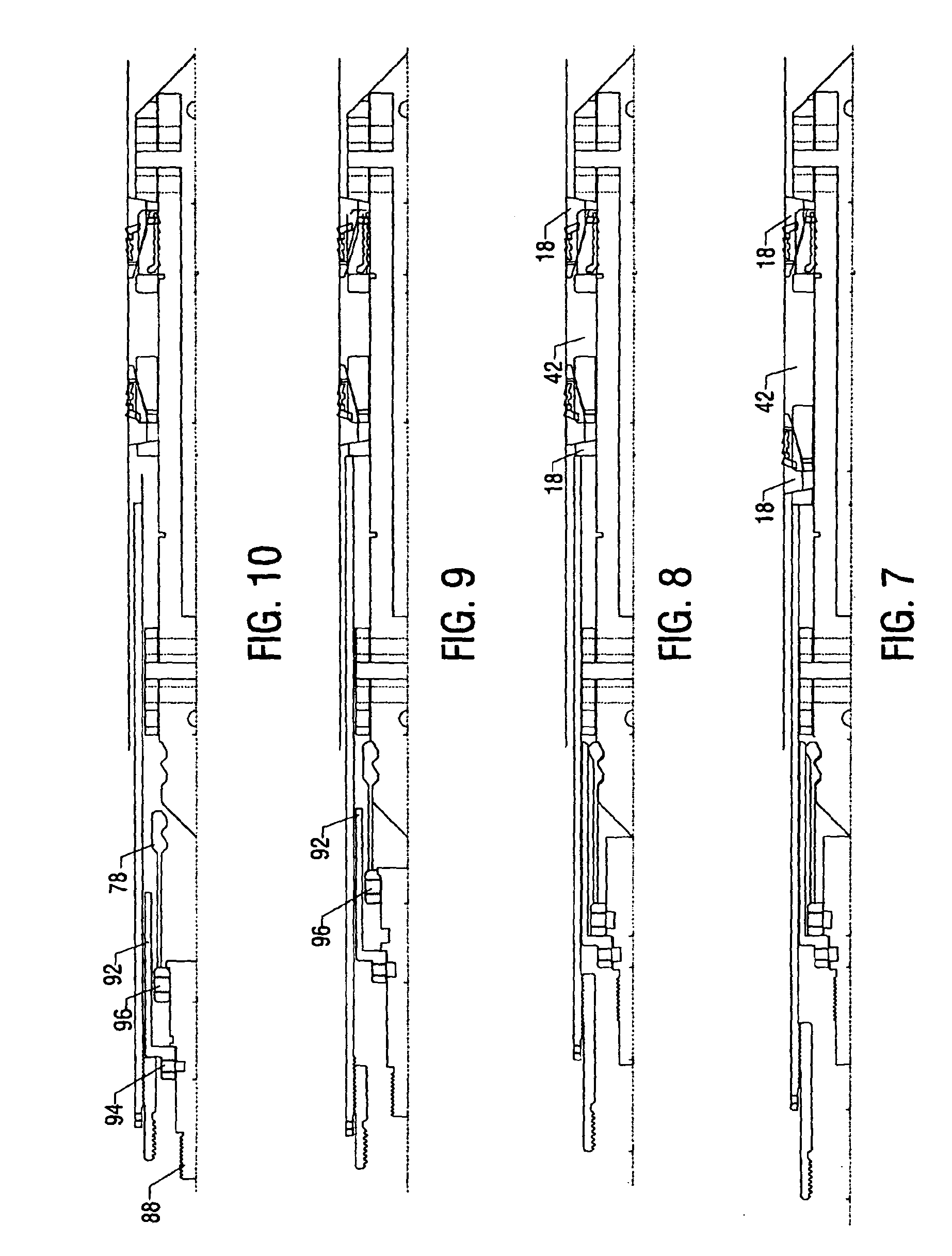

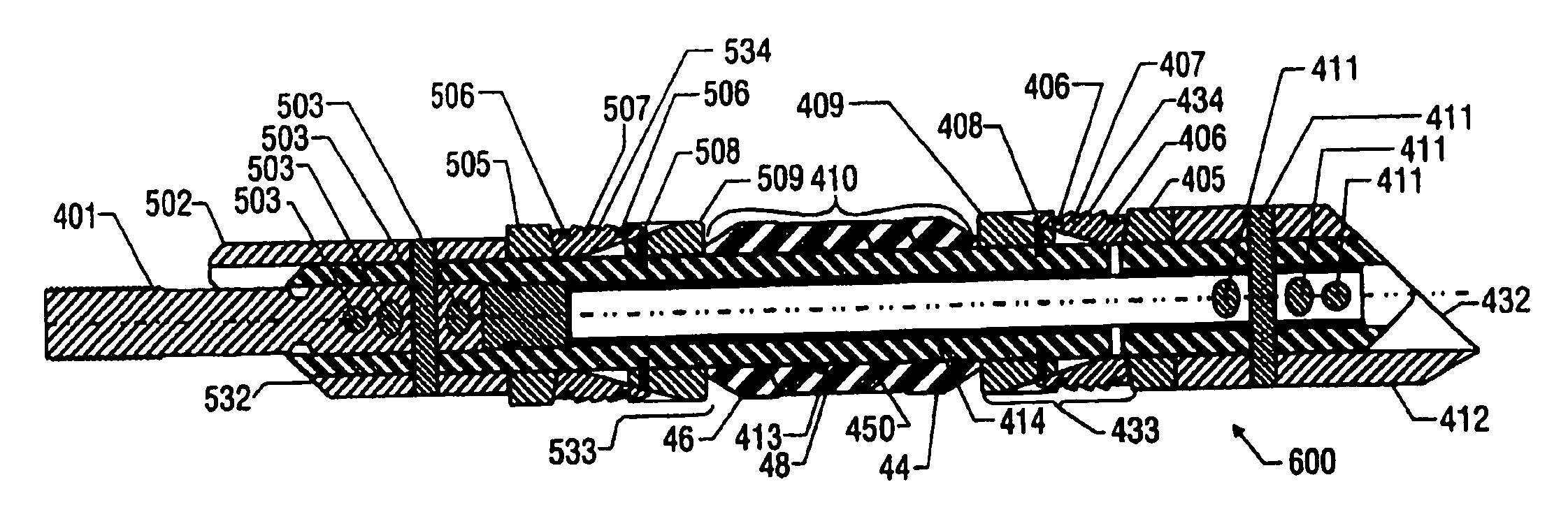

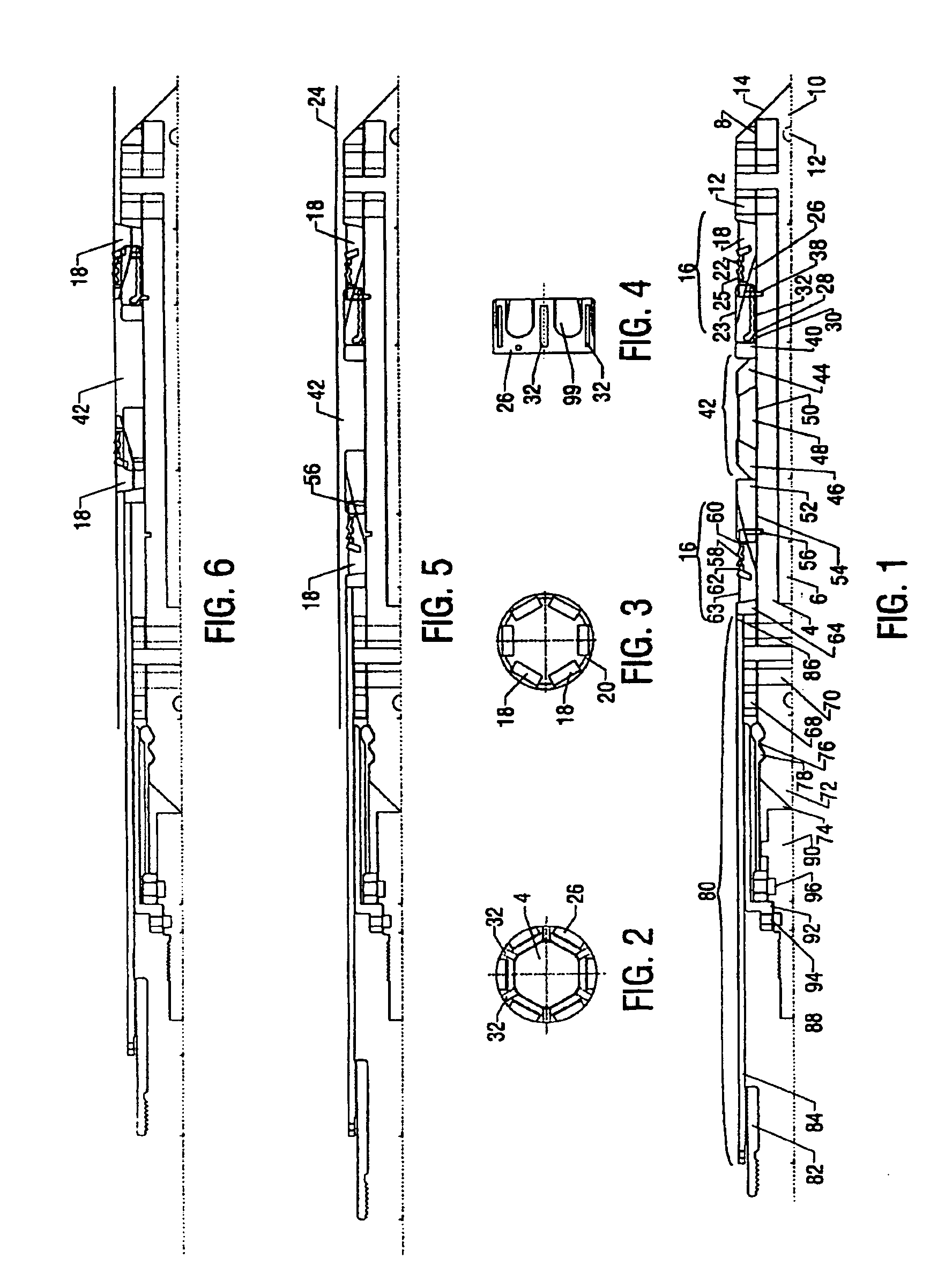

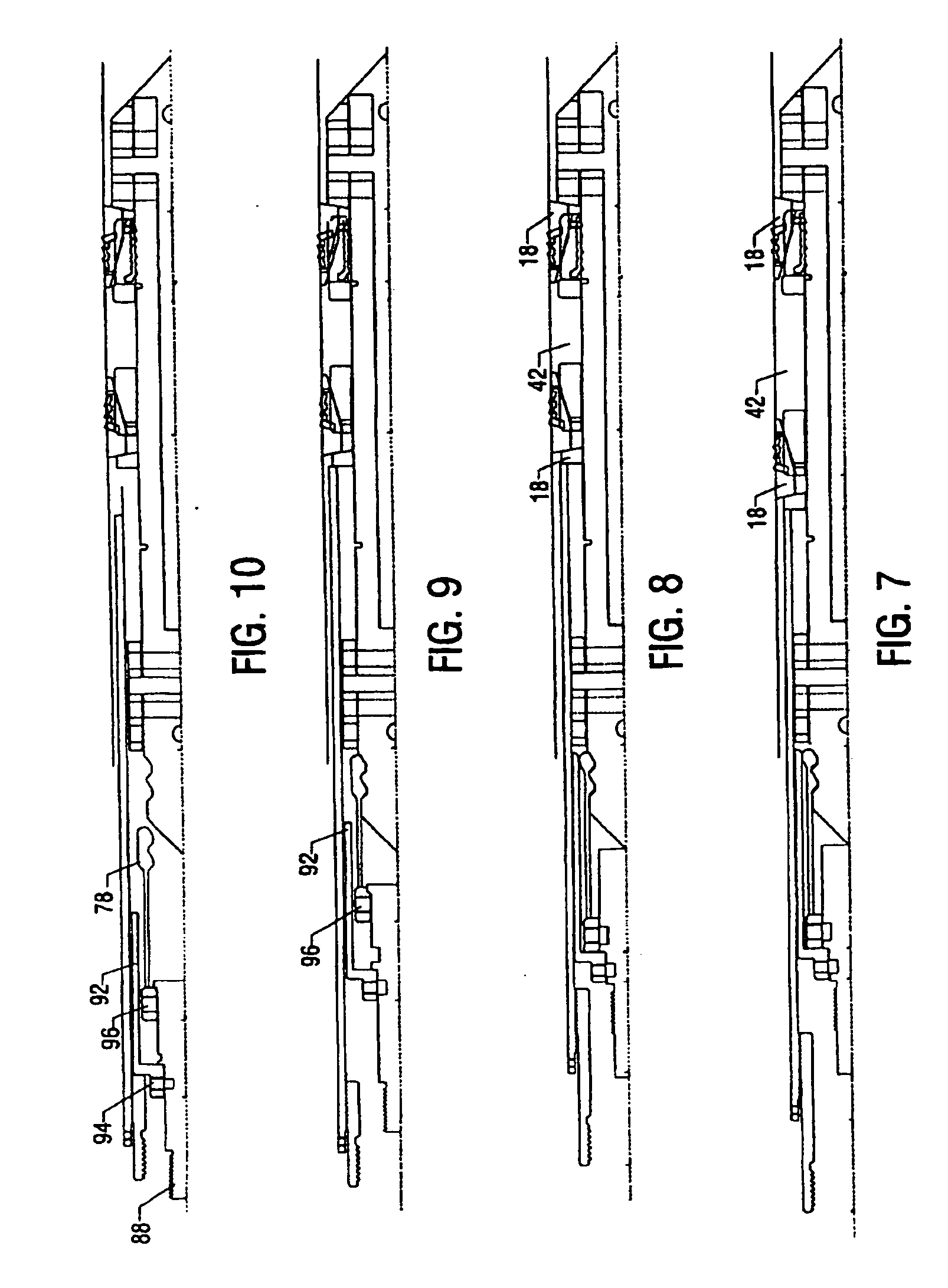

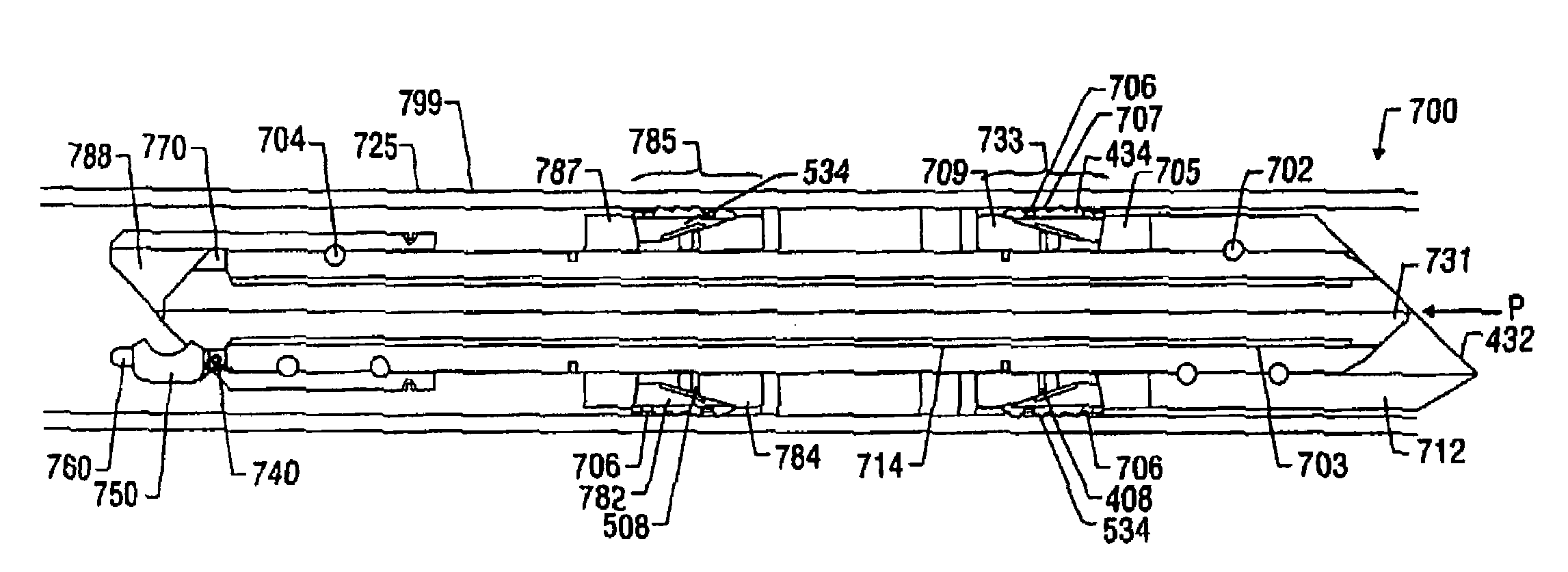

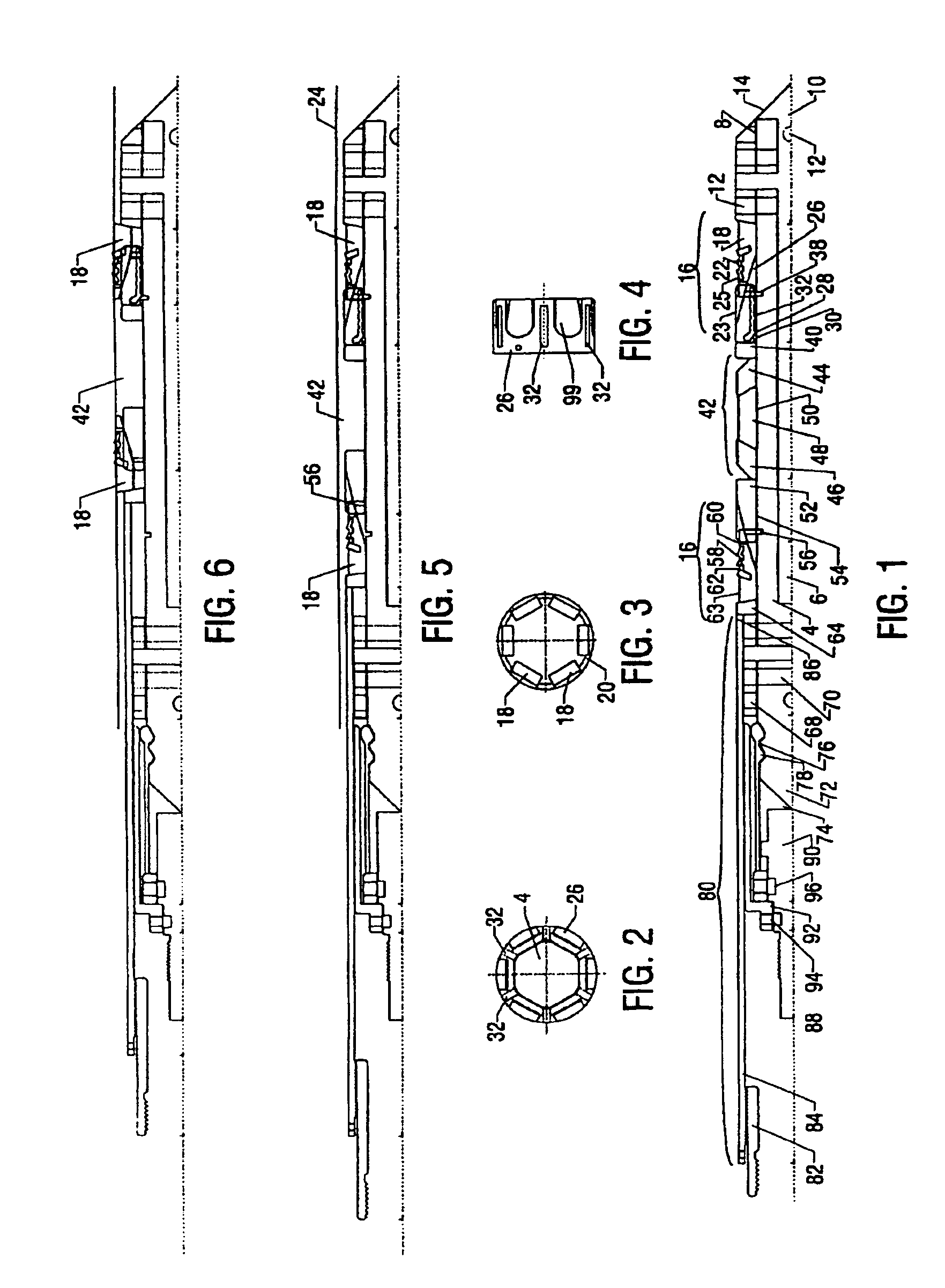

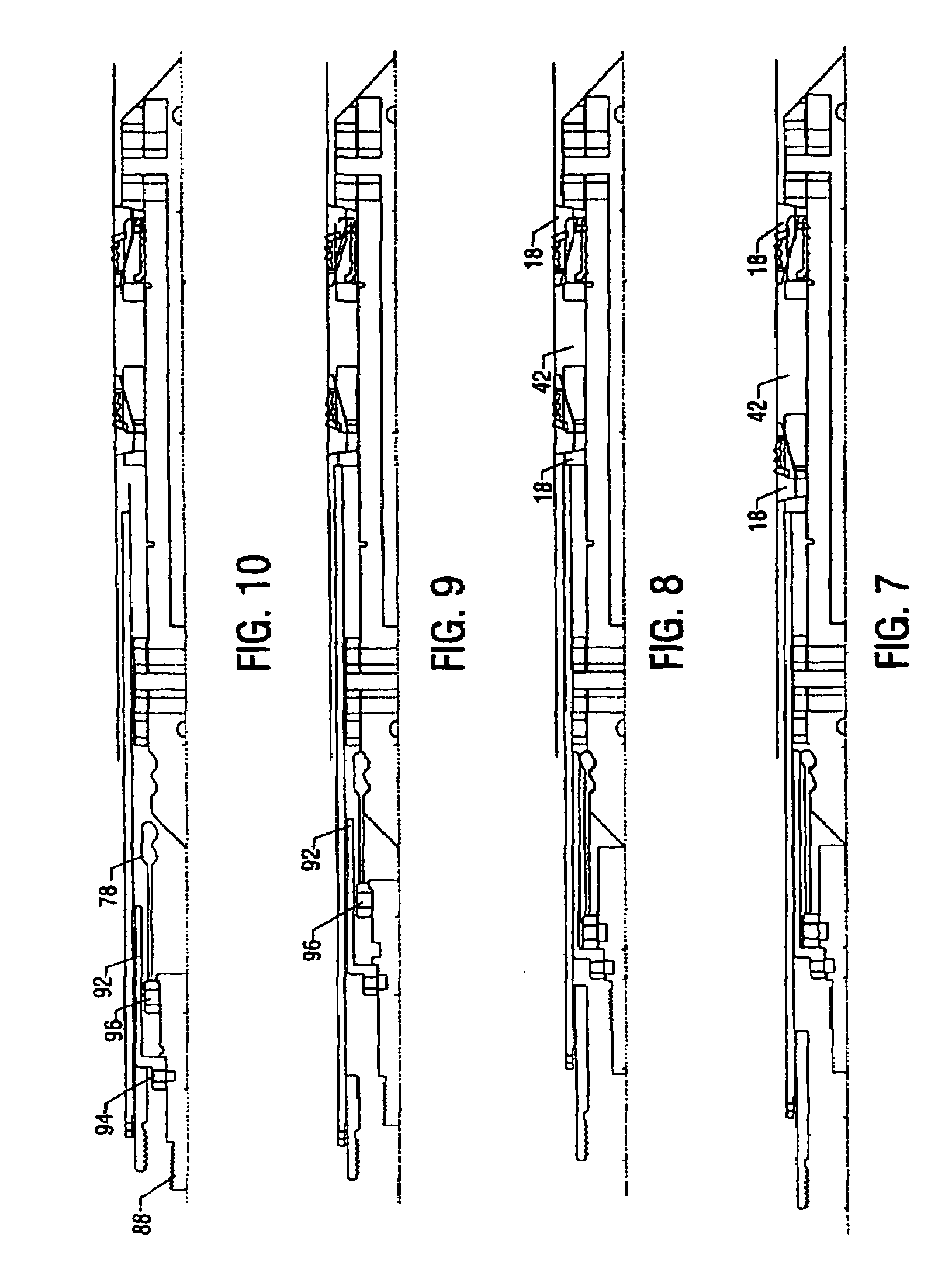

Drillable bridge plug

A method and apparatus for use in a subterranean well. The apparatus typically includes a subterranean plug including a mandrel having an outer surface and a non-circular cross-section and a packing element arranged about the mandrel, the packing element having a non-cylindrical inner surface matching the mandrel outer surface such that concentric rotation between the mandrel and the packing element is precluded. The apparatus is substantially non-metallic to facilitate quick drill-out of the plug. The apparatus is alternatively adaptable as a cement retainer.

Owner:BJ SERICES

Drillable bridge plug

InactiveUS20040045723A1Fluid removalWell/borehole valve arrangementsMechanical engineeringSurface matching

A method and apparatus for use in a subterranean well is described. The apparatus typically includes a mandrel and a packing element. The mandrel may have an outer surface and a non-circular cross-section and a the packing element may be arranged about the mandrel, the packing element having a non-circular inner surface matching the mandrel outer surface such that concentric rotation between the mandrel and the packing element is precluded. The apparatus may include slips having cavities to facilitate removal of the apparatus. The apparatus also may include a valve for controlling fluid flow through a hollow mandrel. The valve may include a flapper having at least one tab to engage at least one recession in the mandrel such that rotation between the mandrel and the valve is precluded when the valve is in a closed position. The apparatus may further include a central member which is releaseably attached to the mandrel by a release mechanism.

Owner:BJ SERVICES CO

Drillable bridge plug

InactiveUS7255178B2Easy to moveFluid removalWell/borehole valve arrangementsMechanical engineeringSurface matching

A method and apparatus for use in a subterranean well is described. The apparatus typically includes a mandrel and a packing element. The mandrel may have an outer surface and a non-circular cross-section and a the packing element may be arranged about the mandrel, the packing element having a non-circular inner surface matching the mandrel outer surface such that concentric rotation between the mandrel and the packing element is precluded. The apparatus may include slips having cavities to facilitate removal of the apparatus. The apparatus also may include a valve for controlling fluid flow through a hollow mandrel. The valve may include a flapper having at least one tab to engage at least one recession in the mandrel such that rotation between the mandrel and the valve is precluded when the valve is in a closed position. The apparatus may further include a central member which is releaseably attached to the mandrel by a release mechanism.

Owner:BJ SERVICES CO

Drillable bridge plug

A method and apparatus for use in a subterranean well is described. The apparatus typically includes a mandrel and a packing element. The mandrel may have an outer surface and a non-circular cross-section and the packing element may be arranged about the mandrel, the packing element having a non-circular inner surface matching the mandrel outer surface such that concentric rotation between the mandrel and the packing element is precluded. The apparatus may include slips having cavities to facilitate removal of the apparatus. The apparatus also may include a valve for controlling upward fluid flow through a hollow mandrel. The valve may include a flapper having at least one tab to engage at least one recession in the mandrel such that rotation between the mandrel and the valve is precluded when the valve is in a closed position. The apparatus may further include a central member which is releaseably attached to the mandrel by a release mechanism.

Owner:BJ SERVICES CO

Improved Catheters

Catheters having a tapered, atraumatic distal tip are provided. In one embodiment, the outer surface of the distal portion of the catheter has a generally non-cylindrical and substantially triangular cross-sectional configuration. The inner surface cross-sectional configuration of the distal portion of the catheter may match the outer surface, or it may have a cylindrical or oval configuration. The terminal orthogonal surface of the distal catheter tip is chamfered or rounded or contoured. In another embodiment, inner and / or outer catheter surfaces have a three dimensional surface conformation and may be dimpled or grooved. The grooves may be generally liner or curved or helical or in a spiral configuration. Dimpled and / or grooved surface discontinuities may be provided in connection with and in addition to lubricious coatings, surfaces, and the like.

Owner:PULSAR VASCULAR

Drillable bridge plug

A method and apparatus for use in a subterranean well is described. The apparatus typically includes a mandrel and a packing element. The mandrel may have an outer surface and a non-circular cross-section and the packing element may be arranged about the mandrel, the packing element having a non-circular inner surface matching the mandrel outer surface such that concentric rotation between the mandrel and the packing element is precluded. The apparatus may include slips having cavities to facilitate removal of the apparatus. The apparatus also may include a valve for controlling upward fluid flow through a hollow mandrel. The valve may include a flapper having at least one tab to engage at least one recession in the mandrel such that rotation between the mandrel and the valve is precluded when the valve is in a closed position. The apparatus may further include a central member which is releaseably attached to the mandrel by a release mechanism.

