Patents

Literature

402 results about "Line defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Line defects are a form of crystallographic defects in which the defects occur in a plane of atoms in the middle of the crystal lattice. These defects occur when a plane of atoms misalign. Moreover, it is difficult to visualize a line defect. This is the main difference between point defect and line defect.

Optical switch having photonic crystal structure

InactiveUS6937781B2Change the refractive indexCladded optical fibreNanoopticsRefractive indexPhotonic crystal structure

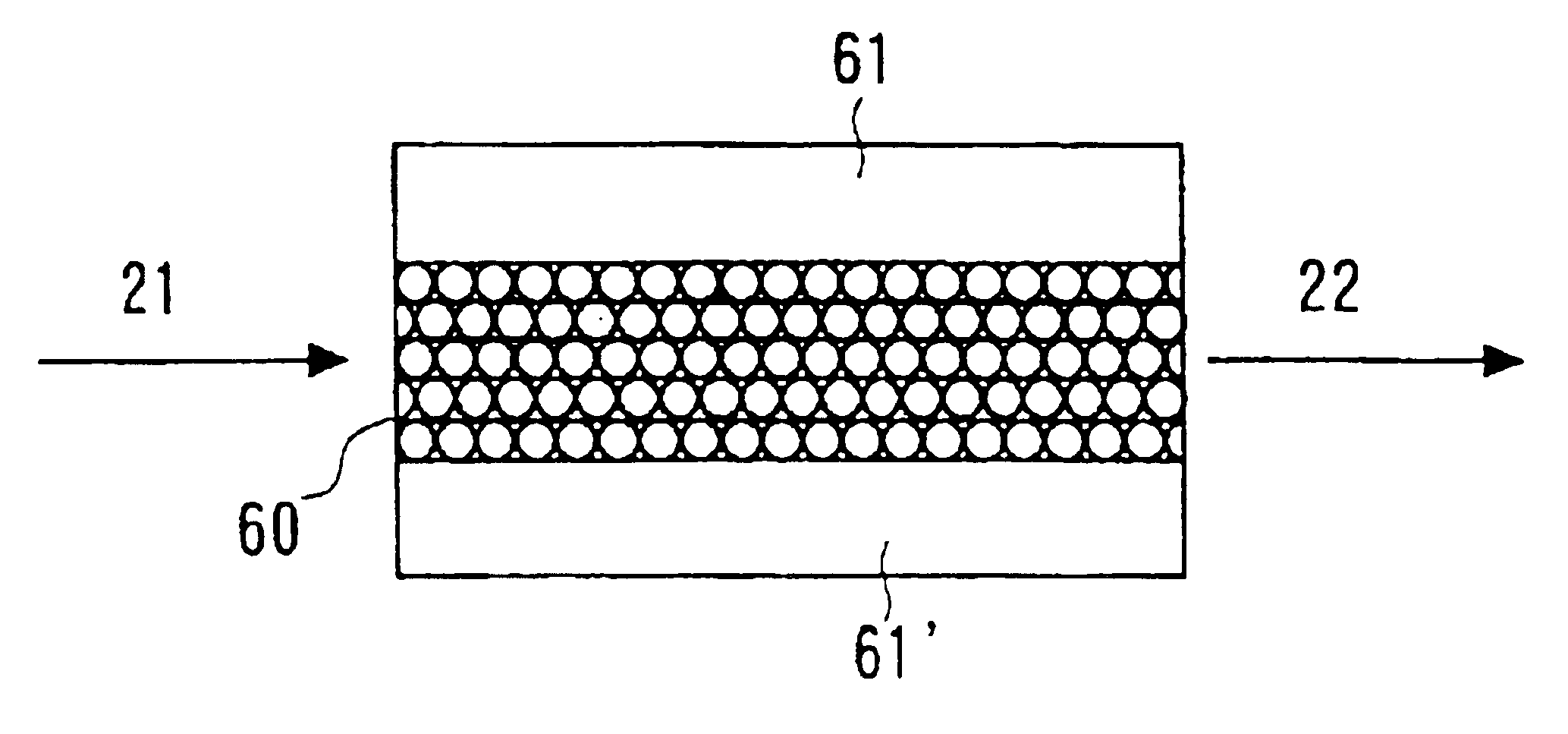

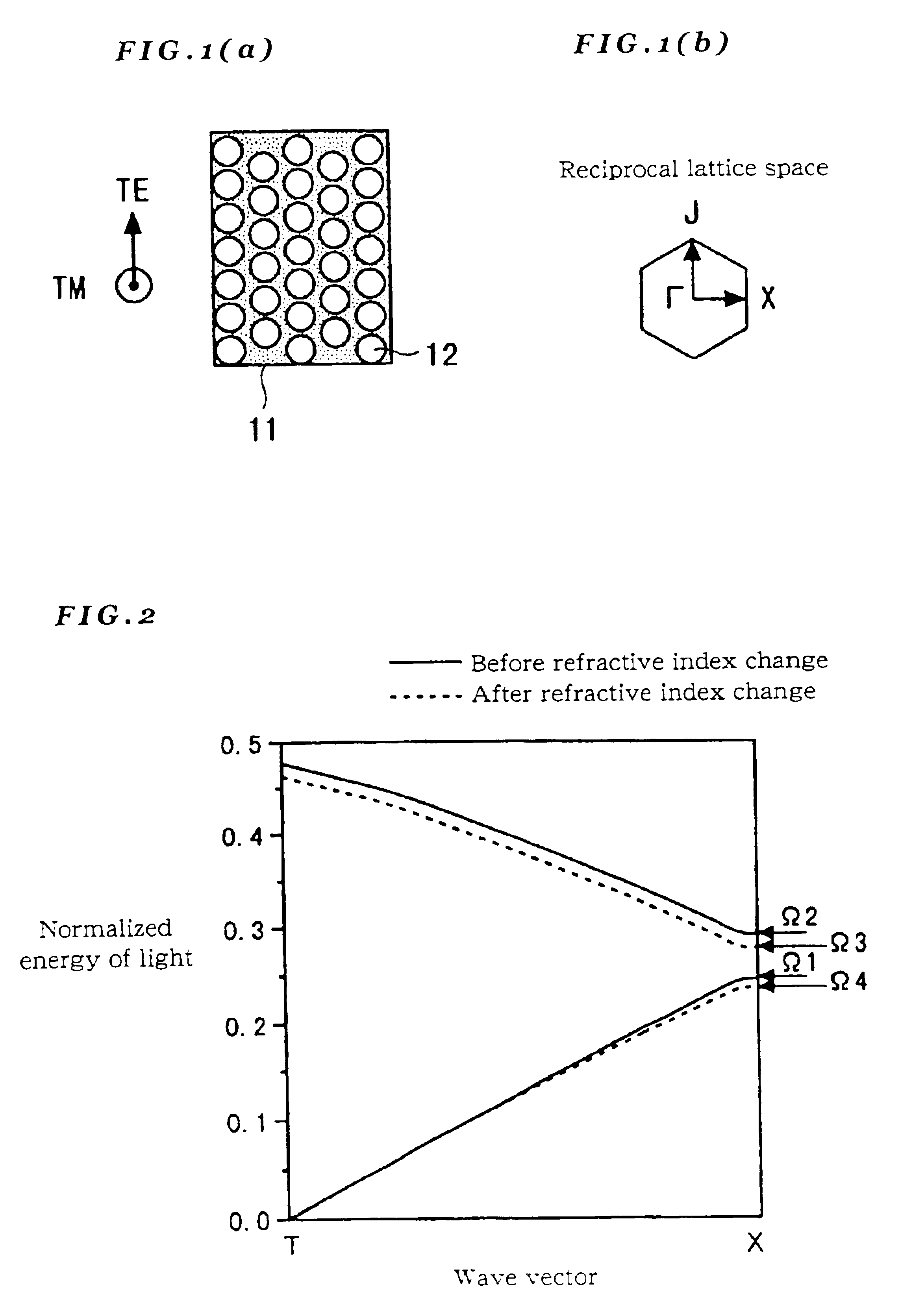

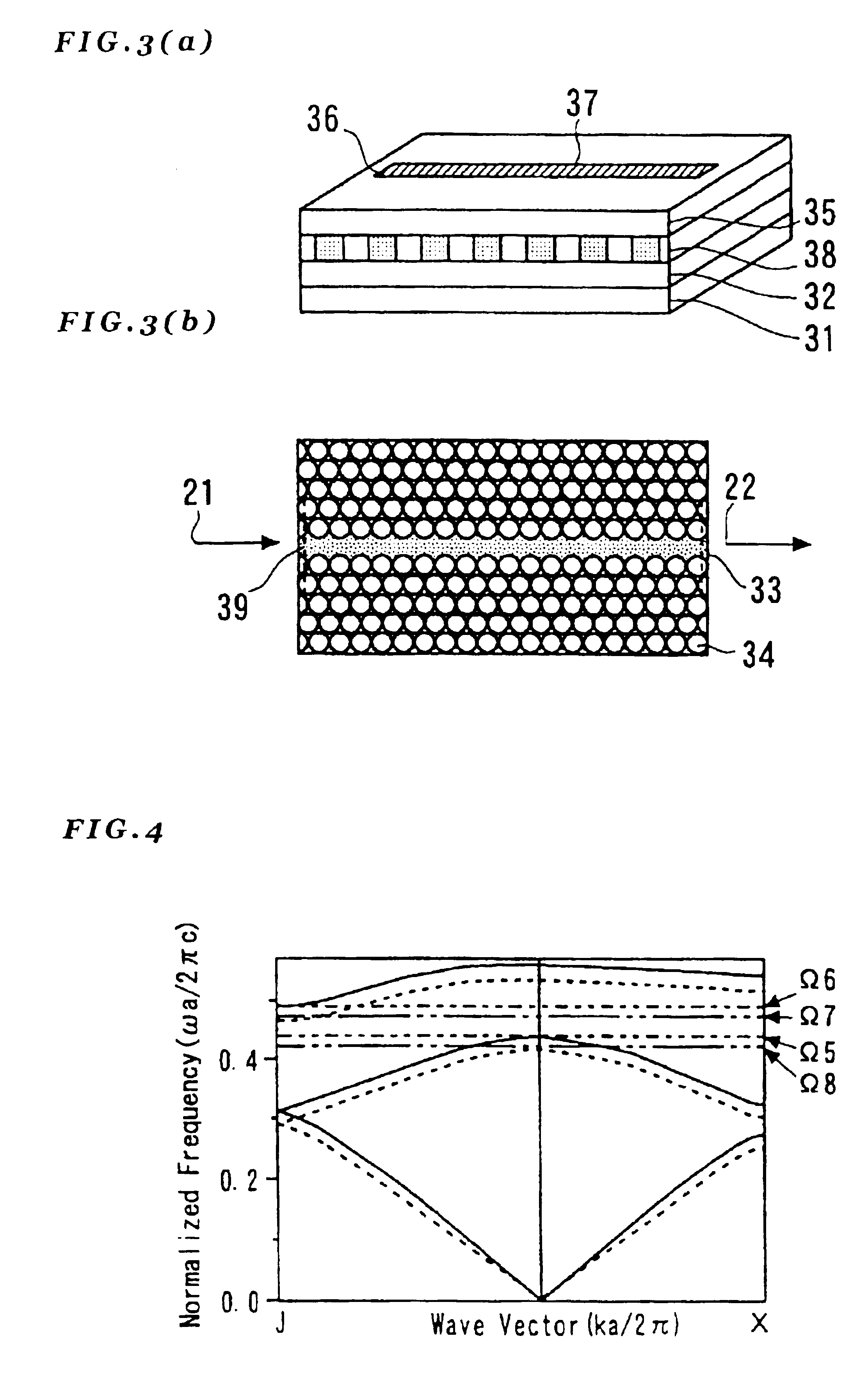

The present invention provides an optical switch having a photonic crystal structure.An optical switch of the invention has a slab optical waveguide structure whose core (35) has a two-dimensional photonic crystal structure where two or more media (33, 34) with different refractive indices are alternately and regularly arranged in a two-dimensional manner. The photonic crystal structure comprises: a line-defect waveguide; and means for altering the refractive index of the line-defect waveguide.

Owner:NEC CORP

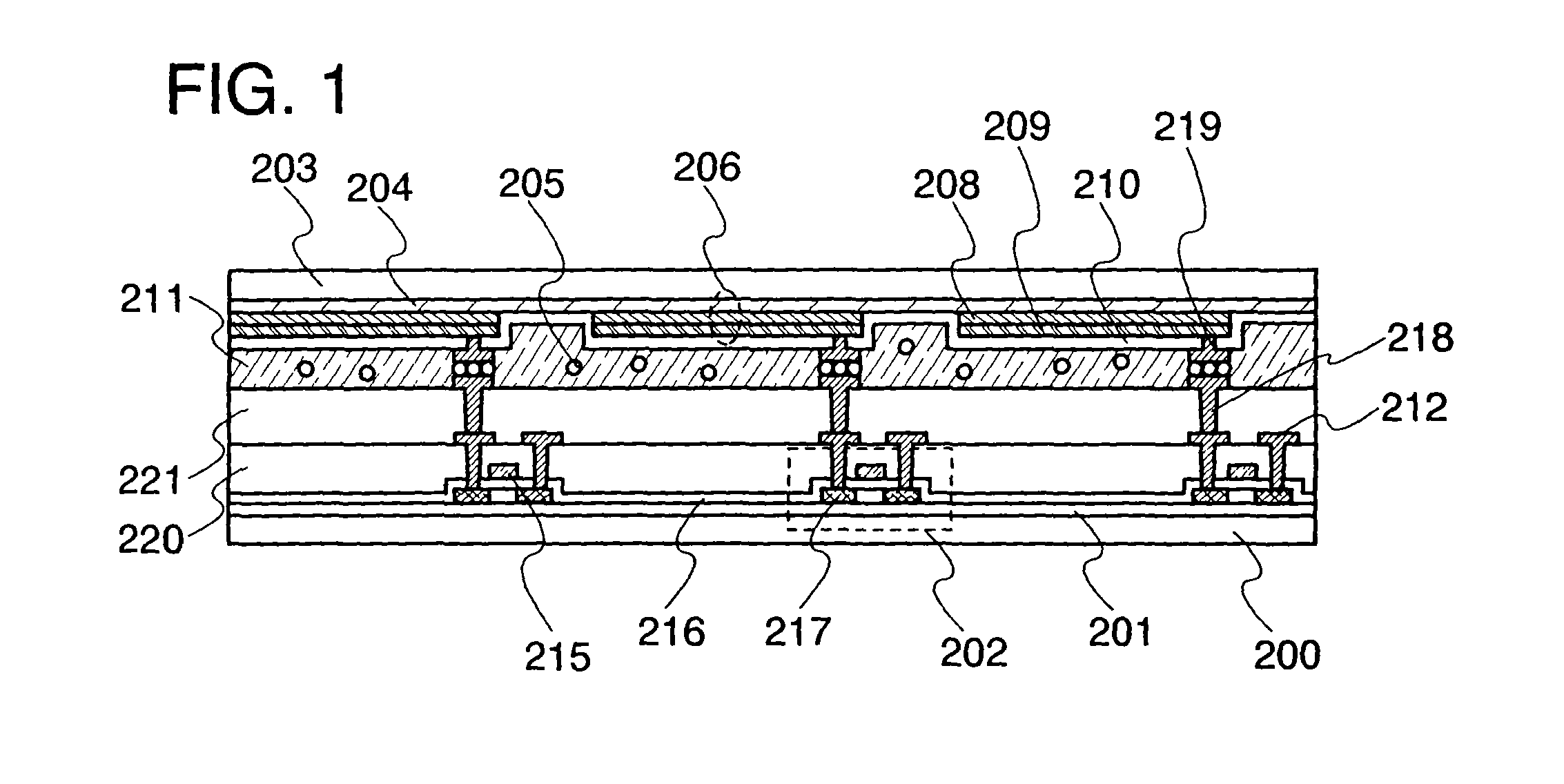

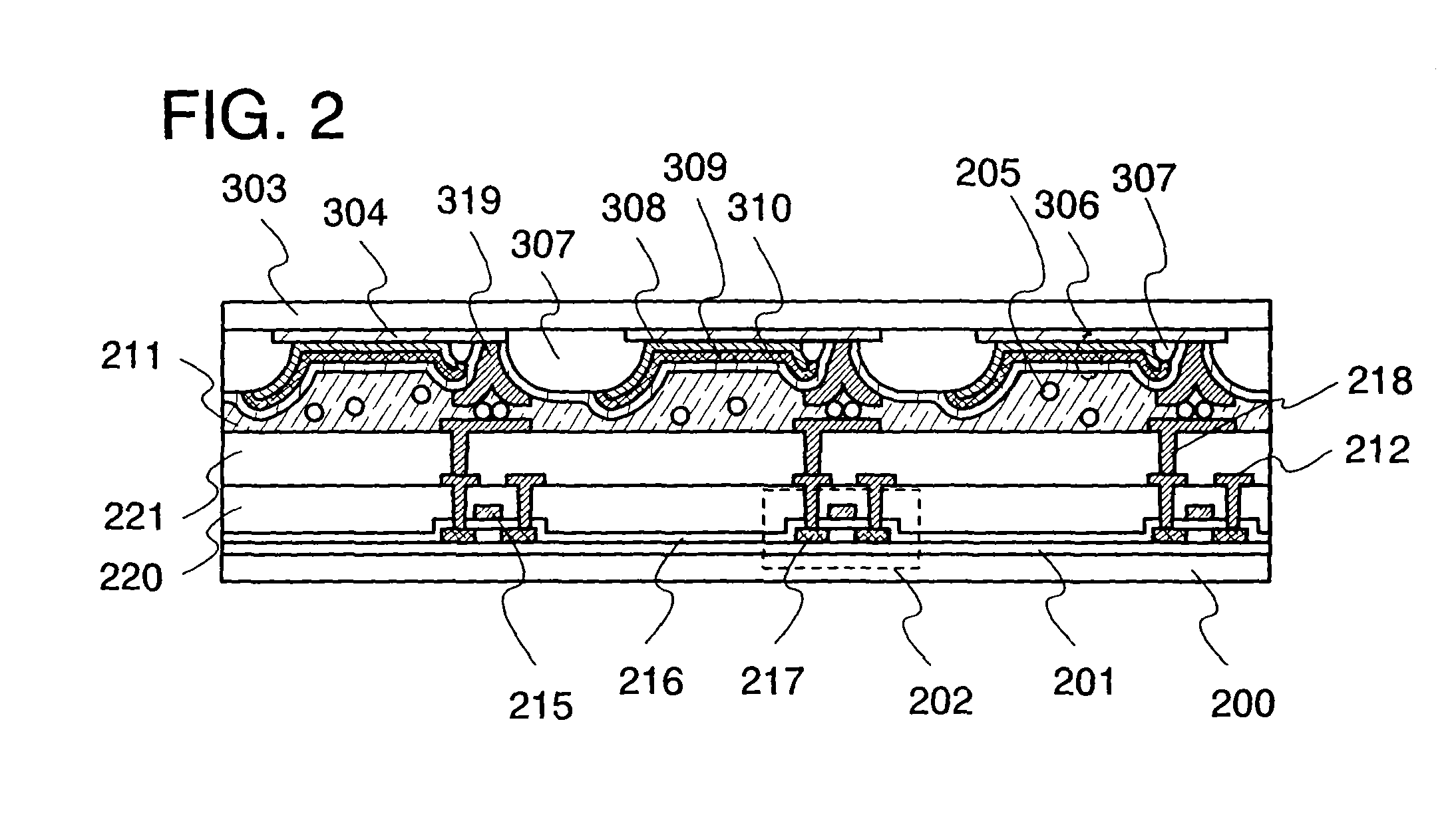

Light-emitting device and manufacturing method thereof

ActiveUS20070029554A1Flexible changeIncrease freedomElectroluminescent light sourcesSolid-state devicesDriver circuitDegrees of freedom

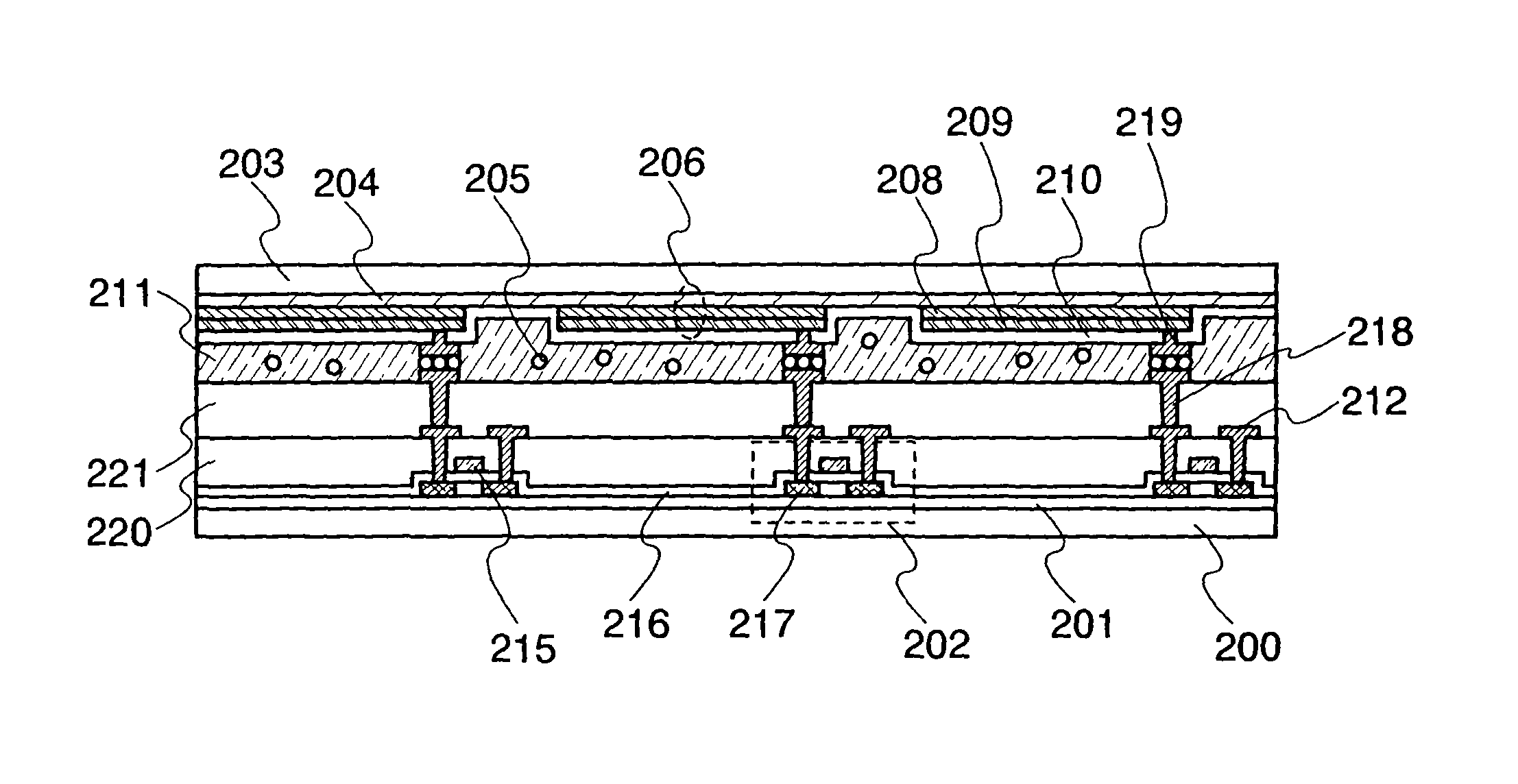

To prevent a point defect and a line defect in forming a light-emitting device, thereby improving the yield. A light-emitting element and a driver circuit of the light-emitting element, which are provided over different substrates, are electrically connected. That is, a light-emitting element and a driver circuit of the light-emitting element are formed over different substrates first, and then electrically connected. By providing a light-emitting element and a driver circuit of the light-emitting element over different substrates, the step of forming the light-emitting element and the step of forming the driver circuit of the light-emitting element can be performed separately. Therefore, degrees of freedom of each step can be increased, and the process can be flexibly changed. Further, steps (irregularities) on the surface for forming the light-emitting element can be reduced than in the conventional technique.

Owner:SEMICON ENERGY LAB CO LTD

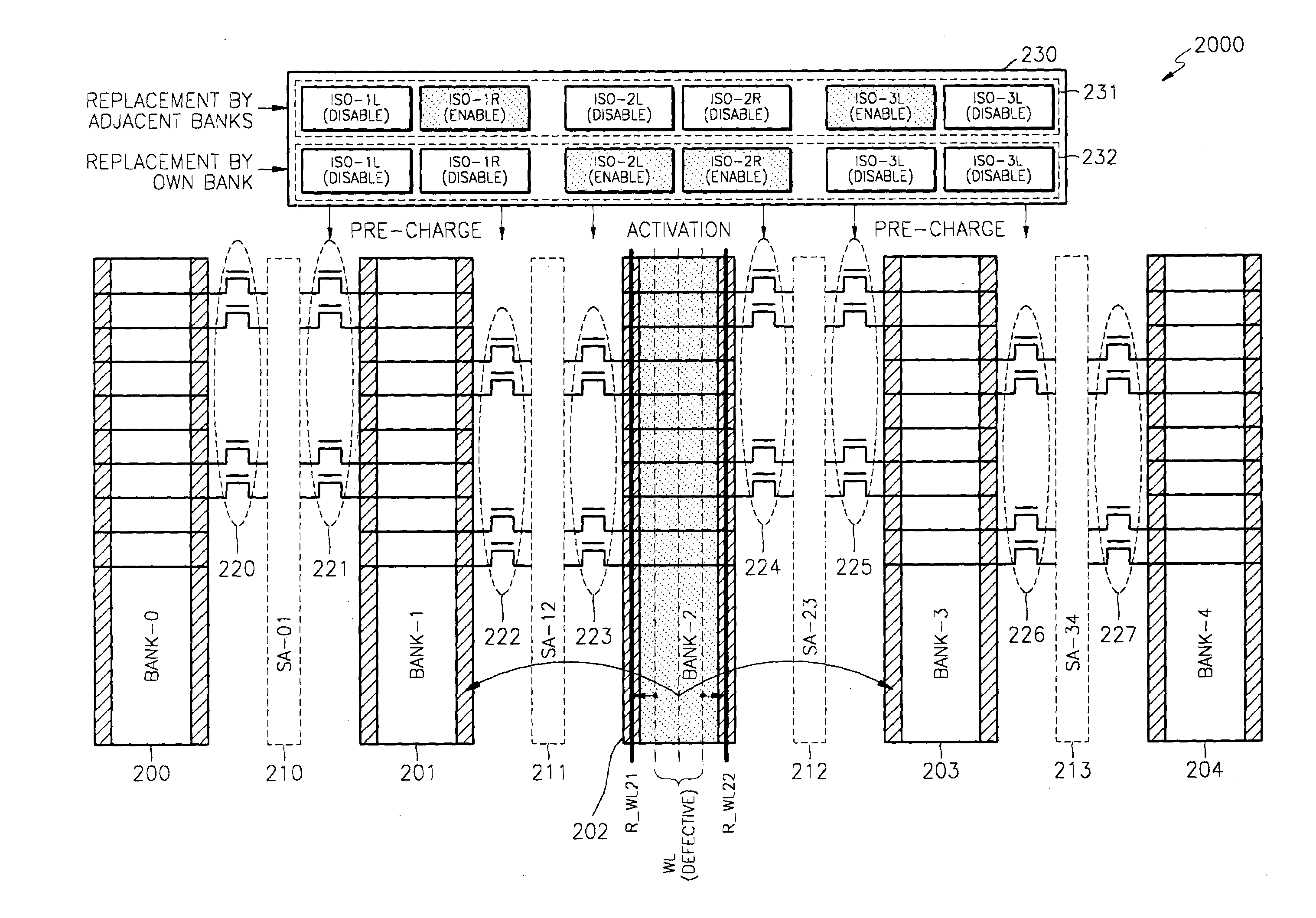

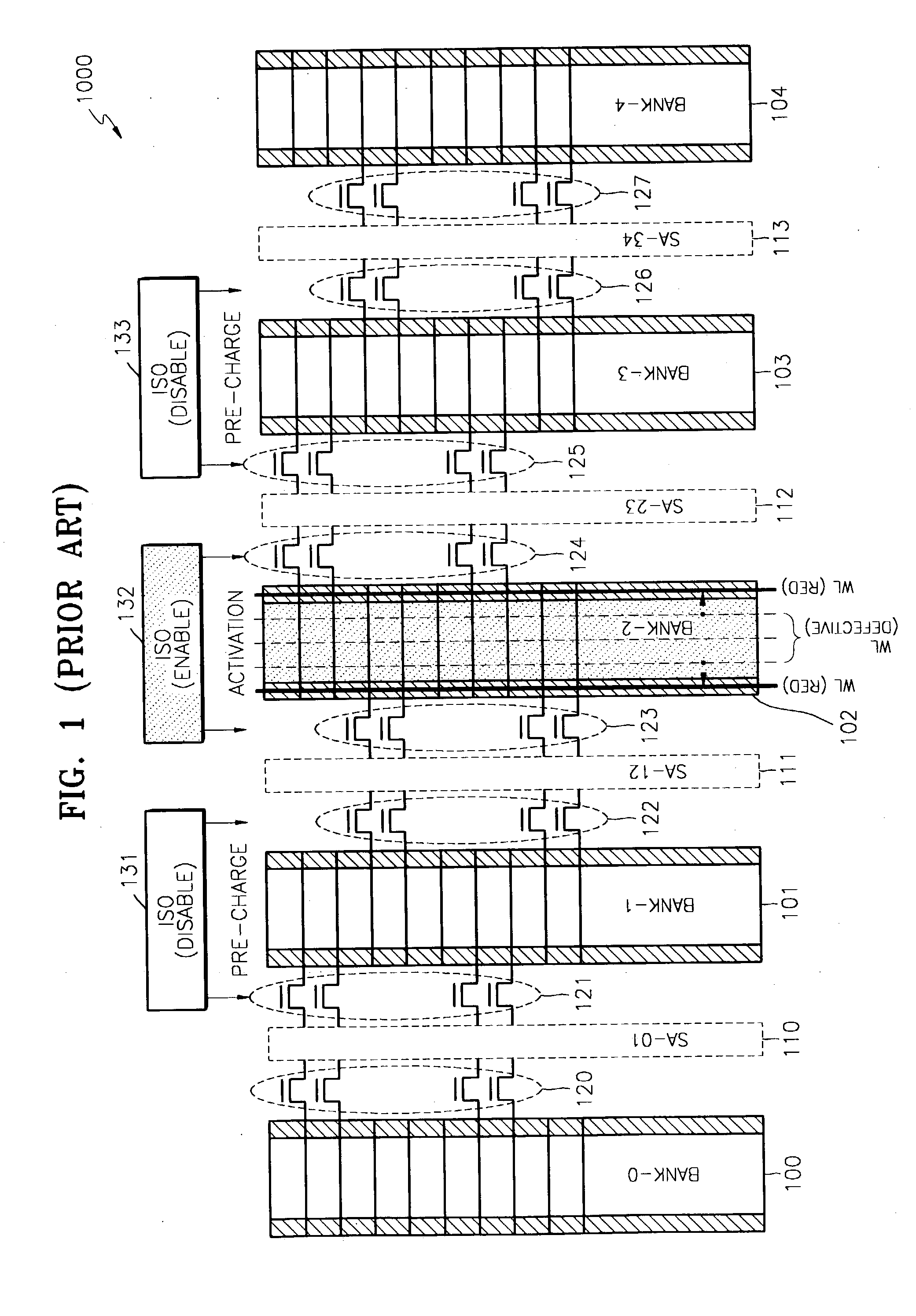

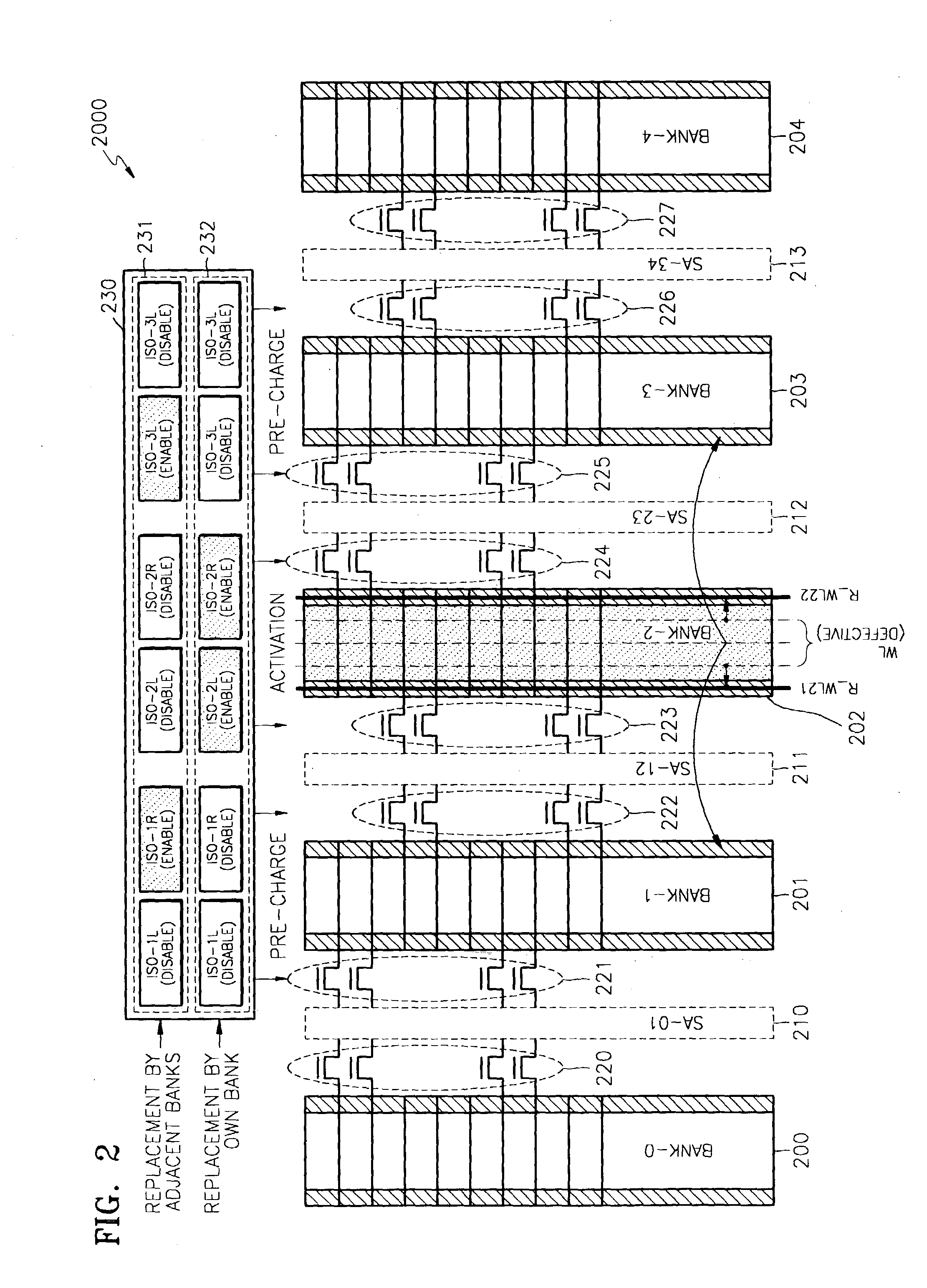

Semiconductor memory device having improved replacement efficiency of defective word lines by redundancy word lines

A semiconductor memory device that efficiently replaces defective word lines by redundancy word lines. The semiconductor memory device includes a plurality of banks, each bank having a plurality of normal word lines and a plurality of redundancy word lines. A defective word line can be replaced by the redundancy word lines when defects occur in the normal word lines. When word line defects occur, redundancy word lines banks adjacent to the bank having the defective work line may be used.

