Curved surface defect automatic detection method and apparatus thereof

A technology for automatic detection and defect detection, applied in the field of image processing and deep learning research, it can solve problems such as accurate positioning of defects, loss of useful image information, and inability to achieve online detection, to prevent overfitting and achieve high-definition , the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

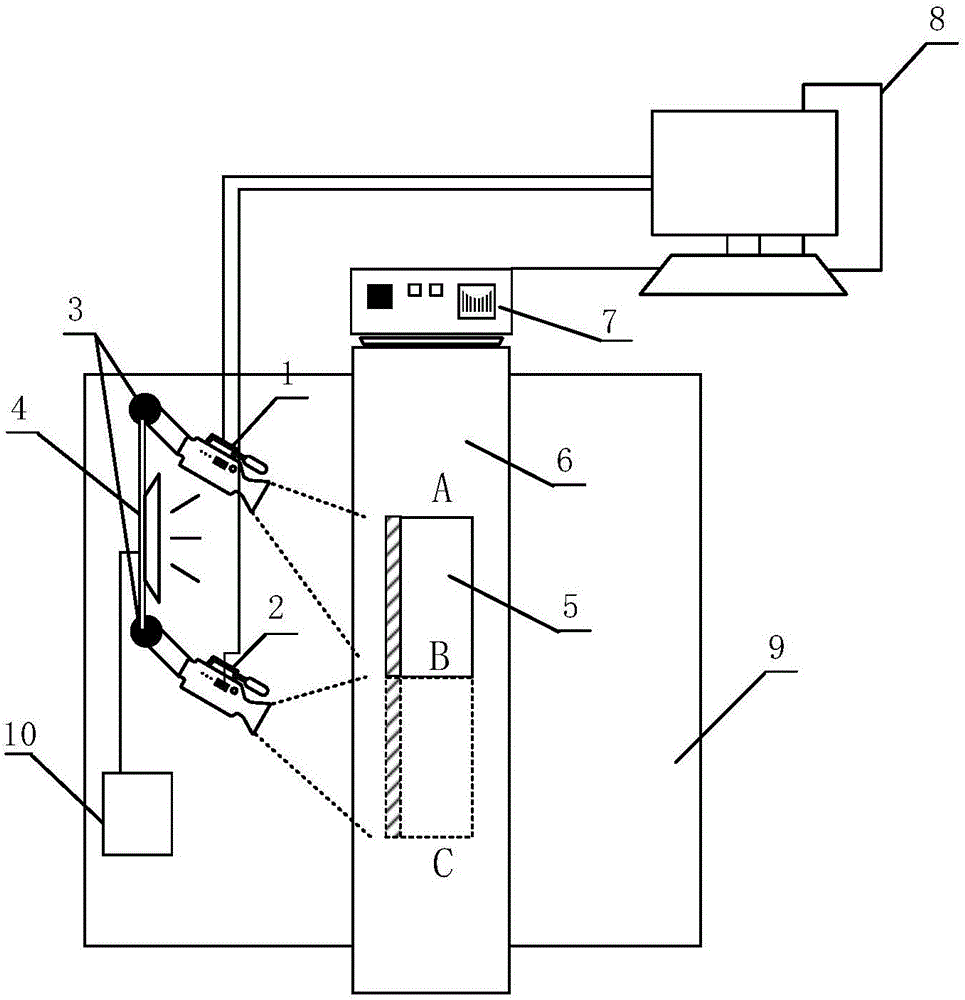

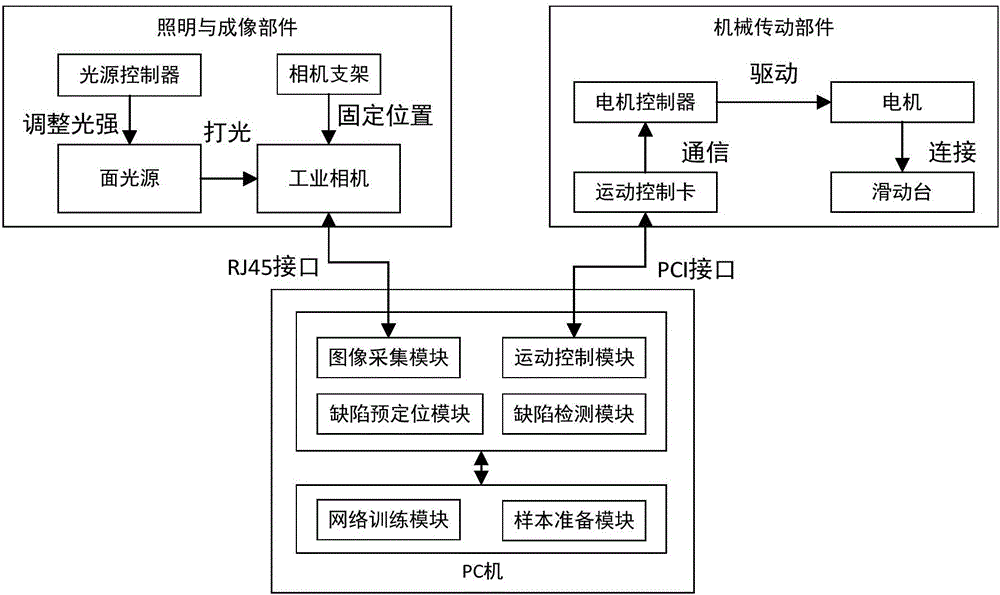

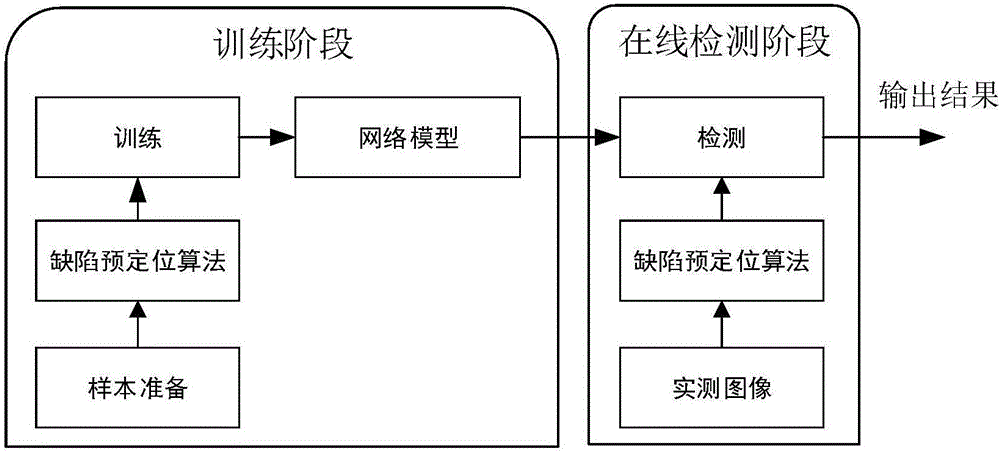

[0052] Such as figure 1 As shown, this embodiment is an automatic detection device for curved surface defects, including two industrial cameras with micro-focus lenses, two three-degree-of-freedom camera brackets, two light sources, a sliding table, a base plate and a motor. Wherein the three-degree-of-freedom camera bracket 3 and the sliding table 6 are fixed on the base plate base 9, and the motor 7 is fixedly connected with the sliding table 6 through a shaft coupling. The workpiece 5 is horizontally placed on the slide table 6. When the workpiece 5 is at the AB position, the image is collected by the industrial camera 1 fixed on the camera bracket 3. When the workpiece 5 moves to the BC position, the image is collected by the industrial camera 2, with The surface light source 4 of the light source controller 10 provides illumination for the camera. The industrial cameras 1 and 2 are connected to the PC (host computer) through the RJ45 network interface, and the motor 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com