Owner:BJ SERVICES CO

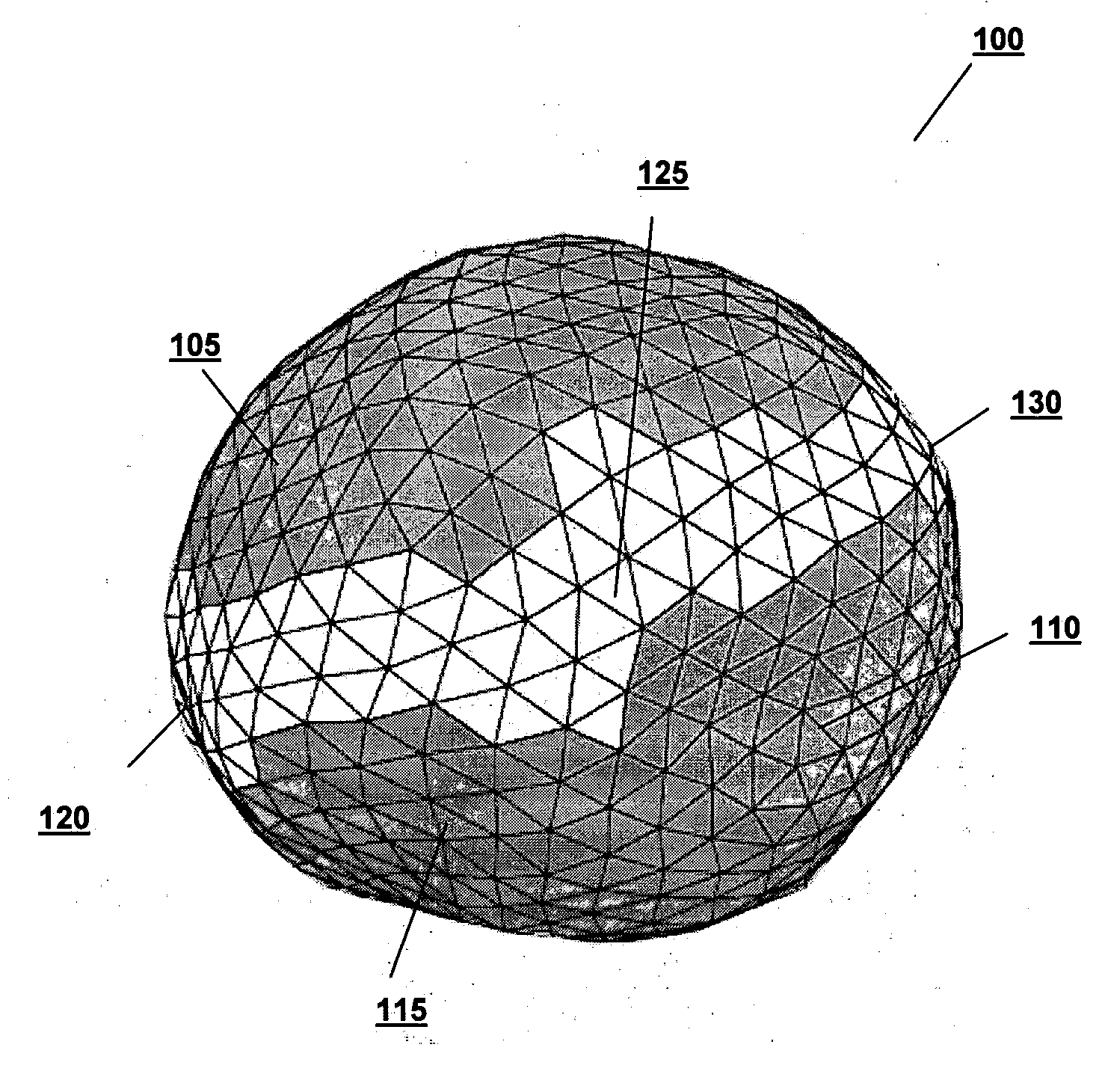

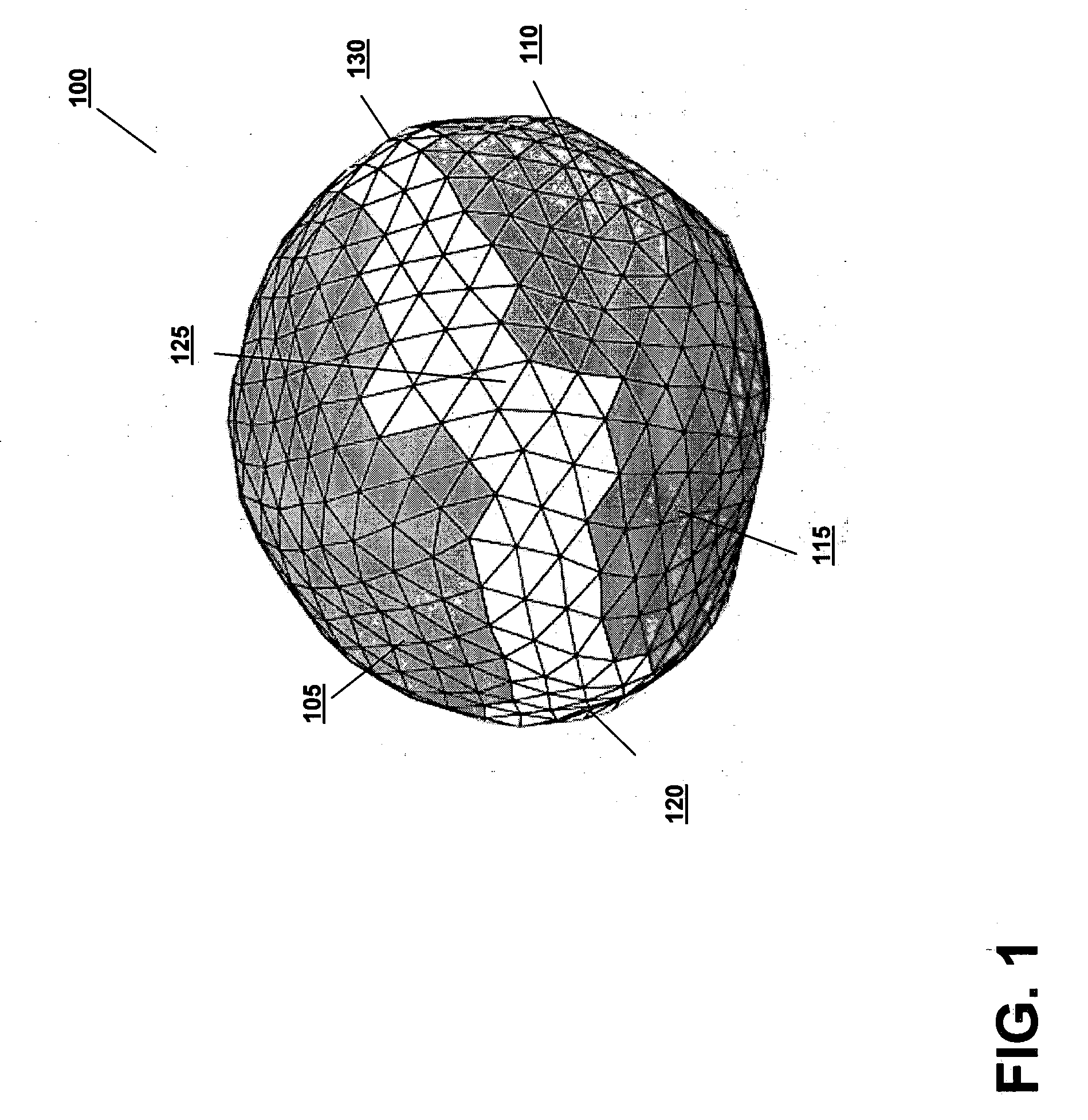

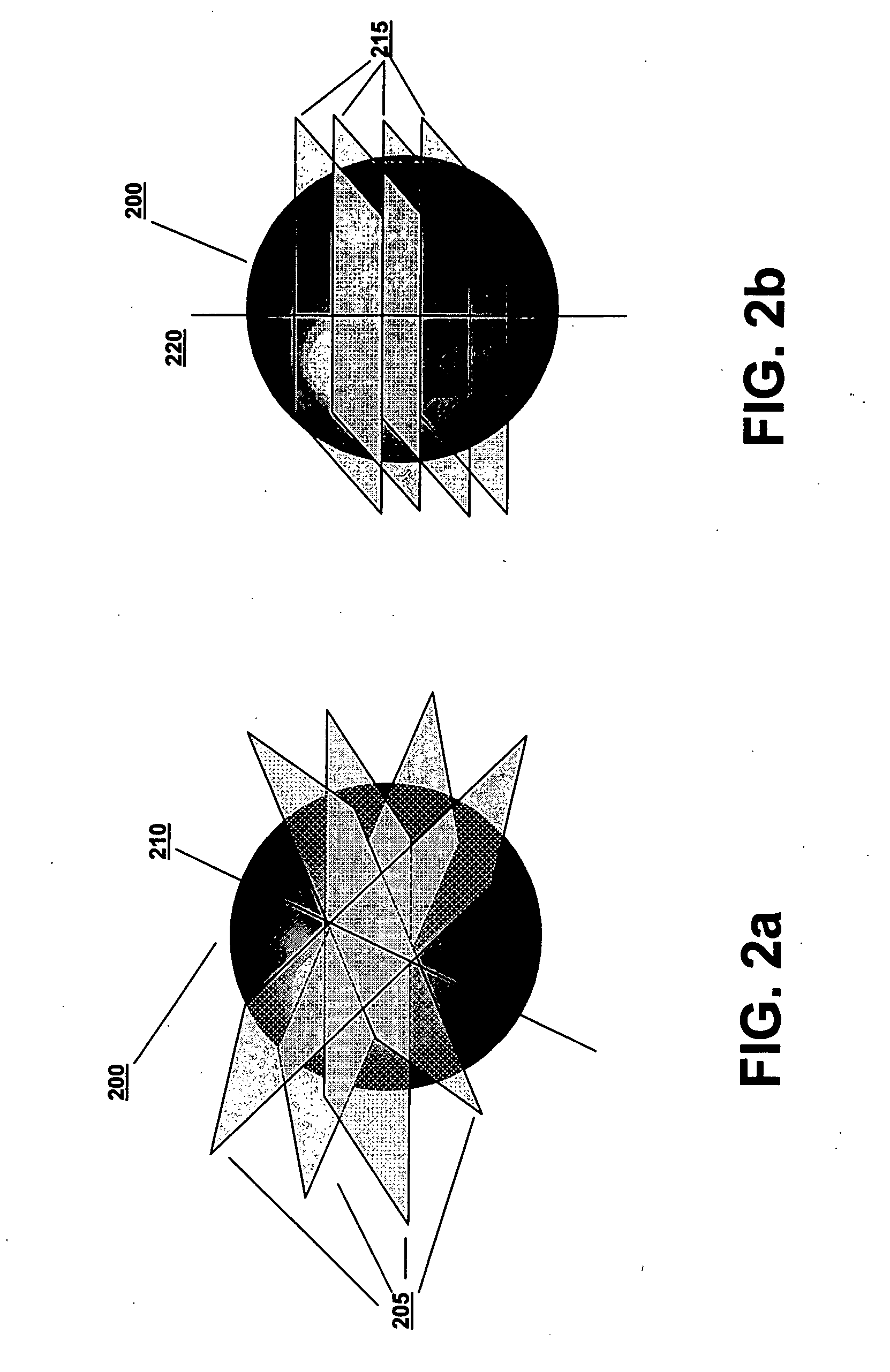

Methods and systems for segmentation and surface matching

ActiveUS20070167699A1Facilitates rapidFacilitates accurate treatment position adjustmentImage enhancementImage analysisRadiologyNuclear medicine

A contoured surface map of a lesion within a patient is obtained by shifting a reference surface to an estimated location in operational images. The process can be repeated to minimize errors, and the contoured surface map can then be segmented.

Owner:ELEKTA AB

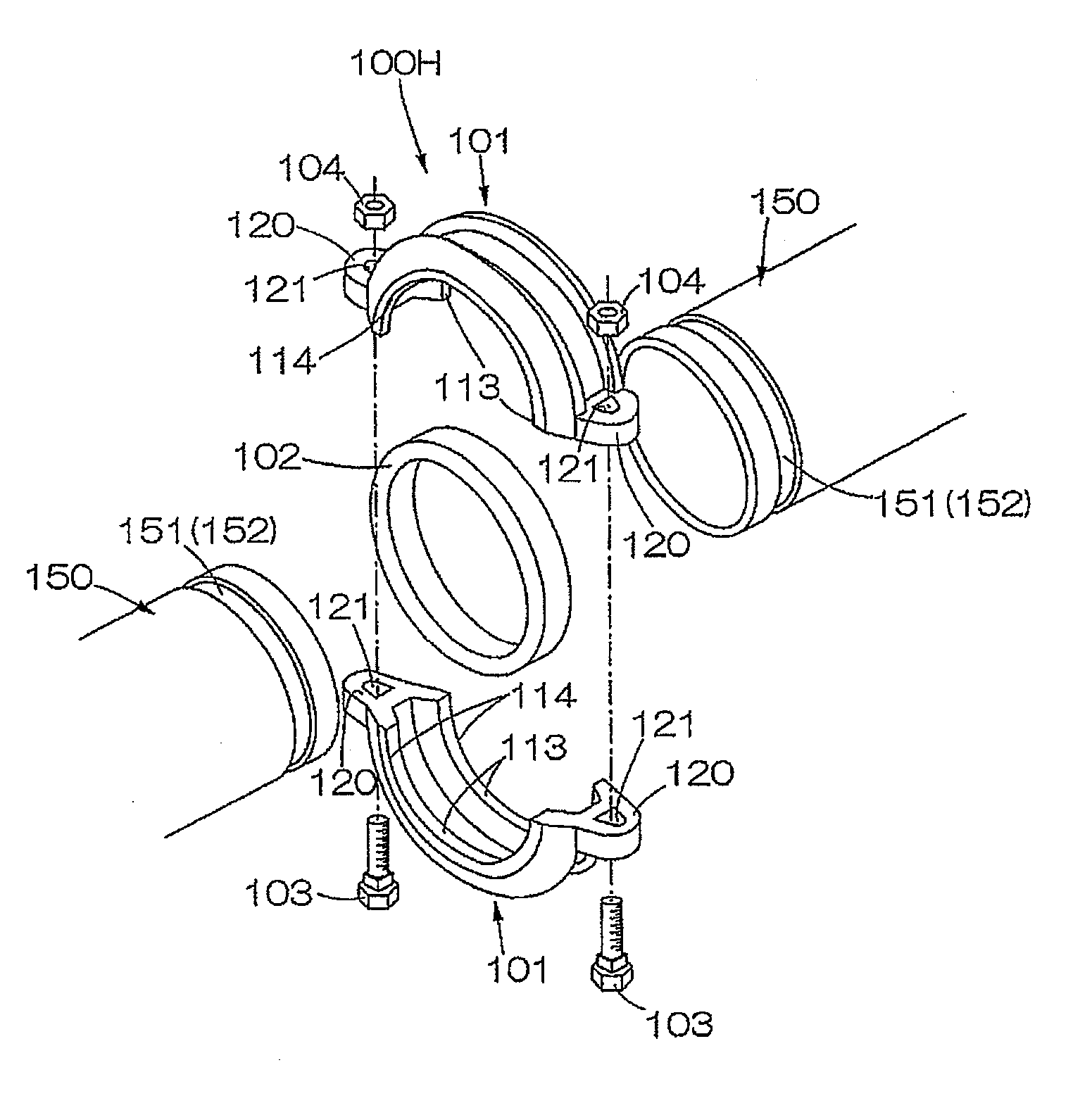

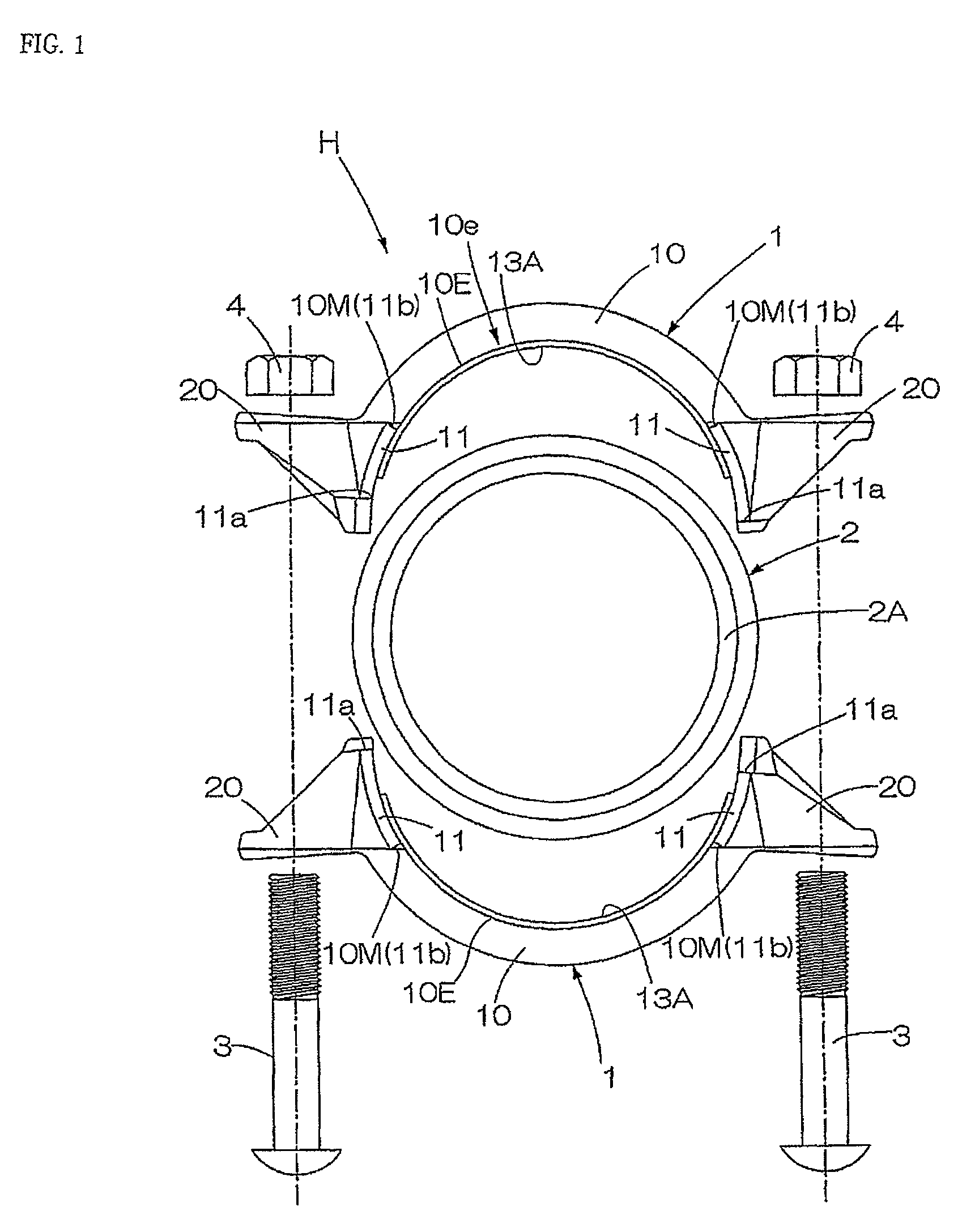

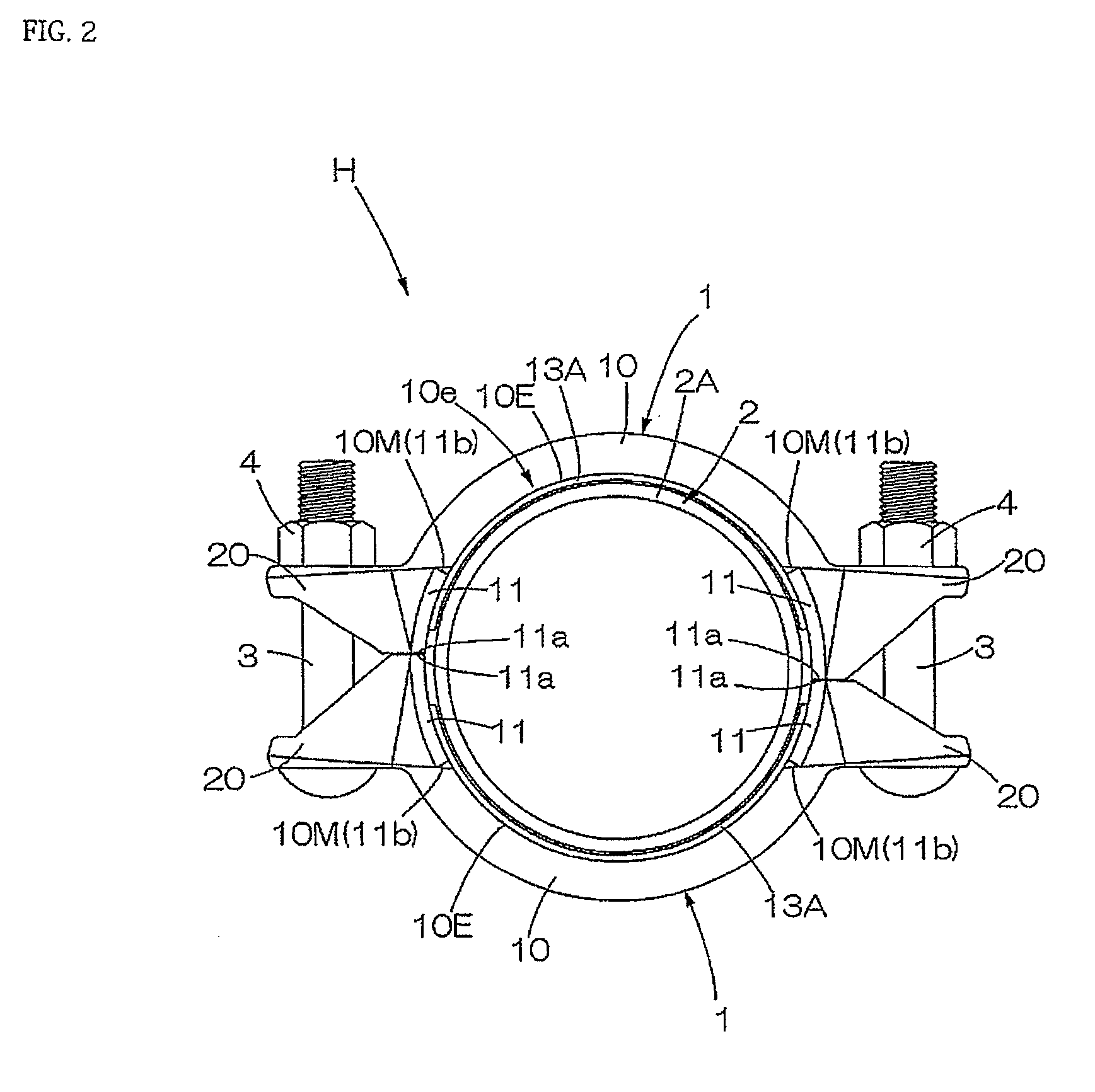

Housing-type pipe joint

ActiveUS20120256416A1Radii of curvature become smallerEasy to installSleeve/socket jointsFlanged jointsCouplingEngineering

Provided is a housing type pipe joint to enable the confirmation of an appropriate fastening degree of a joint and reduce a load of a fastening work. The housing-type pipe joint includes a pair of joint segments, an elastic seal ring, and a fastening means fastening the pair of joint segments, in which the joint segments each have an arc portion, flange portions extending from both ends of the arc portion, a concave groove formed in an inner peripheral surface of the arc portion to have the elastic seal ring fit therein, and in which the fastening means makes the flanges of the both joint segments approach each other to make the arc portions bend so that radii of curvature of the arc portions become smaller, and when, as a result of the bending, peripheral edges of the arc portions match outer surfaces of the pipes that are to be coupled, the coupling of the pipes is completed, the housing-type pipe joint including marks on the peripheral edge regions of the arc portions, wherein, when the peripheral edges of the arc portions corresponding to the marks come into contact with the outer surfaces of the pipes, the coupling of the pipes is completed.

Owner:VICTAULIC OF JAPAN

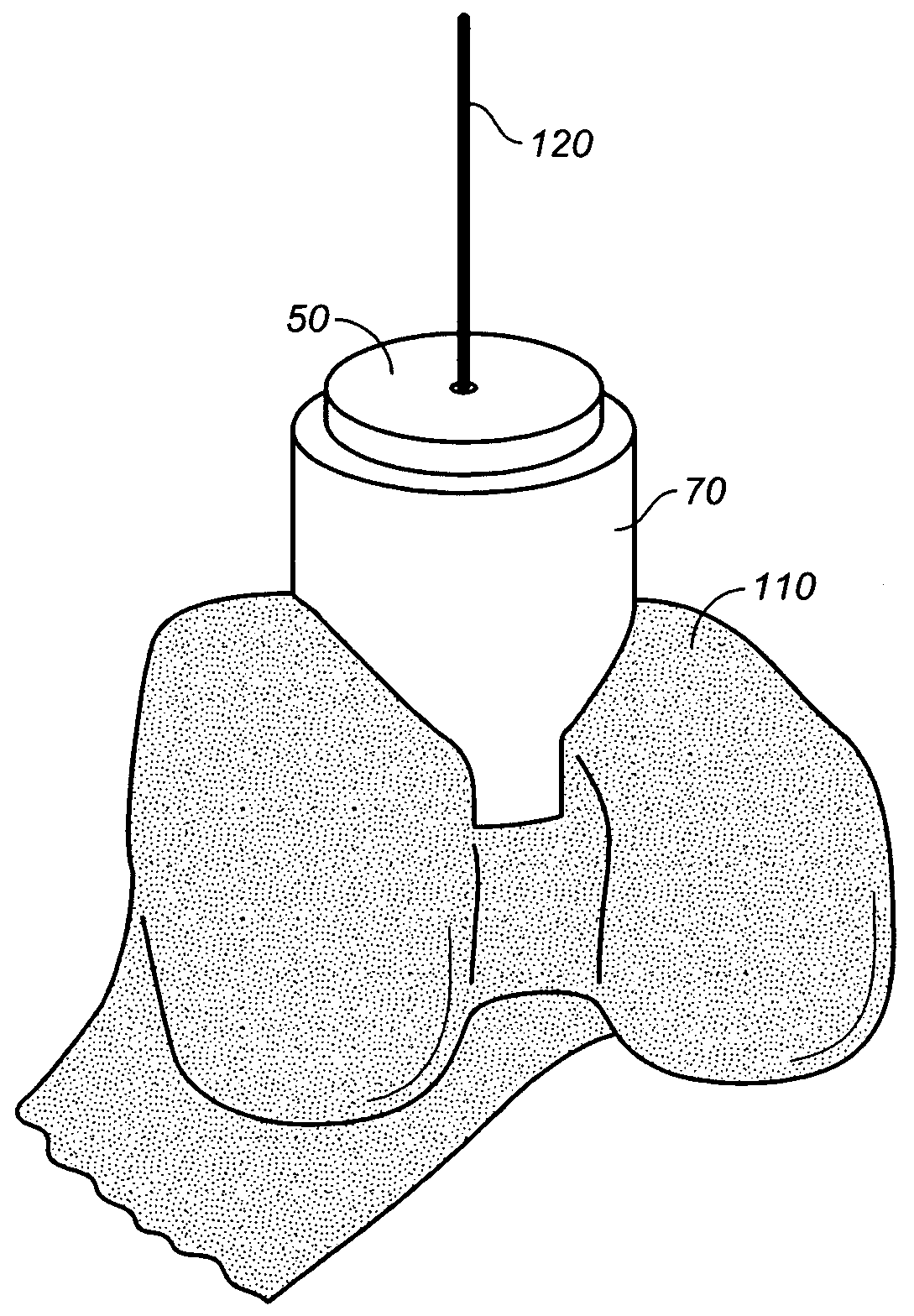

Device and method for allograft and tissue engineered osteochondral graft surface matching, preparation, and implantation

ActiveUS20090209962A1Precise surface matchingEasy constructionBone implantOsteosynthesis devicesOsteochondral graftingSacroiliac joint