Owner:SAMSUNG ELECTRONICS CO LTD

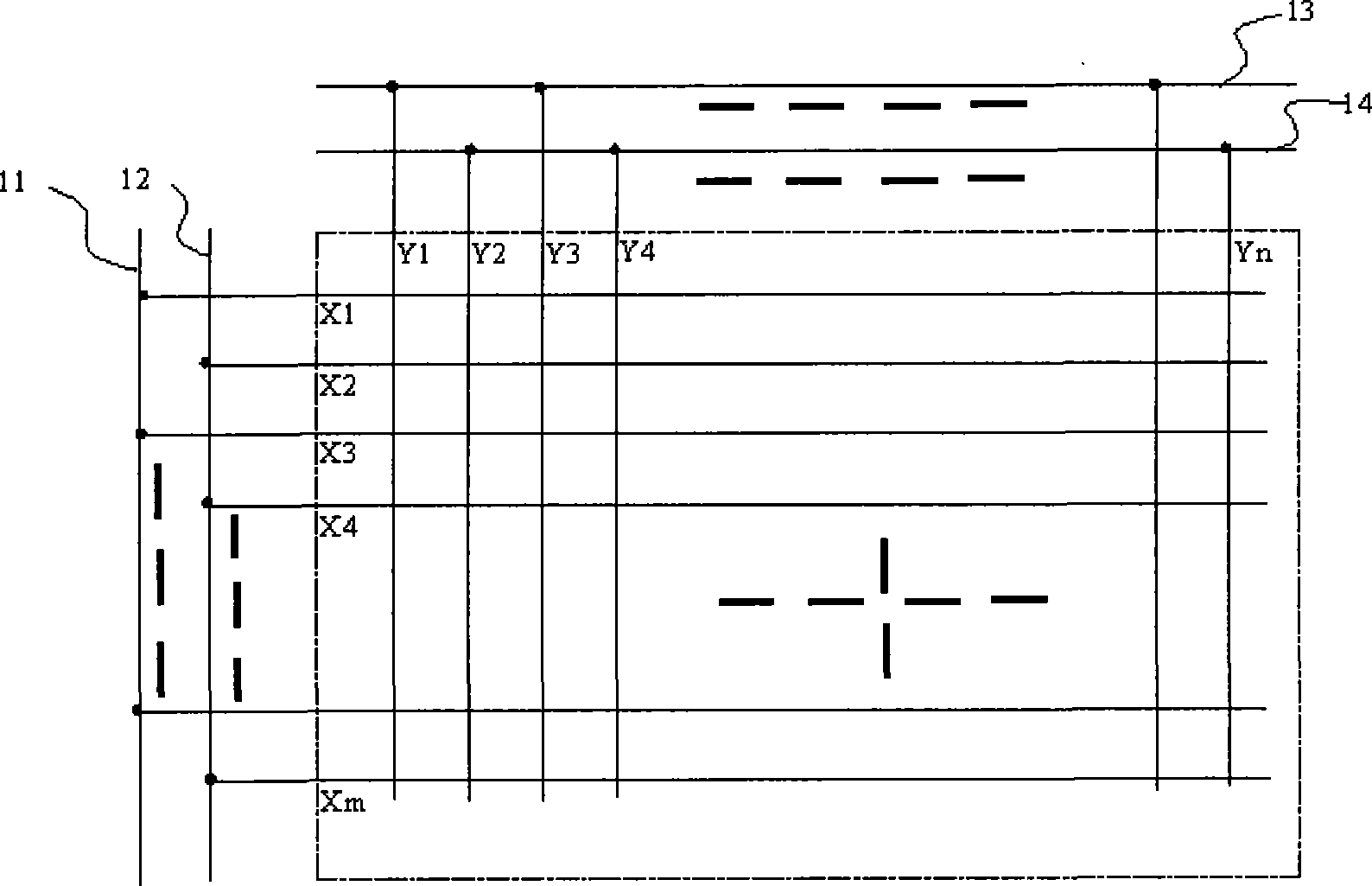

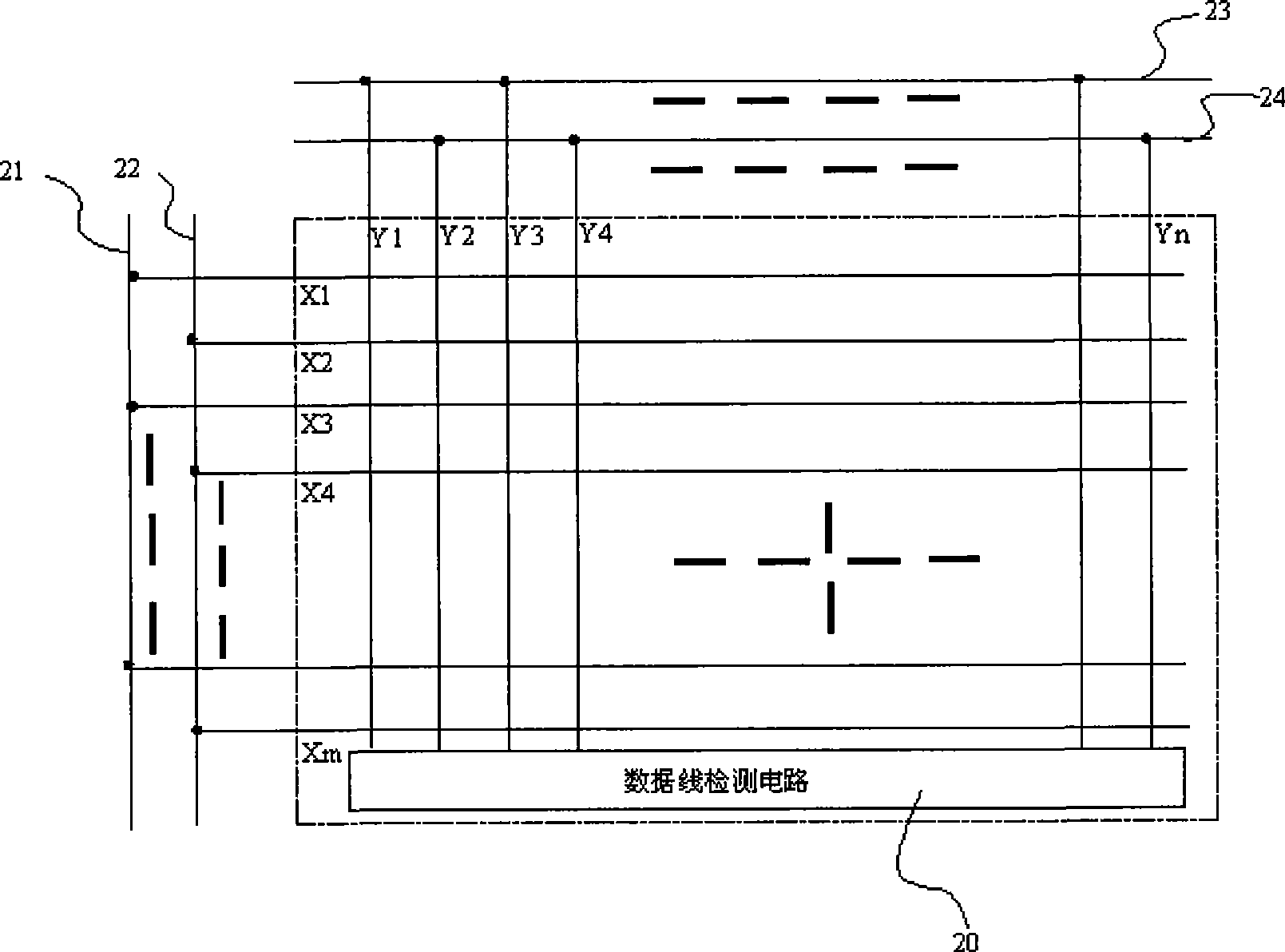

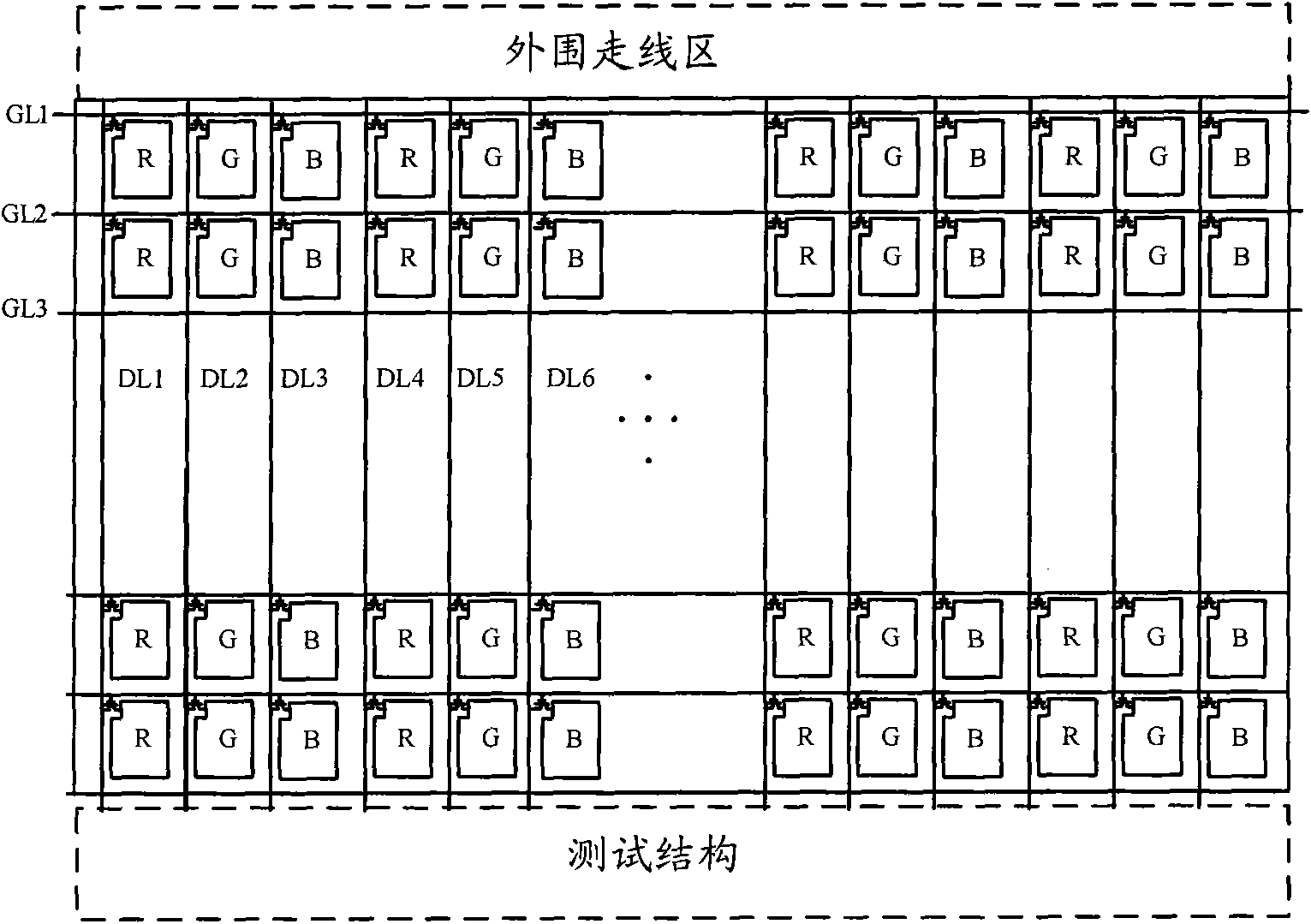

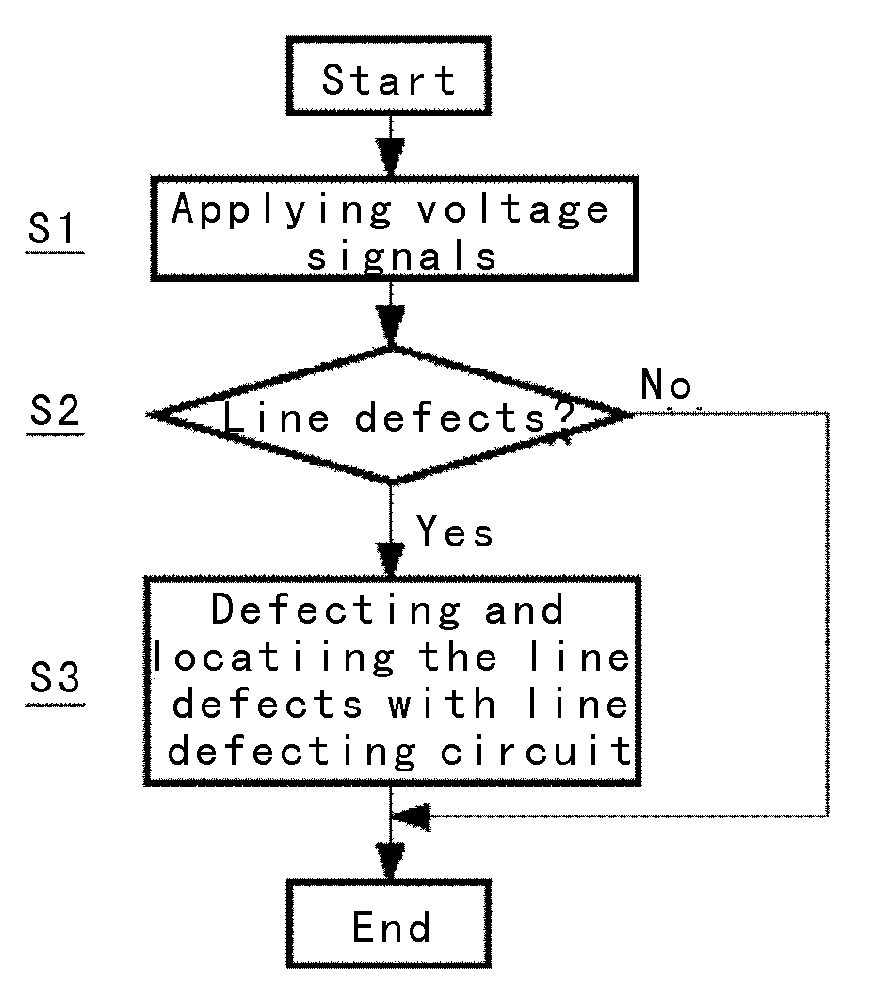

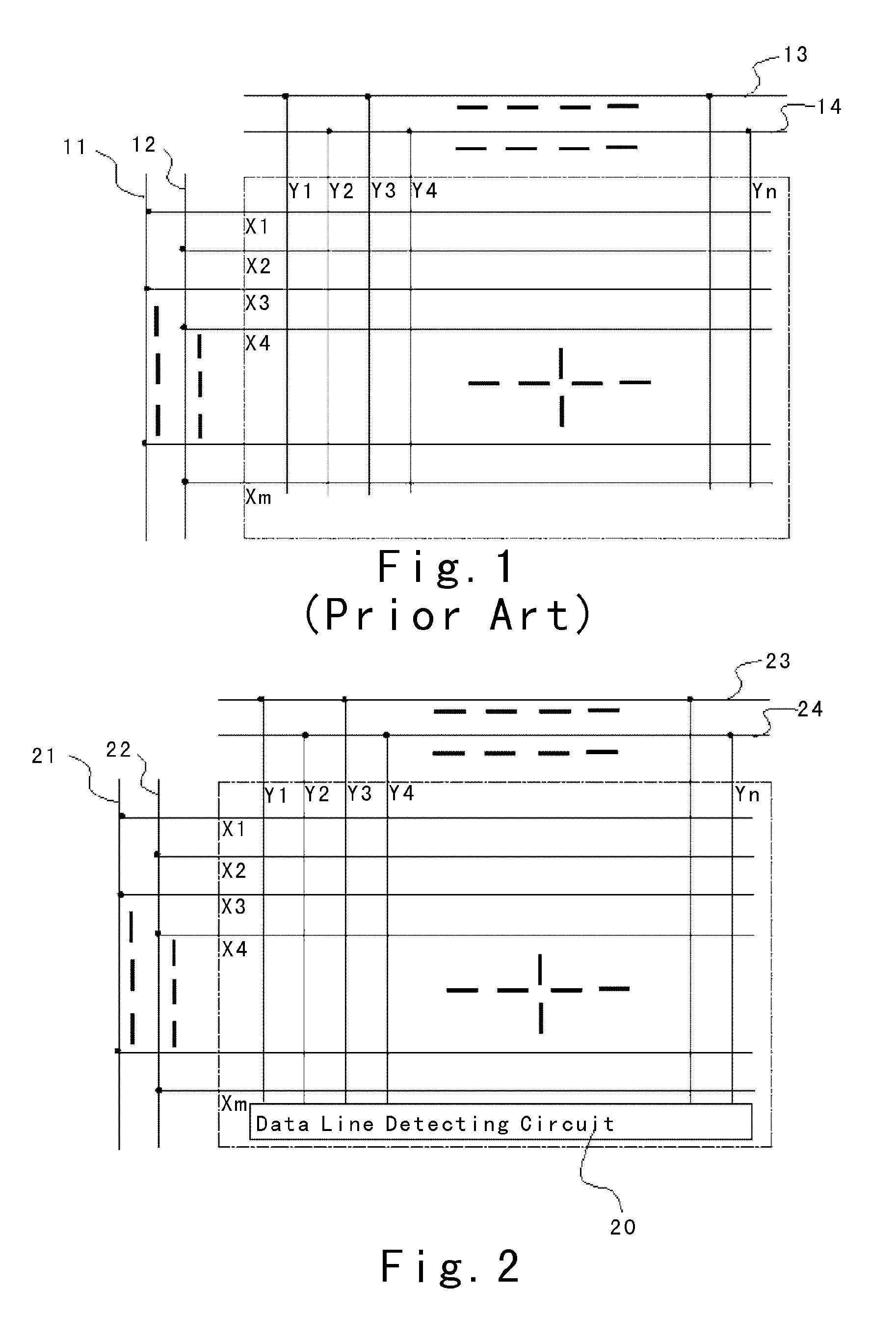

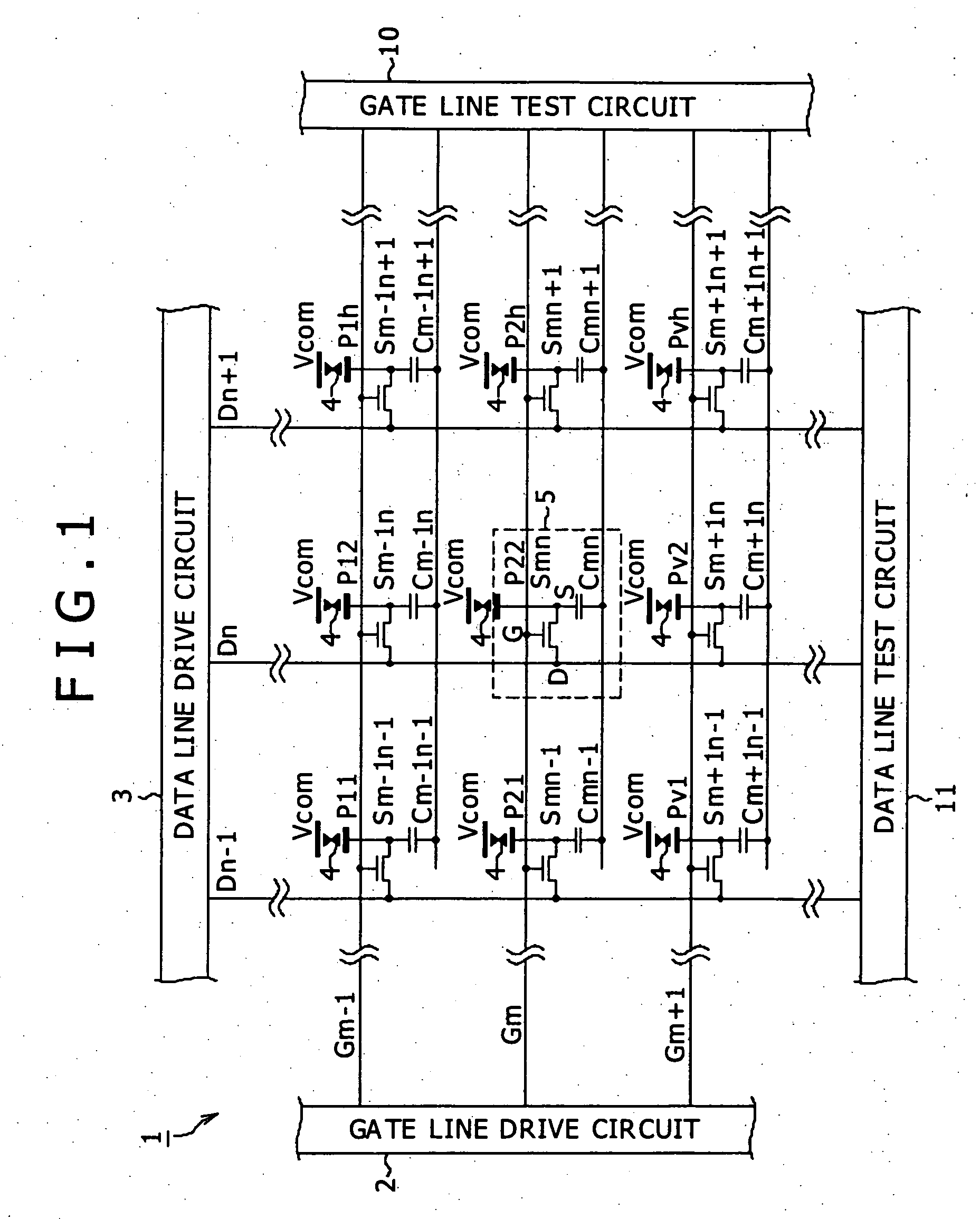

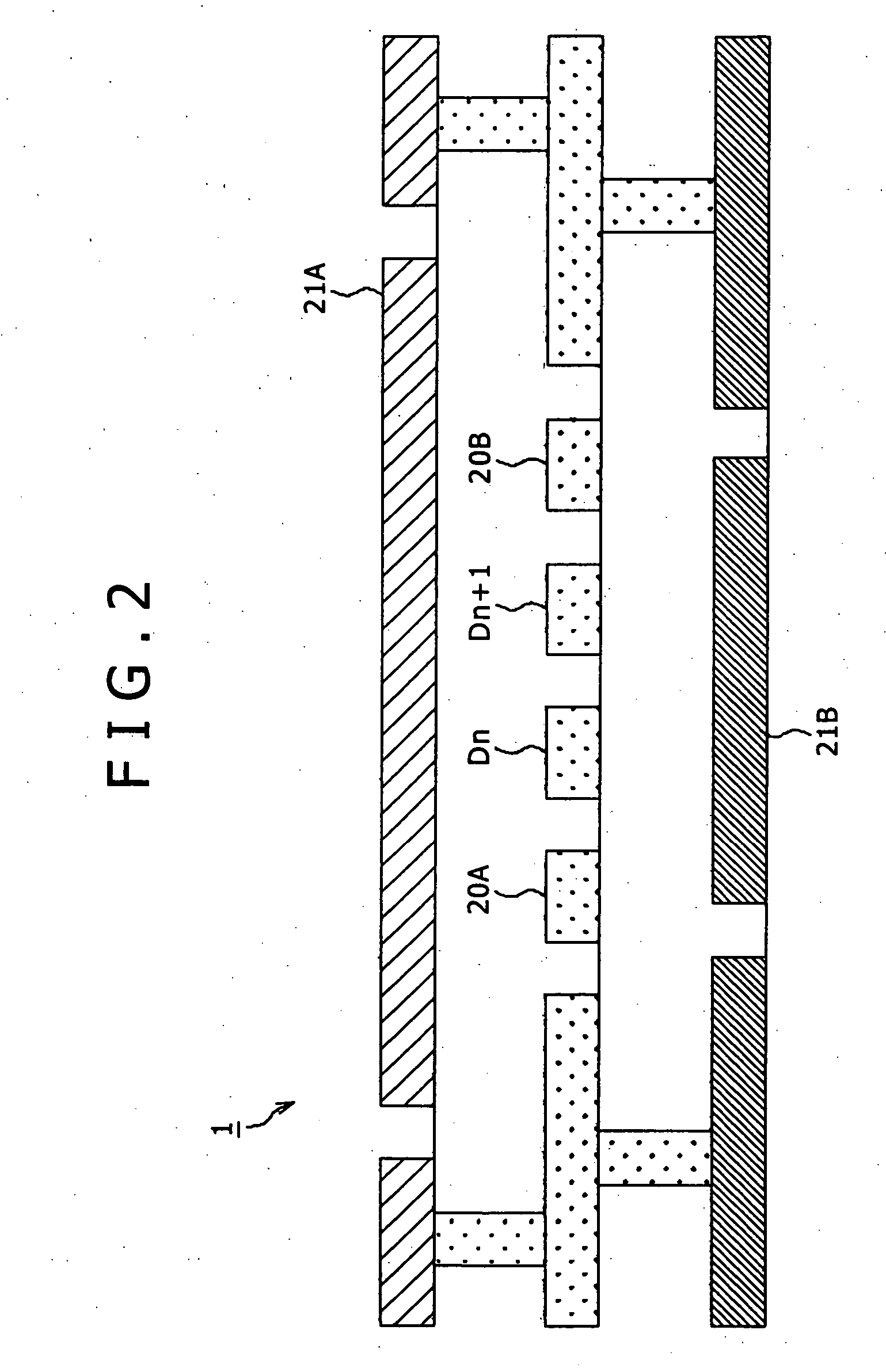

Array substrate and defect detecting method thereof

ActiveCN101364022APrecise positioningRapid positioningStatic indicating devicesNon-linear opticsSignal onEngineering

The invention discloses an array basal plate and a method for detecting the defects thereof. The array basal plate includes one or more shorting bars used for applying signals on a plurality of data lines and a plurality of grid lines of the array basal plate during the detection. The array basal plate is characterized in that the array basal plate further includes a line detection circuit used for receiving the signals on the data lines and the grid lines, and detecting and positioning the defects of the data lines and the grid lines. The array basal plate and the method for detecting the defects thereof can accurately and rapidly position the line defects on the array basal plate.

Owner:KUSN INFOVISION OPTOELECTRONICS

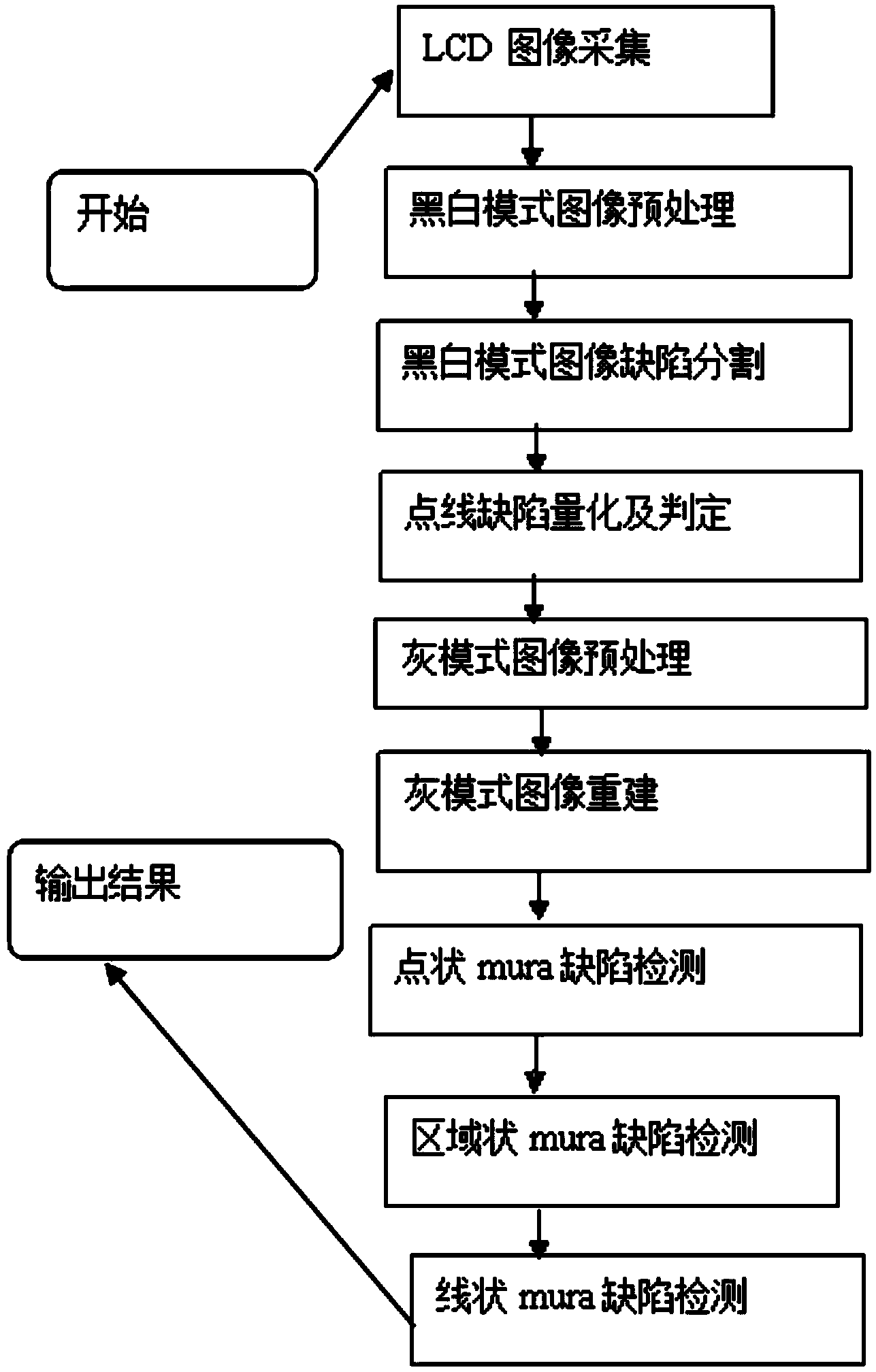

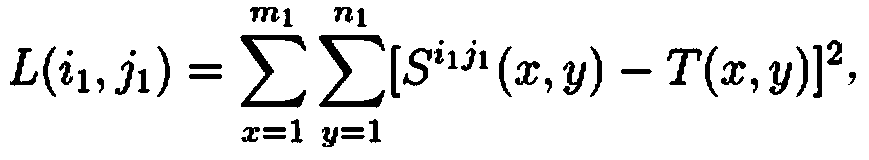

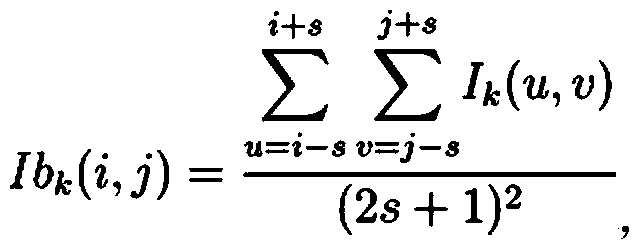

LCD general defect detecting method

ActiveCN103413288AClear effectReduce in quantityImage enhancementImage analysisEngineeringMechanical engineering

The invention discloses an LCD general defect detecting method. The LCD general defect detecting method comprises the following steps of (1) carrying out preprocessing on images, (2) separating defects of images of a black and white mode, (3) determining point defects and line defects, (4) zooming grey mode images, (5) reestablishing images, (6) detecting point-shaped foreign body defects, (7) detecting area-shaped foreign body defects, and (8) detecting line-shaped foreign body detects. The LCD general defect detecting method carries out Gaussian smoothing on the images to remove noise, gradient values are then solved, edge points are determined preliminarily according to the gradient values, the edge position is finally located precisely in detail, and effects are made to be clearer.

