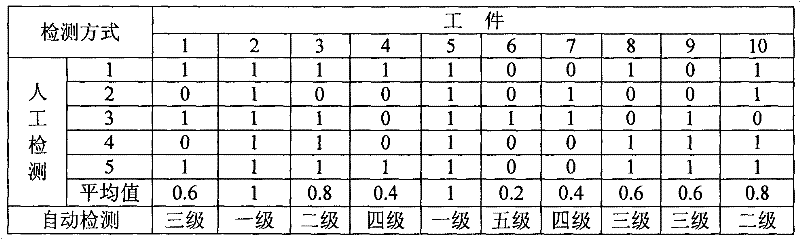

Patents

Literature

340 results about "Surface map" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, geology, and cartography, a surface map is a 2D perspective representation of a 3-dimensional surface. Surface maps usually represent real-world entities such as landforms or the surfaces of objects. They can, however, serve as an abstraction where the third, or even all of the dimensions correspond to non-spatial data. In this capacity they act more as graphs than maps.

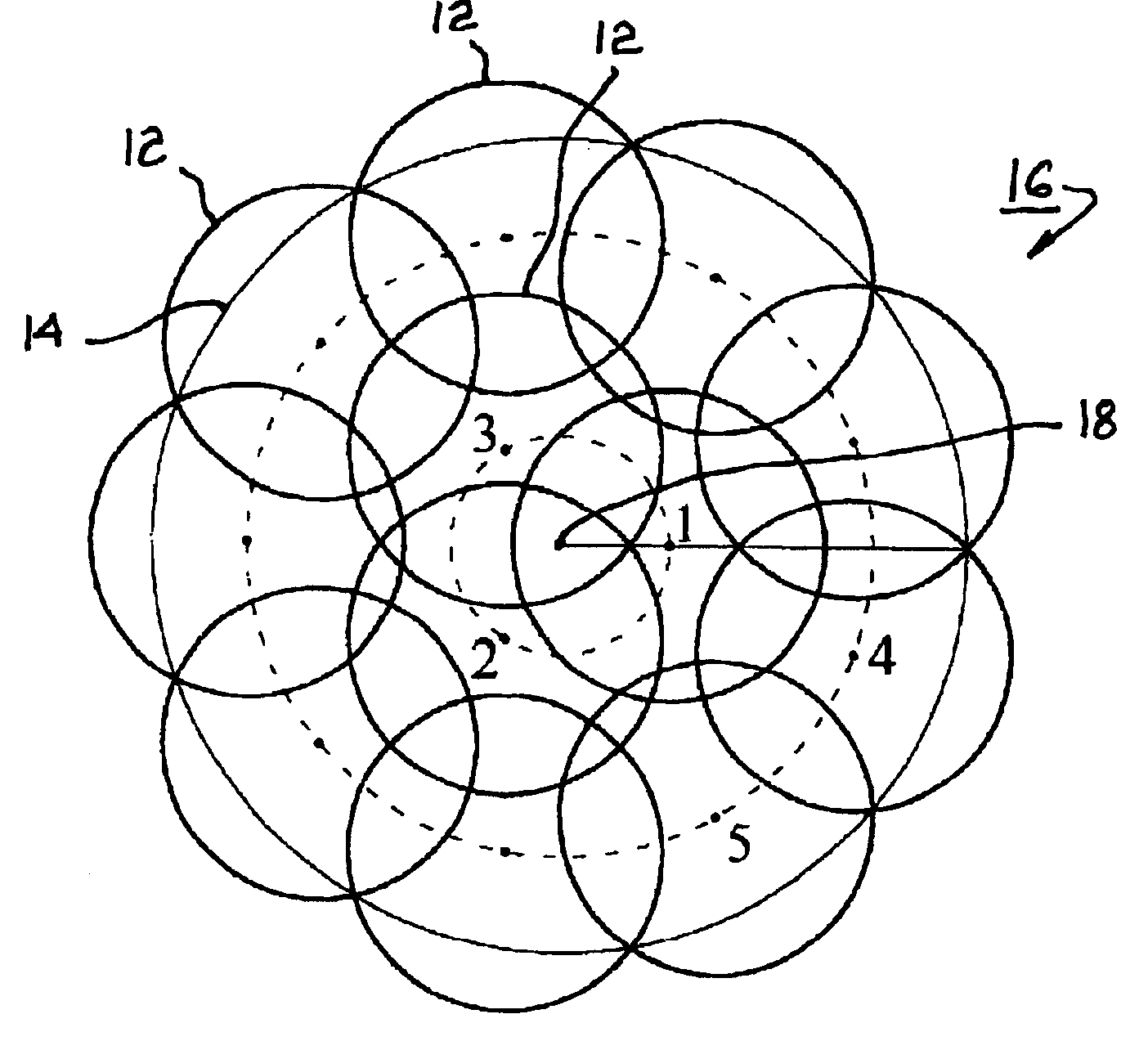

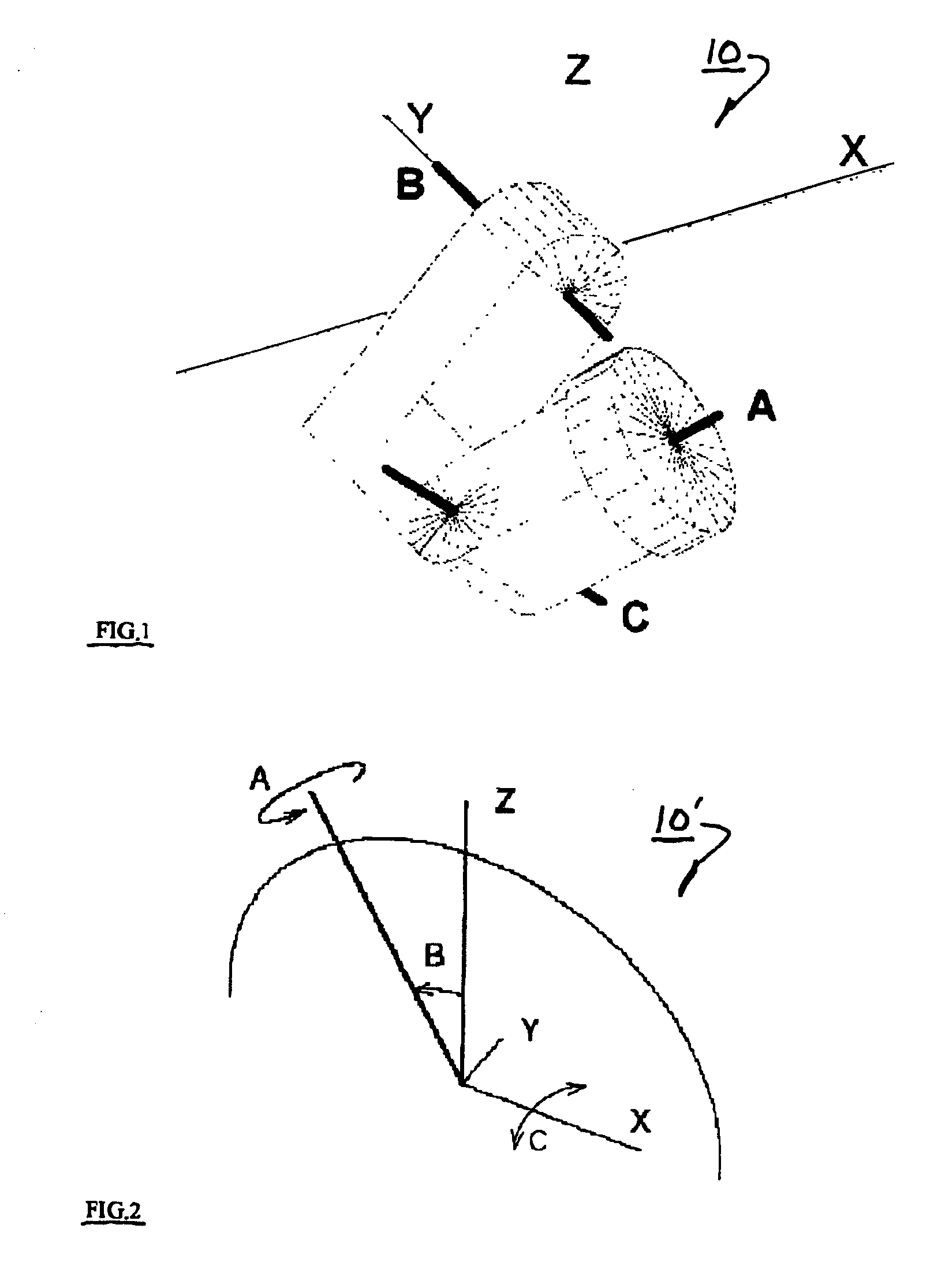

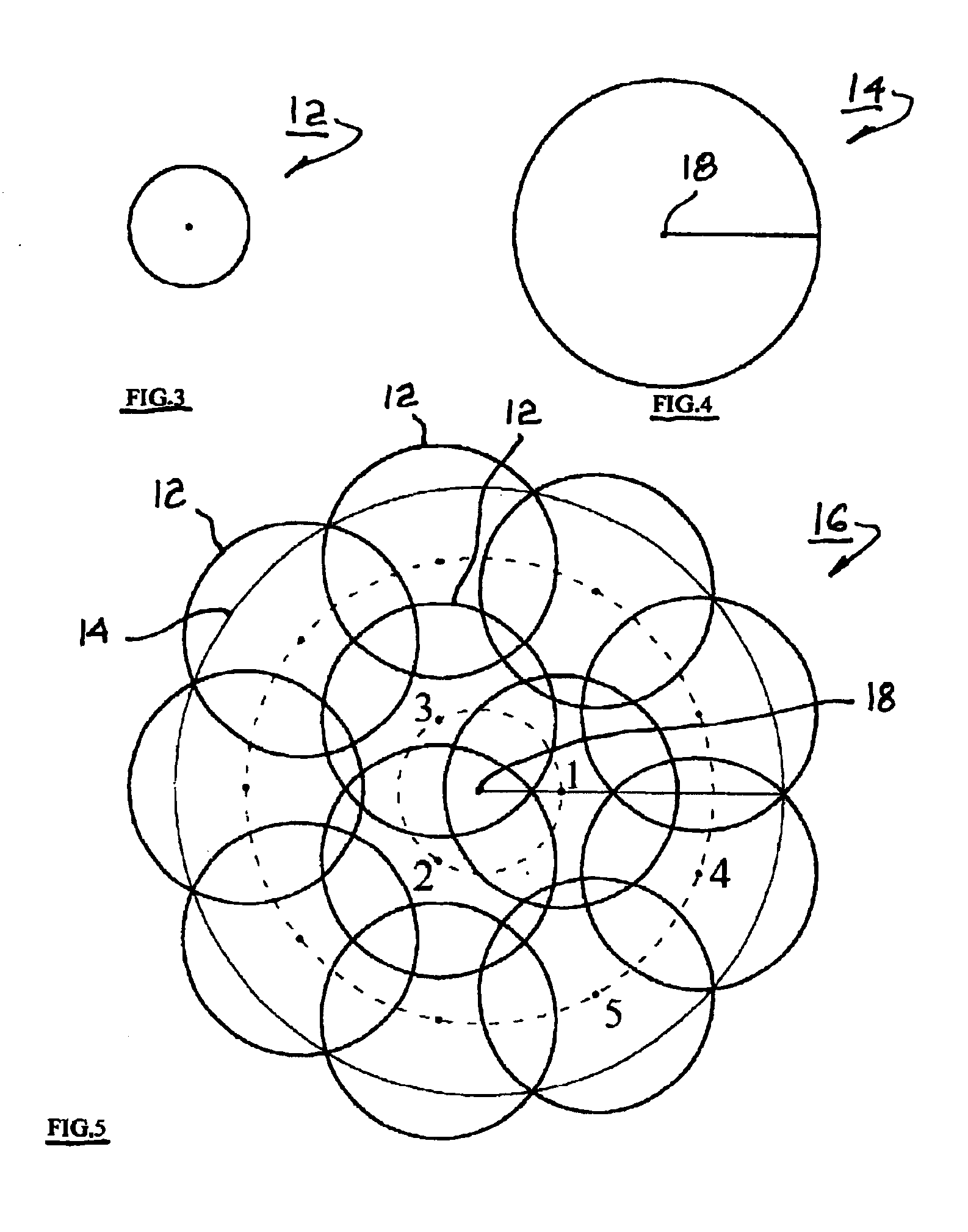

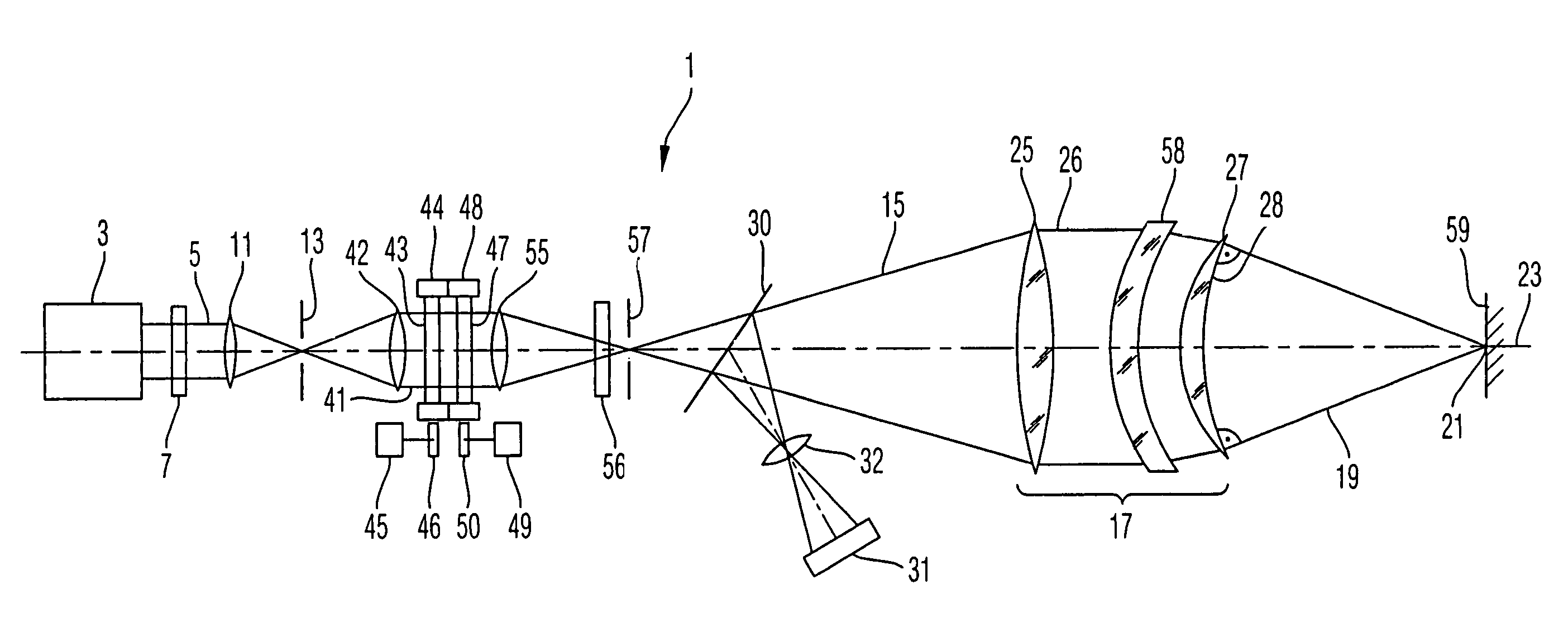

Method for self-calibrated sub-aperture stitching for surface figure measurement

InactiveUS6956657B2Minimize any discrepancyImprove accuracyOptical measurementsInterferometersGraphicsBest fit sphere

A method for accurately synthesizing a full-aperture data map from a series of overlapped sub-aperture data maps. In addition to conventional alignment uncertainties, a generalized compensation framework corrects a variety of errors, including compensators that are independent in each sub-aperture. Another class of compensators (interlocked) include coefficients that are the same across all the sub-apertures. A constrained least-squares optimization routine maximizes data consistency in sub-aperture overlap regions. The stitching algorithm includes constraints representative of the accuracies of the hardware to ensure that the results are within meaningful bounds. The constraints also enable the computation of estimates of uncertainties in the final results. The method therefore automatically calibrates the system, provides a full-aperture surface map, and an estimate of residual uncertainties. Therefore, larger surfaces can be tested with greater departures from a best-fit sphere to greater accuracy than was possible in the prior art.

Owner:QED TECH INT

Medical image projection and tracking system

InactiveUS20120078088A1Accurately measure body surface areaReliably identify wound areaDiagnostic recording/measuringSensorsCorrection algorithmPixel mapping

A system comprising a convergent parameter instrument and a laser digital image projector for obtaining a surface map of a target anatomical surface, obtaining images of that surface from a module of the convergent parameter instrument, applying pixel mapping algorithms to impute three dimensional coordinate data from the surface map to a two dimensional image obtained through the convergent parameter instrument, projecting images from the convergent parameter instrument onto the target anatomical surface as a medical reference, and applying a skew correction algorithm to the image.

Owner:POINT OF CONTACT

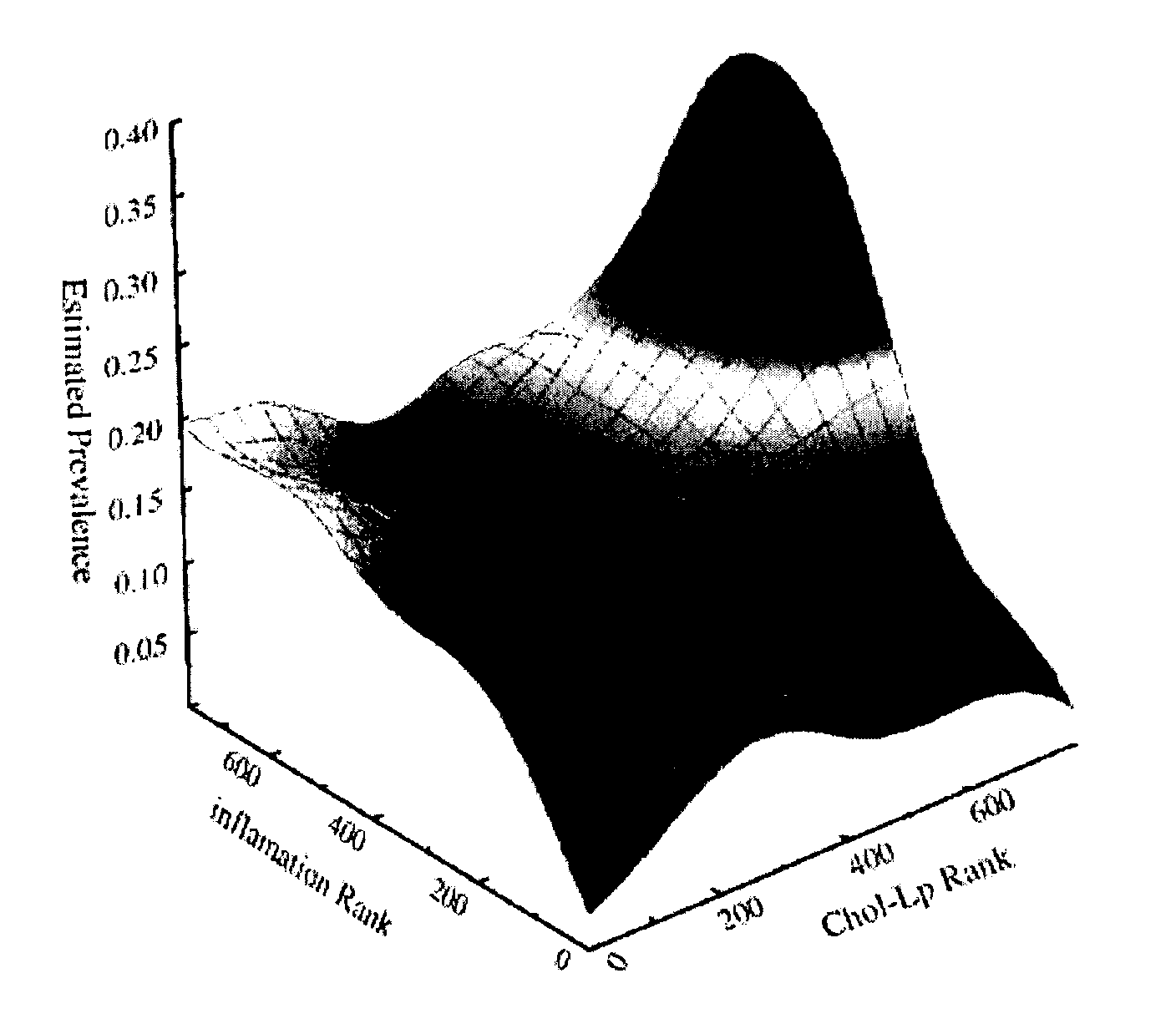

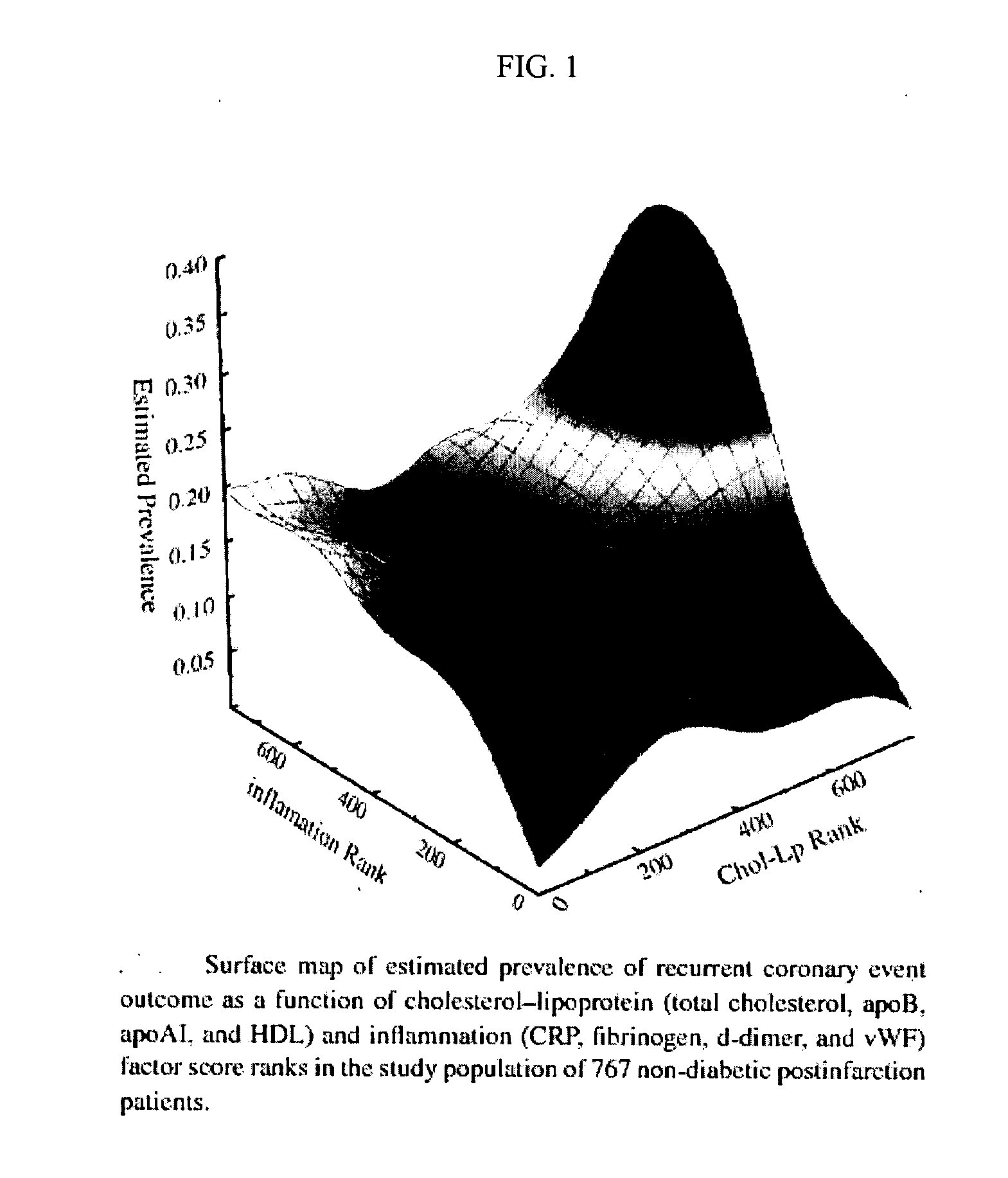

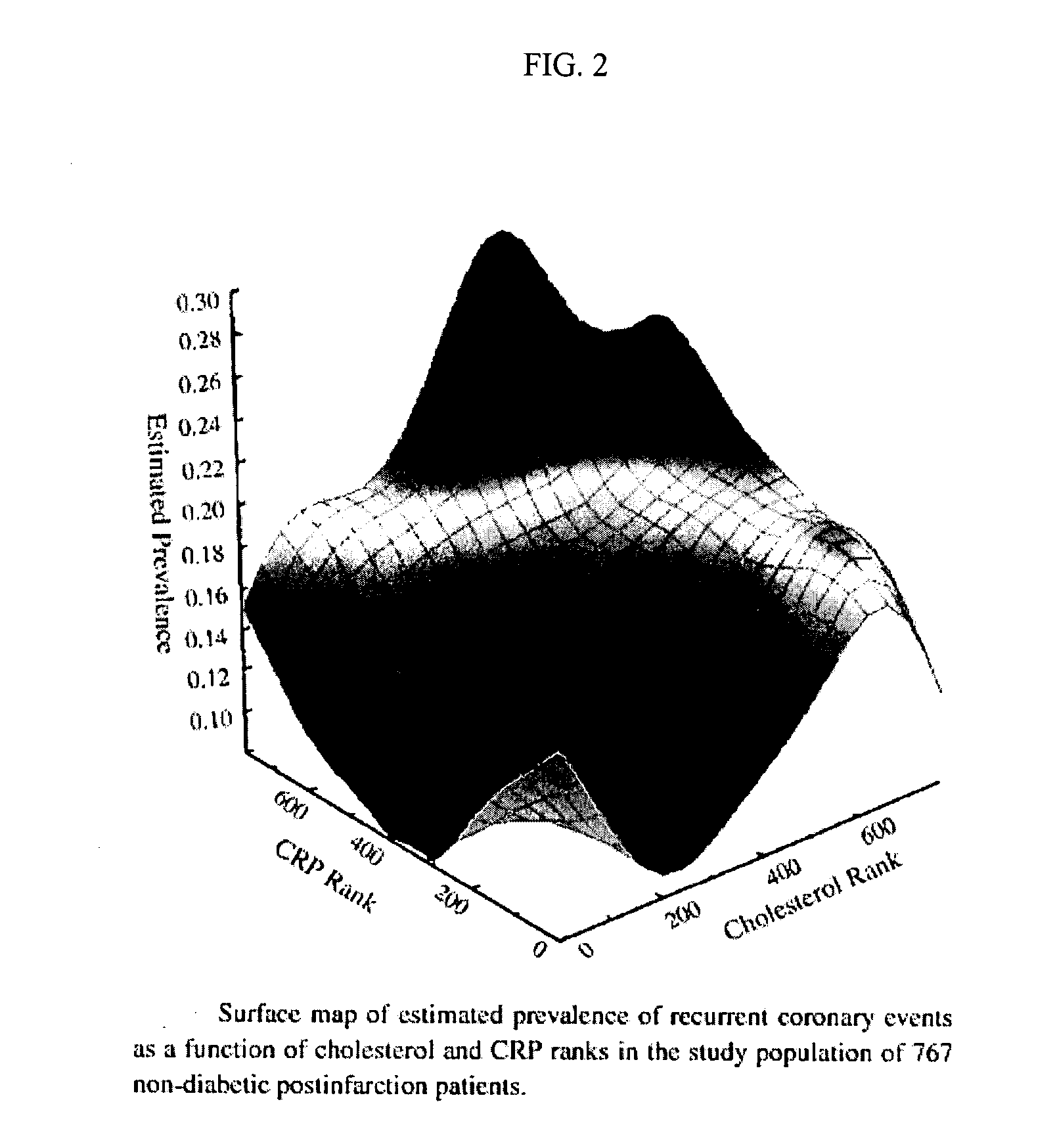

Identifying risk of a medical event

InactiveUS20080009684A1Data processing applicationsHealth-index calculationMultiple risk factorsAnalysis method

Described is a method of determining the relative risk of an outcome based on an analysis of multiple risk factors. A graphical method is used to take values corresponding to risk parameters and an event outcome to produce a smoothed surface map representing relative risk over an entire space defined by n risk factors. Applying a query data point to the surface map permits the determination of the estimated outcome probability for the query data point, based on its location on the surface map. The method then reports a relative risk or other probability measure associated with the query data point. Also described is a method of analysis in which subpopulations previously identified as high-risk can be further analyzed with respect to risk posed by additional factors.

Owner:UNIVERSITY OF ROCHESTER

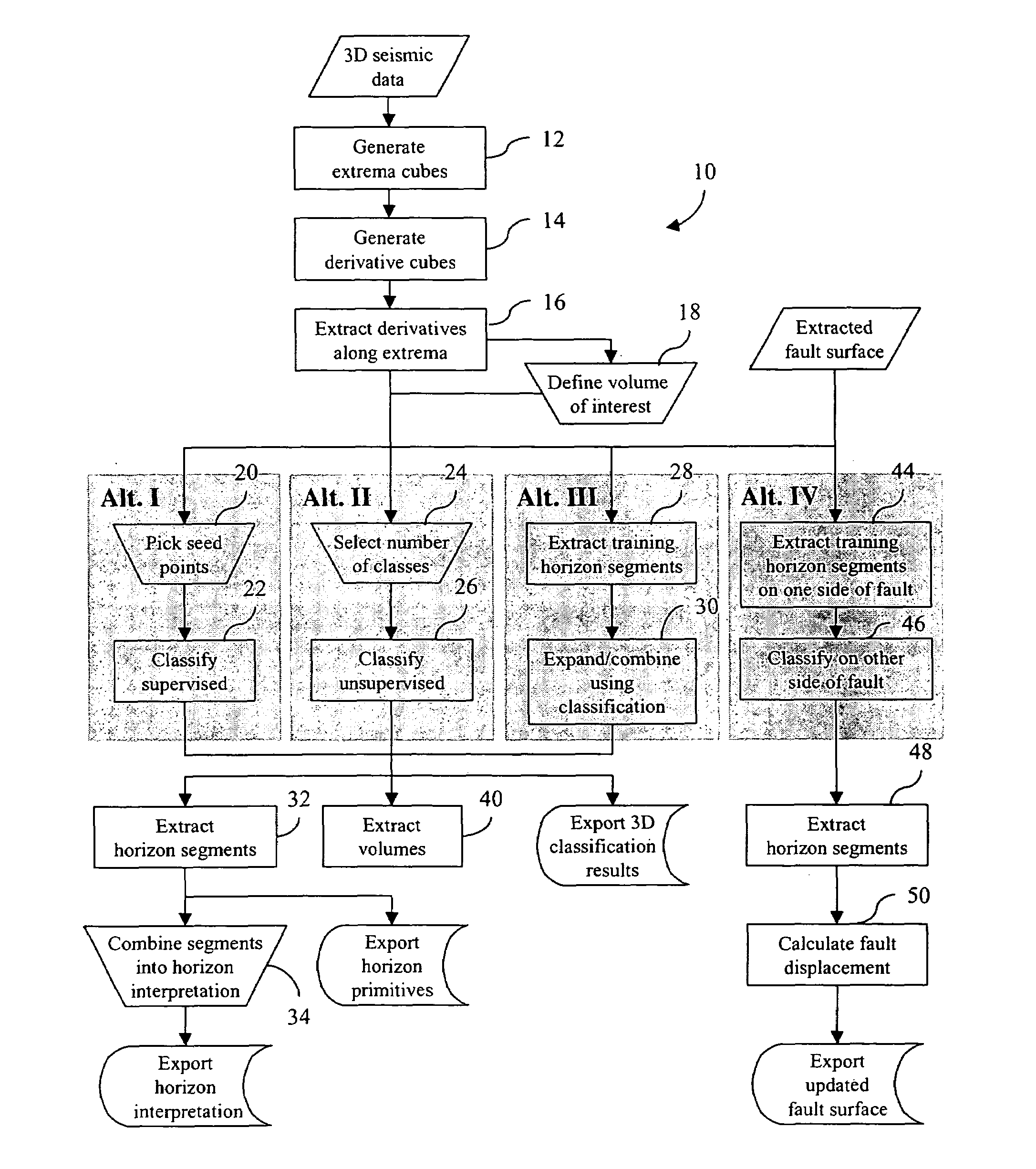

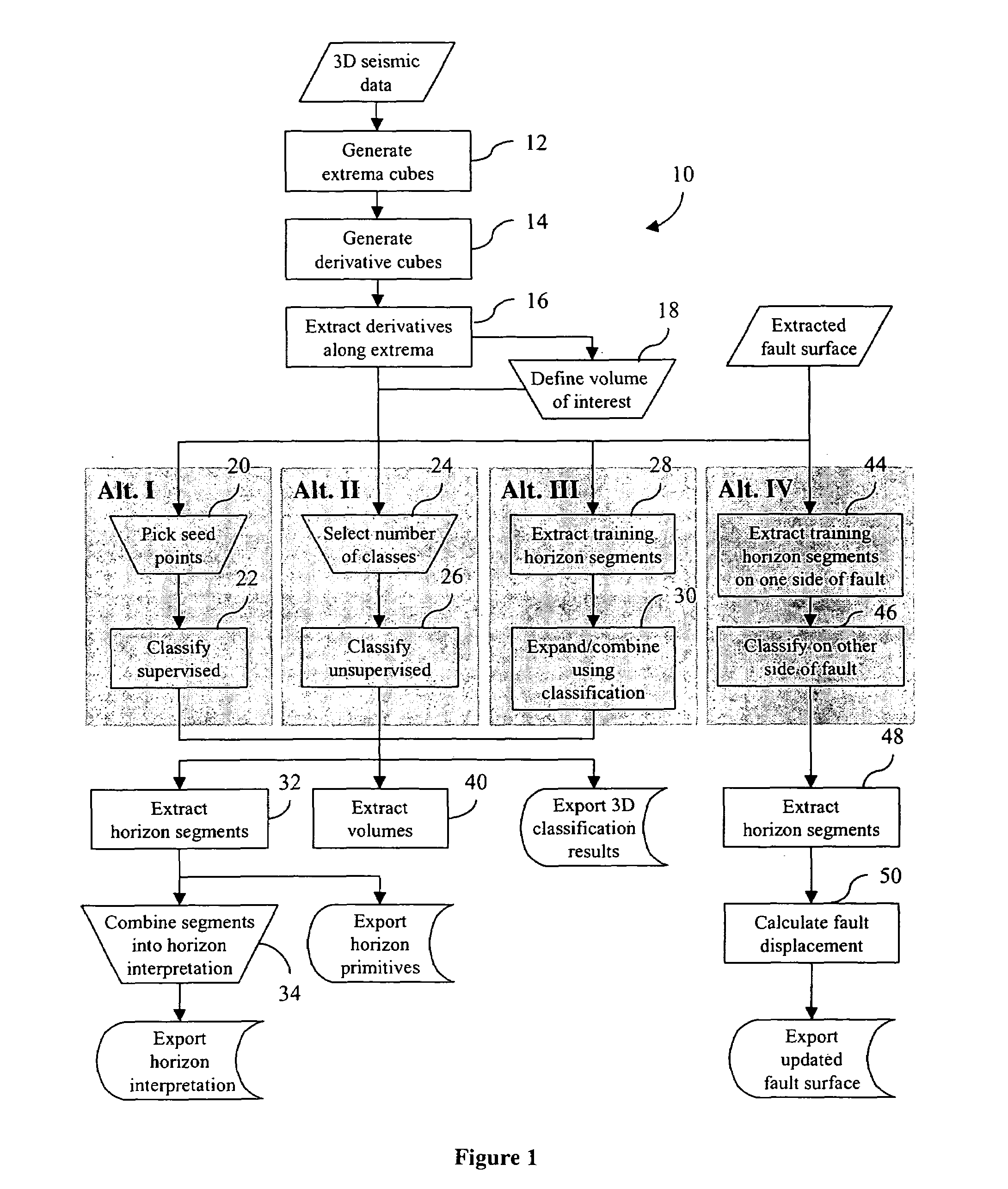

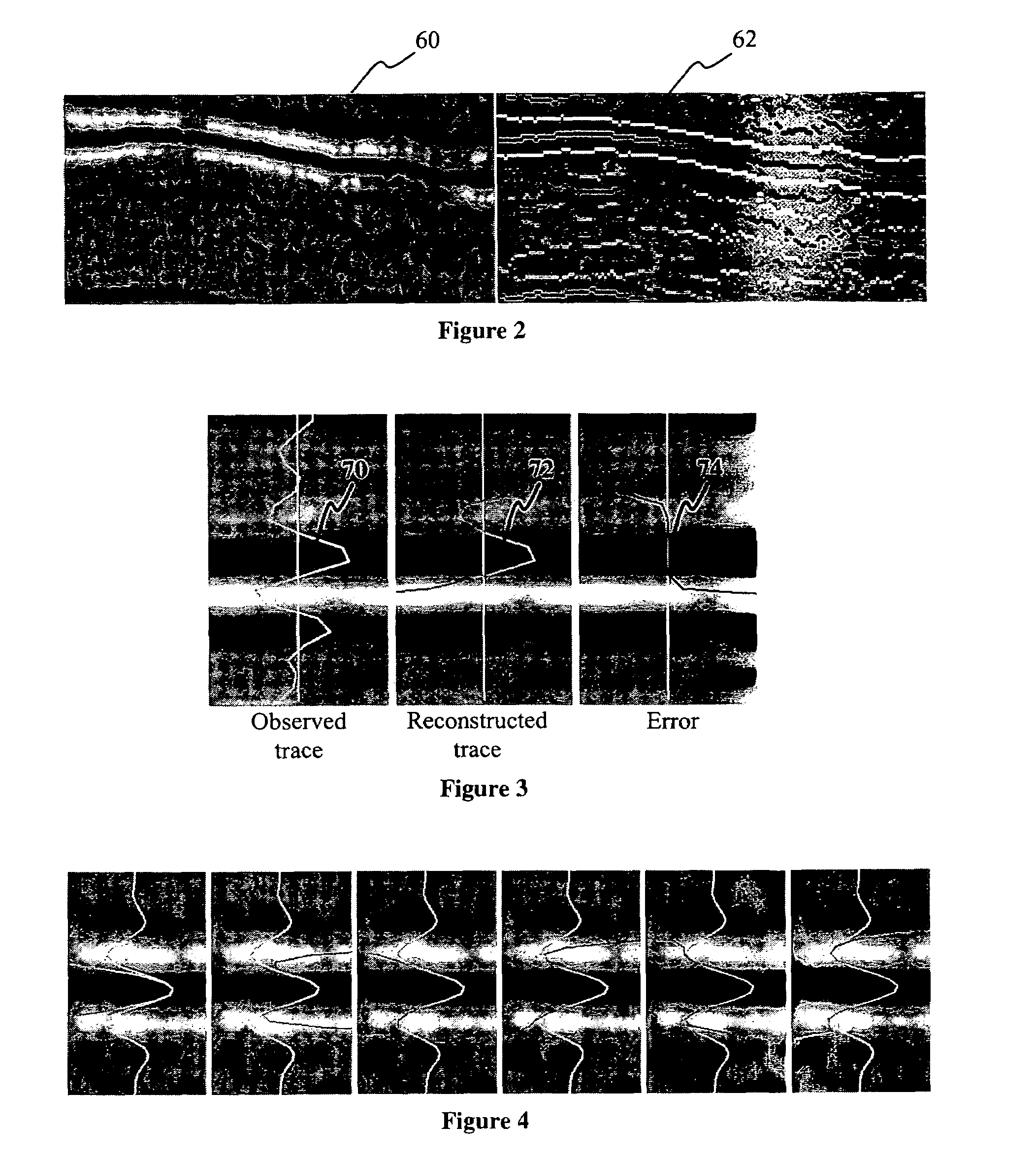

Extrema classification

InactiveUS7248539B2Improve automate interpretationSeismic signal processingSpecial data processing applicationsClass modelWaveform shaping

A method for automated extraction of surface primitives from seismic data is presented. A preferred embodiment of the method includes defining, typically with sub-sample precision, positions of seismic horizons through an extrema representation of a 3D seismic input volume; deriving coefficients that represent the shape of the seismic waveform in the vicinity of the extrema positions; sorting the extrema positions into groups that have similar waveform shapes by applying classification techniques with the coefficients as input attributes using unsupervised or supervised classification based on an underlying statistical class model; and extracting surface primitives as surface segments that are both spatially continuous along the extrema of the seismic volume and continuous in class index in the classification volume. Three primary applications of the surface primitives are described: combining surface primitives into complete horizon interpretations; defining closed volumes within the seismic volume as the closure of vertically arranged surface primitives; or estimating fault displacement based on the surface primitives. A related computer system and computer program product for implementing the method are also described.