Owner:JAMALI AMIR

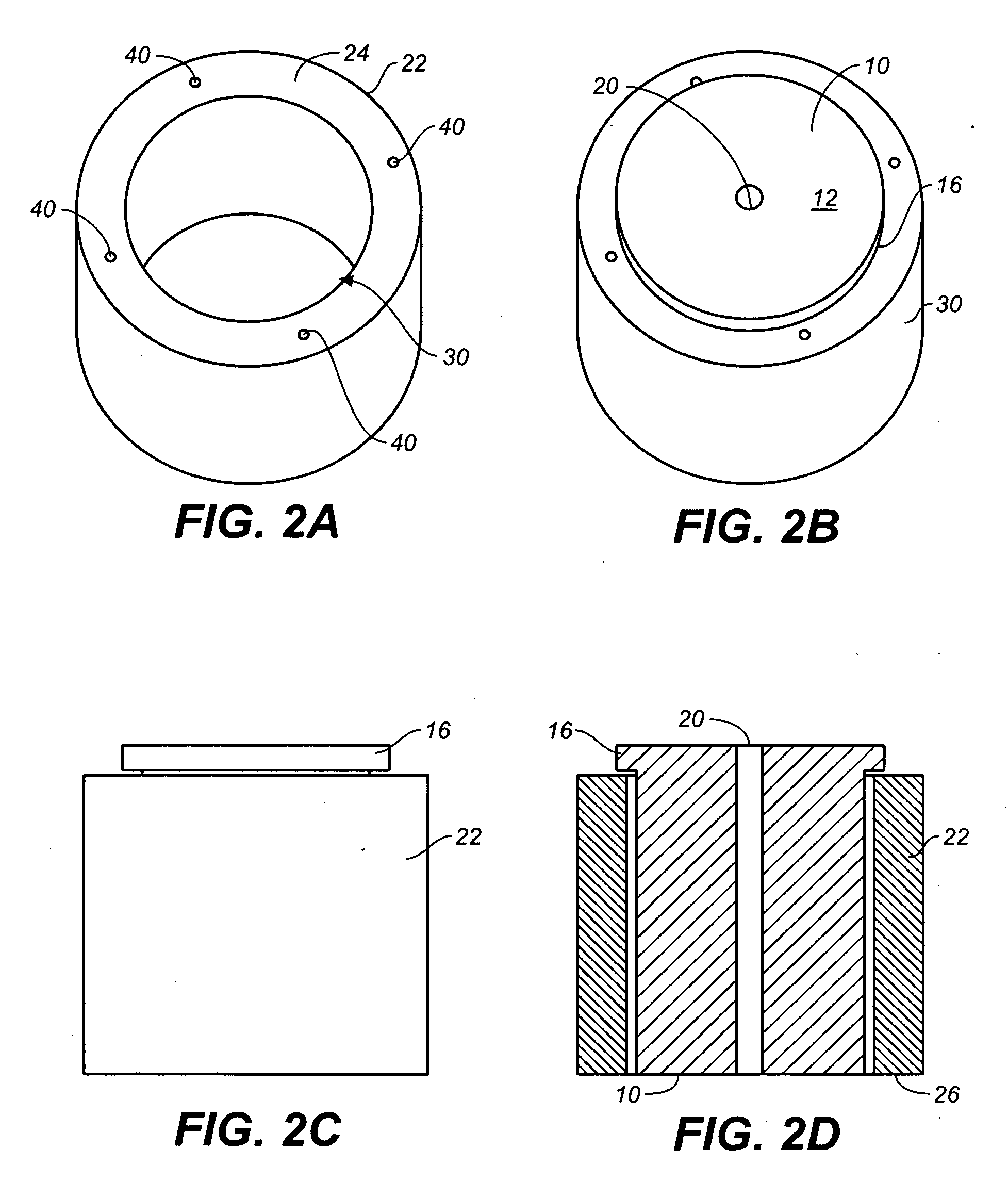

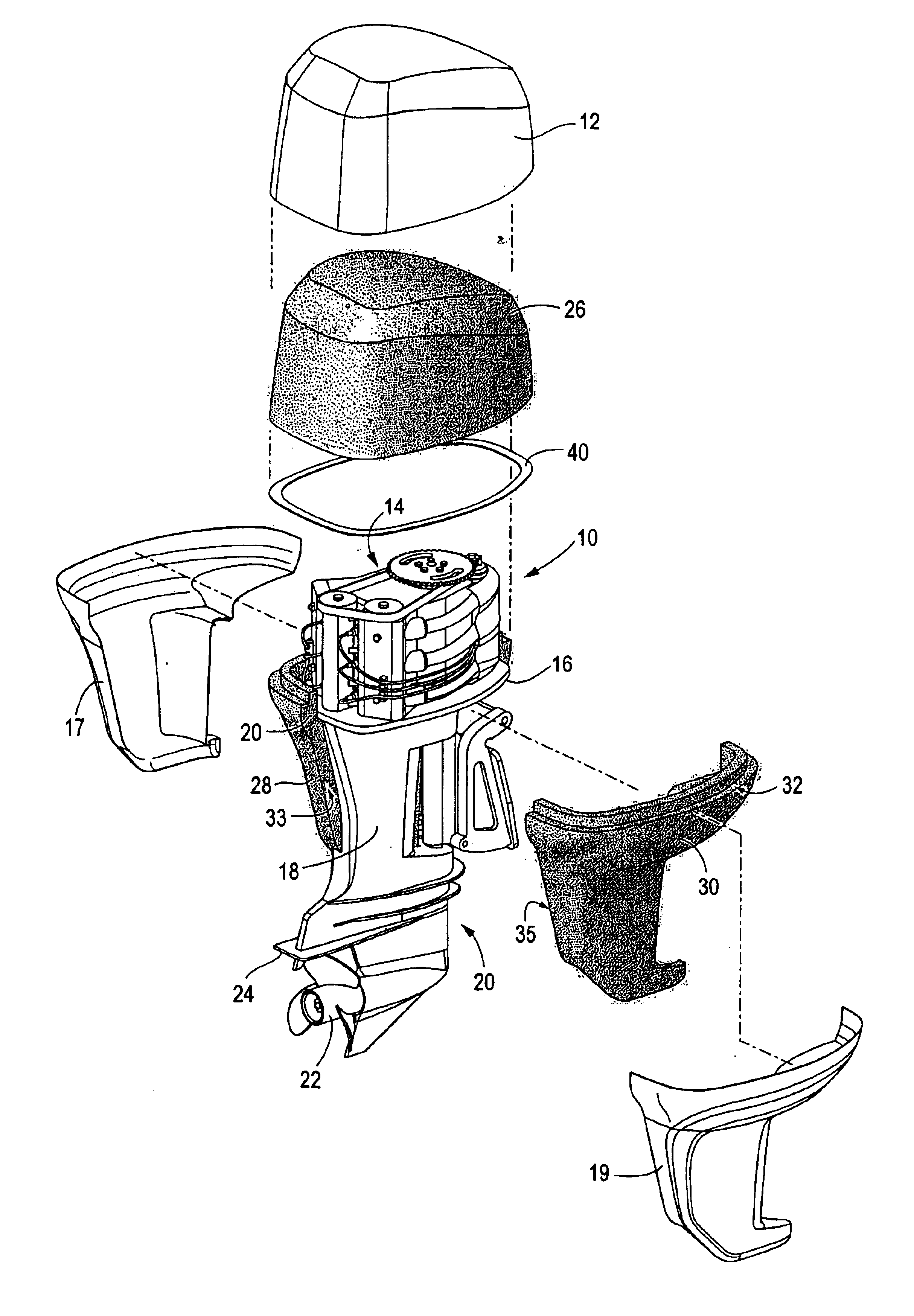

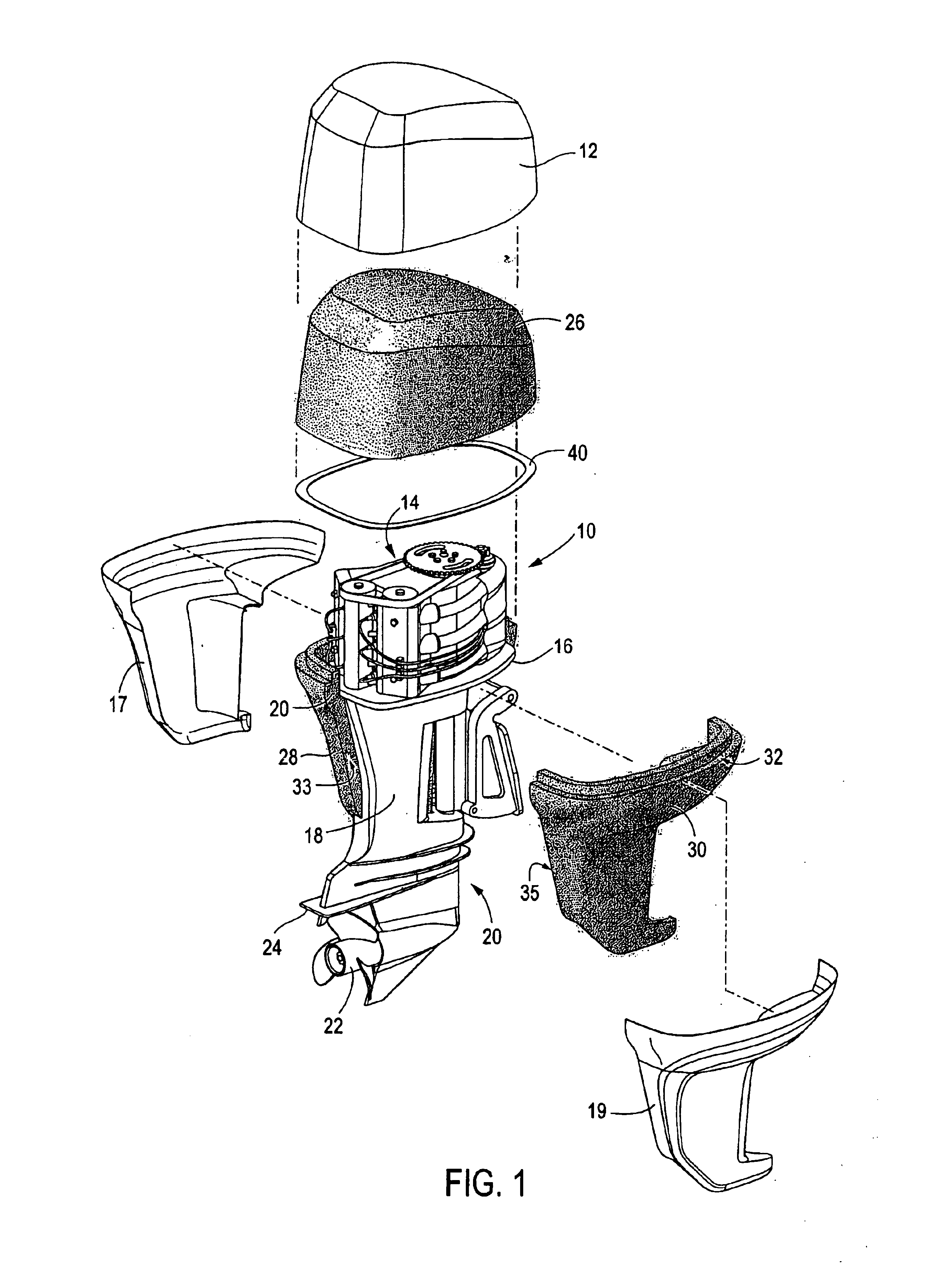

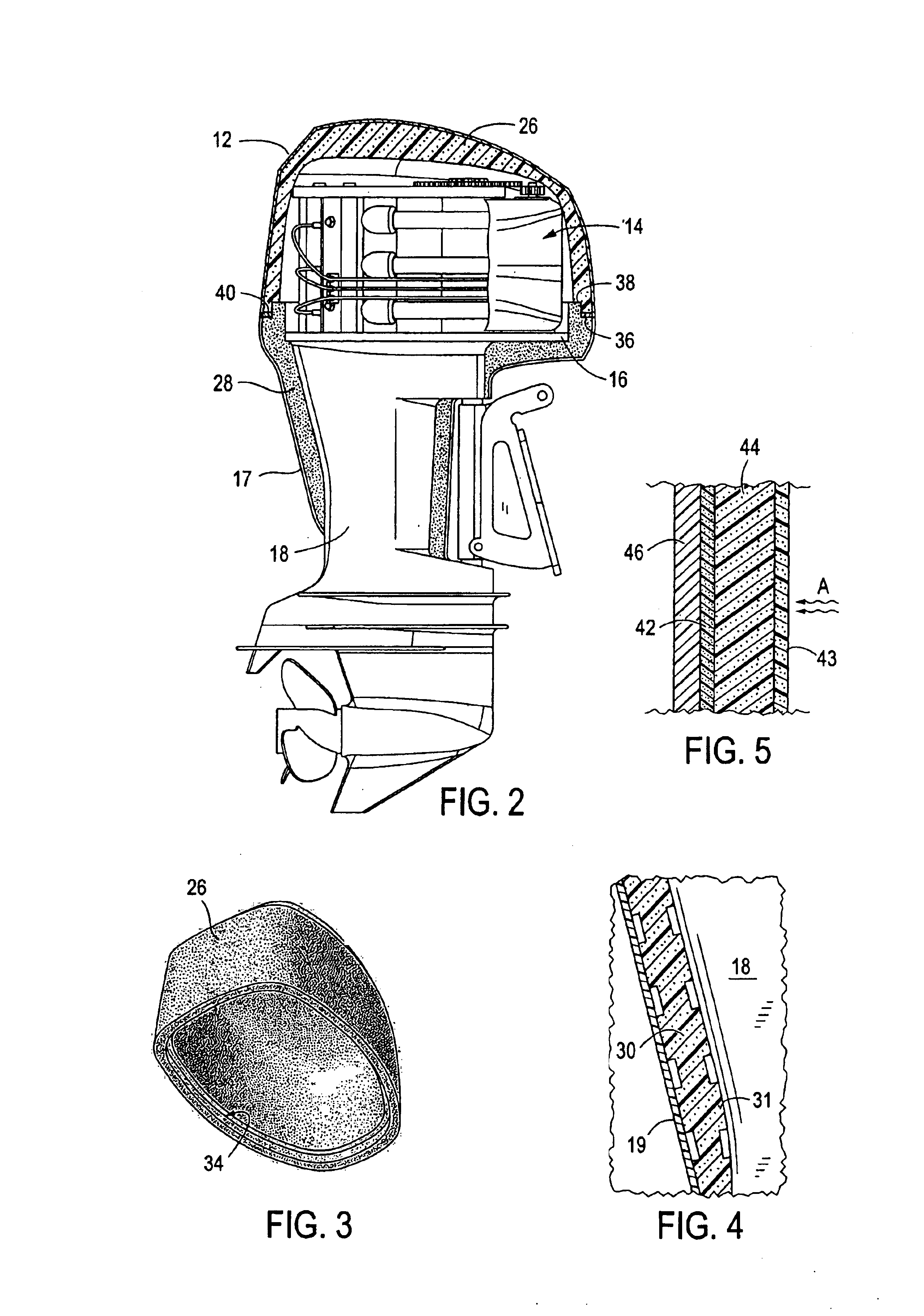

Sound insulation for outboard motors

InactiveUS6875066B2Reduce decreaseGood surface fitExhaust apparatusPropulsion power plantsPulp and paper industrySurface matching

Sound insulation for an engine contained within an outer casing, the insulation made up from a minimal number of interlocking molded foam insulation pieces forming a substantially continuous shroud surrounding the operating parts of the engine and having an outer surface matching the inner shape of the outer casing and in contact therewith. Preferably the outer casing is used to generate the molds used to manufacture the molded sound insulation pieces, thereby providing a good surface fit between the outer insulation surface and the inner casing surface.

Owner:POLYMER TECH CORP

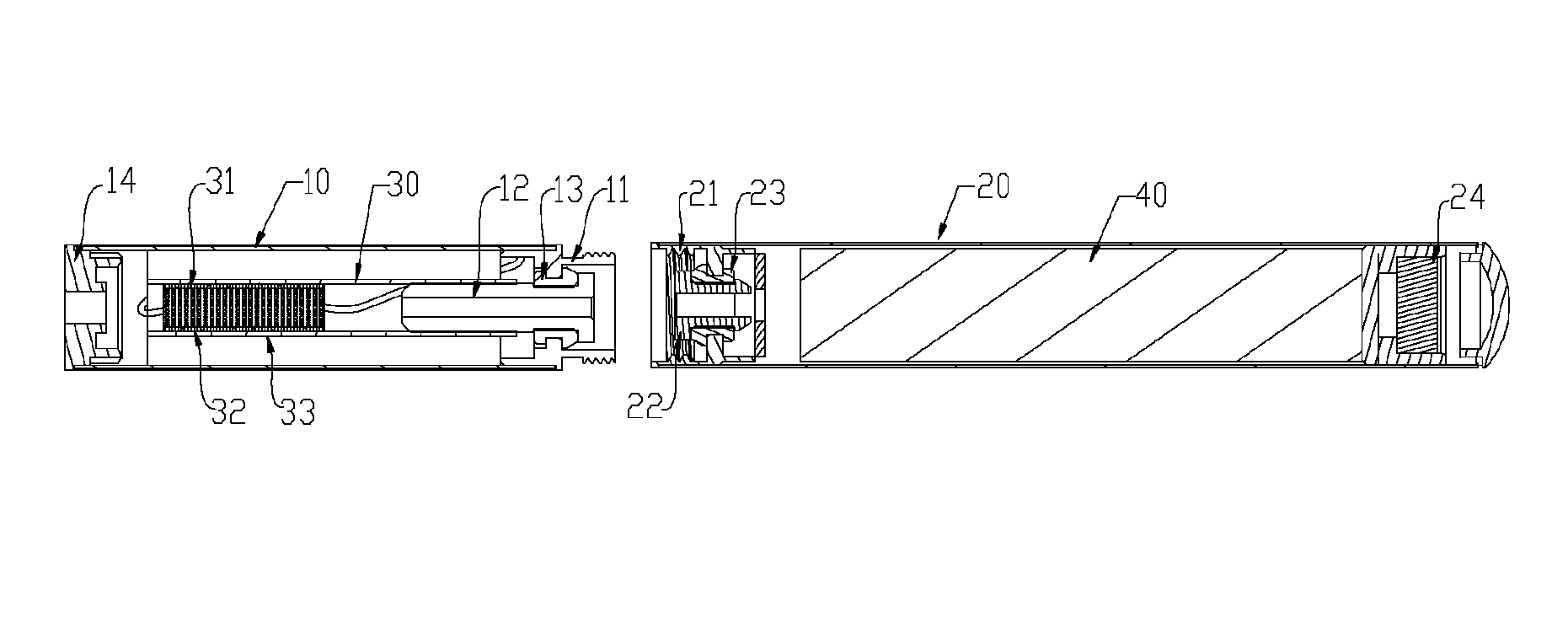

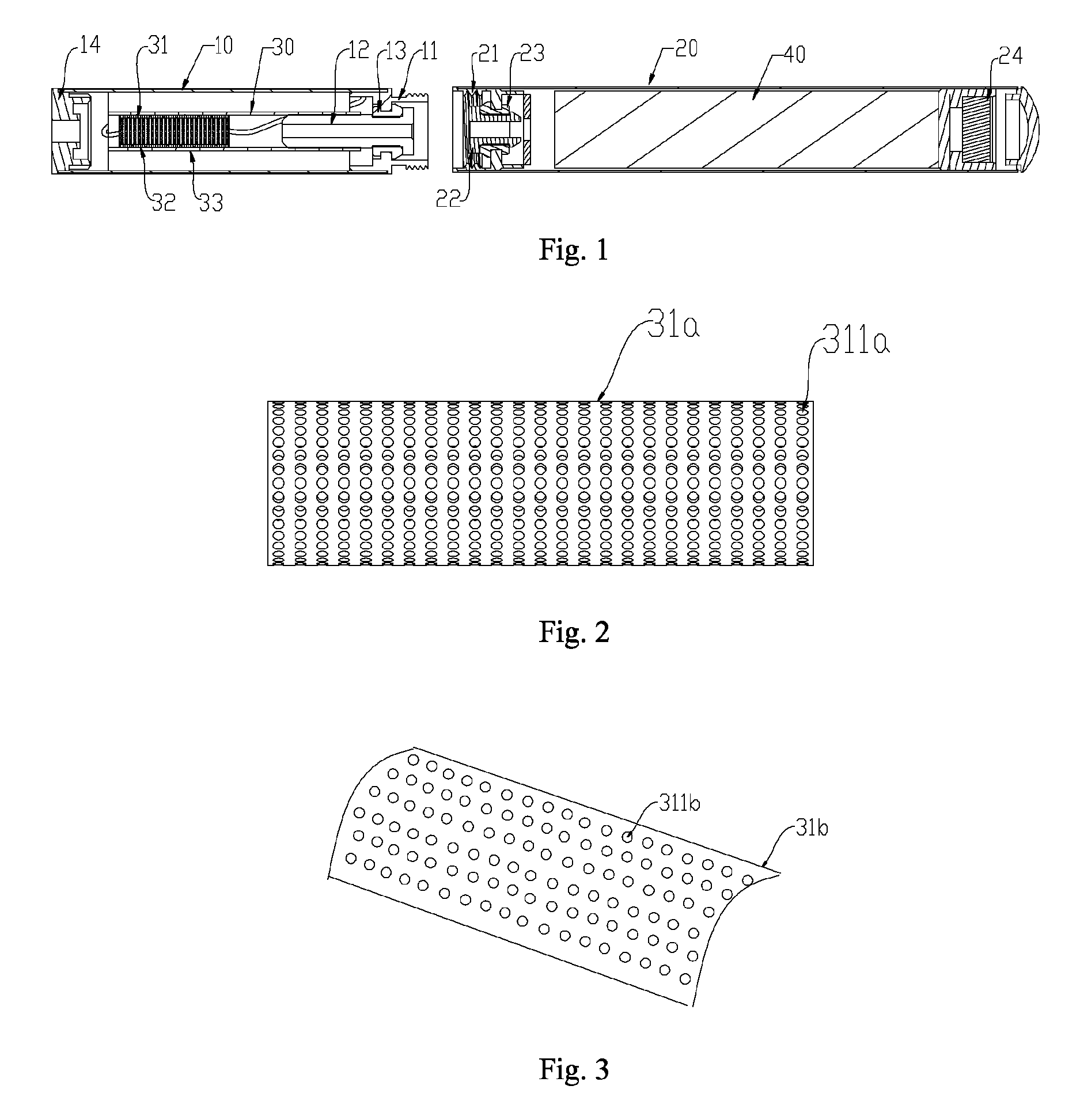

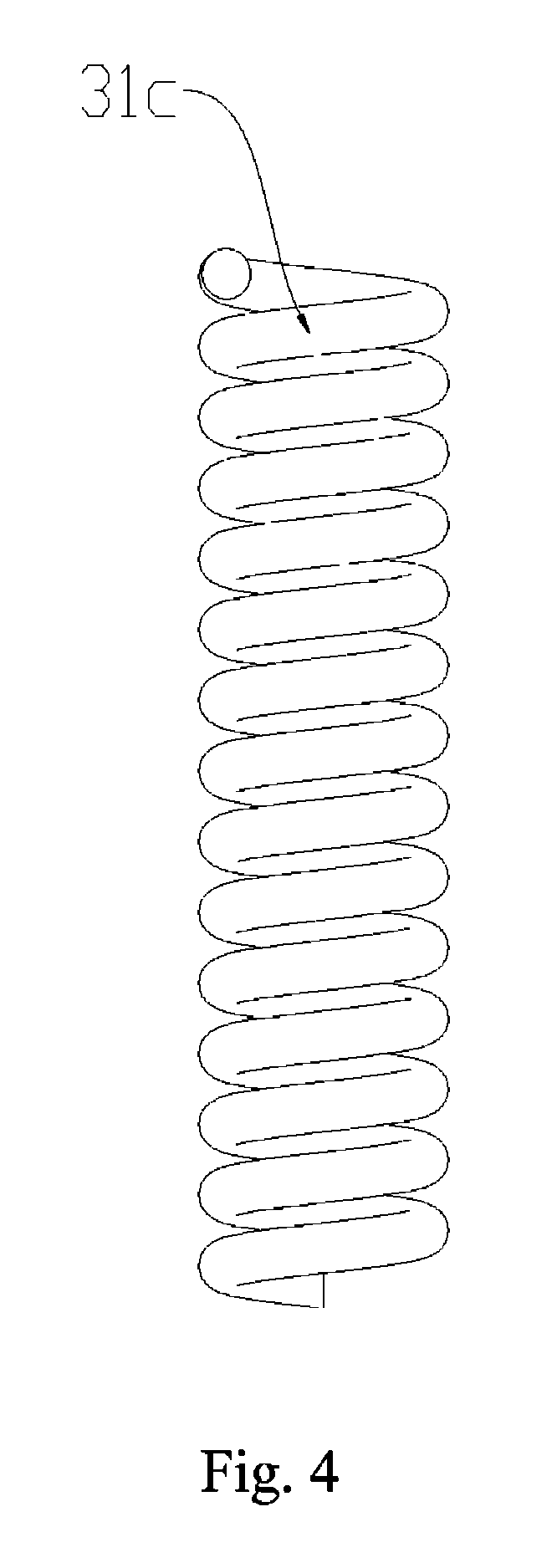

Electronic cigarette

An electronic cigarette comprising an atomizer and a first case configured for accommodating the atomizer is provided; the atomizer includes a heating mechanism, a breather pipe, and oil storage cotton, the heating mechanism is received inside the breather pipe, and the oil storage cotton envelops an outer surface of the breather pipe; wherein, the heating mechanism is positioned along an axial direction of the breather pipe, and has a shape matching an inner surface of the breather pipe. The heating mechanism in the electronic cigarette has a large effective heating area so that more smoke can be generated by the atomizer.

Owner:HUIZHOU KIMREE TECH

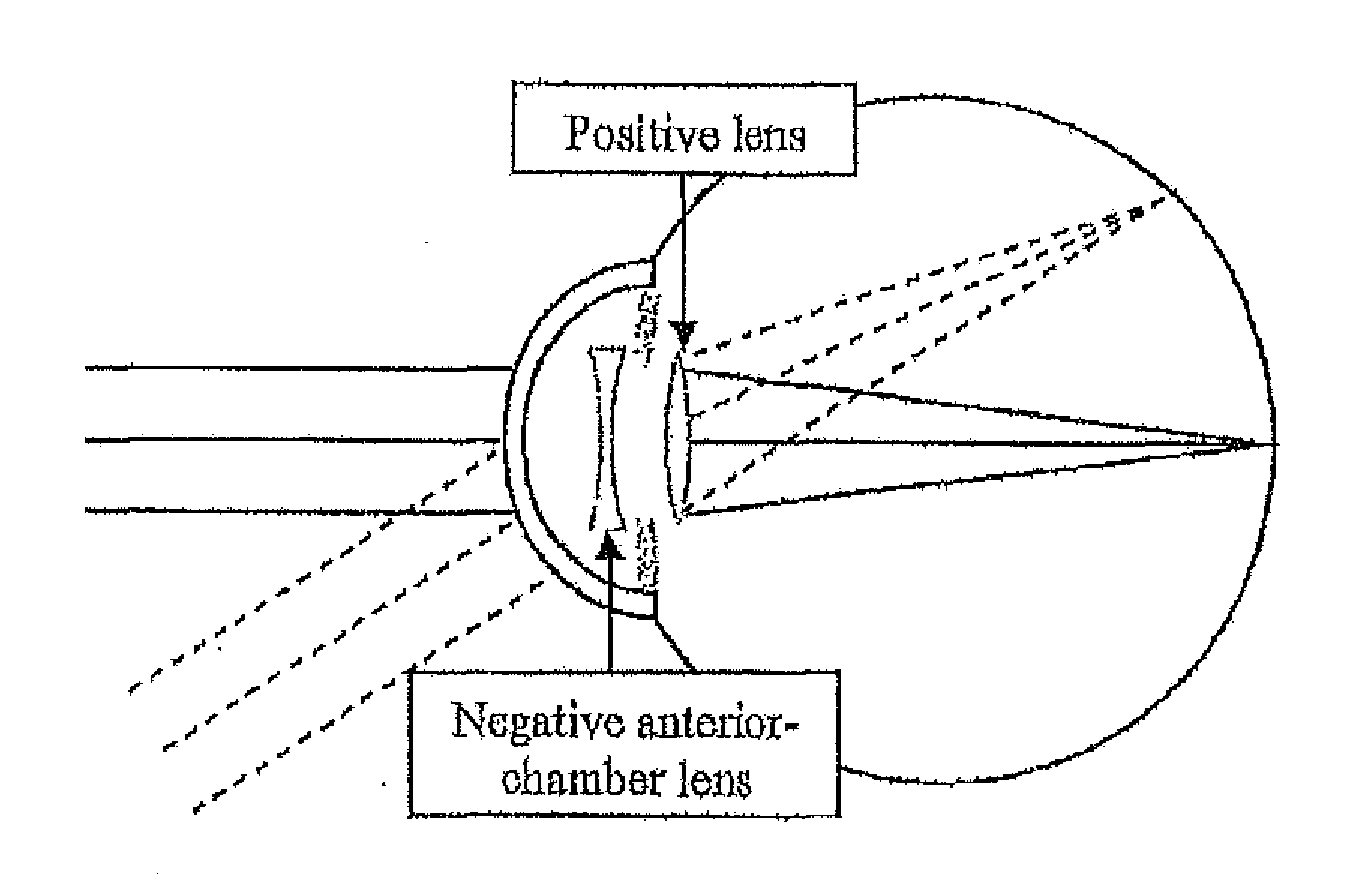

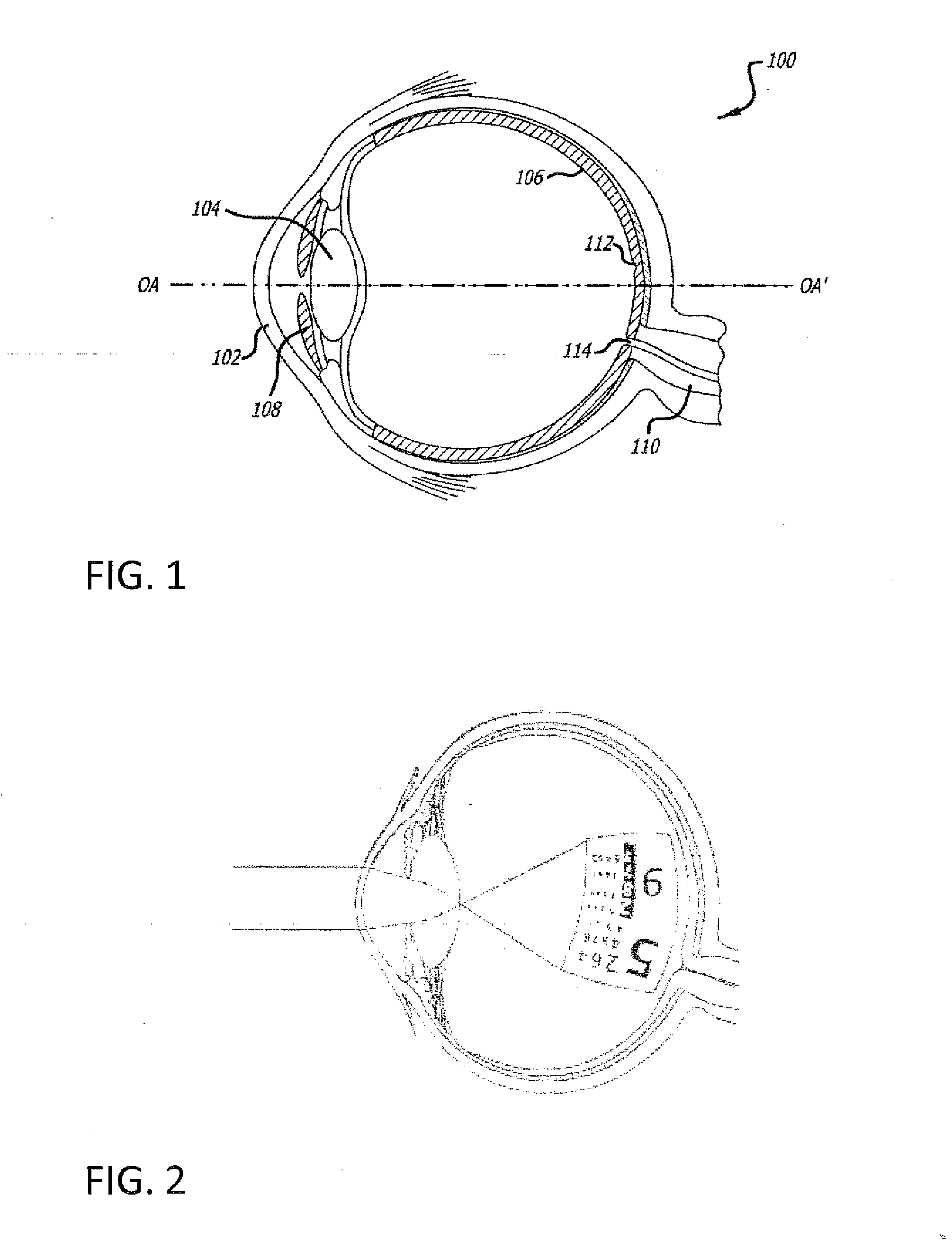

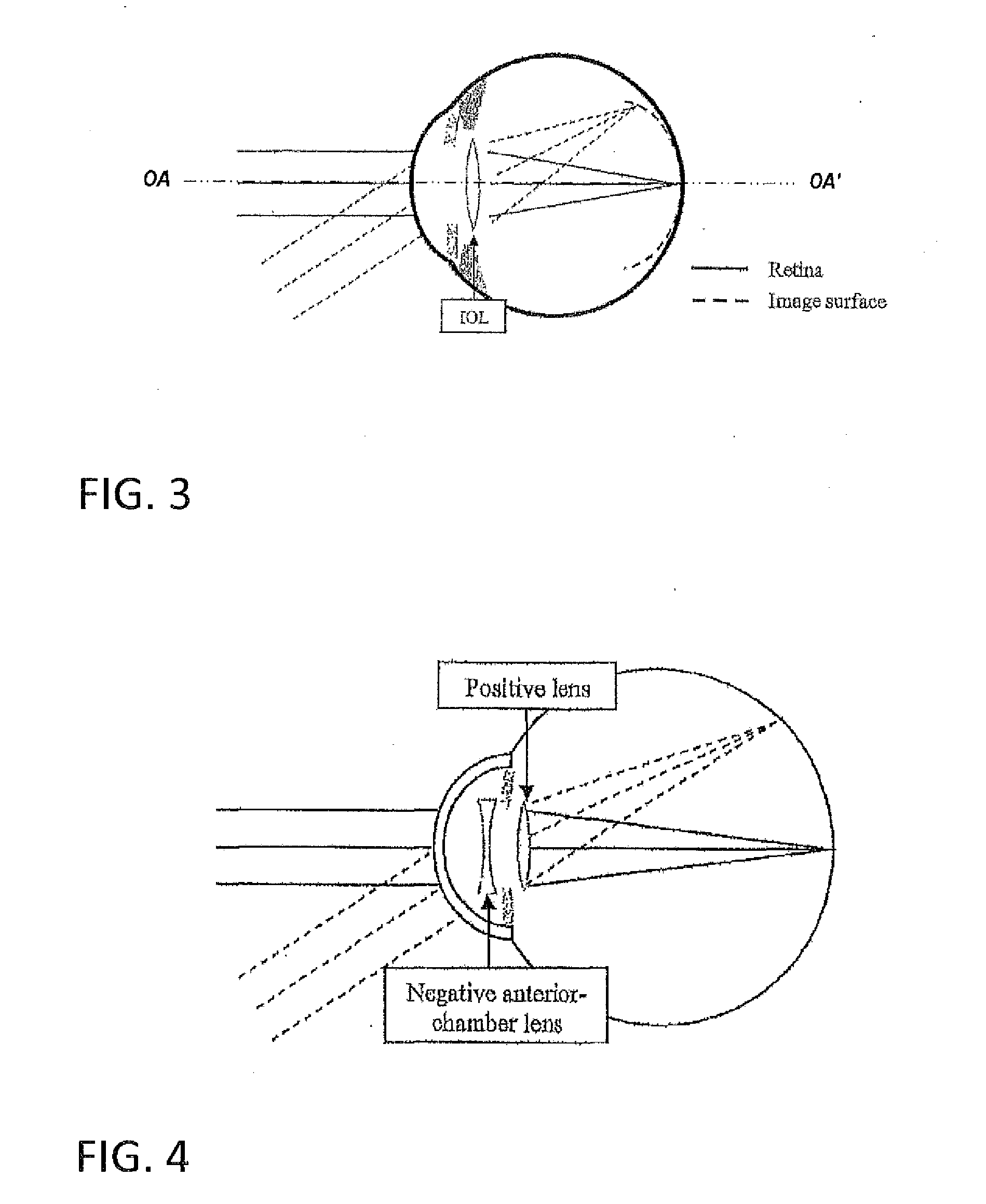

Intraocular lens that matches an image surface to a retinal shape, and method of designing same