Owner:NANJING UNIV

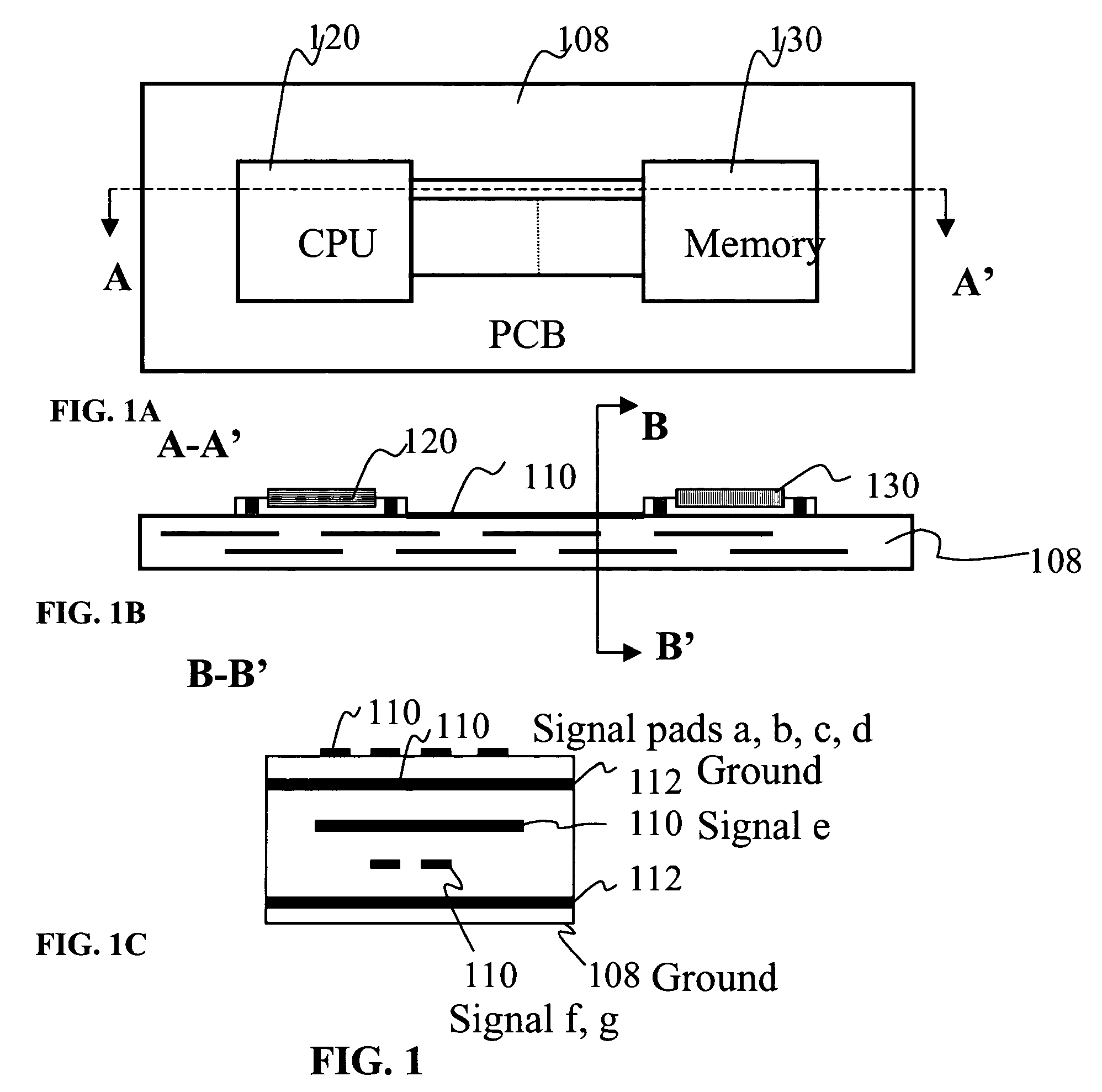

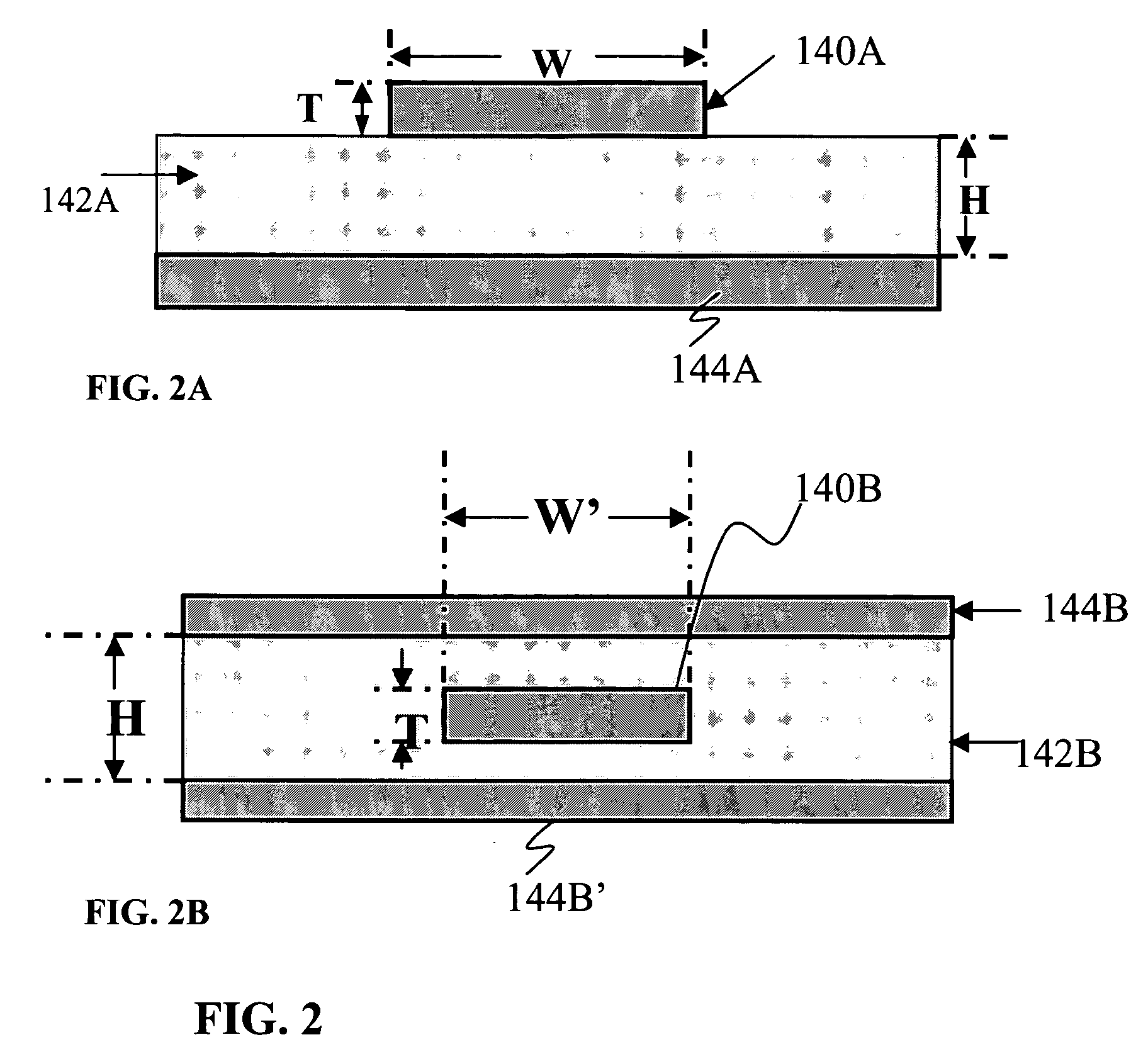

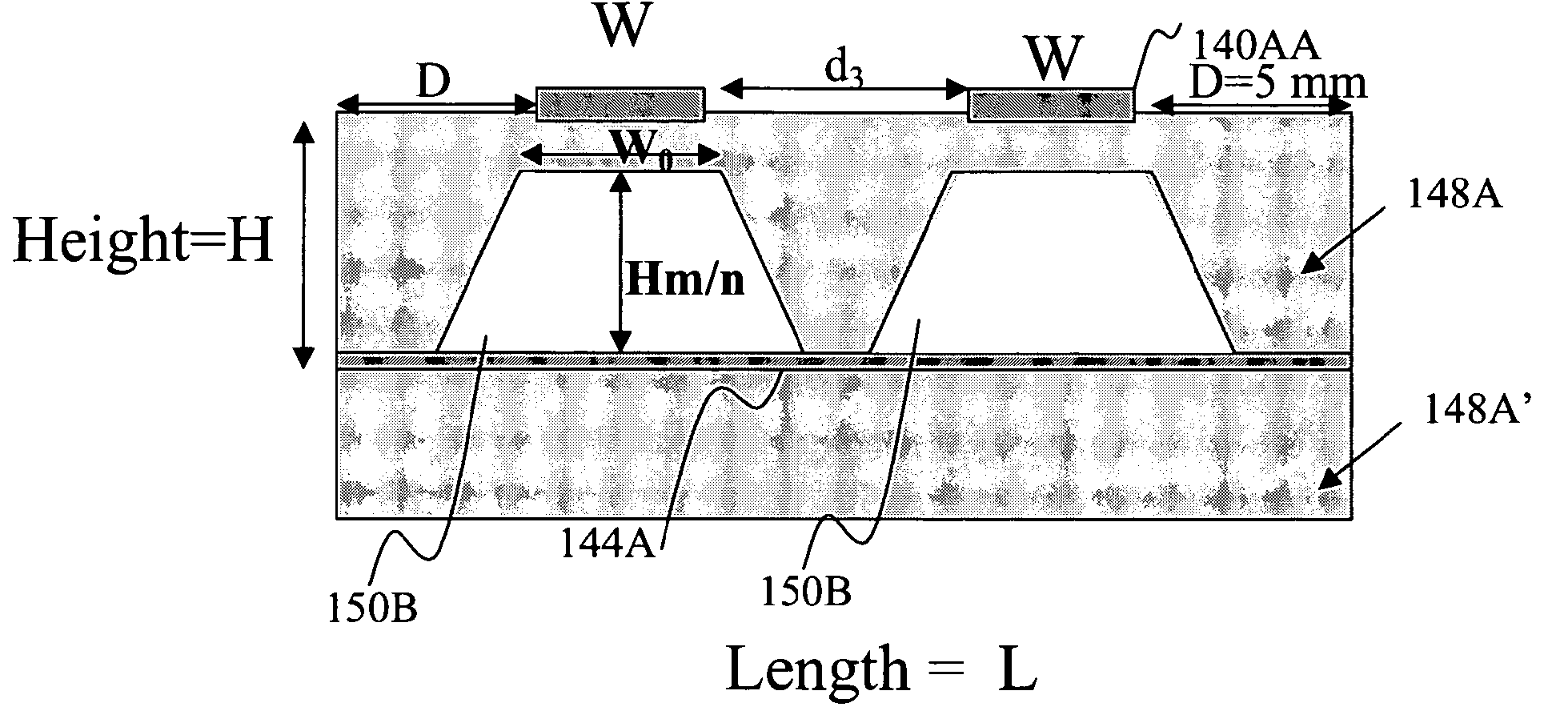

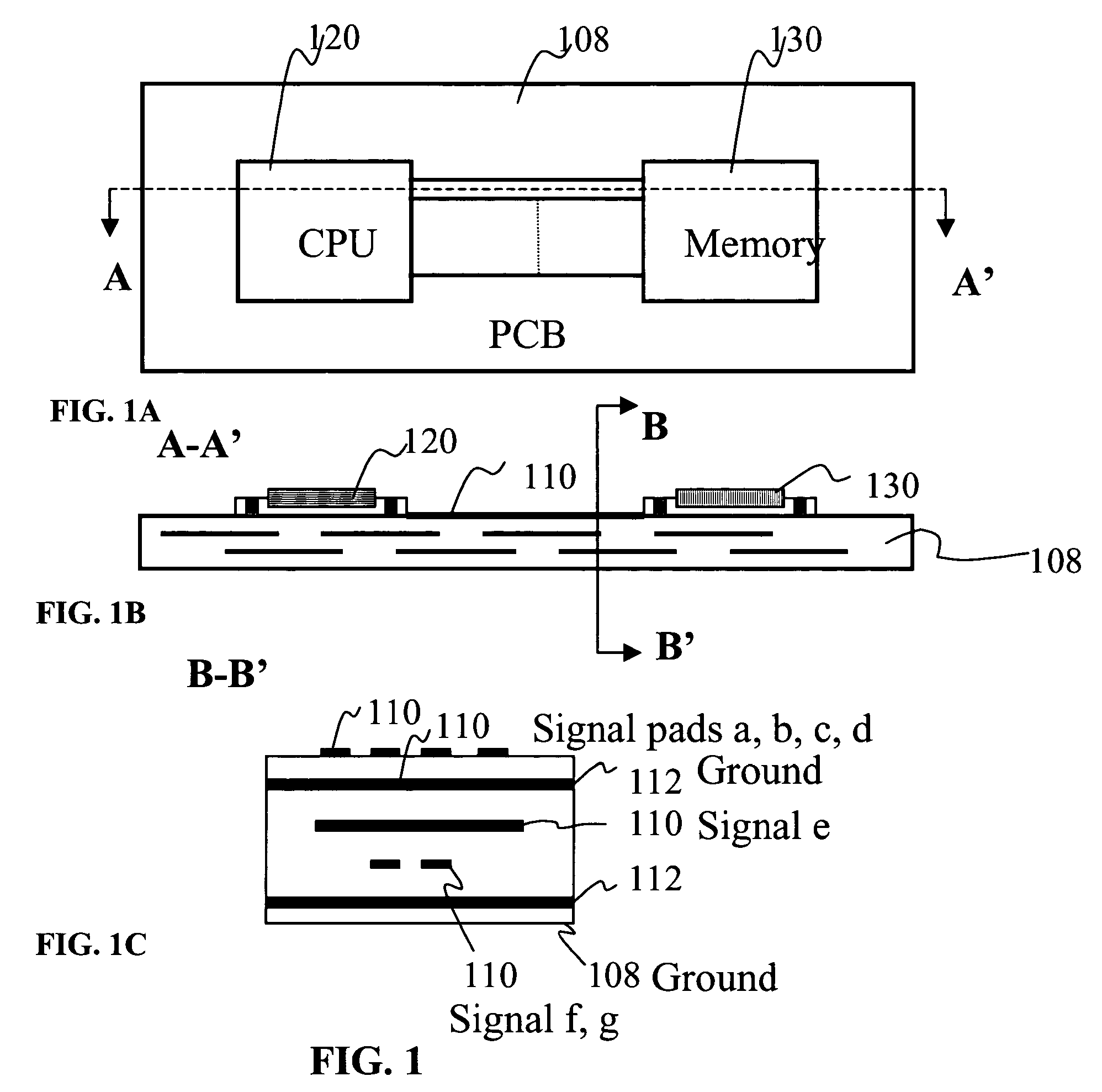

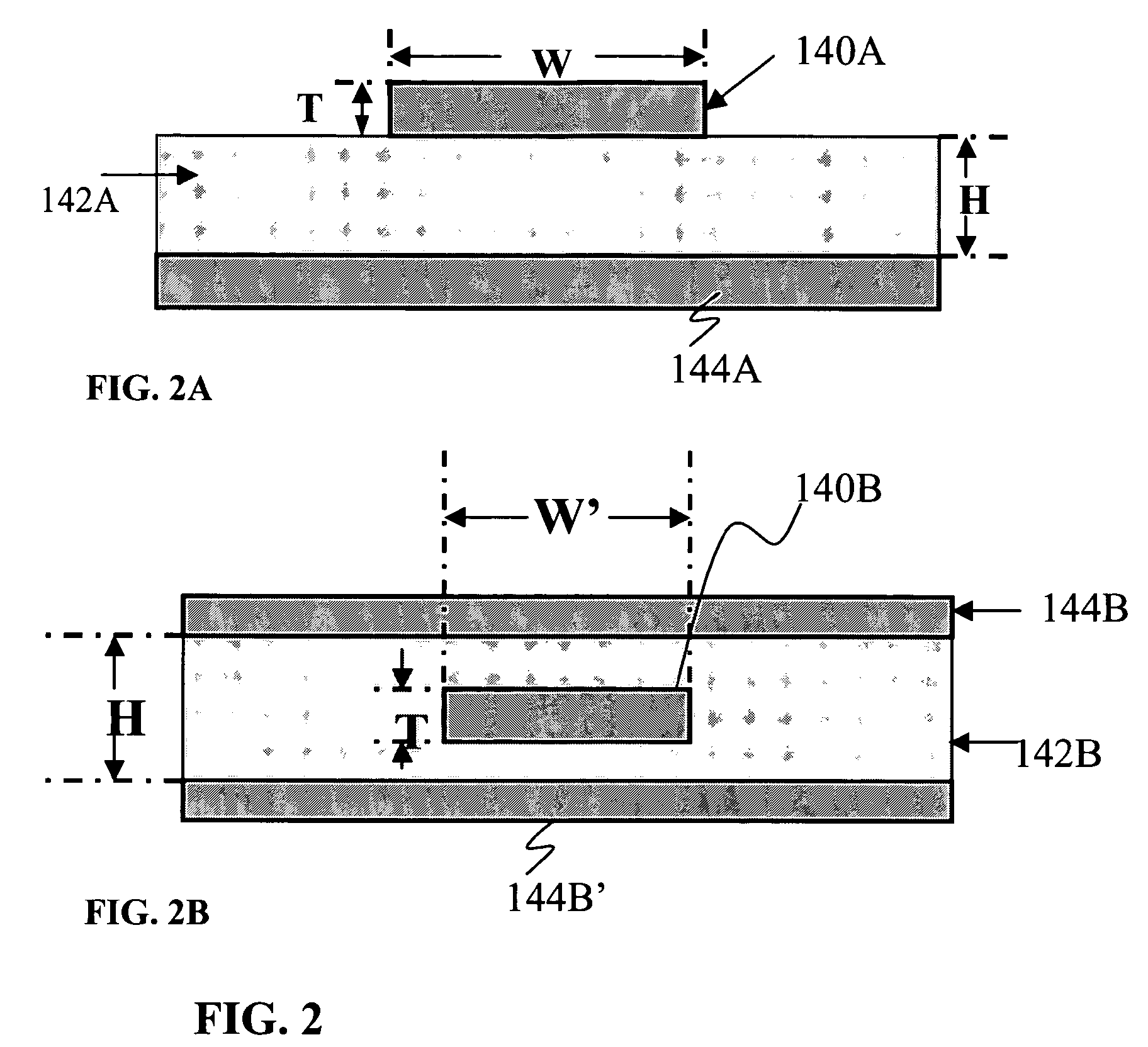

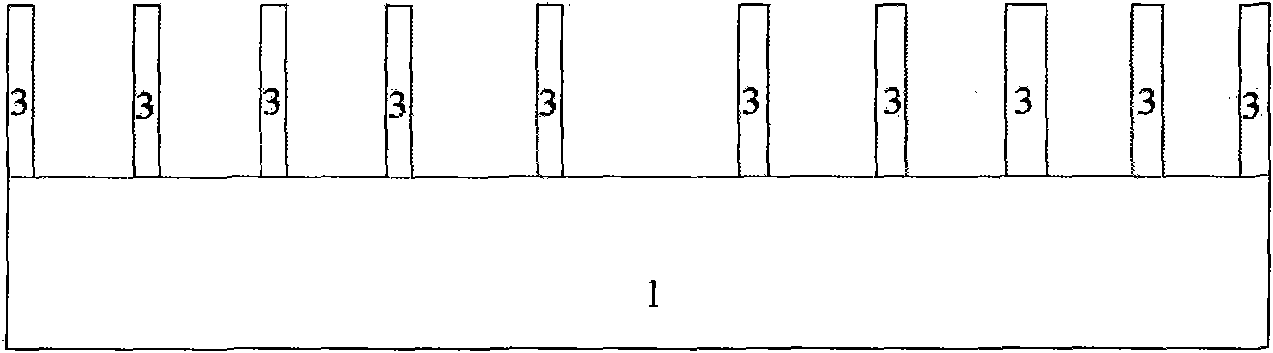

High speed electrical interconnects and method of manufacturing

ActiveUS20050237137A1Reduce effective loss-tangentHigh bandwidthSolid-state devicesWaveguidesManufacturing technologyDielectric substrate

High-speed interconnect systems for connecting two or more electrical elements are provided. Interconnect system has the means, which could reduce the microwave loss induced due to the dielectrics. Reducing the effective loss tangent of the dielectrics reduces the microwave loss. With optimize design of the interconnects, the speed of the electrical signal can be made to closer to the speed of the light. The interconnect systems consists of the electrical signal line, inhomogeneous dielectric systems and the ground line, wherein inhomogeneous dielectric system consisting of the opened-trenches into the dielectric substrate or comb-shaped dielectrics to reduce the microwave loss. Alternatively dielectric structure can have the structure based on the fully electronic or electromagnetic crystal or quasi crystal with the line defect. Alternatively, dielectric structure can be made to comb-shaped structure with teethes having thickness and space making the air pocket to reduce the microwave loss. The interconnect system, can be made in rigid or flex board for off-chip interconnects for IC packages, connectors and cables, where conventional manufacturing technology can be used and yet to increase the bandwidth of the interconnects.

Owner:BANPIL PHOTONICS

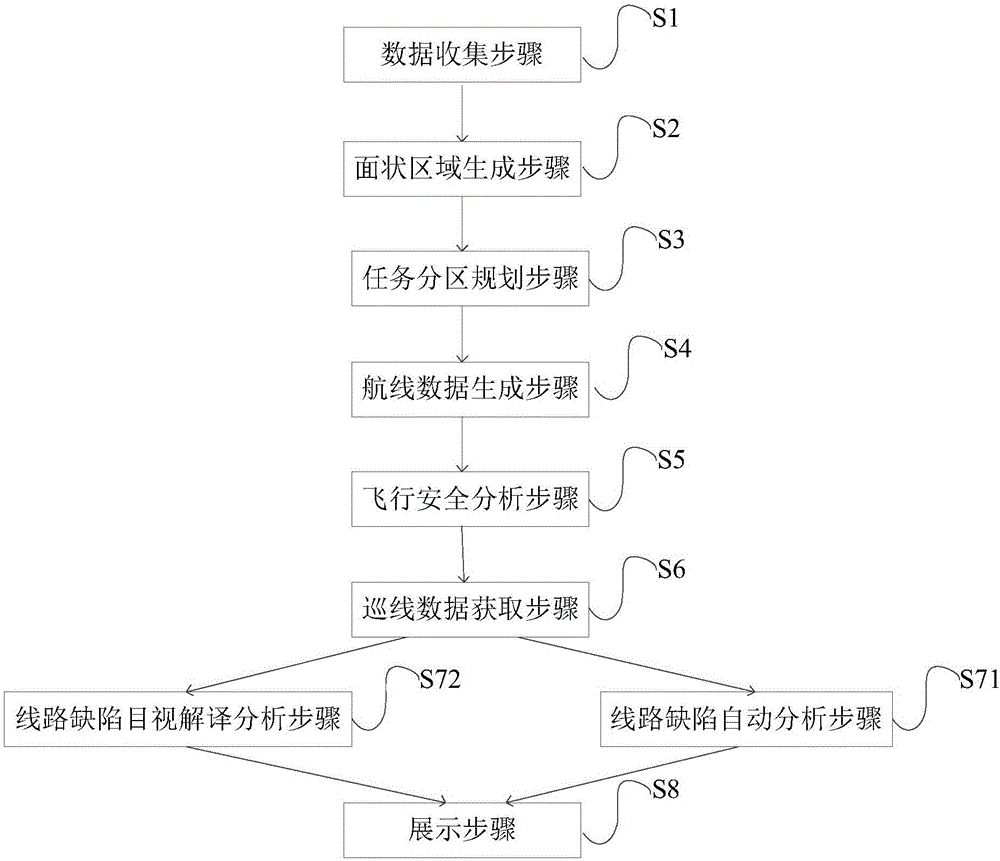

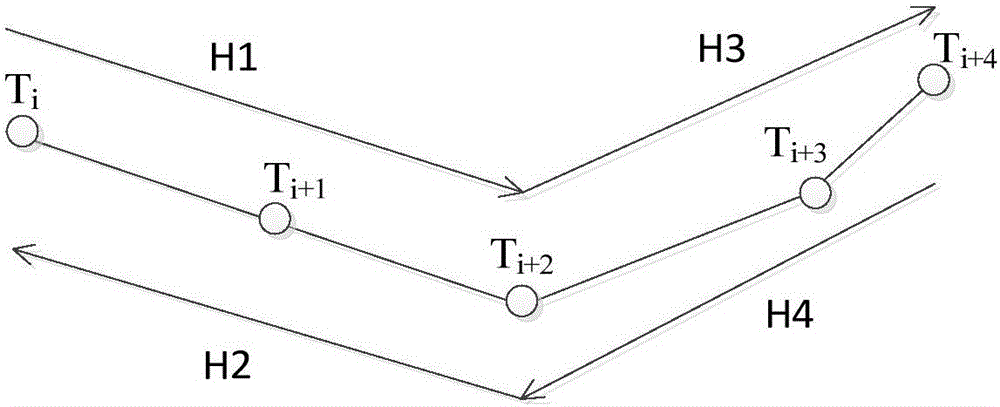

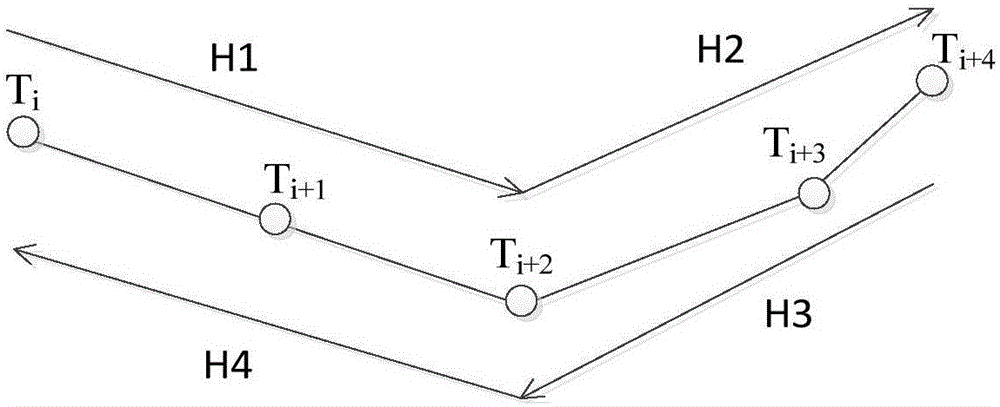

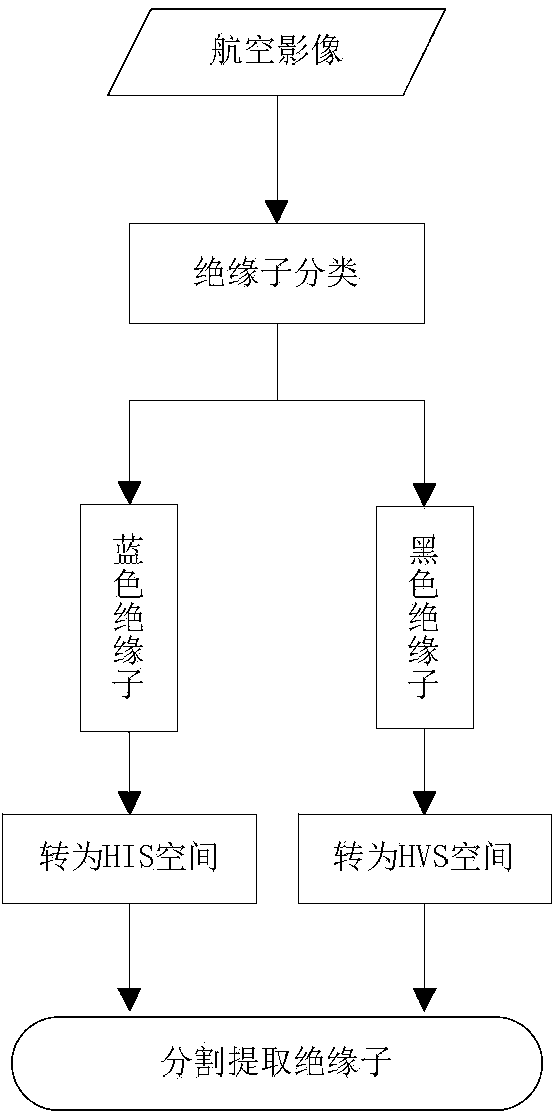

Unmanned plane patrol method and system

ActiveCN106371456ARealize automatic planningAutomate analysisPosition/course control in three dimensionsApparatus for overhead lines/cablesData acquisitionUncrewed vehicle

The invention provides an unmanned plane patrol method and system. The method comprises steps that a data acquisition step, the data is acquired; a facial area generation step, a facial area object is generated; a task sub area planing step, the DEM data is processed through GIS buffer area analysis to generate the facial area object, and the facial area object is divided into multiple sub areas according to a height difference threshold of an unmanned plane; a course data generation step, the preliminary course data is sequentially connected to generate the course data; a patrol data acquisition step, the unmanned plane flies along a line determined by the course data and acquires the patrol data, and the patrol data comprises the original image data and the POS data; and an automatic line defect analysis step, a power line dangerous point interpretation result is automatically generated. Through the method, automatic patrol of the unmanned plane is realized through automatic task area patrol planning and automatic line defect analysis of the unmanned plane.

Owner:CHINA TOPRS TECH

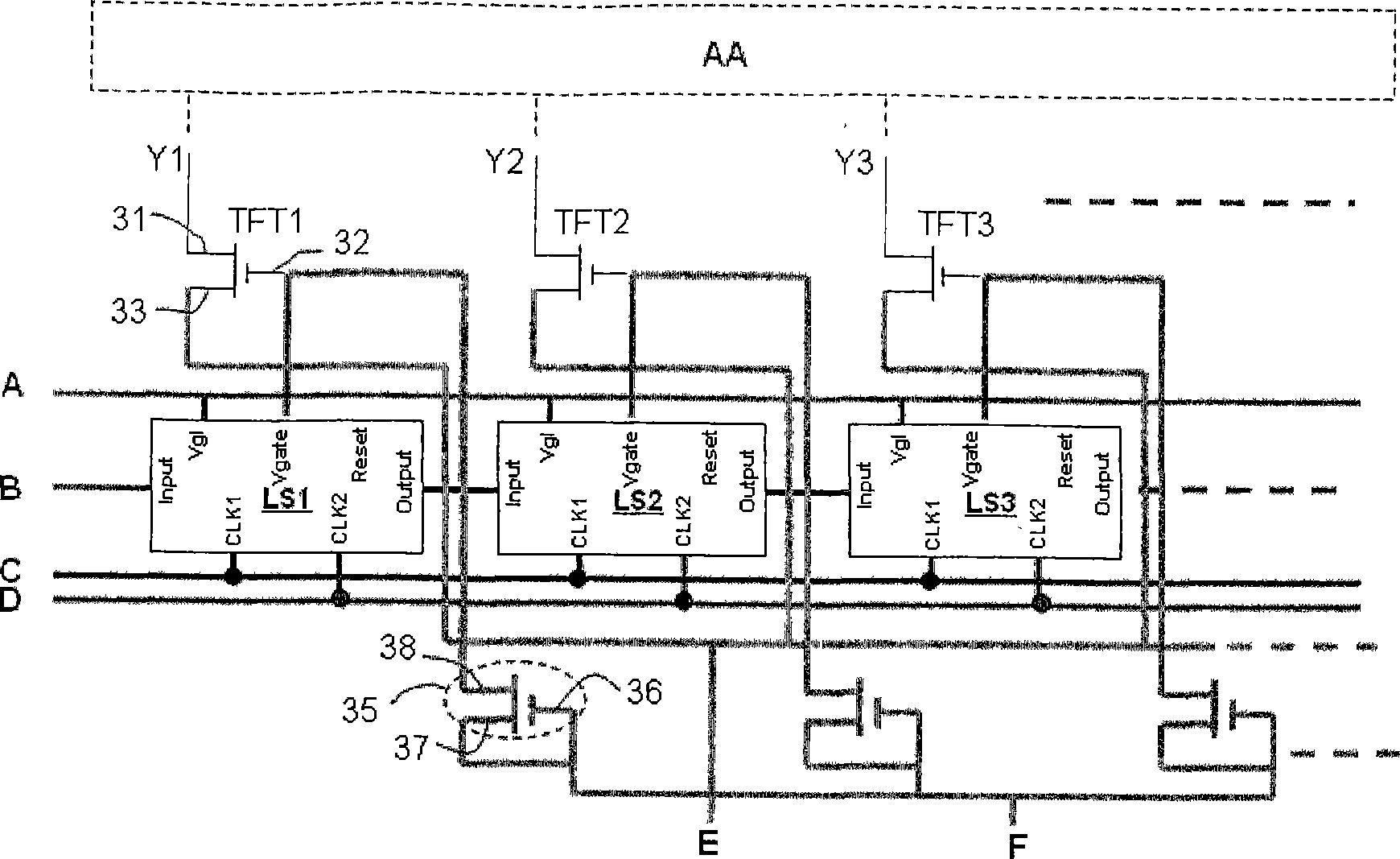

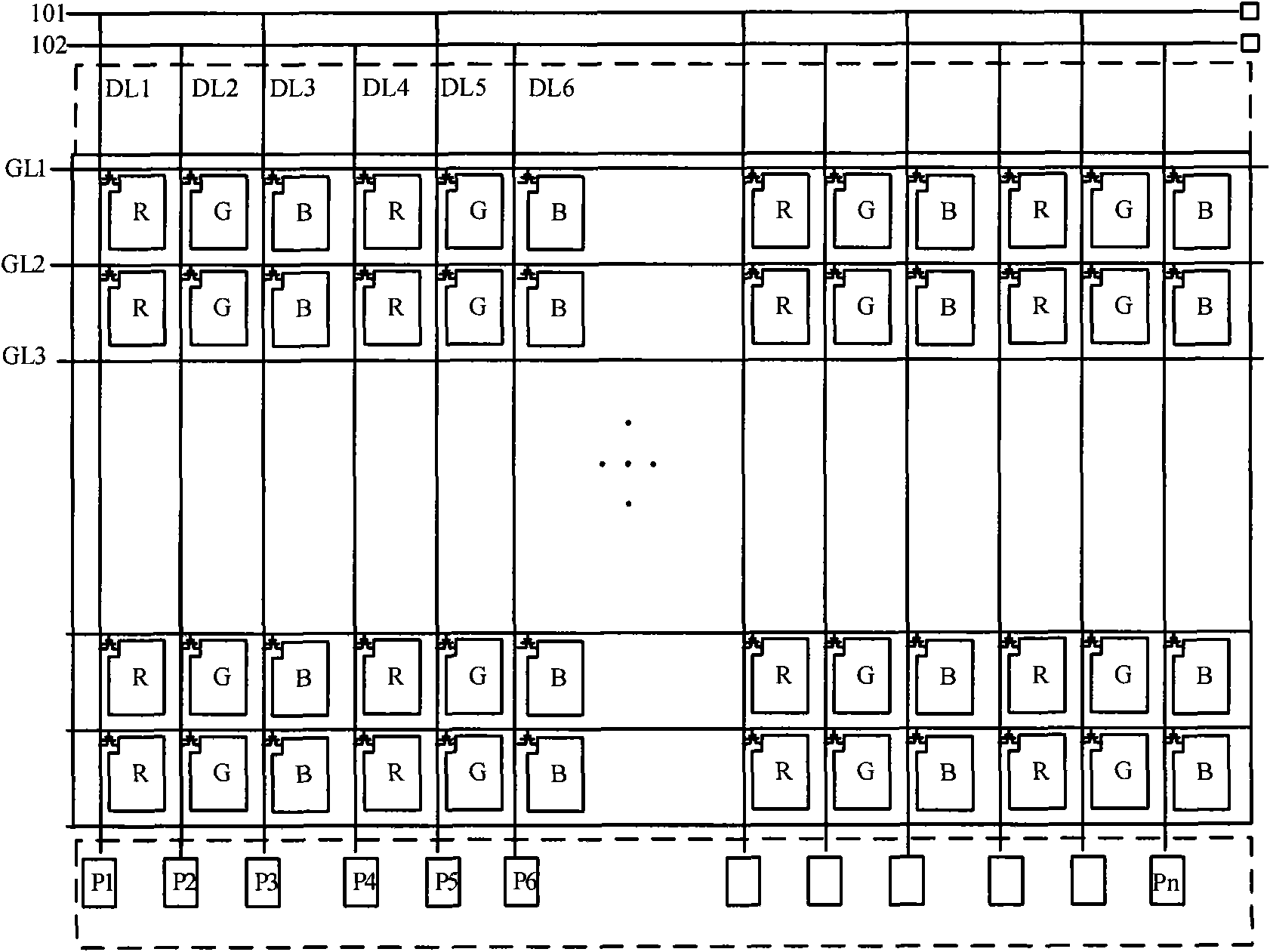

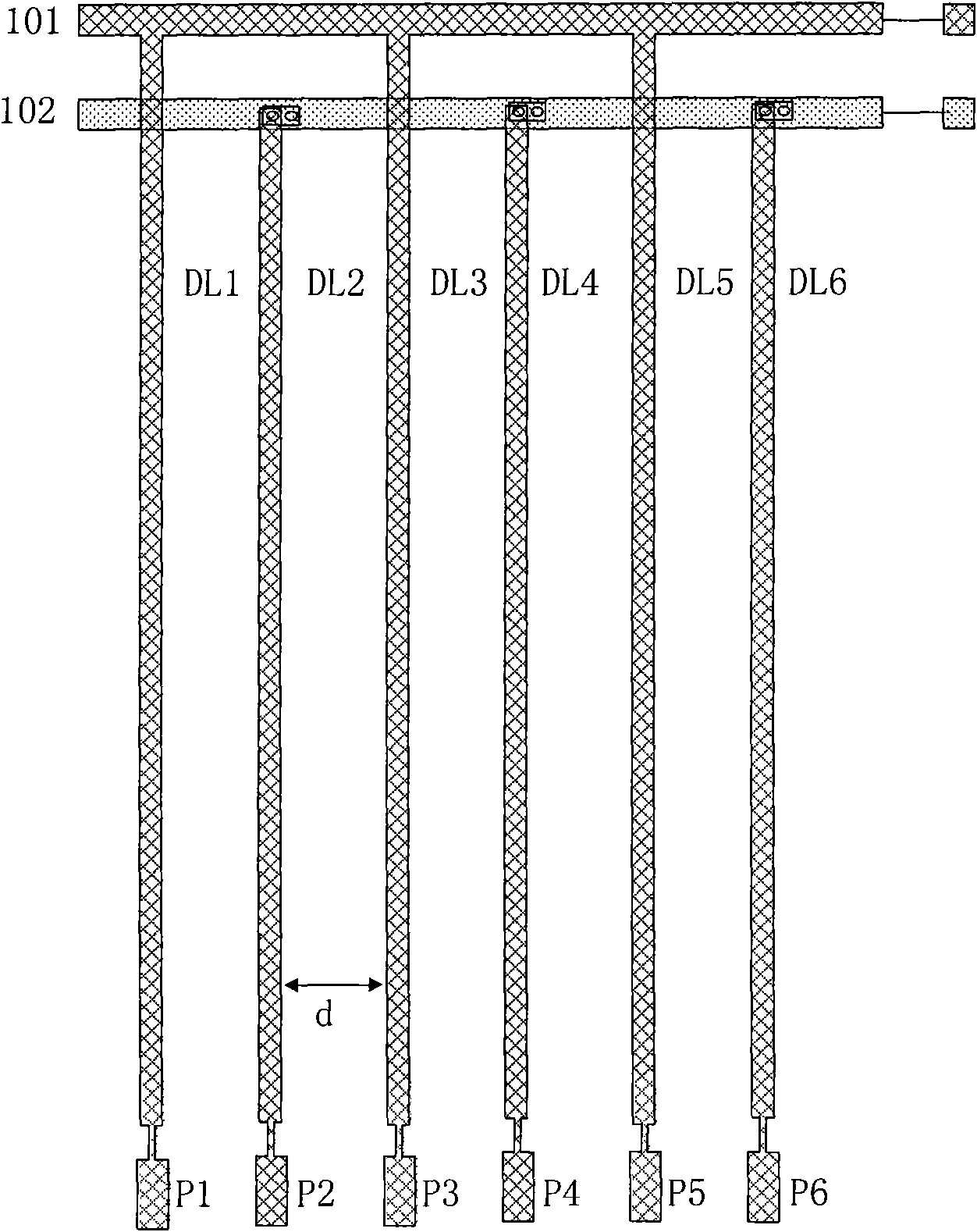

A method for testing line defects of LCD (liquid crystal display) panel, array substrate and drive wires

ActiveCN102109688AReduce in quantityReduce the number of probesElectrical testingNon-linear opticsLiquid-crystal displayEngineering

A method for testing line defects of an LCD panel, an array substrate and drive wires. The LCD panel comprises a plurality of groups of drive wires and a plurality of detection terminals, and each group of the drive wires at least comprises two drive wires, wherein the LCD panel further comprises a plurality of first switches, a plurality of second switches, a first switch control wire used for controlling the plurality of first switches, and a second switch control wire used for controlling the plurality of second switches, and one end of each of the two drive wires of at least one group of the drive wires is connected with one detection terminal through one first switch and one second switch respectively. At least two drive wires share one first detection terminal, so that the using times of probes can be reduced; the distance among the detection terminals are enlarged, and the defect of detection error caused by short circuit of the adjacent probes as soon as the probes are slightly bent can be avoided.