Owner:SCHLUMBERGER TECH CORP

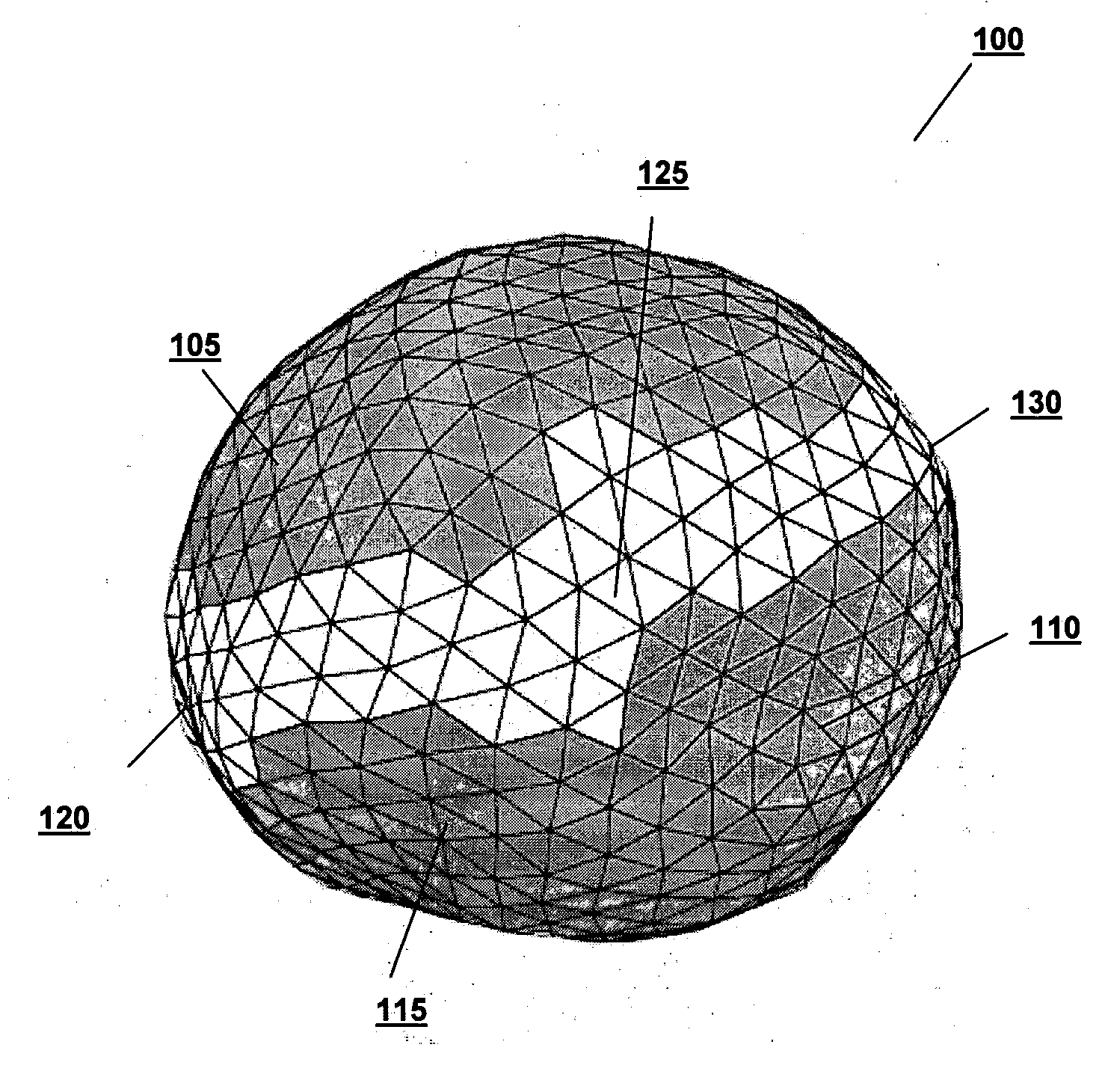

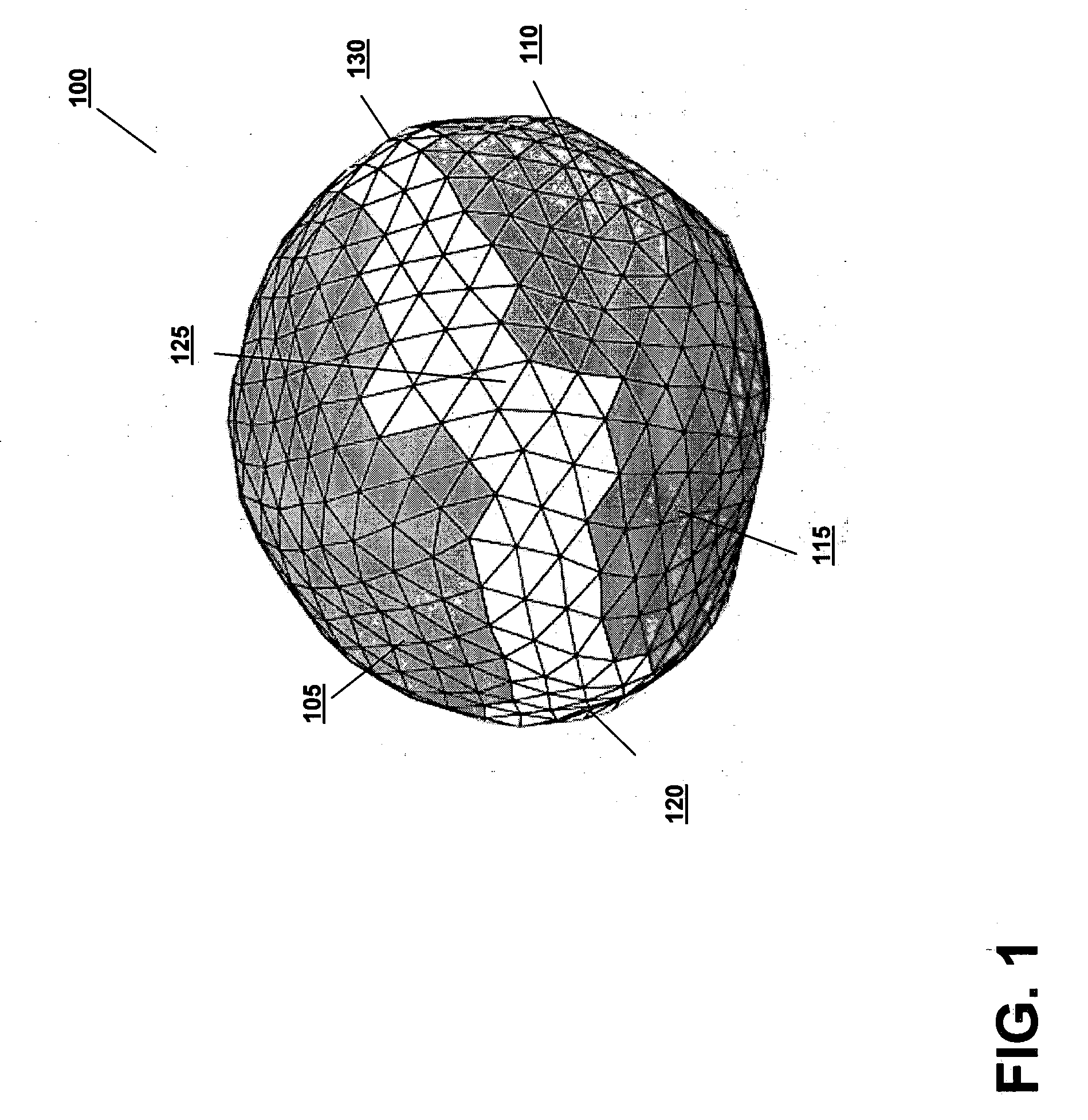

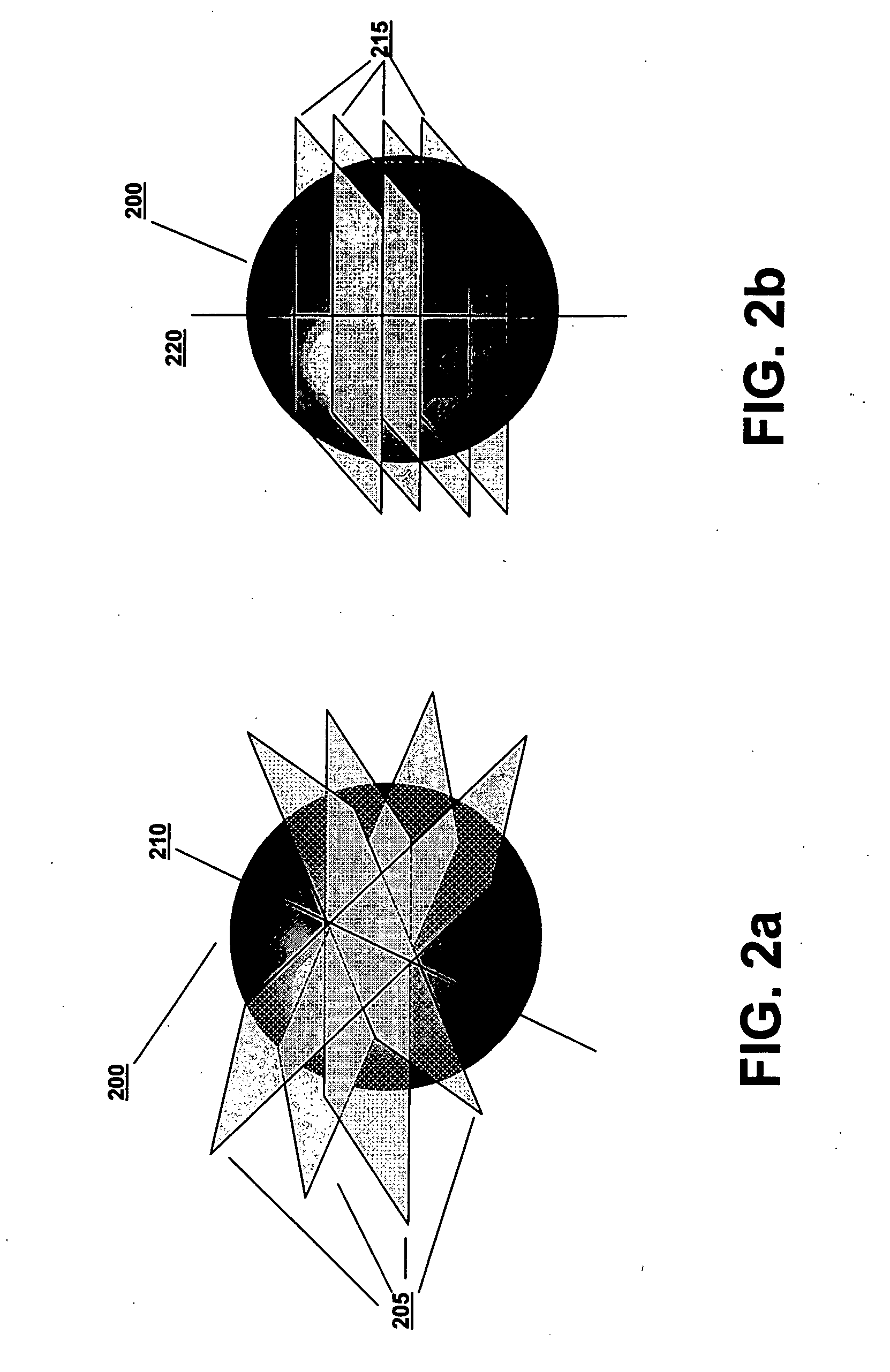

Methods and systems for segmentation and surface matching

ActiveUS20070167699A1Facilitates rapidFacilitates accurate treatment position adjustmentImage enhancementImage analysisRadiologyNuclear medicine

A contoured surface map of a lesion within a patient is obtained by shifting a reference surface to an estimated location in operational images. The process can be repeated to minimize errors, and the contoured surface map can then be segmented.

Owner:ELEKTA AB

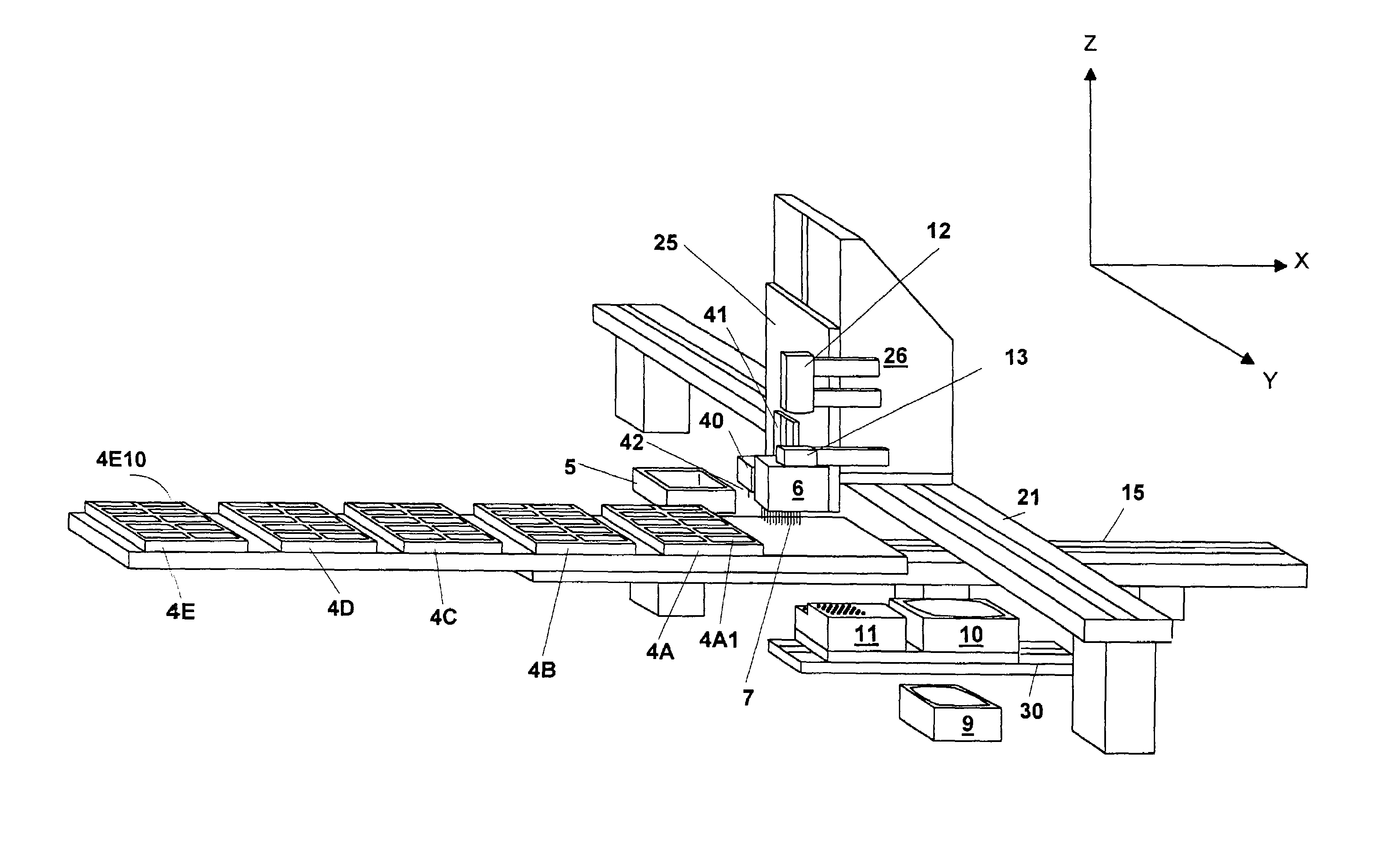

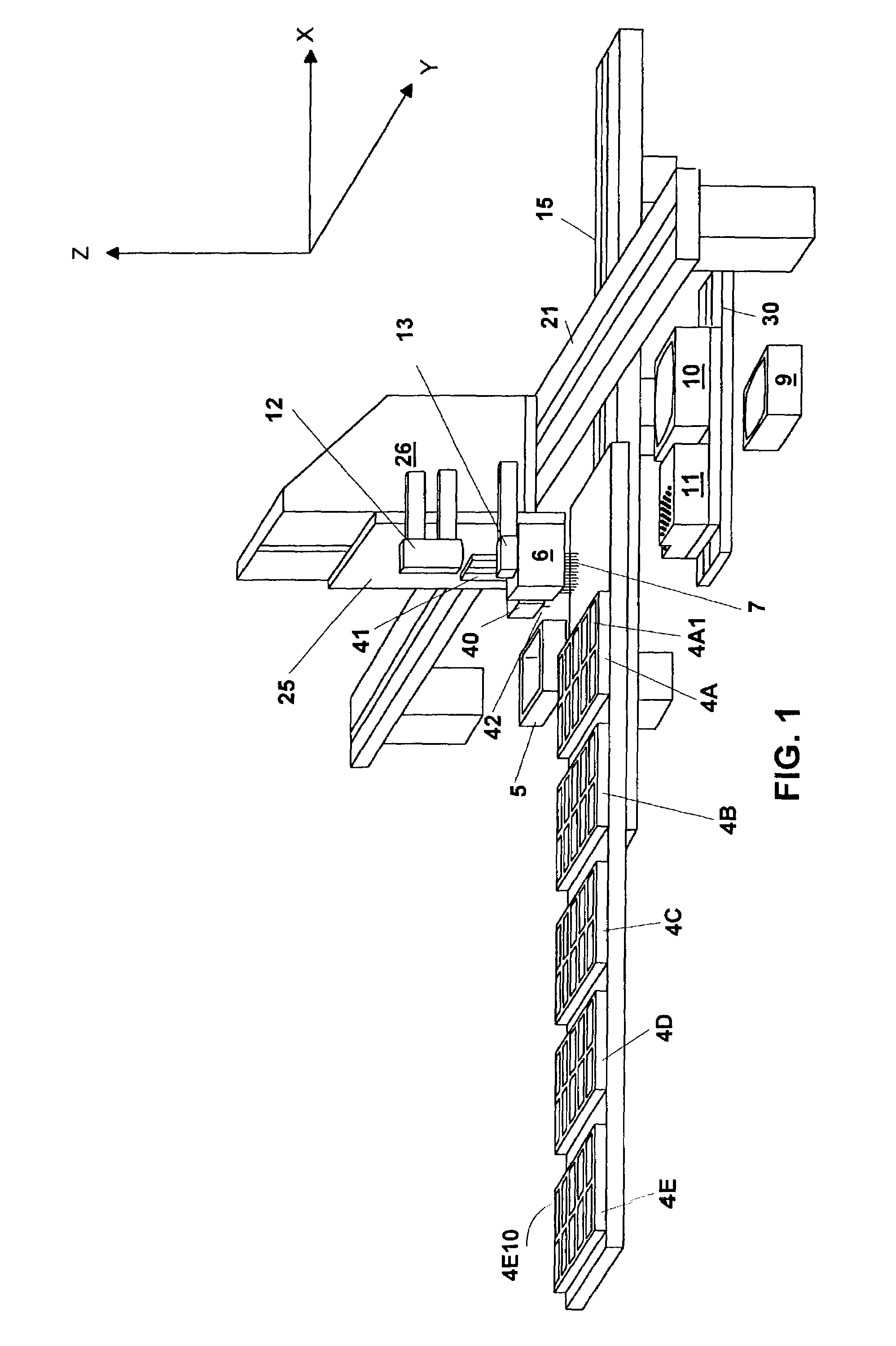

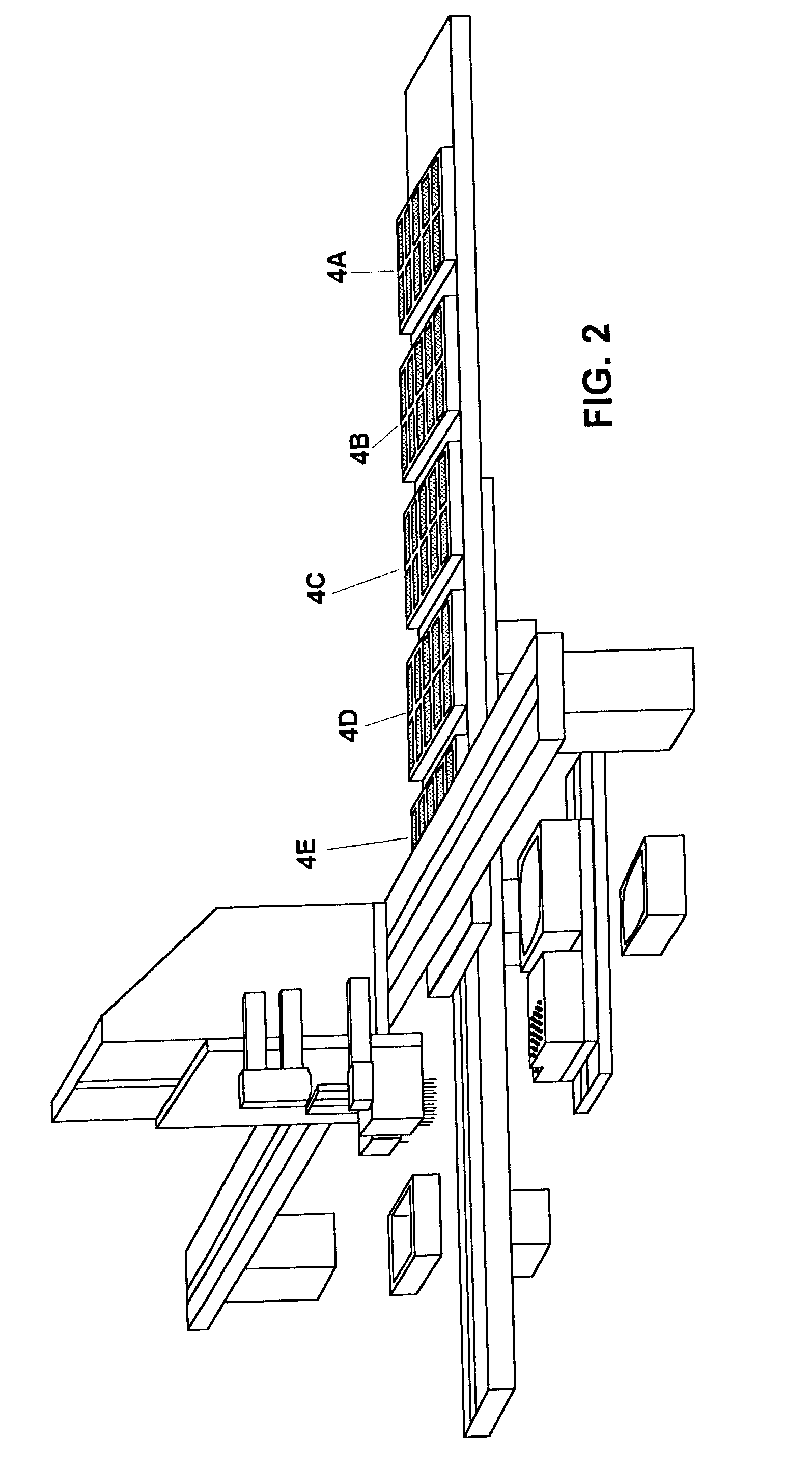

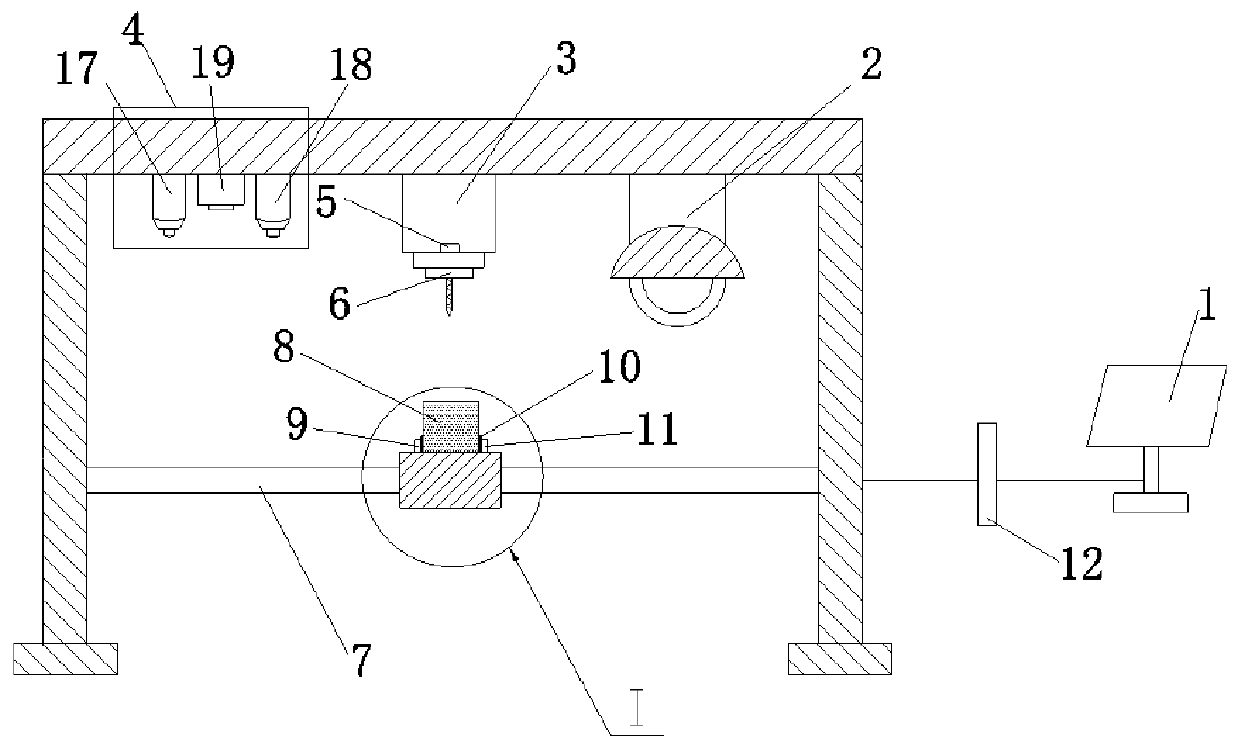

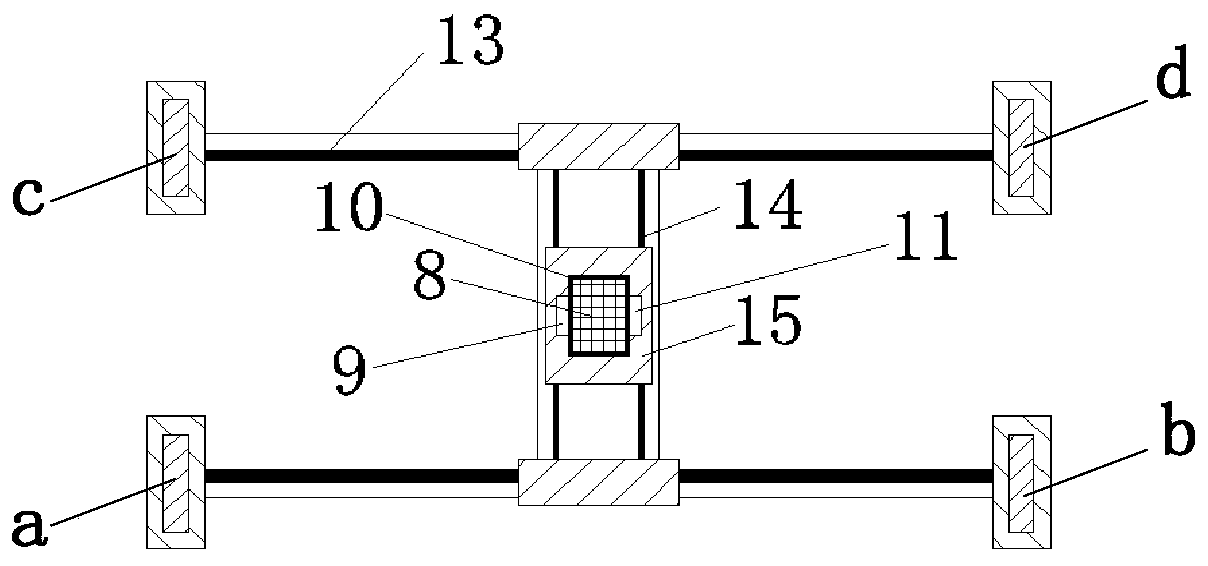

Microarray dispensing with real-time verification and inspection

InactiveUS7025933B2Improve spotImprove accuracySequential/parallel process reactionsElement comparisonAnalysis dataReal time validation

A microarrayer for spotting solution onto a receiving surface in an automated microarray dispensing device. Elements of the present invention include: at least one dispense head for spotting the receiving surface, at least one light source capable of illuminating the receiving surface, at least one camera operating in conjunction with the at least one light source. The at least one camera is capable of acquiring and transmitting surface image data to a computer. The computer is programmed to receive the surface image data and analyze it. The computer will then generate post analysis data based on the analysis of the surface image data. The post analysis data is available for improving the spotting of the solution onto the receiving surface. In a preferred embodiment, the surface image data includes information relating to receiving surface alignment, information relating to spot quality, and receiving surface identification information. In a preferred embodiment, the analysis of the information relating to receiving surface alignment enables the computer to make automatic adjustments to the relative positions of the at least one dispense head and the receiving surface to increase the accuracy of the spotting. In a preferred embodiment, the analysis of the information relating to spot quality identifies a spot as pass or fail. An operator is then able to rework the spot. In a preferred embodiment, the analysis of the receiving surface identification information enables the computer to track each receiving surface. In a preferred embodiment the receiving surface is a plurality of slides.