An intraocular lens (IOL), system, and method having a base lens and a complementary lens selected to form a curved image surface matching a retina surface when placed in an eye's line of sight.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

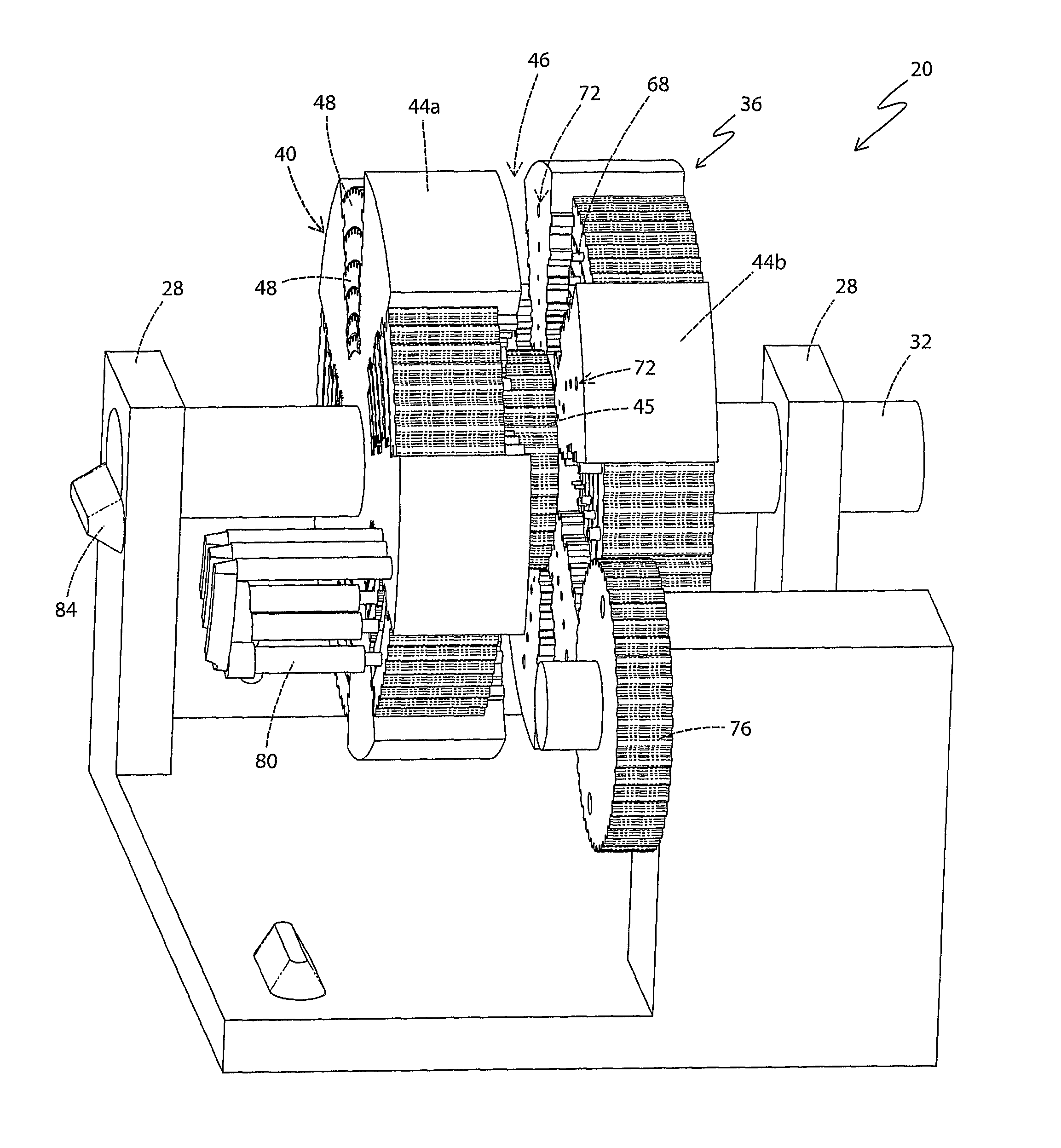

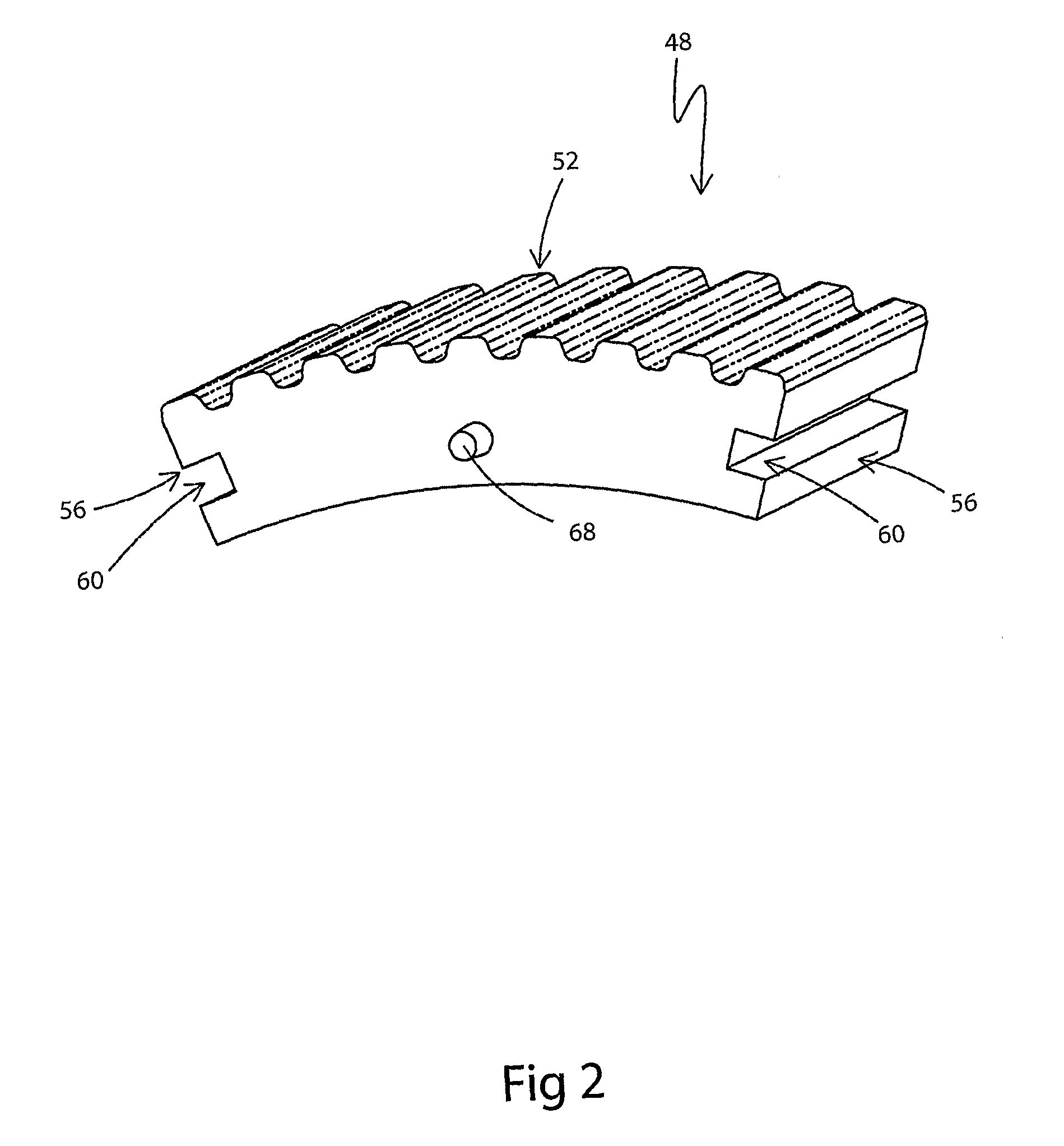

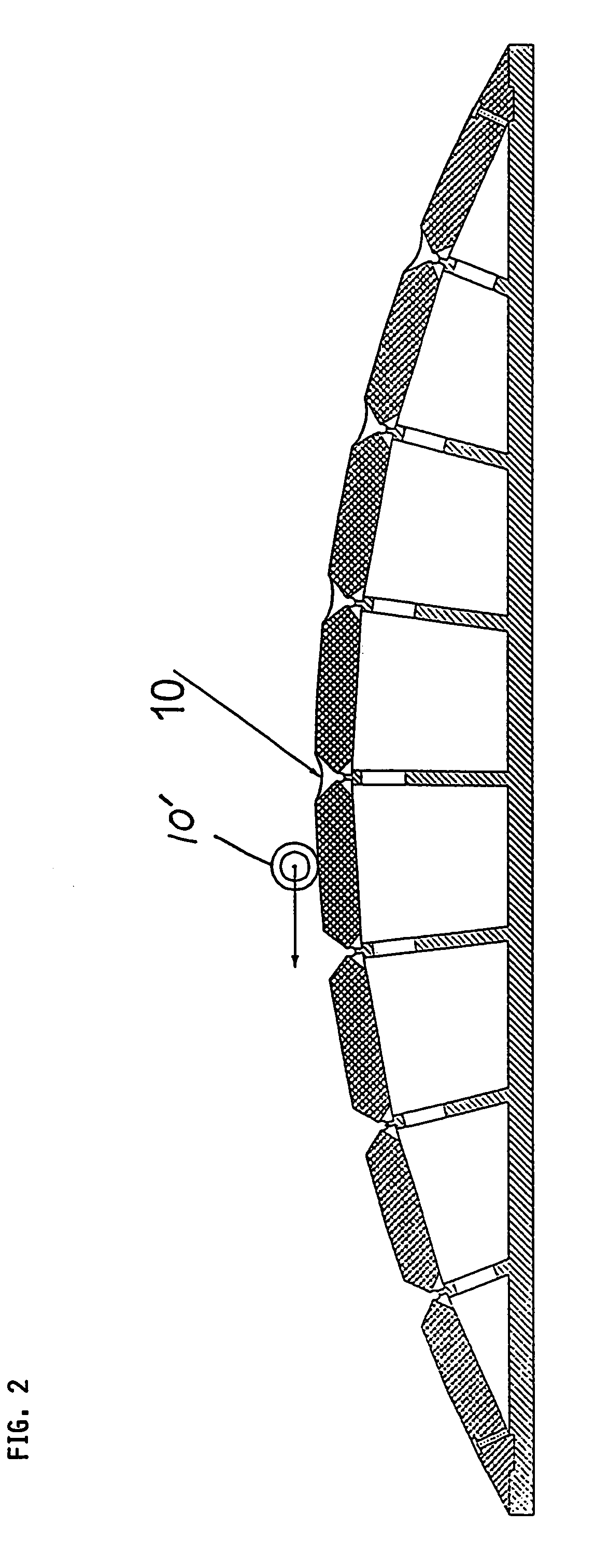

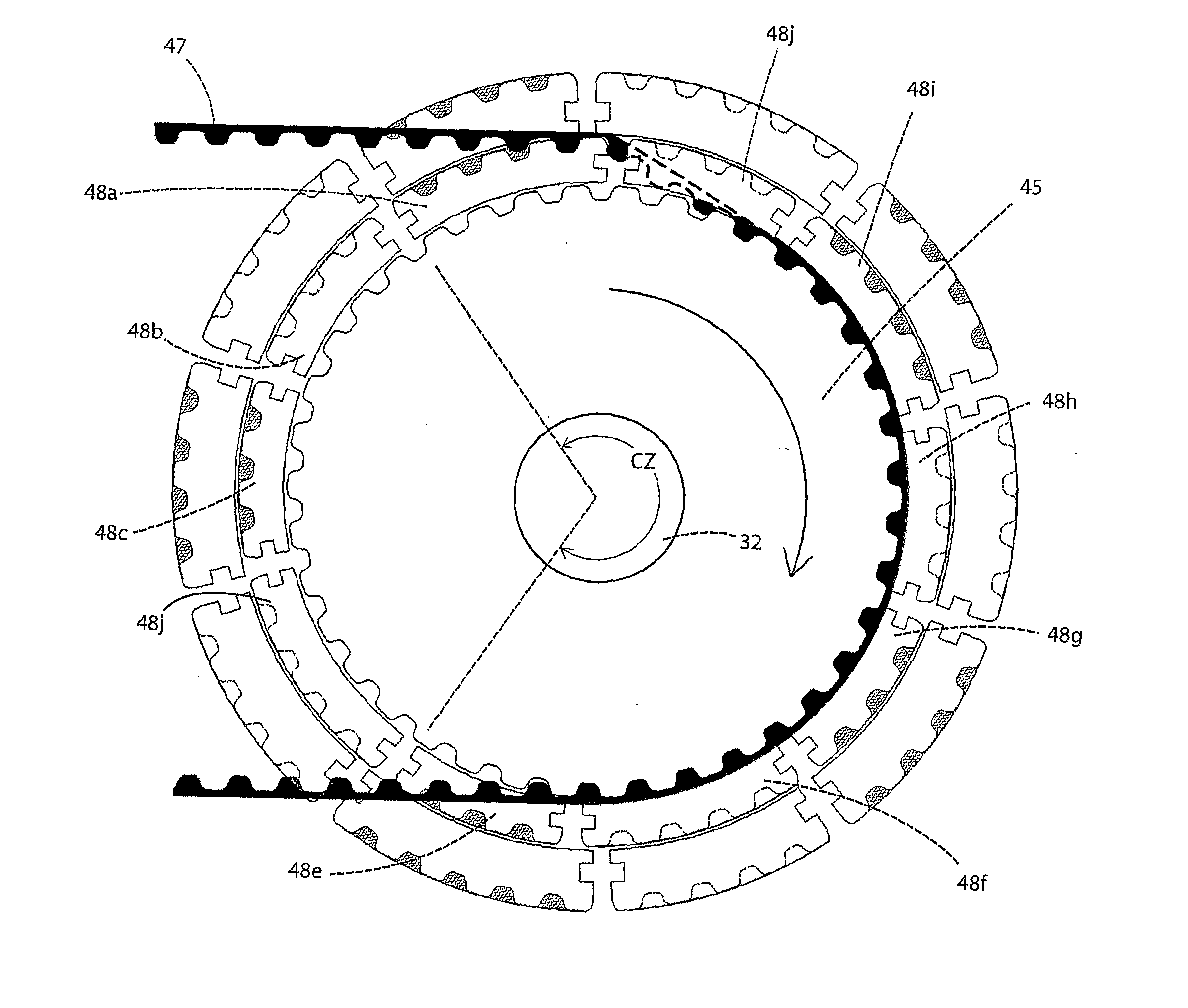

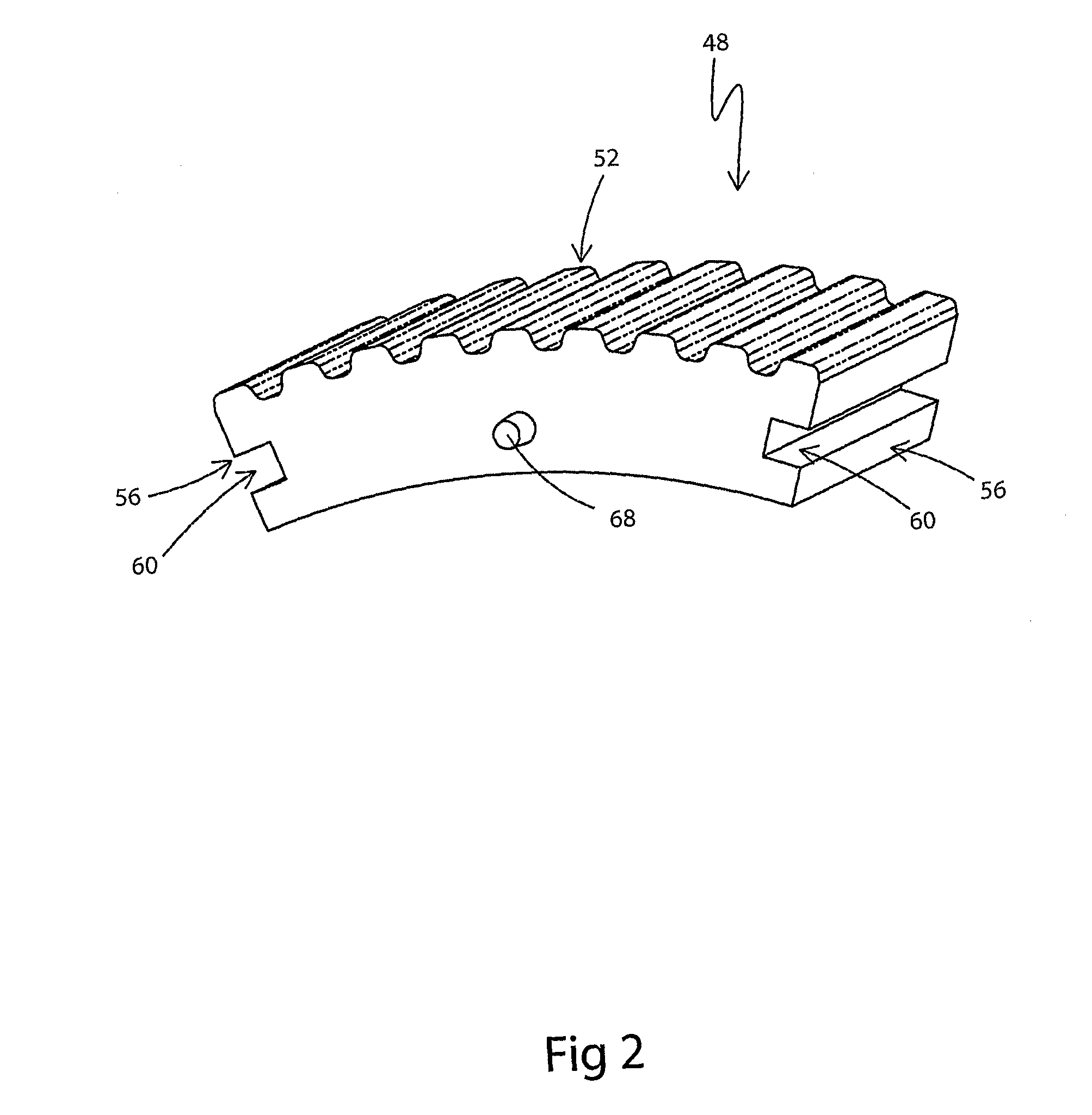

Synchronized segmentally interchanging pulley transmission system

A segmented pulley transmission [20] is provided. A pulley assembly [36] is rotationally mounted on an axle [32]. The pulley assembly [36] includes a core pulley [45] having a first set of mating features on a peripheral surface thereof. A pulley segment set comprises a number of pulley segments [48] slidably mounted in the pulley assembly and arranged in a ring concentric with the core pulley [45]. The pulley segments [48] are individually actuatable out of the pulley assembly into an engaging position and into the pulley assembly into a non-engaging position. The pulley segments [48] have a second set of mating features [52] on an peripheral surface matching the first set of mating features. An endless drive member [47] has corresponding mating features on an inside surface for engaging the first and second sets of mating features of the core pulley [45] and the pulley segments [48] in an engaging position. Contact between the endless drive member [47] and a core pulley defines a contact zone [CZ]. An actuator [80] actuates the pulley segments [48] between the engaging and non-engaging positions when the pulley segments [48] are outside of the contact zone [CZ]. One of the pulley segments [48] in the pulley segment set is a key pulley segment [48a] that is positioned relative to the care pulley [45] such that when the key pulley segment [48a] is actuated to the engaging position and rotated into the contact zone [CZ], the corresponding mating features of the endless drive member [47] engage the first set of mating features of the core pulley [45] and the second set of mating features [52] of the key pulley segment [48a] without the introduction of significant slack or tension.

Owner:1783590 ONTARIO

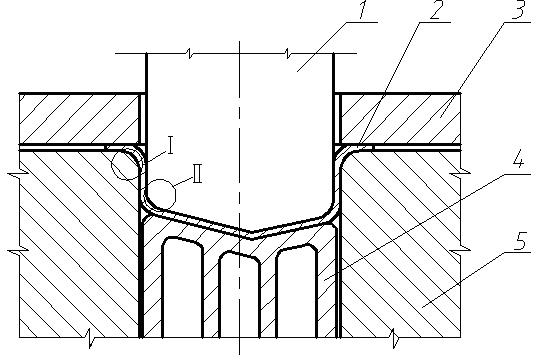

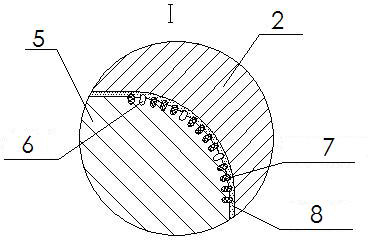

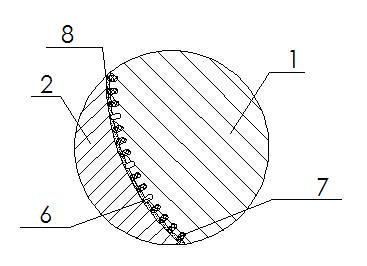

Texturing and self-lubricating treatment method for metal plastic forming die

The invention discloses a texturing and self-lubricating treatment method for a metal plastic forming die. In the invention, texturing and micromachining treatment is firstly carried out on a die surface, and then forming, adhering and machining treatment of a self-lubricating composite material is carried out on the die. Because the texturing and self-lubricating treatment is carried out on a metal plastic forming die surface, optimization distribution of lubricating property of the die surface is realized while the die carrying capacity and the molded surface matching precision are ensured,the flowing of the material and the lubricating and abrasive resistance of the die are improved, the die life is prolonged and the product quality is enhanced.

Owner:JIANGSU UNIV

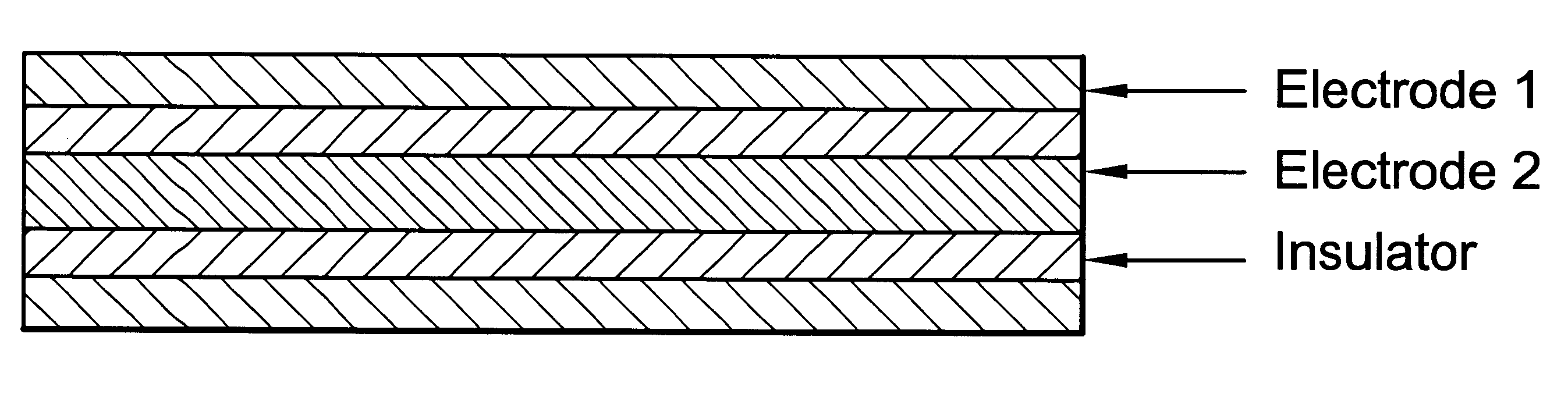

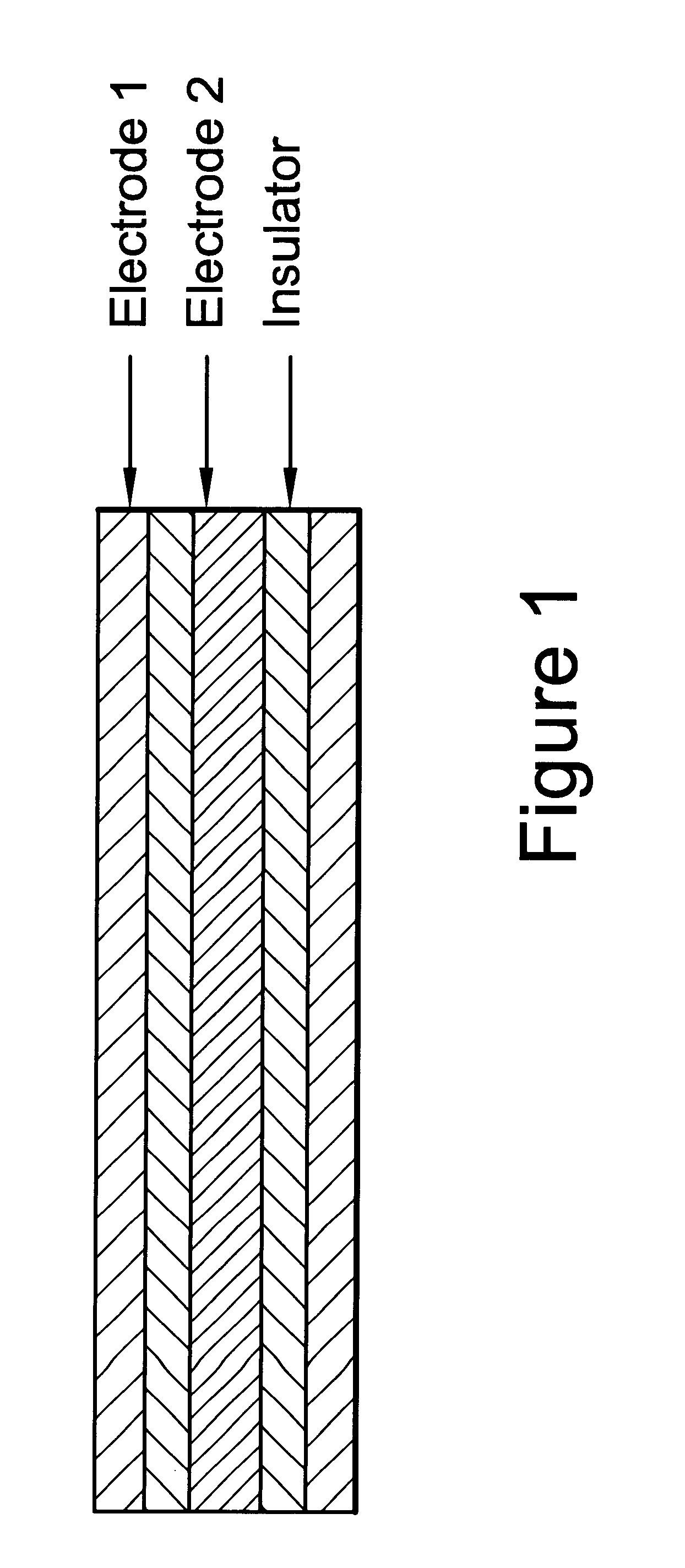

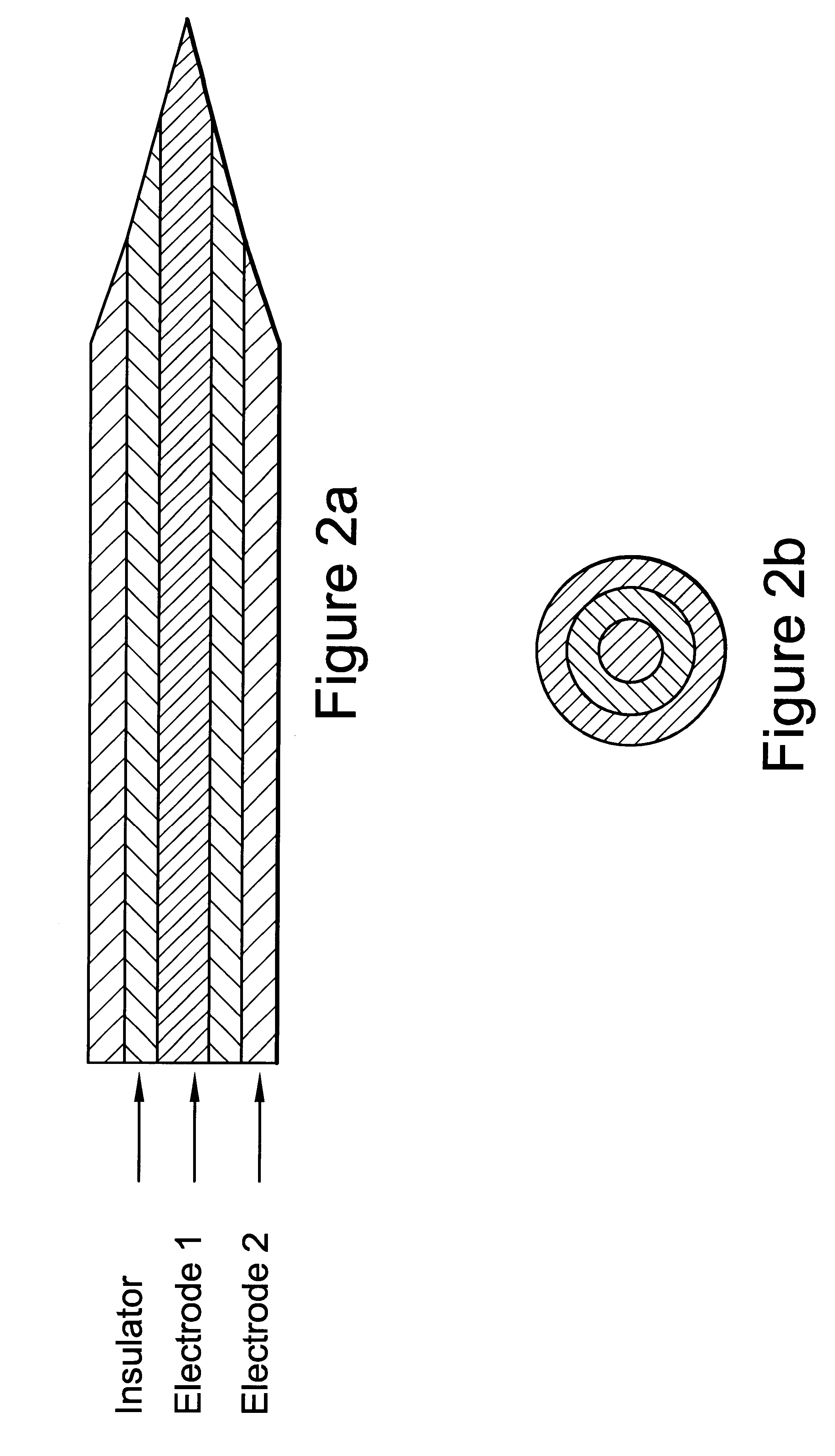

Apparatus and method for measuring the moisture level within enamel dentine or tooth tissue

InactiveUS6424861B2DentistryDiagnostic recording/measuringElectrical resistance and conductancePorosity

A probe comprising two spaced electrodes is provided between which electrical resistance through enamel, dentine or tooth tissue is measured. The electrodes comprise inner and outer coaxial electrodes spaced by an insulating layer. The diameter of the probe is preferably 1 mm. The tip of the probe may be shaped to match the surface being measured. The signal from the probe is A to D converted for analysis. The rate of change of resistance gives a measure of the rate of change of moisture level (porosity). The porosity is related to tooth sensitivity and so the system can provide an objective measurement of tooth sensitivity.