Owner:BEIHAI HKC OPTOELECTRONICS TECH CO LTD

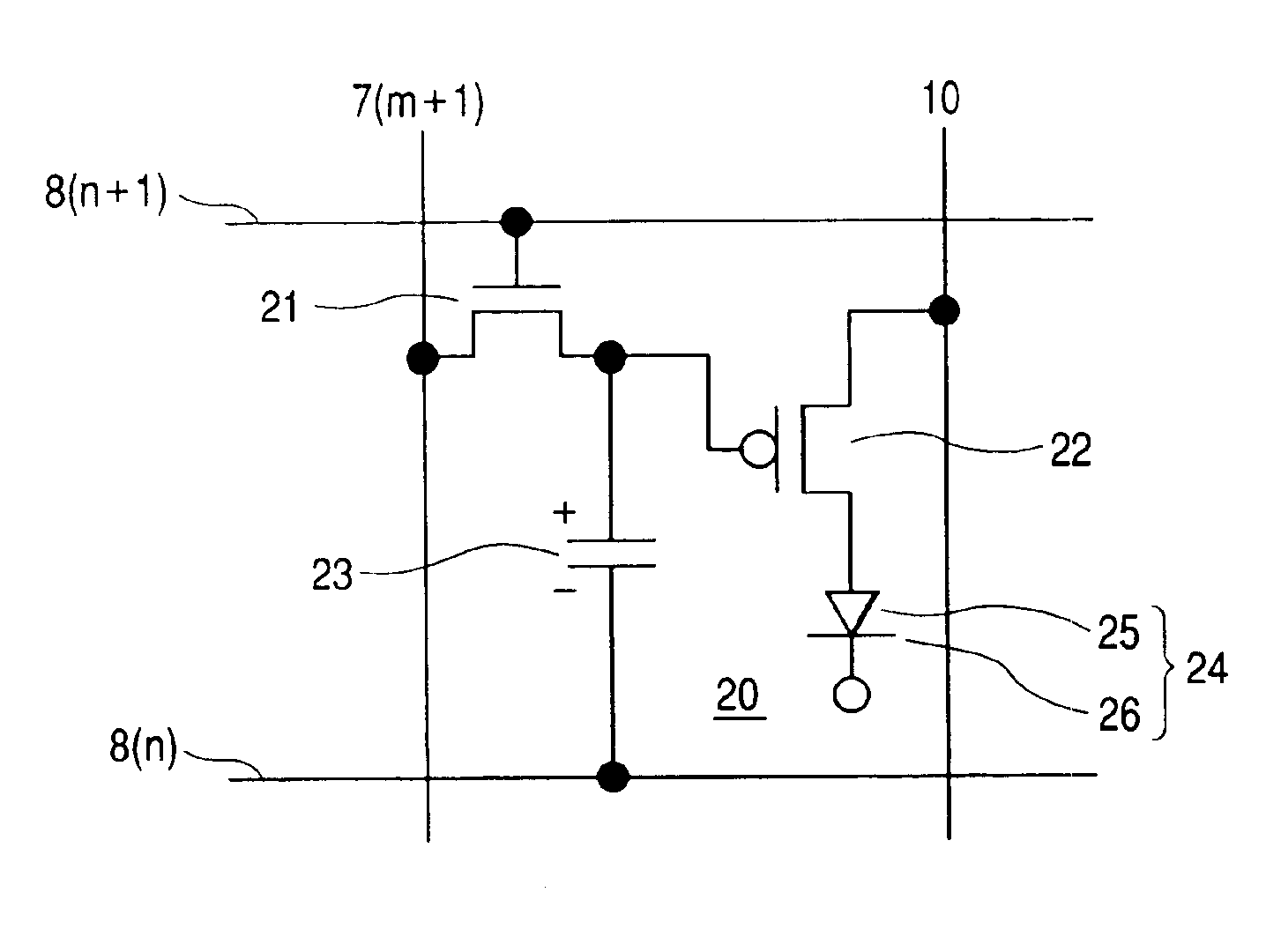

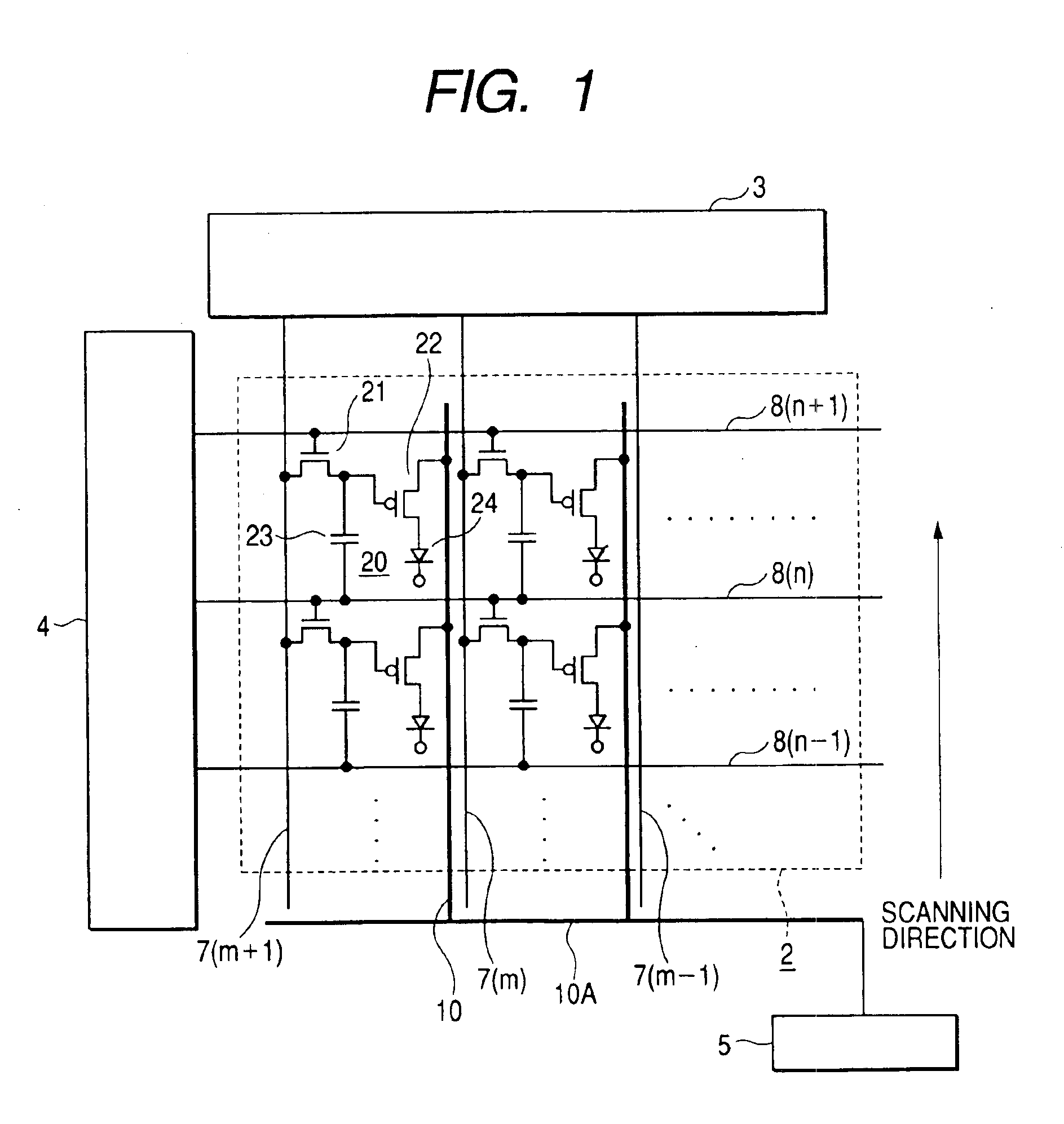

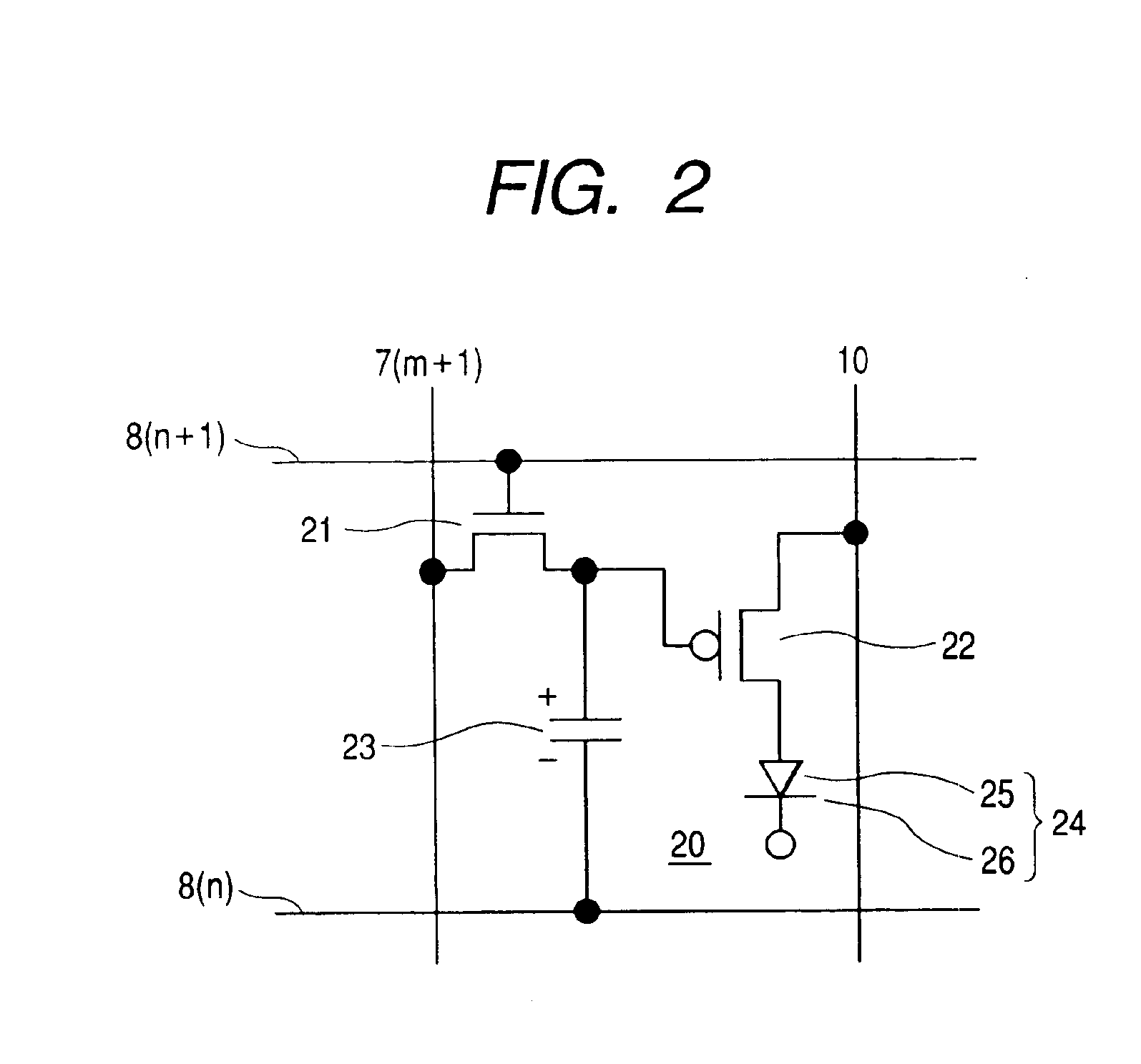

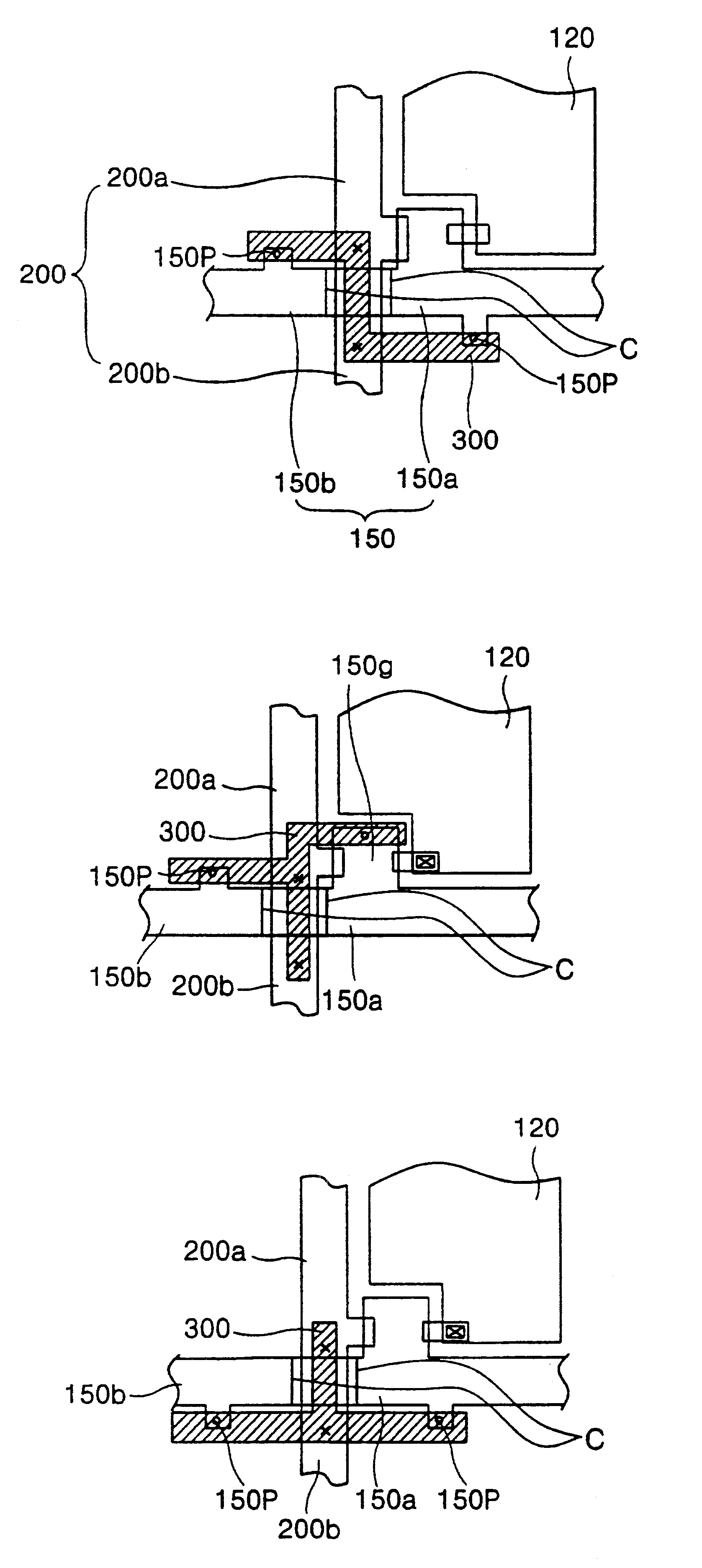

Display module

InactiveUS6919886B2Prevent such display fault as line defectAvoids increase of number of productionSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceData signal

An organic light emitting diode (OLED) display module is provided wherein the aperture ratio of the respective pixels thereof improves and such display faults as line defect is prevented so as to allow image to be displayed with high quality. The display module is provided with a capacitor, a first terminal of which is connected to an output terminal of the first transistor as selected by the scanning line and a second terminal of which is connected to the gate placed anterior thereto, wherein the electric current is supplied to an organic emitting device in response to the data signal as supplied from the data line through the second transistor, which turns into on-state condition when the first transistor is put into an off-state condition, and as stored in the capacitor.

Owner:SAMSUNG DISPLAY CO LTD +1

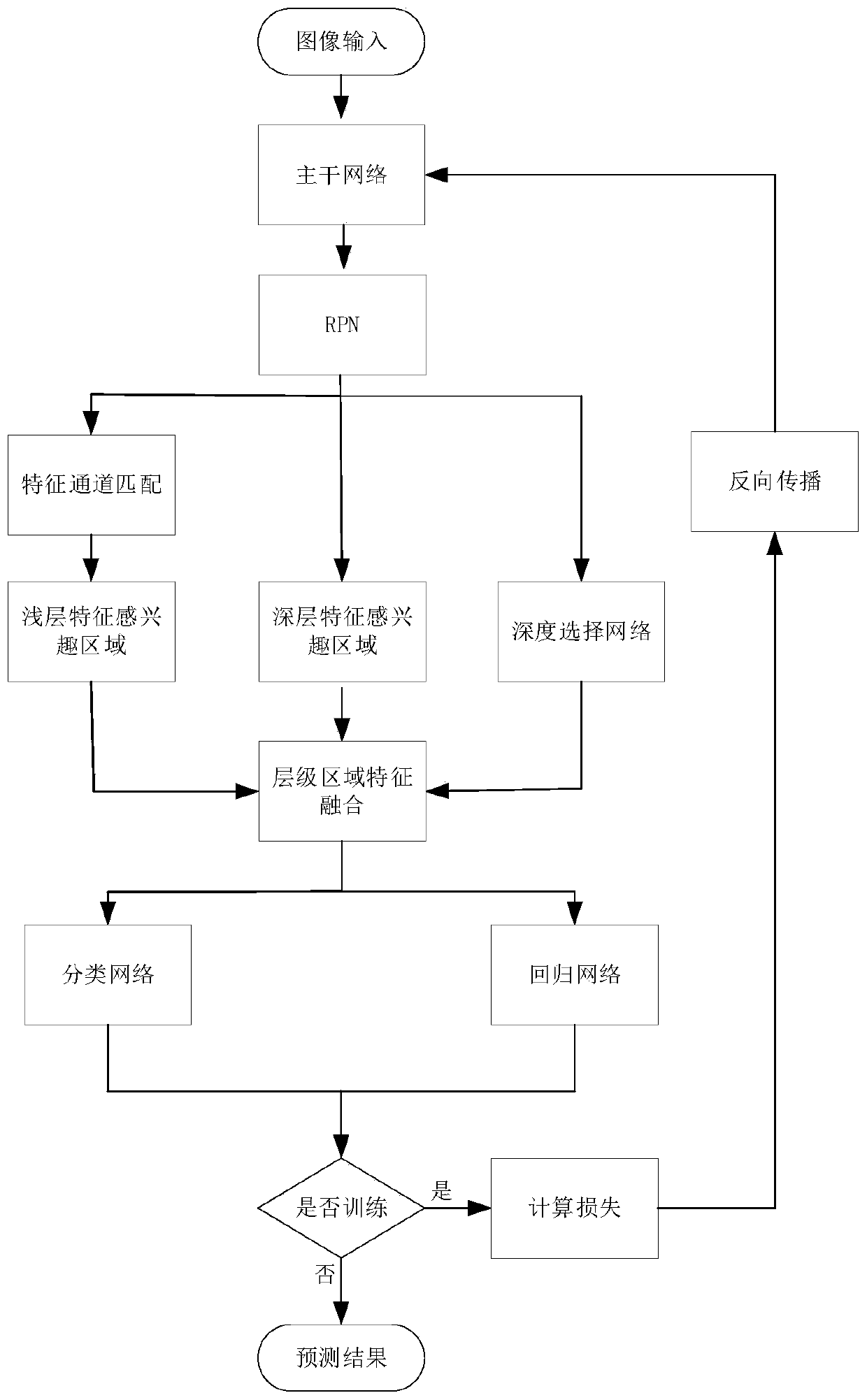

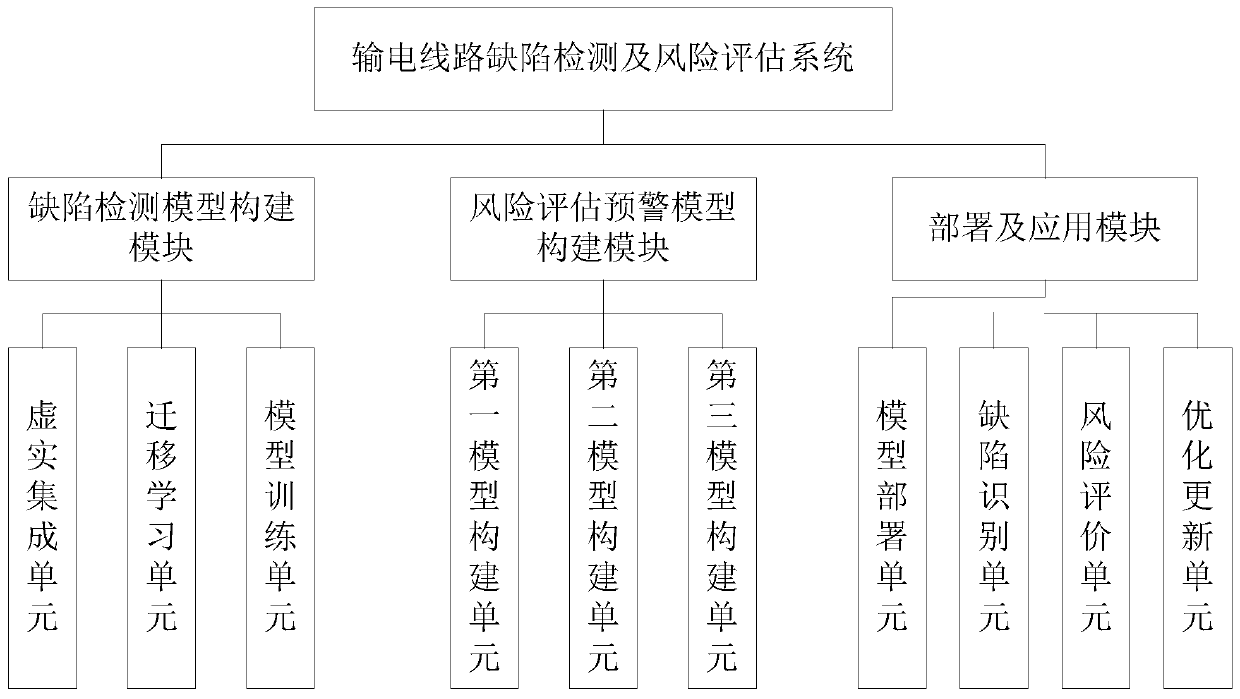

Power transmission line defect detection method based on hierarchical region feature fusion learning

ActiveCN110335270AImprove perceptionShorten the timeImage enhancementImage analysisPattern recognitionLine defects

The invention discloses a power transmission line defect detection method based on hierarchical region feature fusion learning. The power transmission line defect detection method comprises the stepsof constructing and calling a Faster R-CNN model; performing RPN network regression on the target features extracted by the backbone network to obtain a target area; carrying out roI pooling operationon an input image to generate local hierarchical region features, and generating weights required by feature fusion through deep selection network learning to fuse a deep feature region and a shallowfeature region; and generating a final prediction result through the classification network and the regression network. According to the invention, a self-learning regional feature fusion weight is generated by using a deep selection network; saving time to adjust parameters, fusion features obtained by model learning can better adapt to defect detection tasks under different complex conditions;the depth model performs prediction by using the regional features, enhances the learning ability of the model for extracting the local features of the target, and reduces the false detection problemof the model in the actual environment due to the complex background of the defect image of the power transmission line and the inter-class difference.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +4

Power line defect diagnosis method based on visible light image

InactiveCN103413150ACharacter and pattern recognitionOptically investigating flaws/contaminationImage extractionImaging Feature

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

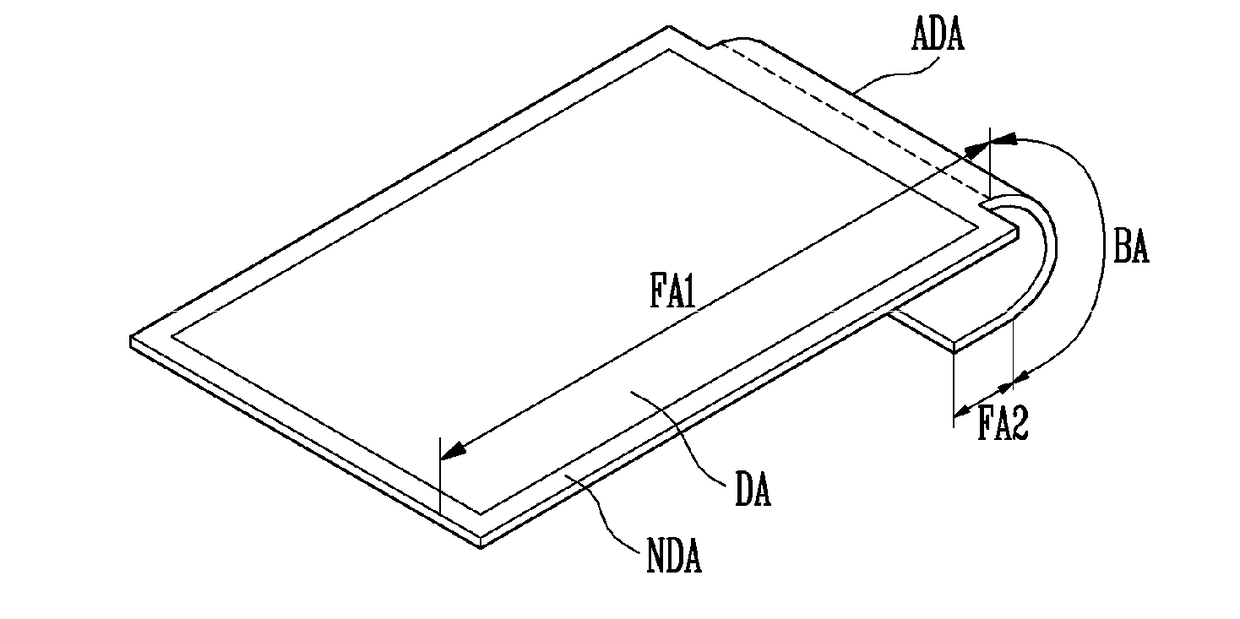

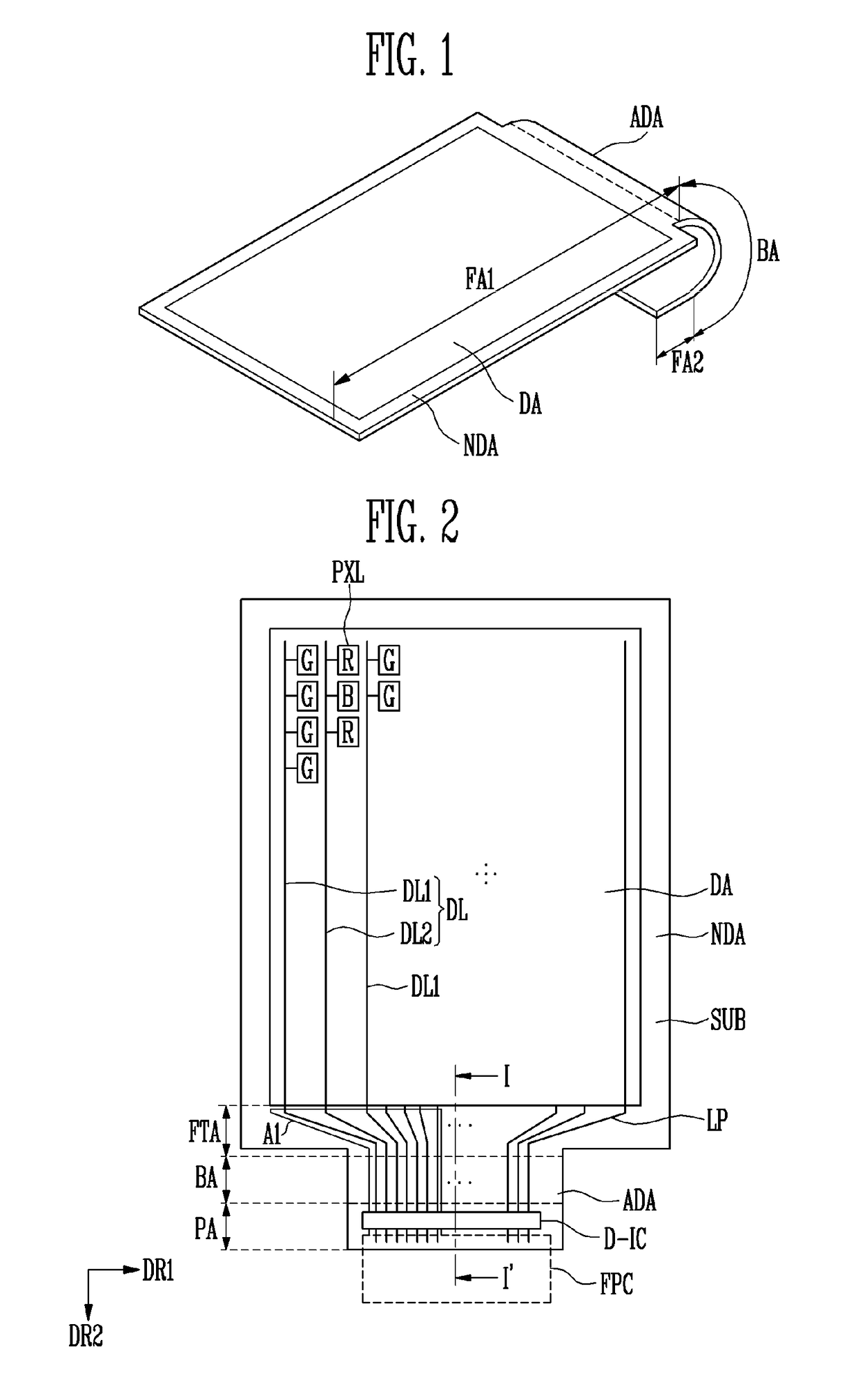

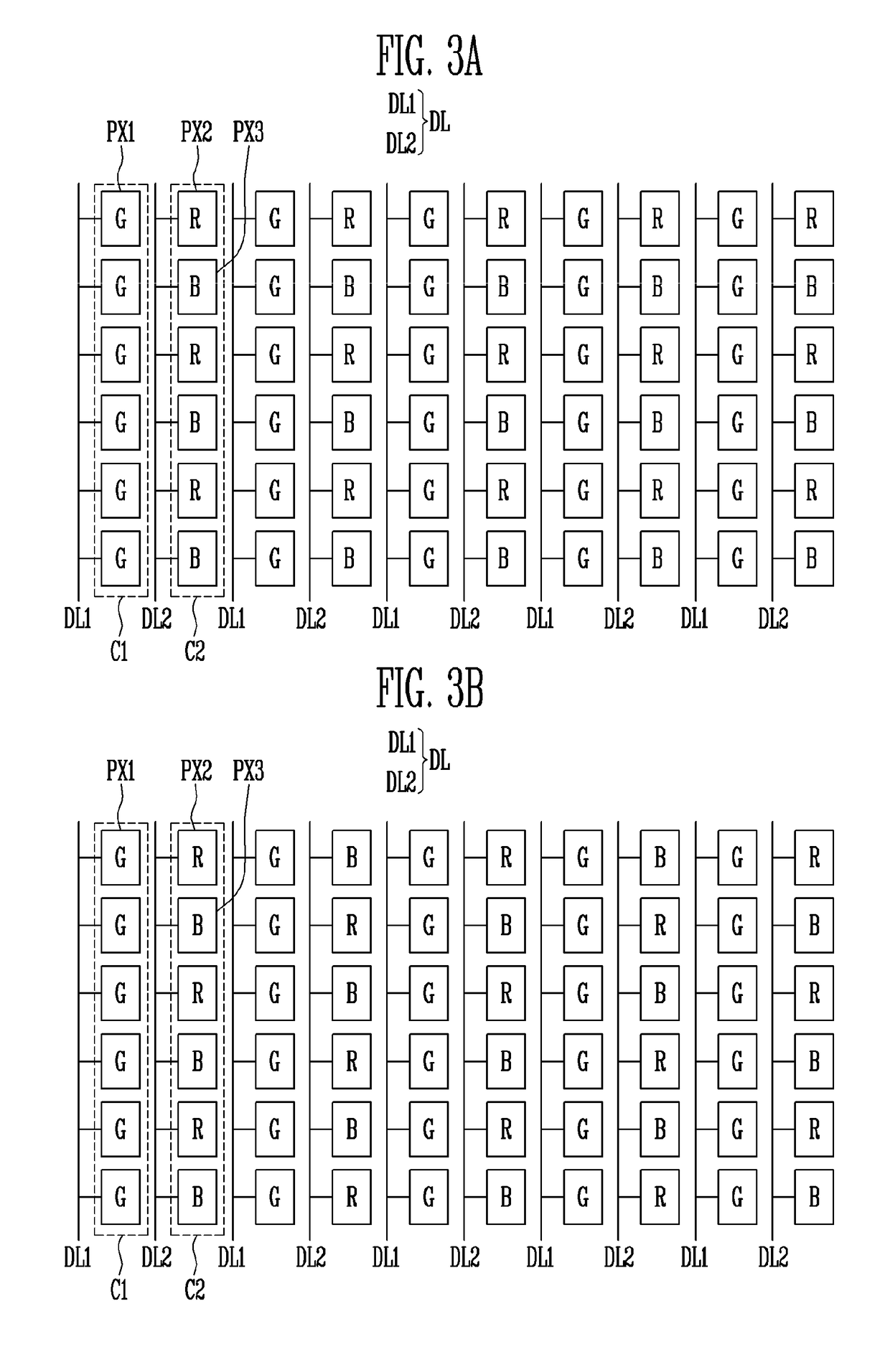

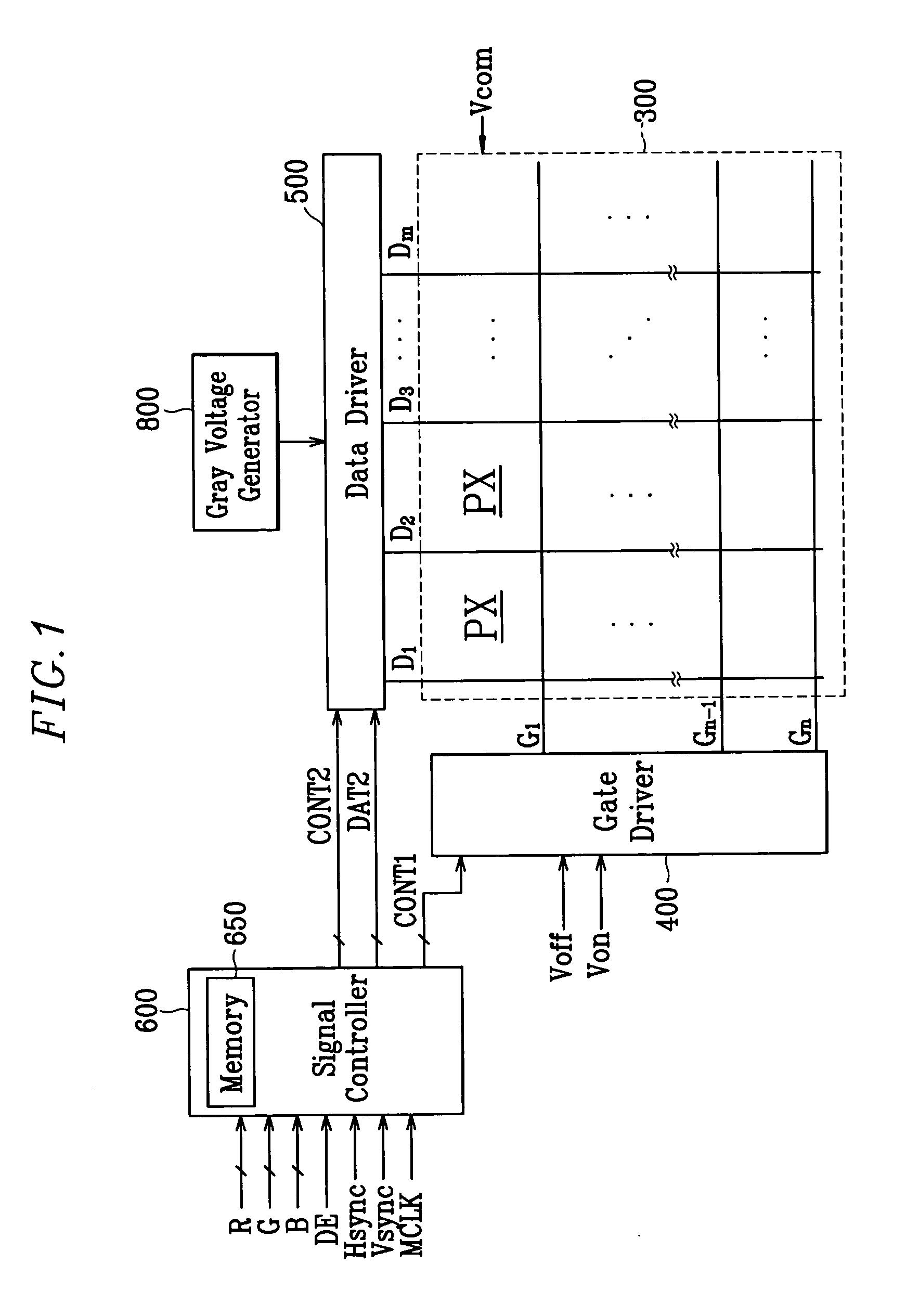

Display device

ActiveUS20180197484A1Reduces resistance deviationReducing vertical line defectsStatic indicating devicesSolid-state devicesDisplay deviceComputer science

A display device includes a substrate which includes a display area and a non-display area, a pixel unit which is provided in the display area and includes a plurality of pixel columns, and data lines which are respectively connected to the pixel columns and apply data signals to the pixel columns. The non-display area includes a fanout area, a bent area, and a pad area which are sequentially arranged. The respective data lines are disposed on different layers in the fanout area and the pad area. A resulting display device can reduce resistance deviation between data signals in a first data line and a second data line, thereby reducing vertical line defects

