Roller hemming device and roller hemming method

一种卷边装置、辊式的技术,应用在辊式卷边技术的改良领域,能够解决褶皱聚集、起波纹成品形状、不能适用白合金车身等问题,达到没有褶皱聚集、良好卷边加工的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

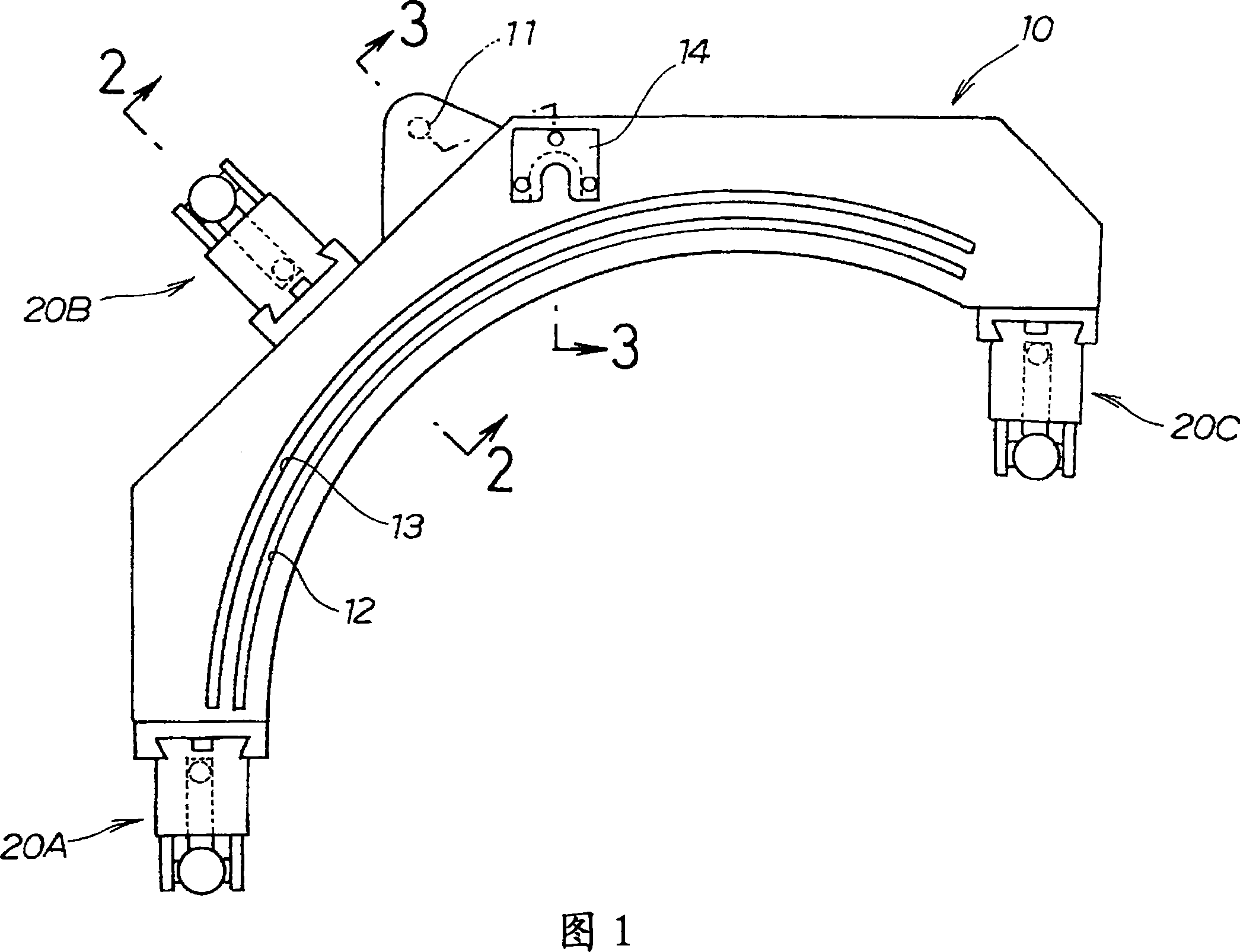

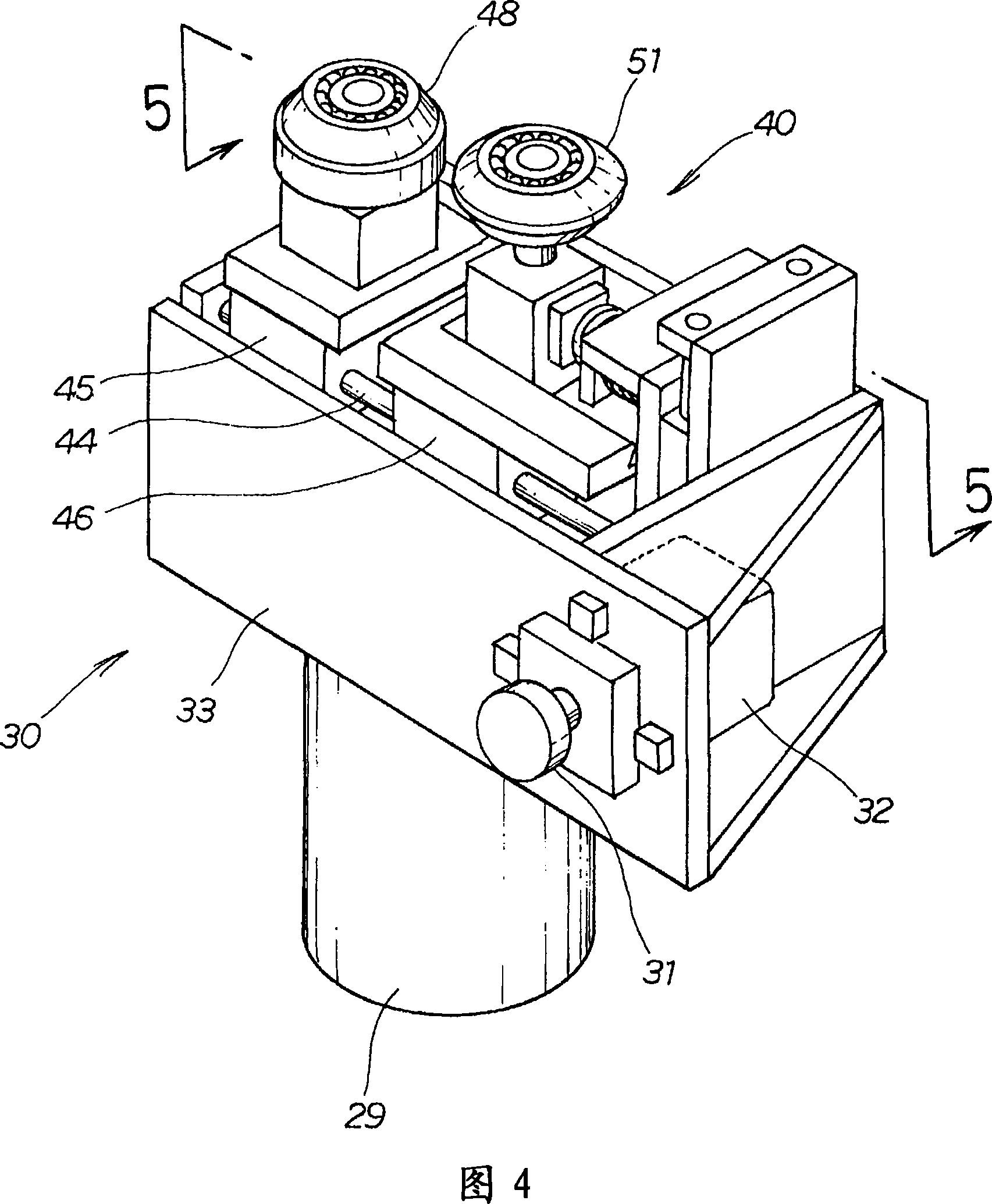

[0061] Hereinafter, typical embodiments of the present invention will be described based on the drawings. Also, the orientation of the drawings matches the orientation of the symbols. Fig. 1 is the front view of the supporting mold of the roller hemming device of typical embodiment of the present invention, and the roller hemming device is composed of the roller mechanism (symbol 40 of Fig. 4,5) installed on the mechanical arm and detachable ground The supporting mold 10 attached to this attachment constitutes.

