Line information and non-line area information extraction method, line defect detection method

A line information, non-line technology, applied in the field of line information and non-line area information extraction, line defect detection, can solve the problem of not being able to accurately find HDI boards and IC substrates, defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

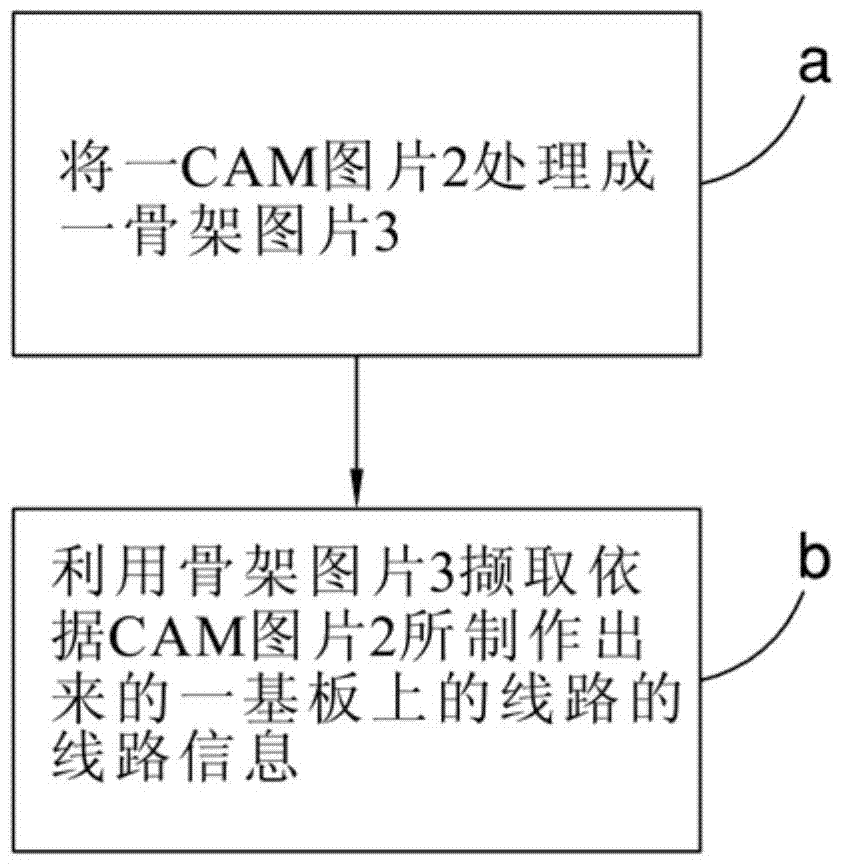

[0054] Figure 1A A flowchart showing a first preferred embodiment of a method for extracting line information of the present invention, which includes the following steps a~b:

[0055] a) Process a computer-aided design picture (hereinafter referred to as CAM picture 2 ) into a skeleton picture 3 .

[0056] b) Use the skeleton picture 3 to extract the line information of each line or specified line on a substrate (such as a printed circuit board) produced according to the CAM picture 2, such as the color scale or line width of each line or specified line and other information. The circuit referred to here generally refers to the conductors formed on the substrate, not limited to the form of wires, for example, conductors in the form of metal pads, solder balls, metal rings, metal pins, etc. belong to it.

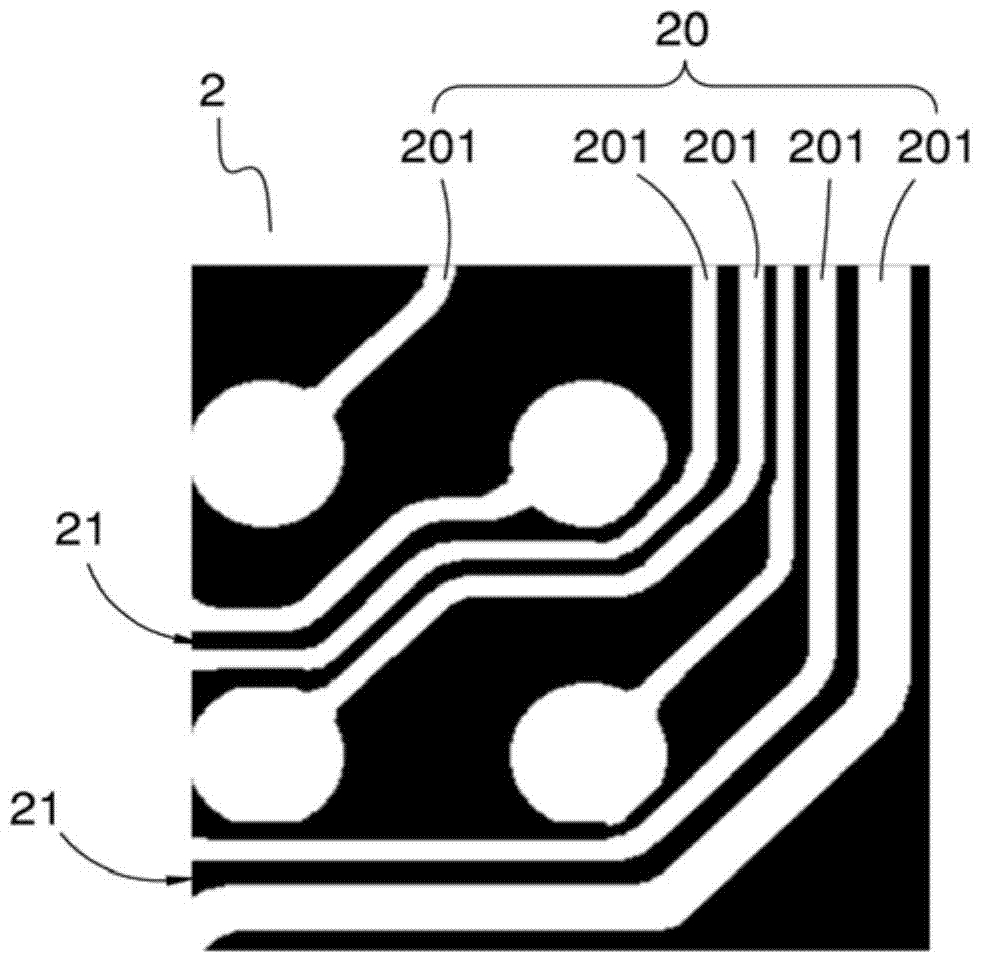

[0057] The CAM picture 2 illustrated in step a is as figure 2 As shown, it includes a CAM circuit pattern 20 (the white part in the figure) and a non-CAM circuit pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com