Owner:SAMSUNG DISPLAY CO LTD

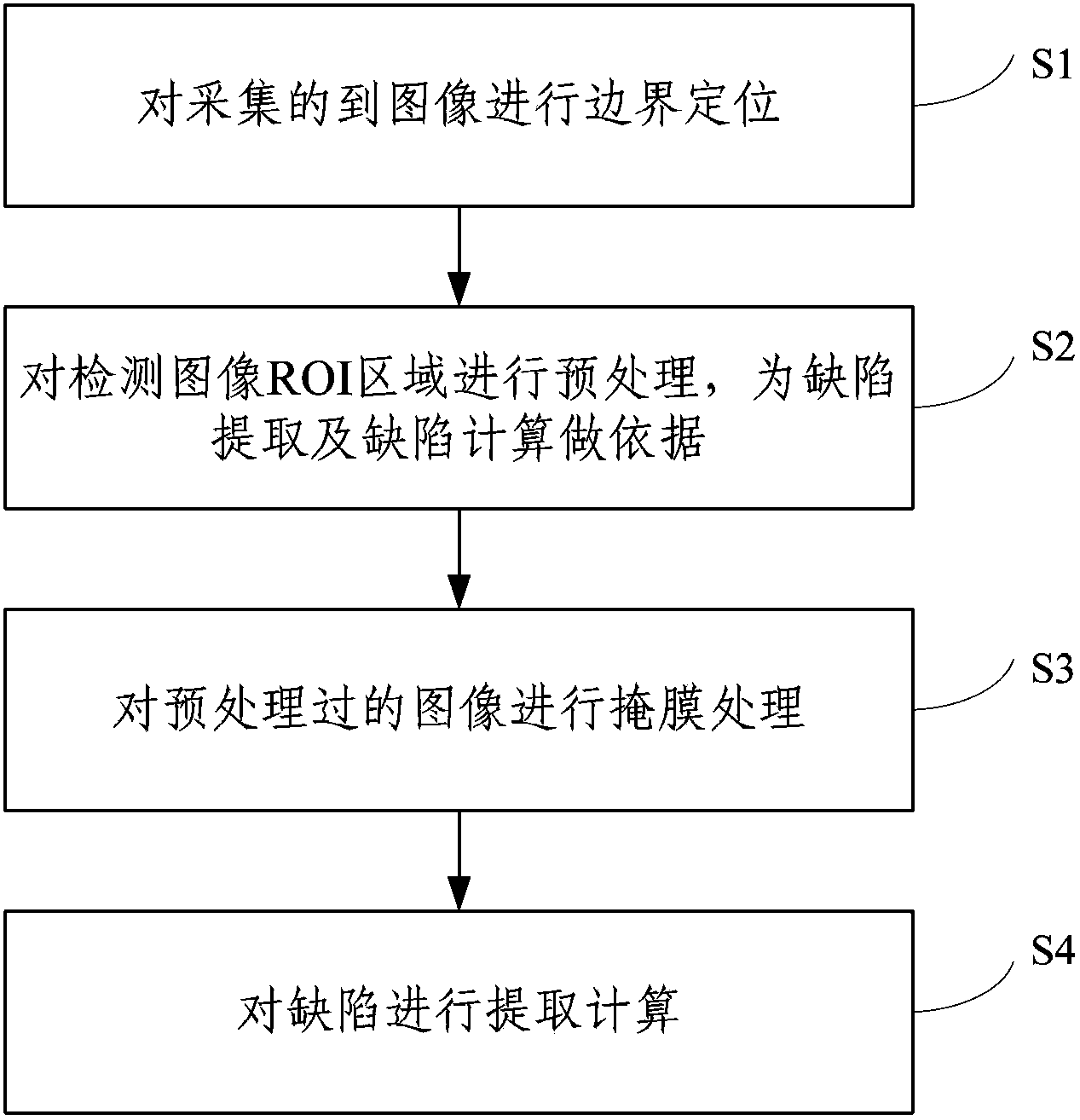

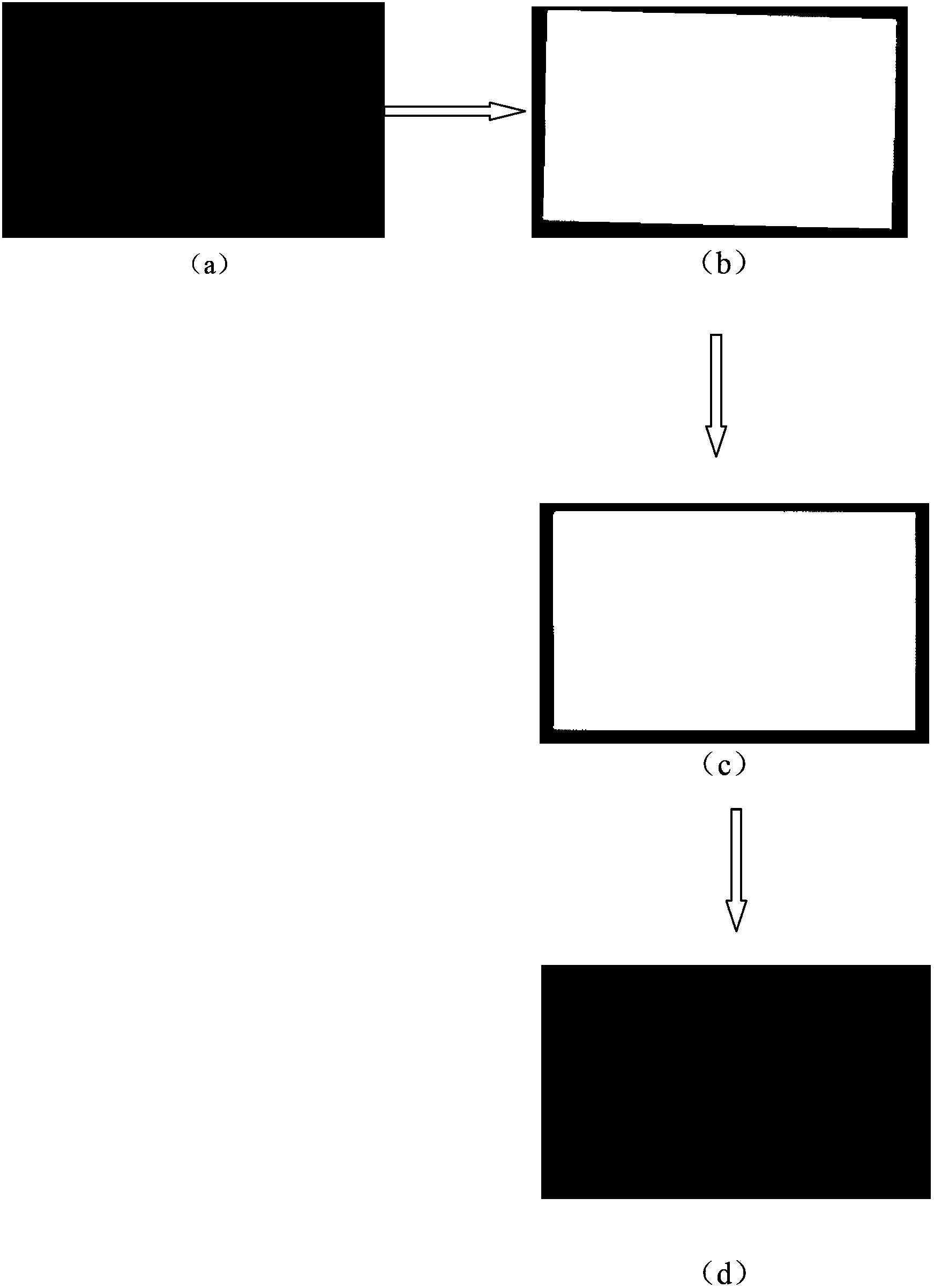

TFT-LCD lighting automatic optical inspection based image processing method

InactiveCN103913461AEasy image processingGuaranteed detection rateImage analysisOptically investigating flaws/contaminationImaging processingImage detection

The invention relates to the technical field of image detection, and especially relates to a TFT-LCD lighting automatic optical inspection based image processing method. The image processing method comprises the following steps: acquiring images of a display screen in different modes; preprocessing the acquired images to remove the background interference; carrying out mask treatment on the preprocessed images; and carrying out defect extraction and calculation. The TFT-LCD lighting automatic optical inspection based image processing method uses a plurality of automatic optical inspection modes, can realize the normal detection of spot, line and Mura defects, and can realize the accurate positioning of light spot and light line defects to a sub-pixel, and the classification of the Mura defects according to an SEMU criterion. The image processing method has the advantages of simple flow, and effective ensure of the detection rate.

Owner:BEIJING C&W ELECTRONICS GRP

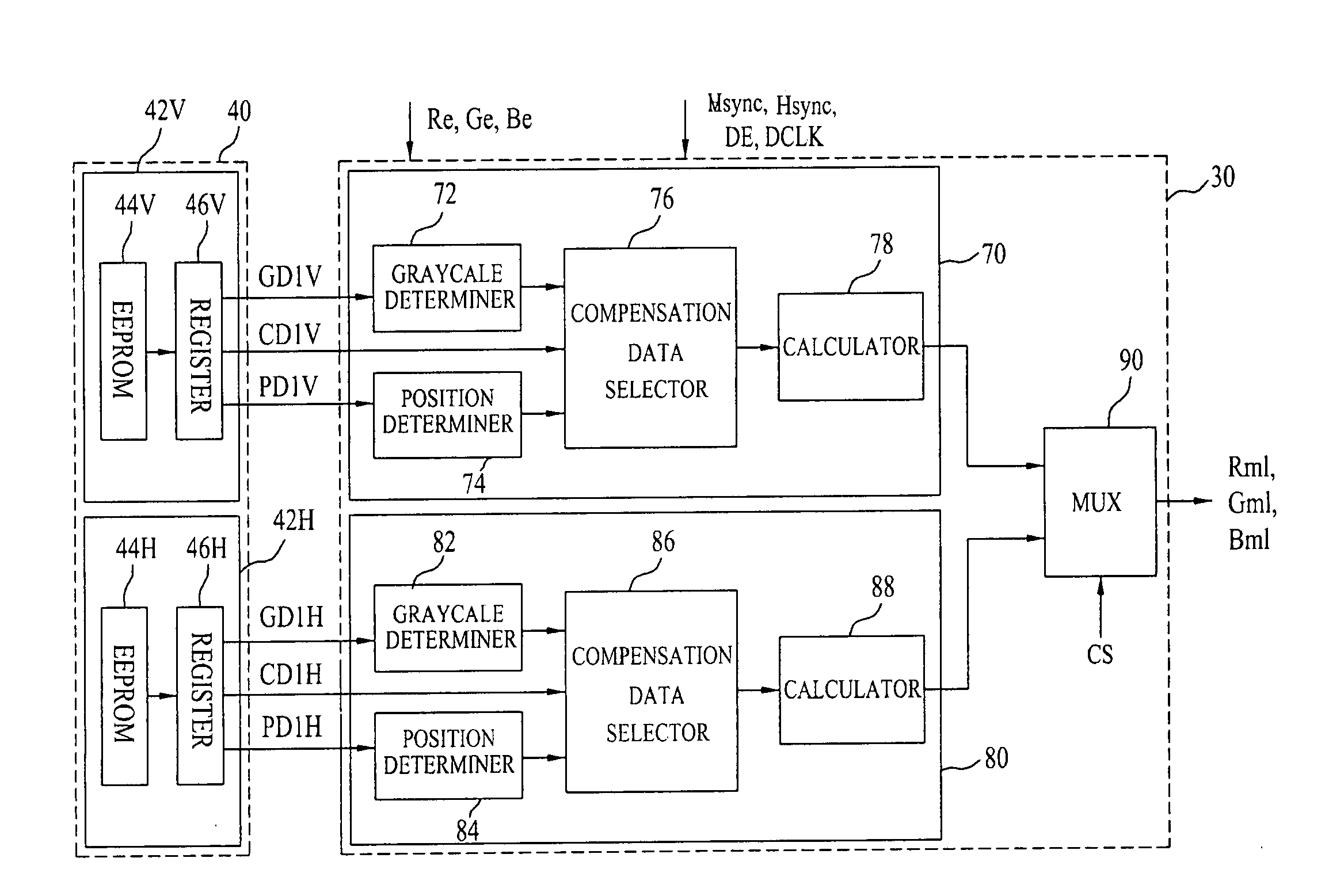

Video display device capable of compensating for display defects

ActiveUS20080309602A1Simple circuit configurationStatic indicating devicesControl signalDisplay device

A video display device capable of compensating for display defects, comprising: liquid crystal panel for displaying an image through a pixel matrix; a data driver for outputting data to data lines of the liquid crystal display panel; a gate driver for driving the gate lines of the liquid crystal display panel; a timing controller for receiving compensated data, uncompensated data and synchronizing signals to output a gate control signal to the gate driver and to output both resultant data and a data control signal to the data driver; and a memory for storing information on point defect information on the liquid crystal display panel, and at least one of horizontal and vertical line defects of the liquid crystal display panel of the liquid crystal display panel; and a data compensation circuit for receiving display data and synchronizing signals, and outputting compensated data to the timing controller based on the information in the memory and uncompensated data to the timing controller, wherein the data compensation circuit includes a vertical line compensator for compensating a vertical line defect of the liquid crystal display panel, a horizontal line compensator for compensating a horizontal line defect of the liquid crystal display panel, and a multiplexer for selecting an output from one of the vertical line compensator and the horizontal line compensator in accordance with whether a defect is a vertical line defect or a horizontal line defect.

Owner:LG DISPLAY CO LTD

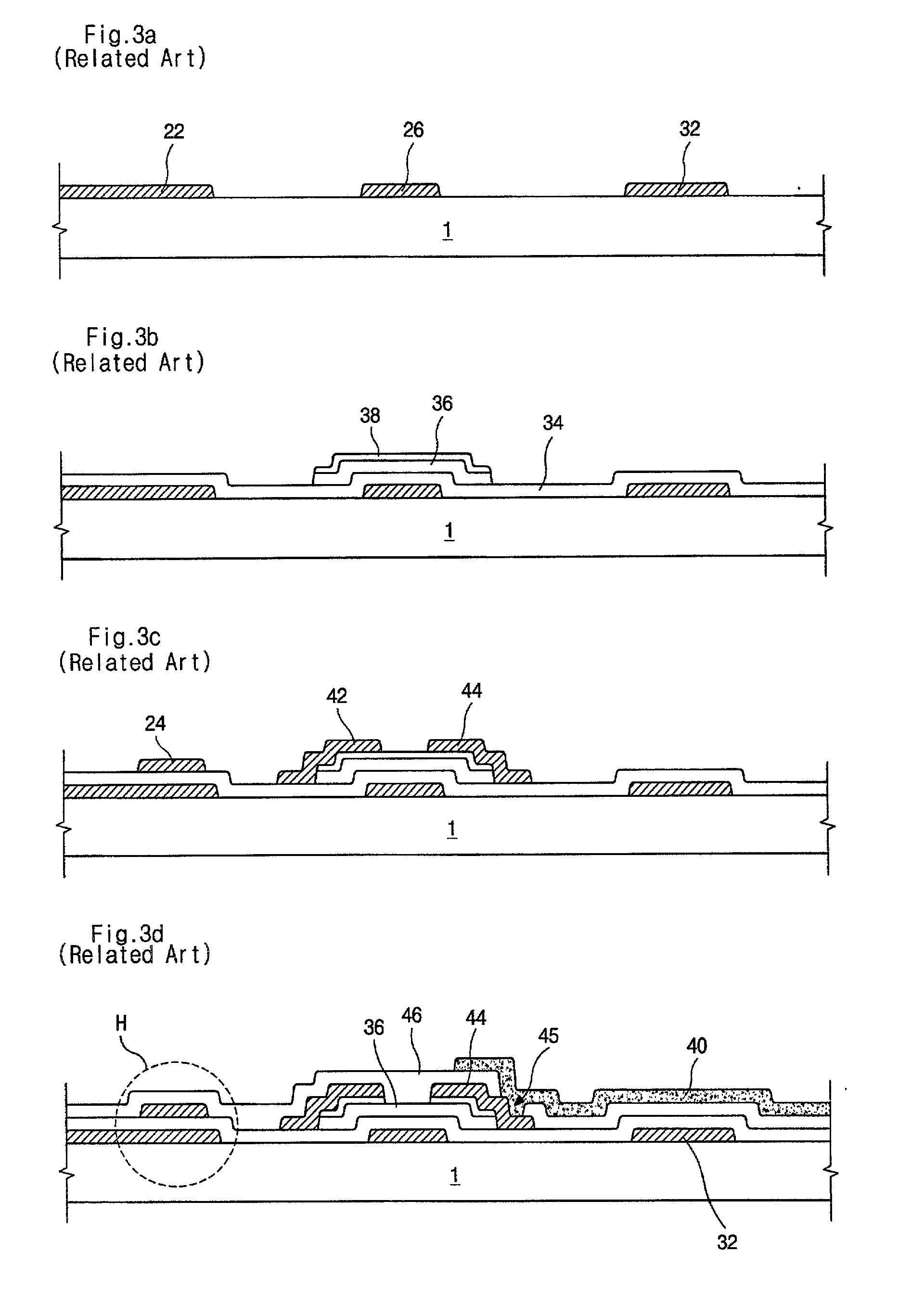

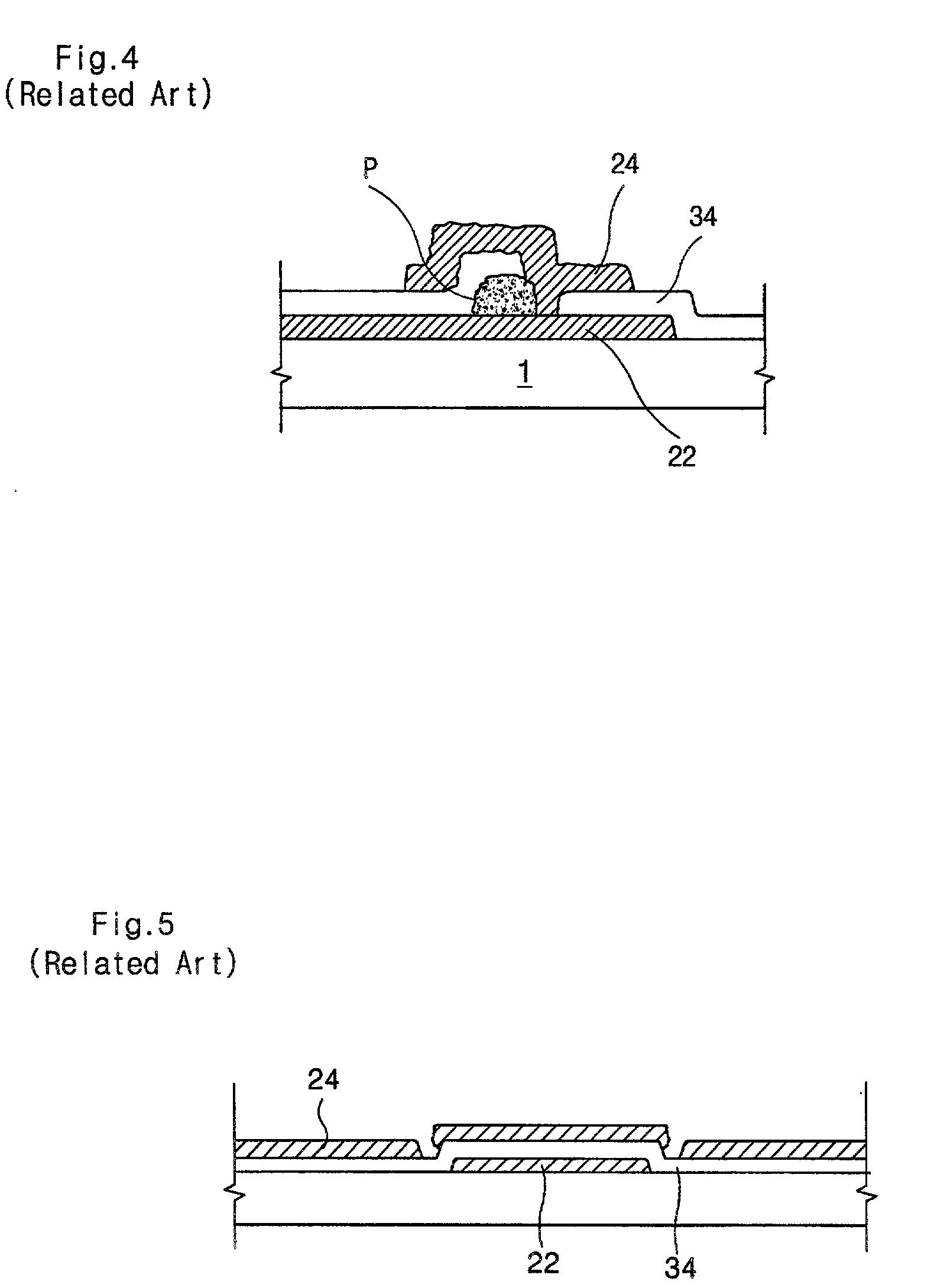

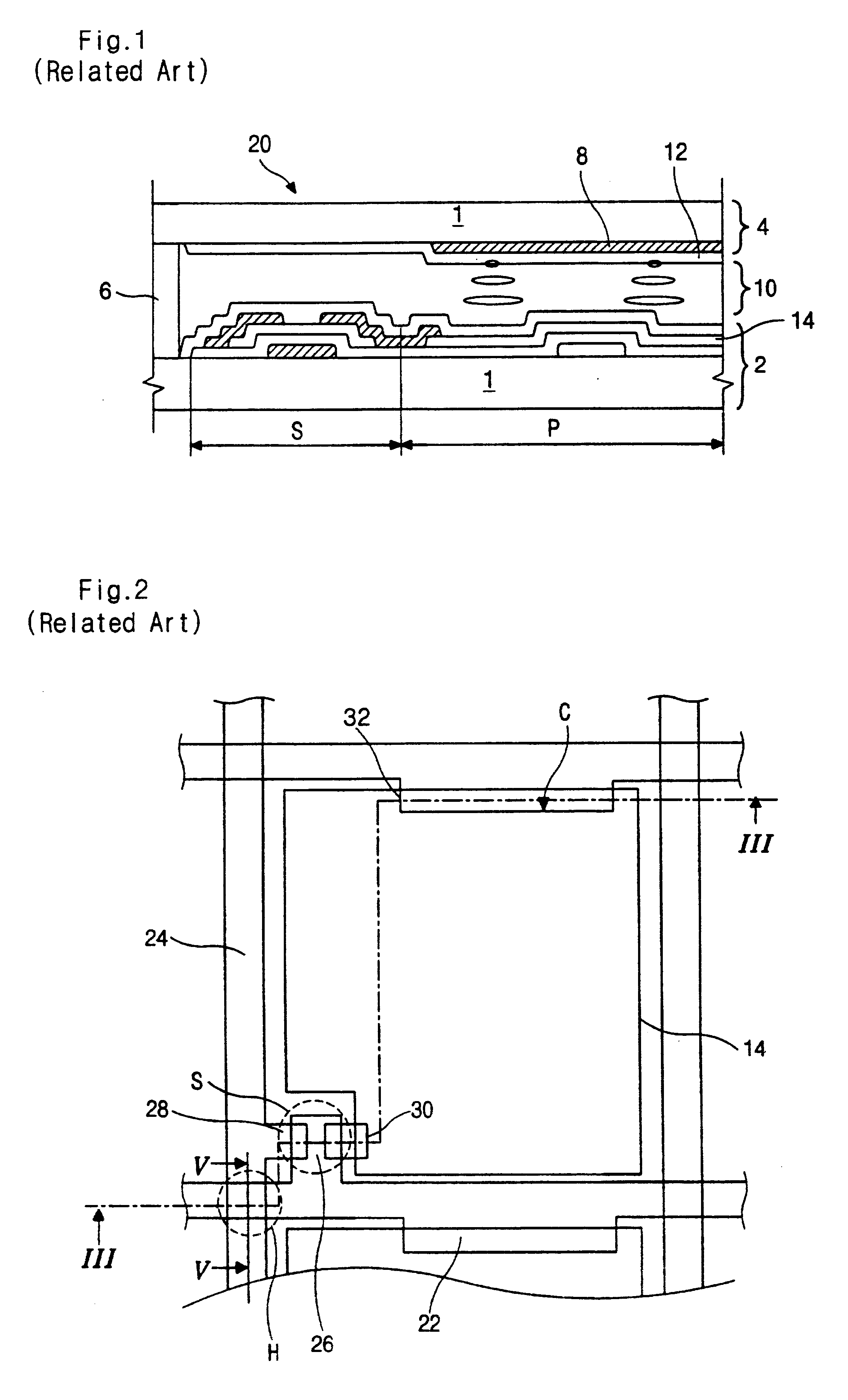

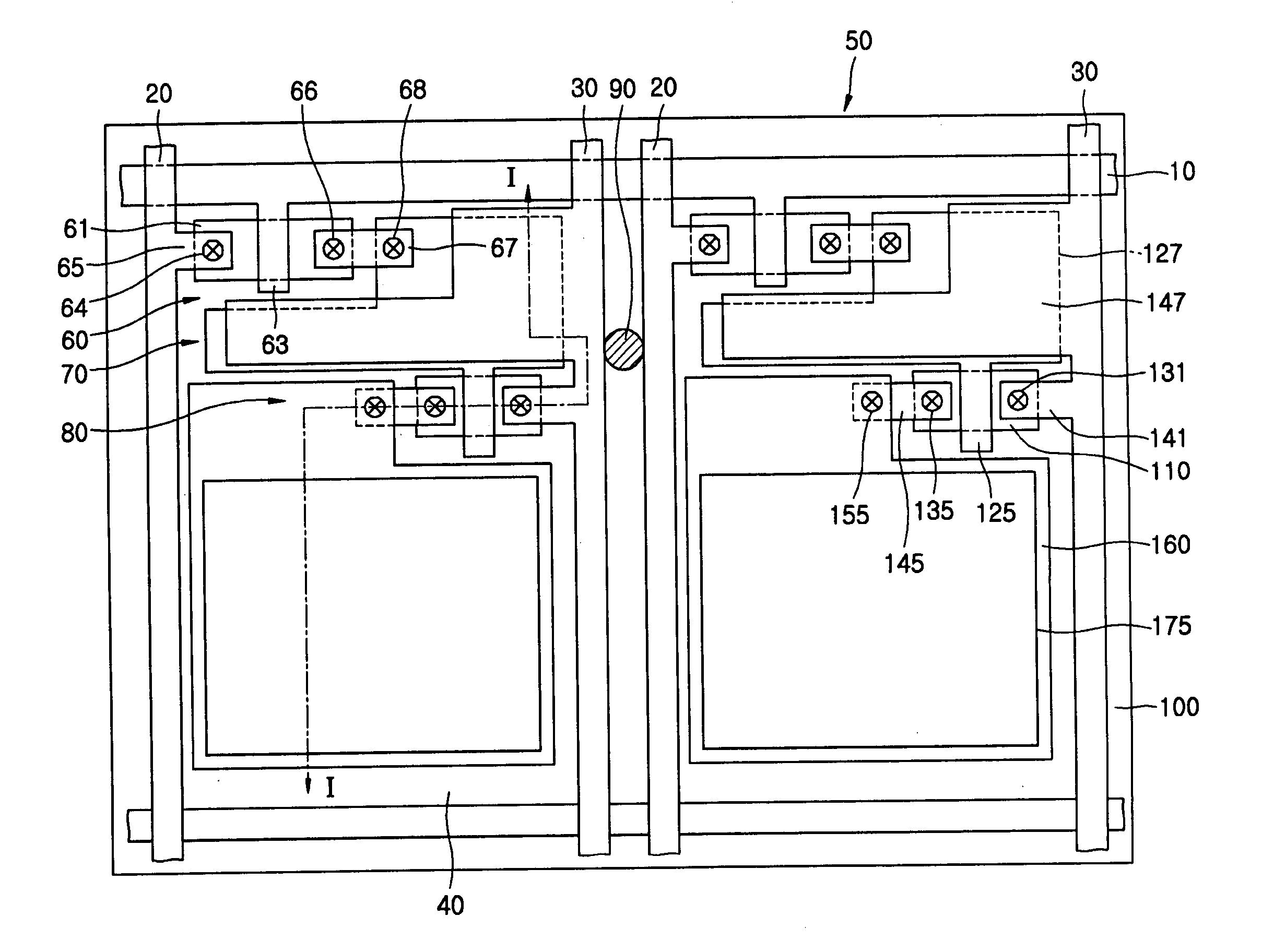

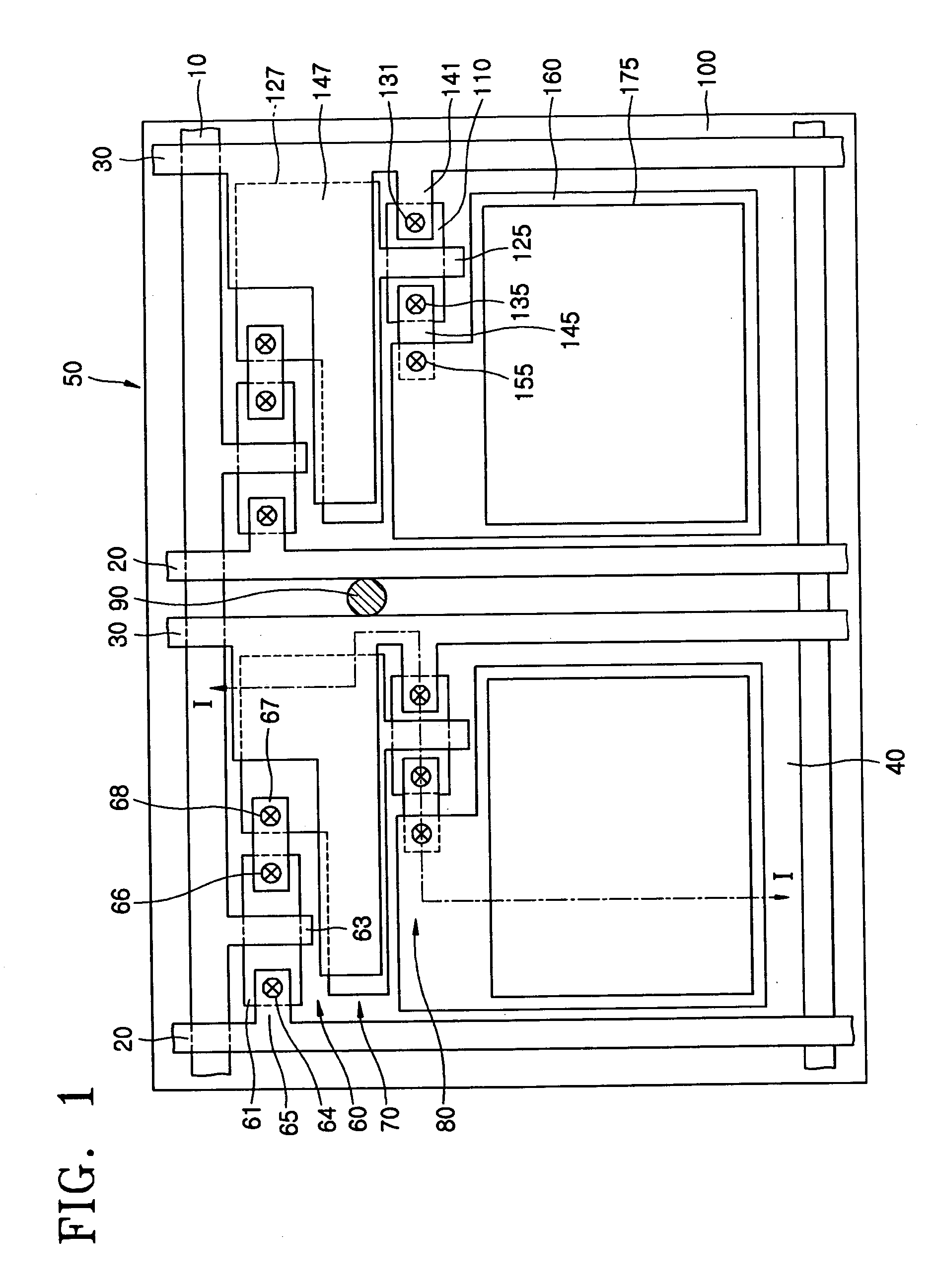

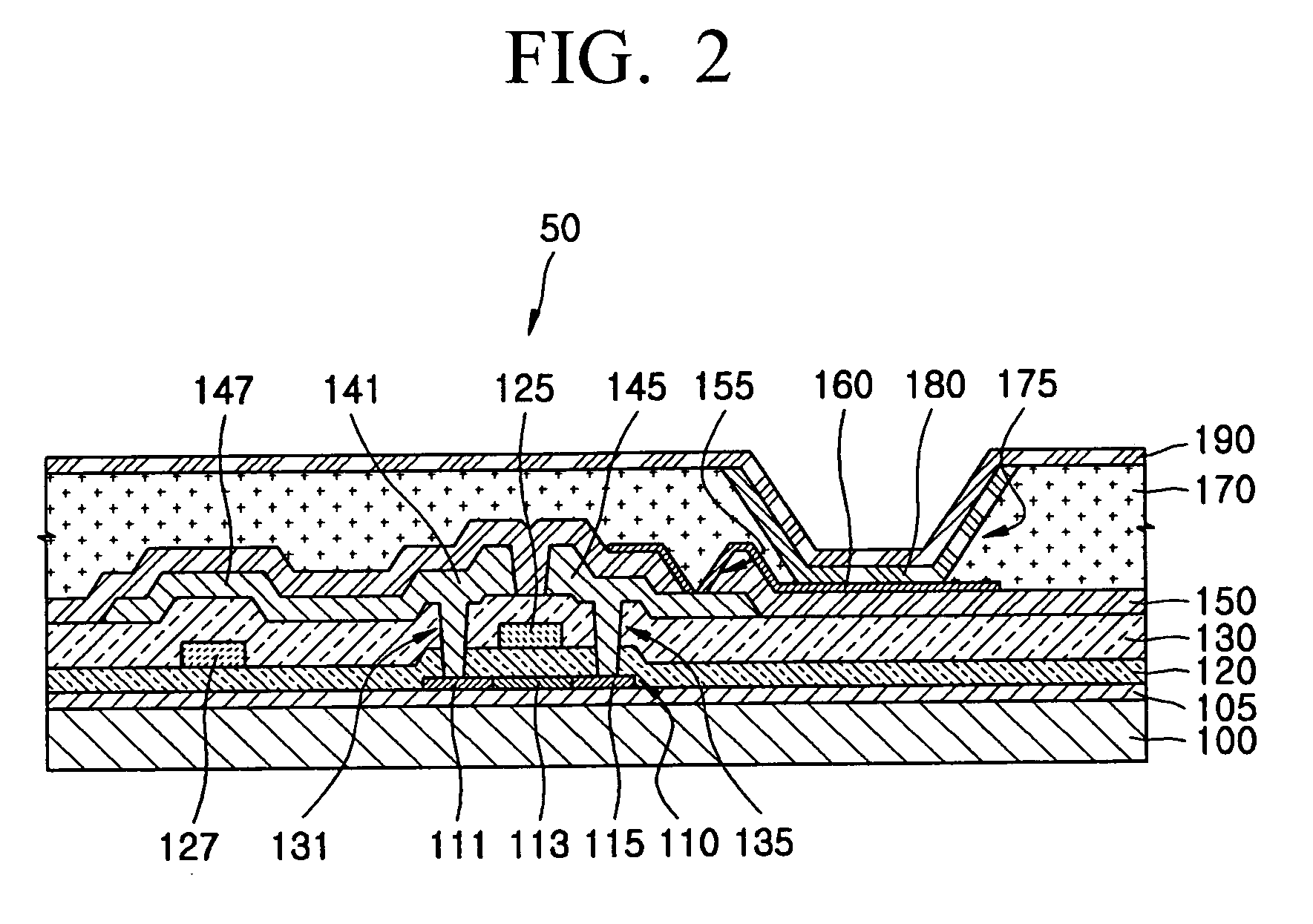

Array substrate for use in LCD device

A TFT array substrate for use in LCD device includes at least one repair line to repair the line defects. The repair line(s) is formed when forming the pixel electrode so that additional process steps are not required. Accordingly, the productivity can increase. Moreover, either the short-circuit or the open-circuit can be repaired due to the the repair line(s). Thus, in the present invention, a TFT array substrate, including: a substrate; a gate line formed on the substrate, arranged in a transverse direction and having a gate electrode; a data line insulated against the gate line by a first insulation layer, arranged in a longitudinal direction perpendicular to the gate line, having a source electrode near the cross point of the gate and data lines, and having first and second data lines which are defined by a cross point of the gate and data lines; a drain electrode space apart from the source electrode over the gate electrode; a pixel electrode connecting to the drain electrode; and a repair line(s) insulated against the data and gate lines by insulation layers and overlapping the gate and data lines, the repair line(s) overlapping a free end of the other repair line and the gate line.