Owner:UNIV OF BRISTOL

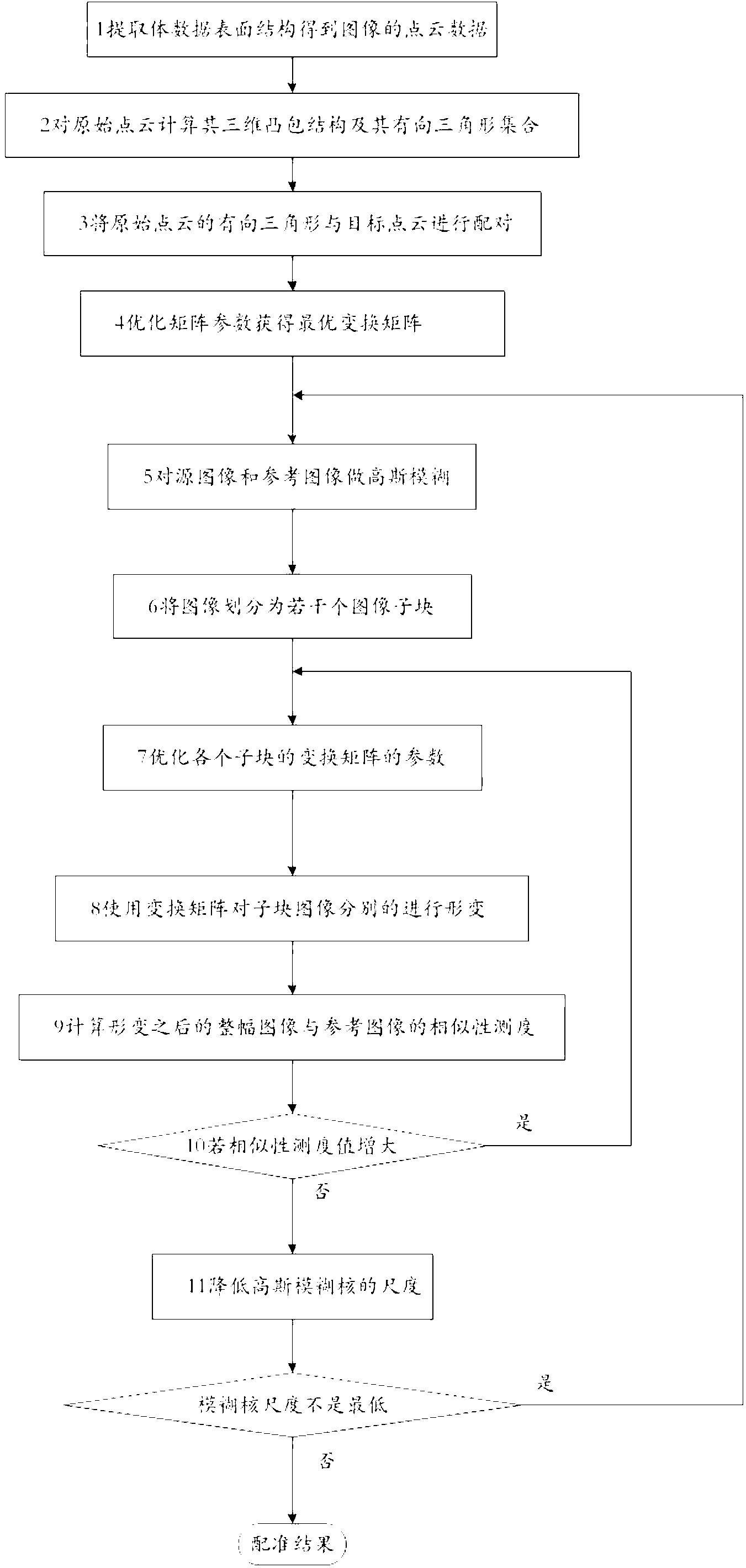

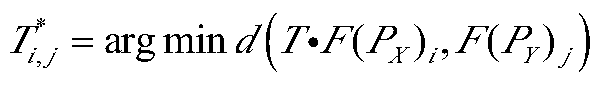

Method for elastically registering medical images by aid of combined convex hull matching and multi-scale classification strategy

ActiveCN103310458AHigh precisionTroubleshoot image registration issuesImage analysisPoint cloudTransformation parameter

The invention provides a method for elastically registering medical images by the aid of a combined convex hull matching and multi-scale classification strategy. The method includes performing point cloud preliminary registration on the basis of convex hull matching, in other words, extracting surface structures of volume data by an iso-surface extraction algorithm, and acquiring the optimal rigid registration result by a point cloud and convex hull surface matching process; performing multi-scale partitioning on the images to elastically register the images, performing different-scale blurring on the images by the aid of a multi-scale iteration procedure, and implementing a coarse-to-fine matching procedure; using mutual information as a similarity measure, combining the similarity measure with a volume distribution interpolation algorithm of three linear portions and acquiring the optimal elastic transformation parameters by means of iterative optimization. The method has the advantages that the images can be registered after large-angle transformation is performed on the images, and the image registration precision is improved.

Owner:ARIEMEDI MEDICAL SCI BEIJING CO LTD

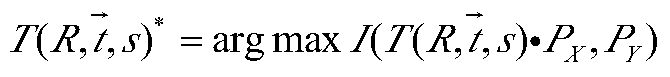

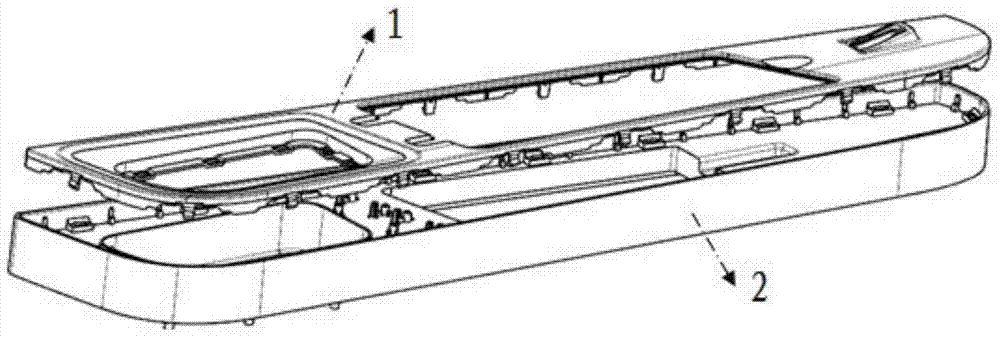

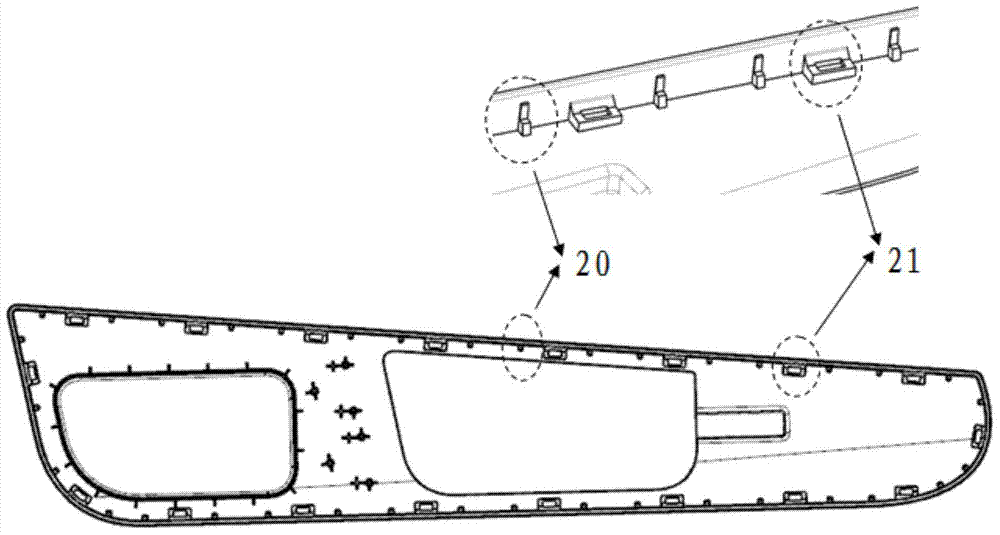

Large plastic plate matching structure based on cantilever buckles

The invention relates to a large plastic plate matching structure based on cantilever buckles. The large plastic plate matching structure comprises a cover plate (1) and a basal plate (2), the buckles (10) and cover plate turning edges (11) are arranged on the periphery of the cover plate at intervals, and the inner side wall of the basal plate is provided with clamping groove bosses (21) matched with the buckles and limiting bosses (20) used for supporting the cover plate turning edges. When the cover plate turning edges are turned to the upper portion of the side wall of the basal plate, the lower end faces of the cover plate turning edges abut against the top surfaces of the limiting bosses. Each clamping groove boss comprises a rectangular cavity (210) extending in the Z direction, the top surface of each limiting boss is a vertical limiting surface (201), and circumferential direction limiting surfaces (202) perpendicular to the vertical limiting surfaces are arranged at the upper ends of the vertical limiting surfaces. The limiting bosses are utilized, the clamping groove bosses are matched with the cover plate turning edges, and the buckles are used for multi-point horizontal surface matching; compared with an existing method that cover plate turning edges and grooves in the side wall of the basal plate are directly buckled and the turning edges directly abut against the bottom surface of the basal plate, better assembly stability is achieved.

Owner:BAOSTEEL DEV CO LTD

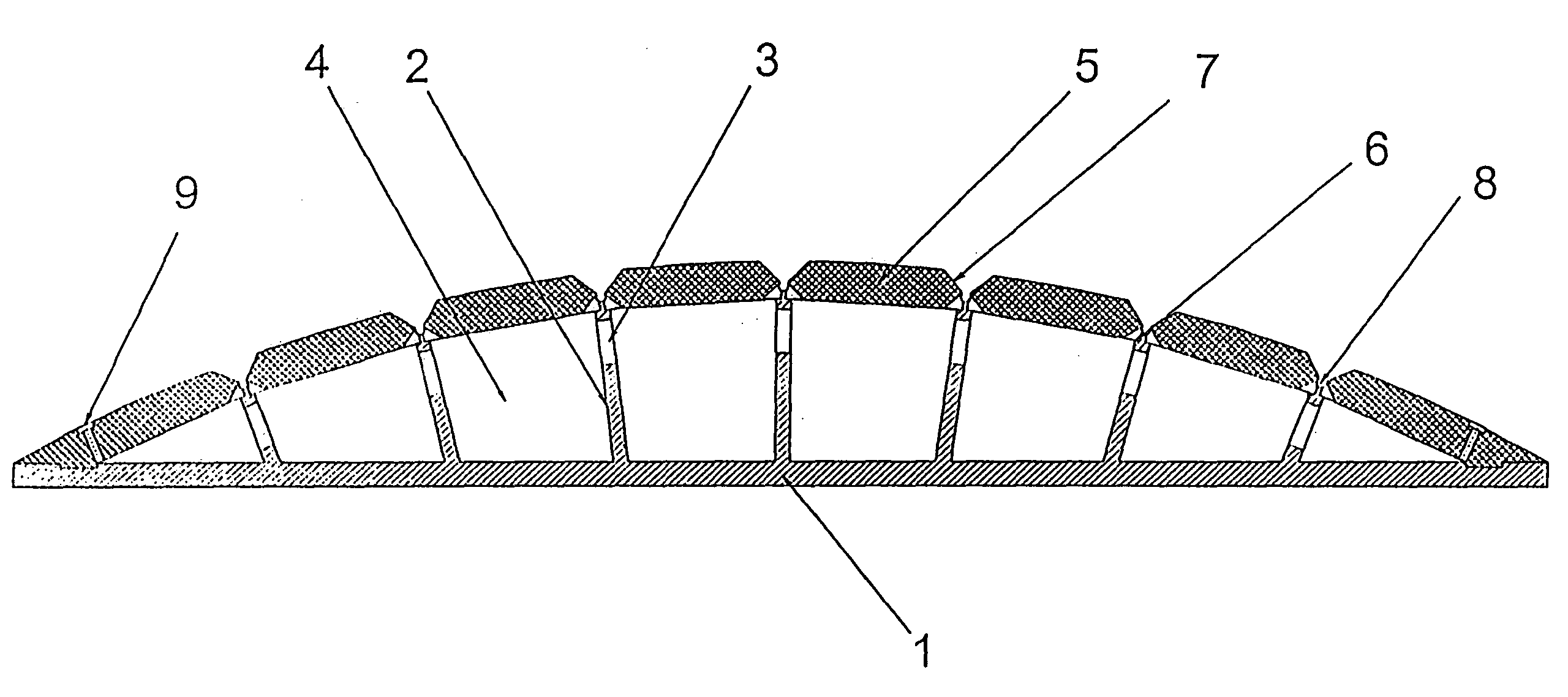

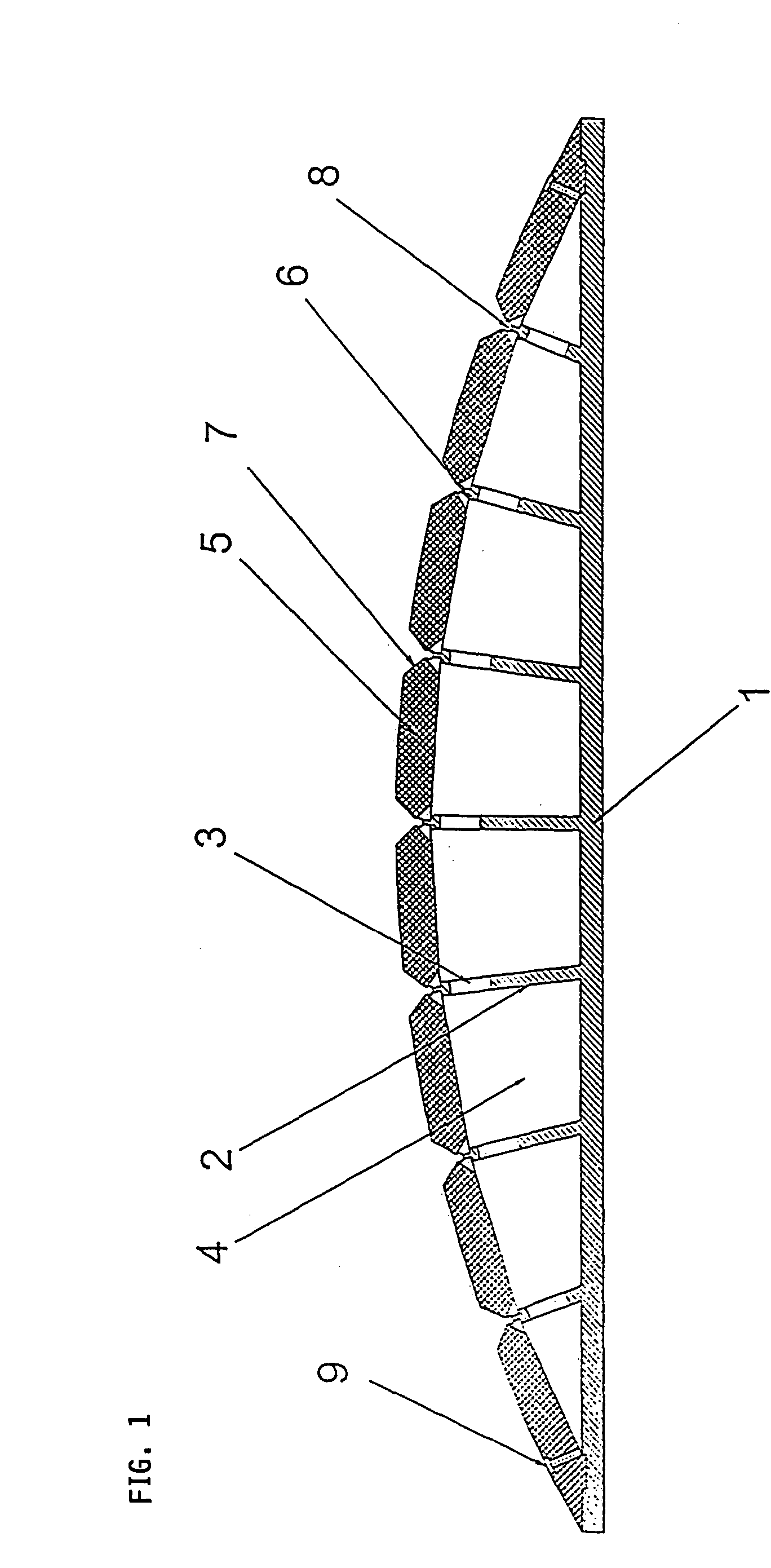

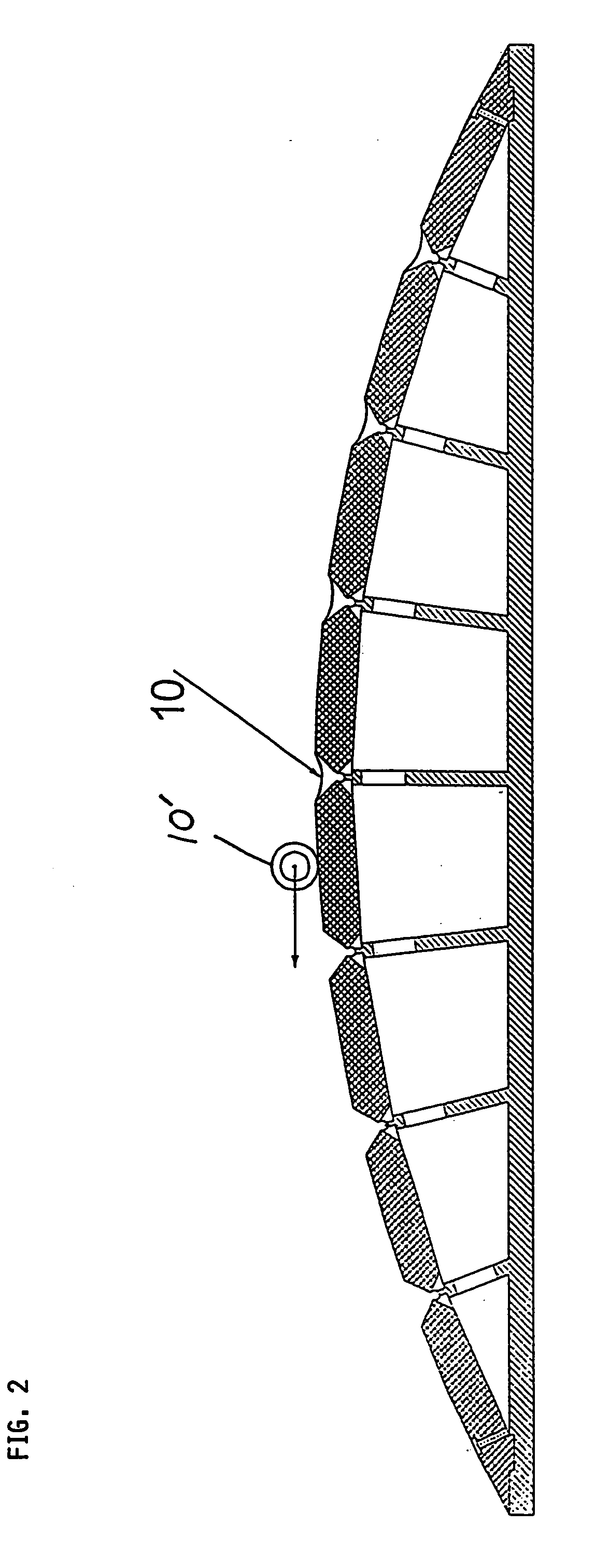

Automated fabrication of an integral fiber reinforced composite structural component using a positioning and assembly support

ActiveUS20040050498A1Precise positioningForming accuratelyLaminationEfficient propulsion technologiesGrid patternModularity

A forming jig includes a grid pattern of support walls arranged on a support base and having upper free ends located along an imaginary curved surface, and modular sectional profile members arranged on the walls to enclose a vacuum chamber within the jig. Grooves, channels and air passages between neighboring profile members communicate into the vacuum chamber. The outer surface of the profile members matches the intended inner surface of a structural component to be fabricated using the jig. In the fabrication process, a film is applied to the outer surface to pre-establish a vacuum, the film is removed while simultaneously a vacuum skin is applied, stringer members are set into the grooves, fiber skin layers are laid up, a sealant is applied around the perimeter, a structural shell is vacuumed onto the skin layers, and then this preformed component is removed from the jig, injected with resin unless the skin layers were pre-impregnated with resin, and cured.

Owner:AIRBUS OPERATIONS GMBH

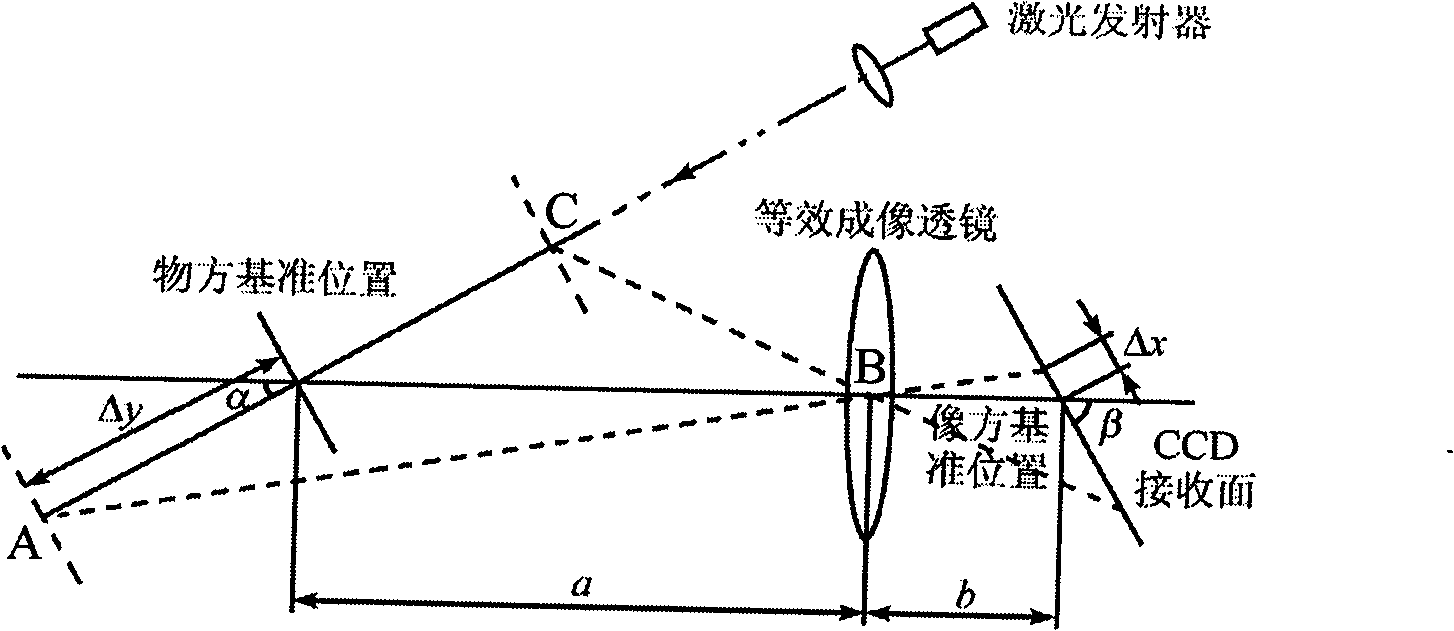

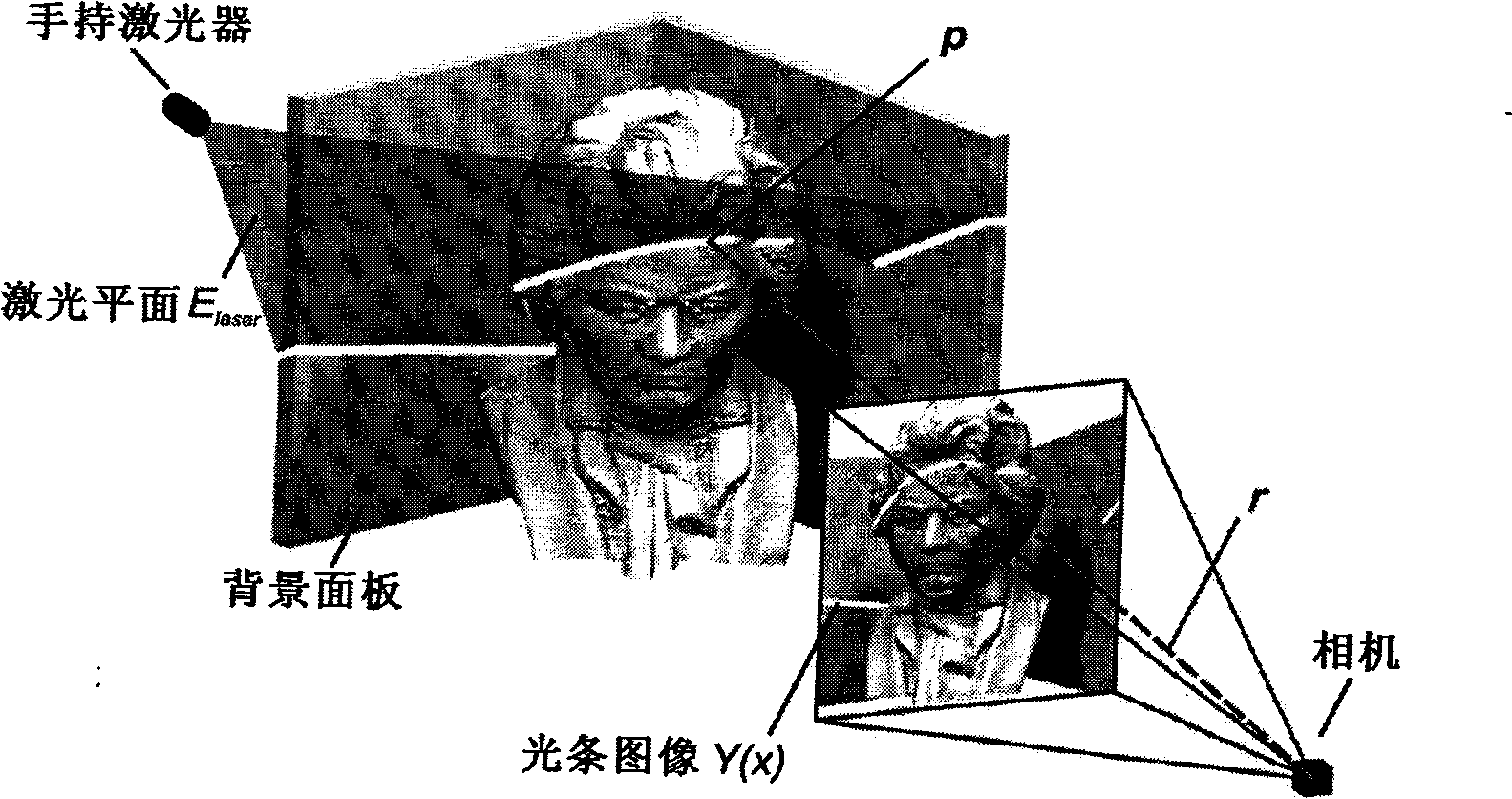

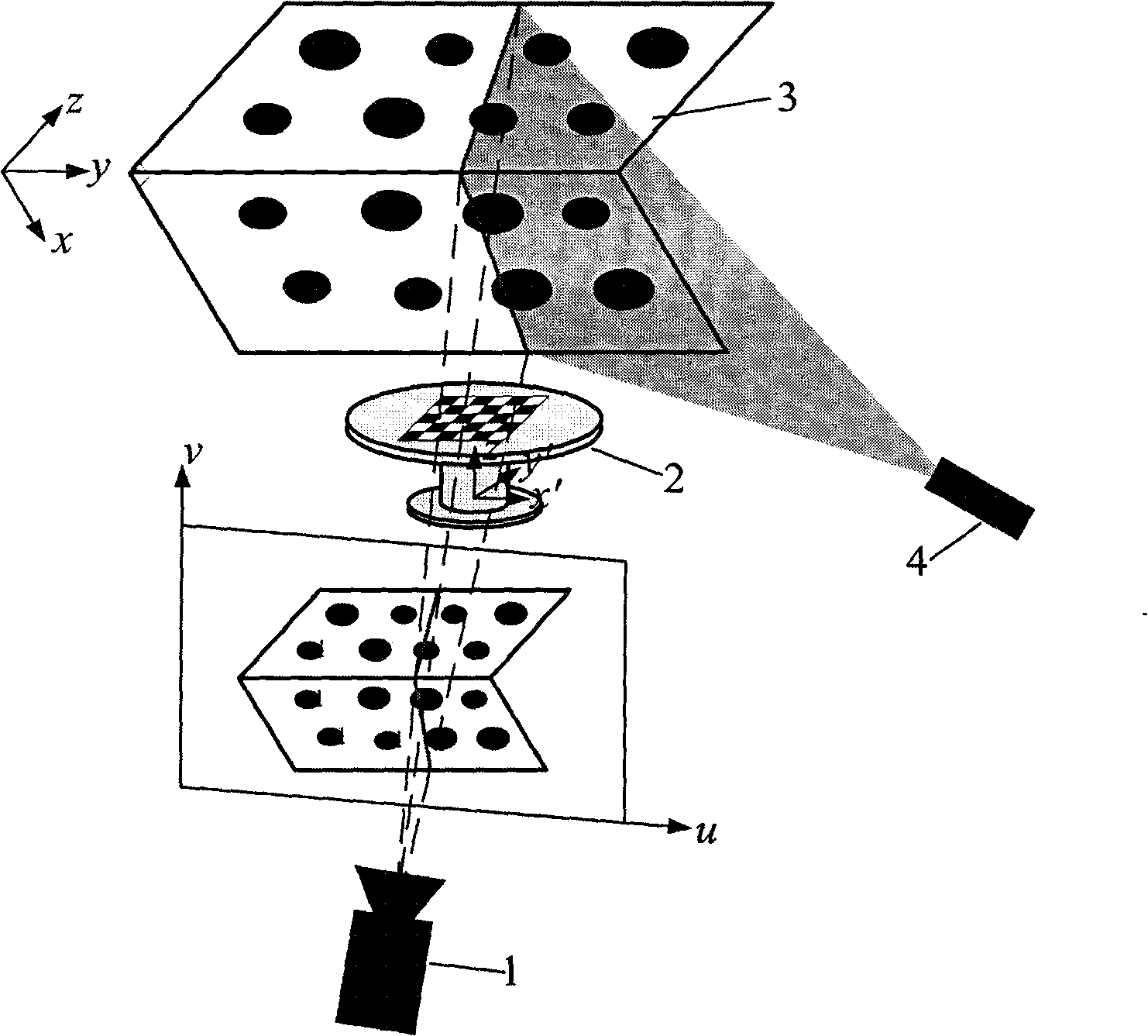

Scanning system and method for three-dimensional images

InactiveCN101526337AOvercome the disadvantages of low processing efficiencyLow costUsing optical meansLaser scanningSurface point

The invention relates to a scanning system and a method for three-dimensional images, wherein the system comprises a pick-up device, a rotating device, mutually orthogonal panels and a light source; and the method comprises: 1. transversely arranging the mutually orthogonal panels; 2. calibrating the CCD camera according to a second marking point on the mutually orthogonal panels to obtain the internal and external parameters of the CCD camera; 3. obtaining the plane equation of a linear laser scanning surface according to the internal and external parameters of the CCD camera, the linear laser emitted from the light source and the images of the mutually orthogonal panels; and 4. determining the three-dimensional coordinates of the surface points of the tested objects according to the plane equation of the linear laser scanning surface and the equation of straight line of the linear laser images. The invention reduces the cost, overcomes the limits to the surface matching of the scanning curve sheets based on a triangle relation in the prior art, and improves the efficiency, precision and flexibility of the scanning by arranging a rotating table and transversely arranging mutually orthogonal panels.