Owner:AGENA BIOSCI

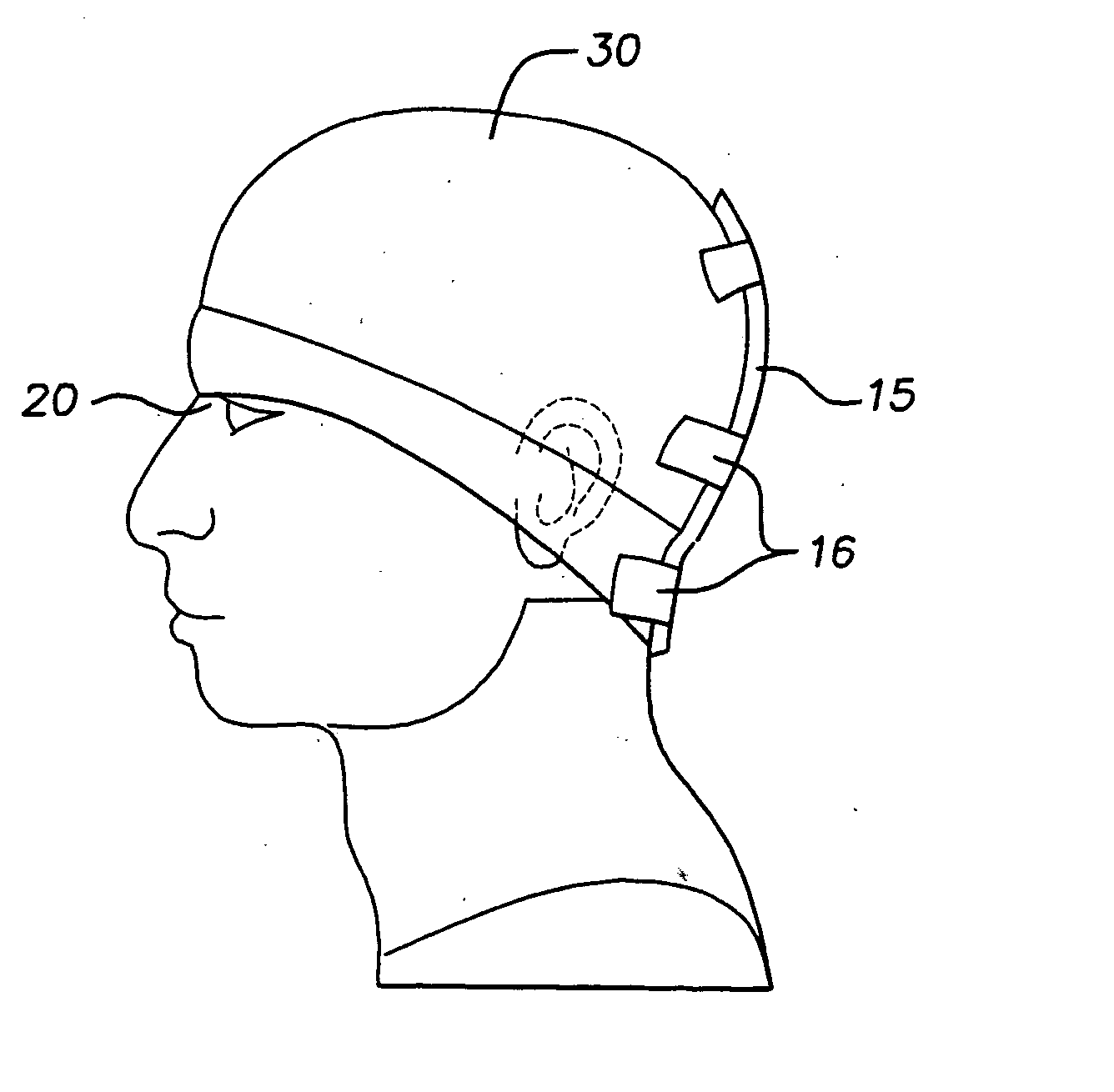

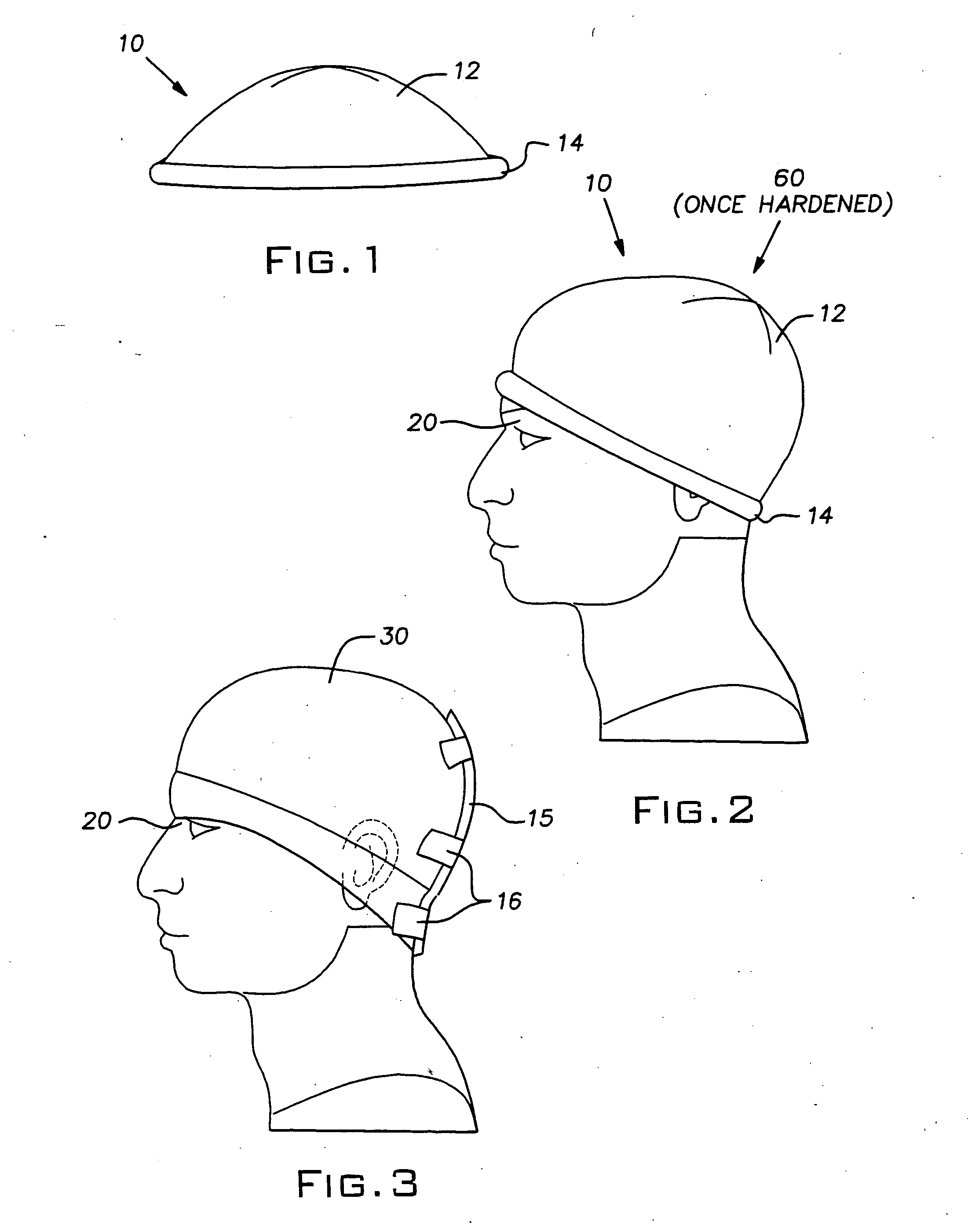

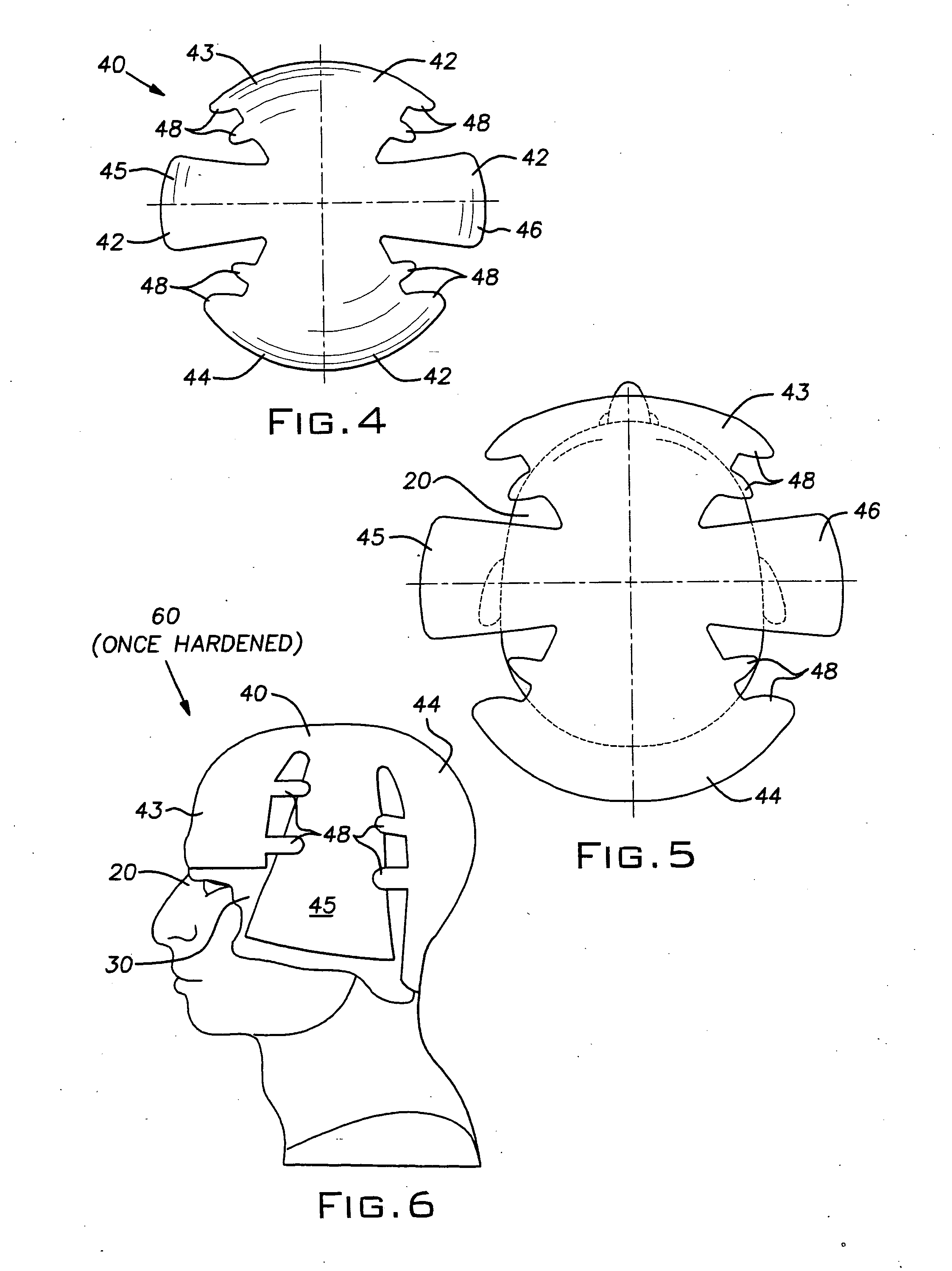

Custom-fitted helmet and method of making the same

A helmet liner that is custom-fitted to a wearer's head, and methods of making the liner, are provided. To make the liner, scanning equipment directly scans the person's head to generate computer-readable data containing a surface map of the head. This data then is used by suitable machining equipment to machine a custom-fitted liner from a universal liner blank, whose resulting convex surface will substantially conform to the shape and contour of the person's head. The scanning equipment desirably is or includes one or a plurality of lasers. A mobile platform including both the scanning and the machining equipment also is provided.

Owner:INTPROP HLDG

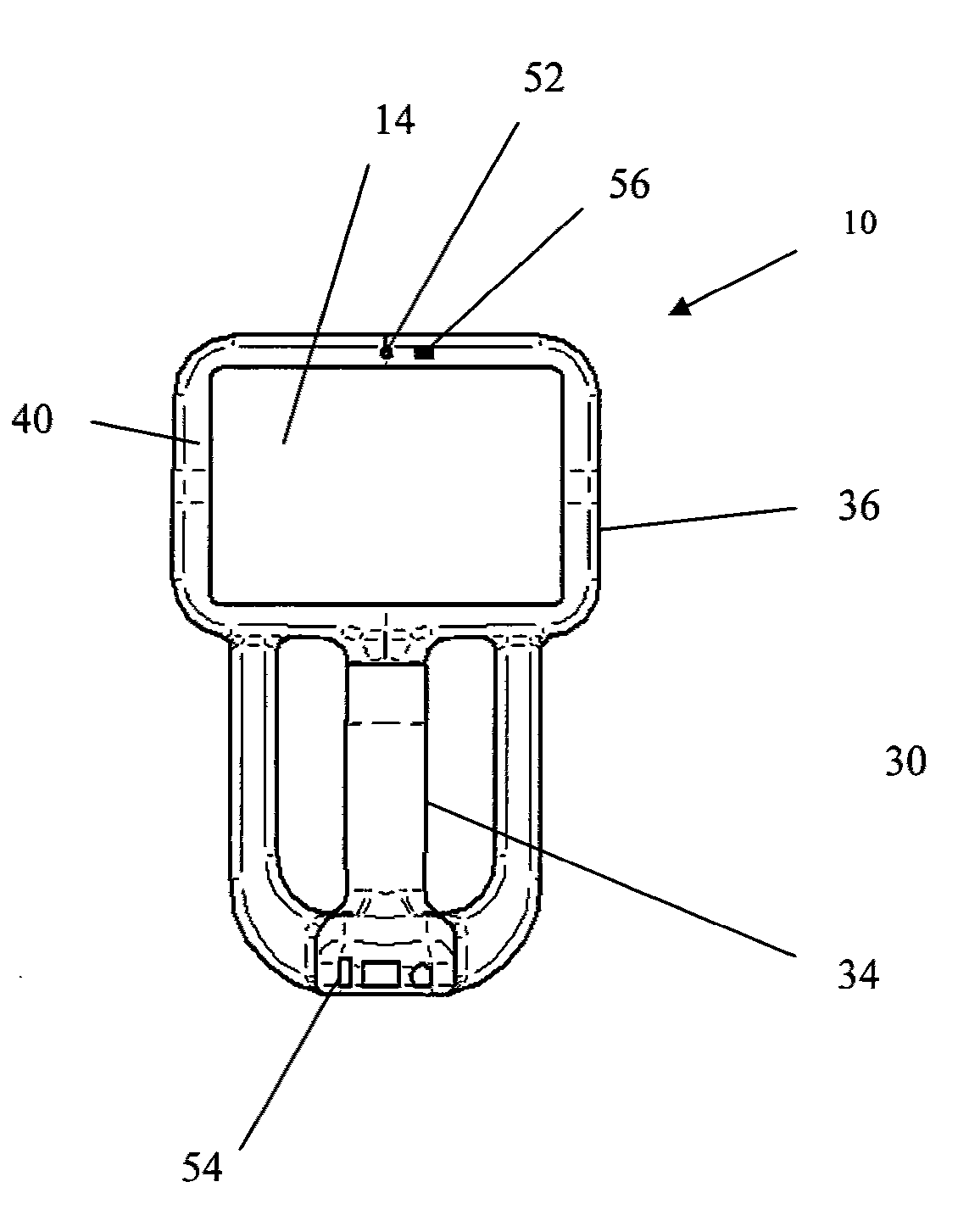

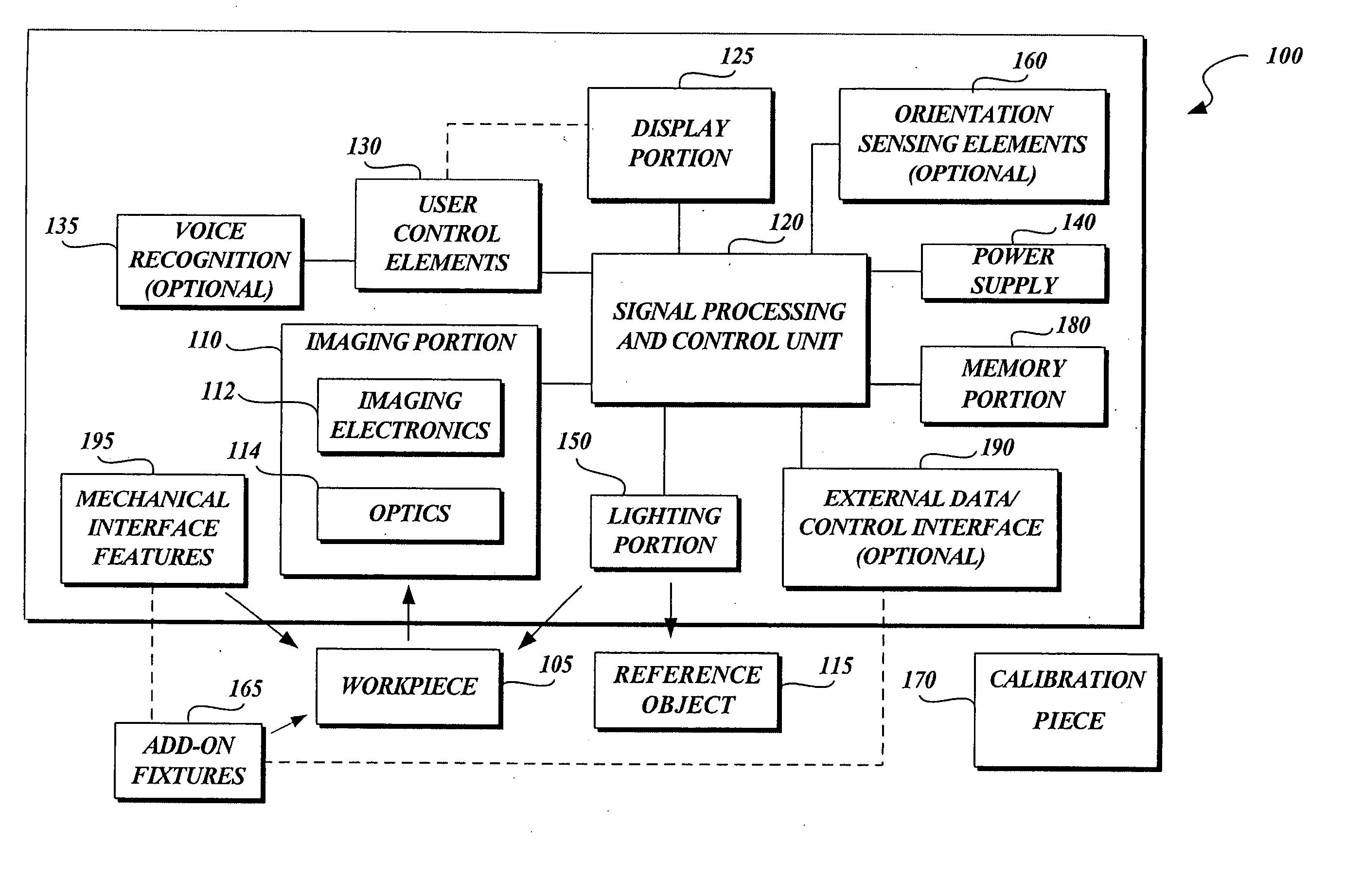

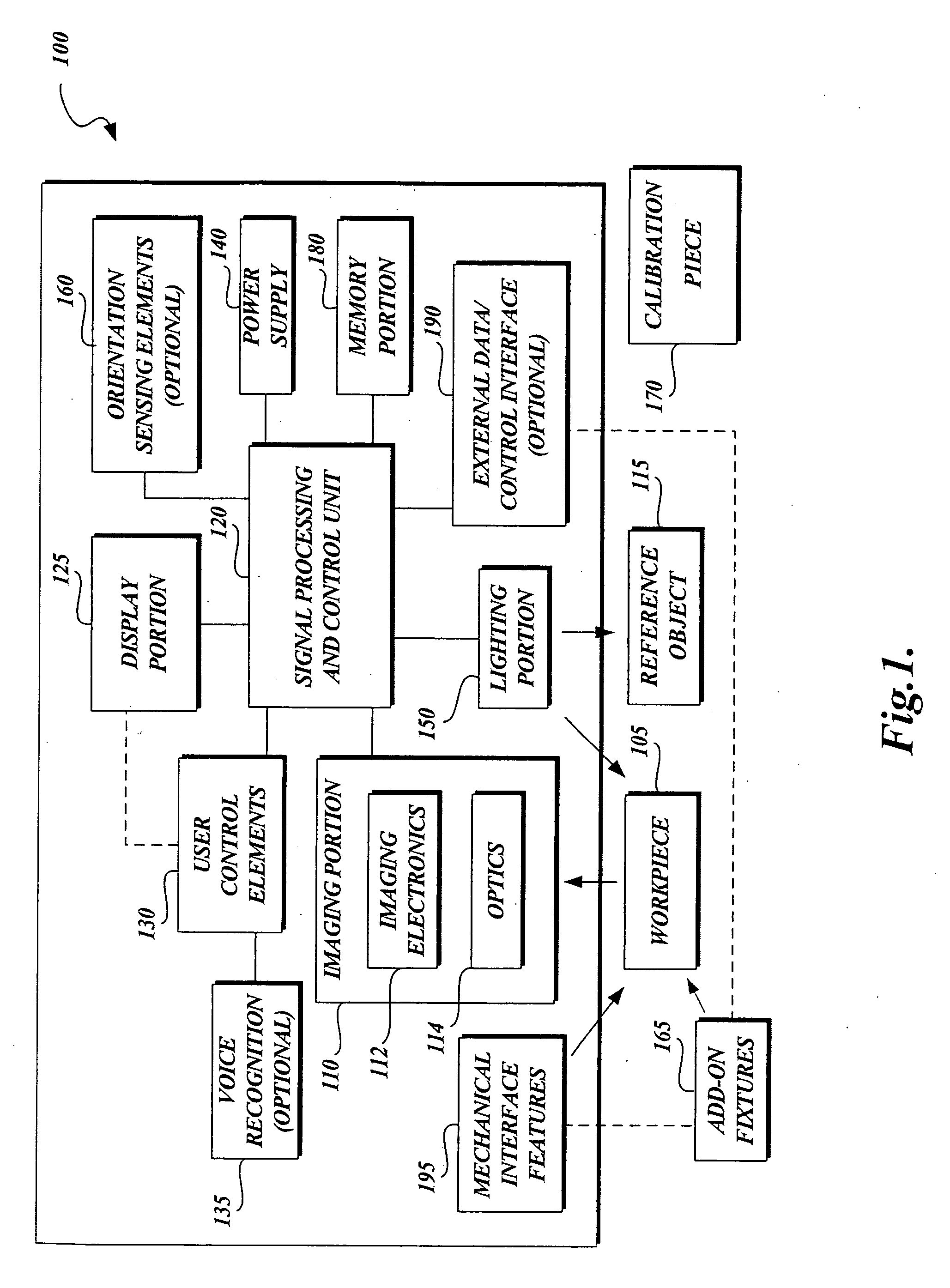

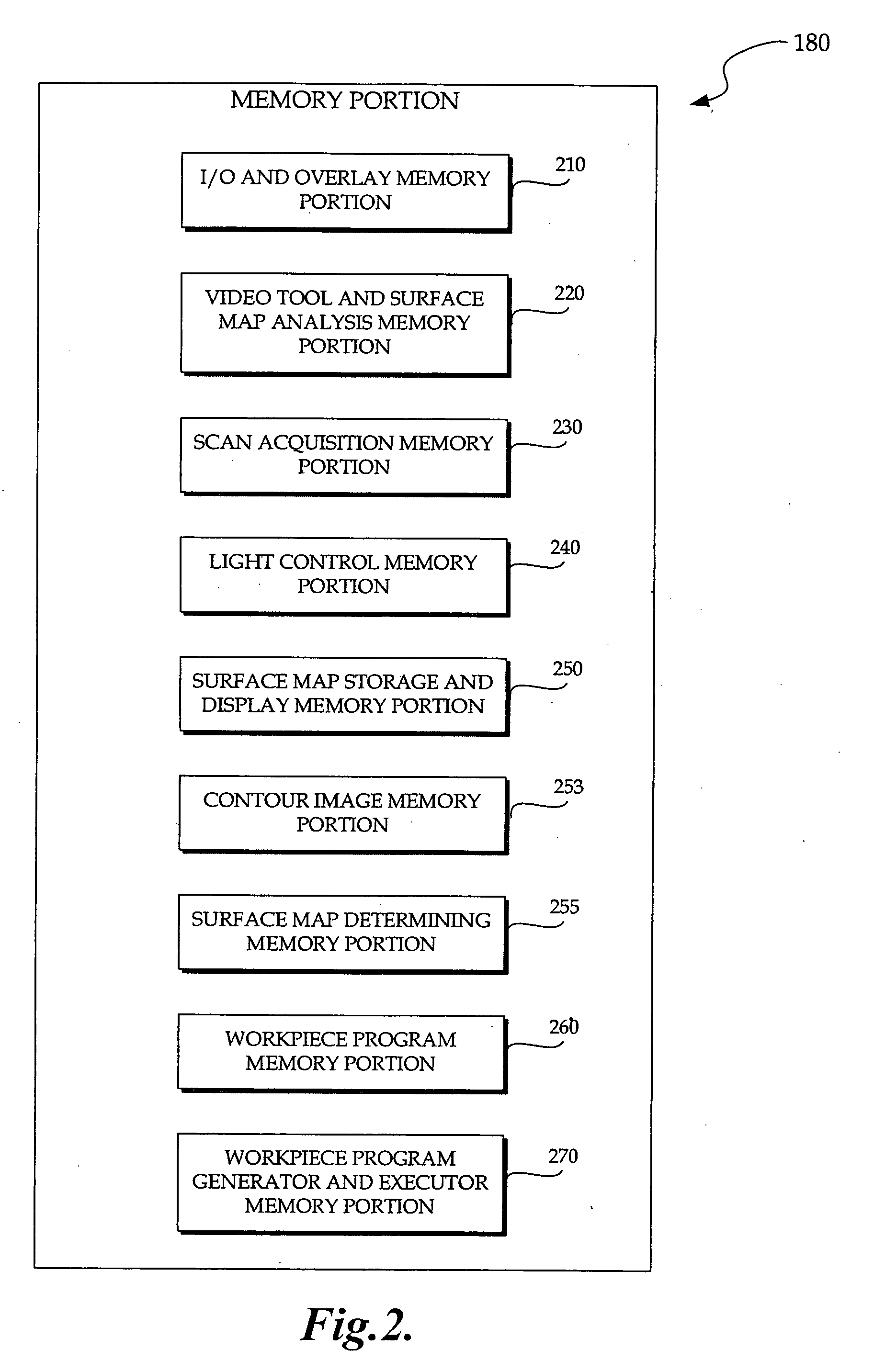

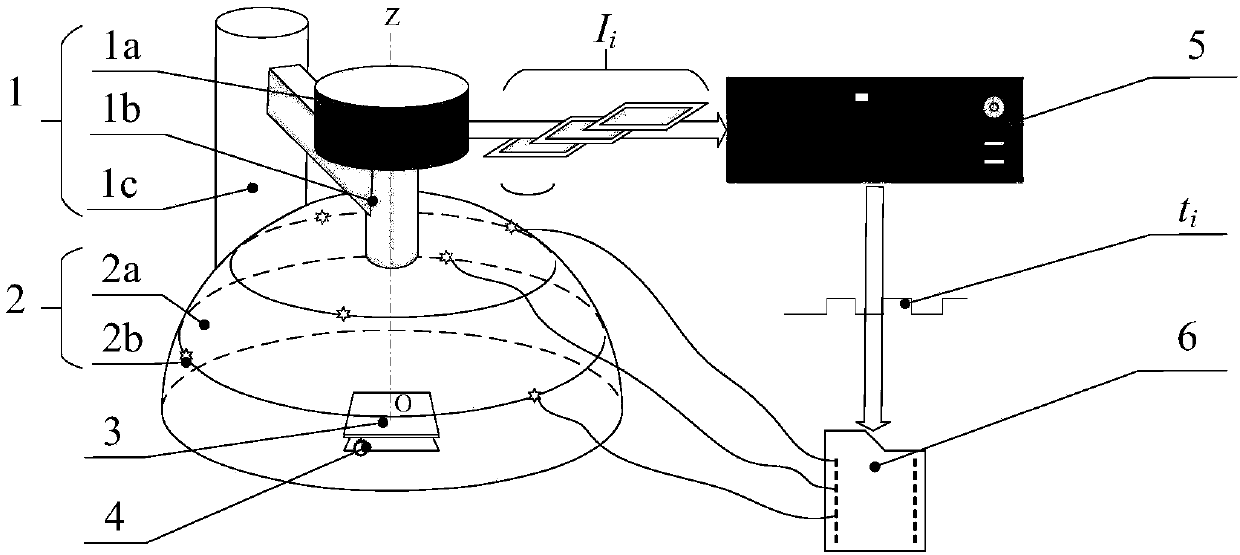

Hand-size structured-light three-dimensional metrology imaging system and method

ActiveUS20070097381A1Enhance the imageImprove measurement resultsImage analysisUsing optical meansDimensional metrologyComputer graphics (images)

A hand-size structured-light three-dimensional metrology imaging system and method. Laser illumination stripes are scanned across a workpiece surface for obtaining z-height and x-coordinate information. A Scheimpflug configuration is used. Utilizing this configuration, a laser illumination stripe across a raised workpiece portion will be shown in a contour image at the image sensor in a focused manner, such that the offsets along the contour image line due to the raised portions of the workpiece surface can be accurately converted to a z-height measurement. The y-axis positions associated with each of the contour images, used for reassembling the information from the contour images into a surface map for the workpiece, may be determined without the need for a position sensor, by including a reference object in the contour images.

Owner:MITUTOYO CORP

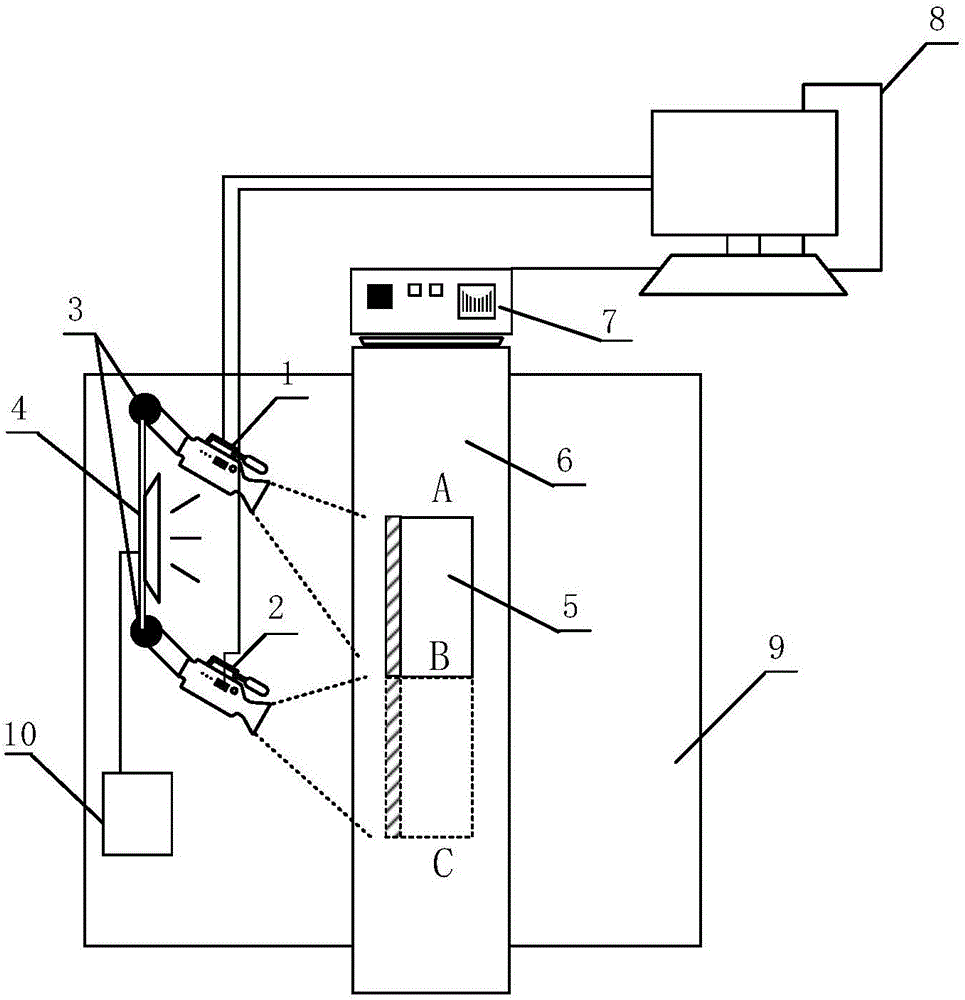

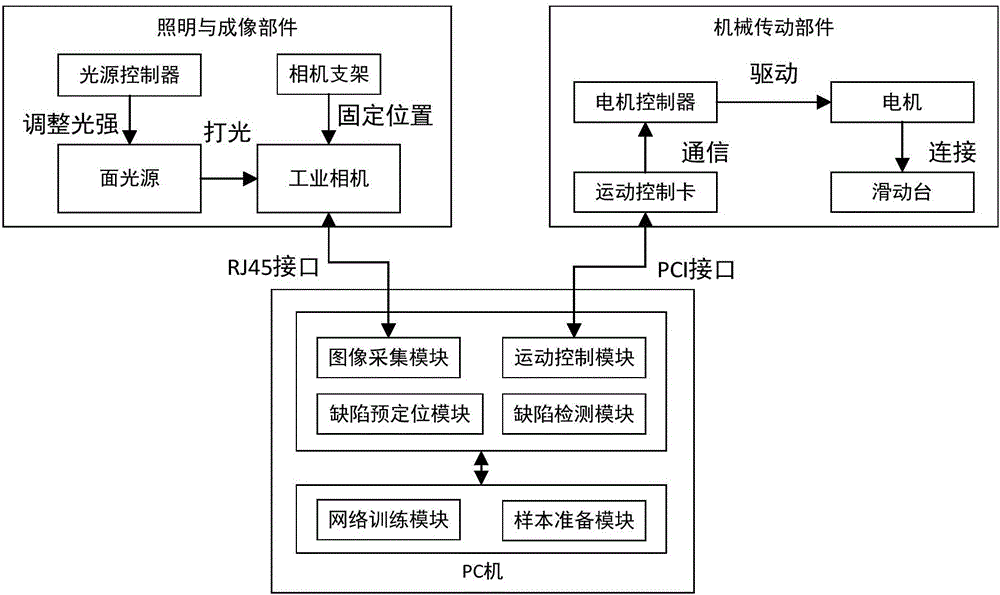

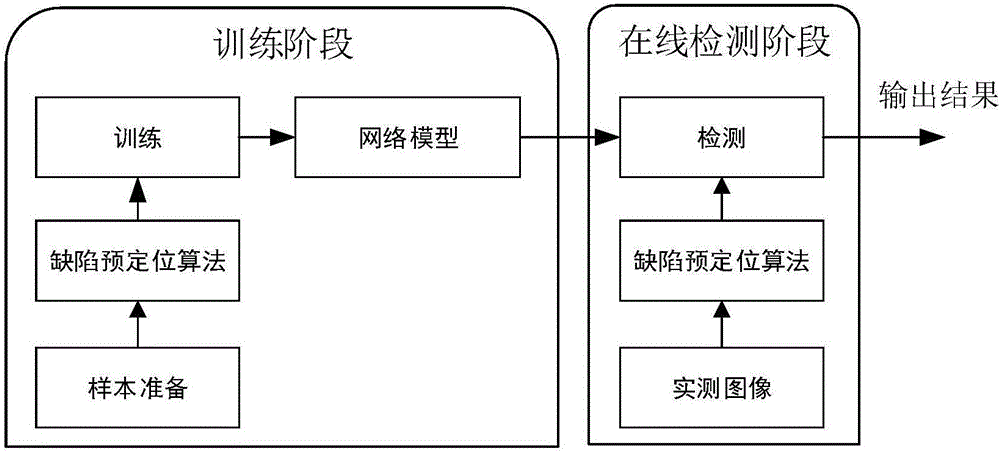

Curved surface defect automatic detection method and apparatus thereof

ActiveCN106127780AImprove clarityBig amount of dataImage enhancementImage analysisSample imageNetwork model

The invention discloses a curved surface defect automatic detection method and an apparatus thereof. The method comprises the following steps: 1, at a training phase, acquiring sample images, constructing a training set, performing manual defect identification on images in the training set, and marking areas where all defects appear; for each image in the training set, executing a defect pre-positioning step so as to obtain areas R where all the defects may appear; comparing the R with the manually marked areas where all the defects appear, and according to an overlap degree of the two, obtaining negative samples and positive samples through division; according to the positive samples and the negative samples, performing offline training of a deep neural network model, and outputting types of defect areas and concrete coordinates; and 2, at an online detection phase, acquiring current curved surface images to be detected, executing a defect pre-positioning step, obtaining sets R, and inputting the R into the network model, and obtaining the types and the concrete coordinates of the defect areas. The method and apparatus have the advantages of high adaptability, high real-time performance and high identification accuracy.

