Pipeline defect phonon diagnostic system and realization method

A diagnostic system and phonon technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as difficult defect detection, economic loss, and inability to monitor material defects in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

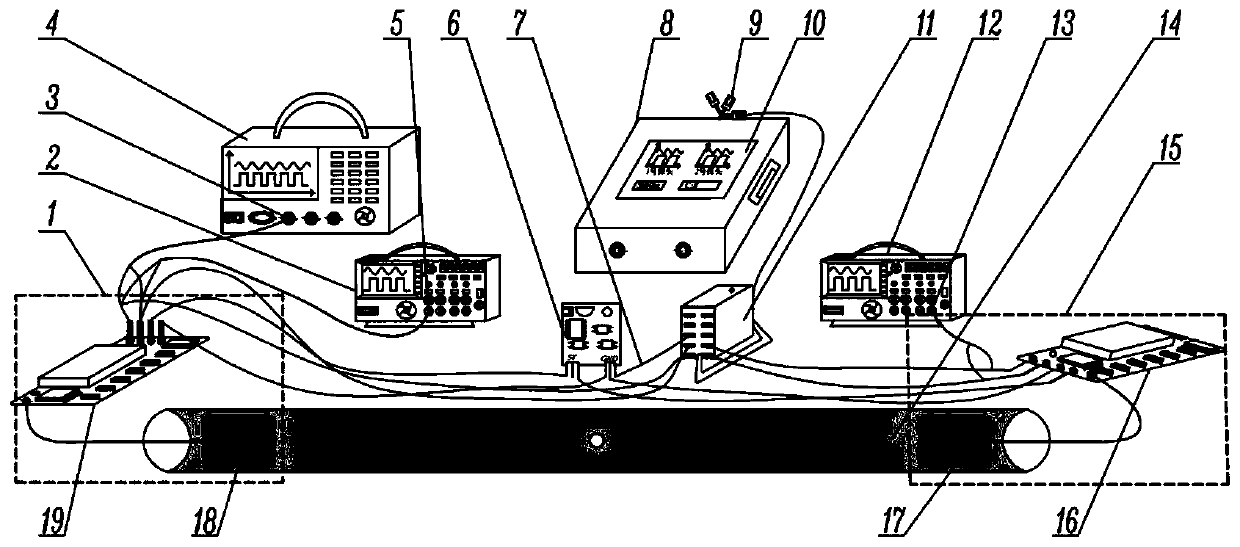

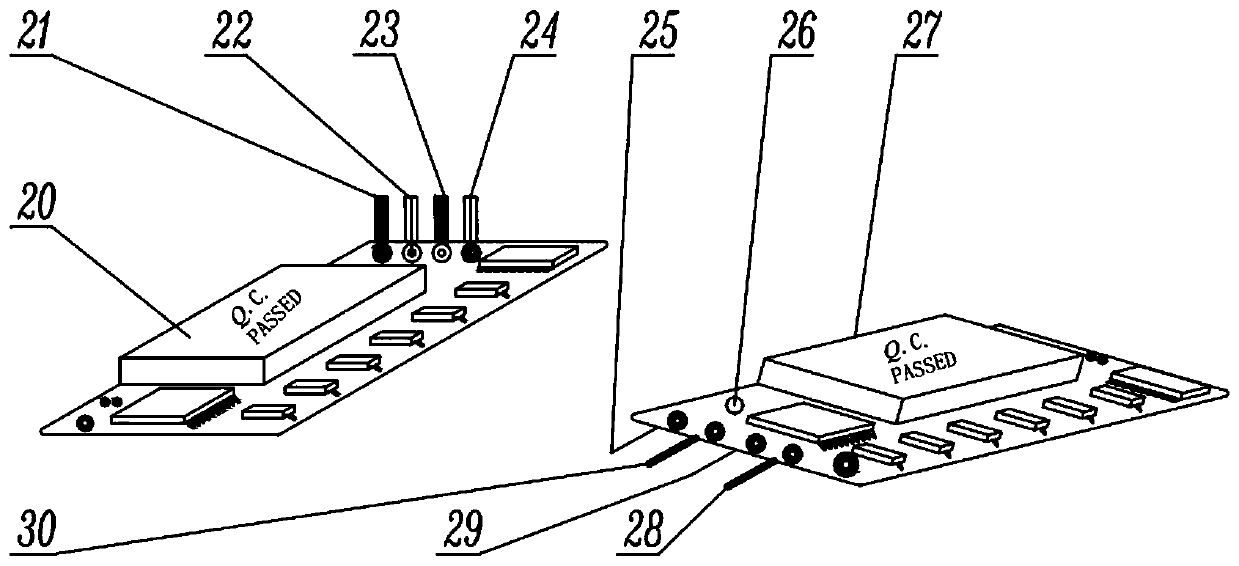

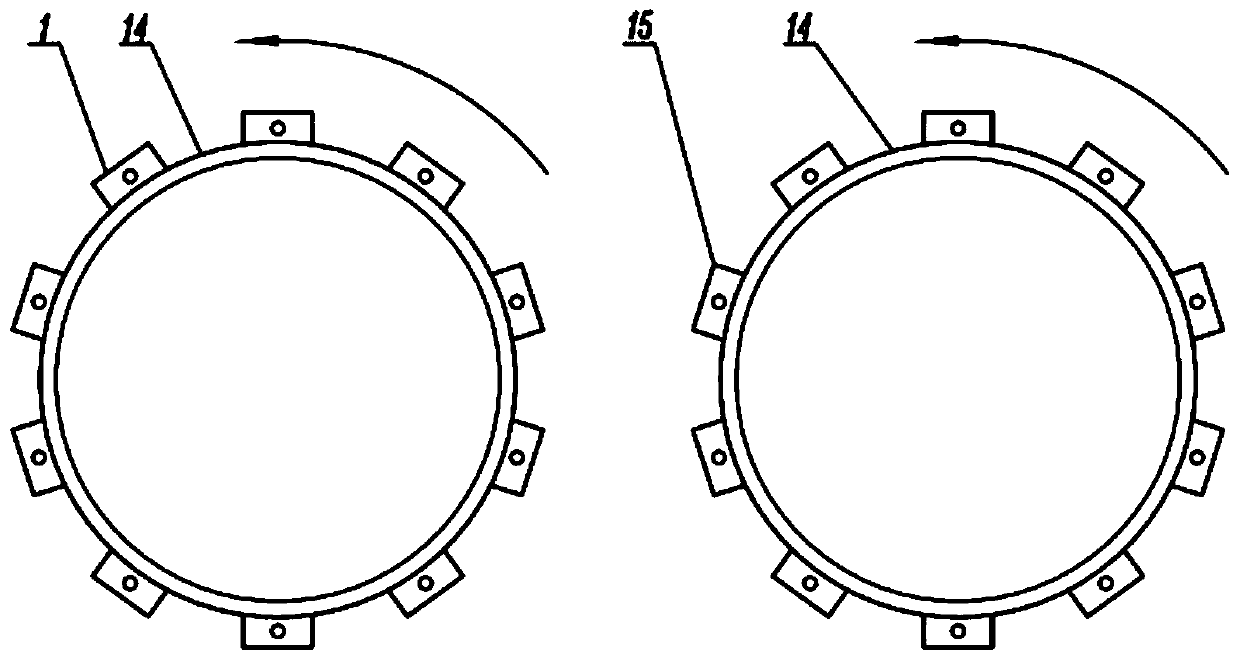

[0072] The application possibilities of the digital phonon diagnostic detection system will be disclosed using the following examples. Such as figure 1 As shown, the described experimental device system includes: phonon emission module 1, oscilloscope 2, signal generator 4, power supply board 6, data signal line 7, industrial computer 8, USB interface 9, liquid crystal display 10, acquisition card 11 , an oscilloscope 12, a 3m steel pipeline 14, a phonon receiving module 15, a phonon receiving probe 16, a phonon signal receiving end 17, a phonon signal transmitting end 18, and a phonon emitting probe 19.

[0073] In order to detect a 3m buried steel pipeline with a small hole in the middle and open at both ends, the following steps will be followed:

[0074] Step 1, the phonon emission probe 19 in the phonon emission module 1 is paired with the phonon signal emission end 18, and the phonon reception probe 16 in the phonon reception module 15 is paired with the phonon signal r...

Embodiment 2

[0086] In engineering practice, there are blind plates fixed by bolts on both sides of the pipeline, which are used to input fluid, such as figure 1 As shown, in the experiment, the 8m side with a blind hole defect is taken as an example. The blind plate on one side is opened and water is poured in to simulate the fluid transmission. The specific steps are as follows:

[0087] Step 1, the phonon emission probe 19 in the phonon emission module 1 is paired with the phonon signal emission end 18, and the phonon reception probe 16 in the phonon reception module 15 is paired with the phonon signal reception end 17;

[0088] Step 2, placing a pair of phonon emitting modules 1 and phonon receiving modules 15 on the two ends of the outer surface of the 8m-long pipeline 14, so that the phonon signal transmitting end 18 and the phonon signal receiving end 17 are at the same horizontal line;

[0089] Step 3, use the data signal line 7 to connect the red line of the output channel 3 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com