[0062] In this die 10, there are bearing surfaces (illustrated with FIG. 2.) and positioning pins 11 on the surface on the rear side of the figure, and a first guide groove 12, a second guide groove 13, and a first guide groove 12 on the surface near the figure. The clamping portion 14 capable of clamping from the outside has clamping mechanisms 20A, 20B, and 20C at the lower left end, upper edge, and right end, respectively.

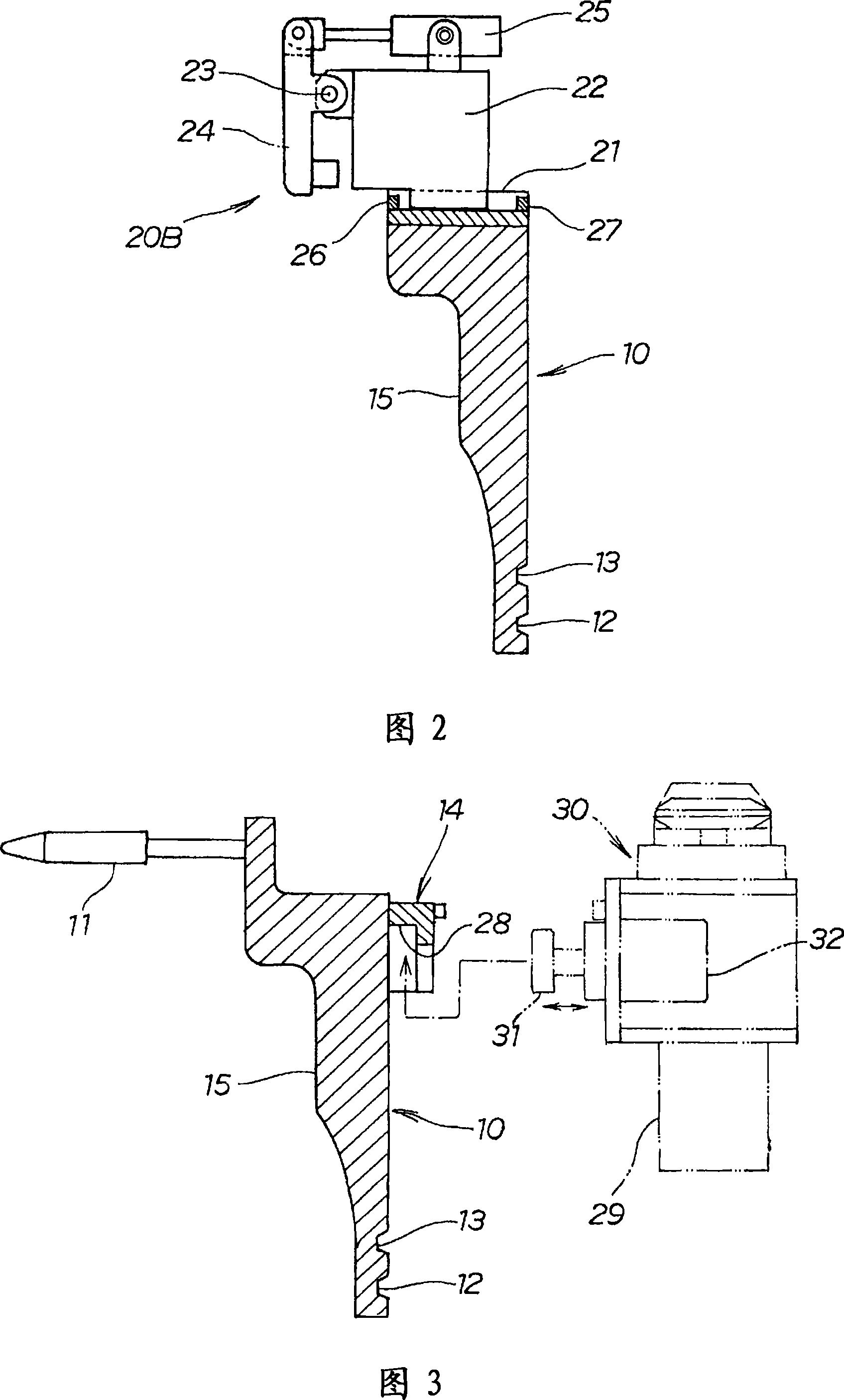

[0063] Fig. 2 is the 2-2 line sectiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com