Owner:SOUTH CHINA UNIV OF TECH

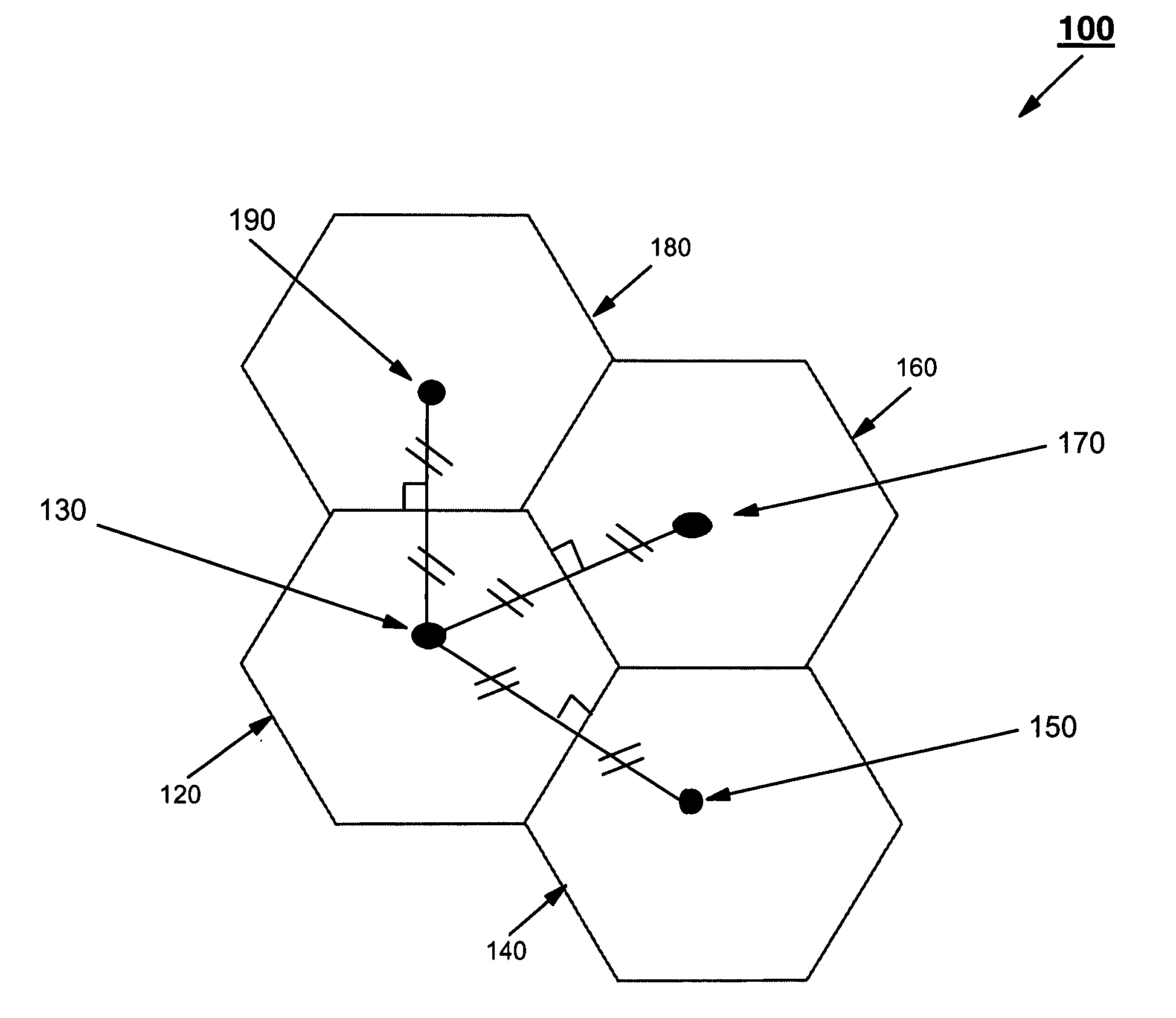

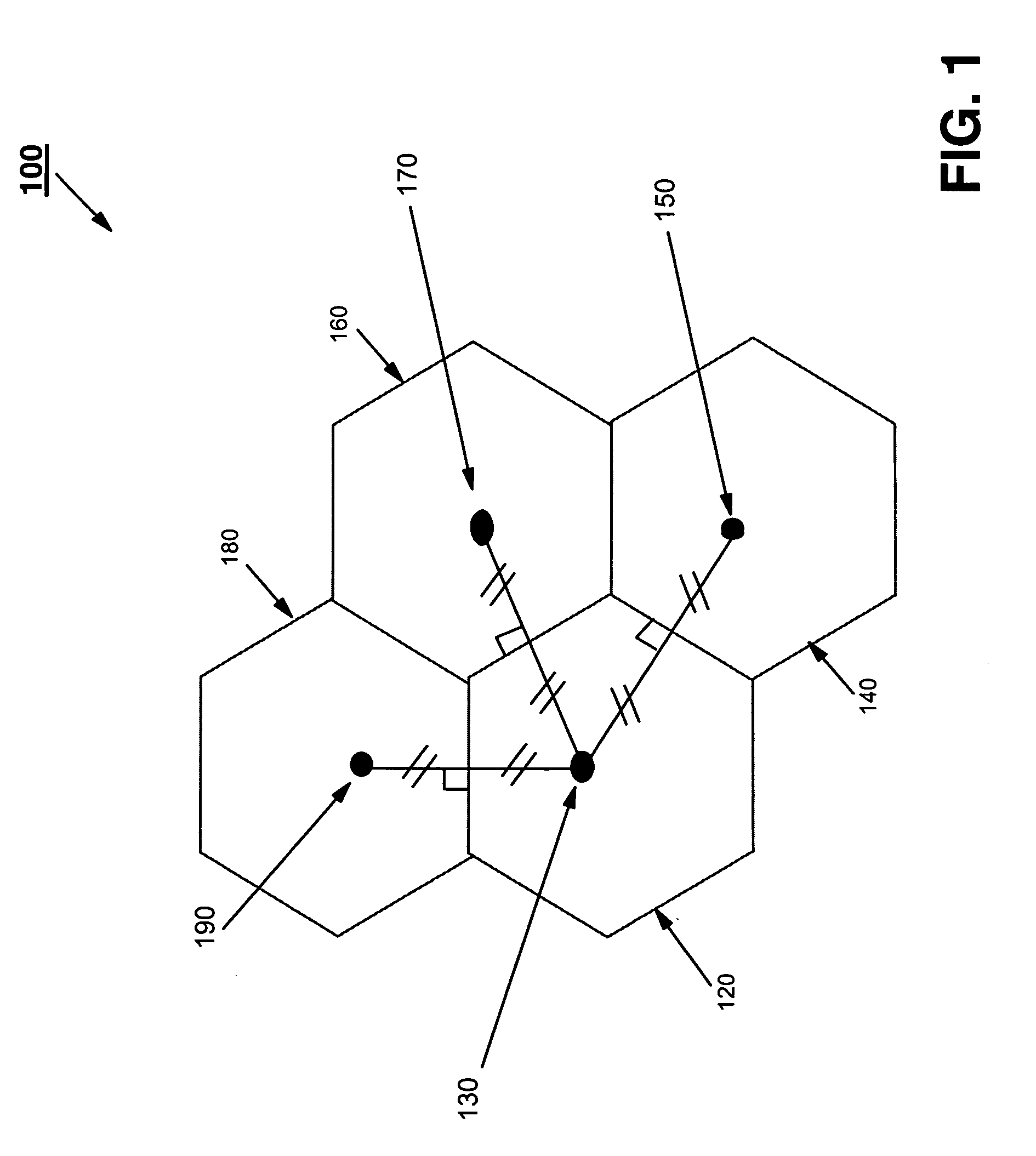

Method, system and program for managing geographic data stored in a database

InactiveUS20050223044A1Data processing applicationsRoad vehicles traffic controlData processing systemGeographic feature

A method, a data processing system and an article of manufacture for managing geographic identifiers stored in a database is described herein. The geographic identifiers each identify a respective geographic feature displayed on a surface map space partitioned by a mosaic of non-rectilinear shaped cells. The data processing system includes an accessing module for accessing a geographic look-up table and an index for the geographic look-up table, the geographic look-up table and the index being stored in the database, an identification module for identifying, from the index, stored row identifiers associated with a subset of the mosaic of non-rectilinear shaped cells, and a retrieving module for retrieving, from the geographic look-up table, stored geographic identifiers associated with the identified stored row identifiers.

Owner:IBM CORP

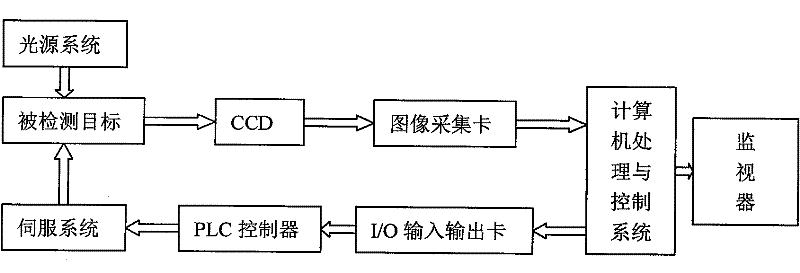

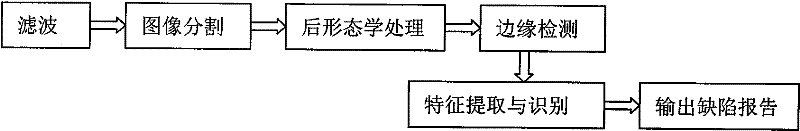

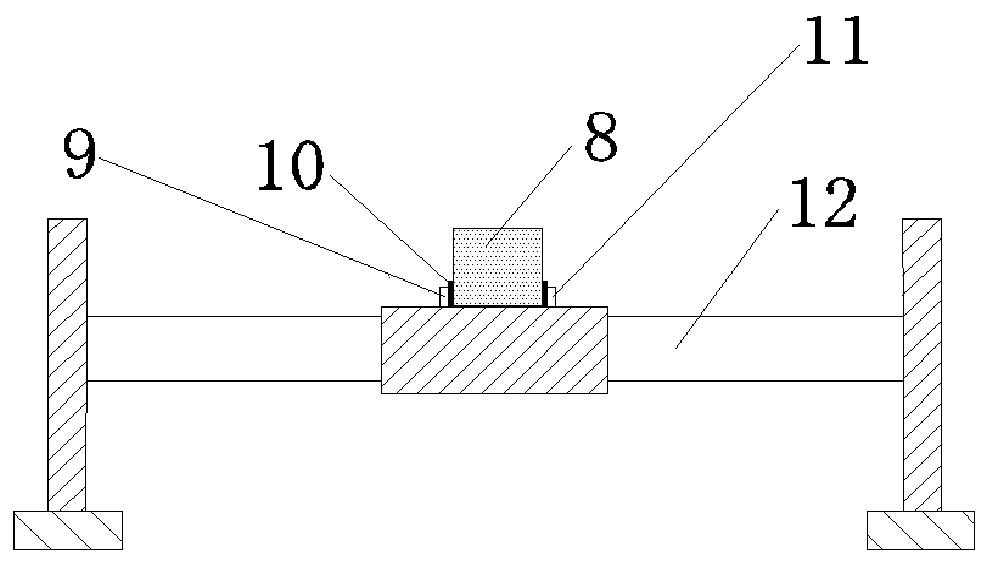

Automatic detection method and device for magnetic tile surface defect based on machine vision

InactiveCN102253050ATo achieve the purpose of defect detectionOptically investigating flaws/contaminationEngineeringImage segmentation

The invention relates to a the machine vision detection field, and provides a method and a device for detecting magnetic tile surface defects through machine vision technology. The technical scheme of the method comprises the following steps: (1) placing a magnetic tile to be detected on a conveyer belt; (2) starting a CCD image acquisition device, acquiring a magnetic tile surface image and transmitting the image to an image processing unit; (3) processing the image acquired in (2) through image filtering, image segmentation, post-morphological processing, edge detection and the like by the image processing unit, transmitting the processed results to a defect detection unit; (4) performing feature extraction of the image processing results in (3) so as to transform the results into a one-dimensional data signal; (5) training and testing the results obtained in (4) by a probability mode identification unit, dividing magnetic tile surface quality into two classes: good magnetic tile and defective magnetic tile so as to reach the purpose of defect detection. The method and device have simple structures, are easy to maintain and expand, have high detection efficiency and low equipment investment.

Owner:GUANGZHOU SHENGTONG QUALITY TESTING OF CONSTR

Method for evaluating surface detects of small-sized workpieces and flow for detecting unqualified workpieces

ActiveCN102353680AMeet online testing requirementsReduce false detection rateOptically investigating flaws/contaminationImaging processingContour analysis

The invention discloses a method for evaluating surface detects of small-sized workpieces. The method comprises the following steps of: acquiring surface images of small-sized workpieces under a specific light source with an industrial camera; detecting various defects such as unfilled corners, edge dropping, abnormity, pockmarks, cracks and the like of the small-sized workpieces based on image processing and profile analyzing methods; evaluating the severity and quantity of defects such as the unfilled corners, the edge dropping and the like of the small-sized workpieces by adopting a convexdefect evaluating parameter and a method for combining the convex defect evaluating parameter with a linearity evaluating parameter; and evaluating the degrees of the pockmark and crack defects with a threshold value segmentation method based on dimensional histogram statistic and the ratio of pockmark pixels. Based on the evaluation, the invention further provides a flow for detecting surface-unqualified workpieces. The flow has low false detecting rate, high detecting speed and wide application range, can meet the online detection requirement of the small-sized workpieces, and is suitable for detecting surface defects of various small-sized workpieces.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

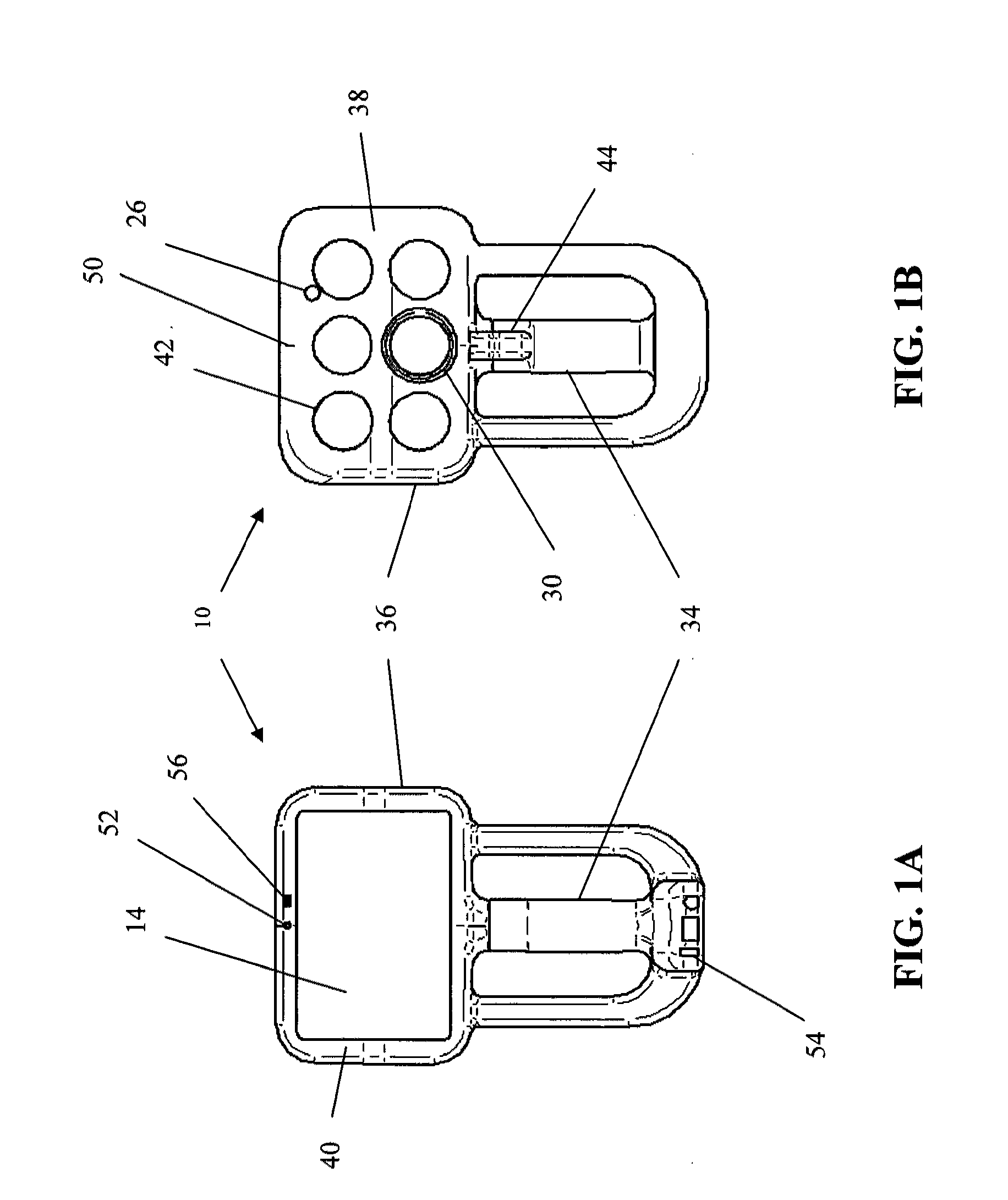

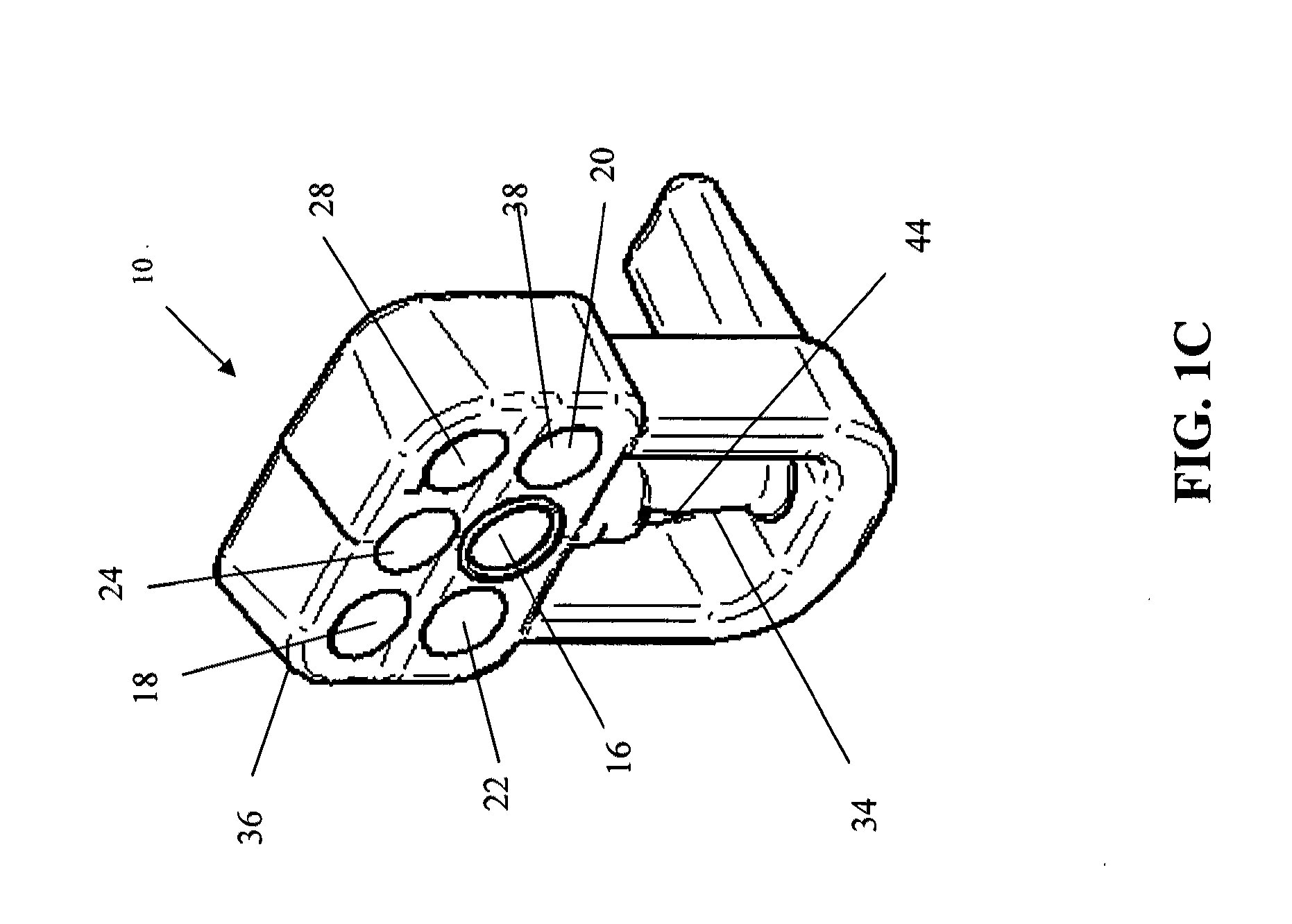

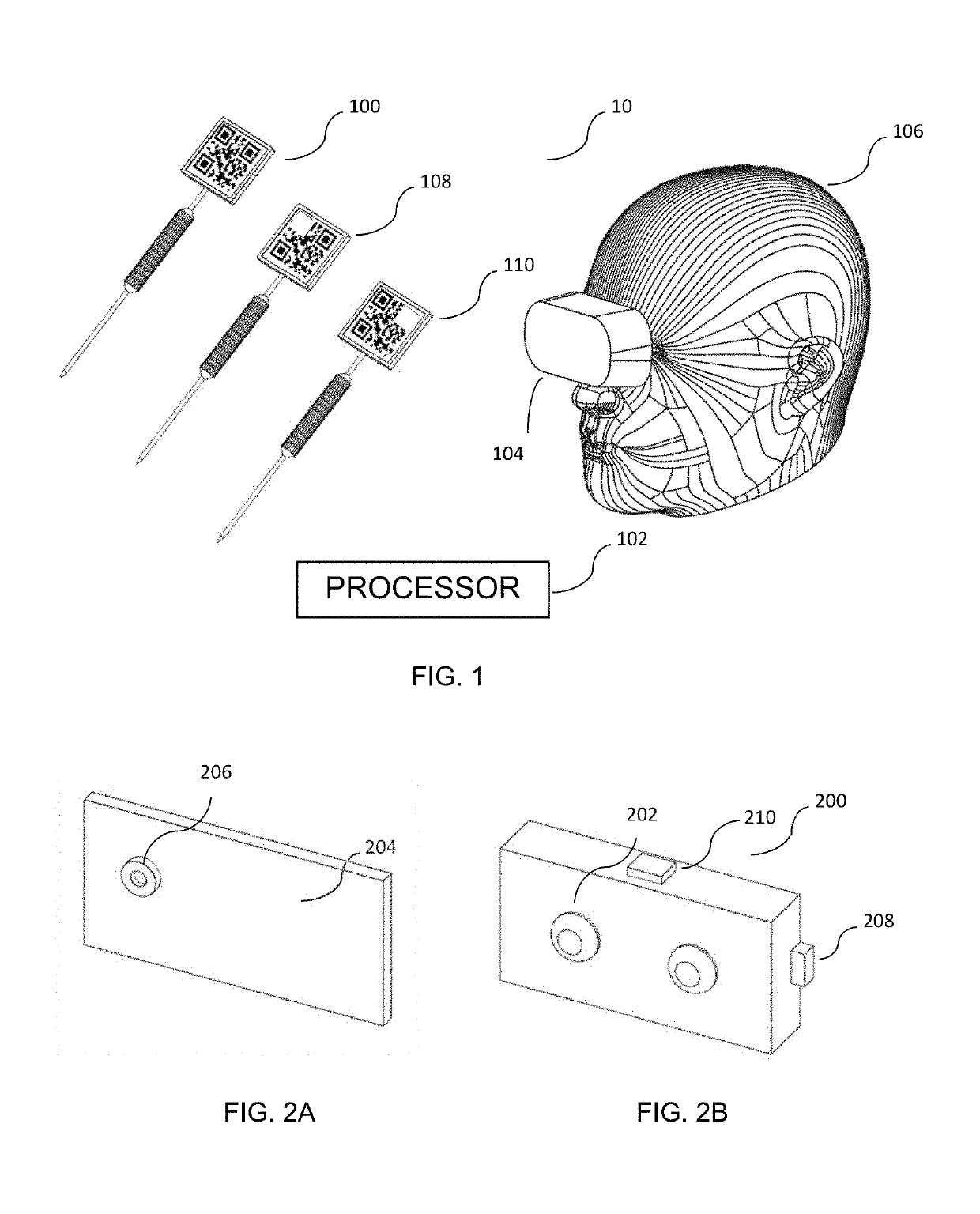

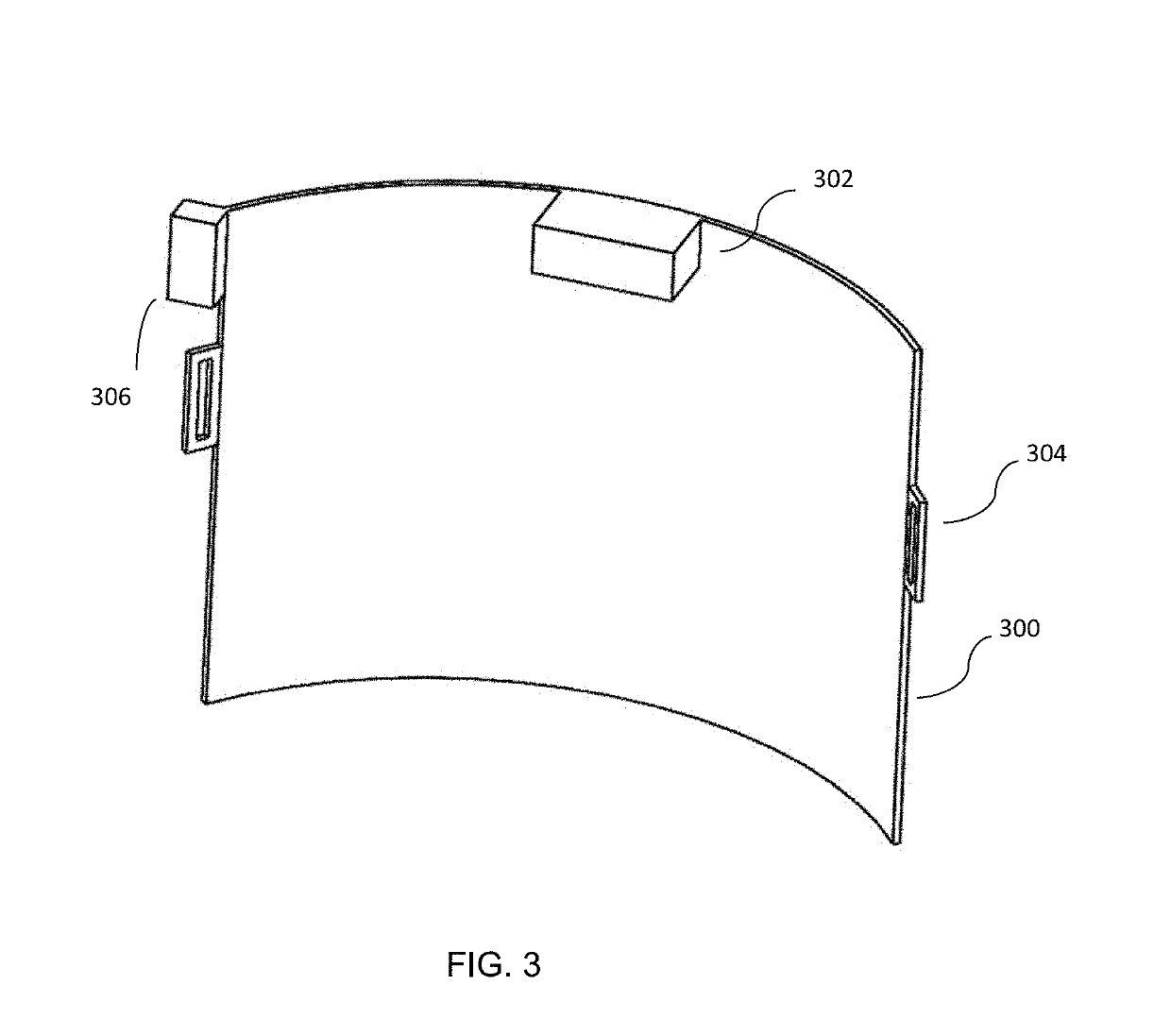

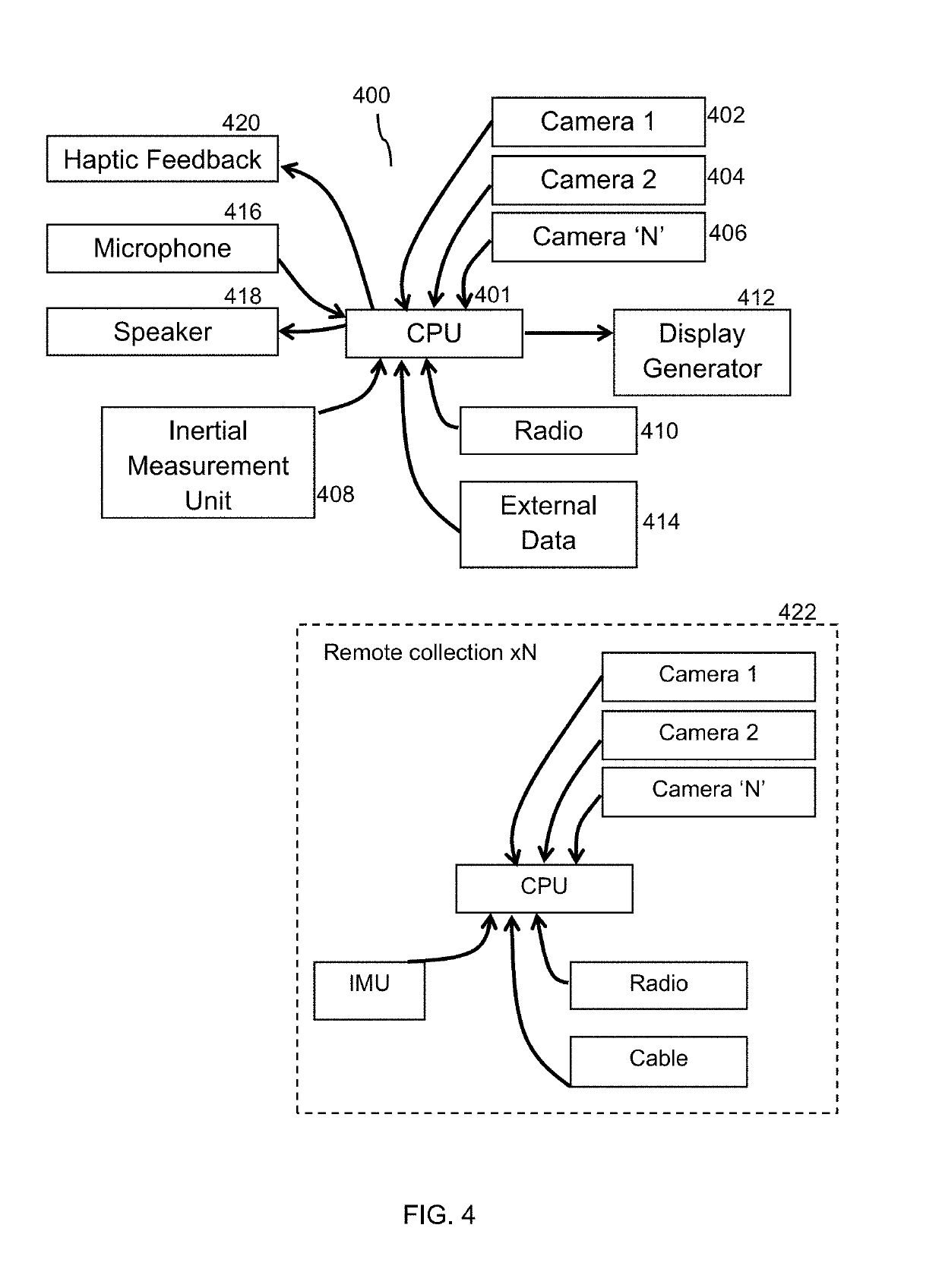

Systems and methods for sensory augmentation in medical procedures

ActiveUS10398514B2Minimizes line of sight obscuration issuePrecise positioningSurgical navigation systemsLaproscopesMixed realityGNSS augmentation

The present invention provides a mixed reality surgical navigation system (10) to be worn by a user (106) during a surgical procedure comprising: a display device (104), to be worn by a user (106) during a surgical procedure, comprising a processor unit (102), a display generator (204), a sensor suite (210) having at least one camera (206) or depth sensor wherein the processing unit (102) creates a reference surface map (5804) of an exposed surface (5806) of an anatomical object (4204) with data received from the sensor suite (210); the processing unit (102) establishes a reference frame (5810) relative to the sensor suite (210) for the reference surface map (5804); orientation of the reference frame (5810) is established by creating additional surface maps (5834) of other anatomical features (5824) of the anatomical object (4204); the processing unit (102) tracks a pose of the anatomical object (4204) relative to the system (10) by creating a displaced surface map (5814) of the exposed surface (5806) and rotating and translating the displaced surface map (5814) and reference frame (5810) to achieve a best fit to the reference surface map (5804).