Owner:桂林大容文化科技有限公司

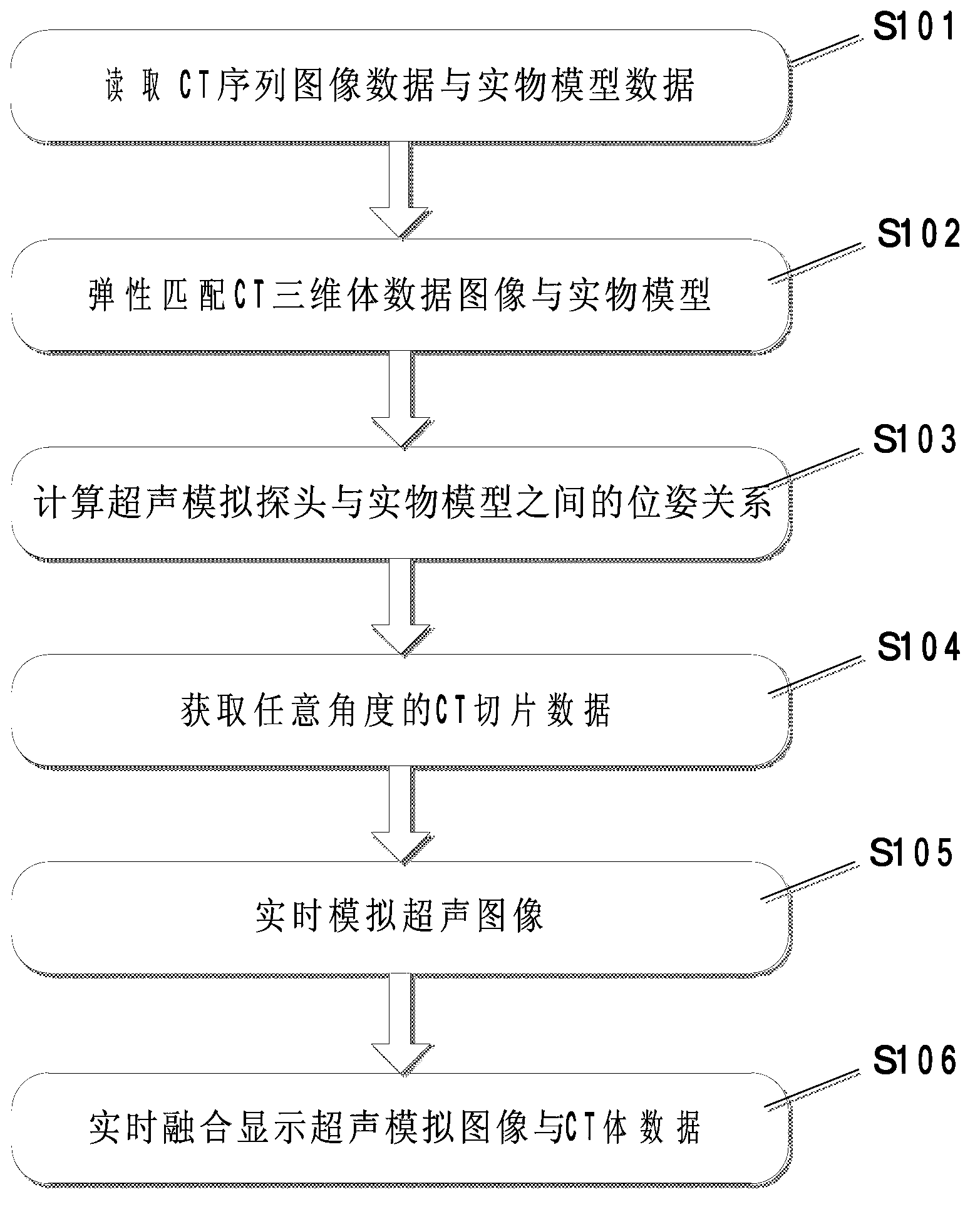

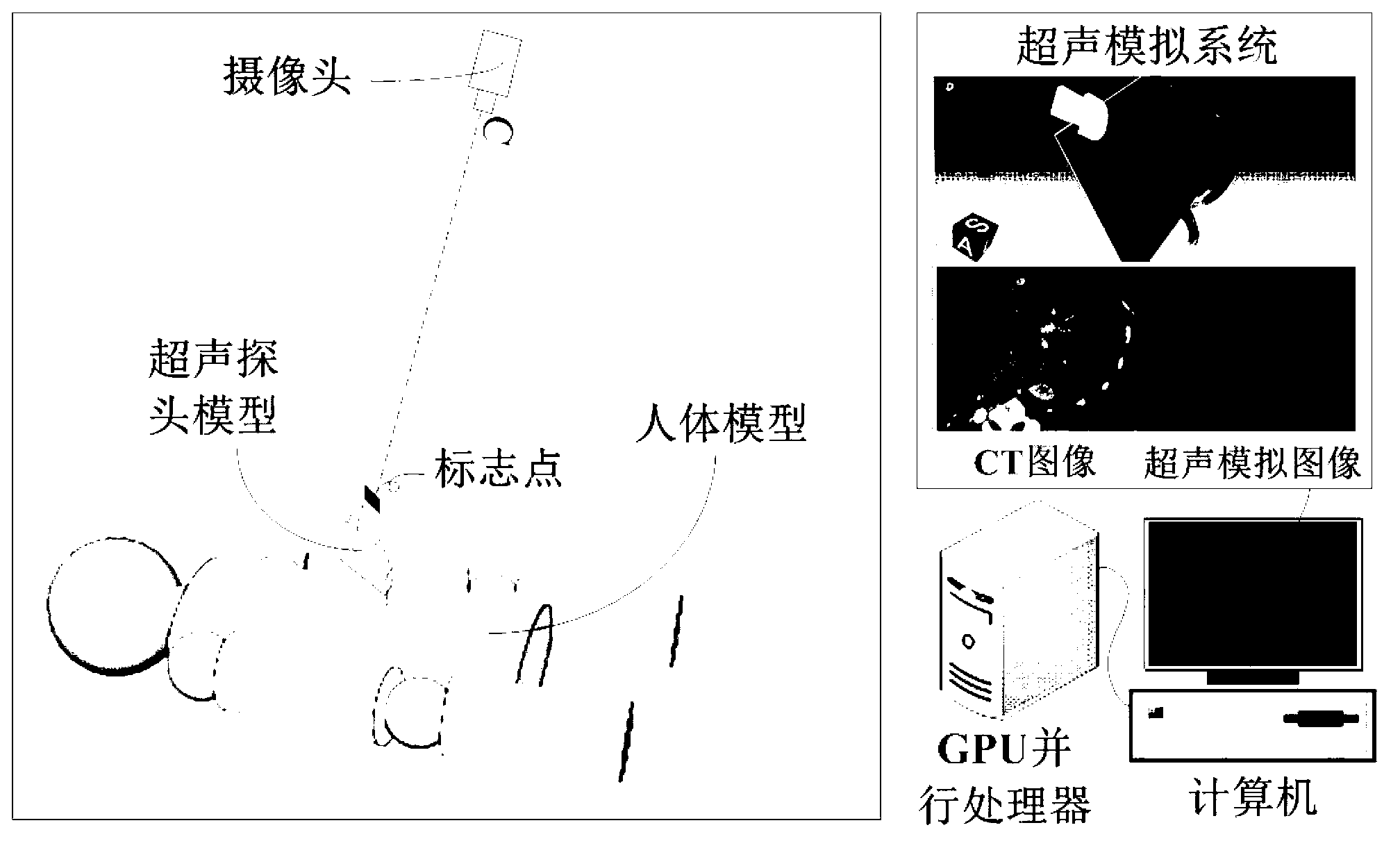

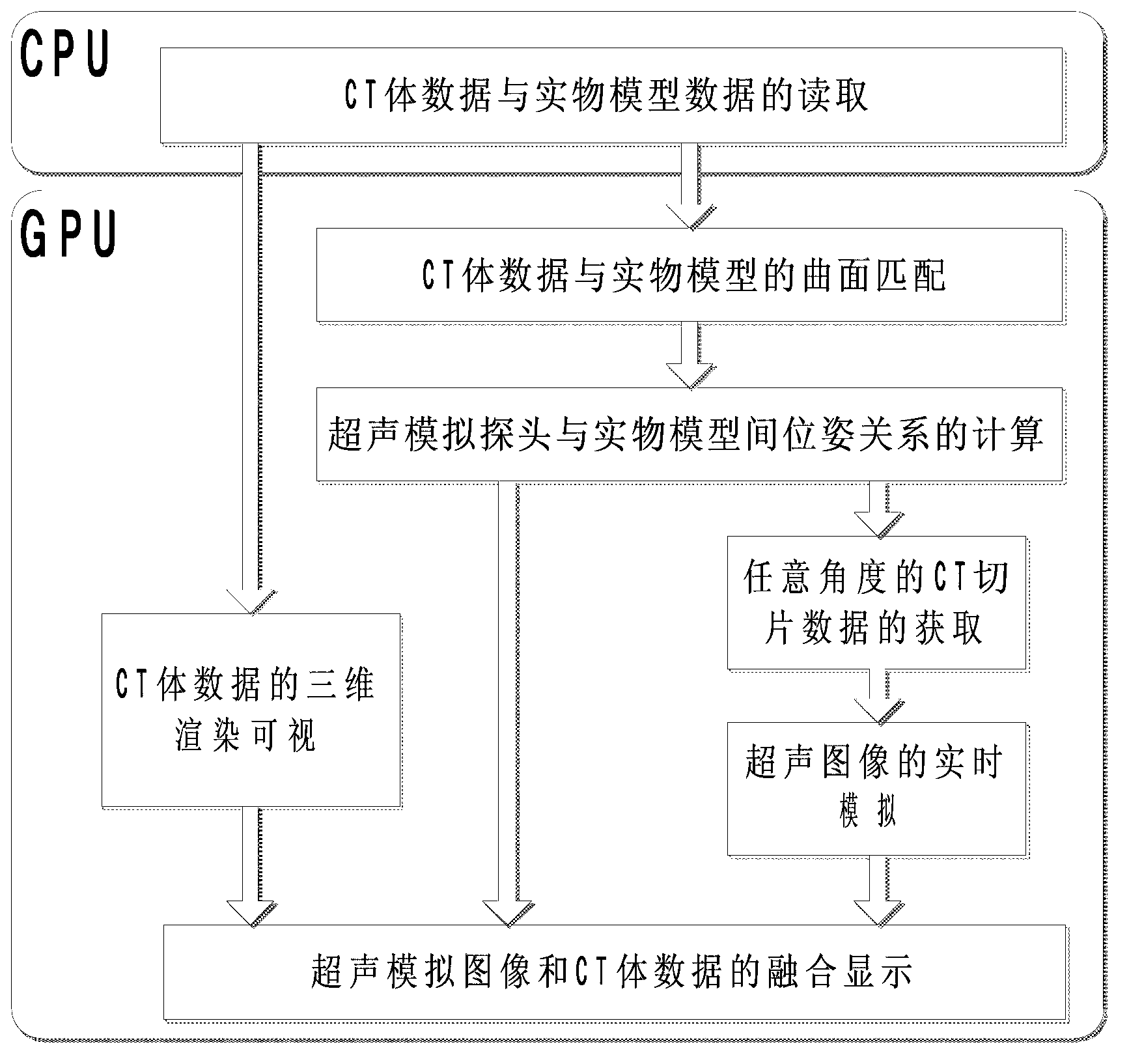

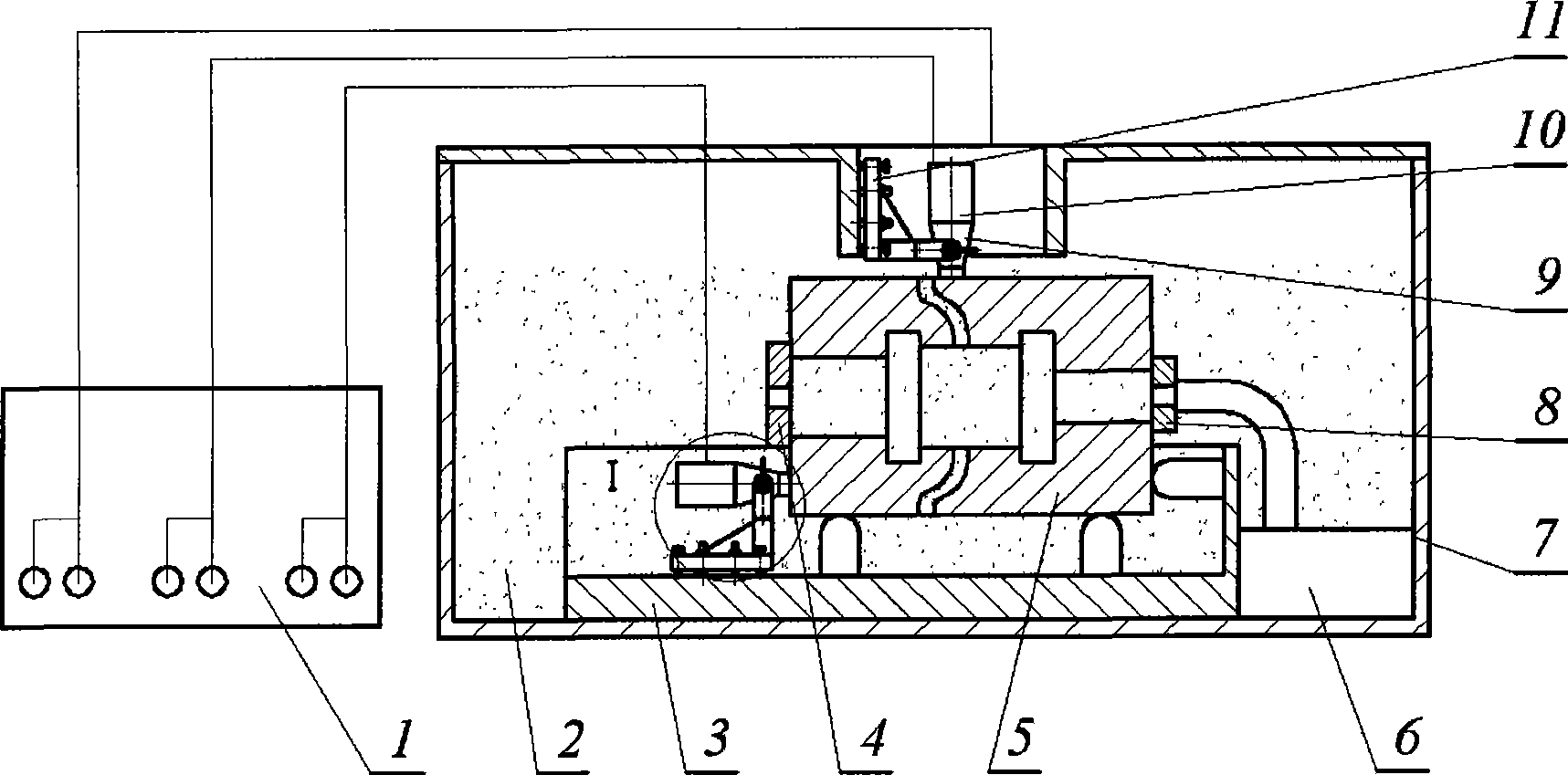

Ultrasonic training system based on CT (Computed Tomography) image simulation and positioning

ActiveCN103295455AReduce computational complexityThe pose matrix is accurateEducational modelsHuman bodyThree dimensional ct

The invention provides an ultrasonic training system based on CT (Computed Tomography) image simulation and positioning. Ultrasound image simulation and CT volumetric data rendering are accelerated to be achieved through a GPU (Graphics Processing Unit) and the real-time performance of the system is improved. A curved surface matching module is used for performing surface matching on read human body CT volumetric data and physical model data with a physical model as the standard and achieving elastic transformation of a curved surface based on an interpolation method of thin plate splines; an ultrasonic simulation probe position tracking module is used for performing real-time calculation on ultrasonic simulation probe positions relative to the physical model by a marking point tracking method and obtaining arbitrary angle CT slice images according to a position matrix; an image enhancement and ultrasonic image simulation generation module is used for improving the vessel contrast ratio in CT images by a multi-scale enhancement method and achieving the ultrasound image simulation based on the CT volumetric data; and an integration display module is used for accelerating to achieve rendering display of the CT volumetric data based on CUDA (Compute Unified Device Architecture) and integrating and displaying ultrasound simulation images and three-dimensional CT images according to the obtained position matrix.

Owner:ARIEMEDI MEDICAL SCI BEIJING CO LTD

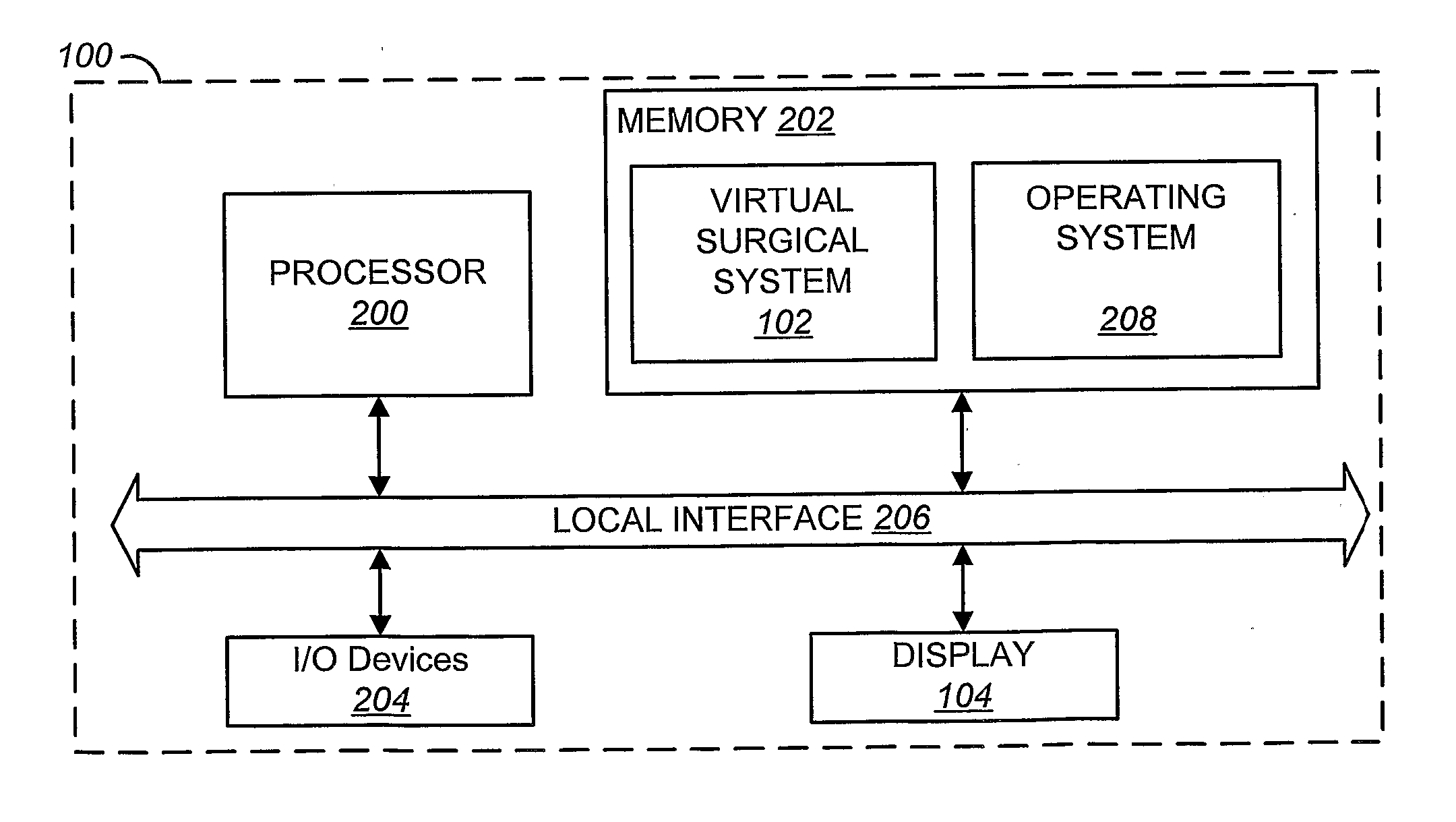

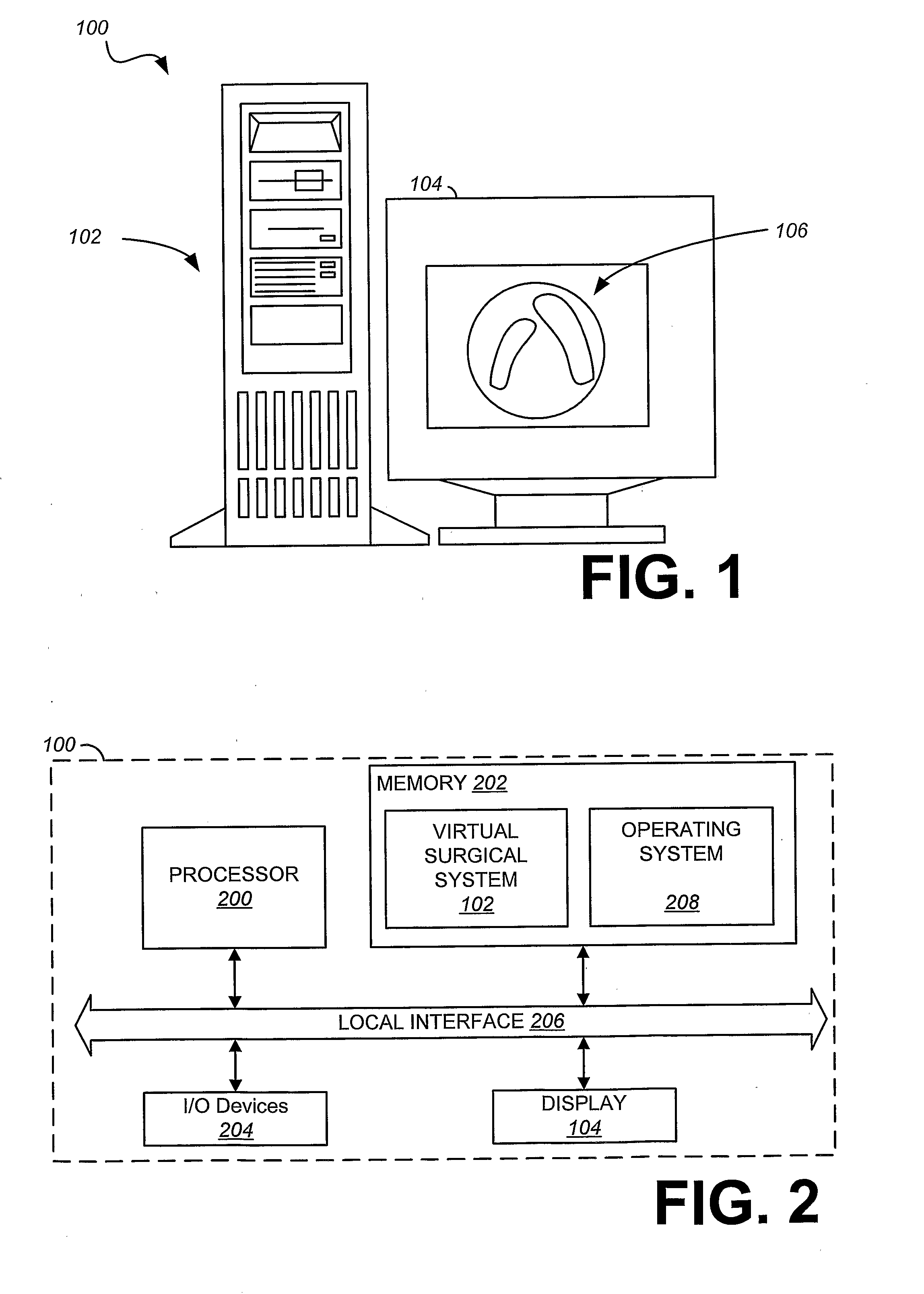

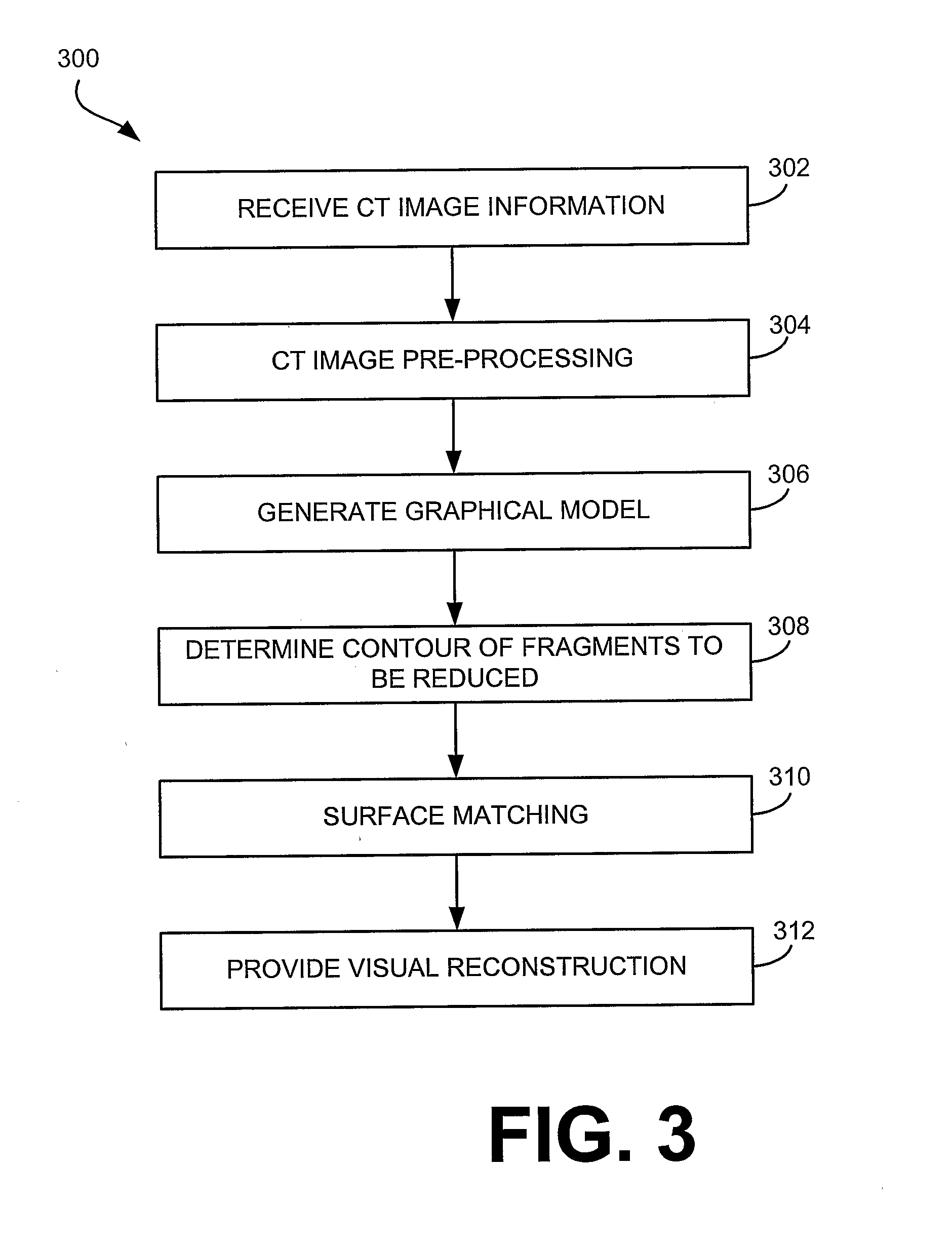

Virtual Surgical System and Methods

A virtual surgical system receives an image, such as a computer tomography (CT) scan, of an area of the patient in need of surgical reconstruction prior to an incision being made in a surgery. Bone fragments that are to be reduced are automatically selected using the virtual surgical system. The system performs surface matching techniques using surface data representing the contour of the end surfaces of the fragments to determine how the corresponding fragments should be oriented to perform the reduction. At least one of the fragments may then be transformed (e.g. via translation and / or rotation) to join the surfaces based on the matched surfaces. An image may be generated of the reconstructed area providing a virtual representation of a reconstructed object. Thus, before actual dissection of the area, and the subsequent physical surgical reduction of the bones, an image of the reconstructed object may be displayed such that a prosthesis may be determined and / or manufactured.

