Textile defect detection method

A technology for defect detection and textiles, which is applied in the direction of optical testing for defects/defects, can solve the problems that are difficult to meet the high efficiency and high precision requirements of industrial automation enterprises, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

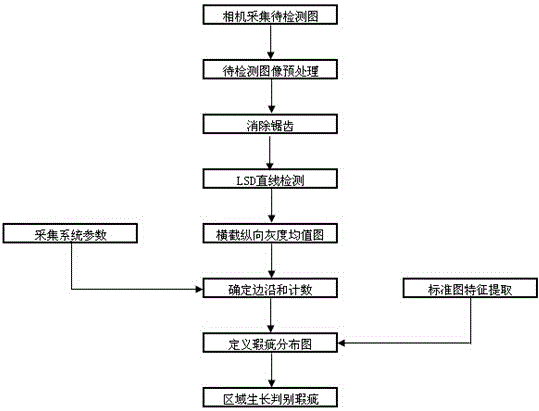

[0015] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0016] According to the accompanying drawing (1) of the description, the implementation steps are described in detail:

[0017] Step (1). Acquisition of images and image preprocessing.

[0018] In order to ensure continuous and stable image acquisition, it is necessary to fix the industrial camera on the production line at a stable speed, with stable lighting, and the image acquisition time interval can be slightly increased, but it must be ensured that there is no information missing during the acquisition process, that is, the content of two consecutive images can be repeated But indispensable. The preprocessing of the image mainly includes several processing processes such as denoising the image, grayscale conversion and image binarization.

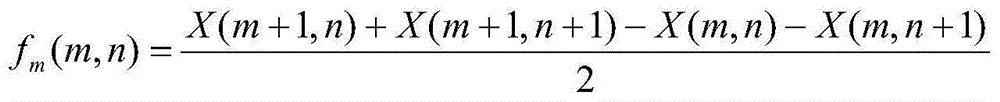

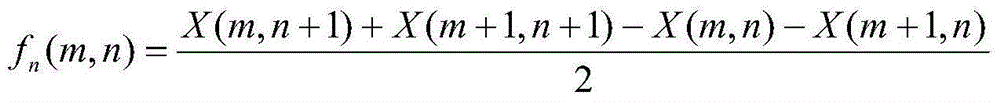

[0019] Step (2). Use the LSD line detection algorithm to extract the edge information of the textile in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com