Multifunctional double-needle chain type machine for curtain processing

A multi-functional, curtain technology, applied in the direction of cloth feeding mechanism, sewing machine components, textiles and papermaking, etc., can solve the problems of high labor intensity, low degree of automation, low work efficiency, etc., to improve splicing accuracy, improve quality, Ease of wrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

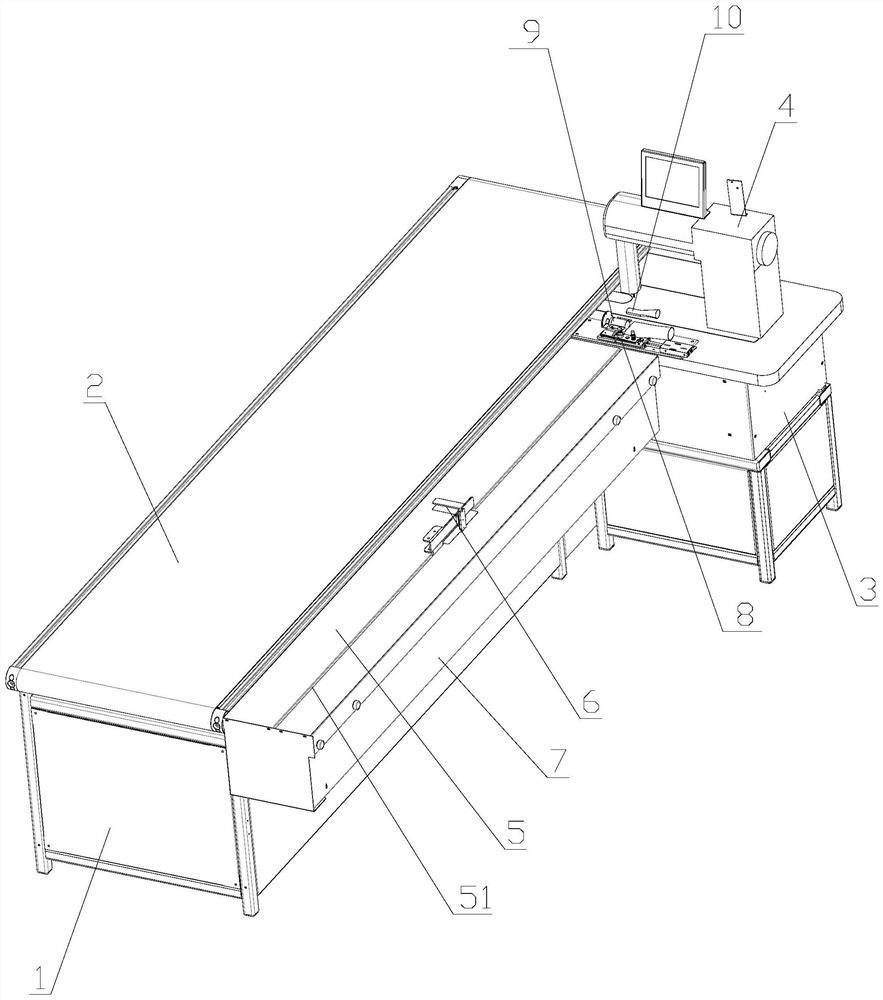

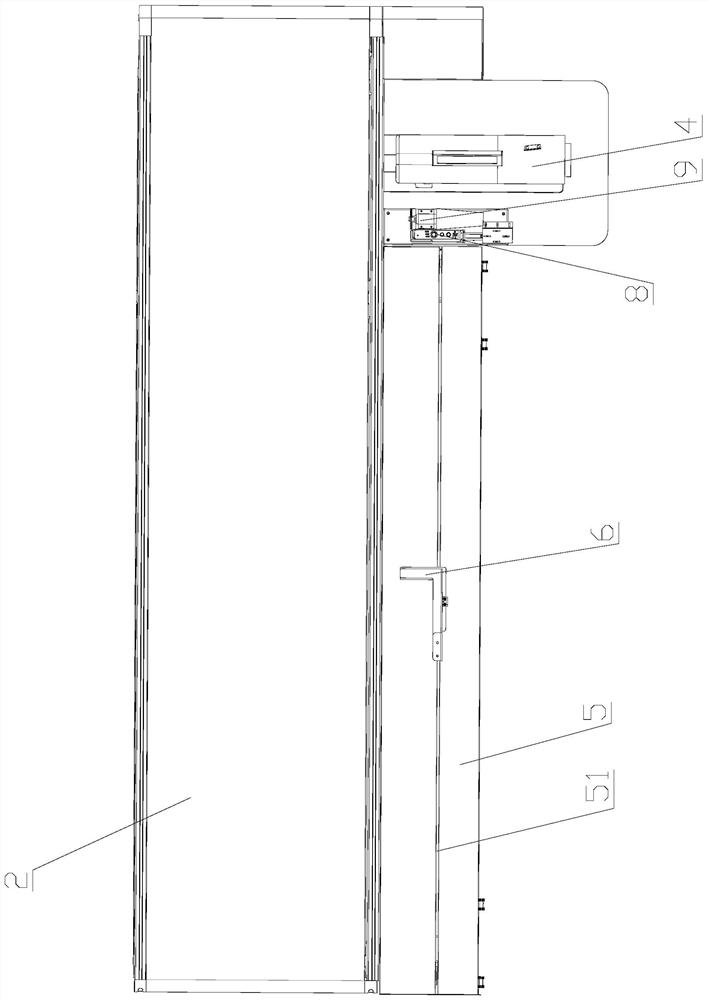

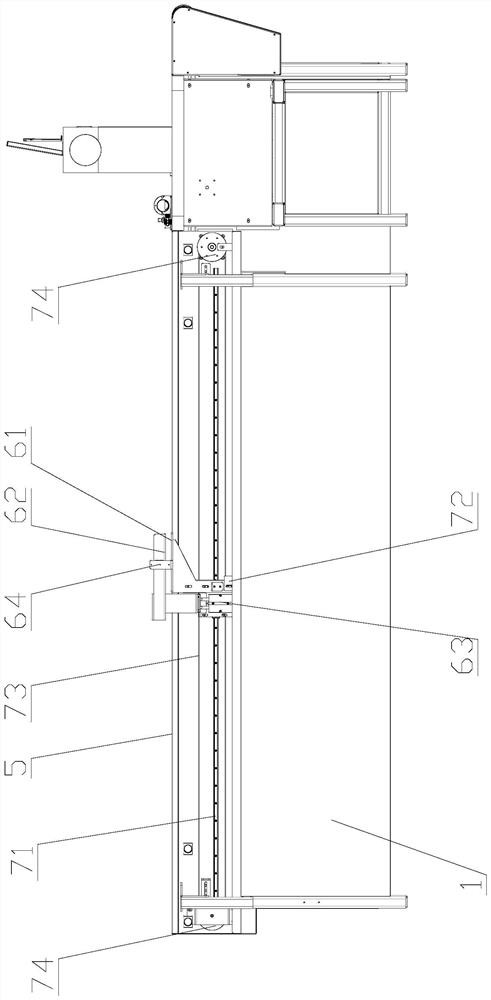

[0027] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8, a multifunctional double-needle chain machine for curtain processing according to the present invention, comprising a frame 1, a conveying belt 2 is arranged horizontally on the upper side of the frame 1, and a sewing mechanism is arranged on the side of the output end of the conveying belt 2 , the sewing mechanism includes a side frame 3 located on the side of the frame 1, the upper end of the side frame 3 is provided with a double-needle chain sewing head 4, and the sewing position of the double-needle chain sewing head 4 is Located on the side near the output end of the conveyor belt 2, a curtain feeding platform 5 is provided on the side of the frame 1 close to the side frame 3, and the upper side of the curtain feeding platform 5 is connected to the The upper end surface of the conveyor belt 2 is flush or close to flush, and the curtain feeding platform 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com