Industrial product surface defect detection method based on sample enhancement

An industrial product and defect detection technology, which is applied in image enhancement, image data processing, instruments, etc., can solve the problems that normal images cannot participate in model training, it is difficult to distinguish defects and background textures, and the demand for image memory is large, so as to improve the overall recognition Accuracy, increasing the amount of training data, and ensuring the effect of uniformity and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific examples.

[0040] The example uses the real collection of patterned textile picture data, including 15 kinds of defects such as staining, seam head, seam head mark, hole, etc. There are 68 kinds of pattern templates, including one template picture for each type, several normal pictures and Defect pictures with annotations, the size of which varies from 4096*1810 to 4096*1696.

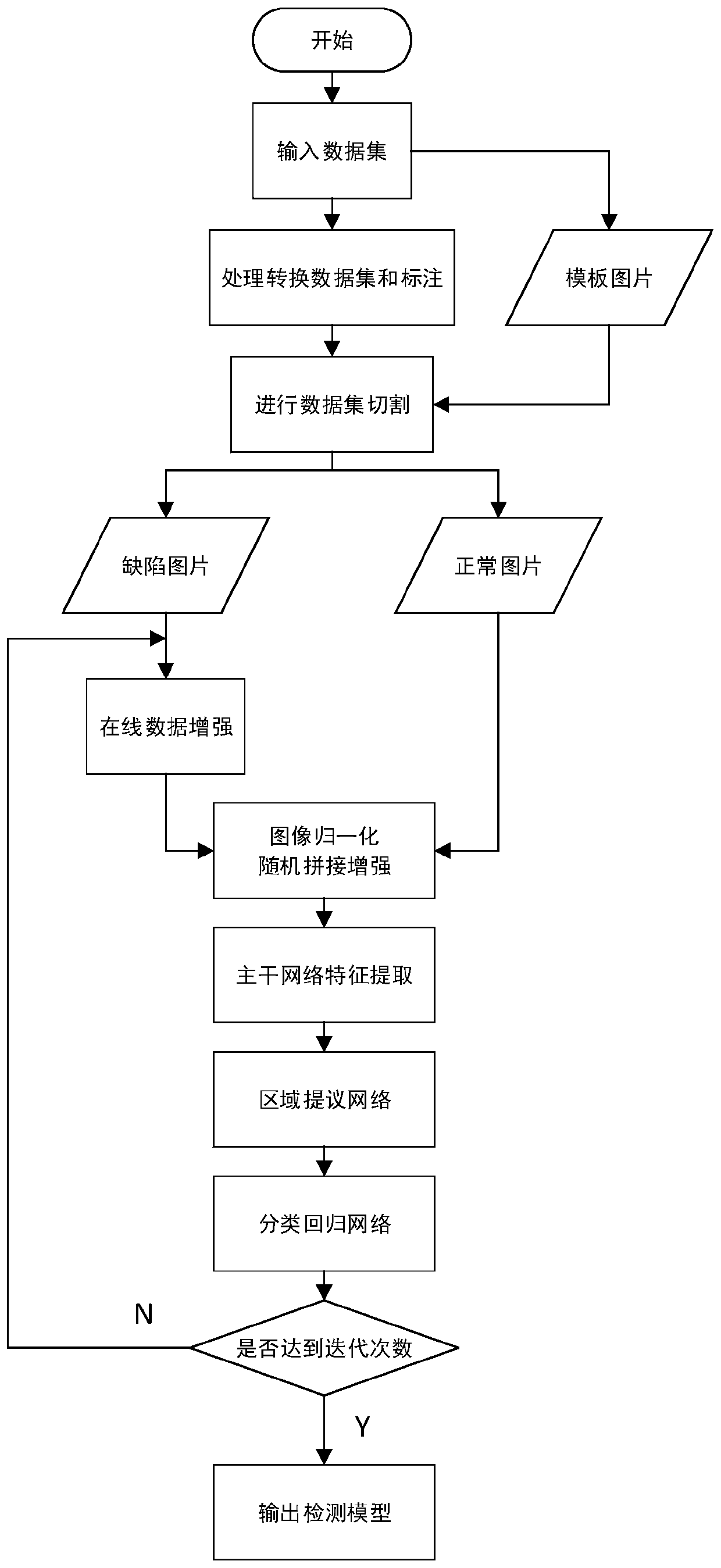

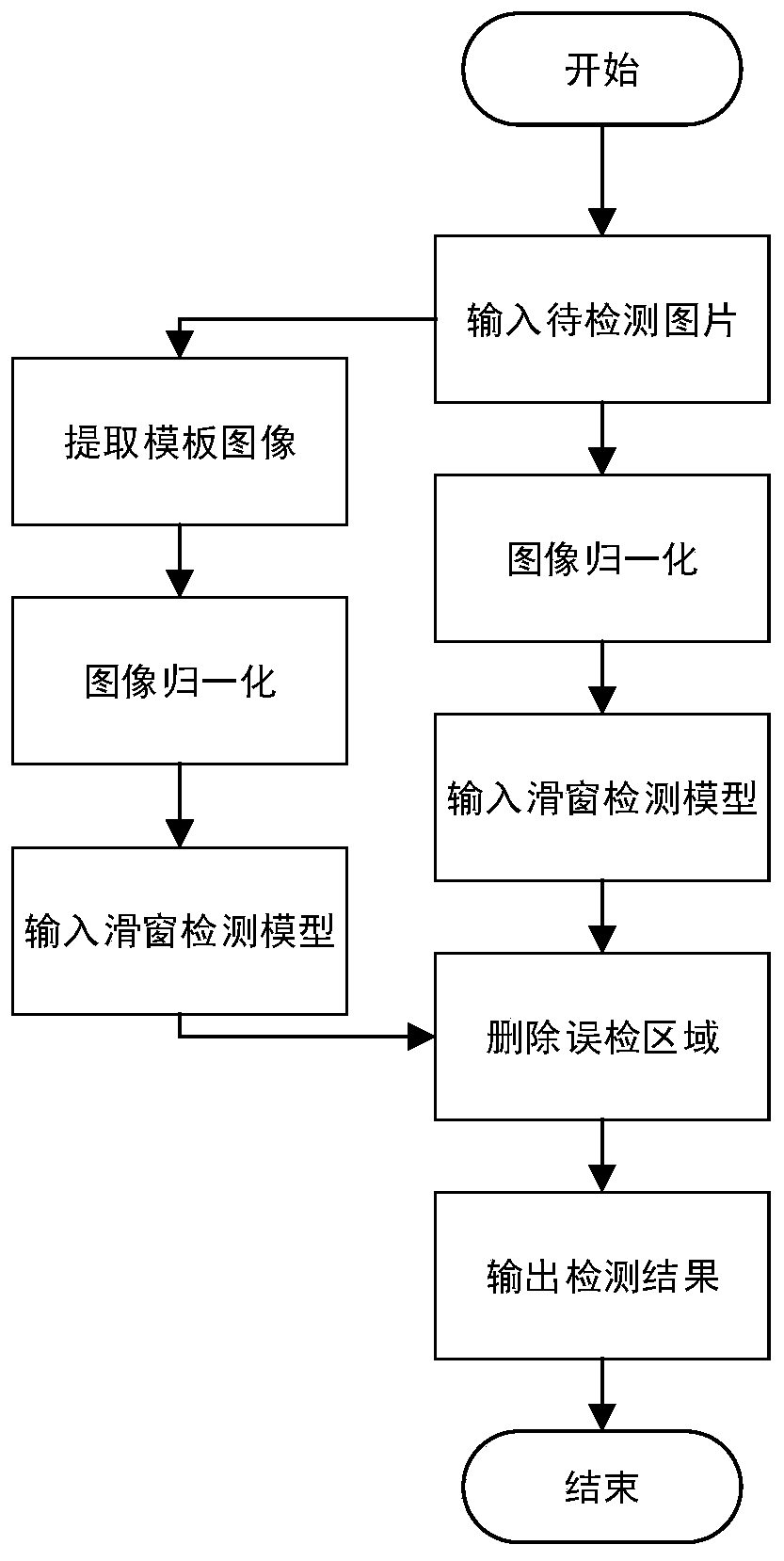

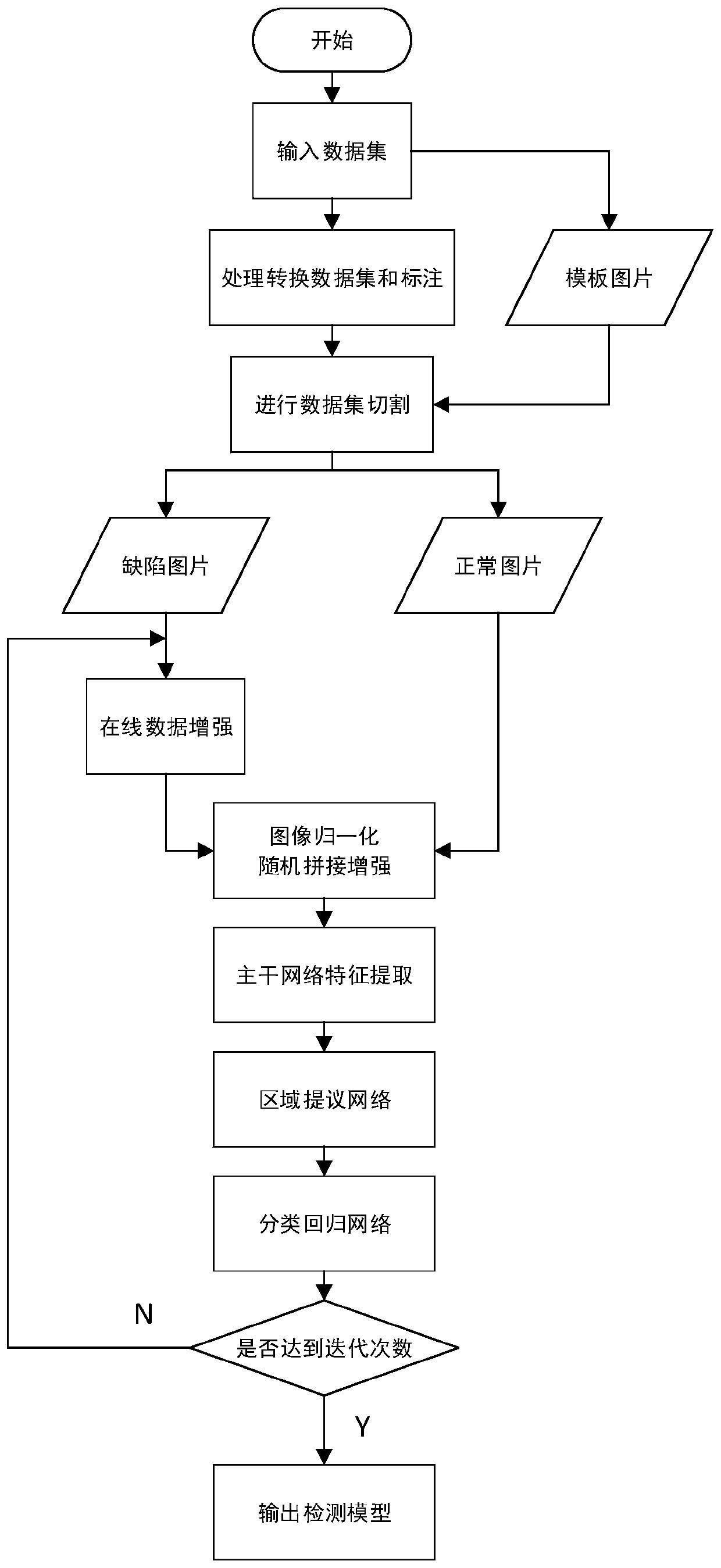

[0041] Such as figure 1 with figure 2 As shown, the method for detecting surface defects of industrial products based on sample enhancement provided in this embodiment includes the following steps:

[0042] 1) Standardize the size of the patterned textile picture set, in which the pictures containing defects have corresponding defect labeling files, perform cutting operations on the defect pictures and the corresponding defect labels of each picture, and divide them into normal pictures according to the labels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com