Array substrate and defect detecting method thereof

An array substrate and defect detection technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as unguaranteed production speed, time-consuming, and wrong judgments by manual visual inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

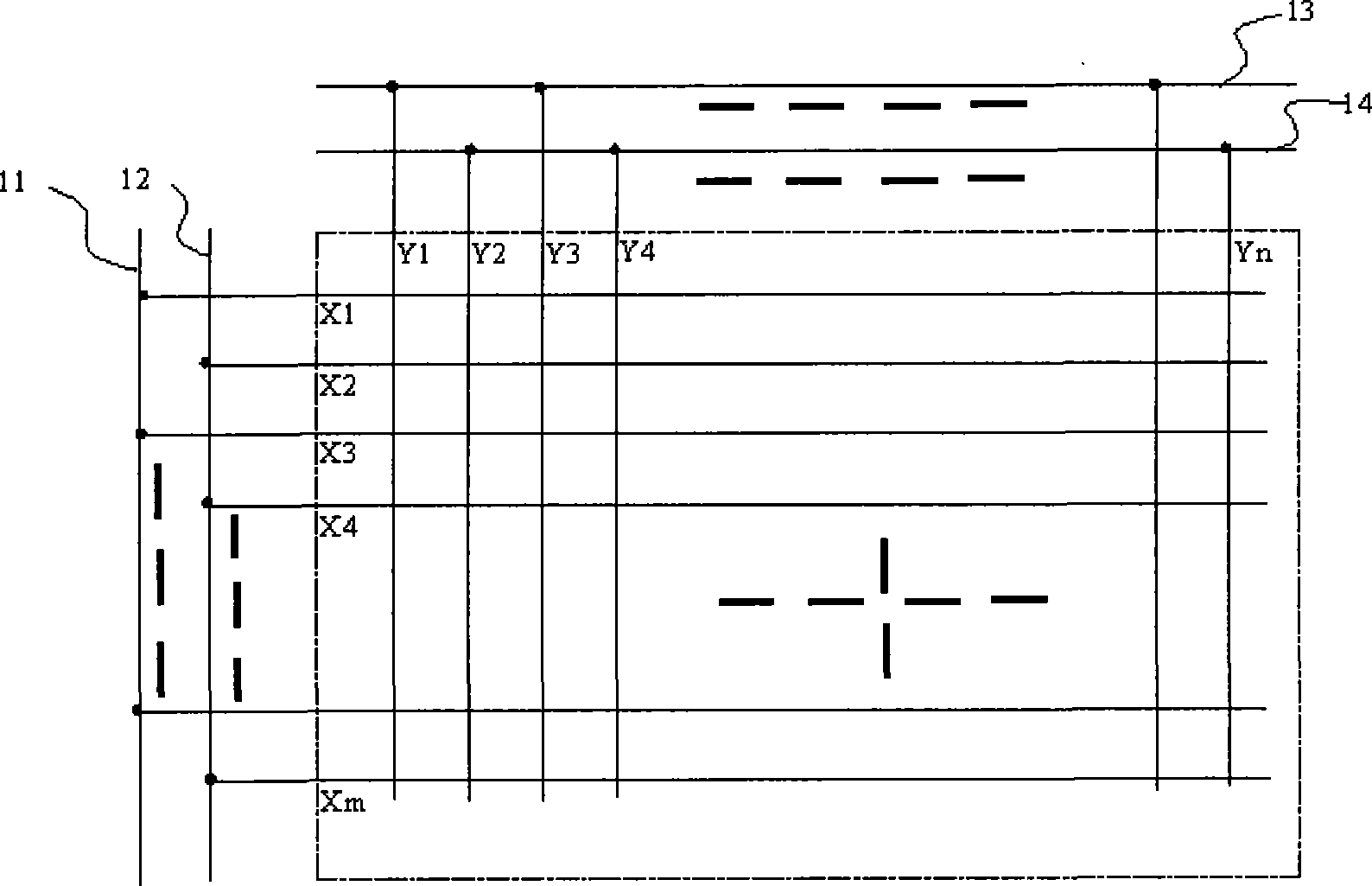

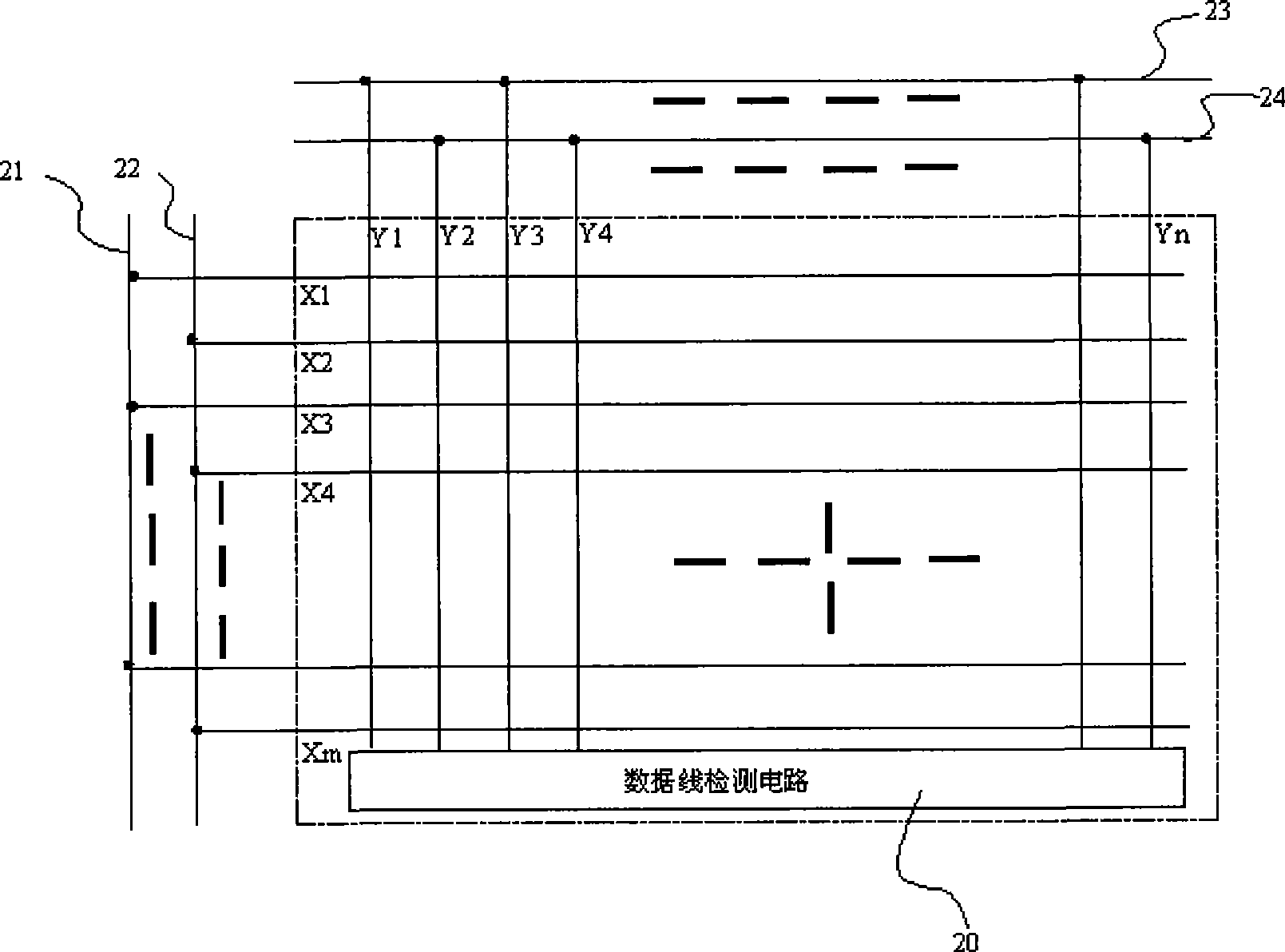

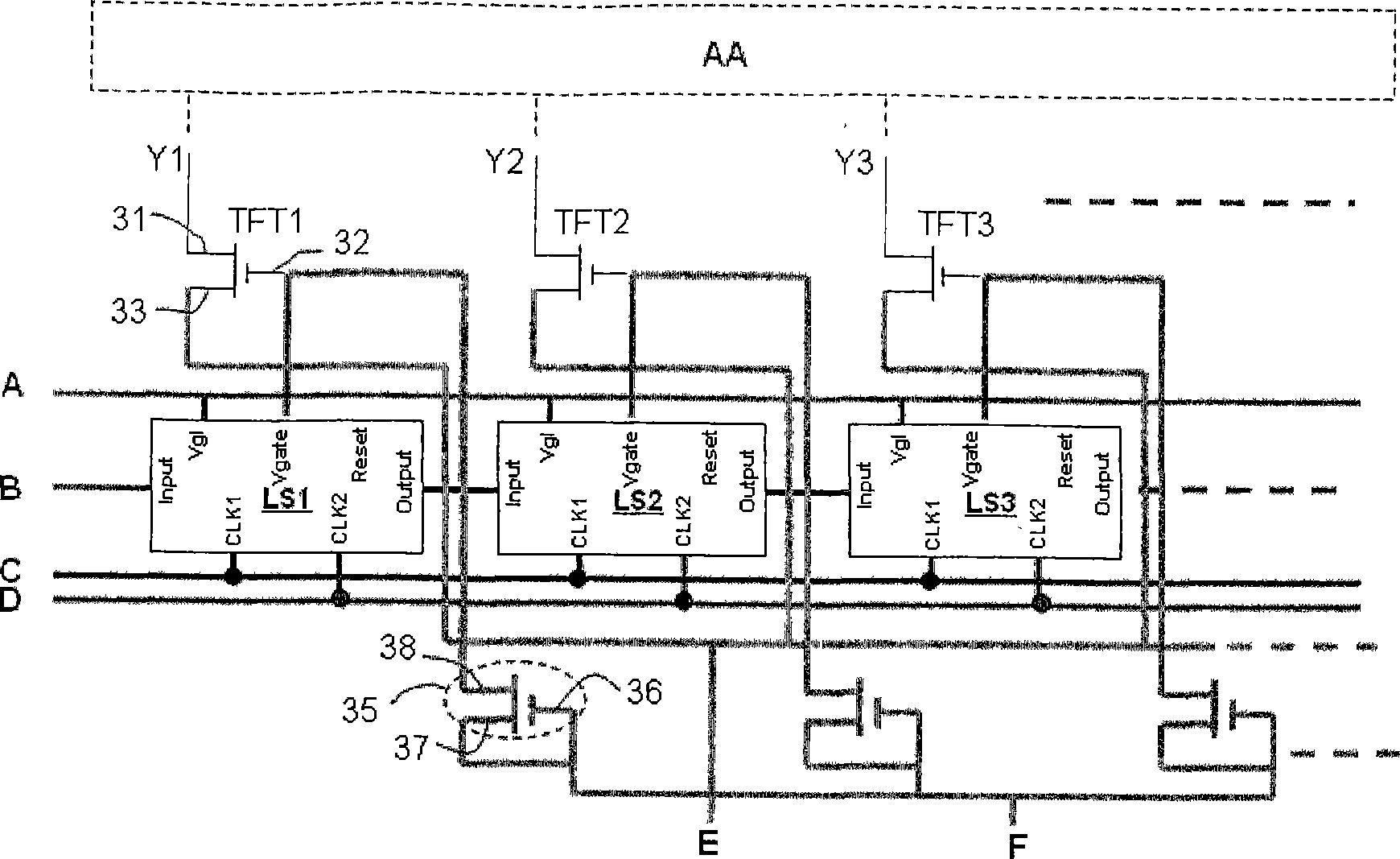

[0028] First refer to Figure 2 to Figure 6B A first embodiment of the present invention will be described. figure 2 is a schematic diagram of an array substrate provided with a data line detection circuit according to a first embodiment of the present invention. The structure of this array substrate and figure 1 Similar to the array substrate, it is also an array substrate with m rows and n columns. On the periphery of the array substrate (that is, the blank area of the non-array substrate on the mother glass substrate), there are: electrically connected odd-numbered row gate lines (X1 , X3...Xm-1) the first grid short-circuit bar 21, electrically connected to the second grid short-circuit bar 22 of the even-numbered row gate