Owner:UNIV OF GEORGIA RES FOUND INC

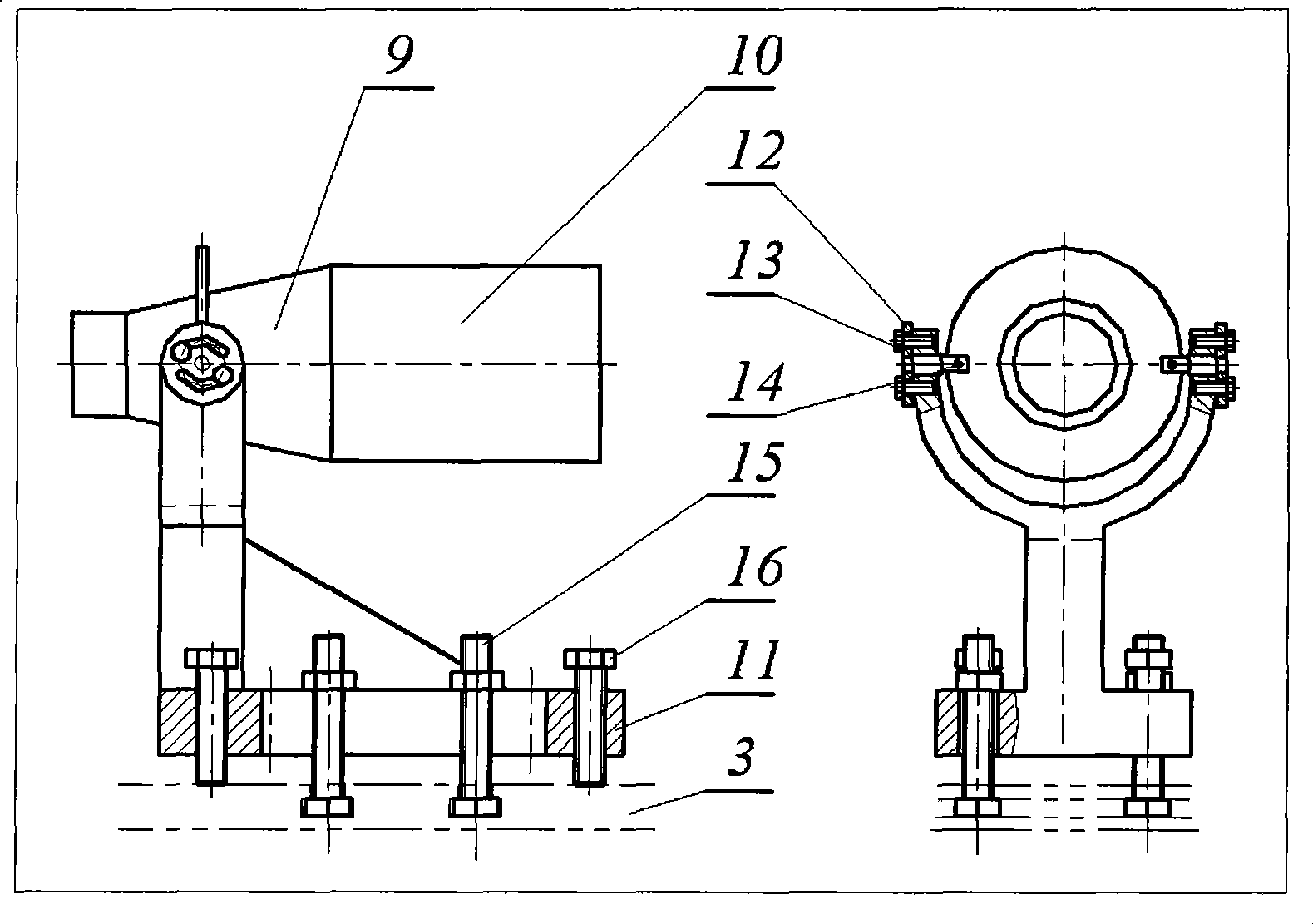

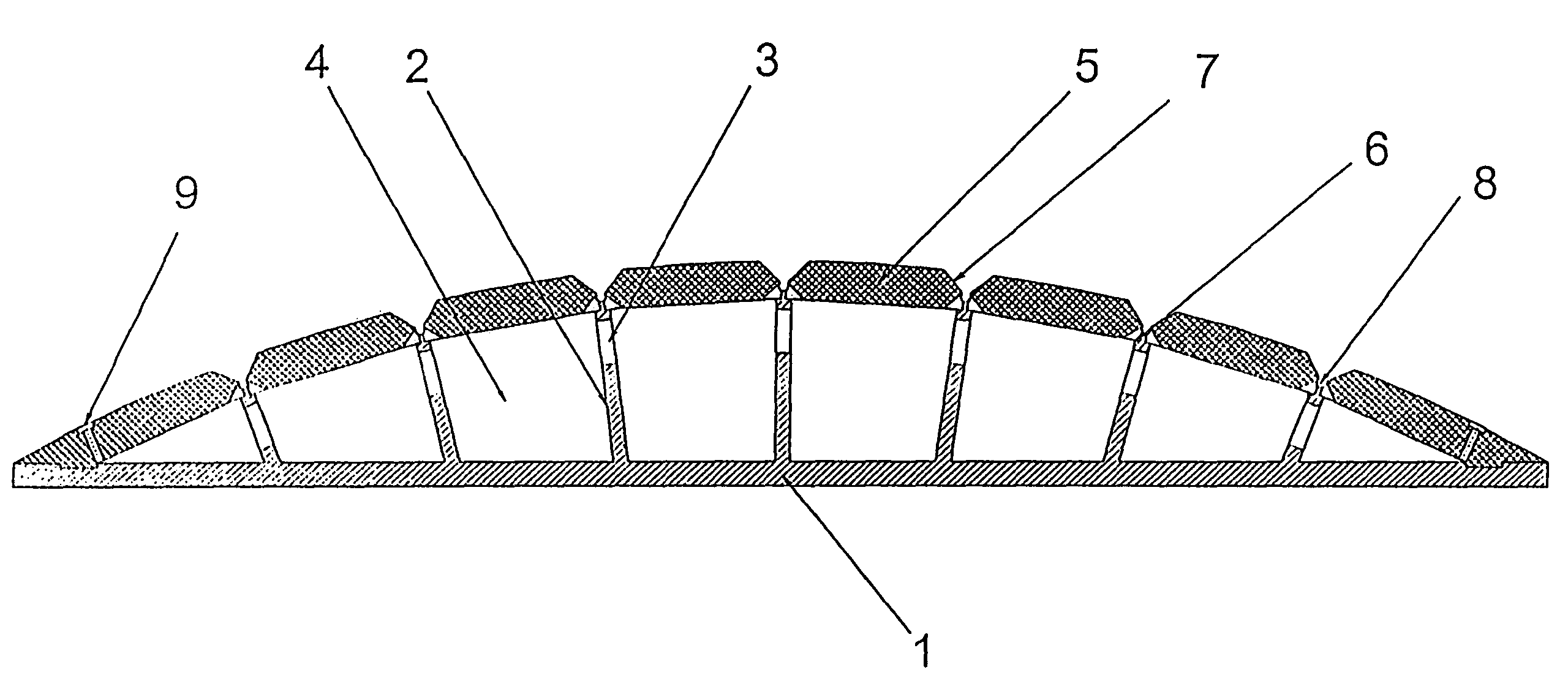

Complicated surface optical finishing processing device and technique

InactiveCN101417401ASolve the problems that cannot be finishedSolve the problem that cannot be finishedCavitationWear particle

The invention discloses a finishing machining device of complex surfaces and a technique thereof, belongs to the field of special processing technology and is characterized in that high-intensity supersonic vibration produced by direct shock excitation to workpieces by an ultrasonic horn acts with the liquid and solid two-phase flow forced on surfaces of complex workpieces, thus producing the impact of workpiece surfaces and grinding particles and liquid cavitation to cause the impact to workpiece surfaces by the grinding particles, and the finishing machining of complex workpiece surfaces is realized; and particularly, inner concave surfaces with complex channels also have the high-intensity supersonic vibration and the all-pervasive characteristic of the liquid and solid two-phase flow. The device and the technique have the advantages of realizing the finishing machining of complex inner and outer surfaces and also solving the problem that inner concave surfaces and dead corners can not be finished and machined. The technology can fully and effectively finish and process inner surfaces, and effectively reduce the surface roughness value of parts, thus greatly improving the surface matching quality, surface wear resistance, surface air tightness, cleanliness and service life of parts.

Owner:TAIYUAN UNIV OF TECH

Orthodontic bracket

An orthodontic bracket placed on a side surface of a tooth for correcting irregularities of teeth is disclosed, which enables orthodontic treatments to be performed without reset of a bracket body and an arch wire with respect to the tooth even in an advanced stage of the treatments. The orthodontic bracket comprises a bonding plate having a bonding surface matching a curve of the tooth, a base having a bottom surface united with the bonding plate and an upper surface as a sliding surface parallel to a long axis of the tooth and taking an approximately rectangular shape in plan with a convex curve formed in accordance with the long axis of the tooth, and a bracket body set on the sliding surface of the base so as to be slidable along the tooth axis. The base has, at the opposite upper sections of the sliding surface, confronting groove-like parallel rails adapted to let slidably the opposite portions of the bracket body therein. Each rail has, at its opposite ends, stoppers to prevent detachment of the bracket body. The sliding surface has, at its widthwise center, a longitudinally-extending visible median line. The bracket body has, on its upper surface, wire slots arranged approximately orthogonal to the above tooth axis.

Owner:KIMURA NORIFUMI

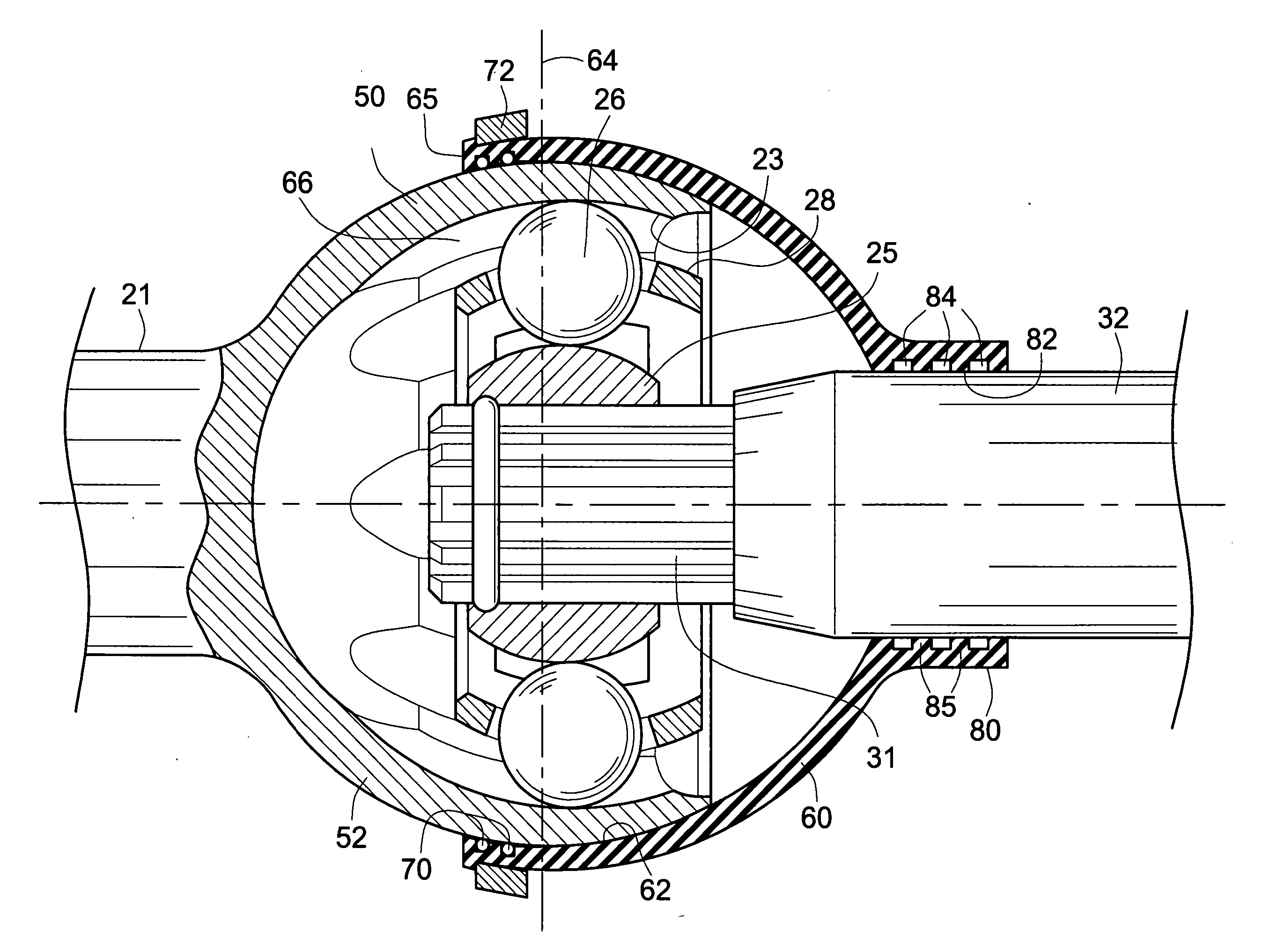

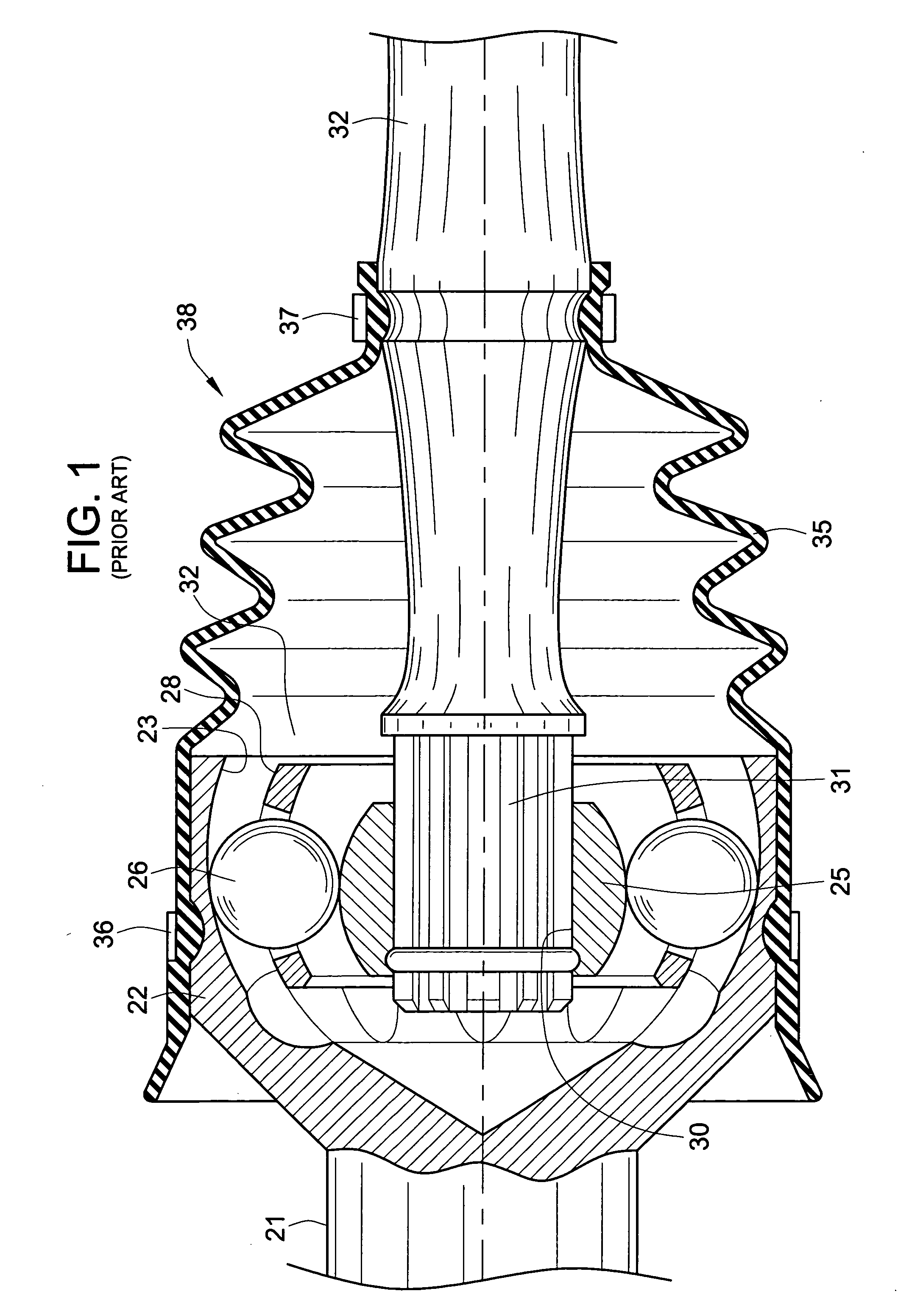

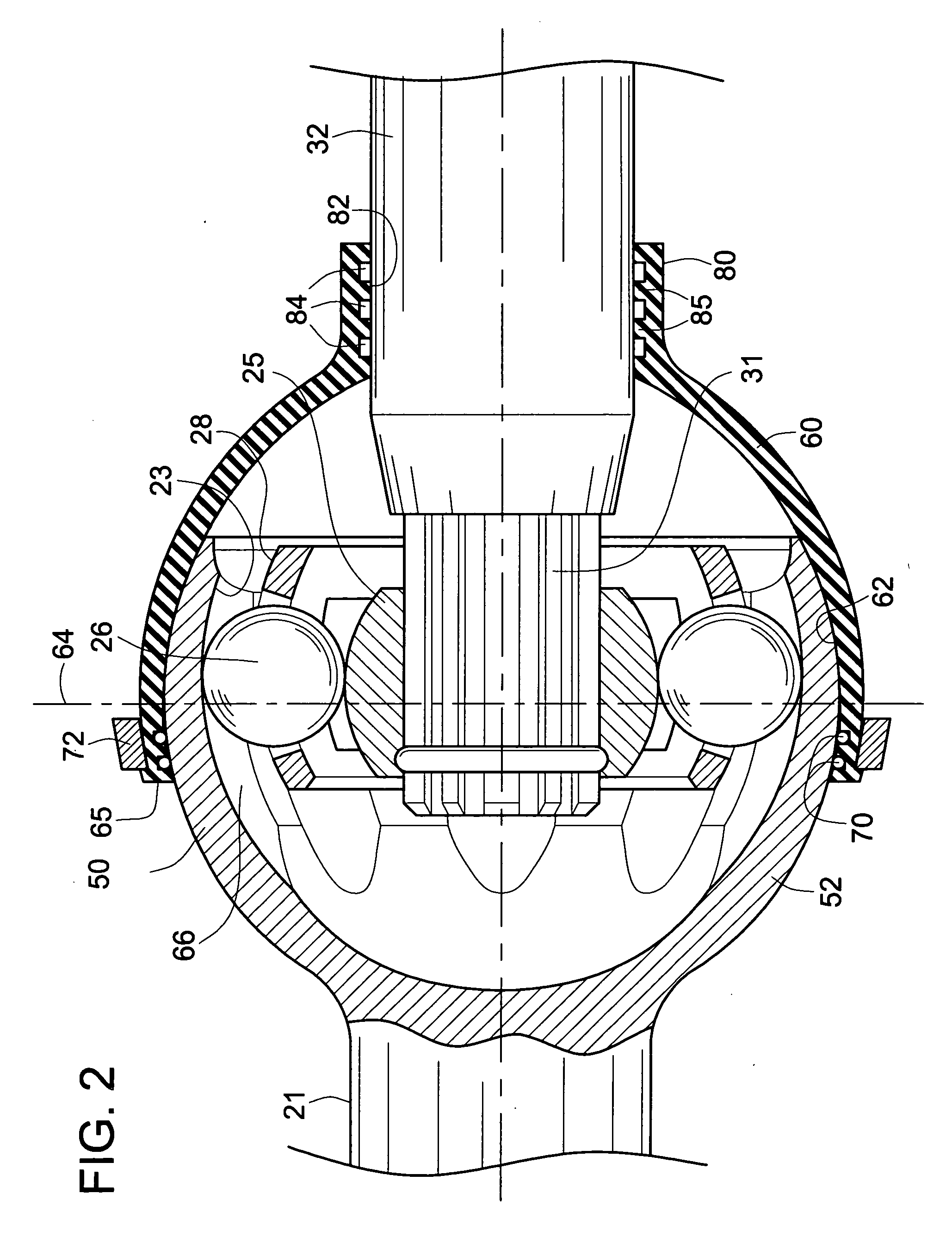

High performance constant velocity universal joint

ActiveUS20060240897A1Reliable and reliableEasy to installYielding couplingRotary machine partsUniversal jointPlastic boots

A high performance constant velocity universal joint is based on a body which encloses the constant velocity joint components and provides a smooth spherical outer surface. A one-piece semi-rigid plastic boot in the form of a truncated sphere has a smooth internal spherical surface sized to match the outer surface of the body. The plastic of the boot is sufficiently elastic to allow the boot to snap over the body, yet sufficiently resilient to snap the open end closed after the boot is snapped over the body to provide a substantial seal preventing entry of debris under the seal. A retaining ring is positioned on the boot near the truncated end to resist plastic creep which would result in enlarging the opening and allowing debris to enter the seal.

Owner:AIRCRAFT GEAR CORP +1

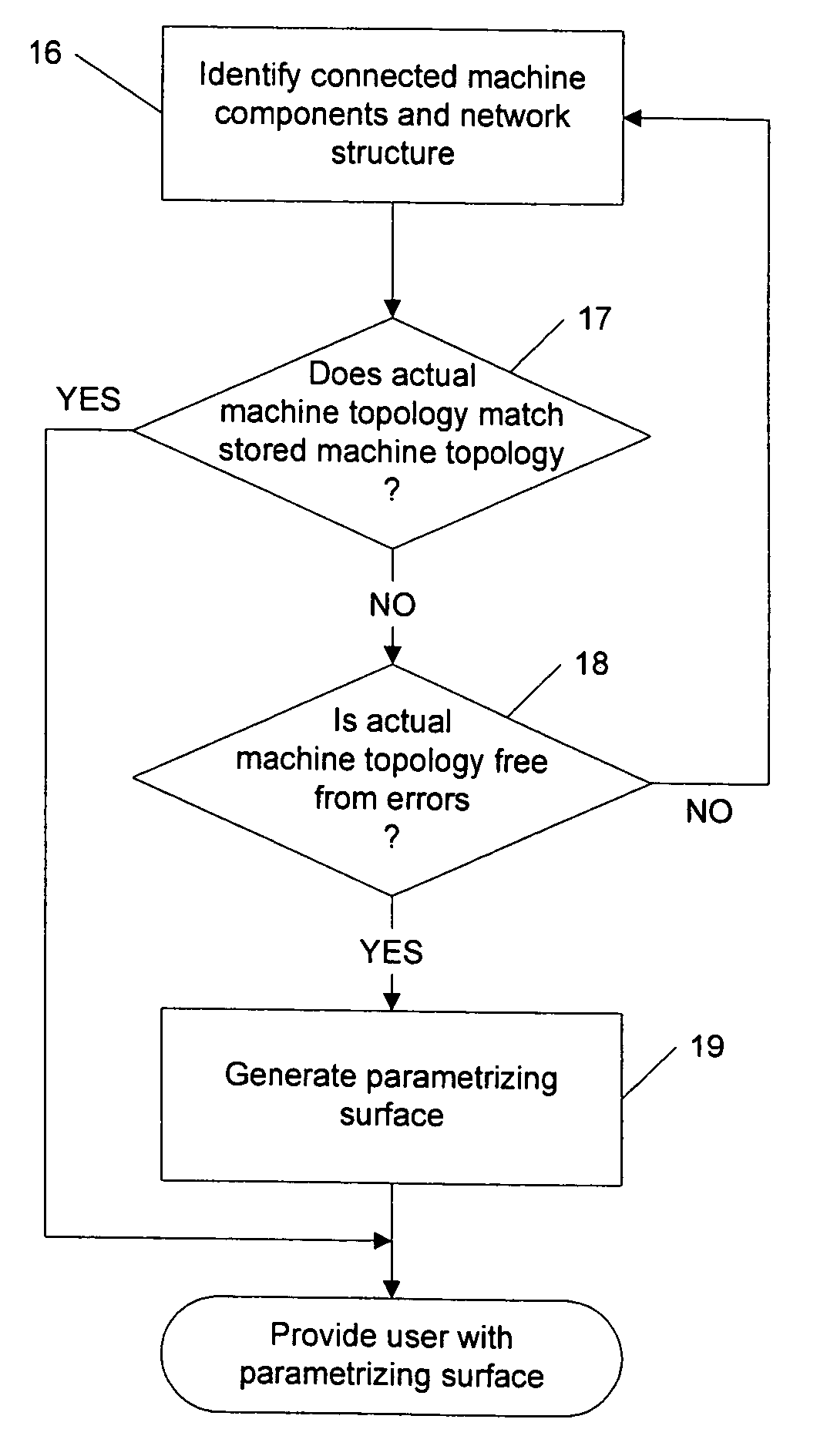

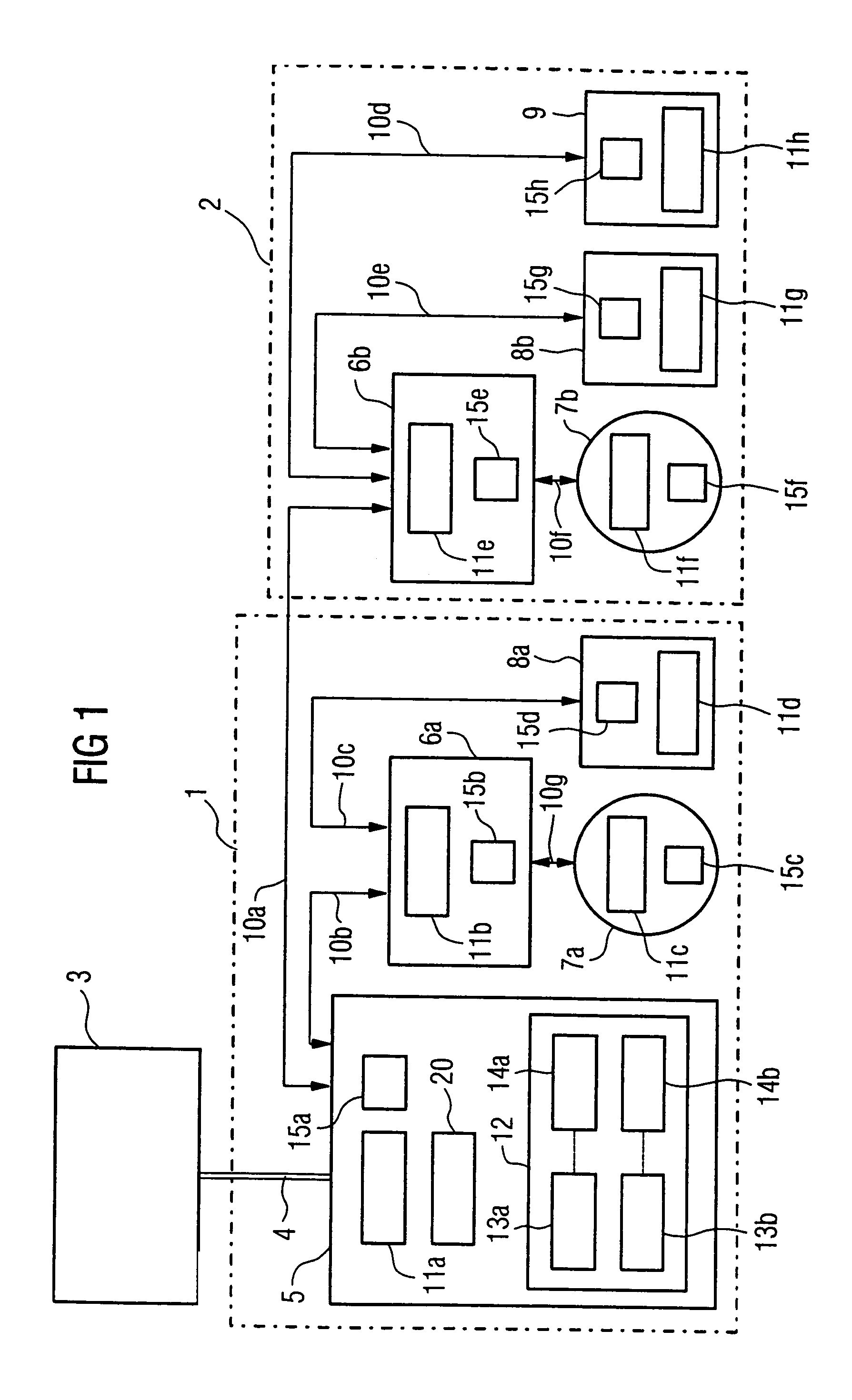

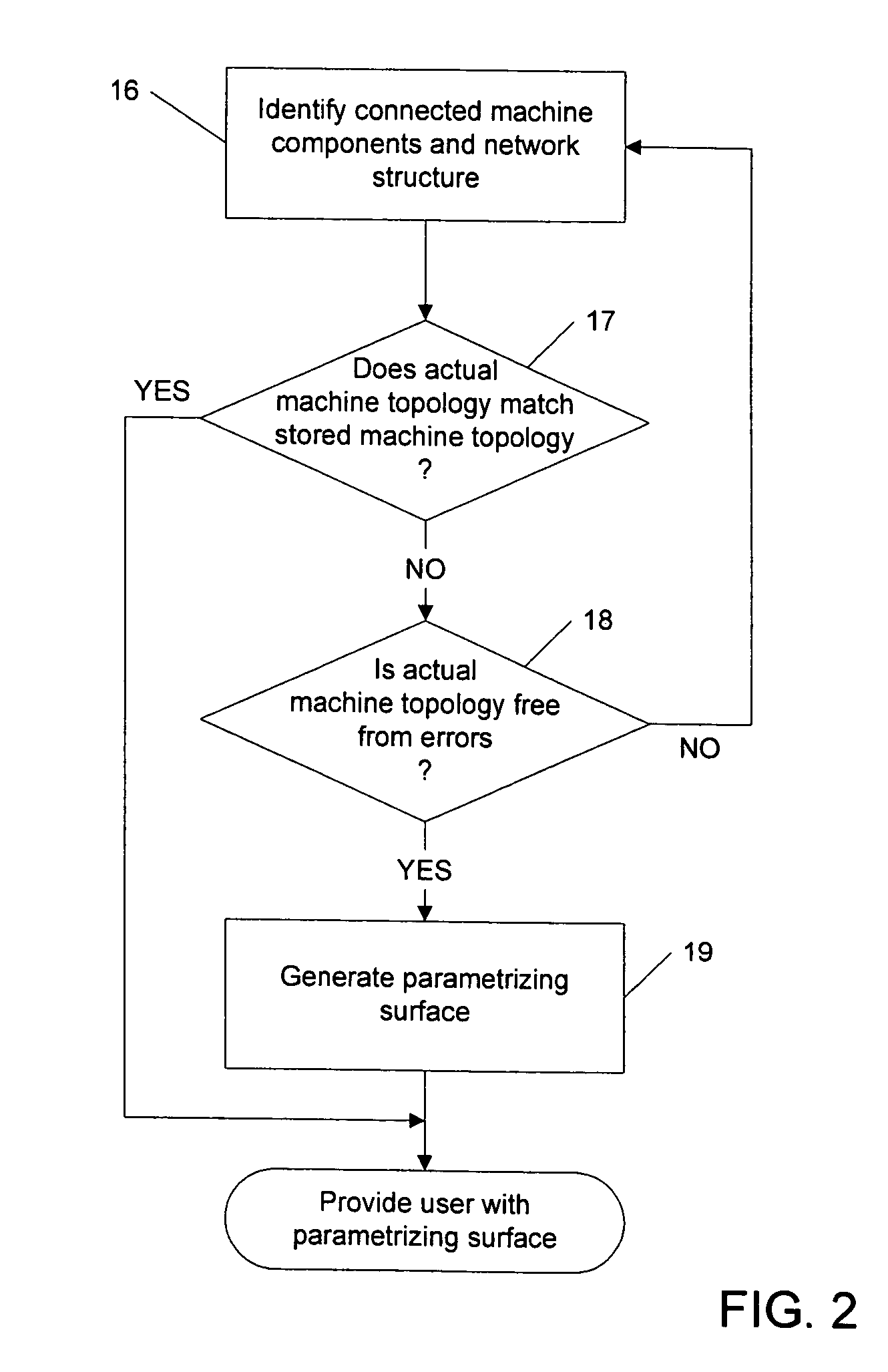

Method and data network for automatically configuring a parameterizing surface of machine tools or production machines