Owner:LG DISPLAY CO LTD

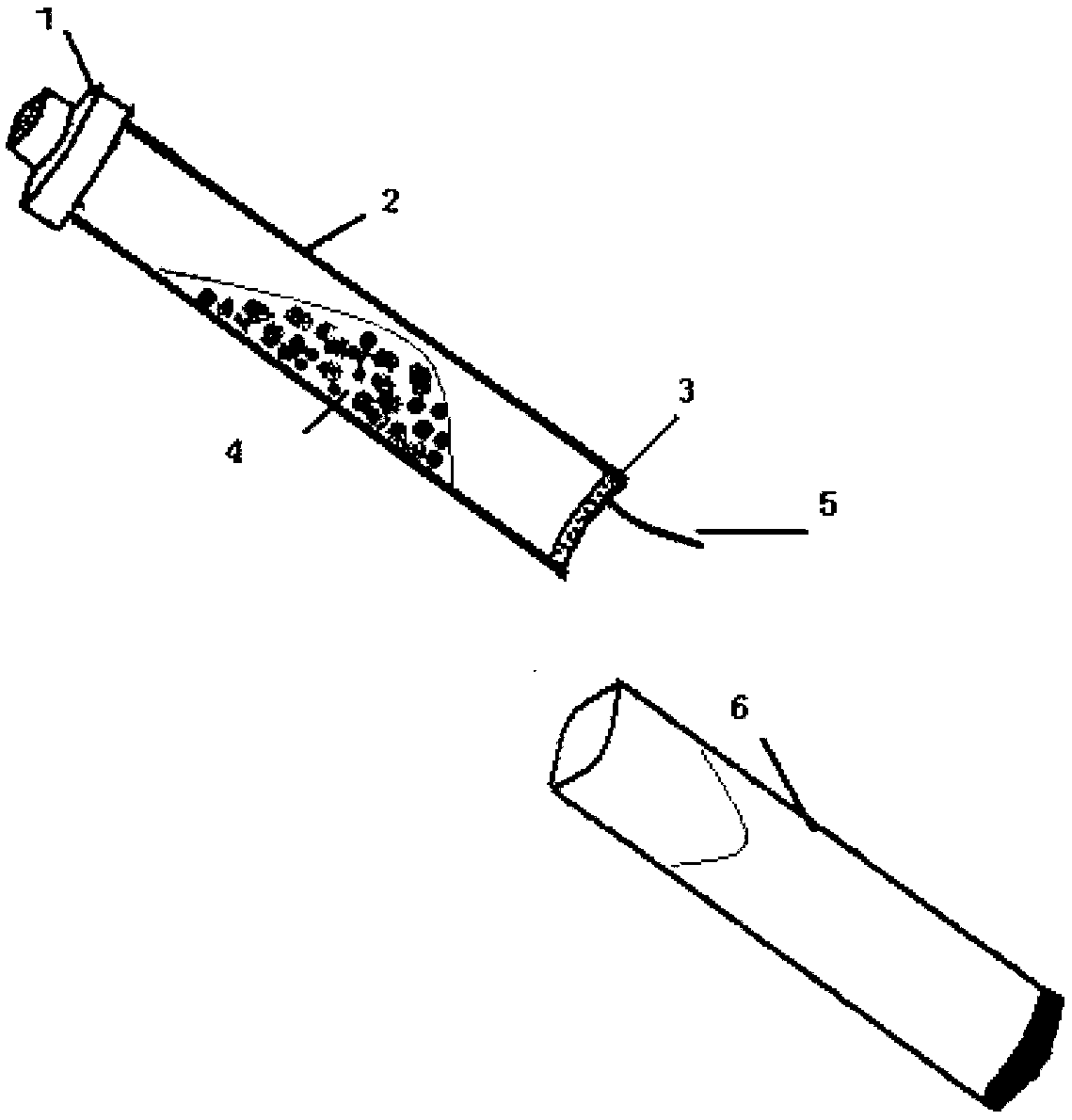

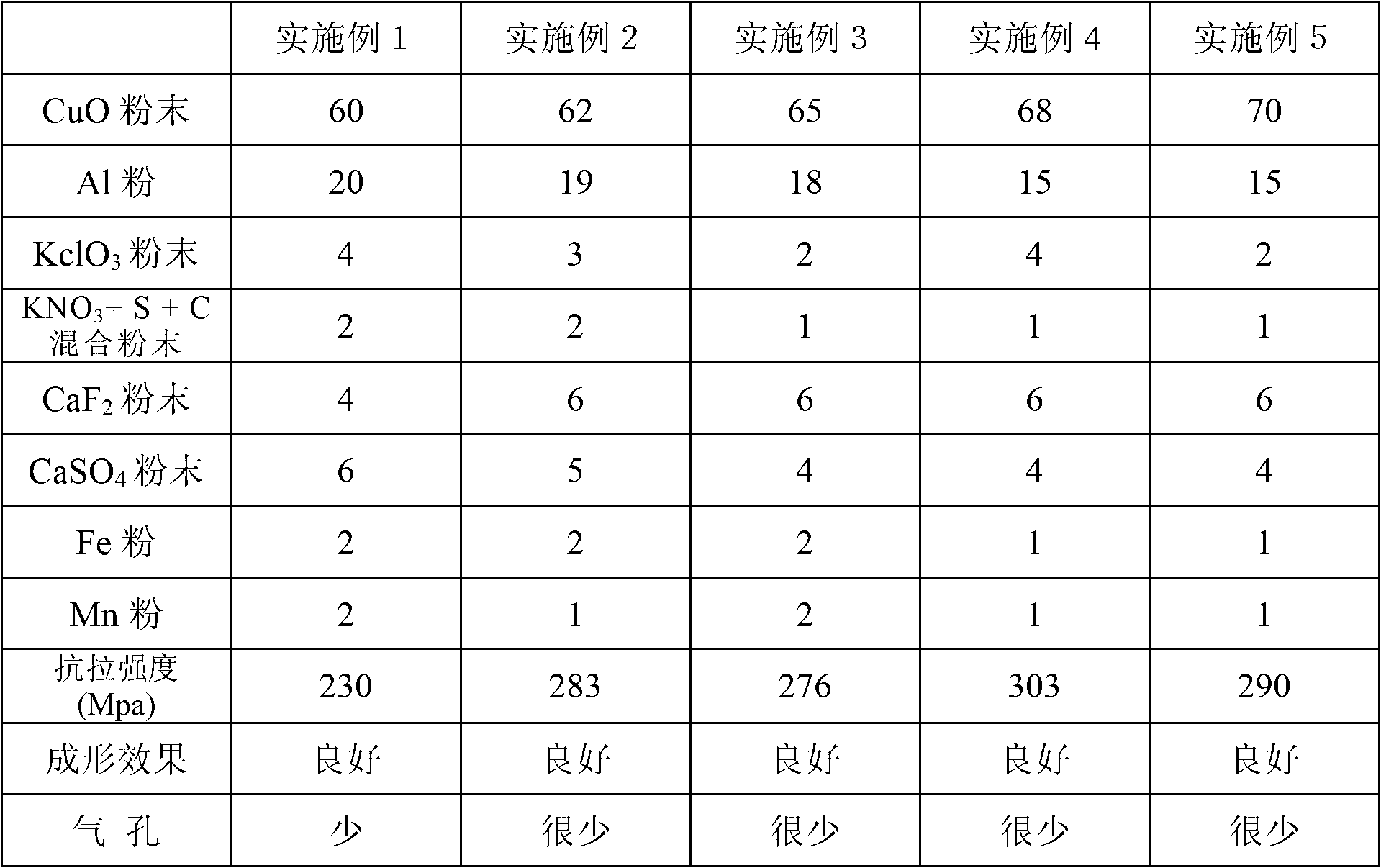

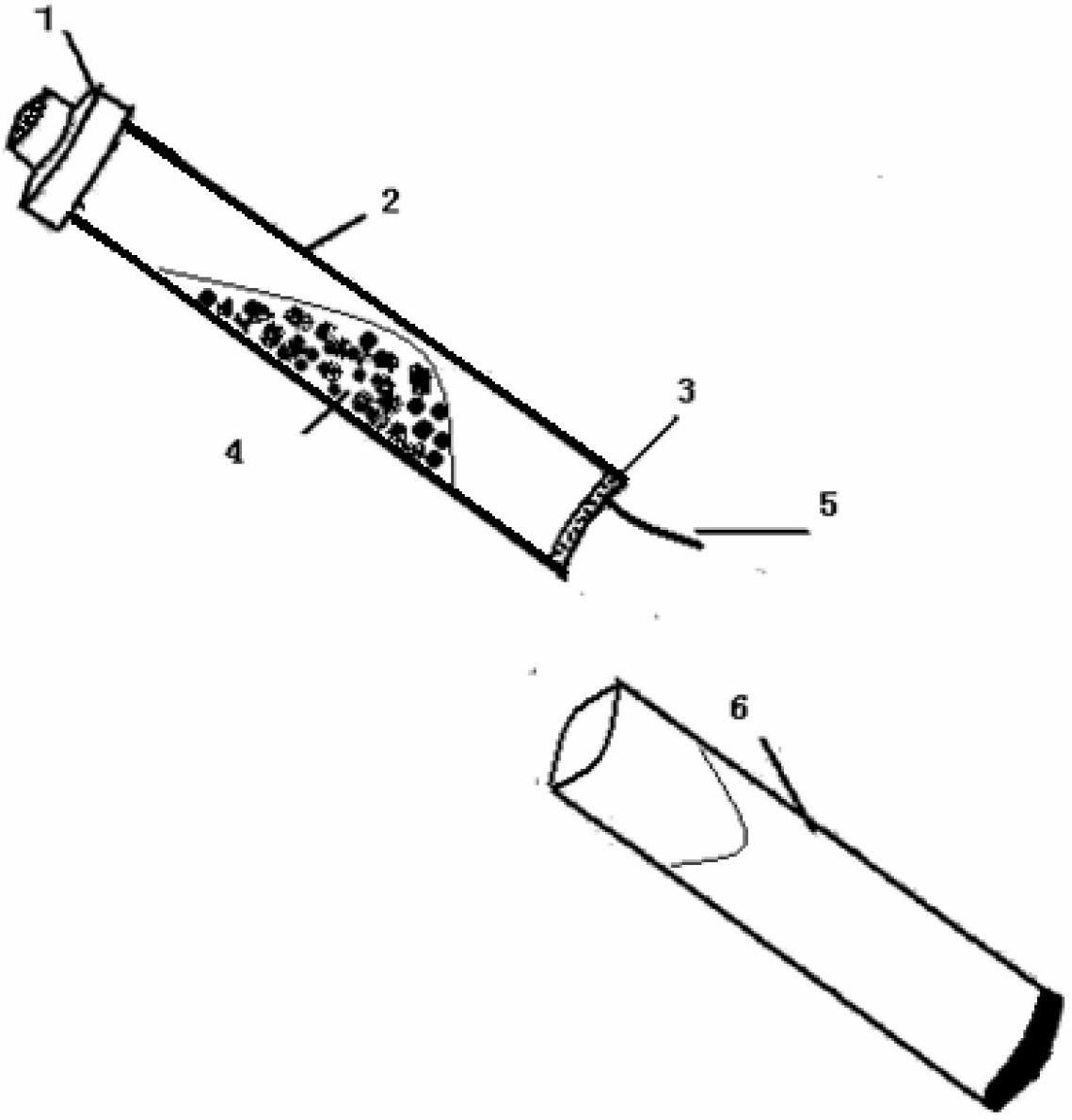

Simple electroless welding pen and preparation method of electroless welding pen

InactiveCN102699521AEasy to makeThe welding operation is simple, fast and safeWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a simple electroless welding pen, which comprises a cartridge, welding flux and a lead. The welding flux is thermite; the simple electroless welding pen comprises the raw material constituents by weight percent: 60-70% of CuO (cupric oxide) powder, 15-20% of Al (aluminum) powder, 2-4% of KClO3 (potassium chlorate), 1-2% of KNO3 (potassium nitrate)+S (sulfur)+C (carbon) mixed powder, 4-6% of CaF2 (calcium fluoride) powder, 4-6% of CaSO4 (calcium sulfate) powder, 1-2% of Fe (Ferrum) powder and 1-2% of Mn (manganese) powder; and the mixed powder is KNO3, S and C freely mixed. According to the method disclosed by the invention, the problems of inexhaustive slag separation and more welding line defects in the welding lines in the prior art are solved without any welding device and power supply. The preparation method has the advantages of simple preparation process and simple, fast and safe welding operation, and is particularly suitable for field emergency operation.

Owner:TIANJIN UNIV

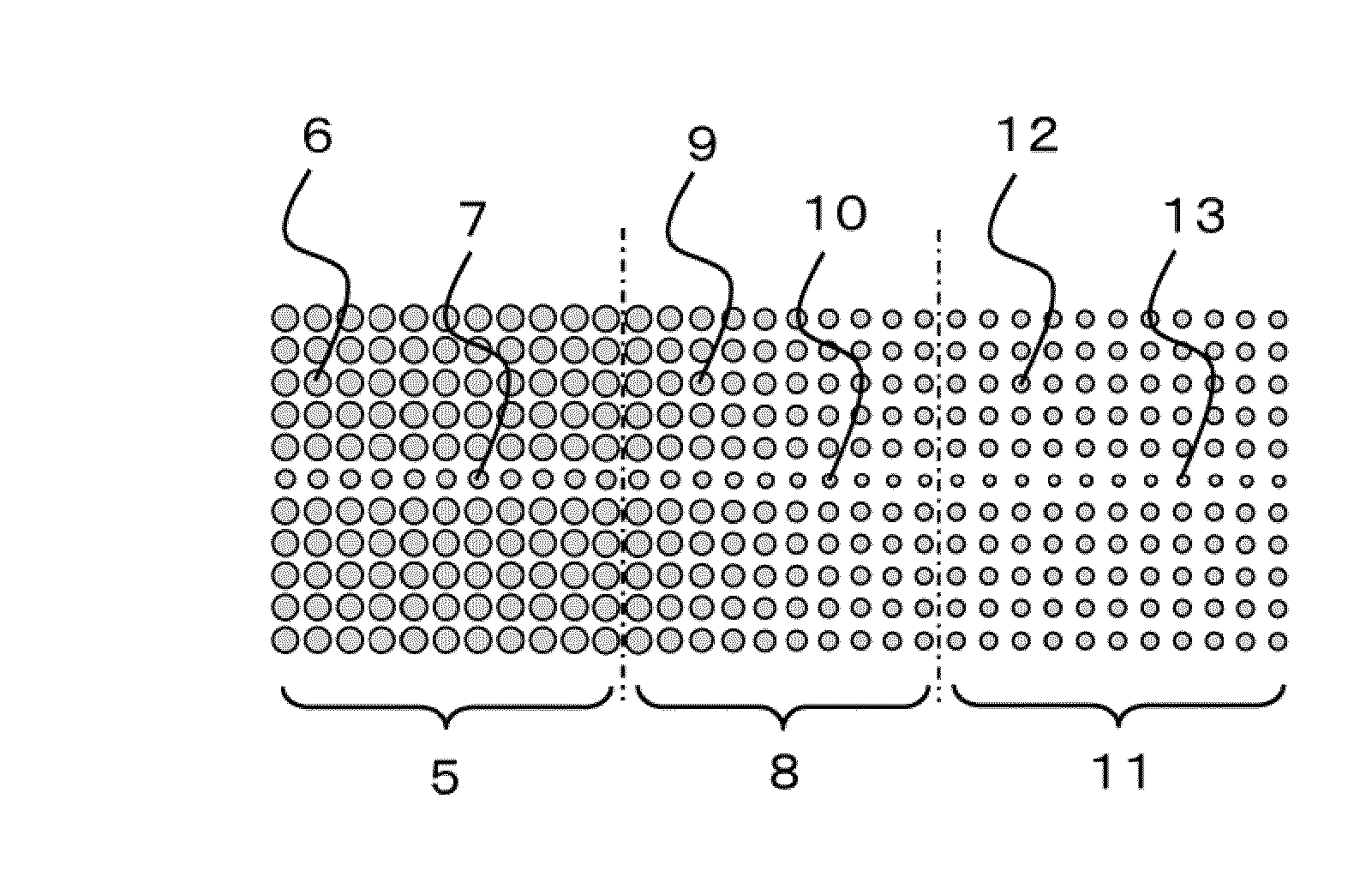

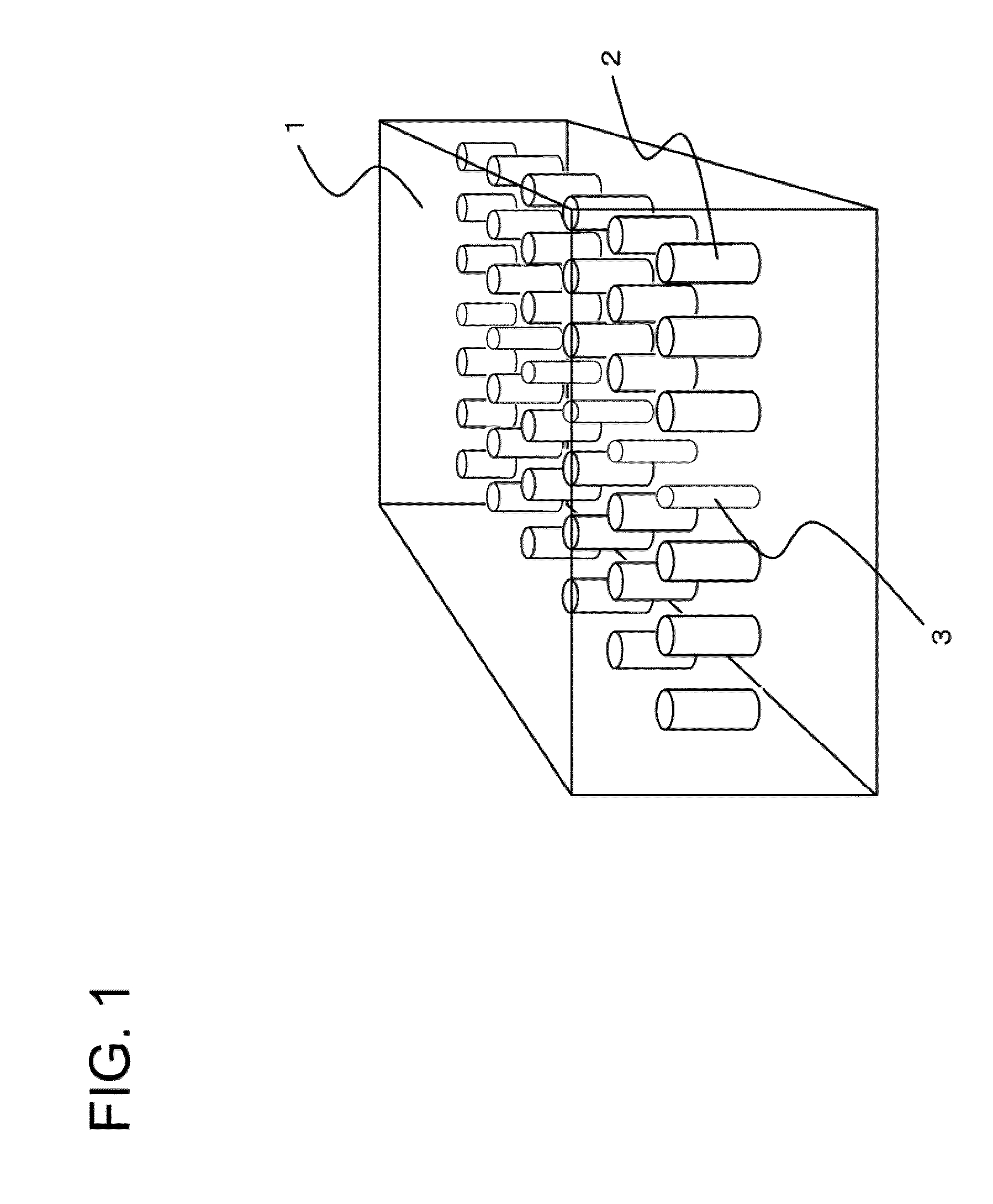

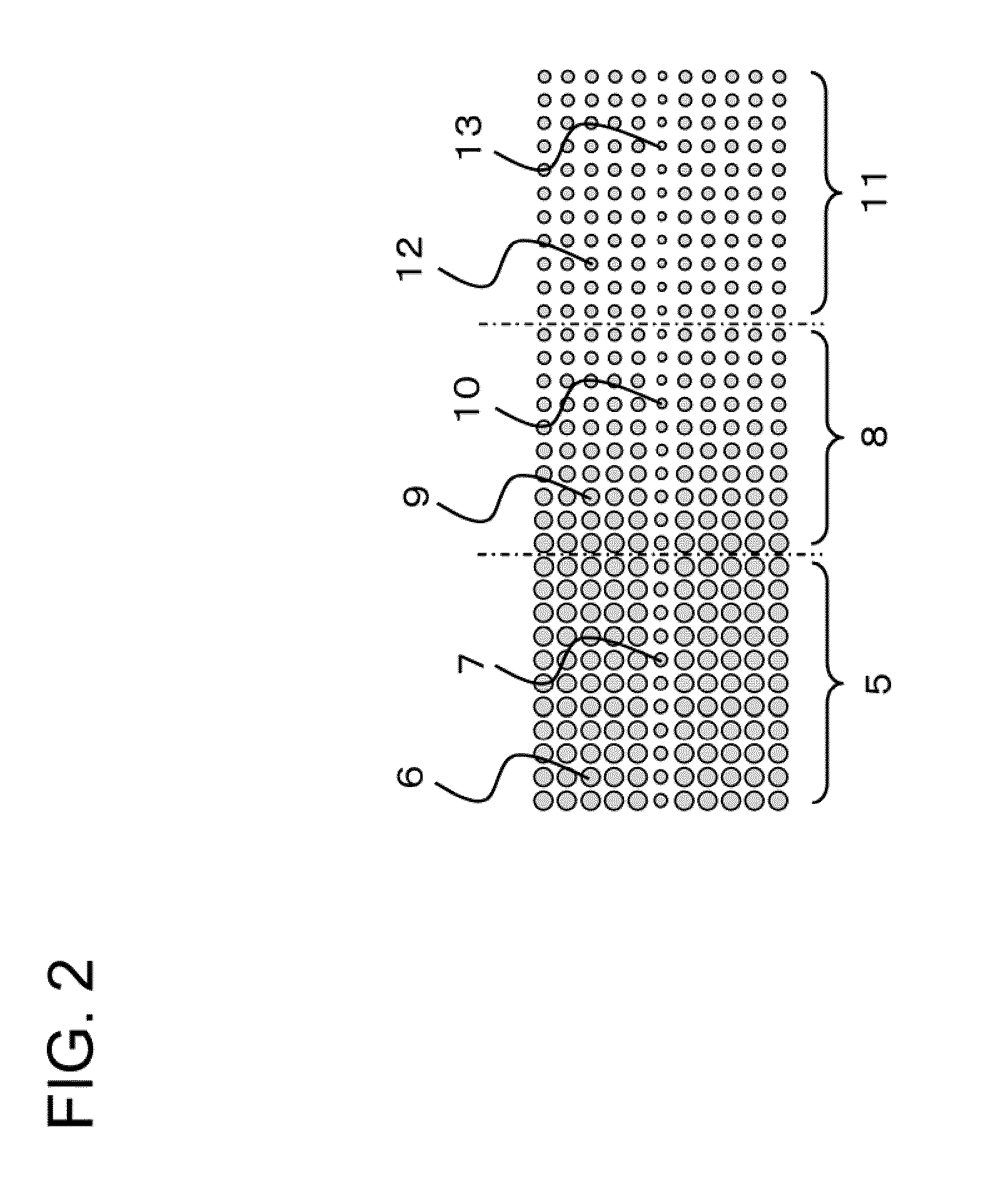

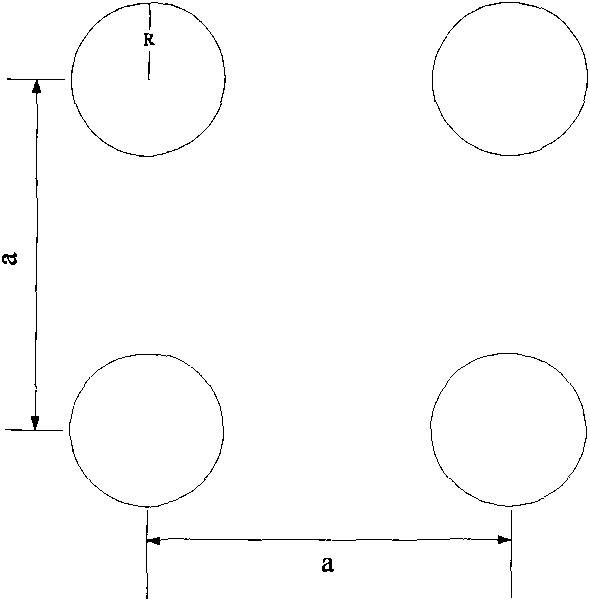

Optical control device

There is provided an optical control device including a plurality of line-defect waveguides provided in a photonic crystal; each line-defect waveguide including a multiplicity of dielectric pillars with a finite height arranged at lattice points of a two-dimensional Bravais lattice. The optical control device comprises: a first line-defect waveguide; a second line-defect waveguide provided with the dielectric pillars having a thickness different from that of the dielectric pillars of the first line-defect waveguide; and a third line-defect waveguide arranged between the first and second line-defect waveguides and provided with the dielectric pillars whose thicknesses are gradually varied from those of the dielectric pillars of the first line-defect waveguide to those of the dielectric pillars of the second line-defect waveguide along a wave guiding direction.

Owner:NEC CORP

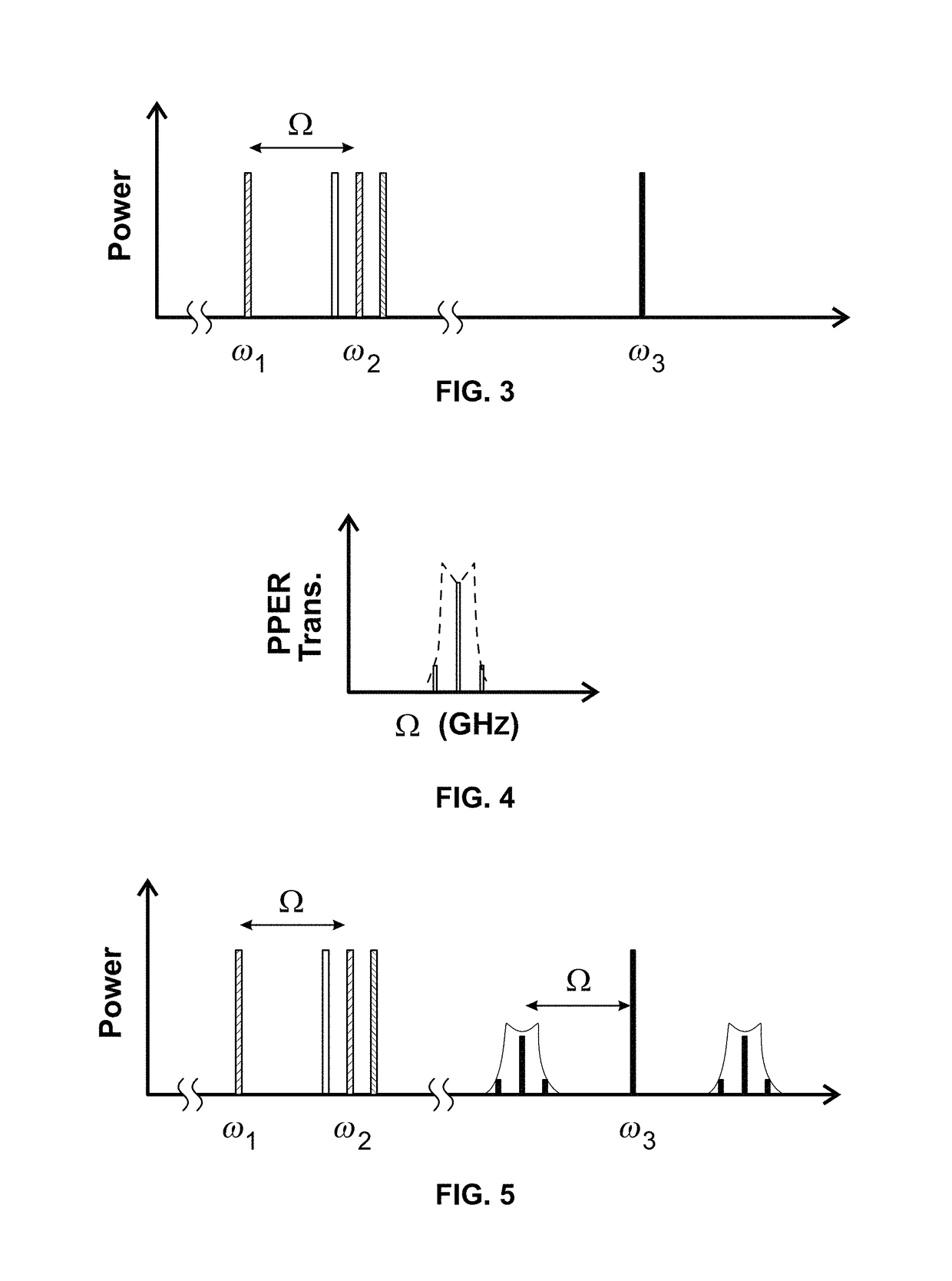

On-chip photonic-phononic emitter-receiver apparatus

A radio-frequency photonic devices employs photon-phonon coupling for information transfer. The device includes a membrane in which a two-dimensionally periodic phononic crystal (PnC) structure is patterned. The device also includes at least a first optical waveguide embedded in the membrane. At least a first line-defect region interrupts the PnC structure. The first optical waveguide is embedded within the line-defect region.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

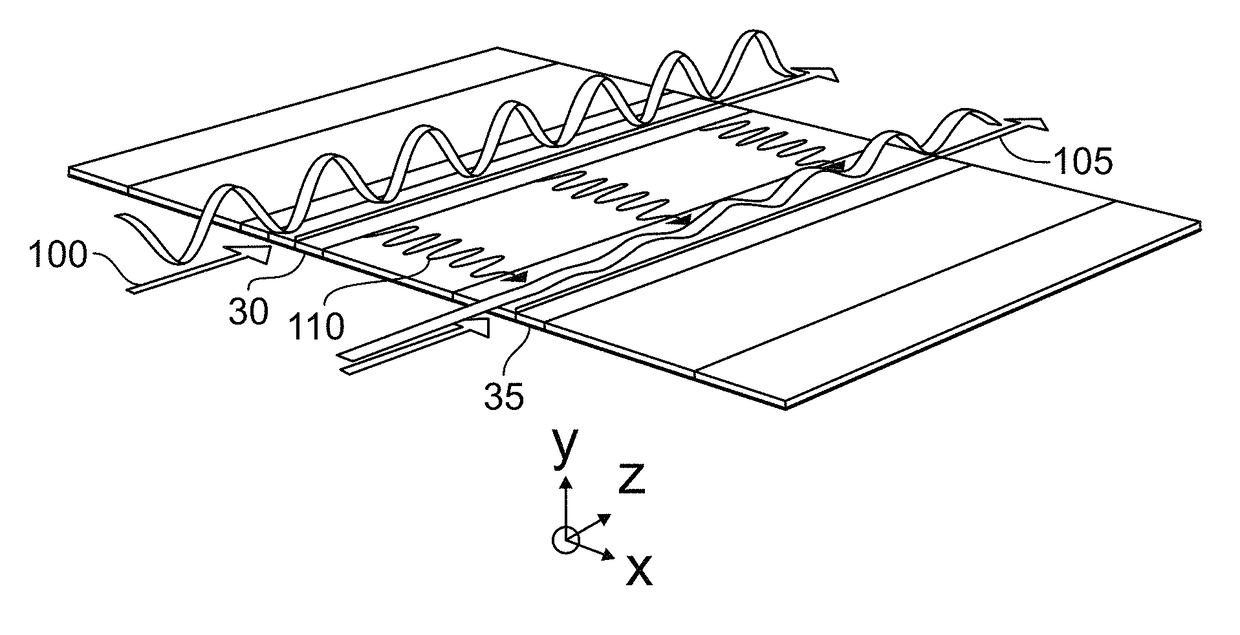

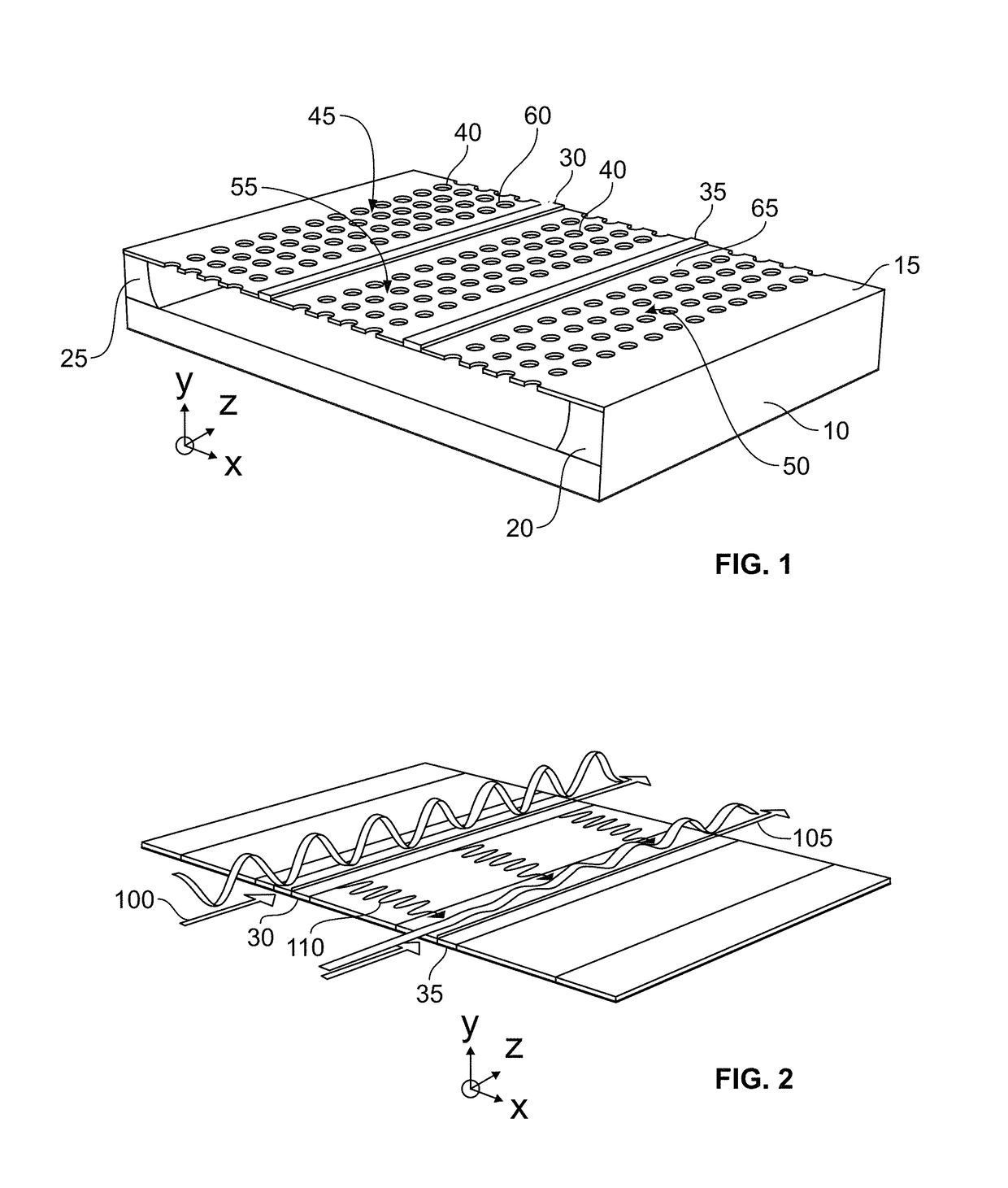

High speed electrical interconnects and method of manufacturing

ActiveUS7298234B2Reduce effective loss-tangentHigh bandwidthSolid-state devicesWaveguidesManufacturing technologyDielectric substrate

High-speed interconnect systems for connecting two or more electrical elements are provided. Interconnect system has the means, which could reduce the microwave loss induced due to the dielectrics. Reducing the effective loss tangent of the dielectrics reduces the microwave loss. With optimize design of the interconnects, the speed of the electrical signal can be made to closer to the speed of the light. The interconnect systems consists of the electrical signal line, inhomogeneous dielectric systems and the ground line, wherein inhomogeneous dielectric system consisting of the opened-trenches into the dielectric substrate or comb-shaped dielectrics to reduce the microwave loss. Alternatively dielectric structure can have the structure based on the fully electronic or electromagnetic crystal or quasi crystal with the line defect. Alternatively, dielectric structure can be made to comb-shaped structure with teethes having thickness and space making the air pocket to reduce the microwave loss. The interconnect system, can be made in rigid or flex board for off-chip interconnects for IC packages, connectors and cables, where conventional manufacturing technology can be used and yet to increase the bandwidth of the interconnects.