lines (X2, X4...Xm); and electrically connected to the odd-numbered column data lines (Y1 , Y3 ... Yn-1) the first data short bar 23 is electrically connected to the second data short bar 24 of the even column data lines (Y2, Y4 ... Yn). The array ...

no. 2 example

[0041] The above description is aimed at the array substrate and the method thereof for detecting and locating the line defects of the data lines. For the gate lines, a similar gate line detection circuit can also be used for processing. refer to Figure 7 , Figure 7 It is a schematic diagram of an array substrate provided with a gate line detection circuit 70 according to a second embodiment of the present invention. Such as Figure 7 As shown, the gate line detection circuit 70 is disposed in the non-display area on the right side of the array substrate. Figure 7 The gate line detection circuit 70 shown can receive the voltage signal transmitted by the gate line, so as to detect and locate the line defect of the gate line. The gate line detection circuit 70 may have the same configuration as the data line detection circuit in the first embodiment except that m gate lines are connected. In addition, the gate line detection method performed by the gate line detection ci...

no. 3 example

[0043] In addition to providing only one data line detection circuit or one gate line detection circuit, a data line detection circuit and a gate line detection circuit may also be provided at the same time to detect defects of the data line and the gate line. Figure 8is a schematic diagram of an array substrate provided with a data line detection circuit and a gate line detection circuit according to a third embodiment of the present invention. Such as Figure 8 As shown, the data line detection circuit 80 and the gate line detection circuit 90 are respectively disposed in the non-display area below and right of the array substrate. Figure 8 The data line detection circuit 80 shown can receive the voltage signal transmitted by the data line, so as to detect and locate the line defect of the data line. The gate line detection circuit 90 can receive the voltage signal transmitted by the gate line, so as to detect and locate the line defect of the gate line. The data line de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com