ActiveUS6981221B2Simple configurationTotal factory controlSpecial data processing applicationsMachine toolEmbedded system

A method and a data network for automatically configuring a parameterizing surface of at least one controller of machine tools or production machines. An actual machine topology is determined via a data network when the machine starts up and compared with stored desired machine topologies. If the actual machine topology differs from the desired machine topology, a corresponding dedicated parameterizing surface is generated from the determined actual machine topology, whereby for parameterizing the controller of the machine only the parameters and / or functions of the identified machine components are indicated to the user. In this way, a dedicated parameterizing surface matching the actual machine configuration can be easily generated.

Owner:SIEMENS AG

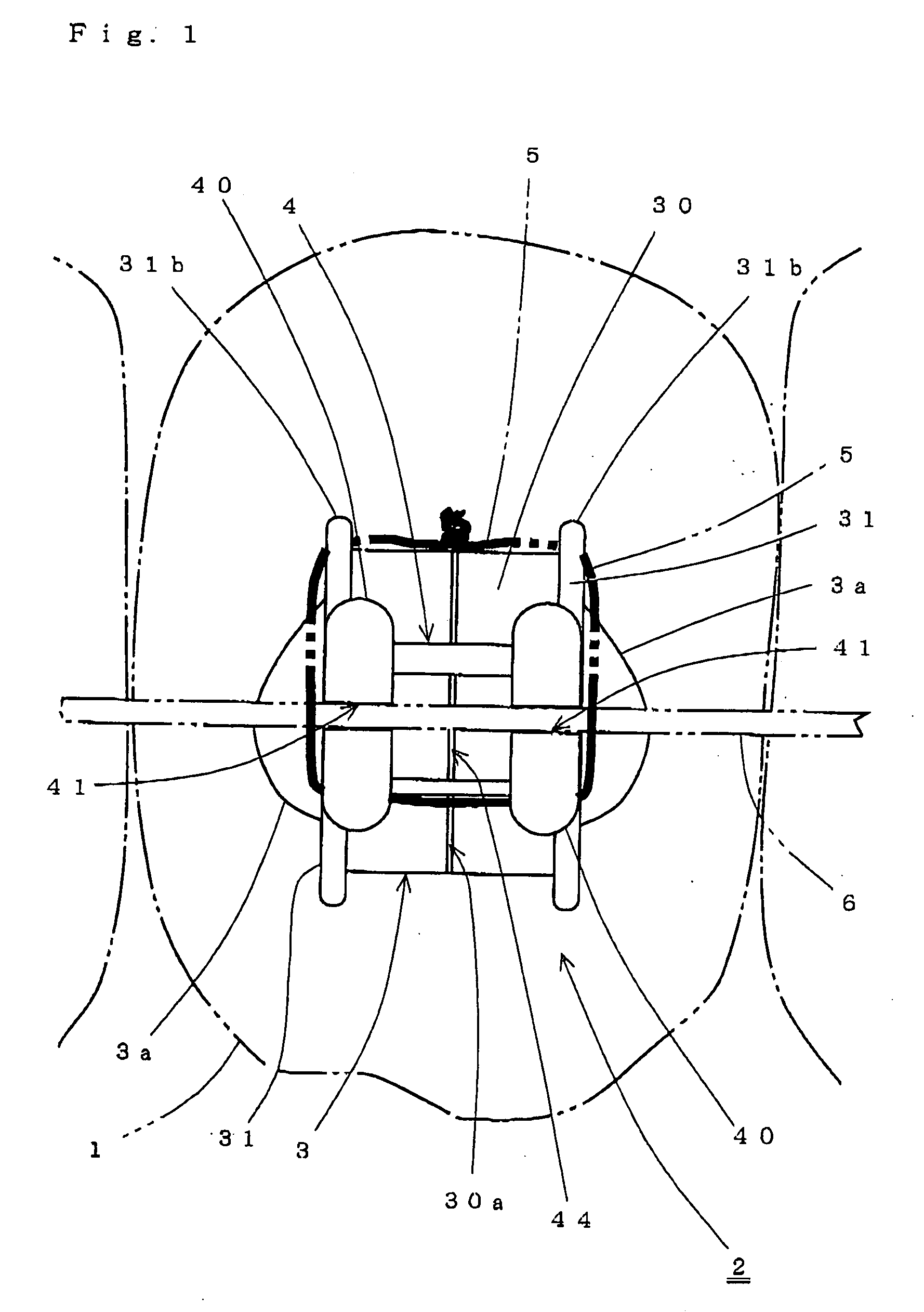

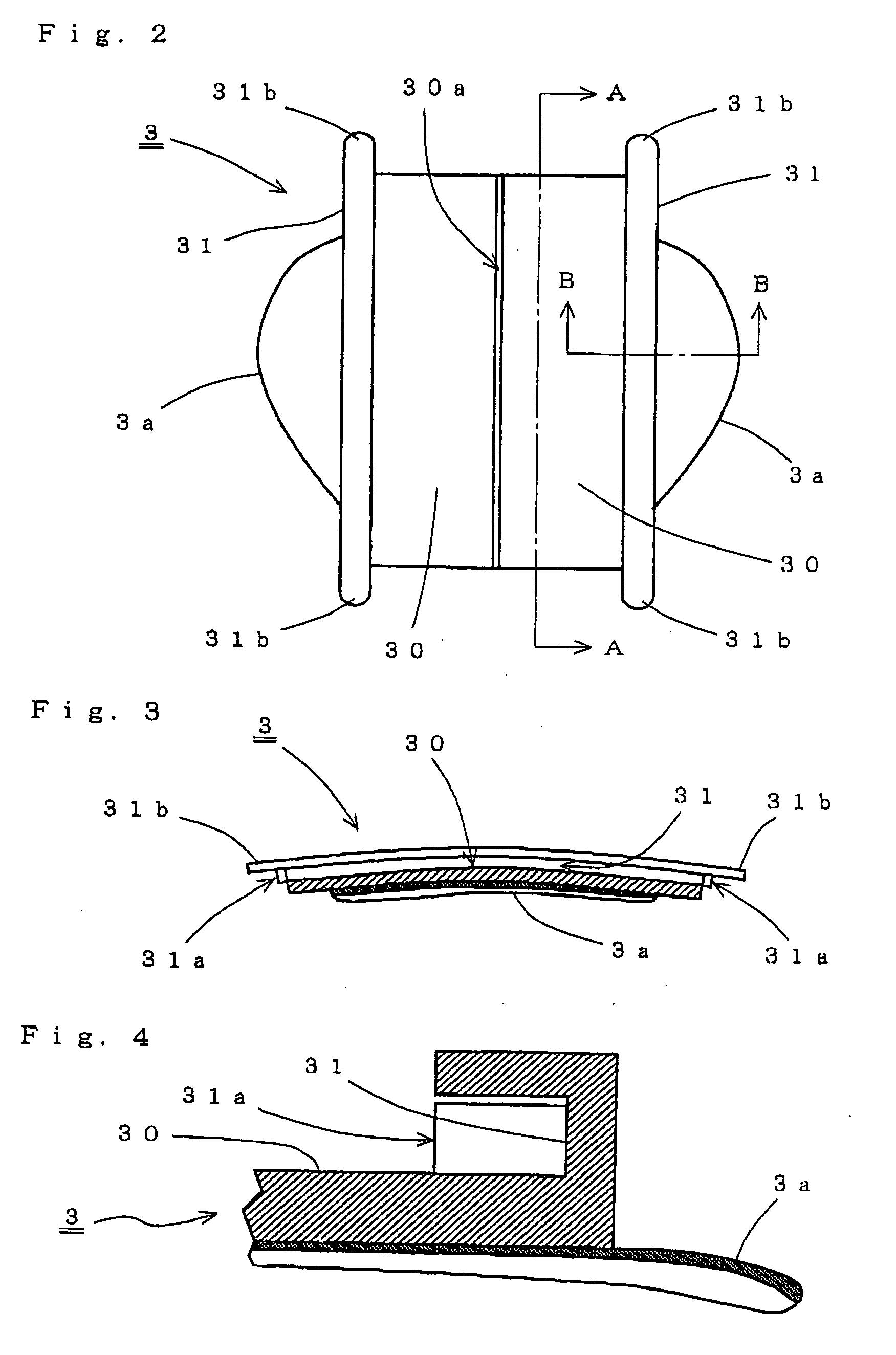

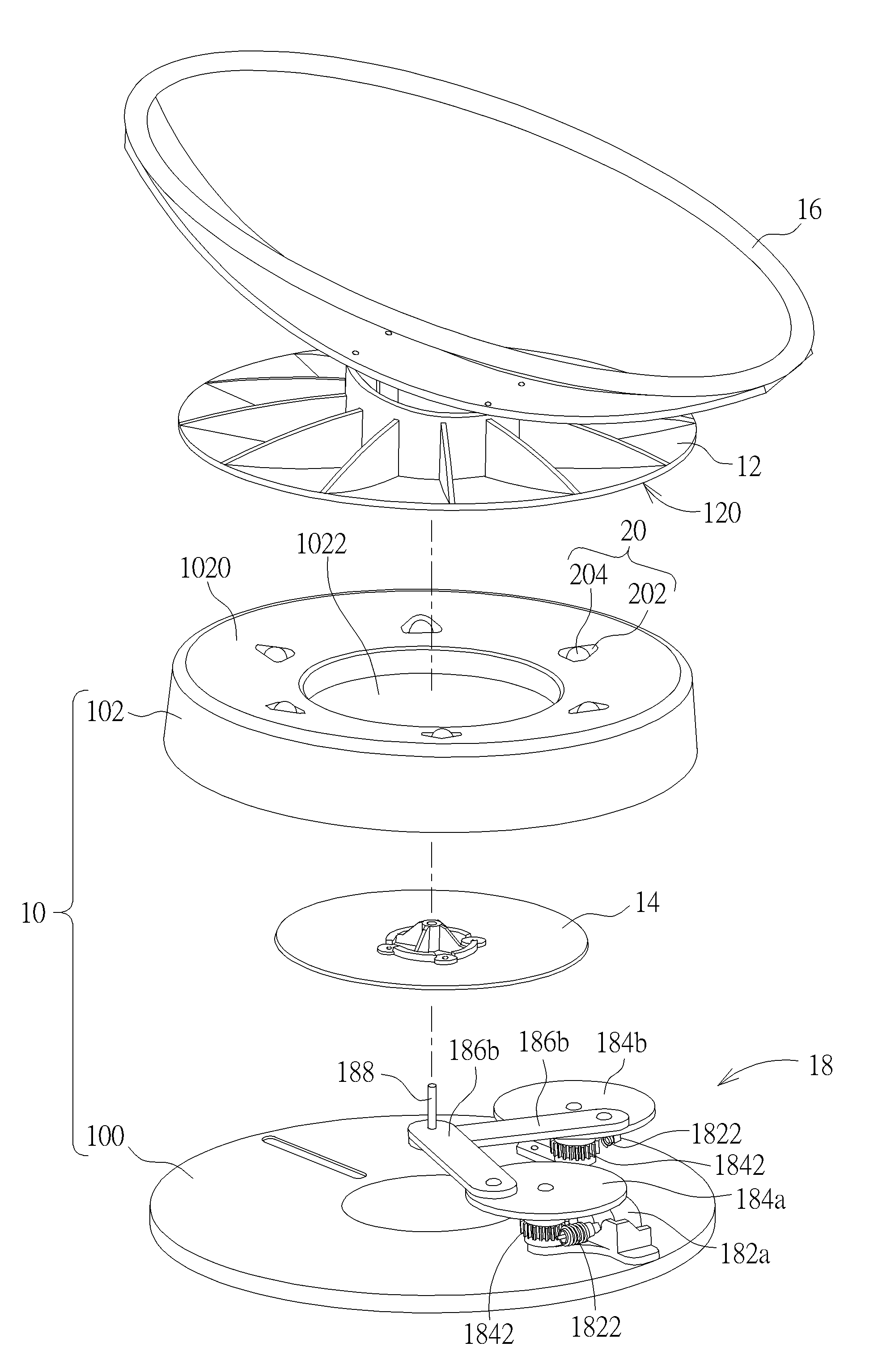

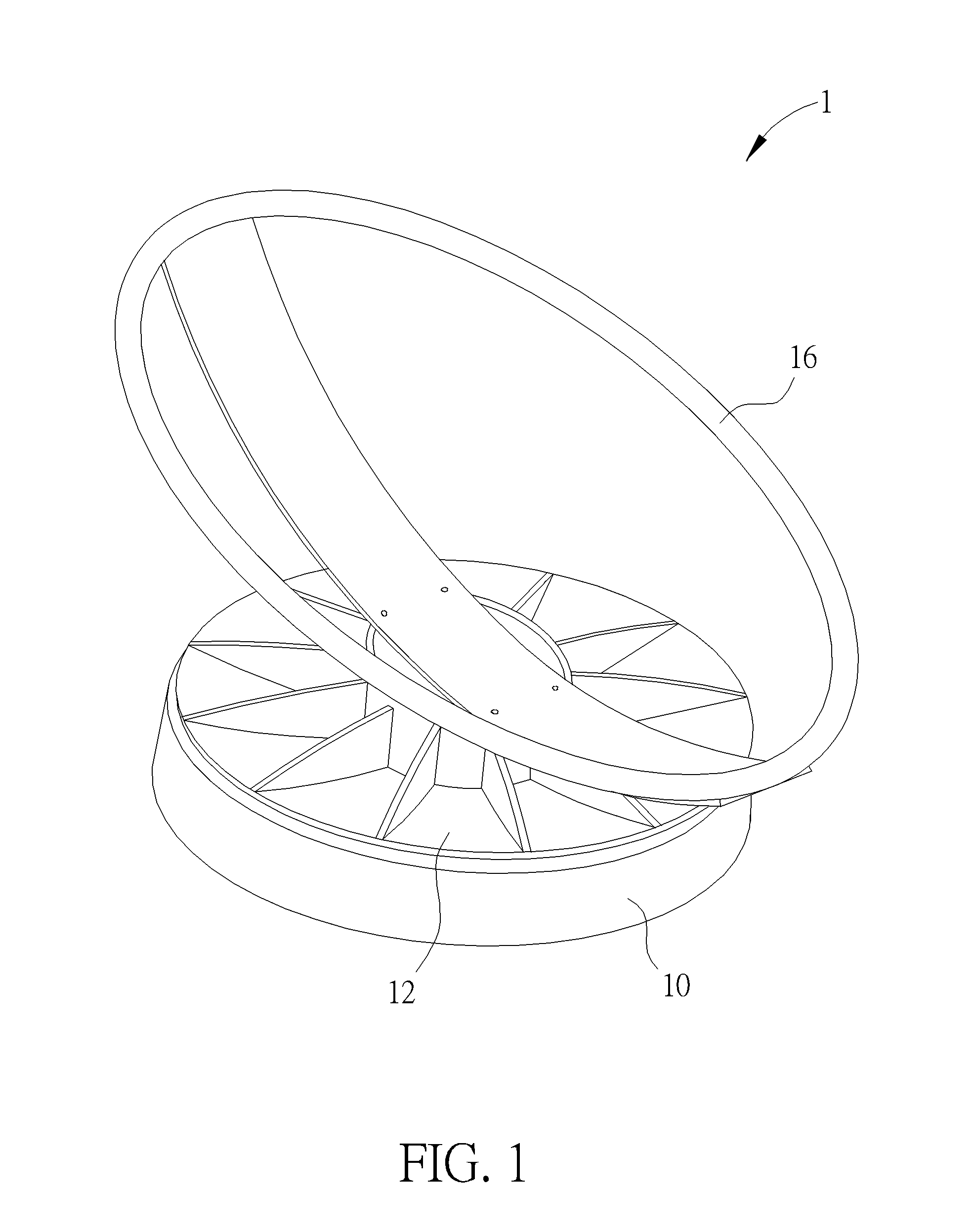

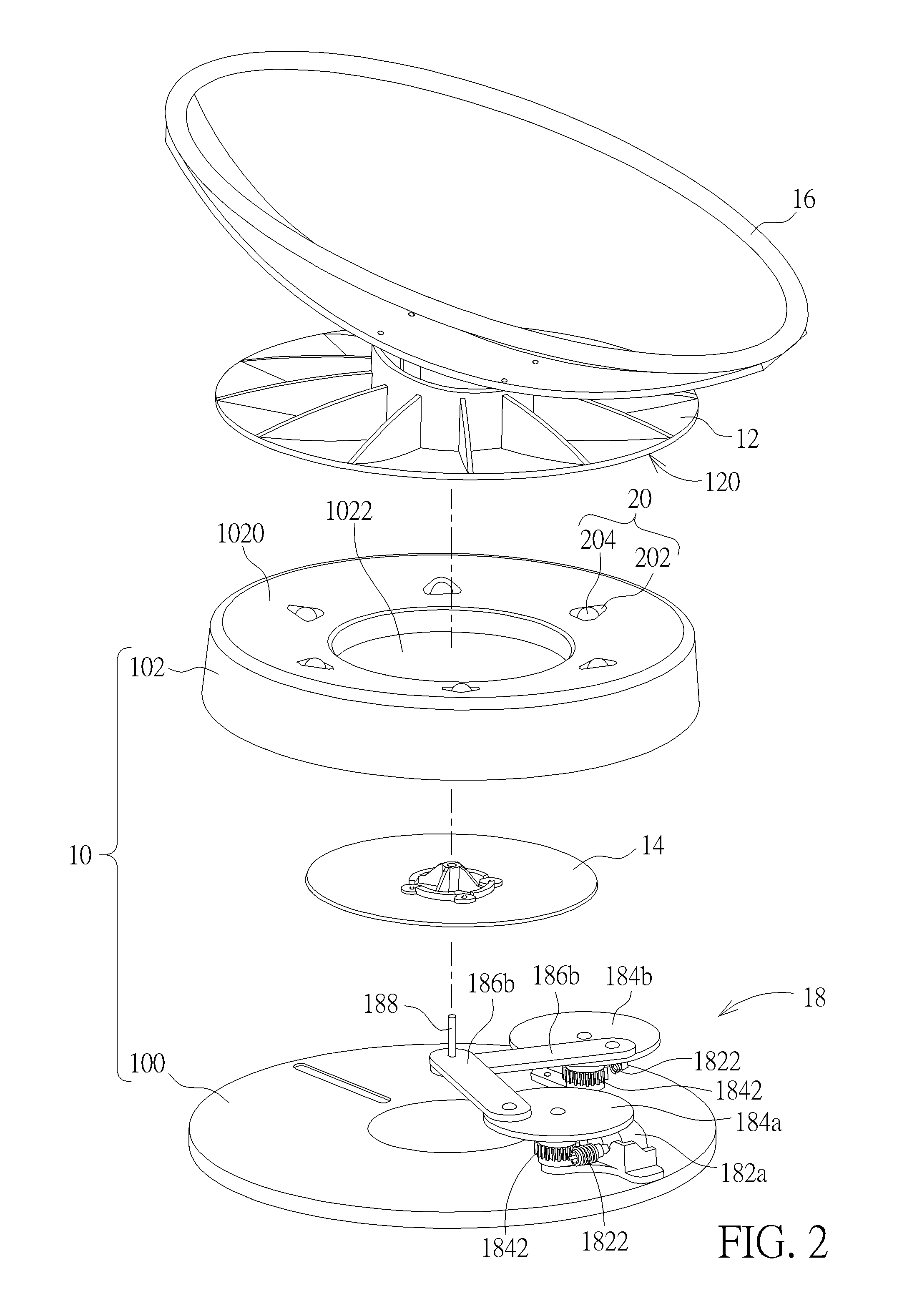

Infant care apparatus

An infant care apparatus capable of providing various swing motions is disclosed. The infant care apparatus includes a base, a sliding mount, and a seat frame. The base has a concave surface. The sliding mount has a convex surface matching with the concave surface and disposed opposite to the concave surface. The sliding mount slides above the concave surface by the convex surface. The seat frame is fixed on the sliding mount to be moved together with the sliding mount. Thereby, the seat frame together with the sliding mount can swing relative to the base in two dimensions. The infant care apparatus can provide various swing motions without any pendulum arm to child sitting thereon. Besides, the infant care apparatus can be assembled in a compact size facilitating transport.

Owner:WONDERLAND SWITZERLAND AG

Automated fabrication of an integral fiber reinforced composite structural component using a positioning and assembly support

ActiveUS6958105B2Precise positioningForming accuratelyLaminationEfficient propulsion technologiesGrid patternModularity

A forming jig includes a grid pattern of support walls arranged on a support base and having upper free ends located along an imaginary curved surface, and modular sectional profile members arranged on the walls to enclose a vacuum chamber within the jig. Grooves, channels and air passages between neighboring profile members communicate into the vacuum chamber. The outer surface of the profile members matches the intended inner surface of a structural component to be fabricated using the jig. In the fabrication process, a film is applied to the outer surface to pre-establish a vacuum, the film is removed while simultaneously a vacuum skin is applied, stringer members are set into the grooves, fiber skin layers are laid up, a sealant is applied around the perimeter, a structural shell is vacuumed onto the skin layers, and then this preformed component is removed from the jig, injected with resin unless the skin layers were pre-impregnated with resin, and cured.

Owner:AIRBUS OPERATIONS GMBH

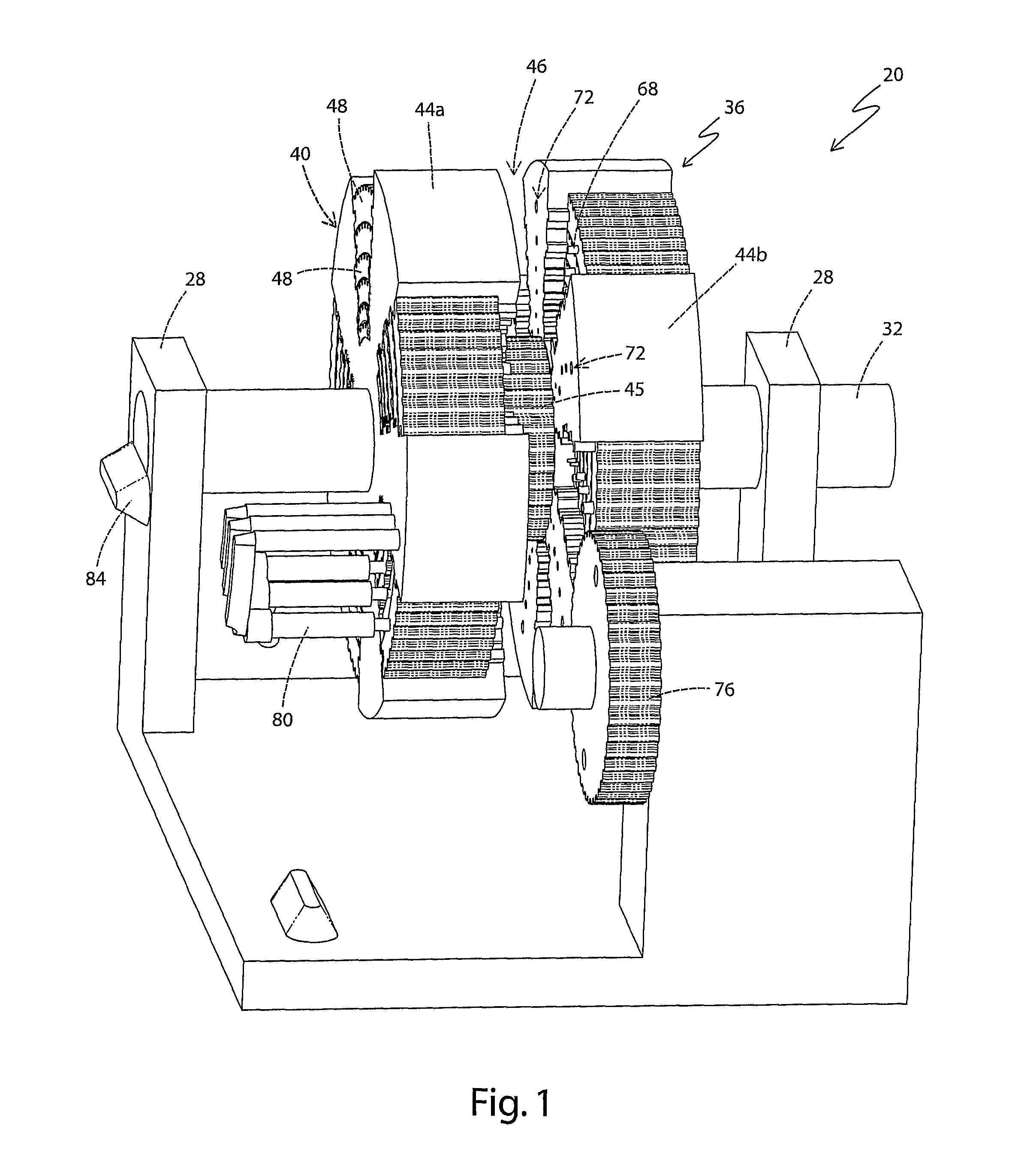

Synchronized segmentally interchanging pulley transmission system

ActiveUS20110045928A1Significant limitationReducing penaltyGearingPortable liftingActuatorContact zone

A segmented pulley transmission is provided. A pulley assembly is rotationally mounted on an axle. The pulley assembly includes a core pulley having a first set of mating features on a peripheral surface thereof. A pulley segment set comprises a number of pulley segments slidably mounted in the pulley assembly and arranged in a ring concentric with the core pulley. The pulley segments are individually actuatable out of the pulley assembly into an engaging position and into the pulley assembly into a non-engaging position. The pulley segments have a second set of mating features on an peripheral surface matching the first set of mating features. An endless drive member has corresponding mating features on an inside surface for engaging the first and second sets of mating features of the core pulley and the pulley segments in an engaging position. Contact between the endless drive member and a core pulley defines a contact zone. An actuator actuates the pulley segments between the engaging and non-engaging positions when the pulley segments are outside of the contact zone. One of the key pulley segments in the pulley segment set is a key pulley segment that is positioned relative to the core pulley such that when the key pulley segment is actuated to the engaging position and rotated into the contact zone, the corresponding mating features of the endless drive member engage the first set of mating features of the core pulley and the second set of mating features of the key pulley segment without the introduction of significant slack or tension.

Owner:1783590 ONTARIO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com