Owner:INSIGHT MEDICAL SYST INC

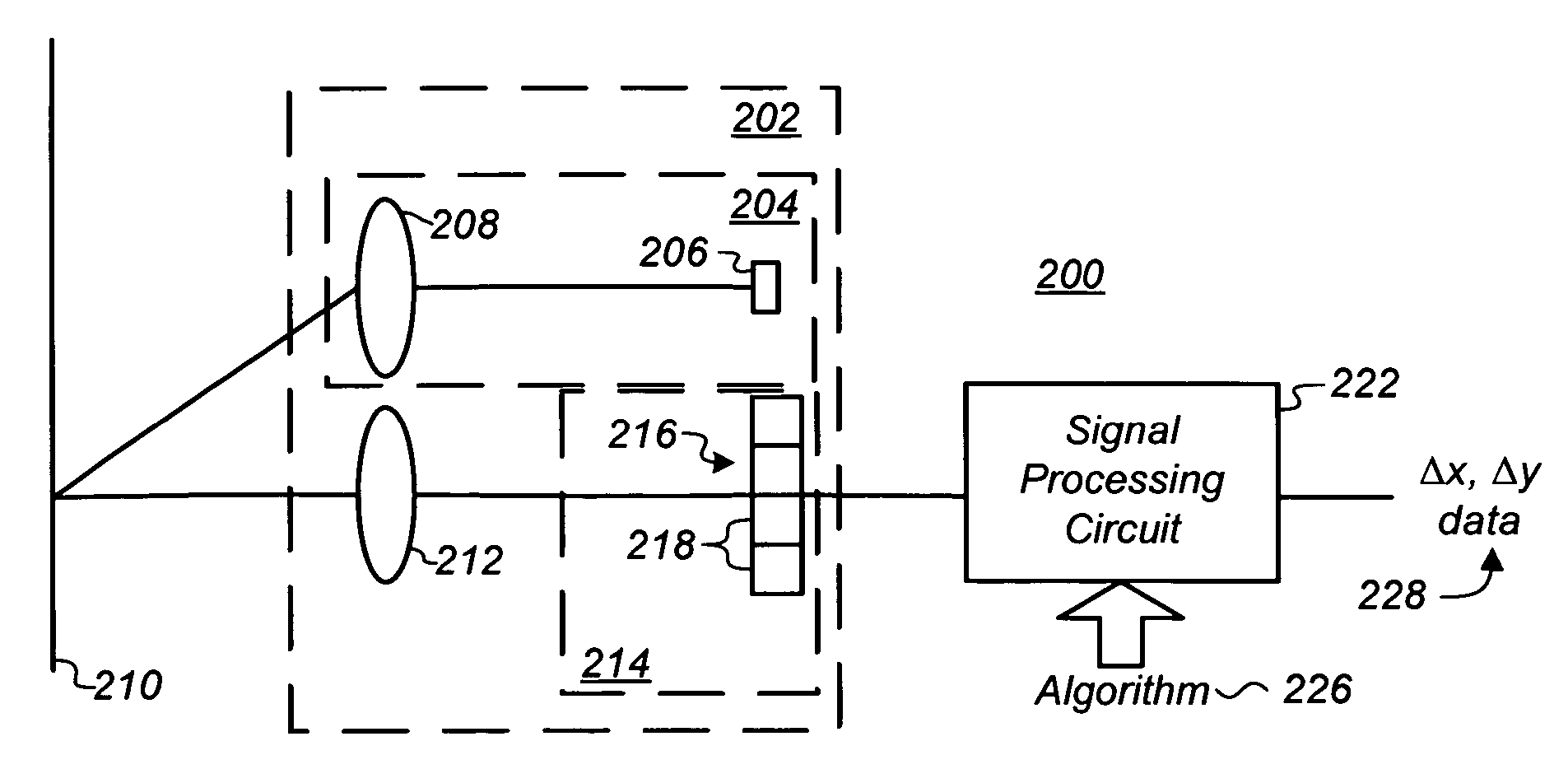

Signal processing method for use with an optical navigation system

ActiveUS7248345B2Cathode-ray tube indicatorsDevices using optical meansArray data structureSignal processing

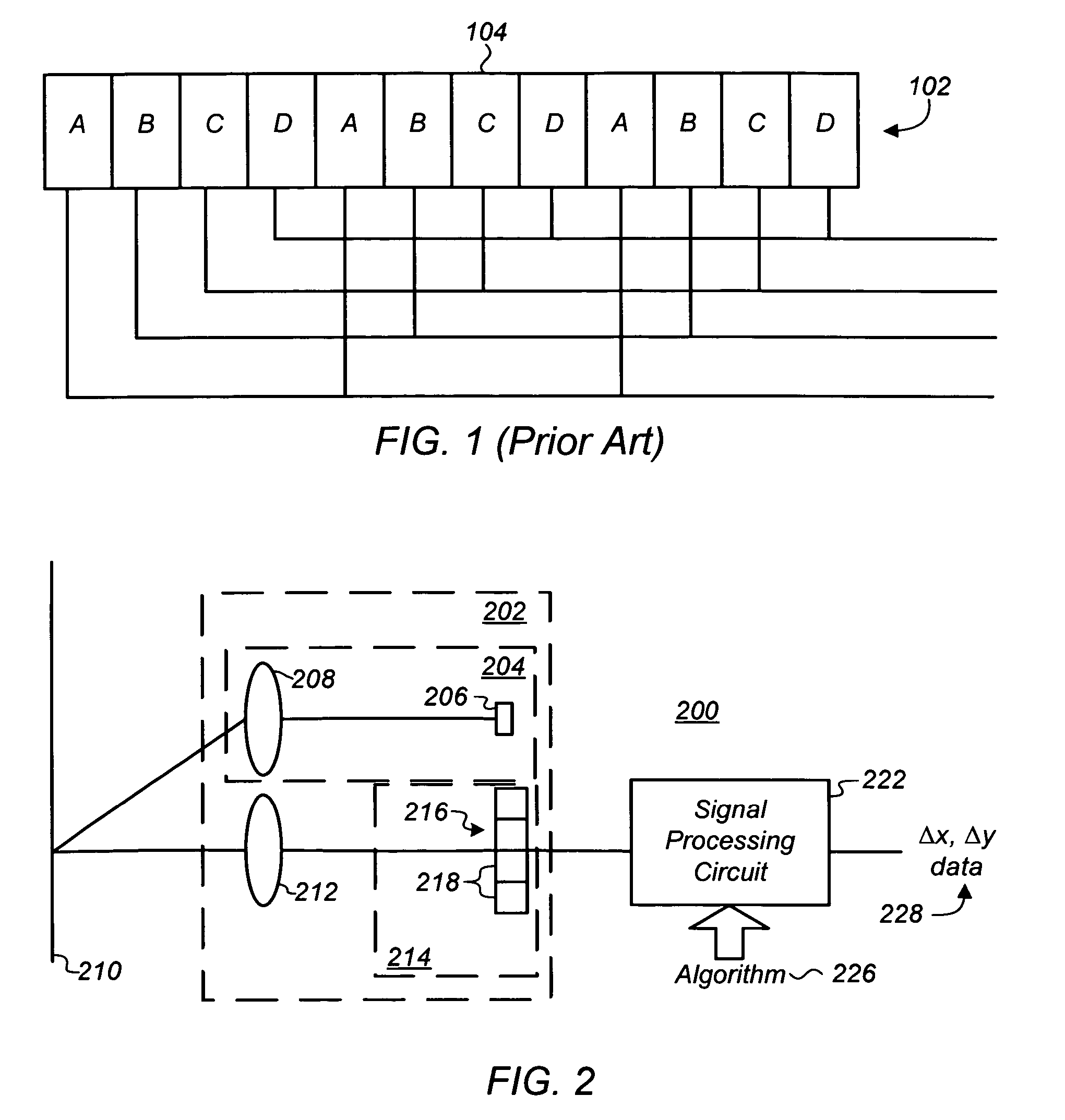

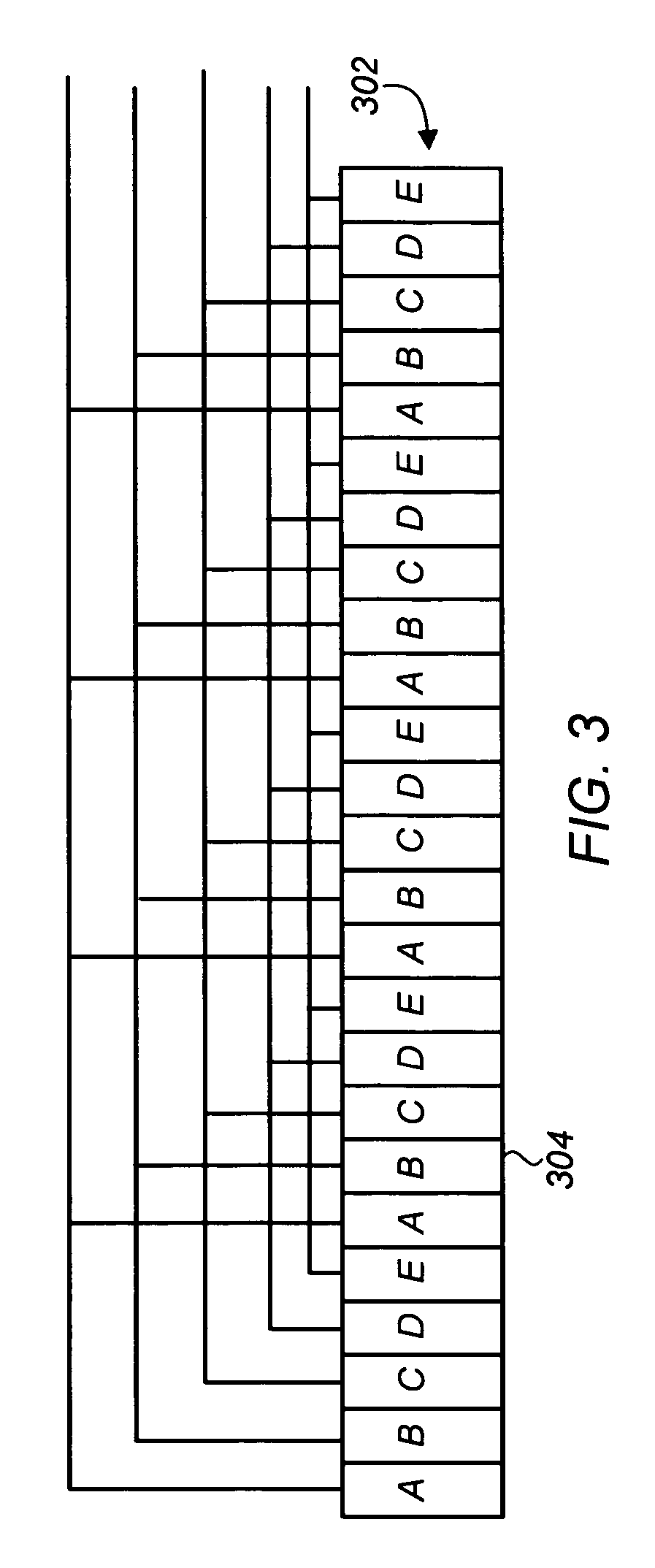

A signal processor and method are provided for detecting movement of a surface relative to an optical sensor having an array of photosensitive elements. Generally, the method involves: (i) sampling each of a number (M) of phase signals from the photosensitive elements, each of the M signals having a magnitude (Ai) and including a tracking signal at a frequency being tracked and a background signal at other frequencies that offsets the tracking signal, where i, an index of the signals, is a whole number between 0 and M-1; (ii) eliminating the offset to the tracking signal due to the background signal to generate M non-offset phase signals having a magnitude (A′i); (iii) adjusting phase angles (θi) of the non-offset phase signals to generate M weighted phase signals (A′iθ′i); and (iv) combining each of the M weighted phase signals (A′iθ′i) to generate an average weighted phase having a phase angle (θ), that when tracked over time indicates a direction and velocity of the movement of an image of the surface mapped to the array.

Owner:CYPRESS SEMICON CORP

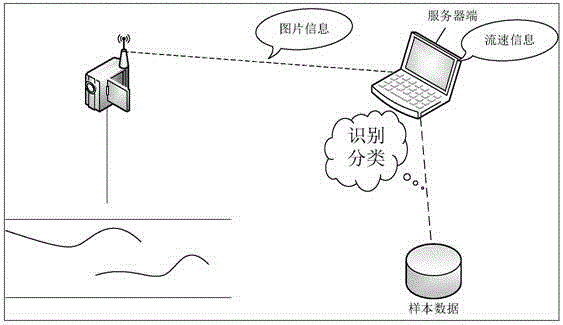

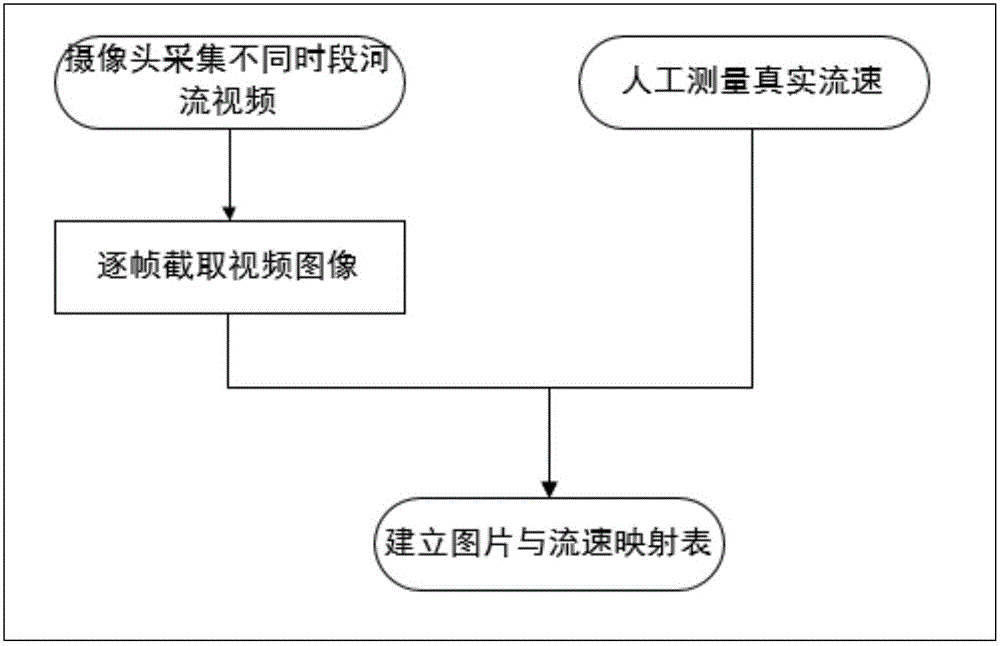

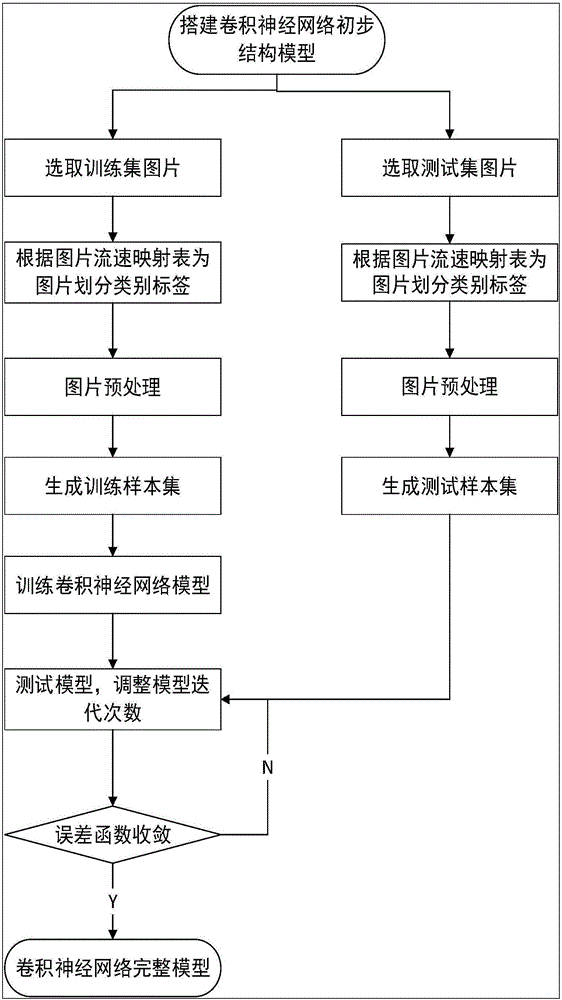

Water flow speed measuring method based on convolutional neural network image identification

ActiveCN106156734ASave human effortConvenient and fast flow rate measurement workCharacter and pattern recognitionImage identificationNerve network

Provided is a water flow speed measuring method based on convolutional neural network image identification. The method comprises the following steps of equipment installing, sample picture collecting, sample data establishing, classifier training and actual measuring. According to the method, a non-contact camera is adopted to acquire surface images of a large quantity of rivers in the different states, the flow speed corresponding to each image is measured in advance, and the images are preprocessed to generate sample data for training and adjusting a convolutional neural network; when the flow speed needs to be measured again, the picture of the surface of a river at that time only needs to be shot by the camera and classified through the trained convolutional neural network, and the flow speed corresponding to the obtained category is the flow speed of the river at that time.

Owner:ZHEJIANG UNIV OF TECH

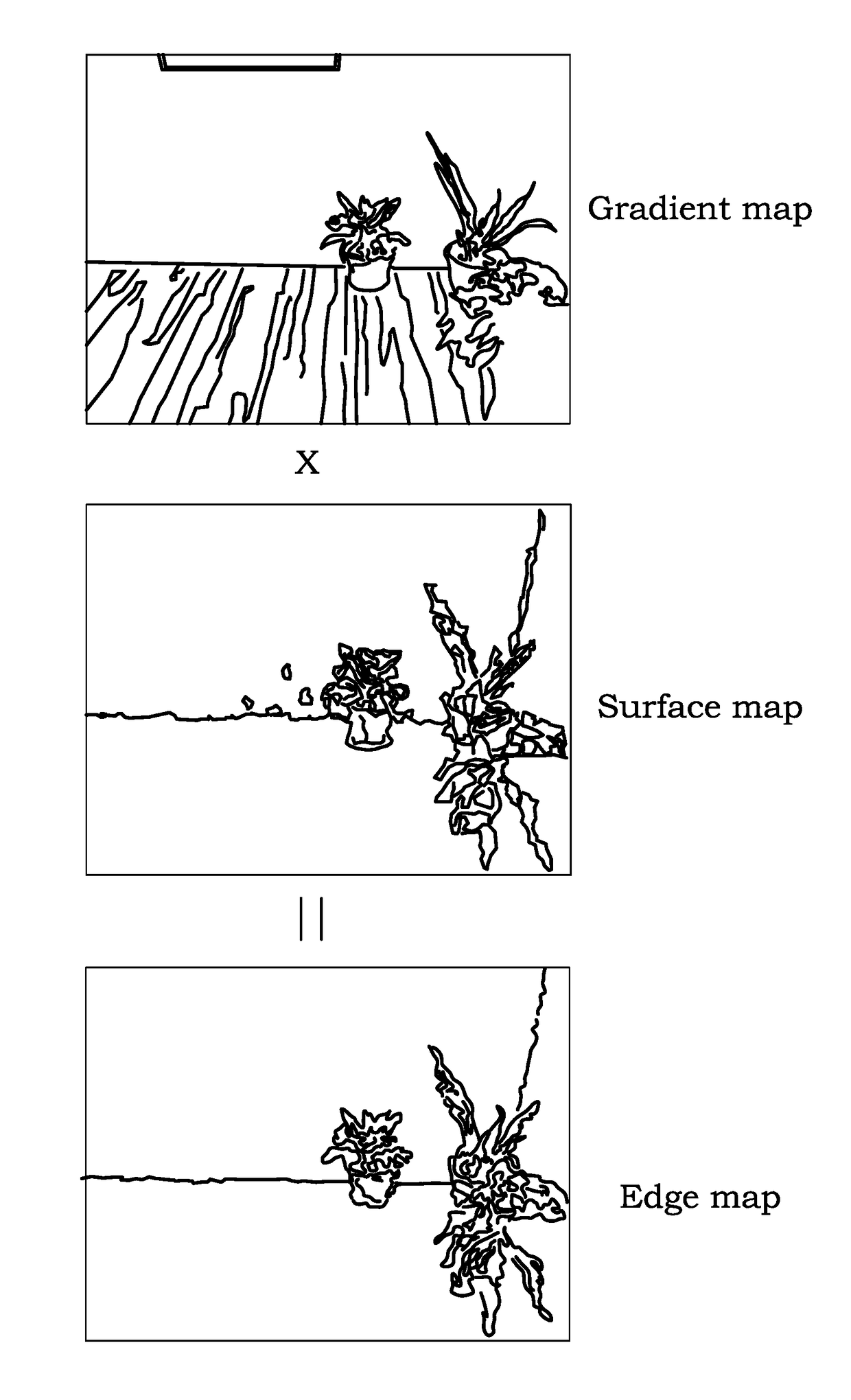

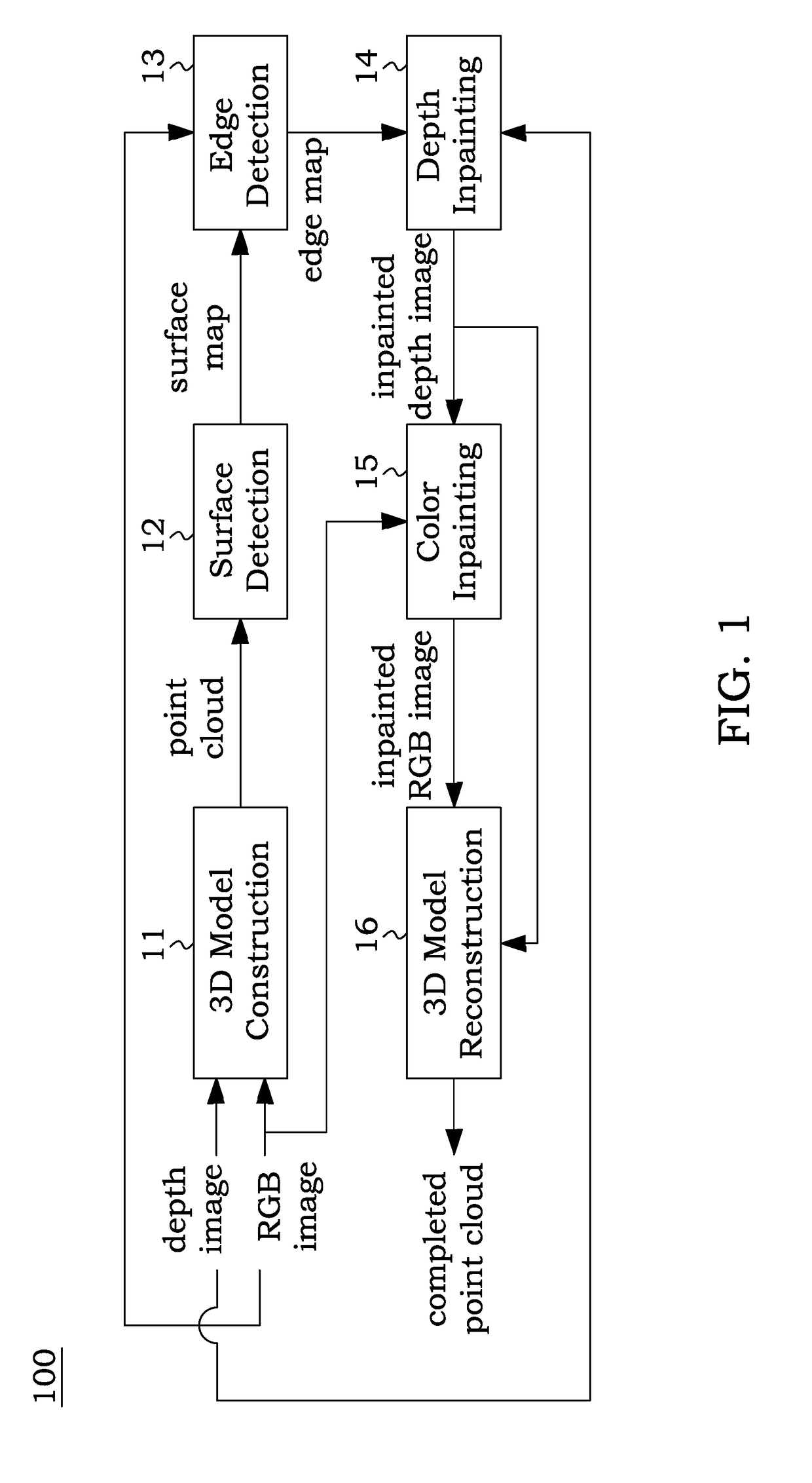

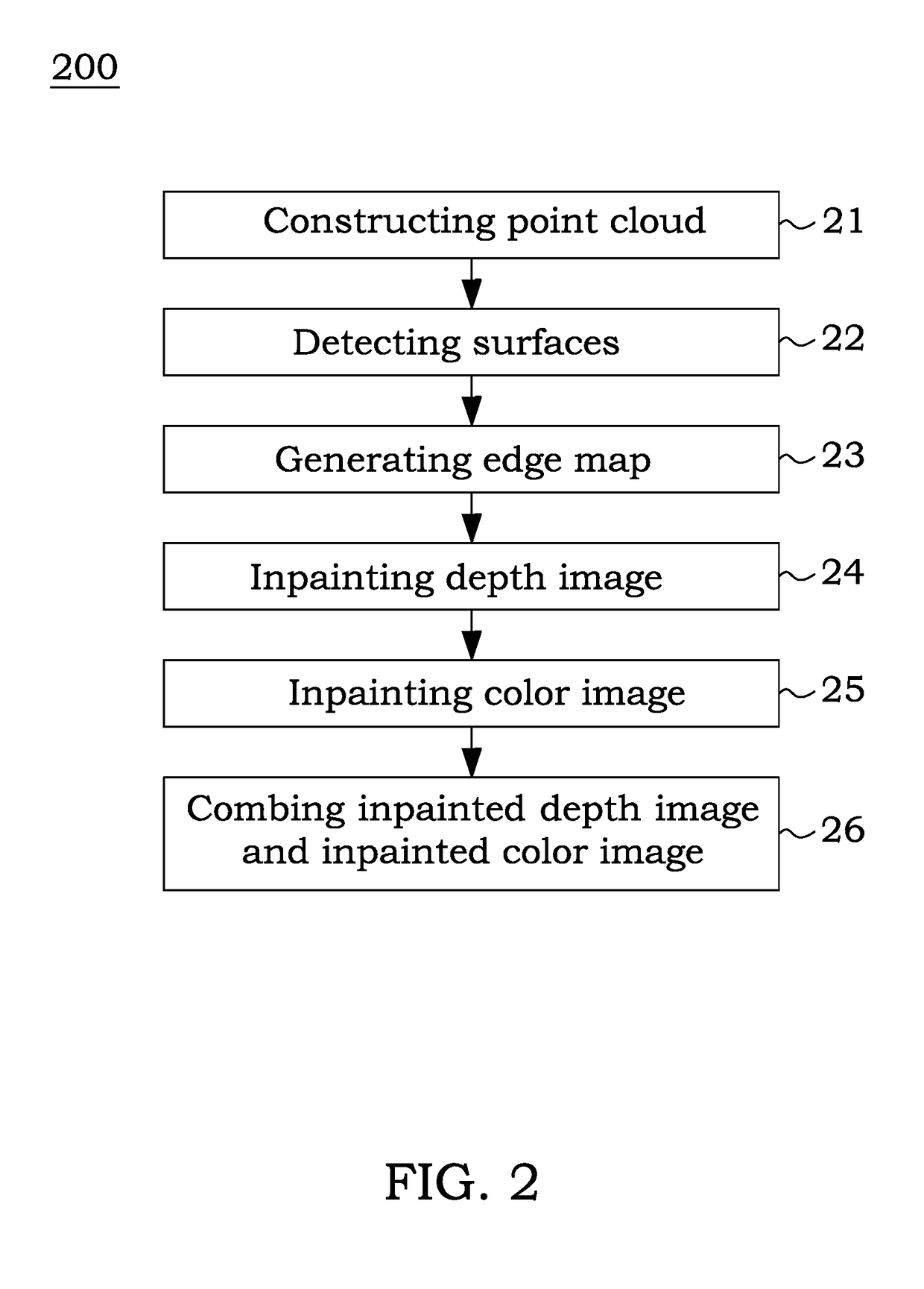

System and a method of restoring an occluded background region

InactiveUS20180300937A1Realistic colorsReal structureDetails involving processing stepsImage enhancementColor imagePoint cloud

A system and method of restoring an occluded background region includes detecting surfaces of a point cloud, thereby resulting in a surface map; substantially enhancing edges between detected surfaces according to a gradient map and the surface map, thereby generating an edge map; inpainting a depth image, thereby generating in an inpainted depth image; and inpainting a color image, thereby generating an inpainted color image.

Owner:NAT TAIWAN UNIV +1

Apparatus for generating volumetric image and matching color textured external surface

ActiveUS20070262983A1Character and pattern recognitionCathode-ray tube indicatorsOptical propertyVolumetric data

Embodiments of the invention provide systems and methods for generating combined image data representing a volumetric image of a subject and a color textured external surface of the subject. According to one embodiment, two-dimensional image data of a surface of the subject can be obtained from a two-dimensional imager. Volumetric data of the subject can be obtained from a volumetric scanner. The two-dimensional imager can have a known optical property and physical position relative to the volumetric scanner. External surface mesh data can be generated based on the volumetric data. The two-dimensional image data can be mapped to the external surface mesh data based on the known physical position of the two-dimensional imager and the volumetric scanner. Display image data including the two-dimensional image data mapped to the external surface map data combined with the volumetric data can be generated and displayed.

Owner:ANATOMAGE

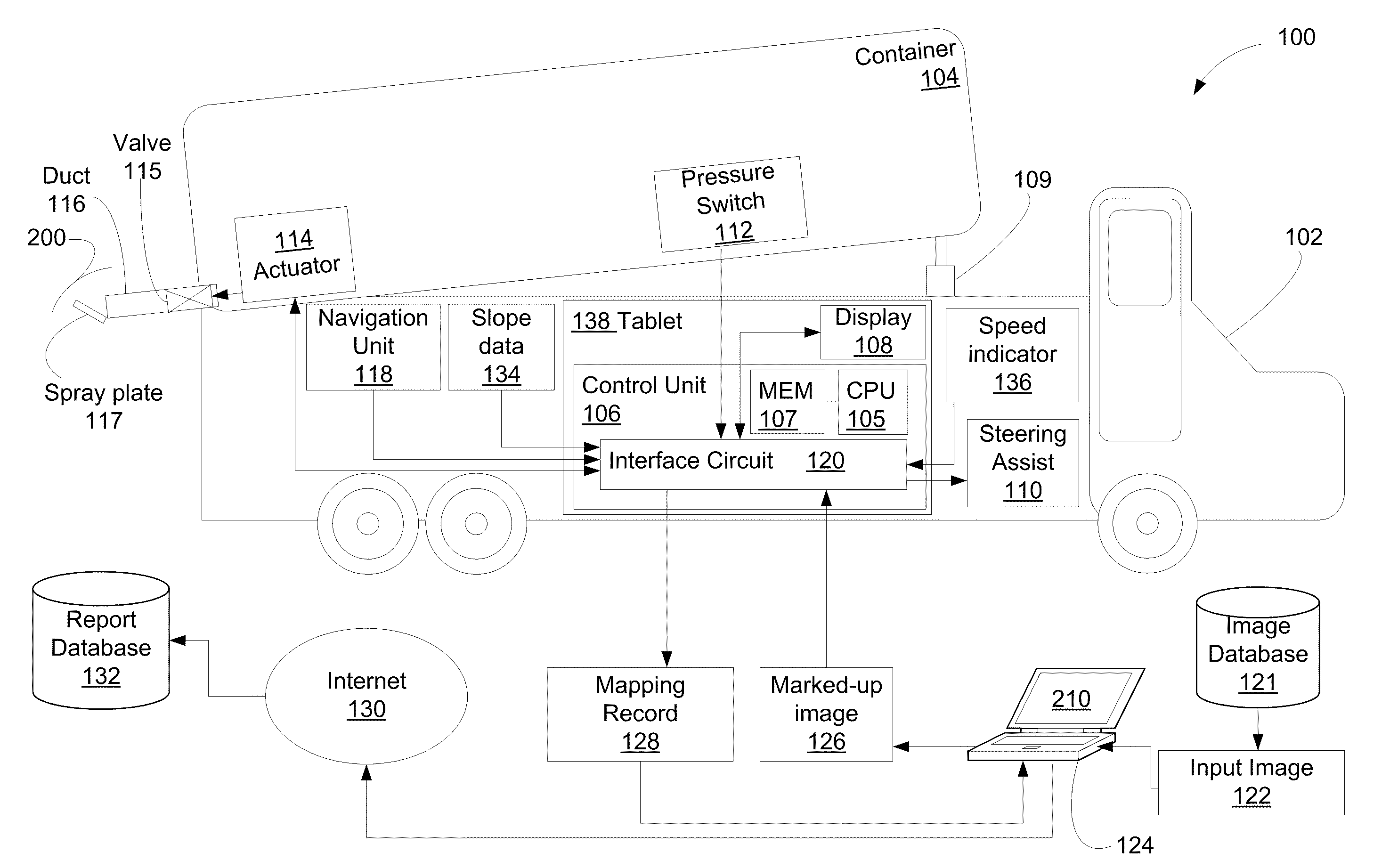

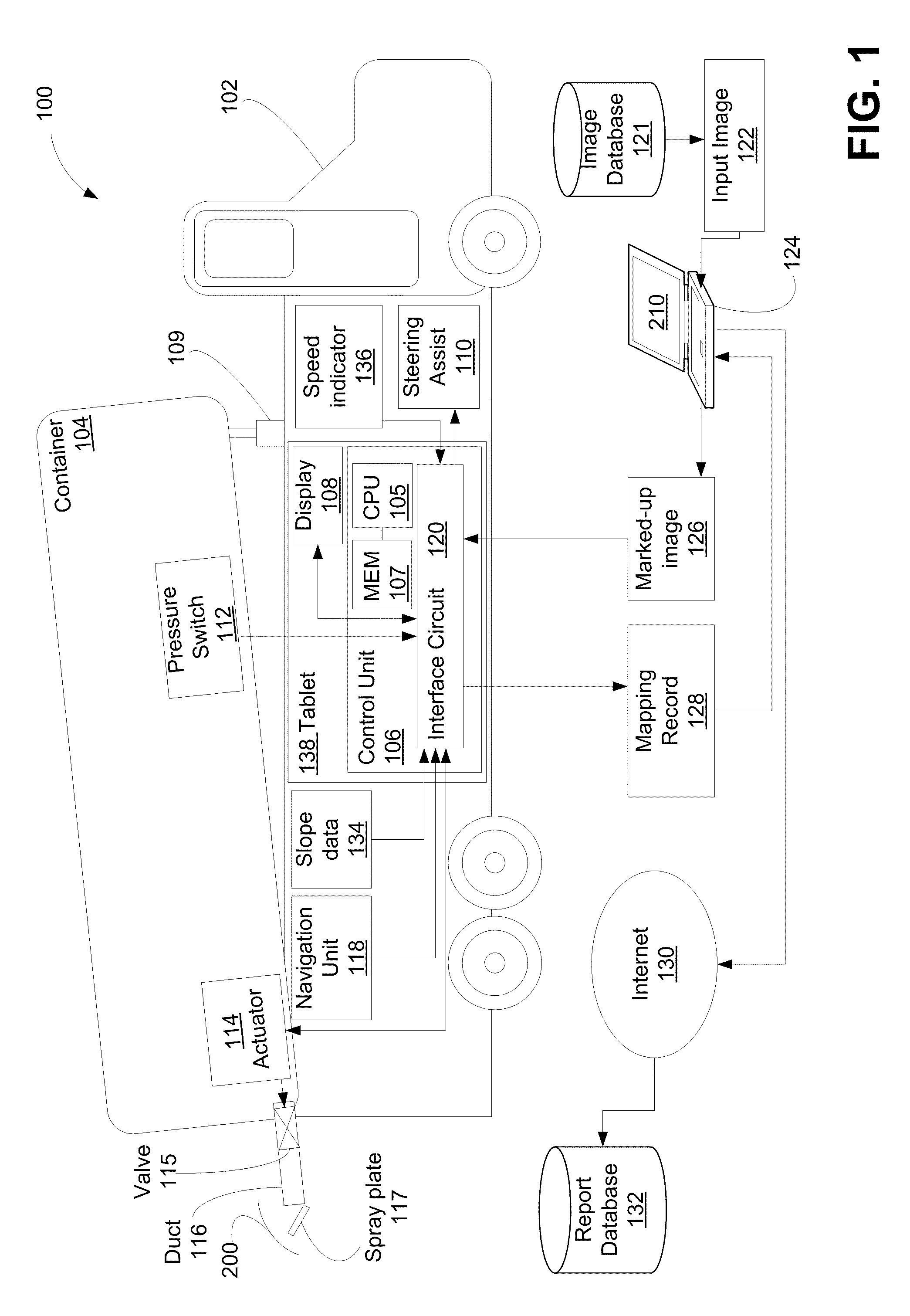

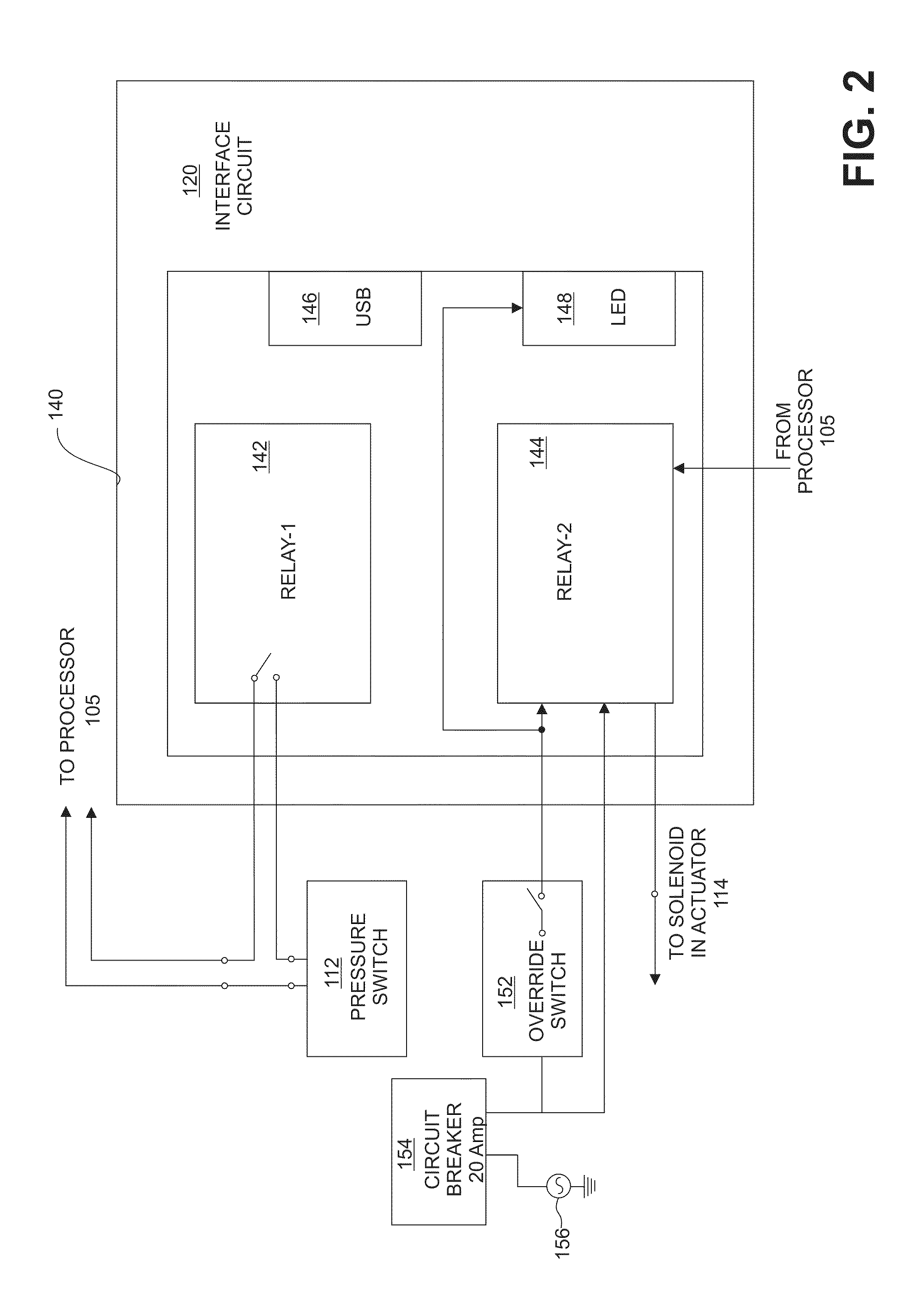

System and method for land application of waste fluids

ActiveUS20110266357A1High resultMore focusedManure treatmentWatering devicesAutomatic controlControl system

A system and method are provided for automated control of application of fluid to a surface. A surface map is annotated with shapes designating zones for spraying, and excluding others. A control system in a vehicle uses the annotated map and GPS to assist the operator of the vehicle avoid spraying on excluded zones, and provides a record of the spraying operation including locations sprayed and fluid spray rates. The control system operates valves to control spraying from a container on the vehicle, based on several parameters, so as to avoid spraying excluded zones and steep slopes, to avoid overlaps, and to limit fluid spray rates below pre-determined maximums. The system further assists the operator by providing a visual guide on a display. A kit can be provided to retrofit a vehicle for landspraying.

