LCD general defect detecting method

A defect and overall technology, applied in the field of LCD defect detection, can solve problems such as single processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

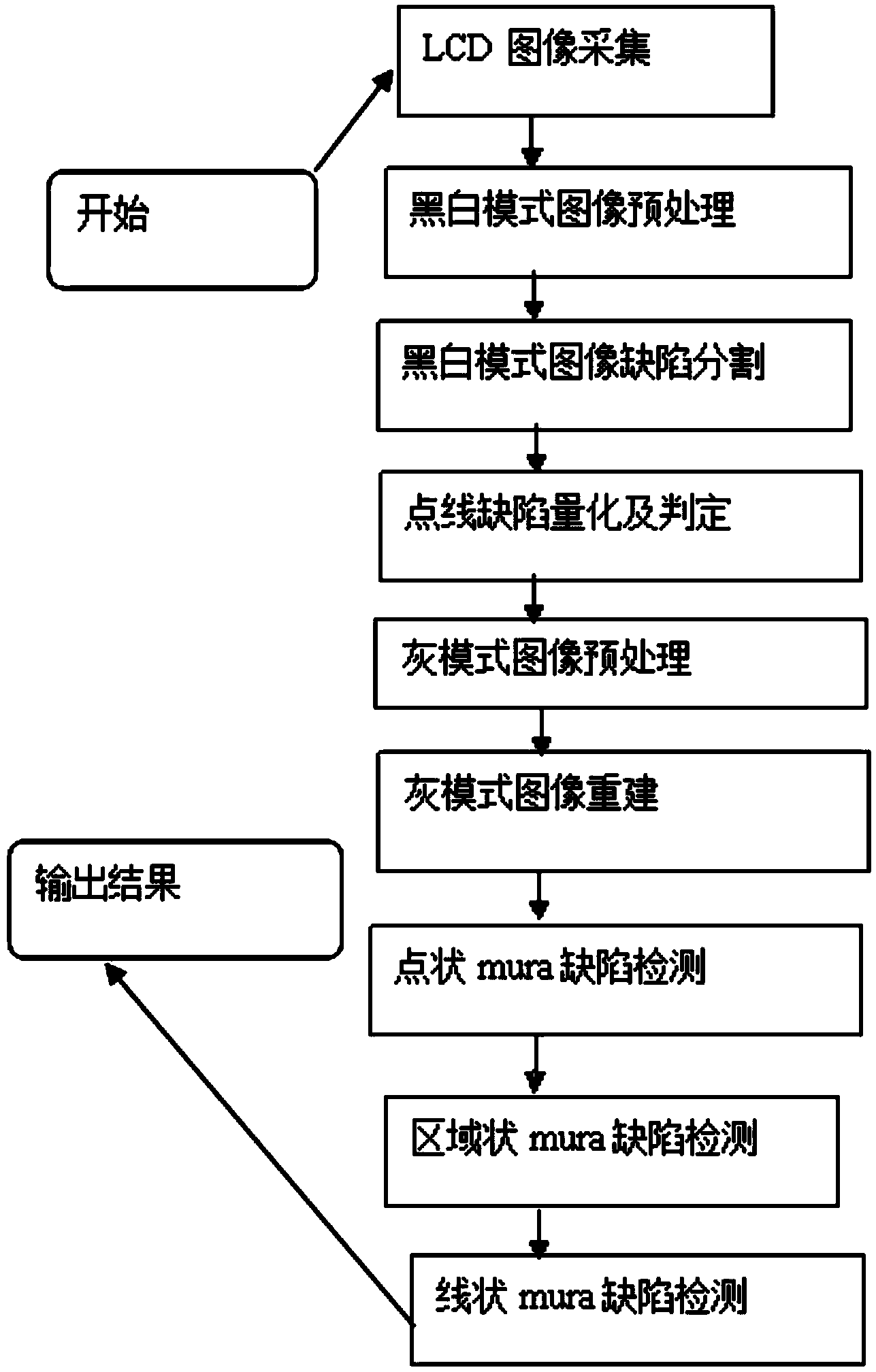

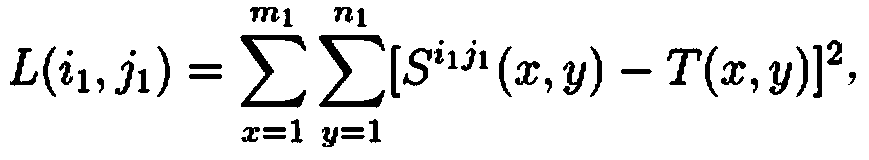

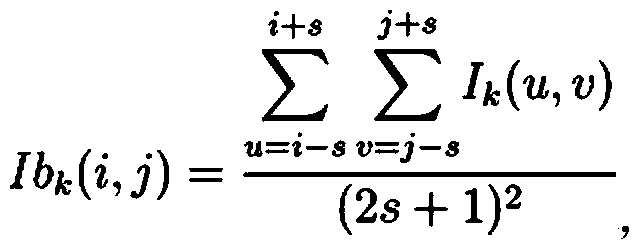

Method used

Image

Examples

Embodiment

[0148] This embodiment includes the following parts:

[0149] 1. Image preprocessing

[0150] Select image I1 of 7 good samples (non-defective samples) in white mode. Take I1 as the input and use the binarization function to perform the binarization operation to obtain I2, and then use I2 as the input to perform contour detection with the contour detection function. The innermost contour area obtained is the target area, the inner contour and the outer layer Between the outlines is a black border area. Calculate the mean, variance, maximum value, and minimum value of the gray value for the target area and the border area, respectively, and take the average V1 of the minimum value of the gray value of the target area of the seven images and the maximum value of the black frame area The value V1+V2 / 2 in the middle of the average value of V2 (V1>V2) is used as the threshold value. Here, 32 is used to binarize the image Ix in the other white mode to be detected, and then extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com