Owner:BANPIL PHOTONICS

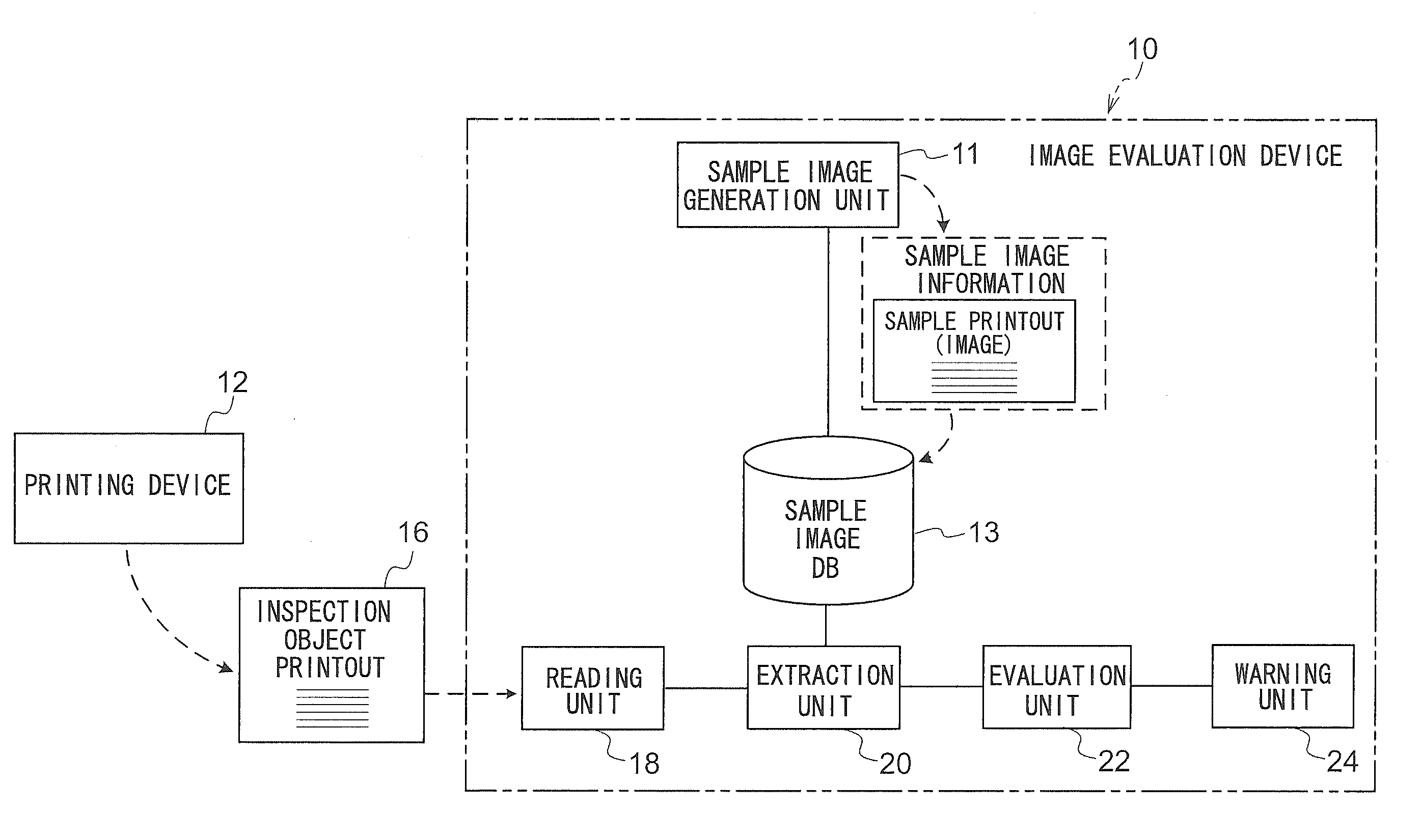

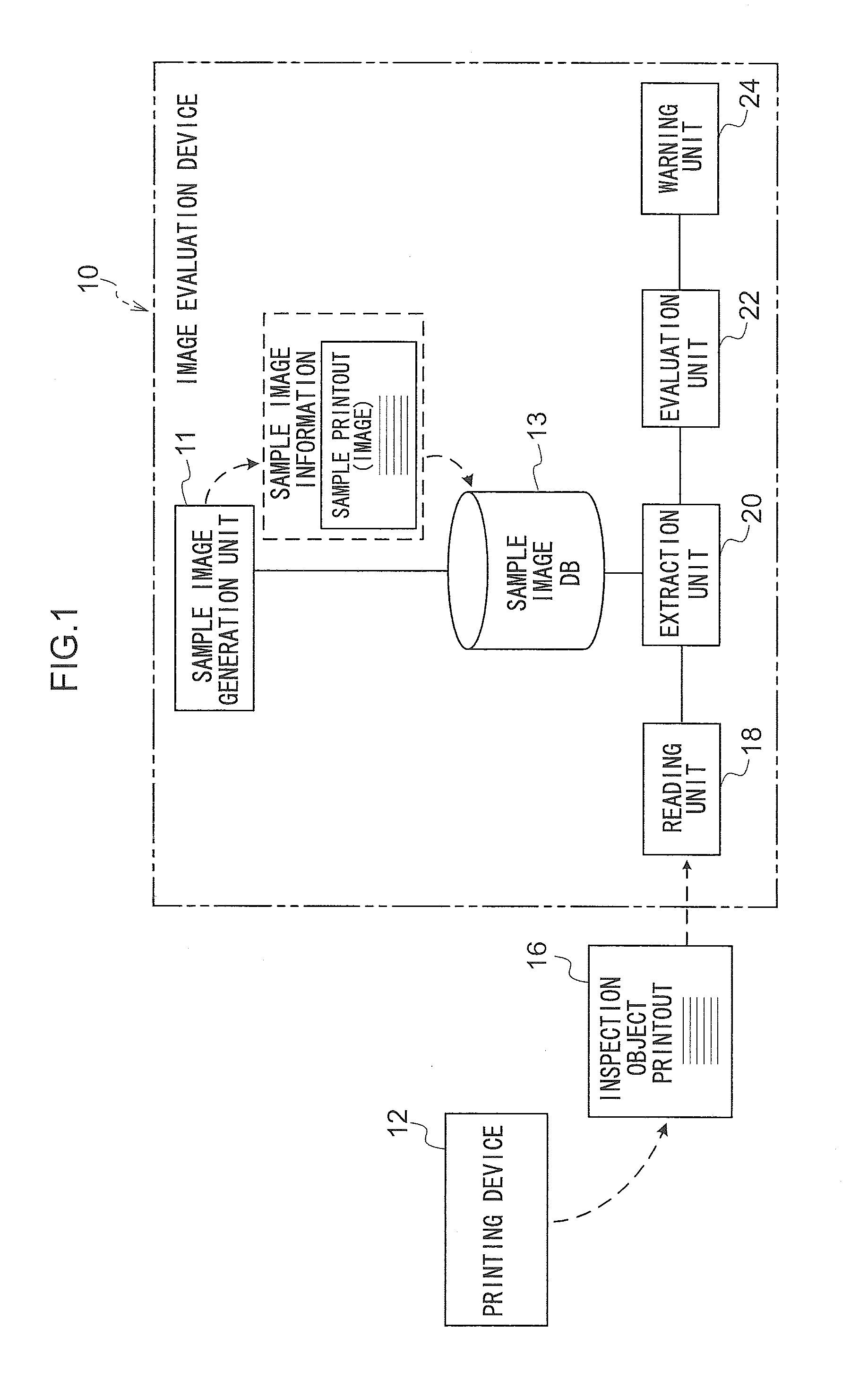

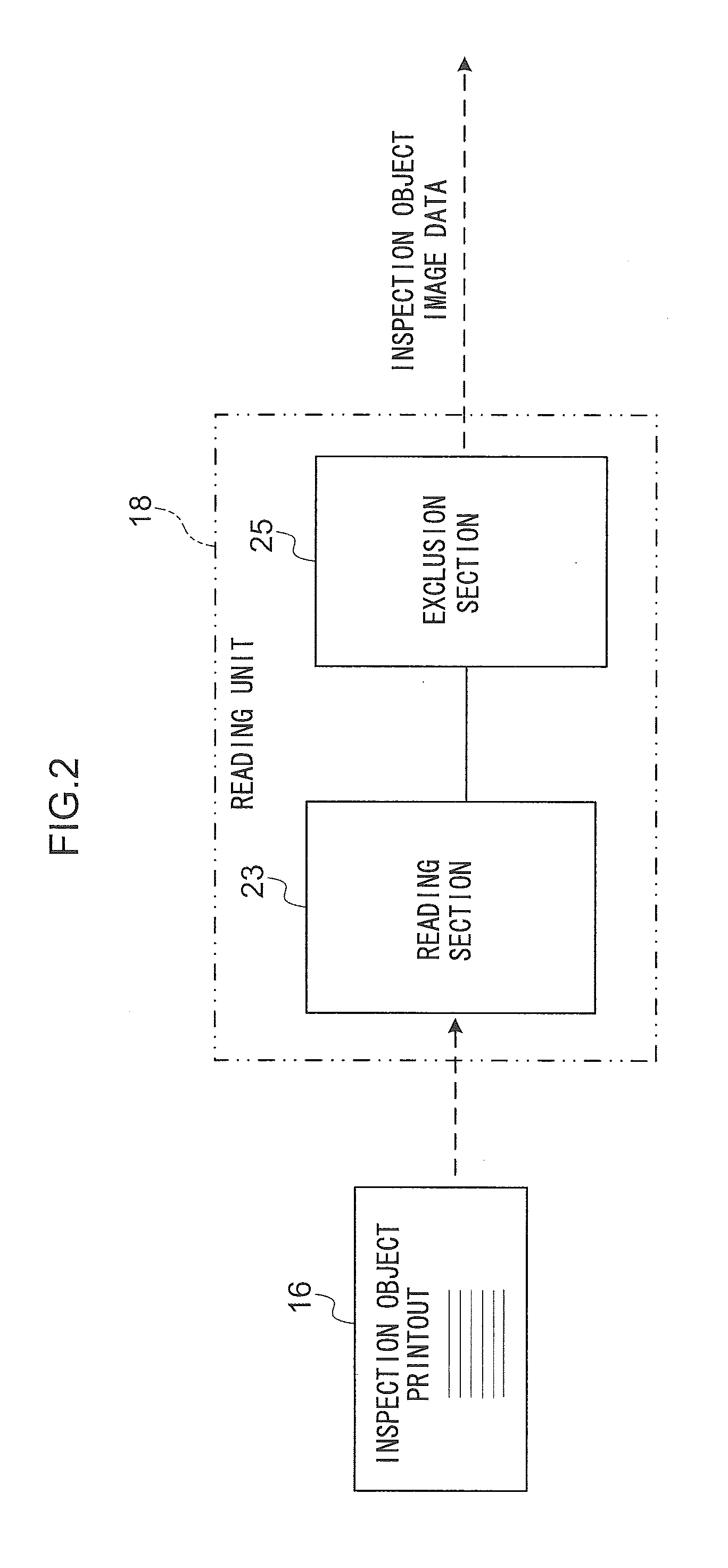

Image evaluation device, image evaluation method and program storage medium

ActiveUS20140093139A1Quickly and accurately determineImage enhancementImage analysisVisibilityImage evaluation

An image evaluation device includes a storage unit that stores sample image data that represent a virtual sample image simulating a sample image included in a sample printout that is recognized as a non-defective printout; a reading unit that reads an inspection object image included in an inspection object printout obtained by printing the sample image on a recording medium by a printing device using image data representing the sample image; an extraction unit that extracts a line defect including a linear pattern formed in a specific direction from the inspection object image represented by inspection object image data, based on a difference value between the sample image data and the inspection object image data; and an evaluation unit that evaluates a visibility of the line defect extracted by the extraction unit.

Owner:FUJIFILM CORP

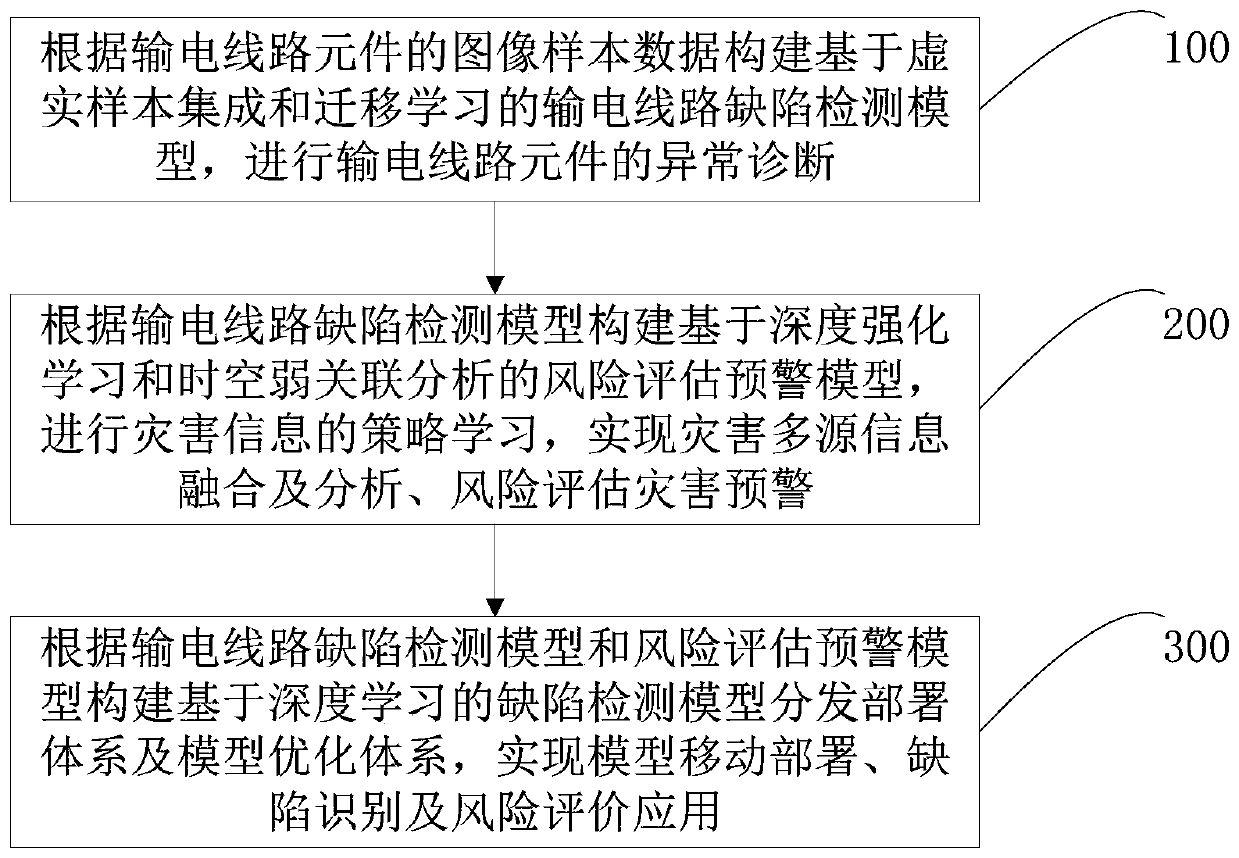

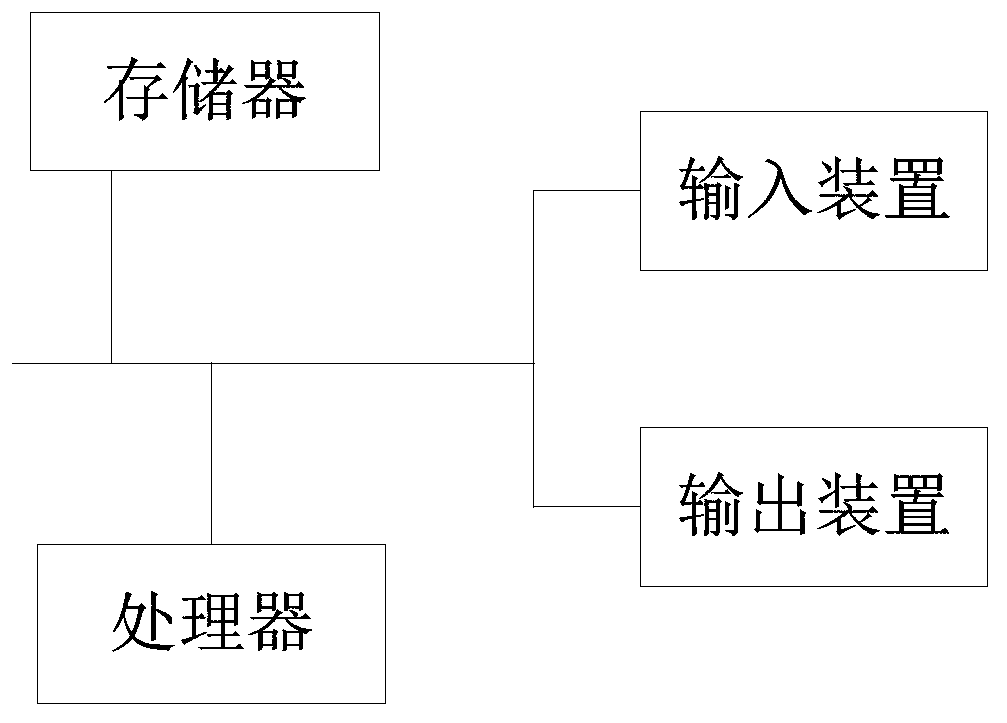

Power transmission line defect detection method and system and electronic equipment

ActiveCN109785289AAchieve integrationRealize analysisImage analysisBiological neural network modelsPattern recognitionAlgorithm

The invention relates to a power transmission line defect detection method and system and electronic equipment. The method comprises the steps of constructing a power transmission line defect detection model based on virtual and real sample integration and transfer learning according to image sample data of power transmission line elements, The method specifically comprises the following steps: step a, constructing a virtual and real integrated virtual sample generation and labeling model, integrating rich ground object information in virtual data and real image data, and fusing the virtual data and the real data; B, constructing a deep learning transfer learning model, and completing model optimization based on transfer learning; And step c, training a deep learning model based on a target detection algorithm, and carrying out abnormity diagnosis on the power transmission line element on the basis of target detection of deep learning. Through deep learning distributed training of massimage samples, the power transmission line defect detection model based on multi-image fusion of visible light, infrared light, ultraviolet light and the like is established, the defect recognition accuracy can be improved, and the inspection working efficiency and quality are improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

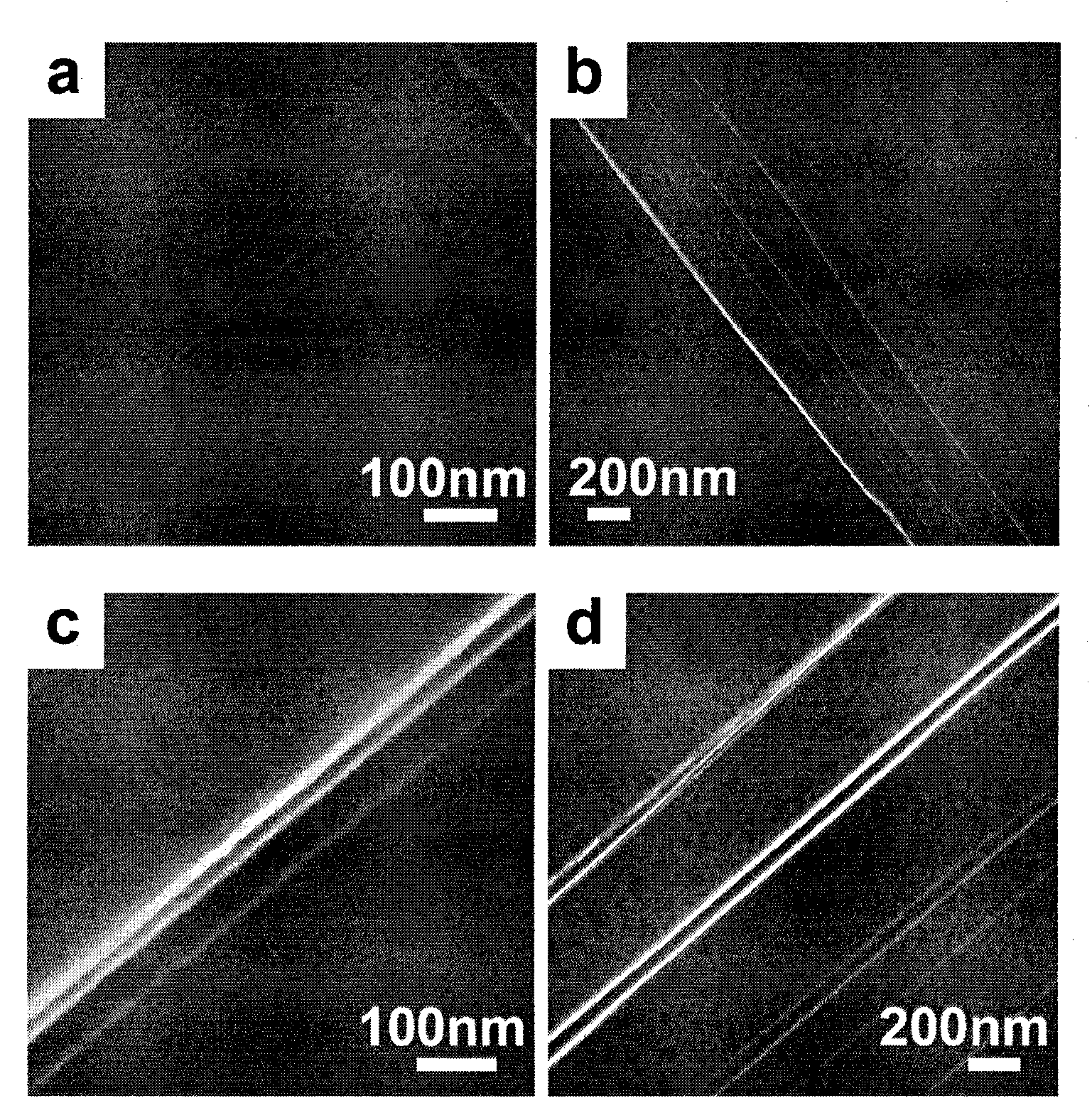

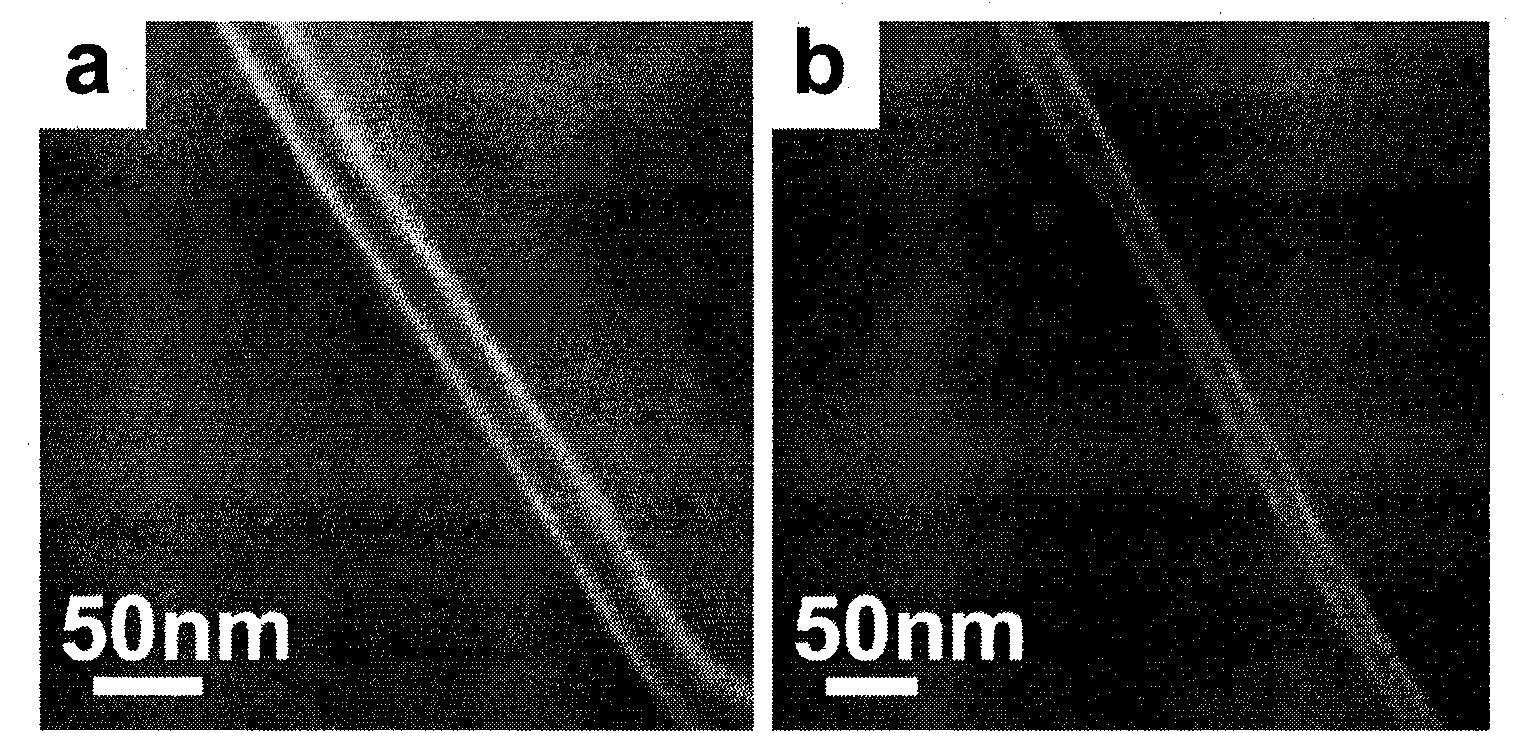

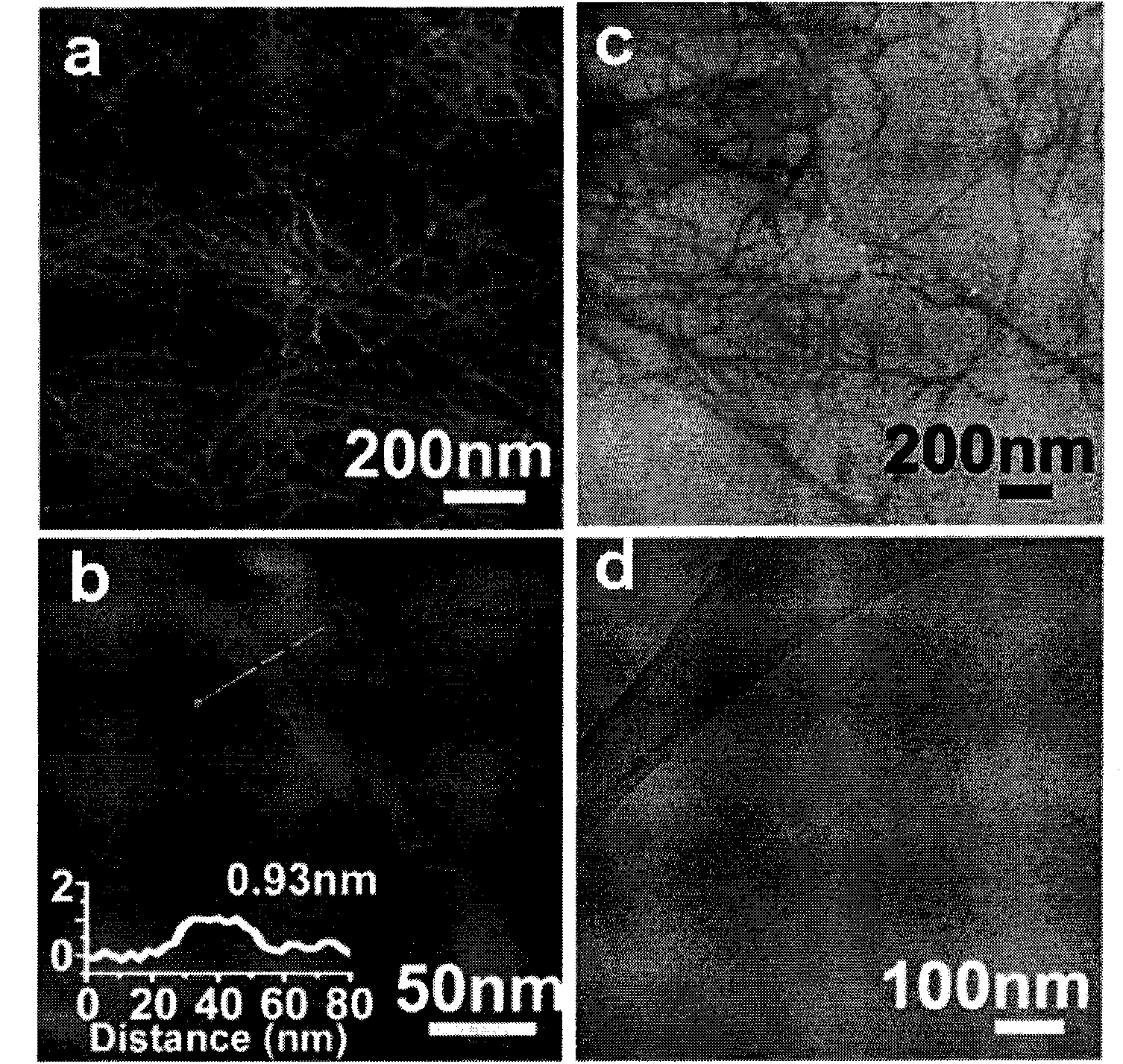

Method for producing graphene belts in controllable macroscopic quantity by chemically cutting grapheme

The invention relates to a technology for producing graphene belts, in particular to a method for producing graphene belts in controllable macroscopic quantity by chemically cutting grapheme. The method comprises the following steps of: firstly obtaining oxidized graphite in a Hummers method, selectively finishing line defects on the surface of the oxidized graphite by utilizing the oxygen-containing functional group in the process of oxidizing the graphite, and producing grapheme with surface line defects by combining high-temperature rapid expansion and peeling, thermal reduction, solvent dispersion and centrifugal separation; then cutting the graphene and recovering the structure of the graphene by utilizing ultrasonic shearing and chemical reduction; and finally removing large pieces of incompletely cut grapheme in a high-speed centrifuging method to further produce the graphene belt with controllable layer number and width. The method can be used for producing the graphene belt with controllable layer number, width and boundary by controlling the key cutting process parameters, such as graphite raw material variety, oxidization process, peeling process, reduction process, dispersion process and centrifugal treatment process, and the method is easy to operate and has low cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