Owner:SUMMIT LIABILITY SOLUTIONS

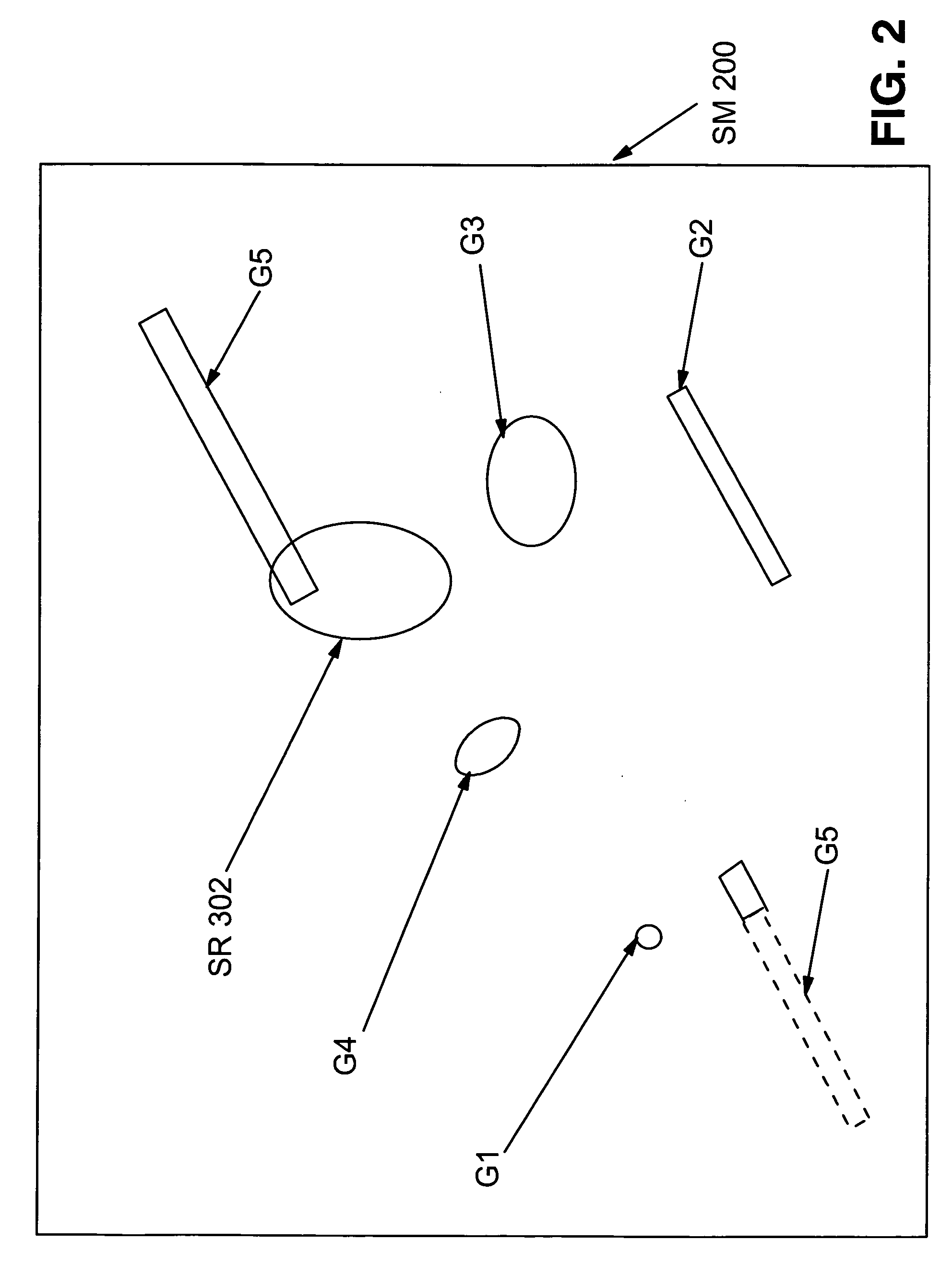

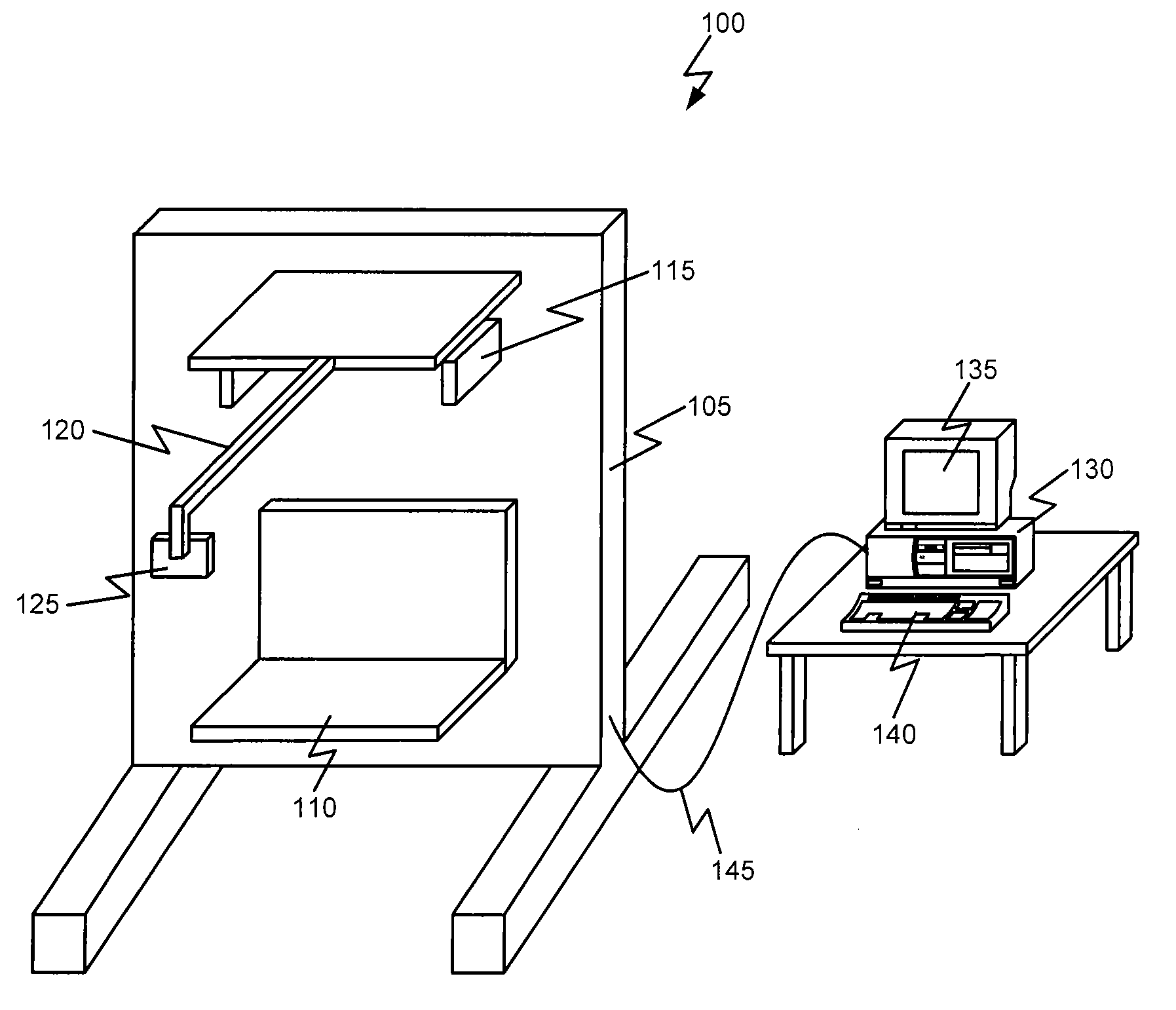

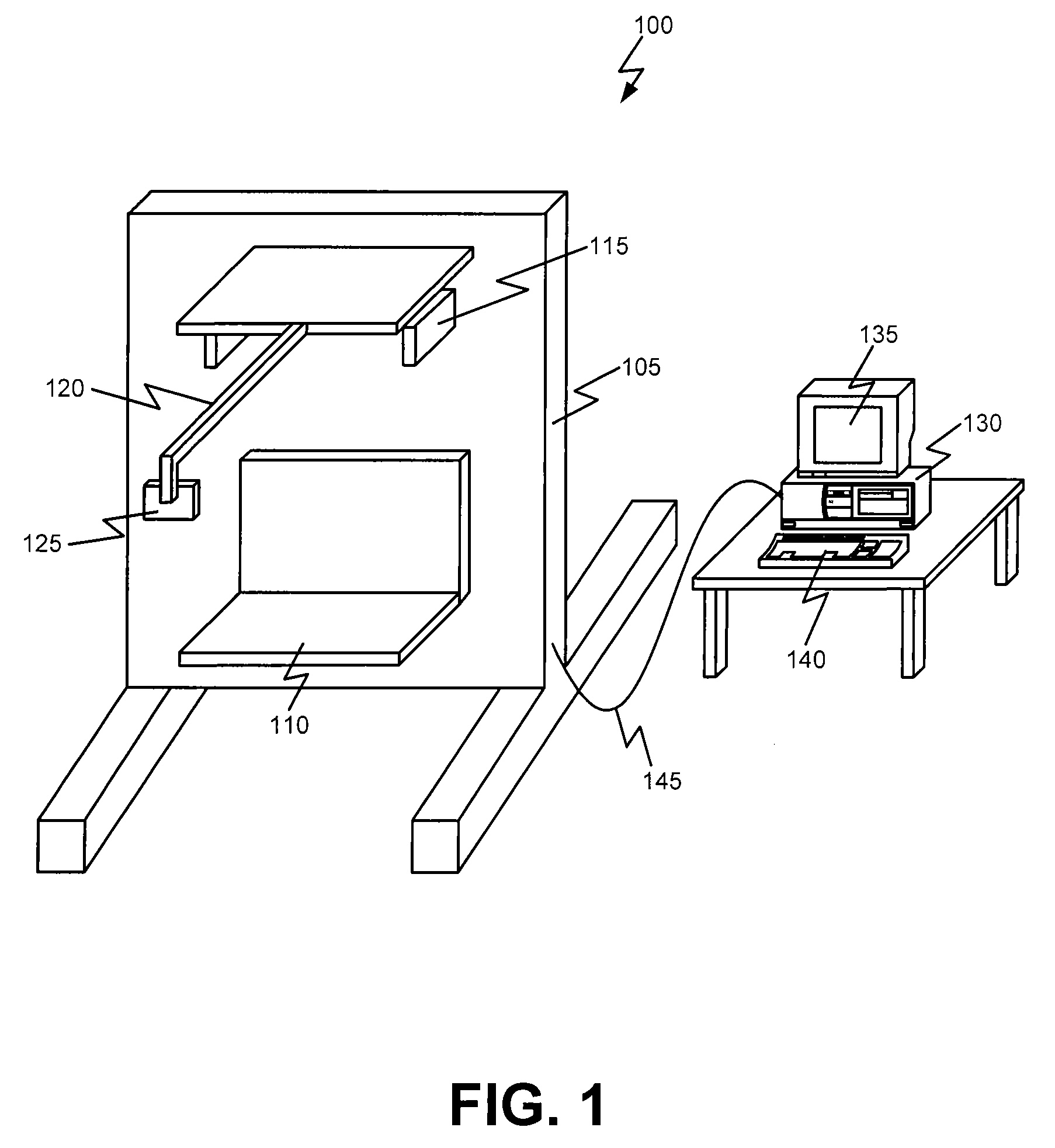

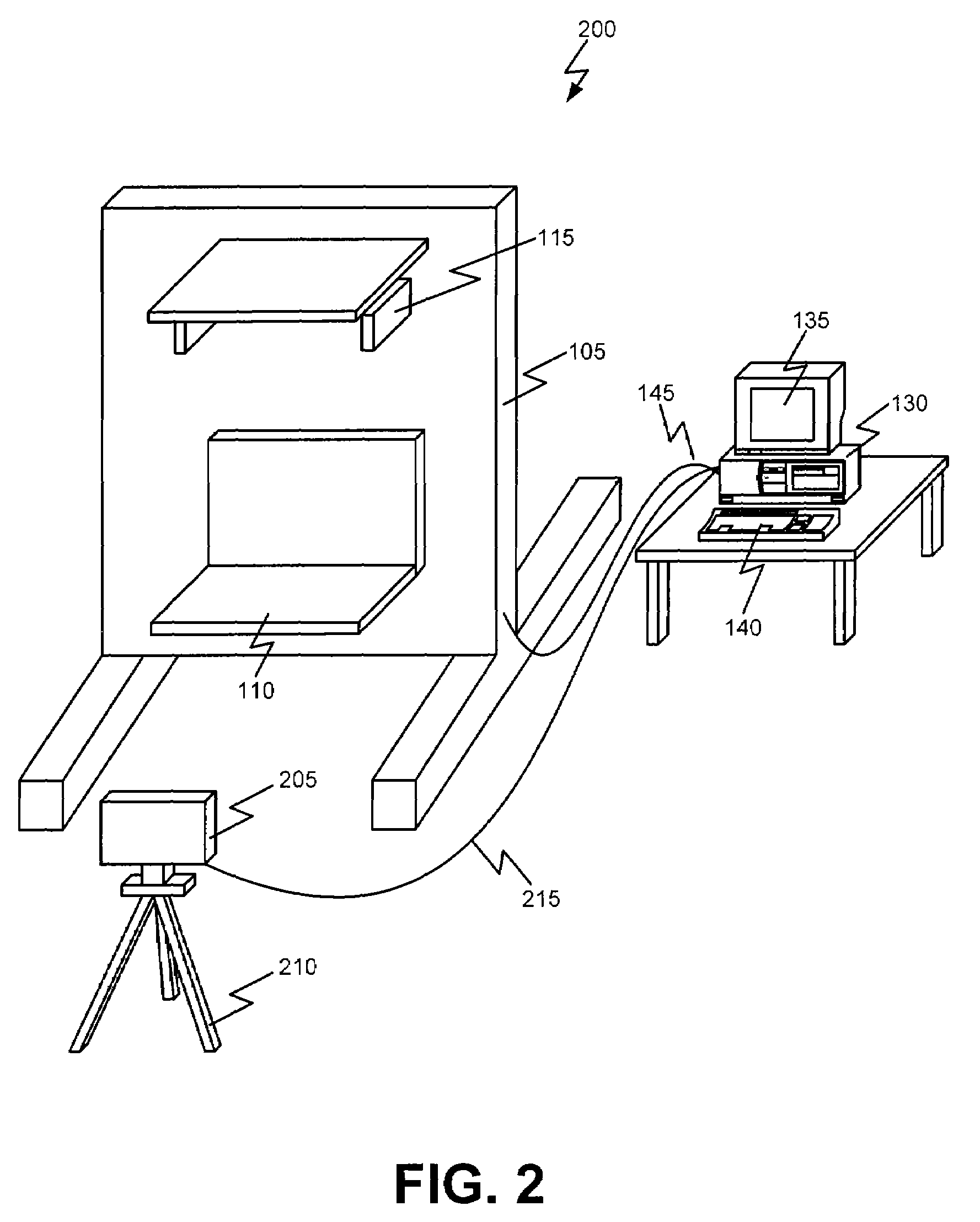

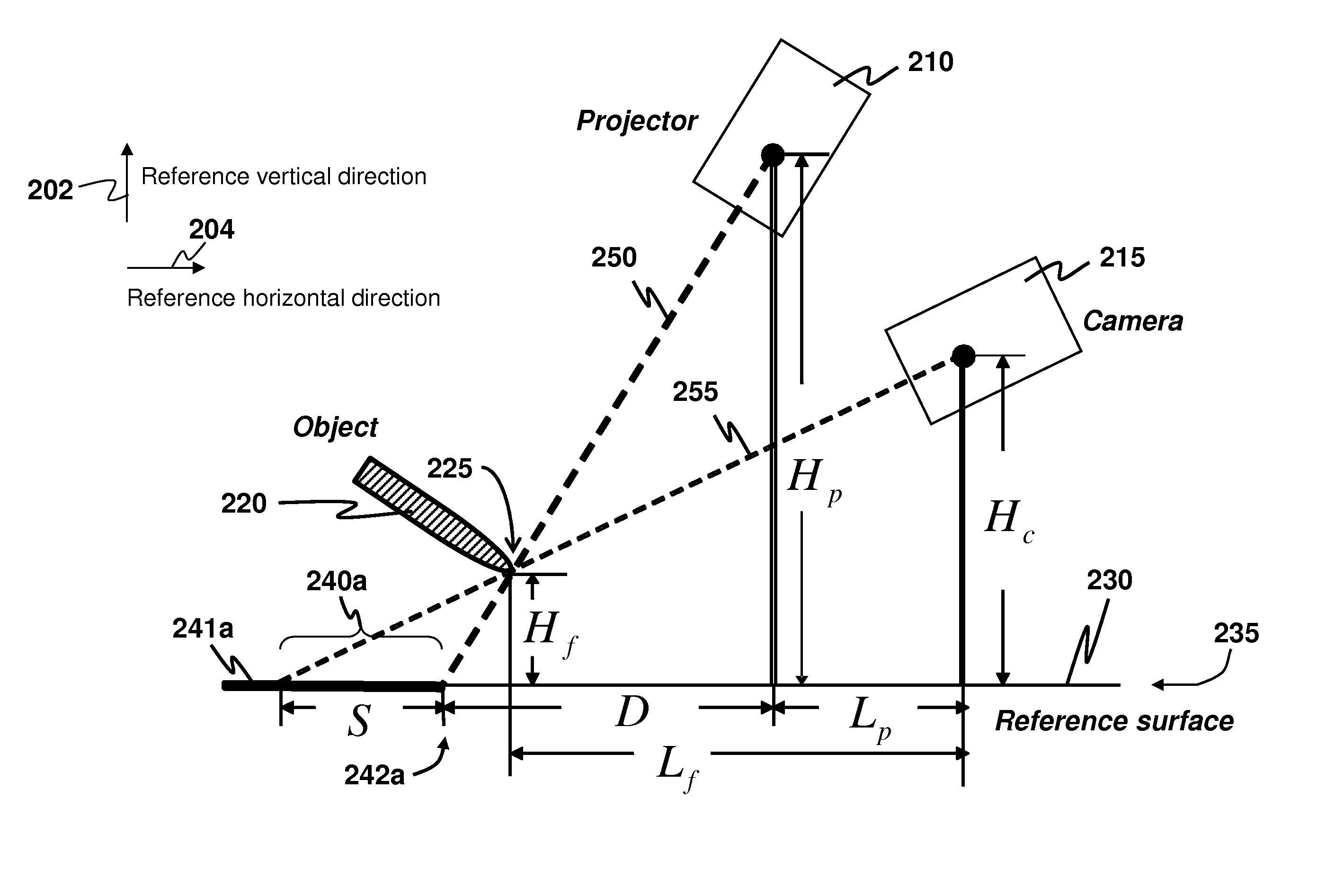

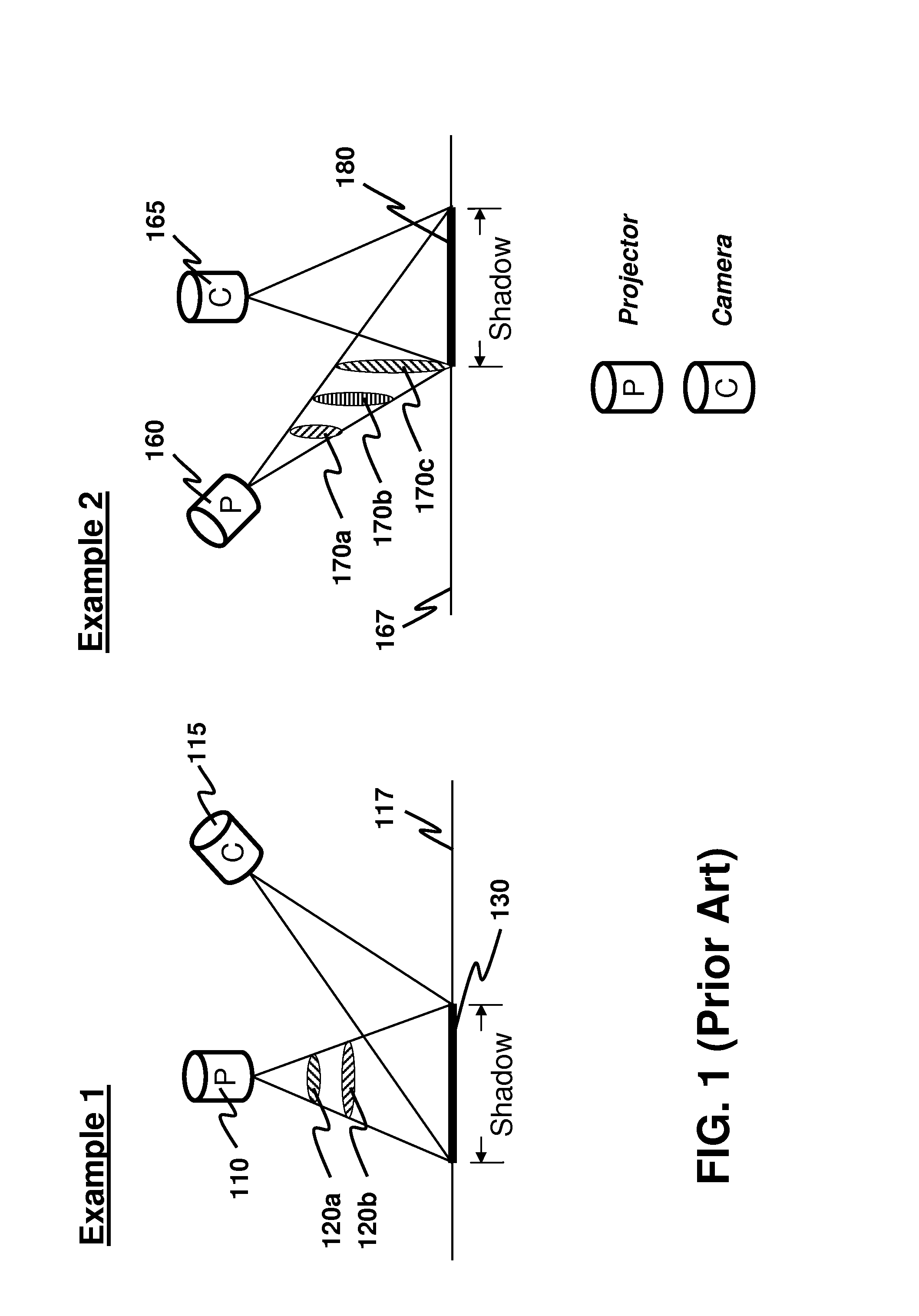

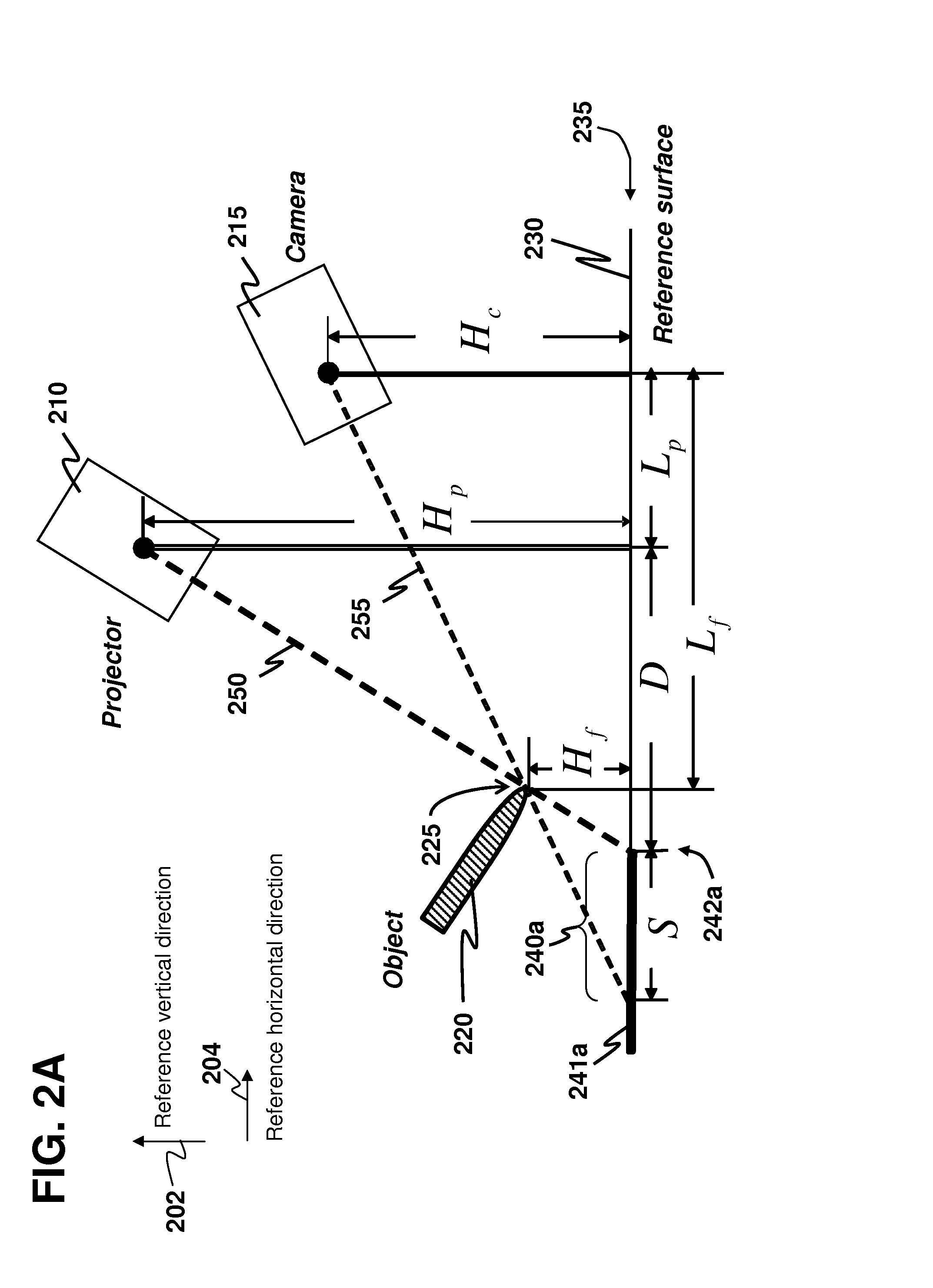

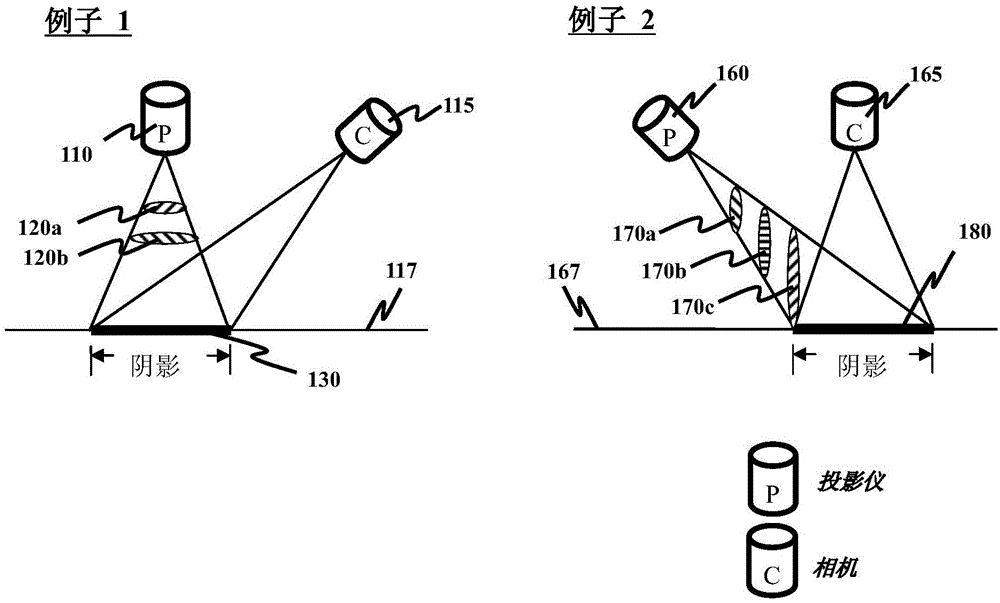

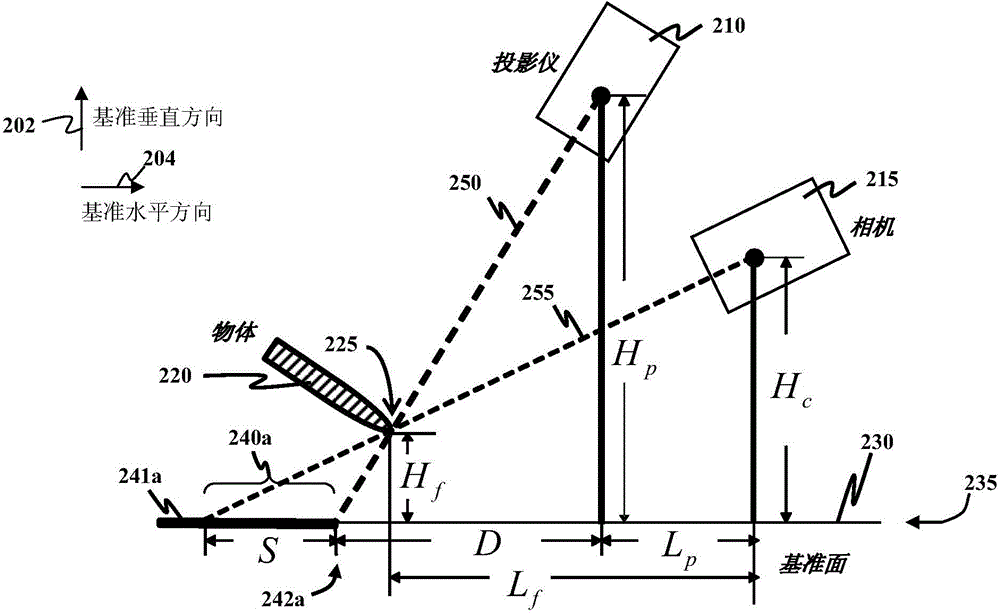

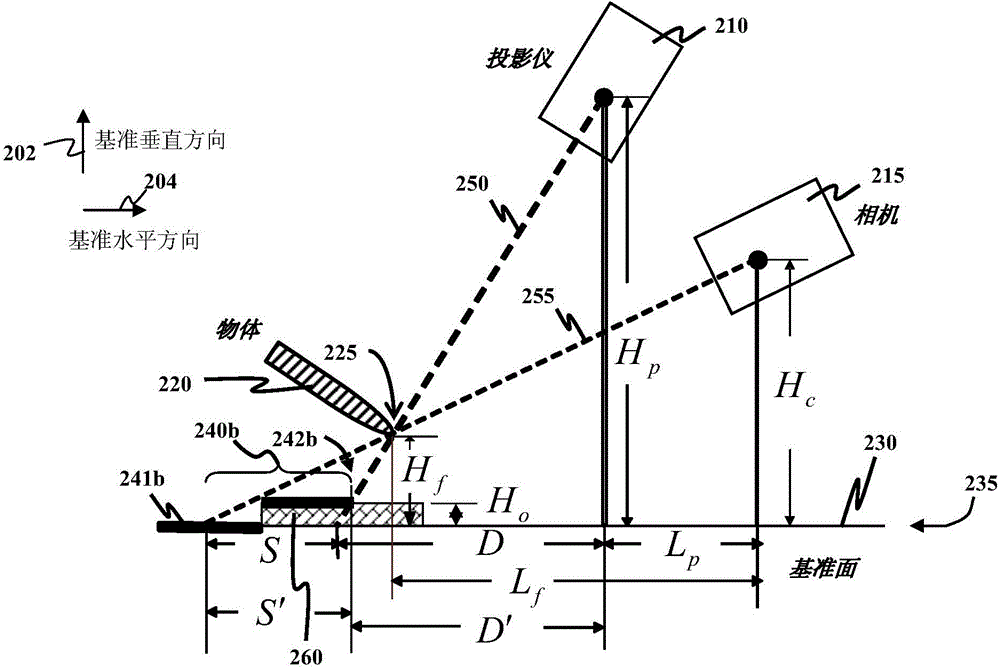

Touch and motion detection using surface map, object shadow and a single camera

The present invention provides an optical method and a system for obtaining positional and / or motional information of an object with respect to a reference surface, including detecting if the object touches the reference surface, by using a projector and one camera. A surface map is used for mapping a location on the reference surface and a corresponding location in a camera-captured image having a view of the reference surface. In particular, a camera-observed shadow length, i.e. a length of the object's shadow observable by the camera, estimated by using the surface map, is used to compute the object's height above the reference surface (a Z coordinate). Whether or not the object touches the reference surface is also obtainable. After an XY coordinate is estimated, a 3D coordinate of the object is obtained. By computing a time sequence of 3D coordinates, the motional information, such as velocity and acceleration, is obtainable.

