Automatic detection method and device for magnetic tile surface defect based on machine vision

A machine vision and automatic detection technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems such as the detection method has not made substantial progress, the chamfering is unqualified, and the modern production operation cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

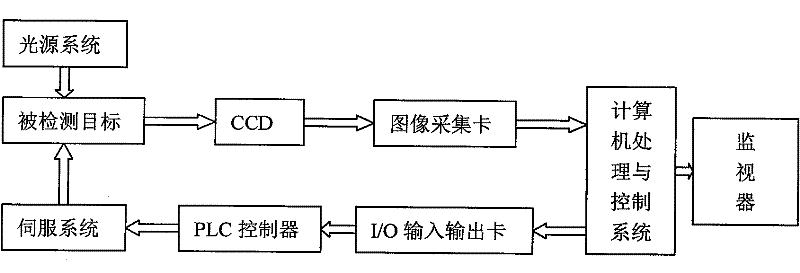

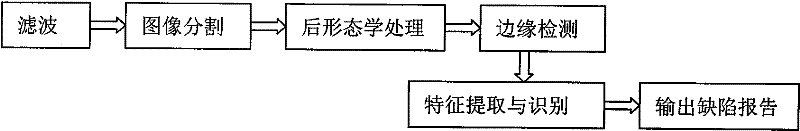

[0014] The numbers collected by the CCD image acquisition card are stored as image files in the form of a two-dimensional matrix, and then the image processing unit uses an adaptive median filter algorithm combining median and average values to filter the collected images, mainly to filter out impulse noise and Gaussian noise, the filtered image is then segmented and binarized based on the bimodal characteristic threshold of the gray histogram. On the basis of binarization, 2×3 rectangular structural elements are selected for mathematical morphology corrosion operations, and then via Roberts operator Edge detection obtains clear defect edge contours and defect areas, and the area features are obtained through pixel-based area feature calibration. The feature data is input into the pattern recognition unit trained by the Harr-like pattern recognition algorithm, and good magnetic tiles and defective magnetic tiles are obtained. Two classifications, and finally output defect d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com