Automatic splicing conveying auxiliary device of wire cord fabric cutting machine and conveying method thereof

A steel cord, automatic splicing technology, applied to tires, other household appliances, household appliances, etc., can solve the problems of poor head and tail alignment of steel cord, splicing deviation, difficult head and tail alignment, etc., to reduce manual assistance time. , Improve the accuracy, prevent the effect of skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

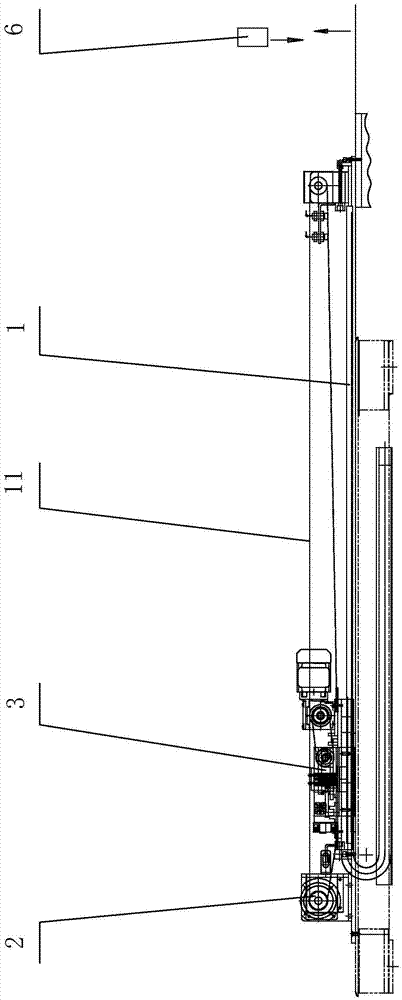

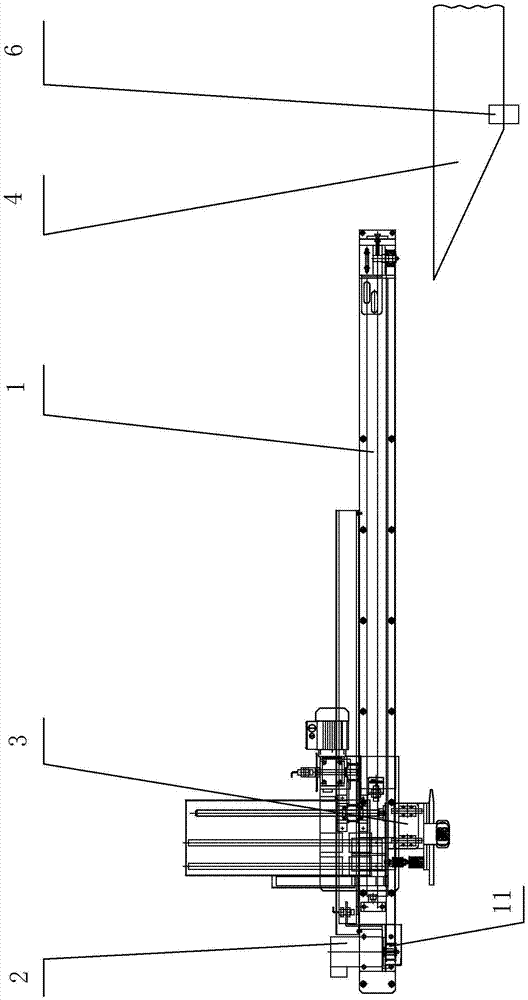

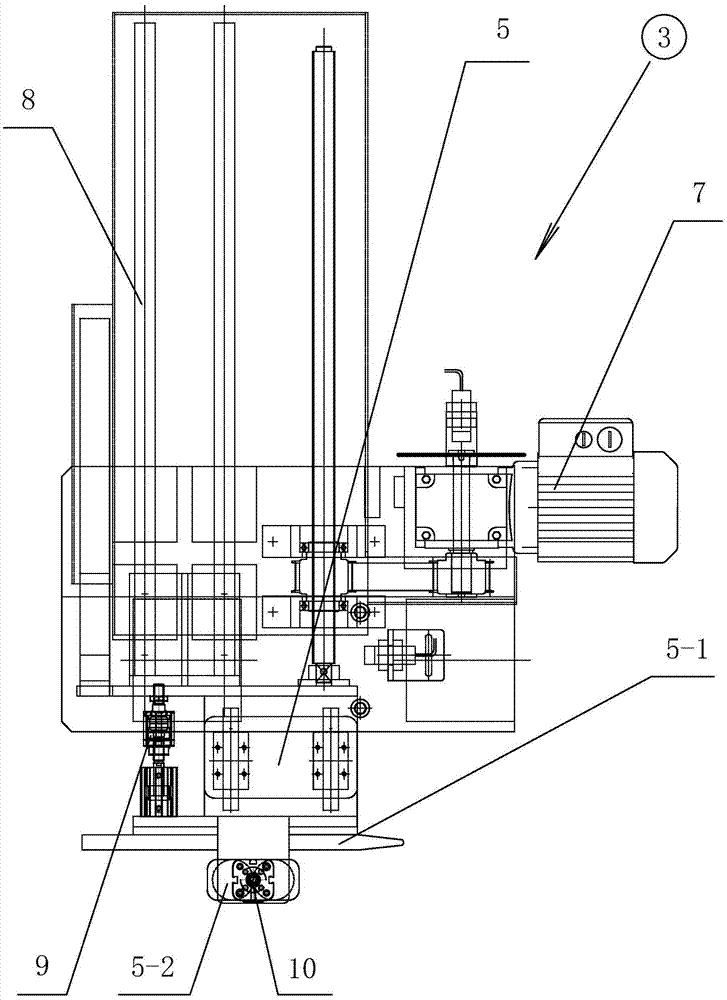

[0026] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0027] The automatic splicing and feeding auxiliary device of the steel cord cutting machine of the present invention includes a linear guide rail mechanism 1, a servo control system 2, a magnetic adsorption mechanism 3 and a sensor 6. The straight side and the same side) are arranged along the conveying direction of the steel cord 4. The servo control system 2 is set at one end of the linear guide rail mechanism 1 and is driven to move back and forth on the linear guide rail mechanism 1 through the synchronous belt drive pair 11. The magnetic adsorption mechanism 3 Install the linear guide rail assembly 8 (horizontally) on the linear guide rail mechanism 1 perpendicular to the conveying direction of the steel cord 4, and drive the servo motor drive mechanism 7 to move back and forth on the linear guide rail assembly 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com