Owner:HONG KONG APPLIED SCI & TECH RES INST

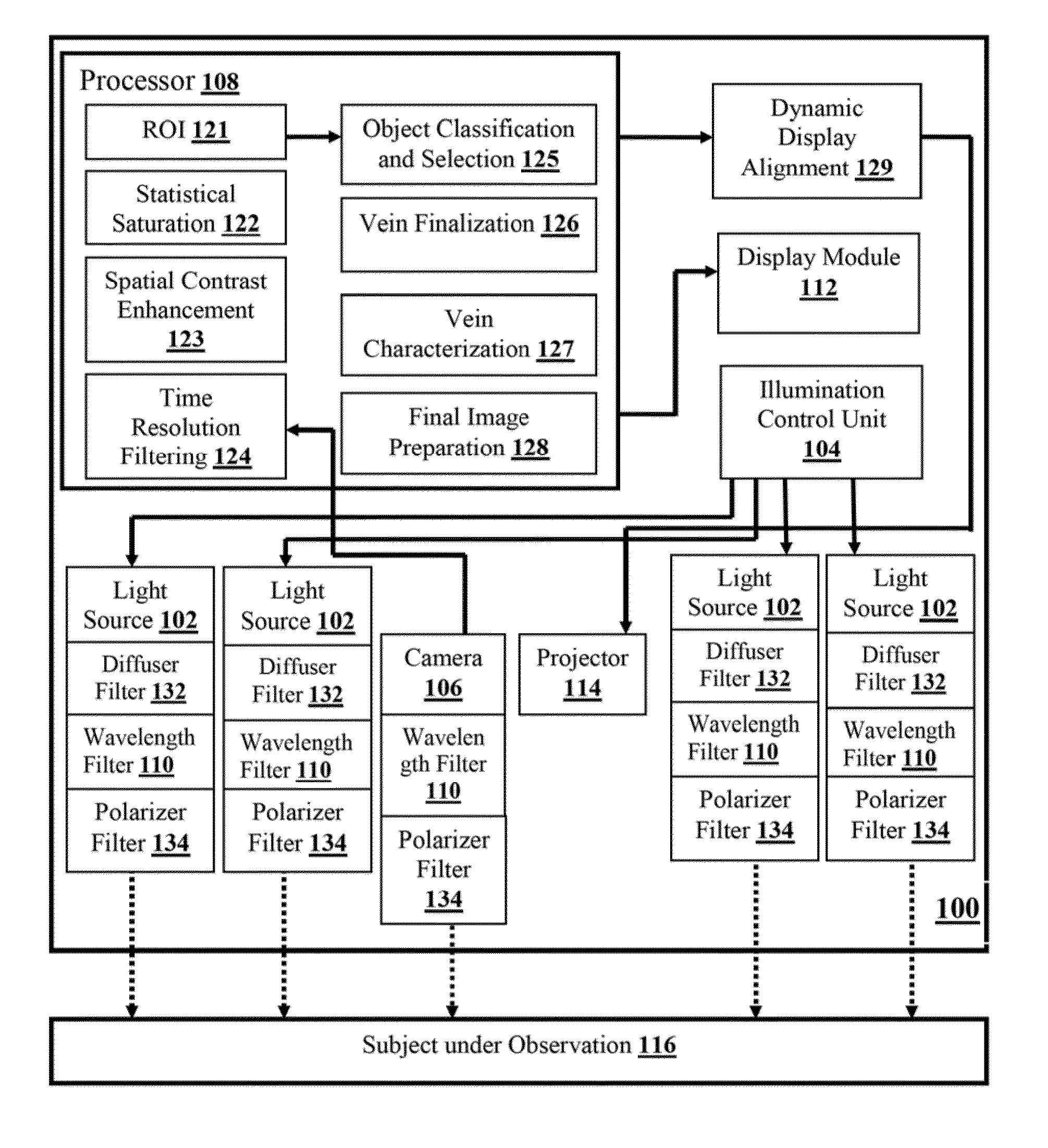

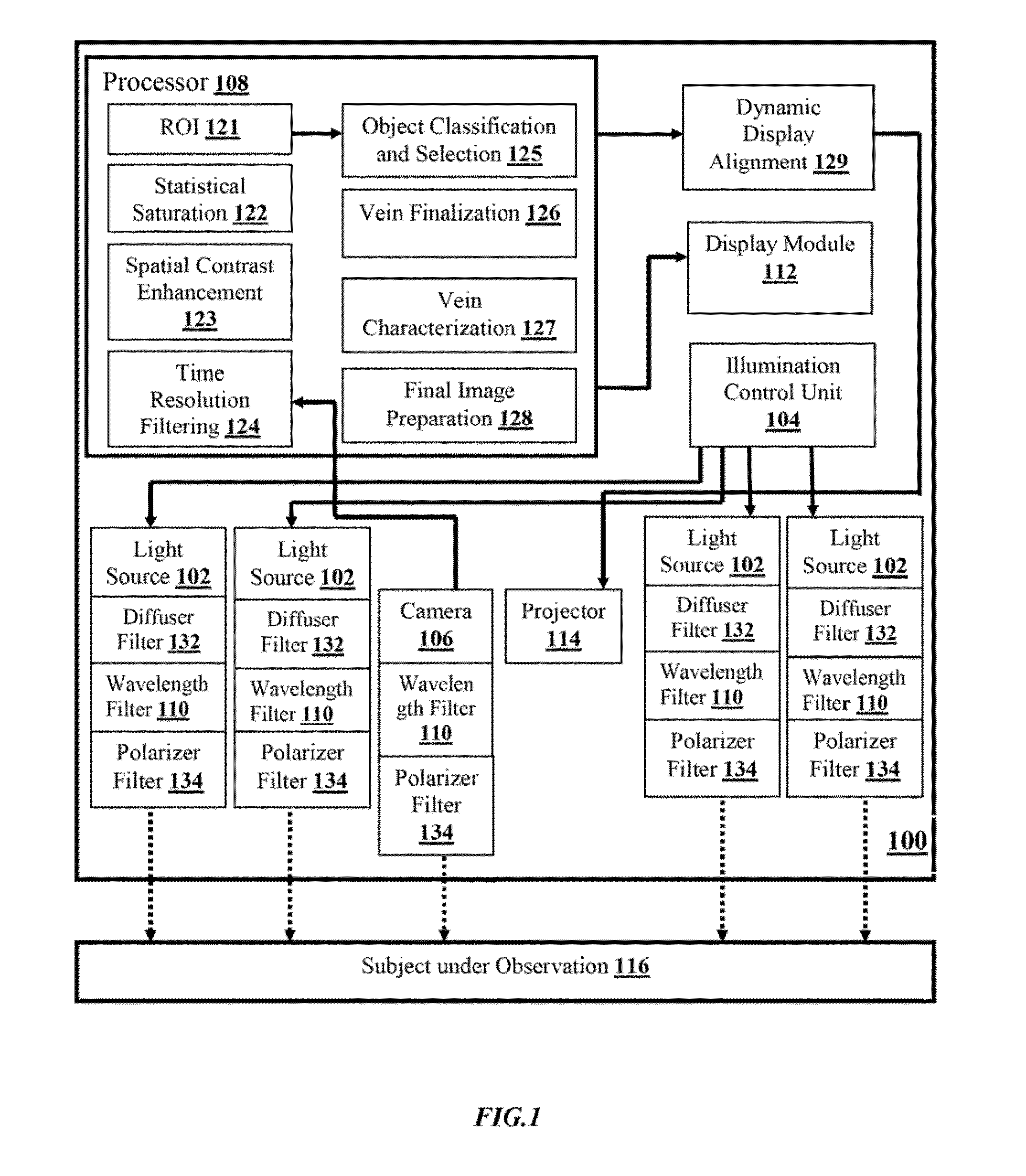

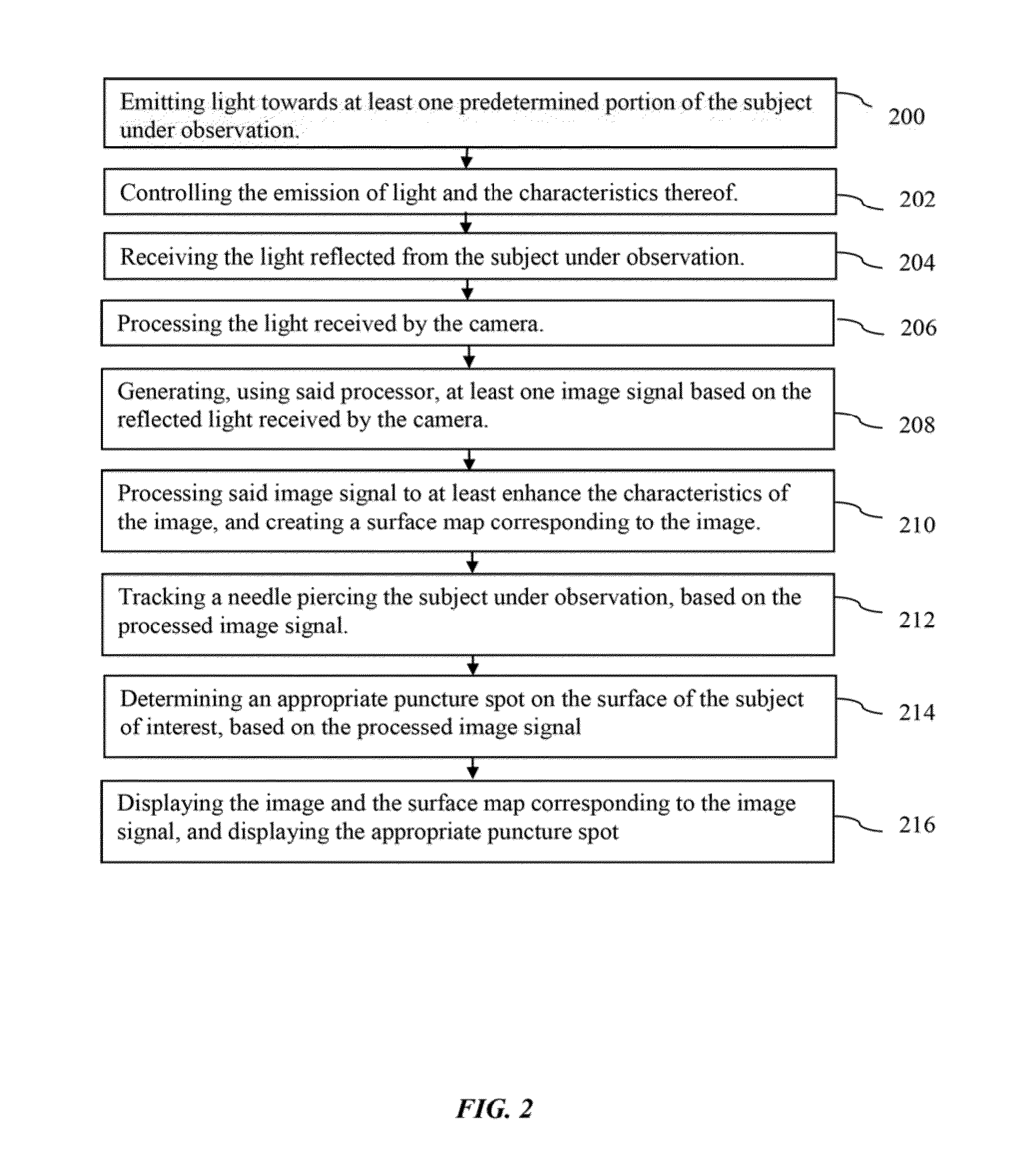

System and method for locating blood vessels and analysing blood

A non-invasive system (100) and method for locating blood vessel and analyzing blood of a subject under observation have been disclosed. The system (100) comprises a processor (108), an imaging module in communication with said processor (108) to capture at least a portion of a subject under observation and a display module (112) in communication with said processor to display said portion of the subject under observation (116). In further embodiments said processor (108) is configured to receive data from said imaging module and to construct a surface map of said portion of said section of said surface under observation (116).

Owner:SAXENA NOOPUR +1

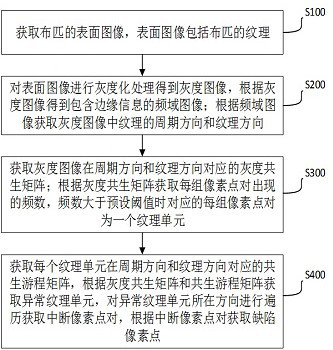

Cloth defect marking method and system based on machine vision

ActiveCN114529549AImprove accuracyImprove detection efficiencyImage enhancementImage analysisMachine visionGray level

The invention relates to the technical field of artificial intelligence, in particular to a cloth defect marking method and system based on machine vision. Obtaining a surface image including the texture of the cloth, obtaining a gray level image corresponding to the surface image, and obtaining a frequency domain image including edge information according to the gray level image; further obtaining the periodic direction and the texture direction of the texture in the gray level image; according to a gray level co-occurrence matrix corresponding to the period direction and the texture direction; selecting each group of corresponding pixel point pairs in the gray level co-occurrence matrix when the occurrence frequency is greater than a preset threshold value as a texture unit; and obtaining a symbiotic run matrix corresponding to each texture unit in the period direction and the texture direction, obtaining an abnormal texture unit according to the gray level co-occurrence matrix and the symbiotic run matrix, obtaining an interruption pixel point pair according to the abnormal texture unit, and obtaining a defect pixel point according to the interruption pixel point pair. Errors caused by noise points of the image are avoided, and efficiency and accuracy of cloth defect detection are improved.

Owner:南通东德纺织科技有限公司

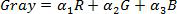

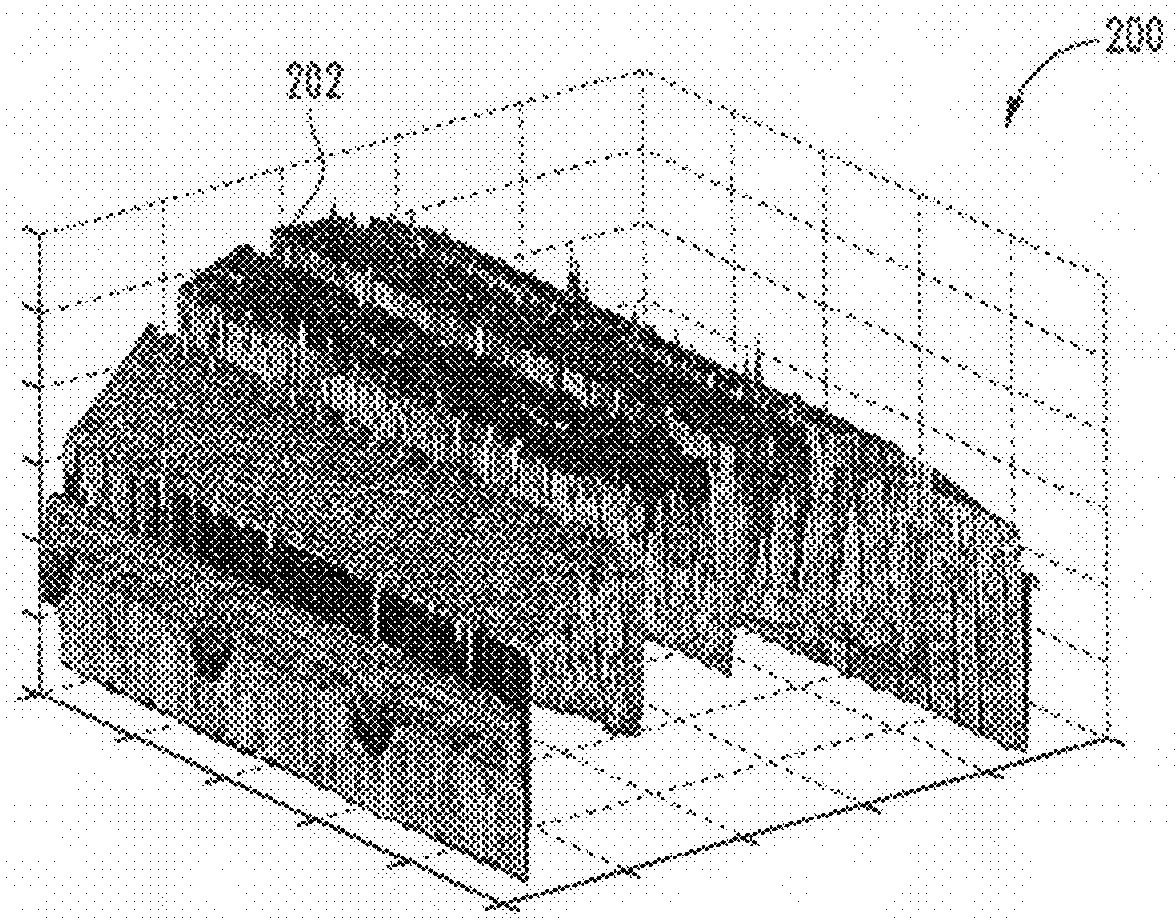

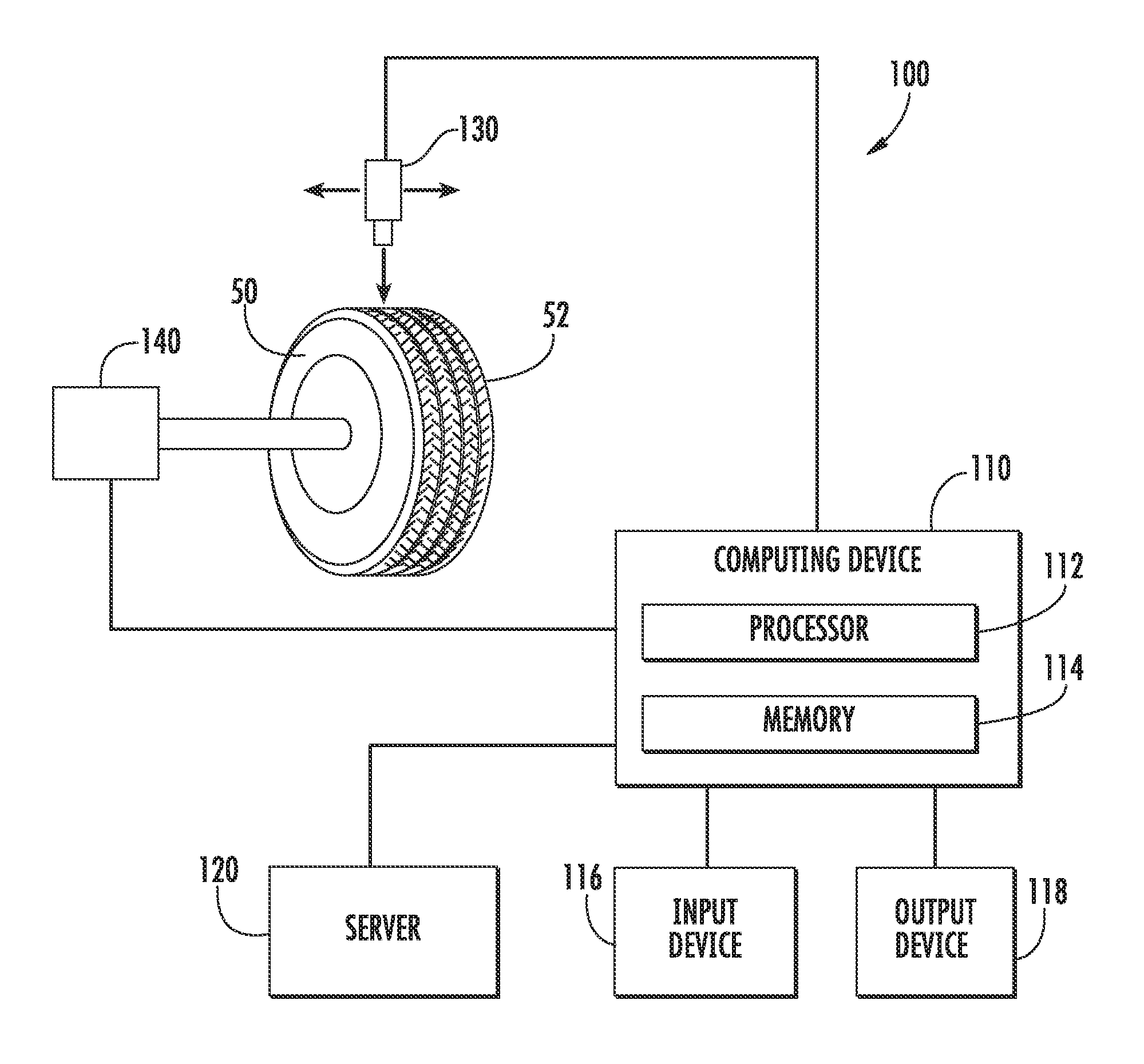

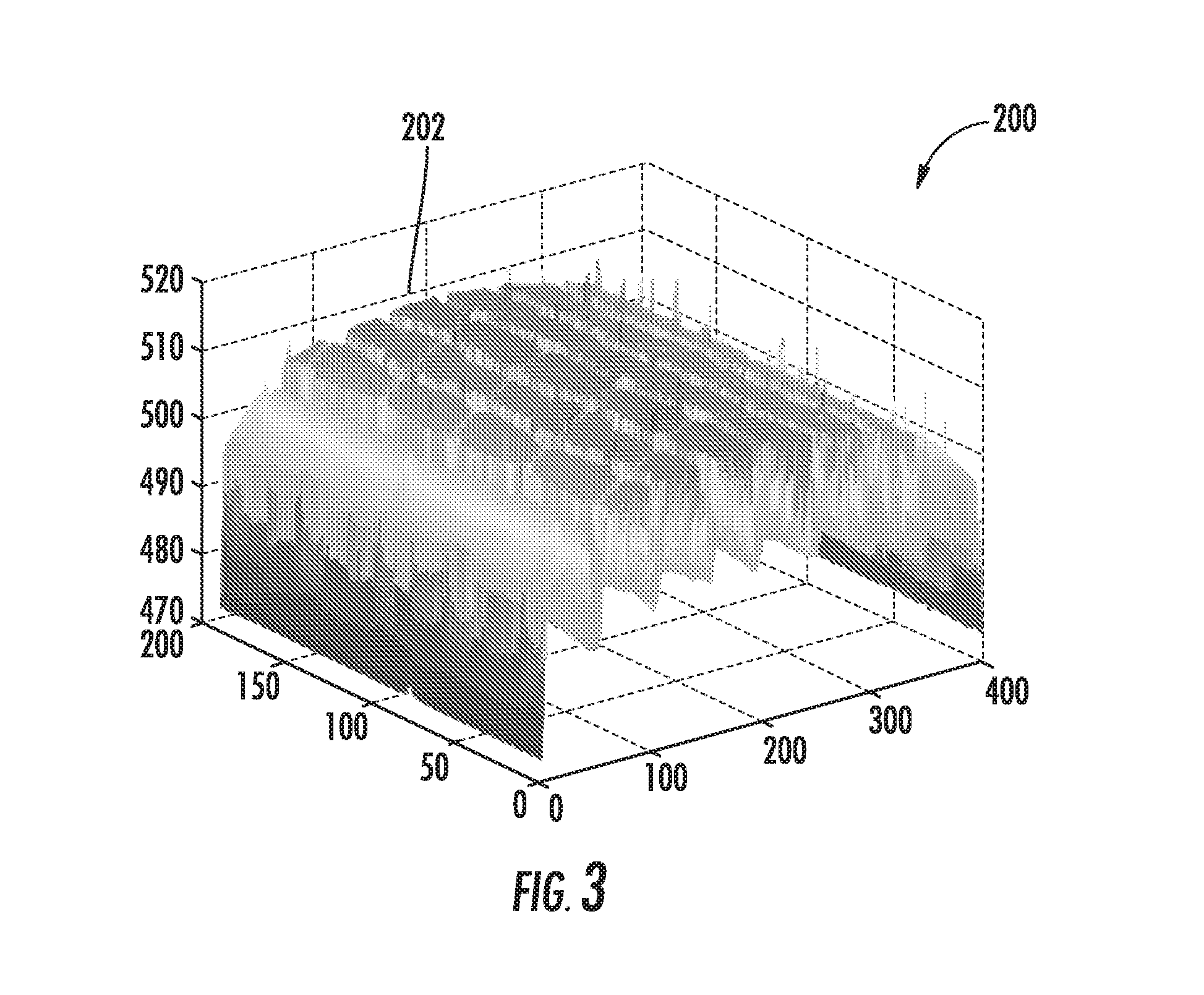

System and method for analyzing tire tread parameters

Systems and methods for analyzing tire tread data to assess tire tread parameters, such as irregular wear characteristics of a tire tread, are provided. More particularly, an automated and robust flattening process c be performed to transform tire tread data, such as a tread surface map, into flattened tire tread data. The flattened tire tread data can provide tread heights defined in a measurement direction that is normal to the surface of the tire tread, as opposed to parallel to a radial axis of the tire. The flattened tread data can be analyzed to assess one or more parameters of the tread of the tire. For instance, local height indicators for the flattened tread data can be determined using a local maximum as a reference. Because the local height indicators are relative heights determined from a local maximum, quantification of tread depth can be more easily obtained.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

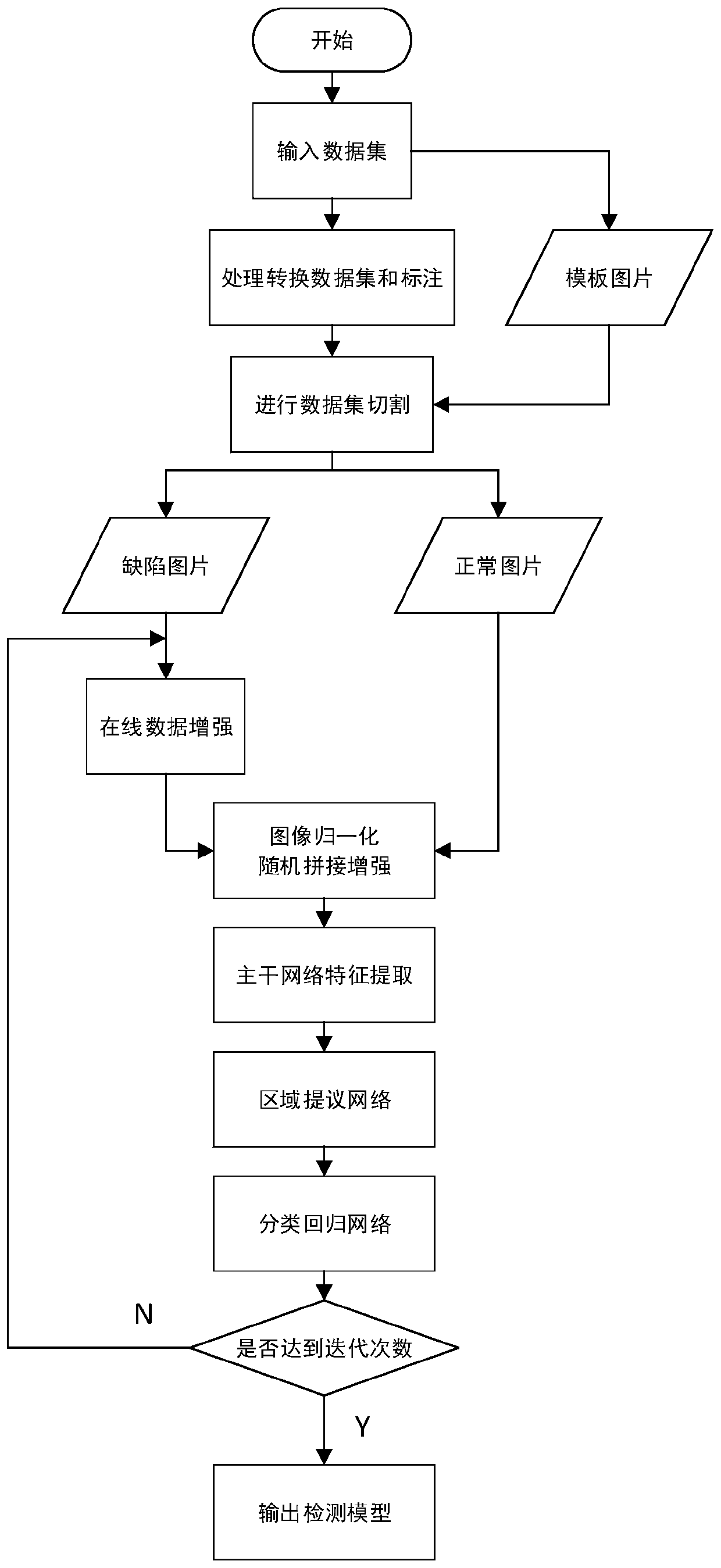

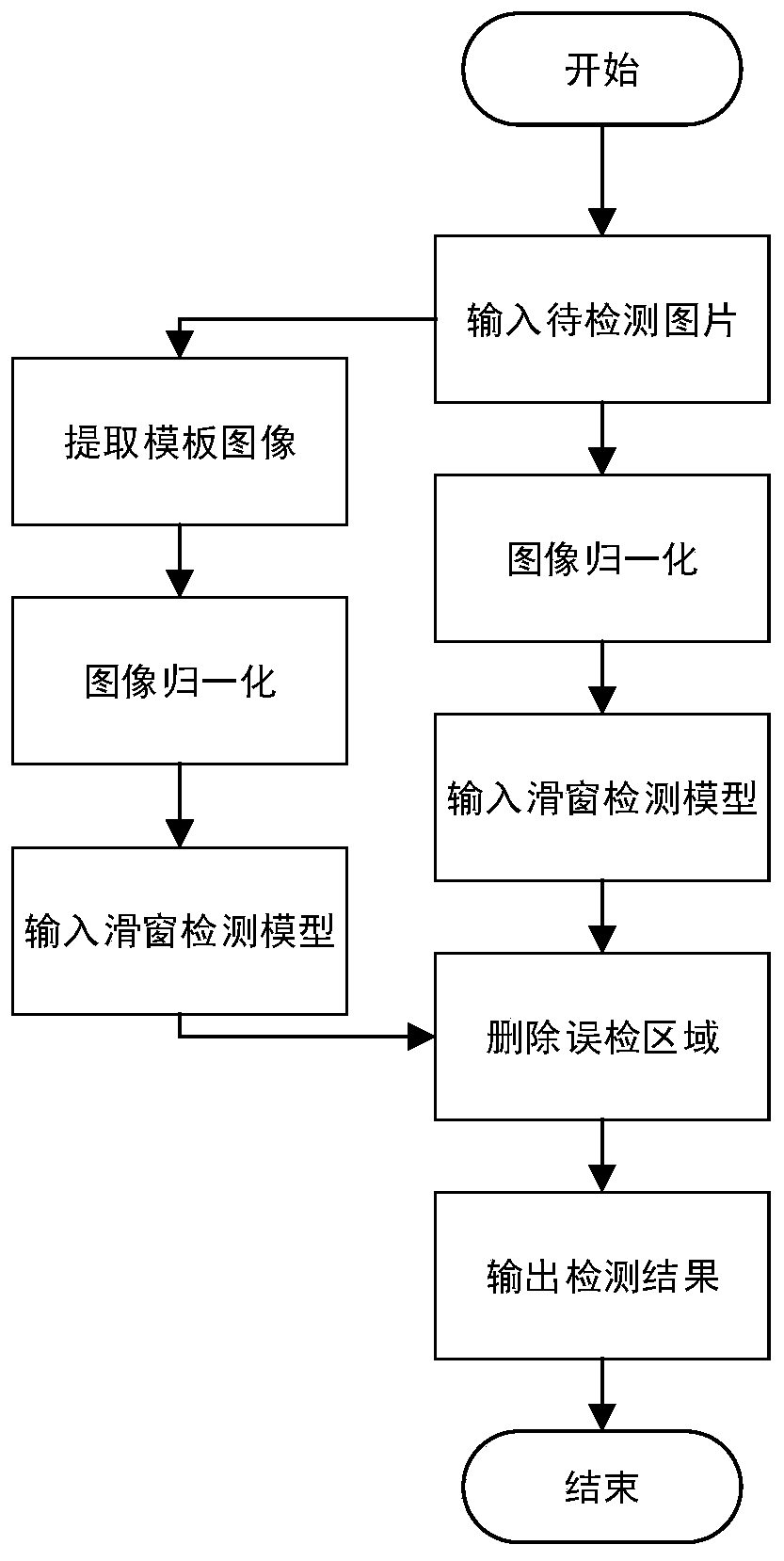

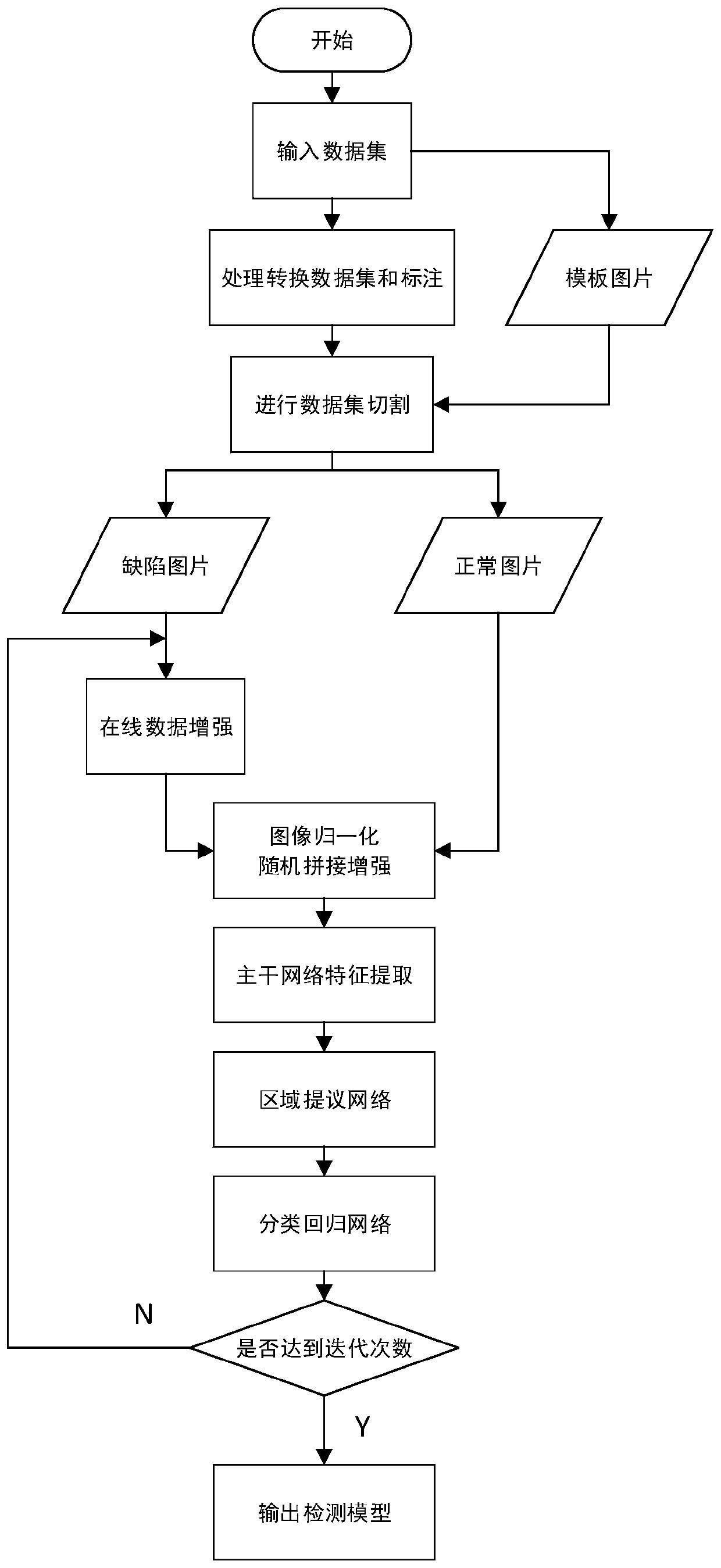

Industrial product surface defect detection method based on sample enhancement

ActiveCN111161243AAvoid quality lossImprove stabilityImage enhancementImage analysisPattern recognitionWindow detection

The invention discloses an industrial product surface defect detection method based on sample enhancement. The method comprises the following steps: 1) carrying out size standardization, normalization, cutting and classification on an industrial product surface image; 2) carrying out data enhancement of random flipping on the picture with the defect; 3) randomly splicing and enhancing the defective picture and the normal picture; 4) carrying out iterative training by using a Cascade-RCNN algorithm; 5) acquiring a Cascade-RCNN detection model; 6) carrying out sliding window detection on the industrial product surface picture to be detected and the texture template picture determining no defect through the Cascade-RCNN detection model, splicing results detected by a sliding window, and comparing the results obtained by the sliding window detection and the texture template picture to finally obtain the defect category and region annotation of the picture to be detected. According to the method, the influence of conditions such as illumination, exposure and displacement on defect detection can be effectively reduced, the detection stability is improved, the resolution capability of thetwo-stage target detector on patterns and backgrounds is improved, and the false detection rate is reduced.

Owner:SOUTH CHINA UNIV OF TECH

Touch and motion detection using surface map, object shadow and a single camera

The present invention provides an optical method and a system for obtaining positional and / or motional information of an object with respect to a reference surface, including detecting if the object touches the reference surface, by using a projector and one camera. A surface map is used for mapping a location on the reference surface and a corresponding location in a camera-captured image having a view of the reference surface. In particular, a camera-observed shadow length, i.e. a length of the object's shadow observable by the camera, estimated by using the surface map, is used to compute the object's height above the reference surface (a Z coordinate). Whether or not the object touches the reference surface is also obtainable. After an XY coordinate is estimated, a 3D coordinate of the object is obtained. By computing a time sequence of 3D coordinates, the motional information, such as velocity and acceleration, is obtainable.