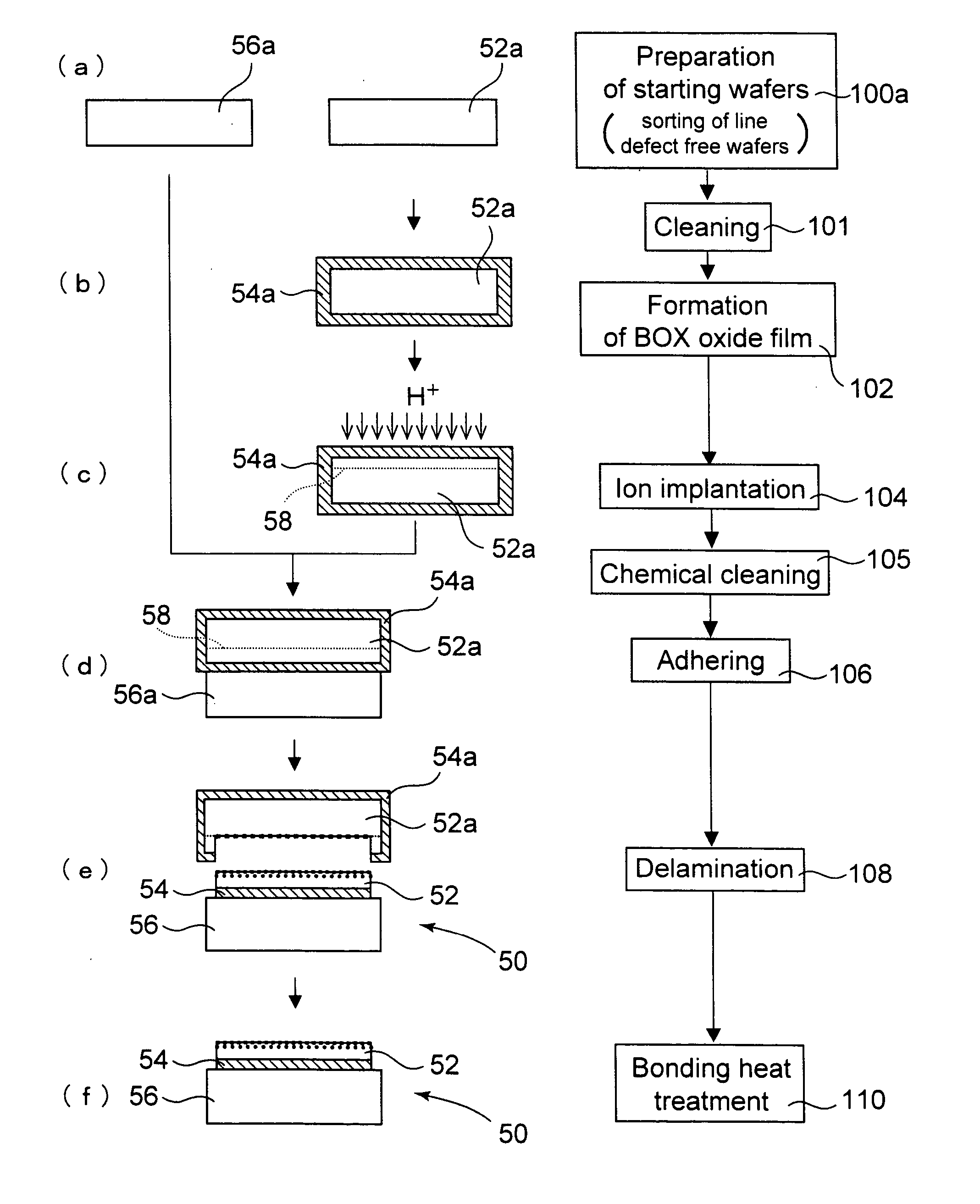

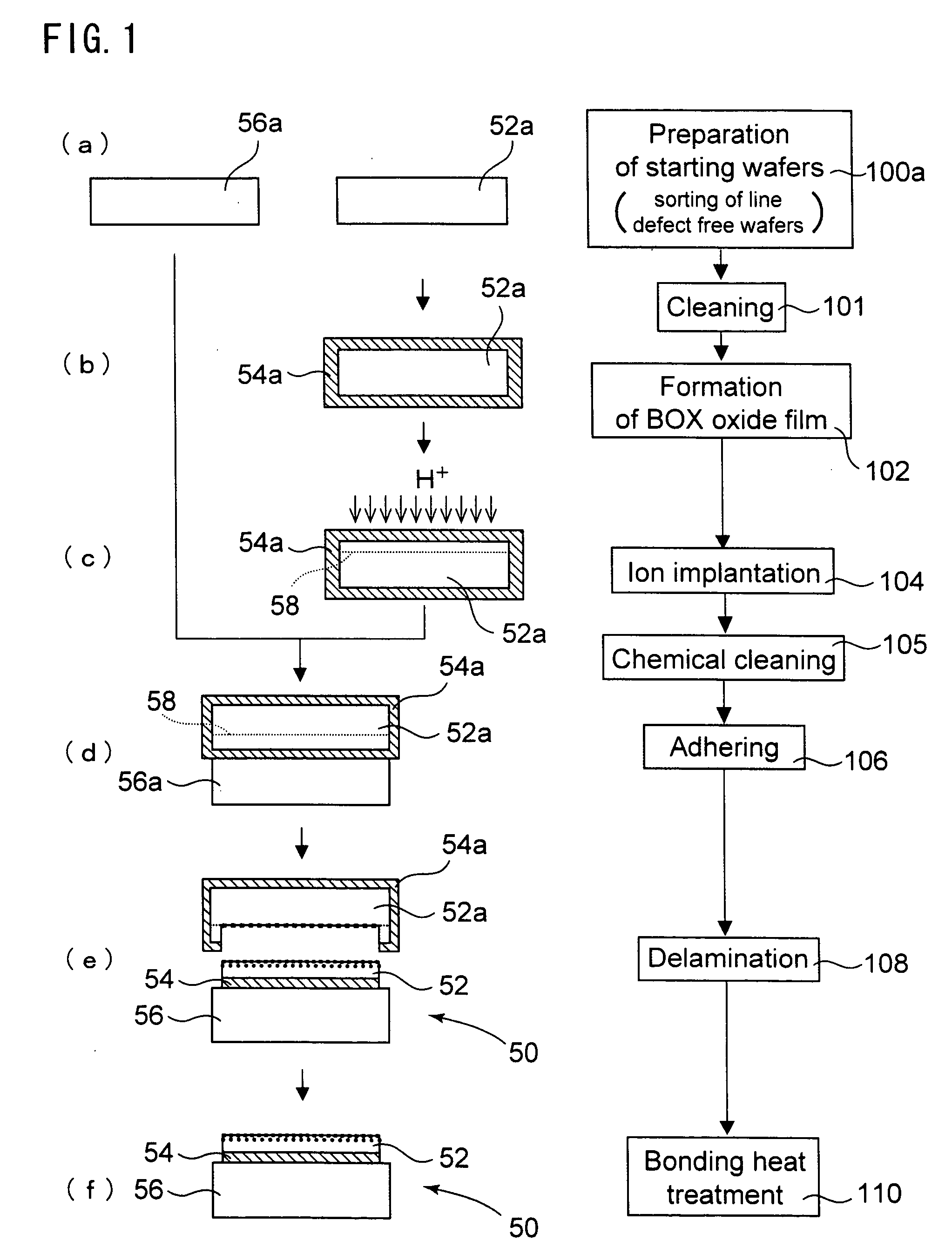

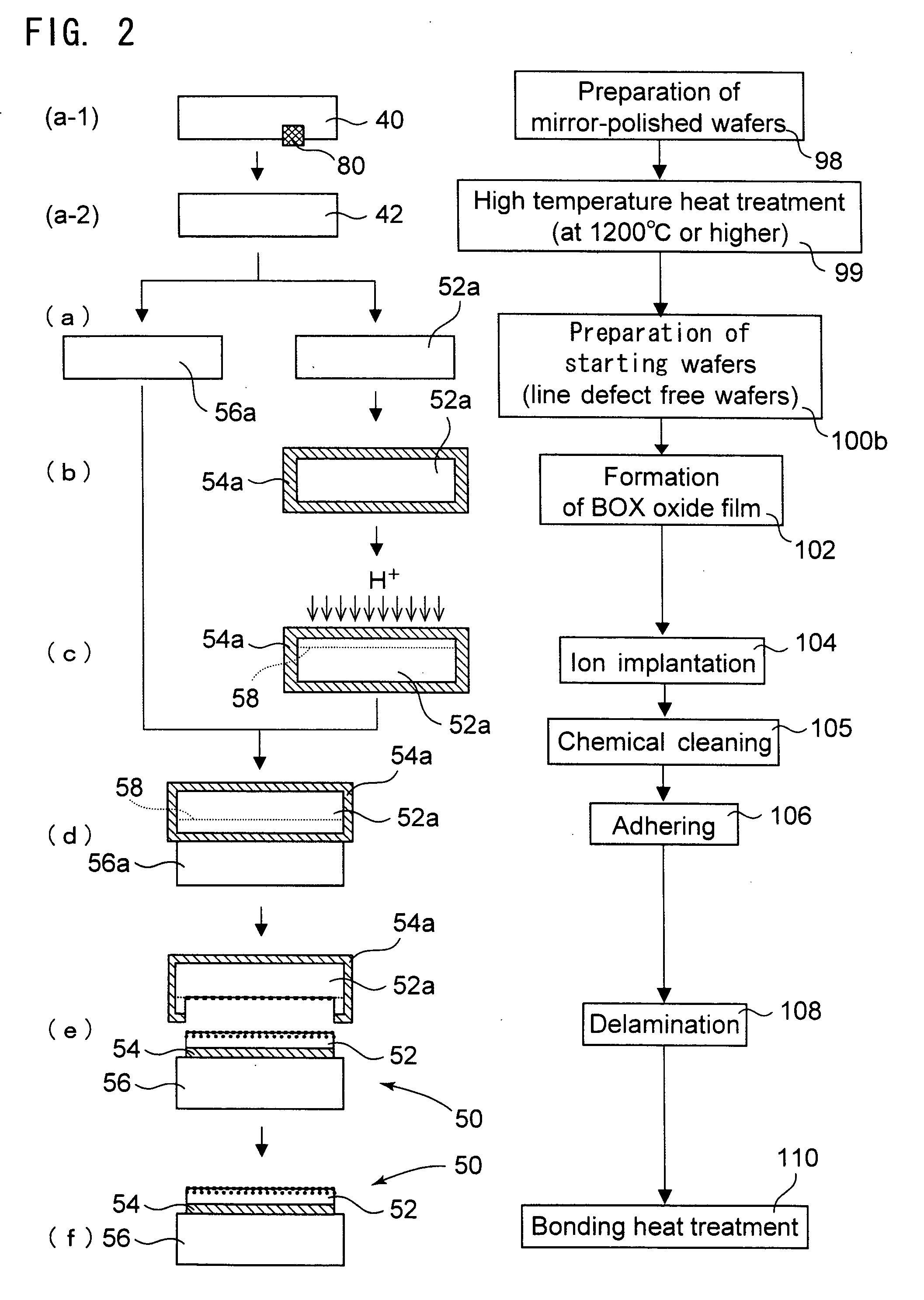

Method for manufacturing soi wafer

InactiveUS20060014330A1Stably annihilatedEasily annihilatedSolid-state devicesSemiconductor/solid-state device manufacturingProduction rateEngineering

The present invention provides a manufacturing method for an SOI wafer with a high productivity in which generation of a void is suppressed in manufacturing the SOI wafer. In a manufacturing method for an SOI wafer of the present invention in which two starting wafers are prepared, an insulating layer is formed on at least one of the two starting wafers and the one wafer is adhered to the other wafer without using an adhesive agent, the starting wafers each with no line defect on a surface thereof are used. In a manufacturing method for an SOI wafer of the present invention in which two starting wafers are prepared, an insulating layer is formed on at least one of the two starting wafers and the one wafer is adhered to the other wafer without using an adhesive agent, the starting wafers are subjected to a high temperature heat treatment in advance.

Owner:SHIN-ETSU HANDOTAI CO LTD

Array substrate for use in LCD device

A TFT array substrate for use in an LCD device includes at least one repair line to repair line defects. The repair line(s) is formed when forming the pixel electrode so that additional process steps are not required. Accordingly, productivity can be increased. Moreover, either a short-circuit or an open-circuit can be repaired due to the repair line(s). Thus, in the present invention, a TFT array substrate, including: a substrate; a gate line formed on the substrate, arranged in a transverse direction and having a gate electrode; a data line insulated against the gate line by a first insulation layer, arranged in a longitudinal direction perpendicular to the gate line, having a source electrode near the cross point of the gate and data lines, and having first and second data lines which are defined by a cross point of the gate and data lines; a drain electrode space apart from the source electrode over the gate electrode; a pixel electrode connecting to the drain electrode; and a repair line(s) insulated against the data and gate lines by insulation layers and overlapping the gate and data lines, one repair line overlapping a free end of the other repair line and the gate line.

Owner:LG DISPLAY CO LTD

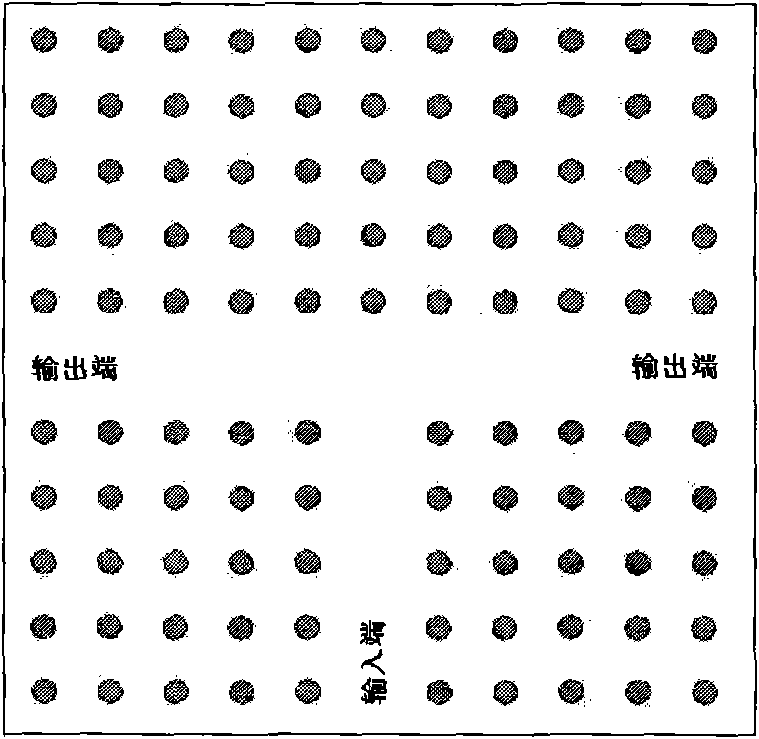

T-shaped photonic crystal power divider

ActiveCN101561531AAdjust amplitude-frequency characteristicsReduce interactionOptical light guidesPhotonic crystalDielectric cylinder

Owner:东莞成电创新电子科技有限公司

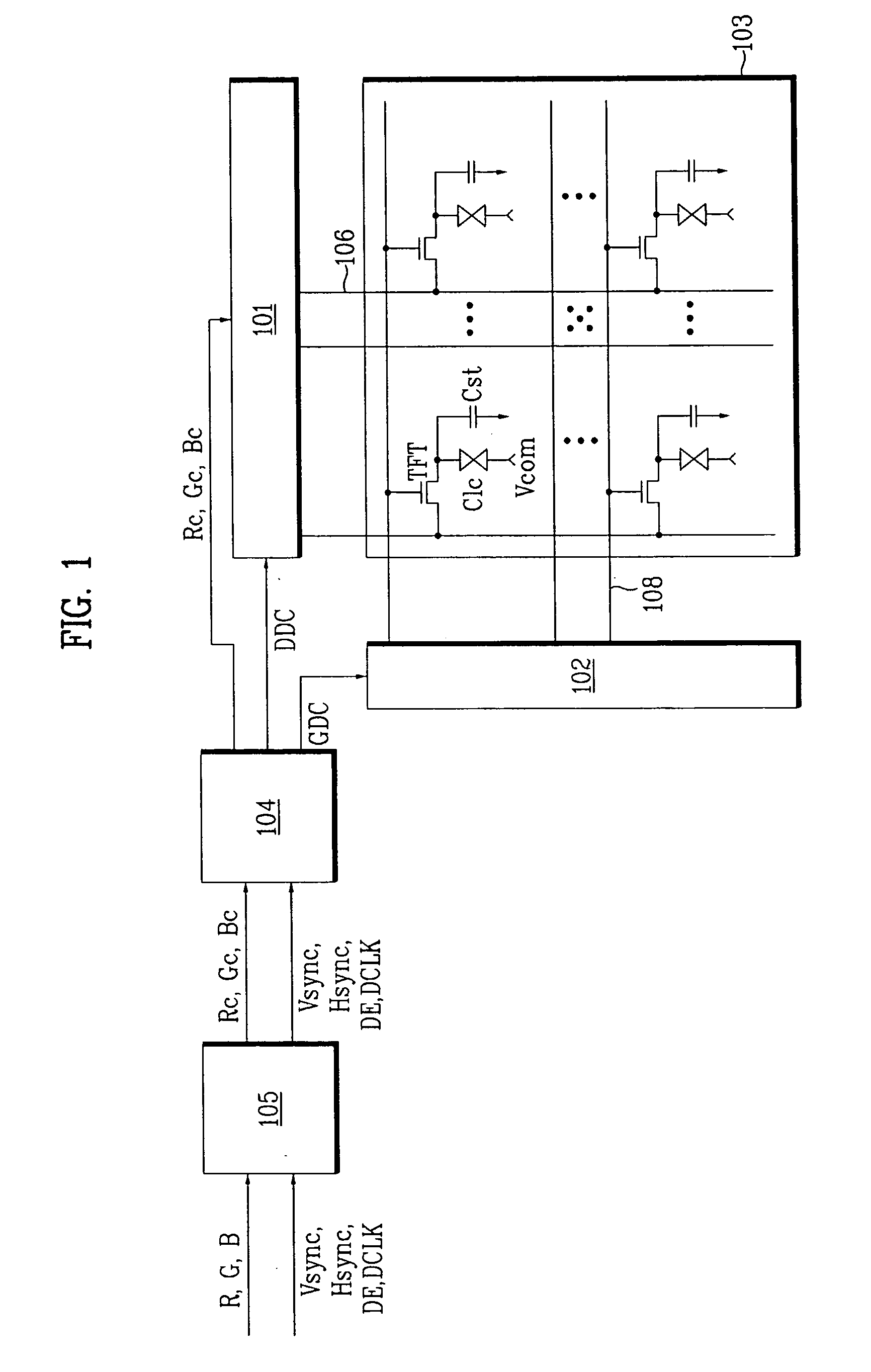

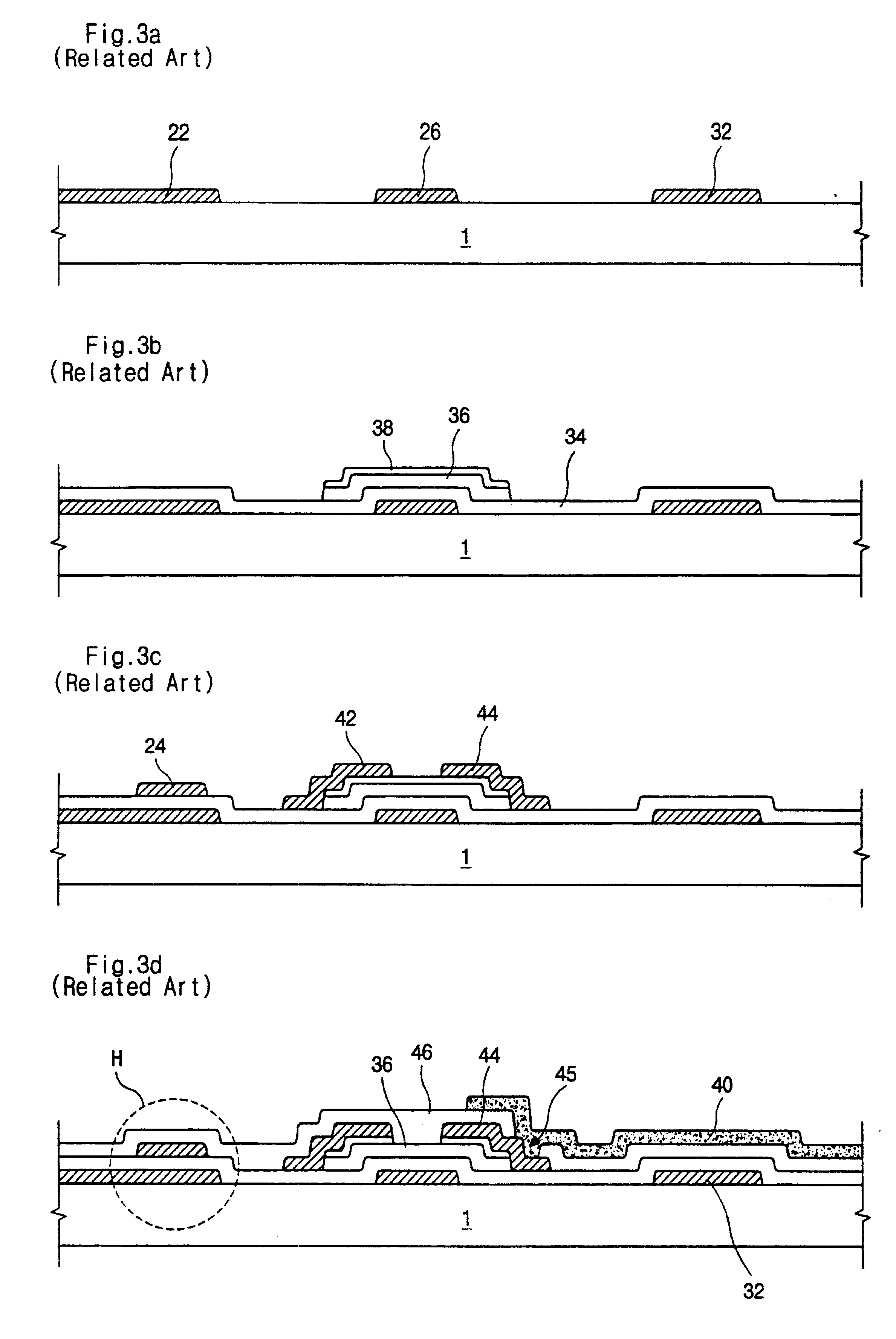

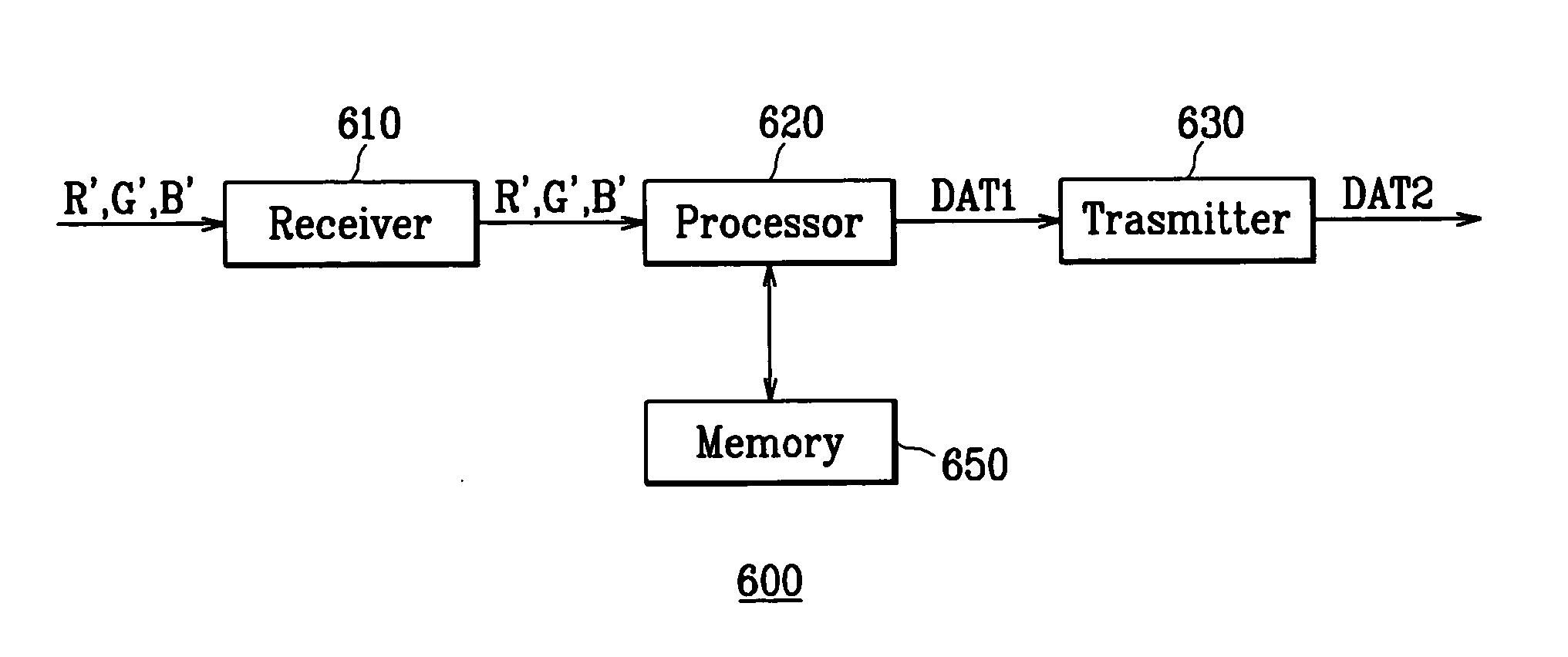

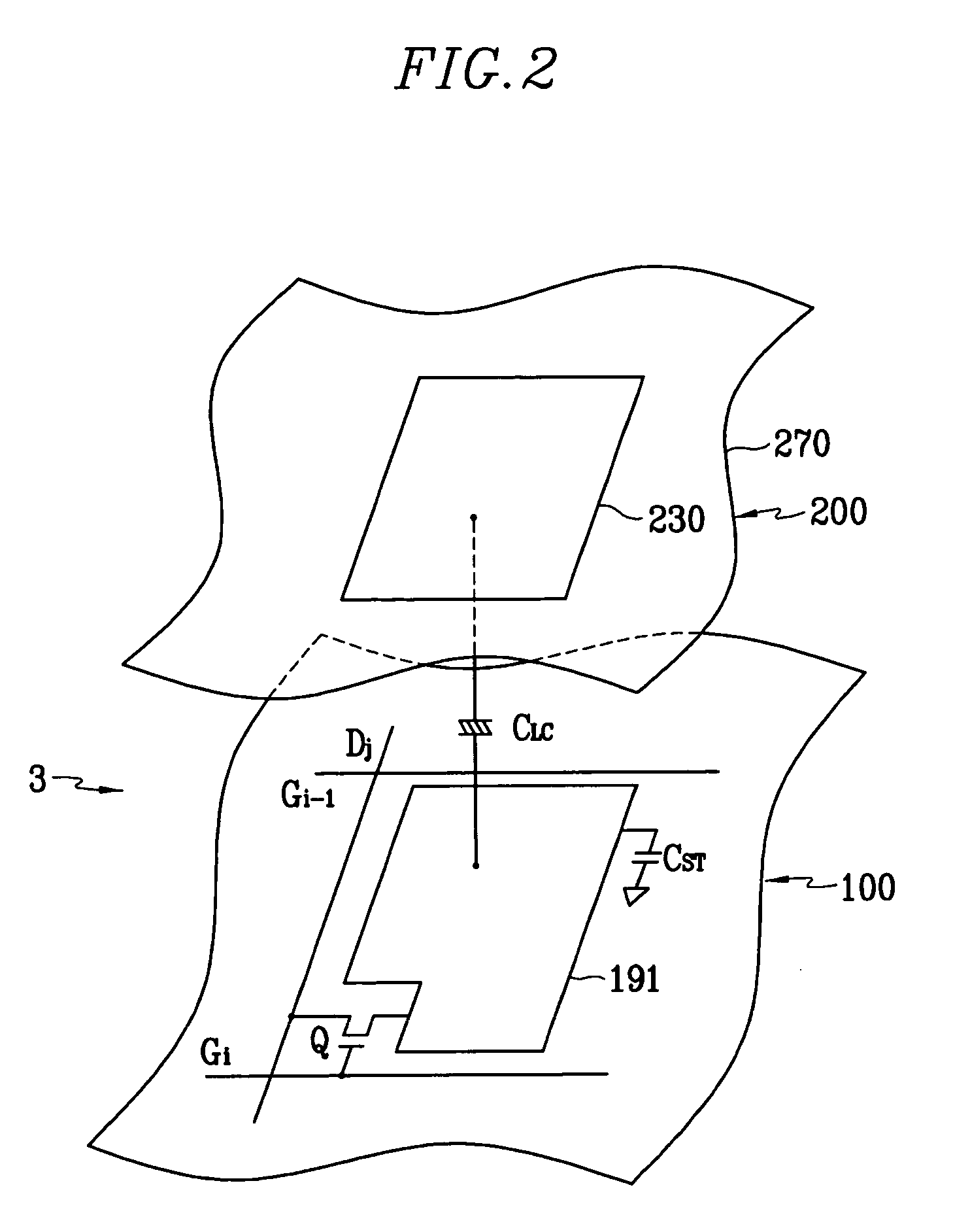

Apparatus and method of driving liquid crystal display apparatus

InactiveUS20060279506A1Prevents cross line defectPrevents cross line defect and flickerStatic indicating devicesLiquid-crystal displayElectrical polarity

An apparatus and method for driving a liquid crystal display apparatus include a receiver for receiving input image data, a data processor for processing output image data output from the receiver, and a memory and a transmitter connected to the data processor. The data processor selects a portion of polarities from the output image data and generates a plurality of polarities of the same number as the portion of the polarities to generate polarity data for one frame. Thus, polarities of pairs of pixels corresponding to inversion units are sequentially inverted, so that arbitrary polarity inversion can be individually performed on the pixels. Therefore, preventing cross line defects that are caused from variation in charging voltages in a conventional two-dot inversion driving scheme that is performed in units of two adjacent pixel rows is possible. Further, reducing flicker caused by polarity inversion in units of one frame is also possible.

Owner:SAMSUNG ELECTRONICS CO LTD

Flat panel display and its method of fabrication

InactiveUS20060102900A1Avoid voltage dropElectroluminescent light sourcesSolid-state devicesMetal foilDisplay device

A flat panel display device which can prevent line defects and voltage drops using a conductive substrate formed of metal foil as a power supply layer includes: a conductive substrate; a first insulating layer formed on one side of the substrate and having a contact hole exposing a part of the conductive substrate; a Thin Film Transistor (TFT) having a semiconductor layer formed on the first insulating layer, a gate electrode, and source and drain electrodes; and a display element having a pixel electrode connected to one of the source and drain electrodes of the TFT. The other of the source and drain electrodes of the TFT is electrically connected to the conductive substrate via the contact hole.

Owner:SAMSUNG DISPLAY CO LTD

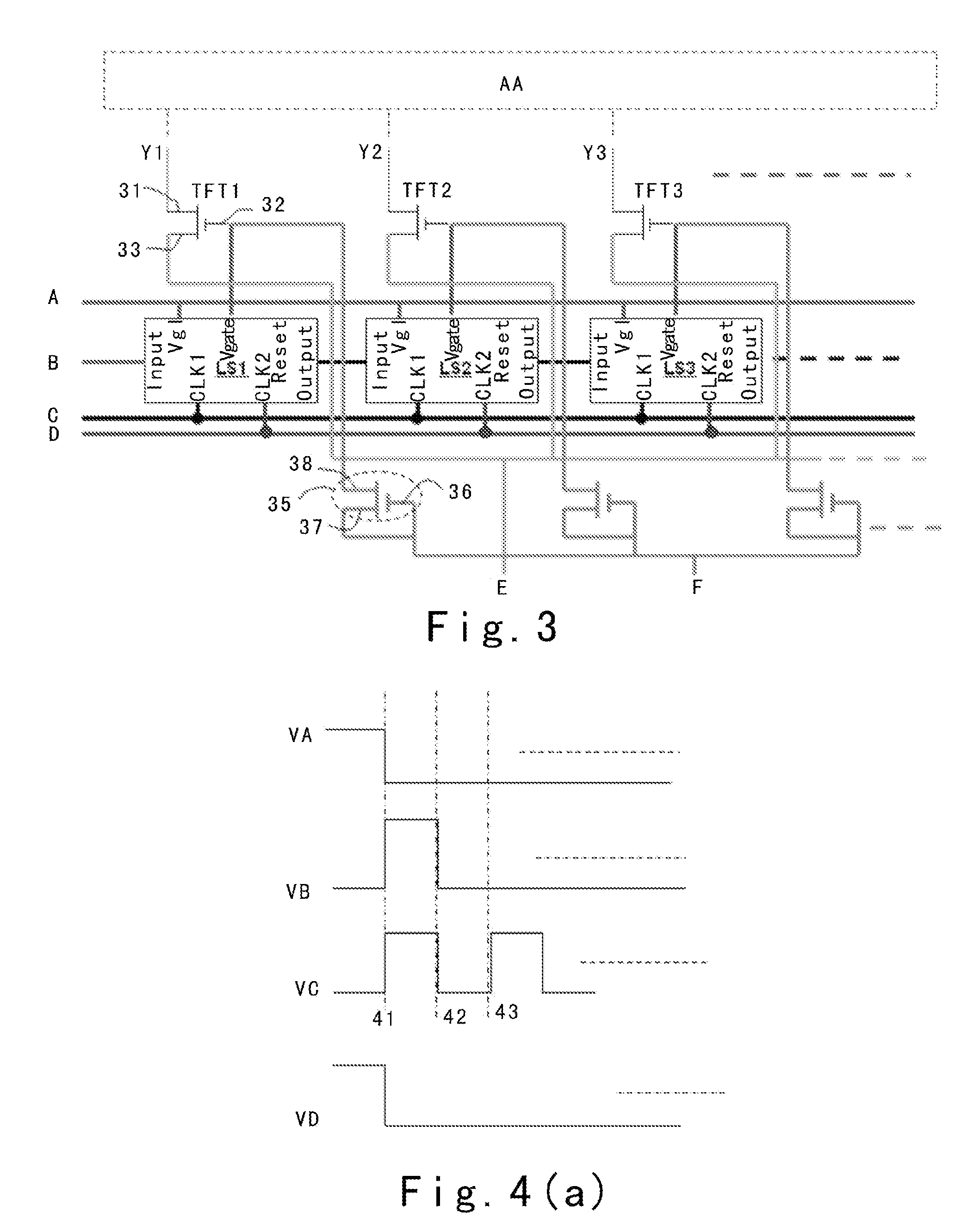

Array substrate and defect-detecting method thereof

InactiveUS20100066383A1The process is fast and accurateStatic indicating devicesFault locationSignal onEngineering

The present invention discloses an array substrate and a defect detecting method thereof. The array substrate comprises one or more shorting bars for applying signals to a plurality of data lines or a plurality of gate lines of the array substrate while testing. The array substrate further comprises a line detecting circuit for receiving signals on the plurality of data lines or the plurality of gate lines, and detecting and locating the line defects of the plurality of data lines or the plurality of gate lines. The array substrate and the defect detecting method thereof provided by the invention can locate the line defects of the array substrate accurately and quickly.

Owner:KUSN INFOVISION OPTOELECTRONICS

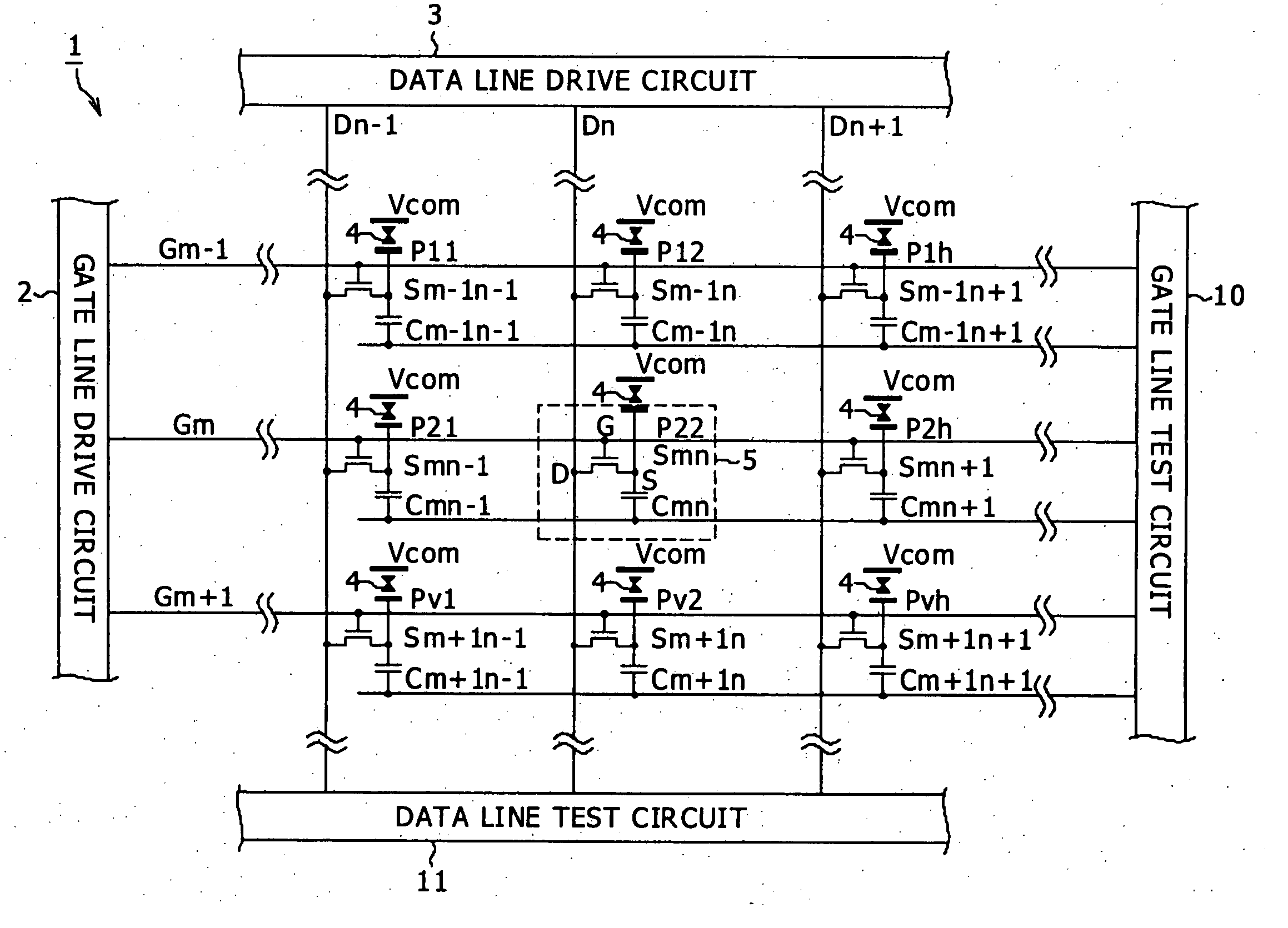

Inspection method semiconductor device and display device

InactiveUS20060192752A1Electrical testingCathode-ray tube indicatorsLiquid-crystal displayDevice material

The present invention allows an efficient test as to the presence of line defects in data lines and gate lines in a liquid crystal display. A logic circuit for a test is provided according to the interconnect layout structure on a semiconductor substrate of a liquid crystal display, and ends of data lines are coupled to inputs of the logic circuit. At the time of the test, test drive signals corresponding to a certain logical value are applied to the data lines, and a determination is made as to defects in the data lines based on the output from the logic circuit, obtained in response to the signal application. This way means that determinations can be made as to defects in the data lines based on a logical value as the output from the logic circuit, i.e., binary values. Such a configuration is also applied to gate lines.

Owner:SONY CORP

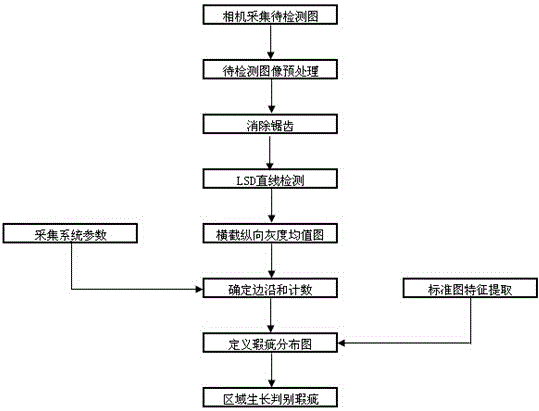

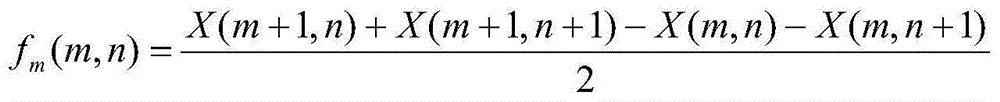

Textile defect detection method

The invention relates to a textile defect detection method. The method comprise the steps that firstly, a to-be-detected textile image with the to-be-cut edge characteristics is collected, and a series of image preprocessing operations are performed on the collected to-be-detected image; secondly, sawteeth of the image are eliminated, and textile edges are roughly determined through an LSD straight line detection algorithm; thirdly, the accurate edge positions are obtained by transversely cutting a longitudinal average gray value variation diagram, real-time edge reference data are determined according to relevant parameters of an acquisition system, and then extracted edge information and the edge reference data are compared to determine the edges and count; defect distribution is determined by combining standard diagram characteristic parameters and ignoring the defects around the edges, all defect communicating regions are obtained by adopting a region growing method, and then the number of a textile where the detects are located is judged by combining the edge positions. According to the textile defect detection method, information reference determination is repeatedly performed on the textile edges, and therefore the precision of on-line edge counting is improved; fine and scattered defects are regrown and communicated, and therefore the precision of on-line defect detection is improved.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com