Owner:HONG KONG APPLIED SCI & TECH RES INST

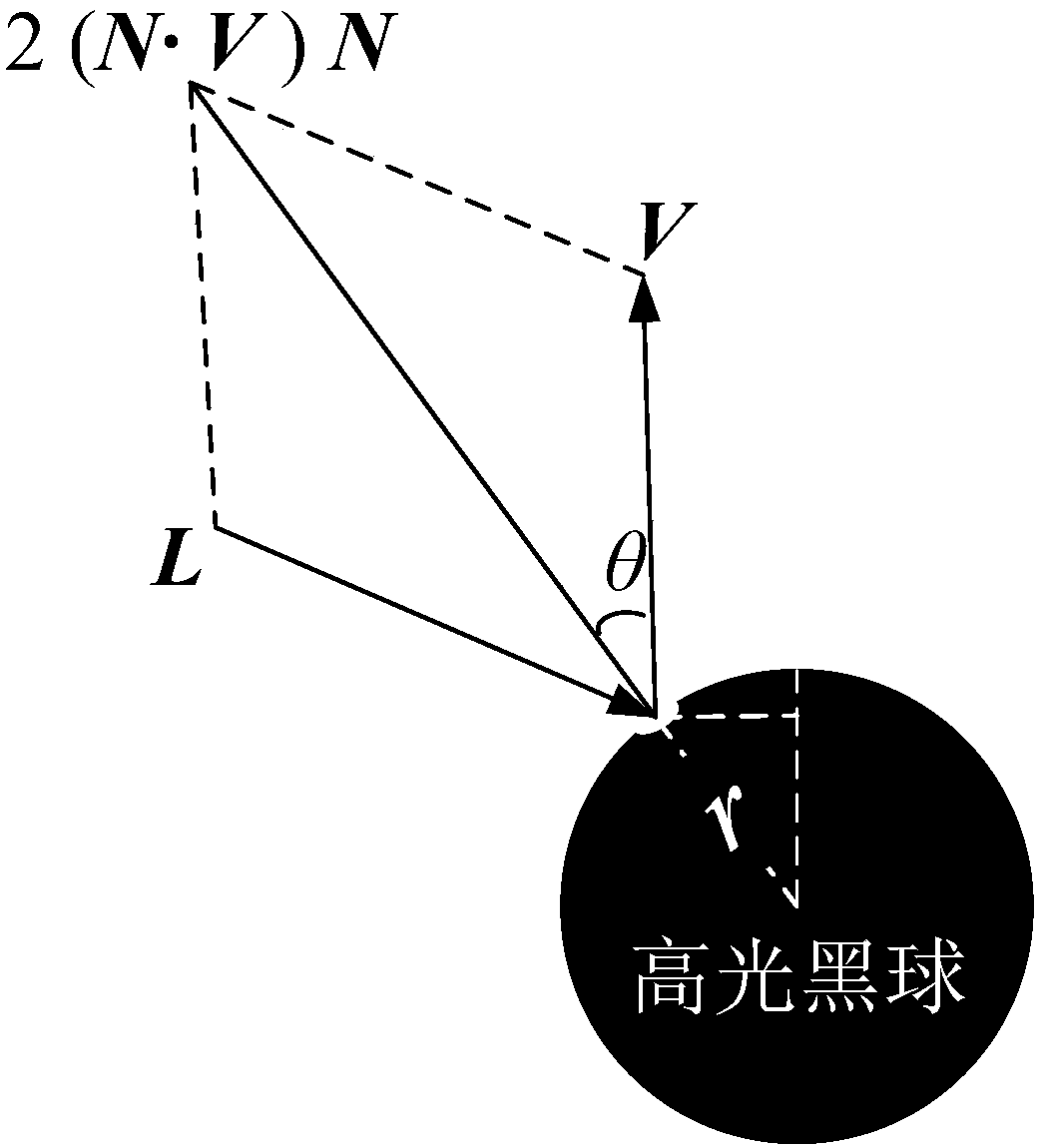

Surface roughness measurement method and device

The invention relates to a surface roughness measurement method and a realization device. The method is characterized by using a high-resolution microscopic camera which is equipped with a long objectdistance microscopic lens to shoot the surface image of a measured object when a single point light source irradiates, wherein after n point light sources are successively lightened, the camera can shoot n surface images I1-In, and the n is greater than or equal to 3; using a high-light black ball to calibrate the direction of the light source and acquiring the unit direction vector L1-Ln of allthe light sources and the transformation ratio coefficient f of a world coordinate (x, y, z) and an image coordinate (u, v); calculating the image coordinate value W(u,v) of a surface depth through the unit direction vector L1-Ln of the light source and the two-dimensional image I1-In of the surface of the measured object; acquiring the world coordinate value Z(x, y) of the surface depth of the measured object through the transformation ratio coefficient f; selecting the appropriate sampling length lr, and sampling the Z(x, y) to acquire a contour curve z(x); using a gaussian filter to filterthe contour curve z(x) so as to obtain a gaussian center line w(x), and separating a roughness profile r(x); and calculating the arithmetic average deviation value of the roughness profile r(x) and taking as the measured value of roughness.

Owner:UNIV OF SCI & TECH BEIJING

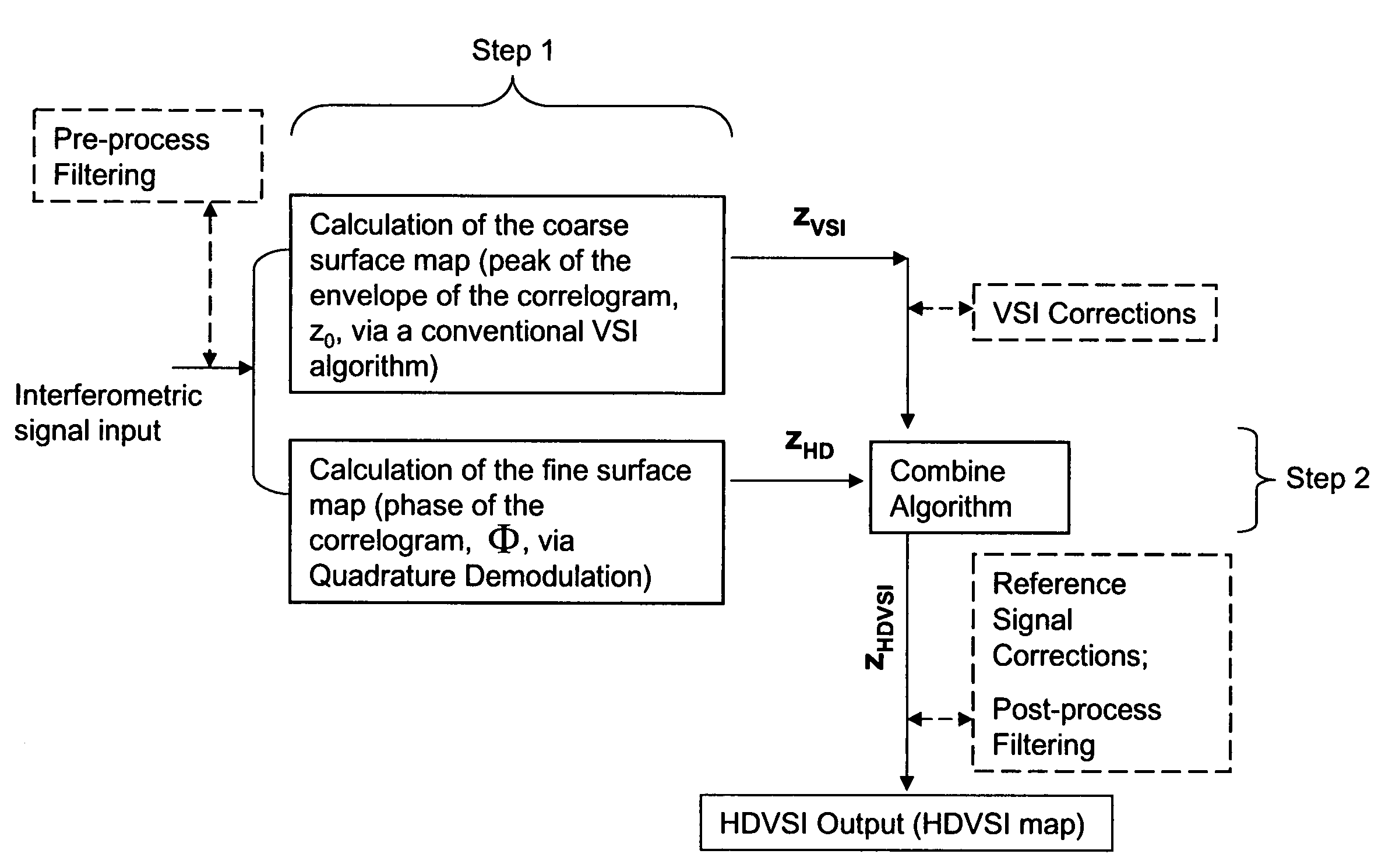

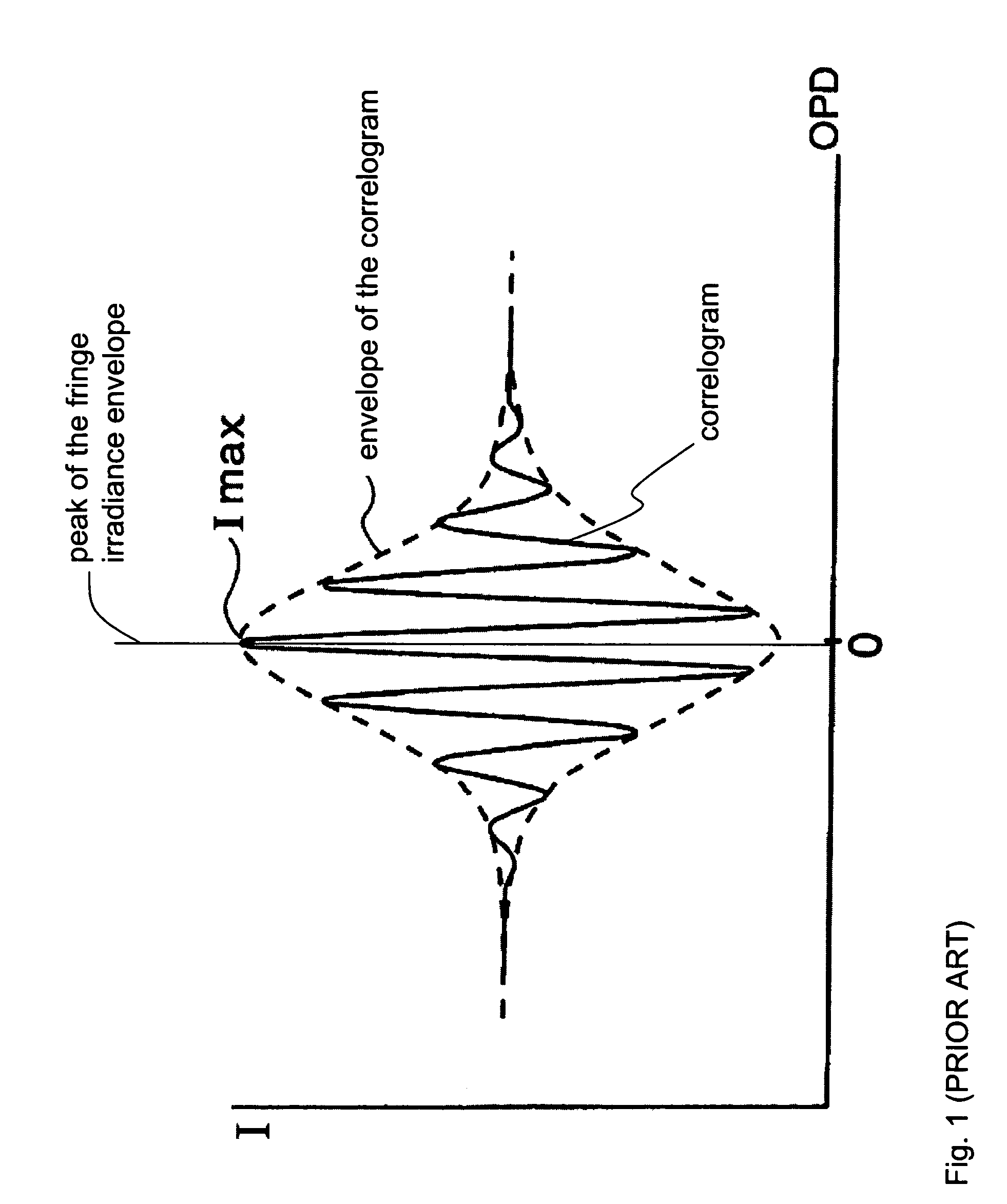

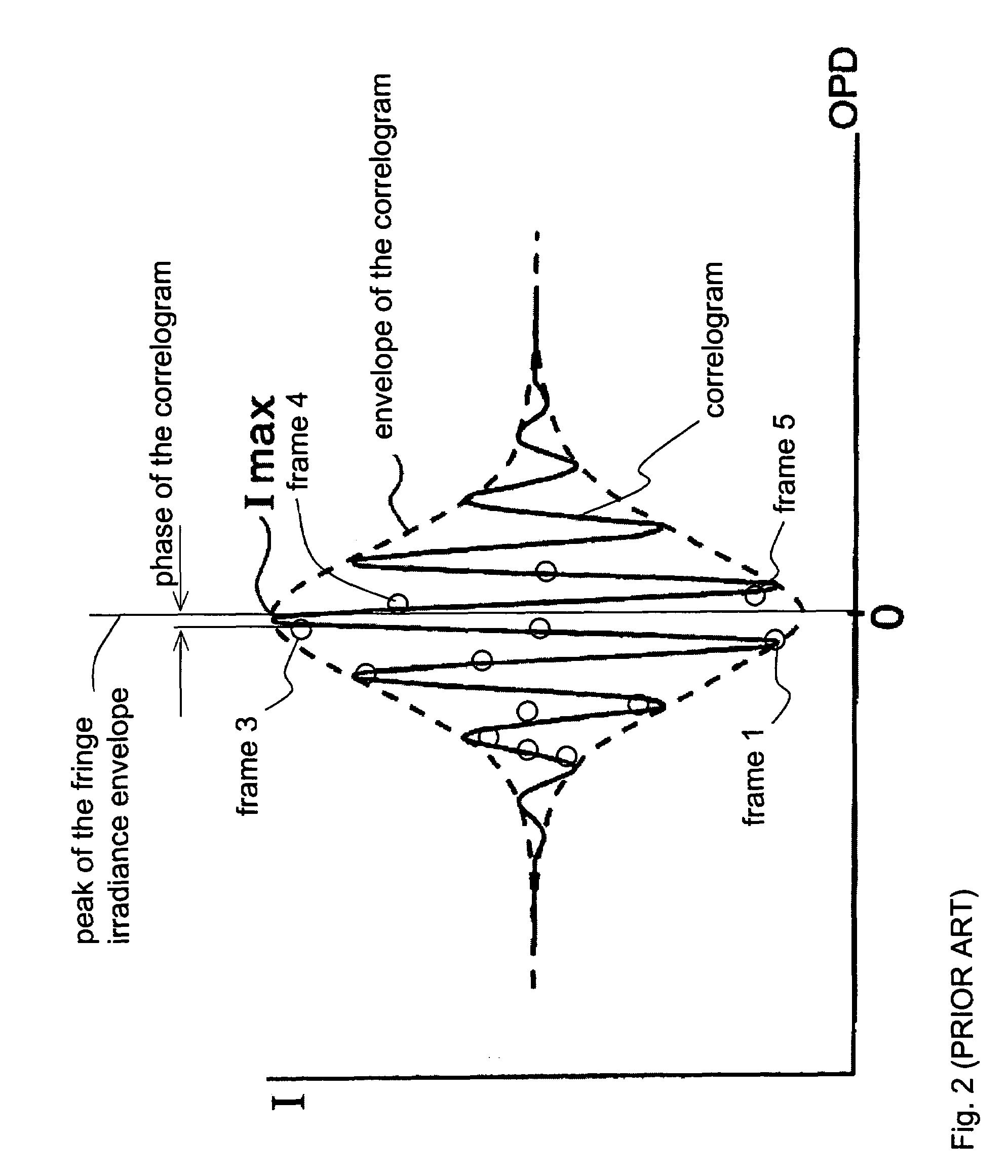

High-definition vertical-scan interferometry

A broadband interferometric vertical scan of a sample surface is performed to produce interference data in conventional manner. A coarse surface profile of the surface is obtained in real time using a conventional technique, such as a center-of-mass calculation. A fine surface map is obtained concurrently using a quadrature-demodulation algorithm applied in real time to the same interference data used for the coarse surface calculation. The fine surface map is then combined with the coarse surface profile using an unwrapping technique that produces a final surface map with sub-nanometer resolution within a large height range.

Owner:BRUKER NANO INC

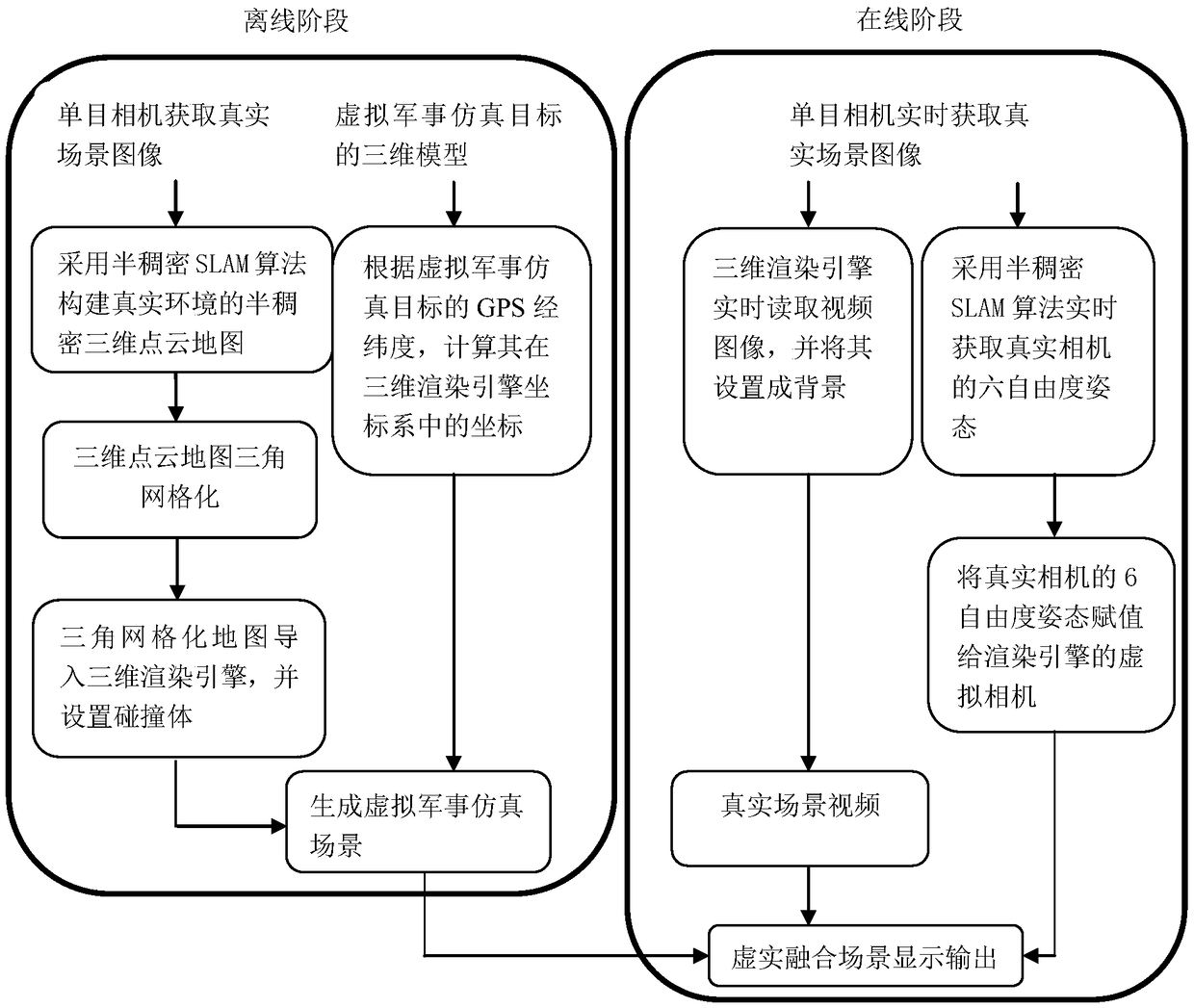

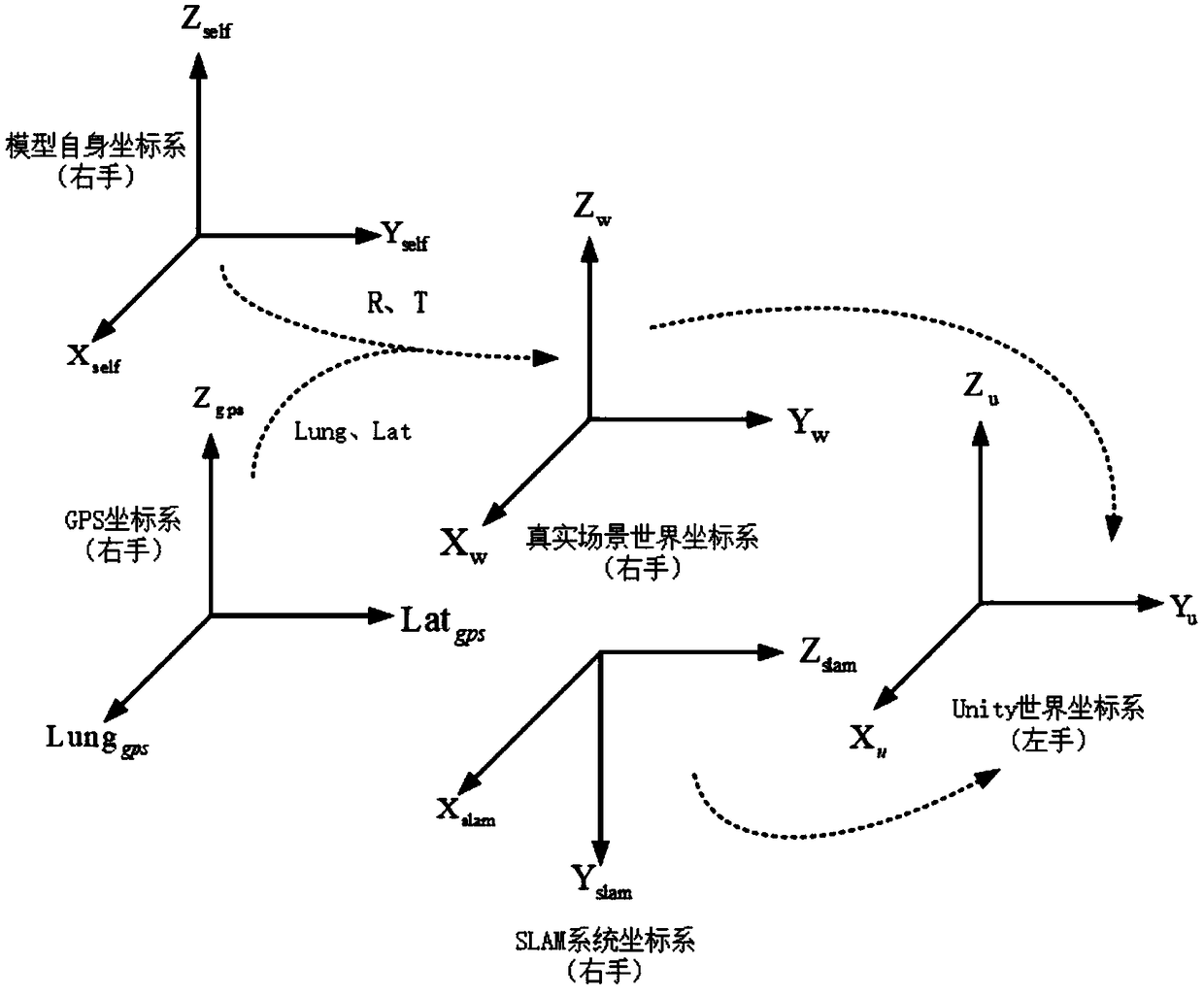

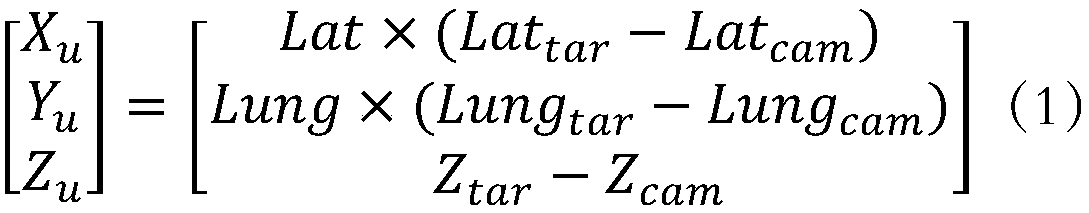

An outdoor augmented reality military simulation training method

InactiveCN109377560ARealize the display effectSolve the simulation problem3D modellingCollision detectionDisplay device

The invention provides a method for generating an augmented reality outdoor military training simulation scene, which comprises the following steps of introducing a triangular surface map model of a real environment into a three-dimensional rendering engine, and arranging a collision body for collision detection; according to the GPS longitude, latitude and elevation information of the given camera and military simulation target, calculating and adding the coordinates of the military simulation target in the world coordinate system of the three-dimensional rendering engine to the three-dimensional rendering scene; reading the video image acquired by the current camera to a three-dimensional rendering engine, and setting the video image as a background; real-timely calculating the camera relative to the real scene of the six-degree-of-freedom pose information, and assigning to the three-dimensional rendering engine of the virtual camera; transmitting the final rendered virtual-real fusion scene picture with the display on the same screen to complete the rendering and displaying of the virtual-real fusion scene to the display device. The method of the invention can realize the fusiondisplay and real-time interaction of the virtual military target and the real scene, and effectively solves the simulation degree problem in the military training simulation field.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

System and Method for Analyzing Tire Tread Parameters

Systems and methods for analyzing tread surface data to assess tire tread parameters, such as irregular wear characteristics of a tire tread, are provided. For example, tread surface data, such as a tread surface map, can be processed to generate a convex hull for the tire. The convex hull can approximate the convex outer surface of the tire. The convex hull can be used as a reference for analyzing the tread surface data. In particular, irregular wear zones in the tire tread can be mathematically concave relative to the convex hull. Comparing the tread surface data to the convex hull can reveal information indicative of irregular wear characteristics of the tire. For instance, the local depth of the measured tread surface data relative to the convex hull can provide a quantitative measure of irregular wear characteristics of the tire.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

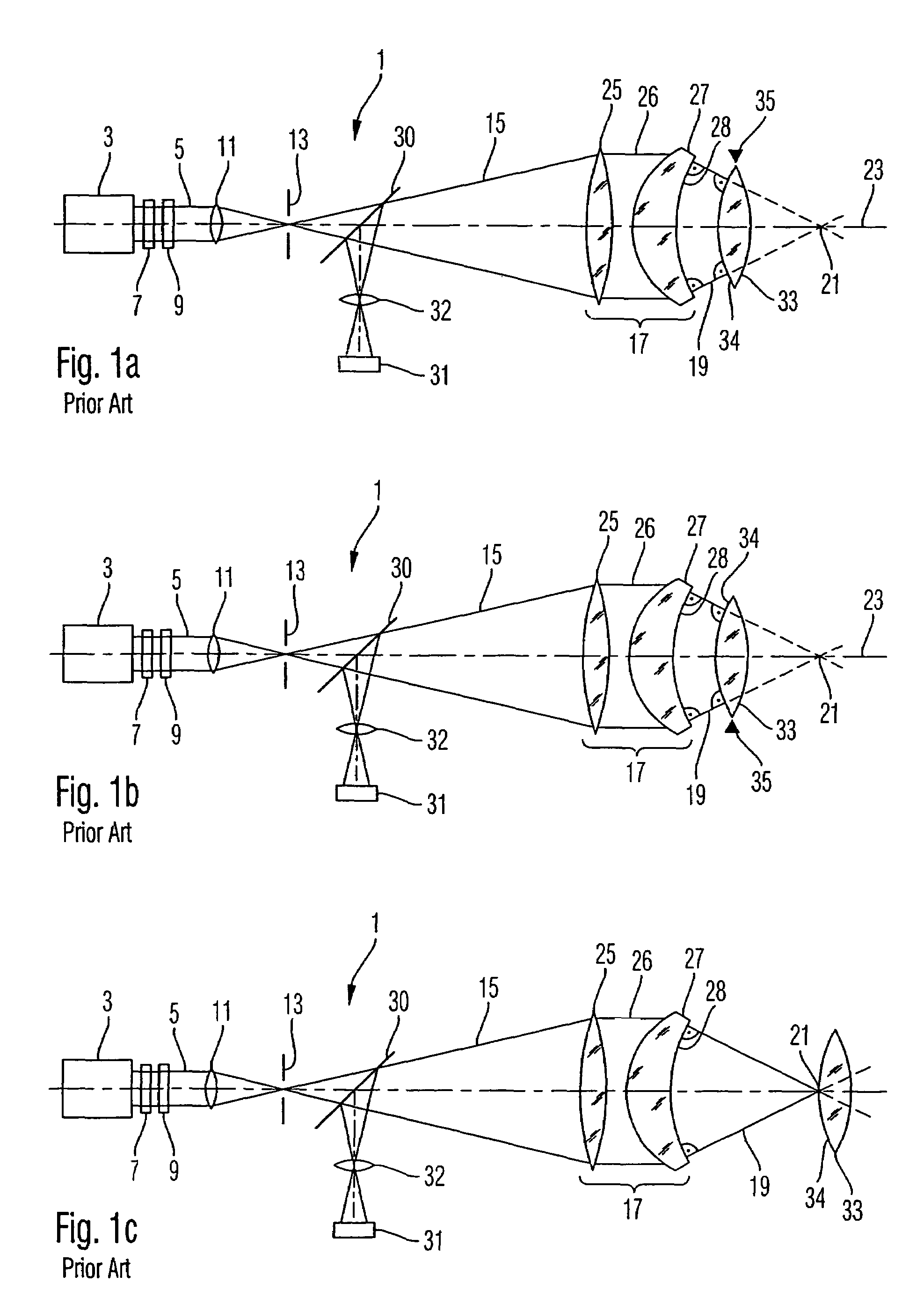

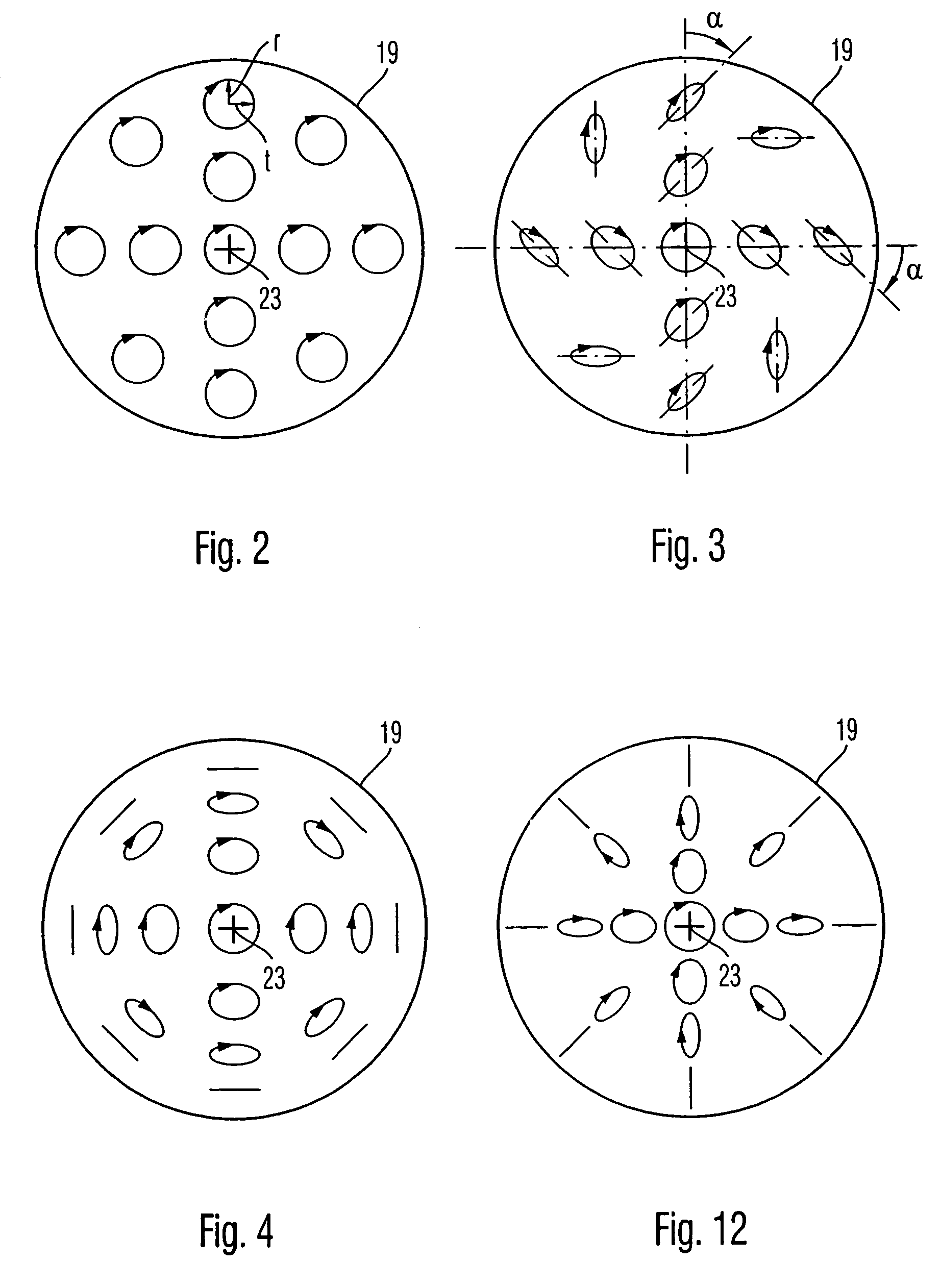

Interferometer apparatus and method of processing a substrate having an optical surface

InactiveUS7289222B1Easy to measureEasy to manufactureInterferometersUsing optical meansOptical axisLight beam

A method of processing a substrate having an optical surface includes using an interferometer which includes optics for providing a beam of measuring light. The optics polarize the beam of measuring light such that a tangential polarization component continuously increases relative to a radial polarization component with increasing distance from an optical axis. The substrate is positioned in the beam of measuring light. Using the system, the interferometer determines a surface map of the optical surface, and determines deviations of the optical surface from a target shape.

Owner:CARL ZEISS SMT GMBH

Rock geometry-mechanics parameter acquisition method and holographic scanning system

ActiveCN111398273AImprove efficiencyImprove automationAnalysing solids using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationDot matrixEngineering

The invention discloses a rock geometric-mechanical parameter holographic scanning system and acquisition method. The system comprises an observation mechanism, a multi-scale penetration sounding mechanism, a grinding mechanism and a rock sample mounting mechanism which are arranged on a three-axis precision motion platform, and an industrial personal computer for controlling the operation mode ofeach mechanism of the platform. In addition, the parameter acquisition method comprises the following steps: sequentially carrying out surface image acquisition, indentation / or rotary-cut penetrationsounding test, pulse echo signal acquisition, surface three-dimensional morphology reconstruction, layer-by-layer polishing and repeated test on a rock sample; carrying out spatial interpolation on the obtained geometric and mechanical three-dimensional parameter dot matrixes formed by accumulating multiple layers of single-layer rock parameters to obtain geometric parameters and parameters of acorresponding mechanical field. According to the scanning system and method, the real space distribution and the corresponding mechanical parameter field of each medium in the rock sample can be obtained, and a more scientific method is provided for analyzing the mechanical property, damage and instability of the rock by combining with a high-performance numerical calculation method.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com